Maytag MLG24PDAGW2, MLG24PNAGW0, MLG24PNAGW1, MLG24PDAGW3, MLG24PDAGW4 Installation Guide

...Page 1

iNSTALLATiON iNSTRUCTiONS COMMERCIAL DRYER

Gas

iNSTRUCTiONS POUR L'INSTALLATION

D'UN SECHE-LINGE COMMERCIAL

A gaz

INSTRUCCIONES DE INSTALACION SECADORA COMERClAL

A gas

ISTRUZIONI DI INSTALLAZIONE

ASCIUGATRICE COMMERCIALE

A gas

MLG24PD

MLG24PN

www.maytagcom merciaNaundw.com

W10184555A

Page 2

TABLEOF CONTENTS

DRYER SAFETY ............................................................................ 3

DRYER DISPOSAL ........................................................................ 4

INSTALLATION REQUIREMENTS .............................................. 4

Tools and Parts .......................................................................... 4

Location Requirements .............................................................. 4

Electrical Requirements - Gas Dryer .......................................... 6

Gas Supply Requirements ........................................................ 6

Venting Requirements ................................................................ 7

TABLEDES

SECURITE DU SECHE-MNGE ................................................ 13

ELIMINATION DU SECHE-MNGE .......................................... 14

EXIGENCES D'INSTALLATION ................................................ 14

Outillage et pi_ces .................................................................... 14

Exigences d'emplacement ...................................................... 15

Specifications electriques - seche-tinge h gaz ......................... 16

Specifications de I'alimentation en gaz .................................. 17

Exigences concemant revacuation .......................................... 18

INSTALLATION INSTRUCTIONS - GAS DRYER .................... 9

Install Leveling Legs .................................................................... 9

Make Gas Connection ................................................................ 9

Connect Vent .............................................................................. 9

Complete Installation ................................................................ 9

ELECTRONIC CONTROLS SETUP ......................................... 10

MAINTENANCE INSTRUCTIONS .......................................... 10

REVERSING THE DOOR SWING (OPTIONAL) ...................... 10

TECHNICAL SPECIFICATIONS - GAS DRYER ...................... 11

WARRANTY .............................................................................. 12

MATIERES

INSTRUCTIONS D'INSTALLATION -

SECHE-LINGE A GAZ .............................................................. 19

Installation des pieds de nivellement ........................................ 19

Raccordement h la canalisation de gaz .................................. 20

Raccordement du conduit d'evacuation ................................ 20

Achever I'instatlation ................................................................ 20

REGLAGE DE LA COMMANDE ELECTRONIQUE ................. 20

INSTRUCTIONS D'ENTRETIEN ............................................. 21

INVERSION DU SENS D'OUVERTURE

DE LA PORTE (FACULTAT_F) ................................................... 21

FICHE TECHNIQUE - SECHE-LINGE A GAZ ........................ 22

GARANTIE ................................................................................ 23

P

INDICE

SEGURIDAD DE LA SECADORA ............................................ 24

ELIMINACKSN DE LA SECADORA .......................................... 25

REQUISITOS DE INSTALACl6N ............................................ 25

Piezas y herramientas .......................................................... 25

Requisitos de ubicaci6n ........................................................ 25

Requisitos electrtcos - secadora a gas ................................ 27

Requisitos del suministro de gas ............................................ 27

Requisitos de ventilaci6n .................................................... 28

INDICE

SICUREZZA DELL'ASClUGATRICE ........................................ 35

L'EUMINAZ_ONE DELUASClUGATRICE .................................. 36

REQUIS_TI D'INSTALLAZIONE ................................................ 36

Attrezzi e componenti .............................................................. 36

Requisiti di ubicazione ............................................................ 36

Requisiti elettrici - asciugatrice a gas .................................... 38

Requisiti di alimentazione det gas ............................................ 38

Requisiti di scarico .............................................................. 39

INSTRUCCIONES DE INSTALACION -

SECADORA A GAS ................................................................ 30

InstataciSn de las paras niveladoras .................................... 30

Conexi6n del suministro de gas ............................................ 30

Conexi6n del ducto de escape ............................................ 30

Complete la instataci6n ........................................................ 31

PREPARAClON DEL CONTROL ELECTR6NICO ................. 31

INSTRUCClONES DE MANTENIMIENTO ............................. 31

COMO INVERTIR EL SENTIDO DE ABERTURA

DE LA PUERTA (OPCIONAL) ................................................. 32

ESPEClFICAClONES TI_CNlCAS - SECADORA A GAS ......33

GARANTIA ................................................................................ 34

ISTRUZIONI DI INSTALLAZIONE- ASClUGATRlCE

A GAS ...................................................................................... 41

Instatlazione dei piedini di regolazione .................................... 41

Eseguire il colleganento gas .................................................... 41

Connessione delto scarico ...................................................... 41

Completamento dell'instattazione ............................................ 41

IMPOSTAZIONI COMANDI ELETTRONlCl ............................ 42

ISTRUZIONI DI MANUTENZIONE ......................................... 42

INVERTIRE LA ROTAZIONE DI APERTURA

(OPZIONALE) .......................................................................... 43

DATI TECNICl - ASCIUGATRICE A GAS .............................. 43

GARANZIA ................................................................................ 44

Page 3

DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

FOR YOUR SAFETY

1. Do not use or store petrol or other flammable materials in this appliance or near th{s appliance.

2. Do not spray aerosols in the vicinity of this appliance while it is in operation.

3. Do not modify this appliance.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use petrol or other flammable vapors and liquids in the vicinity of this

or any other appliance.

-WHAT TO DO {F YOU SMELL GAS:

® Do not try to light any appliance.

® Do not touch any electrical switch; do not use any phone in your building.

® Clear the room, building, or area of all occupants.

® immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

® if you cannot reach your gas supplier, call the fire department.

- {nstallation and service must be performed by a qualified installer, service agency, or

the gas supplier.

3

Page 4

DRYERDISPOSAL

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be treated

as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and

electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the product.

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

m 20 cm (8") or 25 cm (10") [] 8 mm (s/16")socket wrench

Pipe wrench [] Utility knife

[] 20 cm (8") or 25 cm (10") [] Vent clamps

adjustable wrench

[] Flat-blade screwdriver resistant to LP gas

[] Phillips screwdriver [] Sealing compound gun

[] Adjustable wrench that and sealing compound (for

opens to 25 mm (1") or installing new exhaust vent)

hex-head socket wrench [] Pliers

[] Level [] Putty knife

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

[] Foot boot (4)

[] Dryer foot (4)

NOTE: The circuit diagram for this machine is located inside the

lower front panel.

[] Pipe-joint compound

Explosion Hazard

Keep flammable materials and vapors, such as petrol,

away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages or sleeping quarters.

Contact your local building inspector.

[] Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

"Recessed Area Installation Instructions" below

for minimum spacing requirements.

[] Do not install on carpet.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

Page 5

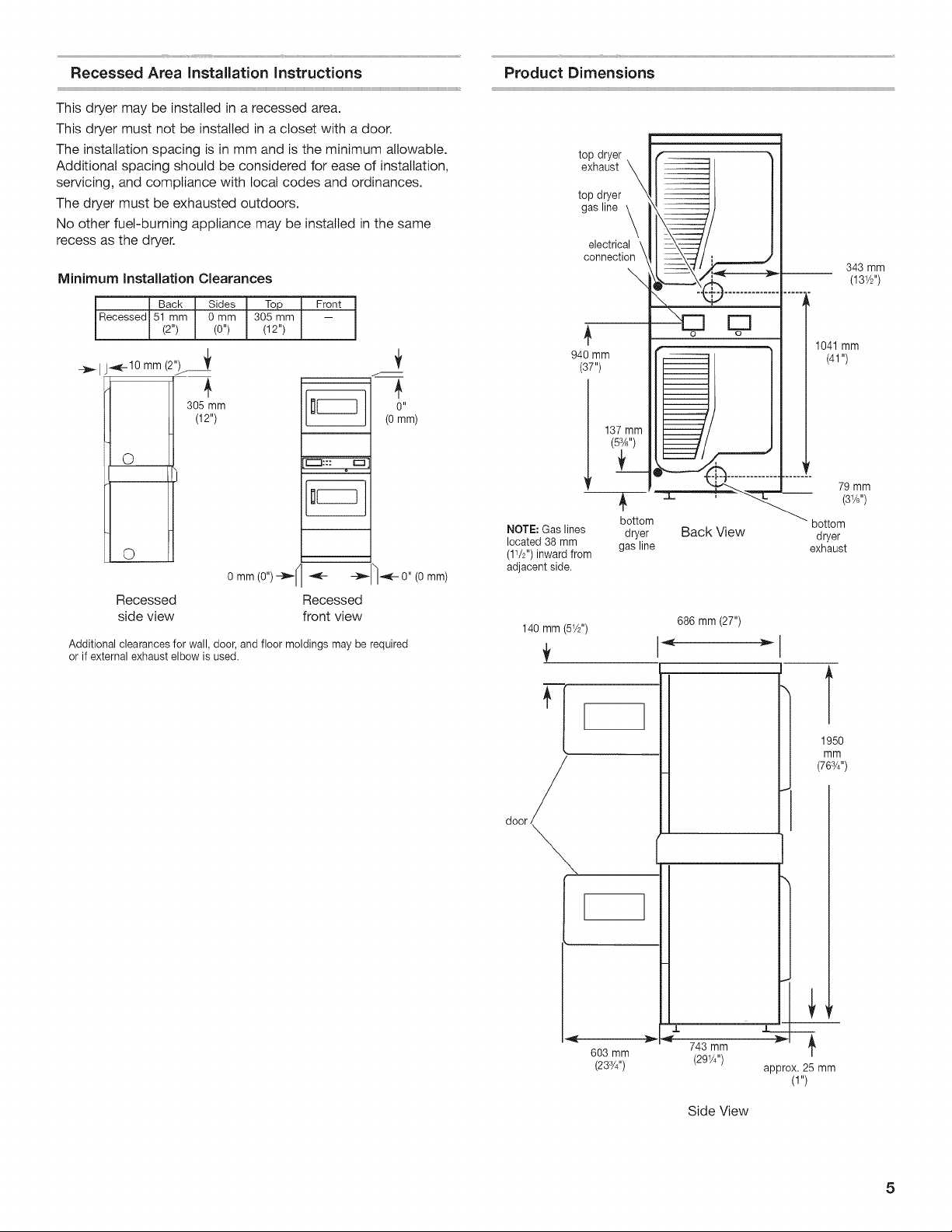

Recessed Area installation instructions

This dryer may be installed in a recessed area.

This dryer must not be installed in a closet with a door.

The installation spacing is in mm and is the minimum allowable.

Additional spacing should be considered for ease of installation,

servicing, and compliance with local codes and ordinances.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

recess as the dryer.

Minimum Installation Clearances

{Recessed{51 mm { 0mm I 305mm { -- I

__ I J_-10 mm (2")f _

Back Sides Top { Front I

(2") (0") (12")

7

Product Dimensions

top dryer

exhaust _

top dryer

gas line _

electrical \

connection

\,

940 mm

(37")

343 mm

(131/2'')

O O

1041 mm

(41 ")

3o5mm

(12")

O

[[--1::: o _-1

(0 mm)

O

o mm(o")_ _ o" (o mm)

Recessed Recessed

side view front view

Additional clearances for wall, door, and floor moldings may be required

or if external exhaust elbow is used.

ix,

0 II

NOTE: Gas lines

located 38 mm

(11/2'') inward from

adjacent side.

140 mm (51/2'')

137 mm

11;

bottom

dryer Back View

gas line

686 mm (27")

bottom

dryer

exhaust

79 mm

(31/8'')

T

1950

mm

(763/4'')

door

603 mm

(233/4'')

J.

743 mm

(291/4'')

Side View

l

approx. 25 mm

(1")

5

Page 6

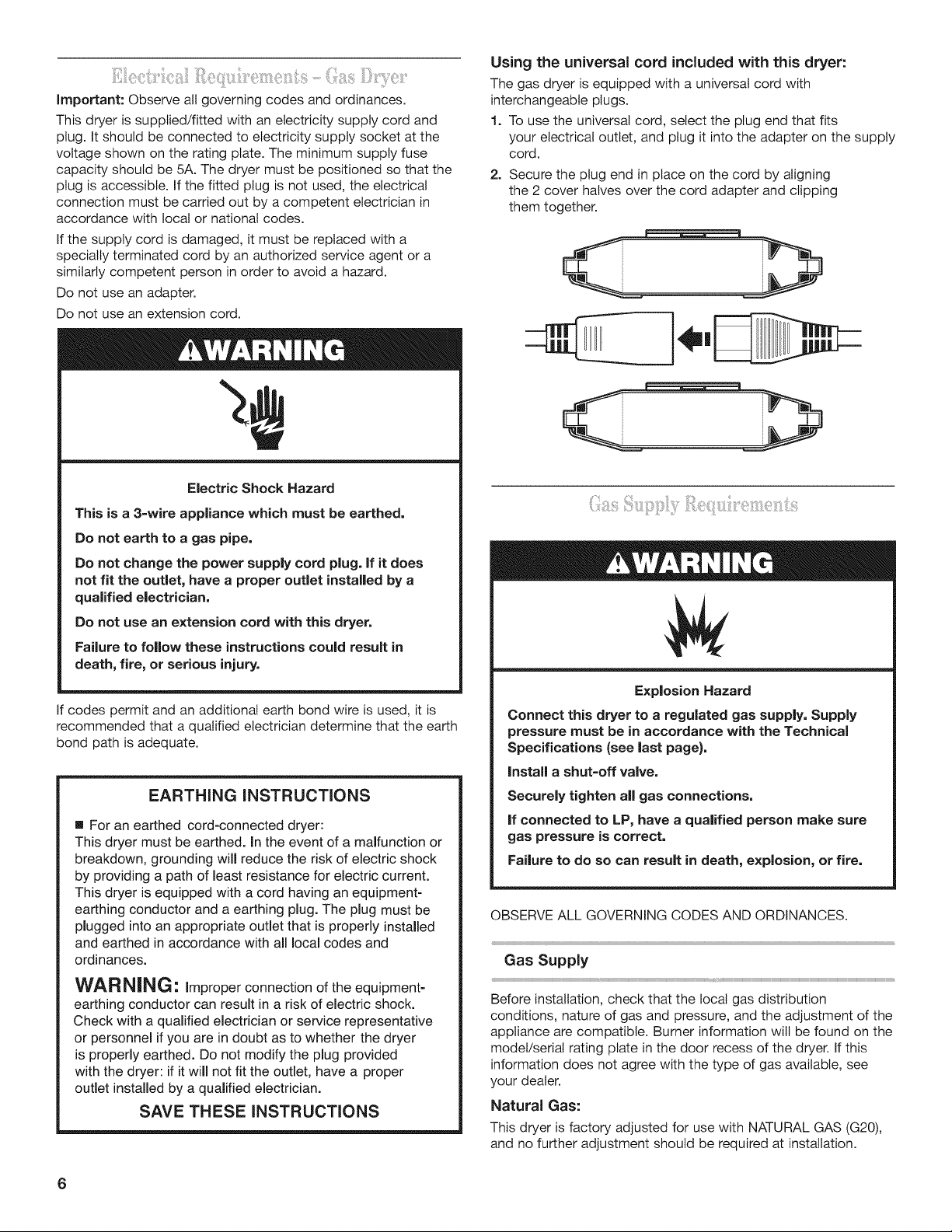

Important: Observe all governing codes and ordinances.

This dryer is supplied/fitted with an electricity supply cord and

plug. It should be connected to electricity supply socket at the

voltage shown on the rating plate. The minimum supply fuse

capacity should be 5A. The dryer must be positioned so that the

plug is accessible. If the fitted plug is not used, the electrical

connection must be carried out by a competent electrician in

accordance with local or national codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or a

similarly competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

Electric Shock Hazard

This is a 3=wire appliance which must be earthed.

Do not earth to a gas pipe.

Do not change the power supply cord plug. if it does

not fit the outlet, have a proper outlet installed by a

qualified electrician.

Do not use an extension cord with this dryer.

Failure to follow these instructions could result in

death, fire, or serious injury.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

EARTHING INSTRUCTIONS

[] For an earthed cord-connected dryer:

This dryer must be earthed. In the event of a malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

earthing conductor and a earthing plug. The plug must be

plugged into an appropriate outlet that is properly instaled

and earthed in accordance with all local codes and

ordinances.

WARNING: Improper connection of the equipment=

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer

is properly earthed. Do not modify the plug provided

with the dryer: if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits

your electrical outlet, and plug it into the adapter on the supply

cord.

2. Secure the plug end in place on the cord by aligning

the 2 cover halves over the cord adapter and clipping

them together.

Explosion Hazard

Connect this dryer to a regulated gas supply. Supply

pressure must be in accordance with the Technical

Specifications (see last page}.

Instal a shut=off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure is correct.

Failure to do so can result in death, explosion, or fire.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Gas Supply

Before installation, check that the local gas distribution

conditions, nature of gas and pressure, and the adjustment of the

appliance are compatible. Burner information will be found on the

model/serial rating plate in the door recess of the dryer. If this

information does not agree with the type of gas available, see

your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

Page 7

L.P. Gas:

This dryer is also certified for use with L.R (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specified on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a competent service technician.

Gas conversion kit, part number 279918, is available for purchase

from your dealer. Full instructions are supplied with the kit.

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should be

minimum 12.5 mm (1/2") ID. When acceptable to the gas supplier

and local codes, 10 mm (3/8") ID rigid supply line may be used

for lengths under 6.1 m (20'). Pipe-joint compounds resistant to

the action of LR gas must be used.

Gas connection to the dryer itself should be made by means of a

flexible gas hose suitable for the appliance and gas category in

accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the appliance and

the wall to prevent straining of the rigid gas supply when the

appliance is moved. An appropriate length of chain and a watt

hook is recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO.228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leak-

detection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the

gas valve within the dryer, accessible after removal of the lower

front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

[] The design of the flue system should be such that any

condensate formed when operating the dryer from cold shall

either be retained and subsequently re-evaporated or

discharged.

[] The dryer vent must not be discharged into a flue which

is used for exhausting fumes from appliances burning gas or

other fuels, chimney, wall, ceiling, or a concealed space of a

building, or any other vent used for venting.

[] Do not use an exhaust hood with a magnetic latch.

[] Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

[] 102 mm (4") heavy metal vent and clamps must be used.

[] Use clamps to seat all joints. Vent must not be connected

or secured with screws or other fastening devices which

extend into the interior of the vent. Do not use duct tape.

iMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing

and kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 305 mm (12") from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Plan installation to use the fewest number of elbows and turns.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING; To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

[] Adequate ventilation has to be provided to avoid the backflow

of gases into the room from other fuel-burning appliances,

including open fires (i.e. available airflow into the room should

match airflow out from the room).

Exhaust Air Flow

A. Good

B. Better

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the center of the bottom dryer back.

The vent can be routed up, down, left, right, behind the dryer

or straight out the back of the dryer.

7

Page 8

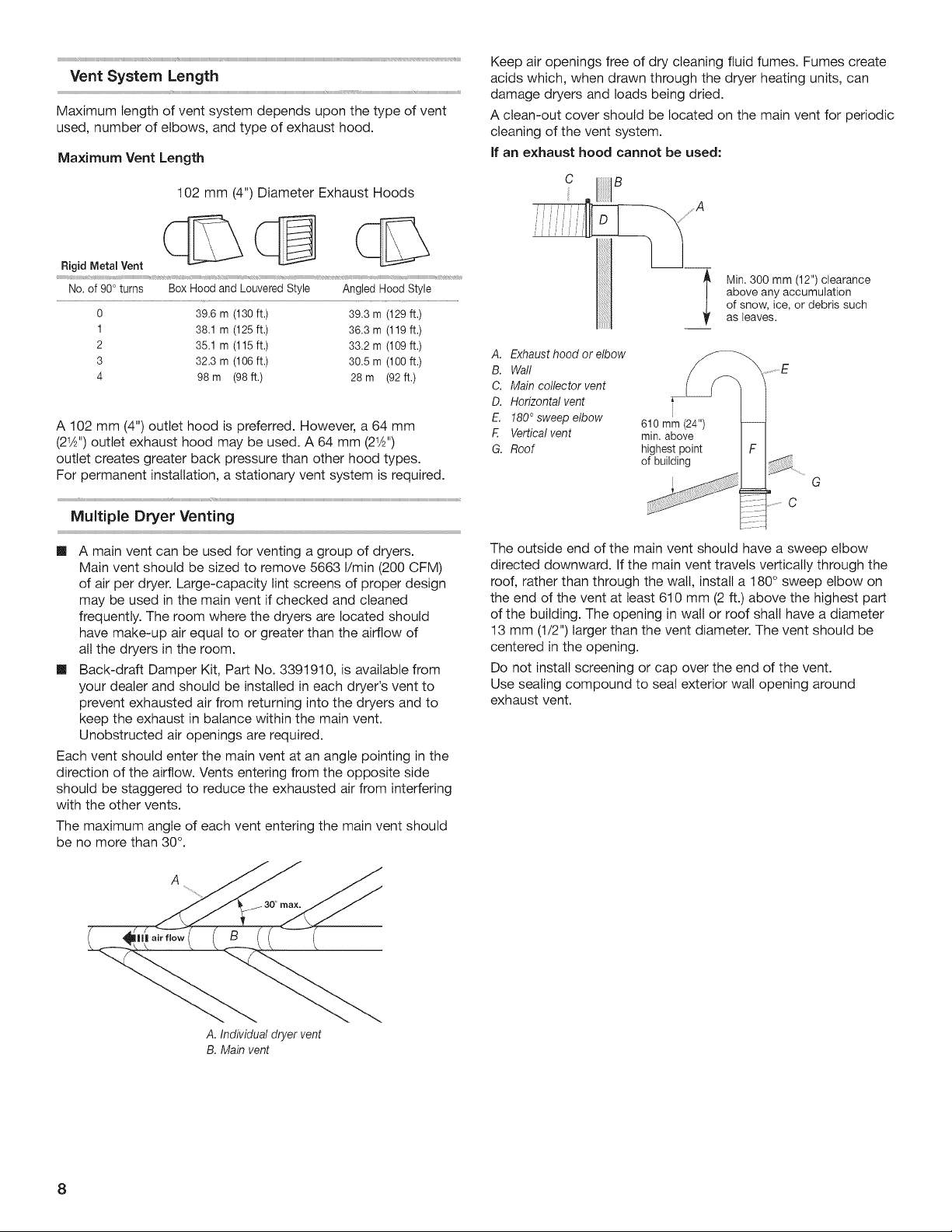

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Maximum Vent Length

102 mm (4") Diameter Exhaust Hoods

Rigid Metal Vent _

t 1 i

No. of 90° turns Box Hood and Louvered Style Angled Hood Style

9 39.6 m (130 ft.) 39.3 m (129 ft.)

1 38.1 m (125 ft.) 36.3 m (119 ft.)

2 35.1 m (115 ft.) 33.2 m (199 ft.)

3 32.3 m (106 ft.) 30.5 m (100 ft.)

4 98 m (98 ft.) 28 m (92 ft.)

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21_'') outlet exhaust hood may be used. A 64 mm (21_'')

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Multiple Dryer Venting

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and loads being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If an exhaust hood cannot be used:

Min. 300 mm (12") clearance

above any accumulation

of snow, ice, or debris such

as {eaves.

A. Exhaust hood or elbow

B. Waft

C. Main collector vent

D. Horizontal vent

E. 180° sweep elbow

E Vertical vent

G. Roof

610 mm(24")

min. above

highestpoint

of building

G

C

[] A main vent can be used for venting a group of dryers.

Main vent should be sized to remove 5663 I/min (200 CFM)

of air per dryer. Large-capacity lint screens of proper design

may be used in the main vent if checked and cleaned

frequently. The room where the dryers are located should

have make-up air equal to or greater than the airflow of

all the dryers in the room.

[] Back-draft Damper Kit, Part No. 3391910, is available from

your dealer and should be installed in each dryer's vent to

prevent exhausted air from returning into the dryers and to

keep the exhaust in balance within the main vent.

Unobstructed air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

The outside end of the main vent should have a sweep elbow

directed downward. If the main vent travels vertically through the

roof, rather than through the walt, install a 180° sweep elbow on

the end of the vent at least 610 mm (2 ft.) above the highest part

of the building. The opening in wall or roof shall have a diameter

13 mm (1/2") larger than the vent diameter. The vent should be

centered in the opening.

Do not install screening or cap over the end of the vent.

Use sealing compound to seat exterior walt opening around

exhaust vent.

A.Individualdryervent

B. Mainvent

Page 9

INSTALLATIONINSTRUCTIONS- GASDRYER

¸iijj

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 102 mm (4") clamp.

NOTE: Slide dryer onto cardboard or hardboard before moving to

avoid damaging floor covering.

1. Using two or more people, move dryer to desired installation

location.

2. Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe the interior of the

drum thoroughly with a damp cloth.

3. Take two of the cardboard corners from the carton and place

them on the floor in back of the dryer. Firmly grasp the body of

the dryer and gently lay it on its back on the cardboard corners.

4. With one of the legs in hand, check the ridges for a diamond

marking. That's how far the leg is supposed to go into the hole.

5. Start to screw the leveling legs into the holes by hand. (Use

a small amount of liquid detergent to lubricate the screw

threads so it is easier to turn the legs.) Use a 1" (25 mm)

wrench or socket wrench to finish turning the legs until you

reach the diamond mark. Then fit a protective foot boot over

each foot.

Now stand the dryer up.

6. Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Move dryer into final position. Do not crush or kink vent. Make

sure dryer is level.

2. Check to be sure there are no kinks in the flexible gas line.

3. With dryer in final position, place level on top of the dryer, first

side to side; then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

Electric Shock Hazard

This is a 3-wire dryer which must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

4. Reconnect power to dryer.

5. Check dryer operation.

Select the full heat cycle (not the air cycle), start and allow

the dryer to complete a full cycle to make sure it is working

properly. Dryer will stop when the time is used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, the dryer stops. To restart dryer, close door and

resetect your cycle.

6. If the burner does not ignite and you can feel no heat inside the

dryer, shut off dryer for five minutes. Check that all supply valve

controls are in "ON" position and that the electrical cord is

plugged in. Repeat five-minute test.

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. If the flexible gas hose has 3/8"

BSP thread, use the supplied conversion thread adapter. Use

pipe-joint compound resistant to the action of LR gas for gas

connections.

If necessary for service, open the toe panel. Use a putty knife

to press on the 2 toe panel locks located at the top of the toe

panel. Pull downward on the toe panel to open. Toe panel is

hinged at the bottom.

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

9

Page 10

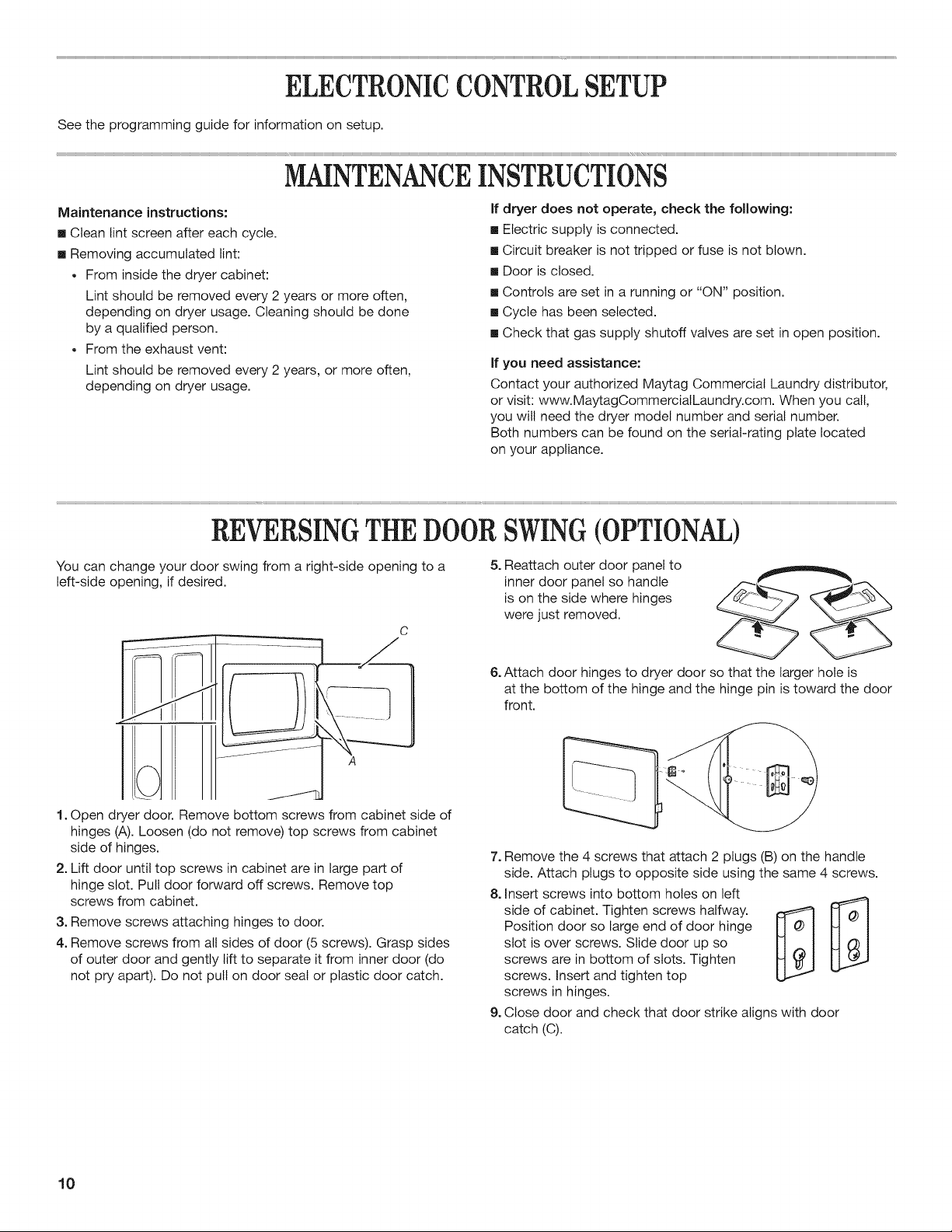

ELECTRONICCONTROL SETUP

See the programming guide for information on setup.

MAINTENANCE INSTRUCTIONS

Maintenance instructions:

mClean lint screen after each cycle.

mRemoving accumulated lint:

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

REVERSINGTHE DOOR SWING (OPTION )

You can change your door swing from a right-side opening to a

left-side opening, if desired.

C

If dryer does not operate, check the following:

[] Electric supply is connected.

[] Circuit breaker is not tripped or fuse is not blown.

[] Door is closed.

[] Controls are set in a running or "ON" position.

[] Cycle has been selected.

[] Check that gas supply shutoff valves are set in open position.

If you need assistance:

Contact your authorized Maytag Commercial Laundry distributor,

or visit: www.MaytagCommercialLaundry.com. When you call,

you will need the dryer model number and serial number.

Both numbers can be found on the serial-rating plate located

on your appliance.

5. Reattach outer door panel to

inner door panel so handle

is on the side where hinges

were just removed.

1. Open dryer door. Remove bottom screws from cabinet side of

hinges (A). Loosen (do not remove) top screws from cabinet

side of hinges.

2. Lift door until top screws in cabinet are in large part of

hinge slot. Pull door forward off screws. Remove top

screws from cabinet.

3. Remove screws attaching hinges to door.

4. Remove screws from all sides of door (5 screws). Grasp sides

of outer door and gently lift to separate it from inner door (do

not pry apart). Do not pull on door seat or plastic door catch.

6. Attach door hinges to dryer door so that the larger hole is

at the bottom of the hinge and the hinge pin is toward the door

front.

7. Remove the 4 screws that attach 2 plugs (B) on the handle

side. Attach plugs to opposite side using the same 4 screws.

8. Insert screws into bottom holes on left

side of cabinet. Tighten screws halfway. _ _1

Position door so large end of door hinge

slot is over screws. Slide door up so

screws are in bottom of slots. Tighten

screws. Insert and tighten top

screws in hinges.

9. Close door and check that door strike aligns with door

catch (C).

10

Page 11

TECHNICALSPECIFICATIONS.GASDRYER

220-240V-50Hz lph 12A max. IP24 Clothes capacity: 9.0 kg max.

European Country:

European Gas Category:

Gas Flow Rate:

Supply Pressure (G20):

Factory Adjusted Pressure:

European Country:

European Gas Category:

Butane Supply Pressure (G30):

Adjusted Pressure:

Propane Supply Pressure (G31):

Adjusted Pressure:

European Country: FR, BE

European Gas Category: 12E+

Supply Pressure (G20): 20 mbar

Supply Pressure (G25): 25 mbar

Adjusted Pressure: N/A

CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, Sl, SK, TR

112H3+

0.562703 m3/hr

20 mbar

7.4 mbar

CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, Sl, SK, TR

112H3+

28-30 mbar

N/A

37 mbar

N/A

AT, CH, CY, CZ, DK, EE, FI, GR,

HU, IT, NO, RO, SE, SK, TR

112H3B/P

0.562703 m3/hr

20 mbar

7.4 mbar

AT, CH, CY, CZ, DK, EE, FI, GR,

HU, IT, NO, RO, SE, SK, TR

112H3B/P

30 mbar

N/A

30 mbar

N/A

NOTE: Conversion kit : From Natural Gas to LP Gas :Whirlpool Part No. W10233219.

Conversion kit : From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10184947.

Manufacturer : Whirlpool Corporation, Benton Harbor, Michigan 49022, USA.

11

Page 12

MAYTAG COMMERCIAL WASHEP DRYER, STACKED DRYER/

DRYER, COMMERCIAL STACK LAUNDRY, AND MULTi-LOAD

COiN OPERATED COMMERCIAL WASHERS AND DRYERS

WAR NTY

LiMiTED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter "Maytag") will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

iTEMS MAYTAG WiLL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DiSCLAiMER OF iMPLiED WARRANTIES; LiMiTATiONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. iMPLiED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABiLiTY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATESAND PROVINCES DO NOT ALLOW THE EXCLUSION OR LiMiTATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

9/07

For written correspondence:

Maytag Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49085 USA

12

Page 13

SECURITEDUSECHE.LINGE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curite importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tous les messages de s_curite et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves h vous

et h d'autres.

Voici le symbole d'alerte de s_curit&

Tousles messages de securite suivront le symbole d'alerte de s_curite et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d6cbs ou de blessure grave si vous ne

suivez pas imm6diatement les instructions.

Risque possible de d6cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curite vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

POUR VOTRE SECUR{TE

1. Ne pas utiliser ou remiser d'essence ou autres materiaux inflammables darts cet appareit menager ou h proximite de cetu{-ci.

2. Ne pas vaporiser d'aerosols _.proximite de cet appareil menager Iorsqu'il est en fonctionnement.

3. Ne pas modifier cet appareit menager.

AVERTISSENiENT • Pour votre securite, les renseignements darts ce manuel doivent

0tre observes pour reduire au minimum les risques d'incendie ou d'explosion ou pour

eviter des dommages au produit, des blessures ou un deces.

- Ne pas entreposer ou utiliser de I'essence ou d'autres vapeurs ou liquides

inflammables h proximite de cet appareil ou de tout autre appareil electromenager.

-QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

®Ne pas tenter d'allumer un appareil.

• Ne pas toucher a un commutateur electrique; ne pas utiliser le telephone se trouvant

sur les lieux.

Evacuer tous les gens de la piece, de I'edifice ou du quartier.

Appeler immediatement le fournisseur de gaz d'un telephone voisin. Suivre ses

instructions.

h. d(ifaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et I'entretien doivent 0tre effectues par un installateur qualifie, une

agence de service ou le fournisseur de gaz.

13

Page 14

#

ELIMINATIONDUSECHE-LINGE

Le marquage de I'appareil est conforme b,la directive europ6enne 2002/96/EC sur les 6quipements 61ectroniques et

electriques, pour gestion des dechets.

En veillant h I'_limination correcte de ce produit, vous 6viterez d'_ventuelles cons6quences n_fastes pour I'environnement et la

sant_ humaine qui peuvent _tre assocl6es au traitement inappropri_ de ce prodult Iorsqu'il a _t_ mis au rebut.

Le symbole figurant sur le produit ou dans les documents qui accompagnent {e produit indique que cet appareil ne dolt pas _tre

trait_ comme dechet menager; on dolt plut6t le remettre hun centre de collecte specialise pour le recyclage des _quipements

electriques et electroniques.

L'elimination de ce produit apres mise au rebut dolt _tre effectu_e conformement aux prescriptions de la reglementation locale

de protection de I'environnement.

Pour I'information d_taill6e concernant le traitement, le recyclage et la r_cup_ration de ce produit, contacter la municipalit_

locale, le service d'_limination des d_chets m_nagers, ou le commer(2ant qui a vendu le produit.

EXIGENCESD'INSTALLATION

X

Rassembler les outils et pi_ces necessaires avant de commencer

I'instattation. Life et respecter les instructions d'instattation

fournies avec chacun des outits de cette liste.

Outil{age n6cessaire

[] Cte h tube de 20 cm (8") [] Couteau utititaire

ou 25 cm (10") [] Brides de fixation

[] Cte h molette de 20 cm (8") [] Compose d'etancheite des

ou 25 cm (10") raccords fitetes - r_sistant

[] Tournevis h lame plate au propane

[] Tournevis Phillips [] Pistotet h calfeutrage et

[] Cle & molette avec compose de catfeutrage

ouverture jusqu'h 25 mm (pour I'instatlation d'un

(1") ou cte & douille h t_te nouveau circuit

hexagonale d'evacuation)

[] Niveau [] Pince

[] Cle h douille de 8 mm [] Couteau h mastic

(5/16")

Pi_ces fournies

Retirer le sac de pi_ces du tambour du s_che-linge. V_rifier la

presence de toutes les pi_ces.

[] Patin (4)

[] Pied du s_che-linge (4)

REMARQUE : Le schema de circuits de ce seche-tinge se trouve

I'interieur du panneau inferieur avant.

14

Page 15

Risque d'explosion

Garder les rnatieres et [es vapeurs inflammables, telie

que ['essence, loin du seche=linge.

Ne pas installer darts un garage.

Le non-respect de ces instructions peut causer

un d_ces, une explosion ou un incendie.

Pour I'installation d'un s_che-linge & gaz :

IMPORTANT : Respecter les dispositions de tousles codes et

r_glements en vigueur.

[] Determiner les exigences des codes : Certains codes limitent

ou prohibent l'instaltation d'un seche-tinge dans un garage,

un placard, ou une chambre _ coucher. Consulter I'inspecteur

local des b_timents.

[] Veilter _ ce que les bords inferieurs de la caisse ainsi que

I'arri_re et les c6tes inferieurs du seche-linge soient exempts

d'obstructions, afin de permettre le passage adequat de I'air

de combustion. Voir ta section "instructions d'instattation dans

un placard ou un encastrement" pour I'espace de

degagement minimal.

[] Ne pas installer sur un tapis.

NOTE : Le seche-linge ne dolt pas _tre installe en un endroit

oQ il serait expose & de reau ou aux intemperies.

Instructions pour I'installation encastr6e

Ce seche-linge peut _tre instatle dans un encastrement.

Ce seche-linge ne dolt pas _tre instatle dans un placard avec

porte.

Les distances de separation sont exprimees en mittim_tres;

it s'agit des distances minimates. II est utile de pr6voir des

distances de separation superieures pour faciliter I'installation

et les travaux d'entretien, ou si ceci est exige par les codes

et r_gtements Iocaux.

Le circuit d'evacuation du seche-linge dolt _tre retie & I'exterieur.

Aucun autre appareit utitisant un combustible ne dolt _tre instatte

dans le m_me encastrement.

Distances de s_paration minimales

Encastr& 151 mm I 0mm I 305mm I -- [

--_1j_--51 mm (2")j

O

Arri_re C6t&s Dessus I Avant I

(0") (12")

305 mm

(12")

r--3::" rm

j.m

0"

(0mm)

O

0mm(0")-_'[[/I _-- __,_[\[__1,0"(0mm)

Encastrement, Encastrement,

vue laterate vue avant

On dolt pr_voir un espacement additionnel pour tenir compte _ventuellement

des moulures du mur, de la porte et du plancher, ou si le circuit d'_vacuation

comporte un coude.

15

Page 16

Dimensions du produit

Bouche de

d_charge

sup_rieure

\

Canal.isation de gaz_

supeneure "-_

Connexion

_lectrique

....m oE:]

940 mm

(37")

(53/8'')

137 mm

Important : Se conformer & tous les codes et r_glements en

vigueur.

Ce seche-linge est equipe d'un cordon d'atimentation electrique

et d'une fiche. II dolt _tre connecte & une prise etectrique de

tension tel qu'indique sur la plaque signal_tique. La capacite

minimate du fusible d'atimentation dolt _tre de 5 A. Le seche-linge

dolt _tre installe de fagon & ce que la fiche soit accessible. Si la

fiche d'origine n'est pas utilisee, la connexion electrique dolt _tre

effectuee par un electricien competent conformement aux codes

Iocaux et nationaux.

343 mm

(131_")

Si le cordon d'alimentation est endommage, it dolt _tre remplace

par un cordon & embout specifique par un agent d'entretien

autorise ou une personne de competence similaire afin d'eviter

tout danger.

o

1041 mm

(41 ")

79 mm

(31/8'')

Ne pas utitiser d'adaptateur.

Ne pas utiliser de c&ble de raltonge.

Canalisations de

gaz situ_es & 38

mm (11/2'') vers

I'int_rieura partirdu

c6t_adjacent.

140 mm (51/8'')

Portes_

Canalisation de gaz

inf_rieure

603 mm

(233/4'')

Vue artiste

686 mm (27")

J.

743 mm

(291/4'')

Vue laterale

Bouche de

d_charge

inf_rieure

1950 mm

(763/4'')

approx,25mm

(1")

Risque de choc electrique

Une raise _ la terre est n_cessaire sur ce s_che=linge.

Ne pas utiliser une tuyauterie de gaz pour le

raccordement _ la terre.

Ne pas changer la fiche du cordon d'alimentation.

Si elle ne correspond pas a la prise de sortie, faire

installer une prise adequate par un _lectricien qualifi_.

Ne pas utiliser de c_ble de rallonge avec ce s_che=linge.

Le non=respect de ces instructions peut causer

un d_c_s, un incendie ou des blessures graves.

Si les codes te permettent et si un conducteur supptementaire

de mise & ta terre est utilise, il est recommande qu'un electricien

qualifie inspecte le parcours du fil de mise & la terre.

INSTRUCTIONS DE MISE A LA TERRE

[] Ce s_cheqinge a _t6 congu pour _tre raccord_ au

secteur et mis a la terre ; la mise & la terre est doric imperative:

En cas disfonctionnement ou de panne, la mise & la terre

r_duira le risque de choc electrique en offrant au courant

61ectrique une voie de moindre r_sistance. Ce s_che-linge

est aliment_ par un cordon _lectrique comportant un

conducteur de liaison a la terre et une fiche de mise b_la terre.

La fiche doit _tre branchee sur une prise de courant

appropri_e correctement install_e et reli_e & la terre

conform_ment &tousles codes et r6glements Iocaux.

AVERTISSEMENT : Unraccordement inappropri_

du conducteur de liaison & la terre peut causer un risque

de choc _lectrique.

En cas de doute concernant la qualit_ de la liaison & la terre

du s_che-linge, consulter un 61ectricien qualifi_, un agent

ou personnel d'entretien. Ne pas modifier la fiche fournie

avec ce s_che-linge : Si elle ne correspond pas & la prise

de sortie, faire installer une prise appropri_e par un

_lectricien qualifi&

CONSERVEZ CES INSTRUCTIONS

16

Page 17

A I'aide du cordon universel fourni avec

ce s_che-linge :

Ce seche-linge _ gaz est equip6 d'un cordon universet avec des

fiches interchangeables.

1. Pour utitiser te cordon universel, selectionner la fiche amovibte

qui correspond & votre prise de courant et brancher dans

radaptateur place sur le cordon d'atimentation.

2. Fixer fiche amovible sur le cordon en alignant les deux moities

de couvercle sur I'adaptateur et en les emboTtant.

<

Risque d'explosion

Connecter ce s_che-linge a une canalisation

d'alimentation en gaz r_glement_e. La pression

de gaz dolt _tre conforme aux exigences techniques

(volt derni_re page).

installer un robinet d'arr_t.

Bien setter tous les raccords de la ligne de gaz.

En cas de connexion au gaz propane, demander

une personne qualifi6e de s'assurer que la pression

d'alimentation en gaz est correcte.

Le non-respect de ces instructions peut causer

un d_c_s, une explosion ou un incendie.

SE CONFORMER A TOUS LES CODES ET REGLEMENTS

EN VIGUEUR.

Gaz naturel :

Ce seche-linge est configure en usine pour une utilisation au GAZ

NATUREL (G20) et aucun r6glage supptementaire n'est necessaire

lots de I'installation.

Gaz propane :

Ce seche-tinge est egalement homotogue pour une utitisation

avec des gaz de petrole liquefi6 (propane ou butane) apres

conversion appropriee. Ne pas tenter de convertir I'appareit pour

une utitisation avec un gaz different de celui indique sur la plaque

signaletique sans consulter le fournisseur de gaz au pr6atabte.

La conversion dolt _tre effectuee par un reparateur qualifie.

La trousse de conversion, numero de ref6rence 279918, est

disponibte & l'achat chez votre revendeur. Des instructions

accompagnent cette trousse.

E×igences concernant le conduit d'alimentation :

Installer un conduit rigide d'alimentation en gaz _ I'emplacement

du seche-linge. Le diametre interne minimal du conduit dolt _tre

de 12,5 mm (1/2"). Lorsque les codes Iocaux et votre fournisseur

de gaz rautorisent, un diam_tre interne de conduit rigide de 10

mm (3/8") peut _tre utitise pour des Iongueurs inferieures _ 6,1 m

(20 pi.). Une p_te d'etancheite pour joints r_sistant _ I'action du

gaz propane dolt _tre utilisee.

Le raccordement au gaz du s_che-tinge lui-m_me dolt _tre

effectue au moyen d'un conduit de gaz flexible qui convienne

rappareit et corresponde _ la categorie de gaz, conformement

aux r_glements d'instattation nationaux. En cas de doute,

contacter le fournisseur de gaz. Le diam_tre interne dolt _tre

d'au moins 10 mm (3/8").

Un dispositif de fixation dolt _tre instalte entre t'appareil et lemur

afin d'eviter que la canalisation d'alimentation en gaz rigide ne

subisse de tension lots d'un deptacement de I'appareil. IIest

recommand_ d'utiliser une Iongueur de chaTne appropri_e et un

crochet mural.

Le raccord du conduit d'alimentation en gaz du s_che-linge est

un fitetage conique NPT de 3/8". Un adaptateur est fourni pour la

conversion & un filetage standard (3/8" BSP) selon la norme

ISO.228-1.

Wrifier t'absence de fuites en utilisant une solution de detection

non corrosive homologuee. Uapparition de bulles indique ta

presence d'une fuite. Reparer toute fuite eventuelle. Un dispositif

de mesure de la pression est fourni avec le robinet de gaz

rinterieur du seche-linge; on peut y acceder apr_s avoir retir_ le

panneau avant inferieur.

Le seche-tinge dolt _tre deconnecte du syst_me d'alimentation

en gaz lots de tout test de pression.

Alimentation en gaz

Avant d'effectuer I'instattation, verifier que les caracteristiques de

distribution, la nature et la pression de gaz locales ainsi que le

r6glage de l'appareil sont compatibles. Les informations

concernant le brOleur se trouvent sur la plaque signaletique situee

sur la paroi interne de ta porte du seche-linge. Si rinformation ne

correspond pas au type de gaz disponibte, consulter votre

revendeur.

17

Page 18

Risque d'Jncendie

UtitJser un conduit d'_vacuation en m_tal Iourd.

Ne pas utilJser un conduit d'_vacuation en plastique.

Ne pas utJliser un conduit d'_vacuation en feuJJle

de m_tal.

Le non=respect de ces instructions peut causer

un d_c_s ou un Jncendie.

AVERTISSEMENT " Pour reduire le risque d'incendie, ce

seche-linge DOlT EVACUER L'AIR A L'EXTERIEUR.

[] Une aeration adequate est necessaire pour eviter le retour des

gaz dans la piece en provenance d'appareils menagers qui

utitisent d'autres carburants comme combustible, y compris

les feux ouverts (autrement dit le debit d'air entrant darts la

piece dolt _tre egal au debit qui en sort).

[] La conception du syst_me d'evacuation dolt permettre &

toute condensation formee lots du fonctionnement de

I'appareil d'etre soit retenue puis evapor6e, soit evacuee.

[] L'event du seche-tinge ne dolt pas _tre connecte &un conduit

d'evacuation de gaz, une cheminee, un mur, un plafond ou un

vide de construction, ou tout autre conduit utitise pour

I'evacuation.

[] Ne pas utitiser un ctapet d'evacuation & fermeture

magn_tique.

[] Ne pas installer le conduit metatlique flexible dans les cavites

fermees des murs, plafonds ou planchers.

[] Utitiser un conduit d'evacuation en metat Iourd de 4"

(102 mm) et des brides de fixation.

[] Utitiser des brides de fixation pour scelter tous les joints.

L'event ne dolt pas _tre connecte ou fixe avec des vis ou

autres dispositifs d'accrochage qui se prolongent & I'interieur

de I'event. Ne pas utiliser de ruban adhesif.

IMPORTANT : Respecter les dispositions de tousles codes

et r_glements en vigueur.

Utiliser un conduit d'evacuation en metat lourd. Ne pas utitiser

un conduit de ptastique ou en feuitle metattique.

On recommande d'utiliser un conduit metatlique rigide pour

r_duire les risques d'ecrasement et de deformation.

Un conduit metatlique flexible dolt 6tre totalement deptoye et

soutenu lorsque le seche-linge est & sa position finale. Enlever

tout exc_s de conduit flexible pour eviter tout affaissement/

deformation susceptible de r_duire le debit d'air et le rendement

du seche-linge.

Terminer le conduit d'evacuation par un clapet de decharge pour

emp_cher les rongeurs et insectes d'entrer darts I'habitation ou

I'entreprise.

Le clapet de decharge dolt _tre situe & au moins 12" (30,5 cm)

au-dessus du sot ou de tout autre objet susceptible de se trouver

sur le trajet de I'air humide rejete (par exempte, fleurs, roches ou

arbustes).

Lors de I'utilisation d'un circuit d'evacuation existant, nettoyer les

peluches sur toute la Iongueur du syst_me et veiller & ce que la

bouche de decharge ne soit pas obstruee par une accumulation

de peluches. Remplacer tout conduit de plastique ou de feuille

metattique mince par un conduit metallique flexible ou rigide.

Planifier l'instaltation pour introduire le nombre minimal de coudes

et de changements de direction.

D_bitd'_vacuation

A. Bond#bitd'#vacuation

B.Meilleurd#bitd'#vacuation

Si des coudes sont utilises ou des changements de direction

effectues, pr_voir autant d'espace que possible. Plier le conduit

graduellement pour eviter de le deformer.

La bouche de sortie est situee _ I'arri_re du seche-linge, en

bas/au centre.

On peut acheminer le conduit d'evacuation par le haut, par le

bas, par la gauche, par la droite, derriere le seche-tinge ou en

ligne droite depuis t'arri_re du seche-linge.

Longueur du circuit d'_vacuation

La Iongueur maximale du circuit d'evacuation depend du type

de conduit utitise, du nombre de coudes et du type de bouche

de decharge.

Longueur maximale du conduit

Clapet de decharge de 102 mm (4")de diam6tre

Conduit _ (_

metallique rigide

Nombred'angles Clapetsdetypebofteet Clapetinclin6

r; ;: ;r r; r r; r r; r ;

&90° &persiennes

0 39,6 m (130 pi.) 39,3 m (129 pi.)

1 38,1 m (125 pi.) 36,3 m (119 pi.)

2 35,1 m (115 pi.) 33,2 m (109 pi.)

3 32,3 m (106 pi.) 30,5 m (100 pi.)

4 98 m (98 pi.) 28 m (92 pi.)

Uemploi d'une bouche de decharge de 102 mm (4") est

preferable. On peut cependant utiliser une bouche de 64 mm

(21A"). Une bouche de decharge de 64 mm (2V2") peut causer

une plus forte retropression que les autres genres de bouches.

Pour une installation permanente, un syst_me d'evacuation

fixe est requis.

18

Page 19

Evacuation multiple du s_che-linge

[] Un conduit d'evacuation principal peut _tre utilise pour un

groupe de seche-linge. Le conduit d'evacuation principal

devrait _tre d'un diam_tre suffisant pour evacuer 5663 I/min

(200 pP/min) d'air par seche-linge. Des filtres h peluches

de forte capacite et de conception adequate peuvent _tre

utitises dans le conduit principal d'evacuation s'ils sont

inspectes et nettoyes fr6quemment. La piece oQ se trouvent

les seche-linge devrait recevoir un apport d'air de debit egal

ou superieur au debit total de debit de tous les s_ches-tinge

installes dans la piece.

[] Des ensembles antirefoulement, n° de piece 3391910, sont

disponibtes chez votre marchand et devraient _tre instatles

dans le conduit d'evacuation de chaque seche-linge pour

emp_cher Fair evacu6 de retourner dans les seche-linge et

pour maintenir une pression equilibr6e dans le conduit

principal d'evacuation. Des orifices de passage

d'air non obstrues sont requis.

Chaque conduit d'evacuation devrait pen6trer dans leconduit

principal hun angle pointant dans la direction du debit d'air.

Les conduits raccordes au conduit principal de part et d'autre

devraient _tre disposes en quinconce pour que I'air evacu6

par un seche-linge ne puisse perturber I'evacuation d'un autre

seche-linge.

Uangle maximal entre le conduit connecte hun seche-tinge et le

conduit principal ne devrait pas depasser 30°.

A

sont attir6s vers les unites de chauffage des seche-linge, peuvent

endommager les seche-linge et le linge en cours de sechage.

Une bouche de nettoyage devrait _tre instaltee dans le conduit

principal d'evacuation pour les nettoyages periodiques du

syst_me d'evacuation.

Si une bouche de d_charge ne peut _tre utilis_e :

C

de toute accumulation de

neige, gtace, ou debris

i 300 mm (12") min. au-dessus

comme des feuittes.

A,

Bouche de ddcharge ou

coude de ddviation

B.

Mur

C.

Cheminde principale de

mise b I'air libre

D.

Conduit horizontal

E.

Coude de ddviation

180°

F.

Conduit vertical

G.

Toit

610mm(2pi)

min.au-dessus

dupoint le

plus61ev6

dub&timent

G

C

d6bit d'air _ B _---

A. Conduitindividueld'dvacuationdus_che-linge

B.Conduitprincipald'dvacuation

Faire en sorte que les vapeurs gen@6es par les liquides de

nettoyage h sec ne puissent pas atteindre les orifices d'entree

d'air " ces vapeurs cr6ent des composes acides qui, Iorsqu'ils

INSTRUCTIONSD'INSTALLATION-SECHE.LINGEA GAZ

Risque du poids excessif

UtiJiser deu× ou plus de personnes pour d_placer et

installer le seche-linge.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

NOTE : Placer le seche-linge sur une feuitle de carton ou un

panneau de bois dur avant de le deplacer sur le ptancher, afin

d'eviter d'endommager le rev_tement du sol.

1. A I'aide de deux personnes ou plus, deptacer le s_che-linge

I'emptacement d'instattation desire.

Uextremit6 exterieure du conduit principal devrait _tre munie d'un

coude de deviation dirige vers le bas. Si le conduit principal suit

une trajectoire verticate h travers le toit, ptut6t qu'h travers lemur,

installer un coude de deviation de 180 ° h l'extremit6 du conduit et

depassant d'au moins 610 mm (2 pi) au-dessus de la partie la

plus elevee du b&timent. Uouverture murate ou dans le toit dolt

avoir un diam_tre superieur de 13 mm (1/2") & celui du conduit

d'evacuation. Le conduit d'evacuation devrait 6tre centr_ dans

I'ouverture.

Ne pas installer une grille ou un couvercte sur I'extr_mite du

conduit d'evacuation. Emptoyez le compose de calfeutrage pour

sceller I'ouverture de mur exterieur autour du passage

d'echappement.

2. Enlever le ruban adhesif dans les angles avant du seche-linge.

Ouvrir le seche-tinge; enlever les brochures et sachets de

pi6ces. Essuyer parfaitement la surface interne du tambour

avec un chiffon humide.

3. Prendre deux comi@es de carton de I'embaltage et les placer

sur le ptancher & I'arri@e du s_che-linge. Saisir fermement le

seche-linge et le placer doucement en appui sur la face arri@e,

sur les corni@es de carton.

4. Prendre Fun des pieds et identifier la marque en losange dans

le fitetage. Ce repere indique jusqu'oQ le pied dolt 6tre visse

dans le trou.

5. Commencer _ visser & la main les pieds de nivetlement dans

les trous. (Utitiser une petite quantite de detergent liquide pour

lubrifier la section filetee, pour qu'il soit plus facile de toumer

les pieds). Utitiser une cle de 25 mm (1") ou une cte & douitle

pour visser les pieds jusqu'au repere. Placer ensuite un patin

de protection sur chaque pied

Placer maintenant le s_che-linge verticatement.

19

Page 20

6.Retirerlafeuittedecartonoulepanneaudeboisdurplace

sousles_che-tinge.Reglerlespiedsduseche-lingevers

lehautouverslebasjusqu'&cequeleseche-tingesoit

d'aptomb.

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_placer et

installer le s_che=linge.

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

1. Retirer le capuchon rouge de la canatisation de gaz.

2. Raccorder la canatisation de gaz au seche-tinge. Le raccord du

conduit d'atimentation en gaz du seche-linge est un filetage

conique NPT de 3/8". Un adaptateur est fourni pour la

conversion & un fitetage standard (3/8" BSP) selon la norme

ISO.228-1. Utitiser un compose d'6tanch6it6 compatible avec

le gaz propane.

Si ceta est necessaire & t'entretien, ouvrir le panneau de plinthe.

Utiliser un couteau & mastic pour appuyer sur les 2 verrous du

panneau de plinthe situ6 sur la partie superieure du panneau

de plinthe. Tirer le panneau de ptinthe vers le bas pour I'ouvrir.

Le panneau de ptinthe est fixe & la partie inferieure.

3. Ouvrir le robinet d'arr_t de la canatisation d'arrivee de gaz.

4. V6rifier tousles raccordements en les badigeonnant d'une

solution de detection des fuites non corrosive approuvee.

Uapparition de bulles indique une fuite. Reparer toute fuite

eventuelle.

:i

1.A I'aide d'une bride de fixation de 102 mm (4"), relier le

conduit d'evacuation & la bouche d'evacuation du s_che-

linge. Si on utilise le conduit d'evacuation existant, s'assurer

qu'il est propre. Le conduit d'evacuation du seche-linge dolt

_tre fixe sur la bouche d'evacuation du seche-linge et dans le

clapet d'evacuation. S'assurer que le conduit d'evacuation est

fixe au clapet d'evacuation & I'aide d'une bride de fixation de

102 mm (4").

1. Placer le seche-linge & I'emplacement final desir6. Ne pas

ecraser ni deformer le conduit d'evacuation. V@ifier que le

seche-linge est de niveau.

2. V6rifier que la canatisation soupte de gaz n'est pas deform6e.

Risque de choc _Jectrique

Cet appareil est un s_che=linge _ 3 conducteurs

qui dolt 6tre reli6 _ la terre.

Bien setter toutes les connexions 61ectriques.

Le non=respect de ces instructions peut causer

un d_c_s, un incendie ou un choc _lectrique.

3. Une fois le seche-linge a son emplacement final, placer un

niveau sur le sommet du s_che-linge, transversalement, puis

darts le sens avant arri@e. Si le seche-linge n'est pas

d'aptomb, ajuster les pieds pour modifier la hauteur et

etabtir un bon aplomb du s_che-linge.

4. Brancher le seche-tinge ou reconnecter la source de courant

electrique.

5. Contr61er le bon fonctionnement du s_che-tinge :

Setectionner un programme complet avec chateur (pas un

programme & I'air), le mettre en marche et laisser le seche-linge

terminer le programme comptet pour s'assurer qu'il fonctionne

correctement. II s'arr_te lorsque la dur6e est ecout6e.

REMARQUE : La porte du s_che-tinge dolt _tre fermee pour

que I'appareil fonctionne. Lorsque la porte est ouverte, le

s_che-linge s'arr_te. Pour remettre le seche-linge en marche,

fermer ta porte et reselectionner un programme.

6. Si on ne per{;oit aucune chateur & I'int@ieur du seche-linge et si

le br01eur ne s'altume pas, arr_ter le seche-linge pendant cinq

minutes. Wrifier que tousles robinets de la canatisation

d'alimentation sont ouverts et que le cordon d'alimentation

electrique est branche. Rep6ter le test de cinq minutes de

fonctionnement.

REGLAGEDELACOMMANDEELECTRONIQUE

Voir le guide de programmation pour des renseignements sur la

mise en marche.

2O

Page 21

INSTRUCTIONSD'ENTRETIEN

Instructions d'entretien :

mNettoyer le filtre & peluches apr_s chaque utilisation.

mComment enlever les peluches accumutees :

• De I'interieur du seche-tinge :

IIfaut retirer les peluches tousles 2 ans ou plus souvent,

selon ['utilisation du seche-linge. Le nettoyage dolt _tre

effectue par une personne qualifiee.

• Du conduit d'evacuation :

IIfaut retirer les peluches tousles 2 ans ou plus souvent,

seton I'utitisation du s_che-linge.

Si le s_che-linge ne fonctionne pas, vdrifier ce qui suit :

[] Le circuit d'alimentation electrique est bien connecte.

[] Les disjoncteurs ne sont pas ouverts et les fusibtes sont intacts.

[] La porte est fermee.

[] Les boutons de commande selectionnent une configuration de

fonctionnement ou sont ptacees sur "ON".

[] Un programme a ete setectionne.

[] Wrifier que les robinets de la canalisation de gaz sont ouverts.

Si vous avez besoin d'assistance :

Veuillez communiquer avec votre distributeur d'ensembte

de buanderie commercial Maytag autorise, ou visitez le site

Web www.MaytagCommercialLaundry.com. Lots de I'appel,

vous aurez besoin des numeros de module et de serie du

seche-linge. Les deux numeros sont indiques sur la plaque

signatetique de I'appareil.

INVERSIONDU SENSD'OUVERTUREDE LA PORTE (FACULTATIF)

Le sens d'ouverture de la porte peut _tre change du c6te droit au

c6te gauche, si desire.

C

5. Fixer & nouveau le panneau de

porte & la porte interne de fagon

ce que la poignee se trouve du

c6te oO les vis viennent d'etre

retirees.

1. Ouvrir la porte du s_che-linge. Oter les vis inferieures du c6te

charni_re de la caisse (A). Desserrer (ne pas retirer) les vis

superieures du c6te charni_re de la caisse.

2. Soutever la porte jusqu'& ce que les vis superieures de la

caisse se trouvent dans la partie large de l'encoche de la

charni_re. Tirer la porte vers I'avant pour la degager des vis.

Retirer les vis superieures de ta caisse.

3. Retirer les vis fixant les charni_res _ ta porte.

4. Retirer les vis de chaque c6te de la porte (5 vis). Saisir les

c6tes de la porte externe et [a soutever doucement pour la

separer de la porte interne (ne pas les separer en forgant).

Ne pas tirer sur le joint ou le Ioquet en plastique de la porte.

6. Fixer les charnieres de porte & la porte du seche-linge de fagon

ce que le trou le plus gros se trouve au fond de la charni_re

et que I'axe de la charni_re soit oriente vers l'avant de la porte.

7=

Oter les 4 vis fixant les 2 bouchons d'obturation (B) du c6te de

la poignee. Fixer les bouchons d'obturation au c6te oppose

I'aide des m_mes 4 vis.

8. Inserer les vis dans les trous inferieurs du

c6te gauche de [a caisse. Serrer les vis

moitie. Positionner la porte de fagon & ce

que le c6te large de I'encoche de la

charni_re de porte se trouve au-dessus

des vis. Faire glisser la porte vers le haut

de fagon & ce que les vis se trouvent au

fond des encoches. Resserrer les vis. Inserer les vis

superieures dans les charni_res et les setter.

9. Fermer la porte et verifier que la g&che de la porte est atignee

avec le Ioquet (C).

21

Page 22

FICHETECHNIQUE- SECHE.LINGEA GAZ

220-240 v- 50 Hz, 1 ph, 12 A max. IP24 Capacit_ max. " 9,1 kg de linge

Pays europ_en "

Cat_gorie europ_enne de gaz :

Pression ajust_e :

Pression de I'alimentation (G20)

Pression r_gl_e a I'usine :

CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

112H3+

0,562703 m3/h

20 mbar

7,4 mbar

AT, CH, CY, CZ, DK, EE, FI, GR,

HU, IT, NO, RO, SE, SK, TR

112H3B/P

0,562703 mS/h

20 mbar

7,4 mbar

l !i if!l!i11iil

Pays europ_en :

Cat_gorie europ_enne de gaz :

Pressiond'alimentation en butane(G30):

Pression ajust_e :

Pressiond'alimentationen propane(G31):

Pression ajust_e :

Pays europ_en : FR, BE

Cat_gorie europ_enne de gaz : 12E+

Pression d'alimentation (G20) : 20 mbar

Pression d'alimentation (G25) : 25 mbar

Pression ajust_e : S/O

REMARQUE : Trousse de conversion : du gaz naturel au GPL : Piece Whirlpool N° W10233219.

Ensemble de conversion du gaz naturel au gaz naturel - France/Belgique :

Piece Whirlpool N° : W10184947

Fabricant : Whirlpool Corporation, Benton Harbor (Michigan) 49022, ETATS-UNIS

CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

112H3+

28-30 mbar

S/O

37 mbar

S/O

AT, CH, CY, CZ, DK, EE, FI, GR,

HU, IT, NO, RO, SE, SK, TR

112H3B/P

30 mbar

30 mbar

S/O

S/O

22

Page 23

GARANTIE DE LA LAVEUSE COMMERCIALE, DU SECHE-LINGE,

DU SECHE-LINGE SUPERPOSEE, DE L'ENSEMBLE DE

BUANDERIE COMMERCIAL SUPERPOSE, ET DES LAVEUSES ET

SECHE-LINGE COMMERCIALES MULTI-CHARGE PAYANTES

MAYTAG

GARANTIE LIMITEE SUR LES PIECES

Pendant cinq ans & compter de ta date d'achat, lorsque cet appareit menager commercial est instatte, utilise et entretenu conformement

aux instructions jointes a ou fournies avec le produit, Maytag marque de Whirlpool Corporation (ci-apres design6e "Maytag') paiera

pour les pieces de rechange specifi6es par t'usine ou les pieces de rechange d'equipement originates du fabricant pour corriger les

vices de materiaux ou de fabrication. Une preuve d'achat originale est requise pour ben6ficier du service de garantie.

MAYTAG NE PAIERA PAS POUR

1. Tous tes autres frais, notamment la main-d'ceuvre, te transport ou les taxes douanieres.

2. Les visites de service pour rectifier l'installation de I'appareil menager commercial, montrer a l'utilisateur comment utiliser l'appareil,

remptacer ou reparer des fusibles, ou rectifier le c&blage ou la plomberie exterieure.

3. Les reparations torsque I'appareil est utilise autrement que pour une utilisation commerciate ordinaire.

4. Les dommages imputables a une mauvaise manipulation du produit pendant une livraison, un vot, un accident, une modification, un

usage impropre, un abus, un incendie, une inondation, des actes de Dieu, une mauvaise installation, une installation non conforme

aux codes locaux d'etectricit6 et de plomberie, ou l'utilisation de produits non approuves par Maytag.

5. Le ramassage et la tivraison. Cet appareit commercial est con£_u pour _tre repar6 sur place.

6. Les reparations aux pieces ou systemes resultant d'une modification non autorisee faite a l'appareil commercial.

7. La depose et la reinstatlation de votre appareit commercial si celui-ci est installe dans un endroit inaccessible ou n'est pas installe

conformement aux instructions d'instattation fournies.

8. Les dommages chimiques ne sont pas couverts par la garantie.

9. Les modifications du b&timent, de la piece ou de I'emplacement necessaires pour faire fonctionner I'appareil commercial

correctement.

CLAUSE D'EXONERATION DE RESPONSABILITE AU TITRE DES GARANTIES IMPLICITES; LIMITATION DES RECOURS

LE SEUL ET EXCLUSIF RECOURS DU CLIENT DANS LE CADRE DE LA PRESENTE GARANTIE LIMITEE CONSISTE EN LA

REPARATION OU LE REMPLACEMENT DU PRODUIT PREVUS CI-DESSUS. LES GARANTIES IMPLIClTES, Y COMPRIS LES

GARANTIES APPLICABLES DE QUALITE MARCHANDE ET D'APTITUDE A UN USAGE PARTICULIER, SONT LIMITI_ES A UN AN OU A

LA PLUS COURTE PERIODE AUTORISEE PAR LA LOI. WHIRLPOOL N'ASSUME AUCUNE RESPONSABILITE POUR LES DOMMAGES

FORTUITS OU INDIRECTS. CERTAINES JURIDICTIONS NE PERMETTENT PAS L'EXCLUSlON OU LA LIMITATION DES DOMMAGES

FORTUITS OU INDIRECTS, OU LES LIMITATIONS DE LA DURI_E DES GARANTIES IMPLIClTES DE QUALITE MARCHANDE OU

D'APTITUDE A UN USAGE PARTICULIER, DE SORTE QUE CES EXCLUSIONS OU LIMITATIONS PEUVENT NE PAS S'APPLIQUER

DANS VOTRE CAS. CETTE GARANTIE VOUS CONFERE DES DROITS JURIDIQUES SPEClFIQUES ET VOUS POUVEZ EGALEMENT

JOUIR D'AUTRES DROITS QUI PEUVENT VARIER D'UNE JURIDICTION/_, UNE AUTRE.

Si vous avez besoin de service, veuillez communiquer avec votre distributeur d'ensemble de buanderie Maytag autorise. Pour tocatiser

votre distributeur d'ensemble de buanderie Maytag autorise, ou pour des demandes de renseignements sur Internet, visitez le site Web

www. MaytagCommercialLaundry.com.

9/07

Vous pouvez ecrire a l'adresse suivante :

Maytag Commercial Laundry Service Department

Benton Harbor, Michigan 49085 USA

2000 M-63 North

23

Page 24

SEGURIDADDELASECADORA

Su seguridad y {a seguridad de los demos es muy irnportante

Hemos incluido muchos mensajes importantes de seguridad en este manual yen su eiectrodom_stico. Lea y obedezca

siempre todos los mensajes de seguridad.

Estesimboio }ellama{a atenciSnsobre pe}igrospotencia{es que pueden ocasionar {amuerte o una {esiSna usted y a losdem_.s.

Todos losmensajes de seguridad iran a continuaciSndel simbolo de advertencia de seguridad y de lapalabra "PELIGRO"

Este es e{ simbolo de advertencia de seguridad.

o "ADVERTENCIA".

Estas pa}abras significan:

Si no sigue las instrucciones de inmediato, usted puede morir

o sufrir una lesiSn grave.

Si no sigue }as instrucciones, usted puede merit o sufrir una

lesiSn grave.

Todos {os mensajes de seguridad }e dirhn e{ pe{igro potencia{, {edirAn cSmo reducir {as posibi{idades de sufrir una {esi6n y {o

que puede suceder si no se siguen {as instrucciones.

PARA SU SEGUR{DAD

1.No atmacene ni use gasolina ni otros vapores inflamabtes cerca de este o cualquier otto electrodomestico.

2. No rode con aerosoles en la proximidad de este aparato mientras este en funcionamiento.

3. No modifique este aparato.

ADVERTENCiA: Para su seguridad, {a informacibn en este manual debe set observada para

minimizar el riesgo de incendio o e×piosiSn, o para prevenir dafios a propiedades, heridas

o la muerte.

- No aimacene ni use gasolina u otros vapores y {iquidos inflamables cerca de _ste o

cualquier otto electrodom_stico.

- PASOS QUE USTED DEBE SEGUIR S{ HUELE A GAS:

® No trate de encender ningdn electrodom_stico.

® No toque ning0n interruptor el_ctrico; no use ningdn tel_fono en su edificio.

• Despeje e{ cuarto, edificio, o zona de todos los ocupantes.

• Llame inmediatamente a su distribuidor de gas desde el tel_fono de un vecino.

Siga las instrucciones de su proveedor de gas.

• Si usted no Iocaliza a su distribuidor de gas, Ilame a los bomberos.

- La instalaciSn y el servicio deben realizarse pot un instalador calificado, agencia de

servicio, o distribuidor de gas.

24

Page 25

P

ELIMINACIONDELASECADORA

Este e{ectrodom6stico estA marcado de acuerdo con la directiva europea 2002/96/EC sobre Residuos de Equipos EI6ctricos y

Electr6nicos (Waste Electrical and Electronic Equipment - WEEE).

Asegur_ndose de que este producto serh eliminado correctamente, usted ayudarh a prevenir consecuencias negativas

potencia{es para el medio ambiente y la salud humana, que podrian causarse pot el manejo inapropiado de este producto.

El simbolo sobre el producto, o en los documentos que acompa_an a{ producto, indica que este electrodom_stico no puede

tratarse como basura dom_stica. Contrariamente, deberh ser entregado al punto de recogida correspondiente para el reciclado

de equipos el_ctricos y electr6nicos.

La eliminaci6n debe Hevarse a cabo de acuerdo con las regulaciones ambientales {ocales para la eliminaci6n de basura.

Para informaci6n mhs detaHada acerca del tratamiento, recuperaci6n y recic{ado de este producto, pot favor, contacte con su

oficina municipal local, su servicio de eliminaci6n de basura dom_stica o la tienda donde compr6 el producto.

REQUISITOSDE INSTALACION

ii::_!iii,_i!!!_iiii_!:iilji_!,i,!!iy_¸ii!,;¸_'ilZ!!!_ii??_i!i_iZ!!ii,_i!!ii_:iiiii;ii!i!:i,!j_iiil

ReOna las herramientas y piezas necesarias antes de comenzar

la instataci6n. Lea y siga las instrucciones provistas con

cuatquiera de las herramientas enlistadas aquL

Herramientas necesarias

[] Llave para tubos [] Llave de cubo

de 20 cm (8") 6 de 8 mm (5/16")

25 cm (10") [] Cuchillo para uso general

[] Llave ajustabte de 20 cm [] Abrazaderas para ducto

(8") 6 25 cm (10")

[] Destornillador de resistente a gas LP

hoja ptana

[] Destornillador Phillips calafateo (para instatar el

[] Llave ajustabte que se abra nuevo ducto de escape)

a 25 mm (1") o Ilave de [] Pinzas

cubo de cabeza hexagonal

[] Nivet

Piezas suministradas

Retire la bolsa de piezas del tambor de la secadora. Verifique que

esten todas las piezas.

[] Cubiertas protectoras para

patas (4)

[] Patas de la secadora (4)

NOTA: El diagrama del circuito para esta mhquina esth situado

dentro del panel frontal inferior.

[] Pegamento para tuber[as

[] Pistola y masitla para

[] Cuchilto para masilla

Peligro de ExplosiSn

Mantenga los materiaies y vapores inflamabies, tales

como la gasoiina, alejados de la secadora.

No instale en un garage.

No seguir estas instrucciones puede ocasionar {a

muerte, explosiSn o incendio.

Si va a instalar una secadora a gas:

IMPORTANTE: Observe todos los c6digos y reglamentos

apticabtes.

[] Verifique los requisitos del c6digo: Algunos c6digos limitan,