Maytag MVW18PDBGW, MVW18CSBGW, MVW18MNBGW Installation Instructions

INSTALLATION INSTRUCTIONS

CommerCial Washer

INSTRUCTIONS D’INSTALLATION

lave-linge CommerCial

INSTRUCCIONES DE INSTALACIÓN

lavadora ComerCial

ISTRUZIONI D’INSTALLAZIONE

lavatriCe CommerCiale

W10722893B

MVW18CS

MVW18MN

MVW18PD

www.maytagcommerciallaundry.com

TABLE OF CONTENTS

Page

Washer Safety .......................................................................... 3

Washer Disposal ...................................................................... 4

Tools & Parts ............................................................................ 5

Dimensions .............................................................................. 6

Location Requirements ...........................................................7

Drain System ............................................................................ 8

Electrical Requirements..........................................................8

Installation Instructions .......................................................... 9

Connect Drain Hose .............................................................. 10

Connect Inlet Hoses .............................................................. 11

Level Washer ..........................................................................12

Installing Coin Slide and Coin Box ....................................... 12

Complete Installation ............................................................ 13

Typical Full Load Sizes .......................................................... 13

Washer Maintenance.............................................................14

If You Need Assistance ......................................................... 15

Alternate Parts & Accessories ............................................. 15

Electronic Controls Set-up Instructions .............................. 16

Warranty ................................................................................. 20

TABLE DES MATIÈRES

Page

Sécurité du lave-linge ........................................................... 21

Élimination du lave-linge ...................................................... 22

Outillage et pièces ................................................................. 22

Dimensions ............................................................................ 23

Exigences d’emplacement ................................................... 24

Système de vidange .............................................................. 25

Spécications électriques .................................................... 26

Instructions d’installation ..................................................... 27

Raccordement du tuyau de vidange .................................... 28

Raccordement des tuyaux d’arrivée d’eau ......................... 29

Établissement de l’aplomb du lave-linge ............................ 30

Installation de la glissière et de la boîte à monnaie ........... 30

Achever l’installation ............................................................. 31

Taille typique des charges complètes ................................. 31

Entretien du lave-linge .......................................................... 32

Si vous avez besoin d’assistance ........................................ 33

Pièces supplémentaires et accessoires .............................. 33

Instructions de paramétrage des commandes

électroniques ......................................................................... 34

Garantie .................................................................................. 39

ÍNDICE

Página

Seguridad de la lavadora ...................................................... 40

Eliminación de la lavadora .................................................... 41

Herramientas y piezas .......................................................... 41

Dimensiones .......................................................................... 42

Requisitos de ubicación ....................................................... 43

Sistema de desagüe .............................................................. 44

Requisitos eléctricos ............................................................ 44

Instrucciones de instalación ................................................ 45

Conexión de la manguera de desagüe ................................ 46

Conexión de las mangueras de entrada ............................. 47

Nivelación de la lavadora ...................................................... 48

Instalación del tragamonedas y la caja de monedas ......... 48

Complete la instalación ....................................................... 49

Tamaños de cargas típicas de volumen completo ............. 49

Mantenimiento de la lavadora .............................................. 50

Si necesita asistencia ........................................................... 51

Piezas y accesorios alternativos ......................................... 51

Instrucciones para programar los controles

electrónicos ...........................................................................52

Garantía .................................................................................. 57

SOMMARIO

Pagina

Sicurezza della lavatrice ....................................................... 58

L’eliminazione della lavatrice ............................................... 59

Attrezzi e componenti ........................................................... 59

Dimensioni ............................................................................. 60

Requisiti di posizionamento ................................................. 61

Sistema di scarico ................................................................. 62

Requisiti elettrici .................................................................... 62

Istruzioni d’installazione ....................................................... 63

Connessione del tubo di scarico ......................................... 64

Collegare i tubi d’ingresso .................................................... 65

Livellamento della lavatrice .................................................. 66

Installazione dello scivolo monete e della gettoniera ........ 66

Completamento dell’installazione ....................................... 67

Dimensioni tipiche a carico completo ................................. 67

Manutenzione lavatrice ......................................................... 68

Se avete bisogno dell’assistenza ......................................... 69

Parti e accessori alternativi .................................................. 69

Istruzioni di congurazione dei comandi elettronici .......... 70

Garanzia ................................................................................. 75

2

WASHER SAFETY

3

WASHER DISPOSAL

This appliance is marked according to the European directive 2012/19/EU on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be

treated as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical

and electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city ofce,

your household waste disposal service or the shop where you purchased the product.

4

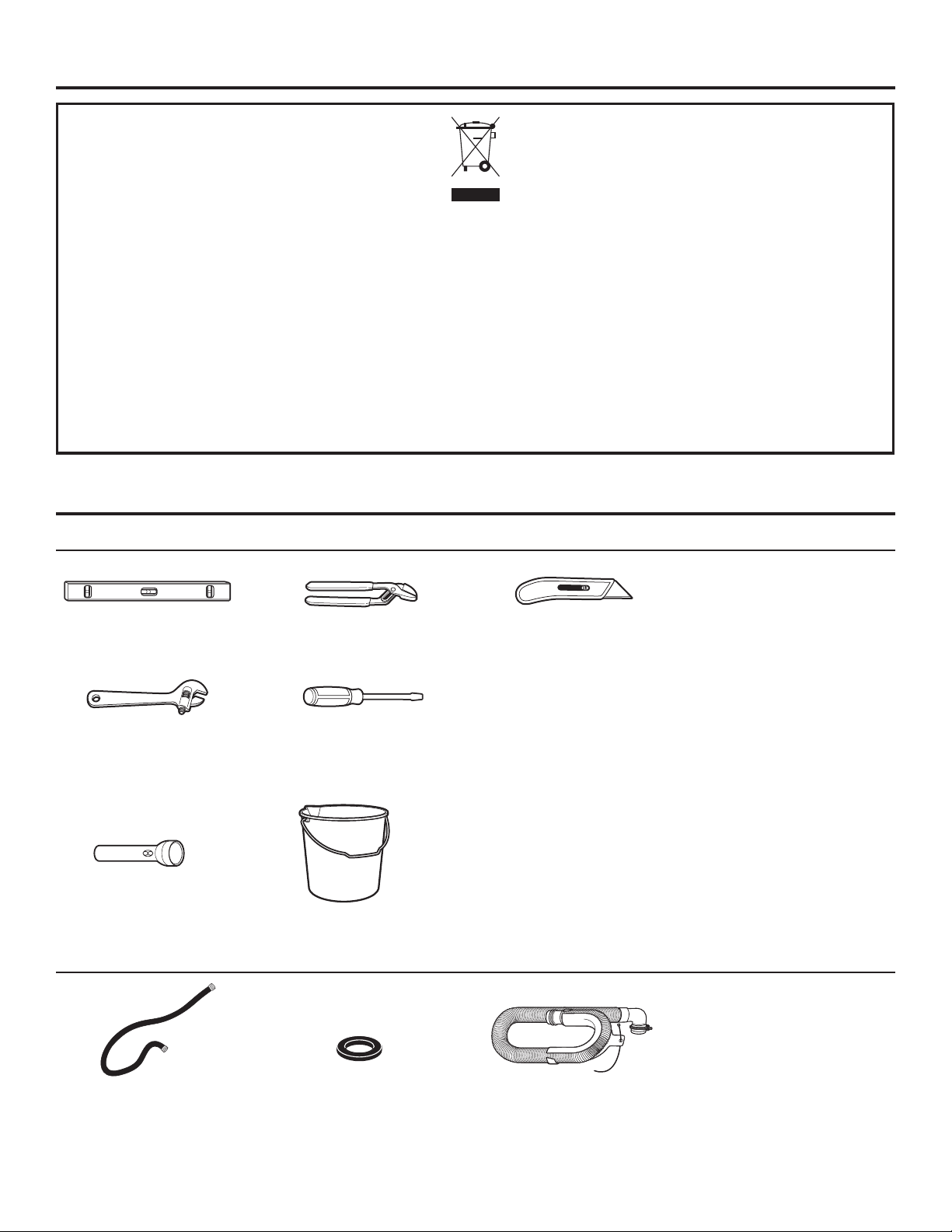

TOOLS & PARTS

Tools Needed:

Level Pliers

Adjustable Wrench Flat-Blade Screwdriver

Optional tools:

Flashlight Bucket

Parts Supplied:

Utility Knife

Water Inlet Hoses (2) Inlet Hose Washers (4)

Drain hose with clamp,

U-form, and cable tie

5

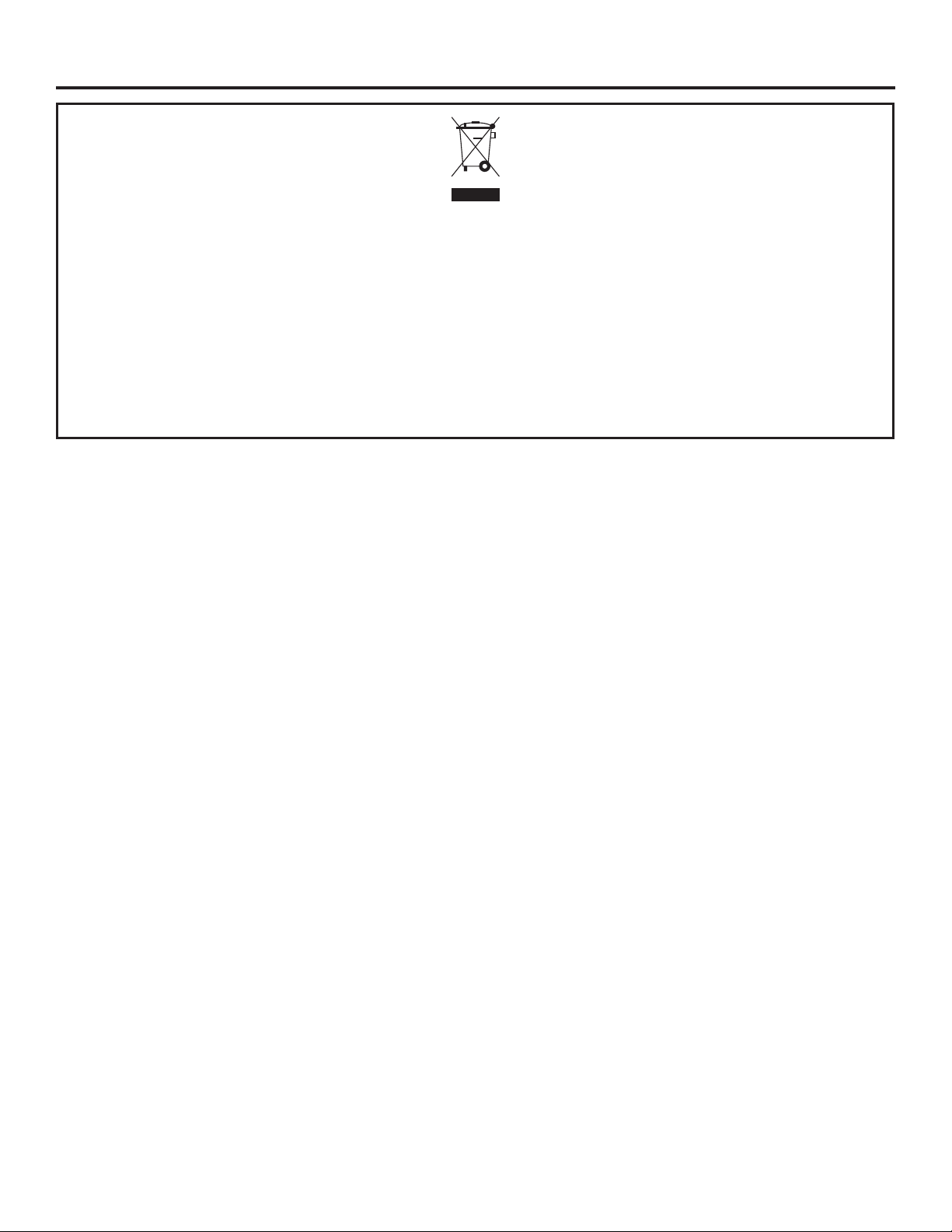

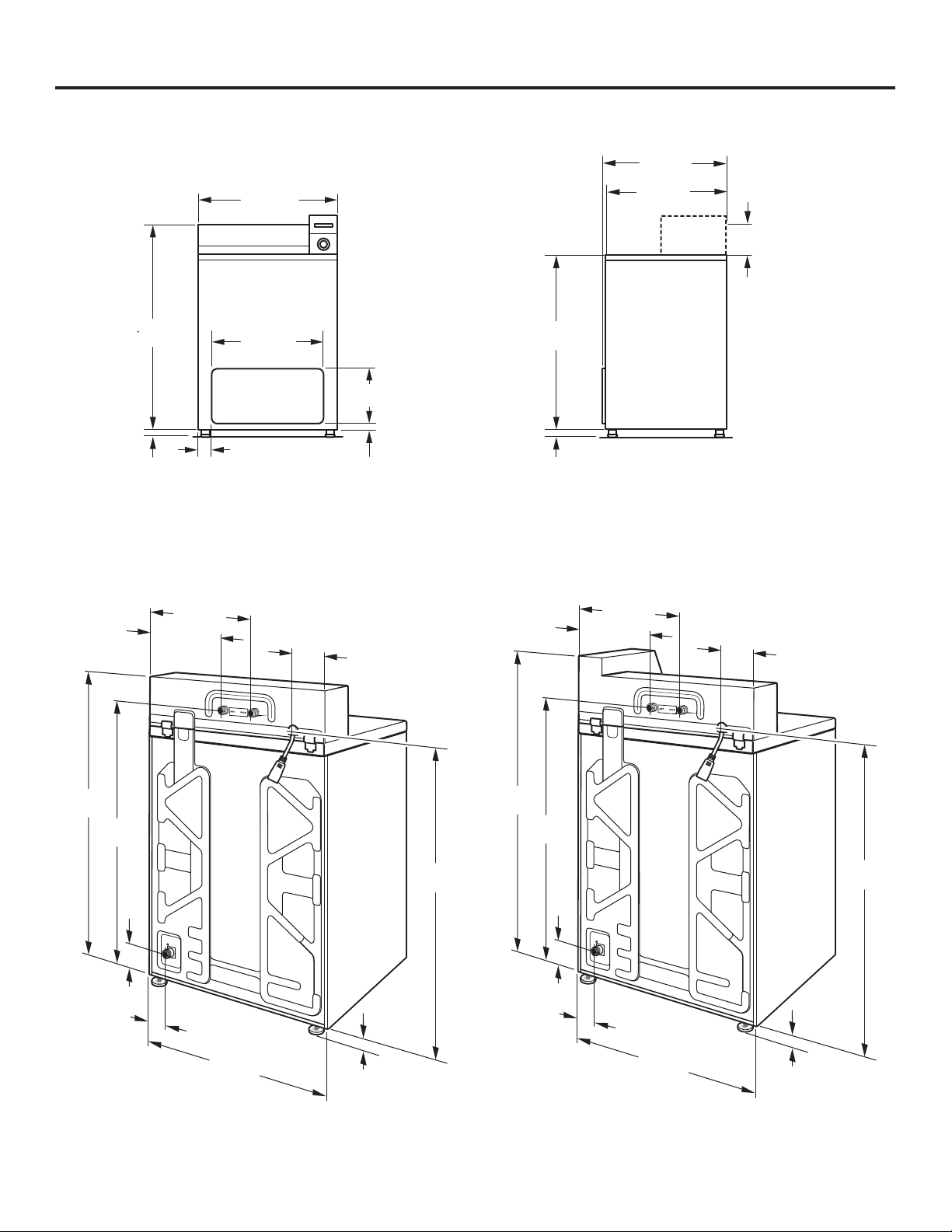

DIMENSIONS

Front View Side View

699 mm

686 mm

.

1,047 m

1

(41

/4")

25 mm

(1")

686 mm

(27")

546 mm

(21

67 mm

(25/8")

1

/2")

267 mm

1

(10

/2")

16 mm

5

(

/8")

889 mm

(35")

25 mm

(1")

(271/2")

(27")

Non-coin-operated

models:

159 mm

1

/4")

(6

Coin-operated

models:

210 mm

1

/4")

(8

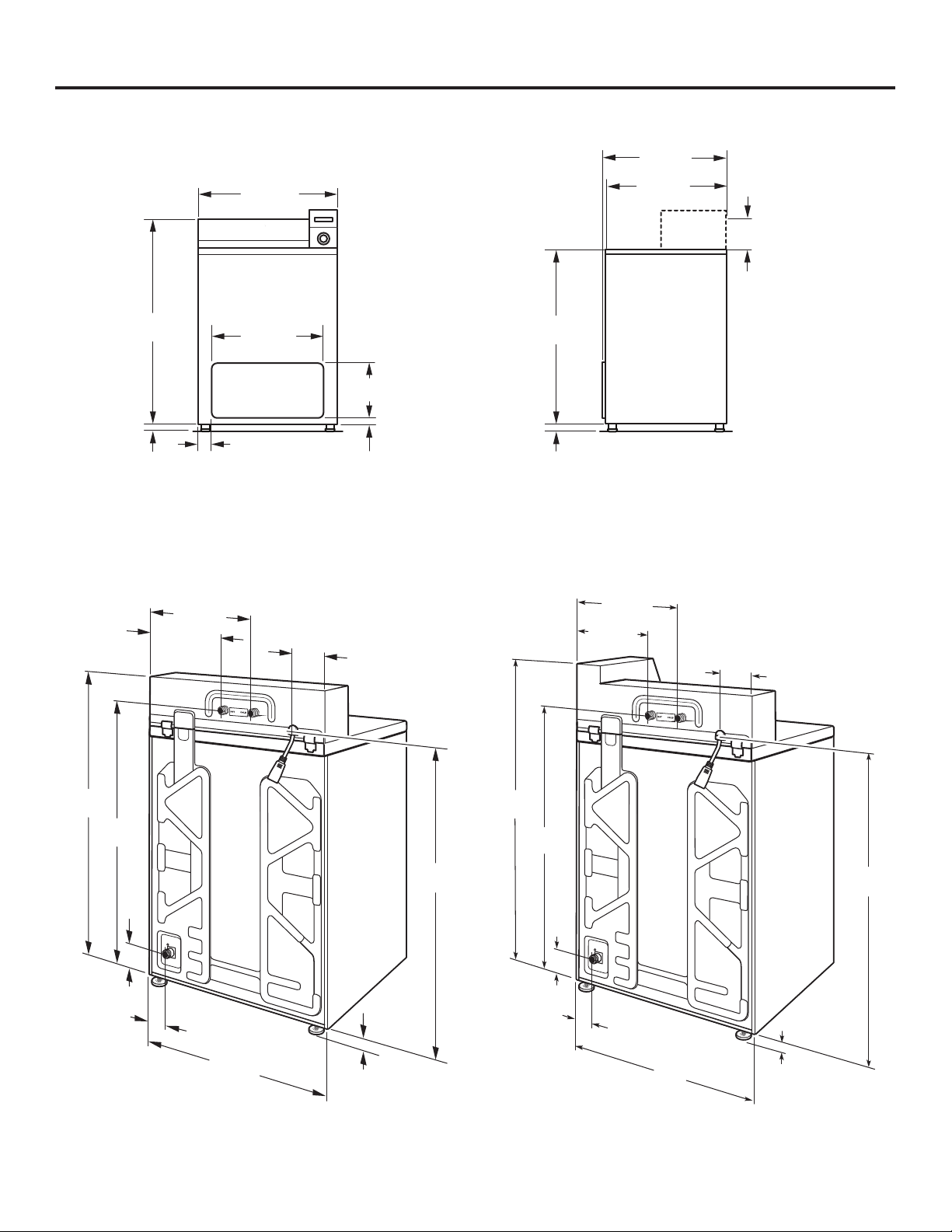

Back View

Non-coin-operated models Coin-operated models

406 mm

(16")

267 mm

(101/2")

108 mm

1

(4

/4")

267 mm

(10

1,047 m

.

(411/4")

914 mm

165 mm

(6

1

/2")

(36")

1

/2")

406 mm

(16")

108 mm

1

(4

/2")

686 mm

(27")

140 mm

(51/2")

25 mm

(1")

902 mm

1

/2")

(35

1,098 m

.

1

(43

/4")

914 mm

165 mm

1

(6

(36")

/2")

686 mm

(27")

140 mm

(51/2")

902 mm

(351/2")

25 mm

(1")

6

LOCATION REQUIREMENTS

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room, or

recessed area. See “Drain System.”

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer where it will be

exposed to the weather. Do not store or operate the washer in

temperatures at or below 0°C (32°F). Some water can remain in

the washer and can cause damage in low temperatures. Proper

installation is your responsibility.

You will need:

n A water heater set to 49°C (120°F).

n An earthed electrical outlet located within 1.2 m (4 ft.) of

power cord on back of washer. See “Electrical Requirements.”

n Hot and cold water faucets located within 1.2 m (4 ft.) of hot

and cold water ll valves on washer, and water pressure

of 138-690 kPa (20-100 psi). A pressure reduction valve

should be used in the supply line where inlet pressure

entering the building exceeds 690 kPa (100 psi) to avoid

damage to the washer mixing valve.

n Single washer installations require 300 mm (12") minimum

risers to provide an air cushion and avoid noise and damage

to valves.

n A level oor with maximum slope of 25 mm (1") under entire

washer. Installing on carpet is not recommended.

n

Floor must support washer’s total weight (with water and load)

of 143 kgs (315 lbs).

n A oor drain under the bulkhead. Prefabricated bulkheads

with electrical outlets, water inlet lines, and drain facilities

should be used only where local codes permit.

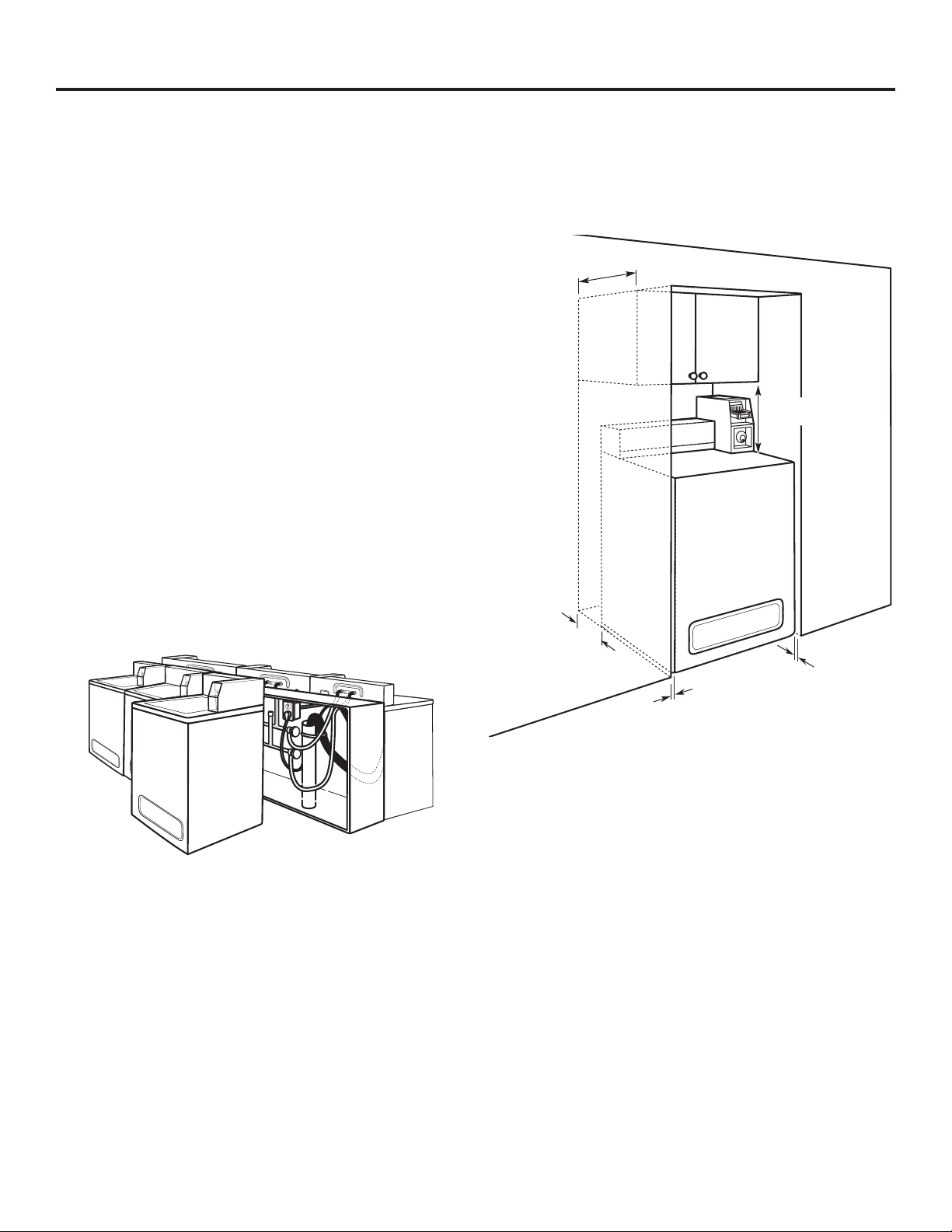

Recessed Area or Closet Installation

This washer may be installed in a recessed area or closet.

The installation dimensions shown are the minimum spaces

allowable. Additional spacing should be considered for ease of

installation and servicing. Companion appliance spacing should

be considered.

Minimum installation spacing

356 mm

(14" max.)

457 mm

457 mm

(18")

(18")

127 mm

(5")

25 mm

(1")

25 mm

(1")

7

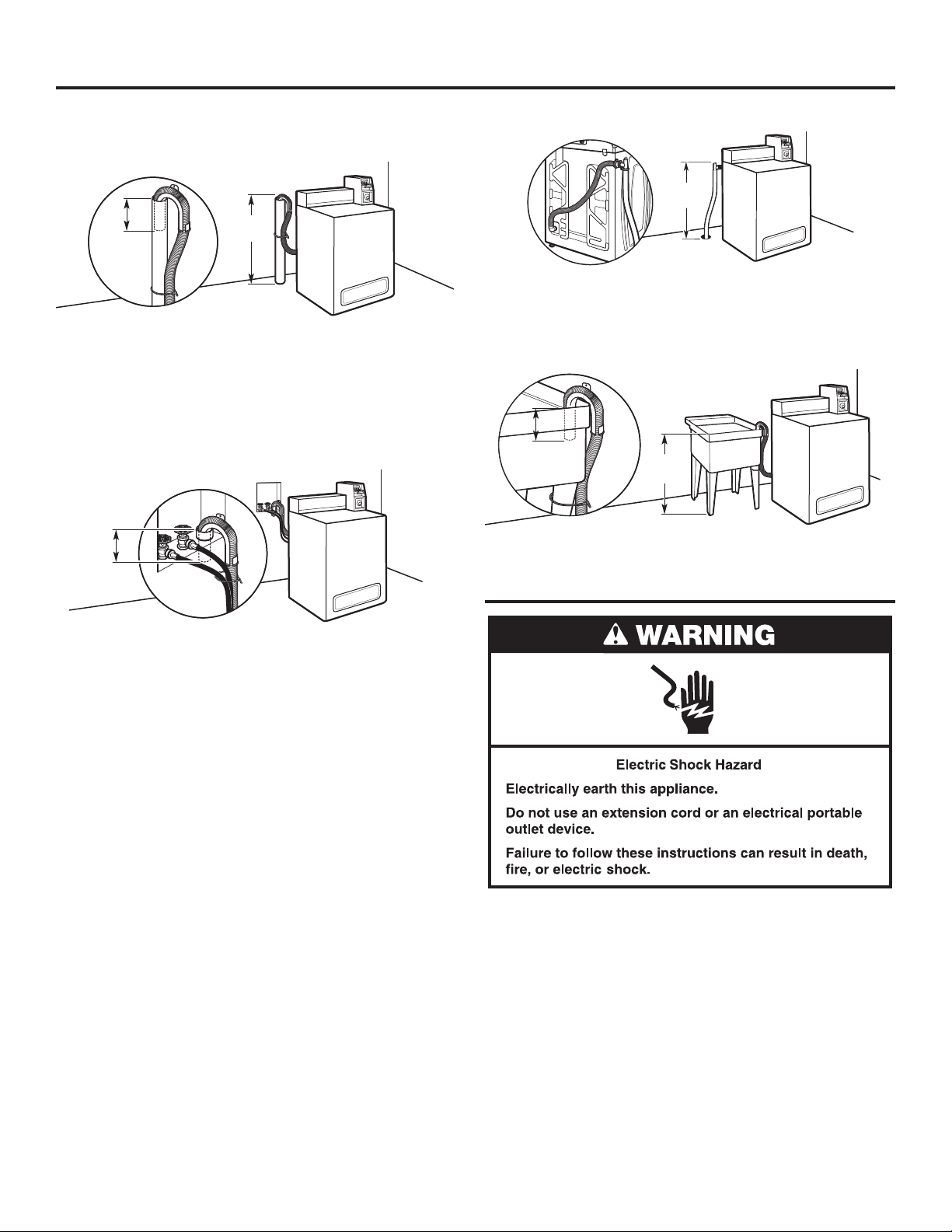

DRAIN SYSTEM

114 mm

(4,5")

Drain system can be installed using a oor drain, wall standpipe,

oor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

990 mm

114 mm

(4,5")

.

(39")

Minimum diameter for a standpipe drain: 51 mm (2"). Minimum

carry-away capacity: 38 L (10 gal.) per minute. Top of standpipe

must be at least 990 mm (39") high; install no higher than

2.44 m (96") from bottom of washer.

Wall standpipe drain system

Floor drain system

710 mm

(28")

Floor drain system requires a Siphon Break Kit (Part Number

285834). Minimum siphon break: 710 mm (28") from bottom

of washer. Additional hoses may be needed.

Laundry tub drain system

.

990 mm

(39")

114 mm

.

(4,5")

See requirements for oor standpipe drain system.

ELECTRICAL REQUIREMENTS

n

A 220-240 volt, 50 Hz., AC only, 10-amp, fused electric supply is

required. A time-delay fuse or circuit breaker is recommended. It

is recommended that a separate circuit serving only this appliance

be provided.

n

After installation, access to mains plug or disconnection from

mains supply via a double-pole switch, must be ensured at all

times in order to ensure immediate deactivation of the washer

in case of emergency.

n

This washer is equipped with a power supply cord having an

earthing plug. The plug should be accessible for disconnection

from the supply.

n

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or similarly qualied persons

in order to avoid a hazard.

8

EARTHING INSTRUCTIONS

This washer must be earthed. In the event of a malfunction

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance – if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

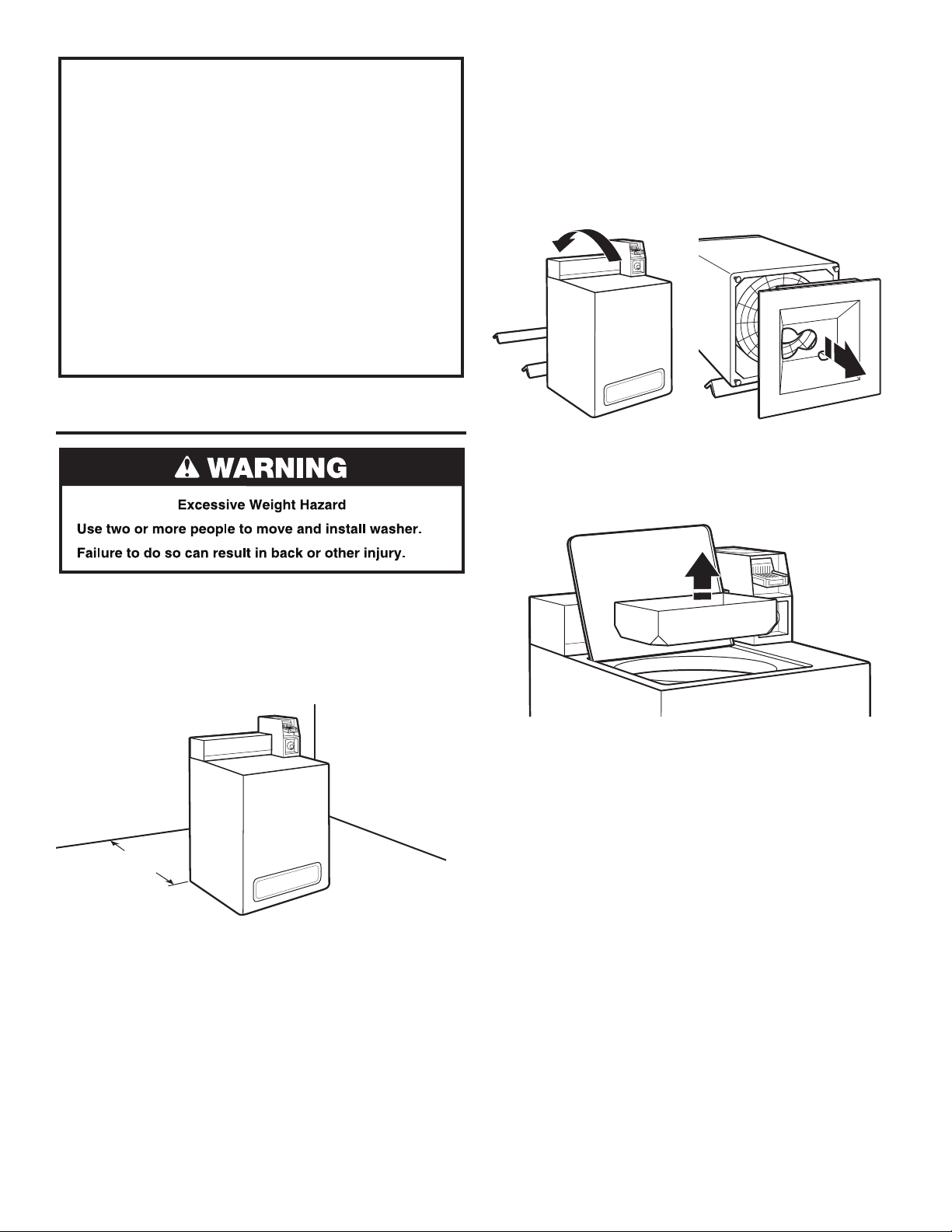

INSTALLATION INSTRUCTIONS

2. To avoid damaging oor, place cardboard supports from

shipping carton on oor behind washer. Tip washer back and

place on cardboard supports. Remove shipping base. Set

washer upright.

IMPORTANT: Removing shipping base is necessary for proper

operation. If your washer includes a sound shield, please refer

to the instructions included with the sound shield to install it

at this time.

NOTE: Keep shipping base in case you need to move washer

later.

3. Remove tape from washer lid, open lid, and remove cardboard

packing tray from tub. Be sure to remove all parts from tray.

NOTE: Tray must be removed prior to plugging the washer

into an outlet. Keep tray in case you need to move washer

later.

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

1. Move washer to within 1.2 m (4 ft) of its nal location; it must

be in a fully upright position.

NOTE: To avoid oor damage, set washer onto cardboard

before moving it and make sure lid is taped shut.

1,2 m

.

(48")

9

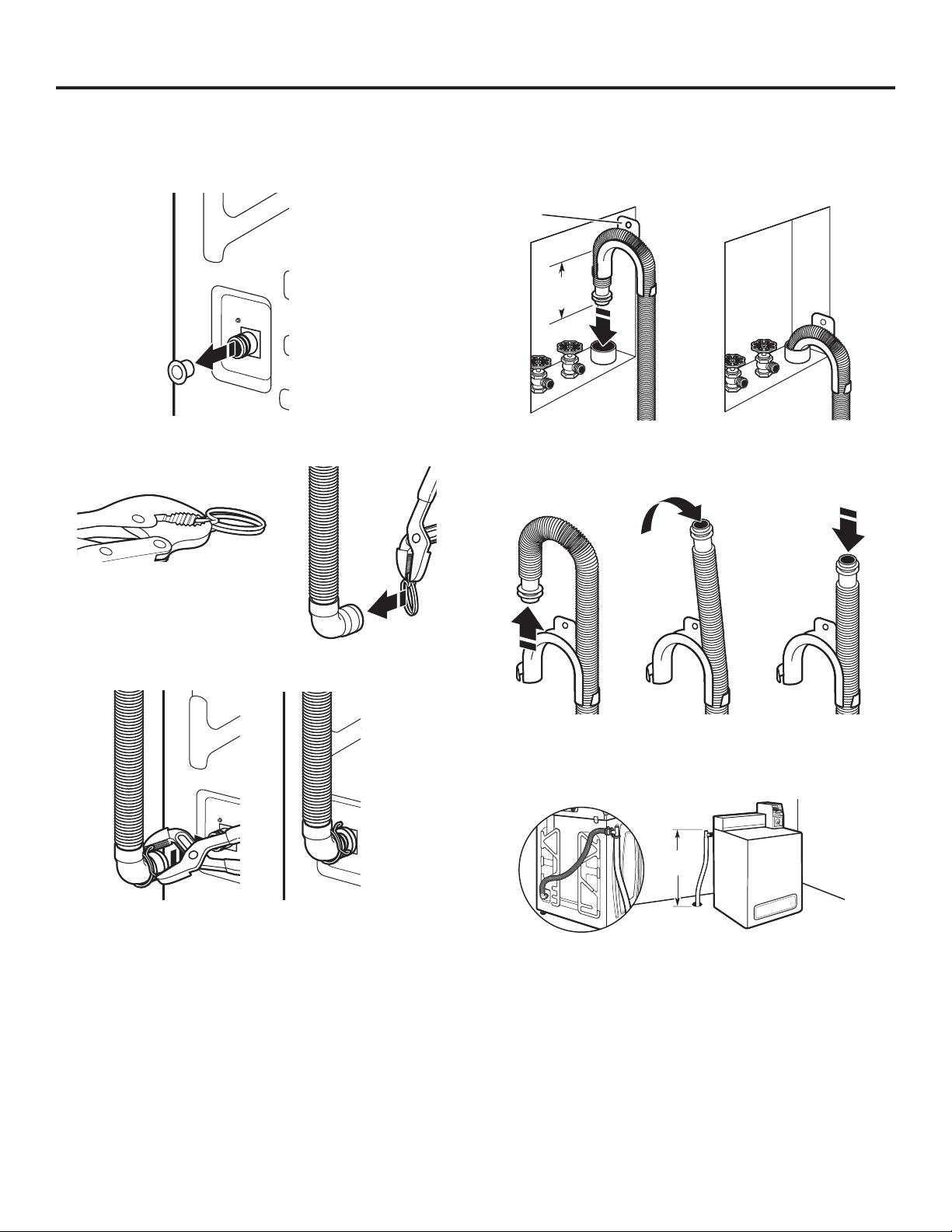

CONNECT DRAIN HOSE

Proper routing of the drain hose avoids damage to your oor

due to water leakage.

Remove drain hose from the washer drum

1. Remove tape from the washer drain port on the back of

the washer.

2. If clamp is not already in place on elbow end of drain hose,

slide it over end as shown.

5. Place hose into standpipe (shown in picture) or over side

of laundry tub.

IMPORTANT: 114 mm (4.5") of drain hose should be inside

standpipe; do not force excess hose into standpipe or lay

on bottom of laundry tub. Drain hose form must be used.

Drain

Drain

hose

hose form

form

114 mm

(4,5")

.

6. For oor drain installations, you will need to remove the drain

hose form from the end of the drain hose. You may need

additional parts with separate directions. See “Tools and Parts.”

3. Squeeze clamp with pliers and slide elbow end of drain

hose onto washer drain port and secure with clamp.

4. The washer drain system can be installed using a oor drain,

wall standpipe, oor standpipe, or laundry tub.

7. The oor drain system requires a siphon break that may be

purchased separately. The siphon break (Part Number 285834)

must be a minimum of 710 mm (28") from the bottom of the

washer. Additional hoses might be needed.

710 mm

(28")

10

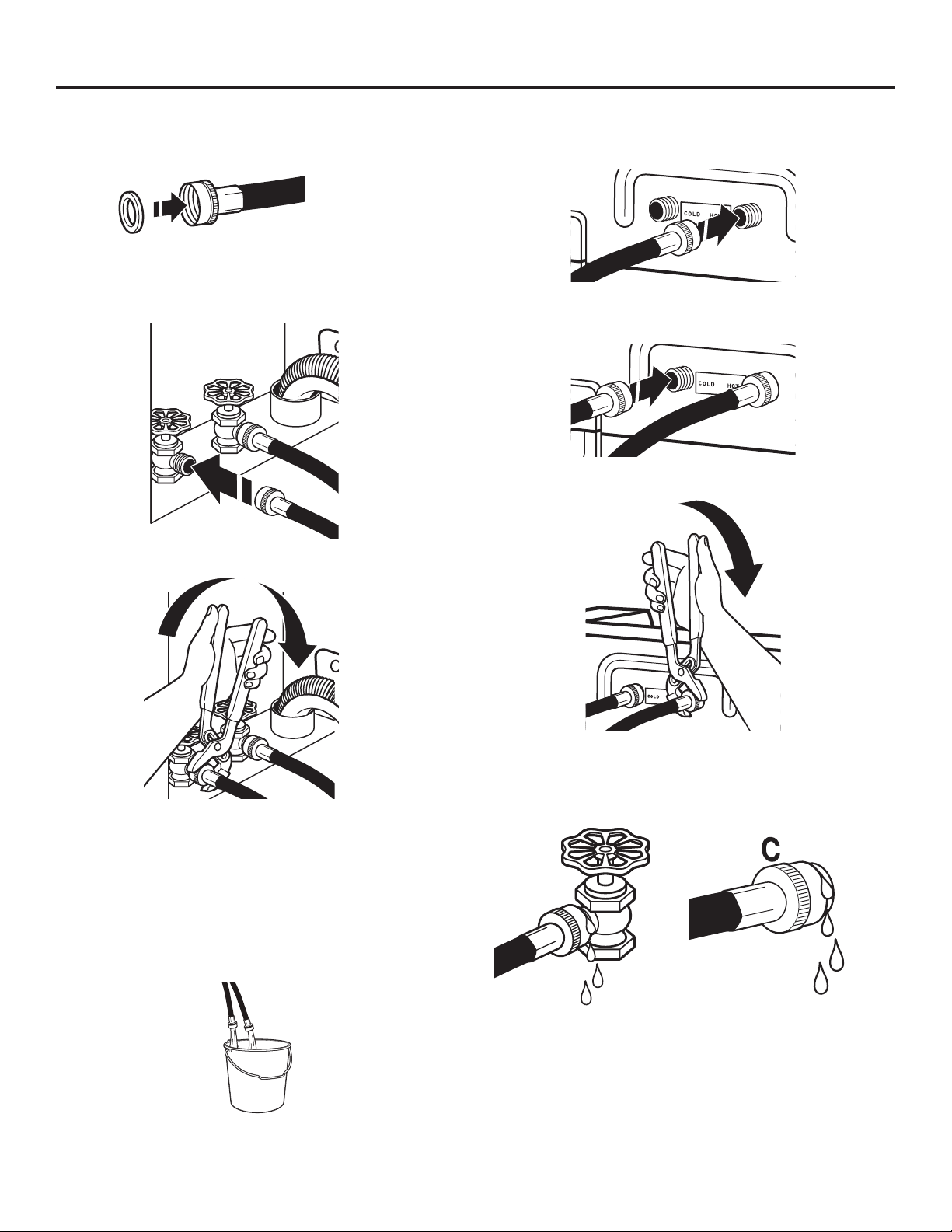

CONNECT INLET HOSES

Insert new hose washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

NOTE: Use new hoses supplied with the washer. Do not reuse

old hoses.

CouplingWasher

Connect Inlet Hoses to Water Faucets

1. Attach hose to hot water faucet. Screw on coupling until

it is seated on washer. Repeat process for cold water.

2.

Use pliers to tighten the couplings an additional two-thirds

turn.

Connect Inlet Hoses to Washer

1. Attach cold water hose to cold water inlet valve marked with

a blue ring. Screw coupling by hand until it is snug.

2.

Attach hot water hose to hot water inlet valve marked with

a red ring. Screw coupling by hand until it is snug.

3.

Use pliers to tighten couplings an additional two-thirds turn.

IMPORTANT: Do not overtighten or use tape or sealants on valve

when attaching to faucets or washer. Damage can result.

Clear Water Lines

n Run water through both faucets and inlet hoses, into a laundry

tub, drainpipe, or bucket, to get rid of particles in the water

lines that might clog the inlet valve screens.

n

Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and that the

cold water hose is connected to the cold water faucet.

NOTE: Do not overtighten. Damage to the valve can result.

4.

Turn on water faucets to check for leaks. A small amount

of water may enter washer. It will drain later.

NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

11

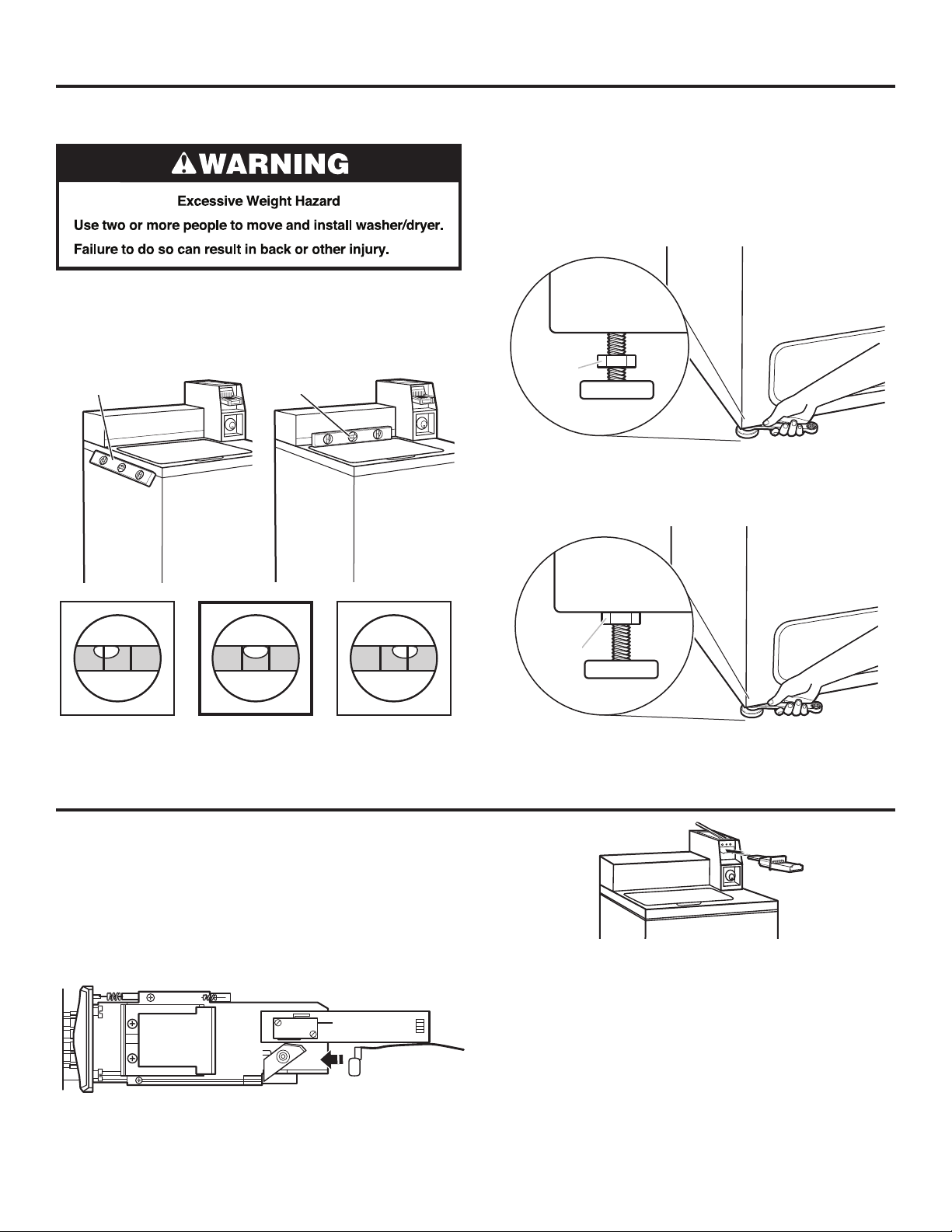

LEVEL WASHER

IMPORTANT: Level washer properly to reduce excess noise

and vibration.

1. Move the washer to its nal location. Place a level on top

edges of washer. Use side seam as a guide to check levelness

of sides. Check levelness of front using lid, as shown. Rock

washer back and forth to make sure all four feet make solid

contact with oor.

Place level here

Place level here

Place level here

Place level here

Use a 9/16" or 14 mm open-end or adjustable wrench to turn

2.

jam nuts clockwise on feet until they are about 13 mm (1/2")

from the washer cabinet. Then turn the leveling foot clockwise

to lower the washer or counterclockwise to raise the washer.

Recheck levelness of washer and repeat as needed.

HELPFUL TIP: You may want to prop up front of washer about

102 mm (4") with a wood block or similar object that will support

weight of washer.

Jam nut

Jam nut

3. When washer is level, use a 9/16" or 14 mm open-end or

adjustable wrench to turn jam nuts counterclockwise on

leveling feet tightly against washer cabinet.

Not Level LEVEL Not Level

INSTALLING COIN SLIDE AND COIN BOX

The coin slide mechanism, service door lock and key, and coin

box lock and key are not included with some models, but can

be obtained from the usual industry sources.

Remove the service door of the meter case by lifting it up

at the back. Install the money-accepting device. (Refer to

manufacturer’s instructions for proper installation.)

An earthing connection is needed for the coin slide, which can

be made by connecting the available harness to the coin slide.

Install a lock and cam on the meter case service door. Install the

coin vault with lock and key in the meter case opening.

For Free Vend, an OPL kit can be purchased from Whirlpool.

Whirlpool part number W10222023, Greenwald part number

Earthing

connection

3001-003.

Jam nut

Jam nut

12

COMPLETE INSTALLATION

Check electrical requirements. Be sure that you have

q

the correct electrical supply and the recommended

earthing method.

Check that all parts are now installed. If there is an extra part,

q

go back through steps to see what was skipped.

Check that you have all of your tools.

q

Check that shipping materials were completely removed

q

from washer.

Dispose of/recycle all packaging materials.

q

Check that the water faucets are on.

q

Check for leaks around faucets and inlet hoses.

q

Remove lm from console and any tape remaining on

q

washer.

Plug into an earthed outlet or connect power.

q

Check that circuit breaker is not tripped or fuse is not blown.

q

Start washer using the payment system (if available) to

q

check that the wash cycle completes without an error code

or water leak.

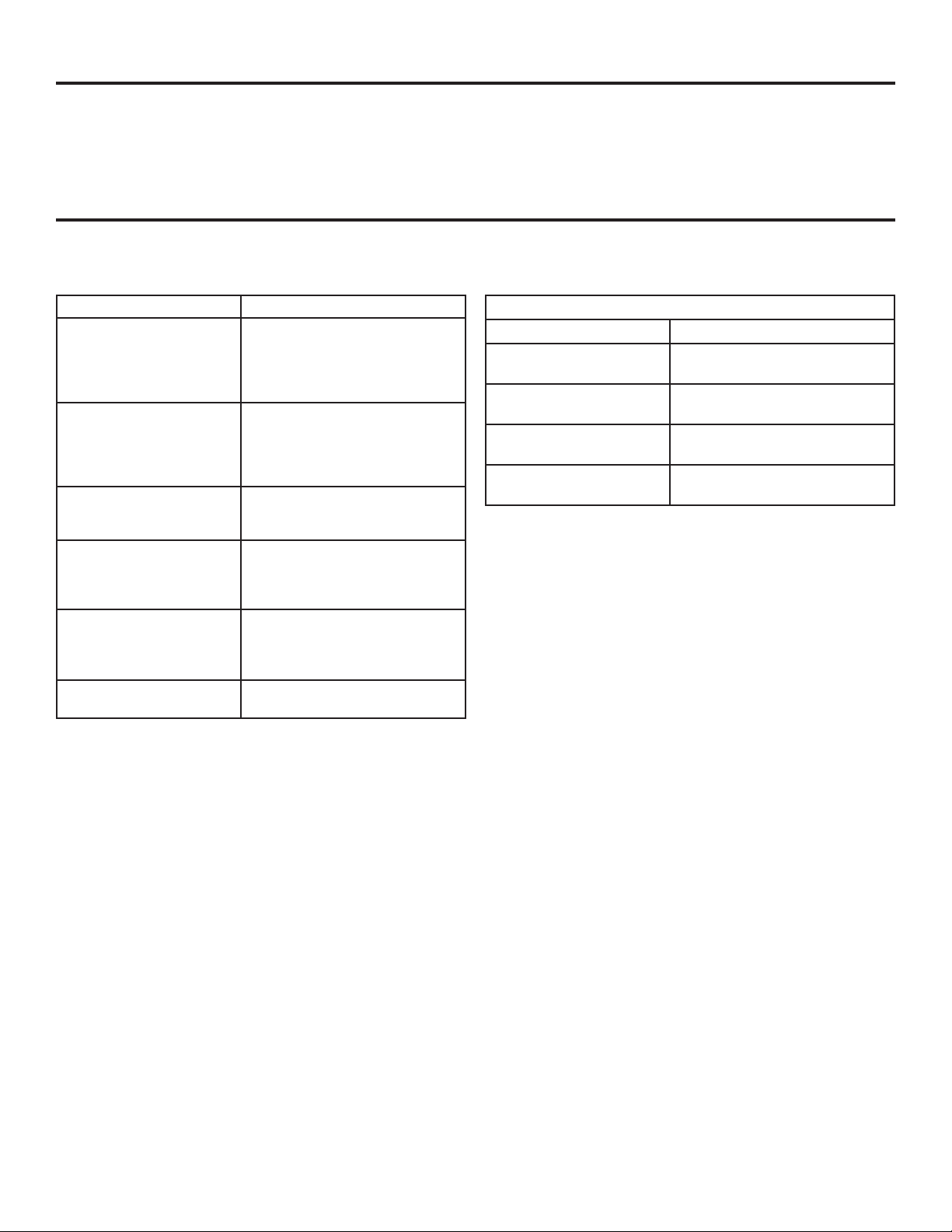

TYPICAL FULL LOAD SIZES

Load Type Loading Suggestion Load Type Loading Suggestion

Mixed Load 3 double sheets

4 pillowcases

6 pair shorts

8 T-shirts

2 shirts

2 blouses

8 handkerchiefs

Permanent Press 2 double or

1 king size sheet

1 tablecloth

1 dress

1 blouse

2 slacks

3 shirts

2 pillowcases

Heavy Work Clothes 3 pair pants

3 shirts

1 coverall

4 pair jeans

1 overall

Knits 3 blouses

4 slacks

6 shirts

4 tops

4 dresses

13

WASHER MAINTENANCE

Operating Tips

It is recommended that berglass items not be washed in coinoperated washers. If these items are washed in the washer, run

the washer through a complete cycle to rinse any residue away

that might be left in the washer.

IMPORTANT: Load detergent, bleach, and fabric softener

before adding clothes and do all of this before starting the

washer as the lid will lock after starting the washer.

Transporting Your Washer

• Shut off both water faucets. Disconnect and drain water

inlet hoses.

• Disconnect drain from drain system and drain any remaining

water into a pan or bucket. Disconnect drain hose from back

of washer.

• Unplug power cord.

• Place inlet hoses and drain hose inside washer basket.

• Drape power cord over edge and into washer basket.

• Place packing tray from original shipping materials back inside

washer and reuse shipping base to support the motor and tub.

If you do not have original packaging, place heavy blankets

or towels above basket, between the washer top and the tub

ring. Close lid and place tape over lip and down the front of the

washer. Keep lid taped until washer is moved to new location.

14

IF YOU NEED ASSISTANCE

Your installation may require additional parts. To order, please contact your authorized Commercial Laundry distributor

from whom you purchased your washer or an authorized service company.

You will need the washer model number and serial number. Both numbers can be found on the serial-rating plate located

on the washer.

ALTERNATE PARTS & ACCESSORIES

Your installation may require additional parts. To order, please

contact the dealer from whom you purchased your washer or

an authorized service company.

If You Have: You Will Need:

Overhead sewer Standard 76 L (20 gal.) 990 mm

(39") tall drain tub or utility sink,

sump pump and connectors

(available from local plumbing

suppliers)

25 mm (1") standpipe 51 mm (2") diameter to

25 mm (1") diameter Standpipe

Adapter Part Number 3363920

Connector Kit Part Number

285835

Lint clogged drain Drain Protector Part Number

367031 Connector Kit Part

Number 285835

Floor drain system Siphon break, Part Number

285834 Connector Kit (x2) Part

Number 285835 Extension Drain

Hose Part Number 285863

Water faucets beyond

reach of ll hoses

2 longer water ll hoses:

1,8 m (6 ft.) 90° bend hose

Part Number 76314, 3,0 m (10 ft.)

Part Number 350008

Inlet hoses are sold as a pair

in kit W10575888

Accessories

If You Have: You Will Need:

Washer Drip Trays

Part Number 8212526

Cap/Cover-Bleach Dispenser

Part Number W10515386A

Fabric Softener Dispenser Kit

Part Number W10461164A

Main Top Rear Support

W10576550 (2 per kit)

15

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

Basic Operation of Commercial Washer

n For additional information, see

www.MaytagCommercialLaundry.com

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is nished, but

failure may occur at a later date due to ESD stress.

n Use an anti-static wrist strap. Connect wrist strap to green

ground connection point or unpainted metal in the washer.

-OR-

Touch your nger repeatedly to a green earth connection point

or unpainted metal in the washer.

n Before removing the part from its package, touch the

anti-static bag to a green earth connection point or

unpainted metal in the washer.

n Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

n When repackaging failed electronic control assembly in

anti-static bag, observe above instructions.

Warm Start (after power failure)

After a delay of up to 8 seconds, the washer is restored to the

portion of the cycle that existed at time of the power failure. To

continue the cycle, press START.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, ‘SELECT CYCLE’ will appear and cycle price will show

0.00.

Display

After the washer has been installed and plugged in, the display

will show ‘SYnC’ for a few seconds, then ‘0 MINUTES’. Once

the washer has been plugged in and the washer lid opened and

closed, the display will show the price. In washers set for free

cycles, the display will ash ‘SELECT CYCLE’, and will display

‘PRICE 0.00’.

GENERAL USER INFORMATION

Blank Display

This condition indicates the washer is inoperative.

‘0 Minutes’ showing in display

This condition indicates the washer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch fails, it must be

replaced before normal operation can be restored.

Cold Start (initial first use)

Washer is programmed at the factory as follows:

n POWER WASH = 19 min agitation

NORMAL = 9 min agitation

DELICATES = 7 min agitation

n NORMAL = 1 rinse and 2 minutes of rinse agitation

POWER WASH = 4 spray rinses with spin-outs

DELICATES = 3 spray rinses with spin-outs

n NORMAL = $1.50

DELICATES = $1.00

POWER WASH = $2.00

16

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

The three key pads on the left side, the top key pad on the right

side, and the digital display are used to set up the controls. The

display can contain 4 numbers and/or letters and a decimal point.

These are used to indicate the set-up codes and related code

values available for use in programming the washer.

How to use the key pads to program the controls

1. The LEFT UPPER (POWER WASH) key pad is used to adjust

the values associated with set-up codes. Pressing the key

pad will increment the value.

Rapid adjustment is possible by holding the key pad down.

2. The LEFT MIDDLE (NORMAL) key pad will advance you

through the set-up codes. Pressing the key pad will advance

you to the next available set-up code. Holding the key pad

down will automatically advance through the set-up codes at

a rate of one (1) per second.

3. The LEFT LOWER (DELICATES) key pad is used to select or

deselect options.

4. The RIGHT UPPER (TEMPERATURE) key pad is used to

decrease set-up code value.

Start Operating Set-Up

n PD Models: Insert access door key, turn, and lift to remove

access door.

IMPORTANT: The console must not be opened unless power is

rst removed from the washer. To access connector AA1:

g Unplug washer or disconnect power.

g Open console, disconnect plug on AA1, close console.

g Plug in washer or reconnect power.

The washer is now in the set-up mode.

Before proceeding, it is worth noting that, despite all of the

options available, an owner can simply choose to uncrate a new

commercial washer, hook it up, plug it in, and have a unit that

operates.

Set-up Codes

n The LEFT MIDDLE (NORMAL) key pad will advance from code

to code.

n The LEFT UPPER (POWER WASH) key pad will increase the

code value.

n The LEFT LOWER (DELICATES) key pad will select or

deselect options.

n The RIGHT UPPER (TEMPERATURE) key pad will decrease

the code value.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two

or three right-hand characters.

CODE EXPLANATION

6.06

NORMAL

6.04

DELICATES

6.08

POWERWASH

g Press the LEFT MIDDLE key pad once to advance to next code.

7.00 ADDITIONAL WASH TIME

7.00 This is the number of minutes that can be added to a Wash Cycle.

g Press the LEFT MIDDLE key pad once to advance to next code.

8.00 ADDITIONAL RINSE TIME

8.00 This is the number of minutes that can be added to a RINSE

g Press the LEFT MIDDLE key pad once to advance to next code.

9.00 CYCLE COUNTER OPTION

9.00 Not Selected ‘OFF’.

9.0C Selected ‘ON’ and not able to be deselected.

g Press the LEFT MIDDLE key pad once to advance to next code.

1.00 MONEY COUNTER OPTION

1.00 Not Selected ‘OFF’.

1.0C Selected ‘ON’.

1.C0 Selected ‘ON’ and not able to be deselected.

g Press the LEFT MIDDLE key pad once to advance to next code.

2.00 SPECIAL PRICING OPTION

2.00 Not Selected ‘OFF’.

2.SP Selected ‘ON’. Press the LEFT LOWER key pad once for this

If SPECIAL PRICING OPTION is selected, there is access to codes ‘3.’

through ‘9.’.

NOTE: An external battery needs to be added to keep the clock running during

periods of power outages.

g Press the LEFT MIDDLE key pad once to advance to next code.

NORMAL Regular Cycle Vend Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 6 coins = $1.50.

DELICATES Regular Cycle Vend Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 4 coins = $1.00.

POWERWASH Regular Cycle Vend Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 8 coins = $2.00.

Choose from 00-05 minutes by pressing the LEFT UPPER key

pad.

Cycle. Choose from 00-05 minutes by pressing the LEFT UPPER

key pad.

NOTE: Additional rinse time only available in defaulted bath

rinses, not in spray rinse option.

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Press the LEFT LOWER key pad 3 consecutive times to select

‘ON’. Once selected ‘ON’ it cannot be deselected.

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Press the LEFT LOWER key pad 3 consecutive times to select

‘ON’ and 3 consecutive times to remove (Not Selected ‘OFF’.)

Counter resets by going from ‘OFF’ to ‘ON’.

To select ‘ON’ and not able to be deselected, rst select ‘ON’,

then within two seconds press the LEFT LOWER key pad twice,

the LEFT UPPER key pad once, and exit the set-up mode.

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

selection.

17

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

CODE EXPLANATION

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3.06

NORMAL

3.04

DELICATES

3.08

POWERWASH

g Press the LEFT MIDDLE key pad once to advance to next code.

5.00 TIME-OF-DAY CLOCK, MINUTES

5.00 This is the TIME-OF-DAY CLOCK, minute setting; select between

g Press the LEFT MIDDLE key pad once to advance to next code.

6.00 TIME-OF-DAY CLOCK, HOURS

6.00 This is the TIME-OF-DAY CLOCK, hour setting; select between

g Press the LEFT MIDDLE key pad once to advance to next code.

7.00 SPECIAL PRICE START HOUR

7.00 This is the start hour; select between 0 and 23 hours by pressing

g Press the LEFT MIDDLE key pad once to advance to next code.

8.00 SPECIAL PRICE STOP HOUR

8.00 This is the stop hour; select between 0 and 23 hours by pressing

g Press the LEFT MIDDLE key pad once to advance to next code.

9.00 SPECIAL PRICE DAY

9.10 This represents the day of the week and whether special pricing

g Press the LEFT MIDDLE key pad once to advance to next code.

NORMAL Special Cycle Vend Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 6 coins = $1.50.

DELICATES Special Cycle Vend Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 4 coins = $1.00.

POWERWASH Special Cycle Vend Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 8 coins = $2.00.

0 and 59 minutes by pressing the LEFT UPPER or RIGHT UPPER

key pad.

NOTE: Uses military time or 24 hr. clock.

0 and 23 hours by pressing the LEFT UPPER or RIGHT UPPER

key pad.

NOTE: Uses military time or 24 hr. clock.

the LEFT UPPER or RIGHT UPPER key pad.

NOTE: Uses military time or 24 hr. clock.

the LEFT UPPER or RIGHT UPPER key pad.

is selected for that day. A number followed by ‘0’ indicates no

selection that particular day (9.10). A number followed by an ‘S’

indicates selected for that day (9.1S).

Days of the week (1-7) can be chosen by pressing the LEFT

UPPER key pad. Press the LEFT UPPER key pad once to select

special pricing for each day chosen.

When exiting set-up code ‘9’, the display must show current day

of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

CODE EXPLANATION

A.00 VAULT VIEWING OPTION

A.00 Not Selected ‘OFF’.

A.SC Selected ‘ON’. Press the LEFT LOWER key pad once for this

g Press the LEFT MIDDLE key pad once to advance to next code.

b.05 VALUE OF COIN 1

b.05 This represents the value of coin 1 in number of 5% increments of

g Press the LEFT MIDDLE key pad once to advance to next code.

C.20 VALUE OF COIN 2

C.20 This represents the value of coin 2 in number of 5% increments of

g Press the LEFT MIDDLE key pad once to advance to next code.

d.00 COIN SLIDE OPTION

d.00 Not Selected ‘OFF’.

d.CS Selected ‘ON’. Press the LEFT LOWER key pad 3 consecutive

g Press the LEFT MIDDLE key pad once to advance to next code.

E.00 ADD COINS OPTION

E.00 Not Selected ‘OFF’.

E.AC Selected ‘ON’. Press the LEFT LOWER key pad 3 consecutive

g Press the LEFT MIDDLE key pad once to advance to next code.

H.00

COOL

H.00

WARM

H.00

HOT

H.00

HEAVY

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

selection. When selected, the money and/or cycle counts will be

viewable (depending on what is selected) when the coin box is

removed.

the larger coin value. 5 x 5% = 25%.

By pressing the LEFT UPPER or RIGHT UPPER key pad, there

is the option of between 1 and 199 for the quantity of 5%

increments.

the larger coin value. 2 x 5% = 100%.

By pressing the LEFT UPPER or RIGHT UPPER key pad, there

is the option of between 1 and 199 for the quantity of 5%

increments.

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

times for this selection.

When coin slide mode is selected, set ‘b.’ equal to value of slide

in 5% increments. Set step 6 (regular cycle price) and step 3

(special cycle price) to number of slide operations. If the installer

sets up ‘CS’ on a coin drop model, it will not register coins.

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

This option causes the customer display to show the number of

coins (coin 1) to enter, rather than the monetary amount.

times for this selection.

COOL Temperature Upgrade Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 1 coins = $0.25.

WARM Temperature Upgrade Price between

0 and 200 by pressing the LEFT UPPER or RIGHT

UPPER key pad. Factory preset for 2 coins = $0.50.

HOT Temperature Upgrade Price - Increase or decrease between

0 and 200 by pressing the LEFT UPPER or RIGHT UPPER key

pad. Factory preset for 3 coins = $0.75.

HEAVY SOIL LEVEL Upgrade Price - Increase or decrease

between 0 and 200 by pressing the LEFT UPPER or RIGHT UPPER

key pad. Factory preset for 1 coins = $0.25.

Increase or decrease

18

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

CODE EXPLANATION

H.00

EXTRA

RINSE

EXTRA RINSE Upgrade Price - Increase or decrease between 0

and 200 by pressing the LEFT UPPER or RIGHT UPPER key pad.

Factory preset for 1 coins = $0.25.

If cycle counter (9.0C) is selected, the following is true:

1 xx Number of cycles in THOUSANDS. 1 02 = 2,000

2xxx Number of cycles in ONES. 2225 = 225

TOTAL CYCLES = 2,225

g Press the LEFT MIDDLE key pad once to advance to next code.

J.Cd COIN/DEBIT OPTION

J.Cd Both coin & debit selected.

J.C_ Coins selected, debit disabled. Press the LEFT LOWER key pad

3 times for this selection.

J._d Debit Card selected, coins disabled. Press the LEFT LOWER key

pad 3 times for this selection.

J.Ed Enhanced Debit is self-selected when a Generation 2 card reader

is installed in the washer. The Ed option cannot be manually

selected or deselected.

g Press the LEFT MIDDLE key pad once to advance to next code.

L.00 PRICE SUPPRESSION OPTION

This option causes the customer display to show ‘ADD’ or

‘AVAILABLE’ rather than the amount of money to add. (Used

mainly in debit installations.)

L.00 Not Selected ‘OFF’.

L.PS Selected ‘ON’. Press the LEFT LOWER key pad once for this

selection.

g Press the LEFT MIDDLE key pad once to advance to next code.

n. CE CLEAR ESCROW OPTION

When selected, money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

n. CE Selected ‘ON’.

n. 00 Not selected ‘OFF’. Press the LEFT LOWER key pad once to

deselect this selection.

g Press the LEFT MIDDLE key pad once to advance to next code.

If money counter (1.0C or 1.C0) is selected, the following is

true:

3 xx Number in THOUSANDS. 3 01 = $1,000.00

4xxx Number in ONES. 4600 = $ 600.00

5 xx Number of HUNDRETHS. 5 75 = $ 00.75

TOTAL = $1,600.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

n PD Models: Reinstall access door.

If preferred, just wait through 2 minutes of inactivity. All settings

will be saved and the display will revert to Select Cycle screen.

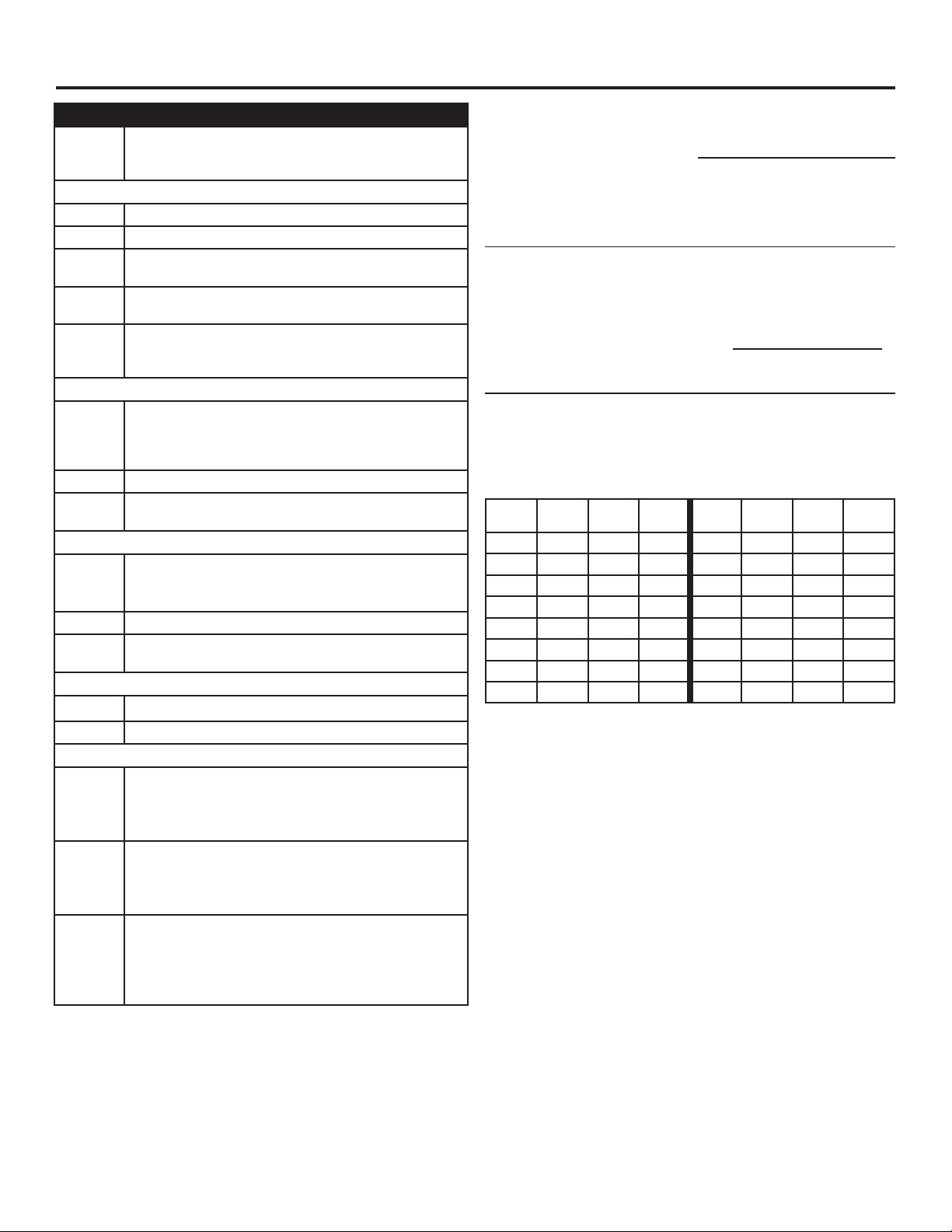

Table 1

A3, A4,

or A5

00 Off Off Cold 08 On Off Cold

01 Off Off Cool 09 On Off Cool

02 Off Off Warm 0A On Off Warm

03 Off Off Hot 0b On Off Hot

04 Off On Cold 0c On On Cold

05 Off On Cool 0d On On Cool

06 Off On Warm 0E On On Warm

07 Off On Hot 0F On On Hot

U.00 COIN (HUNDREDTH) INCREMENT OFFSET

U.00 For use with card reader applications only.

g Press the LEFT MIDDLE key pad once to advance to next code.

A3.02 NORMAL Cycle Settings. Allows the owner to select the cycle

default options of Water Temperature, Soil Level, and Extra Rinse.

See Table 1 for specic settings. Normal is set to 02 from the

factory.

A4.00 DELICATES Cycle Settings. Allows the owner to select the cycle

default options of Water Temperature, Soil Level, and Extra Rinse.

See Table 1 for specic settings. Delicates is set to 00 from the

factory.

A5.OF POWERWASH Cycle Settings. Allows the owner to select the

cycle default options of Water Temperature, Soil Level, and Extra

Rinse.

See Table 1 for specic settings. Powerwash is set to 0F from the

Technician Service Access Code

This method is only available on washers set to free vend (6 00).

To enter service mode:

Press the LEFT UPPER, RIGHT LOWER, RIGHT UPPER, and

LEFT LOWER key pads within 10 seconds.

To exit service mode:

Wait 2 minutes without touching any key pads (without diagnostic

modes running)

or

Power down the washer, then reapply power

NOTE: If a service cycle is in progress upon exiting service mode,

the cycle will complete normally with cycle status information

displayed. The display will resume normal customer operation

mode when the cycle ends.

factory.

This is “VIEW ONLY” and cannot be cleared.

Press the LOWER MIDDLE key pad once to advance

to next code.

Extra

Rinse

Soil

Level

Wash

Temp

A3, A4,

or A5

Extra

Rinse

Soil

Level

Wash

Temp

19

MAYTAG® COMMERCIAL WASHER, DRYER, STACKED DRYER/

DRYER, COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD COIN

OPERATED COMMERCIAL WASHERS AND DRYERS WARRANTY

LIMITED WARRANTY ON PARTS

For the rst ve years from the date of purchase, when this commercial appliance is installed, maintained and operated according

to instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for

factory specied parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original

purchase date is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, re, ood, acts

of God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not

approved by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a non-Whirlpool authorized service technician.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY

GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR

PROVINCE TO PROVINCE.

If you need service, please contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

1/11

For written correspondence:

Maytag® Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

20

SÉCURITÉ DU LAVE-LINGE

21

ÉLIMINATION DU LAVE-LINGE

Le marquage de l’appareil est conforme à la directive européenne 2012/19/EU sur les équipements électroniques

et électriques, pour gestion des déchets.

En veillant à l’élimination correcte de ce produit, vous éviterez d’éventuelles conséquences néfastes pour l’environnement

et la santé humaine qui peuvent être associées au traitement inapproprié de ce produit lorsqu’il a été mis au rebut.

Le symbole fugurant sur le produit ou dans les documents qui accompagnent le produit indique que cet appareil ne doit pas

être traité comme déchet ménager; on doit plutôt le remettre à un centre de collecte spécialisé pour le recyclage des

équipements électriques et électroniques.

L’élimination de ce produit après mise au rebut doit être effectuée conformément aux prescriptions de la réglementation

locale de protection de l’environnement.

Pour l’information détaillée concernant le traitement, le recyclage et la récupération de ce produit, contacter la municipalité

locale, le service d’élimination des déchets ménagers, ou le commerçant qui a vendu le produit.

OUTILLAGE ET PIÈCES

Outillage nécessaire :

Niveau Pince Couteau utilitaire

Clé à molette Tournevis à lame plate

Outillage facultatif :

Lampe de poche Seau

Pièces fournies :

Tuyaux d’alimentation (2) Rondelles pour tuyau

d’alimentation (4)

22

Tuyau de vidange avec

bride, bride de retenue en

forme de u et attache-câble

DIMENSIONS

Vue de face Vue latérale

699 mm

(271/2")

686 mm

(27")

1,047 m

1,047 m

1

(41

/4")

25 mm

(1")

686 mm

(27")

546 mm

(21

67 mm

(25/8")

1

/2")

267 mm

1

(10

/2")

16 mm

5

(

/8")

889 mm

(35")

25 mm

(1")

Modèles non

Non-coin-operated

payants

models:

159 mm

1

/4")

(6

Modèles

Coin-operated

payants

models:

210 mm

1

/4")

(8

Vue arrière

Modèles non payants Modèles payants

267 mm

(10

1,047 m

(411/4")

914 mm

165 mm

(6

1

/2")

(36")

1

/2")

406 mm

(16")

108 mm

1

(4

/2")

686 mm

(27")

140 mm

(51/2")

25 mm

(1")

902 mm

1

/2")

(35

267 mm

(10

1,098 m

1

(43

/4")

914 mm

165 mm

(6

1

/2")

(36")

1

/2")

406 mm

(16")

108 mm

1

(4

/2")

686 mm

(27")

140 mm

(51/2")

25 mm

(1")

902 mm

1

/2")

(35

23

Loading...

Loading...