Maytag MLG20PRAWW, MLE20PDBYW, MLE20PRAYW, MLE20PRBYW, MLG20PDAWW Installation Instructions

...Page 1

INSTALLATION

INSTRUCTIONS

CommerCial StaCked WaSher/dryer

GaS or eleCtriC

INSTRUCTIONS

D’INSTALLATION

laveuSe/SéCheuSe SuperpoSéeS

à uSaGe CommerCial

à Gaz ou éleCtrique

INSTRUCCIONES

DE INSTALACIÓN

lavadora/SeCadora ComerCialeS

TABLE OF CONTENTS

Page

Stacked Washer/Dryer Safety ............. 2

Tools & Parts ........................................ 5

Alternate Parts and Accessories ........ 6

Dimensions/Clearances ...................... 7

Stacked Washer/Gas Dryer

Installation Requirements ................... 8

Stacked Washer/Electric Dryer

Installation Requirements ................. 11

Dryer Venting Requirements ............ 15

Dryer Gas Supply Requirements ...... 18

Installing Stacked Washer/Dryer ...... 19

Washer Drain System ........................ 22

Electric Dryer Electrical

Connections ....................................... 23

Leveling ............................................... 27

Reversing Dryer Door Swing ............. 29

Stacked Washer/Dryer

Maintenance Instructions .................. 31

If You Need Assistance ...................... 32

Electronic Control Setup

Instructions ........................................ 33

Warranty ............................................. 39

W10045641B

apiladaS a GaS o eléCtriCaS

TABLE DES MATIÈRES

Page

Sécurité de la laveuse/sécheuse

superposées ....................................... 40

Outils et pièces .................................. 43

Pièces supplémentaires

et accessoires .................................... 44

Dimensions/Distances

de dégagement .................................. 45

Exigences d’installation pour

la laveuse/sécheuse à gaz

superposées ....................................... 46

Exigences d’installation pour la

laveuse/sécheuse électriques

superposées ..................................... 49

Exigences concernant

l’évacuation de la sécheuse ............. 54

Spécications de l’alimentation

en gaz de la sécheuse ....................... 57

Installation de la laveuse/sécheuse

superposées ...................................... 58

Système d’évacuation

de la laveuse ....................................... 61

Raccordements de la sécheuse

électrique ........................................... 62

Nivellement ......................................... 66

Inversion du sens d’ouverture

de la porte de la sécheuse ................. 68

Instructions d’entretien de la

laveuse/sécheuse superposées ....... 70

Si vous avez besoin d’assistance ..... 71

Instructions de réglage du tableau

de commande électronique .............. 72

Garantie .............................................. 79

www.maytagcommerciallaundry.com

ÍNDICE

Página

Seguridad de la lavadora/

secadora apiladas .............................. 80

Herramientas y piezas ....................... 83

Piezas y accesorios adicionales ...... 84

Dimensiones y espacios libres ......... 85

Requisitos de instalación de la

lavadora/secadora a gas apiladas ... 86

Requisitos de instalación de la

lavadora/secadora eléctricas

apiladas .............................................. 89

Requisitos de ventilación

de la secadora ................................... 94

Requisitos del suministro

de gas de la secadora ....................... 97

Instalación de la lavadora/

secadora apiladas .............................. 98

Sistema de desagüe

de la lavadora ................................... 101

Conexiones eléctricas

de la secadora eléctrica ................. 102

Nivelación .......................................... 106

Cómo invertir el cierre

de la puerta de la secadora ............. 108

Instrucciones de mantenimiento

de la lavadora/secadora apiladas ... 110

Si necesita ayuda ............................. 111

Instrucciones de programación

del control electrónico .................... 112

Garantía ............................................ 120

Page 2

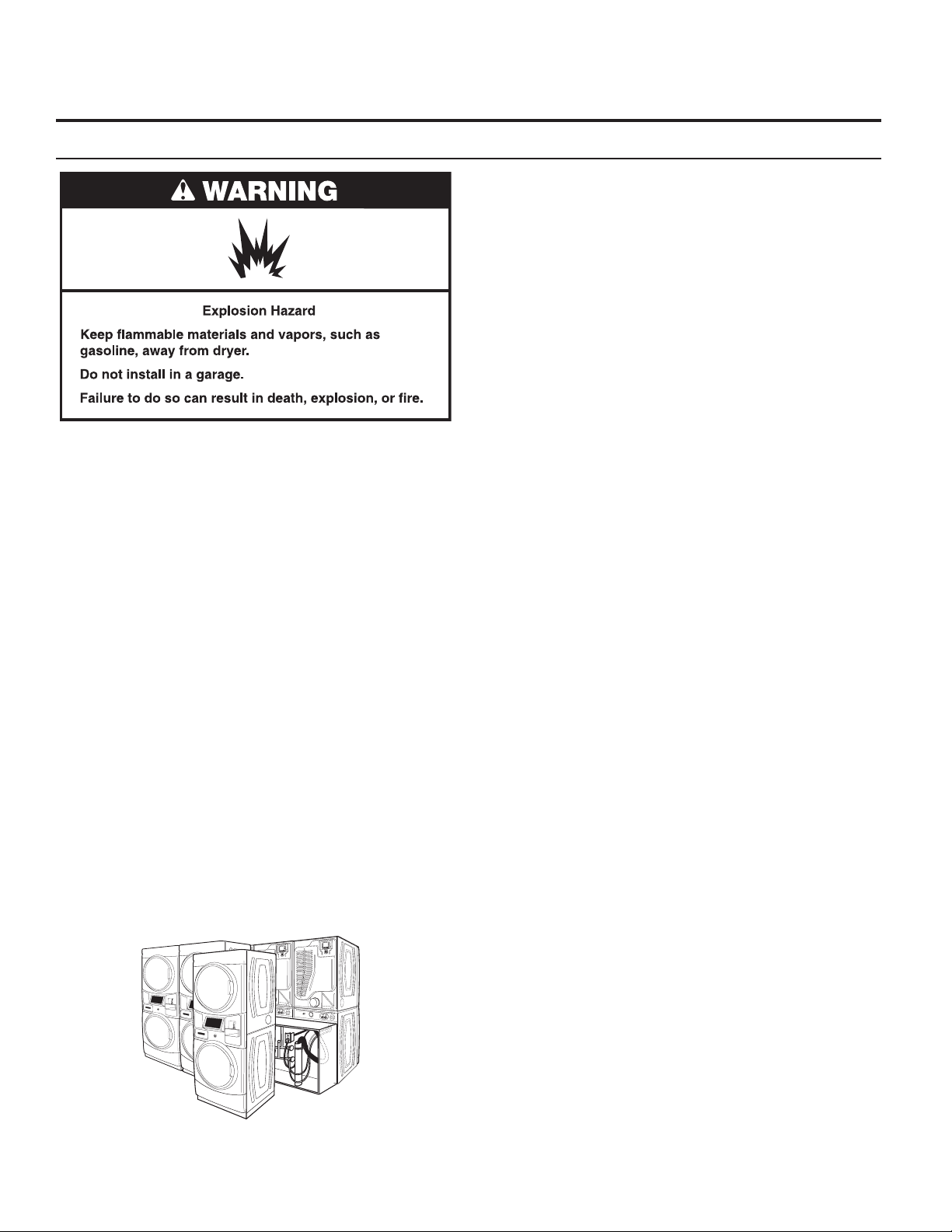

STACKED WASHER/DRYER SAFETY

n It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer

smells gas. This information should be obtained from your gas supplier.

n Post the following warning in a prominent location.

2

Page 3

STACKED WASHER/DRYER SAFETY

3

Page 4

STACKED WASHER/DRYER SAFETY

4

Page 5

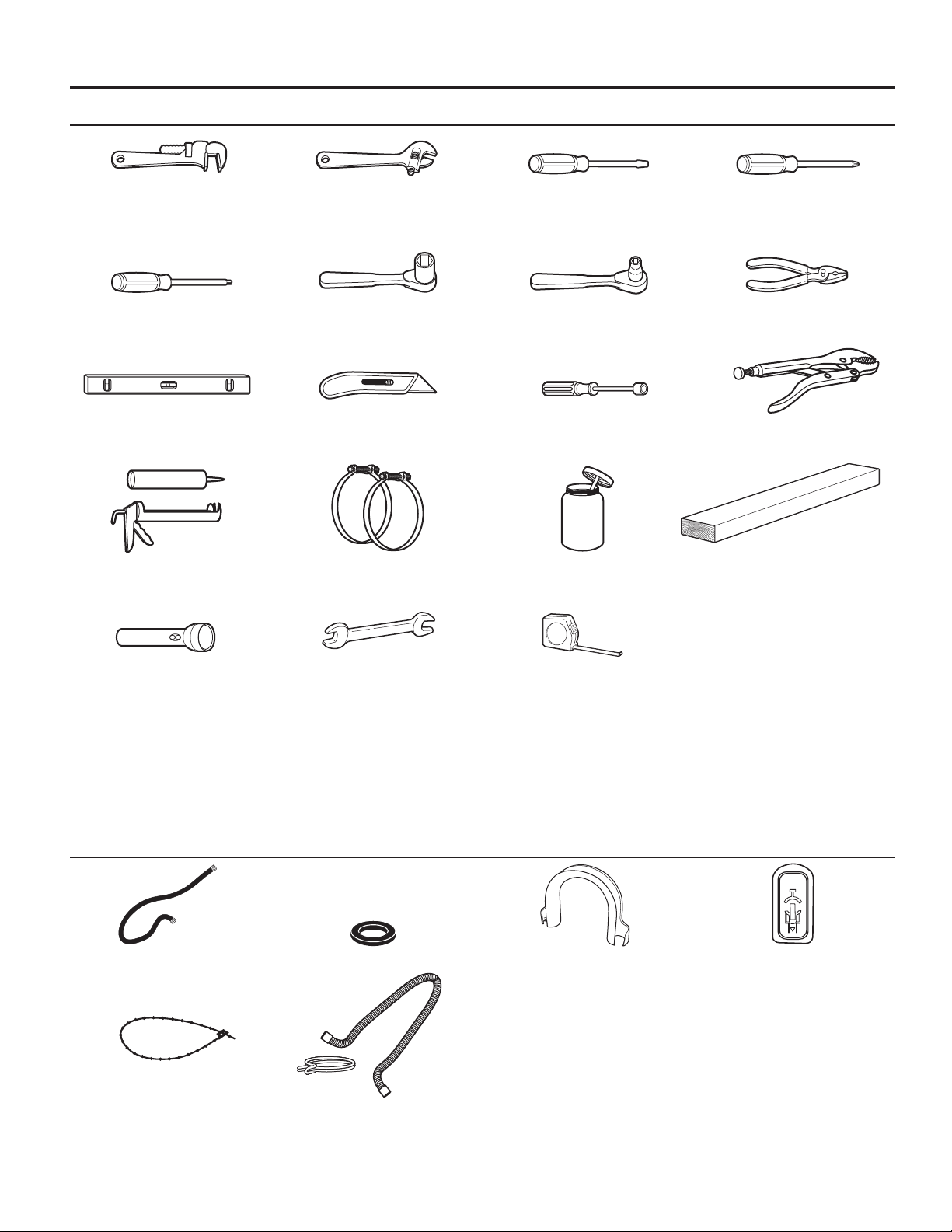

TOOLS & PARTS

Tools Needed:

8" (203 mm) 8" (203 mm) or 10" (254 mm) at-blade screwdriver phillips screwdriver

or 10" (254 mm) adjustable wrench

pipe wrench that opens to 1" (25 mm)

Torx®† T-20 security 1" (25 mm) hex-head 5⁄16" socket wrench pliers

screwdriver or bit socket wrench (that open to 19/16" [39 mm])

level utility knife 1/4" (6 mm) nut driver locking pliers

caulk gun and caulk vent clamps pipe-joint compound 27" (686 mm) wood block

(for installing new exhaust vent) suitable for gas type

ashlight (optional) 1/2" (13 mm) and 9/16" ruler or measuring tape

(14 mm) open-end wrenches

Parts Supplied:

water inlet hoses (2) inlet hose washers (4) U-shaped hose form transit bolt hole plug (4)

beaded tie strap

drain hose/clamp

†® TORX is a registered trademark of Saturn Fasteners, Inc.

5

Page 6

ALTERNATE PARTS AND ACCESSORIES

Alternate Parts

Your installation may require additional parts. If you are

interested in purchasing one of the items listed here, call

the toll-free number in the “If You Need Assistance” section.

If You Have You Will Need to Buy

Overhead sewer Standard 20 gal. (76 L) 39"

(990 mm) tall drain tub or utility

sink, sump pump and connectors

(available from local plumbing

suppliers)

1" (25 mm) standpipe 2" (51 mm) diameter to 1" (25 mm)

diameter Standpipe Adapter

Part Number 3363920

Connector Kit Part Number 285835

Drain hose too Extension Drain Hose Part

short Number 285863

Connector Kit Part Number 285835

Lint clogged drain Drain Protector Part Number 367031

Connector Kit Part Number 285835

Floor drain system Siphon break, Part Number 285834

Connector Kit (x2) Part Number

285835

Extension Drain Hose Part

Number 285863

Water faucets 2 longer water ll hoses:

beyond reach 6 ft. (1.8 m) 90° bend hose

of ll hoses Part Number 76314

10 ft. (3.0 m) Part Number 350008

Accessories

Enhance your washer/dryer with these premium accessories.

For more high-quality items or to order,

call 1-800-901-2042, or visit us at

www.maytag.com/accessories.

In Canada call: 1-800-807-6777 or visit us at

www.whirlpoolparts.ca.

Part Number Accessory

8212526 Washer drip tray, ts under all

31682 All-purpose appliance cleaner

1903WH Laundry supply storage cart

279818 3-way dryer venting kit

285834 Siphon break kit

6

Page 7

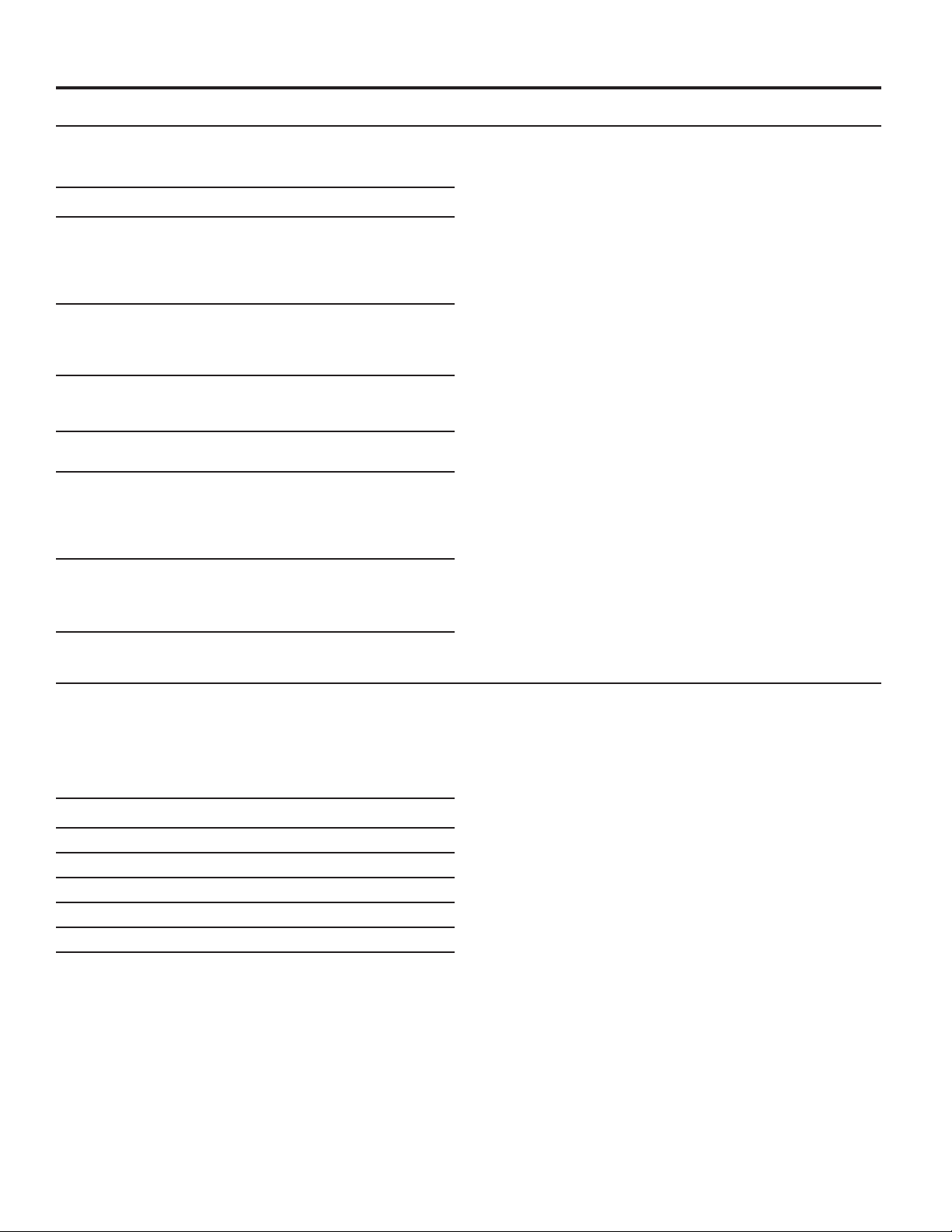

DIMENSIONS/CLEARANCES

Dimensions

Front View Side View Back View

74"

(1880 mm)

1"

(25 mm)

27"

(686 mm)

51"

(1295 mm)

1

/2

29 "

(751 mm)

74"

(1880 mm)

1"

(25 mm)

Clearances

Side Clearances Back/Top Clearances

0"

(0 mm)

0"

(0 mm)

7

Page 8

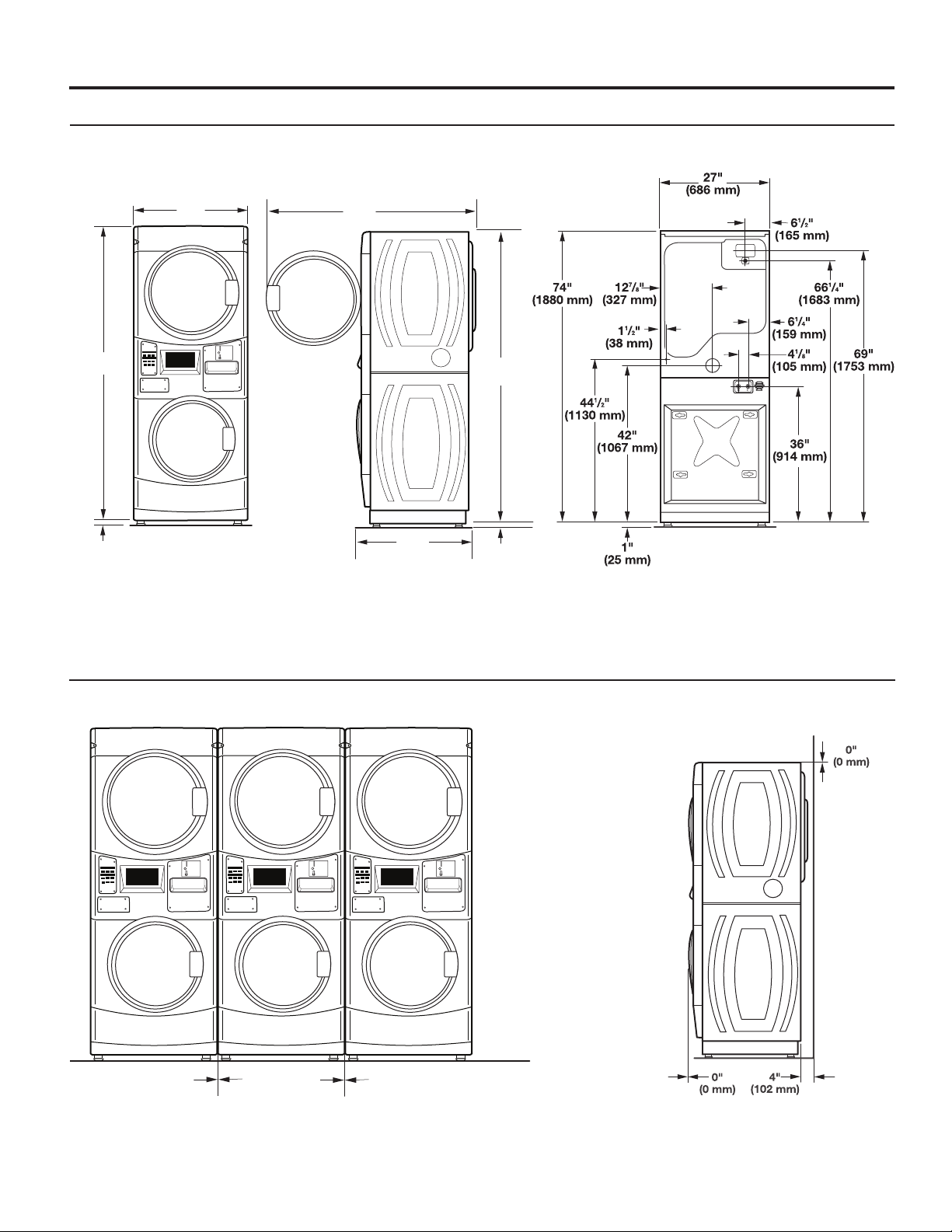

STACKED WASHER/GAS DRYER INSTALLATION

REQUIREMENTS

Stacked Washer/Gas Dryer Location

Stacked washer/gas dryer installation clearances

n The location must be large enough to allow the washer

and dryer doors to be fully opened.

n

Additional spacing should be considered for ease of

installation and servicing. The doors open more than 180°.

The washer door is not revers ble.

n

Additional clearances might be required for wall, door, and

oor moldings.

n

Additional spacing of 1" (25 mm) on all sides of the washer/

dryer is recommended to reduce noise transfer.

n Companion appliance spacing should also be considered.

When installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

n

Selecting the proper location for your washer/dryer improves

performance and minimizes noise and possible washer “walk.”

Your washer/dryer can be installed in a basement, laundry room,

or recessed area. See “Drain System.”

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer/dryer where

it will be exposed to the weather. Do not store or operate the

washer/dryer in temperatures at or below 32°F (0°C). Some

water can remain in the washer and can cause damage in low

temperatures. Proper installation is your responsibility.

You will need:

n A water heater set to deliver 120°F (49°C) water to the

washer.

n

A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

n

Hot and cold water faucets located within 4 ft. (1.2 m) of the

hot and cold water ll valves, and water pressure of 20–100

psi (137.9–689.6 kPa).

n

A level oor with a maximum slope of 1" (25 mm) under

entire washer/dryer. Installing the washer/dryer on soft oor

surfaces, such as carpets or surfaces with foam backing,

is not recommended.

n

A sturdy and solid oor to support the washer/dryer with

a total weight (water and load) of 450 lbs (204 kg).

n

A oor drain under the bulkhead. Prefabricated bulkheads

with electrical outlets, water inlet lines, and drain facilities

should be used only where local codes permit.

Check code requirements: Some codes limit or do not

permit installation of clothes dryers in garages, closets,

or sleeping quarters. Contact your local building inspector.

n

Make sure that lower edges of the cabinet, plus the back and

bottom sides of the washer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area Installation Instructions” below for minimum

spacing requirements.

Recessed Area Installation Instructions

This washer/dryer may be installed in a recessed area. For

recessed area installations, minimum clearances can be found

on the warning label on the rear of the dryer or in “Dimensions/

Clearances.”

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

The dryer must be exhausted outdoors.

8

Page 9

STACKED WASHER/GAS DRYER INSTALLATION

Stacked Washer/Gas Dryer Electrical Requirements

IMPORTANT: The washer/dryer must be electrically grounded

in accordance with local codes and ordinances or, in the

absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, latest edition, or Canadian Electrical Code, CSA

C22.1. If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

that the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

n Do not ground to a gas pipe.

n Do not have a fuse in the neutral or ground circuit.

n A 120 volt, 60 Hz, AC only, 15- or 20-amp, fused electrical

circuit is required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this washer/dryer be provided.

n This washer/dryer is equipped with a power supply cord

having a 3-prong grounding plug.

n To minimize the possibility of shock, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualied electrician.

n If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

n Check with a qualied electrician if you are not sure the

washer/dryer is properly grounded.

REQUIREMENTS

Stacked Washer/Gas Dryer Grounding

9

Page 10

STACKED WASHER/GAS DRYER INSTALLATION

REQUIREMENTS

Stacked Washer/Gas Dryer Gas Supply

IMPORTANT: Observe all governing codes and ordinances.

This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1/NFPA 54 or CAN/CSA B149.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

The design of this washer/dryer has been certied by CSA

International for use at altitudes up to 10,000 feet (3048 m)

above sea level at the B.T.U. rating indicated on the model/

serial plate. Burner input adjustments are not required when

the washer/dryer is operated up to this elevation.

When installed above 10,000 feet (3048 m), a four percent

(4%) reduction of the burner B.T.U. rating shown on the model/

serial plate is required for each 1,000 foot (305 m) increase in

elevation. For assistance when converting to other gas types

and/or installing above 10,000 feet (3048 m) elevation, contact

your local service company.

10

Page 11

STACKED WASHER/ELECTRIC DRYER INSTALLATION

REQUIREMENTS

Stacked Washer/Electric Dryer Location

Stacked washer/electric dryer installation clearances

n The location must be large enough to allow the washer and

dryer doors to be fully opened.

n Additional spacing should be considered for ease of

installation and servicing. The doors open more than 180°.

The washer door is not reversible.

n Additional clearances might be required for wall, door, and

oor moldings.

n Additional spacing of 1" (25 mm) on all sides of the washer/

dryer is recommended to reduce noise transfer.

n Companion appliance spacing should also be considered.

Recessed Area Installation Instructions

This washer/dryer may be installed in a recessed area. For

recessed area installations, minimum clearances can be found

Selecting the proper location for your washer/dryer improves

performance and minimizes noise and possible washer “walk.”

Your washer/dryer can be installed in a basement, laundry room,

or recessed area. See “Drain System.”

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer/dryer where

it will be exposed to the weather. Do not store or operate the

washer/dryer in temperatures at or below 32°F (0°C). Some

water can remain in the washer and can cause damage in low

temperatures. Proper installation is your responsibility.

You will need:

n A water heater set to deliver 120°F (49°C) water to the

washer.

n A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

n Hot and cold water faucets located within 4 ft. (1.2 m)

of the hot and cold water ll valves, and water pressure

of 20–100 psi (137.9–689.6 kPa).

n A level oor with a maximum slope of 1" (25 mm) under

entire washer/dryer. Installing the washer/dryer on soft oor

surfaces, such as carpets or surfaces with foam backing,

is not recommended.

n A sturdy and solid oor to support the washer/dryer with

a total weight (water and load) of 450 lbs (204 kg).

n A oor drain under the bulkhead. Prefabricated bulkheads

with electrical outlets, water inlet lines, and drain facilities

should be used only where local codes permit.

on the warning label on the rear of the dryer.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

The dryer must be exhausted outdoors.

11

Page 12

STACKED WASHER/ELECTRIC DRYER INSTALLATION

REQUIREMENTS

Stacked Washer/Electric Dryer Electrical

Requirements

Washer Electrical Requirements

n Do not have a fuse in the neutral or ground circuit.

n This washer/dryer is equipped with a power supply cord

having a 3 prong grounding plug.

n To minimize the possibility of shock, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualied electrician.

n If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

n Check with a qualied electrician if you are not sure the

washer is properly grounded.

Stacked Washer/Electric Dryer Grounding

12

Page 13

STACKED WASHER/ELECTRIC DRYER INSTALLATION

REQUIREMENTS

Dryer Electrical Requirements

It is your responsibility:

n To contact a qualied electrical installer.

n To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996 and dryer circuits

involved in remodeling after 1996.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch

Park, Quincy, MA 02269.

n To supply the required 3 or 4 wire, single phase, 240 volt, 60

Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt

electrical supply, if specied on the serial/rating plate) on a

separate 30-amp circuit, fused on both sides of the line. A

time delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

n Do not use an extension cord.

n If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

n This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor

is permanently connected to the neutral conductor (white

wire) within the dryer. If the dryer is installed with a 4-wire

electrical supply connection, the neutral ground conductor

must be removed from the external ground connector (green

screw), and secured under the neutral terminal (center or

white wire) of the terminal block. When the neutral ground

conductor is secured under the neutral terminal (center

or white wire) of the terminal block, the dryer cabinet is

isolated from the neutral conductor.

n If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see “Optional 3-wire

connection” section.

n A 4-wire power supply connection must be

used when the appliance is installed in a location where

grounding through the neutral conductor is prohibited.

Grounding through the neutral is prohibited for (1) new

branch-circuit installations, (2) recreational vehicles, and

(3) areas where local codes prohibit grounding through the

neutral conductor.

Electric Dryer Power Supply Cord

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

n A UL listed 30-amp power supply cord, rated 240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft. (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or “U” shaped spade terminals

with upturned ends.

n A UL listed strain relief.

If your outlet looks like this:

Then choose a 4-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

4-wire power supply cord, at least 4 ft. (1.22 m)

long, must have four 10-gauge copper wires and

match a 4-wire receptacle of NEMA Type 14-30R.

4-wire

receptacle

(14-30R)

The ground wire (ground conductor) may be either

green or bare. The neutral conductor must be

identied by a white cover.

If your outlet looks like this:

Then choose a 3-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

3-wire power supply cord, at least 4 ft. (1.22 m)

long, must have three 10-gauge copper wires and

match a 3-wire receptacle of NEMA Type 10-30R.

3-wire

receptacle

(10-30R)

13

Page 14

STACKED WASHER/ELECTRIC DRYER INSTALLATION

REQUIREMENTS

Dryer Direct Wire

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

n Flexible armored cable or nonmetallic sheathed copper

cable (with ground wire), covered with exible metallic

conduit. All current-carrying wires must be insulated.

n 10-gauge solid copper wire (do not use aluminum).

n At least 5 ft. (1.52 m) long.

14

Page 15

DRYER VENTING REQUIREMENTS

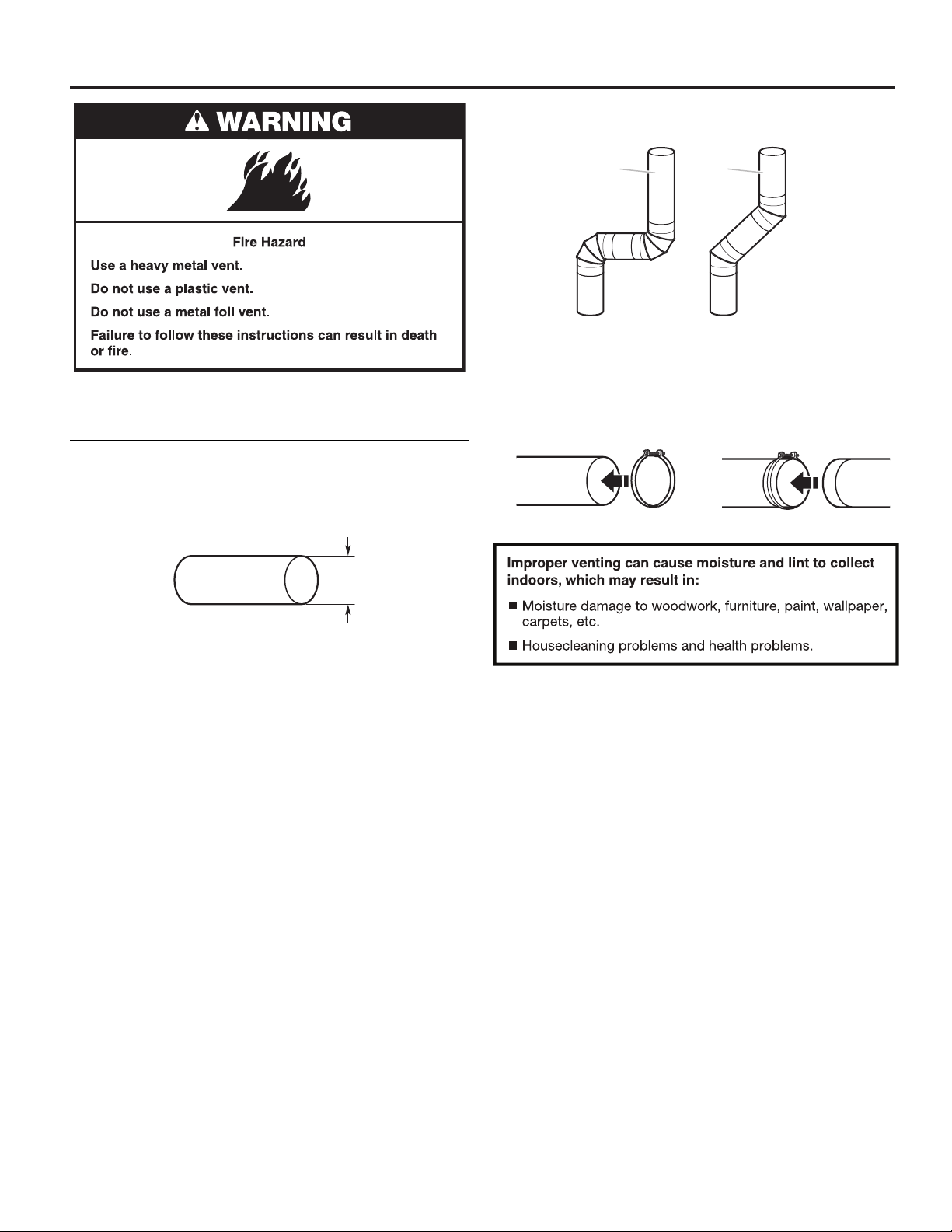

Elbows:

■ 45° elbows provide better airow than 90° elbows.

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used for

exhausting.

4"

(102 mm)

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with

screws or other fastening devices that extend into interior

of duct and catch lint. Do not use duct tape.

4" (102 mm) heavy, metal exhaust vent

■ Only a 4" (102 mm) heavy, metal exhaust vent and clamps

may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to

clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may

result in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 7

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or exible metal vents. Review “Vent System Chart” and

if necessary, modify existing vent system to achieve best drying

performance.

3

⁄4 ft. (2.4 m).

15

Page 16

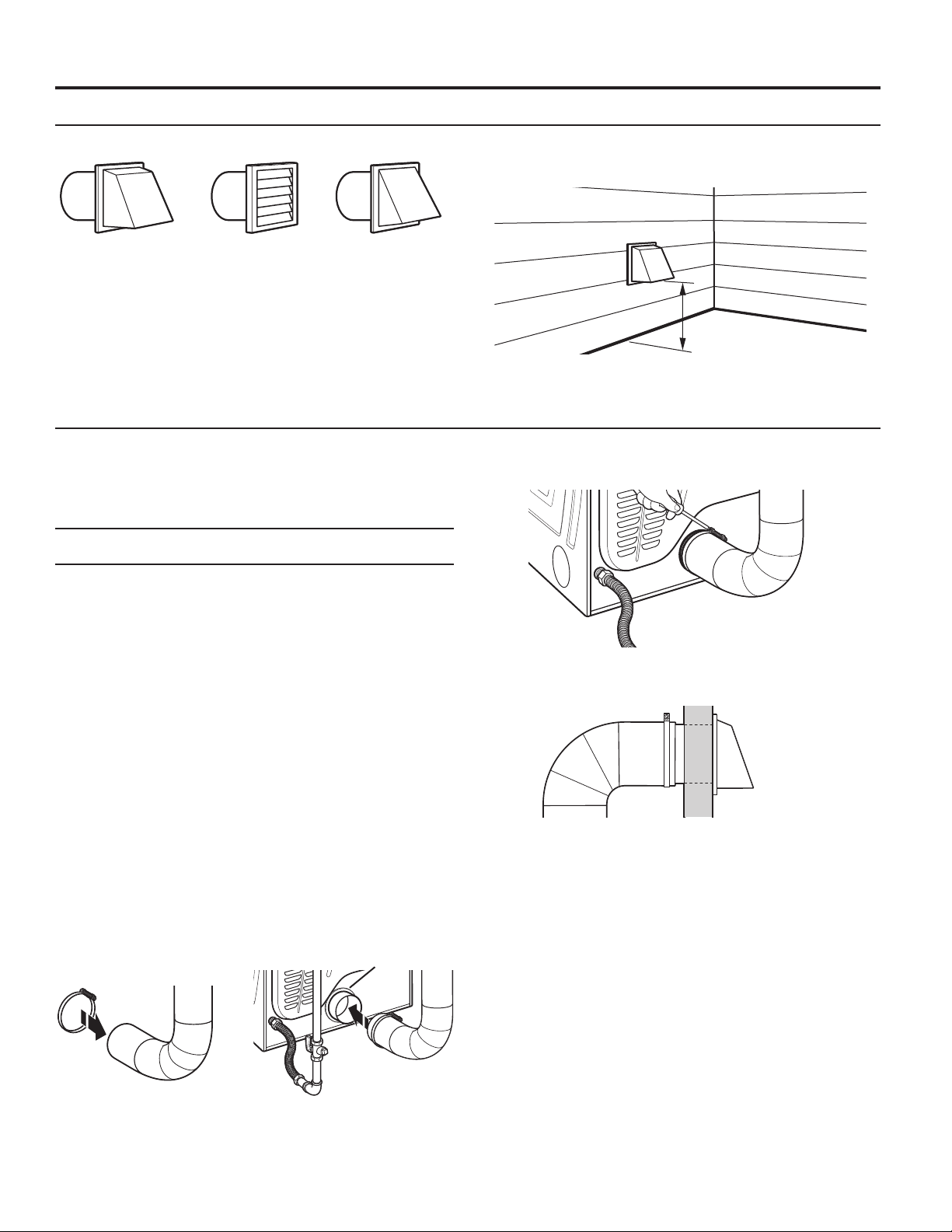

DRYER VENTING REQUIREMENTS

Vent Hoods

4" (102 mm) Diameter Exhaust Hoods

box hood louvered hood angled hood

Vent System Length

Maximum Vent Length/Vent Connection

Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

owers, rocks, bushes, or snow).

12" min.

(305 mm)

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent)

No. of Box and Angled

90˚ Turns Louvered Hood Hood

0 135 ft. (41.2 m) 129 ft. (39.3 m)

1 125 ft. (38.1 m) 119 ft. (36.3 m)

2 115 ft. (35.1 m) 109 ft. (33.2 m)

3 106 ft. (32.3 m) 100 ft. (30.5 m)

4 98 ft. (29.9 m) 92 ft. (28.0 m)

For vent systems not covered by the vent specication chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

“Recessed Area Installation Instructions” in the “Stacked

Washer/Gas Dryer Location” and “Stacked Washer/Electric

Dryer Location” sections.

A 4" (102 mm) outlet hood is preferred. However, a 21⁄2"

(64 mm) outlet exhaust hood may be used. A 21⁄2" (64 mm)

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

3. Tighten hose clamp with Phillips screwdriver.

4. Make sure the vent is secured to exhaust hood with

a 4" (102 mm) clamp.

5. Move dryer into nal position. Do not crush or kink vent.

Make sure dryer is level.

2. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer.

NOTE: Do not remove vent collar.

Vent collar

16

Page 17

DRYER VENTING REQUIREMENTS

If an Exhaust Hood Cannot be Used

The outside end of main vent should have a sweep elbow

directed downward.

12" min.

(305 mm)*

* Minimum clearance above

any accumulation of snow,

ice, or debris such as leaves

If main vent travels vertically through the roof, rather than

through wall, install a 180° sweep elbow on end of vent at least

2 ft. (610 mm) above surface of roof.

The opening in wall or roof shall have a diameter 1⁄2" (13 mm)

larger than vent diameter. Vent should be centered in opening.

Do not install screening over end of vent for best performance.

24" min.

(610 mm)

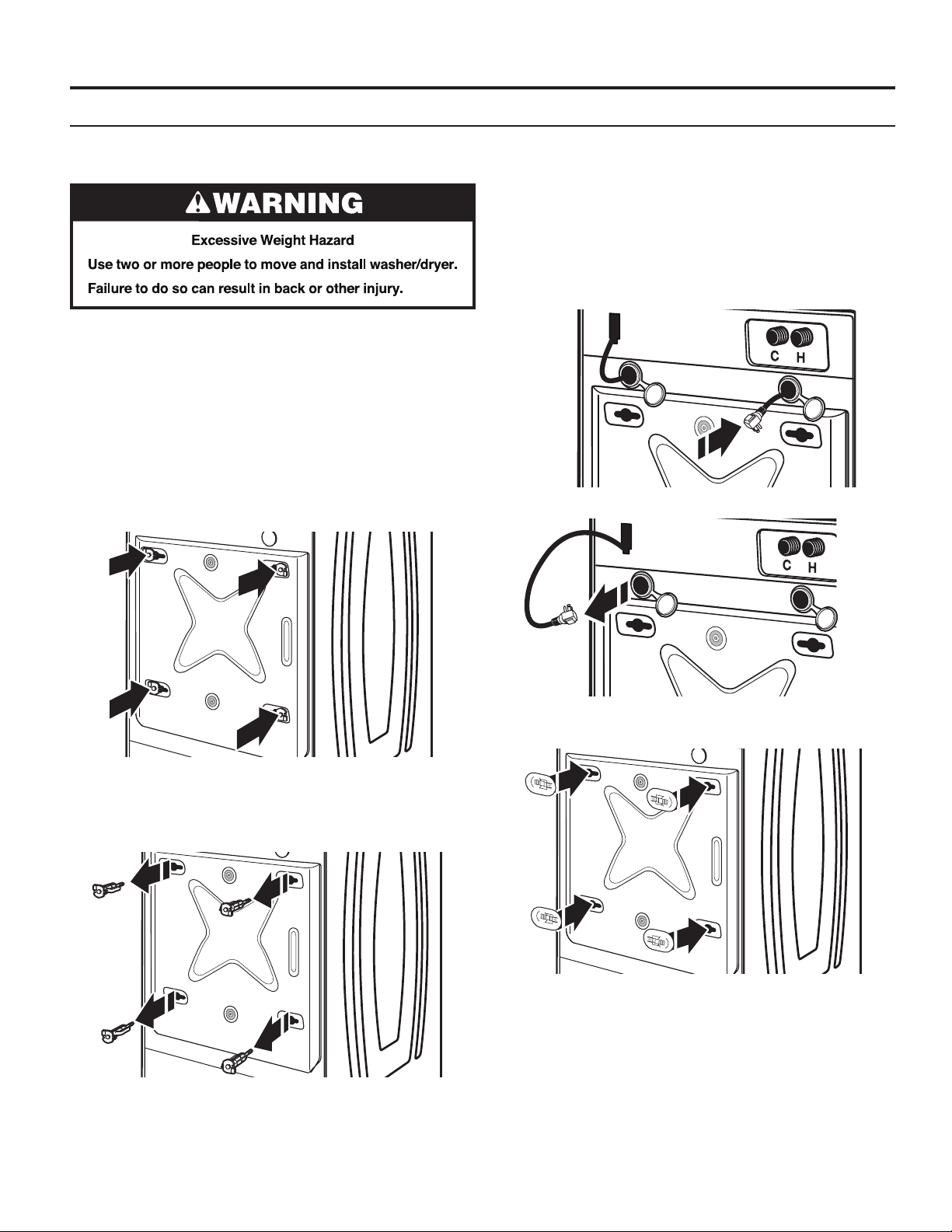

Multiple Dryer Venting

A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 200 CFM of air per dryer.

Large-capacity lint screens of proper design may be used in

main vent if checked and cleaned frequently. The room where

the dryers are located should have make-up air equal to or

greater than CFM of all the dryers in the room.

Each vent should enter the main vent at an angle pointing in

the direction of the airow. Vents entering from the opposite

side should be staggered to reduce the exhausted air from

interfering with the other vents.

Back-draft Damper Kit, Part No. 3391910, is available from

your distributor and should be installed in the vent of each

dryer to keep exhausted air from returning into dryers and to

keep exhaust in balance within main vent. Unobstructed return

air openings are required.

30˚ max.

air ow

The maximum angle of each vent entering the main vent should

be no more than 30°.

17

Page 18

DRYER GAS SUPPLY REQUIREMENTS

Type of Gas

This dryer is equipped for use with natural gas. It is designcertied by CSA International for LP (propane and butane)

gases with appropriate conversion. No attempt shall be made

to convert dryer from gas specied on serial/rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a qualied service technician.

Gas conversion kit part numbers are listed on gas valve burner

base.

Gas Supply Line

Recommended Method

Flexible Metal Appliance Connector

Provide a gas supply line of 1⁄2" (13 mm) rigid (IPS) pipe to

dryer location. Pipe joint compounds that resist action of LP

gas must be used. Do not use TEFLON®† tape. With LP gas,

piping or tubing size can be 1⁄2" (13 mm) minimum. Usually, LP

gas suppliers determine size and materials used in the system.

Gas Supply Pressure Testing

A 1/8" (3 mm) NPT minimum plugged tapping, accessible for

gauge testing, must be installed immediately downstream of

the installed shut-off valve to the dryer (as shown above). The

dryer must be disconnected from the gas supply piping system

during any pressure testing of the system at test pressures in

excess of 1/2" psig (352 kg/m2).

Alternate Method

It is recommended that a new exible stainless steel gas line,

design-certied by CSA International, be used for connecting

the dryer to the gas supply line. (The gas pipe which extends

through the lower rear of the dryer is provided with 3⁄8"

(10 mm) male pipe thread.)

NOTE: Do not kink or damage the exible stainless steel gas

line when moving the door.

Rigid Pipe Connection

The rigid pipe connection requires a combination of pipe ttings

to obtain an in-line connection to dryer.

The gas supply may also be connected using 3⁄ 8" (10 mm)

approved copper or aluminum tubing. If the total length of

the supply line is more than 20 ft. (6.1 m), larger tubing will

be required.

If using natural gas, do not use copper tubing. Pipe joint

compounds that resist action of type of gas supplied must

be used.

Shut-off valve required

The supply line must be equipped with a manual shut-off

valve installed within 6 ft. (1.8 m) of dryer in accordance

with National Fuel Gas Code, ANSI Z223.1. This valve should

be located in same room as dryer. It should be in a location

that allows ease of opening and closing. Do not block access

to shut-off valve. In Canada, an individual manual shut-off

valve must be installed in accordance with the B149 installation

codes CAN/CGA B149.1 and CAN/CGA B149.2.

18

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 19

INSTALLING STACKED WASHER/DRYER

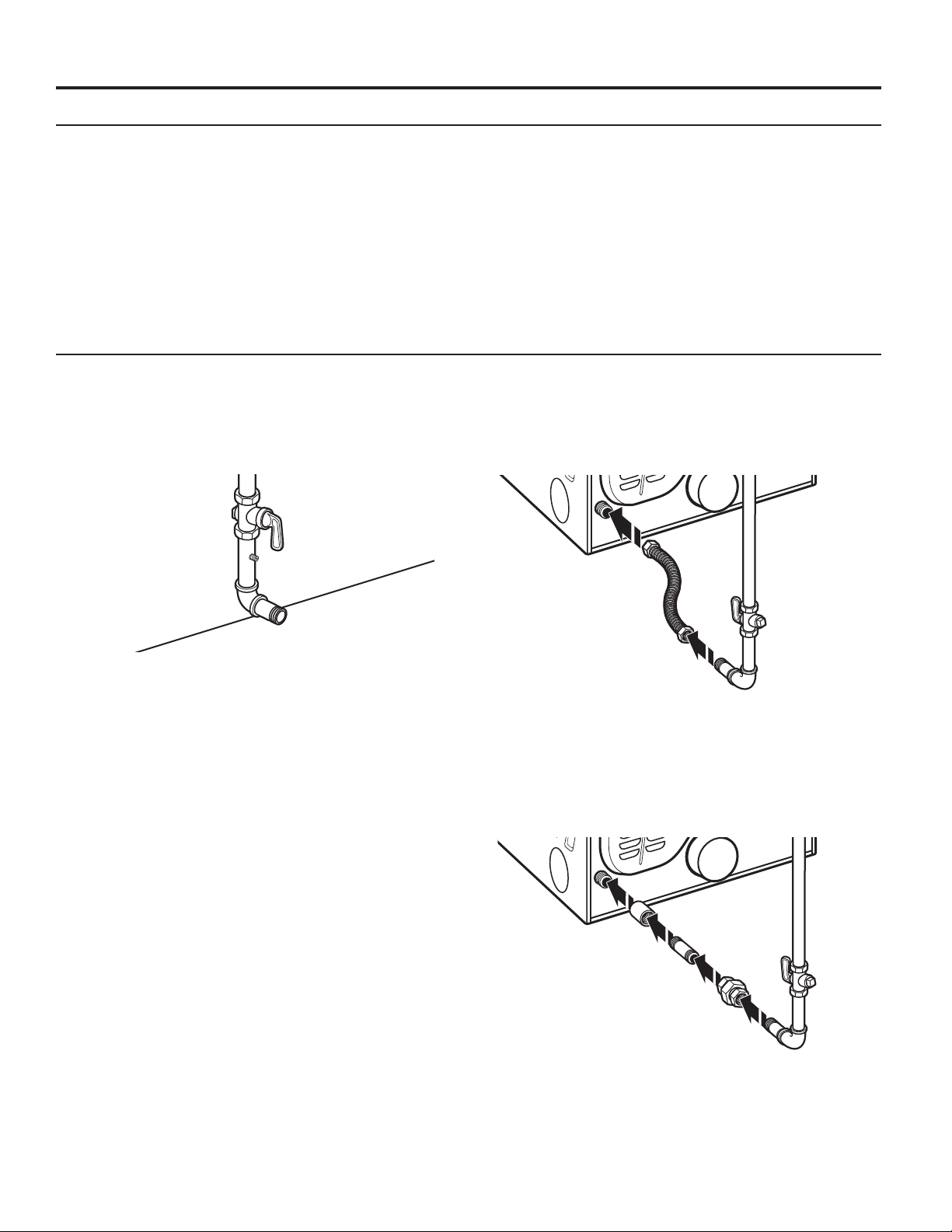

Remove Transport System

NOTE: Slide washer/dryer onto cardboard or hardboard before

moving to avoid damaging oor covering.

IMPORTANT: Position the washer/dryer so that the rear of

the washer is within approximately 3 ft. (900 mm) of its nal

location.

There are 4 shipping bolts in the rear panel of the washer that

support the suspension system during transportation. These

bolts also retain the power cord inside the washer until the

bolts are removed.

1. Keep the washer/dryer in the upright position while removing

the shipping bolts.

2. Using a 1/2" (13 mm) wrench, loosen each of the bolts.

4. Models with separate washer power cords: Push the power

cord plug into the opening on the right side of the rear panel

and pull the power cord through the opening on the left side

of the rear panel and close holes with the attached cap. Do

not pull plug end of power cord through the right side hole.

NOTE: To avoid damage to internal washer parts or the

power cord, if the cord does not pull out of the washer rear

panel easily, do not force it. Remove the washer rear panel

and guide the power cord around the obstruction and out

the hole on the left side of the rear panel.

3. Once the bolt is loose, move it to the center of the hole

and completely pull out the bolt, including the plastic spacer

covering the bolt. Once all 4 bolts are removed, discard the

bolts and spacers.

5. Close the bolt holes with the 4 transport bolt hole plugs.

IMPORTANT: If the washer/dryer is to be transported, call

your product distributor or installer. To avoid suspension and

structural damage, your washer/dryer must be properly set up

for relocation by a trained professional.

19

Page 20

INSTALLING STACKED WASHER/DRYER

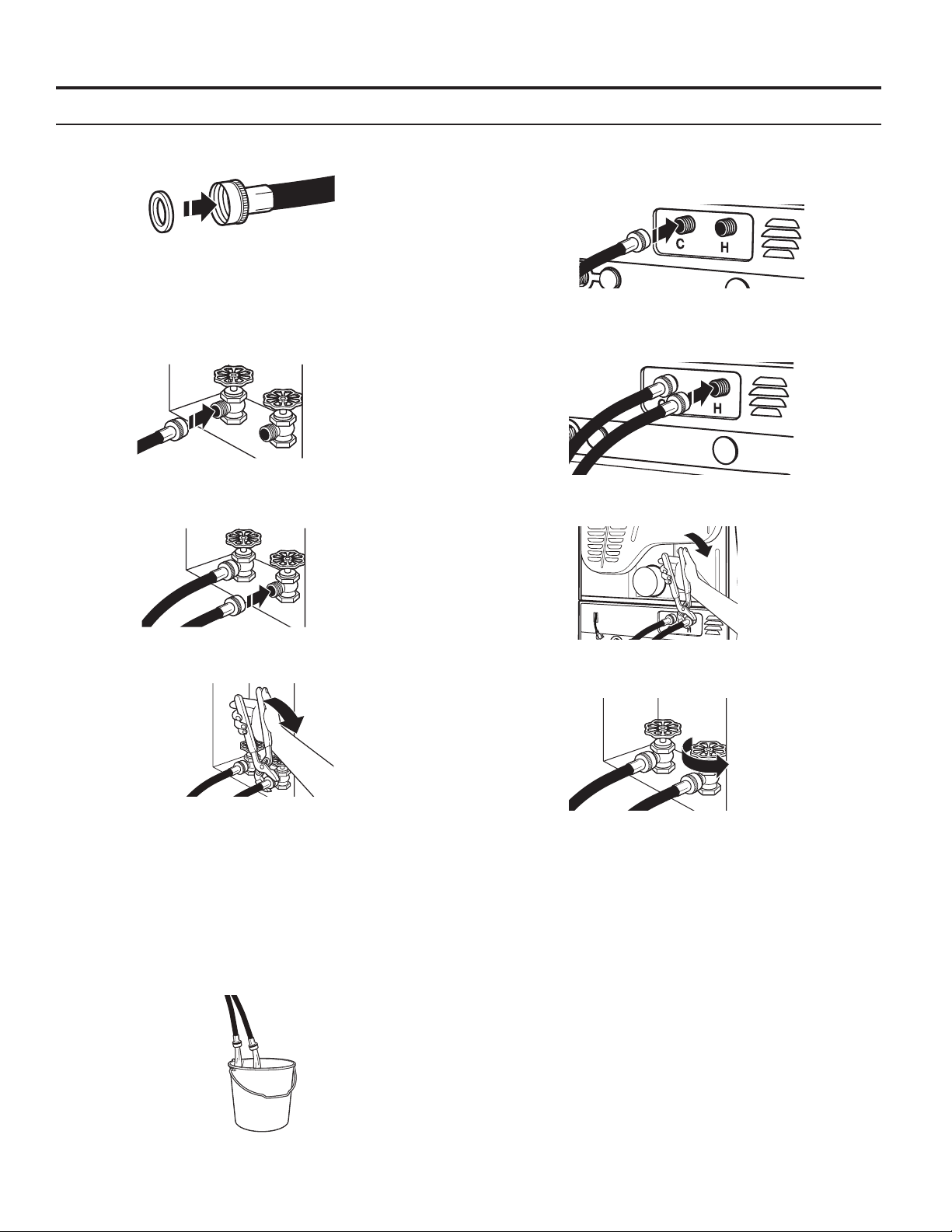

Connect Inlet Hoses

Insert new hose washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

Connect Inlet Hoses to Washer

1. Attach the cold water hose to the washer’s cold water inlet

valve. Screw on coupling by hand until it is seated on the

washer.

washer

coupling

Connect Inlet Hoses to Water Faucets

Make sure the washer drum is empty.

1. Attach a hose to the hot water faucet. Screw on coupling

by hand until it is seated on the washer.

2. Attach a hose to the cold water faucet. Screw on coupling

by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

2. Attach the hot water hose to the washer’s hot water inlet

valve. Screw on coupling by hand until it is seated on the

washer.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the valve can result.

4. Turn on the water faucets completely and check for leaks.

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

Clear Water Lines

n Run water through both faucets and inlet hoses, into a

laundry tub, drainpipe, or bucket, to get rid of particles

in the water lines that might clog the inlet valve screens.

n Check the temperature of the water to make sure that the

hot water hose is connected to the hot water faucet and that

the cold water hose is connected to the cold water faucet.

20

NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

Page 21

INSTALLING STACKED WASHER/DRYER

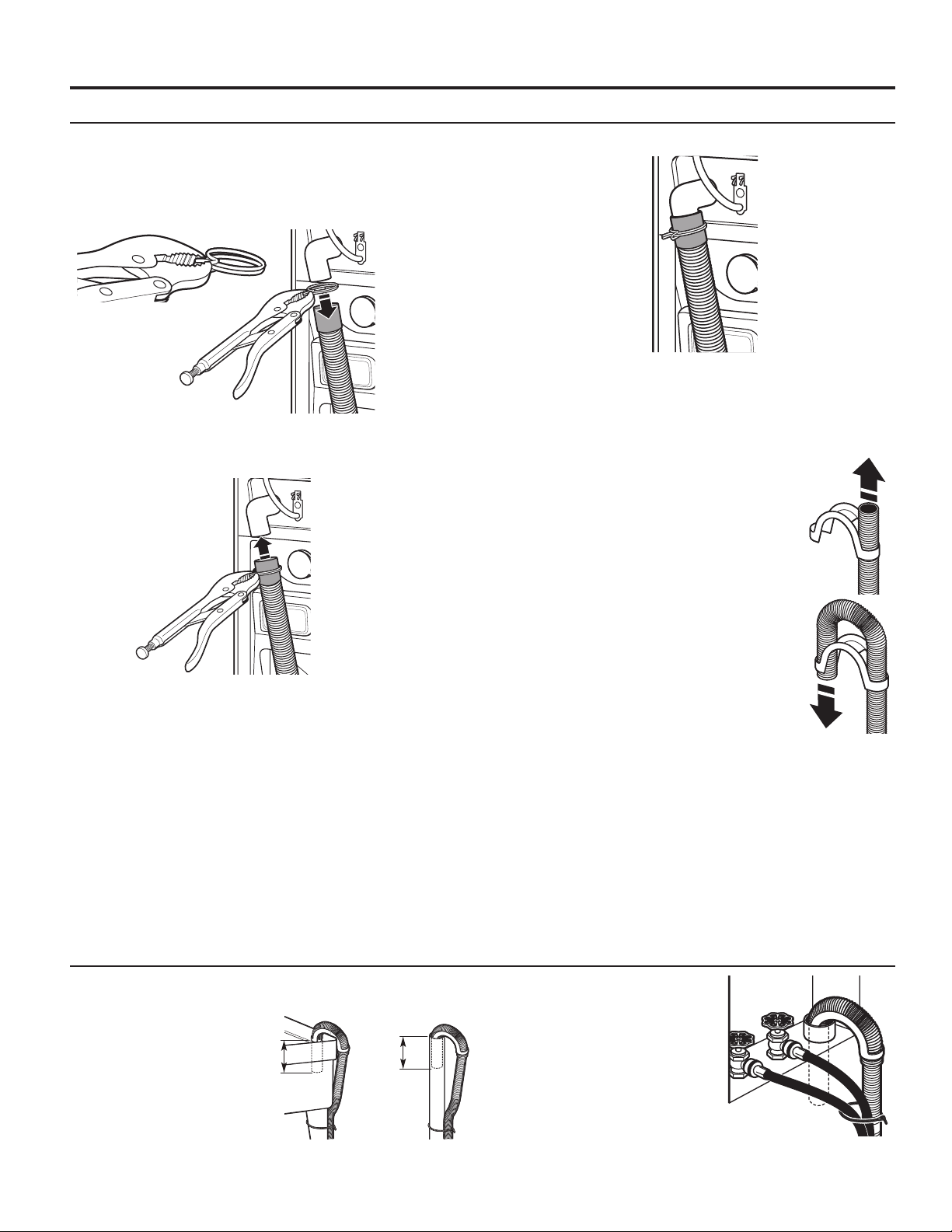

Route Drain Hose

Proper routing of the drain hose avoids damage to your oor

due to water leakage. Read and follow these instructions.

Remove drain hose from the washer drum

1. Using locking pliers, squeeze hose clamp tabs together and

insert over the end of the drain hose.

2. Slide the drain hose onto the washer connection.

3. Once the drain hose is in place, release the pliers.

4. The washer drain system can be installed using a oor drain,

wall standpipe, oor standpipe, or laundry tub.

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated drain hose.

Snap either end of the drain hose form to the

drain hose at the point where the corrugation

begins.

Secure Drain Hose

1. Drape the power cord over the washer top.

2. Move the washer to its nal location.

3. Place the drain hose

in the laundry tub or

standpipe as shown.

4. Secure the drain hose using

the supplied beaded tie

strap.

41/2"

(114 mm)

41/2"

(114 mm)

Bend drain hose over drain hose form and

snap into place.

NOTE: Hose must not extend more than 1"

(25 mm) past the end of the U bend.

To keep drain water from going back into the washer:

n Do not straighten the drain hose, do not force excess drain

hose into standpipe. Hose should be secure, but loose

enough to provide a gap for air.

n Do not lay excess hose on the bottom of the laundry tub.

Floor drain

You may need additional parts. See “Alternate Parts.”

5. If the washer faucets and the

drain standpipe are recessed, put

the hooked end of the drain hose

in the standpipe as shown.

NOTES:

n Do not force excess drain hose

back into the rear of the washer.

n To avoid siphoning, do not

seal the drain hose into the

standpipe.

21

Page 22

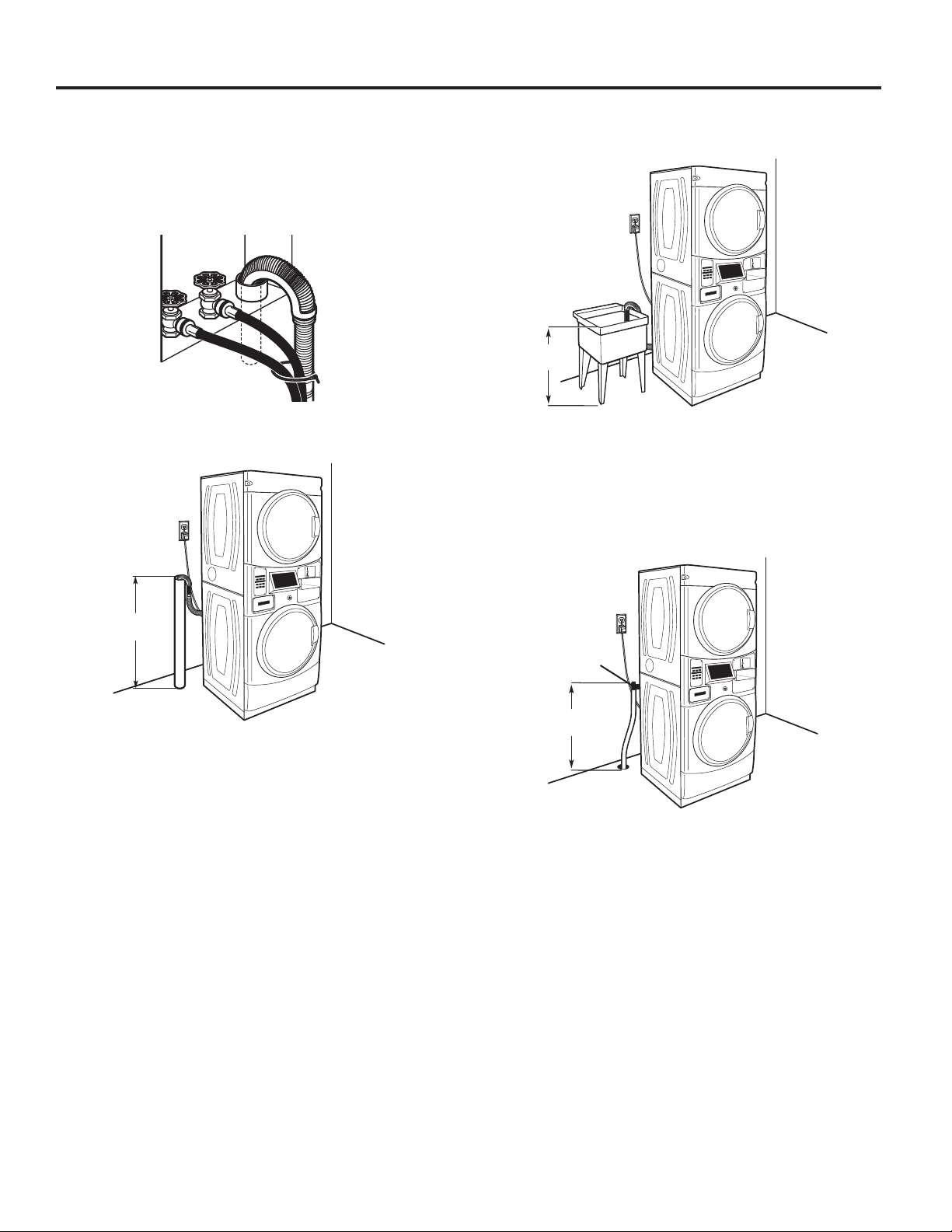

WASHER DRAIN SYSTEM

The washer can be installed using the standpipe drain system

(oor or wall), the laundry tub drain system, or the oor drain

system.

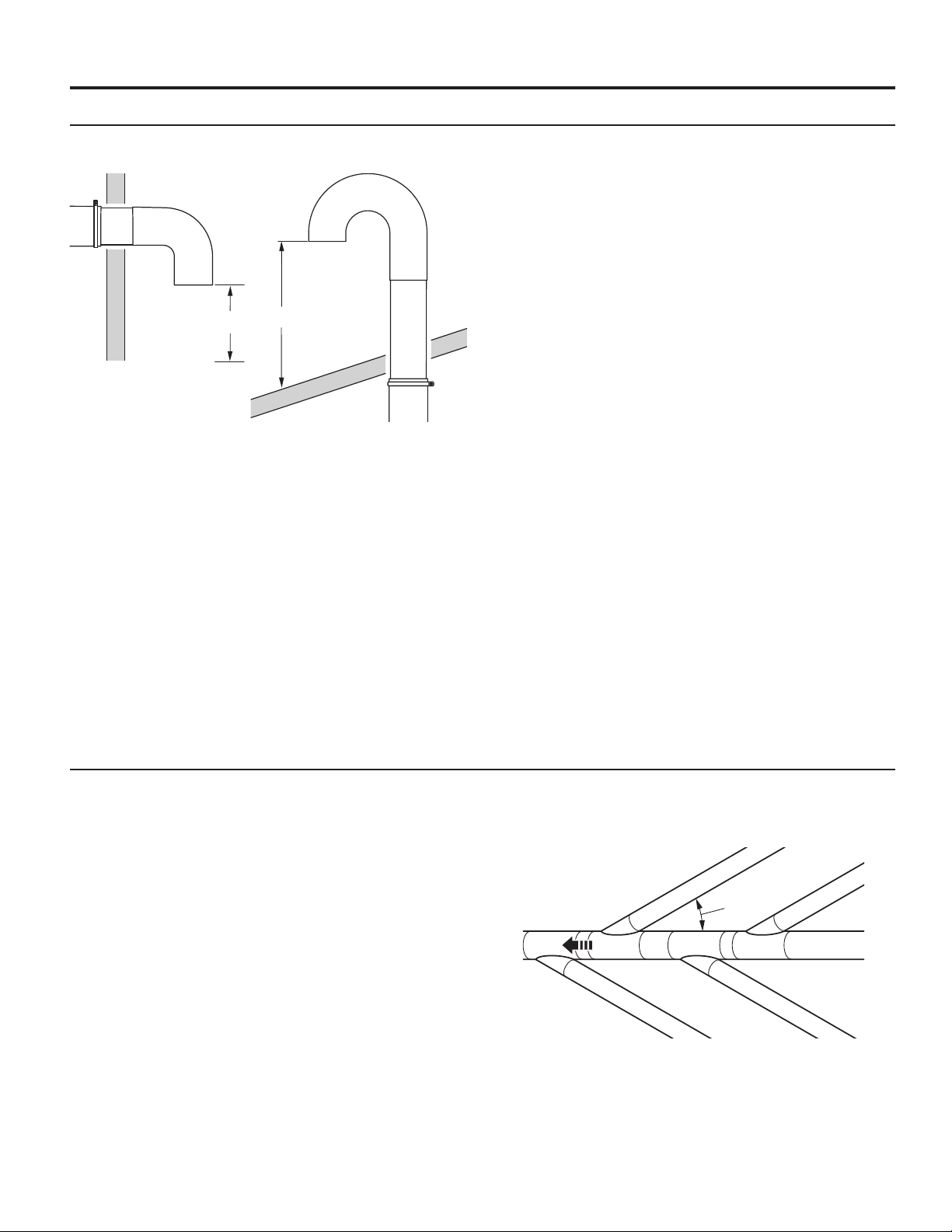

Standpipe drain system – wall or oor

The standpipe drain requires a minimum diameter standpipe of

2" (50 mm). The minimum carry-away capacity can be no less

than 10 gal. (38 L) per minute.

Wall

The top of the standpipe must be at least 30" (762 mm) high

and no higher than 96" (2.4 m) from the bottom of the washer.

Floor

Laundry tub drain system

The laundry tub needs a minimum 20 gal. (76 L) capacity.

The top of the laundry tub must be at least 30" (762 mm)

above the oor.

30

"

(762 mm)

Floor drain system

The oor drain system requires a siphon break that may be

purchased separately.

The siphon break (Part Number 285834) must be a minimum of

28" (710 mm) from the bottom of the washer. Additional hoses

might be needed.

30

" min.

(762 mm)

Syphonbreak

28

"

(710 mm)

22

Page 23

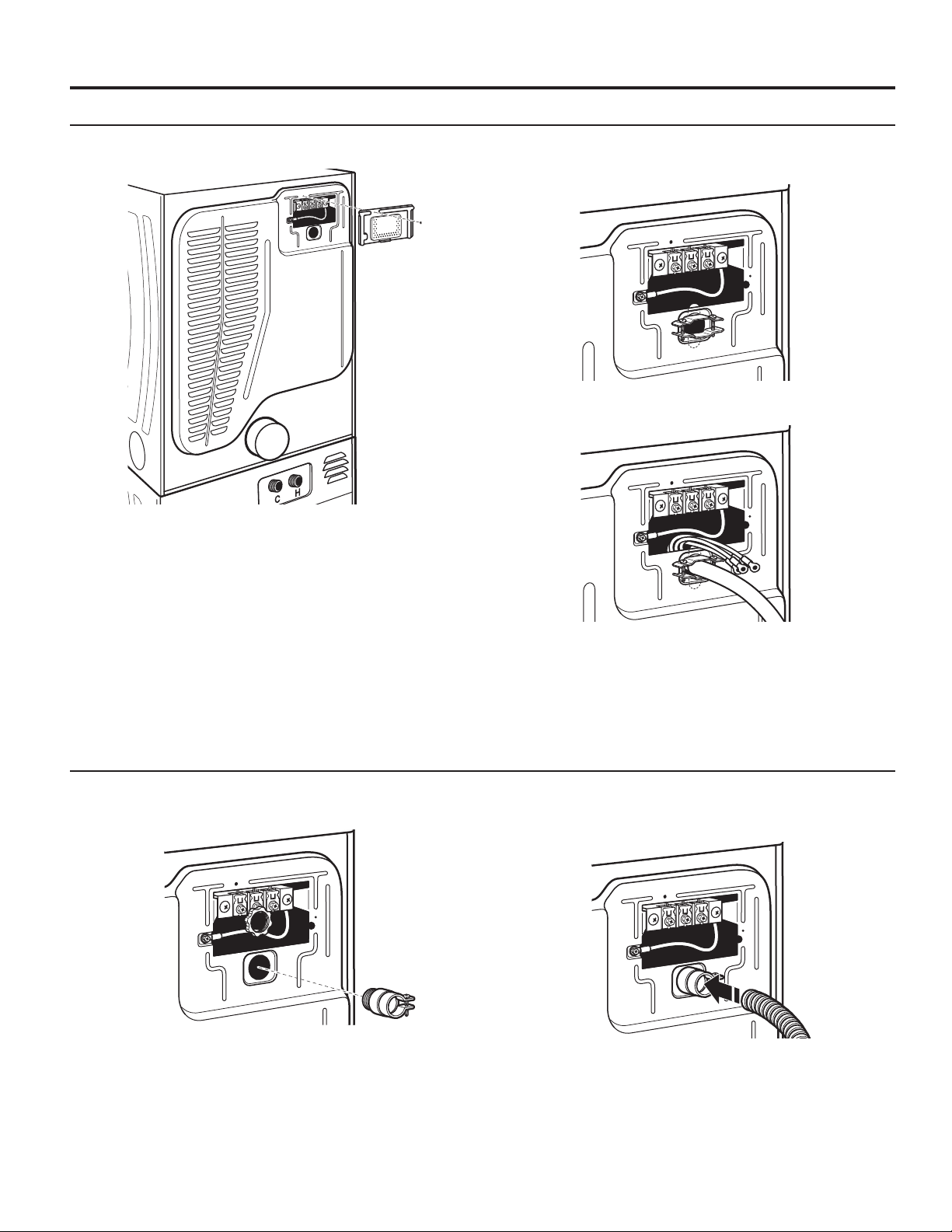

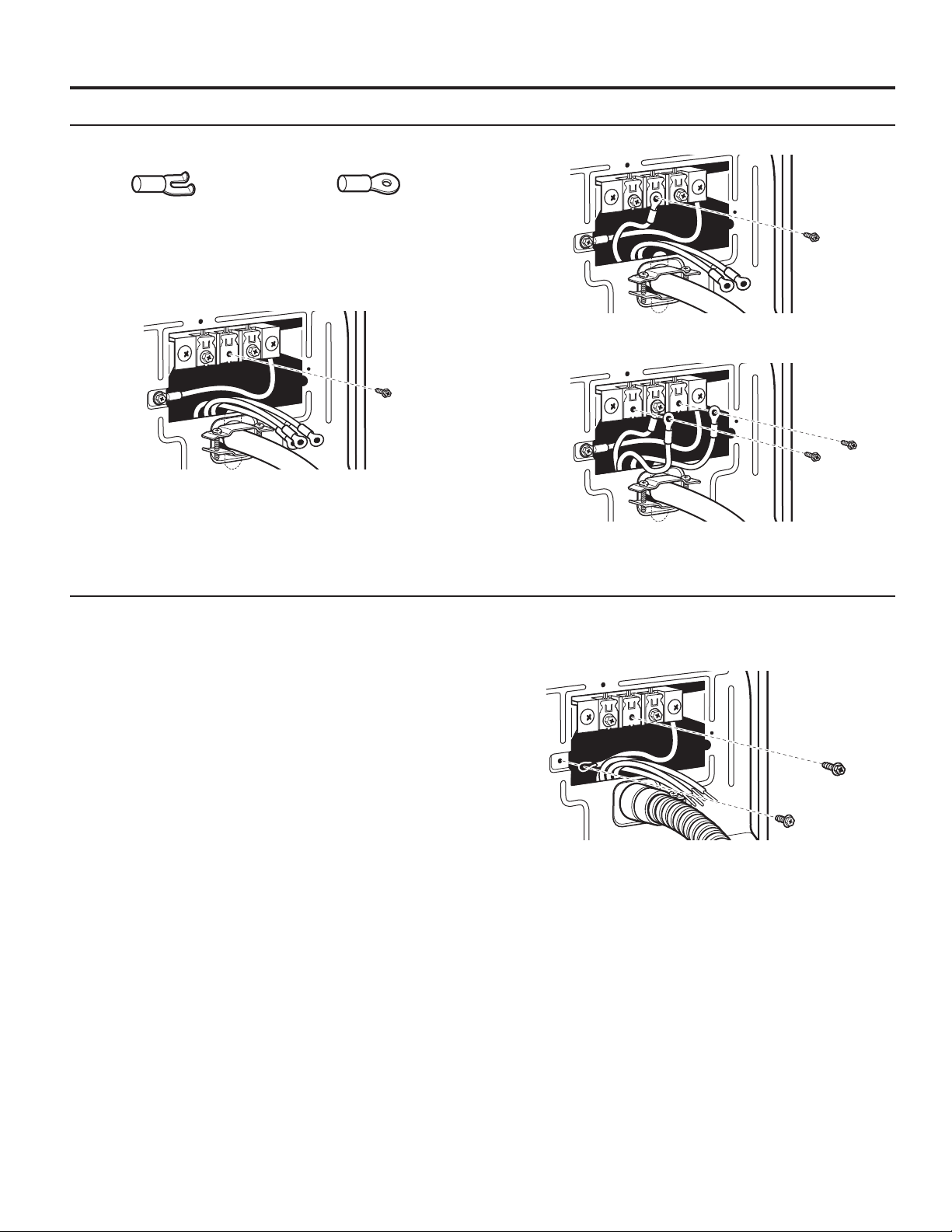

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Strain Relief

Remove Terminal Block Cover

Power Supply Cord Strain Relief

1. Insert strain relief.

2. Insert power cord into strain relief.

Strain Relief

Direct Wire Strain Relief

1. Insert strain relief. 2. Insert conduit into strain relief and tighten clamp.

23

Page 24

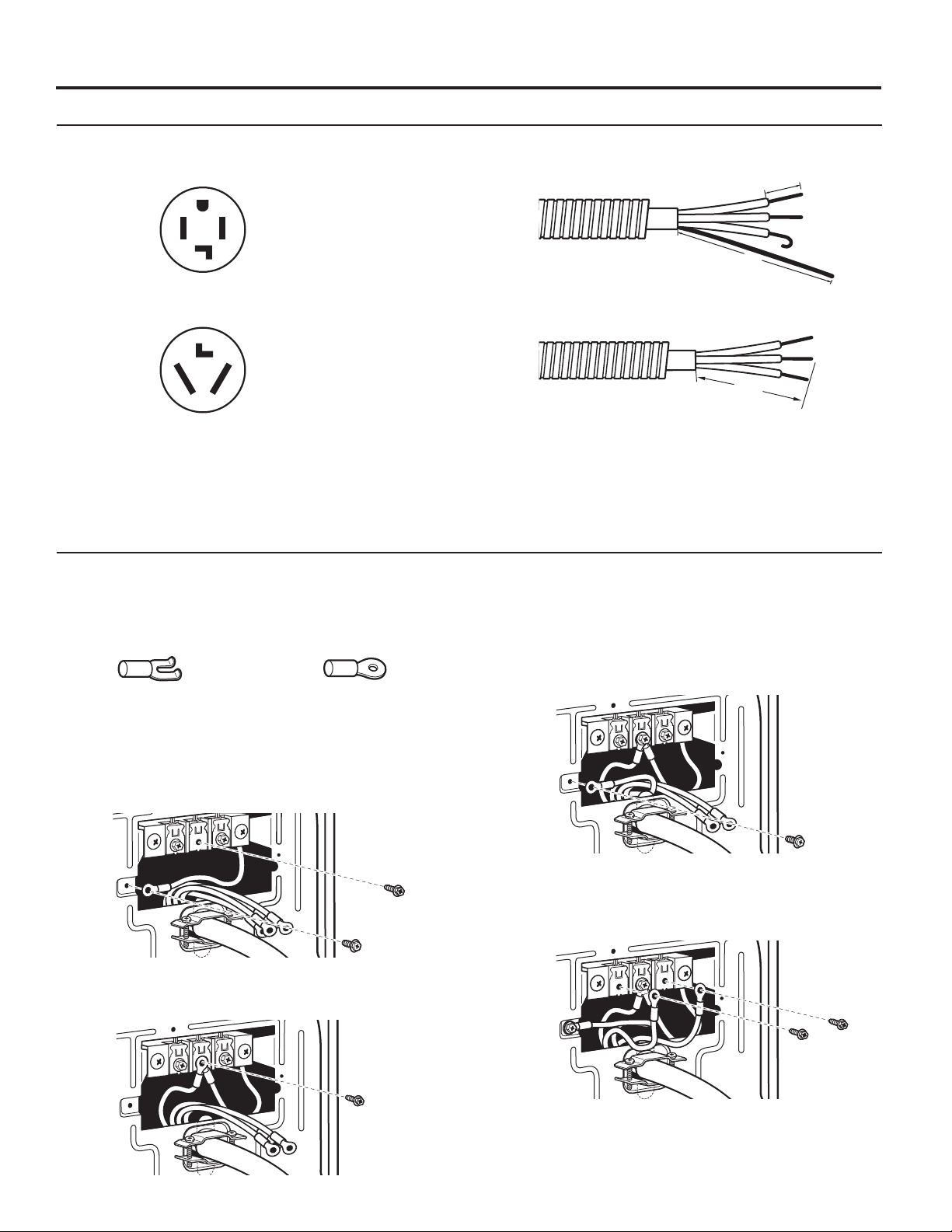

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connection Options

Power Cord

Direct Wire

4-wire receptacle (NEMA Type 14-30R)

3-wire receptacle (NEMA Type 10-30R)

4-wire direct

3-wire direct

Connecting 4-Wire Connection: Power Supply Cord

IMPORTANT: A 4-wire connection is required where local

codes do not permit the use of 3-wire connections.

1"

(25 mm)

5"

(127 mm)

3"

(89 mm)

Standard Power Supply Cord Connectors

Flanged spade connector Ring Connector

Connecting Ground and Neutral Wires

1. Remove center terminal block screw and the ground wire

by removing the external ground connector screw.

2. Connect ground and neutral wire to center terminal block.

Connecting Direct Wire Ground

3. Connect ground wire (green or bare) with external ground

connector screw.

Connecting Remaining Wires

4. Connect remaining wires with outer terminal block screws.

24

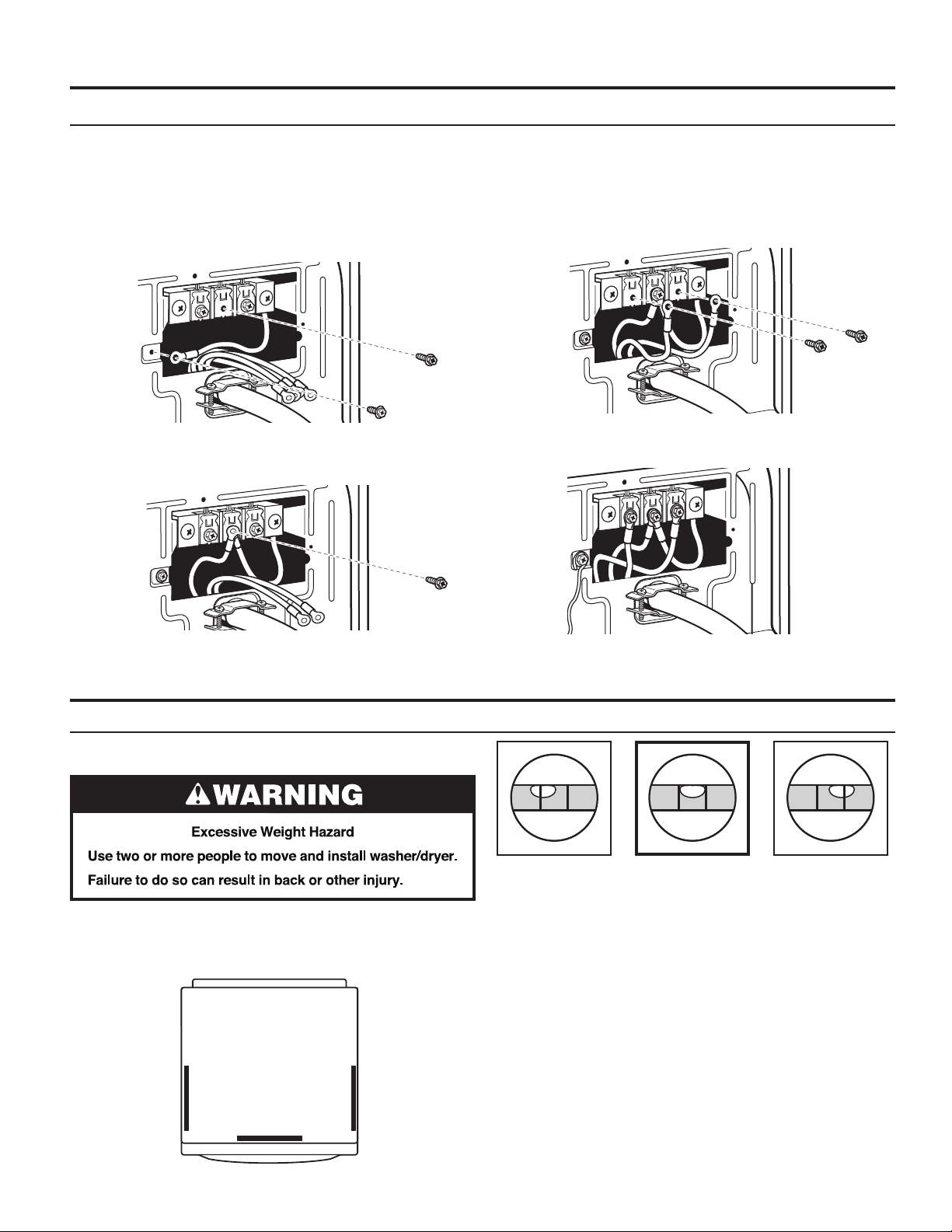

Page 25

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connecting 3-Wire Connection: Power Supply Cord

Standard Power Cord Connectors

Flanged spade connector Ring Connector

Connecting Neutral Wire

1. Loosen or remove center terminal block screw.

2. Connect neutral wire to center terminal block.

3. Connect remaining wires with outer terminal block screws.

Connecting 4-Wire Connection: Direct Wire

IMPORTANT: A 4-wire connection is required where local

codes do not permit the use of 3-wire connections.

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer can be moved if needed.

Strip 5" (127 mm) of outer covering from end of cable,

leaving bare ground wire at 5" (127 mm). Cut 11⁄2" (38 mm) from

3 remaining wires. Strip insulation back 1" (25 mm). Shape

ends of wires into a hook shape.

Connecting Ground and Neutral Wires

1. Remove center terminal block screw and the ground wire

by removing the external ground connector screw.

25

Page 26

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connecting 4-Wire Connection: Direct Wire

Connecting Ground and Neutral Wires (cont.)

Connecting Remaining Wires

2. Connect ground and neutral wire to center terminal block.

Connecting Direct Wire Ground

3. Connect ground wire (green or bare) with external ground

connector screw.

4. Connect remaining wires to outer terminal block.

Connecting 3-Wire Connection: Direct Wire

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer can be moved if needed.

Strip 31⁄2" (89 mm) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape ends of

wires into a hook shape.

Connecting Neutral Wire

1. Loosen or remove center terminal block screw.

2. Connect neutral wire to center terminal block.

3. Connect remaining wires to outer terminal block.

26

Page 27

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connecting 3-Wire Connection: Optional

Use for direct wire or power supply cord where local codes

do not permit connecting cabinet-ground conductor to

neutral wire.

Connecting Neutral Wire

1. Remove center terminal block screw. Also remove neutral

ground wire by removing external ground conductor screw.

2.

Connect neutral wire and neutral wire of power supply cord/

cable to center terminal block.

3. Connect remaining wires to outer terminal block.

4. Connect a separate copper ground wire from the external

ground conductor to an adequate ground.

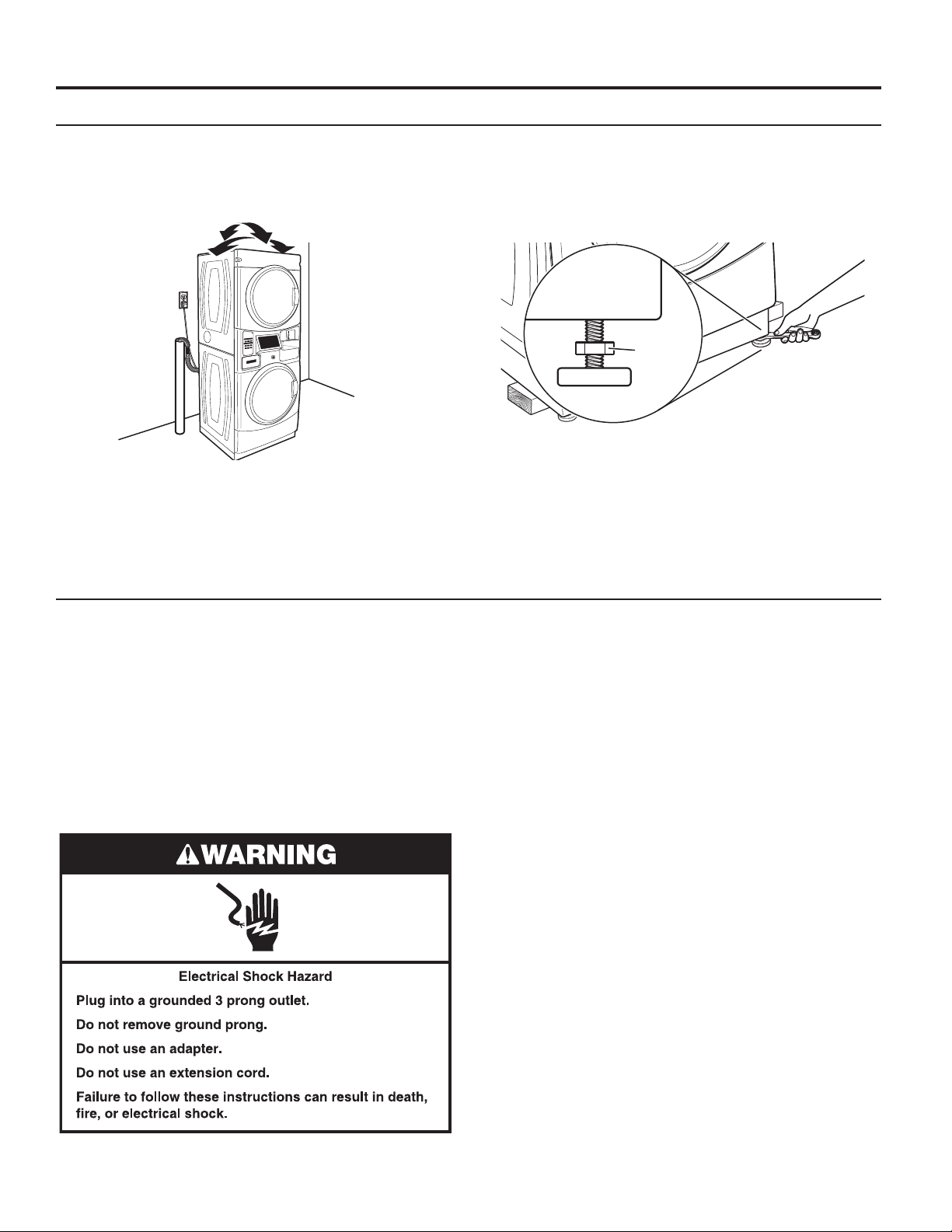

Leveling Stacked Washer/Dryer

Leveling your washer/dryer properly reduces excess noise and

v bration.

1. Remove cardboard from beneath washer/dryer. Place a level

on top edges of washer/dryer, checking each side and front.

If not level, tip washer/dryer and adjust feet up or down as

shown in Steps 3 and 4, repeating as necessary.

LEVELING

Not Level LEVEL Not Level

27

Page 28

LEVELING

Leveling Stacked Washer/Dryer (cont.)

2. Grip washer/dryer from top and rock back and forth,

making sure all four feet are rmly on oor. Repeat, rocking

washer/dryer from side to side. If washer/dryer rocks, go

to Step 3 and adjust leveling feet. If all four feet are in rm

contact with oor, go to Step 4.

3. If washer/dryer is not level, use a 9/16" or 14 mm openend

or adjustable wrench to turn jam nuts clockwise (as viewed

from above) on feet until they are about 1/2" (13 mm)

from the washer/dryer cabinet. Then turn the leveling foot

counterclockwise to lower the washer/dryer or clockwise

Complete Installation

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See “Electrical Requirements.”

2. Check that all parts are now installed. If there is an extra part,

go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

5. Check that the water faucets are on.

6. Check for leaks around faucets and inlet hoses.

to raise the washer/dryer. Recheck levelness of washer/dryer

and that all four feet are rmly in contact with the oor. Repeat

as needed.

HELPFUL TIP: You may want to prop up front of washer/

dryer about 4" (102 mm) with a wood block or similar object

that will support weight of washer/dryer.

Jam nut

4. When washer/dryer is level and all four feet are rmly

in contact with the oor, use a 9/16" or 14 mm open-end

or adjustable wrench to turn jam nuts counterclockwise

(as viewed from above) on leveling feet tightly against

washer/dryer cabinet.

HELPFUL TIP: You may want to prop washer/dryer with

wooden block.

8. To test and to clean your washer, measure 1/2 the detergent

manufacturer’s recommended amount of High Efciency (HE)

detergent for a medium-size load. Pour the detergent into the

detergent dispenser. Select any cycle and allow the washer

to complete one whole cycle.

9. Check dryer operation. Using a full heat cycle, let the dryer

run for at least ve minutes. Dryer will stop when time is

used up.

NOTE: Dryer door must be closed for dryer to operate. When

door is open, dryer stops, but timer continues to run. To restart

dryer, close door and push cycle button.

If the burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for ve minutes. Check that all supply

valve controls are in “ON” position and that the electrical cord

is plugged in. Repeat ve-minute test.

7. Plug into a grounded outlet, or connect power.

28

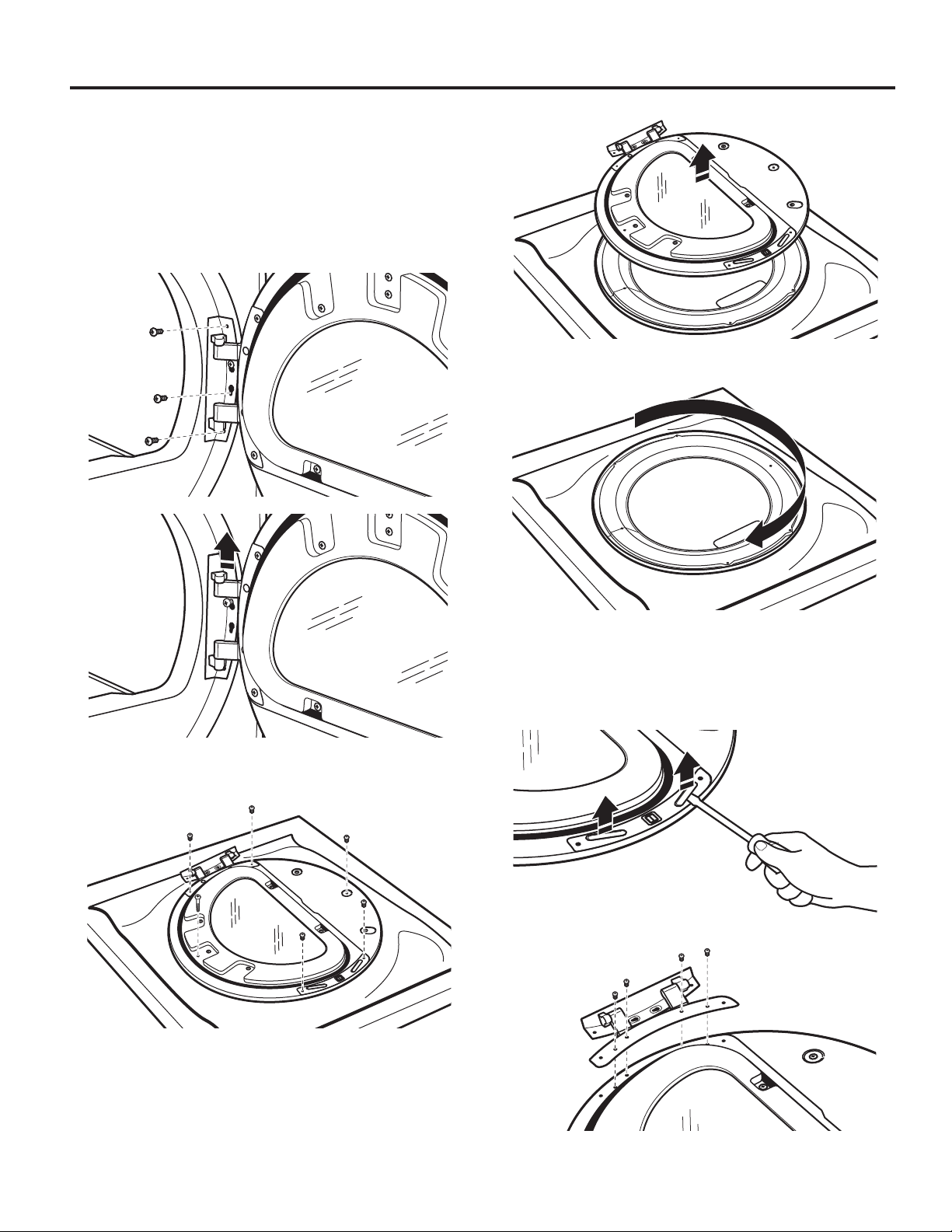

Page 29

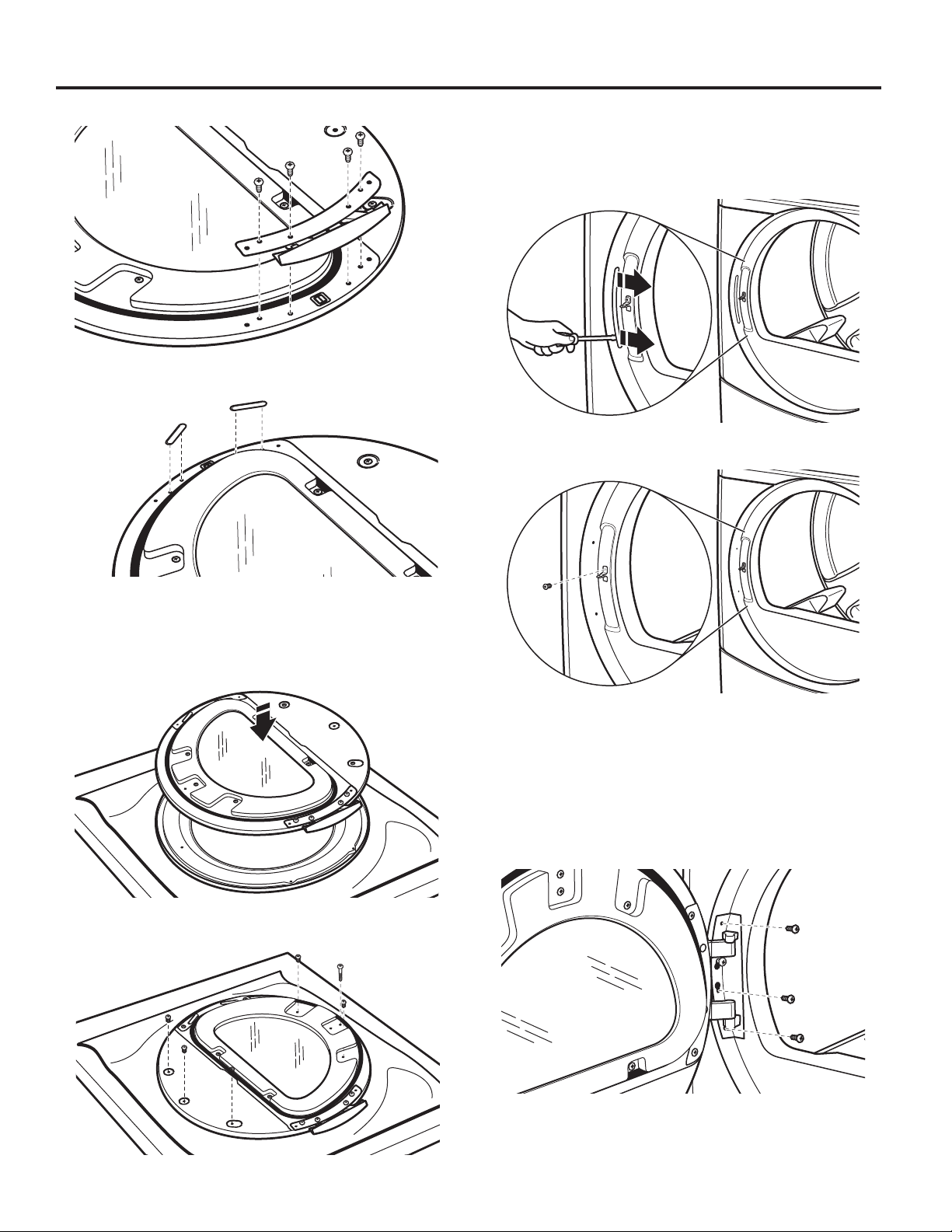

REVERSING DRYER DOOR SWING

NOTE: Dryer only. Washer door is not reversible.

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space to

avoid scratching of the surface.

2. Remove 3 of the 4 screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw

with keyhole opening and lift the door off the screw.

4. Lift the inner door assembly off outer door assembly.

5. Rotate outer door 180°.

3. Lay the door assembly on a previously prepared at surface

with the inside (inner door assembly) facing up, and remove

6 phillips-head screws to release outer door assembly from

inner door assembly.

NOTE: It is important that you remove only 6 indicated screws.

Reverse Hinge

1. Use a small at-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, without scratching inner door surface, and lift up

strip.

2. Remove the 4 screws that attach to inner door hinge.

29

Page 30

REVERSING DRYER DOOR SWING

3. Move hinge to other side. Reinstall 4 screws.

4. Reinstall plug strips on opposite side of the inner door.

Reverse the strike

1. Use a small at-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, without scratching dryer surface, and lift

up strip.

2. Remove the strike using a Phillips screwdriver.

5. Check for ngerprints on the glass. Clean if necessary.

Replace the Door Assembly

1. Place the inner door assembly inside the outer door

assembly.

2. Reassemble the inner and outer door assemblies with the

6 screws.

3. Insert strike on the opposite side.

Reinstall the door

1. Partially insert the third screw from the top; then slide the

hinge onto this screw while hooking the hinge into the front

panel hole. Reattach door to dryer front panel with the

remaining three screws.

30

2. Check for ngerprints on the glass. Clean if necessary.

3. Close door and check that it latches securely.

Page 31

STACKED WASHER/DRYER MAINTENANCE INSTRUCTIONS

Washer

Cleaning the Door Seal/Bellow

To clean washer interior:

1. Open the washer door and remove any clothing or items

from the washer.

2. Inspect inner glass door. If debris is present, wipe it off using

a damp cloth.

3. Inspect the colored seal/bellow between the door opening

and the basket for stained areas. Pull back the seal/bellow

to inspect all areas under the seal/bellow and to check for

foreign objects.

Seal/bellow

4. If stained areas are found, wipe down these areas of the

seal/bellow:

a) Mix a dilute solution, using 3/4 cup (177 mL) of liquid

chlorine bleach, and 1 gal. (3.8 L) of warm tap water.

b) Wipe the seal/bellow area with the dilute solution, using

a damp cloth.

c) Let stand 5 minutes.

d) Wipe down area thoroughly with a dry cloth and let the

washer interior air dry with door open.

IMPORTANT:

1. Open the washer door and remove any clothing or items

from the washer.

2. Use liquid chlorine bleach:

Open the dispenser drawer and immediately add 2/3

cup (160 mL) of liquid chlorine bleach to the bleach

compartment.

NOTE: Do not add any detergent. Use of more than 2/3 cup

(160 mL) of bleach will cause product damage over time.

3. Close the washer door and the dispenser drawer.

4. To start the Washer Cleanout cycle, rst enter “Service

Mode.” Then press and hold the lower-right (QUICK CYCLE)

button for 2 seconds. With the entire display ashing, press

the center-right (BRIGHTS) button.

To exit out of the service mode and activate the clean wash

cycle, push the BRIGHTS button, then turn the key.

NOTE: The door will lock, the basket will rotate 1/2 turn,

then the door will unlock and lock again, then the Washer

Cleanout Cycle will continue.

n The washer will not ll, but the basket will rotate while

the washer runs a short sensing cycle. This will take

approximately 3 minutes.

5. The cycle will determine whether clothing or other items are

in the washer.

a) If no items are detected in the washer, it will proceed to

Step 7.

b) If any items are detected in the washer, “F-34” will be

displayed. Then the door will unlock.

n Wear rubber gloves when cleaning for prolonged periods.

n Refer to the bleach manufacturer’s instructions for proper

use.

Maintenance Instructions:

This washer has a special cycle that uses higher water volumes

in combination with liquid chlorine bleach to thoroughly clean

the inside of the washer.

NOTES:

n Read these instructions completely before beginning the

cleaning process.

n If necessary, the cleaning cycle may be interrupted by

pressing the lower-right (QUICK CYCLE) button twice.

However, this will not immediately stop the cycle. The

washer will continue with several rinse and drain steps to

ensure that all remaining bleach is rinsed from the washer.

n Enter the service mode and then press and hold the

lower-right (QUICK CYCLE) button to cancel the failure

code.

Then repeat steps 1, 3, and 4 to start the cycle again.

6. Once the cycle has begun, allow the cycle to complete.

7. After the cycle is complete, leave the door open slightly to

allow for better ventilation and drying of washer interior.

31

Page 32

STACKED WASHER/DRYER MAINTENANCE INSTRUCTIONS

Washer

Always do the following to maintain washer

freshness:

n Use only HE High Efciency detergent.

n Leave the door slightly open after each cycle to allow for

better ventilation and drying of washer interior.

n Clean the washer monthly using the Washer Maintenance

Procedure, using 2/3 cup (160 mL) of liquid chlorine bleach.

n If the procedure does not sufciently improve the washer

freshness, please evaluate your installation and usage

conditions for other causes.

Cleaning the exterior

Use a soft damp cloth or sponge to wipe up any spills.

Occasionally wipe the outside of your washer to keep it looking

new. Use mild soap and water. Do not use abrasive products.

Cleaning the dispenser drawer

The dispenser drawer is removable for easy cleaning.

1. Unlock the dispenser drawer for removal by inserting

a at-blade screwdriver into the catch release. Remove

the dispenser drawer.

2. Remove the inserts (the siphon from the softener and bleach

compartments).

3. Wash the parts under running water.

NOTE: Do not wash components in the dishwasher.

4. Replace the inserts and return the dispenser to the drawer.

Water inlet hoses

Dryer

Maintenance instructions:

• Clean lint screen before and after each cycle.

• Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2

years or more often, depending

on dryer usage. Cleaning should

be done by a qualied person.

From the exhaust vent:

Lint should be removed every 2

years, or more often, depending

on dryer usage.

• Keep area around dryer clear and free from combustible

materials, gasoline and other ammable vapors and liquids.

• Keep dryer area clear and free from items that would

obstruct the ow of combustion and ventilation air.

If dryer does not operate, check the following:

• Electrical supply is connected.

• Circuit breaker is not tripped or house fuse is

not blown.

• Door is closed. Listen closely to hear the door switch

activate.

• Cycle selection button has been pushed rmly.

• For gas dryers, check that gas supply shut-off

valves are set in open position.

Replace the inlet hoses after 5 years of use to reduce the risk

of hose failure. Periodically inspect and replace inlet hoses if

bulges, kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, record the date of

replacement.

IF YOU NEED ASSISTANCE

Contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag® Commercial Laundry

distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

If you cannot locate your distributor, the Commercial Laundry Support Center will answer any questions about operating or

maintaining your washer/dryer not covered in the “Installation Instructions.”

Just dial 1-800 NO BELTS (1-800-662-3587) — the call is toll free.

When you call, you will need the washer/dryer model numbers and serial numbers. Both numbers can be found on the serial-rating

plate located in the dryer door well.

32

Page 33

ELECTRONIC CONTROL SETUP INSTRUCTIONS

WHITES

PERM.

PRESS

COLORS

DELICATES

AND KNITS

BRIGHTS

QUICK

CYCLE

WASHER

Washer control

NOTE: After the washer/dryer has been installed and plugged

in, the display will show “0 MINUTES” on the washer and dryer

portions of the display. After the washer and dryer doors have

been opened and closed, the display will show the price for

each machine. On washer/dryers set for free cycles, the display

sections will ash “SELECT CYCLE.”

1. PD Models: Insert coins until “SELECT CYCLE” ashes on

the display portion of the washer or dryer that is to be run.

PR Models: A debit card is required rather than coins.

Generation 1 or 2 debit card systems may be used; but

when the Generation 2 debit system is used, the controls

will automatically be set to Enhanced Debit mode (J. Ed).

In Enhanced Debit mode, the card balance will also display

when a debit card is inserted into the reader.

2. Door must be closed on the desired washer/dryer before

cycle selection is made.

3. Press the fabric setting button for the washer/dryer cycle

desired. After the cycle is started, the time will display and

count down.

DRYER

WHITES

& COLORS

PERM.

PRESS

Dryer control

DELICATES

General Washer/Dryer User Information

SCROLLING “OUT OF ORDER” MESSAGE, FOLLOWED BY A

FAILURE OR DIAGNOSTIC CODE, SHOWING IN DISPLAY –

condition indicates the washer/dryer is inoperative. Diagnostic

codes being displayed on the upper portion of the display

pertain to the dryer section, and diagnostic codes displayed

on the lower portion of the display apply to the washer section.

Diagnostic codes displayed on both the upper and lower

portions of the display pertain to the control system of both

the washer and dryer.

“0 MINUTES” SHOWING IN DISPLAY – This indicates the

cycle is complete and the washer/dryer cannot be operated.

Coins dropped or debit inputs during this condition will be

stored in escrow but cannot be used until normal operation is

restored by opening and closing the door. If a door switch has

failed, causing “0 MINUTES” to remain in the display after the

door is opened and closed, it must be replaced before normal

operation can be restored.

COLD START (Initial rst use) – Washer/dryer is programmed

at the factory as follows:

This

4. If a cycle is interrupted by opening the door or power loss,

“RESELECT CYCLE” will ash in the display. To restart the

washer/dryer, close door and reselect desired cycle.

NOTE: When set for free vend operation an ongoing dryer cycle

will cancel if the door is opened.

Washer 11-minute wash period

$1.75 wash price (PD models)

$0.00 wash price (PR models)

3 rinses (extra rinse not enabled)

Dryer 5 minutes per quarter for PD models

45 minutes dry time for PR models

$1.50 dry price (xed cycle with top off – PD

Models)

$0.00 dry price (xed cycle – PR Models)

33

Page 34

ELECTRONIC CONTROL SETUP INSTRUCTIONS

WARM START (after power failure) – A few seconds after

power is restored, if a cycle was in progress at the time of the

power failure, “RESELECT CYCLE” will ash in the display,

indicating the need for a key press to restart washer or dryer.

WASHER DOOR LOCK – Prior to beginning a cycle, there is a

door lock routine of lock/unlock/relock, then cycle begins. The

door will remain locked until the end of a cycle or approximately

2 minutes after a power interruption.

PRICING – After the door is opened and then closed following

the completion of a cycle, the display indicates the cycle

price (unless set for free operation, where the display will ash

“SELECT CYCLE”). As coins are dropped or debit inputs arrive,

the display will change to lead the user through the initiation of

a cycle.

There are four (4) types of dryer pricing:

Fixed “Vend” Pricing

A dryer setup for “Fixed Cycle” operation can only accept

additional time accumulated by increments equal to the length

of a complete dry cycle. A maximum of 99 minutes may be

purchased; no additional credit is given for coins dropped

with 99 minutes in the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator pricing

is in effect. Cycle time can be purchased one coin at a time

(PD models) up to the maximum time of 99 minutes.

DEBIT CARD READY – This washer/dryer is debit card

ready. It will accept a variety of debit card systems, but does

NOT come with a debit card reader. Refer to the debit card

reader manufacturer for proper washer/dryer setup. In models

converted to a Generation 1 debit card system, debit pulses

represent the equivalent of one coin (coin 1).

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

PD/PR Models: Insert service switch key and turn

counterclockwise.

PR Models: Once a Generation 2 debit card reader is installed

(according to the reader manufacturer’s instructions), the

set-up modes can only be changed by inserting a set-up

card (supplied by the reader manufacturer) into the card slot.

Inserting the service switch key and turning will only allow

access to the service mode.

The washer/dryer is now in the set-up mode. The lower fabric

setting buttons and the lower portion of the display are used

to set up the digital control for the washer. The upper three

fabric setting buttons and the upper portion of the display

are used to set up the controls for the dryer.

The display can contain 4 numbers and/or letters

and a decimal point on both the top and bottom display

portions. These are used to indicate the set-up codes and

related code values available for use in programming the

washer/dryer.

Fixed Cycle With Top Off Pricing

A dryer set to offer “Top Off” capability will allow time to be

added to an existing dry cycle in increments equal to the

number of minutes of dry time per quarter (coin 1), up to 99

minutes, regardless of the cost required to start the dryer. No

credit is given for coins or debit inputs entered when the control

is displaying 99 minutes.

PR Models: In Enhanced Debit Mode, the top off price can be

set independently (see VALUE OF COIN 2), and the top off time

is calculated according to the following equation:

top off time = x full cycle length

top off price

full cycle price

Penny increment offset is not applied to top off purchases.

FREE CYCLES – This is established by setting the cycle price

to zero. When this happens, “SELECT CYCLE” will appear

rather than a cycle price. Any cycle started as a free cycle

will automatically terminate when the door is opened.

How to Use the Buttons to Program the Controls

1. The lower-left (PERM. PRESS) button is used to adjust the

values associated with washer set-up codes and the upperleft (WHITES & COLORS) button is for the dryer. Pressing

the button will change the value by increments. Rapid

adjustment is possible by holding the button down.

2. The lower-middle (DELICATES AND KNITS) button will

advance through the set-up codes. Pressing the button will

advance both the washer and dryer to the next available

set-up code. Some set-up codes are washer- or dryerspecic and will not be displayed on both the washer and

dryer portions of the display. Holding down the lower-middle

(DELICATES AND KNITS) button will automatically advance

through the set-up codes at a rate faster than 1 per second.

3. The lower-right (QUICK CYCLE) button is used to select or

deselect washer options; upper-right (DELICATES) is used for

dryer option selection or deselection.

34

Page 35

ELECTRONIC CONTROL SETUP INSTRUCTIONS

Start Operating Set-up

Washer/dryers are preset at the factory and do not require any

programming. However, if you want to change the settings,

follow the “Set-Up Codes” guide.

The code at the beginning of each segment is the factory default

setting for the PD Models and is the same for the PR Models

unless noted otherwise.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two

or three right-hand characters.

Set-Up Codes

Code Explanation

6 07 REGULAR CYCLE PRICE (WASHER)

6 07 Represents the number of quarters (coin 1) to start

the washer; may adjust from 0–39. (See VALUE OF

COIN 1.) Advance from 0–39 by pressing the lowerleft (PERM. PRESS) button. Factory default of 7

quarters = $1.75.

6 00 PR MODELS ONLY: Factory default of 6 00,

or 0 quarters.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

606 REGULAR CYCLE PRICE (DRYER)

606 Represents the number of quarters (coin 1) needed

to start the dryer; may adjust from 0–39 (See

VALUE OF COIN 1). Advance from 0–39 by pressing

the upper-left (WHITES & COLORS) button. Factory

default of 6 quarters = $1.50.

600 PR MODELS: Factory default of 6 00, or 0 quarters.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

7 11 WASH LENGTH (WASHER)

7 11 This is the number of minutes for WASH. Washer

comes from the factory preset with 11 minutes.

Choose from 9–17 minutes by pressing the

lower-left (PERM. PRESS) button.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

705 REGULAR DRY TIME (DRYER)

705 PD MODELS: Represents the number of minutes

per quarter (coin 1).

Factory default of 5 minutes per coin.

Example: 6 quarters x 5 minutes = 30 minutes.

By pressing the upper-left (WHITES & COLORS)

button, value adjusts from 1–99 minutes.

745 PR MODELS: Represents the cycle length for free

cycles. As example: “7 45” = 45 minutes.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

Code Explanation

8 00 ADDITIONAL RINSE OPTION (WASHER)

This option is either NOT SELECTED “00” or

SELECTED “ar.”

8 00 Not Selected “00.”

8 Ar Selected “ar.” Cannot be combined with the Super

Cycle rinse option.

• Press the lower-right (QUICK CYCLE) button

once to change this selection.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

800 TYPE OF DRYER PRICING (DRYER)

800 Fixed Cycle with Top Off. For detailed description,

see “General Washer/Dryer User Information.”

8FC PR MODELS ONLY: Factory default of FC. Fixed

Cycle. For detailed description, see “General

Washer/Dryer User Information.” Use the upperright (DELICATES) button to change this selection.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

9 00 CYCLE COUNTER OPTION

This option is either NOT SELECTED “00” or

SELECTED “0C.”

9 00 Not Selected “00.”

9 0C Selected “0C” and not able to be deselected.

• Press the lower-right (QUICK CYCLE) button

3 consecutive times to select “0C.” Once

selected “0C” it cannot be deselected.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

If cycle counter (9 0C) is selected, the following is true:

1 00 Cycles in HUNDREDS 1 02 = 200

2 00 Cycles in ONES 2 25 = 25

TOTAL CYCLES = 225

This is “VIEW ONLY” and cannot be cleared.

• Press the lower-middle (DELICATES AND KNITS) button once

to advance to next code.

35

Page 36

ELECTRONIC CONTROL SETUP INSTRUCTIONS

Code Explanation

1. 00 MONEY COUNTER OPTION

This option is either NOT SELECTED “00” or

SELECTED “0C.”

1. 00 Not Selected “00.”

1. 0C Selected “0C.”

• Press the lower-right (QUICK CYCLE) button

3 consecutive times to select “0C” and 3

consecutive times to deselect (Not Selected

“00”). Counter resets by going from “OFF”

to “ON.”

1. C0 Selected “C0” and not able to be deselected.

• To select “C0” and not able to be deselected,

rst select “0C,” then within 2 seconds, press the

lower-middle (DELICATES AND KNITS) button

twice, the lower-left (PERM. PRESS) button

once, and exit set-up mode.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

2. 00 SPECIAL PRICING OPTIONS

This option is either NOT SELECTED “00” or

SELECTED “SP.”

2. 00 Not Selected “00,” and next available code will be

A.00

2. SP Selected “SP.”

• Press the lower-right (QUICK CYCLE) button

once to change this selection.

If SPECIAL PRICING OPTION is selected, there is access to

codes “3.XX” through “9.XX.”

•Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

If money counter (1.0C or 1.C0) is selected, the following is

true:

3 00 Dollars in HUNDREDS 3 01 = $100.00

4 00 Dollars in ONES 4 68 = $ 68.00

5 00 Number of CENTS 5 75 = $ 00.75

TOTAL = $168.75

OPTIONS 3.XX – 9.XX TO USE IF SPECIAL PRICING

IS SELECTED

Code Explanation

3. 07 SPECIAL CYCLE PRICE (WASHER)

3. 07 Represents the number of quarters (coin 1) to start

the washer; may adjust from 0–39. (See VALUE OF

COIN 1.)

• Advance from 0–39 by pressing the lower-left

(PERM. PRESS) button. Factory default of 7

quarters = $1.75

3. 00 PR MODELS ONLY: Factory default of 0 quarters.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

3.06 SPECIAL CYCLE PRICE (DRYER)

3.06 Represents the number of quarters (coin 1)

to start the dryer; may adjust from 0–39.

(See VALUE OF COIN 1).

• Advance from 0–39 by pressing the upper-left

(WHITES & COLORS) button. Factory default

of 6 quarters = $1.50.

3.00 PR MODELS: Factory default of 0 quarters.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

4.05 SPECIAL DRY TIME (DRYER)

4.05 PD MODELS: Represents the number of minutes

per quarter (coin 1).

• Factory default of 5 minutes per coin.

Example: 6 quarters x 5 minutes = 30 minutes.

• By pressing the upper-left (WHITES & COLORS)

button, the value can be adjusted from 1–99

minutes.

4.45 PR MODELS: Represents the xed cycle time

in minutes. Example: “4 45” = 45 minutes.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

5. 00 TIME-OF-DAY CLOCK, MINUTES

5. 00 This is the TIME-OF-DAY CLOCK, minute setting;

select 0–59 minutes by pressing the lower-left

(PERM. PRESS) button.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

6. 00 TIME-OF-DAY CLOCK, HOURS

NOTE: Uses military time or 24 hr. clock.

6. 00 This is the TIME-OF-DAY CLOCK, hour setting;

select 0–23 hours by pressing the lower-left

(PERM. PRESS) button.

• Press the lower-middle (DELICATES AND KNITS)

button once to advance to next code.

36

Page 37

ELECTRONIC CONTROL SETUP INSTRUCTIONS

Code Explanation

7. 00 SPECIAL PRICE START HOUR

NOTE: Uses military time or 24 hr. clock.

7. 00 This is the start hour; 0–23 hours.

• Select START HOUR by pressing the

lower-left (PERM. PRESS) button.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

8. 00 SPECIAL PRICE STOP HOUR

NOTE: Uses military time or 24 hr. clock.

8. 00 This is the stop hour; 0–23 hours.

• Select STOP HOUR by pressing the

lower-left (PERM. PRESS) button.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

9. 10 SPECIAL PRICE DAY

9. 10 This represents the day of the week and whether

special pricing is selected for that day. A number

followed by “0” indicates no selection that

particular day (9.10). A number followed by an “S”

indicates selected for that day (9.1S). To change

the value of “0” and “S,” use the lower-right

(QUICK CYCLE) button. Days of the week (1–7) are

selected by pressing the lower-left (PERM. PRESS)

button.

When exiting set-up code “9,” the display must show the

current day of week:

• Press the lower-middle (DELICATES AND

A. 00 VAULT VIEWING OPTION

This option is either NOT SELECTED “00” or

A. 00 Not Selected “00.”

A. SC Selected “SC.”

• Press the lower-right (QUICK CYCLE) button

• Press the lower-middle (DELICATES AND

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1=Sunday 1S

20 Day 2=Monday 2S

30 Day 3=Tuesday 3S

40 Day 4=Wednesday 4S

50 Day 5=Thursday 5S

60 Day 6=Friday 6S

70 Day 7=Saturday 7S

KNITS) button once to advance to next code.

SELECTED “SC.”

once to change this selection. When selected,

the money and/or cycle counts will be viewable

(if counter option(s) is selected) when the coin

box is removed.

KNITS) button once to advance to next code.

Code Explanation

b. 05 VALUE OF COIN 1

b. 05 This represents the value of coin 1 in number

of nickels: 05 = $0.25.

• By pressing the lower-left (PERM. PRESS)

button, there is an option of 1–199 nickels.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

C. 20 VALUE OF COIN 2/VALUE OF DRYER

TOP OFF

C. 20 This represents the value of coin 2 in number

of nickels: 20 = $1.00.

C. 05 PR MODELS: Factory default of $0.25.

For models using Enhanced Debit, this eld

represents the value of top off in nickels.

• By pressing the lower-left (PERM. PRESS)

button, there is an option of 1–199 nickels.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

E. 00 ADD COINS OPTION

This option is either NOT SELECTED “00” or

SELECTED “AC.” This option causes the customer

display to show the number of coins (coin 1) to

enter, rather than the dollars-and-cents amount.

The number in the display changes as the coins

are accepted.

E. 00 Not Selected “00.”

E. AC Selected “AC.”

• Press the lower-right (QUICK CYCLE) button

3 consecutive times to change this selection.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

F. 00 ENHANCED PRICING OPTION (WASHER)

F. 00 Not Selected “00.”

F. CP Cycle-Based pricing enabled. This option

allows conguration of different prices for cold,

warm, and hot water wash cycles.

F. SU Super Cycle pricing enabled. This option allows

customers to upgrade cycles by depositing

extra money. Set-up codes “H.” and “h.” will

be displayed only when this option is enabled.

• Press the lower-right (QUICK CYCLE) button

to change this selection.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

37

Page 38

ELECTRONIC CONTROL SETUP INSTRUCTIONS

Code Explanation

H. 01 SUPER CYCLE UPGRADE PRICE (WASHER)

(Skipped unless Super Cycle pricing is enabled.)

H. 01 This represents the number of coin 1 required to

upgrade a base cycle to a super cycle.

• Advance from 0–39 by pressing the

lower-left (PERM. PRESS) button.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

h. 01 SUPER CYCLE TYPE (WASHER)

( Skipped unless Super Cycle pricing is enabled.)

h. 01 This represents the Super Cycle upgrade option.

• Press the lower-left (PERM. PRESS) button

to step through upgrade options 1 through

3 as follows:

01 – enhanced wash, extra 3 minutes

of wash tumble in addition to the

programmed wash time.

02 – extra rinse for all cycles.

03 – both 01 and 02.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

J. Cd PAYMENT MODE (COIN/DEBIT OPTION)

J. Cd Both coin and debit selected. Press the lower-right

(QUICK CYCLE) button 3 consecutive times to

change this selection.

J. C_ Coins selected, debit disabled. Press the lower-

right (QUICK CYCLE) button 3 consecutive times

to change this selection.

J._d PR models: Factory default to J._d. Debit Card

selected, coins disabled. Press the lower-right

(QUICK CYCLE) button 3 consecutive times to

change this selection.

J. Ed Enhanced Debit is self-selected when a Generation

2 card reader is installed in the washer/dryer.

The Ed option cannot be manually selected or

deselected.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

L. 00 PRICE SUPPRESSION OPTION

This option causes the customer display to show

“ADD” or “AVAILABLE” rather than the amount of

money to add. (Used mainly in debit installations.)

L. 00 Not Selected “00.”

L. PS Selected “PS.”

• Press the lower-right (QUICK CYCLE) button

once to change this selection.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

n. CE CLEAR ESCROW OPTION

When selected, money held in escrow for 30

minutes without further escrow or cycle activity will

be cleared.

n. 00 Not Selected “00.”

n. CE Selected “CE.”

• Press the lower-right (QUICK CYCLE) button

once to change this selection.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

Code Explanation

r. 800 TOP SPIN SPEED RPM (WASHER)

r. 800 This can be selected from the following spin

speeds: 600 rpm, 750 rpm, 800 rpm, 1000

(displays as 999) rpm.

• Step between speeds by pressing the lower-left

(PERM. PRESS) button. Factory default of 800

rpm.

• Press the lower-middle (DELICATES AND

KNITS) button once to advance to next code.

U. 00 PENNY INCREMENT OFFSET (WASHER)

U. 00 This represents the penny increment price offset

used in Generation 2 (Enhanced Debit) PR models.

Choose from 0–4 pennies by pressing the lowerleft (PERM. PRESS) button.