Maytag rh2030, rh2330, rh2036 Instructions Manual

I

I

-

pati No. 6267131883~80 Rev. D

-

3~”

and

36”

Vented

c~st0rn Series

Range Hood

IQ

I-i

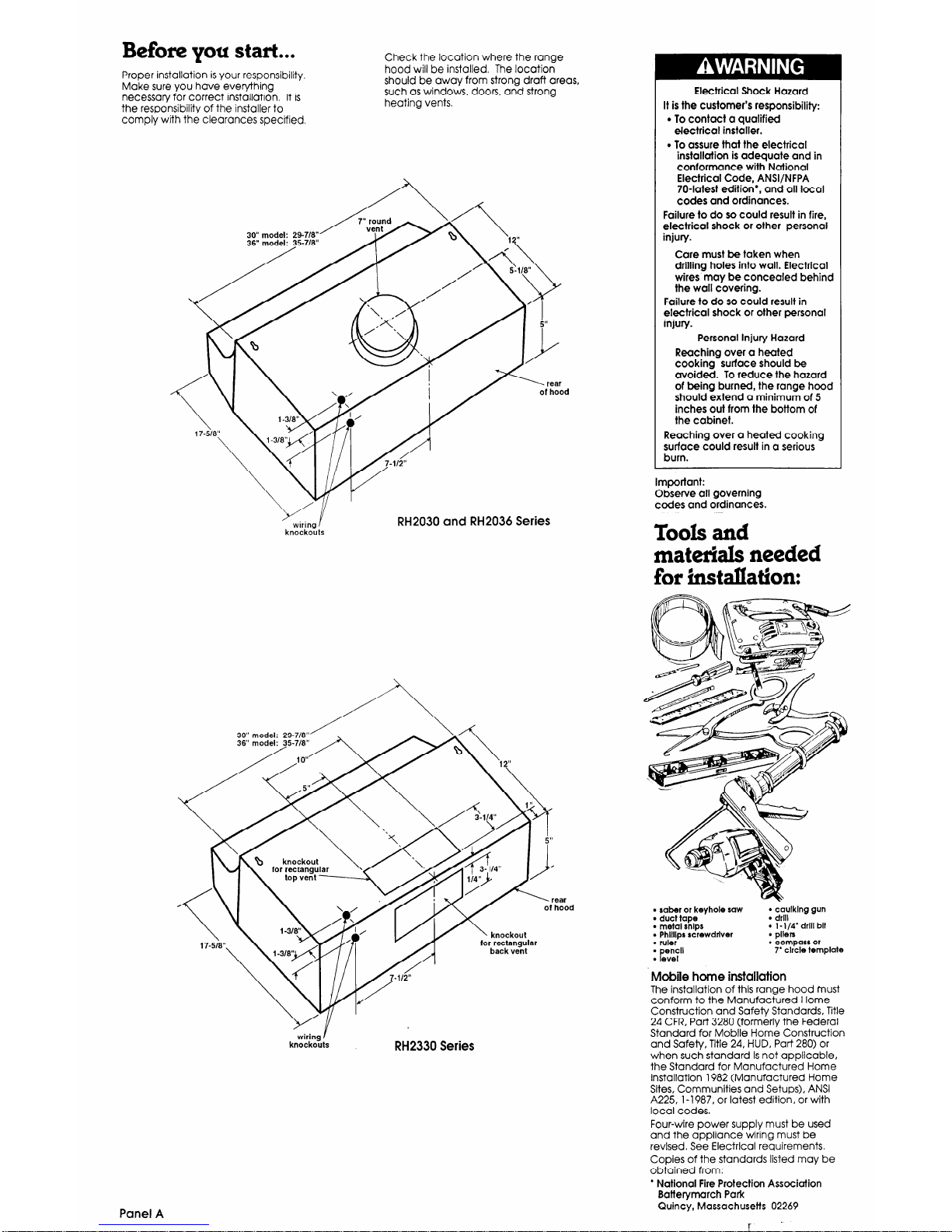

Before you start...

Proper installation is your responsibility.

Make sure you have everything

necessary for correct installation. It is

the responsibility of the installer to

comply with the clearances specified.

Check the location where the range

hood will be installed. The location

should be away from strong draft areas,

such as windows, doors, and strong

heating vents.

knockouts

30” model: 29-7/W

wiring I

knockouts

RH2330 Series

Panel A

Electrical Shock Hazard

It is the customer’s responsibility:

. To contact a qualified

electrical installer.

. To assure that the electrical

installation is adequate and in

conformance with National

Electrical Code, ANSI/NFPA

704atest edition*, and all local

codes and ordinances.

Failure to do so could result in fire,

electrical shock or other personal

injury.

Care must be taken when

drilling holes into wall. Electrical

wires may be concealed behind

the wall covering.

Failure to do so could result in

electrical shock or other personal

injury.

Personal Injury Hazard

Reaching over a heated

cooking surface should be

avoided. To reduce the hazard

of being burned, the range hood

should extend a minimum of 5

inches out from the bottom of

the cabinet.

Reaching over a heated

cooking

surface could result in a serious

burn.

Important:

Observe all governing

codes and ordinances.

Tools and

materials needed

for installation:

l

saber or keyhole saw

l

duct tape

l

metal snips

l

Phllllps rcrewdrlver

l

ruler

l

encll

P l evel

l

caulklng gun

l

drill

l

l-1/4’drlll bit

l

pliers

. compass or

7’ circle template

Mobile home installation

The installation of this range hood must

conform to the Manufactured Home

Construction and Safety Standards, Title

24 CFR, Part 3280 (formerly the Federal

Standard for Moblle Home Construction

and Safety, Title 24, HUD, Part 280) or

when such standard Is not applicable,

the Standard for Manufactured Home

lnstallatlon 1982 (Manufactured Home

Sites, Communities and Setups), ANSI

A225, l-l 987, or latest edition, or with

local codes.

Four-wire power supply must be used

and the appliance wiring must be

revlsed. See Electrlcal requirements.

Copies of the standards listed may be

obtained from:

l

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Electrical

requirements

Venting

requirements

Electrical Shock Hazard

0 Electrical ground is required on this

appliance.

l

If cold water pipe Is interrupted by

plastic, non-metallic gaskets or

other insulating materials, Do Not

use for grounding.

l

Do Not ground to a gas plpe.

l

Do Not modify the power supply

cord plug. If it does not fit the outlet,

have a proper outlet Installed by a

qualified electrlclan.

l

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the

neutral or grounding circuit could

result in an electrical shock.

l

Do Not use an extension cord with

this appliance.

l

Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

Failure to follow these instructlons

could result in serious injury or death.

If codes permit and a separate grounding

wire is used, It is recommended that a

qualified electrician determine that the

grounding path is adequate.

A

n A 115volt, 60-Hz, AC-only, fused

electrlcal supply is required. The total

ampere load used, Including the range

hood, must not exceed 90% of rated

capacity of the circuit. The ampere

rating of the range hood is located on

the serial/rating plate located on the

underside of the range hood.

B

n It is the personal responsibility and

obligation of the customer to contact a

qualified electrician to assure that the

electrical installation is adequate and in

conformance with the Natlonal

ElectrIcal Code ANSI/NFPA 70-latest

edition’ and all local codes and

ordinances.

C

w The range hood must be

connected with copper wire only.

D

n The range hood should be

connected directly to the fuse

disconnect (or circuit breaker) box

through flexible armored or non metallic

sheathed copper cable. A U-L,-listed

strain relief must be provlded at each

end of the power supply cable. Wire

slzes (COPPER WIRE ONLY) and

connector must conform with the rating

of the appliance as specified on the

serial/rating plate.

Wire sizes must conform to the

requirements of the National Electrical

Code ANSI/NT-PA 70-latest edition*, and

oil local codes and ordinances.

Fire Hazard

l

Venting system MUST terminate to

the outside.

l

Do Not terminate the ductwork in

an attic or other enclosed space.

l

Do Not use 4” laundry-type wall

caps.

l

Do Not use plastic-type ductwork.

Failure to follow recommended

venting instructions may result in a

fire.

CAUTION: To reduce risk of fire and to

properly exhaust air, be sure to duct

air outside. -

Do Not vent exhaust air

into spaces within walls or ceilings or

into attics, crawl spaces or garages.

Ductwork needed for installation is not

included. Backdraft damper supplied

with product must be properly installed.

If roof or wall cap has a damper, Do Not

use damper supplied with hood.

Determine which outside venting

method needs to be used.

The length of the ductwork and number

of elbows should be kept at o minimum

to provide efficient performance. The

size of the ductwork should be uniform.

Do Not install two elbows together. Use

ductwork system. Ductwork can

terminate either thought the roof or wall.

Use caulking to seal exterior wall or roof

opening around exhaust hood, For the

most efficient and quiet operation, it is

recommended that the range hood be

vented vertically through the roof

through 7” round ductwork.

Flexible metal ductwork is Not

recommended.

If it is used, calculate

each foot of flexible metal ductwork as

two feet of straight metal ductwork.

Flexible metal elbows count twice as

much as standard elbows. Use metal

ductwork only.

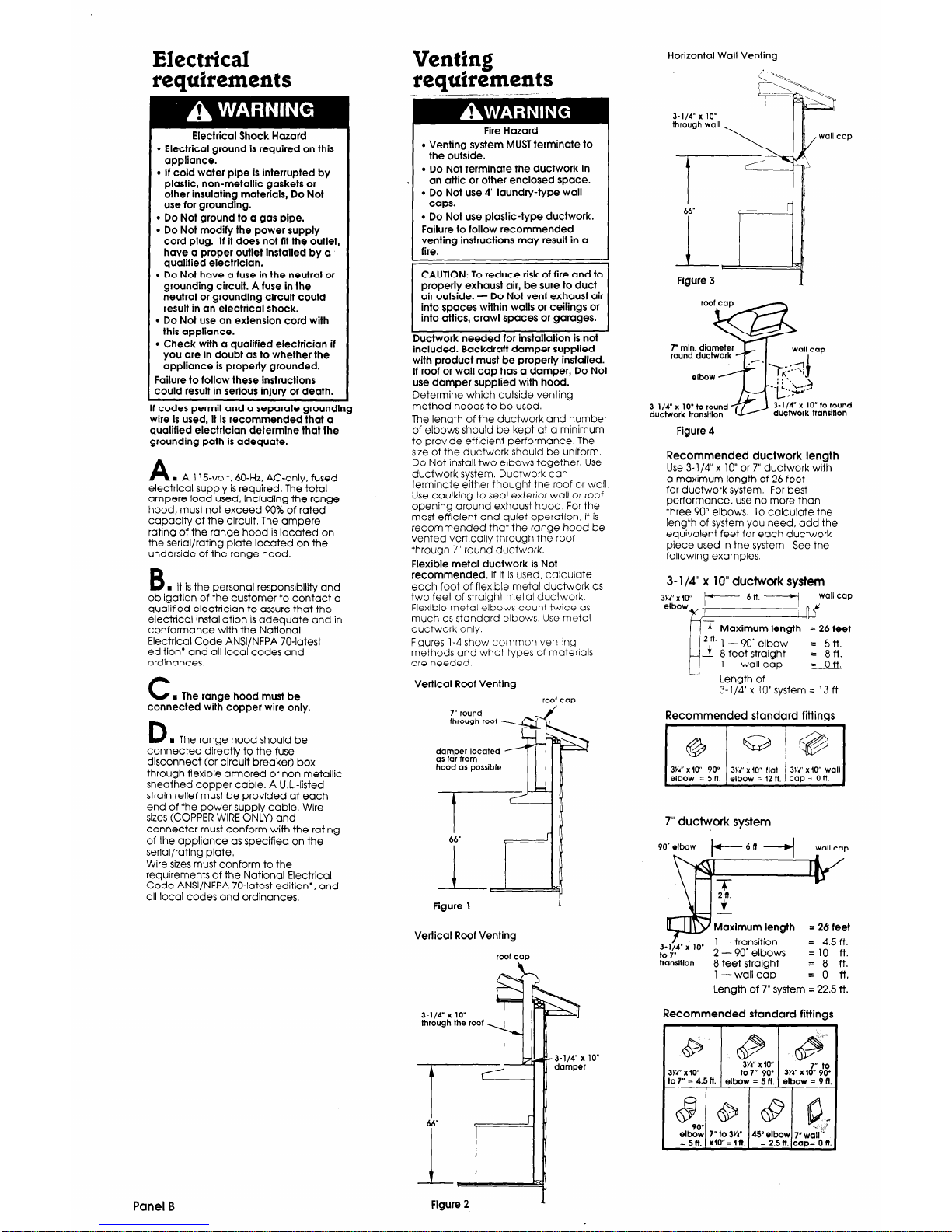

Figures l-4 show common venting

methods and what types of materials

are needed.

Vertical Roof Venting

roof cap

damper located

as far from

hood as possible

Figure 1

Vertical Roof Venting

roof caD

3-l/4’ x 10’

through the roof

Horizontal

Wall Venting

Figure 3

7’ mln. diameter

round ductwork

wall cap

J-1/4” x 1O’to round

ductwork transltlon

Figure 4

3-l/4’ x 1O’to round

ductwork trandtlon

Recommended ductwork length

Use 3- l/4” x 10” or 7” ductwork with

a maximum length of 26 feet

for ductwork system. For best

performance. use no more than

three 90” elbows. To calculate the

length of system you need, odd the

equivalent feet for each ductwork

piece used in the system. See the

following examples.

3- l/4” x 10” ductwork system

3Yi'

x IO”

elbow

/p--- 6ft.----

wallcap

7 Maximum length = 26 feet

6”:

t2n. 1

- 90’ elbow

4 8 feet stralght

= 5ft.

= 8ft.

I

1 -wall cop

= oft

-.

Length of

3- l/4’ x 10’ system = 13 ft.

Recommended standard fittings

I 1

I

3Y4” x IO” 90” 3Y4” x iO’* flat ’ 3Y4” x IO” wall

elbow = 5 tt. elbow = 12 tt caD = 0 ft.

J

7” ductwork system

90' elbow

wallcap

Maxlmum length

= 26

feet

fiv”’ ’ ‘O’

1 -transition = 4.5 ft.

2

- 90’ elbows

=lO ft.

transltlon

8 feet straight = 8 ft.

1 -wall cap = 0 l=t,

Length of 7’ system = 22.5 ft.

Recommended standard fittings

3Y4” x lo"

I

3Y4” x lo”

to 7” 90’

3Y4” x 1s &

to7” = 4.5n. elbow = 5

n.

elbow = 9tt.

8 @ CP

elb%

8,

7” to 3Y4” “.! 4,

Elbow 7”wgll*’

= 5n.

Xlo”=ltt.

= 2.5

n.

cap= 0 tt.

Panel B

Figure 2

Loading...

Loading...