Page 1

TECHNICAL SPECIFICATIONS

Model PSH4BI Series

M1200 Product Line

R-410A Ultra High Efficiency Heat Pump

22.0 SEER — 2-3-4 Ton Capacity

Page 2

• M1200 – 12 YEAR ALL

PARTS LIMITED WARRANTY

• M1200 WITH UPGRADED

WARRANTY PACKAGE -

12 YEAR ALL PARTS & LABOR

LIMITED WARRANTY

• Both the standard and

upgraded limited warranty

packages offer a 12 Year

Dependability Promise to

replace the entire unit, if the

unit’s major component (heat

exchanger or compressor)

fails within the rst 12 years

of operation, to the original

owner. All split system

products must be installed

with a matched indoor air

handler or indoor coil

to qualify.

• Product registration (by

consumer or dealer) required

for 12-year Warranty and

Dependability Promise within

a limited period of time after

the installation. See current

warranty document for

details. This can be viewed at

www.maytaghvac.com or

ask your sales representative.

• Dealer is responsible for

registration of labor portion

of warranty.

The iQ Drive® Heat Pump System features fully variable

speed compressor technology and variable speed indoor

and outdoor motors. The system provides variable cooling

capacity as needed. It operates near the nominal rated

capacity at the thermostat set point and modulates as

temperature difference between set point and room

temperature changes. The system may run at additional 18%

capacity to provide rapid cooling or heating. The system

has a built-in humidity control that will activate humidifier

equipment (if supplied), and reduces blower speed if indoor

relative humidity is greater than set point (default set at 60%).

Features and Benefits

• iQ Drive – Inverter driven Panasonic rotary compressor which provides

fully variable operation.

• R-410A Refrigerant – Environmentally friendly non-ozone depleting

refrigerant.

• Designed using galvanized steel – with a polyester urethane coat

finish. The 950 hour salt spray finish resists corrosion 50% better than

comparable units.

• Copper Tube / Aluminum Fin Coils – Both indoor and outdoor coils are

designed to optimize heat transfer, minimize size and cost, and increase

durability and reliability.

• Permanently Lubricated Motor – A heavy duty brushless motor for long

lasting reliability and quiet operation. Requires no maintenance and is

completely protected from rain and snow.

• Compressor Sound Blanket – Engineered to significantly reduce unwanted

compressor noise.

• Swept-Wing Fan Blade – Engineered to provide quiet operation. The

specific energy absorbing hub is designed to reduce noise while operating

through various frequencies.

• Louvered Condenser Guard – Durable metal guard protects the coil from

yard hazards and extreme weather.

• Removable Top Grille Assembly – Allows ease of service from the top

without disconnecting fan motor leads.

• High Pressure Switch – Protects against abnormally high system

pressures. Auto-reset feature prevents nuisance service visits.

• Low Pressure Switch – Protects against loss of system refrigerant charge.

• Liquid Line Filter Drier – Included with unit, field installed.

• One Piece Top/Orifice – Designed for maximum airflow and

quiet operation.

• Easy Compressor and Control Access – Designed to make servicing

easier for the contractor, access panels are provided to all controls and

the compressor from the side of the unit.

• Highest Efciency with the lowest Sound Levels – Up to 22 SEER with

sound ratings of 59-72dB depending upon operating conditions.

2

Page 3

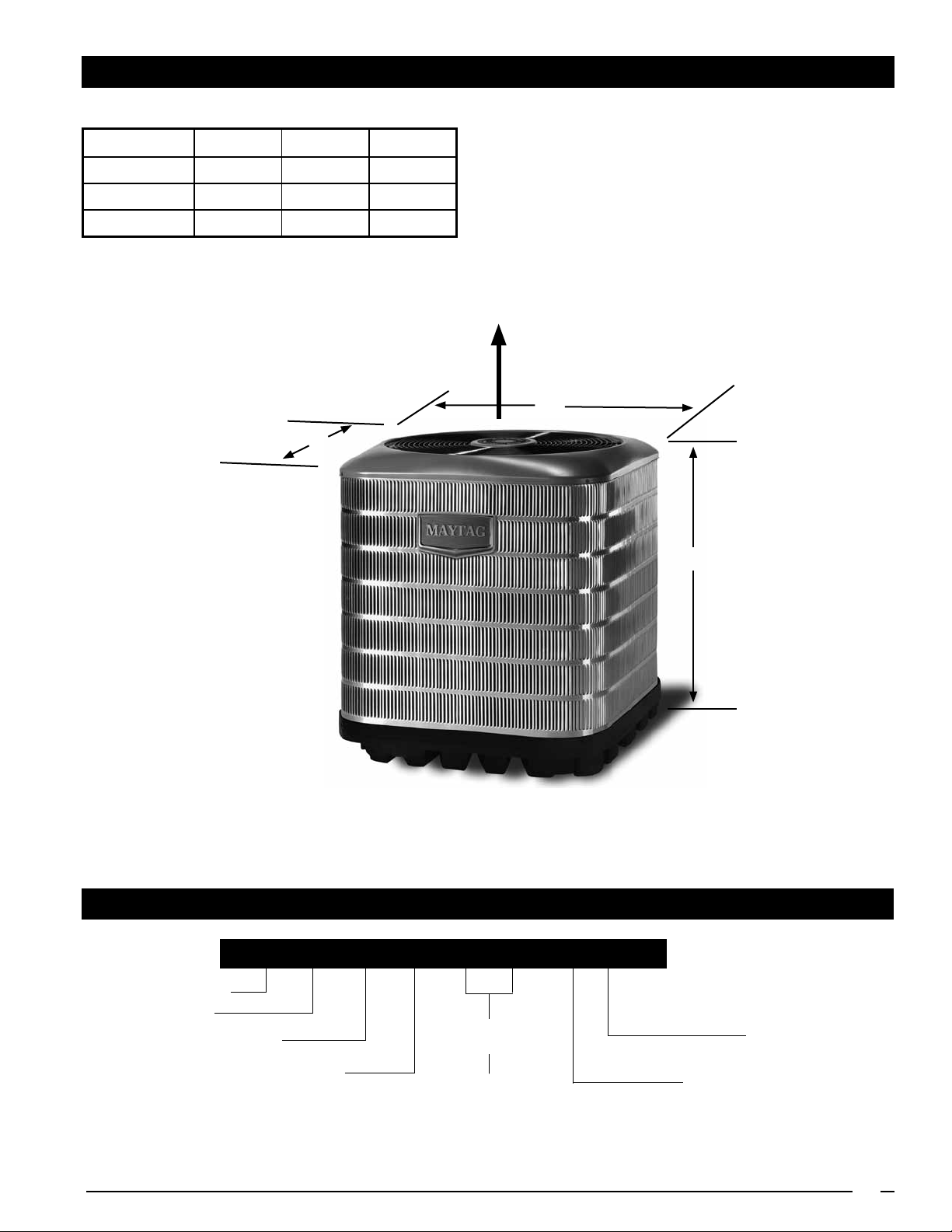

DIMENSIONS/OUTDOOR SECTION

22 SEER — Ultra High Efficiency

PSH4BI 024K 036K 048K

H 37 41 45

W 31 1/4 31 1/4 31 1/4

D 31 1/4 31 1/4 31 1/4

Air Discharge

Allow Adequate Clearance for Airow

D

W

IDENTIFICATION CODE

P S H 4 B I 036 K

P - Premier

S - Split

H - Heat Pump

Generation 1, 2, 3, etc.

Product

Identier

BI = Braze 20-25 SEER

H

Electrical Code

K = 208/230-60-1

Nominal Capacity

(000) BTU

3

Page 4

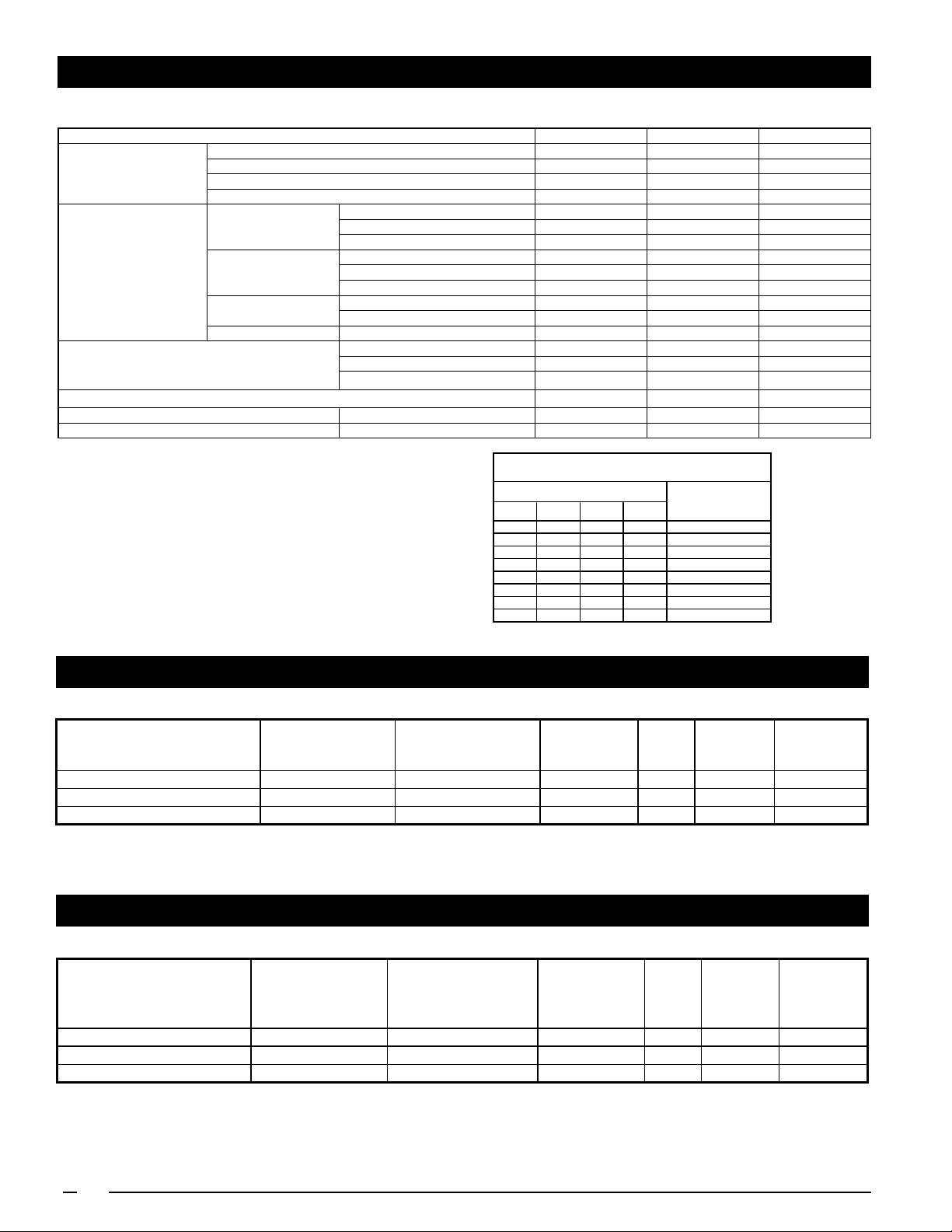

PHYSICAL AND ELECTRICAL SPECIFICATIONS/OUTDOOR UNITS

22 SEER — Ultra High Efficiency

Model Number PSH4BI- 024K 036K 048K

Electrical Data

Condenser Data

Refrigerant suction line O.D.

(all length of liquid line are

3/8” O.D.)

Refrigerant charge (R-410A) in ounces for outdoor unit, indoor unit and 15’ lineset.

Weight Net 190 220 225

Approximate (lbs.) Ship 200 230 235

(1) Operating Voltage Range: 187v min. — 253v max.

(2) HACR Type Circuit Breakers may be used.

(3) Requires Reducer.

Note:

Refrigerant Tubing Limitations-The compressor manufacturer

imposes a maximum equivalent line set length of 100ft.

Furthermore, vertical elevation shall not exceed 50 ft.

Volts-Cycles-Phase (1) 208/230-60-1 208/230-60-1 208/230-60-1

Total Amps 13.0 18.0 22.0

Delay Fuse Max. (2) 25 35 45

Min. Circuit Ampacity 16.6 22.9 27.1

Coil

Fan Motor

Fan Blade

Compressor Data RLA 11.4 16.4 20.4

2

Area(ft

) 20.3 22.8 25.4

Rows-FPI 1 - 20 1 - 20 1 - 20

Tube Dia 3/8” O.D. 3/8” O.D. 3/8” O.D.

Type Brushless DC Brushless DC Brushless DC

Amps 1.6 1.6 1.6

HP 0.5 0.5 0.5

Dia-# Blades 24” - 2 24” - 2 24” - 2

SCFM 3200 3400 3600

0-24 ft. 3/4” 7/8” 7/8”

25-39 ft. 3/4” 7/8” 1 1/8” (3)

40-75 ft. 7/8”(3) 1 1/8” (3) 1 1/8” (3)

171 203 203

COPPER WIRE SIZE — AWG

(1% Voltage Drop)

Supply Wire Length-Feet

200 150 100 50

6 8 10 14 15

4 6 8 12 20

4 6 8 10 25

4 4 6 10 30

3 4 6 8 35

3 4 6 8 40

2 3 4 6 45

2 3 4 6 50

Wire Size based on N.E.C. for 60° type copper conductors.

Supply Circuit

Ampacity

SYSTEM COOLING CAPACITIES

22 SEER — Ultra High Efficiency — Single Phase

Outdoor Unit

Model Number PSH4BI-

024K B6VMAI24KB 11,300-26,900 14.6 22 22,800 500-950

036K B6VMAI36KB 14,200-40,700 13.0 21 35,000 680-1110

048K B6VMAI48KC 14,300-48,000 12.5 21 44,500 725-1800

Minimum operating ambient temperature is 40°F

NOTE: Each system was operated at its nominal capacity.

Indoor conditions were 80F° dry-bulb temperature and 67F° wet-bulb temperature (approx. 51% relative humidity, 95

Indoor Unit

Range

Cooling Capacity @95°

OD BTUH

EER @ Nominal

Capacity

SYSTEM HEATING CAPACITIES

22 SEER — Ultra High Efficiency — Single Phase

Outdoor Unit

Model Number PSH4BI-

024K B6VMAI24KB 6,500-24,100 22,400 10 3.9 500-950

036K B6VMAI36KB 11,300-39,900 34,000 9.6 3.4 680-1110

048K B6VMAI48KC 11,400-47,800 46,000 10 3.6 725-1800

Minimum operating ambient temperature is 12°F

NOTE: Each system was operated at its nominal capacity.

Indoor conditions were 70F° dry-bulb temperature and 47F° dry bulb temperature, 43F

Indoor Unit

Heating Capacity @47° OD

See current AHRI Directory for certified combinations and ratings.

www.ahridirectory.org

Range

Nominal Capacity HSPF

BTUH

° wet bulb outdoor temperature

SEER

° outdoor temperature.)

Nominal

Capacity

COP @

Nominal

Capacity

Range

SCFM

CFM

4

Page 5

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

Indoor

Twb - in

23.2 1.39 30.6 22.6 1.58 29.2 22.1 1.80 27.7 21.5 2.03 26.9 21.2 2.16 26.1 20.8 2.28 24.4 20.1 2.55 22.6 19.2 2.84

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Indoor

Tdb - °F

60 2.2 1.79 0.36 2.8 2.31 0.36 3.2 2.62 0.36 4.5 3.70 0.35 5.8 4.80 0.36 6.7 5.80 0.34 7.2 6.12 0.34 8.4 7.51 0.33

70 2.0 1.40 0.42 2.7 1.84 0.42 3.0 2.10 0.42 4.3 3.01 0.42 5.5 3.97 0.41 6.4 4.69 0.40 6.8 5.01 0.40 8.0 6.16 0.38

80 1.9 1.14 0.50 2.6 1.51 0.50 2.8 1.68 0.50 4.0 2.39 0.49 5.3 3.18 0.49 6.0 3.73 0.47 6.5 4.05 0.47 7.6 4.90 0.46

60 6.8 3.20 0.62 7.6 3.45 0.64 8.0 3.67 0.64 9.6 4.27 0.66 11.2 4.90 0.67 12.4 5.43 0.67 12.9 5.65 0.67 14.7 6.51 0.66

70 6.5 2.63 0.73 7.3 2.86 0.74 7.7 3.01 0.75 9.2 3.51 0.77 10.8 4.05 0.78 11.9 4.46 0.78 12.4 4.65 0.78 14.1 5.34 0.77

80 6.3 2.21 0.84 7.0 2.39 0.85 7.4 2.52 0.86 8.8 2.93 0.88 10.3 3.38 0.89 11.4 3.75 0.89 11.9 3.91 0.89 13.5 4.47 0.88

60 11.2 2.48 1.32 13.2 2.87 1.35 13.8 2.96 1.37 17.2 3.56 1.42 20.6 4.03 1.50 22.9 4.40 1.53 24.0 4.57 1.54 27.4 5.00 1.60

70 10.8 2.13 1.48 12.4 2.41 1.51 13.4 2.56 1.53 16.7 3.05 1.60 19.9 3.50 1.67 22.2 3.81 1.71 23.2 3.93 1.73 26.5 4.31 1.80

80 10.4 1.84 1.66 12.4 2.14 1.70 12.9 2.20 1.72 16.1 2.63 1.79 19.3 3.03 1.87 21.4 3.26 1.92 22.5 3.41 1.93 25.7 3.73 2.02

60 14.6 2.83 1.51 16.0 3.05 1.54 16.9 3.20 1.54 19.6 3.60 1.60 22.5 4.03 1.64 24.6 4.32 1.67 25.6 4.45 1.69 28.7 4.85 1.73

70 14.1 2.47 1.67 15.4 2.65 1.70 16.2 2.76 1.72 18.9 3.13 1.77 21.7 3.50 1.82 23.7 3.75 1.86 24.6 3.86 1.87 27.6 4.22 1.92

80 13.5 2.13 1.86 14.8 2.30 1.88 15.6 2.41 1.90 18.2 2.72 1.96 20.8 3.03 2.01 22.8 3.25 2.06 23.6 3.36 2.06 26.5 3.67 2.12

EXPANDED RATINGS - 2 TON WITH G7 FURNACE B CABINET

Outdoor Temperature: 60°F 70°F 80°F 90°F 95°F 100°F 110°F 120°F

COOLING

Indoor

Tdb - in

Speed

80 62 13.5 13.5 0.36 12.9 12.9 0.43 12.2 12.2 0.52 11.5 11.5 0.64 11.1 11.1 0.71 10.7 10.7 0.77 9.8 9.8 0.92 8.8 8.8 1.08

80 67 14.2 11.4 0.34 13.4 10.9 0.43 12.6 10.5 0.53 11.8 10.1 0.64 11.4 9.9 0.70 10.9 9.7 0.76 10.1 9.3 0.89 9.1 8.9 1.03

80 72 15.2 9.0 0.30 14.8 8.8 0.38 13.8 8.4 0.49 12.8 8.0 0.61 12.2 7.8 0.68 11.7 7.5 0.74 10.5 7.0 0.90 9.3 6.4 1.06

Minimum

75 62 12.7 11.5 0.36 12.0 11.1 0.43 11.3 10.7 0.53 10.5 10.3 0.65 10.1 10.0 0.71 9.7 9.7 0.78 8.8 8.8 0.93 7.9 7.9 1.09

80 62 17.3 17.3 0.56 16.6 16.6 0.66 15.8 15.8 0.77 15.0 15.0 0.91 14.5 14.5 1.00 14.1 14.1 1.07 13.1 13.1 1.27 12.0 12.0 1.48

80 67 18.6 14.2 0.50 17.7 13.7 0.62 16.7 13.3 0.76 15.7 12.9 0.90 15.1 12.6 0.98 14.6 12.4 1.06 13.5 11.9 1.23 12.4 11.4 1.40

80 72 20.0 11.2 0.52 19.1 10.9 0.61 18.2 10.6 0.73 17.0 10.1 0.88 16.4 9.8 0.96 15.8 9.6 1.05 14.4 9.0 1.26 12.9 8.3 1.49

Intermediate

75 62 16.5 14.1 0.55 15.7 13.7 0.65 14.8 13.3 0.77 13.9 12.8 0.90 13.5 12.6 0.99 13.0 12.3 1.06 12.0 11.7 1.25 10.9 10.9 1.45

80 62 25.0 24.0 1.01 23.9 23.5 1.19 22.9 22.9 1.37 21.9 21.9 1.56 21.3 21.3 1.65 20.7 20.7 1.76 19.5 19.5 1.95 18.1 18.1 2.14

80 67 27.1 18.9 0.98 25.9 18.7 1.15 24.6 18.4 1.33 23.3 18.0 1.53 22.6 17.7 1.64 21.9 17.4 1.75 20.4 16.6 1.97 18.9 15.7 2.22

Nominal

80 72 29.4 16.1 0.99 28.1 15.6 1.16 26.6 15.1 1.34 25.2 14.5 1.53 24.3 14.2 1.62 23.5 14.0 1.71 21.6 13.2 1.89 19.7 12.4 2.07

75 62 24.1 19.6 1.00 23.1 19.1 1.16 22.0 18.6 1.35 20.8 18.1 1.54 20.1 17.8 1.63 19.5 17.5 1.74 18.1 16.8 1.92 16.6 16.0 2.13

80 62 30.0 27.8 1.36 28.6 27.1 1.57 27.2 26.5 1.80 25.8 25.7 2.04 25.2 25.2 2.16 24.6 24.6 2.28 23.1 23.1 2.53 21.4 21.4 2.76

80 72 35.3 18.8 1.33 33.7 18.2 1.55 32.0 17.6 1.78 30.1 16.9 2.02 29.1 16.5 2.13 28.1 16.1 2.25 25.9 15.3 2.46 23.6 14.3 2.67

80 67 32.0

Maximum

75 62 28.9 22.8 1.34 27.6 22.1 1.55 26.3 21.4 1.77 24.8 20.8 2.01 24.0 20.4 2.13 23.3 20.1 2.25 21.6 19.3 2.50 19.9 18.5 2.74

Outdoor Temperature: 12°F 17° 20° 30° 40° 47° 50° 60°

Speed

Note: Capacity and Sensible Capacity are shown in units of thousands of Btu/h.

HEATING

Minimum

Intermediate

Nominal

Maximum

5

Page 6

kW

Sensible

Capacity

Total

Capacity

kW

ity

Capac-

Sensible

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

3.67 45.3 3.48 3.81

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

EXPANDED RATINGS - 3 TON WITH G7 FURNACE B CABINET

COOLING

6

Outdoor Temperature: 60°F 70°F 80°F 90°F 95°F 100°F 110°F 120°F

Indoor

Twb - in

Indoor

Tdb - in

Speed

80 62 16.2 16.2 0.44 15.4 15.4 0.55 14.5 14.5 0.66 13.8 13.8 0.80 13.6 13.6 0.88 13.3 13.3 0.95 13.0 13.0 1.11 12.8 12.8 1.29

80 67 17.3 14.4 0.38 16.2 13.9 0.52 15.2 13.4 0.66 14.1 12.9 0.80 13.6 12.6 0.87 13.1 12.3 0.94 12.1 11.7 1.08 11.0 11.0 1.21

80 72 17.8 11.0 0.41 17.0 10.7 0.51 15.9 10.3 0.63 14.9 9.8 0.78 14.6 9.7 0.86 14.2 9.5 0.93 13.8 9.3 1.10 13.7 9.0 1.29

Minimum

75 62 14.8 13.9 0.46 13.8 13.5 0.57 13.0 13.0 0.68 12.4 12.4 0.82 12.1 12.1 0.89 11.9 11.9 0.96 11.6 11.6 1.12 11.4 11.4 1.29

80 62 24.9 23.7 0.91 23.7 23.0 1.08 22.5 22.4 1.26 21.5 21.5 1.46 20.9 20.9 1.57 20.4 20.4 1.68 19.2 19.2 1.92 17.6 17.6 2.18

80 67 27.1 19.9 0.91 25.7 19.0 1.07 24.3 18.4 1.25 22.9 17.9 1.45 22.2 17.6 1.56 21.4 17.3 1.68 20.0 16.6 1.93 18.4 15.7 2.20

80 72 29.3 15.8 0.80 27.6 15.3 0.99 26.2 14.7 1.20 24.7 14.2 1.43 24.0 13.9 1.54 23.1 13.5 1.64 21.4 12.8 1.91 19.4 11.9 2.17

Intermediate

75 62 23.7 19.2 0.91 22.6 18.6 1.08 21.4 18.1 1.26 20.2 17.5 1.47 19.6 17.2 1.57 19.0 17.0 1.69 17.7 16.3 1.92 16.2 15.4 2.18

80 62 37.6 31.7 1.76 35.9 30.8 2.02 34.3 30.0 2.30 32.5 29.2 2.59 31.5 28.5 2.73 30.3 27.8 2.89 28.2 26.8 3.19 25.9 25.6 3.51

80 67 38.4 24.9 1.73 37.5 24.9 2.00 36.2 24.5 2.29 34.6 23.8 2.59 33.6 23.4 2.75 32.5 22.9 2.92 30.1 21.9 3.26 27.2 21.1 3.63

Nominal

80 72 44.2 22.1 1.71 42.1 21.3 2.00 40.2 20.5 2.29 38.0 19.7 2.61 36.9 19.3 2.77 35.6 18.8 2.93 32.9 17.8 3.25 29.9 16.7 3.59

75 62 35.9 26.3 1.76 34.5 25.6 2.03 32.9 24.9 2.30 31.2 24.0 2.60 30.2 23.5 2.75 29.2 23.1 2.90 27.506 22.222 3.24 24.9 20.7 3.52

80 62 43.2 37.0 2.28 41.3 36.0 2.59 39.3 35.0 2.93 37.3 34.1 3.27 36.1 33.4 3.45 34.8 32.7 3.61 32.6 31.7 3.97 30.0 30.0 4.35

67 45.5 32.3 2.33 44.0 30.5 2.63 42.2 29.2 2.95 40.2 28.2 3.29 39.1 27.7 3.48 37.9 27.3 3.66 35.4 26.2 4.06 32.7 24.9 4.47

80

80 72 51.4 26.0 2.24 49.1 25.1 2.58 46.6 24.1 2.96 44.0 23.1 3.33 42.4 22.6 3.51 41.0 22.0 3.69 37.7 20.7 4.07 34.1 19.5 4.46

Maximum

Indoor

Tdb - °F

75 62 41.1 30.4 2.28 39.5 29.4 2.59 37.6 28.5 2.94 35.6 27.6 3.28 34.5 27.1 3.46 33.4 26.5 3.63 31.0 25.4 3.99 28.4 24.2 4.36

Outdoor Temperature: 12°F 17° 20° 30° 40° 47° 50° 60°

Note: Capacity and Sensible Capacity are shown in units of thousands of Btu/h.

HEATING

Speed

60 6.3 2.97 0.62 7.1 3.26 0.64 7.4 3.36 0.64 9.1 4.04 0.66 10.7 4.78 0.66 12.1 5.45 0.65 12.6 5.75 0.64 14.7 7.01 0.62

80 5.8 2.11 0.80 6.4 2.28 0.83 6.8 2.38 0.83 8.3 2.86 0.85 9.8 3.36 0.85 11.0 3.85 0.83 11.5 4.08 0.83 13.5 4.96 0.80

70 6.0 2.48 0.71 6.7 2.70 0.72 7.1 2.85 0.73 8.6 3.39 0.74 10.2 4.04 0.74 11.5 4.59 0.73 12.0 4.86 0.73 14.0 5.89 0.70

Minimum

60 11.1 2.87 1.13 12.1 3.06 1.15 12.7 3.18 1.17 15.0 3.67 1.19 17.5 4.19 1.22 19.5 4.61 1.24 20.3 4.76 1.25 23.4 5.42 1.26

Intermedi-

70 10.8 2.51 1.26 11.8 2.68 1.29 12.4 2.79 1.30 14.6 3.19 1.34 17.0 3.65 1.37 18.9 4.01 1.38 19.8 4.17 1.39 22.8 4.75 1.41

ate

80 10.6 2.21 1.40 11.5 2.35 1.43 12.1 2.44 1.45 14.3 2.81 1.49 16.7 3.23 1.52 18.5 3.54 1.53 19.4 3.66 1.55 22.3 4.19 1.56

60 20.8 2.90 2.11 22.8 3.06 2.18 24.0 3.16 2.23 28.0 3.44 2.39 32.0 3.68 2.55 34.9 3.85 2.66 36.1 3.90 2.71 40.1 4.10 2.87

80 19.8 2.29 2.54 21.7 2.42 2.62 22.9 2.50 2.68 26.7 2.73 2.87 30.6 2.94 3.06 33.3 3.07 3.18 34.4 3.10 3.25 38.3 3.27 3.44

70 20.2 2.55 2.32 22.2 2.70 2.41 23.4 2.78 2.46 27.3 3.04 2.64 31.2 3.26 2.81 34.0 3.40 2.93 35.2 3.46 2.98 39.1 3.63 3.16

Nominal

60 25.2 2.63 2.80 27.4 2.78 2.88 28.7 2.87 2.93 33.1 3.13 3.10 37.4 3.38 3.25 40.4 3.52 3.36 41.6 3.59 3.40 45.8 3.80 3.53

70 24.9 2.42 3.01 27.1 2.55 3.11 28.4 2.63 3.16 32.7 2.87 3.34 36.9 3.08 3.51 39.9 3.23 3.62 41.1 3.29

80 24.3 2.16 3.28 26.5 2.29 3.38 27.7 2.36 3.44 32.0 2.58 3.64 36.1 2.78 3.81 39.0 2.90 3.93 40.2 2.95 3.99 44.3 3.13 4.14

Maximum

Page 7

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

Indoor

Twb - in

45.3 35.2 2.65 43.4 34.2 2.96 41.4 33.2 3.30 39.3 32.2 3.66 38.2 31.7 3.84 37.1 31.1 4.03 34.9 30.0 4.40 32.6 28.8 4.78

55.6 50.8 3.44 53.5 49.9 3.79 51.6 48.8 4.19 49.5 47.7 4.62 48.4 47.2 4.85 47.3 46.5 5.07 45.2 45.0 5.53 43.2 43.2 6.01

45.6 3.46 57.8 44.5 3.85 55.5 43.4 4.27 53.1 42.3 4.71 52.0 41.8 4.93 50.9 41.2 5.16 48.5 40.1 5.60 46.1 39.0 6.05

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Indoor

Tdb - °F

60 5.6 2.70 0.61 6.3 2.99 0.62 6.8 3.22 0.62 8.4 4.13 0.60 10.1 4.63 0.64 11.2 5.24 0.63 11.8 5.56 0.62 13.6 6.67 0.59

70 5.4 2.23 0.71 6.1 2.48 0.72 6.5 2.63 0.73 8.0 3.18 0.74 9.6 3.81 0.74 10.8 4.31 0.73 11.3 4.55 0.73 13.0 5.46 0.70

80 5.1 1.84 0.82 5.8 2.03 0.84 6.3 2.19 0.84 7.8 2.81 0.81 9.3 3.20 0.85 10.4 3.60 0.85 10.9 3.81 0.84 12.5 4.54 0.81

60 14.1 3.33 1.24 15.2 3.53 1.27 16.0 3.65 1.28 18.5 4.14 1.31 21.3 4.62 1.35 23.4 5.05 1.36 24.2 5.22 1.36 27.3 5.85 1.37

70 13.6 2.85 1.40 14.8 3.03 1.43 15.5 3.15 1.44 17.9 3.55 1.48 20.6 4.00 1.51 22.6 4.34 1.52 23.4 4.49 1.53 26.5 5.04 1.54

80 13.3 2.50 1.56 14.4 2.64 1.59 15.1 2.75 1.61 17.5 3.12 1.65 20.1 3.49 1.69 22.1 3.80 1.70 22.8 3.92 1.71 25.9 4.42 1.72

60 27.2 2.67 2.99 30.3 2.87 3.09 32.1 2.98 3.16 37.9 3.33 3.33 43.1 3.60 3.51 46.5 3.76 3.62 47.8 3.81 3.67 52.1 4.02 3.80

70 26.9 2.41 3.27 30.0 2.60 3.38 31.8 2.70 3.45 37.5 3.01 3.65 42.7 3.25 3.84 46.0 3.40 3.96 47.4 3.46 4.01 51.5 3.62 4.17

80 26.3 2.15 3.58 29.3 2.32 3.70 31.1 2.41 3.78 36.6 2.69 3.99 41.7 2.90 4.21 44.9 3.03 4.35 46.2 3.08 4.40 50.3 3.23 4.56

60 30.1 2.59 3.41 32.7 2.75 3.49 34.1 2.84 3.53 39.2 3.14 3.66 44.1 3.41 3.79 47.3 3.58 3.87 48.8 3.65 3.92 53.4 3.89 4.02

70 30.0 2.42 3.64 32.6 2.57 3.72 34.1 2.65 3.77 39.1 2.93 3.92 44.0 3.18 4.05 47.3 3.35 4.14 48.7 3.41 4.18 53.3 3.64 4.30

80 29.6 2.21 3.93 32.2 2.35 4.02 33.6 2.43 4.05 38.6 2.68 4.22 43.4 2.91 4.37 46.6 3.06 4.46 48.0 3.12 4.51 52.6 3.33 4.64

Outdoor Temperature: 60°F 70°F 80°F 90°F 95°F 100°F 110°F 120°F

EXPANDED RATINGS - 4 TON WITH G7 FURNACE C CABINET

COOLING

Indoor

Tdb - in

Speed

80 62 16.9 16.9 0.40 16.0 16.0 0.51 15.1 15.1 0.62 14.3 14.3 0.76 14.0 14.0 0.84 13.7 13.7 0.91 13.3 13.3 1.06 13.1 13.1 1.26

80 67 18.2 13.7 0.34 16.9 13.5 0.48 15.7 13.2 0.62 14.6 12.8 0.76 14.1 12.6 0.84 13.5 12.4 0.91 12.5 11.9 1.06 11.5 11.0 1.22

80 72 18.0 11.5 0.37 17.5 11.3 0.47 16.3 10.8 0.60 15.3 10.5 0.74 14.9 10.3 0.82 14.5 10.2 0.90 14.0 10.0 1.05 13.7 9.8 1.25

Minimum

75 62 15.3 15.0 0.42 14.3 14.3 0.53 13.5 13.5 0.66 12.8 12.8 0.78 12.5 12.5 0.86 12.3 12.3 0.93 12.0 12.0 1.07 11.8 11.8 1.26

80 62 31.0 30.8 1.09 29.7 29.7 1.28 28.4 28.4 1.48 27.1 27.1 1.69 26.4 26.4 1.80 25.6 25.6 1.91 23.8 23.8 2.15 21.9 21.9 2.39

80 67 32.3 23.6 1.00 31.2 23.1 1.22 29.8 22.6 1.45 28.3 22.0 1.68 27.4 21.7 1.80 26.5 21.4 1.92 24.6 20.5 2.17 22.4 19.5 2.42

80 72 35.9 20.1 1.01 34.2 19.4 1.22 32.3 18.8 1.44 30.6 18.1 1.67 29.6 17.7 1.79 28.4 17.2 1.90 26.1 16.2 2.15 23.5 15.2 2.39

Intermediate

75 62 29.4 24.9 1.09 28.0 24.2 1.28 26.6 23.4 1.49 25.0 22.7 1.70 24.2 22.3 1.81 23.4 21.8 1.92 21.7 20.9 2.15 19.8 19.8 2.38

80 62 47.3 43.4 2.64 45.4 42.3 2.96 43.4 41.4 3.29 41.3 40.3 3.64 40.2 39.8 3.83 39.2 39.1 4.01 37.3 37.3 4.40 35.3 35.3 4.78

80 67 50.9 38.8 2.64 48.9 37.8 2.96 46.6 36.8 3.30 44.3 35.8 3.67 43.0 35.3 3.87 41.7 34.8 4.08 39.0 33.8 4.52 36.6 32.9 4.99

80 72 55.9 29.4 2.62 53.0 28.4 2.97 50.2 27.3 3.36 47.6 26.4 3.73 46.4 25.9 3.92 45.2 25.4 4.10 42.9 24.5 4.47 40.4 23.6 4.82

Nominal

75 62

80 62

80 67 60.3

80 72 65.4 34.2 3.49 62.6 33.1 3.91 60.0 32.2 4.35 57.6 31.3 4.80 56.4 30.9 5.01 55.3 30.4 5.23 53.0 29.7 5.68 50.6 28.8 6.10

Maximum

75 62 53.2 41.2 3.45 51.3 40.2 3.81 49.3 39.2 4.22 47.2 38.2 4.64 46.1 37.6 4.87 45.0 37.1 5.09 42.7 35.9 5.54 40.4 34.7 6.01

Outdoor Temperature: 12°F 17° 20° 30° 40° 47° 50° 60°

Speed

Note: Capacity and Sensible Capacity are shown in units of thousands of Btu/h.

HEATING

Minimum

Intermediate

Nominal

Maximum

7

Page 8

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

Indoor

Twb - in

80 62 13.5 13.5 0.34 12.9 12.9 0.41 12.2 12.2 0.50 11.5 11.5 0.61 11.1 11.1 0.68 10.7 10.7 0.74 9.8 9.8 0.88 8.8 8.8 1.03

Indoor

Tdb - in

80 67 14.2 10.9 0.33 13.4 10.5 0.41 12.6 10.0 0.51 11.8 9.7 0.62 11.3 9.5 0.67 10.9 9.3 0.73 10.0 8.9 0.85 9.1 8.5 0.98

80 72 15.2 9.0 0.29 14.8 8.8 0.36 13.8 8.4 0.47 12.8 8.0 0.58 12.2 7.8 0.65 11.7 7.5 0.71 10.5 7.0 0.86 9.3 6.4 1.01

75 62 12.7 11.4 0.34 12.0 11.1 0.41 11.2 10.7 0.51 10.5 10.2 0.62 10.1 10.0 0.68 9.6 9.6 0.75 8.8 8.8 0.89 7.9 7.9 1.04

80 62 17.5 17.5 0.52 16.8 16.8 0.61 16.0 16.0 0.71 15.2 15.2 0.84 14.7 14.7 0.92 14.3 14.3 0.99 13.3 13.3 1.17 12.2 12.2 1.37

80 67 18.9 13.8 0.46 17.9 13.3 0.57 16.9 12.9 0.70 15.9 12.5 0.83 15.4 12.2 0.90 14.8 12.0 0.98 13.7 11.6 1.13 12.6 11.1 1.29

80 72 20.3 11.4 0.48 19.4 11.1 0.56 18.4 10.7 0.67 17.2 10.2 0.81 16.6 10.0 0.89 16.0 9.7 0.97 14.6 9.1 1.16 13.1 8.4 1.38

75 62 16.7 14.3 0.51 15.9 13.9 0.60 15.0 13.5 0.71 14.1 13.0 0.83 13.7 12.7 0.91 13.2 12.5 0.98 12.2 11.9 1.15 11.1 11.1 1.34

80 62 25.4 24.4 0.97 24.3 23.9 1.14 23.3 23.3 1.32 22.3 22.3 1.50 21.7 21.7 1.59 21.1 21.1 1.69 19.8 19.8 1.87 18.4 18.4 2.06

80 67 27.6 18.6 0.94 26.4 18.5 1.11 25.1 18.2 1.28 23.7 17.7 1.47 23.0 17.5 1.57 22.3 17.2 1.68 20.8 16.4 1.90 19.2 15.5 2.13

80 72 29.9 16.4 0.95 28.6 15.9 1.12 27.1 15.4 1.29 25.6 14.8 1.47 24.7 14.5 1.56 23.9 14.2 1.64 22.0 13.4 1.82 20.0 12.6 1.99

75 62 24.5 19.9 0.96 23.5 19.5 1.12 22.3 18.9 1.30 21.1 18.4 1.48 20.5 18.1 1.57 19.8 17.8 1.67 18.4 17.1 1.85 16.9 16.3 2.05

80 62 30.5 28.3 1.31 29.1 27.6 1.51 27.7 27.0 1.73 26.3 26.2 1.96 25.6 25.6 2.08 25.0 25.0 2.19 23.5 23.5 2.43 21.8 21.8 2.65

22.9 1.33 31.2 22.4 1.52 29.7 21.8 1.73 28.2 21.2 1.95 27.4 20.9 2.07 26.6 20.6 2.20 24.8 19.8 2.46 23.0 19.0 2.73

80 67 32.5

80 72 35.9 19.1 1.28 34.3 18.5 1.49 32.6 17.9 1.71 30.6 17.2 1.94 29.6 16.8 2.05 28.6 16.4 2.16 26.4 15.6 2.37 24.0 14.6 2.57

75 62 29.4 23.2 1.29 28.1 22.5 1.49 26.7 21.8 1.70 25.2 21.1 1.93 24.5 20.8 2.05 23.7 20.4 2.16 22.0 19.7 2.40 20.2 18.8 2.63

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Indoor

Tdb - °F

60 2.5 2.14 0.34 3.1 2.64 0.34 3.5 2.95 0.34 4.7 4.00 0.34 5.9 5.14 0.34 6.8 6.03 0.33 7.2 6.44 0.33 8.4 8.00 0.31

70 2.3 1.74 0.40 2.9 2.16 0.40 3.3 2.41 0.40 4.5 3.26 0.40 5.6 4.20 0.39 6.5 4.92 0.39 6.8 5.26 0.38 8.0 6.53 0.36

80 2.2 1.40 0.47 2.8 1.73 0.47 3.1 1.93 0.47 4.2 2.62 0.47 5.4 3.37 0.47 6.1 3.95 0.46 6.5 4.22 0.45 7.6 5.24 0.43

60 6.9 3.29 0.61 7.7 3.59 0.63 8.1 3.77 0.63 9.8 4.39 0.65 11.4 5.07 0.66 12.6 5.59 0.66 13.1 5.82 0.66 14.9 6.69 0.65

70 6.6 2.72 0.71 7.4 2.96 0.73 7.8 3.11 0.74 9.4 3.62 0.76 11.0 4.18 0.77 12.1 4.61 0.77 12.6 4.81 0.77 14.3 5.52 0.76

80 6.4 2.28 0.82 7.1 2.48 0.84 7.5 2.60 0.85 9.0 3.03 0.87 10.5 3.50 0.88 11.6 3.86 0.88 12.1 4.03 0.88 13.7 4.62 0.87

60 13.6 3.04 1.31 14.9 3.26 1.34 15.7 3.40 1.36 18.5 3.84 1.41 21.3 4.26 1.47 23.3 4.56 1.50 24.2 4.69 1.51 27.1 5.11 1.56

70 13.1 2.62 1.47 14.0 2.73 1.50 15.2 2.93 1.52 17.9 3.31 1.59 20.6 3.68 1.64 22.6 3.93 1.68 23.4 4.04 1.70 26.2 4.40 1.75

80 12.7 2.26 1.65 14.0 2.43 1.69 14.7 2.53 1.71 17.3 2.85 1.78 20.0 3.17 1.84 21.8 3.39 1.89 22.7 3.49 1.90 25.4 3.80 1.96

60 14.8 2.94 1.48 16.2 3.16 1.51 17.1 3.29 1.52 19.9 3.73 1.57 22.9 4.16 1.61 25.0 4.46 1.64 26.0 4.59 1.66 29.1 5.02 1.70

70 14.3 2.55 1.64 15.6 2.74 1.67 16.4 2.85 1.69 19.2 3.23 1.74 22.1 3.61 1.79 24.1 3.87 1.82 25.0 3.99 1.84 28.0 4.36 1.88

80 13.7 2.21 1.82 15.0 2.38 1.85 15.8 2.48 1.87 18.5 2.81 1.93 21.2 3.14 1.98 23.2 3.36 2.02 24.0 3.46 2.03 26.9 3.79 2.08

Outdoor Temperature: 60°F 70°F 80°F 90°F 95°F 100°F 110°F 120°F

EXPANDED RATINGS - 2 TON IQ HEAT PUMP WITH B6VMAI AIR HANDLER

Speed

COOLING

8

Minimum

Intermediate

Nominal

Maximum

Outdoor Temperature: 12°F 17° 20° 30° 40° 47° 50° 60°

Speed

Note: Capacity and Sensible Capacity are shown in units of thousands of Btu/h.

HEATING

Minimum

Intermediate

Nominal

Maximum

Page 9

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

Indoor

Twb - in

32.3 2.28 45.8 30.5 2.57 43.9 29.2 2.88 41.8 28.2 3.22 40.7 27.8 3.40 39.5 27.3 3.58 36.9 26.2 3.96 34.0 24.9 4.37

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Indoor

Tdb - °F

60 6.0 2.98 0.59 6.8 3.29 0.60 7.2 3.48 0.61 8.9 4.15 0.63 10.6 4.91 0.63 11.9 5.52 0.63 12.4 5.80 0.63 14.3 6.86 0.61

70 5.7 2.51 0.67 6.4 2.76 0.68 6.9 2.92 0.69 8.4 3.49 0.71 10.1 4.13 0.71 11.3 4.64 0.71 11.8 4.87 0.71 13.6 5.76 0.69

80 5.5 2.11 0.76 6.2 2.33 0.78 6.6 2.46 0.79 8.1 2.94 0.81 9.7 3.48 0.82 10.8 3.90 0.81 11.3 4.10 0.81 13.1 4.85 0.79

60 11.1 2.91 1.12 12.1 3.11 1.14 12.7 3.24 1.15 15.0 3.71 1.18 17.5 4.24 1.21 19.5 4.65 1.23 20.3 4.84 1.23 23.4 5.51 1.25

70 10.8 2.54 1.25 11.8 2.71 1.27 12.4 2.82 1.28 14.6 3.23 1.32 17.0 3.70 1.35 18.9 4.06 1.37 19.8 4.22 1.37 22.8 4.81 1.39

80 10.6 2.23 1.39 11.5 2.39 1.41 12.1 2.49 1.43 14.3 2.85 1.47 16.7 3.25 1.50 18.5 3.57 1.52 19.4 3.71 1.53 22.3 4.23 1.54

60 20.4 2.76 2.16 22.6 2.95 2.24 23.9 3.06 2.28 28.1 3.39 2.42 32.1 3.69 2.55 34.9 3.89 2.63 36.0 3.96 2.66 39.7 4.22 2.76

70 19.8 2.44 2.38 22.0 2.61 2.47 23.3 2.71 2.52 27.4 3.01 2.67 31.3 3.27 2.81 34.0 3.44 2.90 35.1 3.51 2.93 38.7 3.74 3.04

80 19.4 2.19 2.60 21.5 2.35 2.69 22.8 2.43 2.74 26.8 2.70 2.91 30.7 2.94 3.06 33.3 3.09 3.15 34.3 3.15 3.19 37.9 3.35 3.31

60 25.2 2.67 2.76 27.4 2.82 2.85 28.7 2.90 2.90 33.1 3.17 3.06 37.4 3.41 3.21 40.4 3.57 3.32 41.6 3.63 3.36 45.8 3.84 3.49

70 24.9 2.45 2.97 27.1 2.58 3.07 28.4 2.66 3.13 32.7 2.90 3.30 36.9 3.12 3.47 39.9 3.27 3.58 41.1 3.33 3.62 45.3 3.52 3.77

80 24.3 2.20 3.24 26.5 2.32 3.34 27.7 2.39 3.40 32.0 2.61 3.59 36.1 2.80 3.77 39.0 2.94 3.89 40.2 2.99 3.94 44.3 3.17 4.10

Indoor

Tdb - in

Outdoor Temperature: 60°F 70°F 80°F 90°F 95°F 100°F 110°F 120°F

EXPANDED RATINGS - 3 TON IQ HEAT PUMP WITH B6VMAI AIR HANDLER

Speed

COOLING

80 62 16.9 16.9 0.43 16.0 16.0 0.54 15.1 15.1 0.65 14.4 14.4 0.78 14.1 14.1 0.86 13.8 13.8 0.93 13.5 13.5 1.09 13.3 13.3 1.26

80 67 18.0 14.1 0.38 16.9 13.6 0.51 15.8 13.1 0.65 14.7 12.6 0.78 14.2 12.3 0.85 13.6 12.0 0.92 12.5 11.4 1.05 11.5 10.8 1.19

80 72 18.5 11.4 0.40 17.7 11.1 0.50 16.5 10.7 0.62 15.5 10.2 0.76 15.2 10.1 0.84 14.8 9.9 0.91 14.4 9.7 1.08 14.2 9.4 1.26

Minimum

75 62 15.4 14.5 0.45 14.4 14.0 0.56 13.5 13.5 0.67 12.9 12.9 0.80 12.6 12.6 0.87 12.4 12.4 0.94 12.0 12.0 1.10 11.9 11.9 1.26

80 62 25.9 24.6 0.86 24.6 23.9 1.02 23.4 23.3 1.19 22.3 22.3 1.38 21.7 21.7 1.49 21.2 21.2 1.59 19.9 19.9 1.82 18.3 18.3 2.06

80 67 28.1 19.8 0.86 26.7 18.9 1.01 25.3 18.3 1.18 23.8 17.8 1.37 23.0 17.5 1.48 22.3 17.2 1.59 20.7 16.6 1.82 19.2 15.6 2.08

80 62 39.2 33.0 1.72 37.4 32.1 1.97 35.7 31.2 2.25 33.9 30.4 2.53 32.8 29.7 2.67 31.6 29.0 2.82 29.4 27.9 3.12 27.0 26.7 3.43

80 72 30.4 16.4 0.76 28.7 15.9 0.94 27.2 15.3 1.14 25.7 14.7 1.35 24.9 14.4 1.46 24.0 14.0 1.56 22.2 13.3 1.81 20.2 12.4 2.05

75 62 24.6 19.9 0.86 23.5 19.3 1.02 22.3 18.8 1.19 21.0 18.2 1.39 20.3 17.9 1.49 19.7 17.6 1.60 18.4 16.9 1.82 16.8 16.0 2.06

Intermediate

80 67 39.9 24.9 1.69 39.1 24.9 1.95 37.7 24.5 2.23 36.0 23.8 2.53 35.0 23.4 2.69 33.9 22.9 2.85 31.3 21.9 3.19 28.3 21.1 3.54

80 72 46.0 23.0 1.67 43.9 22.2 1.95 41.9 21.4 2.24 39.6 20.5 2.55 38.4 20.1 2.71 37.1 19.6 2.86 34.3 18.5 3.18 31.1 17.4 3.51

Nominal

75 62 37.4 27.4 1.72 35.9 26.7 1.98 34.3 25.9 2.25 32.5 25.0 2.54 31.5 24.5 2.69 30.5 24.0 2.83 28.652 23.124 3.17 25.9 21.5 3.44

80 62 45.0 38.5 2.23 43.0 37.5 2.53 40.9 36.5 2.86 38.9 35.5 3.20 37.6 34.8 3.37 36.2 34.1 3.53 34.0 33.0 3.88 31.3 31.3 4.25

80 72 53.5 27.1 2.19 51.1 26.1 2.52 48.5 25.1 2.89 45.8 24.1 3.25 44.2 23.5 3.43 42.7 22.9 3.61 39.3 21.6 3.98 35.5 20.3 4.36

80 67 47.4

Maximum

75 62 42.9 31.6 2.23 41.1 30.6 2.53 39.2 29.7 2.87 37.1 28.7 3.21 35.9 28.1 3.38 34.8 27.6 3.55 32.3 26.4 3.90 29.6 25.1 4.26

Outdoor Temperature: 12°F 17° 20° 30° 40° 47° 50° 60°

HEATING

Note: Capacity and Sensible Capacity are shown in units of thousands of Btu/h.

Speed

Minimum

Intermediate

Nominal

Maximum

9

Page 10

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

kW

Sensible

Capacity

Total

Capacity

43.8 3.48 59.9 42.7 3.88 57.4 41.7 4.30 55.0 40.6 4.74 53.8 40.1 4.96 52.7 39.6 5.19 50.2 38.5 5.64 47.7 37.5 6.09

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

COP kW

Total

Capacity

Outdoor Temperature: 60°F 70°F 80°F 90°F 95°F 100°F 110°F 120°F

EXPANDED RATINGS - 4 TON IQ HEAT PUMP WITH B6VMAI AIR HANDLER

COOLING

10

Indoor

Twb - in

Indoor

Tdb - in

Speed

80 62 17.2 17.2 0.38 16.3 16.3 0.48 15.4 15.4 0.59 14.6 14.6 0.72 14.3 14.3 0.79 14.0 14.0 0.86 13.6 13.6 1.00 13.4 13.4 1.19

80 72 18.3 11.7 0.35 17.8 11.5 0.44 16.6 11.0 0.57 15.6 10.7 0.70 15.2 10.5 0.77 14.8 10.4 0.85 14.3 10.2 0.99 14.0 10.0 1.18

80 67 18.5 14.6 0.32 17.3 14.4 0.45 16.1 14.1 0.58 14.9 13.7 0.72 14.3 13.4 0.79 13.8 13.2 0.86 12.7 12.7 1.00 11.7 11.7 1.15

Minimum

75 62 15.6 15.2 0.40 14.6 14.6 0.50 13.7 13.7 0.62 13.1 13.1 0.74 12.8 12.8 0.81 12.6 12.6 0.88 12.2 12.2 1.01 12.0 12.0 1.19

80 62 30.2 30.0 1.08 28.9 28.9 1.27 27.7 27.7 1.47 26.4 26.4 1.68 25.7 25.7 1.79 24.9 24.9 1.90 23.2 23.2 2.13 21.3 21.3 2.37

80 67 31.5 23.3 0.99 30.3 22.8 1.21 29.0 22.3 1.43 27.5 21.8 1.67 26.7 21.4 1.79 25.8 21.1 1.91 23.9 20.3 2.15 21.8 19.3 2.40

80 62 49.0 44.9 2.43 47.0 43.8 2.72 44.9 42.8 3.02 42.7 41.7 3.35 41.6 41.2 3.52 40.6 40.5 3.69 38.6 38.6 4.04 36.5 36.5 4.39

75 62 28.6 24.3 1.08 27.3 23.6 1.27 25.9 22.8 1.48 24.4 22.1 1.69 23.6 21.7 1.80 22.8 21.3 1.91 21.1 20.4 2.13 19.3 19.3 2.36

80 72 35.0 19.6 1.00 33.3 18.9 1.21 31.5 18.3 1.43 29.8 17.6 1.66 28.8 17.2 1.78 27.7 16.8 1.89 25.4 15.8 2.13 22.9 14.8 2.37

Intermediate

80 72 57.8 30.4 2.41 54.9 29.4 2.73 52.0 28.3 3.09 49.3 27.3 3.43 48.0 26.8 3.60 46.8 26.3 3.77 44.4 25.4 4.11 41.8 24.4 4.43

80 67 52.7 37.3 2.43 50.6 36.3 2.72 48.2 35.3 3.03 45.8 34.4 3.38 44.5 33.9 3.56 43.2 33.5 3.75 40.4 32.4 4.15 37.5 31.3 4.59

Nominal

75 62 46.8 36.4 2.44 44.9 35.4 2.72 42.8 34.3 3.03 40.7 33.3 3.36 39.6 32.8 3.53 38.4 32.2 3.70 36.1 31.1 4.04 33.7 29.8 4.39

80 62 57.5 52.6 3.46 55.4 51.6 3.82 53.4 50.5 4.22 51.2 49.4 4.65 50.1 48.8 4.88 48.9 48.1 5.11 46.8 46.6 5.57 44.7 44.7 6.05

80 67 62.4

80 72 67.7 35.4 3.51 64.8 34.3 3.94 62.1 33.3 4.38 59.6 32.4 4.83 58.4 32.0 5.05 57.2 31.5 5.27 54.8 30.7 5.72 52.4 29.8 6.14

Maximum

Indoor

75 62 55.1 42.6 3.47 53.1 41.6 3.84 51.0 40.5 4.25 48.8 39.5 4.67 47.7 38.9 4.90 46.6 38.3 5.13 44.2 37.2 5.58 41.8 35.9 6.05

Outdoor Temperature: 12°F 17° 20° 30° 40° 47° 50° 60°

Speed

Note: Capacity and Sensible Capacity are shown in units of thousands of Btu/h.

HEATING

60 7.0 3.66 0.56 7.6 3.95 0.56 7.9 4.13 0.56 9.3 4.83 0.56 10.8 5.66 0.56 11.9 6.34 0.55 12.5 6.65 0.55 14.3 7.84 0.53

Tdb - °F

70 6.7 3.01 0.65 7.3 3.25 0.65 7.6 3.40 0.66 8.9 3.97 0.70 10.3 4.66 0.65 11.4 5.21 0.64 11.9 5.47 0.64 13.7 6.45 0.62

80 6.4 2.51 0.75 7.0 2.71 0.76 7.3 2.84 0.76 8.6 3.31 0.76 10.0 3.88 0.75 11.0 4.35 0.74 11.5 4.56 0.74 13.2 5.38 0.72

Minimum

60 14.2 3.52 1.18 15.4 3.75 1.20 16.1 3.89 1.22 18.7 4.39 1.25 21.5 4.94 1.28 23.6 5.36 1.29 24.5 5.55 1.29 27.6 6.23 1.30

70 13.7 3.03 1.33 14.9 3.22 1.35 15.6 3.35 1.37 18.1 3.78 1.41 20.8 4.25 1.43 22.8 4.61 1.45 23.7 4.78 1.45 26.7 5.36 1.46

Intermediate

80 13.4 2.65 1.48 14.5 2.82 1.51 15.2 2.93 1.53 17.7 3.31 1.57 20.3 3.72 1.60 22.3 4.04 1.62 23.1 4.18 1.62 26.1 4.69 1.63

60 27.2 2.64 3.02 30.3 2.88 3.09 32.1 3.01 3.13 37.9 3.42 3.25 43.1 3.76 3.35 46.5 3.98 3.42 47.8 4.07 3.45 52.1 4.33 3.52

70 26.9 2.38 3.31 30.0 2.60 3.38 31.8 2.72 3.42 37.5 3.09 3.56 42.7 3.40 3.67 46.0 3.60 3.74 47.4 3.68 3.77 51.5 3.92 3.86

80 26.3 2.13 3.62 29.3 2.32 3.70 31.1 2.43 3.75 36.6 2.76 3.89 41.7 3.04 4.02 44.9 3.21 4.10 46.2 3.28 4.13 50.3 3.49 4.22

Nominal

60 30.4 2.75 3.24 33.0 2.92 3.31 34.5 3.02 3.35 39.6 3.33 3.48 44.5 3.62 3.60 47.8 3.81 3.68 49.3 3.88 3.72 53.9 4.14 3.82

70 30.3 2.57 3.46 32.9 2.73 3.53 34.5 2.82 3.58 39.5 3.11 3.72 44.4 3.38 3.85 47.8 3.56 3.94 49.2 3.63 3.97 53.8 3.86 4.08

80 29.9 2.35 3.73 32.5 2.50 3.81 34.0 2.58 3.85 39.0 2.85 4.01 43.8 3.10 4.15 47.1 3.26 4.24 48.5 3.32 4.28 53.1 3.54 4.40

Maximum

Page 11

ACCESSORIES - CONDENSING UNIT

Controller/Thermostat - 920620*

* Revision “D” or later.

11

Page 12

Before purchasing this appliance, read important energy cost and efficiency

information available from your retailer. Specifications and illustrations subject

to change without notice and without incurring obligations.

Manufactured under license by NORDYNE, O’Fallon, MO. ®Registered Trademark/ TM Trademark

of Maytag Corporation or its related companies. ©2012. All rights reserved.

350D-1212 (Replaces 350D-0212

Printed in U.S.A. (12/12)

Loading...

Loading...