Maytag MVW6200KW Technical Manual

FOR SERVICE TECHNICIAN’S USE ONLY

DANGER

Only authorized technicians should

perform diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can

result in death or electrical shock.

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Ƀ

Verify the controls are in the off position so that the appliance does not start when energized.

Ƀ

Allow enough space to perform the voltage measurements without obstructions.

Ƀ

Keep other people a safe distance away from the appliance to prevent potential injury.

Ƀ

Always use the proper testing equipment.

Ƀ

After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at approximately 3000 V. It takes as

little as 10 V to destroy, damage, or weaken the main control assembly. The new main control assembly may appear to

work well after repair is finished, but a malfunction may occur at a later date due to ESD stress.

Ƀ

Use an anti-static wrist strap. Connect wrist strap to green earth connection point or unpainted metal in the

appliance.

– OR –

Touch your finger repeatedly to a green ground connection point or unpainted metal in the appliance.

Ƀ

Before removing the part from its package, touch the anti-static bag to a green ground connection point or unpainted

metal in the appliance.

Ƀ

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

Ƀ

When repackaging main control assembly in anti-static bag, observe above instructions.

IMPORTANT SAFETY NOTICE — “For Technicians only”

This service data sheet is intended for use by persons having electrical, electronic, and mechanical experience and

knowledge at a level generally considered acceptable in the appliance repair trade. Any attempt to repair a major

appliance may result in personal injury and property damage. The manufacturer or seller cannot be responsible, nor

assume any liability for injury or damage of any kind arising from the use of this data sheet.

W11416395A

1

FOR SERVICE TECHNICIAN’S USE ONLY

Contents

GENERAL INFORMATION ...............................................................3-8

Washer Safety ............................................................................................4

Product Specifications............................................................................ 5-6

Maytag® Model Number Nomenclature .......................................................7

Model Number and Serial Number Label Location .......................................8

Tech sheet Location ...................................................................................8

Service Guide ..................................................................................... 9-18

Service Guide...........................................................................................10

Activating Service Mode ...........................................................................10

Reading Binary codes ..............................................................................11

Button Activation & Encoder Test ..............................................................12

Service Test Mode ....................................................................................12

Service Test Mode Chart/Component Activation ........................................13

Software Version Display..........................................................................14

Diagnostic Cycle Chart ............................................................................. 15

Faults & Error Codes ..........................................................................16–18

Troubleshooting ................................................................................19-28

Troubleshooting Guide ........................................................................20–22

Main Control (ACU) Board Connectors and Pinouts ...................................23

Troubleshooting Tests.........................................................................24–28

Component Locations ..............................................................................28

Component Access ........................................................................... 29-40

Removing the Console .............................................................................30

Removing the User Interface (UI) ..............................................................31

Removing the Water Inlet Valve .................................................................32

Removing the Main Control ......................................................................32

Removing the Bulk Dispenser ...................................................................33

Removing the Tub Ring, Impeller, and Basket ............................................34

Removing the Lid Lock .............................................................................37

Removing the Lid and Hinge .....................................................................38

Removing the Shifter ................................................................................39

Removing the Drain Pump ........................................................................40

Removing the Drive Belt and Motor ...........................................................40

Removing the Splutch ..............................................................................41

Removing the Gearcase ...........................................................................42

DO NOT REMOVE OR DESTROY2

FOR SERVICE TECHNICIAN’S USE ONLY

GENERAL INFORMATION

This section (page 4-8) provides general safety, parts, and information for the “Maytag® 4.8 cu. ft. Top Load Washer.”:

Ƀ

Washer Safety

Ƀ

Product Specifications

Ƀ

Product Features

dz Control Panel

Ƀ

Model Number Nomenclature

Ƀ

Model Number and Serial Number Label Location

Ƀ

Tech Sheet Location

DO NOT REMOVE OR DESTROY

3

FOR SERVICE TECHNICIAN’S USE ONLY

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic precautions, including the following:

Ƀ

Read all instructions before using the appliance.

Ƀ

Do not wash articles that have been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry-cleaning solvents, or other

flammable or explosive substances, as they give off vapors that could

ignite or explode.

Ƀ

Do not add gasoline, dry-cleaning solvents, or other flammable or

explosive substances to the wash water. These substances give off

vapors that could ignite or explode.

Ƀ

Under certain conditions, hydrogen gas may be produced in a

hot-water system that has not been used for 2 weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If the hot-water system has not

been used for such a period, before using a washing machine, turn

on all hot-water faucets and let the water flow from each for several

minutes. This will release any accumulated hydrogen gas. As the gas

is flammable, do not smoke or use an open flame during this time.

Ƀ

Do not allow children to play on or in the appliance. Close supervision

of children is necessary when the appliance is used near children.

Ƀ

Before the appliance is removed from service or discarded, remove

the door.

Ƀ

Do not reach into the appliance if the tub or agitator is moving.

Ƀ

Do not install or store this appliance where it will be exposed to the

weather.

Ƀ

Do not tamper with controls.

Ƀ

Do not repair or replace any part of the appliance or attempt any

servicing unless specifically recommended in the user maintenance

instructions or in published user-repair instructions that you

understand and have the skills to carry out.

Ƀ

Do not use replacement parts that have not been recommended by the

manufacturer (e.g. parts made at home using a 3D printer).

Ƀ

See the Installation Instructions for grounding requirements and

installation.

SAVE THESE INSTRUCTIONS

WARNING

Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing.

Service Personnel – Do not contact the thermostat bracket while the appliance is energized.

DO NOT REMOVE OR DESTROY4

FOR SERVICE TECHNICIAN’S USE ONLY

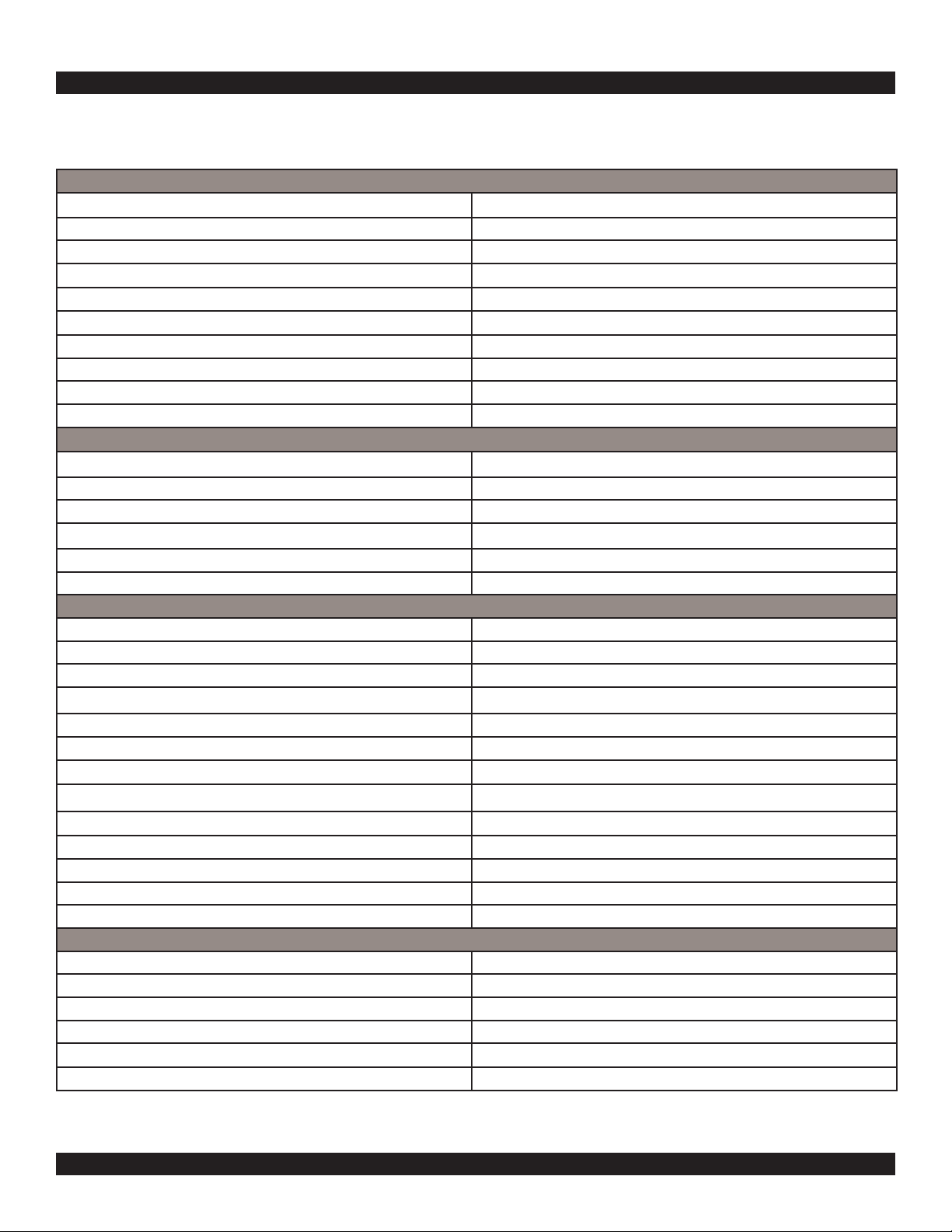

PRODUCT SPECIFICATIONS

Maytag® 4.8 cu. ft. Top Load Washer

Dimensions

Capacity (DOE) US (cu. ft.) 4.8

Capacity IEC CAN (cu. ft) 51∕

Depth with Door Open 90 Degree (IN, inches) 271∕

Depth (IN, inches) 271∕

Height to Top of Cabinet (IN, inches) 38

Height with Lid Open 571∕

Height (IN, inches) 42

Maximum Height (IN, inches) 4211∕

Minimum Height (IN, inches) 42

Width (IN, inches) 271∕

Exterior

Adjustable Feet Yes

Lid/Door Finish Edge Glass

Lid/Door Lock Yes

Lid/Door Swing NA

Slow Close Lid Yes

Window Yes

Details

Advanced Vibration Control™ Yes

Automated Dispenser Drawer

Automatic Load Size Sensing Technology Yes

Dispense System Single Dose, Detergent, Fabric Softener, Bleach

2

2

2

2

16

2

Out of Balance Sensing Yes

Suspension System 4 Springs, 4 Dampers, Liquid Filled Upper Balance Ring

Drum Material Stainless Steel

Drum Rear/Base Material Plastic

Hoses Included Drain Hose

Motor Drive Type Belt

Motor Horsepower 1/3 HP

Wash Action Impeller

Maximum Spin Speed (RPM) 750

Controls

Automatic Temperature Controls Yes

Control Type Knobs

Electronic Display Type LED

Location of Controls Rear Console

Feedback-Status Indicators Done, Rinse, Sensing, Spin, Wash

LED Color White

DO NOT REMOVE OR DESTROY

5

FOR SERVICE TECHNICIAN’S USE ONLY

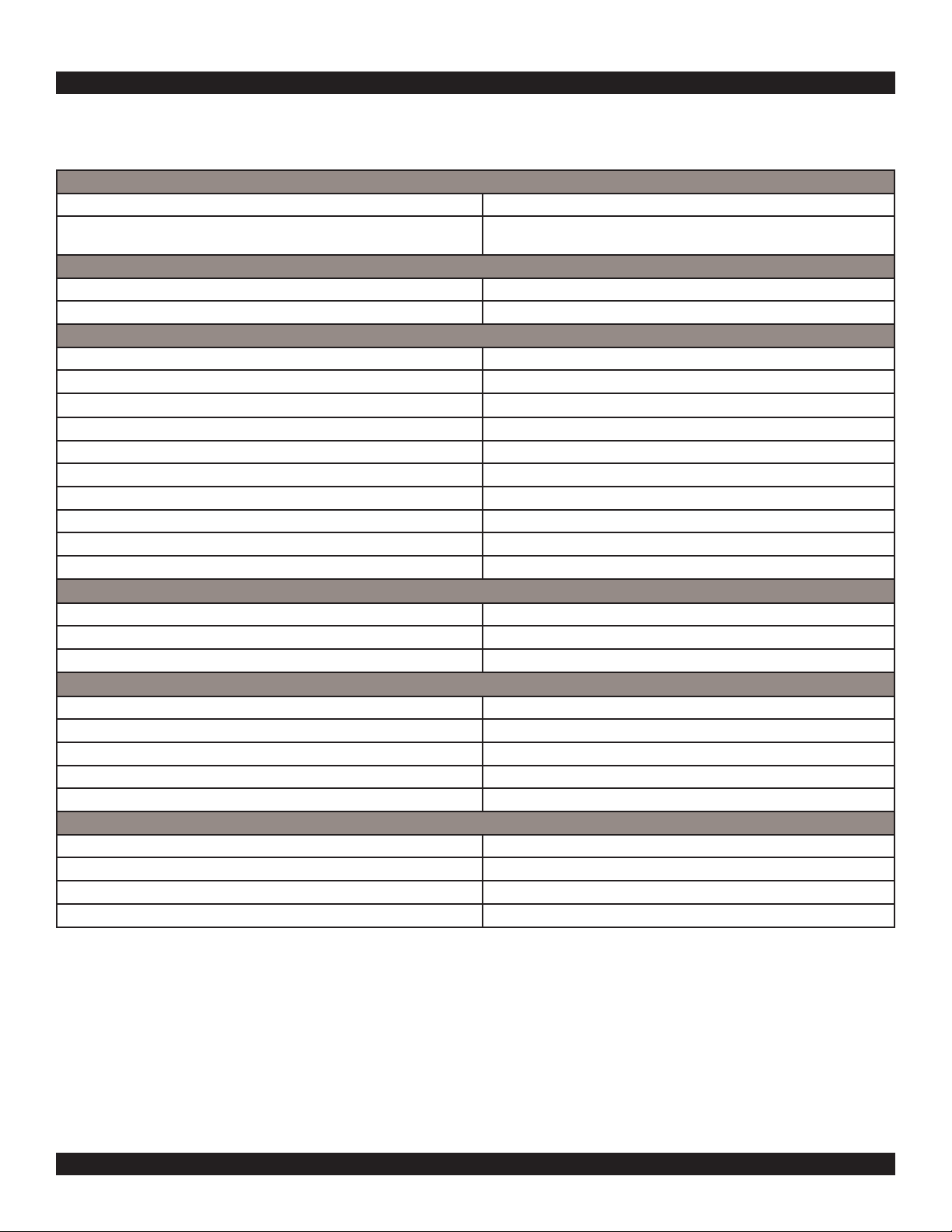

PRODUCT SPECIFICATIONS

Maytag® 4.8 cu. ft. Top Load Washer

Cycles

Number of Wash Cycles 10

Washer Cycle Selections Bulky Items, Clean Washer with affresh®, Delicates, Drain and Spin, Heavy

Duty, Normal, Quick Wash, Towels, Whites, Wrinkle Control

Options

Number of Washer Options 4

Washer Option Selections Deep Fill, Extra Rinse, Fabric Softener, Temperature

Modifiers

Number of Soil Levels 3

Soil Selections Light, Normal, Heavy

Number of Wash/Rinse Temperatures 5

Temperature Selections Hot, Cold, Tap Cold, Cool, Warm

Number of Rinse Options 2

Rinse Temperature Cold

Number of Water Levels 3

Water Levels Auto, High, Medium

Number of Spin Speeds 3

Pre Soak No

Features

Pedestal Options No

Sound Package No

Water Faucet N/A

Certifications

CUL Yes

Energy Rating (kWh/year) 340

UL Yes

IMEF 11∕

IWF 61∕

Electrical

Ampere 6

Hertz (HZ) 60

Power Cord Included Yes

Volts 120

27

2

DO NOT REMOVE OR DESTROY6

FOR SERVICE TECHNICIAN’S USE ONLY

MAYTAG® MODEL NUMBER NOMENCLATURE

MODEL NUMBER M V W 6200 K W

Brand

M = Maytag

Access/Fuel

H = Horizontal (Front load)

V = Vertical (Top load)

G = Gas

E = Electric

W = Workspace

Product Type

B = Combo

D = Dryer

P = Pedestal

T = Thin Twin/Stack

W = Washer

Capacity

6XXX = 4.7 cu.ft.

7XXX = 5.2 cu.ft.

8XXX = 5.3 cu.ft.

Year

K = 2020

Color

W = White

DO NOT REMOVE OR DESTROY

7

FOR SERVICE TECHNICIAN’S USE ONLY

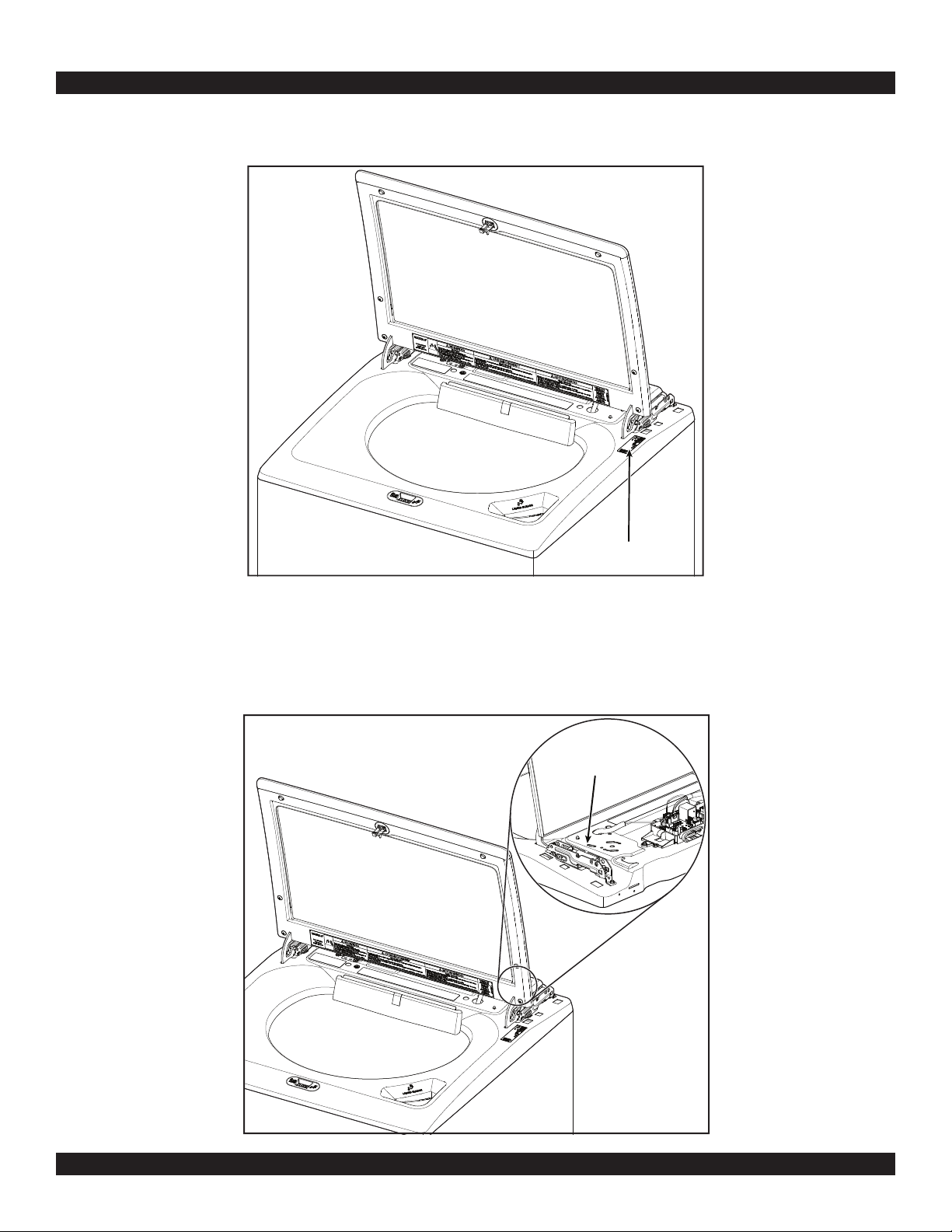

MODEL NUMBER AND SERIAL NUMBER LABEL LOCATION

The Model Number and Serial Number Label location is as shown below:

The Tech Sheet Location is as shown below:

Model Number and

Serial Number Label

TECH SHEET LOCATION

Tech Sheet Location

(Below the Console)

DO NOT REMOVE OR DESTROY8

FOR SERVICE TECHNICIAN’S USE ONLY

SERVICE GUIDE

This section (page 10-18) provides general safety, parts, and information for the “Maytag® 4.8 cu. ft. Top Load Washer.”:

Ƀ

Service Guide

Ƀ

Activating Service Mode

Ƀ

Reading Binary codes

Ƀ

Button Activation & Encoder Test

Ƀ

Service Test Mode

Ƀ

Service Test Mode Chart/Component Activation

Ƀ

Software Version Display

Ƀ

Diagnostic Cycle Chart

Ƀ

Faults & Error Codes

DO NOT REMOVE OR DESTROY

9

FOR SERVICE TECHNICIAN’S USE ONLY

SERVICE GUIDE

Before servicing, check the following:

Ƀ

Make sure there is power at the wall outlet.

Ƀ

Has a household fuse blown or circuit breaker tripped? Was a regular

fuse used? Inform customer that a time-delay fuse is required.

Ƀ

Are both hot and cold water faucets open and water supply hoses

unobstructed?

Ƀ

Make sure drain hose is not sealed into drain pipe, and that there is an

air gap for ventilation. Ensure drain height is between 39" (991 mm)

and 8' (2.4 m) above the floor.

Ƀ

All tests/checks should be made with a VOM (volt-ohm-milliammeter)

or DVM (digital-voltmeter) having a sensitivity of 20,000 Ω per VDC or

greater.

Ƀ

Resistance checks must be made with washer unplugged or power

disconnected.

IMPORTANT: Avoid using large diameter probes when checking

harness connectors as the probes may damage the connectors upon

insertion.

Ƀ

Check all harnesses and connections before replacing components.

Look for connectors not fully seated, broken or loose wires and

terminals, or wires not pressed into connectors far enough to engage

metal barbs.

Ƀ

A potential cause of a control not washer functioning is corrosion

or contamination on connections. Use an ohmmeter to check for

continuity across suspected connections.

Ƀ

To properly check voltage:

1. Unplug appliance or disconnect power.

2. Attach voltage measurement probes to proper connectors.

3. Plug in appliance or reconnect power and verify voltage reading.

4. Unplug appliance or disconnect power after completing voltage

measurements.

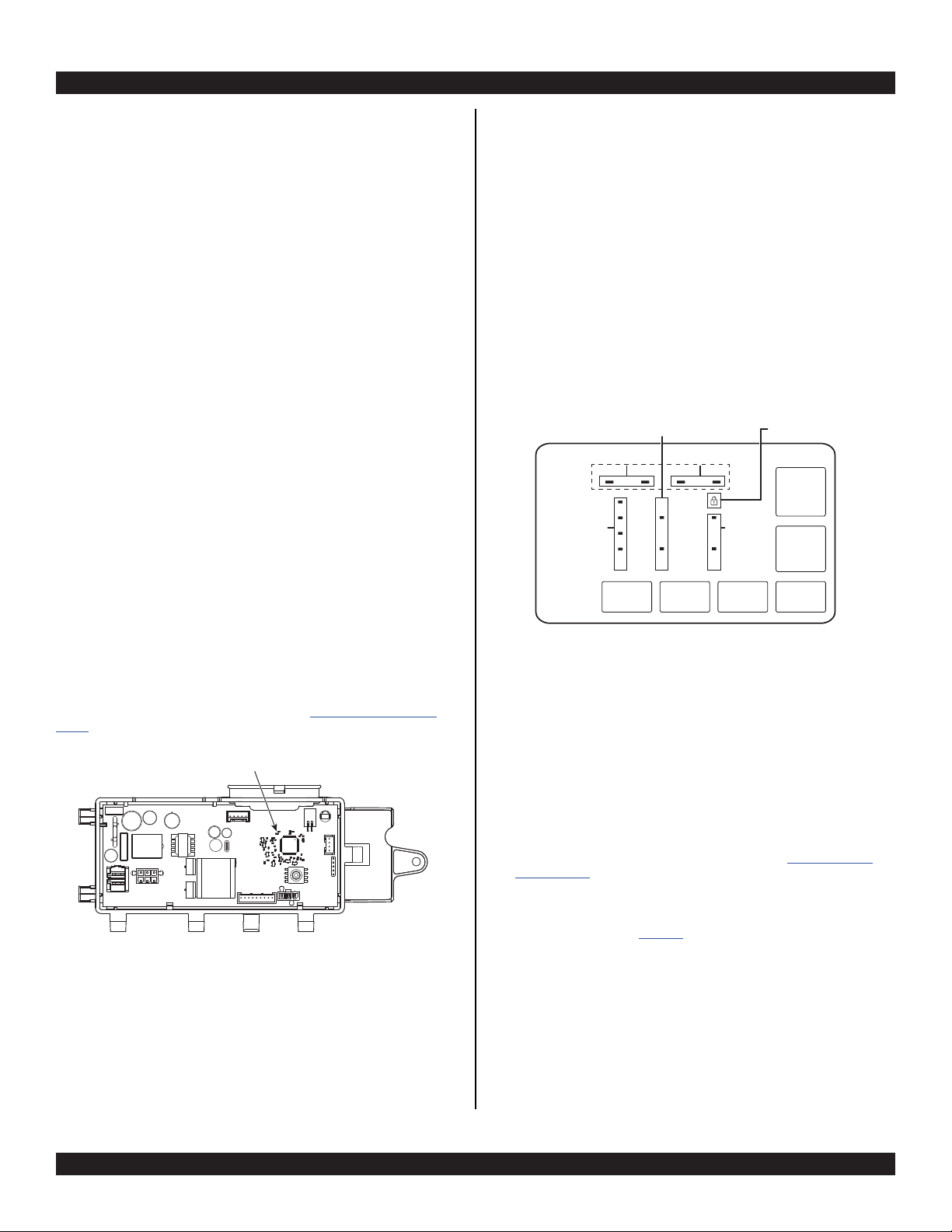

DIAGNOSTIC LED – MAIN CONTROL (ACU)

A troubleshooting tool has been implemented onto the main control

board—a diagnostic LED.

LED Flashing – The Control is detecting correct incoming line voltage and

the processor is functioning.

LED OFF or ON – Control malfunction. Perform TEST #1: Main Control

(ACU), to verify main control functionality.

LED

Location

SERVICE MODE

These tests allow factory or service personnel to test and verify all

inputs to the main control board. You may want to do a quick and

overall checkup of the washer with these tests before going to specific

troubleshooting tests.

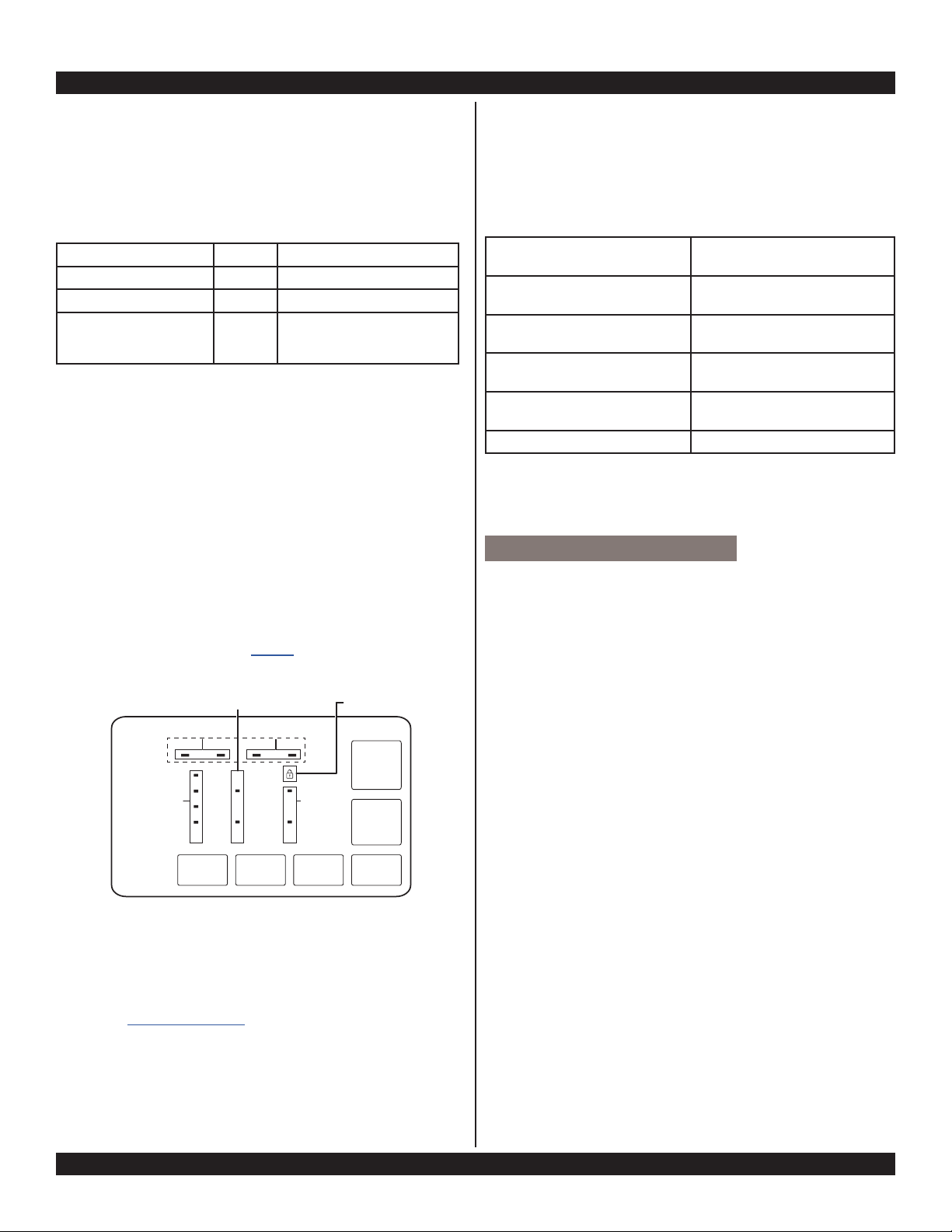

ACTIVATING SERVICE MODE

1. Be sure the washer is in standby mode (plugged in with all LEDs

off).

2. Follow the steps below within 8 seconds:

dz Press and Release Key 1

dz Press and Release Key 2

dz Press and Release Key 3

dz Repeat this 3 button sequence 2 more times

3. If this test mode has been entered successfully, all indicators on

the HMI will be illuminated for 1 second then will be turned OFF.

After this, If there are no saved fault codes, the STATUS indicators

(Sense, Soak, Wash and Done) will blink two times and then all the

indicators will be turned OFF.

LED group 2

LED group 5

Status

Indicator

LED

group 1

Key 1

LED group 6

group 3

Key 2

Figure 2: Diagram of the HMI screen and navigational buttons.

Unsuccessful Activation

If entry into Diagnostic mode is unsuccessful, refer to the following

indications and actions:

Indication: None of the LEDs will turn on.

Action: Turn on the appliance by pressing the POWER Button or rotating

the knob and select any cycle.

➢

If LEDs turn on after pressing the POWER Button or turning the

knob, then try to enter Service mode again: repeat step 2 mentioned

in activating sequence and complete it within 8 seconds. If these

re-entry procedures fail to enter into Diagnostic mode, there is likely

a faulty button in the HMI. Replace the HMI.

➢

If no LEDs come on after selecting the cycle, go to TEST #1: Main

Control (ACU).

LED group 4

Key 6/

POWER

LED

Key 5/

START

Key 4Key 3

Figure 1 - Diagnostic LED

Activation with Saved Fault Codes

If there is a saved fault code, it will be flashing in the display. Review the

Fault/Error Codes table on page 16 for the recommended procedure. If

there is no saved fault code. All LEDs will turn OFF.

DO NOT REMOVE OR DESTROY10

FOR SERVICE TECHNICIAN’S USE ONLY

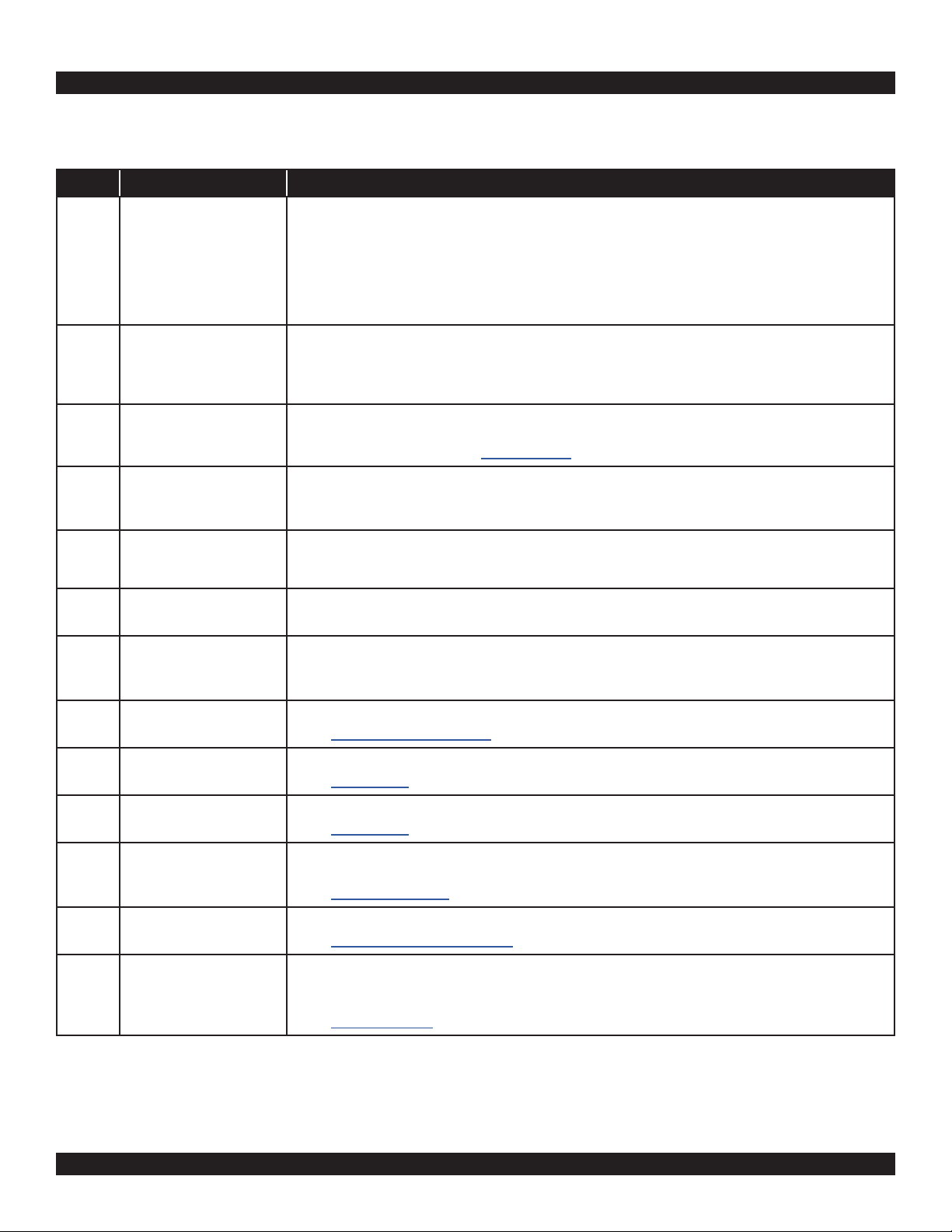

SERVICE DIAGNOSTIC MENU TABLE

Button Press Function Behavior

Key 1 - Momentary press - Enter Button Activation & Encoder test

- Press and hold for 5 seconds. - Exits Service Diagnostics

Key 2 - Momentary press - Activates Service Test Mode

- Press and hold for 5 seconds. - Software Version Display

Key 3 - Momentary press - Displays Next Error Code

- Press and hold for 5 seconds. - Clears the Error Codes

dz See “Activating Service Diagnostic Mode” to activate these buttons.

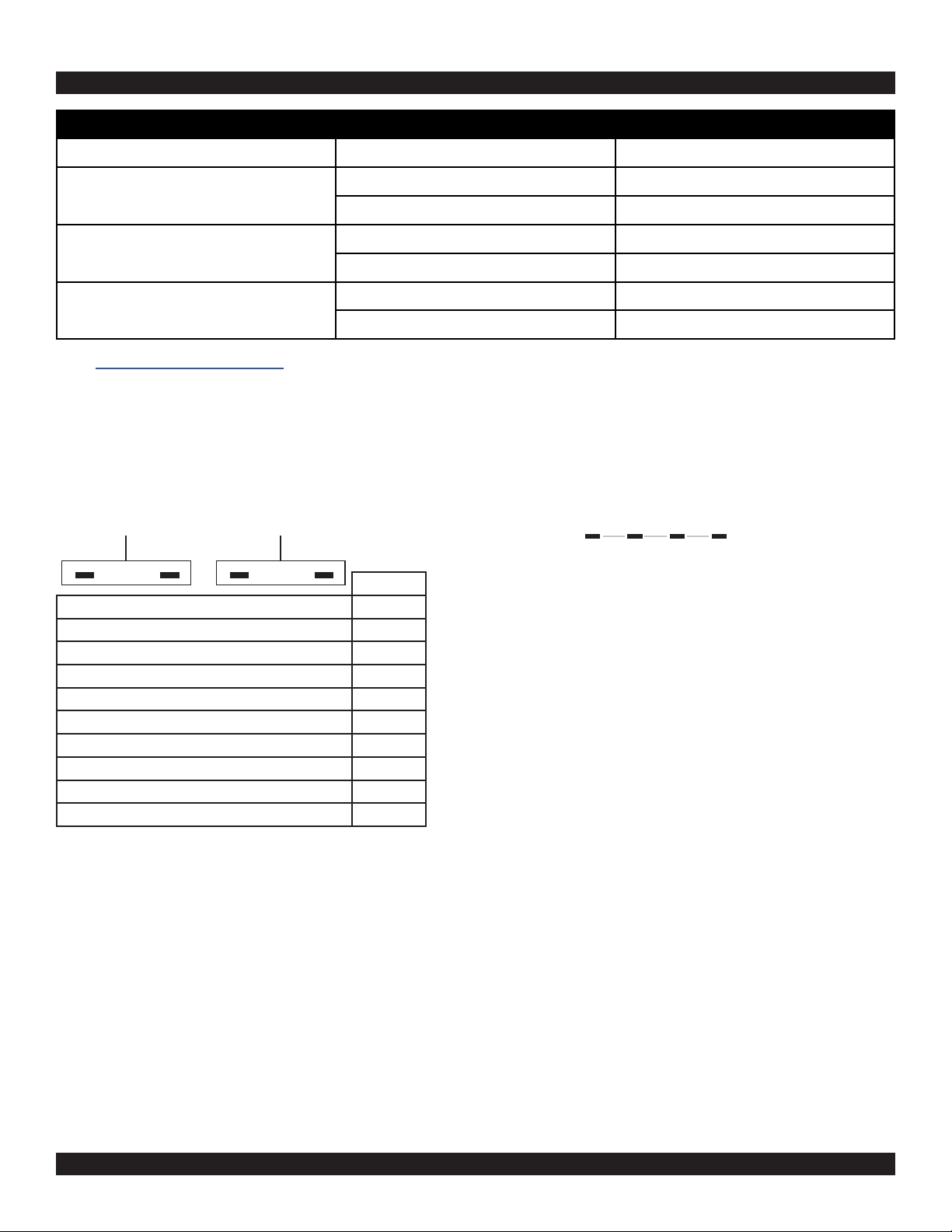

READING BINARY CODES

dz LED ON means 1

dz LED OFF means 0

dz The status bar will blink 2x, to display a FxEx code.

dz The first LEDs blinking will represent the F-number, and the Lid Lock LED/LED 4 will be ON.

dz The Second LEDs blinking will represent the E-number, and the Lid Lock LED/LED 4 will be OFF.

LED group 5 LED group 6

Sense Soak Wash Done

Value

0 0 0 0 0

0 0 0 1 1

0 0 1 0 2

0 0 1 1 3

0 1 0 0 4

0 1 0 1 5

0 1 1 0 6

0 1 1 1 7

1 0 0 0 8

1 0 0 1 9

Example: F3E2

1. Wash and Done are ON

2. All are OFF

3. Wash is ON

4. All are OFF

5. Back to step 1

DO NOT REMOVE OR DESTROY

11

FOR SERVICE TECHNICIAN’S USE ONLY

BUTTON ACTIVATION & ENCODER TEST

NOTE: The Service Diagnostic mode must be activated before entering the

Button Activation & Encoder Test; see procedure on page 10.

Entry Procedure

Press and release Key 1 used to activate Service Diagnostic mode.

The following test will be available:

DIAGNOSTIC: Button Activation & Encoder Test

The Encoder Test will be active immediately after successfully entering into the

Button Activation & Encoder Test:

➢

When the Encoder Test starts, one of the LED from status indicator group

will be turned ON.

➢

Rotate the knob CW/CCW from the current position until a full knob

rotation is completed. Notice that the LEDs from Status indicator group

will turn ON/OFF while the knob is rotated. After the Encoder Test is

completed, all the LEDs will be turned ON and the Button Activation test

will be active.

Button Activation Test

Pressing each button will toggle ON/OFF its corresponding LEDs:

➢

LED group 1 will toggle ON/OFF with Key 1.

➢

LED group 2 will toggle ON/OFF with Key 2.

➢

LED group 3 will toggle ON/OFF with Key 3.

➢

LED group 4 will toggle ON/OFF with Key 4.

➢

LED group 5 will toggle ON/OFF with Key 5/START.

➢

LED group 6 will toggle ON/OFF with Key 6/POWER.

➢

If LEDs do not toggle ON/OFF after pressing buttons and rotating the

cycle selector knob go to TEST: #4 HMI.

SERVICE TEST MODE

NOTE: The Service Diagnostic mode must be activated before entering Service

test mode; see procedure on page 10.

NOTE: If, at any point, the user presses the POWER button or opens the door

when not requested by the test sequence during Service test mode, the washer

exits to standby mode.

NOTE: Door must be closed to perform test.

Active Fault Code Display in Service Test Mode

If the display begins flashing while in Service test mode, it is displaying an active

fault code. Active fault codes are codes that are currently detected. Only one

active fault code can be displayed at a time.

Entry Procedure

To enter Service test mode, press and release Key 2 used to activate the

Service Diagnostic mode then press and release the START button. All LEDs

will turn ON indicating that the Service test mode entry was successful.

Perform All Tests: After pressing the START button, the test sequence from

page 13 will start.

Exit Procedure

When the test is complete, press the POWER button to exit Service test mode

and return to standby mode.

Exit Procedure

To exit Button Activation & Encoder test, press and hold Key 1 used to activate

Service Diagnostic mode.

DO NOT REMOVE OR DESTROY12

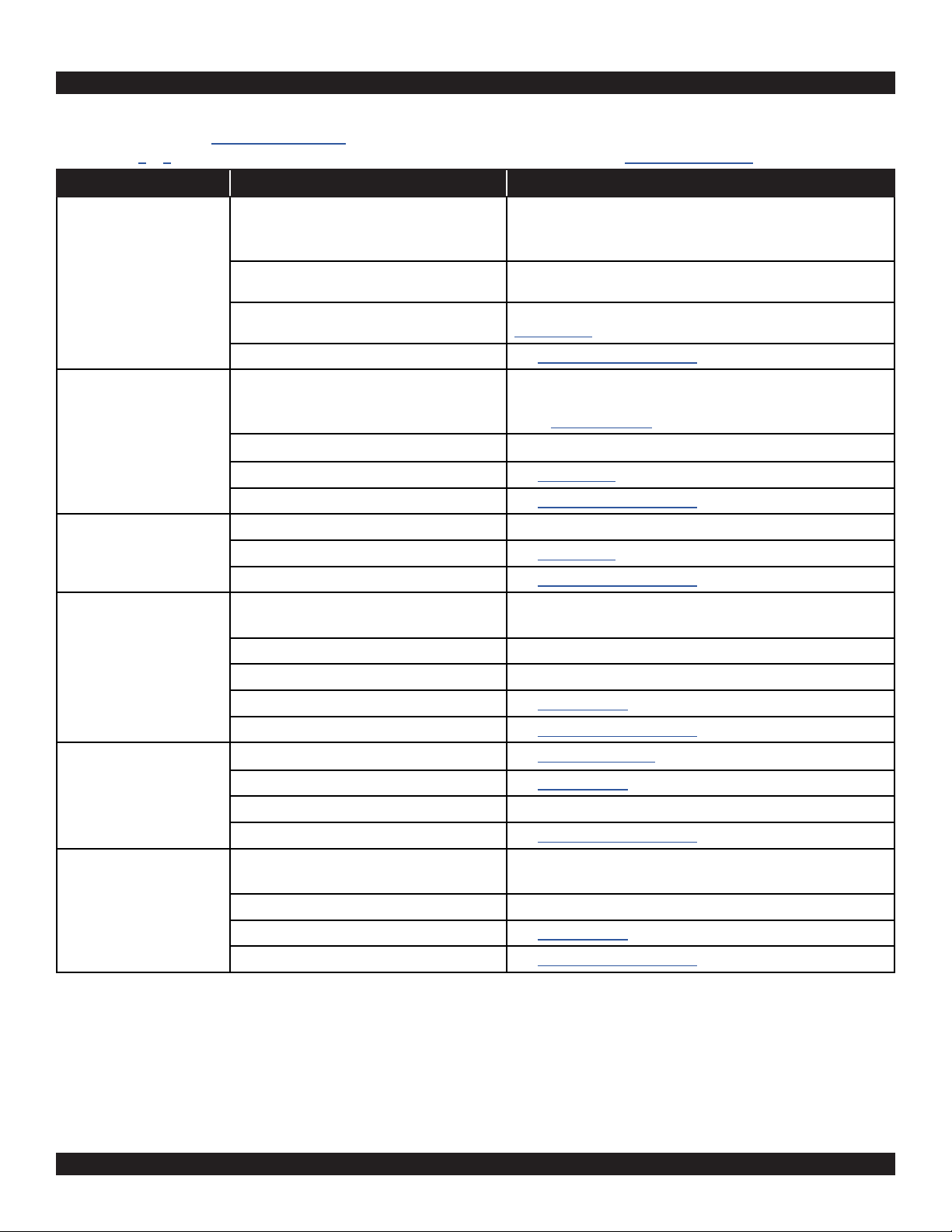

FOR SERVICE TECHNICIAN’S USE ONLY

SERVICE TEST MODE CHART/COMPONENT ACTIVATION

Step# Action Component HMI response

User enters Service test mode through

Service Diagnostics by pressing

1

releasing Key 2 used in entry sequence.

Door must be closed. All LEDs are OFF and machine is waiting for the

START button to be pressed.

Press and release the START button to

begin the test. Water valves test starts

2

3

4

5

6

automatically.

Drain pump test starts automatically.

1. Press Key 1 to repeat the Water

Valve test sequence.

2. Press Key 2 to skip the Drain Pump

test sequence.

Wash Sequence starts automatically.

1. Press Key 1 to repeat the Drain test

sequence.

2. Press Key 2 to skip the wash test

sequence.

Spin Test sequence starts automatically.

1. Press Key 1 to repeat wash test

sequence.

2. Press Key 2 to skip spin test

sequence.

End of Service Cycle starts automatically.

1. Press Key 1 to repeat spin test

sequence.

2. Press Key 2 to skip water valves test

sequence.

3. No key press will take to Service

mode.

Water Valves Test Sequence:

dz Cold Water Valve Opens for 10 seconds

or until 70 mm water is filled and then

closes.

dz Hot Water Valve Opens for 10 seconds

and closes.

Drain Pump Test Sequence:

dz Drain Pump Turns ON for 45 seconds or

till reaching 3 mm water column in the

tub.

Wash Test Sequence:

dz Lid Lock closes.

dz Shifter changes its position to wash.

dz Wash action performed for 5 seconds in

both CW/CCW.

dz Lid Unlocks.

Spin Test Sequence:

dz Lid Lock closes.

dz Shifter changes its position to spin.

dz Slow spin at 140 rpm for 5 seconds.

dz Medium spin at 300 rpm for 5 seconds.

dz Final spin at 500 rpm for 30 seconds

or skip after 25 seconds if 500 rpm not

reached.

dz Lid Unlocks after basket speed comes to

less than 60 rpm.

End of cycle sequence:

dz Shifter turn to wash.

Sense LED from Status Indicators is ON during

this sequence.

Soak Phase LED from status indicator is ON

during this sequence.

Wash LED from Status Indicators is ON during

this sequence.

Done LED from Status Indicators is ON during

this sequence.

All LEDs from Status Indicators is ON during

this sequence.

DO NOT REMOVE OR DESTROY

13

FOR SERVICE TECHNICIAN’S USE ONLY

SOFTWARE VERSION DISPLAY

NOTE: The Software Version Display mode will time out after 5 minutes of user

inactivity and return to standby mode.

Entry Procedure

To enter Software Version Display, press and hold Key 2 used to activate the

Service Diagnostic mode for 5 seconds. Upon entry, the display will

automatically cycle through the following information:

Component Identifier Value display

ACU Application Firmware 1 XX:YY:ZZ

HMI Application Firmware 2 XX:YY:ZZ

Setting FIle 3 PN1:PN2:PN3:PN4:PN5:PN6:

PN7:PN8

Ƀ

Where XX.YY.ZZ corresponds to the 3 sets of 2 digit numbers that

describe a software version and PN1.PN2.PN3.PN4.PN5.PN6.PN7.PN8

is the 8 digit settings file part number.

Ƀ

The ACU, HMI and Settings file information will be displayed in the LEDs

(SENSE, SOAK, WASH, and DONE) in binary format. Consider SENSE

LED the most significant bit.

Ƀ

The identifier value of the component information will be displayed in

LED Group1/TEMPERATURE Group in binary format. Consider HOT LED

from top as the most significant bit. (For Example: Cold LED blinks, then

the Identifier is 1. Cold and Cool LED blinks, then the Identifier is 3).

Ƀ

LED ON = 1, LED OFF = 0.

Exit Procedure

Pressing the POWER button will exit Software Version Display and return washer

to standby mode.

Ƀ

When the F# digits are displayed, the LID LOCK LED will be turned ON.

Ƀ

When the E# digits are displayed, the LID LOCK LED will be turned OFF.

Up to five Fault/Error codes may be stored. Additional presses of Key 3 will

cause the system to display the next fault code. If there are no fault codes

saved, the LEDs will blink two times for each Key 3 press.

Advancing Through Saved Fault/Error Codes

Procedure for advancing through saved fault codes:

Press and release Key 3 used to

activate service diagnostics

Most recent fault code is

displayed.

Repeat Second most recent fault code is

displayed.

Repeat Third most recent fault code is

displayed.

Repeat Fourth most recent fault code is

displayed.

Repeat Fifth most recent fault code is

displayed.

Repeat Back to the most recent fault code.

Clearing Fault Codes

To clear stored fault codes, enter Service Diagnostic mode. Then press and hold

Key 3 used to enter Service Diagnostic mode for 5 seconds. Once the stored

fault codes are successfully erased, the LEDs will blink two times.

EXITING SERVICE DIAGNOSTIC MODE

Use below method to exit diagnostic mode.

dz Pressing the POWER button once.

FAULT/ERROR CODES

Refer to service fault/error codes on page 16.

Fault/Error Code Display Method

LED group 2

LED group 5

LED

group 1

Key 1

Ƀ

Fault codes are composed by a F# and an E#. The F# has two digits

LED group 6

group 3

Key 2

LED group 4

Key 6/

POWER

LED

Key 5/

START

Key 4Key 3

and indicates the suspect System/Category. The E# has two digits and

indicates the suspect Component system.

Ƀ

The fault codes are displayed in binary format at the LEDs (SENSE,

SOAK, WASH, and DONE). When the LED is ON it represents a binary 1

and when the LED is OFF it represents a binary 0.

Refer to "Reading Binary Codes".

DO NOT REMOVE OR DESTROY14

FOR SERVICE TECHNICIAN’S USE ONLY

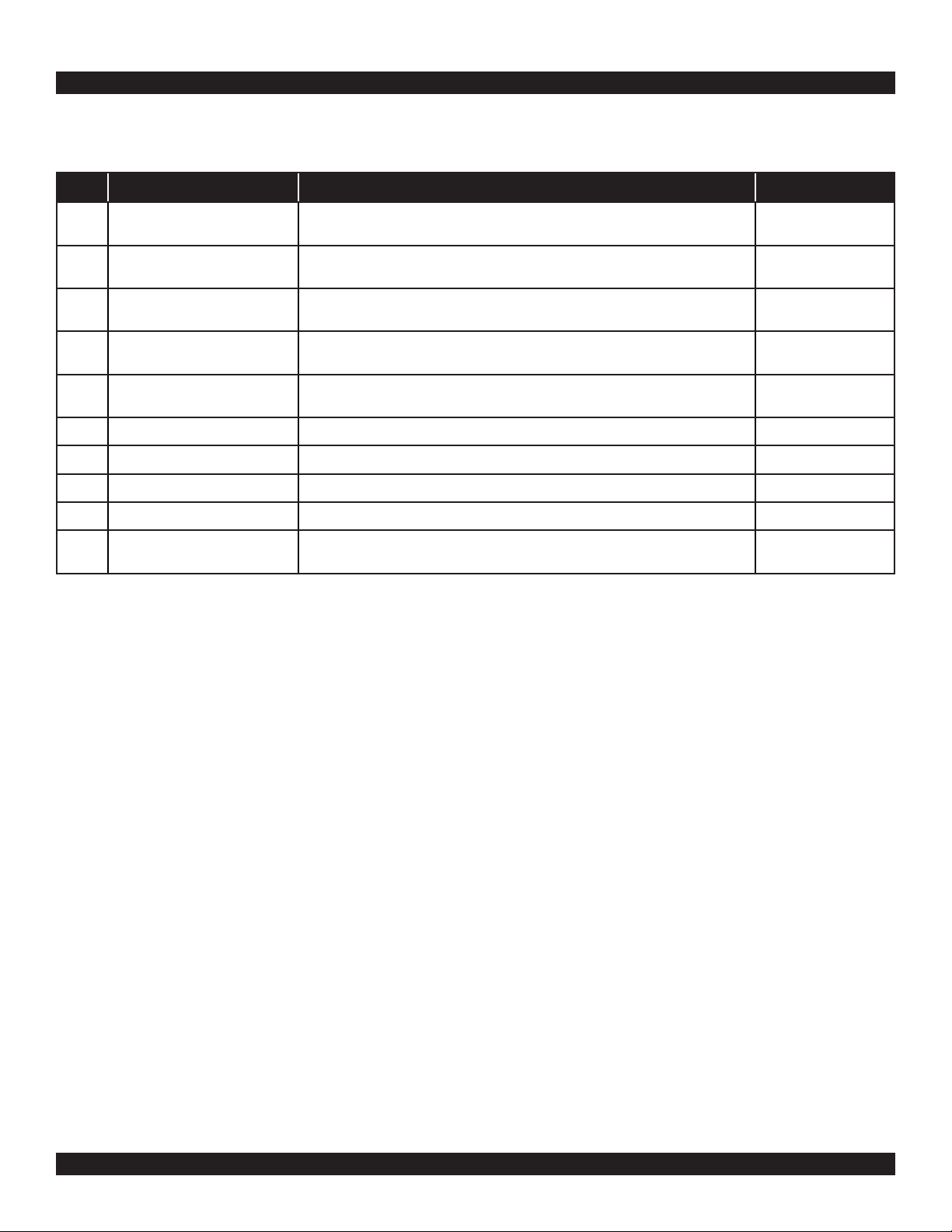

DIAGNOSTIC CYCLE CHART

It is recommended to take note of, then clear the Fault History before running the Diagnostic Cycle.

NOTE: The basket must be empty during this test. Some loads will not be available on all models.

Step Washer Function Recommended Procedure Estimated Time (s)

Warm water fills through the

1

Detergent valve

Hot water fills through the

2

Detergent valve

Cold water fills through the

3

Detergent valve

4 Drain pump turns on

5 Lid locks

6 Shift to Wash Use Wash test sequence to manually test the shifter. 30

7 Wash Use Wash test sequence to manually test the motor operation in both direction. 5

8 Shift to Spin Use Spin test sequence to manually test the shifter. 30

9 Spin up to 500 RPM then stop Use Spin test sequence to manually test the motor. 200

10 Unlock lid

Total test time in minutes is expected to be between 4 - 7 minutes.

Steps 1-3 will display Sense LED. Step 4 will display Soak LED. Steps 5-7 will display Wash LED. Steps 8-10 will display Done LED.

If no water, use Water Valve test sequence to manually turn on and test the hot and

cold water valves.

If no water, use Water Valve test sequence to manually turn on and test the valve. 5

If no water, use Water valve test sequence to manually turn on and test the valve. 5

If water is not draining, use Drain Pump test sequence to manually turn on and test

the drain pump.

Lid must be closed. If lid does not lock, use Wash test sequence to manually test

the lid lock.

If lid does not unlock, use service Water valve test sequence to manually test the

lid lock.

60

15

5

5

DO NOT REMOVE OR DESTROY

15

FOR SERVICE TECHNICIAN’S USE ONLY

FAULTS AND ERROR CODES

Faults marked with “‡” will stop the cycle execution. If no action is taken within 5–10 minutes, the display will turn off.

All faults can be viewed in the ‘Fault History’ section of Service mode.

Code Description Explanation and Recommended Procedure

Fault is displayed when suds prevent the basket from spinning up to speed or the pressure sensor detects

rising suds level. The main control will flush water in an attempt to clear suds. If the water flush is unable to

correct the problem, this may indicate:

F0E2 Oversuds

F0E3 Overload

‡

dz Not using HE detergent.

dz Excessive detergent usage.

dz Check pressure hose connection from tub to main control. Is hose pinched, kinked, plugged, or leaking air?

dz Mechanical friction on drive mechanism or basket (items between basket and tub).

Fault is displayed when the main control detects a load size that exceeds the washer’s capacity OR basket

cannot be turned. This may signify:

dz Load size exceeds washer capacity. Remove excess laundry, then restart the cycle.

dz Mechanical friction on drive mechanism or basket (items between basket and tub).

F0E4

Spin Limited by Water

Temperature

F0E5 Off Balance Load

Load Detected When

F0E7

F0E8 Water Ring

F0E9 OB Pause

Running Clean Washer

‡

Cycle

‡

‡

F1E1 Main Control (ACU) Fault

F2E1 HMI Stuck Button

F2E2 HMI Disconnected

F3E2 Pressure System Fault

‡

‡

Fault is displayed when the water temperature is too high to have spin at final speed. Speed will be limited to

500 RPM.

dz Check water valve function. See TEST #2: Valves.

Fault is stored when an off balance condition is detected.

dz Check for weak suspension. Basket should not bounce up and down more than once when pushed.

dz Items should be distributed evenly when loading.

Fault is displayed when clothes are detected in the basket when clean washer cycle is selected.

dz Remove any load from the basket before running clean washer cycle.

Fault is displayed when too much residual water is detected.

dz Run Drain and Spin Cycle.

Fault is displayed when an off balance condition is detected and after user interventions.

dz Check for weak suspension. Basket should not bounce up and down more than once when pushed.

dz Items should be distributed evenly when loading.

Fault is displayed indicating a main control (ACU) fault.

‡

dz See TEST #1: Main Control (ACU).

Fault is stored indicating that the user interface is detecting that a button is continuously activated.

dz See TEST #4: HMI.

Fault is displayed if the HMI is disconnected from the ACU.

dz See TEST #4: HMI.

Fault is displayed when the main control detects an out of range or absent pressure signal.

dz Check pressure hose connection from tub to main control. Is hose pinched, kinked, plugged, or leaking air?

dz See TEST #6: Water Level.

F3E3

F5E1

Inlet Water Temperature

‡

Fault

Lid Switch Fault - Lid Is

‡

Open

Fault is stored when the inlet thermistor is detected to be open or shorted.

dz See TEST #5: Temperature Thermistor.

Fault is displayed if lid is in locked state, but lid switch is open; control not sensing the strike in the lid lock.

dz User presses START with lid open.

dz The main control cannot detect the lid switch opening and closing properly.

dz See TEST #8: Lid Lock.

DO NOT REMOVE OR DESTROY16

FOR SERVICE TECHNICIAN’S USE ONLY

FAULTS AND ERROR CODES

Faults marked with “‡” will stop the cycle execution. If no action is taken within 5–10 minutes, the display will turn off.

All faults can be viewed in the ‘Fault History’ section of Service mode.

Code Description Explanation and Recommended Procedure

Fault is displayed when one of the following conditions occurs:

dz Excessive force on lid is preventing lock bolt from retracting.

Lid Lock Will Not Unlock

F5E3

‡

dz Wash media buildup is preventing lock bolt from retracting.

dz Main control cannot determine if lid lock is in an unlocked state.

dz See TEST #8: Lid Lock.

Lid Lock Will Not Lock

F5E4

F6E1

F7E1

F7E3

F7E4

Lid Not Opened Between

‡

Cycles

Communication Error: HMI

Cannot Hear ACU

Tachometer missing or

Wrong Signal

‡

Basket Engaged During

Wash

Basket Re-engagement

Failure

F7E6 Motor Circuit Open

‡

dz Check lid lock for obstructions.

dz See TEST #8: Lid Lock.

Fault is displayed when one of the following conditions occurs:

dz User presses START with lid open.

dz User presses START after a predetermined number of consecutive washer cycles without opening lid.

dz The main control cannot detect the lid switch opening and closing properly.

dz See TEST #8: Lid Lock.

Fault is displayed when communication between the HMI and the ACU has not been detected.

Fault is displayed when one of the following conditions occurs:

‡

dz Check continuity in the HMI harness.

dz Complete TEST #1: Main Control (ACU) and TEST: #4 HMI.

Fault is stored when the ACU cannot read the speed or power from the tachometer.

dz Check connections to the ACU.

dz Complete TEST #1: Main Control (ACU).

dz Complete Sensor Feedback Motor Speed Tachometer test.

Fault is stored when the main control determines the shifter is not engaging the basket for spin or disengaging

it for wash.

dz Check shifter connectors.

dz Check for clothing or another item wedged between the impeller and the basket that could bind them together.

dz Check that the shifter slider moves freely.

dz See TEST #3a: Drive System – Shifter.

Fault is stored when main control detects one or more of the motor lines is open.

dz Check motor circuit.

dz See TEST #1: Main Control (ACU), TEST #3: Drive System or TEST #3b: Drive System – Motor.

F7E7

F8E1 Long Fill

Motor unable to reach target

RPM

‡

DO NOT REMOVE OR DESTROY

Fault is stored when motor cannot reach the target RPM.

dz Check basket for obstructions.

dz See TEST #1: Main Control (ACU), TEST #3b: Drive System – Motor.

Fault is displayed when the water level does not change for a period of time OR water is present but the control

does not detect the water level changing.

dz Is water supply connected and turned on?

dz Are hose screens plugged?

dz Is water siphoning out of the drain hose?

dz Check for proper drain hose installation.

dz Low water pressure; fill times longer than 10 minutes.

dz Is the pressure hose connection from the tub to the main control pinched, kinked, plugged, or leaking air?

dz See TEST #2: Valves and TEST #6: Water Level.

17

FOR SERVICE TECHNICIAN’S USE ONLY

FAULTS AND ERROR CODES

Faults marked with “‡” will stop the cycle execution. If no action is taken within 5–10 minutes, the display will turn off.

All faults can be viewed in the ‘Fault History’ section of Service mode.

Code Description Explanation and Recommended Procedure

Fault is displayed when main control senses water level that exceeds washer capacity.

dz Check pressure hose connection from tub to main control. Is hose pinched, kinked, plugged, or leaking air?

dz Check for proper drain hose installation. Is water siphoning out of the drain hose? Drain hose must not be

more than 4.5" (114 mm) into the drain pipe. Make sure drain hose is not sealed into drain pipe, and that

F8E3 Overflow or Flood Condition

F8E6 Water Hazard

‡

‡

there is an air gap for ventilation. Ensure that drain height is between 39" (991 mm) and 8' (2.4 m) above

the floor.

dz May signify problem with water inlet valves.

dz Pressure transducer fault on main control.

dz See TEST #2: Valves and TEST #6: Water Level.

Fault is displayed when main control senses water in the tub and the lid has been left open for more than

10 minutes.

dz Check pressure hose connection from tub to main control. Is hose pinched, kinked, plugged, or leaking air?

dz Check for proper drain hose installation. Is water siphoning out of the drain hose? Drain hose must not be

more than 4.5" (114 mm) into the drain pipe. Make sure drain hose is not sealed into drain pipe, and that

there is an air gap for ventilation. Ensure that drain height is between 39" (991 mm) and 8' (2.4 m) above

the floor.

dz May signify problem with water inlet valves.

dz Pressure transducer fault on main control.

dz May signify problem with lid lock.

dz See TEST #2: Valves, TEST #6: Water Level, or TEST #8: Lid Lock.

F9E1

Drain Pump System

Problem - Long Drain

Fault is displayed when the water level does not change after the drain pump is on.

dz Is the drain hose or the drain pump clogged?

‡

dz Is the drain hose height greater than 8' (2.4 m)?

dz Is the pressure hose connection from the tub to the main control pinched, kinked, plugged, or leaking air?

dz Too much detergent.

dz Is the pump running? If not, see TEST #7: Drain Pump.

DO NOT REMOVE OR DESTROY18

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING

This section (page 20-28) provides general safety, parts, and information for the “Maytag® 4.8 cu. ft. Top Load Washer.”:

Ƀ

Troubleshooting Guide

Ƀ

Main Control (ACU) Board Connectors and Pinouts

Ƀ

Troubleshooting Tests

Ƀ

Component Locations

DO NOT REMOVE OR DESTROY

19

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING GUIDE

NOTE: Always check for Faults and Error Codes first. Some tests will require accessing components.

See figures. 7 & 8 for Component Locations. For detailed troubleshooting procedures, refer to “Troubleshooting Tests.”

Problem Possible Cause Checks & Tests

Won’t Power Up

• No operation

• No keypad response

• No LEDs or display

Won’t Start Cycle

No response when START is

pressed

HMI Won’t Accept

Selections

Won’t Fill

Overfills

Won’t Dispense Fabric

Softener Or Oxi (Oxi not

on all models)

No power to washer.

Connections between main control and HMI.

Connection problem between AC plug and main

control.

User Interface problem. Check connections and continuity between main control and HMI. See

Main Control problem. See TEST #1: Main Control (ACU).

Lid lock mechanism not functioning. 1. Lid not closed due to interference.

Connections between main control and HMI. Check connections and continuity between main control and HMI.

User Interface problem. See TEST #4: HMI.

Main Control problem. See TEST #1: Main Control (ACU).

Connections between main control and HMI. Check connections and continuity between main control and HMI.

User Interface problem. See TEST #4: HMI.

Main Control problem. See TEST #1: Main Control (ACU).

No water supplied to washer. 1. Check water connections to washer.

Plugged filter/screen. Check for plugged filter or screen in the water valve or hoses.

Drain hose installation. Check for proper drain hose installation.

Valve problem. See TEST #2: Valves.

Main Control problem. See TEST #1: Main Control (ACU).

Pressure hose. See TEST #6: Water Level.

Valve problem. See TEST #2: Valves.

Washer requires calibration. Perform Service Calibration.

Pressure transducer on main control. See TEST #1: Main Control (ACU).

No water supplied to washer. 1. Check water connections to washer.

Obstruction in dispenser. Clean obstruction from dispenser.

Valve problem. See TEST #2: Valves.

Main Control problem. See TEST #1: Main Control (ACU).

Check power at outlet, check circuit breakers, fuses, or junction box

connections.

Check the AC power cord for continuity.

TEST #4: HMI.

2. Lock not closed due to interference.

3. See TEST #8: Lid Lock.

2. Verify that hot and cold water supply is on.

2. Verify that hot and cold water supply is on.

DO NOT REMOVE OR DESTROY20

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING GUIDE

NOTE: Always check for Faults and Error Codes first. Some tests will require accessing components.

See figures. 7 & 8 for Component Locations. For detailed troubleshooting procedures, refer to “Troubleshooting Tests.”

Problem Possible Cause Checks & Tests

Incorrect Water

Temperature

Won’t Agitate

Won’t Spin

Won’t Drain`

Cycle Time Longer Than

Expected

Water hose installation. Make sure inlet hoses are connected properly.

Temperature thermistor. See TEST #5: Temperature Thermistor.

Valve problem. See TEST #2: Valves.

Main Control problem. See TEST #1: Main Control (ACU).

Water covering the impeller? See TEST #6: Water Level.

Is lid lock showing open during the cycle? See TEST #8: Lid Lock.

Harness connections. Check harness connections between main control and drive system.

Shifter problem. See TEST #3a: Drive System – Shifter.

Motor problem. See TEST #3b: Drive System – Motor.

Main Control problem. See TEST #1: Main Control (ACU).

Is lid lock showing open during the cycle? See TEST #8: Lid Lock.

Harness connections. Check harness connections between main control and drive system.

Shifter problem. See TEST #3a: Drive System – Shifter.

Motor problem. See TEST #3b: Drive System – Motor.

Main Control problem. See TEST #1: Main Control (ACU).

Drain hose installation. Check for proper drain hose installation. Make sure it is not inserted

more than 4.5" (114 mm). Make sure drain hose is not sealed into

drain pipe, and that there is an air gap for ventilation.

Standpipe position. Ensure drain height is between 39" (991 mm) and 8" (2.4 m) above

the floor.

Plugged drain hose. Check drain hose for obstructions.

Obstructions to drain pump. Check tub sump under impeller plate & basket for obstructions.

Harness connections. Check harness connections between main control and drain pump.

Drain pump. See TEST #7: Drain Pump.

Main Control problem. See TEST #1: Main Control (ACU).

Oversuds. 1. Verify use of HE detergent.

2. Excessive detergent usage.

Off balance. 1. Load is off balance.

2. Balance ring water leak.

Drain hose installation. Check for proper drain hose installation. Make sure it is not inserted

more than 4.5" (114 mm). Make sure drain hose is not sealed into

drain pipe, and that there is an air gap for ventilation.

Standpipe position. Ensure drain height is between 39" (991 mm) and 8' (2.4 m) above

the floor.

Draining slowly. Check for pump or drain hose obstructions.

Water pressure drop. Results in longer fill time.

Friction or drag on drive. Check motor and bearings; check for items between tub and basket.

Weak suspension. Basket should not bounce up and down more than once when

pushed.

DO NOT REMOVE OR DESTROY

21

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING GUIDE

NOTE: Always check for Faults and Error Codes first. Some tests will require accessing components.

See figures. 7 & 8 for Component Locations. For detailed troubleshooting procedures, refer to “Troubleshooting Tests.”

Problem Possible Cause Checks & Tests

Poor Wash Performance

Please see “Quick

Reference Guide”

Oversuds. 1. Verify use of HE detergent.

2. Excessive detergent usage.

Load is Tangling. 1. Washer not loaded properly.

2. Perform Service Calibration.

Incorrect water level. 1. Perform Service Calibration.

2. See TEST #2: Valves.

3. See TEST #6: Water Level.

Clothes wet after cycle is complete (not water

saturated, but very damp).

Load not rinsed. 1. Check proper water supply.

Not cleaning clothes. 1. Washer not loaded properly.

Fabric damage. 1. Washer overloaded.

Wrong option or cycle selection. Refer customer to “Quick Reference Guide”.

1. Overloaded washer.

2. Oversuds (see above).

3. Items caught in tub sump.

4. Weak suspension.

5. Shifter not moving into position.

6. Cold/Rinse water > 105°F (40.5°C).

7. See TEST #7: Drain Pump.

8. See TEST #3b: Drive System – Motor.

2. Not using HE detergent.

3. Washer not loaded properly.

4. Shifter not moving into spin position.

5. See TEST #2: Valves.

6. See TEST #3b: Drive System – Motor.

2. Not using HE detergent.

3. Not using correct cycle.

4. Shifter not moving into position.

5. See TEST #3b: Drive System – Motor.

2. Bleach added incorrectly.

3. Sharp items in tub.

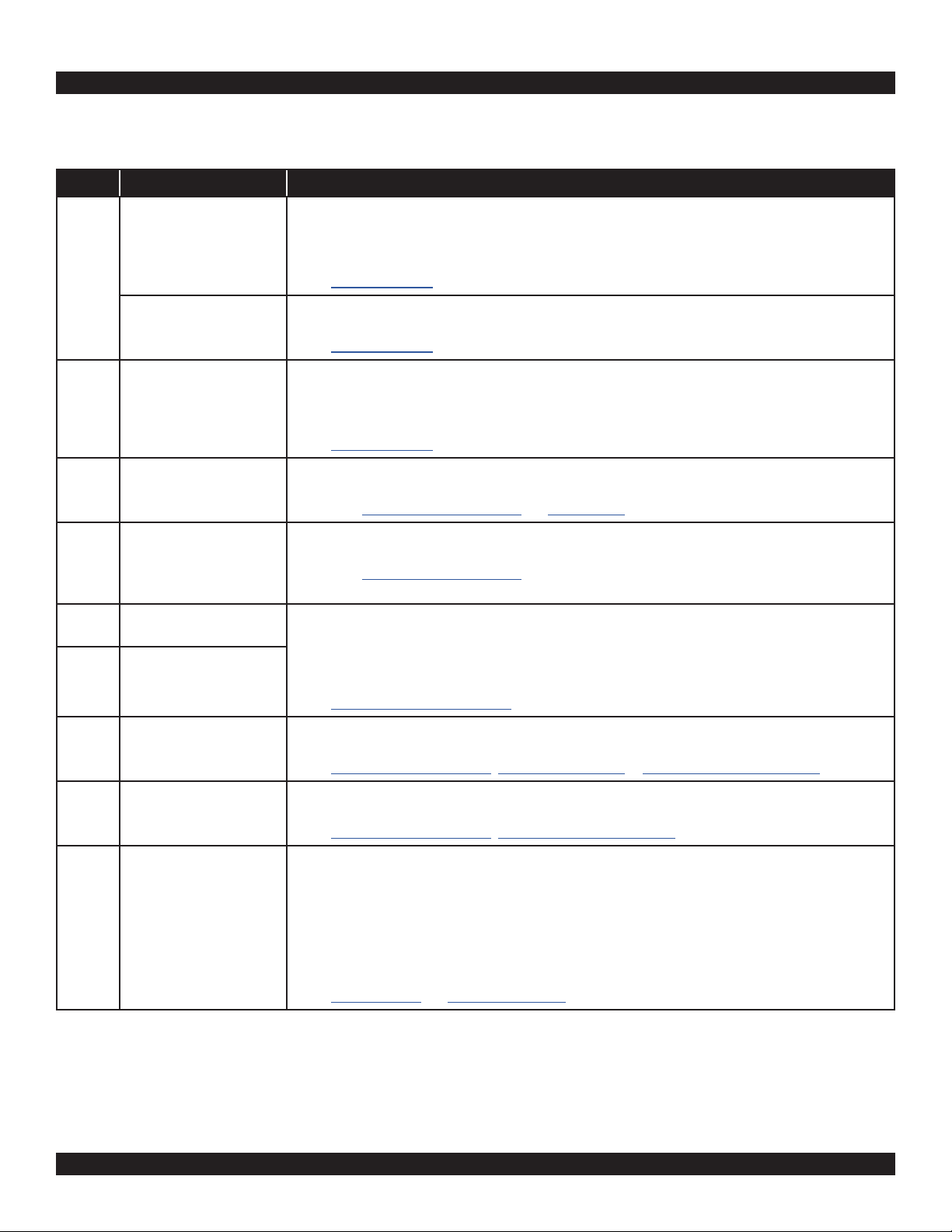

Troubleshooting Pinched Wires in the Harness

Figure 3 - Troubleshooting pinched wires in Harness

IMPORTANT: Verify that the harness is routed under the guides in the main control (ACU) as shown above before re-installing the console.

DO NOT REMOVE OR DESTROY22

FOR SERVICE TECHNICIAN’S USE ONLY

POWER CORD

GN GN

RD

RD

BK

RIBBED

WH

SMOOTH

OR

WH

BU

BK

BK

LBU

BR

WH

OR

2

1

1

2

3

4

5

6

7

8

9

LINE FILTER

CAPACITOR

J1J1

1

2

J6J6

1

2

3

4

5

6

CCW_MOTOR

SHIFTER

DRAIN_PUMP

CW_MOTOR

NC

NEUTRAL

NEUTRAL

LINE

1

2

3

4

5

6

LINE_OUT

NC

WATER_VALVE_1

NC

WATER_VALVE_2

WATER_VALVE_3

NC

AGND

NTC 1

J8

J8

1

2

3

4

5

6

7

8

9

POWER CORD

GN GN

RD

RD

RD

BK

RIBBED

WH

SMOOTH

BK

OR

WH

BU

BK

BK

YL

BU

GY

BK

PK

LBU

BR

WH

OR

OR

1

2

3

4

5

2

1

1

2

3

4

5

6

7

8

1

2

3

4

9

LINE FILTER

CAPACITOR

J1J1

1

2

J2 J2

1

2

3

4

J5J5

1

2

3

4

5

J6J6

1

2

3

4

5

6

CCW_MOTOR

SHIFTER

DRAIN_PUMP

CW_MOTOR

12 V7

5V

WIN_DATA

AGND

NC

NC

NEUTRAL

SHIFTER_STATUS

NEUTRAL

LINE

AGND

TACH_PWR

TACH_FB

1

2

3

4

5

6

LINE_OUT

NC

WATER_VALVE_1

NC

WATER_VALVE_2

WATER_VALVE_3

NC

AGND

NTC 1

J8

J8

1

2

3

4

5

6

7

8

9

POWER CORD

IF

3

4

GN GN

GN

GNYL

GN

BK

BK

RIBBED

WH

WH

SMOOTH

2

1

LINE FILTER

1

2

3

RFI_FILTER

1

2

3

GND1

GND1

GND

J1J1

1

2

NEUTRAL

LINE

POWER CORD

IF

1

2

3

4

GN GN

GN

GNYL

RD

RD

GN

BK

BK

RIBBED

WH

WH

SMOOTH

COMMON

BU

GY

BK

PK

LBU

BR

RD

WH

YL

YL

OR

OR

2

1

1

2

3

4

CAPACITOR

1

3

PSC MOTOR

4

LINE FILTER

1

2

3

4

RFI_FILTER

1

2

3

4

GND1

CAPACITOR

1

3

GND1

GND

J1J1

1

2

J2 J2

1

2

3

4

PSC

4

J6J6

1

2

3

4

5

6

CCW_MOTOR

SHIFTER

DRAIN_PUMP

CW_MOTOR

NC

NEUTRAL

SHIFTER_STATUS

NEUTRAL

LINE

AGND

TACH_PWR

TACH_FB

1

2

3

4

5

6

POWER CORD

IF

1

2

3

4

GN GN

GN

GNYL

RD

GN

BK

BK

RIBBED

WH

WH

SMOOTH

LBU

BR

RD

WH

OR

OR

2

1

CAPACITOR

1

LINE FILTER

1

2

3

4

RFI_FILTER

1

2

3

4

GND1

CAPACITOR

1

GND1

GND

J1J1

1

2

J6J6

1

2

3

4

5

6

CCW_MOTOR

SHIFTER

DRAIN_PUMP

CW_MOTOR

NC

NEUTRAL

NEUTRAL

LINE

1

2

3

4

5

6

POWER CORD

GN GN

RD

RD

RD

RD

LBU

WH

BK

WH

SMOOTH

BK

OR

WH

BU

BK

BK

YL

BU

GY

BK

PK

LBU

BR

WH

BKWH

BKWH

BKWH

OR

OR

1

2

3

4

5

2

1

1

2

3

4

5

6

7

8

1

2

3

1

2

3

4

9

J1J1

1

2

J2 J2

1

2

3

4

J5J5

1

2

3

4

5

J4 J4

1

2

3

J6J6

1

2

3

4

5

6

SPLICE N

CCW_MOTOR

SHIFTER

DRAIN_PUMP

CW_MOTOR

12 V7

5V

WIN_DATA

AGND

NC

NC

NEUTRAL

SHIFTER_STATUS

NEUTRAL

LINE

LID_SW_AC_LOAD6_OUT

LINE

LL_SW_LOCK

AGND

TACH_PWR

TACH_FB

1

2

3

4

5

6

LINE_OUT

NC

WATER_VALVE_1

NC

WATER_VALVE_2

WATER_VALVE_3

NC

AGND

NTC 1

J8

J8

1

2

3

4

5

6

7

8

9

RESISTOR

220OHMS 0.5W CF

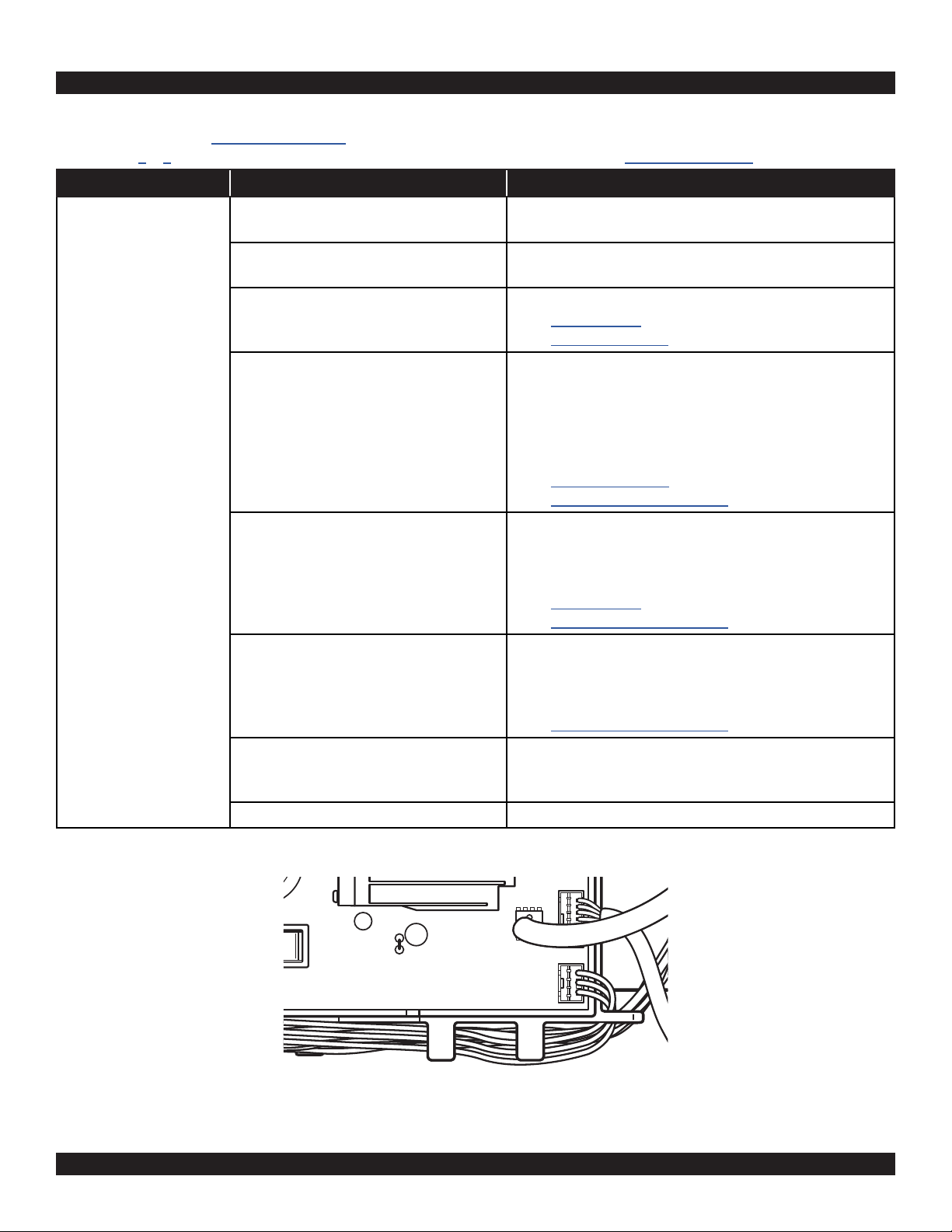

MAIN CONTROL (ACU) BOARD CONNECTORS AND PINOUTS

J5 HMI/WIN

J2 Tach

Power

DO NOT REMOVE OR DESTROY

J1

= Pin 1

PSC MOTOR

POWER

VALVES

J8 Valves

J4 Lid Lock J6 PSC Motor

Figure 4 - Main Control (ACU)

HMI / WIN

LID LOCK

Figure 5 - Connector and Pinouts

TACH

23

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING TESTS

TEST #1: Main Control (ACU)

This test checks for incoming and outgoing power to and from main control.

This test assumes that proper voltage is present at the outlet.

1. Unplug washer or disconnect power.

2. Remove console to access main control.

3. Verify that all connectors are inserted all the way into the main control.

4. With a voltmeter set to AC, connect black probe to J1-1 (Neutral) and

red probe to J1-2 (Line). Plug in washer or reconnect power.

➢

If 120 VAC is present, go to step 5.

➢

If 120 VAC is not present, check the AC power cord for continuity

(See Figure 7.)

5. Is the “Diagnostic LED” flashing or continuously “ON” or “OFF”?

See Figure 1 for LED location).

➢

Flashing: (+5 VDC present and micro operating) proceed to HMI Test.

➢

ON: (+5 VDC but micro failure) continue to step 8.

➢

OFF: (+5 VDC missing or micro failure) continue to step 6.

6. Check if console HMI is affecting the main control DC supply.

a. Unplug washer or disconnect power.

b. Remove connector J5 from main control.

c. Plug in washer or reconnect power.

7. Perform voltage checks inside header J5 on the board – do not short

pins together.

a. With a voltmeter set to DC, connect black probe to J5-4 (Circuit Gnd)

and red probe to J5-1 (+12 VDC).

➢

If DC voltage is not present, go to step 8.

➢

If the DC voltage is present, but the diagnostic LED is not flashing,

continue to step 8.

8. Main Control has malfunctioned.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Perform Service Diagnostic cycle to

verify repair.

TEST #2: Valves

This test checks the electrical connections to the valves, and the valves

themselves.

1. Check the relays and electrical connections to the valves by performing

Water Valve test sequence under Component Activation. Each test

activates and deactivates the selected valve. The following steps

assume one (or more) valve(s) did not turn on.

2. For the valve(s) in question check the individual solenoid valves.

a. Unplug washer or disconnect power.

b. Remove console to access main control.

c. Remove connector J8 from main control. Refer to Figure 7 - Main

Control.

d. Check harness continuity and connection to solenoid valves.

3. Check resistance of the valve coils across the following J8 connector

pinouts:

Valve Pinout

Fabric Softener J8, 1 & 6

Hot J8, 1 & 5

Resistance should be 890–1090 Ω.

➢

If resistance readings are tens of ohms outside of range, replace the

valve assembly.

➢

If resistance readings are within range, replace main control and

perform Service Diagnostics to verify repair.

Cold J8, 1 & 3

TEST #3: Drive System

1. Enter Service mode and view Fault Codes. If F7E1, F7E3, F7E4, F7E6

or F7E7 faults are shown then there is likely a motor or shifter related

issue Take note of the faults and clear the faults.

2. Once the error codes are cleared, enter Component Activation mode

and run the Slow Agitation test; if the motor runs after 15–20 seconds,

there is not a problem with the motor, control, or motor wiring harness

connections.

3. Next, within Component Activation mode, run the Spin Low Speed

cycle. If the motor hums briefly and then shuts down, go to Fault Code

display mode and check for fault codes.

4. After running agitation and spin test, check for fault codes.

TEST #3a: Drive System – Shifter

This test checks connections, shifter coil, and harness.

NOTE: Lid must be closed and locked for the motor to agitate or spin.

IMPORTANT: Drain water from tub before accessing bottom of washer.

Functional Check:

1. Check the shifter and electrical connections by performing both the

Spin and Wash test under Component Activation Mode. The following

steps assume that this step was unsuccessful.

2. Unplug washer or disconnect power.

3. The motor and shifter should be able to be turned independently of

each other. If they are locked together, there is a shifter slider issue.

Proceed to step 11.

➢

If basket and impeller turn freely, go to step 4.

➢

If basket and/or impeller do not turn freely, determine what is causing

the mechanical friction or lockup.

4. Remove console to access main control.

5. Visually check that the J2 and J6 connectors are inserted all the way

into the main control.

➢

If visual checks pass, go to step 6.

➢

If connector is not inserted properly, reconnect J2 and J6 and repeat

step 1.

Shifter Motor:

NOTE: Before starting the electrical check, verify that the cam on the

splutch is moving freely and not binding.

DO NOT REMOVE OR DESTROY24

FOR SERVICE TECHNICIAN’S USE ONLY

6. Remove connector J6 from main control. With an ohmmeter, verify

resistance of the shifter motor across the following J6 connector

pinouts:

Resistance should be 2 kΩ to 3.5 kΩ.

Component J6 Connector Pinout

Shifter J6, 2 & 6

➢

If values are correct, reconnect J6 and proceed to step 7.

➢

If values are open or out of range, go to step 12.

7. With a voltmeter set to AC, connect the black probe to J6-2 and red

probe to J6-6. Plug in washer or reconnect power. Activate shifter

motor by switching the shifter output ON and OFF. Energize outputs

using Component Activation mode.

NOTE: Motor must be stopped to toggle the shifter. Alternately, Spin and

Agitate can be commanded to switch shifter in Component Activation

mode.

IMPORTANT: Lid must be closed to run the Spin and Wash tests.

➢

If 120 VAC is present, go to step 8.

➢

If 120 VAC is not present, go to step 11.

Shifter Switch:

8. With a voltmeter set to DC, connect the black probe to J2-2 (Circuit

Gnd) and red probe to J2-1 (Shifter Switch). In Component Activation

mode, switch between Spin and Agitate modes. Voltage should toggle

between 0 and +5 VDC.

SPIN = +5 VDC

AGITATE = 0 VDC

➢

If voltage corresponds to setting, go to step 9.

➢

If voltage does not switch, go to step 11.

Optical Sensor:

9. With a voltmeter set to DC, connect the black probe to J2-2 (Circuit

Gnd) and a red probe to J2-3 (Tach Pwr).

➢

If +12 VDC is present, go to step 10.

➢

If +12 VDC is not present, go to step 16.

10. Activate Motor Speed Tachometer from Sensor Feedback. Slowly turn the

basket by hand.

NOTE: Spinning the basket too fast will result in a safety fault for the lid

lock. The screen will display the basket speed in RPM.

➢

If the tachometer is not verified, go to step 11.

➢

If the tachometer is verified, go to step 16.

11. Unplug washer or disconnect power.

12. Tilt washer back to access the bottom of the washer and the drive

motor area.

13. Visually check the electrical connections to the shifter.

➢

If visual check passes, go to step 14.

➢

If connections are loose, reconnect the electrical connections and

repeat step 1.

14. With an ohmmeter, check the harness for continuity between the shifter

and main control using the pinouts in the following chart.

➢

If there is continuity, go to step 15.

➢

If there is no continuity, replace the lower washer harness and repeat

step 1.

Shifter to Main Control & Drain Pump

Shifter Pin 1 to Main Control J2-4

Shifter Pin 2 to Main Control J2-3

Shifter Pin 3 to Main Control J6-6

Shifter Pin 4 to Main Control J2-1

Shifter Pin 5 to Main Control J2-2

Shifter Pin 6 to Main Control J6-2

15. Replace the shifter assembly.

a. Unplug washer or disconnect power.

b. Replace shifter assembly.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Calibrate washer and perform

Automatic Test to verify repair.

16. If the preceding steps did not correct the problem, replace the main

control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Calibrate washer and perform

Automatic Test to verify repair.

TEST #3b: Drive System – Motor

This test checks the motor, motor windings, wiring, and start capacitor.

IMPORTANT: Drain water from tub before accessing bottom of washer.

1. Check the motor and electrical connections by performing the wash

test sequence under Component Activation. Verify that the basket is

spinning in a clockwise direction while performing Low, Mid or High

Spin Speed test under Component Activation. The following steps

assume that this step was unsuccessful.

2. Unplug washer or disconnect power.

3. Check to see if basket will turn freely.

➢

If basket turns freely, go to step 4.

➢

If basket does not turn freely, determine what is causing the mechanical

friction or lockup.

4. Remove console to access main control.

5. Visually check that the J2 and J6 connectors are inserted all the way

into the main control.

➢

If visual checks pass, go to step 6.

➢

If visual checks fail, reconnect connectors and repeat step 1.

6. Plug in washer or reconnect power. Run the Motor Slow Wash test

under Component Activation.

7. With a voltmeter set to AC, connect black probe to J6-6 (Neutral) and

red probe to J6-4 (CW Winding).

➢

If 120 VAC is cycling ON during CW rotation, go to step 8.

➢

If 120 VAC is not present, go to TEST #1: Main Control (ACU).

8. With a voltmeter set to AC, connect black probe to J10-6 (Neutral), red

probe to J6-1 (CCW Winding).

➢

If 120 VAC is cycling ON during CCW rotation, go to step 9.

➢

If 120 VAC is not present, go to TEST #1: Main Control (ACU).

9. Unplug washer or disconnect power.

10. Remove connector J6 from main control. With an ohmmeter, check

resistance of motor windings across the following J6 connector

pinouts:

Motor Winding J10 Pinout Resistance

CW Winding J6, 4 & 6 5-9.5 Ω

CCW Winding J6, 1 & 6 5-9.5 Ω

➢

If values are open or out of range, go to step 11.

➢

If values are correct, go to step 15.

11. Tilt washer back to access drive system.

DO NOT REMOVE OR DESTROY

25

FOR SERVICE TECHNICIAN’S USE ONLY

12. Visually check the mounting bracket and electrical connections to the

motor and shifter.

➢

If visual check passes, go to step 13.

➢

If connections are loose, reconnect the electrical connections,

reassemble motor cover, and repeat step 1.

13. With an ohmmeter, check the harness for continuity between the main

control, motor, and run capacitor using the following test points.

Motor Harness Check

Motor Connector Pin-1 to Chassis GND

Motor Connector Pin-4 to Main Control J6-1

Motor Connector Pin-4 to Motor Capacitor Pin 1

Motor Connector Pin-3 to Main Control J6-4

Motor Connector Pin-3 to Motor Capacitor Pin 3

Motor Connector Pin-2 to Main Control J6-6

➢

If there is continuity, go to step 14.

➢

If there is no continuity, replace the lower machine harness and repeat

step 1.

14. With an ohmmeter, check resistance of motor windings at the following

motor connections.

Motor Winding Pinout Resistance

CW Winding Pins 3 & 2 5-9.5 Ω

CCW Winding Pins 4 & 2 5-9.5 Ω

➢

If values are open or out of range, replace motor.

➢

If values are correct, go to step 15.

15. Test Motor Run Capacitor.

NOTE: A faulty capacitor may cause the motor to “hum”, not start, or

turn slowly.

a. Discharge the capacitor by touching the leads of a 20,000 Ω resistor to

the two terminals.

b. Disconnect the wires from the capacitor terminals.

c. With an ohmmeter, measure across the terminals and note reading.

➢

If a steady increase in resistance is noted, continue to step 16.

➢

If the capacitor is either shorted or open, replace capacitor, calibrate,

and repeat step 1.

16. If the preceding steps did not correct the motor problem, replace the

main control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Calibrate washer and perform the

Diagnostic Cycle or Component Activation to verify repair.

TEST #4: HMI

Conduct each test within HMI test in Service mode including Key, LED,

and Encoder Tests. This procedure is performed when any of the following

situations occurs during the HMI Tests.

➢

Key presses do not display correctly on the HMI.

➢

The LED group indicators doesn't lit up.

➢

Encoder turns do not display correctly on the HMI.

1. Unplug washer or disconnect power.

2. Access the console’s electronic assemblies and visually check that the

J5 connector is inserted all the way into the main control and that the

HMI harness connector is fully seated on the HMI. Ensure the ribbon

cables are properly connected on both ends.

3. If both visual checks pass, follow procedure under TEST #1: Main

Control (ACU) to verify supply voltages.

4. Verify the continuity of the HMI harness.

ACU PIN Color HMI PIN

J5-1 Red J1-1

J5-3 Yellow J1-2

J5-4 Black J1-3

➢

If continuity fails, replace the HMI harness and go to step 5.

➢

If continuity passes, replace the user interface and go to step 5.

5. Reassemble all parts and panels.

6. Plug in washer or reconnect power.

7. To verify repair, activate the Service mode, and then perform HMI test.

TEST #5: Temperature Thermistor

This test checks valves, main control, temperature thermistor, and wiring.

1. Check the thermistor by performing the Inlet Thermistor test under

Sensor Feedback mode in Service mode on page 10.

2. The screen will display the inlet thermistor temperature in degrees

Celsius. The cold valve will open and the displayed temperature will

drop. Then the hot valve will open and the displayed temperature will

increase.

➢

If the machine operates as expected then the thermistor is operating

correctly.

➢

If the temperature increases first then decreases, check the hose

connections and repeat.

➢

If the displayed temperature does not act as described then proceed to

step 3.

3. Unplug washer or disconnect power.

4. Remove console to access main control.

5. Remove connector J8 from the main control. With an ohmmeter,

measure the resistance of the temperature thermistor between pins

J8-9 and J8-8. Verify that the approximate resistance, shown in the

table below, is within ambient temperature range.

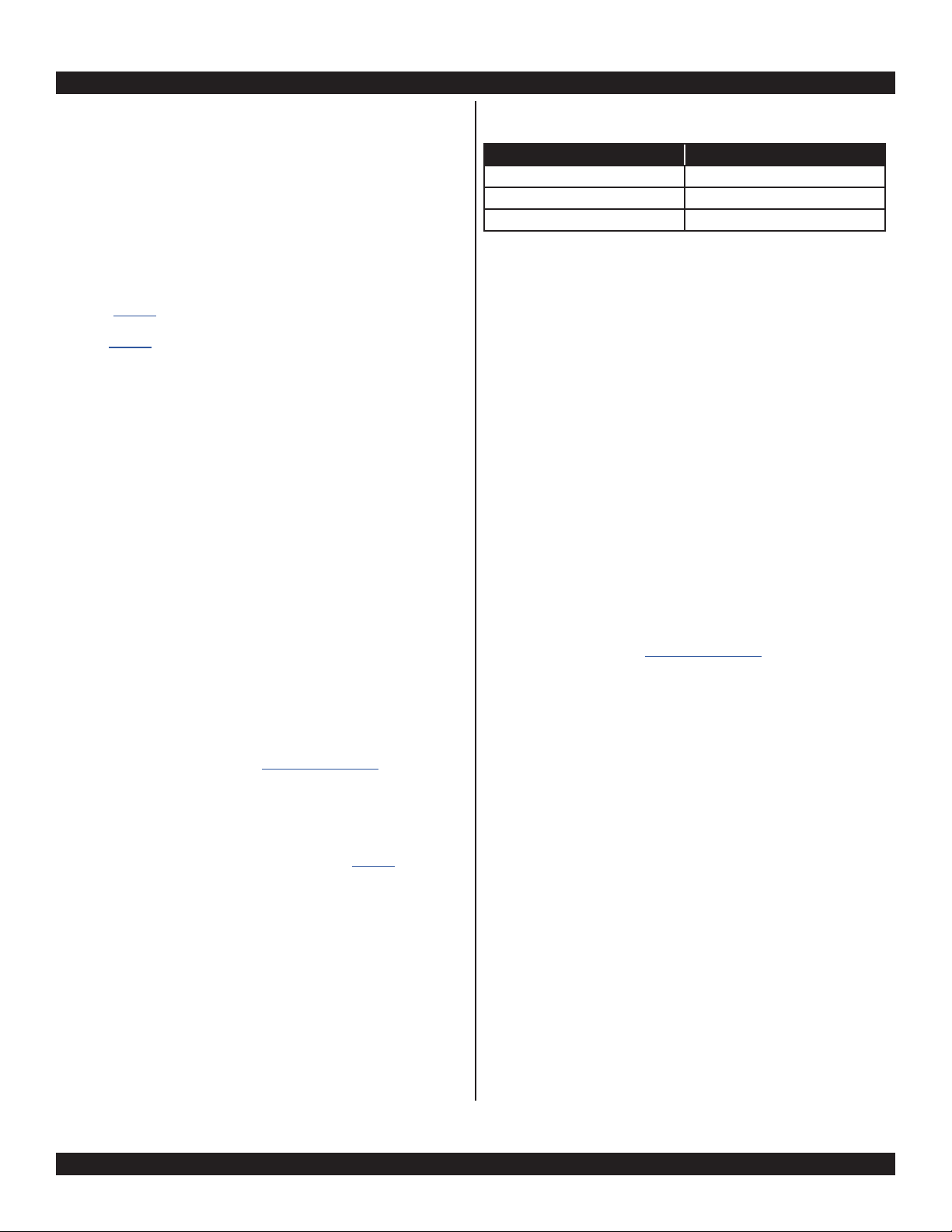

THERMISTOR RESISTANCE

Approx. Temperature Approximate Resistance

°F °C kΩ

32 0 163

41 5 127

50 10 100

59 15 79

68 20 62

77 25 50

86 30 40

95 35 33

104 40 27

113 45 22

122 50 18

131 55 15

140 60 12

149 65 10

DO NOT REMOVE OR DESTROY26

FOR SERVICE TECHNICIAN’S USE ONLY

➢

If the resistance is within the range shown in the table, go to step 6.

➢

If the resistance is infinite or close to zero, replace the valve assembly.

NOTE: Most thermistor errors are a result of the resistance being out

of range. If the temperature thermistor malfunctions, the washer will

default to pre-programmed wash settings.

6. If the thermistor is good, replace main control and perform step 1 again

to verify repair.

TEST #6: Water Level

This test checks the water level sensing components.

NOTE: Usually, if the pressure transducer malfunctions, the washer will

generate a long fill, or long drain error (F8E1 or F9E1).

1. Check the functionality of the pressure transducer by running by

running the Water Level Pressure Sensor cycle within Service Sensor

Feedback.

2. Verify that the valves open and the basket begins to fill. The screen

should display the water level rising as the basket fills, then decreasing

as the basket drains.

NOTE: The water level in the basket might not raise high enough to be

visible but that is normal.

3. If step 2 behaves correctly skip to step 9, otherwise continue to step 4.

4. Unplug washer or disconnect power.

5. Remove console to access main control.

6. Check hose connection between the pressure transducer on the main

control and the pressure dome attached to the tub.

7. Check to ensure hose is routed correctly in the lower cabinet and not

pinched or crimped inside the console or by the back panel.

8. Verify there is no water, suds, or debris in the hose or dome.

Disconnect hose from main control and blow into hose to clear water,

suds, or debris.

9. Check hose for leaks. Replace if needed.

10. If the preceding steps did not correct the problem, replace main control

and perform Service Diagnostics. Run Water Level Pressure Sensor

cycle within Service Sensor Feedback to verify.

TEST #7: Drain Pump

Perform the following checks if washer does not drain.

IMPORTANT: Drain water from tub before accessing the bottom of the

washer.

1. Check for obstructions in the usual areas. Clean and then perform step 2.

2. Check the drain pump and electrical connections by turning on the

drain pump in Service Component Activation mode. The following steps

assume that this step was unsuccessful.

3. Unplug washer or disconnect power.

4. Remove console to access main control.

5. Visually check that the J6 connector is inserted all the way into the

main control.

➢

If visual check passes, go to step 6.

➢

If connector is not inserted properly, reconnect J6 and repeat step 2.

6. Remove connector J6 from main control. With an ohmmeter, verify

resistance values shown below across the following J6 connector

pinouts:

Component J15 Pinout Resistance

Drain Pump J6, 3 & 6 17.8-21.8 Ω

➢

If values are open or out of range, go to step 7.

➢

If values are correct, go to step 11.

7. Tilt washer back to access drain pump. Verify pump is free from

obstructions.

8. Visually check the electrical connections at the drain pump.

➢

If visual check passes, go to step 9.

➢

If connections are loose, reconnect the electrical connections and

repeat step 2.

9. With an ohmmeter, check harness for continuity between the drain

pump and main control. See chart below:

Main Control to Drain Pump

Drain Pump Pin 1 to Main Control J6-3 (Lt. Blue Wire)

Drain Pump Pin 3 to Main Control J6-6 (White Wire)

➢

If there is continuity, go to step 10.

➢

If there is no continuity, replace the lower washer harness and repeat

step 2.

10. With an ohmmeter, measure the resistance across the two pump

terminals. Resistance should be as shown in the chart below:

Component Resistance

Drain Pump 17.8-21.8 Ω

➢

If values are open or out of range, replace the pump motor.

➢

If the resistance at the pump motor is correct, go to step 11.

11. If the preceding steps did not correct the drain problem, replace the

main control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Perform Service Diagnostics to

verify repair.

TEST #8: Lid Lock

Perform the following checks if the washer does not lock (or unlock).

1. Check the lid lock by performing Lid Lock test under Service Load

Control mode in Service Diagnostic mode. The following steps assume

that this step was unsuccessful.

2. Unplug washer or disconnect power.

3. Remove console to access main control.

4. Visually check that the J4 connector is inserted all the way into the

main control.

➢

If visual check passes, go to step 5.

➢

If connector is not inserted properly, reconnect J4 and repeat step 1.

5. Check the lid lock motor winding and switches by removing J4 from the

main control and checking the resistance values shown in the following

table:

LID LOCK RESISTANCE

Component Resistance Contacts Measured

Lock Switch

Solenoid

Lock Switch

Lid Switch

➢

If resistance values are good, go to step 6.

➢

If switch measurements do not match the values shown in the table for

unlocked (or locked) condition, a problem exists in the lid lock. Replace

the lid lock mechanism.

NOTE: Ensure that the protective corrugated tubing passes through

the hole in the top and that the push mount clip is connected to the top

from below. Additionally, route the lid lock wires through the retaining

clips on the ACU.

50-160 Ω J4-2 J4-3

Locked = 0 Ω

Unlocked = Open

Lid Open = Open

Circuit

J4-1 J4-2

J4-2 J4-1

DO NOT REMOVE OR DESTROY

27

FOR SERVICE TECHNICIAN’S USE ONLY

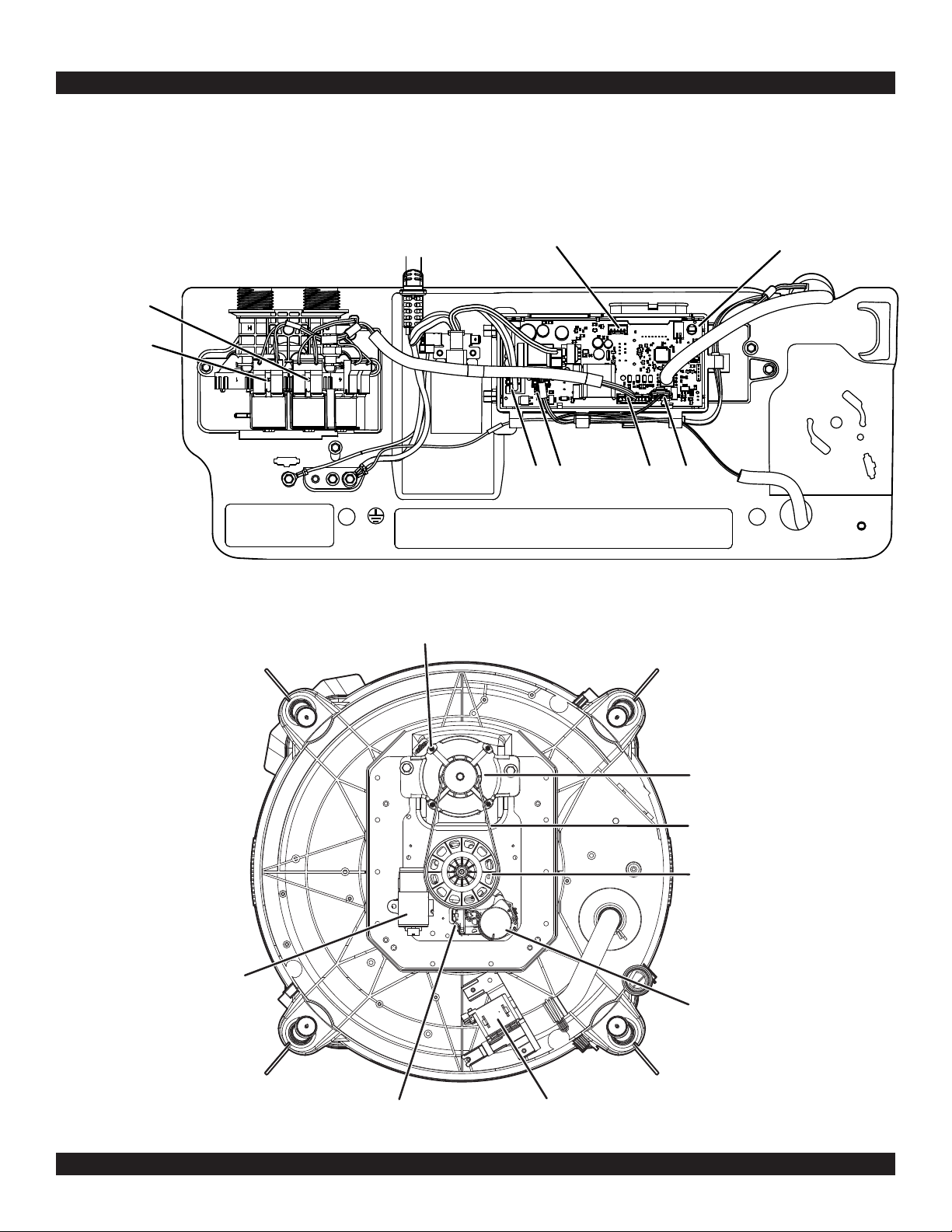

Shifter Assembly Connector

Drain Pump

6. If the preceding steps did not correct the lock problem, replace the main control.

a. Unplug washer or disconnect power.

b. Replace the main control.

c. Reassemble all parts and panels.

d. Plug in washer or reconnect power. Perform Service Diagnostics to verify repair.

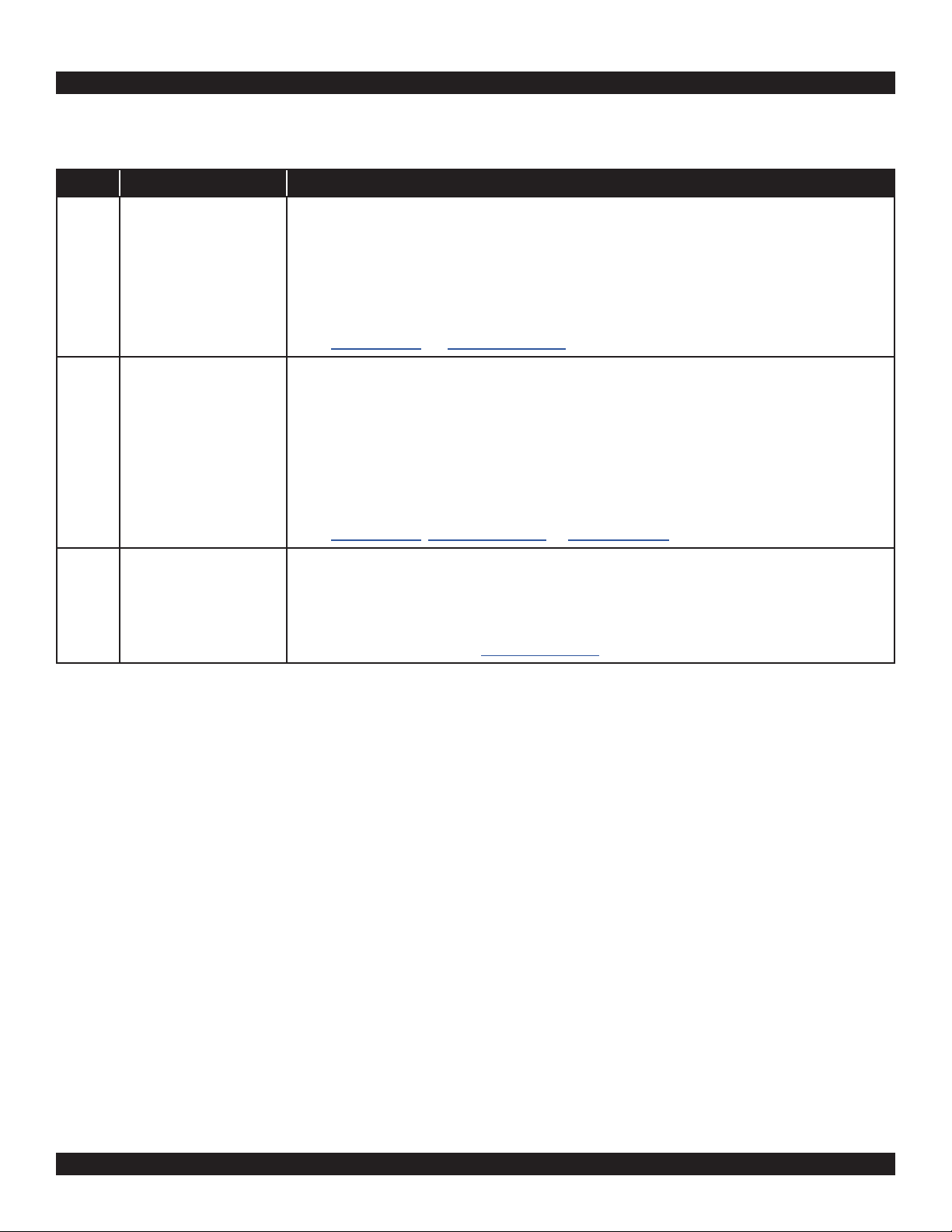

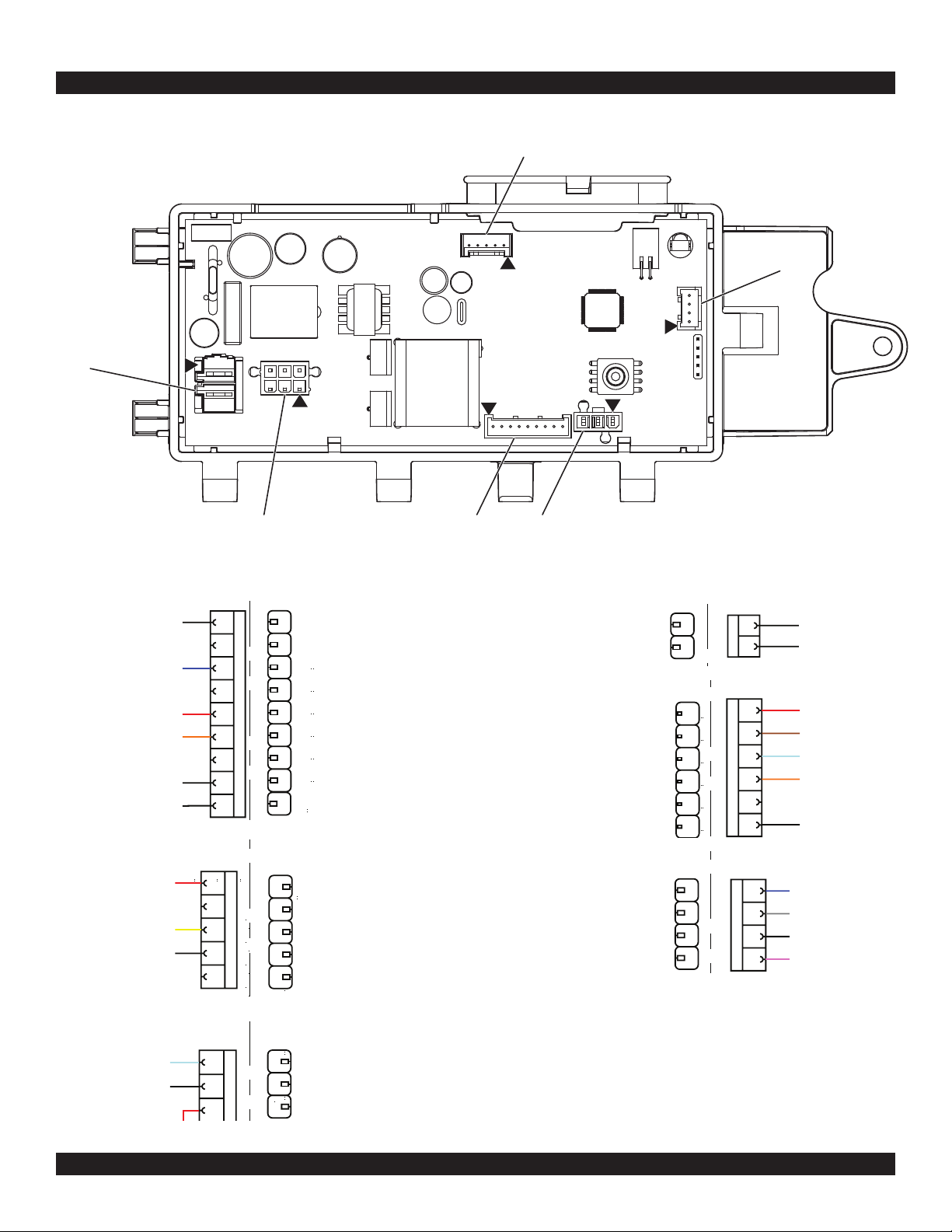

COMPONENT LOCATIONS

Cold water Valve

Hot water Valve

J5

J2

Figure 7 - Main Control (ACU)

PSC Motor Connector

J6

J8 J4J1

PSC Motor Connector

Drive Belt

Shaft Pulley

Run Capacitor

Shifter Assembly

Figure 8 - Bottom View - PSC

DO NOT REMOVE OR DESTROY28

FOR SERVICE TECHNICIAN’S USE ONLY

COMPONENT ACCESS

This section (page 28-41) provides service parts access, removal, and replacement instructions for the “Maytag® 4.8 cu. ft. Top Load Washer.”:

Ƀ

Removing the Console

Ƀ

Removing the User Interface (UI)

Ƀ

Removing the Water Inlet Valve

Ƀ

Removing the Main Control

Ƀ

Removing the Bulk Dispenser

Ƀ

Removing the Tub Ring, Impeller, and Basket

Ƀ

Removing the Lid Lock

Ƀ

Removing the Lid and Hinge

Ƀ

Removing the Shifter

Ƀ

Removing the Drain Pump

Ƀ

Removing the Drive Belt and Motor

Ƀ

Removing the Splutch

Ƀ

Removing the Gearcase

DO NOT REMOVE OR DESTROY

29

FOR SERVICE TECHNICIAN’S USE ONLY

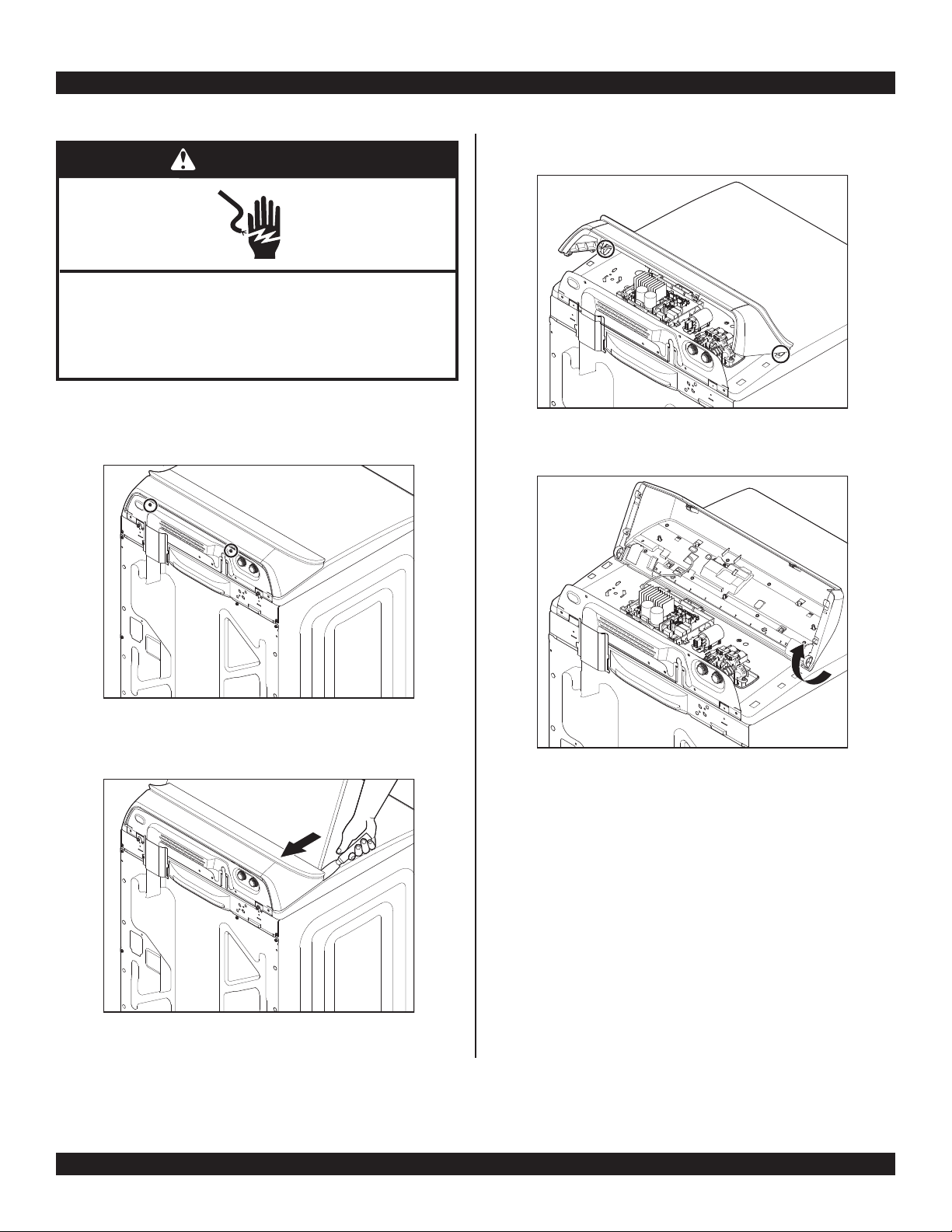

Removing the Console

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Unplug washer or disconnect power.

2. Turn off the water supply to the washer.