Maytag MLG24PNAGW, MLG24PDAGW Installation Instructions

INSTALLATION INSTRUCTIONS COMMERCIAL DRYER

(original instructions)

Gas

INSTRUCTIONS POUR L’INSTALLATION

D’UN SECHE-LINGE COMMERCIAL

(traduction des instructions d’origine)

A gaz

INSTRUCCIONES DE INSTALACIÓN SECADORA COMERCIAL

(traducción de las instrucciones originales)

A gas

ISTRUZIONI DI INSTALLAZIONE

ASCIUGATRICE COMMERCIALE

(traduzione delle istruzioni originali)

A gas

MLG24PD

MLG24PN

www.maytagcommerciallaundry.com

W10184555D

TABLE OF CONTENTS

DRYER SAFETY ........................................................................... 3

DRYER DISPOSAL ....................................................................... 4

INSTALLATION REQUIREMENTS .............................................. 4

Tools and Parts .......................................................................... 4

Location Requirements .............................................................. 4

Electrical Requirements – Gas Dryer ........................................ 5

Gas Supply Requirements ........................................................ 6

Venting Requirements .............................................................. 7

TABLE DES MATIÈRES

SECURITE DU SECHE-LINGE ................................................ 13

ELIMINATION DU SECHE-LINGE ........................................... 14

EXIGENCES D’INSTALLATION ............................................... 14

Outillage et pièces ....................................................................14

Exigences d’emplacement .......................................................15

Spécifications électriques – sèche-linge à gaz ........................16

Spécifications de l’alimentation en gaz ...................................17

Exigences concernant l’évacuation ..........................................18

INSTALLATION INSTRUCTIONS – GAS DRYER .................... 9

Install Leveling Legs .................................................................. 9

Make Gas Connection ............................................................... 9

Connect Vent ............................................................................. 9

Complete Installation ................................................................ 9

ELECTRONIC CONTROL SETUP .......................................... 10

MAINTENANCE INSTRUCTIONS .......................................... 10

REVERSING THE DOOR SWING (OPTIONAL) ...................... 10

TECHNICAL SPECIFICATIONS – GAS DRYER .................... 11

WARRANTY ............................................................................. 12

INSTRUCTIONS D’INSTALLATION –

SECHE-LINGE A GAZ ............................................................. 20

Installation des pieds de nivellement .................................... 20

Raccordement à la canalisation de gaz ................................ 20

Raccordement du conduit d’évacuation ............................. 20

Achever l’installation .............................................................. 20

REGLAGE DE LA COMMANDE ELECTRONIQUE................ 21

INSTRUCTIONS D’ENTRETIEN ............................................ 21

INVERSION DU SENS D’OUVERTURE

DE LA PORTE (FACULTATIF) ................................................ 21

FICHE TECHNIQUE – SECHE-LINGE A GAZ........................ 22

GARANTIE ............................................................................... 23

ÍNDICE

SEGURIDAD DE LA SECADORA ........................................... 24

ELIMINACIÓN DE LA SECADORA ......................................... 25

REQUISITOS DE INSTALACIÓN ............................................ 25

Piezas y herramientas .......................................................... 25

Requisitos de ubicación ....................................................... 25

Requisitos eléctricos – secadora a gas ............................... 26

Requisitos del suministro de gas ........................................... 27

Requisitos de ventilación .................................................... 28

INDICE

SICUREZZA DELL’ASCIUGATRICE ........................................ 35

L’ELIMINAZIONE DELL’ASCIUGATRICE ............................... 36

REQUISITI D’INSTALLAZIONE ................................................ 36

Attrezzi e componenti ............................................................. 36

Requisiti di ubicazione ............................................................ 36

Requisiti elettrici – asciugatrice a gas .................................... 37

Requisiti di alimentazione del gas .......................................... 38

Requisiti di scarico .............................................................. 39

INSTRUCCIONES DE INSTALACIÓN –

SECADORA A GAS ................................................................ 30

Instalación de las patas niveladoras .................................... 30

Conexión del suministro de gas ........................................... 30

Conexión del ducto de escape ............................................ 30

Complete la instalación ....................................................... 31

PREPARACIÓN DEL CONTROL ELECTRÓNICO ................. 31

INSTRUCCIONES DE MANTENIMIENTO ............................. 31

CÓMO INVERTIR EL SENTIDO DE ABERTURA

DE LA PUERTA (OPCIONAL) ................................................. 32

ESPECIFICACIONES TÉCNICAS – SECADORA A GAS ...... 33

GARANTÍA ............................................................................... 34

ISTRUZIONI D’INSTALLAZIONE – ASCIUGATRICE

A GAS ....................................................................................... 41

Installazione dei piedini di regolazione .................................... 41

Eseguire il collegamento gas ................................................... 41

Connessione dello scarico ...................................................... 41

Completamento dell’installazione ........................................... 41

IMPOSTAZIONI COMANDI ELETTRONICI ........................... 42

ISTRUZIONI DI MANUTENZIONE ......................................... 42

INVERTIRE LA ROTAZIONE DI APERTURA

(OPZIONALE) .......................................................................... 42

DATI TECNICI – ASCIUGATRICE A GAS .............................. 43

GARANZIA ............................................................................... 44

2

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

FOR YOUR SAFETY

1. DO NOT USE OR STORE PETROL OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of re or explosion, or to prevent property damage, personal injury, or death.

– Do not store or use petrol or other ammablevapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the re department.

•

– Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

IMPORTANT: When discarding or storing your old clothes dryer, remove the door.

3

DRYER DISPOSAL

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

n

200 mm (8") or 250 mm

(10") Pipe wrench

n 200 mm (8") or 250 mm

(10") adjustable wrench

n Flat-blade screwdriver

n Phillips screwdriver

n Adjustable wrench that

opens to 25 mm (1") or

hex-head socket wrench

n Level

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

n Foot boot (4)

n Dryer foot (4)

n 8 mm (5/16") socket wrench

n Utility knife

n Vent clamps

n Pipe-joint compound

resistant to LP gas

n Sealing compound gun

and sealing compound (for

installing new exhaust vent)

n Pliers

n Putty knife

Location Requirements

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

n Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages or sleeping quarters.

Contact your local building inspector.

n Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air.

See “Recessed Area Installation Instructions” on the next

page for minimum spacing requirements.

n Do not install on carpet.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

4

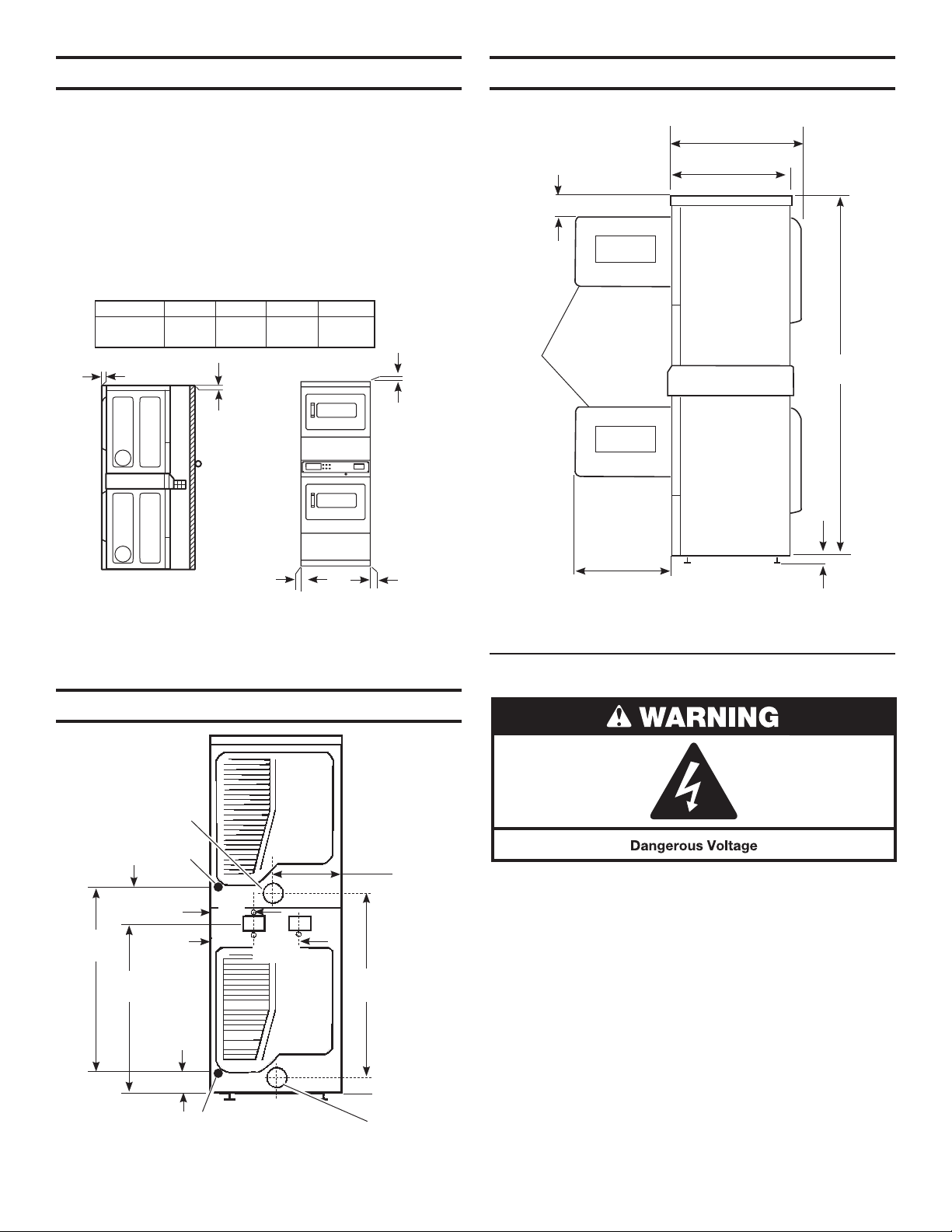

Recessed Area Installation Instructions

This dryer may be installed in a recessed area.

This dryer must not be installed in a closet with a door.

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

recess as the dryer.

Minimum Installation Clearances

Back Sides Top Front

Recessed 51 mm 0 mm 305 mm —

(2") (0") (12")

51 mm (2")

Product Dimensions (cont.)

737 mm (29")

127 mm (5")

Door

686 mm (27")

1940 mm

(763⁄8")

305 mm

(12")

0 mm (0")

Recessed

side view

Additional clearances for wall, door, and floor moldings may be

required or if external exhaust elbow is used.

Recessed

front view

0 mm

(0")

0 mm

Product Dimensions

Top dryer

exhaust

Top dryer

gas line

343 mm

235 mm

(91⁄4")

1054 mm

(411/2")

NOTE: Gas lines

located 32 mm

(11⁄4") inward

from adjacent

side.

460 mm

(181⁄8")

940 mm

(37")

140 mm

(51⁄2")

Bottom

gas line

dryer

Gas

Back View

Electric

1054 mm

(411⁄2")

83 mm

(31⁄4")

Bottom

dryer

exhaust

(0")

(131⁄2")

603 mm

(233⁄4")

Side View

approx. 25 mm

(1")

Electrical Requirements – Gas Dryer

Important: Observe all governing codes and ordinances.

You will need an earthed electrical outlet located within 610 mm

(2 feet) of either side of the dryer.

This dryer is supplied/fitted with an electricity supply cord and

plug. It should be connected to electricity supply socket at the

voltage shown on the rating plate. The minimum supply fuse

capacity should be 12A. The dryer must be positioned so that the

plug is clearly visible and accessible. This plug also provides the

function of an emergency stop control for the user. If the fitted

plug is not used, the electrical connection must be carried out

by a competent electrician in accordance with local or national

codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or

a similarly competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

5

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system

impedance to which the gas dryer should be connected

is declared to be 0.012 Ohm + j0.007 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the

most appropriate for this product.

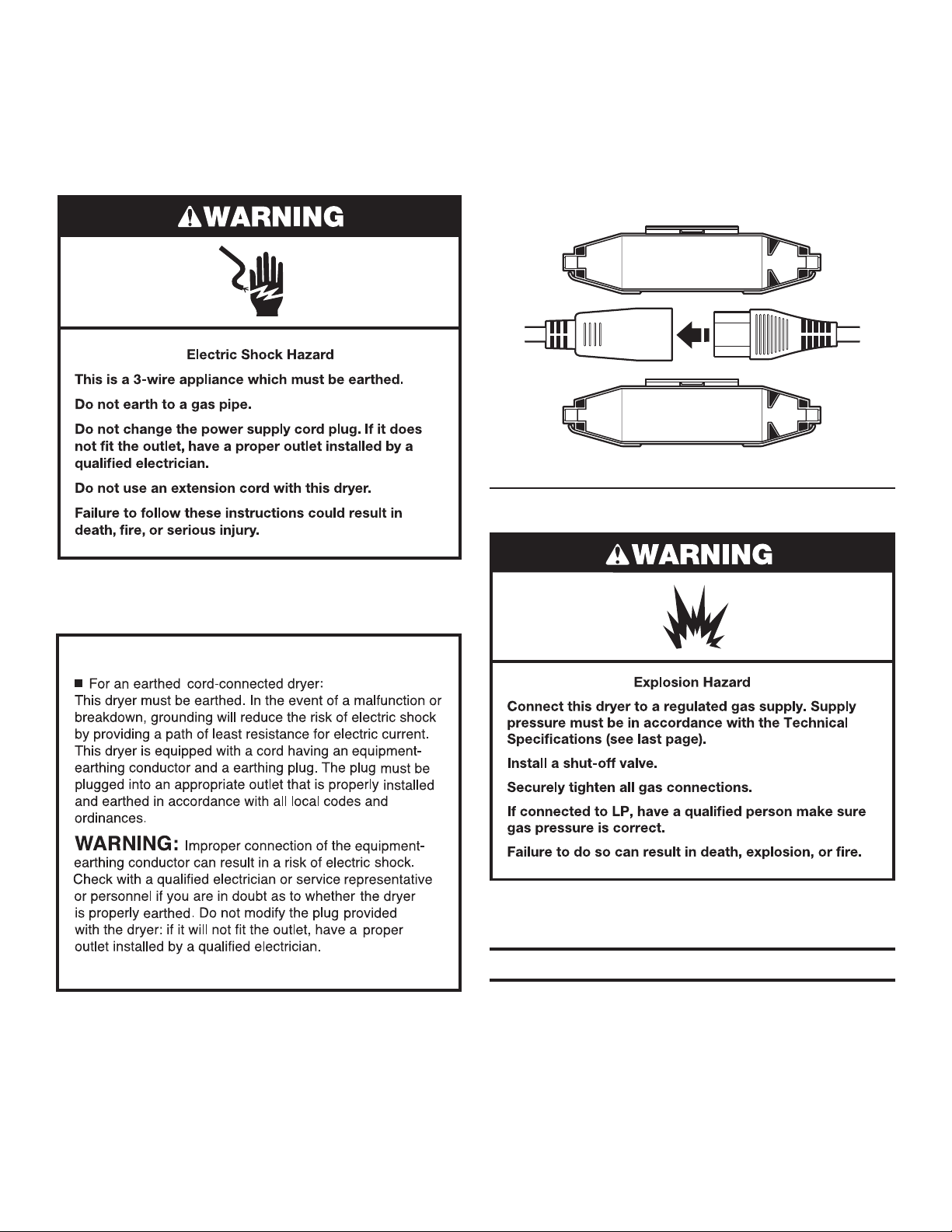

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits

your electrical outlet, and plug it into the adapter on the

supply cord.

2. Secure the plug end in place on the cord by aligning

the 2 cover halves over the cord adapter and clipping

them together.

Gas Supply Requirements

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

EARTHING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IMPORTANT: Observe all governing codes and ordinances.

Gas Supply

Before installation, check that the local gas distribution

conditions, nature of gas and pressure, and the adjustment of

the appliance are compatible. Burner information will be found

on the model/serial rating plate in the door recess of the dryer.

If this information does not agree with the type of gas available,

see your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

6

L.P. Gas:

This dryer is also certified for use with L.P. (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specified on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a competent service technician. Gas

conversion kit, part number W10233219, is available for purchase

from your dealer. Full instructions are supplied with the kit.

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should be

minimum 12.5 mm (1/2") ID. When acceptable to the gas supplier

and local codes, 10 mm (3/8") ID rigid supply line may be used

for lengths under 6.1 m (20'). Pipe-joint compounds resistant to

the action of L.P. gas must be used.

Gas connection to the dryer itself should be made by means

of a flexible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the appliance

and the wall to avoid straining of the rigid gas supply when the

appliance is moved. An appropriate length of chain and a wall

hook is recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO.228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leaks

found. A pressure measurement tapping is provided on the

gas valve within the dryer, accessible after removal of the lower

front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

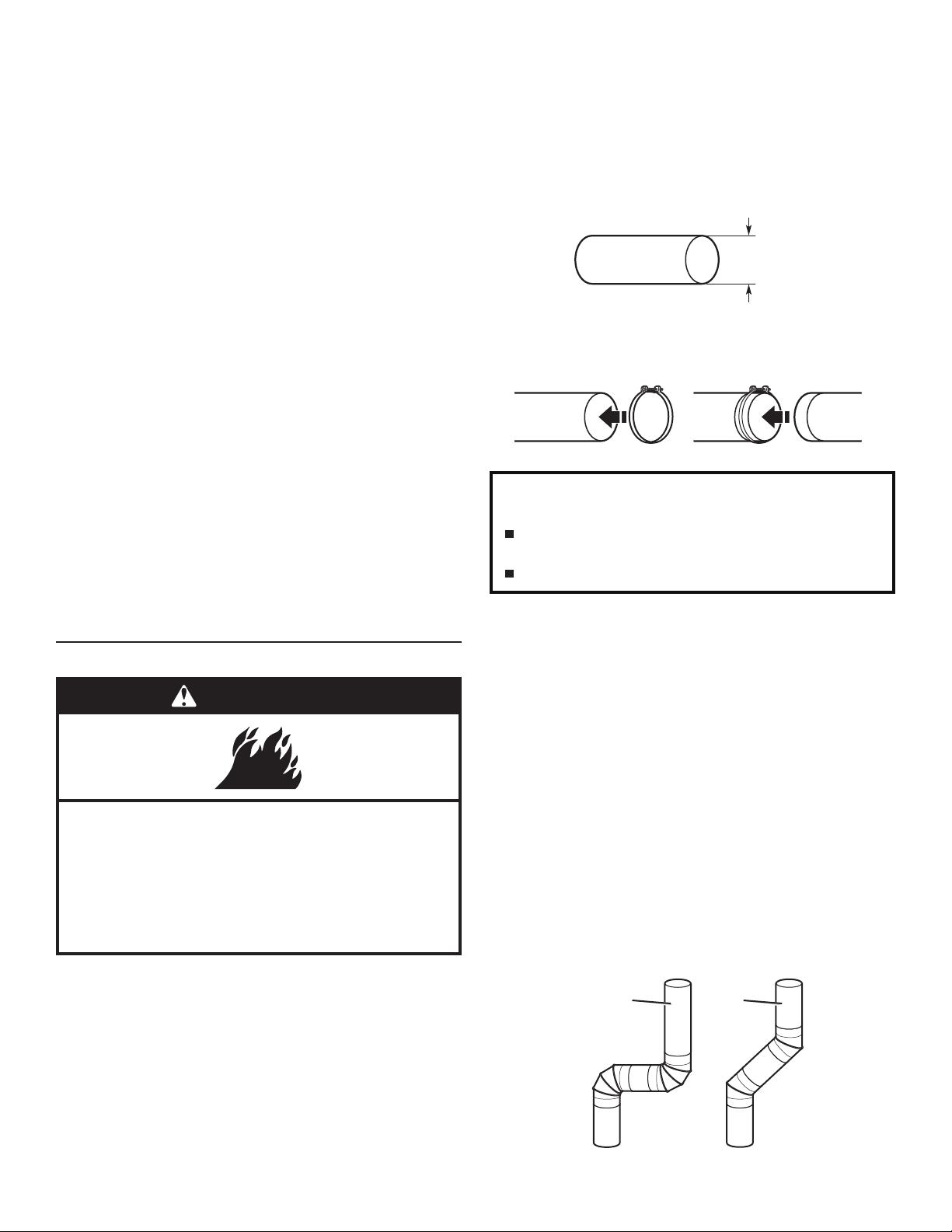

Venting Requirements

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

n Following these venting requirements will minimise ducting

air noise.

n Adequate ventilation has to be provided to avoid the backflow

of gases into the room from other fuel-burning appliances,

including open fires (i.e. available airflow into the room should

match airflow out from the room).

n The design of the flue system should be such that any

condensate formed when operating the dryer from cold

shall either be retained and subsequently re-evaporated or

discharged. Following these instructions should adequately

meet this requirement.

n Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

n Do not use an exhaust hood with a magnetic latch.

n Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

n Only a 102 mm (4") heavy metal exhaust vent and clamps

may be used.

Heavy metal

exhaust vent

n Use clamps to seal all joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent and catch lint. Do not use duct

tape.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Housecleaning problems and health problems.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended for best drying performance

and to avoid crushing and kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that will result in reduced airflow

and poor performance.

The total length of flexible metal vent should not exceed 2.4 m

(73⁄4 ft.).

An exhaust hood should cap the vent to keep rodents and

insects from entering the building.

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, bushes, or snow).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Plan installation to use the fewest number of elbows and turns.

A

Exhaust Air Flow

A. Good

B. Better

102 mm

(4")

B

7

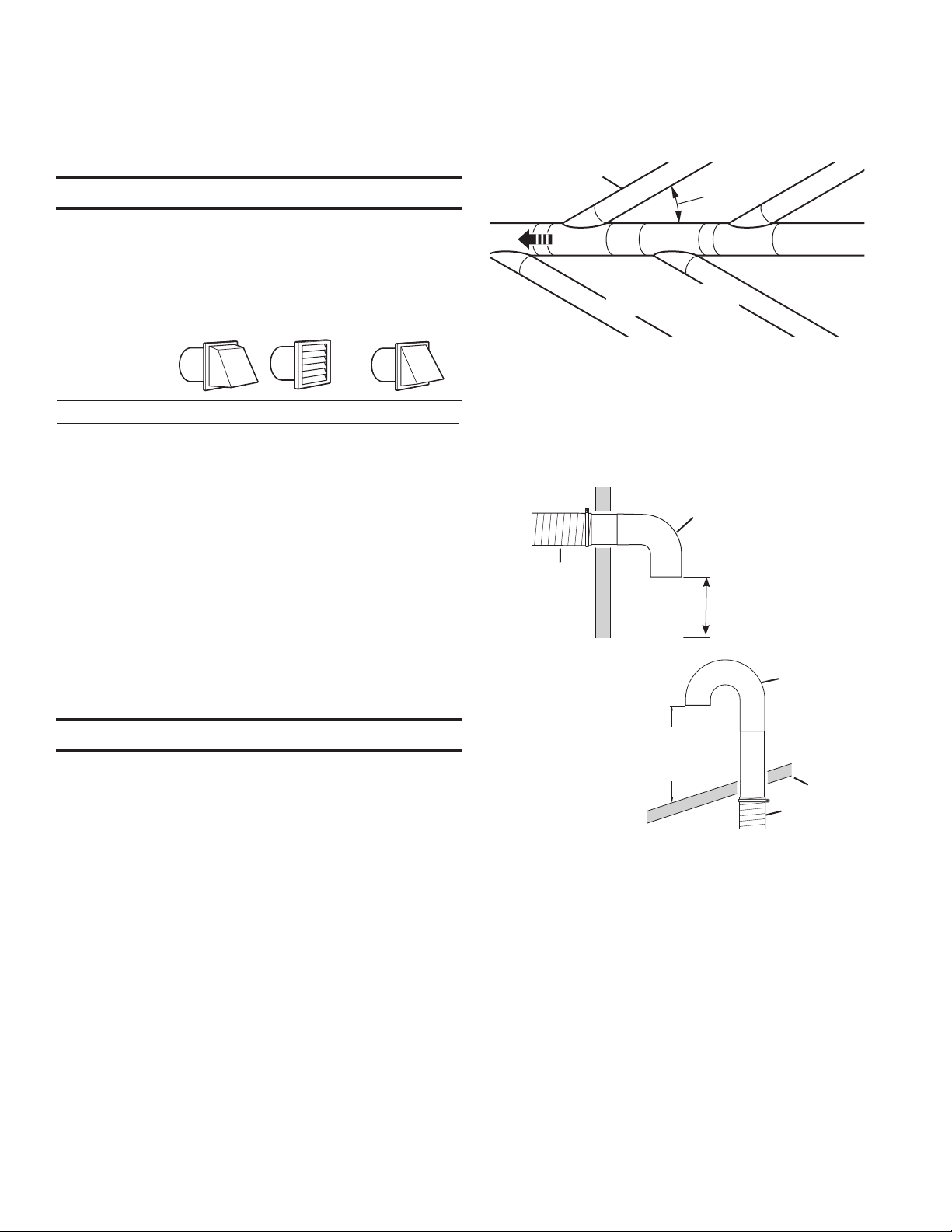

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Vent System Length

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

A

30˚ max.

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Maximum Vent Length

102 mm (4") Exhaust Hoods

Box Louvered 64 mm (21⁄2") Angled

Rigid Metal Vent

No. of 90° turns

0

1

2

3

4

Box Hood and Louvered Style

39.6 m (130 ft.)

38.1 m (125 ft.)

35.1 m (115 ft.)

32.3 m (106 ft.)

29.9 m (98 ft.)

Angled Hood Style

39.3 m (129 ft.)

36.3 m (119 ft.)

33.2 m (109 ft.)

30.5 m (100 ft.)

28 m (92 ft.)

If dryer is installed in a confined area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area Installation Instructions”

in the “Location requirements” section.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21⁄2"

) outlet exhaust hood may be used. A 64 mm (21⁄2"

)

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Multiple Dryer Venting

n A main vent can be used for venting a group of dryers. Main

vent should be sized to remove 5663 l/min (200 CFM) of air

per dryer. Large-capacity lint screens of proper design may

be used in the main vent if checked and cleaned frequently.

The room where the dryers are located should have make-up

air equal to or greater than the airflow of all the dryers in the

room.

n A back-draft damper kit is needed and is available from a

commercial laundry distributor; it should be installed in the

vent of each dryer to keep exhausted air from returning

into the dryers and to keep the exhaust in balance within

the main vent. Unobstructed return air openings are required.

air ow

A. Individual dryer vent

B. Main vent

B

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

B

24" min.

(610 mm)

A

Min. 300 mm (12")

clearance above any

12" min.

(305 mm)

accumulation of snow, ice,

or debris such as leaves.

E

F

C

G

D

C

A. Exhaust hood or elbow

B. Wall

C. Main collector vent

D. Horizontal vent

E. 180° sweep elbow

F. Vertical vent

G. Roof

610 mm (24")

min. above

highest point of

building

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the wall, install a 180° sweep elbow on

the end of the vent at least 610 mm (2 ft.) above the highest part

of the building. The opening in wall or roof shall have a diameter

13 mm (

1/2"

) larger than the vent diameter. The vent should be

centered in the opening.

Do not install screening or cap over the end of the vent.

8

INSTALLATION INSTRUCTIONS – GAS DRYER

Install Leveling Legs

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body

of the dryer and gently lay it on its back on the cardboard

corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That’s how far the leg is supposed to go into the hole.

5. Start to screw the leveling legs into the holes by hand.

(Use a small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 25 mm (1")

wrench or socket wrench to finish turning the legs until you

reach the diamond mark. Then fit a covered foot boot over

each foot.

6. Now stand the dryer up.

7. Remove cardboard or hardboard from under dryer. Adjust

the legs of the dryer up or down until the dryer is level.

Make Gas Connection

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. If the flexible gas hose has 3/8"

BSP thread, use the supplied conversion thread adapter. Use

pipe-joint compound resistant to the action of L.P. gas for gas

connections.

If necessary for service, open the toe panel. Use a putty knife

to press on the 2 toe panel locks located at the top of the toe

panel. Pull downward on the toe panel to open. Toe panel is

hinged at the bottom.

3. Open the shut-off valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

Connect Vent

1. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 102 mm (4") clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

3. Check that there are no kinks in the flexible gas line.

Complete Installation

1. With dryer in final position, place level on top of the dryer, first

side to side, then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

WARNING

Electric Shock Hazard

This is a 3-wire dryer which must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

2. Reconnect power to dryer.

3. Check dryer operation. Select the full heat cycle (not the air

cycle), start and allow the dryer to complete a full cycle to

make sure it is working properly. Dryer will stop when the time

is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, the dryer stops. To restart dryer, close door and

reselect your cycle.

4. If the burner does not ignite and you can feel no heat inside the

dryer, shut off dryer for five minutes. Check that all gas supply

valve controls are in “ON” position and that the electrical cord

is plugged in. Repeat five-minute test.

9

ELECTRONIC CONTROL SETUP

See the programming guide for information on setup.

MAINTENANCE INSTRUCTIONS

Maintenance instructions:

n Clean lint screen after each cycle.

n Removing accumulated lint (disconnect dryer from electricity

and gas supply before starting this task):

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

If dryer does not operate, check the following:

n Electric supply is connected.

n Circuit breaker is not tripped or fuse is not blown.

n Door is closed.

n Controls are set in a running or “ON” position.

n Cycle has been selected.

n Check that gas supply shut-off valves are set in open position.

If you need assistance:

Contact your authorized Maytag® Commercial Laundry distributor

or visit: www.MaytagCommercialLaundry.com. When you call,

you will need the dryer model number and serial number.

Both numbers can be found on the serial-rating plate located

on your dryer.

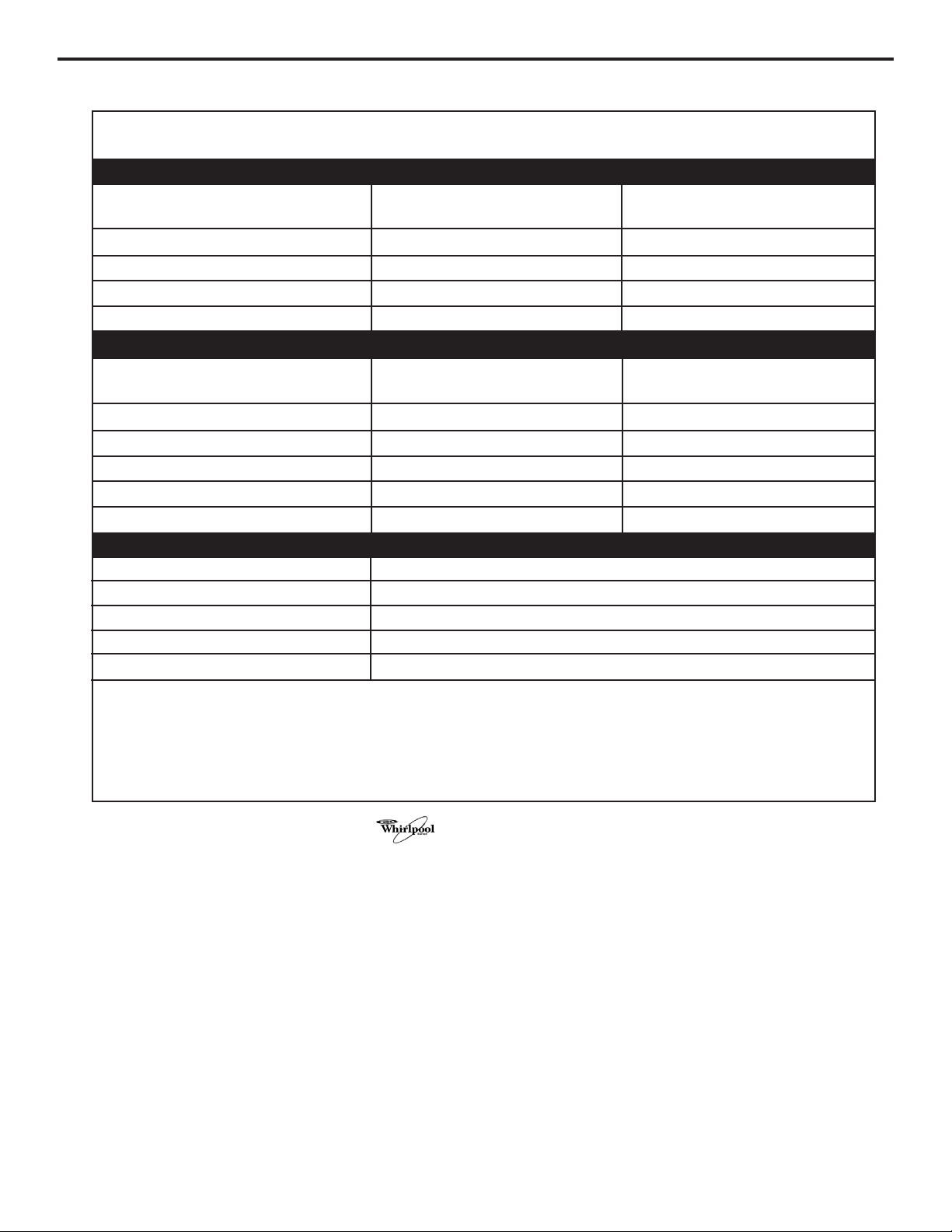

REVERSING THE DOOR SWING (OPTIONAL)

You can change your door swing from a right-side opening to

a left-side opening, if desired.

C

B

A

1. Open dryer door. Remove bottom screws from cabinet side

of hinges (A). Loosen (do not remove) top screws from cabinet

side of hinges.

2. Lift door until top screws in cabinet are in large part of hinge

slot. Pull door forward off screws. Remove top screws from

cabinet.

3. Remove screws attaching hinges to door.

4. Remove screws from all sides of door (5 screws). Grasp sides

of outer door and gently lift to separate it from inner door (do

not pry apart). Do not pull on door seal or plastic door catch.

5. Reattach outer door panel to

inner door panel so handle

is on the side where hinges

were just removed.

6. Attach door hinges to dryer door so that the larger hole is

at the bottom of the hinge and the hinge pin is toward the

door front.

7. Remove the 4 screws that attach 2 plugs (B) on the handle

side. Attach plugs to opposite side using the same 4 screws.

8. Insert screws into bottom holes on left

side of cabinet. Tighten screws halfway.

Position door so large end of door hinge

slot is over screws. Slide door up so

screws are in bottom of slots. Tighten

screws. Insert and tighten top screws

in hinges.

9. Close door and check that door strike aligns with door

catch (C).

10

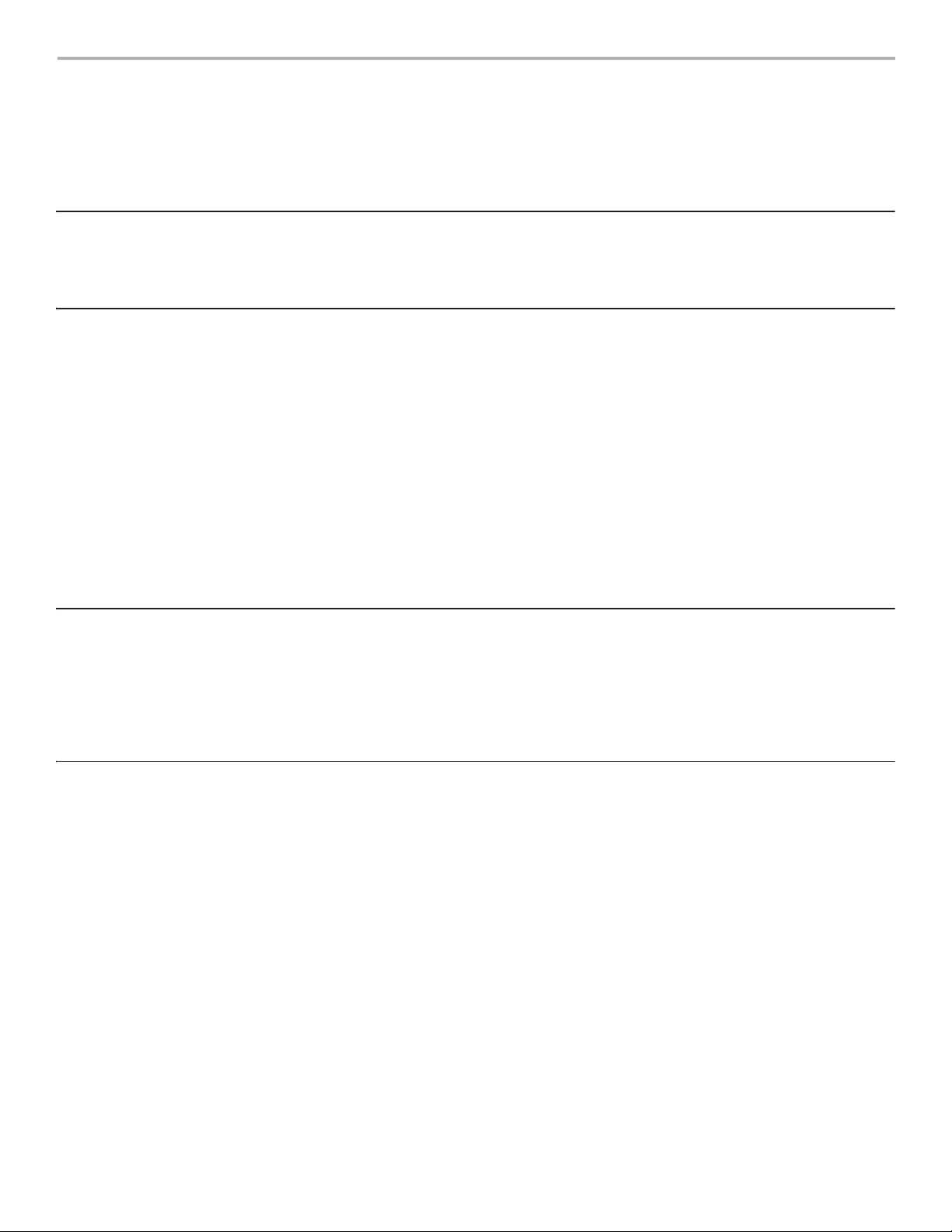

TECHNICAL SPECIFICATIONS – GAS DRYER

220-240V~50Hz 1ph 12A max. IP24 Clothes capacity: 9.0 kg max. each dryer. Sound pressure level,

Lpa: 58 dBA (uncertainty, Kpa: +/–10 dBA) Total mass: 135 kg max.

Factory set for NATURAL GAS: Injector size: 2.2 mm Heat input gross: 5.9 kW

European Country: CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

European Gas Category:

Gas Flow Rate:

Supply Pressure (G20):

Factory Adjusted Pressure:

II

2H3+

3

0.562703 m

/hr

20 mbar

7.4 mbar 7.4 mbar

CY, CZ, DK, EE, FI, GR, HU, IT,

NO, RO, SE, SK, TR

II

2H3B/P

3

0.562703 m

/hr

20 mbar

With LP Gas Conversion Kit: Injector size: 1.25 mm Heat input gross: 6.4 kW

European Country:

European Gas Category:

Butane Supply Pressure (G30):

Adjusted Pressure:

Propane Supply Pressure (G31):

Adjusted Pressure:

CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

II

2H3+

28-30 mbar

N/A N/A

37 mbar 30 mbar

N/A

CY, CZ, DK, EE, FI, GR, HU, IT,

NO, RO, SE, SK, TR

II

2H3B/P

30 mbar

N/A

With France/Belgium NATURAL GAS conversion kit: Injector size: 1.65 mm Heat input gross: 5.9 kW

European Country:

European Gas Category:

Supply Pressure (G20):

Supply Pressure (G25):

Adjusted Pressure:

FR, BE

I

2E+

20 mbar

25 mbar

N/A

NOTE: Conversion kit:From Natural Gas to LP Gas: Whirlpool Part No. W10233219.

Conversion kit: From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10181947.

Manufacturer: Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturing Site: Whirlpool Corporation, 1300 Marion-Agosta Rd., Marion, OH 43302, U.S.A.

EU representatives: Maytag UK Ltd., 2 St. Annes Blvd., Redhill, RH1 1AX, UK

& Bauknecht Hausgeräte GmbH, D-73614 Schorndorf, Germany

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

WE (nous): BAUKNECHT HAUSGERÄTE GmbH, D-73614 Schorndorf

representing (représentant): WHIRLPOOL EUROPE S.r.l I-21025 COMERIO

declare under our sole responsibility that the product

déclarons sous notre propre responsabilité que le produit

dryer Maytag MLG24PD

(sèche-linge) :

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

auquel se référe cette déclaration est conforme aux normes suivantes ou autres documents normatifs

EN 60335-1:2002+A1+A2+A11+A12+A13

EN 60335-2-11:2003+A1+A2

EN 12752-1:1999

EN 62233:2008

EN ISO 10472-1:2008

EN ISO 10472-4:2008

EN 55014-1:2006

EN 55014-2:1995+A1:2001

EN 61000-3-12:2005

EN 61000-3-11:2000

following the provisions of Directive(s):

suivant les prévisions des Directives :

2009/142/EC EUROPEAN GAS APPLIANCE DIRECTIVE

2006/95/EC LOW VOLTAGE DIRECTIVE

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (CEE Directive Compatibilité

Electro-magnétique)

2006/42/EC MACHINERY DIRECTIVE

Schorndorf, 29.04.2010 Roberto Mottura

Place and date: Director PDC, FC

lieu et date :

Name and signature of authorised person

Maytag MLG24PN

(CEE Directive Basse Tension)

represented by

Nom et signature de la personne autorisée

11

MAYTAG® COMMERCIAL WASHER, DRYER, STACKED DRYER/

DRYER, COMMERCIAL STACK LAUNDRY, AND MULTI-LOAD

COIN OPERATED COMMERCIAL WASHERS AND DRYERS

WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not app roved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a Non-Whirlpool authorized Service Technician.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PA RTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STAT E OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

1/11

For written correspondence:

Maytag

®

Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

12

SECURITE DU SECHE-LINGE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

POUR VOTRE SECURITE

1. NE PAS UTILISER OU REMISER D’ESSENCE OU AUTRES MATÉRIAUX INFLAMMABLES DANS CET APPAREIL MÉNAGER

OU À PROXIMITÉ DE CELUI-CI.

2. NE PAS VAPORISER D’AÉROSOLS À PROXIMITÉ DE CET APPAREIL MÉNAGER LORSQU’IL EST EN FONCTIONNEMENT.

3. NE PAS MODIFIER CET APPAREIL MÉNAGER.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

AVERTISSEMENT : Pour votre sécurité, les renseignements dans ce manuel doivent

être observés pour réduire au minimum les risques d’incendie ou d’explosion ou pour

éviter des dommages au produit, des blessures ou un décès.

– Ne pas entreposer ou utiliser de l’essence ou d’autres vapeurs ou liquides

inflammablesàproximitéde cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher àun commutateur électrique; ne pas utiliser le téléphone se trouvant

•

sur les lieux.

Évacuer tous les gens de la pièce, de l’édifice ou du quartier.

•

Appeler immédiatement le fournisseur de gaz d’un téléphone voisin. Suivre ses

•

instructions.

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

•

– L’installation et l’entretien doivent être effectués par un installateur qualifié, une

agence de service ou le fournisseur de gaz.

IMPORTANT : Pour mettre l’ancien sèche-linge au rebut ou pour la remiser, enlever la porte.

13

13

ÉLIMINATION DU SECHE-LINGE

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l’installation. Lire et respecter les instructions d’installation

fournies avec chacun des outils de cette liste.

Outillage nécessaire

n Clé à tube de 200 mm (8")

ou 250 mm (10")

n Clé à molette de 200 mm

(8") ou 250 mm (10")

n Tournevis à lame plate

n Tournevis Phillips

n Clé à molette avec

ouverture jusqu’à 25 mm

(1") ou clé à douille à tête

hexagonale

n Niveau

n Clé à douille de 8 mm

(5/16")

n Couteau utilitaire

n Brides de fixation

n Composé d’étanchéité des

raccords filetés – résistant

au propane

n Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation

d’un nouveau circuit

d’évacuation)

n Pince

n Couteau à mastic

Pièces fournies

Retirer le sac de pièces du tambour du sèche-linge. Vérifier

la présence de toutes les pièces.

n Patin (4)

n Pied du sèche-linge (4)

14

14

Loading...

Loading...