Maytag MLG24PDAWW1, MLG24PDAXW2, MLG24PRAWW1, MLG24PRAWW2, MLG24PRAWW3 Installation Guide

...Page 1

INSTALLATIONINSTRUCTIONS

COMMERCIALSTACKEDDRYER

Gas (120-Volt,60-Hz)or Electric (120/240-Volt,60-Hz)

INSTRUCTIONSPOUR L'INSTALLATIONffUNE

# #

SECHEUSECOMMERCIALESUPERPOSEE

h gaz (120Volts, 60 Hz) ou (_lectrique (120/240Volts, 60 Hz)

Table of Contents/Table des mati_res ........................................ 2

\ ..............

Actual unit may or may not

contain doors with windows,

depending on model

Seton te modete, te pr6sent

appareit n'offre peut-_tre pas

de hubtot de porte.

www.maytagcommercJallaundry.com

W10184580A

SP - W10184581A

Page 2

TABLEOF CONTENTS TABLEDESMATIERES

DRYER SAFETY ............................................................................ 2

INSTALLATION REQUIREMENTS .............................................. 5

Tools and Parts .......................................................................... 5

Location Requirements .............................................................. 5

Electrical Requirements - Gas Dryer ........................................ 6

Electrical Requirements - Electric Dryer (U.S. only) ................ 6

Gas Supply Requirements ........................................................ 7

Venting Requirements .............................................................. 8

iNSTALLATION INSTRUCTIONS - GAS DRYER .................. 10

Make Gas Connection .............................................................. 10

Connect Vent ............................................................................ 10

Complete Installation .............................................................. 10

iNSTALLATION iNSTRUCTIONS- ELECTRIC DRYER ........ 10

Make Electrical Connection ...................................................... 11

Connect Vent ............................................................................ 15

Complete Installation .............................................................. 15

REVERSING THE DOOR SWING (OPTIONAL) ...................... 15

MAINTENANCE INSTRUCTIONS .......................................... 16

ELECTRONIC CONTROL SETUP ........................................... 16

WARRANTY .............................................................................. 21

SECURITE DE LA SECHEUSE .............................................. 22

EXIGENCES D'INSTALLATION ................................................ 25

Outitlage et pi_ces .................................................................... 25

Exigences d'emplacement ...................................................... 25

Specifications etectriques - s6cheuse h gaz ........................... 26

Specifications electriques - s_cheuse etectrique

(E.-U. seulement) ..................................................................... 26

Specifications de I'atimentation en gaz .................................. 27

Exigences concernant I'evacuation .......................................... 28

INSTRUCTIONS D'INSTALLATION - S_=CHEUSE A GAZ ....31

Raccordement h la canalisation de gaz ...................................... 31

Raccordement du conduit d'evacuation ................................ 31

Achever I'instatlation ................................................................ 31

INSTRUCTIONS D'INSTALLATION - S_eCHEUSE

ELECTRIQUE ............................................................................ 32

Raccordement electrique ........................................................ 32

Raccordement du conduit d'evacuation ................................ 37

Achever l'installation ................................................................ 37

INVERSION DU SENS D'OUVERTURE DE LA PORTE .......... 37

INSTRUCTIONS D'ENTRETIEN .............................................. 38

REGLAGE DE LA COMMANDE ELECTRONIQUE ................ 38

GARANTIE ................................................................................ 44

DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Page 3

WARNING - ".iskofFire"

- Clothes dryer installation must be performed by a qualified installer.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials, if flexible metal

(foil type) duct is installed, it must be of a specific type identified by the appliance

manufacturer as suitable for use with clothes dryers. Flexible venting materials are

known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

WARNING: For your safety, the information in this manual must be followed to minimize I

the risk of fire or explosion, or to prevent property damage, personal injury, or death, j

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

®Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

= Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• if you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

3

Page 4

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer. [] Do not repair or replace any part of the dryer or attempt

[] Do not place items exposed to cooking oils in your dryer, any servicing unless specifically recommended in this

Items contaminated with cooking oils may contribute to Use and Care Guide or in published user-repair instruc=

a chemical reaction that could cause a load to catch fire. tions that you understand and have the skills to carry out.

[] Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

[] Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] Clean lint screen before or after each load.

[] Keep area around the exhaust opening and adjacent sur-

rounding areas free from the accumulation of lint,dust,

and dirt.

[] The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

[] See installation instructions for grounding requirements.

SAVE THESE INSTRUCTIONS

[] It is recommended that the owner post, in a prominent location, instructions for the customer's use in the event the customer smells

gas. This information should be obtained from your gas supplier.

[] Post the following warning in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

Page 5

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

[] 8" (20 cm) or 10" (25 cm) [] Security T-20 TORX_'tdriver

pipe wrench [] Level

[] 8" (20 cm) or 10" (25 cm) [] 5/16" open-end wrench

adjustable wrench

[] Flat-blade screwdriver

[] Phillips screwdriver resistant to LP gas

[] Adjustable wrench that [] Caulk gun and caulk (for

opens to 1" (25 mm) or 1" installing new exhaust vent)

(25 mm) hex-head socket

wrench [] Pliers

1 ® TORX is a registered trademark of Acument Intellectual Properties, LLC.

[] Vent clamps

[] Pipe-joint compound

[] Putty knife

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

[] 10-32 x 5/16" serrated screw (4)

[] Security cotter pin (2)

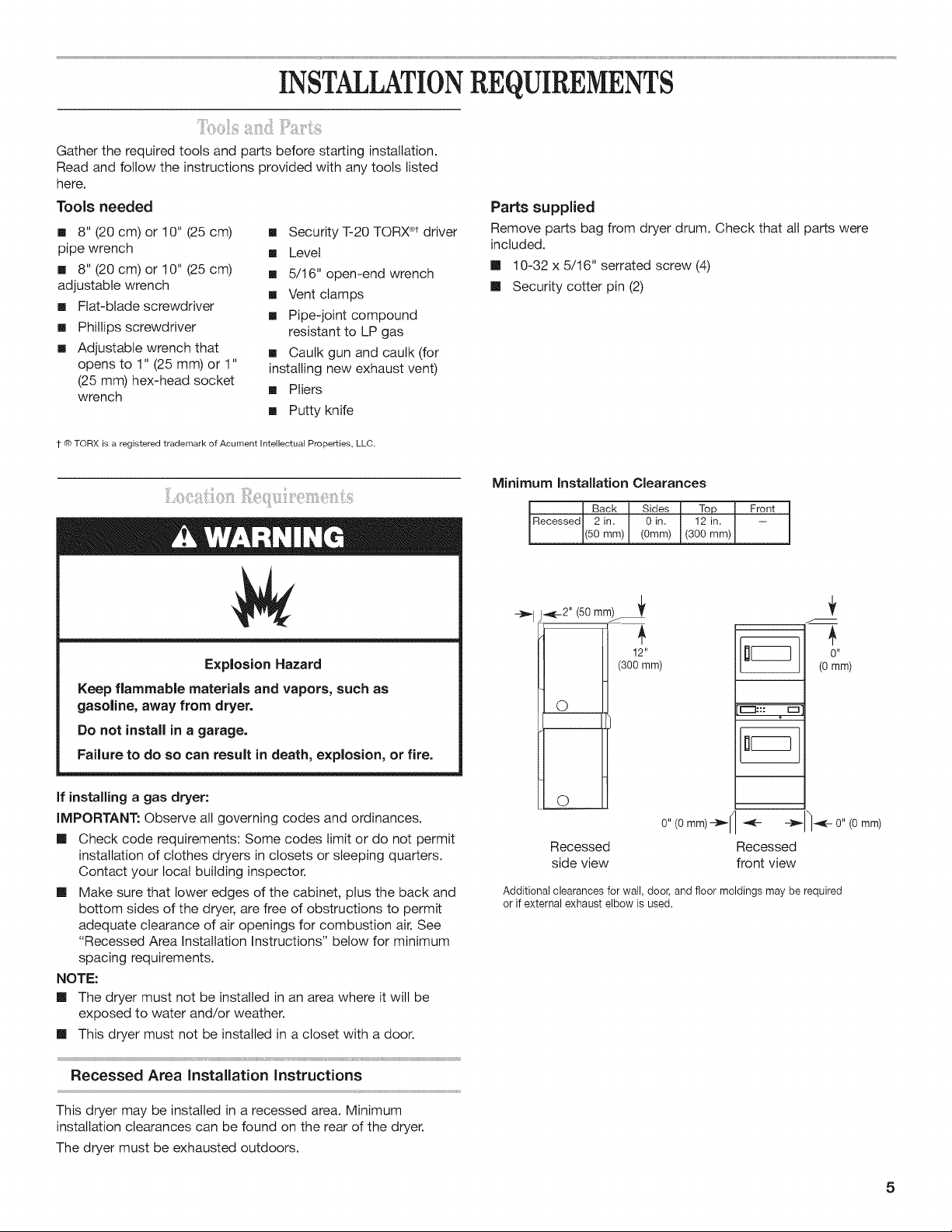

Minimum Installation Clearances

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not permit

installation of clothes dryers in closets or sleeping quarters.

Contact your local building inspector.

[] Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

"Recessed Area Installation Instructions" below for minimum

spacing requirements.

NOTE:

[] The dryer must not be installed in an area where it will be

exposed to water and/or weather.

[] This dryer must not be installed in a closet with a door.

............................................................................................................................................................... i

Recessed Area Installation instructions

IRecessedl 2in, I 0in, I 12in, I -- I

-_1 j_-2" (50 mm_

Back Sides Top Front

(50 mm) (0mm) (300 mm)

+

j--

+

12"

(300 mm)

0

r---I::: E3

0

0"(0mm)-_ll/l_ _l'-l__l,0"(0mm)

Recessed Recessed

side view frontview

Additional clearances for wall, door, and floor moldings may be required

or if external exhaust elbow is used.

(0mm)

+

+

This dryer may be installed in a recessed area. Minimum

installation clearances can be found on the rear of the dryer.

The dryer must be exhausted outdoors.

5

Page 6

Product Dimensions

Top dryer

exhaust

\

Topdryer

gasline

53/8 ''

(137 mm)

37"

(940 mm)

53/8''

(343 mm)

41"

(1041 mm)

131/2''

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

NOTE: Gas lines

located 11/2'' (38 mm)

inward from adjacent

side.

51/2'' (140 mm)

door_

(603 mm)

(13_mm)

233/4''

Bottom

dryer

gas line

i J

Back View

27" (686 mm)

10½"

(267 mm)

71/2''

(191 mm)

J.

291/4,, _

(743mm)

Side View

@--

O

(1950 mm)

approx. 1"

(25mm)

31/8 ''

(79 mm)

BoSom

dryer

exhaust

T

763/4''

IMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, inthe absence

of local codes, with the National Electrical Code, ANSl/NFPA 70,

latest edition.

if codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

[] A 120 volt, 60 Hz, AC only, 15-amp, fused electrical circuit

is required. A time-delay fuse or circuit breaker isalso

recommended, it is recommended that a separate circuit

serving only this dryer be provided.

Recommended Ground Method

The dryer, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSl/NFPA 70, latest edition.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

Page 7

}iii!ii3:e,i:!:ii::; :'ii,ssiil}ii!! i :e !:iiis!:ii:?e:!i:is,ii! sixi ............ii!i iii, si:ii t :' il,s

(U, {}s}iiii: }i

iMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, in the absence

of local codes, with the National Electrical Code, ANSl/NFPA 70,

latest edition.

The National Electrical Code requires a 4-wire supply connection

for homes built after 1996, dryer circuits involved in remodeling

after 1996, and all mobile home installations.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine

that the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

[] A four-wire or three-wire, single-phase, 120/240 volt, 60 Hz,

AC only electrical supply (or four-wire or three-wire,

120/208 volt, if specified on the model/serial rating plate) is

required on a separate, 30-amp circuit, fused on both sides of

the line. A time-delay fuse or circuit breaker is recommended.

Recommended Ground Method

It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformity with the National Electrical Code, ANSl/NFPA 70,

latest edition, and all local codes and ordinances.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Explosion Hazard

Use a new CSA international approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

iMPORTANT: Observe all governing codes and ordinances.

This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSi Z223.1/NFPA 54.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

The design of this dryer has been certified by CSA international

for use at altitudes up to 10,000 feet (3048 m) above sea level at

the B.T.U. rating indicated on the model/serial plate. Burner input

adjustments are not required when the dryer is operated up to

this elevation.

When installed above 10,000 feet (3048 m), a four percent (4%)

reduction of the burner B.T.U. rating shown on the model/serial

plate is required for each 1,000 foot (305 m) increase in elevation.

For assistance when converting to other gas types and/or

installing above 10,000 feet (3048 m) elevation, contact your

local service company.

Type of Gas

This dryer is equipped for use with natural gas. It is design-

certified by CSA international for L.R (propane and butane) gases

with appropriate conversion. No attempt shall be made to convert

the dryer from the gas specified on the serial/rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a qualified service technician.

Gas conversion kit part numbers are listed on the gas valve

burner base.

7

Page 8

Gas Supply Line

Gas Supply Pressure Testing

Recommended method

[] Provide a gas supply line of 1_,,rigid (IPS) pipe to the dryer

location. Pipe joint compounds that resist the action of LP gas

must be used. Do not use TEFLON _'ttape. With LP gas,

piping or tubing size can be 1Z_"minimum. Usually, LP gas

suppliers determine the size and materials used in the system.

Alternate method

[] The gas supply may also be connected using %" approved

copper or aluminum tubing. If the total length of the supply

line is more than 20 feet (6.1 m), larger tubing will be required.

If using natural gas, do not use copper tubing. Pipe joint

compounds that resist the action of LP gas must be used.

Flexible metal appliance connector

[] It is recommended that a new flexible stainless steel gas line,

design-certified by CSA International, be used for connecting

the dryer to the gas supply line. (The gas pipe which extends

through the lower rear of the dryer is provided with %" male

pipe thread.)

[] Do not kink or damage the flexible stainless steel gas line

when moving the dryer.

Rigid pipe connection

The rigid pipe connection requires a combination of pipe fittings

to obtain an in-line connection to the dryer.

[][]Must include a shutoff valve:

The supply line must be equipped with a manual shutoff

valve. In the U.S., the valve must be installed within 6 ft. (1.8

m) of dryer in accordance

with National Fuel Gas

Code, ANSI Z223.1. In

Canada, an individual

manual shutoff valve must

be installed in accordance

with the B149 installation

codes CAN/CGA B149.1

and CAN/CGA B149.2.

This valve should be

located in the same room

as the dryer. It should be in

a location that allows ease of opening and closing. Do not

block access to shutoff valve. The valve is for turning on or

shutting off gas to the dryer.

Installed in a confined area:

Ifthe dryer is installed in a confined area such as a bathroom,

provision must be made for enough air for combustion and

ventilation. Check governing codes and ordinances or refer to

the "Recessed Area Installation Instructions" in the "Location

Requirements" section.

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

A. Gas supply line

B. Shutoff valvein "open" position

C. To dryer

D. NPT 1/8" min. plugged tapping

B D

A %" NPT minimum plugged tapping, accessible for gauge

testing, must be installed immediately upstream of the installed

shut-off valve to the dryer.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of the system at test

pressures in excess of 1/2psig.

Fire Hazard

Use a heavy metal vent.

Do not use a p_astic vent.

Do not use a meta_ foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

[] The dryer vent must not be exhausted into any gas vent,

chimney, wail, ceiling, attic, crawtspace, or a concealed space

of a building.

[] Only rigid or flexible metal duct shall be used for exhausting.

[] Do not use an exhaust hood with a magnetic latch.

[] Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

[] 4" (102 mm) heavy metal vent and clamps must be used. Do

not use plastic or metal foil vent.

[] Use clamps to seat all joints. The duct shall not be assembled

with screws or other fastening means that extend into the

duct and catch lint. Do not use duct tape.

[] The total length of flexible metal vent shall not exceed 7,%ft

(2.4 m).

IMPORTANT: Observe all governing codes and ordinances.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal vent.

Page 9

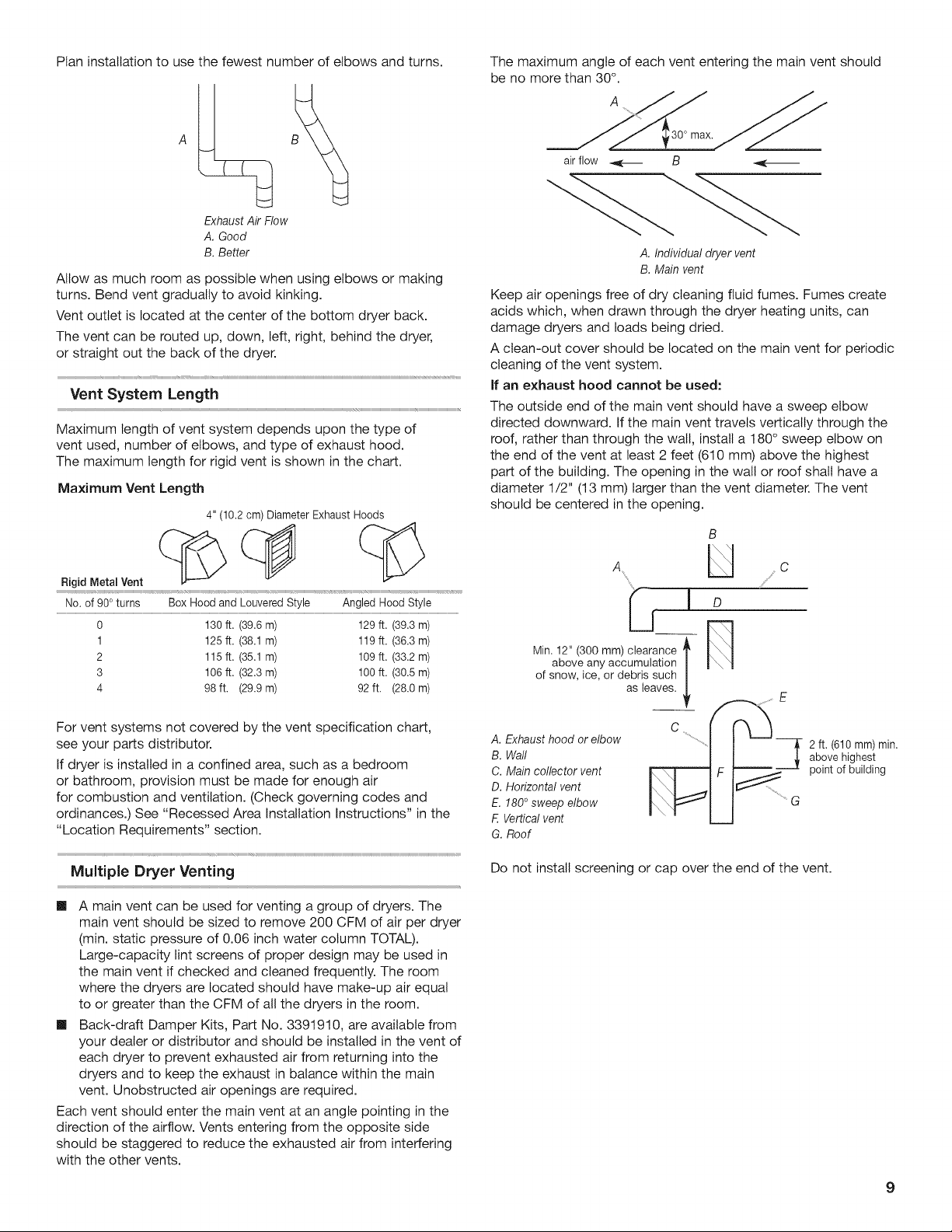

Planinstallationtousethefewestnumberofelbowsandturns.

A

ExhaustAirFlow

A.Good

B.Better

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Vent System Length

Maximum length of vent system depends upon the type of

vent used, number of elbows, and type of exhaust hood.

The maximum length for rigid vent is shown in the chart.

Maximum Vent Length

4" (10.2 cm) Diameter Exhaust Hoods

The maximum angle of each vent entering the main vent should

be no more than 30°.

air flow _ B _,_--

A.Individualdryervent

B.Mainvent

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and loads being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the watt, install a 180° sweep elbow on

the end of the vent at least 2 feet (610 mm) above the highest

part of the building. The opening in the wall or roof shall have a

diameter 1/2" (13 mm) larger than the vent diameter. The vent

should be centered in the opening.

B

Rigid Metal Vent

No. of 90 ° turns Box Hood and Louvered Style Angled Hood Style

0 130 ft. (39.6 m) 129 ft. (39.3 m)

1 125 ft. (38.1 m) 119 ft. (36.3 m)

2 115 ft. (35.1 m) 109 ft. (33.2 m)

3 106 ft. (32.3 m) 100 ft. (30.5 m)

4 98 ft. (29.9 m) 92 ft. (28.0 m)

For vent systems not covered by the vent specification chart,

see your parts distributor.

If dryer is installed in a confined area, such as a bedroom

or bathroom, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See "Recessed Area Installation Instructions" in the

"Location Requirements" section.

Multiple Dryer Venting

[] A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 200 CFM of air per dryer

(min. static pressure of 0.06 inch water column TOTAL).

Large-capacity lint screens of proper design may be used in

the main vent if checked and cleaned frequently. The room

where the dryers are located should have make-up air equal

to or greater than the CFM of all the dryers in the room.

[] Back-draft Damper Kits, Part No. 3391910, are available from

your dealer or distributor and should be installed in the vent of

each dryer to prevent exhausted air from returning into the

dryers and to keep the exhaust in balance within the main

vent. Unobstructed air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

U .....C

ff

MIn 12ov(e30aOnymam_ctmea;a_ice F_

iiiiiiiil;ile ssuc l

2ft. (610 mm) min.

above highest

point of building

E"Verticalvent

G.Roof

Do not install screening or cap over the end of the vent.

9

Page 10

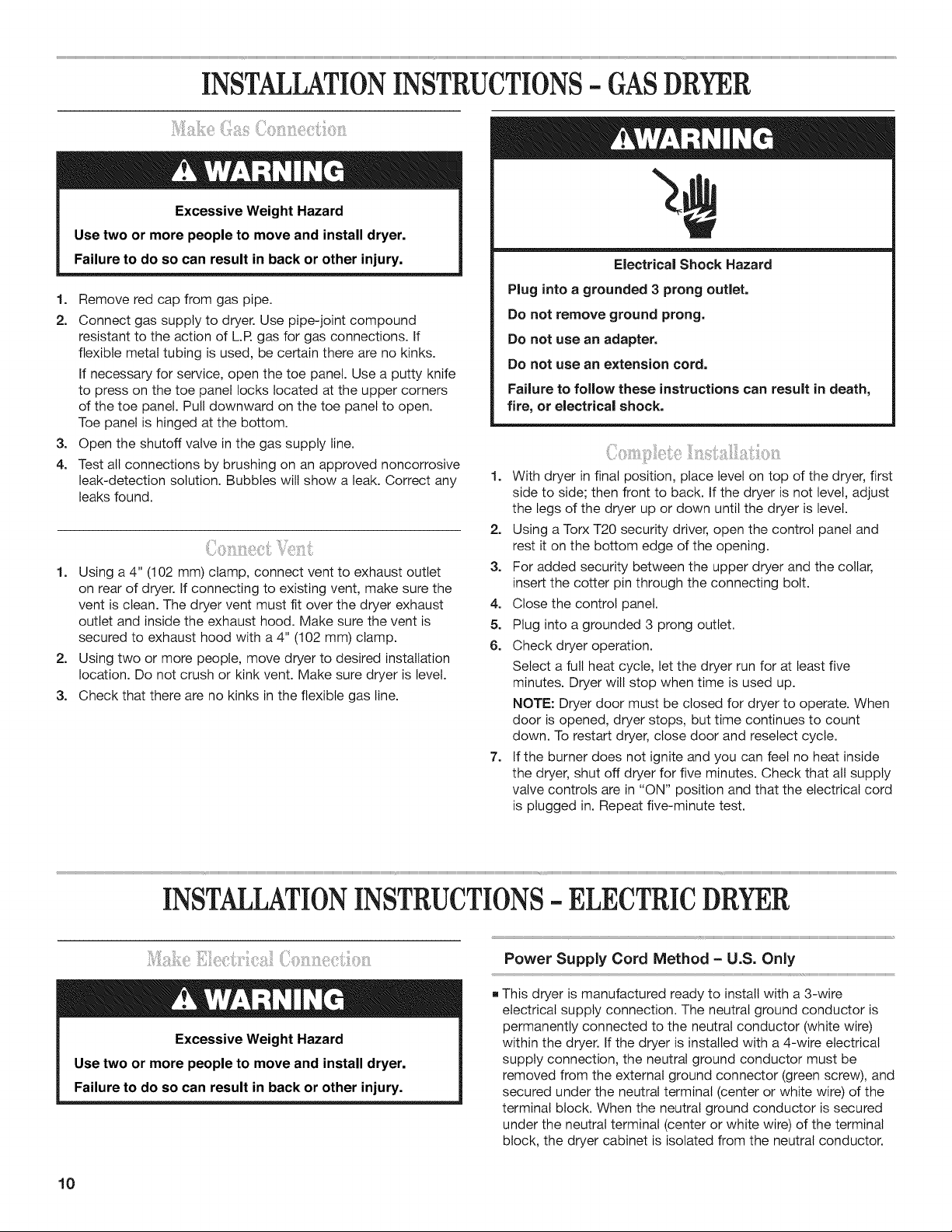

INSTALLATIONINSTRUCTIONS- GASDRYER

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. Use pipe-joint compound

resistant to the action of LR gas for gas connections. If

flexible metal tubing is used, be certain there are no kinks.

If necessary for service, open the toe panel. Use a putty knife

to press on the toe panel locks located at the upper corners

of the toe panel. Pull downward on the toe panel to open.

Toe panel is hinged at the bottom.

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

on rear of dryer. If connecting to existing vent, make sure the

vent is clean. The dryer vent must fit over the dryer exhaust

outlet and inside the exhaust hood. Make sure the vent is

secured to exhaust hood with a 4" (102 mm) clamp.

2. Using two or more people, move dryer to desired installation

location. Do not crush or kink vent. Make sure dryer is level.

3. Check that there are no kinks in the flexible gas line.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. With dryer in final position, place level on top of the dryer, first

side to side; then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

2. Using a Torx T20 security driver, open the control panel and

rest it on the bottom edge of the opening.

3. For added security between the upper dryer and the collar,

insert the cotter pin through the connecting bolt.

4. Close the control panel.

5. Plug into a grounded 3 prong outlet.

6. Check dryer operation.

Select a full heat cycle, let the dryer run for at least five

minutes. Dryer will stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is opened, dryer stops, but time continues to count

down. To restart dryer, close door and resetect cycle.

7. If the burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for five minutes. Check that all supply

valve controls are in "ON" position and that the electrical cord

is plugged in. Repeat five-minute test.

INSTALLATIONINSTRUCTIONS-ELECTRICDRYER

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

10

Power Supply Cord Method - U.S. Only

This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground conductor must be

removed from the external ground connector (green screw), and

secured under the neutral terminal (center or white wire) of the

terminal block. When the neutral ground conductor is secured

under the neutral terminal (center or white wire) of the terminal

block, the dryer cabinet is isolated from the neutral conductor.

Page 11

Power Supply Cord Method = U.S. Only

[] If local codes do not permit the connection of a neutral ground

wire to the neutral wire, see "Optional 3-wire connection"

section.

[]A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through the

neutral conductor is prohibited. Grounding through the neutral

is prohibited for (1) new branch-circuit installations, (2) mobile

homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductors.

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

....s 0

A. External ground conductor screw

B. Tab

C. Terminal block cover

D. Hold-down screw

2=

Remove hold-down screw and the terminal block cover.

3.

Assemble 3A"(19 mm) UL-listed strain relief (UL marking on

strain relief) into the hole below the terminal block opening.

Tighten strain relief screws just enough to hold the two clamp

sections together. Install power supply cord through the

strain relief.

A. Strain relief clamp sections

B. Dryer cabinet

C. Strain relief screws

4=

Complete installation following instructions for your type of

electrical connection:

• Four-wire (recommended method)

Three-wire (if four-wire ts not available)

Power Supply Cord,

Four=wire electrical connection:

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground wire

from the external ground conductor screw.

Fasten under center, silver-colored

terminal block screw.

7. Connect the ground wire of the power

supply cord to the external ground

conductor screw. Tighten screw.

B

Y

D

8. Connect the neutral wire (white or center)

of the power supply cord under the center

screw of the terminal block. Tighten

screw.

9. Connect the other wires to outer terminal

G

A. Spade terminals with D.Neutral (white)

upturned ends E.Ring terminals

B. Neutral F. Ground wire

C.¾" (19 mm) UL-fisted G.Ground prong

strain relief

F .... E ''_

block screws. Tighten screws.

10. Tighten strain relief screws.

11. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

Four-wire power supply cord must have four, No. 10 copper wires and match a four-wire

receptacle of NEMA Type 14-30R. The fourth wire (ground conductor) must be identified

by a green cover and the neutral conductor by a white cover.

0

E ......................

A.Externalgroundconductorscrew

B.Applianceneutralgroundwire

C.Centerterminalblockscrew

D.Outerterminalblockscrews

E.Strainreliefscrew

F. Neutral(centerwire)

G.Groundwire

Page 12

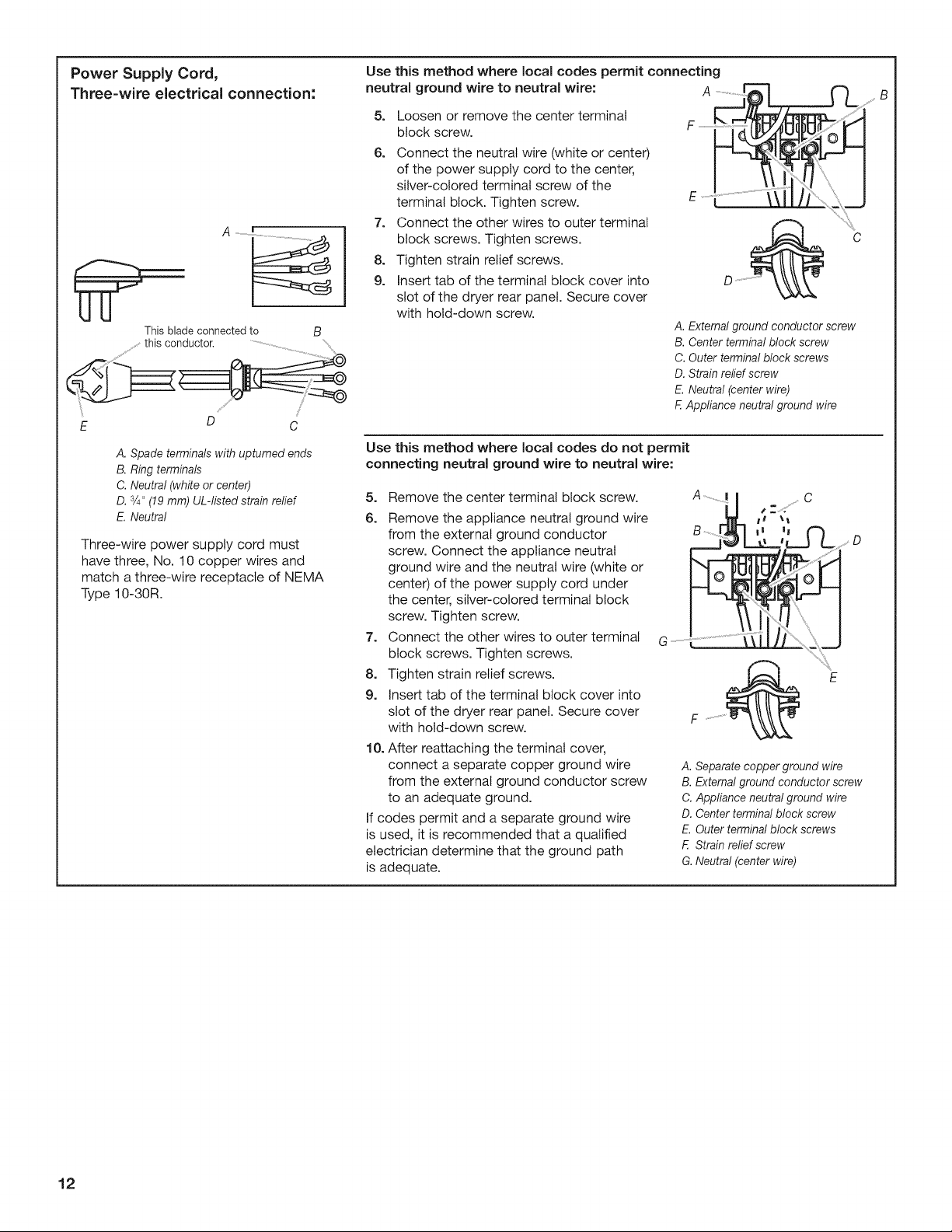

Power Supply Cord,

Three=wire electrical connection:

_m A ....................

Thisbladeconnectedto B

.....thisconductor. ...................................

E D C

A. Spade terminals with upturned ends

B.Ring terminals

C.Neutral (white or center)

D. ¾" (19 mm) UL-Iisted strain relief

E. Neutral

Three-wire power supply cord must

have three, No. 10 copper wires and

match a three-wire receptacle of NEMA

Type 10-30R.

Use this method where local codes permit connecting

neutral ground wire to neutral wire: A ................................ _Z_

5. Loosen or remove the center terminal l_l _.__ O__1

block screw. F .....................

Connect the neutral wire (white or center)

of the power supply cord to the center,

silver-colored terminal screw of the

terminal block. Tighten screw.

E ..........

7. Connect the other wires to outer terminal _ .........

8. Tighten strain relief screws.

block screws. Tighten screws. _ C

9. Insert tab of the terminal block cover into D ............

slot of the dryer rear panel. Secure cover

with hold-down screw.

A. External ground conductor screw

B. Center terminal block screw

C. Outer terminal block screws

D. Strain relief screw

E. Neutral (center wire)

F.Appliance neutral ground wire

Use this method where local codes do not permit

connecting neutral ground wire to neutral wire:

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground wire

from the external ground conductor

A...............!.... C

g ............

I I \l

screw. Connect the appliance neutral

ground wire and the neutral wire (white or

center) of the power supply cord under

the center, silver-colored terminal block

screw. Tighten screw.

7. Connect the other wires to outer terminal

block screws. Tighten screws.

8. Tighten strain relief screws.

E

9. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

F ..................

10. After reattaching the terminal cover,

connect a separate copper ground wire

from the external ground conductor screw

to an adequate ground.

If codes permit and a separate ground wire

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

A. Separate copper ground wire

B. External ground conductor screw

C. Appliance neutral ground wire

D. Center terminal block screw

E. Outer terminal block screws

F. Strain relief screw

G. Neutral (center wire)

B

12

Page 13

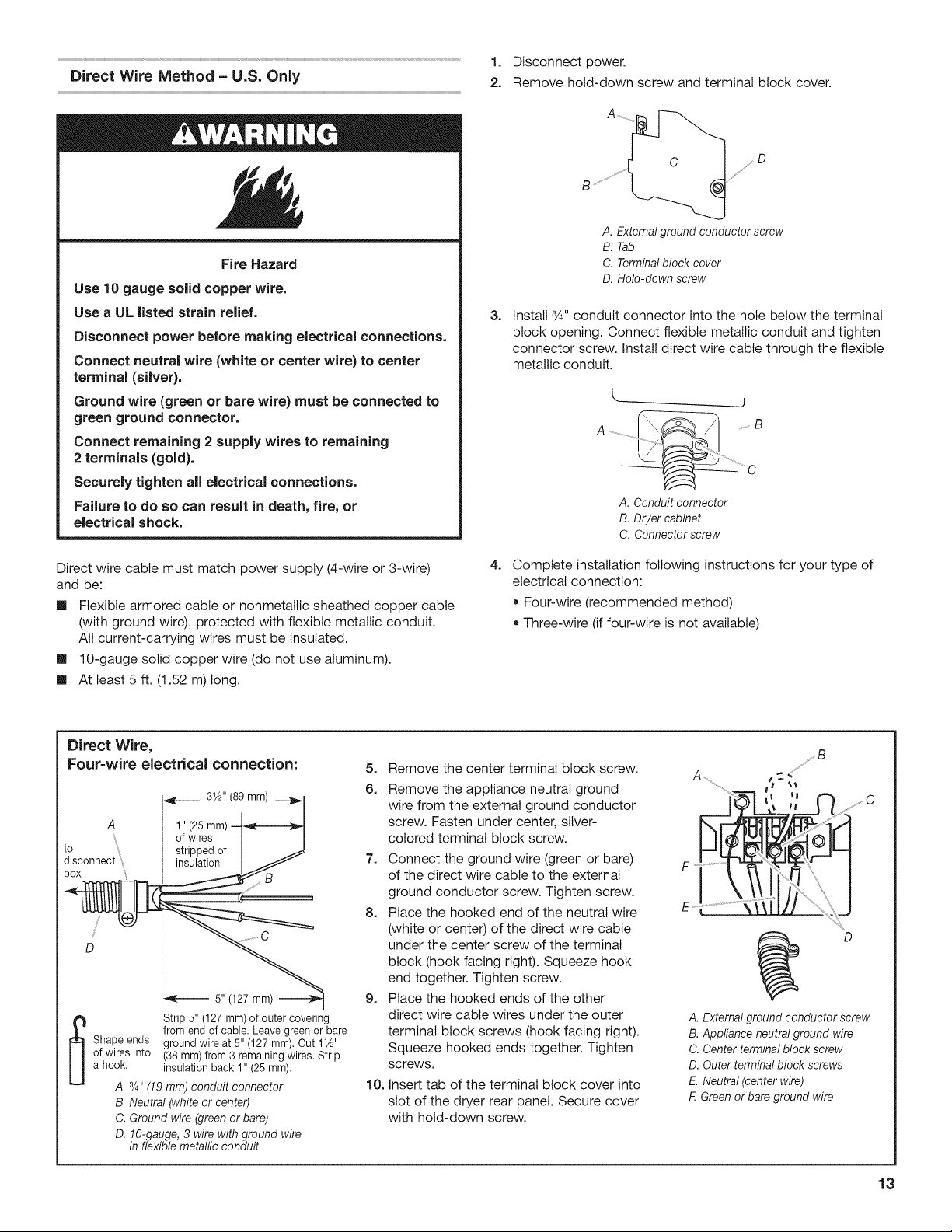

Direct Wire Method - U.S. Only

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

2. Remove hold-down screw and terminal block cover.

A. External ground conductor screw

B. Tab

C. Terminalblock cover

D. Hold-down screw

3=

Install ,_A"conduit connector into the hole below the terminal

block opening. Connect flexible metallic conduit and tighten

connector screw. Install direct wire cable through the flexible

metallic conduit.

B

A. Conduitconnector

B.Dryercabinet

C. Connectorscrew

Direct wire cable must match power supply (4-wire or 3-wire)

and be:

[] Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit.

All current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum).

[] At least 5 ft. (1.52 m) long.

Direct Wire,

Four=wire electrical connection:

to I °_r_ e_jof/_

_ 5" (127mm) _

Shape ends ground wireat5" (127 mm). CutI_A"

ofwiresinto (38 mm) from3remaining wires. Strip

ahook. insulationback1"(25 mm).

A. _/4"(19mm)conduitconnector

fromendof cable.Leavegreenor bare

Strip 5" (127 mm) of outercovering

B.Neutral(whiteorcenter)

C.Groundwire(greenor bare)

D. lO-gauge,3wirewith groundwire

in flexiblemetallicconduit

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground

wire from the external ground conductor

screw. Fasten under center, silver-

colored terminal block screw.

7. Connect the ground wire (green or bare)

of the direct wire cable to the external

ground conductor screw. Tighten screw.

8. Place the hooked end of the neutral wire

(white or center) of the direct wire cable

under the center screw of the terminal

block (hook facing right). Squeeze hook

end together. Tighten screw.

9. Place the hooked ends of the other

direct wire cable wires under the outer

terminal block screws (hook facing right).

Squeeze hooked ends together. Tighten

screws.

10. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

4=

Complete installation following instructions for your type of

electrical connection:

Four-wire (recommended method)

Three-wire (if four-wire is not available)

F

E¸

A. External ground conductor screw

B.Appliance neutral ground wire

C.Center terminal block screw

D.Outer terminal block screws

E.Neutral (center wire)

F.Green or bare ground wire

13

Page 14

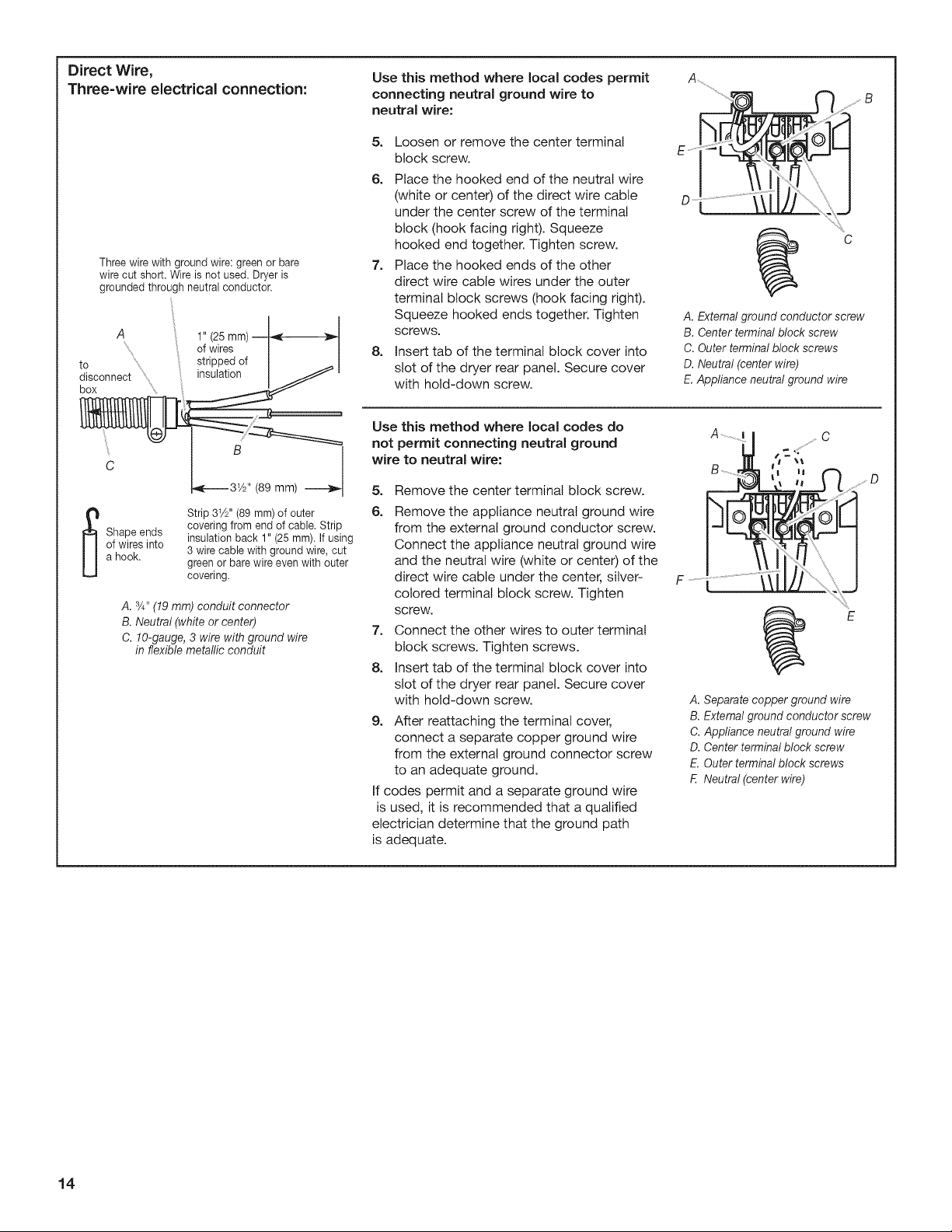

Direct Wire,

Three=wire electrical connection:

Three wire with ground wire: green or bare

wire cut short. Wire is not used. Dryer is

grounded through neutral conductor.

A 1" (25 mm)

ofwires

to strippedof

disconnect insulation

box _

Use this method where local codes permit

connecting neutral ground wire to

neutral wire:

5. Loosen or remove the center terminal

block screw.

6. Place the hooked end of the neutral wire

(white or center) of the direct wire cable

under the center screw of the terminal

block (hook facing right). Squeeze

hooked end together. Tighten screw.

7. Place the hooked ends of the other

direct wire cable wires under the outer

terminal block screws (hook facing right).

Squeeze hooked ends together. Tighten

screws.

8. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

C

A. External ground conductor screw

B. Center terminal block screw

C. Outer terminal block screws

D. Neutral (center wire)

E.Appliance neutral ground wire

Be

C

(89 mm)

Strip 31½''(89 mm) of outer

Shapeends

of wiresinto

a hook.

A. 3/4"(19 ram)conduit connector

B. Neutral (white or center)

C. lO-gauge, 3 wire with ground wire

in flexible metallic conduit

covering from end of cable. Strip

insulation back 1" (25 mm). If using

3 wire cable with ground wire, cut

green or bare wire even with outer

covering.

Use this method where local codes do

not permit connecting neutral ground

wire to neutral wire:

5. Remove the center terminal block screw.

6. Remove the appliance neutral ground wire

from the external ground conductor screw.

Connect the appliance neutral ground wire

and the neutral wire (white or center) of the

direct wire cable under the center, silver-

colored terminal block screw. Tighten

screw.

7. Connect the other wires to outer terminal

block screws. Tighten screws.

8. Insert tab of the terminal block cover into

slot of the dryer rear panel. Secure cover

with hold-down screw.

9. After reattaching the terminal cover,

connect a separate copper ground wire

from the external ground connector screw

to an adequate ground.

If codes permit and a separate ground wire

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

A......... C

A. Separate copper ground wire

B. External ground conductor screw

C. Appliance neutral ground wire

D. Center terminal block screw

E. Outer terminal block screws

F. Neutral (center wire)

14

Page 15

CI_i:i¸,_::i_i_i:i__i:::__iii_ii__iiii_i!i__:i_ii:_

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (102 mm) clamp.

2. Using two or more people, move dryer to desired installation

location. Do not crush or kink vent. Make sure dryer is level.

1. With dryer in final position, place level on top of the dryer, first

side to side; then front to back. Ifthe dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

2. Using a Torx T20 security driver, open the control panel and

rest it on the bottom edge of the opening.

REVERSINGTHEDOORSWING(OPTIONAL)

You can change your door swing from a right-side opening to a

left-side opening, if desired.

C

3. For added security between the upper dryer and the collar,

insert the cotter pin through the connecting bolt.

4. Close the control panel.

5. Plug in dryer or reconnect power.

6 Check dryer operation.

Select a full heat cycle, let the dryer run for at least five

minutes. Dryer wilt stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is opened, dryer stops, but time continues to count

down. To restart dryer, close door and reselect cycle.

7. Now start the dryer and allow it to complete a full heat cycle

to make sure it is working properly.

5_

Reattach outer door panel to

inner door panel so handle

is on the side where hinges

were just removed.

A

1. Open dryer door. Remove bottom screws from cabinet side of

hinges (A). Loosen (do not remove) top screws from cabinet

side of hinges.

2. Lift door until top screws in cabinet are in large part of

hinge slot. Pull door forward off screws. Remove top

screws from cabinet.

3. Remove screws attaching hinges to door.

4. Remove screws from all sidess of door (5screws). Grasp

sides of outer door and gently lift to separate it from inner

door (do not pry apart). Do not pull on door seal or plastic

door catch.

6_

Attach door hinges to dryer door so that the larger hole is

at the bottom of the hinge and the hinge pin is toward the

door front.

7. Remove the 4 screws that attach 2 plugs (B) on the handle

side. Attach plugs to opposite side using the same 4 screws.

8. Insert screws into bottom holes on left

side of cabinet. Tighten screws halfway.

Position door so large end of door hinge

slot is over screws. Slide door up so

screws are in bottom of slots. Tighten

screws. Insert and tighten top

screws in hinges.

9. Close door and check that door strike aligns with door

catch (C).

15

Page 16

MAINTENANCEINSTRUCTIONS

Maintenance instructions:

mClean lint screen after each cycle.

mRemoving accumulated lint:

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

mKeep area around dryer clear and free from combustible

materials, gasoline and other flammable vapors and liquids.

mKeep dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air.

ELECTRONICCONTROL SETUP

BASIC OPERATION OF COMMERCIAL WASHER

[] For additional information, see www.Ma__a_C0mmercia&aundt_

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

iMPORTANT

E|ectros_atic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is finished,

but failure may occur at a later date due to ESD stress.

[] Use an anti-static wrist strap. Connect wrist strap to green

ground connection point or unpainted metal in the appliance

-OR-

Touch your finger repeatedly to a green ground connection point

or unpainted metal in the appliance.

[] Before removing the part from its package, touch the anti-

static bag to a green ground connection point or unpainted

metal in the appliance.

[] Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

[] When repackaging failed electronic control assembly in anti-

static bag, observe above instructions.

If dryer does not operate, check the following:

[] Electrical supply is connected.

[] Circuit breaker is not tripped or house fuse is not blown.

[] Door is closed.

[] Controls are set in a running or "ON" position.

[] Cycle has been selected.

[] For gas dryers, check that gas supply shutoff valves are set

in open position.

If you need assistance:

The Commercial Laundry Support Center will answer any

questions about operating or maintaining your dryer not covered

in the Installation Instructions. Just dial 1-800 NO BELTS

(1-800-662-3587) -- the call is toll free.

When you call, you will need the dryer model number and serial

number. Both numbers can be found on the serial-rating plate

located in the dryer door well.

GENERAL USER iNFORMATION

Blank display

This condition indicates the appliance is inoperative. Enter set-up

mode to view diagnostic code.

'0 Minutes' showing in display

This condition indicates the appliance cannot be operated. Coins

dropped or debit inputs during this condition will be stored in escrow

but cannot be used until normal operation is restored by opening

and closing the door. If a door switch fails, it must be replaced before

normal operation can be restored.

Cold Start (initial first use)

Appliance is programmed at the factory as follows:

[] 5 minutes dry time/quarter (coin 1).

[] $1.50 dry price (fixed cycle with top off - PD Models).

[] $0.00 dry price (fixed cycle - PR Models).

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, 'RESELECT CYCLE' will flash

in the display. This is to indicate the need for a fabric setting

key pad to be pressed to restart dryer.

16

Page 17

Pricing

After the door is opened following the completion of a cycle, the

display indicates the cycle price (unless set for free operation). As

coins or debit inputs arrive, the display will change to beadthe user

through the initiation of a cycle.

There are four (4)types of pricing:

Fixed 'Vend' Pricing

A dryer set up for 'Fixed Cycle' operation can only accept additional

time accumulated by increments equal to the length of a complete

dry cycle. A maximum of 99 minutes may be purchased; no

additional credit is given when 99 minutes is in the display.

Accumulator Pricing

Ifthe price is set to one coin 1,then accumulator mode is in effect

(stacked PD models also require Fixed Cycle with Top Off option to

be selected). Cycle time can be purchased one coin at atime (PD

models) up to the maximum time of 99 minutes. Stacked PD

machines will credit all money to a cycle with a single button press

while in accumulator pricing.

Fixed Cycle With Top Off Pricing

A dryer set to offer 'Top Off' capability will allow time to be added to

an existing dry cycle in increments equal to the number of minutes

of dry time per quarter (coin 1), up to 99 minutes, regardless of the

cost required to start the machine. No credit is given for coins or

debit inputs entered when the control is displaying 99 minutes.

PR Models: In Enhanced Debit Mode, the top off price can be set

independently. (See VALUE OF COIN 2), and the top off time is

calculated according to the following equation:

top off price = top off time

full cycle price full cycle length

Penny increment offset is not applied to top off purchases.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, 'SELECT CYCLE' wilt appear rather than a cycle price.

Any cycle started as a free cycle will automatically terminate when

the door isopened.

Debit Card Ready

This appliance is debit card 'cable' ready. It wilt accept a variety of

debit card systems; but, does NOT come with a debit card reader.

Refer to the debit card reader manufacturer for proper machine

set-up. In models converted to a Generation 1 debit card system,

debit pulses represent the equivalent of one coin (coin 1).

CONTROL S_:T-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

The fabric setting key pads along with the digital display are used to

set-up the dryer controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related code

values available for use in programming the appliance.

How to use the key pads to program the controls

1. The WHITES AND COLORS key pad is used to adjust the values

associated with set-up codes. Pressing the key pad will

increment the value by one (1). Rapid adjustment is possible by

holding the key pad down.

2. The PERM. PRESS key pad will advance you through the set-up

codes. Pressing the key pad will advance you to the next

available set-up code. Holding the key pad down will

automatically advance through the set-up codes at a rate of one

(1)per second.

3. The DELICATES key pad is used to select or desetect options.

DISPLAY

After the dryer has been installed and plugged in, the display will

show '0 minutes.'

Stacked PR Models

Once the unit has been plugged in and the dryer door opened and

closed, the display wilt show the price. In PR and PN models set for

free cycles, the display will flash 'SELECT CYCLE' (not shown).

Stacked PD Models

UPPER DRYER

WHITES & PERM.

COLORS PRESS DELICATES

IMPORTANT: The console must not be opened unless power is

first removed from the dryer. To access connector AA1:

-> Unplug dryer or disconnect power.

-> Open console, disconnect plug on AA1, close console.

-> Plug in dryer or reconnect power.

[] Stacked PD Models: Insert access panel key and turn

counter-clockwise.

[] Stacked PR Models: Once the debit card reader is installed

(according to the reader manufacturer's instructions), the

set-up mode can be entered by inserting a manual set-up card

(supplied by the reader manufacturer) into the card slot.

If manual set-up card is not available, manual set-up mode can be

entered by turning the access panel key.

The dryer is now in the set-up mode.

Before proceeding it is worth noting that, despite all the options

available, an owner can simply choose to uncrate a new commercial

machine, hook it up, plug it in, and have a unit which operates.

[] PD units are pre-set at the factory for fixed cycle price with top off.

[] PR units are pre-set for free cycle operation so they can

be run without readers or coins.

17

Page 18

S_T-UP CODI:S

[] The PERM.PRESS key pad will advance you from code to code.

[] The WHITE AND COLORS key pad will change the code value.

[] The DELICATES key pad will select or deselect options.

FOR PR MODELS: The set-up codes are the same as for the PD

models except where noted.

NOTE: On all stacked dryer models, programming selections apply

to both dryers. Stackded dryer selections are accessed by pressing

the LOWER DRYER key pads.

The set-up code is indicated bythe one or two left-hand characters.The

set-up code valueis indicated bythe two or three right-handcharacters.

REGULAR CYCLE PRICE

o_

Representsthe numberof quarters(coin1);mayadjustfrom

0-39. (SeeVALUEOFCOIN1b.05) Advancefrom0-39 by

pressingtheWHITESANDCOLORSkeypad.

Factorypresetfor 6quarters=$1.50.

PRMODELSONLY:Factorypresetfor 0 quarters.

•-->Pressthe PERM.PRESSkey padonceto advanceto nextcode.

n r_C

_u J

-I FI C

REGULAR DRY TIME

Representsthe numberof minutesperquarter(coin1).

Factorypresetfor 5minutespercoin.

Example:6 quartersx 5 minutes= 30 minutes.

BypressingtheWHITESANDCOLORSkeypad,you canadjust

thevaluefrom 1-99 minutes.

•-->Pressthe PERM.PRESSkey padonceto advanceto nextcode.

_FIFI

LO_UU

nnn

TYPE OF DRYER PRICING

FixedCyclewith TopOff.Fordetaileddescription,seeGeneral

UserInformation.

DGF

o_

FixedCycle.Fordetaileddescription,seeGeneralUser

Information.

UseDELICATESkeypadto makethis selection.

PRMODELSONLY:Factorysetfor FC.

_n_

_u u CYCLE COUNTER OPTION

This optionis eitherSELECTED'ON' or NOTSELECTED'OFF'.

-_'-_L"""""_ NotSelected'OFF'.

'-?_ Selected'ON'and not ableto bedeselected.PressDELICATES

keypad3 consecutivetimes to select'ON'.Onceselected'ON'

it cannotbedesebcted.

-> Pressthe PERM.PRESSkey padonceto advanceto nextcode.

I FI FI

_uu

MONEY COUNTEROPTION

ThisoptioniseitherSELECTED'ON'or NOTSELECTED'OFF'.

I FI FI

NotSelected'OFF'.

Selected'ON'.

PresstheDELICATESkeypad3 consecutivetimestoselect

'ON'and3consecutivetimesto remove(NotSelected'OFF'.)

Counterresetsbygoingfrom'OFF'to 'ON'.

IFR

--->Pressthe PERM.PRESSkeypadonceto advanceto nextcode.

J__.uu SPECIAL PRICING OPTION

/==---I/J/JI

_ Selected'ON'.Pressthe DELICATESkey padoncefor this

If SPECIALPRICINGOPTIONis selected, youhaveaccessto codes

'3.' through 'g.'.

-> PressthePERM.PRESSkeypadonceto advanceto nextcode.

OPTIONSTO

DL_.U U

2._

-> PressthePERM.PRESSkeypad onceto advanceto nextcode.

i U f'_ L.-

i _.u J SPECIAL DRY TIME

i

%_._ Representsthe numberof minutesperquarter(coin 1).

-> PressthePERM.PRESSkeypad onceto advanceto nextcode.

C FI FI

u u TIME-OF-DAY CLOCK, MINUTES

C FI FI

J-J-_5 Thisis theTIME-OF-DAYCLOCK,minutesetting; select0-59

-> PressthePERM.PRESSkeypad onceto advanceto nextcode.

c n n TIME-OF-DAY CLOCK, HOURS

J-LL_ju u

cnn

u.A_j ThisistheTIME-OF-DAYCLOCK,hoursetting;select0-23

•.-1PressthePERM. PRESSkeypadoncetoadvancetonextcode.

Selected'ON'and notableto bedeselected.

Toselect 'ON'and notableto bedeselected,first select'ON',

thenwithin two secondspressthe DELICATESkey padtwice,

theWHITESANDCOLORSkeypadonce,andexittheset-up

mode.

Thisoption is eitherSELECTED'ON'or NOTSELECTED'OFF'.

n n Not Selected'OFF'.

selection.

USEIFSPECIALPRICINGISSELECTED:

SPECIALCYCLEPRICE

Representsthe numberd quarters(coin 1); mayadjustfrom

0-39. (SeeVALUEOFCOIN1 b.05)Advancefrom 0-39 by

pressingtheWHITESANDCOLORS.Factorypreset

for 6quarters=$1.50.

PR MODELSONLY:Factorypresetfor 0 quarters.

Factorypresetfor 5 minutespercoin.

Example:6quartersx 5 minutes=30 minutes.

Bypressingthe WHITESANDCOLORSkeypad,youcanadjust

the valuefrom 1-99 minutes.

minutesby pressingtheWHITESANDCOLORSkey pad.

NOTE:Usesmilitarytime-24 hr.clock.

hoursbypressingtheWHITESAND COLORS keypad.

18

Page 19

OPTIONSTOUSEiFSPECIALPRiCiNGiSSELECTED(continued):

jGu u SPECIAL PRICE START HOUR

NOTE:Usesmilitarytime-24 hr.clock.

-I1-11-1

/._ This isthe start hour,0-23 hours.SelectSTARTHOURby

pressingtheWHITESANDCOLORSkeypad.

-e Pressthe PERM.PRESSkeypad onceto advanceto nextcode.

Onn

_LLL_.U U SPECIAL PRICE STOP HOUR

NOTE:Usesmilitarytime-24 hr.clock.

o._ This isthe stop hour;0-23 hours.SelectSTOPHOURby

pressingtheWHITESANDCOLORSkeypad.

-e Pressthe PERM.PRESSkeypad onceto advanceto nextcode.

L_. I u SPECIAL PRICE DAY

,'_ __'_ Thisrepresentsthe dayof theweekandwhetherspecial

pricingis selectedforthat day.A numberfollowed by '0'

indicatesnoselectionthat particularday(9.10).A number

followed byan'S' indicatesselectedfor thatday(9.1S).

Daysofthe week(1-7) canbechosenby pressingthe

WHITESANDCOLORSkeypad.PressDELICATES

keypadonceto selectspecialpricingfor eachdaychosen.

Whenexitingsetup code'9.', thedisplaymust showcurrent

dayof week:

DISPLAY DAYOFWEEK CODE(selected)

10 Day1 =Sunday 1S

20 Day2 =Monday 2S

30 Day3 =Tuesday 3S

40 Day4 =Wednesday 4S

50 Day5 =Thursday 5S

60 Day6 =Friday 6S

70 Day7 =Saturday 7S

-_ Pressthe PERM.PRESSkeypad onceto advanceto nextcode.

_uu

VAULT VIEWING OPTION

This option iseitherSELECTED'ON'or NOTSELECTED'OFF'.

NotSelected'OFF'.

-I Cf"

Selected'ON'.Press DELICATESkey padoncefor this

selection.Whenselected,themoneyand/orcyclecounts

will beviewable(if countingisselected)when thecoin box is

removed.

Pressthe

_u5

L nC

PERM.PRESSkey padonceto advanceto nextcode.

VALUE OF COIN 1

This representsthevalueof coin 1in numberof nickels:

O5= $O.25.

BypressingtheWHITESANDCOLORSkey padyou havethe

option d 1-199 nickels.

-e Pressthe

J_LL-_CU

PERM.PRESSkey padonceto advanceto nextcode.

VALUE OF COIN 2

This representsthevalueof coin 2in numberof nickels:

20 = $1.00.

BypressingtheWHITESANDCOLORSkey padyou havethe

option d 1-199 nickels.

PRMODELSONLY:ForPRmodels using EnhancedDebit,this

field representsthevalueof topoff in nickels

PRMODELS:Factorypresetfor $0.25.

-->Pressthe

PERM.PRESSkey padonceto advanceto nextcode.

COIN SLIDE OPTION

This optionis eitherSELECTED'ON'or NOTSELECTED'OFF'.

.Ifll-I

NotSelected'OFF'.

Selected'ON'.

PresstheDELICATESkey pad3 consecutivetimesfor this

selection.Whencoinslidemodeisselected,set'b.' equalto

valued slideinnickels.Set'606'(REGULARCYCLEPRICE)

and'3.06'(SPECIALCYCLEPRICE)to numberofslide

operations.

NOTE:Ifthe installersetsup'CS'ona coin drop model,itwill

not registercoins.

Pressthe PERM.PRESSkey padonceto advanceto nextcode.

c n _ ADD COINS OPTION

_uu

This optionis eitherSELECTED'ON'or NOTSELECTED'OFF'.

This optioncausesthecustomerdisplayto showthe number

ofcoins (coin 1)to enter,ratherthanthe dollars-and-cents

amount.

r n n Not Selected 'OFF'.

Selected'ON'.

PresstheDELICATESkeypad3 consecutivetimesfor this

selection.

PRMODELSONLY:Inenhanceddebitmode,thisoption is

not selectable.

-e Presst

IF I

,=_j_ t='-i

_ePERM.PRESSkeypadonceto advanceto nextcode.

COIN/DEBIT OPTION

Bothcoin & debitselected.

It-

Coinsselected,debitdisabled.

PressDELICATESkeypadfor thisselection.

I i

DebitCardselected,coinsdisabled.

PressDELICATESkeypadfor thisselection.

IC;

,.J._

EnhancedDebitis self-selectedwhen a Generation2 card

readeris installedinthe dryer.The'Ed'option cannotbe

manuallyselectedor deselected.

-e Pressthe PERM.PRESSkeypadonceto advanceto nextcode.

i n _ PRICE SUPPRESSION OPTION

L_._u u

This optionis eitherSELECTED'ON'ORNOTSELECTED'OFF'.

This optioncausesthecustomerdisplayto show'AVAILABLE'

or 'ADD'ratherthanthe amountof moneyto add.(Used

mainlyin debit installations.)

__.___ Not Selected'OFF'.

_._o c Selected'ON'.Pressthe DELICATESkeypadoncefor this

selection.

-e Pressthe PERM.PRESSkeypadonceto advanceto nextcode.

L_-_C CLEAR ESCROW OPTION

This optioniseitherSELECTED'ON'ORNOTSELECTED'OFF'.

Whenselected,moneyheldinescrowfor30 minuteswithout

furtherescroworcycleactivitywill becleared.

n._2_ Selected'ON'.

f_j_j Notselected'OFF'.PresstheDELICATESkeypadonceforthis

selection.

-) PressthePERM.PRESSkey padoncetoadvanceto nextcode.

__ n PENNY iNCREMENT OFFSET

_=l_ju u

u._ Thisrepresentsthepennyincrementpriceoffsetusedin

Generation2 (EnhancedDebit)PRmodels.Choosefrom 0-4

penniesbypressingtheWHITESANDCOLORSkeypad.

-_ Pressthe PERM.PRESSkeypadoncetoadvanceto nextcode.

19

Page 20

If cycle counter (9.0C) is selected, the following is true:

100 Represents the number of cycles in HUNDREDS. 1 02 = 200

200 Represents the number of cycles in ONES. 22`5= 25

TOTAL = 225

cycles

This is "VIEW ONLY" and cannot be cleared.

Press the PERM. PRESS key pad once to advance

to next code.

If money counter (1.0C or 1.C0) is selected, the following is true:

300 Number of dollars in HUNDREDS. 3 01 = $100.00

400 Number of dollars in ONES. 4 68 = $ 68.00

500 Number of CENTS. 5 7,5= $ 00.75

TOTAL = $168.75

END OF SET-UP PROCEDURES

EXIT FROM SET=UP MODS

m STACKEDMODELS: Turn access panel keyback to originalposition.

DiAGNOSTiC GUIDIE

If the set-up mode is entered and one of the following has occurred,

the appropriate diagnostic code will be in the display.

STACKED DRYERS

d / F = O1 invalid dryerdoor circuitstatestate- Sahara

d '-/ F=O$

d'_q d9

d "? F=Ol

1=-, d

d m

d In- H-,o d ,o

d/7 d/7

d _n _n

control does not differentiatebetweeninvalid

stateand opendoor state.

CCUerror - Saharacontrolwill sendthis error

whenthe motor feedbackcircuit issensing

voltagewith the dooropenor whenthe motor

shouldn't beon. Thecontrol doesn't knowif

the relayis bad(stuck on),the relaydrive

circuit is bad(shortedcausingthe motorrelay

to stayon), orthe relayfedbackcircuitis bad.

Lowvoltage

CCUerror - Saharacontrolwill sendthis error

whenthe motor feedbackcircuit issensing

voltagewith the dooropenor whenthe motor

shouldn't beon. Thecontrol doesn't knowif

the relayis bad(stuck on),the relaydrive

circuit is bad(shortedcausingthe motorrelay

to stayon), orthe relayfedbackcircuitis bad.

Coin2 Failure

0

Upperdryer motor sensecircuit erroron

control board or dueto powerline interference

(upperdryer cyclesand upper dryer display

disableduntil diagnosticcode is manually

cleared).

Gen2 DebitCard

Lowerdryerdoor senseerroron control board

or dueto powerlineinterference(lowerdryer

cyclesandlower dryerdisplaydisableduntil

diagnosticcode ismanuallycleared).

Upperdryer motor control circuit error(upper

dryer cyclesand upperdryer displaydisabled

untildiagnosticcodeis manuallycleared).

2O

Page 21

MAYTAG COMMERCIAL WASHE DRYER,STACKED DRYER/

DRYER,COMMERCIAL STACK LAUNDRY, AND MULTi-LOAD

COiN OPERATED COMMERCIAL WASHERS AND DRYERS

WAR NTY

LiMiTED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter "Maytag") will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DiSCLAiMER OF iMPLiED WARRANTIES; LiMiTATiONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THiS LiMiTED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. iMPLiED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABiLiTY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LiMiTATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

For written correspondence:

Maytag Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49085 USA

9/07

21

Page 22

P P P

SECURITEDELASECHEUSE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curite importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tous les messages de s_curite et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves h vous

et h d'autres.

Voici le symbole d'alerte de s_curit&

Tousles messages de securite suivront le symbole d'alerte de s_curite et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

r

Tous les messages de s_curite vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

AVERTISSEMENT - "Risque d'incendie"

m

L'instaliation de {a s_cheuse a {inge doit _tre effectu_e par un installateur qualifi_.

m

installer la s_cheuse conforrn_rnent aux instructions du fabricant et aux codes {ocaux,

m

Ne pas installer de s_cheuse h tinge avec des rnat_riaux d'_vacuation en piastique

souple, Si un conduit m_tallique soupie (de type papier d'a{uminium) est installS,

celui-ci doit _tre d'un type sp_cifique identifi6 par le fabricant de {'apparel{ et

convenir h une utilisation avec {es s_cheuses a linge, Les mat_riaux d'_vacuation

soupies sont connus pour s'affaisser, 6tre facilement _cras_s et bloquer {a charpie,

Ces situations obstrueront {e d_bit d'air de {a s_cheuse a {inge et augmenteront {e

risque d'incendie,

Pour r_duire {e risque de blessure grave ou de d_c_s, suivre routes

{es instructions d'insta{lation,

Conserver ces instructions,

22

Page 23

AVERTISSEMENT • Pour votre securite, les renseignements darts ce manuel doivent

_tre observes pour reduire au minimum les risques d'incendie ou d'explosion ou pour

eviter des dommages au produit, des blessures ou un deces.

- Ne pas entreposer ou utiliser de I'essence ou d'autres vapeurs ou liquides

inflammables a proximite de cet appareil ou de tout autre appareil electromenager.

- QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

®Ne pas tenter d'allumer un appareil.

• Ne pas toucher a un commutateur electrique; ne pas utiliser le telephone se trouvant

sur les lieux.

• _:vacuer tous les gens de la piece, de I'edifice ou du quartier.

• Appeler immediatement le fournisseur de gaz d'un telephone voisin. Suivre ses

instructions.

• h.defaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et I'entretien doivent _tre effectues par un installateur qualifie, une

agence de service ou le fournisseur de gaz.

AVERTISSEMENT : L'odorat ne permet pas toujours la d6tection d'une fuite de gaz.

Les distributeurs de gaz recommandent I'emploi d'un detecteur de gaz (homologation UL ou CSA).

Pour d'autre information, contacter le fournisseur de gaz local.

En cas de d6tection d'une fuite de gaz, ex6cuter les instructions "Que faire dans le cas d'une odeur de gaz".

iMPORTANT : L'installation du gaz doit se conformer aux codes Iocaux, ou en I'absence de codes Iocaux, au code canadien

d'installation B149.1 du gaz naturel ou du propane.

La secheuse doit 6tre 61ectriquement reliee & la terre conformement aux codes Iocaux, ou en I'absence de codes Iocaux, au Code

canadien de I'electricit6, CSA C22.1.

Dans I'#tat du Massachusetts, les instructions d'installation suivantes sont applicables :

[] Les travaux d'installation et reparation doivent 6tre execut6s par un plombier ou tuyauteur qualifie ou licencie, ou par le

personnel qualifie d'une entreprise licenciee par I'Etat du Massachusetts.

[] Si une vanne & boisseau spherique est utilis6e, elle dolt comporter une manette "T".

[] Si un conduit de raccordement flexible est utilise, sa Iongueur ne doit pas depasser 3 pi.

23

Page 24

IMPORTANTES INSTRUCTIONS DE SI_CURITI_

AMERTISSEMENT • Pour r6duire le risque d'incendie, de choc 61ectrique ou de blessure Iors de I'utilisation de

la s6cheuse, il convient d'observer certaines pr6cautions el6mentaires dont les suivantes :

• Lire toutes les instructions avant d'utiliser la s6cheuse.

• Ne pas placer des articles expos6s aux huiles de cuisson

dans votre secheuse. Les articles contamin6s par des

huiles de cuisson peuvent contribuer & une r6action

chimique qui pourrait causer a la charge de s'enflammer.

• Ne pas faire s6cher dans la machine des articles qui ont

d6j& et6 nettoy6s, lav6s, imbib6s, ou tach6s d'essence,

de solvants pour nettoyage a sec, d'autres substances

inflammables, ou de substances explosives puisqu'elles

d6gagent des vapeurs qui peuvent provoquer un

incendie ou une explosion.

• Ne pas permettre & des enfants de jouer sur ou

I'int6rieur de la s6cheuse. Une surveillance 6troite est

n6cessaire Iorsque la s6cheuse est utilis6e pros d'eux.

• Avant d'enlever la s6cheuse du service ou la jeter, enlever

la porte du compartiment de s6chage.

• Ne pas mettre la main dans la s6cheuse si le tambour est

en mouvement.

• Ne pas installer ni entreposer la s6cheuse oQ elle sera

expos6e aux intemp6ries.

• Ne pas jouer avec les commandes.

CONSERVEZ CES INSTRUCTIONS

• Ne pas reparer ni remplacer une piece de la secheuse ou

essayer d'en faire I'entretien & moins d'une recommandation

specifique dans le guide d'utlilisation et d'entretien, ou