Maytag PSD243LGRW-PPSD243LGW0, PSD243LGRW, PSD243LGRQ-PPSD243LGC0, PSD243LGRQ Owner’s Manual

Congratulations on your purchase

of a Maytag Performa TM refrigerator! Your

satisfaction is very important to us, so please

read this guide carefully. You will find instructions

on the proper operation and maintenance of your

new appliance.

Save time and money. If something should go wrong,

we suggest consulting the "Before You Call for

Service" section of this book. It is designed to help

you solve basic problems before consulting a servicer.

If you have questions, write us (include your model

number and phone number) or call:

Maytag Services sM

Attn: CAIR '°Center

P.O. Box 2370

Cleveland, TN 37320-2370

1-800-688-9900 U.S.A.

1-800-688-2002 CANADA

1-800-688-2080 U.S.A. TTY (for deaf, hearing

impaired or speech impaired)

(Mon.-Fri., 8 a.m.-8 p.m. Eastern Time)

Internet: http://www.maytag.com

Important

Installation

Fresh Food Features ...

Freezer Features

Dispenser Features ..............

Filtration System .....................

Water Filter Data ..................... 13

Care and Cleaning ................. 14-16

Normal Operating Sounds ............. 17

BeforeYou Call for Service .......... 18-19

Warranty ........................... 21

Manuel du Proprietaire ................ 22

Manual del Proprietario ................ 44

Form No. A/3/03 Part No.12591319 MCS Part No.16022157 @2003 Appliance Sales Co. Litho U.S.A.

RECOGNIZE SAFETY

SYMBOLS, WORDS,

LABELS

To reduce risk of injury or death,

follow basic precautions, including

the following:

Warning and Important Safety In-

structions appearing in this manual are

not meantto cover allpossible conditions

and situations that may occur Common

sense, caution and care must be exer-

cised when installing, maintaining or

operating refrigerator

Always contact your dealer, distributor,

service agent or manufacturer about

problems or conditions you do not under-

stand

To reduce risk of fire, electric shock, serious injury ordeath when using your refrigerator, follow these basic precautions,

including the following:

1 Read all instructions before using the refrigerator.

2. Observe all local codesand ordinances.

3. Be sure to follow grounding instructions.

4. Check with a qualified electrician if you are not sure this

appliance is properly grounded.

5. DO NOT ground to a gas line.

6 DO NOT ground to a cold-water pipe.

7. Refrigerator is designed to operate on a separate 103 to

126 volt, 15 amp., 60 cycle line. DO NOT modify plug on

power cord. If plug does not fit electrical outlet, have prop-

er outlet installed by a qualified electrician.

8. DO NOT use a two-prongadapter, extension cord or power

strip

9. DO NOT remove warningtag from power cord.

10. DO NOTtamper with refrigerator controls.

11. DO NOT service or replace any part of refrigeratorunless

specifically recommended in owner's manual or published

DANGER - Immediate hazards which

WILL result in severe personal injury

or death.

WARNING - Hazardsor unsafeprac-

tices which COULD result in severe

personal injury or death.

CAUTION - Hazards or unsafe prac-

tices which COULD result in minor

personal injury.

user-repairinstructions.DONOT attemptserviceifinstructions

are notunderstoodorif theyare beyondpersonalsktl level.

12. Always disconnect refrigerator from electrical supply before

attempting any service. Disconnectpower cord bygrasping

the plug, not the cord.

13. Install refrigerator according to Installation Instructions. All

connections for water, electrical power and grounding must

comply with local codes and be made by licensed person-

nel when required.

14. Keep your refrigerator in good condition. Bumping or drop-

ping refrigerator can damage unit or cause unit to malfunc-

tionor leak. Ifdamage occurs, have refrigeratorchecked by

qualified service technician

15 Replace worn power cords and/or loose plugs.

16. Always read and follow manufacturer's storage and ideal

environmentinstructionsforitemsbeing storedinrefrigerator.

IMPORTANT: Child entrapment and

suffocation are not problems of the

past. Junked or abandoned refrigera-

tors are still dangerous - even if they

sit out for "just a few days." If you are

getting rid of your old refrigerator,

please follow the instruclons below to

help prevent accidents.

Before youthrow away your old refrig-

erator or freezer:

Takeoff the doors.

Leave the shelves in

place so children

may not easily climb

inside.

i i

l,ll,

'1

£ fliTIBiilITlliTi!l!

I

These instructions were provided to aid

you in the installation of your refrigerator.

THEBEST

THE0PE G

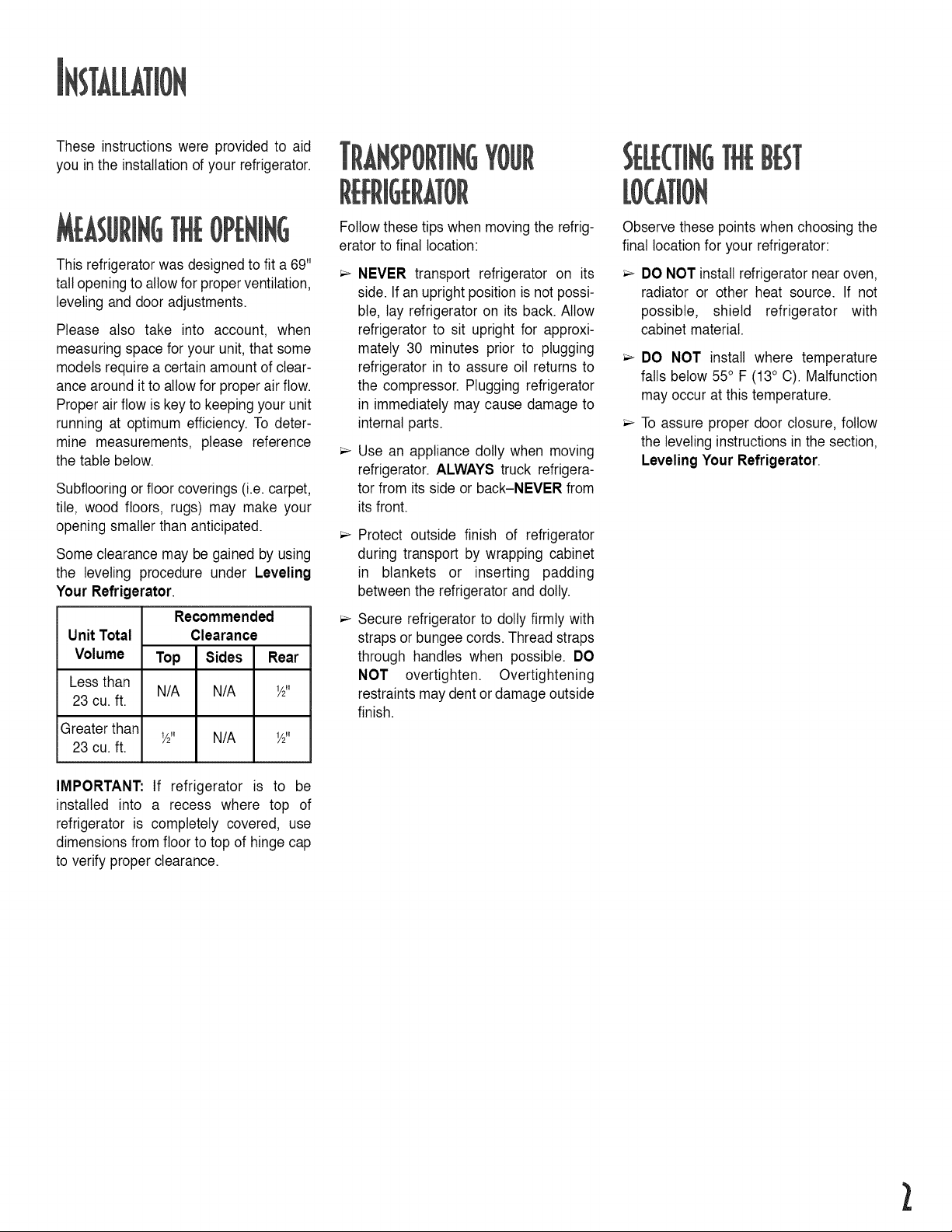

This refrigerator was designed to fit a 69"

tallopening to allow for properventilation,

leveling and door adjustments.

Please also take into account, when

measuring space for your unit, that some

models require a certain amount of clear-

ance around it to allow for proper air flow.

Proper air flow is key to keeping your unit

running at optimum efficiency. To deter-

mine measurements, please reference

the table below.

Subflooring or floor coverings (i.e. carpet,

tile, wood floors, rugs) may make your

opening smaller than anticipated.

Some clearance may be gained by using

the leveling procedure under Leveling

Your Refrigerator.

Recommended

UnitTotal

Volume

Less than

23 cu. ft.

Greaterthan

23 cu. ft.

Clearance

Top Sides Rear

N/A N/A Y2"

_" N/A Y2"

Follow these tips when moving the refrig-

erator to final location:

NEVER transport refrigerator on its

side. Ifan upright position is not possi-

ble, lay refrigerator on its back. Allow

refrigerator to sit upright for approxi-

mately 30 minutes prior to plugging

refrigerator in to assure oil returns to

the compressor. Plugging refrigerator

in immediately may cause damage to

internal parts.

Use an appliance dolly when moving

refrigerator. ALWAYS truck refrigera-

tor from its side or back-NEVER from

its front.

Protect outside finish of refrigerator

during transport by wrapping cabinet

in blankets or inserting padding

between the refrigerator and dolly.

Secure refrigerator to dolly firmly with

straps or bungee cords. Thread straps

through handles when possible. DO

NOT overtighten. Overtightening

restraints maydent or damage outside

finish.

Observe these points when choosing the

final location for your refrigerator:

DO NOT install refrigerator near oven,

radiator or other heat source. If not

possible, shield refrigerator with

cabinet material.

DO NOT install where temperature

falls below 55° F (13° C). Malfunction

may occur at this temperature.

To assure proper door closure, follow

the leveling instructions in the section,

Leveling Your Refrigerator.

IMPORTANT: If refrigerator is to be

installed into a recess where top of

refrigerator is completely covered, use

dimensions from floor to top of hinge cap

to verify proper clearance.

2

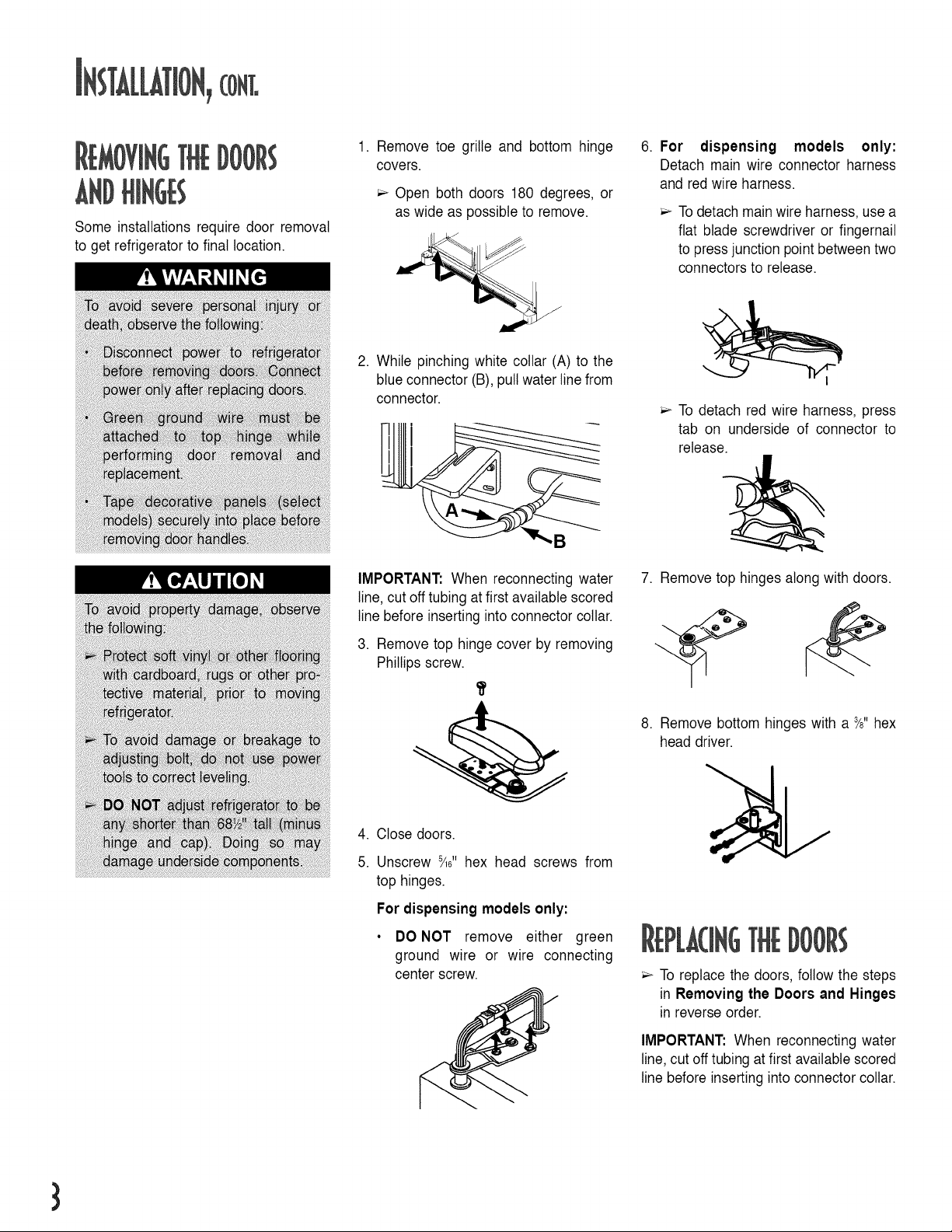

Some installations require door removal

to get refrigerator to final location.

1. Remove toe grille and bottom hinge

covers.

Open both doors 180 degrees, or

as wide as possible to remove.

2. While pinching white collar (A) to the

blue connector (B),pull water linefrom

connector.

,B

6. For dispensing models only:

Detach main wire connector harness

and red wire harness.

Todetach mainwire harness, use a

flat blade screwdriver or fingernail

to press junction point between two

connectors to release.

To detach red wire harness, press

tab on underside of connector to

release.

IMPORTANT: When reconnecting water

line, cut offtubing at first available scored

line before inserting into connector collar.

3. Remove top hinge cover by removing

Phillips screw.

4. Close doors.

5. Unscrew _6" hex head screws from

top hinges.

For dispensing modelsonly:

• DO NOT remove either green

ground wire or wire connecting

center screw.

7. Remove top hinges along with doors.

8. Remove bottom hinges with a _8"hex

head driver.

THEDOORS

To replace the doors, follow the steps

in Removing the Doors and Hinges

in reverse order.

3

IMPORTANT: When reconnecting water

line, cut offtubing at first available scored

line before inserting into connector collar.

If installing handles for the first time, the

fresh food handles can be located within

the fresh food section. The handle trim

will be located in the literature pack.

Remove two ¼" hex nut screws from

bottom of refrigerator and freezer

door.

Removing handles may be necessary

when transporting unit through tight

spaces.

Removebottomportionof handleswith

a very smallflat-blade screwdriver.

IMPORTANT: Wrap blade of screwdriver

with masking tape to avoid damaging

unit.

i iiii

Align door handles with top and bot-

tom sets of door clips, and slide down

untilscrew holeson bottomof handles

match with door screw holes.

Insert ¼" hex nut screws previously

removed into screw holes at bottom of

handle section.

Snap trim over bottom portion of han-

dles and retainers on bottom of door.

t!

Remove two handle base screws.

Pull handle up and out to release from

unit. Fit may be tight.

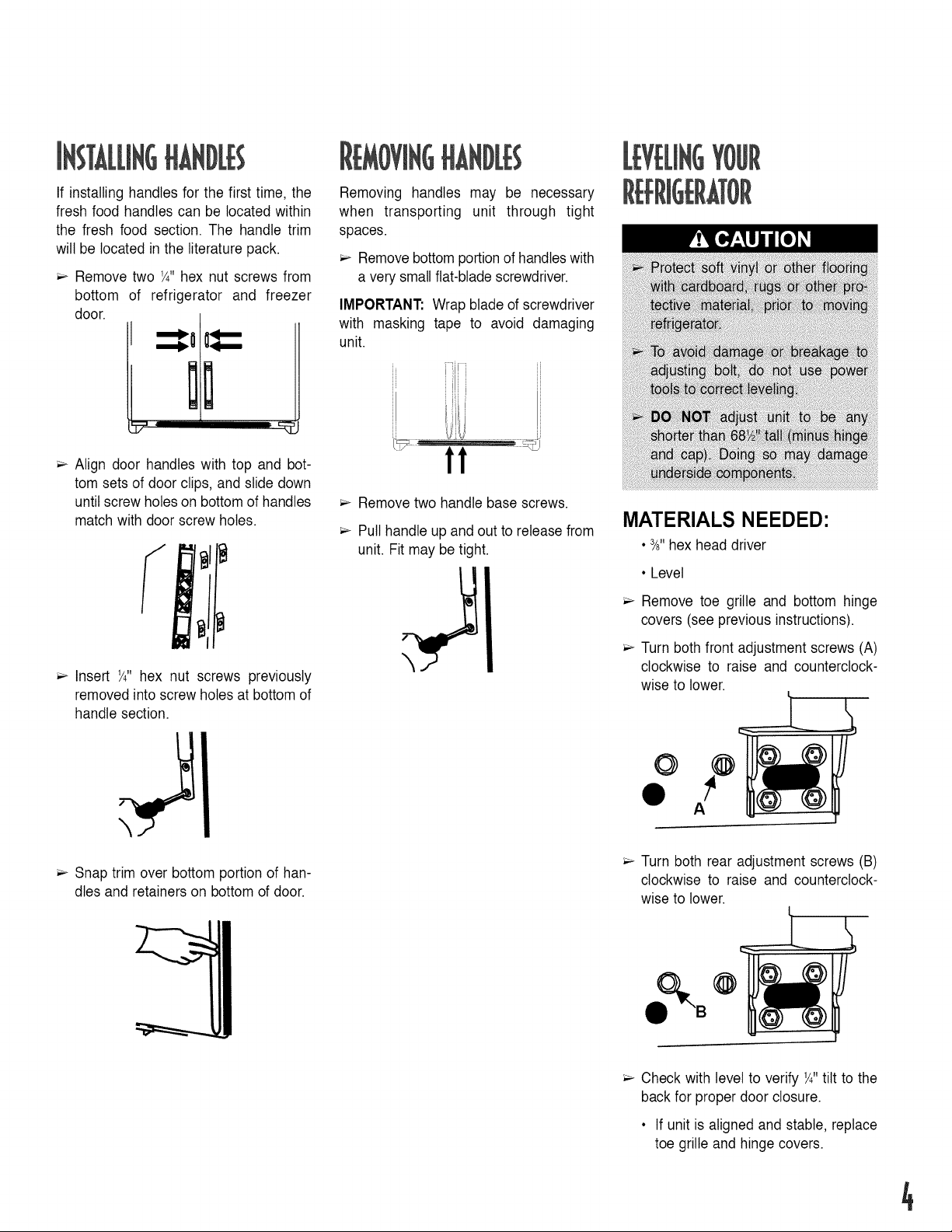

MATERIALS NEEDED:

• _" hex head driver

• Level

Remove toe grille and bottom hinge

covers (see previous instructions).

Turn both front adjustment screws (A)

clockwise to raise and counterclock-

wise to lower.

O

Turn both rear adjustment screws (B)

clockwise to raise and counterclock-

wise to lower.

A

Check with level to verify Y4"tilt to the

back for proper door closure.

• If unit is aligned and stable, replace

toe grille and hinge covers.

4

If required, correct rocking of unit by

turning rear adjustment screw clock-

wise to raise rocking corner.

If doors are uneven:

• Determine which door needs to be

raised.

• Turn front roller adjustment screw

clockwise to raise front corner of

door.

If the unit has reached the bottom

limit of its adjustment range, and

doorsare still not level-lower oppo-

site door by turning roller adjust-

ment screw counterclockwise.

Remove plastic cap from water valve

inlet port.

Place brass nut and sleeve on copper

tube end as illustrated.

Brass

Nut Sleeve

Place end of copper tubing into water

valve inlet port.Shape tubing slightly-

DO NOT KINK - so that tubing feeds

straight into inlet port.

Check with level to verify ¼"tilt to the

back for proper door closure.

• Ifunit is aligned andstable, replace

toe grille and hinge covers.

MATERIALS NEEDED"

• ¼" (6 mm) outer diameter flexible cop-

per tubing

• Brass nut and sleeve (see literature

pack)

• Shut-off valve

Requires a ¼"(6 mm) hole to be drilled

into water supply before valve attach-

ment

• Adjustable wrench

NOTE: Add 8' (2.5 m)to tubing length

needed to reach water supply for

creation of service loop.

Create service loop with tubing using

care to avoid kinks in tubing.

Slide brass nut over

sleeve and screw nut

into inlet port. Tighten

nut with wrench. Pull on

tubing to confirm con-

nection is secure.

IMPORTANT: DO NOT overtighten.

Cross-threading may occur.

Locate water tubing

clamp and install with

¼" hex head screw.

Turn on water supply

and check for leaks and

correct, if present.

Monitor water connection for 24

hours. Correct leaks, if necessary.

5

REFRIGERATOR

Placethermometer in glassof water in

middle of refrigerator.

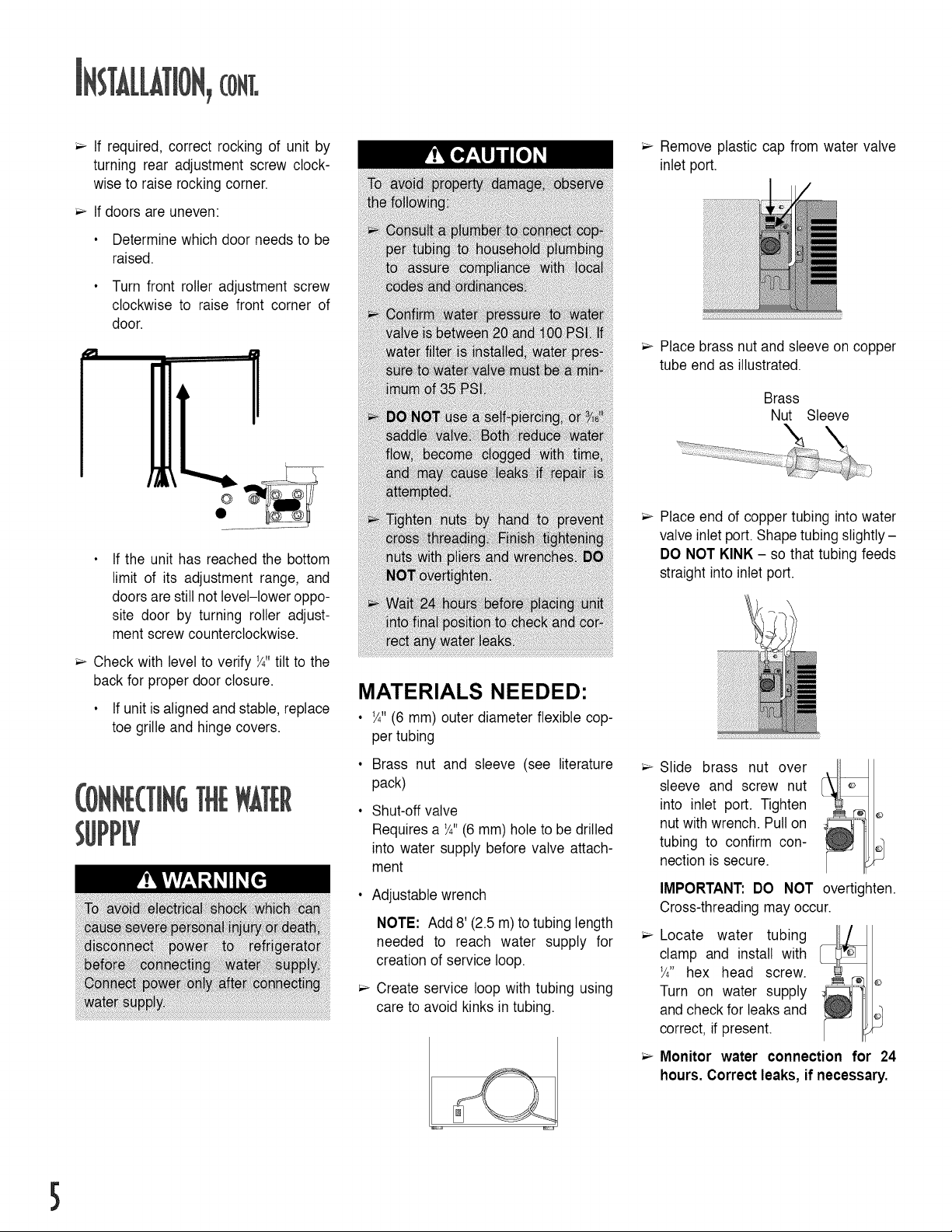

This refrigerator isdesigned to operate at

a household temperature of 55°to 100° F

(13° to 43° C).

INITIAL TEMPERATURE

SETTINGS

Locate refrigerator and freezer controls

on upper-left watt of refrigerator section

and set both controls to 4.

IMPORTANT: Neither section will cool if

freezer control is set to OFF.

MATERIALS NEEDED:

• 2 thermometers measure -5° to 50° F

(-21° to 10° C)

• 2 drinking glasses

IMPORTANT: Due to design of unit,

always start temperature adjustments

with freezer section.

FREEZER

Place thermometer in glass of veg-

etable oil in middle of freezer.

Allow 24 hours for temperatures to

stabilize.

Checkto seeiftemperatureis 0°to 2° F

(-17° to -16° C).

• Turn control to next highest number

if too warm.

• Turn controlto next lowest number if

too cold.

• Allow 5to 8 hours for adjustmentsto

take effect.

Allow 24 hours for temperatures to

stabilize.

Check to see if temperature is 38° to

40° F (3° to 4° C).

• Turn control to next highest number

if too warm.

• Turn controlto next lowest number if

too cold.

• Allow 5to 8 hours for adjustmentsto

take effect.

Repeat as necessary.

Repeat as necessary.

6

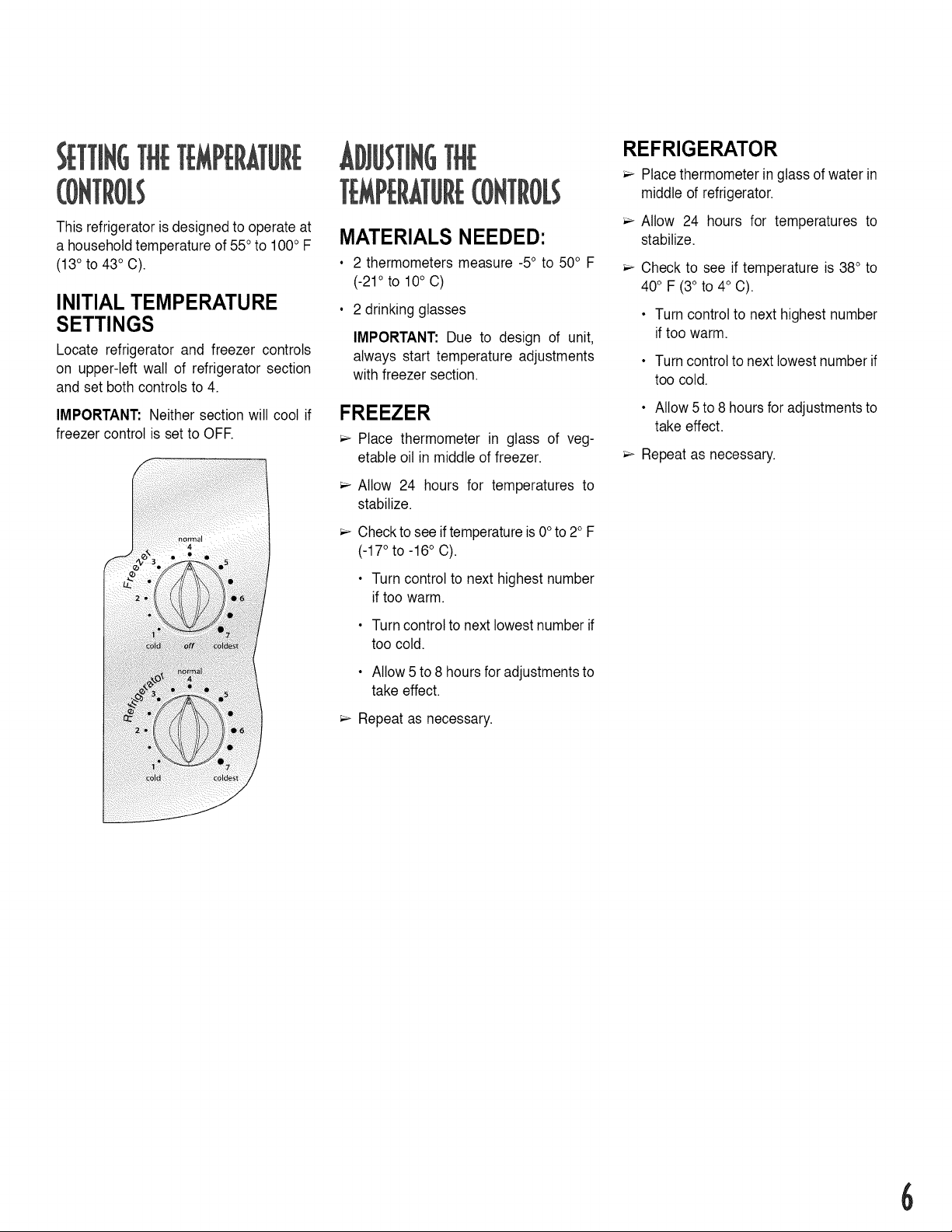

IT EDOORBU( S

Door buckets adjust to meet individual

storage needs.

To remove buckets:

Lift the door bucket up until it clears

the retainers on the door liner, then

pull the door bucket straight out.

To reinstall buckets:

Slide bucket in above desired door

liner retainer and push down until

bucket stops.

Select models feature sealed shelves

with a pulloutdesign to reach items in the

back. For ease of cleaning, glass shelf

may be removed by pulling to full exten-

sion and lifting out of frame.

To remove shelf and frame:

See instructions for Sealed Shelves.

(SELECT MODELS)

The Dairy Center provides convenient

storage for items such as butter, yogurt,

cheese, etc.

This compartment is an adjustable fea-

ture located in the door. It can be moved

to several different locations to accom-

modate storage needs.

To remove bin:

Slide dairy center up and pull out.

To reinstall bin:

Slide assembly in above desired door

liner retainer and push down until it

stops.

To remove dairy door:

Press in sides of dairy door and pull

out.

To reinstall dairy door:

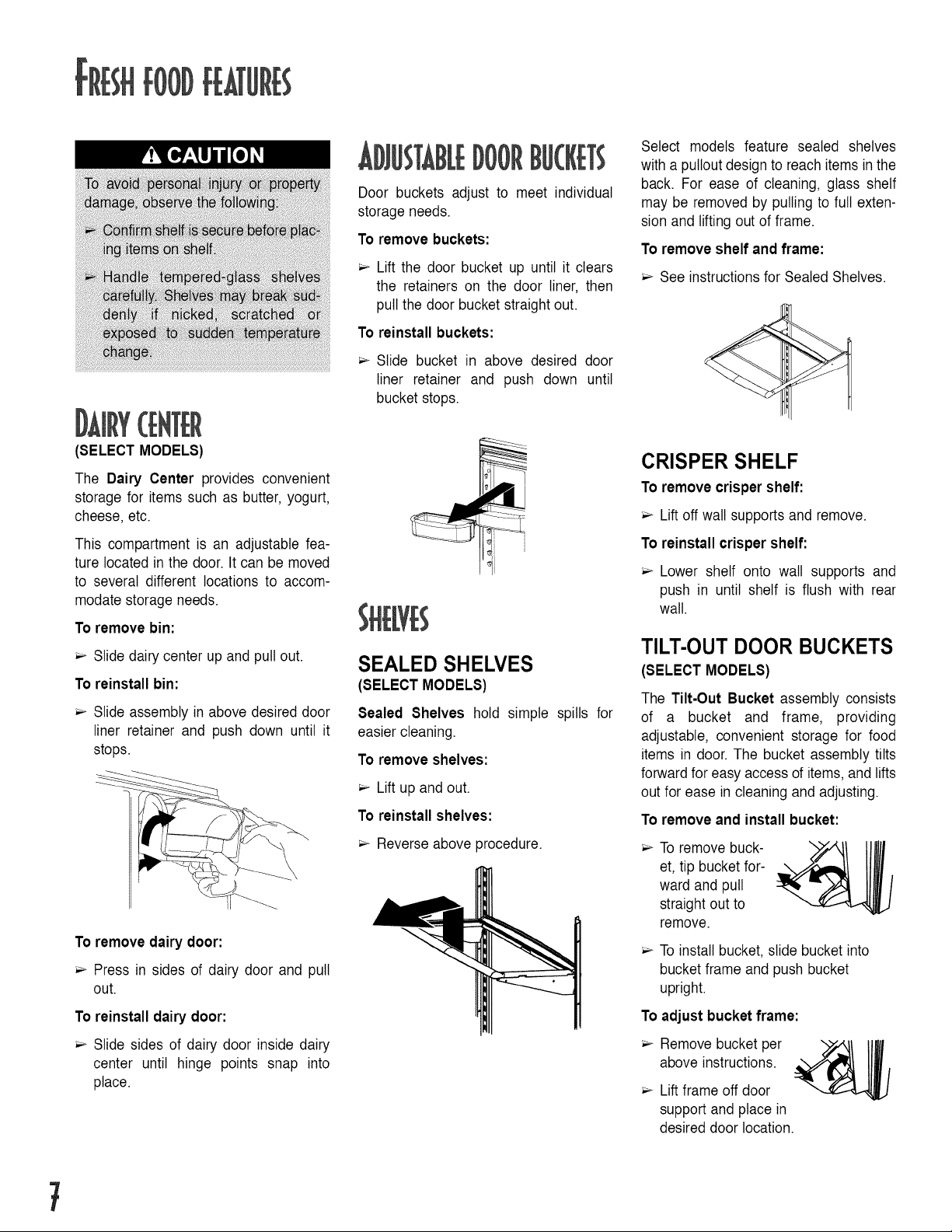

SEALED SHELVES

(SELECT MODELS)

Sealed Shelves hold simple spills for

easier cleaning.

To remove shelves:

Lift up and out.

To reinstall shelves:

Reverse above procedure.

CRISPER SHELF

To remove crisper shelf:

Lift off wall supports and remove.

To reinstall crisper shelf:

Lower shelf onto wall supports and

push in until shelf is flush with rear

wall.

TILT-OUT DOOR BUCKETS

(SELECT MODELS)

The Tilt-Out Bucket assembly consists

of a bucket and frame, providing

adjustable, convenient storage for food

items in door. The bucket assembly tilts

forward for easyaccess of items, and lifts

out for ease in cleaning and adjusting.

To remove and install bucket:

Toremove buck-

et, tip bucket for-

ward and pull

straight out to

remove.

Toinstall bucket, slide bucket into

bucket frame and push bucket

upright.

To

adjust bucket frame:

Slide sides of dairy door inside dairy

center until hinge points snap into

place.

7

Remove bucket per Y/f '!! IIJl

above instructions.

Lift frame off door

support and place in

desired door location.

(SELECT MODELS)

The Snack Drawer can be used for

storage offood items.

To remove drawer:

Pull drawer out to full extension.

Tilt up front of drawer and pull straight

out.

To reinstall drawer:

Reverse above procedure.

The Crisper keeps produce fresh longer

by providing an environment with

adjustable humidity.

CONTROLS

The controls regulate the amount of

humidity in the crisper drawer. Use the

low settingfor non-leafy produce. Usethe

high setting for leafy produce.

SETTINGS

LOW

• apples • grapes

• cauliflower • oranges

• corn • zucchini

• cucumbers

HIGH

• asparagus • fresh herbs

• broccoli • fresh sprouts

• cabbage • lettuce

• celery • spinach

.lDRAWER

The Deli Drawer system provides a

drawer with a variable temperature

control that can keep the compartment

colder than refrigerator temperature.

NOTE: Cold air directed to the dell

drawer system can decrease refrigerator

temperature. Refrigerator control may

need to be adjusted.

CONTROLS

Located on the wall to the left ofthe draw-

er, the controls regulate the air tempera-

ture inthe Delldrawer. Setcontrol levelto

cold to provide normal refrigerator tem-

perature. Use the coldest setting for stor-

ing meat, poultry or fish.

To remove drawer(s):

Pull drawer out to full extension.

Tilt upfront of drawer and pull straight

out.

(SELECT MODELS)

The Can Rack slides

out from underneath

the sealed shelf. The

can rack holds up to

twelve 12-ounce bev-

erage cans.

To remove and install can rack:

Toremove, empty contents of can

rack. Pull can rack forward to full

extension and lift front to release

from shelf rail. Pull straight out to

remove.

Toinstall, reverse above procedure.

Please observe the following recommen-

dations when storing produce in humid-

ity-controlled crispers:

DO NOT wash produce before placing

in crispers. Any additional moisture

added to the crispers may cause pro-

duce to prematurelyspoil.

DO NOT line crispers with paper tow-

els. Towelswill retain moisture.

Follow control instructions carefully.

Incorrect controlsettings may damage

produce.

To remove drawer(s):

Pull drawer out to full extension.

Tilt up front of drawer and pull straight

out.

To reinstall drawer(s):

Reverse above procedure.

To reinstall drawer(s):

Reverse above procedure.

ANI)

(STYLE MAYVARY)

To remove shelves:

Remove shelf _,

from wall mount-

ing clips and pull

out of left side

mounting holes.

To reinstall shelves:

Reverse above procedure.

Baskets slide out for easy access of

items in back.

To remove baskets:

Pull basket forward to full extension.

Lift front handleto release basketfrom

rails and remove.

To reinstall baskets:

Reverse above procedure.

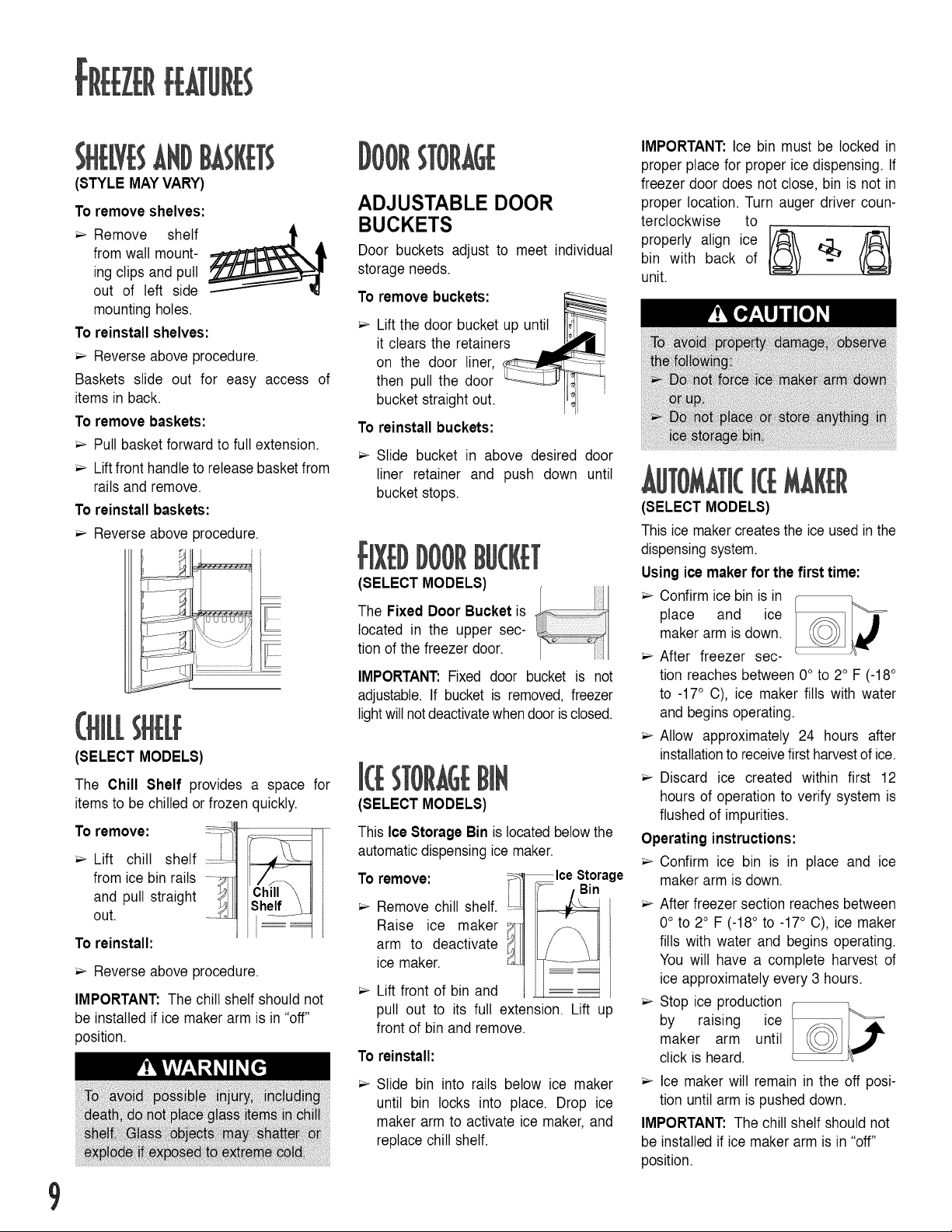

(SELECT MODELS)

The Chill Shelf provides a space for

items to be chilled or frozen quickly.

To remove:

Lift chill shelf __-.....

from ice bin rails 711

and pull straight

out. -

To reinstall:

Reverse above procedure.

IMPORTANT: The chill shelf should not

be installed if ice maker arm is in "off"

position.

)ORSTORAGE

ADJUSTABLE DOOR

BUCKETS

Door buckets adjust to meet individual

storage needs.

To remove buckets:

Lift the door bucket up until

it clears the retainers

on the door liner,

then pull the door

bucket straight out.

To reinstall buckets:

Slide bucket in above desired door

liner retainer and push down until

bucket stops.

IJ

# Bg(

(SELECT MODELS)

The Fixed Door Bucket is

located in the upper sec-

tion of the freezer door.

IMPORTANT: Fixed door bucket is not

adjustable. If bucket is removed, freezer

lightwill notdeactivatewhendoor isclosed.

STORAGEBran

(SELECT MODELS)

ThisIce Storage Binis located belowthe

automaticdispensingice maker.

To remove: _ IceStorage

Remove chill shelf.....J_l

Raise ice maker

arm to deactivate

ice maker.

Lift front of bin and

pull out to its full extension. Lift up

front of bin and remove.

To reinstall:

Slide bin into rails below ice maker

until bin locks into place. Drop ice

maker arm to activate ice maker, and

replace chill shelf.

IMPORTANT: Ice bin must be locked in

proper place for proper ice dispensing. If

freezer door does not close, bin is not in

proper location. Turn auger driver coun-

terclockwise to

bin with back of

properly align ice 5 _-_ _

unit.

(SELECT MODELS)

This ice makercreates the ice usedin the

dispensingsystem.

Using ice makerfor the first time:

Confirm ice bin is in

place and ice

maker arm is down.

After freezer sec-

tion reaches between 0° to 2° F (-18°

to -17° C), ice maker fills with water

and begins operating.

Allow approximately 24 hours after

installationto receivefirstharvest of ice.

Discard ice created within first 12

hours of operation to verify system is

flushed of impurities.

Operating instructions:

Confirm ice bin is in place and ice

maker arm is down.

After freezer section reaches between

0° to 2° F (-18° to -17° C), ice maker

fills with water and begins operating.

You will have a complete harvest of

ice approximately every 3 hours.

Stop ice production

by raising ice

maker arm until

click is heard.

Ice maker will remain in the off posi-

tion until arm is pushed down.

IMPORTANT: The chill shelf should not

be installed if ice maker arm is in "off"

position.

( ELECTMODELS)

A lightactivates within the dispenser area

at full power when dispensing ice or

water.

; ;ERPAD

The Dispenser Pad is located on the

back watt of the dispensing area. When

the dispenser pad is pressed, the

selectionchosen on the dispenser control

panel will dispense.

NOTE:

During initial use of water dispenser,

there will be a 1- to 2-minute delay

while water tank fills before water dis-

penses. Discard first 10-14 containers

of water after initially connecting

refrigerator to household water supply

and after extended periods of nonuse.

To dispensewater:

Choose water selection from dis-

penser control panel.

To dispense ice:

Select cubed or crushed ice mode by

pushing appropriate button on

dispenser control panel. A green

indicator light above button shows

mode selection.

Press container against dispenser

pad. When dispensing crushed ice,

hold container as close to chute as

possible to reduce spraying. Selection

mode may not be changed while ice

dispenser is in operation.

The Removable Tray at the bottom of

the dispenser area is designed to collect

small spills and may be easily removed

for cleaning and emptying purposes.

IMPORTANT: Removable tray does not

drain. Continuous water running into tray

will cause tray to overflow.

Press sturdy, wide-mouthed container

against dispenser pad.

Release pressure on dispenser pad to

stop water from dispensing. A small

amount of water may continue to dis-

pense and collect in dispenser tray.

Large spills should be wiped dry.

]0

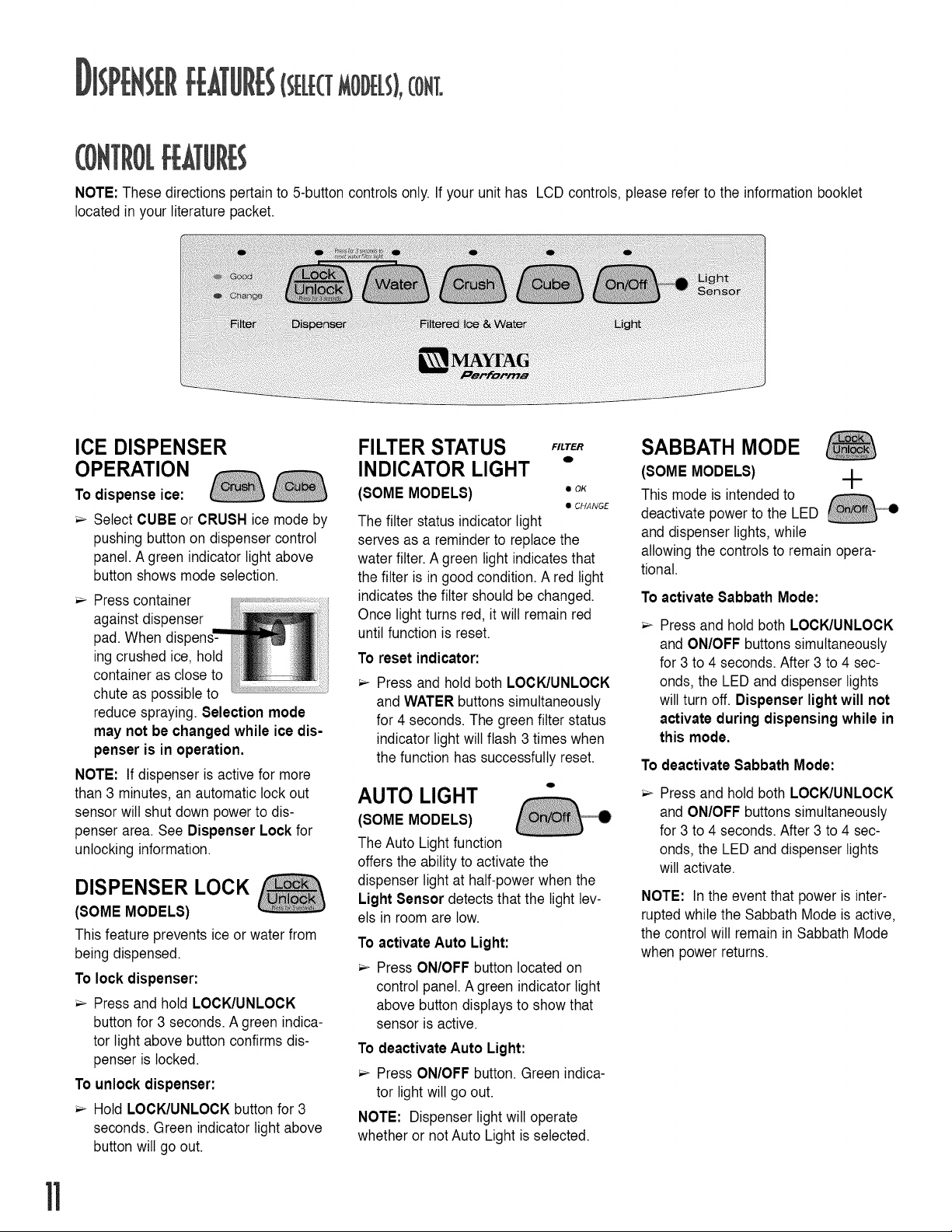

( ELECTMODELS),CONTo

NOTE: These directions pertain to 5-button controls only. If your unit has LCD controls, please refer to the information booklet

located in your literature packet.

ICE DISPENSER

OPERATION

To dispense ice:

Select CUBE or CRUSH ice mode by

pushing button on dispenser control

panel. A green indicator light above

button shows mode selection.

Press container

against dispenser

pad. When dis

ing crushed ice, hold

container as close to

chute as possible to

reduce spraying. Selection mode

may not be changed while ice dis-

penser is in operation.

NOTE: If dispenser isactive for more

than 3 minutes, an automatic lock out

sensor will shut down power to dis-

penser area. See Dispenser Lock for

unlocking information.

DISPENSER LOCK

(SOME MODELS)

This feature prevents ice or water from

being dispensed.

To lock dispenser:

Press and hold LOCK/UNLOCK

button for 3 seconds. A green indica-

tor light above button confirms dis-

penser is locked.

To unlock dispenser:

Hold LOCK/UNLOCK button for 3

seconds. Green indicator light above

button will go out.

FILTER STATUS F,,T

INDICATOR LIGHT °

(SOME MODELS) • o,

The filter status indicatorlight

serves as a reminder to replace the

water filter. A green light indicatesthat

the filter is in good condition. A red light

indicatesthe filter should be changed.

Once light turns red, it will remain red

until function is reset.

To reset indicator:

Press and hold both LOCK/UNLOCK

and WATER buttons simultaneously

for 4 seconds. The green filter status

indicator light will flash 3 times when

the function has successfully reset.

° C/tANGE

o

AUTO LIGHT

(SOME MODELS)

The Auto Light function

offers the ability to activate the

dispenser light at half-power when the

Light Sensor detects that the light lev-

els in room are low.

To

activate Auto Light:

Press ON/OFF button located on

control panel.A green indicator light

above button displays to show that

sensor is active.

To deactivate Auto Light:

Press ON/OFF button. Green indica-

tor light will go out.

NOTE: Dispenser light will operate

whether or notAuto Light is selected.

SABBATH MODE

(SOME MODELS)

This mode isintended to

deactivate power to the LED

and dispenser lights, while

allowing the controls to remain opera-

tional.

To activate Sabbath Mode:

Press and hold both LOCK/UNLOCK

and ON/OFF buttonssimultaneously

for 3 to 4 seconds. After 3 to 4 sec-

onds, the LED and dispenser lights

will turn off. Dispenser light will not

activate during dispensing while in

this mode.

To deactivate Sabbath Mode:

Press and hold both LOCK/UNLOCK

and ON/OFF buttonssimultaneously

for 3 to 4 seconds. After 3 to 4 sec-

onds, the LED and dispenser lights

will activate.

NOTE: In the event that power is inter-

rupted while the Sabbath Mode is active,

the control will remain inSabbath Mode

when power returns.

( (TMODElS}

Removesealing label from end of filter

and insert into filter head.

• Rotate gently clockwise until filter

stops and snap filter cover closed.

Reduce water spurts by flushing air

from system. Run water continuously

for 2 minutes through dispenser until

water runs steady.

• Additional flushing may be required

in some households where water is

of poor quality.

.ACINGWATERFILTER

IMPORTANT: Air trapped in system may

cause water and cartridge to eject. Use

caution when removing.

Turn filter counterclockwise until it

releases from filter head.

[}01

Filter should bechanged every 6 months.

IMPORTANT: Condition of water and

amount used determines life span of

water filter cartridge. If water use is high,

or if water is of poor quality, replacement

may need to take place more often.

DOlO RA

TO order a replacement filter cartridge

modelOWF51 (part no. 12589210), orfor

service, contact your local dealer or

Maytag ServicesSM,Maytag Customer

Assistance, U.S.A.: 1-877-232-6771.

Remove blue bypass cap and retain

for later use.

Drain water from filter into sink and

dispose in normal household garbage.

Wipe up excess water in filter cover.

Removesealing label from end of filter

and insert into filter head.

• Rotate gently clockwise until filter

stops and snap filter cover closed.

Reduce water spurts by flushing air

from system. Run water continuously

for 2 minutes through dispenser until

water runs steady.

• Additional flushing may be required

in some households where water is

of poor quality.

During initial use, allow about a 1- to

2-minute delay inwater dispersal to allow

internal water tank to fill.

Dispenser feature may be used without

water filter cartridge. If you choose this

option, replace filter with blue bypass

cap.

]2

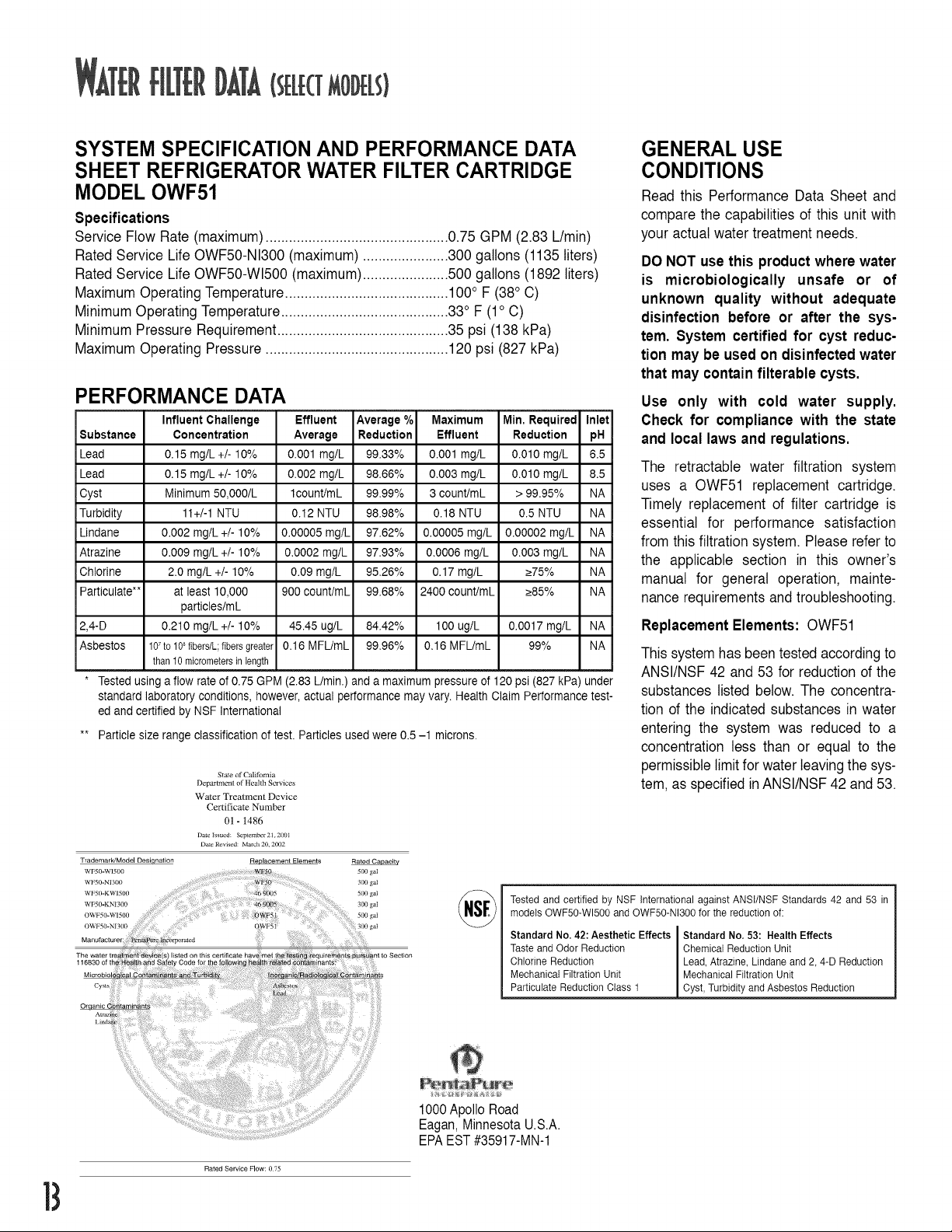

{ ELECTMO[}ELSI

SYSTEM SPECIFICATION AND PERFORMANCE DATA

SHEET REFRIGERATOR WATER FILTER CARTRIDGE

MODEL OWF51

Specifications

Service Flow Rate (maximum)...............................................0.75 GPM (2.83 L/min)

Rated Service Life OWF50-NI300 (maximum) ......................300 gallons (1135 liters)

Rated Service Life OWF50-WI500 (maximum)......................500 gallons (1892 liters)

Maximum Operating Temperature..........................................100° F (38° C)

Minimum Operating Temperature...........................................33° F (1° C)

Minimum Pressure Requirement............................................35 psi (138 kPa)

Maximum Operating Pressure ...............................................120 psi (827 kPa)

PERFORMANCE DATA

Substance

Lead

Lead

Cyst

Turbidity

Lindane

Atrazine

Chlorine

Particulate**

2,4-D

Asbestos

* Testedusing a flow rate of 0.75 GPM (2.83 L/min.) and a maximum pressure of 120 psi (827 kPa) under

standard laboratory conditions, however, actual performance may vary. Health Claim Performance test-

ed and certified by NSF International

** Particle size range classification of test. Particles used were 0.5 -1 microns.

Trademark/Model Desiqnation

Influent Challenge

Concentration

0.15 mg/L +/- 10%

0.15 mg/L +/- 10%

Minimum 50,000/L

11+/-1 NTU

0.002 mglL +/- 10%

0.009 mg/L +t- 10%

2.0 mglL +I- 10%

at least 10,000

particles/mL

0.210 mgtL +/- 10%

107to108fibers/L:fibersgreater

thant0 micrometersinlength

State of California

Department of Heallb Services

Water Trealment Device

Certificate Namber

01 - 1486

Date Issued: Scptm_aber 2t. 2(X)l

Date Revised: March 20, 2(X)2

Effluent Average % Maximum

Average Reduction Effluent

0.001 mg/L 99.33% 0.001 mg/L

0.002 mg/L 98.66% 0.003 mg/L

lcount/mL 99.99% 3 count/mL

0.12 NTU 98.98% 0.18 NTU

0.00005 mg/L 97.62% 0.00005 mg/L

0.0002 mg/L 97.93% 0.0006 mg/L

0.09 mgtL 95.26% 0.17 mg/L

900 count/mL 99.68% 2400 count/mL

45.45 ug/L 84.42% 100 ug/L

0.16 MFL/mL 99.96% 0.16 MFL/mL

Replacement Elements

500 gal

300 ga]

5O0 gal

300 gal

500 ga]

300 gal

Min, Required Inlet

Reduction pH

0.010 mg/L 6.5

0.010 mg/L 8.5

> 99.95% NA

0.5 NTU NA

0.00002 mg/L NA

0.003 mg/L NA

_>75% NA

_>85% NA

0.0017 mg/L NA

99% NA

Tested and certified by NSF International against ANSI/NSF Standards 42 and 53 in

models OWF50-Wl500 and OWF50-NI300 for the reduction of:

Standard No. 42: Aesthetic Effects

Taste and Odor Reduction

Chlorine Reduction

Mechanical Filtration Unit

Particulate Reduction Class 1

GENERAL USE

CONDITIONS

Read this Performance Data Sheet and

compare the capabilities of this unit with

your actual water treatment needs.

DO NOT use this product where water

is microbiologically unsafe or of

unknown quality without adequate

disinfection before or after the sys-

tem. System certified for cyst reduc-

tion may be used on disinfected water

that may contain filterable cysts.

Use only with cold water supply.

Check for compliance with the state

and local laws and regulations.

The retractable water filtration system

uses a OWF51 replacement cartridge.

Timely replacement of filter cartridge is

essential for performance satisfaction

from this filtration system. Please refer to

the applicable section in this owner's

manual for general operation, mainte-

nance requirements and troubleshooting.

Replacement Elements: OWF51

This system has beentested accordingto

ANSI/NSF 42 and 53 for reduction of the

substances listed below. The concentra-

tion of the indicated substances in water

entering the system was reduced to a

concentration less than or equal to the

permissiblelimit for water leavingthe sys-

tem, as specifiedin ANSI/NSF 42 and 53.

Standard No. 53: Health Effects

Chemical Reduction Unit

Lead, Atrazine, Lindane and 2, 4-D Reduction

Mechanical Filtration Unit

Cyst, Turb d ty and Asbestos Reduct on

Rated Service Flow: 0 75

1000ApolloRoad

Eagan,MinnesotaU.S.A.

EPAEST#35917-MN-1

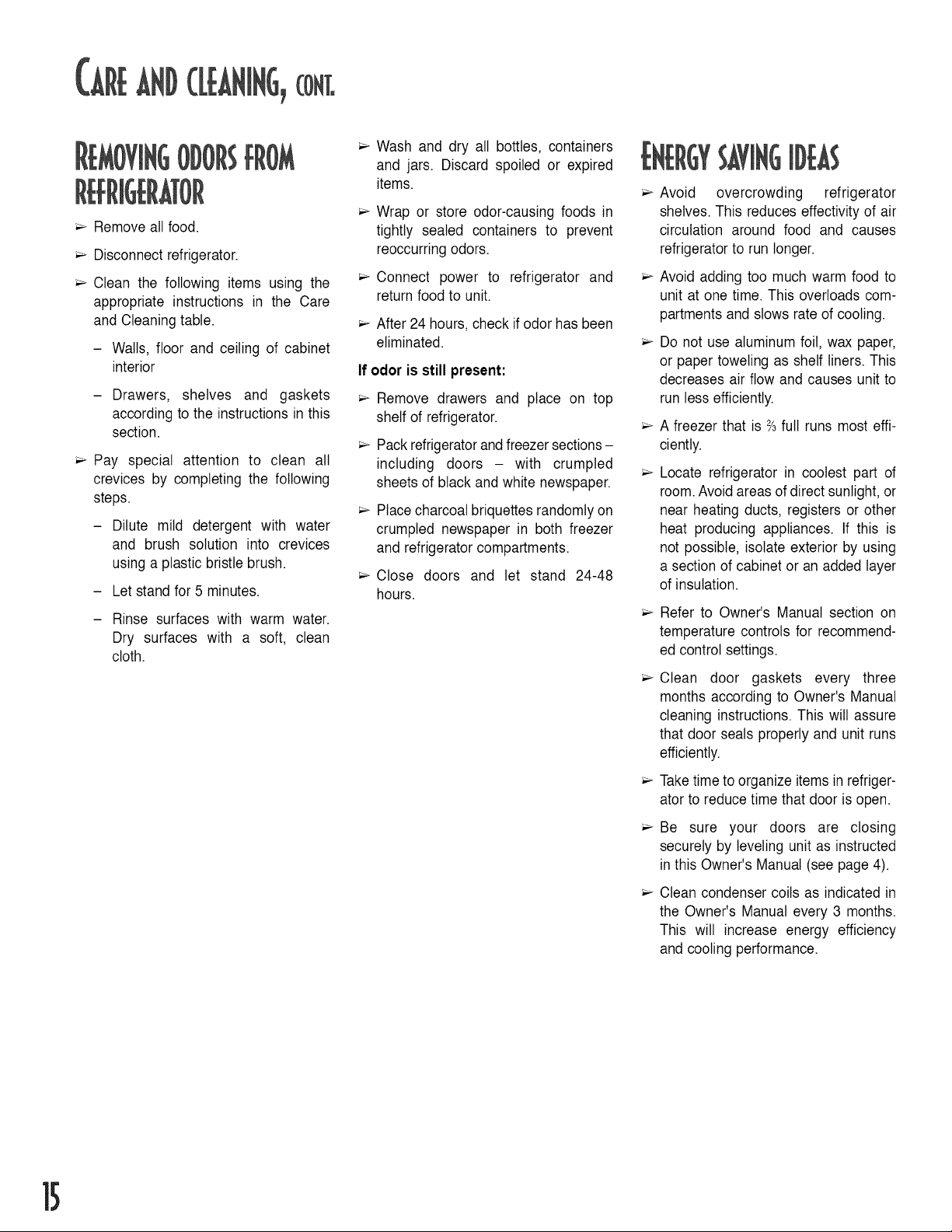

PART

Textured Doors

and Exterior

Cabinet Interior

Stainless Steel Doors

and Exterior

IMPORTANT: Damage

to stainless steel finish

due to improper use of

cleaning products or

non-recommended

products is not covered

under this product's

warranty.

Door Gaskets

Condenser Coil

Remove base grille to

access

Condenser Fan Outlet

Grille

See back of refrigerator

DO NOT USE

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents or

solvents

Metal or plastic-textured

scouring pads

Abrasive or harsh cleaners

Ammonia

Chlorine bleach

Concentrated detergents or

solvents

Metal or plastic-textured

scouring pads

Vinegar-based products

Citrus-based cleaners

Abrasive or harsh cleaners

Metal or plastic-textured

scouring pads

DO

Use 4tablespoons of baking soda dissolved in 1 quart (1 liter)

warm soapy water.

Rinse surfaceswith clean warm water and dry immediately to

avoid water spots.

Use warm, soapy water and a soft, clean cloth or sponge.

Rinse surfaces with clean warm water and dry immediately to

avoid water spots.

After cleaning, rinse and dry. To restore luster and remove

streaks, follow with Stainless Steel Magic Spray* (Part No.

20000008).

Use a vacuum cleaner hose nozzle.

Use a vacuum cleaner hose nozzle with brush attachment.

Accessories Shelves,

buckets, drawers, etc.

* Cleaner is available for order through your manufacturer. Please contact them, using the information on the front cover of your

Owner's Manual, for further ordering information.

A dishwasher

Follow removal and installation instructions from appropriate

feature section.

Allow items to adjust to room temperature.

Dilute mild detergent with water and use a soft clean cloth or

sponge for cleaning.

Use a plastic bristle brushto get into crevices.

Rinse surfaces with clean warm water.

Dry glass and clear items immediately to avoid spots.

]4

0 S

> Remove all food.

> Disconnect refrigerator.

> Clean the following items using the

appropriate instructions in the Care

and Cleaningtable.

- Walls, floor and ceiling of cabinet

interior

- Drawers, shelves and gaskets

according to the instructions in this

section.

> Pay special attention to clean all

crevices by completing the following

steps.

- Dilute mild detergent with water

and brush solution into crevices

using a plastic bristle brush.

- Let stand for 5 minutes.

- Rinse surfaces with warm water.

Dry surfaces with a soft, clean

cloth.

> Wash and dry all bottles, containers

and jars. Discard spoiled or expired

items.

Wrap or store odor-causing foods in

tightly sealed containers to prevent

reoccurring odors.

Connect power to refrigerator and

return food to unit.

> After 24 hours, check ifodor has been

eliminated.

If odor is still present:

Remove drawers and place on top

shelf of refrigerator.

Pack refrigeratorandfreezersections -

including doors - with crumpled

sheets of black and white newspaper.

Placecharcoal briquettes randomly on

crumpled newspaper in both freezer

and refrigerator compartments.

Close doors and let stand 24-48

hours.

Avoid overcrowding refrigerator

shelves. This reduces effectivity of air

circulation around food and causes

refrigerator to run longer.

Avoid adding too much warm food to

unit at one time. This overloads com-

partments and slows rate of cooling.

Do not use aluminum foil, wax paper,

or paper toweling as shelf liners. This

decreases air flow and causes unit to

run less efficiently.

A freezer that is _3full runs most effi-

ciently.

Locate refrigerator in coolest part of

room. Avoidareas of direct sunlight, or

near heating ducts, registers or other

heat producing appliances. If this is

not possible, isolate exterior by using

a section of cabinet or an added layer

of insulation.

Refer to Owner's Manual section on

temperature controls for recommend-

ed control settings.

Clean door gaskets every three

months according to Owner's Manual

cleaning instructions. This will assure

that door seals properly and unit runs

efficiently.

Taketimeto organize items in refriger-

ator to reduce time that door is open.

Be sure your doors are closing

securely by leveling unit as instructed

in this Owner's Manual (see page 4).

Clean condenser coils as indicated in

the Owner's Manual every 3 months.

This will increase energy efficiency

and cooling performance.

FRESHFOOD

L TBULBS

FRESHFOOD

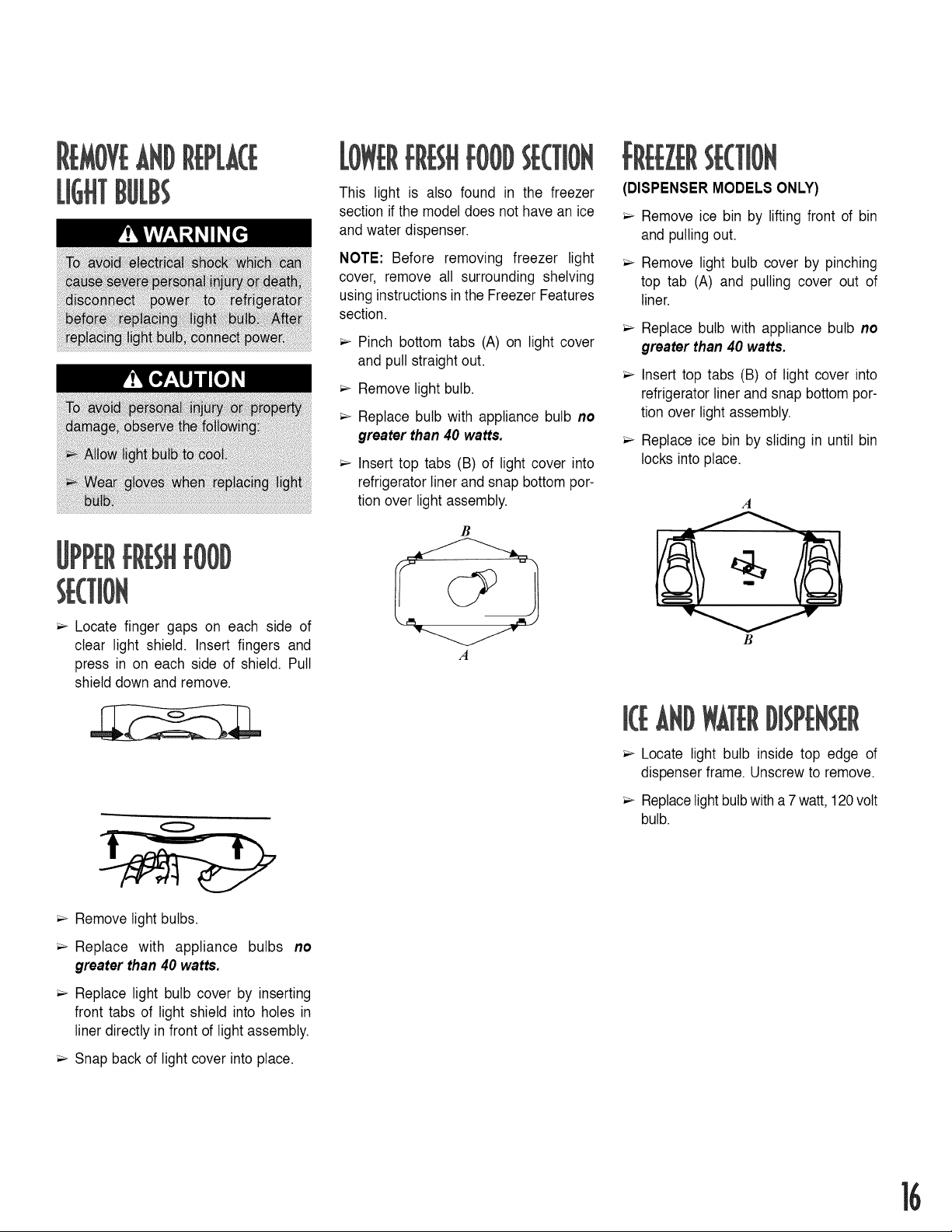

Locate finger gaps on each side of

clear light shield. Insert fingers and

press in on each side of shield. Pull

shield down and remove.

This light is also found in the freezer

section if the model does not have an ice

and water dispenser.

NOTE: Before removing freezer light

cover, remove all surrounding shelving

using instructionsin the Freezer Features

section.

Pinch bottom tabs (A) on light cover

and pull straight out.

Remove light bulb.

Replace bulb with appliance bulb no

greater than 40 watts.

Insert top tabs (B) of light cover into

refrigerator liner and snap bottom por-

tion over light assembly.

!Y

A

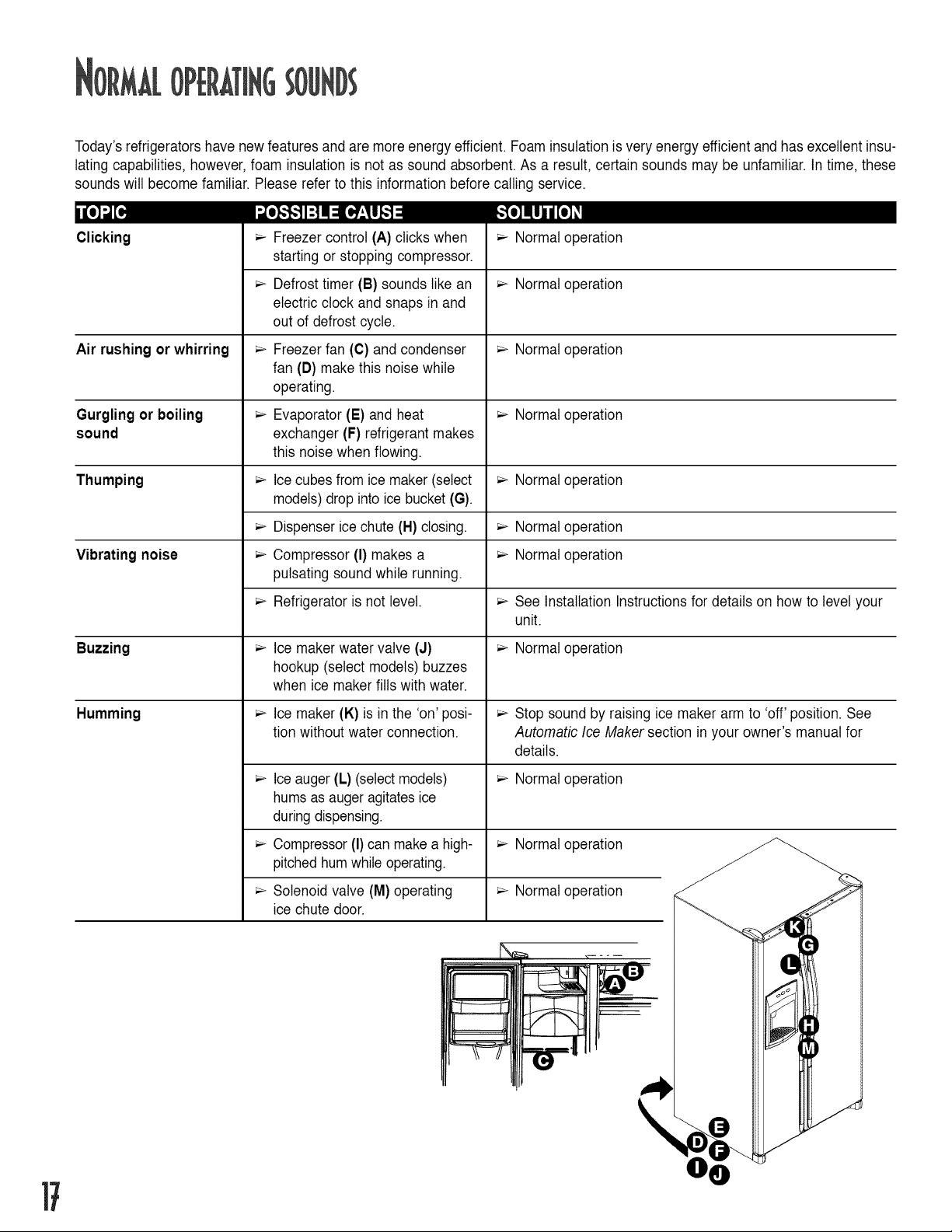

(DISPENSER MODELS ONLY)

Remove ice bin by lifting front of bin

and pulling out.

Remove light bulb cover by pinching

top tab (A) and pulling cover out of

liner.

Replace bulb with appliance bulb no

greater than 40 watts.

Insert top tabs (B) of light cover into

refrigerator liner and snap bottom por-

tion over lightassembly.

Replace ice bin by sliding in until bin

locks into place.

A

fi

Remove light bulbs.

Replace with appliance bulbs no

greater than 40 watts.

Replace light bulb cover by inserting

front tabs of light shield into holes in

liner directly in front of light assembly.

Snap back of light cover into place.

ICEANDWATERDISPENSER

Locate light bulb inside top edge of

dispenser frame. Unscrew to remove.

Replacelightbulbwitha 7 watt,120volt

bulb.

]6

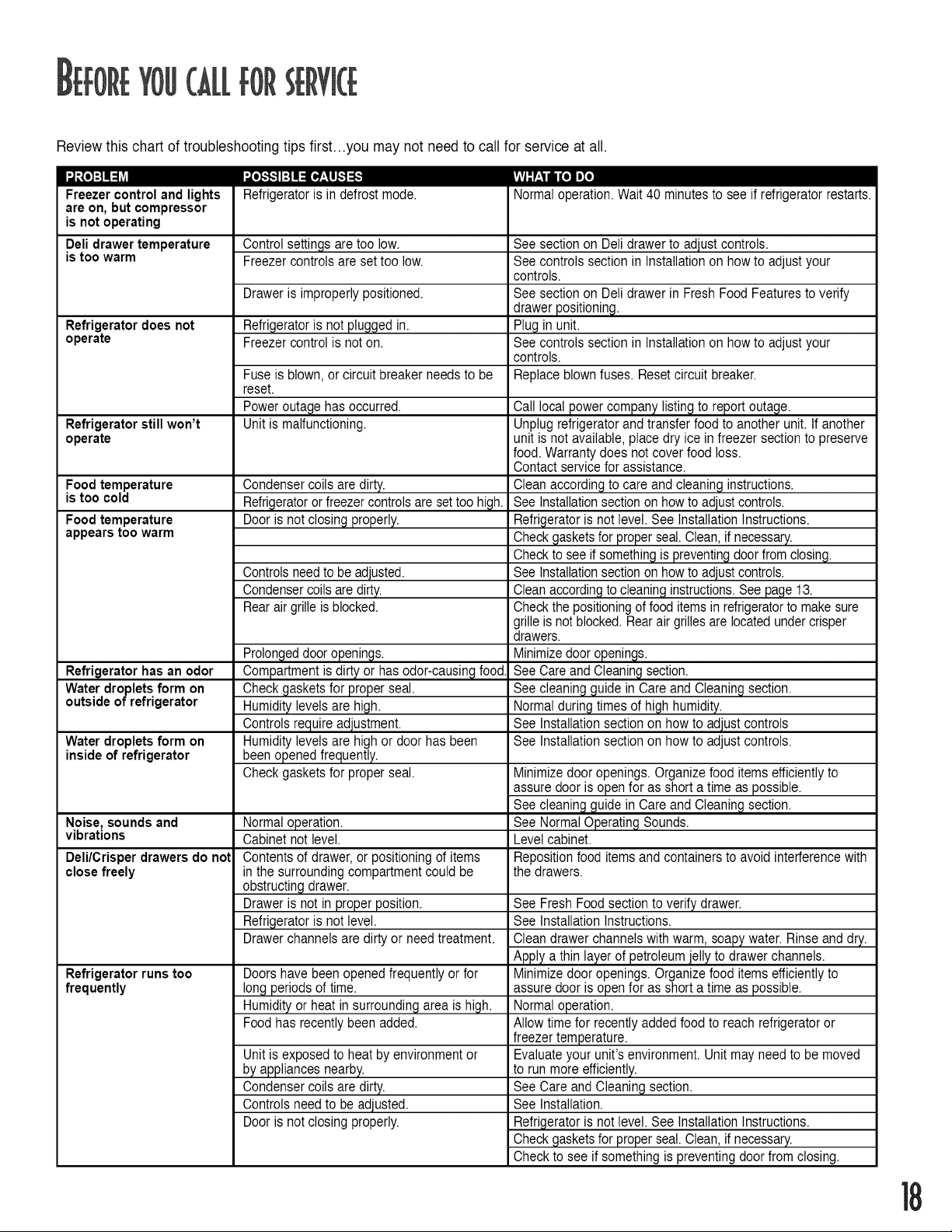

Today'srefrigerators have new features and are more energy efficient. Foam insulationis very energy efficient and hasexcellent insu-

lating capabilities, however, foam insulation is not as sound absorbent. As a result, certain sounds may be unfamiliar. In time, these

sounds will become familiar. Please refer to this information before calling service.

/L*]r,,l[a

Clicking Freezer control (A) clicks when

starting or stopping compressor.

Defrost timer (B) sounds like an _ Normal operation

electric clock and snaps in and

out of defrost cycle.

Air rushing or whirring _ Freezer fan (C) and condenser _ Normal operation

fan (B) make this noise while

operating.

Gurgling or boiling _ Evaporator (E) and heat _ Normal operation

sound exchanger (F) refrigerant makes

this noise when flowing.

Thumping _ Ice cubes fromice maker (select _ Normal operation

models) drop intoice bucket ((3).

Dispensericechute (H)closing. _ Normal operation

Vibrating noise _ Compressor (I) makes a _ Normal operation

pulsating sound while running.

Refrigerator is not level. _ See Installation Instructions for details on how to level your

Buzzing _ Ice maker water valve (J) _ Normal operation

hookup (select models) buzzes

when ice maker fills with water.

o]nLu-[o]

Normal operation

unit.

Humming _ Ice maker (K) is in the 'on' posi- _ Stop sound by raising ice maker arm to 'off' position. See

tion without water connection. Automatic Ice Maker section in your owner's manual for

details.

Iceauger (L) (selectmodels) _ Normal operation

hums as augeragitates ice

during dispensing.

Compressor (I)can make ahigh-

pitched hum while operating.

Solenoid valve (M) operating

ice chute door.

Normal operation

Normal operation

]7

Review this chart of troubleshooting tips first...you may not need to call for service at all.

BEd L_wJ -] _ -I L'i

Freezer control and lights

are on, but compressor

is not operating

Deli drawer temperature

is too warm

Refrigerator does not

operate

Refrigerator still won't

operate

Food temperature

is too cold

Food temperature

appears too warm

Refrigerator has an odor

Water droplets form on

outside of refrigerator

Water droplets form on

inside of refrigerator

Noise, sounds and

vibrations

Deli/Crisper drawers do not

close freely

Refrigerator runs too

frequently

Refrigerator is in defrost mode.

Control settings are too low.

Freezer controls are set too low.

Drawer is improperly positioned.

Refrigeratoris notpluggedin.

Freezercontrolis noton.

Fuse is blown, or circuit breaker needs to be

reset.

Power outage has occurred.

Unit is malfunctioning.

Condenser coils are dirty.

Refrigerator or freezer controls are set too high.

Door is not closing properly.

Controls needto be adjusted.

Condenser coils are dirty.

Rearair grille is blocked.

Prolongeddoor openings.

Compartment is dirty or has odor-causing food

Check gaskets for proper seal.

Humidity levels are high.

Controls require adjustment.

Humidity levels are high or door has been

been opened frequently.

Check gaskets for proper seal.

Normal operation.

Cabinet not level.

Contents of drawer, or positioning of items

in the surrounding compartment could be

obstructing drawer.

Drawer is not in proper position.

Refrigerator is not level.

Drawer channels are dirty or need treatment.

Doors have been opened frequently or for

long periods of time.

Humidity or heat in surrounding area is high.

Food has recently been added.

Unit is exposed to heat by environment or

by appliances nearby.

Condenser coils are dirty.

Controls need to be adjusted.

Door is not closing properly.

il I I;I I |wI Iie

Normal operation. Wait 40 minutes to see if refrigerator restarts.

See section on DeNdrawer to adjust controls.

See controls section in Installation on how to adjust your

controls.

See section on Deli drawer in Fresh Food Features to verify

drawer positioning.

Plug in unit.

See controls section in Installation on how to adjust your

controls.

Replace blown fuses. Reset circuit breaker.

Call local power company listing to report outage.

Unplug refrigerator and transfer food to another unit. If another

unit is not available, place dry ice in freezer section to preserve

food. Warranty does not cover food loss.

Contact service for assistance.

Clean according to care and cleaning instructions.

See Installationsection on how to adjust controls.

Refrigerator is not level. See Installation Instructions.

Check gasketsfor proper seal. Clean, if necessary.

Checkto see if something is preventing door from closing.

See Installationsection on how to adjust controls.

Clean accordingto cleaning instructions.See page 13.

Checkthe positioning of food items in refrigeratorto makesure

grille is notblocked. Rear air grilles are located under crisper

drawers.

Minimizedoor openings.

See Care and Cleaning section.

See cleaning guide in Care and Cleaning section.

Normal during times of high humidity.

See Installation section on how to adjust controls

See Installation section on how to adjust controls.

Minimize door openings. Organize food items efficiently to

assure door is open for as short a time as possible.

See cleaning guide in Care and Cleaning section.

See Normal Operating Sounds.

Level cabinet.

Reposition food items and containers to avoid interference with

the drawers.

See Fresh Food section to verify drawer.

See Installation Instructions.

Clean drawer channels with warm, soapy water. Rinse and dry.

Apply athin layer of petroleum jelly to drawer channels.

Minimize door openings. Organize food items efficiently to

assure door is open for as short a time as possible.

Normal operation.

Allow time for recently added food to reach refrigerator or

freezer temperature.

Evaluate your unit's environment. Unit may need to be moved

to run more efficiently.

See Care and Cleaning section.

See Installation.

Refrigerator is not level. See Installation Instructions.

Check gasketsfor proper seal. Clean, if necessary.

Check to see if something is preventing door from closing.

ice and Water

"e I'- '

Water appears cloudy

Particles in water and/or

ice cubes

No indicator lights are lit Freezer door is not closed. Verify that freezer door is closed. Power is removed from the control

on dispenser control when freezer door is opened.

(select models) Refrigerator is not plugged in. Plug in unit.

Neither ice nor water is Freezer door is not closed. Verify that freezer door is closed. Power is removed from the control

dispensed when pads are when freezer door is opened.

pushed (select models) Water tank is filling. At initial use, there is an approximate 45-second delay in dispensing

Ice maker is not producing Ice maker has just recently been installed Wait 24 hours for ice production to begin and for ice maker to

enough ice or ice is or a large amount of ice has just been used. restock after emptied.

malformed (select models) Water pressure is too low. Low water pressure can cause valve to leak. Water pressure must be

Ice maker is not producing Ice maker arm is not in correct position. Confirm ice maker arm is down. See Freezer Features section in your

ice (select models) owner's manual for details.

Unit is leaking water Plastic tubing was used to complete water The manufacturer recommends using copper tubing for installation.

Ice forms in inlet tube to Water pressure is low. Water pressure must be between 20 to 100 pounds per square

ice maker inch to function properly. A minimum pressure of 35 pounds per

Water flow is slower than Water pressure is low. Water pressure must be between 20 to 100 pounds per square

normal inch to function properly. A minimum pressure of 35 pounds per

Dispenser water is not cold Allow approximately 12 hours for water in holding tank to chill.

Air or air bubbles in water. This is normal when first using dispenser and will disappear with use.

Carbon dust from water filter cartridge. Initial water ejected through cartridge may contain harmless carbon

Concentrations of minerals in water will form Particles are not harmful and naturally occur in water supplies.

particles when water becomes frozen and melts.

Fuse is blown, or circuit breaker needs to be reset. Replace any blown fuses. Check circuit breakers for any tripped circuits.

Power outage has occurred. Call local power company listing to report outage.

Refrigerator is in Sabbath Mode (select models). See Dispenser Features section for further information.

Ice maker or ice maker-equipped unit has just Wait 24 hours for ice production to begin and for ice maker to

recently been installed or a large amount of ice restock after emptied.

has just been used.

Water filter is clogged or needs to be changed. Change water filter.

Water filter is clogged or needs to be changed. Change water filter.

Improper water valve was installed. Check water connection procedure in your Installation Instructions. Self-

Household water supply is not reaching water valve. Check water connection procedure in your Installation Instructions.

Copper or plastic tubing has kinks. Turn off water supply and remove kinks. If kinks cannot be removed,

Water pressure is too low. Water pressure must be between 20 to 100 pounds per square

Check freezer temperature. See the controls section in your owner's manual for assistance

Ice bin is not installed properly. See Ice Bin section for proper installation and alignment.

connection. Plastic is less durable and can cause leakage. The manufacturer is

Improper water valve was installed. Check water connection procedure in your Installation Instructions. Self-

Freezer temperature is too high. See controls section in chapter called Installing Your Refrigerator on

Improper water valve was installed. Check water connection procedure in your Installation Instructions. Self-

Copper or plastic tubing has kinks. Turn off water supply and remove kinks. If kinks cannot be removed,

Water filter is clogged or needs to be changed.

Refrigerator has been recently installed.

Water supply in holding tank has been depleted.

Water has settled into water lines outside holding

tank and has warmed to room temperature.

dust flushed from cartridge. Particles are safe for consumption. Will

disappear after the first few uses.

while the internal water tank is filling.

between 20 to 100 pounds per square inch to function properly.A

minimum pressure of 35 pounds per square inch is recommended for

units with water filters.

piercing and %" saddle valves cause low water pressure and may

clog the line over time. The manufacturer is not responsible for property

damage due to improper installation or water connection.

replace tubing.

inch to function properly. A minimum pressure of 35 pounds per

square inch is recommended for units with water filters.

on how to adjust your controls. Freezer must be between 0 to

2° F (-18 to -17° C) to produce ice.

not responsible for property damage due to improper installation

or water connection,

piercing and %6"saddle valves cause low water pressure and may clog

the line over time. The manufacturer is not responsible for property

damage due to improper installation or water connection.

square inch is recommended for units with water filters.

how to adjust your controls. Freezer is recommended to be between

0 to 2° F (-18 to -17° C).

square inch is recommended for units with water filters.

piercing and %" saddle valves cause low water pressure and may clog

the line over time. The manufacturer is not responsible for property

damage due to improper installation or water connection,

replace tubing.

Change water filter.

Discard first glass of water and refill.

ISNO](0¥ DBYTHESEW AN]IE£

1. Conditions and damages resulting from any of the following:

a. Improper installation, delivery or maintenance.

b. Any repair, modification, alteration or adjustment not authorized by the

manufacturer or an authorized servicer.

c. Misuse, abuse, accidents or unreasonable use.

d. Incorrect electric current, voltage or supply.

e. Improper setting of any control.

2. Warranties are void if the original serial numbers have been removed,

altered, or cannot be readily determined.

3. Light bulbs.

4. Products purchased for commercial or industrial use.

5. The cost of service or service call to:

a. Correct installation errors.

b. Instruct the user on the proper use of the product.

c. Transport the appliance to the servicer.

6. Consequential or incidental damages sustained by any person as a result

of any breach of these warranties. Some states do not allow the exclusion

or limitation of consequential or incidental damages, so the above exclu-

sion may not apply.

To purchase accessories or replacement parts not covered by your

product warranty:

Please have your model and serial numbers ready and call our parts

specialists at 1-877-232-6771 inside U.S.A. from 7 a.m. to 7 p.m. central

time Monday through Friday. Outside the U.S.A., contact your local

appliance dealer or parts distributor.

Call the dealer from whom your appliance was purchased or call Maytag

ServicessM,Maytag Customer Assistance at 1-800-688-9900, U.S.A. or

1-800-688-2002 Canada to locate an authorized servicer.

Be sure to retain proof of purchase to verify warranty status. Refer to

WARRANTY for further information on owner's responsibilities for

warranty service.

If the dealer or service company cannot resolve the problem, write to

Maytag ServicessM,Attn: CAIR_Center, P.O. Box 2370, Cleveland, TN

37320-2370, or call 1-800-688-9900 U.8.A. or 1-800-688-2002 Canada.

U.S.A. customers using TTY for deaf, hearing impaired or speech

impaired, call 1-800-688-2080.

NOTE: When writing or calling about a service problem, please include

the following information:

a. Your name, address and telephone number;

b. Model number and serial number;

c. Name and address of your dealer or servicer;

d. A clear description of the problem you are having;

e. Proof of purchase (sales receipt).

NOTE: Some Reverse Osmosis home water systems cause tow water

pressure. Low water pressure can affectthe water and ice dispensing sys-

tem by causingsmall or hollow ice cubes and slow water flow from the dis-

penser. Service problems related to the home's Reverse Osmosis water

system are not covered by the warranty.

Nous vous f_licitons de votre achat

d'un r_frig_rateur Maytag PerformaTM!

important pour nous que vous soyez totalement

satisfait, et nous vous demandons donc de lire ce guide

attentivement. Vous y trouverez des instructions qui vous

permettront d'utiliser et entretenir convenablement votre

nouvel appareil.

t_conomisez temps et argent. Si quelque chose ne fonc-

tionnait pas correctement, nous vous sugg_re-rions de

consulter darts cette brochure la section

<<Fontionnemenb_. Uinformation qui y est pr_sent_e vous

aidera a r_soudre quelques probl_mes simples avant de

faire intervenir un technicien.

Importates

Installation

1_16mentsdu com

produits frais

1_16mentsdu compartiment cong

Pour toute question, 6crivez-nous (communiquez le

num6ro de module et votre num6ro de t616phone) ou

t_16phonez a •

Maytag Services sM

Attention : CAIR _'Center

P.O. Box 2370

Cleveland, TN 37320-2370

1-800-688-9900 t_.-U.

1-800-688-2002 CANADA

(Lundi-vendredi 8 h 00- 20 h 00, HSE)

Site Internet : http:/iwww.maytag.com

Caracteristiques du

Systeme de filtration ............................................ 34

Donnees sur le filtre a eau .................................. 35

Conseils et entretien ....................................... 36-38

Bruits normaux ..................................................... 39

Fontionnement ................................................ 40-41

Garantie ................................................................. 43

Manual del proprietario ........................................ 44

J J

DESECURITE

Les mises en garde et les consignesde

securite importantes enoncees dans ce

manuelnecouvrentpastouteslessituations

susceptiblesdesepresenter.

II faut donc faire preuvede bon sens, de

prudenceet d'attentionIorsde la mise en

service,rentretienou la raiseen marchedu

refrigerateur.En cas de problemedifficile_.

resoudre, toujours communiquer avec le

detaillant,le distributeur,le prestatairede

serviceapres-venteou lefabricant.

t

APPRENEZ A

RECONNA|TRE CES

S.YMBOLES, MOTS ET

ETIQUETTES RELATIFS A

LA SECURITE

2}

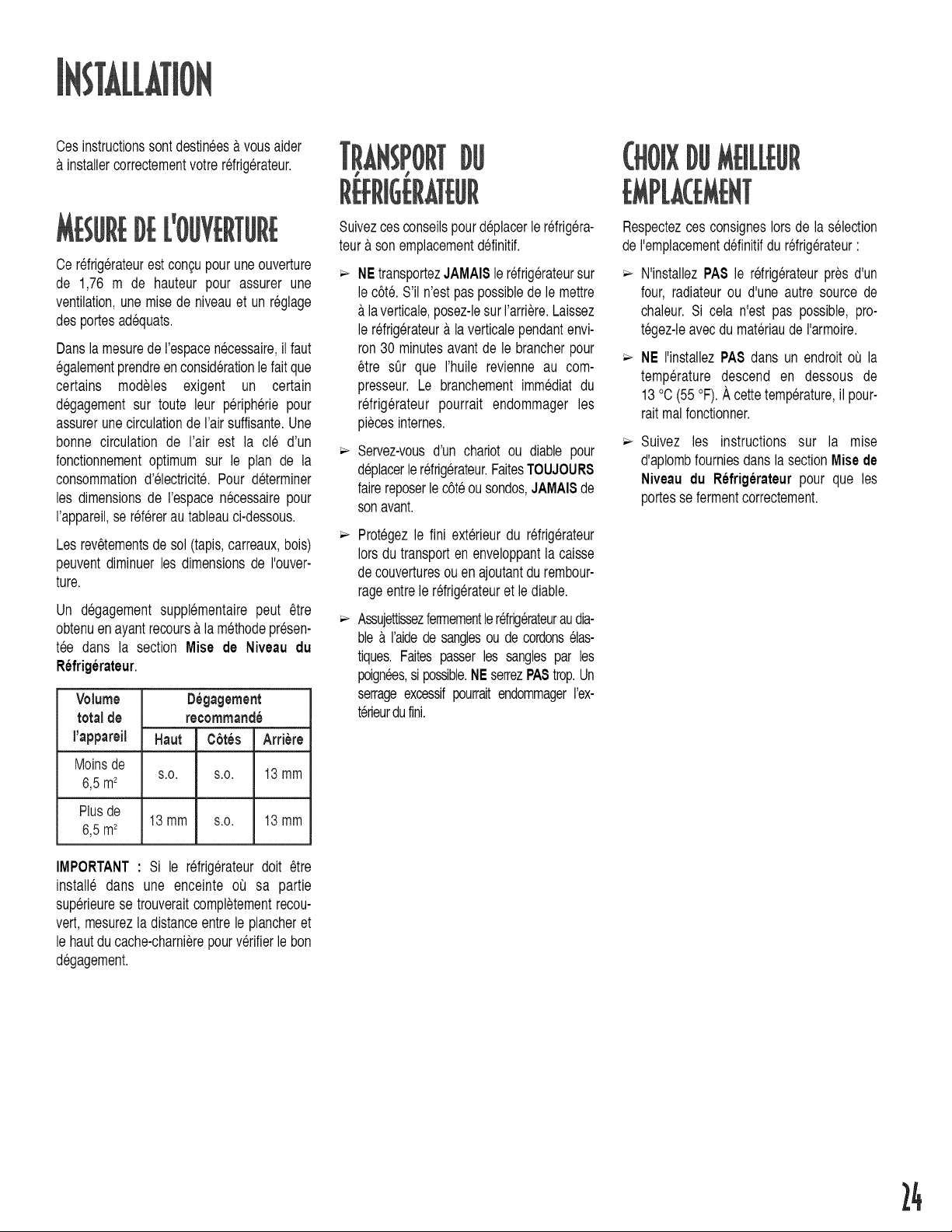

CE;C I S

Cesinstructionssontdestinees#.vousaider

#.installercorrectementvotrerefrigerateur.

DU[L

DE

Cerefrigerateurestcongupouruneouverture

de 1,76 m de hauteur pour assurer une

ventilation,une raisedeniveauet unreglage

desportesadequats.

Dansla mesurederespacenecessaire,ilfaut

egalementprendreenconsiderationlefaitque

certains modeles exigent un certain

degagementsur toute leur peripheriepour

assurerunecirculationdeFairsuffisante.Une

bonne circulation de I'air est la cle d'un

fonctionnementoptimumsur le plan de la

consommationd'electricit&Pour determiner

les dimensionsde I'espacenecessairepour

rappareil,se refererautableauci-dessous.

Lesrev_tementsdesol (tapis,carreaux,bois)

peuventdiminuerles dimensionsde I'ouver-

ture.

Un degagementsupplementairepeut _tre

obtenuenayantrecoursa lamethodepresen-

tee dans la section Mise de Niveau du

Refrigerateur.

Volume

total de

I'appareil

Moinsde

6,5m2

Plusde

6,5m2

Degagement

recommande

Haut Cbtes

s.o. s.o. 13mm

13mm s.o. 13mm

Arfiere

Suivezcesconseilspourd@lacerlerefrigera-

teur_.sonemplacementdefinitif.

NEtransportezJAMAI8lerefrigerateursur

le c6t&S'iln'estpaspossibledelemettre

&laverticale,posez-lesurrarriere.Laissez

le refrigerateur&laverticalependantenvi-

ron30 minutesavantde lebrancherpour

_tre sQr que rhuile revienne au com-

presseur.Le branchementimmediatdu

refrigerateur pourrait endommager les

piecesinternes.

Servez-vousd'un chariotou diable pour

d@lacerlerefrigerateur.FaitesTOUJOUR8

fairereposerlec6teousondos,JAMAISde

sonavant.

Protegezle fini exterieurdu refrigerateur

Iorsdutransporten enveloppantla caisse

decouverturesouenajoutantdurembour-

rageentrele refrigerateuretlediable.

Assujettissezfermementlerefrigerateuraudia-

ble_.raidede sanglesou decordonselas-

tiques.Faitespasserles sanglespar les

poignees,si possible.NEserrezPA8trop.Un

serrageexcessifpourraitendommagerI'ex-

terieurdufini.

RespectezcesconsignesIorsde laselection

deI'emplacementdefinitifdurefrigerateur'

N'installezPA8 le refrigerateurpres d'un

four, radiateurou d'une autre sourcede

chaleur.Si cela n'est pas possible,pro-

tegez-leavecdu materiaudeI'armoire.

NE I'installezPA8dans unendroit ou la

temperature descend en dessous de

13°C(55°F).A cettetemperature,il pour-

raitmalfonctionner.

Suivez les instructions sur la mise

d'aplombfourniesdanslasectionMisede

Niveaudu Refrigerateurpour que les

portesse fermentcorrectement.

IMPORTANT: Si le refrigerateurdolt _tre

installe dans une enceinte ot_ sa partie

superieurese trouveraitcompletementrecou-

vert,mesurezla distanceentrele plancheret

le hautducache-charnierepourverifierle bon

degagement.

DESTB ETDES

Certainesinstallationsexigentle retrait des

portesavantded@lacerlerefrigerateura.son

emplacementfinal.

1. Retirer la grille et les couvre-charnieres

inferieurs.

Ouvrirlesdeuxportes& 180°, ouaussi

grandquepossible,pourlesdemonter.

2. Tout en serrant le collier blanc (A) au

connecteurbleu(B),tirezlalignepourI'eau

duconnecteur.

,B

IMPORTANT: Avantd'insererla ligne pour

I'eaudansle connecteur,decoupezlatuyau-

terie & la premiereligne disponiblesur la

tuyauterie.

3. Retirerlecouvre-charnieresuperieurapres

avoirenlevelaviscruciforme.

6. Modelesavec distributeurseulement:

Detacherle harnaisde raccordementdufil

principal. Detacherle hamaisde c&blage

rouge.

Detacherle harnais de raccordement

du fil principalutiliserun tournevisa.

lameplateou un onglepour appuyer

surle pointde jonctionentreles deux

connecteursafinde lesdegager.

Detacherle harnaisde c_.blagerouge

appuyersurlapattesetrouvantsur le

dessousdu connecteurpourdegager

celui-ci.

7. Enlever les charnieres superieures en

m_metempsquelesportes.

4. Fermerles portes.

5. Devisserles vis a. six pans % po des

charnieressuperieures.

Modelesavecdistributeurseulement:

NEPA8enleverle filde mise&laterre

vert oulaviscentralede raccordement

duill.

8. Enleverlescharnieresinferieuresavecun

tourne-ecrouhexagonalde%po.

D{S[ES

Pour remonter les portes, suivre dans

rordreinverselesetapesindiqueessousla

section Retrait des Portes et des

Chamieres.

IMPORTANT: Avantd'insererla ligne pour

reau dansleconnecteur,decoupezlatuyau-

terie & la premiereligne disponiblesur la

tuyauterie.

);EDESPO

,#

l ;

DENIVEAUl)U

S'il s'agitd'une posede poigneesinitiale,la

poigneedu compartimentpour produitsfrais

setrouvedansce compartiment.Lagarniture

de la poignee se trouve dans le sac de

documentation.

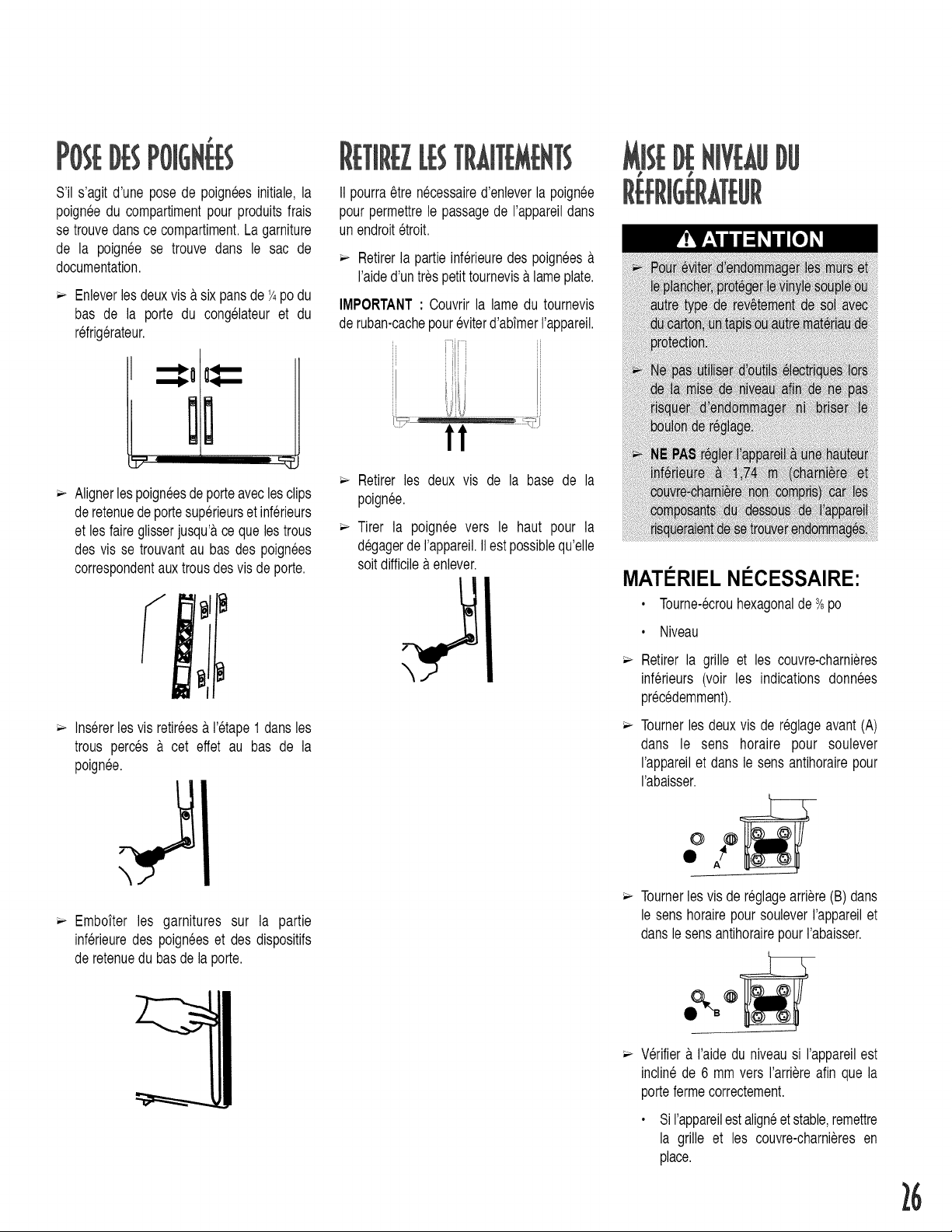

Enleverlesdeuxvis&sixpansde74podu

bas de la porte du congelateuret du

refrigerateur.

Alignerlespoigneesdeporteaveclesclips

deretenuedeportesuperieurset inferieurs

etlesfaireglisserjusqu'&ce quelestrous

desvis setrouvantau basdes poignees

correspondentauxtrousdesvisdeporte.

II pourra_trenecessaired'enleverla poignee

pourpermettrele passagede I'appareildans

unendroitetroit.

Retirerla partieinferieuredespoignees&

I'aided'untrespetittournevis&lameplate.

IMPORTANT: Couvrirla lamedu tournevis

deruban-cachepoureviterd'abfmerI'appareil.

t!

Retirer les deux vis de la base de la

poignee.

'_ Tirer la poignee vers le haut pour la

degagerdeI'appareil.IIestpossiblequ'elle

soitdifficile&enlever.

MATERIEL NECESSAIRE:

• Tourne-ecrouhexagonalde%po

• Niveau

'_ Insererles visretirees&I'etape1dartsles

trous perces & cet effet au bas de la

poignee.

EmboTterles garnitures sur la pattie

inferieuredes poigneeset des dispositifs

deretenuedubasde laporte.

Retirer la grille et les couvre-charnieres

inferieurs (voir les indications donnees

precedemment).

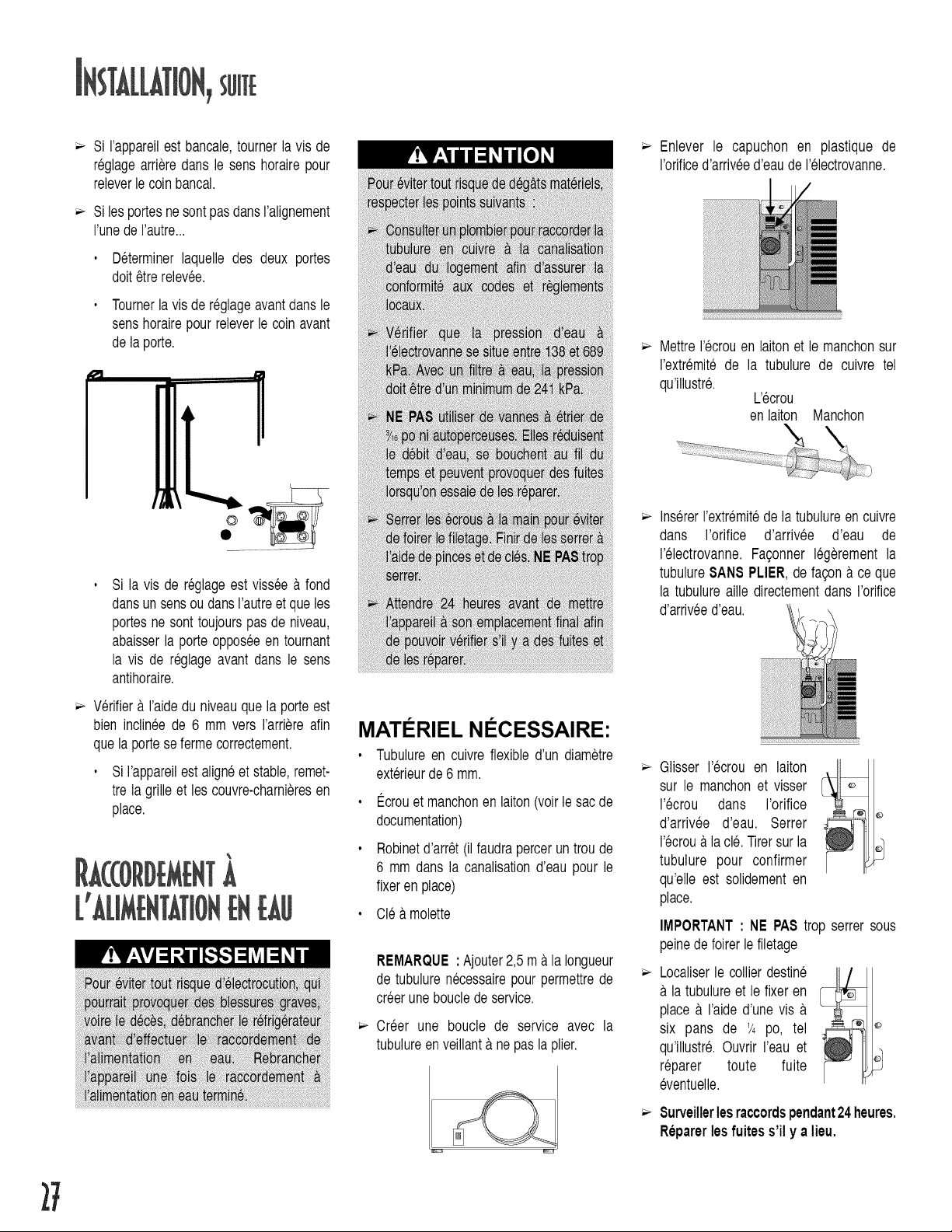

Tournerlesdeuxvis de reglageavant(A)

dans le sens horaire pour soulever

I'appareilet dans le sensantihorairepour

I'abaisser.

O

Tournerlesvis dereglagearriere(B)dans

le senshorairepoursouleverI'appareilet

danslesensantihorairepourI'abaisser.

'_ Verifier&I'aideduniveausi I'appareilest

inclinede 6 mmvers I'arriereafin quela

portefermecorrectement.

• SiI'appareilestaligneetstable,remettre

la grille et les couvre-charnieresen

place.

Sirappareilestbancale,tournerlavisde

reglagearrieredanslesenshorairepour

releverlecoinbancal.

SilesportesnesontpasdansI'alignement

I'unedeI'autre...

• Determinerlaquelledesdeuxportes

dolt_trerelevee.

• Tournerlavisdereglageavantdansle

senshorairepourreleverlecoinavant

delaporte.

Silavisdereglageestvissee#.fond

dansunsensoudansI'autreetqueles

portesnesonttoujourspasdeniveau,

abaisserlaporteopposeeentournant

lavisdereglageavantdanslesens

antihoraire.

Enlever le capuchon en plastique de

rorificed'arriveed'eaude I'electrovanne.

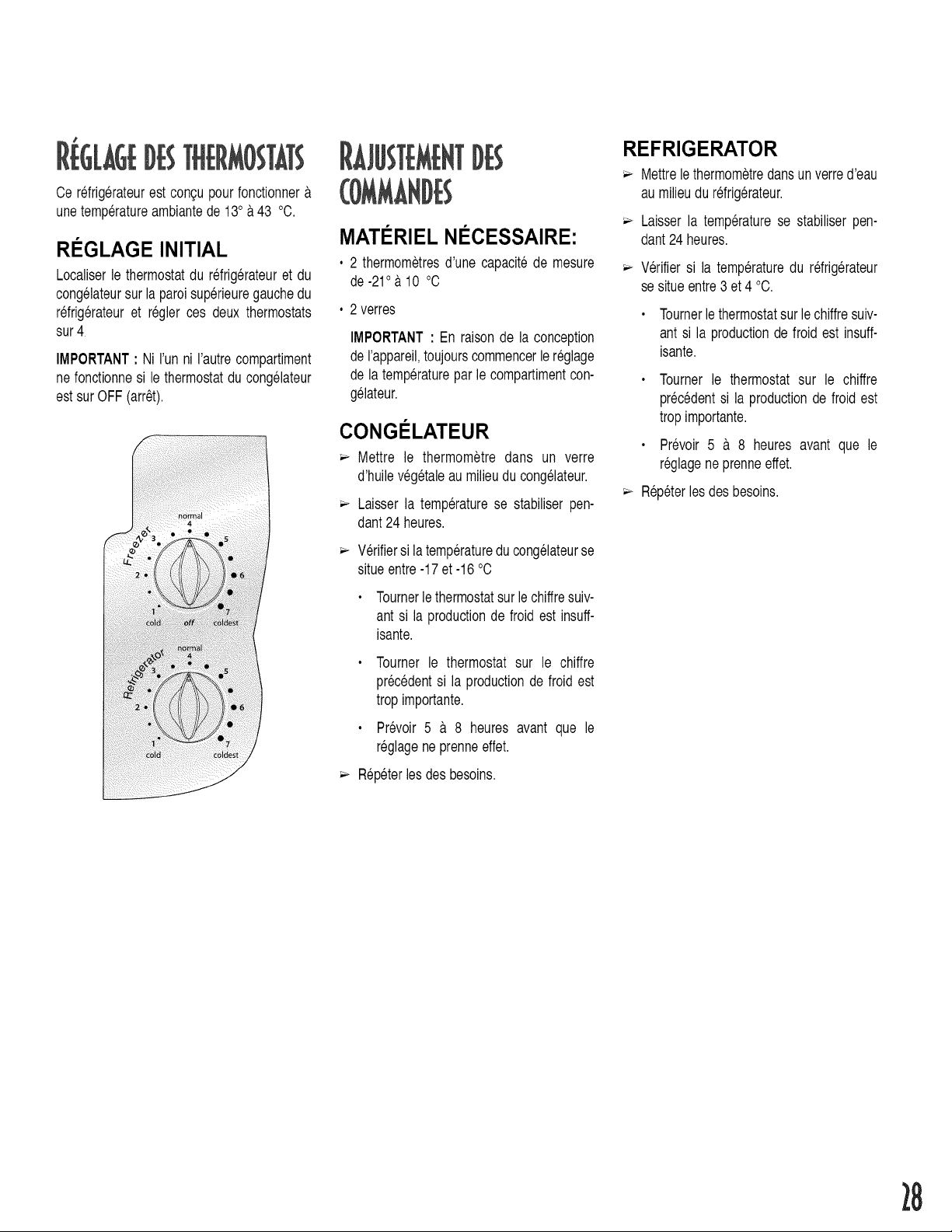

MettreI'ecrouenlaitonet lemanchonsur

rextremite de la tubulure de cuivre tel

qu'illustr&

L'ecrou

enlaiton Manchon

Insererrextremitedela tubulureencuivre

dans I'orifice d'arrivee d'eau de

I'electrovanne.Fagonnerlegerementla

tubulureSAN8PLIER,defagonace que

la tubulureaille directementdansI'orifice

d'arriveed'eau.

Verifier#.raideduniveauquelaporteest

bieninclineede6 mmversrarriereafin

quelaportesefermecorrectement.

• SiI'appareilestaligneetstable,remet-

trela grilleet lescouvre-charnieresen

place.

[

MATI RIEL NI CESSAIRE:

• Tubulureen cuivreflexibled'un diametre

exterieurde 6mm.

Ecrouet manchonen laiton(voirle sacde

documentation)

Robinetd'arr_t(ilfaudraperceruntrou de

6 mm dansla canalisationd'eau pour le

fixerenplace)

• Cle_.molette

REMARQUE:Ajouter2,5m&la Iongueur

de tubulurenecessairepour permettrede

creerunebouclede service.

Creer une boucle de service avec la

tubulureenveillanta nepaslaplier.

Glisser I'ecrou en laiton ,I

sur le manchonet visser

I'ecrou dans I'orifice

d'arrivee d'eau. Serrer

recroua.lacl& Tirersurla

tubulure pour confirmer

qu'elleest solidementen

place.

IMPORTANT: NE PA8 trop serrersous

peinedefoirerlefiletage

Localiserle collierdestine

_.latubulureet lefixeren

placea.raide d'unevisa.

six pans de 1/4po, tel

qu'illustr&Ouvrir reau et

reparer toute fuite

eventuelle.

8urveillerlesraccordspendant24heures.

Reparerles fuites s'ilya lieu.

@

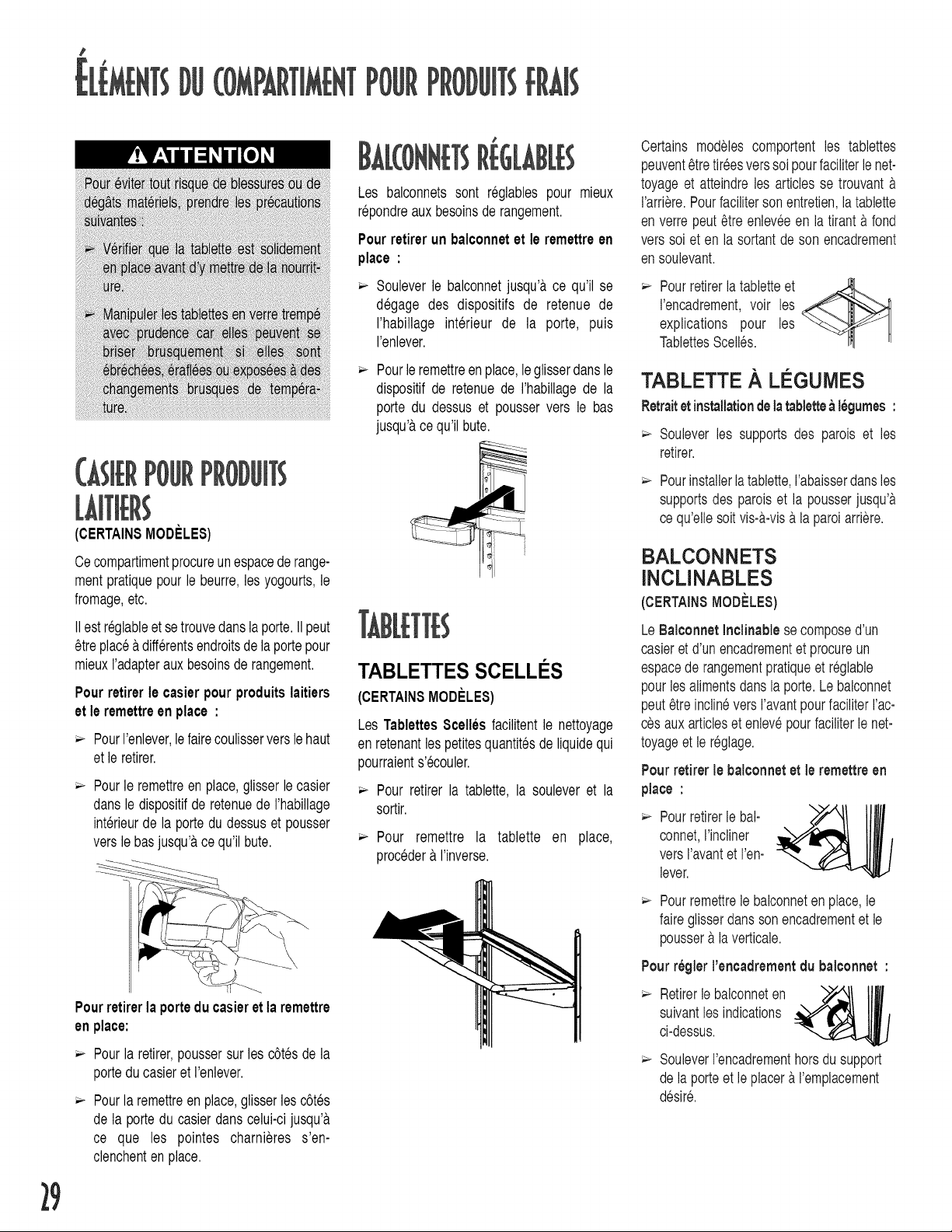

Cerefrigerateurestco%upourfonctionner&

unetemperatureambiantede1309.43°C.

RI=GLAGE INITIAL

Localiserle thermostatdurefrigerateuret du

congelateursurlaparoisuperieuregauchedu

refrigerateuret regler ces deux thermostats

sur4

IMPORTANT: Ni run ni I'autrecompartiment

nefonctionnesi le thermostatdu congelateur

estsurOFF(arr_t).

MATERIEL NECESSAIRE:

• 2 thermometresd'unecapacitede mesure

de-21o& 10 °C

• 2verres

IMPORTANT: En raisonde la conception

derappareil,toujourscommencerlereglage

de latemperatureparlecompartimentcon-

gelateur.

CONGELATEUR

Mettre le thermometre dans un verre

d'huilevegetaleau milieuducongelateur.

Laisserla temperaturese stabiliserpen-

dant24heures.

Verifiersilatemperaturedu congelateurse

situeentre-17et-16°C

Tournerlethermostatsurlechiffresuiv-

antsi la productionde froidest insuff-

isante.

REFRIGERATOR

Mettrelethermometredansunverred'eau

aumilieudu refrigerateur.

Laisserla temperaturese stabiliserpen-

dant24heures.

Verifiersi la temperaturedu refrigerateur

sesitueentre3et 4 °C.

• Tournerlethermostatsur lechiffresuiv-

antsi la productionde froidest insuff-

isante.

• Tournerle thermostat sur le chiffre

precedentsi la productionde froidest

tropimportante.

• Prevoir 5 & 8 heures avant que le

reglageneprenneeffet.

R@eterlesdesbesoins.

Tourner le thermostatsur le chiffre

precedentsi la productionde froidest

tropimportante.

Prevoir5 #. 8 heures avant que le

reglageneprenneeffet.

Repeterlesdesbesoins.

Les balconnetssont reglables pour mieux

repondreauxbesoinsderangement.

Pourretirer un balconnetet le remettreen

place :

Certains modulescomportentles tablettes

peuvent_tretir6esverssoi pourfaciliterlenet-

toyageet atteindreles articlesse trouvant&

rarriere.Pourfacilitersonentretien,latablette

enverrepeut_treenleveeen latirant&fond

verssolet en lasortantdeson encadrement

ensou]evant.

POURPROWTS

(CERTAIN8MODELES)

Cecompartimentprocureunespacederange-

mentpratiquepourlebeurre,lesyogourts,le

fromage,etc.

IIestreglableetsetrouvedanslaporte.IIpeut

_treplace&differentsendroitsde laportepour

mieuxradapterauxbesoinsde rangement.

Pourretirer le casierpourproduitslaitiers

et leremettreen place:

PourI'enlever,lefairecoulisserverslehaut

etle retirer.

Pourle remettreen place,glisserlecasier

dansle dispositifde retenuede I'habillage

interieurde la portedudessuset pousser

verslebasjusqu'&cequ'ilbute.

Souleverle balconnetjusqu'&ce qu'il se

degage des dispositifs de retenue de

I'habillage interieur de la porte, puis

I'enlever.

Pourleremettreenplace,leglisserdansle

dispositifde retenuede I'habillagede la

portedu dessuset pousservers le bas

jusqu'&cequ'ilbute.

TABLETTES SCELLI S

(CERTAIN8MODELE8)

LesTablettes8celles facilitentle nettoyage

enretenantlespetitesquantitesde liquidequi

pourraients'ecouler.

Pour retirerla tablette,la souleveret la

sortir.

Pour remettre la tablette en place,

proceder&rinverse.

Pourretirerlatabletteet

I'encadrement,voir les

explications pour les

TablettesScell6s.

TABLETTE .& LEGUIVlES

Retraitetinstallationdelatablettea legumes:

Souleverles supportsdes parois et les

retirer.

Pourinstallerlatablette,I'abaisserdansles

supportsdesparoiset la pousserjusqu'&

cequ'ellesoitvis-a-visala paroiarriere.

BALCONNETS

INCLINABLES

(CERTAIN8MODELE8)

LeBalconnetInclinablesecomposed'un

casieretd'unencadrementet procureun

espacede rangementpratiqueet reglab]e

pourlesalimentsdanslaporte.Lebalconnet

peut_treinclin6versI'avantpourfaciliterrac-

cesauxarticlesetenle%pourfaciliterle net-

toyageet ler6g]age.

Pourretirer leba]connetetle remettreen

place :

_- Pourretirerlebal-

connet,I'incliner

versravantetFen°

lever.

Pourretirerlaporteducasieretla remettre

enplace:

Pourlaretirer,poussersur lesc6tesde la

porteducasieret I'enlever.

Pourla remettreenplace,glisserles c6tes

de laporteducasierdartscelui-cijusqu'&

ce que les pointes charnieres s'en-

clenchenten place.

29

Pourremettrelebalconneten place,le

faireglisserdanssonencadrementetle

poussera laverticale.

PourreglerI encadrementdu balconnet :

Retirerle balconneten _'_1 II_l

suivantlesindications

ci-dessus.

Soulever!'encadrementhorsdusupport

delaporteet leplacera remplacement

desir&

Loading...

Loading...