Page 1

INSTALLATION INSTRUCTIONS

COMMERCIAL WASHER-EXTRACTOR

MYR20, MYR25, MYR30, MYR40, MYR55, MYR65

MYS20, MYS30, MYS40, MYS55, MYS65

Table of Contents.................................................2

www.maytagcommerciallaundry.com

WFR124390E

Page 2

TABLE OF CONTENTS

WASHER SAFETY .......................................................................2

DIMENSIONS AND TECHNICAL SPECIFICATION .................4

INSTALLATION REQUIREMENTS .............................................. 9

LOCATION REQUIREMENTS ..................................................... 9

ELECTRICAL REQUIREMENTS ...............................................10

FLOOR REQUIREMENTS .........................................................20

INSTALLATION OF THE WASHER-EXTRACTOR

WITHOUT PEDESTAL BASE ....................................................21

INSTALLATION OF THE RIGID WASHER-EXTRACTOR

WITHOUT PEDESTAL BASE ....................................................22

INSTALLATION INSTRUCTION ................................................ 23

ELECTRICAL CONNECTION ...................................................24

WASHER MAINTENANCE ........................................................28

WARRANTY ...............................................................................29

WASHER SAFETY

2

Page 3

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

washer, follow basic precautions, including the following:

Do not allow children to play on, in, or with

the washer. Close supervision of children

is necessary when the washer is used near

children.

Before the washer is removed from service

or discarded, remove the door or lid.

Do not reach into the washer if the drum,

tub, or agitator is moving.

Do not install or store the washer where it

will be exposed to the weather.

Do not tamper with controls.

Do not repair or replace any part of the

washer or attempt any maintenance unless

that you understand and have the skills

to carry out.

See “Electrical Requirements” for

grounding instructions.

This appliance must have power locked

out using proper lockout and tag out

procedure during service and when

replacing parts. Refer to the OSHA

standard for “The Control of Hazardous

Energy (Lockout/Tag out)”, Title 29 Code

of Federal Regulations (CFR) Part

1910.147.

Read all instructions before using the

washer.

Do not wash articles that have been

previously cleaned in, washed in, soaked

in, or spotted with gasoline, dry-cleaning

substances as they give off vapors that

could ignite or explode.

Do not add gasoline, dry-cleaning

substances to the wash water. These

substances give off vapors that could

ignite or explode.

Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for 2 weeks or

more. HYDROGEN GAS IS EXPLOSIVE.

If the hot water system has not been

used for such a period, before using the

washer, turn on all hot water faucets and

minutes. This will release any accumulated

this time.

IMPORTANT:

The Circuit must be a dedicated circuit and may not be

combined with any lighting circuit.

Adequate grounding is essential to washer operation.

Do not fuse the neutral or grounding circuit.

Certain internal parts are intentionally not grounded and may

present a risk of electrical shock only during service. Do

not contact the inlet valve coil straps while the appliance is

energized.

This appliance must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

3

Page 4

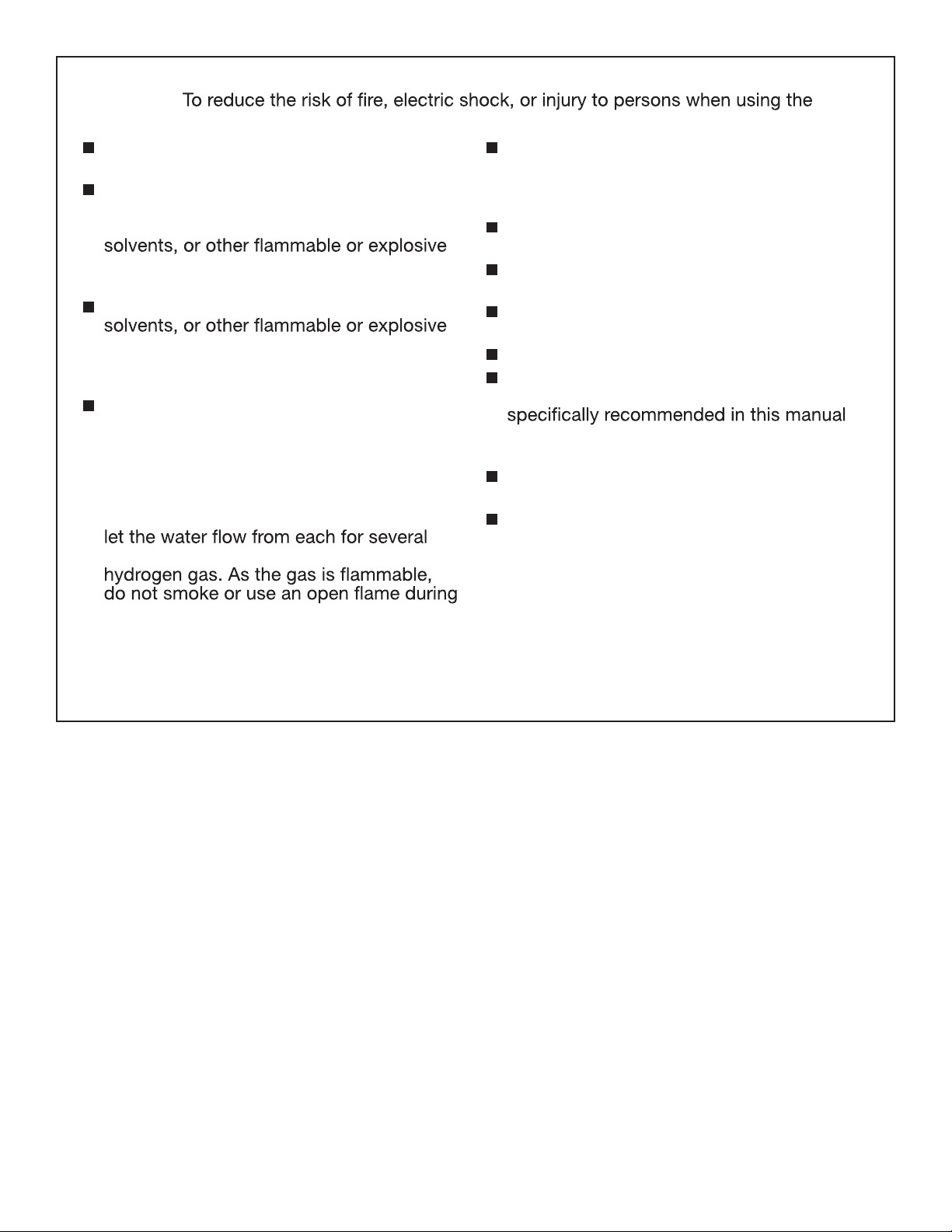

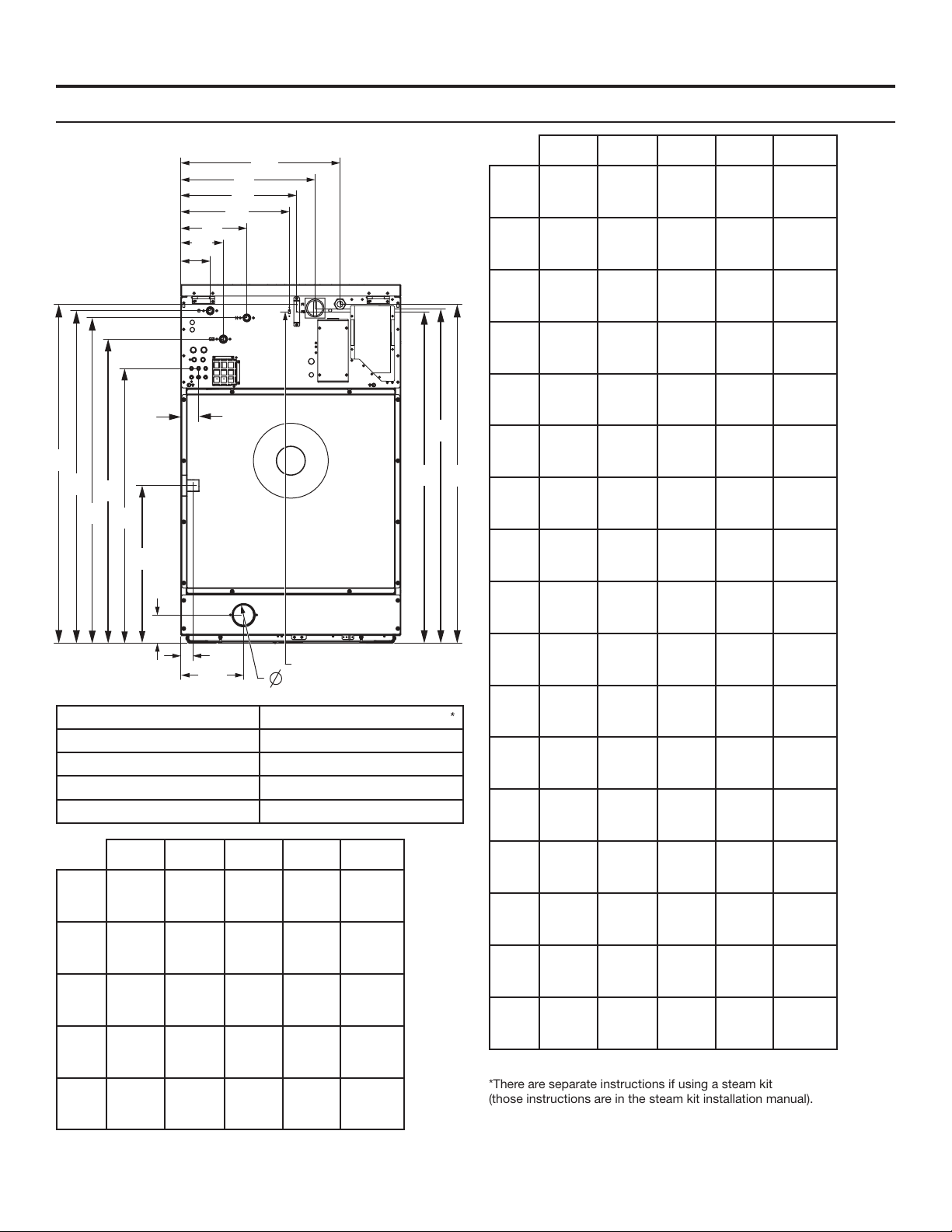

DIMENSIONS AND TECHNICAL SPECIFICATIONS

Model

MYR20 73 (2.58) 530 (20.9) 352 (13.9) 9 (20) 838 200

MYR25 101 (3.55) 620 (24.4) 352 (13.9) 11 (25) 760 200

MYR30 131 (4.61) 620 (24.4) 454 (17.9) 14 (30) 760 200

MYR40 171 (6.04) 750 (29.5) 411 (16.2) 18 (40) 693 200

MYR55 230 (8.14) 750 (29.5) 548 (21.6) 25 (55) 693 200

MYR65 262 (9.25) 750 (29.5) 621 (24.4) 30 (65) 693 200

MYS20 73 (2.58) 530 (20.9) 352 (13.9) 9 (20) 1165 400

MYS30 131 (4.61) 620 (24.4) 454 (17.9) 14 (30) 1085 400

MYS40 171 (6.04) 750 (29.5) 411 (16.2) 18 (40) 985 400

MYS55 230 (8.14) 750 (29.5) 548 (21.6) 25 (55) 985 400

MYS65 262 (9.25) 750 (29.5) 621 (24.4) 30 (65) 912 350

Cylinder Volume

Liters (cu. ft.)

Cylinder diameter

mm (in.)

Cylinder depth

mm (in.)

Dry load

capacity kg (lb)

Max. spin

RPM

Max. extract

force (G-force)

Dimensions

Washer Dimensions

D

E

A

C

B

Model

MYR20

MYR25

MYR30

MYR40

MYR55

MYR65

MYS20

MYS30

MYS40

MYS55

MYS65

Additional Clearances:

■ Additional spacing of 25 mm (1") on both sides of the washer

is required.

■ Additional spacing of 500 mm (20") between the rear of the

washer and the wall is required.

■ Additional spacing of 865 mm (34") above the washer is

required.

A B C D E

Width

mm

(in.)

660

(26)

750

(29.5)

750

(29.5)

890

(35.0)

890

(35.0)

890

(35.0)

710

(28.4)

795

(31.3)

970

(38.2)

970

(38.2)

970

(38.2)

Door

Opening

mm (in.)

328

(12.9)

410

(16.1)

410

(16.1)

459

(18.1)

459

(18.1)

459

(18.1)

328

(12.9)

410

(16.1)

459

(18.1)

459

(18.1)

459

(18.1)

Depth

mm

(in.)

686

(27)

725

(28.5)

840

(33.1)

876

(34.5)

1011

(39.8)

1085

(42.7)

721

(28.4)

872

(34.3)

901

(35.5)

1037

(40.8)

1110

(43.7)

Height

mm (in.)

1112

(43.8)

1222

(48.1)

1222

(48.1)

1410

(55.5)

1410

(55.5)

1410

(55.5)

1112

(43.8)

1222

(48.1)

1410

(55.5)

1410

(55.5)

1410

(55.5)

Door

Height

mm (in.)

425

(16.8)

419

(16.5)

419

(16.5)

537

(21.2)

537

(21.2)

537

(21.2)

423

(16.7)

420

(16.5)

546

(21.5)

546

(21.5)

546

(21.5)

4

Page 5

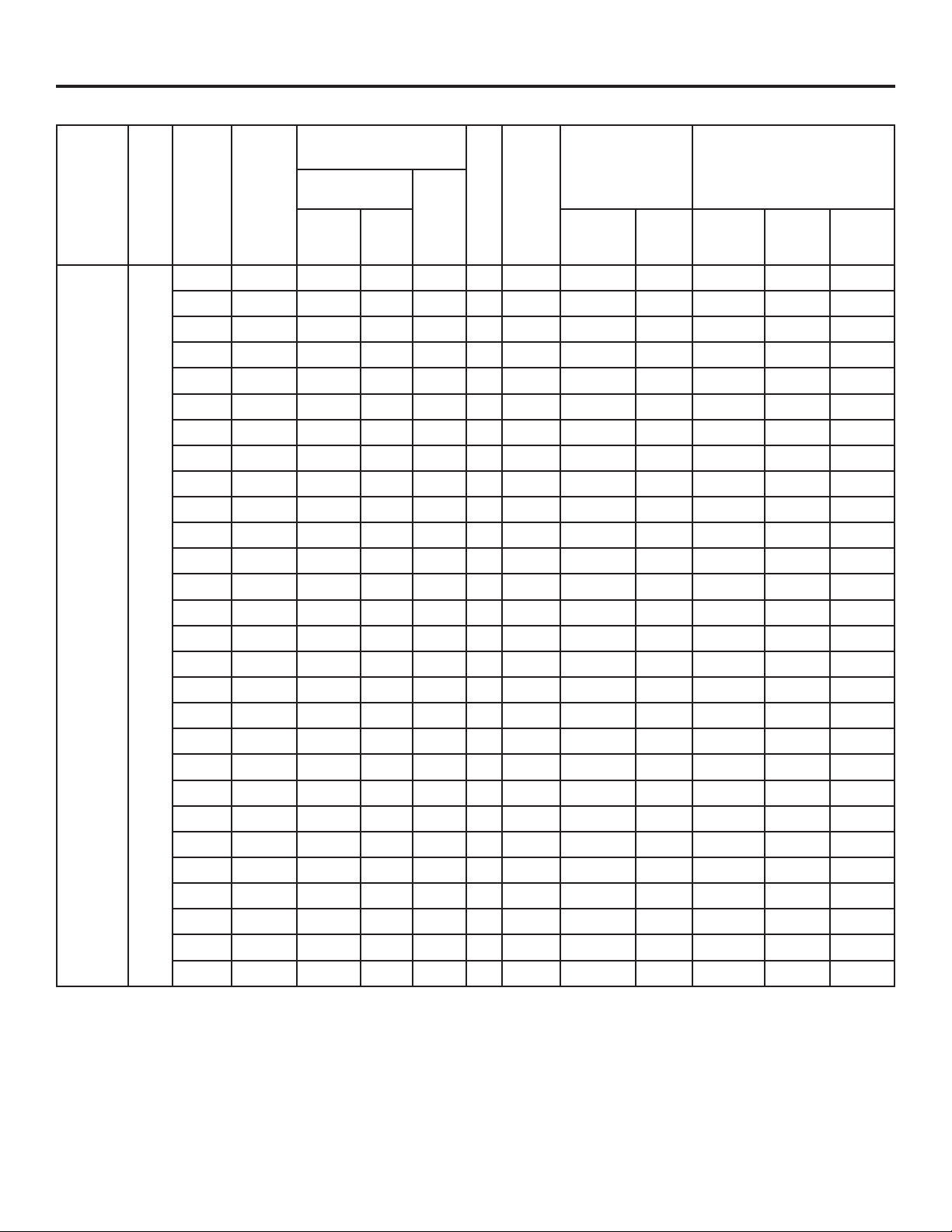

Dimensions

J2

A1

A2

E3

DIMENSIONS AND TECHNICAL SPECIFICATIONS

Washer Rear Dimensions

H1

J1

I1

B1

D1

C1

G1

C2

D2

B2

G2

F2

E2

F1

I2

E1

A. Electrical Connection

B. Hot Water G. Liquid Soap Connection

C. Cold Water H. Disconnect

D. 2nd Cold Water (Option) I. USB Port

E. Drain J. Fuses

MYR20 MYR25 MYR30 MYR40 MYR55 MYR65

A1

mm

(in.)

A2

mm

(in.)

B1

mm

(in.)

B2

mm

(in.)

C1

mm

(in.)

451

(17.7)

1045

(41.1)

225

(8.8)

1000

(39.4)

101

(4.0)

543

(21.4)

1156

(45.5)

225

(8.8)

1108

(43.6)

101

(4.0)

F. Steam Connection (Option)*

543

(21.4)

1156

(45.5)

225

(8.8)

1108

(43.6)

101

(4.0)

578

(22.7)

1343

(52.8)

289

(11.4)

1224

(48.2)

175

(6.8)

578

(22.7)

1343

(52.8)

289

(11.4)

1224

(48.2)

175

(6.8)

H2

J3

578

(22.7)

1343

(52.8)

289

(11.4)

1224

(48.2)

175

(6.8)

MYR20 MYR25 MYR30 MYR40 MYR55 MYR65

C2

mm

(in.)

D1

mm

(in.)

D2

mm

(in.)

E1

mm

(in.)

E2

mm

(in.)

E3

mm

(in.)

F1

mm

(in.)

F2

mm

(in.)

G1

mm

(in.)

G2

mm

(in.)

H1

mm

(in.)

H2

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

*There are separate instructions if using a steam kit

(those instructions are in the steam kit installation manual).

I1

I2

J1

J2

J3

1023

(40.3)

146

(5.7)

927

(36.5)

168

(6.6)

95

(3.7)

70

(2.8)

60

(2.3)

826

(32.5)

368

(14.5)

1032

(42.6)

280

(11)

1019

(40.1)

305

(12)

1054

(41.5)

1019

(40.1)

1133

(44.6)

146

(5.7)

1035

(40.8)

213

(8.4)

95

(3.7)

70

(2.8)

70

(2.7)

937

(36.9)

458

(18)

1140

(44.9)

371

(14.6)

1130

(44.5)

394

(15.5)

1155

(45.5)

1130

(44.5)

1133

(44.6)

146

(5.7)

1035

(40.8)

213

(8.4)

95

(3.7)

70

(2.8)

70

(2.7)

937

(36.9)

458

(18)

1140

(44.9)

371

(14.6)

1130

(44.5)

394

(15.5)

1155

(45.5)

1130

(44.5)

1321

(52)

175

(6.8)

1224

(48.2)

283

(11.1)

133

(5.2)

70

(2.8)

45

(1.8)

534

(21)

70

(2.7)

1095

(43.1)

492

(19.4)

1330

(52.3)

406

(16.0)

1317

(51.8)

429

(16.8)

1343

(52.9)

1318

(51.8)

1321

(52)

175

(6.8)

1224

(48.2)

283

(11.1)

133

(5.2)

70

(2.8)

45

(1.8)

534

(21)

70

(2.7)

1095

(43.1)

492

(19.4)

1330

(52.3)

406

(16.0)

1317

(51.8)

429

(16.8)

1343

(52.9)

1318

(51.8)

1321

(52)

175

(6.8)

1224

(48.2)

283

(11.1)

133

(5.2)

70

(2.8)

45

(1.8)

534

(21)

70

(2.7)

1095

(43.1)

492

(19.4)

1330

(52.3)

406

(16.0)

1317

(51.8)

429

(16.8)

1343

(52.9)

1318

(51.8)

5

Page 6

DIMENSIONS AND TECHNICAL SPECIFICATIONS

J2

A1

A2

E3

Dimensions

Washer Rear Dimensions

H1

J1

I1

B1

D1

C1

G1

C2

B2

D2

G2

J3

F2

E2

F1

I2

E1

A. Electrical Connection F. Steam Connection (Option)*

B. Hot Water G. Liquid Soap Connection

C. Cold Water H. Disconnect

D. 2nd Cold Water (Option) I. USB Port

E. Drain J. Fuses

MYS20 MYS30 MYS40 MYS55 MYS65

A1

mm

(in.)

A2

mm

(in.)

B1

mm

(in.)

B2

mm

(in.)

C1

mm

(in.)

502

(19.8)

1048

(41.3)

225

(8.8)

1003

(39.4)

101

(4.0)

588

(23.2)

1159

(45.7)

225

(8.8)

1112

(43.8)

101

(4.0)

657

(25.8)

1347

(53)

300

(11.8)

1228

(48.4)

175

(6.9)

657

(25.8)

1347

(53)

300

(11.8)

1228

(48.4)

175

(6.9)

657

(25.8)

1347

(53)

300

(11.8)

1228

(48.4)

175

(6.9)

H2

MYS20 MYS30 MYS40 MYS55 MYS65

C2

mm

(in.)

D1

mm

(in.)

D2

mm

(in.)

E1

mm

(in.)

E2

mm

(in.)

E3

mm

(in.)

F1

mm

(in.)

F2

mm

(in.)

G1

mm

(in.)

G2

mm

(in.)

H1

mm

(in.)

H2

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

*There are separate instructions if using a steam kit

(those instructions are in the steam kit installation manual).

I1

I2

J1

J2

J3

1028

(40.5)

146

(5.8)

930

(36.7)

229

(9)

90

(3.5)

70

(2.8)

70

(2.8)

826

(32.5)

419

(16.5)

1035

(40.8)

330

(13)

1023

(40.3)

355

(14)

1048

(41.3)

1023

(40.3)

1137

(44.8)

146

(5.8)

1041

(41)

229

(9)

90

(3.5)

70

(2.8)

70

(2.8)

936

(36.9)

502

(19.8)

1146

(45.2)

416

(16.4)

1133

(44.6)

441

(17.4)

1159

(45.7)

1133

(44.6)

1324

(52.2)

175

(6.9)

1228

(48.8)

270

(10.7)

111

(4.4)

70

(2.8)

63

(2.5)

698

(27.5)

70

(2.8)

1094

(43.1)

572

(22.5)

1334

(52.5)

486

(19.2)

1321

(52)

511

(20.2)

1347

(53)

1321

(52)

1324

(52.2)

175

(6.9)

1228

(48.8)

270

(10.7)

111

(4.4)

70

(2.8)

63

(2.5)

698

(27.5)

70

(2.8)

1094

(43.1)

572

(22.5)

1334

(52.5)

486

(19.2)

1321

(52)

511

(20.2)

1347

(53)

1321

(52)

1324

(52.2)

175

(6.9)

1228

(48.8)

270

(10.7)

111

(4.4)

70

(2.8)

63

(2.5)

698

(27.5)

70

(2.8)

1094

(43.1)

572

(22.5)

1334

(52.5)

486

(19.2)

1321

(52)

511

(20.2)

1347

(53)

1321

(52)

6

Page 7

DIMENSIONS AND TECHNICAL SPECIFICATIONS

Dimensions

Crated Dimensions

Model

MYR20 705 (27.8) 841 (33.1) 1270 (50.0)

MYR25 800 (31.5) 880 (34.6) 1381 (54.4)

MYR30 800 (31.5) 991 (39.0) 1381 (54.4)

MYR40 940 (37.0) 1029 (40.5) 1560 (61.43)

MYR55 940 (37.0) 1169 (46.0) 1560 (61.4)

MYR65 940 (37.0) 1242 (48.9) 1560 (61.4)

MYS20 756 (29.8) 854 (33.4) 1270 (50.0)

MYS30 841 (33.1) 1010 (39.8) 1381 (54.4)

MYS40 1003 (39.5) 1042 (41.0) 1560 (61.4)

MYS55 1003 (39.5) 1178 (46.4) 1560 (61.4)

MYS65 1003 (39.5) 1251 (49.3) 1560 (61.4)

Crated Width

mm (in.)

Approximate Weight

Model Uncrated-kg (lb) Crated-kg (lb)

MYR20 151 (333) 166 (365)

MYR25 203 (447) 218 (480)

MYR30 222 (489) 237 (523)

MYR40 312 (688) 328 (724)

MYR55 332 (732) 349 (769)

MYR65 347 (764) 364 (802)

MYS20 188 (415) 202 (446)

MYS30 264 (582) 279 (616)

MYS40 386 (851) 403 (889)

MYS55 406 (894) 423 (933)

MYS65 428 (944) 446 (984)

Crated Depth

mm (in.)

Crated Height

mm (in.)

Water Heating (Factory Option Only)

Model

MYR20 8 or 12

MYR25 8 or 12

MYR30 8 or 12

MYR40 16

MYR55 18

MYR65 18

MYS20 8 or 12

MYS30 8 or 12

MYS40 16

MYS55 18

MYS65 18

Electrical heating, optional alternate heating

element size-kW

7

Page 8

DIMENSIONS AND TECHNICAL SPECIFICATIONS

Water, Drain, External Supply Connections

Model

MYR20 2 Yes 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) YES

MYR25 2 Yes 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) YES

MYR30 2 Yes 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) YES

MYR40 2 Yes 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) NO

MYR55 2 Yes 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) NO

MYR65 2 Yes 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) NO

MYS20 2 Ye s 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) YES

MYS30 2 Ye s 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) YES

MYS40 2 Ye s 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) NO

MYS55 2 Ye s 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) NO

MYS65 2 Ye s 19 (3/4" BSPP*) 1-8 (20-120) 4 10 76 (3) NO

* = 3/4" GHT adapter included for machines sold in North America.

Number

of water

inlets

Optional

third

water

inlet

Inlet sizes

mm (in.)

Operating

Pressure

Bar (Psi)

Number of

dispenser

compartments

External

chemical

connections,

number

Drain

valve

drain, Size

mm (in.)

Drain

Pump

Option

Energy/Water Usage

Average Cycle Water Use

Model

lbs

MYR20 20 4 11.7 2.925

Hot

Water

Total

Water

Total/Hot

Ratio

MYR25 25 6 17.6 2.925

MYR30 30 8 23.4 2.925

MYR40 40 11 32.2 2.925

MYR55 55 14 41.0 2.925

MYR65 65 17 49.7 2.925

MYS20 20 4 11.7 2.925

MYS30 30 8 23.4 2.925

MYS40 40 11 32.2 2.925

MYS55 55 14 41.0 2.925

MYS65 65 17 49.7 2.925

Gallons

8

Page 9

Tools and Parts

Parts supplied:

Water inlet hoses (2) Inlet hose washers (4) Service Keys

Drain Hose Hose clamp

INSTALLATION REQUIREMENTS

LOCATION REQUIREMENTS

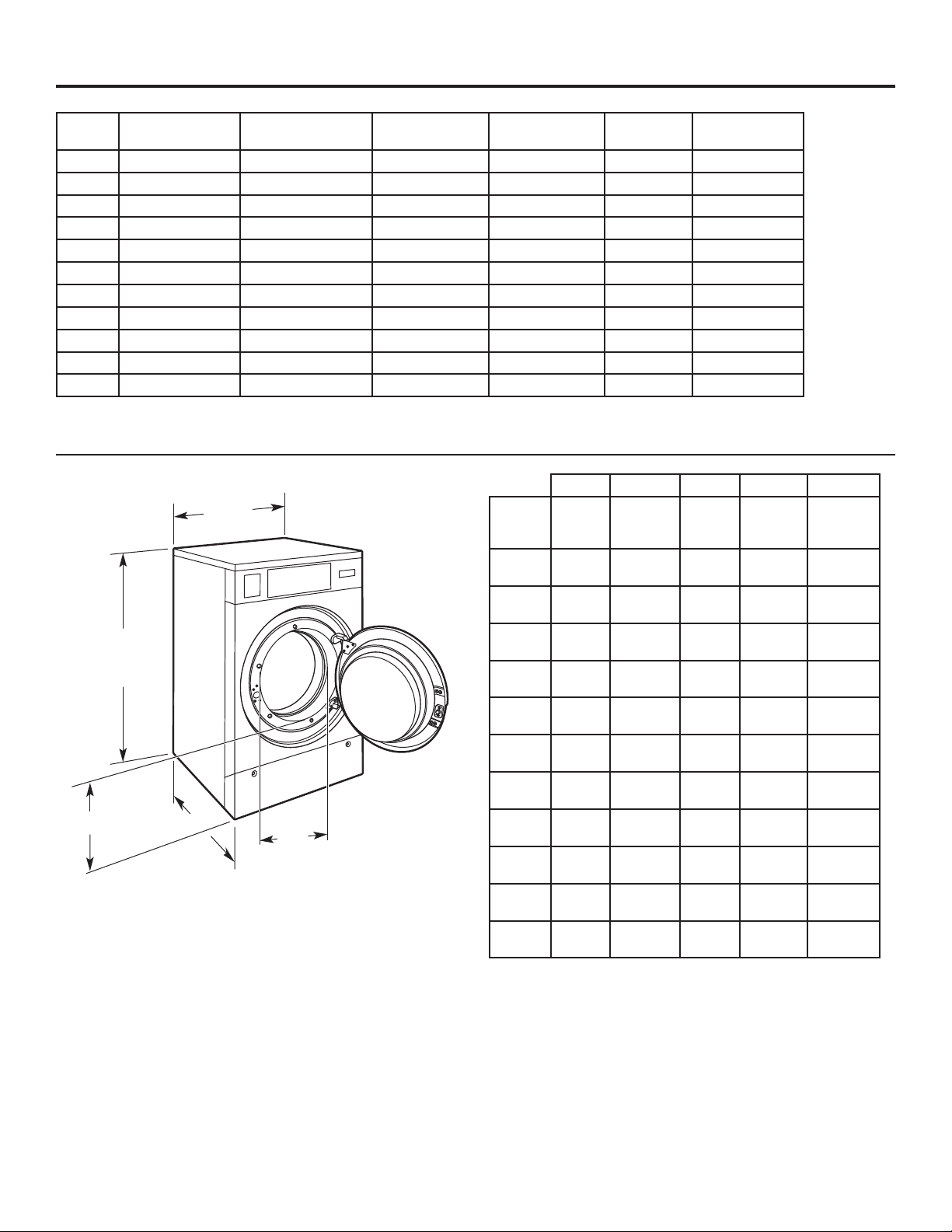

Forces transmitted by the washing machine

MYR20 MYR25 MYR30 MYR40 MYR55 MYR65

Static oor load (Kn - lb) 1.49 (334) 1.99 (447) 2.18 (489) 3.07 (688) 3.26 (731) 3.40 (764)

Dynamic oor load (Kn - lb) 2.42 (543) 4.01 (900) 5.12 (1150) 5.60 (1260) 7.52 (1690) 8.82 (1981)

Maximum vertical load (Kn - lb) 3.91 (877) 6.00 (1347) 7.30 (1639) 8.67 (1948) 10.80 (2421) 12.22 (2745)

Dynamic load frequency (Hz) 13.97 13.20 13.17 11.59 11.55 11.59

G factor 200 200 200 200 200 200

Anchorage points 4 4 4 8 8 8

Min Concrete Thk. (mm - in) 100 (4) 100 (4) 150 (6) 150 (6) 200 (8) 200 (8)

9

Page 10

ELECTRICAL REQUIREMENTS

MYR20 (Rigid Mount Washing Machine)

Capacity

lbs

20 838

RPM

Motor &

Control

Voltage

100 11.52 X 1P 11.52 15 14 16 10 14

110 10.47 X 1P 10.47 15 14 16 10 14

115 10.02 X 1P 10.02 15 14 16 10 14

120 09.60 X 1P 9.6 15 14 16 10 14

127 09.07 X 1P 9.07 15 14 16 10 14

200 04.99 X 1P 4.99 15 14 16 10 14

208 04.80 X 1P 4.8 15 14 16 10 14

220 04.54 X 1P 4.54 15 14 16 10 14

230 04.34 X 1P 4.34 15 14 16 10 14

240 04.16 X 1P 4.16 15 14 16 10 14

208 01.07 6.0 16.68 3P 17.75 25 20 12

220 01.01 6.7 17.64 3P 18.65 25 20 12

230 00.96 7.3 18.44 3P 19.4 25 20 12

240 00.92 8.0 19.25 3P 20.17 25 20 12

380 00.58 6.7 10.19 3P 10.77 16 10 14

400 00.55 7.4 10.73 3P 11.28 16 10 14

415 00.53 8.0 11.13 3P 11.66 16 10 14

440 00.50 6.7 8.82 3P 9.32 16 10 14

480 00.46 8.0 9.62 3P 10.08 16 10 14

208 01.07 9.0 25.02 3P 26.09 32 25 10

220 01.01 10.1 26.46 3P 27.47 40 32 8

230 00.96 11.0 27.67 3P 28.63 40 32 8

240 00.92 12.0 28.87 3P 29.79 40 32 8

380 00.58 10.1 15.29 3P 15.87 20 16 12

400 00.55 11.1 16.09 3P 16.64 20 16 12

415 00.53 12.0 16.69 3P 17.22 25 20 12

440 00.50 10.1 13.23 3P 13.73 20 16 12

480 00.46 12.0 14.43 3P 14.89 20 16 12

(V)

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

kw / Amps

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

ductor

Con-

Size

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

10

Page 11

MYR25 (Rigid Mount Washing Machine)

ELECTRICAL REQUIREMENTS

Capacity

lbs

25 790

RPM

Motor &

Control

Voltage

100 17.16 X 1P 17.16 25 12 25 20 12

110 15.6 X 1P 15.6 20 12 20 16 12

115 14.92 X 1P 14.92 20 12 20 16 12

120 14.3 X 1P 14.3 20 12 20 16 12

127 13.51 X 1P 13.51 20 12 20 16 12

200 07.8 X 1P 07.8 15 14 16 10 14

208 07.5 X 1P 07.5 15 14 16 10 14

220 07.09 X 1P 07.09 15 14 16 10 14

230 06.78 X 1P 06.78 15 14 16 10 14

240 06.50 X 1P 06.50 15 14 16 10 14

208 01.67 6.0 16.68 3P 18.35 25 20 12

220 01.57 6.7 17.64 3P 19.21 25 20 12

230 01.51 7.3 18.44 3P 19.95 25 20 12

240 01.44 8.0 19.25 3P 20.69 25 20 12

380 00.91 6.7 10.19 3P 11.1 16 10 14

400 00.87 7.4 10.73 3P 11.60 16 10 14

415 00.83 8.0 11.13 3P 11.96 16 10 14

440 00.79 6.7 8.82 3P 09.61 16 10 14

480 00.72 8.0 9.62 3P 10.34 16 10 14

208 01.67 9.0 25.02 3P 26.69 40 32 8

220 01.57 10.1 26.46 3P 28.03 40 32 8

230 01.51 11.0 27.67 3P 29.18 40 32 8

240 01.44 12.0 28.87 3P 30.31 40 32 8

380 00.91 10.1 15.29 3P 16.2 20 16 12

400 00.87 11.1 16.09 3P 16.96 25 20 12

415 00.83 12.0 16.69 3P 17.52 25 20 12

440 00.79 10.1 13.23 3P 14.02 20 16 12

480 00.72 12.0 14.43 3P 15.15 20 16 12

(V)

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

kw / Amps

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Con-

ductor

Size

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

11

Page 12

ELECTRICAL REQUIREMENTS

MYR30 (Rigid Mount Washing Machine)

Capacity

lbs

30 790

RPM

Motor &

Control

Voltage

(V)

100 19.44 X 1P 19.44 25 12 25 20 12

110 17.67 X 1P 17.67 25 12 25 20 12

115 16.90 X 1P 16.90 25 12 25 20 12

120 16.20 X 1P 16.20 20 12 20 16 12

127 15.31 X 1P 15.31 20 12 20 16 12

200 09.72 X 1P 09.72 15 14 16 10 14

208 08.10 X 1P 08.10 15 14 16 10 14

220 07.66 X 1P 07.66 15 14 16 10 14

230 07.33 X 1P 07.33 15 14 16 10 14

240 07.02 X 1P 07.02 15 14 16 10 14

208 01.80 6.0 16.68 3P 18.48 25 20 12

220 01.70 6.7 17.64 3P 19.34 25 20 12

230 01.63 7.3 18.44 3P 20.07 25 20 12

240 01.56 8.0 19.25 3P 20.81 25 20 12

380 00.98 6.7 10.19 3P 11.17 16 10 14

400 00.94 7.4 10.73 3P 11.67 16 10 14

415 00.90 8.0 11.13 3P 12.03 16 10 14

440 00.85 6.7 8.82 3P 09.67 16 10 14

480 00.78 8.0 9.62 3P 10.40 16 10 14

208 01.80 9.0 25.02 3P 26.82 40 32 8

220 01.70 10.1 26.46 3P 28.16 40 32 8

230 01.63 11.0 27.67 3P 29.30 40 32 8

240 01.56 12.0 28.87 3P 30.43 40 32 8

380 00.98 10.1 15.29 3P 16.27 20 16 12

400 00.94 11.1 16.09 3P 17.03 25 20 12

415 00.90 12.0 16.69 3P 17.59 25 20 12

440 00.85 10.1 13.23 3P 14.08 20 16 12

480 00.78 12.0 14.43 3P 15.21 20 16 12

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

kw / Amps

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Con-

ductor

Size

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

12

Page 13

MYR40 (Rigid Mount Washing Machine)

ELECTRICAL REQUIREMENTS

Capacity

lbs

40 693

RPM

Motor &

Control

Voltage

(V)

100 26 X 1P 26.00 35 8 32 25 10

110 23.64 X 1P 23.64 30 10 32 25 10

115 22.61 X 1P 22.61 30 10 32 25 10

120 21.67 X 1P 21.67 30 10 32 25 10

127 20.47 X 1P 20.47 25 12 25 20 12

200 13 X 1P 13.00 20 12 16 10 14

208 12.5 X 1P 12.50 15 14 16 10 14

220 11.82 X 1P 11.82 15 14 16 10 14

230 11.3 X 1P 11.30 15 14 16 10 14

240 10.83 X 1P 10.83 15 14 16 10 14

208 2.78 12 33.36 3P 36.14 63 50 6

220 2.62 13.4 35.28 3P 37.90 63 50 6

230 02.51 14.7 36.89 3P 39.40 63 50 6

240 02.41 16.0 38.49 3P 40.90 63 50 6

380 01.52 13.4 20.38 3P 21.90 32 25 10

400 01.44 14.9 21.46 3P 22.90 32 25 10

415 01.39 16.0 22.26 3P 23.65 32 25 10

440 01.31 13.4 17.64 3P 18.95 25 20 12

480 01.20 16.0 19.25 3P 20.45 25 20 12

Current

During

Max

Draw

kw / Amps

Electric

(kW)

Heat

Electric

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Con-

ductor

Size

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

13

Page 14

ELECTRICAL REQUIREMENTS

MYR55 (Rigid Mount Washing Machine)

Capacity

lbs

55 693

RPM

Motor &

Control

Voltage

(V)

100 27.04 X 1P 27.04 35 8 40 32 8

110 24.58 X 1P 24.58 30 10 32 25 10

115 23.51 X 1P 23.51 30 10 32 25 10

120 22.53 X 1P 22.53 30 10 32 25 10

127 21.29 X 1P 21.29 30 10 32 25 10

200 13.52 X 1P 13.52 20 12 20 16 12

208 13 X 1P 13.00 20 12 16 10 14

220 12.29 X 1P 12.29 15 14 16 10 14

230 11.76 X 1P 11.76 15 14 16 10 14

240 11.27 X 1P 11.27 15 14 16 10 14

208 2.89 13.50 37.53 3P 40.42 63 50 6

220 2.73 15.1 39.69 3P 42.42 63 50 6

230 2.61 16.5 41.50 3P 44.11 63 50 6

240 2.5 18.0 43.30 3P 45.8 63 50 6

380 01.58 15.10 22.93 3P 24.51 32 25 10

400 01.50 16.70 24.14 3P 25.64 32 25 10

415 01.45 18.00 25.04 3P 26.49 32 25 10

440 01.36 15.1 19.85 3P 21.21 32 25 10

480 01.25 18.0 21.65 3P 22.9 32 25 10

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

kw / Amps

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Con-

ductor

Size

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

14

Page 15

MYR65 (Rigid Mount Washing Machine)

Capacity

lbs

RPM

Voltage

(V)

Motor &

Control

Current

During

Max

Draw

Heat

1P

/3P

Total

Amps

(A)

North American

Models

Models Outside of North

America

Electric

kw / Amps

Hot

Water

or

Steam

Electric

(kW)

Amps

(A)

Circuit

Breaker

(D-Curve)

Con-

ductor

Size

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

28

ELECTRICAL REQUIREMENTS

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

Capacity

lbs

65 693

RPM

Motor &

Control

Voltage

(V)

100 27.46 X1P 27.46 35 8403

110 24.96 X1P 24.96 30 10 32 25 10

115 23.87 X1P 23.87 30 10 32 25 10

120 22.88 X1P 22.88 30 10 32 25 10

127 21.62 X1P 21.62 30 10 32 25 10

200 13.73 X1P 13.73 20 12 20 16 12

208 13.2 X1P 13.2 20 12 16 10 14

220 12.48 X1P 12.48 15 14 16 10 14

230 11.94 X1P 11.94 15 14 16 10 14

240 11.44 X1P 11.44 15 14 16 10 14

208 2.93 13.5 37.53 3P 40.46 63 50 6

220 2.77 15.1 39.69 3P 42.46 63 50 6

230 2.65 16.5 41.5 3P 44.15 63 50 6

240 2.54 18 43.3 3P 45.84 63 50 6

380 1.6 15.1 22.93 3P 24.53 32 25 10

400 1.52 16.7 24.14 3P 25.66 32 25 10

415 1.47 18 25.04 3P 26.51 32 25 10

440 1.39 15.1 19.85 3P 21.24 32 25 10

480 1.27 18 21.65 3P 22.92 32 25 10

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

kw / Amps

Amps

(A)

Hot

Water

or

Steam

1P

/3P

North American

Total

Amps

(A)

Circuit

Breaker

(D-Curve)

Models

Models Outside of North

America

Con-

ductor

Size

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Con-

ductor

Size

15

Page 16

ELECTRICAL REQUIREMENTS

MYS20 (Maytag Multi-Load Soft Mount Washers)

Capacity

lbs

20 1165

RPM

Motor &

Control

Voltage

(V)

110 15.32 X 1P 15.32 20 12

115 14.65 X 1P 14.65 20 12

120 14.04 X 1P 14.04 20 12

127 13.27 X 1P 13.27 20 12

208 8.10 X 1P 8.10 15 14

220 7.66 X 1P 7.66 15 14 10 8 14

230 7.33 X 1P 7.33 15 14 10 8 14

240 7.02 X 1P 7.02 15 14 10 8 14

220 1.70 6.7 17.64 3P 19.34 25 20 12

230 1.63 7.3 18.44 3P 20.07 25 20 12

240 1.56 8 19.25 3P 20.81 25 20 12

380 0.98 6.7 10.19 3P 11.17 16 13 14

400 0.94 7.4 10.73 3P 11.67 16 13 14

415 0.90 8 11.13 3P 12.03 16 13 14

440 0.85 6.7 8.82 3P 9.67 13 10 14

480 0.78 8 9.62 3P 10.40 13 10 14

220 1.70 10.1 26.46 3P 28.16 40 32 8

230 1.63 11 27.67 3P 29.30 40 32 8

240 1.56 12 28.87 3P 30.43 40 32 8

380 0.98 10.1 15.29 3P 16.27 20 16 12

400 0.94 11.1 16.09 3P 17.03 25 20 12

415 0.90 12 16.69 3P 17.59 25 20 12

440 0.85 10.1 13.23 3P 14.08 20 16 12

480 0.78 12 14.43 3P 15.21 20 16 12

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Wire

AWG

SOOW

Cable

90C

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Wire

AWG

SOOW

Cable

90C

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

16

Page 17

MYS30 (Maytag Multi-Load Soft Mount Washers)

ELECTRICAL REQUIREMENTS

Capacity

lbs

30 1085

RPM

Motor &

Control

Voltage

(V)

110 24.96 X 1P 24.96 30 10

115 23.87 X 1P 23.87 30 10

120 22.88 X 1P 22.88 30 10

127 21.62 X 1P 21.62 30 10

208 13.20 X 1P 13.20 20 12

220 12.48 X 1P 12.48 15 14 16 13 14

230 11.94 X 1P 11.94 15 14 16 13 14

240 11.44 X 1P 11.44 15 14 16 13 14

220 2.77 6.7 17.64 3P 20.41 25 20 12

230 2.65 7.3 18.44 3P 21.09 32 25 10

240 2.54 8 19.25 3P 21.79 32 25 10

380 1.60 6.7 10.19 3P 11.79 16 13 14

400 1.52 7.4 10.73 3P 12.25 16 13 14

415 1.47 8 11.13 3P 12.60 16 13 14

440 1.39 6.7 8.82 3P 10.21 13 10 14

480 1.27 8 9.62 3P 10.89 16 13 14

220 2.77 10.1 26.46 3P 29.23 40 32 8

230 2.65 11 27.67 3P 30.32 40 32 8

240 2.54 12 28.87 3P 31.41 40 32 8

380 1.60 10.1 15.29 3P 16.89 25 20 12

400 1.52 11.1 16.09 3P 17.61 25 20 12

415 1.47 12 16.69 3P 18.16 25 20 12

440 1.39 10.1 13.23 3P 14.62 20 16 12

480 1.27 12 14.43 3P 15.70 20 16 12

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Wire

AWG

SOOW

Cable

90C

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Wire

AWG

SOOW

Cable

90C

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

17

Page 18

ELECTRICAL REQUIREMENTS

MYS40 (Maytag Multi-Load Soft Mount Washers)

Capacity

lbs

40 985

RPM

Motor &

Control

Voltage

(V)

110 30.63 X 1P 30.63 40 8

115 29.30 X 1P 29.30 40 8

120 28.08 X 1P 28.08 35 8

127 26.53 X 1P 26.53 35 8

208 16.20 X 1P 16.20 20 12

220 15.32 X 1P 15.32 20 12 20 16 12

230 14.65 X 1P 14.65 20 12 20 16 12

240 14.04 X 1P 14.04 20 12 20 16 12

208 3.60 12 33.36 3P 36.96 63 50 6

220 3.40 13.4 35.28 3P 38.68 63 50 6

230 3.25 14.7 36.89 3P 40.14 63 50 6

240 3.12 16 38.49 3P 41.61 63 50 6

380 1.97 13.4 20.38 3P 22.35 32 25 10

400 1.87 14.9 21.46 3P 23.33 32 25 10

415 1.80 16 22.26 3P 24.06 32 25 10

440 1.70 13.4 17.64 3P 19.34 25 20 12

480 1.56 16 19.25 3P 20.81 25 20 12

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Wire

AWG

SOOW

Cable

90C

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Wire

AWG

SOOW

Cable

90C

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

18

Page 19

MYS55 (Maytag Multi-Load Soft Mount Washers)

ELECTRICAL REQUIREMENTS

Capacity

lbs

55 985

RPM

Motor &

Control

Voltage

(V)

208 18.60 X 1P 18.60 25 12

220 17.59 X 1P 17.59 25 12 25 20 12

230 16.82 X 1P 16.82 25 12 25 20 12

240 16.12 X 1P 16.12 20 12 20 16 12

220 3.91 15.1 39.69 3P 43.60 63 50 6

230 3.74 16.5 41.5 3P 45.24 63 50 6

240 3.58 18 43.3 3P 46.88 63 50 6

380 2.26 15.1 22.93 3P 25.19 32 25 10

400 2.15 16.7 24.14 3P 26.29 32 25 10

415 2.07 18 25.04 3P 27.11 40 32 8

440 1.95 15.1 19.85 3P 21.80 32 25 10

480 1.79 18 21.65 3P 23.44 32 25 10

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Wire

AWG

SOOW

Cable

90C

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Wire

AWG

SOOW

Cable

90C

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

MYS65 (Maytag Multi-Load Soft Mount Washers)

Capacity

lbs

65 915

RPM

Motor &

Control

Voltage

(V)

208 18.60 X 1P 18.60 25 12

220 17.59 X 1P 17.59 25 12 25 20 12

230 16.82 X 1P 16.82 25 12 25 20 12

240 16.12 X 1P 16.12 20 12 20 16 12

220 3.91 15.1 39.69 3P 43.60 63 50 6

230 3.74 16.5 41.5 3P 45.24 63 50 6

240 3.58 18 43.3 3P 46.88 63 50 6

380 2.26 15.1 22.93 3P 25.19 32 25 10

400 2.15 16.7 24.14 3P 26.29 32 25 10

415 2.07 18 25.04 3P 27.11 40 32 8

440 1.95 15.1 19.85 3P 21.80 32 25 10

480 1.79 18 21.65 3P 23.44 32 25 10

Current

During

Max

Draw

Electric

(kW)

Heat

Electric

Amps

(A)

Hot

Water

or

Steam

1P

/3P

Total

Amps

(A)

North American

Models

Circuit

Breaker

(D-Curve)

Wire

AWG

SOOW

Cable

90C

Models Outside of North

America

Circuit

Breaker

(D-Curve)

Fuse

(Slow

Blow)

Wire

AWG

SOOW

Cable

90C

This appliance is intended to be connected to a supply circuit protected by an over current-protective drive (fuse breaker) sized

according to the "Circuit Breaker (D-Curve)" column appropriate to your location.

19

Page 20

FLOOR REQUIREMENTS

Mounting Holes Placement

G

C

B

D

C

F

A

C

E

B

D

E

C

A

Front

Distance

Model

MYR20

MYR25

MYR30

MYR40

MYR55

MYR65

MYS20

MYS30

MYS40

MYS55

MYS65

A

(mm/in.)

B

(mm/in.)

C

(mm/in.)

D

(mm/in.)

E

(mm/in.)

519/20.4 474/18.7 N/A N/A 70/2.7

615/24.2 474/18.7 N/A N/A 67/2.6

615/24.2 574/22.6 N/A N/A 67/2.6

751/29.6 580/22.8 82/3.2 416/16.4 51/2

751/29.6 716/28.2 82/3.2 552/21.7 51/2

751/29.6 789/31.0 82/3.2 625/24.6 51/2

379/14.9 592/23.3 N/A N/A 166/6.5

499/19.7 708/27.9 N/A N/A 148/5.8

669/26.3 661/26.0 N/A N/A 151.0/5.9

669/26.3 797/31.4 N/A N/A 151.0/5.9

669/26.3 870/34.3 N/A N/A 151.0/5.9

There are separate instructions if using a pedestal

(those instructions are in the pedestal installation manual).

There are separate instructions if using an optional front mount

adapter plate (those details are in the front mount adapter plate

installation manual).

F

(mm/in.)

65

/2.6

65

/2.6

65

/2.6

52

/2

52

/2

52

/2

45

/1.8

47

/1.8

50

/2.0

50

/2.0

50

/2.0

G

(mm/in.)

167

/6.6

186

/7.3

201

/7.9

253

/9.9

253

/9.9

253

/9.9

84

/3.3

177

/4.6

190

/7.5

190

/7.5

190

/7.5

20

Page 21

INSTALLATION OF THE WASHER-EXTRACTOR WITHOUT

Anchoring MYR models (Rigid Machines)

WARNING

Crush Hazard

Washer can tip over if not properly installed on

platform or pedestal.

Washer must be bolted to the floor per installation

instructions.

Failure to follow these instructions can result in death

or serious injury.

PEDESTAL BASE

A static engineer must be consulted to evaluate the static

requirements with respect to permissible loads, vibrations, and

noise level in the building where the washer is installed.

The manufacturer does not recommend installing the washer in a

room with a cellar underneath or on a oor with rooms underneath.

The washer must be leveled from side to side, as well as from front

to rear. If the washer is not properly leveled, it may become out of

balance even though the drum remains balanced.

Rigid washers must be anchored to the oor. Correct construction

of the anchorage to the oor is essential to ensure correct

operation of the appliance and to prevent serious damage to its

structure.

Rigid washers must not be installed on non-foundation oors

without authorization from a technician familiar with the structure

and weight-bearing capacity of the building.

Check the weight of the washer and its contents, plus the dynamic

forces generated during spinning. The manufacturer does not

accept responsibility for any damage due to vibration in this type of

installation.

Anchoring MYS models (Soft Machines)

WARNING

Crush Hazard

Washer can tip over if not properly installed on

platform or pedestal.

Shipping brackets must be removed per installation

instructions before operating.

Failure to follow these instructions can result in death

or serious injury.

Shipping brackets need to be uninstalled from the soft washers

prior to operation. Remove the toe panel, front panel, and rear

cover to access the shipping bracket. The shipping brackets are

painted white for ease of identication.

Leveling feet are provided with soft machines. Use the feet to

level the machine in it's nal operating location. Anchoring is not

required but four 12 mm holes are provided if anchoring is desired.

There is a whisker switch behind the toe panel, located below the

tub and to the left of the drain. This switch is set at the factory,

but in the event that it falls out of adjustment, with the shipping

brackets installed, this switch should be set so the whisker is

centered in the opening.

21

Page 22

INSTALLATION OF THE RIGID WASHER-EXTRACTOR

4 inch

minimum

100 mm

WITHOUT PEDESTAL BASE

Using Expansion Bolts

Before anchoring the machine to the oor, make sure that its minimum resistance is equal or higher than 3500 psi (25 N/mm2).

First mark the locations of the mounting holes using the dimensions specied in the “Rigid Washing Machines” chart.

Next drill the mounting holes. Follow the manufacturing installation instructions, but the holes must be at least 4" (100 mm) deep.

The holes must not go all the way through the oor. Clean the holes with compressed air.

For the smoothest operation Whirlpool recommends that the washer be set with a precision, high strength, non-metallic, non-shrink

grout designed for precision grouting. Grout should have a minimum compressive strength of 10,000 PSI (69 MPa), when mixed to a

plastic consistency and fully cured.

a. If the washer is to be grouted in, it should be level and spaced between 3/8" (9 mm) and 1/2" (13 mm) off the oor to make room for

the grout.

b. Remove the washer leaving the spacers behind.

c. Mix the grout to a plastic consistency per the manufacturer's instructions.

d. Trowel the grout in to a depth slightly greater than the height of the spacers.

e. Reinstall the washer over the mounting fasteners. Use the fasteners to pull the washer down securely on the spacers. Do not fully

torque the fasteners.

f. Clean away any excess grout outside the washer as per the manufacturer's instructions.

g. Allow the grout to set for the minimum time recommended by the grout manufacturer for light use.

h. Tighten the bolts until the machine is securely fastened.

If not using grout, place the washer-extractor in position over the holes, then insert the expansion bolts in the holes. Be sure to use

5/8-11 (M16) expansion bolts, and that they protrude above the surface by 2" (50 mm). Once in place, tighten the bolts. Place the

washer-extractor in position above the bolts, and gradually tighten the nuts one after another to 195 Nm (144 ft lb).

Using J-bolts

Before anchoring the machine to the oor, make sure that its minimum resistance is equal or higher than 3500 psi (25 N/mm2).

First mark the locations of the mounting holes using the dimensions specied in the "Rigid Washing Machines" chart. Next make holes

to a depth, at minimum, equal to 4" (100 mm). Make the holes big enough to insert the J-bolt and clean using compressed air. Insert

the J-bolts in the holes and secure using a suitable anchoring compound, ensuring that the bolt protrudes above the surface by

2" (50 mm). Be sure to use 5/8-11 (M16) J-bolts.

Place the washer-extractor in position above the bolts, and gradually tighten the nuts one after another 195 Nm (144 ft lb).

Check the condition of the J-bolts one week after installation.

minimum

4 inch

100 mm

22

Page 23

Connect the Drain Hose

INSTALLATION INSTRUCTION

1. The drain hose can be found shipped inside the drum

with the installation kit. The clamp for this hose is in the

installation kit. Attach the drain to the drain connection

located near the bottom of the rear of the washer. This is a

gravity-fed system, so you must install the drain hose with

the outlet lower than the drain connection to ensure proper

drainage. Do not kink the hose.

Drain Hose

2. The drain hose should end over, or in a floor drain or

drainage canal.

3. The drainage canal or drain pipe must be sized properly

to handle the total output of all washers connected to the

system. Each time a washer is added to the drain pipe,

the size of the pipe must increase to accommodate the

additional volume. The drain pipe at the first washer must

be 3" (76 mm) diameter. The pipe must increase to

4" (100 mm) diameter before the second washer and

5" (127 mm) diameter before the third washer.

4. For connecting the optional drain pump kit (Ordered

separately) refer to the instructions supplied with that kit.

Drain Connections

Use the provided drain hose to connect the washer’s drain pipe

to the facility drain or drain channel. Secure with the provided

clamp. The capacity of discharged water for each washer model

is 55.5 gal/min (210 L/min).

Water Hardness

Determine the water hardness level in water supply. Good wash

results are dependent on water hardness. In areas that have

medium and very hard water levels, a water softener may be

required.

Contact your water or soap distributor for determining the proper

soap and detergents to be used with your hardness levels for the

best wash results.

Water Supply Connections

Washers have 2 water inlets. For connection dimensions, see

“Dimensions and Technical Specications.”

1. Always use the exible hoses delivered with the washer. Do

not use a xed connection to the water supply.

2. Keep proper water pressure within range. See “Dimensions

and Technical Specifications.”

3. The water connection to the washer

requires a 3/4" British Standard Pipe

Thread fitting. The grooved end is a

U.S. thread. Threading an GHT

fitting or the GHT end of the

adapter hose will damage the

threads of the washer.

4. Flush water lines to remove debris.

Install the grooved side of the

adapter hoses to the hot and cold

side of the valves. Tighten fittings.

5. Attach non-grooved end of the adapter

hoses to the washer. Tighten fittings.

6. Turn on water and check for leaks in the

system.

3/4" Garden

Hose (GHT) tting

3/4" British Standard

Pipe Thread (BSPP)

tting

External Supply Connections

All external liquid soap hose connections must be tight. Double

check that the clamps are tight after connections are made.

Make sure any unused open connections are sealed with an

appropriate cover.

The connections for the liquid soap are on the rear of the

washer and must be drilled open in order to use them. Only

drill out the connections that will be used. There are eight (8)

3/8" (9 mm) diameter connections; use a 5/16" (8 mm) diameter

drill bit to drill out these holes. There can only be eight (8)

pumps in the system. Be sure to clean out all the drill shavings

completely so they do not clog the inlets and hoses. Connect to

liquid soap pumps to the left openings rst. Set the ow rate of

the pumps between 16 and 26 gal/hr (60 and 100 l/hr).

Liquid Soap

Connections

IMPORTANT: The incoming water dilutes the liquid soap and

brings it into the tub assembly.

Check with your liquid soap provider to ensure that your

soap is inert to Polypropylene (PP) and Polyvinyl Chloride (PVC)

materials.

Make sure the hoses and wiring for the liquid soap pumps are

not damaged, pinched, rubbed or damage to the machine could

occur.

The liquid soap pumps used must be capable of providing the

requested quantity in less than 30 seconds.

23

Page 24

Knock out for

ELECTRICAL CONNECTION

Use appropriate gauge of solid copper wire. (See chart

in “Electrical Requirements” section).

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white) to terminal (N).

Ground wire (green or bare wire) must be connected

to ground connector (PE).

Connect remaining 3 supply wires to remaining

3 terminals (L1, L2 and L3).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

Fire Hazard

Connection to Washer:

The washer must be electrically grounded in accordance with all local codes or, in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, latest edition, or Canadian Electrical Code, CSA C22.1.

Direct Wire Installation:

Power supply cable must match power supply (3-wire or 4-wire) and be:

To access the disconnect, lift the top cover and support it with the prop rod.

Copper wire of appropriate gauge for amperage requirement (see “Manufacturer’s Recommended Minimal Conductor section”).

Solid wire is recommended. Do not use aluminum wire.

Flexible armored cable or exible conduit must be used for the supply connections. Use the hole in the rear of the washer for

routing. Connection is made directly to the disconnect switch inside the back top panel of the washer. The Aluminum Lug for

Ground is next to that disconnect body. A Flat-head screwdriver can be used for the power wires to the disconnect as well as

the ground to the lug. Incoming service wires are applied to the top of the disconnect body. If the washer is single phase, (only 2

power wires) the outside positions of the disconnect should be used (leaving the center pole empty). Tighten down all connections

including the unused position in the single-phase service case. Leaving a small radius of slack for the wires inside the washer,

check that the cable is well held in place.

Electrical Connection

24

Page 25

ELECTRICAL CONNECTION

Check the rating plate on the washer. Make sure that the supply phase and voltage match the rating of the washer. Some locations

require an autonomous power switch (I) at the current input, with a minimum of 0.12" (3 mm) between contacts. Fit a 300 mA, type

A, immediate response differential protection. Check your local regulations.

Insert the exible armored cable or exible conduit through the hole in the rear panel. Secure the armored cable or conduit to the

rear panel. Connect the wiring per the correct illustration.

L1

PE

Single Phase

L2

PE

L1

Three Phase

L2

L3

25

Page 26

ELECTRICAL CONNECTION

PE L1 L2 L3

L1

L2

L3

PE L1 L2 L3

PE L1 L2 L3

C2

C

H

F1

F2

C2

C

H

F1

F2

C2

C

H

F1

F2

2

3

1

3

2

3

4

Multiple Single-Phase Machines in Line

When installing multiple single-phase washers into an existing 3-phase power supply, alternating the phases used as the hot leg is

recommended to evenly distribute power on the system. See illustration.

Instructions For Grounding

This appliance must be connected to an equipment grounding conductor that must run with the circuit conductors and connected to

the aluminum ground lug inside the rear electric panel.

Connect the terminal strip and check that the connections correspond to the operating voltage. Fit a 300 mA, type A, immediate

response differential protection.

The machine must be grounded. See the illustration on the previous page.

Equipotential Bonding

In addition to the equipment-grounding conductor discussed earlier that runs with the circuit conductor's and is connected to the

equipment grounding terminal, all washers or appliances in the vicinity must be permanently interconnected with a equipotential

bonding conductor.

The external connection points marked on the back of the washer serve for this purpose. See illustration below.

The cross-sectional area of the conductor must be at least electrically equivalent to the cross-sectional area of the copper conductor

used to power the washer.

1. Protective grounding structure

2. External protective conductor connection point

3. Protective conductor

4. Grounding identication

26

Page 27

ELECTRICAL CONNECTION

Lights

Electrical connection of the liquid soap supply system, if supplied (Optional on vended machines)

The power supplied to the liquid soap system must come from an external electric source. Do not connect the system in the washer.

All work must be performed by a qualied technician in compliance with all applicable local codes. Refer to the wiring diagram found

inside the washer attached to the side panel.

There is a labeled terminal block on the rear of the washer for control signal connections. There is a corresponding strip of LED lights

to show when each signal is active. Refer to the wiring diagram found inside the washer attached to the side panel. Supply pump

control signals are 24 VAC, maximum current is 10 mA. Wiring from the liquid soap system must be UL Recognized (AVLV2 and

AVLV8) and rated for 300 V minimum. Route all wires through the supplied plastic bushing, making sure to secure them with the cable

clamp. Afx the cover to the terminal block access before applying electric power to the washer. See the Programming Guide for

details on programming the liquid soap system.

1 Detergent signal

2 Bleach signal

3 Softener signal

4 Programmable signal 1

5 Programmable signal 2

6 Programmable signal 3

10

9

8

7

7 Programmable signal 4

8 Programmable signal 5

9 No output (do not use)

10 Neutral (common)

6

5

4

3

2

1

LED

C

C2

F1

F2

H

External Liquid Soap

Connection Cover

27

Page 28

WASHER MAINTENANCE

Maintenance Schedule

After Each Load

Remove debris from the wash drum including paper clips,

coins, and other hard items.

When not in use, leave the washer door open to allow the

washer to air out and prolong gasket life.

Daily Maintenance

Clean water, detergent, and other stains off of the washer

with a soft cloth dampened with a mild detergent solution.

Dry with a soft cloth. Do not use abrasives.

Clean detergent residue and other contamination off the door

seal with a soft cloth dampened only with a mild detergent

solution. Do not use solvents or acids. Do not lubricate seal

with oil or grease.

Remove residue from the detergent hoppers with a plastic

scraper. Wipe the hoppers with a soft cloth dampened with

water.

Check water inlets for leaks. Correct as necessary.

Check drain valve for leakage during a wash cycle (the valve

is in open position when there is no electricity to it).

4. Check mounting bolt tightness. Retighten if necessary.

5. Inspect all hoses and connections inside the washer for

leaks and correct as necessary.

6. Wipe off any stains with a soft cloth dampened with water

or a mild detergent solution. Be sure that control components

are not exposed to dust and moisture during cleaning.

7. Put covers back on and check that all bolts are properly

torqued.

8. Turn on power at circuit breaker or fuse box.

Maintenance Every 1000 Working Hours or 6 Months

Turn off hot and cold water to the washer at the valves.

Clean water lters.

Clean and remove dirt and dust from:

– the inverter cooling n

– the motor cooling ns

– the inverter internal fan

– the external fan

– the external air relieves

Make sure the fan in the inverter cool ns is functioning.

Maintenance Every 200 Working Hours or Every Month

Make sure external liquid soap supply system is not leaking.

Check all hose joints, screw joints and all connections in the

system.

Maintenance Every 500 Working Hours or 3 Months

Observe the washer from the back for one wash cycle.

Be sure that water does not leak out of the drain during

the wash part of the cycle and that it drains freely at the

beginning of extraction. Clean the drain if either of these

symptoms are observed.

1. Turn off power to washer at the circuit breaker or fuse box.

2. Check the tightness of the bolts securing the rear panel

of the washer.

3. Check the belt for damage and proper tightness.

28

Page 29

The cost of repair or replacement under these excluded circumstances

shall be borne by the customer.

1. All other costs including labor, transportation, shipping, or custom duties

for covered parts.

2. Factory specified replacement parts if this commercial appliance is

used for other than normal, commercial use or when it is used in a manner

that is inconsistent to published user or operator instructions and/or

installation instructions.

3. Service calls to correct the installation of your commercial appliance,

to instruct you on how to use your commercial appliance, to replace

or repair house fuses, or to correct external wiring or plumbing.

4. Service calls to repair or replace appliance light bulbs, air filters, or water

filters. Consumable parts are excluded from warranty coverage.

5. Damage resulting from improper handling of product during delivery, theft,

accident, alteration, misuse, abuse, fire, flood, acts of God, improper

installation, installation not in accordance with local electrical or plumbing

codes, or use of products not approved by Maytag.

6. Pick up and delivery. This commercial appliance is designed to be

repaired on location.

7. Repairs to parts or systems resulting from unauthorized modifications

made to the commercial appliance.

8. The removal and reinstallation of your commercial appliance if it is

installed in an inaccessible location or is not installed in accordance

with published installation instructions.

9. Damage resulting from exposure to chemicals.

10. Changes to the building, room, or location needed in order to make the

commercial appliance operate correctly.

11. Factory specified replacement parts on commercial appliances with

original model/serial numbers that have been removed, altered, or cannot

be easily determined.

12. Discoloration, rust, or oxidation of stainless steel surfaces.

13. Factory specified replacement parts as a result of incorrect diagnosis

or repair by an “unauthorized” service company.

14. Replacement parts during the sixth through tenth years from the date of

original purchase where the commercial appliance is installed, operated

and maintained in a setting other than a vended and/or multi-housing

environment.

15. Replacement parts during the sixth through tenth years from the

date of original purchase where the defective part is not preventing the

functioning of the product.

•

•

•

•

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PART REPLACEMENT AS

PROVIDED HEREIN. Maytag recommends that you use an

under this warranty to provide additional replacement parts as

service company.

warranty is valid only when the commercial appliance is used

in the country in which it was purchased. This limited

warranty is effective from the date of the original consumer

service under this limited warranty.

FIVE YEAR LIMITED WARRANTY

(PARTS ONLY — LABOR NOT INCLUDED)

maintained according to the instructions attached to or

replacement parts to correct defects in materials or

was purchased. This limited warranty does not include labor.

SIXTH THROUGH TENTH YEAR LIMITED WARRANTY

(CERTAIN COMPONENT PARTS ONLY –

LABOR NOT INCLUDED)

specified replacement parts for the following components to

when this commercial appliance was purchased. This is a

does not include labor.

DISCLAIMER OF IMPLIED WARRANTIES

T locations do not allow

.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

locations

.

0 /1

TEN YEAR LIMITED WARRANTY

WHAT IS COVERED

WHAT IS NOT COVERED

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

a longer or more comprehensive warranty than the limited warranty that comes with this

service plan. The benefits to you given by this warranty are in

addition to other rights and remedies available to you under law in relation to the goods or services to which this warranty relates. Please

contact Maytag for further information on warranty terms.

For written correspondence:

Maytag Commercial Laundry

®

Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632 USA

IF YOU NEED SERVICE:

Contact your authorized Maytag Commercial Laundry

distributor.

To locate your authorized Maytag Commercial Laundry

distributor,

visit

www.maytagcommerciallaundry.com.

LIMITED

MYS20, MYS30, MYS40, MYS55, MYS65

MYR20, MYR25, MYR30, MYR40, MYR55, MYR65

29

Page 30

ON-PREMISE

MYR20, MYR25, MYR30, MYR40, MYR55, MYR65

MYS20, MYS30, MYS40, MYS55, MYS65

IF YOU NEED SERVICE:

Contact your authorized Maytag Commercial Laundry

To locate your authorized Maytag Commercial Laundry

visit

www.maytagcommerciallaundry.com.

WHAT IS COVERED

YEAR LIMITED WARRANTY

(PARTS ONLY — LABOR NOT INCLUDED)

YEAR LIMITED WARRANTY

(CERTAIN COMPONENT PARTS ONLY –

LABOR NOT INCLUDED)

•

•

•

•

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PART REPLACEMENT AS

PROVIDED HEREIN.

distributor.

distributor,

YEAR LIMITED WARRANTY

DISCLAIMER OF IMPLIED WARRANTIES

For written correspondence:

®

Maytag Commercial Laundry

Benton Harbor, Michigan 49022-2632 USA

WHAT IS NOT COVERED

All other costs including labor, transportation, shipping, or custom duties

for covered parts.

Factory specified replacement parts if this commercial appliance is

used for other than normal, commercial use or when it is used in a manner

that is inconsistent to published user or operator instructions and/or

installation instructions.

Service calls to correct the installation of your commercial appliance,

to instruct you on how to use your commercial appliance, to replace

or repair house fuses, or to correct external wiring or plumbing.

Service calls to repair or replace appliance light bulbs, air filters, or water

filters. Consumable parts are excluded from warranty coverage.

Damage resulting from improper handling of product during delivery, theft,

accident, alteration, misuse, abuse, fire, flood, acts of God, improper

installation, installation not in accordance with local electrical or plumbing

codes, or use of products not approved by Maytag.

Pick up and delivery. This commercial appliance is designed to be repaired

on location.

Repairs to parts or systems resulting from unauthorized modifications

made to the commercial appliance.

The removal and reinstallation of your commercial appliance if it is installed

in an inaccessible location or is not installed in accordance

with published installation instructions.

Damage resulting from exposure to chemicals.

Changes to the building, room, or location needed in order to make the

commercial appliance operate correctly.

Factory specified replacement parts on commercial appliances with

original model/serial numbers that have been removed, altered, or cannot

be easily determined.

Discoloration, rust, or oxidation of stainless steel surfaces.

Factory specified replacement parts as a result of incorrect diagnosis

or repair by an “unauthorized” service company.

Replacement parts during the years from the date of

original purchase where the commercial appliance is installed, operated

and maintained in a setting other than a vended and/or multi-housing

environment.

Replacement parts during the years from the

date of original purchase where the defective part is not preventing the

functioning of the product.

The cost of repair or replacement under these excluded circumstances

shall be borne by the customer.

2000 N M 63

Service Department

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

30

e

0 /1

Page 31

NOTES

31

Page 32

WFR124390E

®/TM

©2019 Maytag. All rights reserved. Used under license in Canada.

08/19

Loading...

Loading...