Maytag CG34700BDT, PGR5715BDW, PGR5715BDQ, PGR5710BDW, PGR5710BDQ Installation Instructions

...Page 1

Gas Conversion

General

All ranges are equipped with fixed orifices and with a

convertible appliance pressure regulator. The unit model

number plate states which gas it is adjusted for at the

factory. To convert the unit to either Natural gas or LP

gas will require the replacement of the orifice hoods, and

the adjustment of the air shutters on the burners and

adjustment of the appliance pressure regulator converter

cap.

Inlet pressure to the appliance pressure regulator should

be as follows for checking the appliance pressure

regulator setting:

INLET PRESSURE IN NATURAL LP

INCHES OF WATER COLUMN

Minimum 5 11

Maximum 14 14

Appliance Pressure Regulator Conversion

The unit appliance pressure regulator must be set to

match the type gas supply used. If converting from

natural gas to LP gas, the appliance pressure regulator

must be converted to regulate LP gas. If converting from

LP gas to natural gas, the appliance pressure regulator

must be converted to regulate natural gas.

To access the regulator from front of range, remove the

storage drawer or warming drawer.

GAS GAS

Reinstall cap nut to appliance pressure regulator and

replace dust cover.

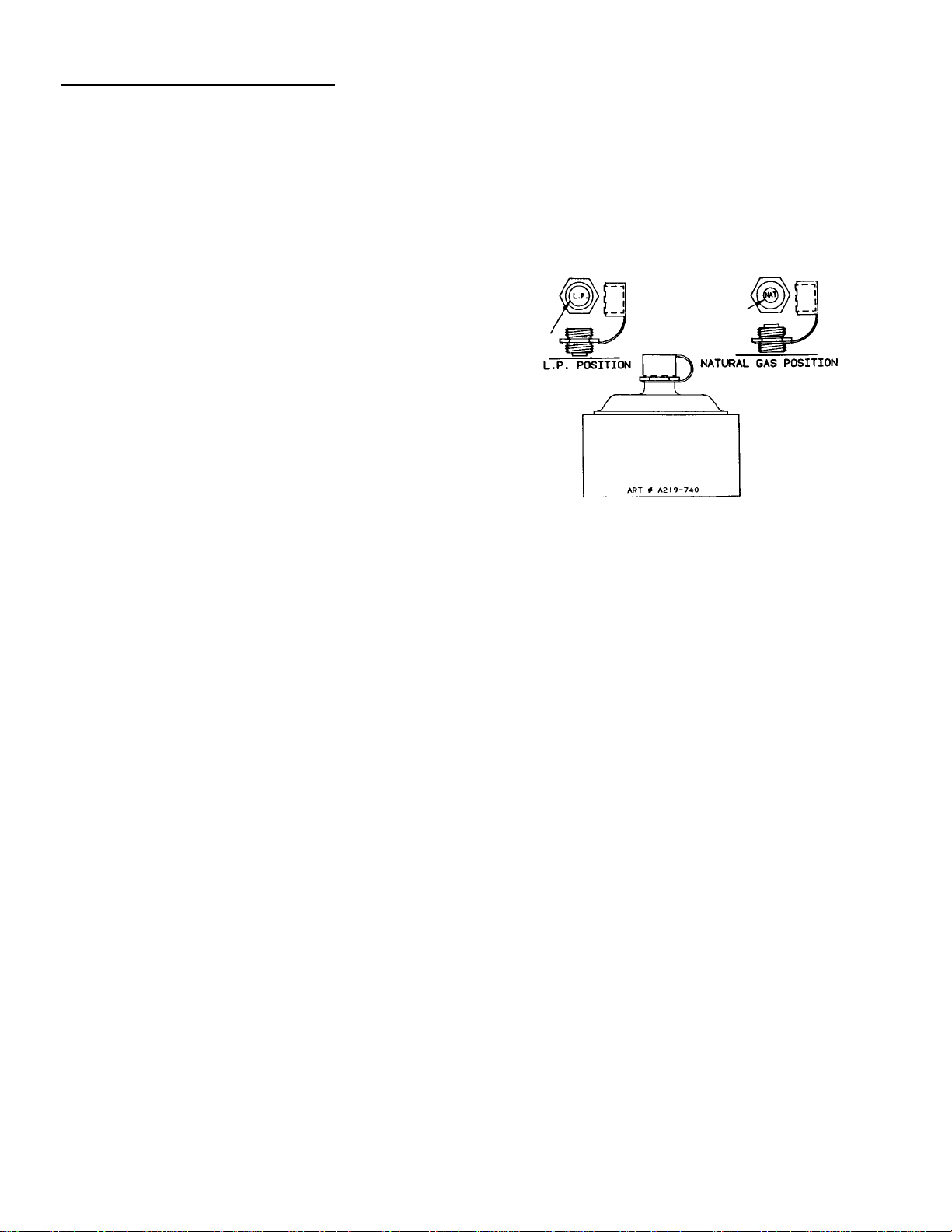

CAUTION: Be sure marking for the type of gas to which

appliance pressure regulator has just been converted is

visible in top of cap nut before replacing plastic dust

cover. (See figure 1.)

FIGURE 1

To replace the storage drawer: Fit the drawer rollers

onto the rails. Lift up drawer front and gently push in to

first stop position. Lift up and continue to slide drawer to

the closed position.

To remove the storage drawer: Pull out to the first stop

position. Lift up front of drawer and pull to the second

position, grasp sides and lift up and out to remove drawer.

To convert the appliance pressure regulator from one gas

to another, remove plastic dust cover from cap nut on top

of appliance pressure regulator. Remove cap nut from

appliance pressure regulator (plastic dust cover comes off

with nut).

IMPORTANT: Remove plastic dust cover from cap nut

and reinstall on opposite side of cap nut.

8101P553-60

(12-03-00)

Page 2

Orifice Conversion

To convert this unit to LP gas from Natural gas will require

the exchange of orifice hoods.

IMPORTANT: Save all natural orifice hoods that are

removed.

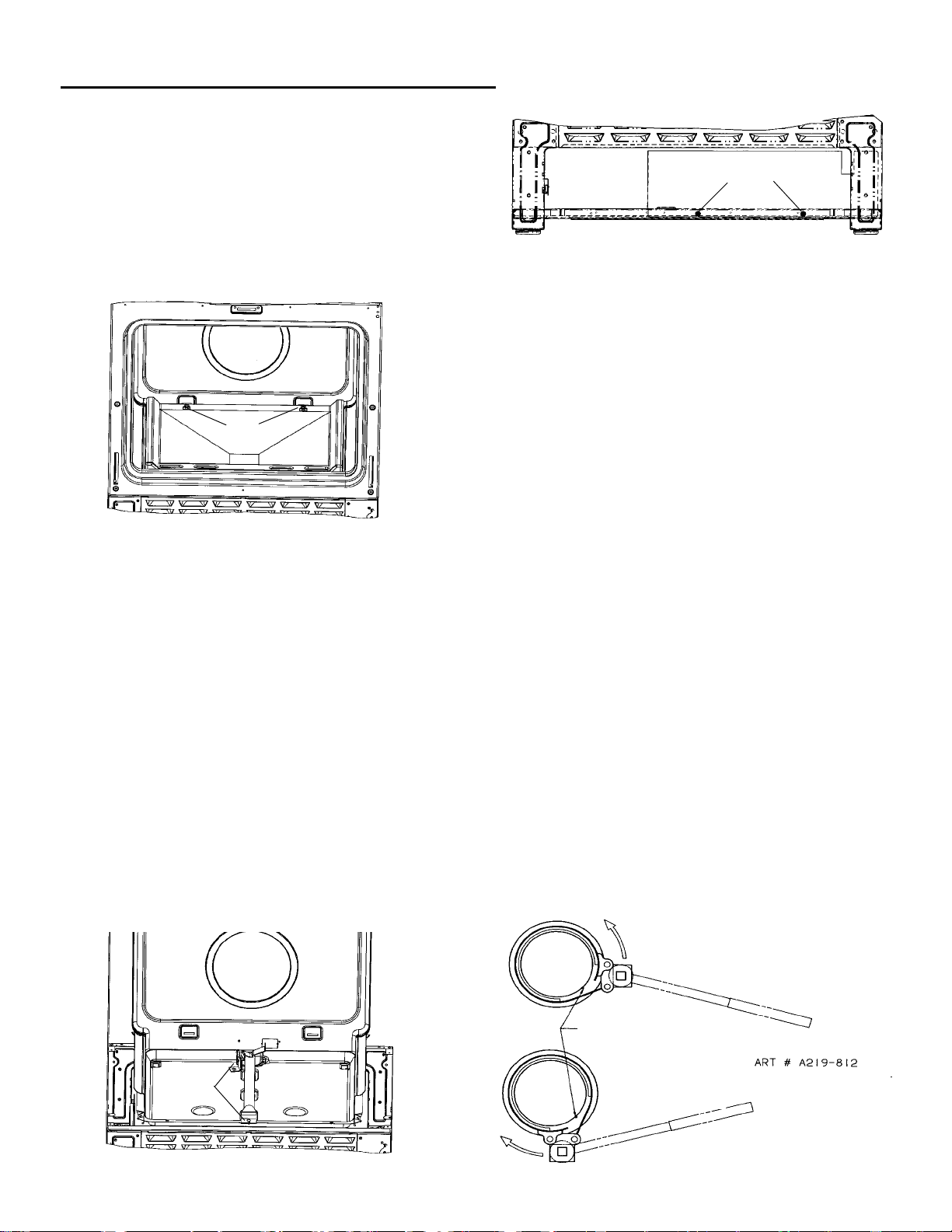

Oven Burner Con version

Remove all oven racks.

1. Bake Burner

a. Remove oven bottom (figure 2).

CLIP

FIGURE 2

b. Remove screw from the bake burner (figure 3).

c. Remove the bake burner from the orifice fitting.

CAUTION: The igniter is fragile. Take care not to

damage it.

d. Gently lay the bake burner in the bottom of the

range.

e. Remove warming drawer or storage drawer.

f. Remove access cover to orifice (figure 4).

g. Remove the bake orifice hood with a ½² (12.7 mm)

socket wrench counter-clockwise.

h. Place the black-colored orifice stamped 1.3 on the

fitting turning it clockwise by hand approximately one

turn. Tighten the orifice hood with a ½² (12.7 mm)

socket wrench clockwise approximately 2½ turns.

i. Replace the bake burner.

j. Replace the oven bottom.

k. Replace access cover and drawer.

SCREW

FIGURE 4

2. Broil Burner Conversion

a. Remove the screw from the broil burner.

b. Gently lay the broil burner on the oven bottom.

CAUTION: The igniter is fragile. Take care not to

damage it.

c. Remove the broil orifice hood with a ½² (12.7 mm)

socket wrench.

d. Place the green-colored orifice hood stamped 57 on

the fitting turning the orifice clockwise by hand

approximately one turn. Tighten the broil orifice hood

with a ½² (12.7 mm) socket wrench clockwise

approximately 2½ turns.

e. Replace broil burner.

f. Replace oven racks.

Surface Burner Conversion

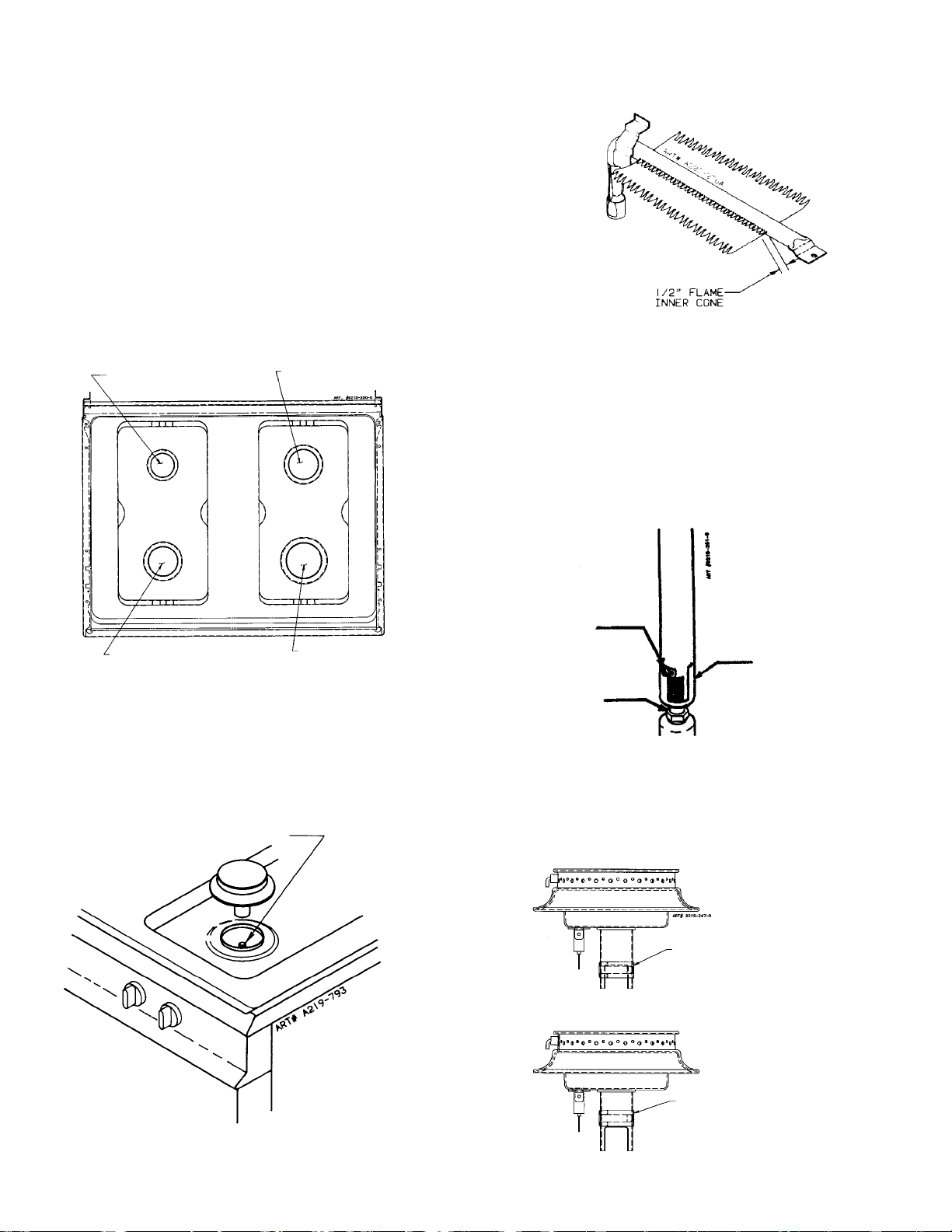

1. Remove all grates.

2. Mark ignitor location on the main top with a pencil. This

mark on the main top is used as a reference point

when replacing the burner assembly to ensure that the

burner is tightened to its original position.

3. Place burner wrench (part no. 8312D075-60, available

from the dealer or authorized service agency) over the

surface burner assembly with the ignitor positioned

inside the gap in the wrench ring (figure 5). This

prevents the ignitor from being damaged when the

wrench grips the burner assembly. Rotate the burner

assembly approximately one-eighth turn

counter-clockwise and lift from the main top.

SCREW

FIGURE 5

FIGURE 3

2

Page 3

4. Remove the surface burner orifice hood with a ½² (12.7

mm) socket wrench counter-clockwise.

IMPORTANT: Save all natural orifice hoods that are

removed.

5. Place the corresponding orifice hood on the burner

fitting according to figure 6. Turn the orifice hood

clockwise by hand approximately one turn. Tighten the

orifice hood clockwise with a ½² socket wrench

approximately 2½ turns.

6. Replace the burner assembly in the main top and

rotate one-eighth turn clockwise using the burner

wrench until the burner locks in place with the igniter

aligned with the reference mark on the main top.

7. Repeat steps 3 through 6 until all orifice hoods have

been changed.

7.5K BTU NATURAL (NO COLOR)

REPLACE WITH ORIFICE (NO COLOR)

STAMPED .85 FOR LP

7.5K BTU NATURAL (NO COLOR)

REPLACE WITH ORIFICE (NO COLOR)

STAMPED .85 FOR LP

Air Shutter - Oven Burner

a. The approximate length of the flame of oven burner is

a 1/2 inch distinct inner blue flame, figure 8.

FIGURE 8

b. Oven burner flame can be checked as follows:

1. Yellow flame on burner - open burner air shutter to

the widest opening that will not cause the flame to lift

or blow off the burner when cold. (See #2 on figure

9.)

2. Distinct blue flame but lifting - close burner air

shutter to the point where it will not cause the flame

to lift or blow off the burner when cold. (See #2 on

figure 9.)

9.2K BTU NATURAL (NO COLOR)

REPLACE WITH ORIFICE (NO COLOR)

STAMPED .85 FOR LP

12K BTU NATURAL (RED)

REPLACE WITH ORIFICE (RED)

STAMPED .65 FOR LP

FIGURE 6

To Reassemble:

Replace burner assembly in main top and rotate

approximately one-eighth turn clockwise using burner

wrench until burner locks into position with ignitor aligned

with reference mark on main top.

ORIFICE HOOD

FIGURE 7

3

LOCK

SCREW

AIR SHUTTER

1

ORIFICE

HOOD

2

FIGURE 9

c. The oven burner air shutter adjustment is the same on

ranges with a gas pilot or electric ignition.

d. Sealed burner adjustment. Adjust the air shutter for the

appropriate gas according to figure 10.

AIR SHUTTER

NATURAL POSITION

FIGURE 10

AIR SHUTTER

LP POSITION

3

Page 4

Conversión de gas

Información general

Todas las estufas están equipadas con orificios fijos y un

regulador convertible de presión de electrodomésticos. La

placa del número de modelo indica para qué gas viene

ajustada de fábrica la estufa. Para convertir la unidad

tanto a gas natural como a gas LP se requerirá el cambio

de las campanas de orificio y el ajuste de los obturadores

de aire en los quemadores, además del ajuste de la tapa

del convertidor del regulador de presión del

electrodoméstico.

La presión de entrada del regulador debe estar del modo

siguiente para verificar el ajuste del regulador:

Vuelva a instalar la tuerca de la tapa en el regulador y

coloque de nuevo la cubierta contra polvo.

PRECAUCIÓN: Asegúrese de que la marca del tipo de

gas para el que convirtió el regulador esté visible en la

parte superior de la tuerca de la tapa antes de colocar la

cubierta de plástico contra polvo. (Vea la figura 1.)

PRESIÓN DE ENTRADA

EN PULGADAS NATURAL LP

DE PRESIÓN DE AGUA

Mínima 5 (1.25) 11 (2.75)

Máxima 14 (3.5) 14 (3.5)

GAS GAS

Conversión del regulador de presión del

electrodoméstico

El regulador de presión debe estar ajustado para el tipo

de gas que se usará. Si la conversión es de gas natural a

gas LP, el regulador debe convertirse para regular gas

LP. Si la conversión es de gas LP a gas natural, el

regulador debe convertirse para regular gas natural.

Para tener acceso al regulador desde el frente de la

estufa, quite el cajón de almacenaje o el cajón calentador.

Para quitar el cajón de almacenaje: Jálelo hacia fuera

hasta la primera posición de trabado. Levante la parte

delantera del cajón y tire hasta la segunda posición,

sujete los lados y levántelo para sacarlo.

Para convertir el regulador de un gas a otro, quite la

cubierta de plástico contra polvo de la tuerca de la tapa

en la parte superior del regulador. Quite la tuerca de la

tapa del regulador (la cubierta de plástico contra polvo se

sale con la tuerca).

POSICIÓN DEL

GAS LP

FIGURA 1

Para volver a colocar el cajón de almacenaje: Coloque

los rodillos del cajón dentro de los rieles. Levante la parte

delantera del cajón y empuje con cuidado hasta la

primera posición de trabado. Levante y continúe

deslizando el cajón hasta la posición de cerrado.

POSICIÓN DEL GAS

NATURAL

IMPORTANTE: Quite la cubierta de plástico de la tuerca

de la tapa y vuelva a instalarla en el lado opuesto de la

tuerca de la tapa.

Page 5

Conversión del orificio

Para convertir esta unidad a gas LP de gas natural será

necesario cambiar las campanas de orificio.

IMPORTANTE: Conserve todas las campanas de orificio

de gas natural que quite.

Conversión del quemador del horno

Quite todas las parrillas del horno.

1. Quemador de horneado

a. Quite el piso del horno (figura 2).

SUJETADOR

FIGURA 2

b. Quite el tornillo del quemador de hornear (figura 3).

c. Quite el quemador de horneado del ajuste del

orificio.

PRECAUCIÓN: El encendedor es frágil. Tenga

cuidado de no dañarlo.

d. Cuidadosamente coloque el quemador de horneado

en el piso de la estufa.

e. Quite el cajón calentador o el cajón de almacenaje.

f. Quite la cubierta de acceso al orificio (figura 4).

g. Quite la campana de orificio de hornear con una

llave de boca tubular de 12.7 mm (1/2”) en contra de

las manecillas del reloj.

h. Coloque la campana de color negro estampada con

1.3 en el accesorio girándolo en sentido de las

manecillas del reloj manualmente una vuelta

aproximadamente. Apriete la campana de orificio

con una llave de boca tubular de 12.7 mm (1/2”) en

el sentido de las manecillas del reloj dos y media

vueltas aproximadamente.

i. Coloque de nuevo el quemador de horneado.

j. Coloque de nuevo el piso del horno.

k. Coloque la cubierta de acceso y el cajón.

TORNILLO

FIGURA 4

2. Conversión del quemador del asador

a. Quite el tornillo del quemador del asador.

b. Cuidadosamente coloque el quemador del asador en

el piso del horno.

PRECAUCIÓN: El encendedor es frágil. Tenga

cuidado de no dañarlo.

c. Quite la campana de orificio del asador con una

llave de boca tubular de 12.7 mm (1/2”) en contra de

las manecillas del reloj.

d. Coloque la campana de color verde estampada con

57 en el accesorio girándolo en sentido de las

manecillas del reloj manualmente una vuelta

aproximadamente. Apriete la campana de orificio del

asador con una llave de boca tubular de 12.7 mm

(1/2”) en el sentido de las manecillas del reloj dos y

media vueltas aproximadamente.

e. Coloque de nuevo el quemador del asador.

f. Coloque de nuevo las parrillas del horno.

Conversión del quemador de la superficie

1. Quite todas las parrillas.

2. Marque con un lápiz la ubicación del encendedor en la

superficie principal. Esta marca en la superficie

principal se usará como punto de referencia cuando

reemplace el quemador para garantizar que el

quemador esté bien ajustado en su posición original.

3. Coloque la llave del quemador (pieza núm.

8312D075-60, disponible a través del distribuidor o

agencia autorizada de servicio) sobre el quemador de

la superficie con el encendedor colocado dentro del

espacio en el anillo de la llave (figura 5). Esto impide

que el encendedor se dañe cuando la llave apriete el

quemador. Gire el quemador aproximadamente un

octavo de vuelta en sentido contrario al de las

manecillas del reloj y sepárelo de la superficie

principal.

PARA AFLOJAR GIRE EN

SENTIDO CONTRARIO AL DE LAS

MANECILLASDEL RELOJ

TORNILLO

FIGURA 3

POSICIÓN DEL

ENCENDEDOR DENTRO

DEL ESPACIO DE LA LLAVE

PARA APRETAR

GIRE EN EL SENTIDO

DE LAS MANECILLAS

DEL RELOJ

REMOCIÓN DE LOS QUEMADORES

SELLADOS DE FÁBRICA

FIGURA 5

2

Page 6

4. Quite la campana de orificio del quemador de la

superficie con una llave de boca tubular de 12.7 mm

(1/2”) girando en contra de las manecillas del reloj.

IMPORTANTE: Conserve todas las campanas de

orificio de gas natural que quite.

5. Coloque la campana de orificio correspondiente en el

accesorio del quemador de acuerdo con la figura 6.

Gire la campana de orificio en el sentido de las

manecillas del reloj manualmente una vuelta

aproximadamente. Apriete la campana de orificio en el

sentido de las manecillas del reloj con una llave de

boca tubular de 12.7 mm (1/2”) dos y media vueltas

aproximadamente.

6. Coloque de nuevo el quemador en la superficie principal y gire un octavo de vuelta en el sentido de las

manecillas del reloj usando la llave del quemador hasta

que éste se trabe en su lugar con el encendedor alineado con la marca de referencia en la superficie

principal.

7. Repita los pasos 3 al 6 hasta que se hayan cambiado

todas las campanas de orificio.

EL ORIFICIODE GAS NATURAL (SIN

COLOR) DE 9.2K BTU SE REEMPLAZA CON

EL ORIFICIO (SIN COLOR) ESTAMPADO

CON .85 PARA GAS LP

EL ORIFICIODE GAS NATURAL (SIN

COLOR) DE 9.2K BTU SE REEMPLAZA CON

EL ORIFICIO (SIN COLOR) ESTAMPADO

CON .85 PARA GAS LP

Obturador de aire — Quemador del horno

a. La longitud aproximada de la llama del quemador del

horno es una llama cónica con el interior azul, bien

definida de 1.27 cm ( 1/2 pulgada), figura 8.

FIGURA 8

CONO INTERIOR DE LA

LLAMA DE 12.7 mm (1/2”)

b. Revise la llama del quemador del horno de la manera

siguiente:

1. Llama amarilla en el quemador — abra el obturador

de aire del quemador a la posición más abierta que

no cause que se apague ni levante la llama cuando

el quemador esté frío. (Vea el número 2 de la

figura9.)

2. Llama azul bien definida pero se levanta - cierre el

obturador de aire hasta el punto en donde no cause

que se levante ni apague la llama cuando el

quemador esté frío. (Vea el número 2 de la figura 9.)

EL ORIFICIODE GAS NATURAL (SIN

COLOR) DE 9.2K BTU SE REEMPLAZA CON

EL ORIFICIO (SIN COLOR) ESTAMPADO

CON .85 PARA GAS LP

FIGURA 6

EL ORIFICIODE GAS NATURAL

(ROJO) DE 12K BTU SE REEMPLAZA

CON EL ORIFICIO (ROJO)

ESTAMPADO CON .65 PARA GAS LP

Para volver a ensamblarlo:

Coloque de nuevo el quemador en la superficie principal y

gírelo aproximadamente un octavo de vuelta en el sentido

de las manecillas del reloj usando la llave del quemador

hasta que se trabe en su lugar con el encendedor

alineado en relación a la marca de la superficie principal.

CAMPANA DE ORIFICIO

3

TORNILLO DE

SEGURIDAD

OBTURADOR

1

CAMPANA DE

ORIFICIO

DE AIRE

2

FIGURA 9

c. El ajuste del obturador de aire del quemador del horno

es el mismo en las estufas con pilotos de gas o de

encendido electrónico.

d. Ajuste del quemador sellado. Ajuste el obturador de

aire al gas correspondiente de acuerdo a la figura 10.

POSICIÓN DE GAS NATURAL

DEL OBTURADOR DE AIRE

FIGURA 10

FIGURA 7

POSICIÓNDE GAS LP

DEL OBTURADOR DE AIRE

3

Page 7

Conversion à un gaz différent

Généralités

Toutes les cuisinières sont équipées d’orifices fixes et

d’un détendeur pour appareil à gaz convertible. La plaque

signalétique indiquant le numéro de modèle signale

également à quel type de gaz l’appareil a été réglé en

usine. Pour convertir l’appareil au gaz naturel ou au gaz

de pétrole liquéfié (GPL), il faut remplacer les capuchons

d’orifice et régler les obturateurs d’air des brûleurs et le

capuchon de conversion du détendeur.

La pression d’arrivée de gaz au détendeur d’un appareil

ménager doit être la suivante lors de la vérification du

réglage du détendeur :

Remonter l’écrou du capuchon sur le détendeur et

remettre le pare-poussière en place.

ATTENTION : Veiller à ce que l’indication du type de gaz

auquel le détendeur vient d’être converti soit visible au

haut de l’écrou du capuchon avant de remettre le

pare-poussière en plastique en place. (Voir la figure 1.)

PRESSION D’ARRIVÉE

DE GAZ EN POUCES GAZ GAZ

DE COLONNE D’EAU (kPa)

Minimum 5 (1,25) 11 (2,75)

Maximum 14 (3,5) 14 (3,5)

NATUREL GPL

Conversion du détendeur de l’appareil

Le détendeur de l’appareil doit être réglé en fonction du

type de gaz utilisé. Pour une conversion du gaz naturel au

gaz GPL, le détendeur doit être converti de façon à ce

qu’il assure la régulation de la pression du gaz GPL. Pour

une conversion du gaz GPL au gaz naturel, le détendeur

doit être converti de façon à ce qu’il assure la régulation

de la pression du gaz naturel.

Pour accéder au robinet d’arrêt du détendeur depuis

l’avant de la cuisinière, enlever le tiroir de rangement ou

le tiroir chauffe-plat.

Pour enlever le tiroir de rangement : Le tirer jusqu’à la

première position d’arrêt. Soulever l’avant du tiroir et tirer

jusqu’à la deuxième position d’arrêt, puis saisir les côtés

du tiroir, le soulever et l’enlever.

Pour convertir le détendeur d’un gaz à un autre, retirer le

pare-poussière en plastique de l’écrou-capuchon situé au

sommet du détendeur. Enlever l’écrou du capuchon du

détendeur (le pare-poussière en plastique s’enlève avec

l’écrou).

POSITION POUR GPL

FIGURE 1

Pour remettre le tiroir de rangement en place : Insérer

les roulements du tiroir sur les rails. Soulever l’avant du

tiroir et pousser doucement jusqu’à la première position

d’arrêt. Soulever et continuer à faire coulisser le tiroir vers

l’arrière jusqu’à ce qu’il soit fermé.

POSITION POUR GAZ

NATUREL

IMPORTANT : Retirer le pare-poussière en plastique de

l’écrou du capuchon et le remonter du côté opposé de

l’écrou du capuchon.

Page 8

Conversion des orifices

La conversion de cet appareil du gaz naturel au gaz GPL

exige le changement des capuchons d’orifice.

IMPORTANT : Conserver tous les capuchons d’orifice

pour gaz naturel retirés.

Conversion du brûleur du four

Retirer toutes les grilles du four.

1. Brûleur de cuisson au four

a. Retirer le fond du four (figure 2).

PINCE

FIGURE 2

b. Retirer la vis du brûleur du four (figure 3).

c. Retirer le brûleur du four du raccord pour orifice.

ATTENTION : Le dispositif d’allumage est fragile.

Veiller à ne pas l’endommager.

d. Coucher délicatement le brûleur du four sur le fond

du four.

e. Enlever le tiroir chauffe-plats ou le tiroir de

rangement.

f. Enlever le couvercle d’accès à l’orifice (figure 4).

g. Retirer le capuchon de l’orifice de brûleur de cuisson

au four à l’aide d’une clé à douille de 13 mm (1/2 po)

en tournant dans le sens anti-horaire.

h. Placer l’orifice noir portant le chiffre 1.3 sur le

raccord en le tournant d’environ un tour à la main

dans le sens horaire. Serrer le capuchon d’orifice à

l’aide d’une clé à douille de 13 mm (1/2 po) en le

tournant d’environ 2,5 tours dans le sens horaire.

i. Remettre le brûleur du four en place.

j. Remettre le fond du four en place.

k.Remettrelecouvercled’accèsetletiroirenplace.

VIS

FIGURE 4

2. Conversion du brûleur de cuisson au gril

a. Retirer la vis du brûleur du gril.

b. Coucher délicatement le brûleur du gril sur le fond

du four.

ATTENTION : Le dispositif d’allumage est fragile.

Veiller à ne pas l’endommager.

c. Retirer le capuchon de l’orifice du brûleur de cuisson

au gril à l’aide d’une clé à douille de 13 mm (1/2 po).

d. Placer l’orifice vert portant le chiffre 57 sur le raccord

en le tournant d’environ un tour à la main dans le

sens horaire. Serrer le capuchon d’orifice à l’aide

d’une clé à douille de 13 mm (1/2 po) en le tournant

d’environ 2,5 tours dans le sens horaire.

e. Remettre le brûleur du gril en place.

f. Remettre les grilles du four en place.

Conversion des brûleurs de la surface de

cuisson

1. Retirer les grilles de tous les brûleurs.

2. Marquer d’un repère au crayon à papier l’emplacement

du dispositif d’allumage sur le dessus de la surface de

cuisson. Ce repère servira de point de référence, lors

de la pose du brûleur, pour s’assurer qu’il est bien

resserré à sa position d’origine.

3. Mettre la clé à brûleur (référence nº 8312D075-60,

disponible auprès du revendeur ou d’un prestataire de

service après-vente agréé) sur le brûleur de la surface

de cuisson en plaçant le dispositif d’allumage dans le

creux de l’anneau de la clé (figure 5). Ceci empêche

que le dispositif d’allumage ne se trouve écrasé lorsque

la clé se resserre sur le brûleur. Faire tourner le brûleur

d’environ un huitième de tour dans le sens anti-horaire

et le soulever de la surface de cuisson.

VIS

FIGURE 3

DANS LE SENS ANTI- HORAIRE

POUR DESSERRER

POSITION DU DISPOSITIF

D’ALLUMAGEDANS LE

CREUX DE LA CLÉ

ILLUST. Nº A219-812

DANS LE SENS

HORAIRE POUR

SERRER

BRÛLEURS INTÉGRÉS - DÉPOSE

FIGURE 5

2

Page 9

4. Retirer le capuchon de l’orifice de brûleur de la surface

de cuisson à l’aide d’une clé à douille de 13 mm

(1/2 po) en tournant dans le sens anti-horaire.

IMPORTANT : Conserver tous les capuchons d’orifice

pour gaz naturel retirés.

5. Placer le capuchon d’orifice correspondant au brûleur

sur le raccord du brûleur tel qu’indiqué à la figure 6. Le

tourner d’environ un tour à la main dans le sens

horaire. Serrer le capuchon d’orifice à l’aide d’une clé à

douille de 13 mm (1/2 po) en le tournant d’environ 2,5

tours dans le sens horaire.

6. Remettre le brûleur en place sur la surface de cuisson

et, à l’aide de la clé à brûleurs, le faire tourner

d’approximativement un huitième de tour dans le sens

horaire jusqu’à ce qu’il s’enclenche en place avec le

dispositif d’allumage aligné sur le repère indiqué sur la

surface de cuisson.

7. Reprendre les étapes 3à6jusqu’àcequetousles

capuchons d’orifice aient été changés.

9.200 BTU, GAS NATUREL (NON COLORÉ)

REMPLACER PAR L’ORIFICE (NON

COLORÉ) MARQUÉ .85 POUR LE GPL

9.200 BTU, GAS NATUREL (NON COLORÉ)

REMPLACER PAR L’ORIFICE (NON

COLORÉ) MARQUÉ .85 POUR LE GPL

Obturateur d’air - Brûleur du four

a. La hauteur approximative de la flamme d’un brûleur du

four doit présenter une partie bleue distincte de 13 mm

(1/2 po) (voir la figure 8).

FIGURE 8

CÔNE DE 13 MM (1/2 PO) AU

CENTRE DE LA FLAMME

b. Pour vérifier la flamme du brûleur du four :

1. Flamme jaune - ouvrir l’obturateur d’air afin d’assurer

son ouverture maximum tout en ayant une flamme

qui ne se soulève pas du brûleur ou qui s’éteigne

lorsque le brûleur est froid. (Voir l’élément 2 de la

figure 9.)

2. Flamme avec partie bleue distincte mais qui se

soulève du brûleur - fermer l’obturateur d’air jusqu’à

ce qu’il produise une flamme qui ne se soulève pas

du brûleur ou s’éteigne lorsque le brûleur est froid.

(Voir l’élément 2 de la figure 9.)

9.200 BTU, GAS NATUREL (NON COLORÉ)

REMPLACER PAR L’ORIFICE (NON

COLORÉ) MARQUÉ .85 POUR LE GPL

12.000 BTU, GAS NATUREL (ROUGE)

REMPLACER PAR L’ORIFICE

(ROUGE) MARQUÉ .65 POUR LE GPL

FIGURE 6

Pour remonter le brûleur :

Remettre le brûleur en place sur la surface de cuisson et,

àl’aidedelacléàbrûleurs,lefairetourner

d’approximativement un huitième de tour dans le sens

horaire jusqu’à ce qu’il s’enclenche en place avec le

dispositif d’allumage aligné sur le repère indiqué sur la

surface de cuisson.

CAPUCHON D’ORIFICE

3

VIS DE

BLOCAGE

1

CAPUCHON

D’ORIFICE

OBTURATEUR

D’AIR

2

FIGURE 9

c. Le réglage de l’obturateur d’air du brûleur du four est le

même pour les cuisinières à allumage par veilleuse ou

électrique.

d. Réglage des brûleurs intégrés. Régler l’obturateur au

gaz approprié en se guidant sur la figure 10.

POSITION DE L’OBTURATEUR

POUR LE GAZ NATUREL

FIGURE 10

FIGURE 7

POSITION DE L’OBTURATEUR

POUR LE GAZ GPL

3

Loading...

Loading...