Maytag MFR30PNCTS, MFS230PTVS, MFS230PTRS, MFS230PAVS, MFS230PARS Installation Instructions

...Page 1

FULL CONTROL

COMMERCIAL WASHER

PROGRAMMING GUIDE

(North America Only)

Table of Contents ..................................................................................................................2

321

654

987

0

W10214576D

www.maytagcommerciallaundry.com

Page 2

TABLE OF CONTENTS

WASHER SAFETY ............................................................. 3

CONTROL PANEL ............................................................. 4

Control Panel Overview ...................................................4

Keypad ........................................................................... 4

How to Enter Program Mode ......................................... 5

Main Menu ...................................................................... 6

GENERAL CONTROL DESCRIPTION ..............................7

Control Features ............................................................. 7

Menu Functions .............................................................. 7

Machine Types ............................................................... 8

Create a Wash Program ................................................. 8

Program Functions ......................................................... 9

WASHER STARTUP ........................................................ 11

Conguration Menu ...................................................... 11

Advanced Menu ........................................................... 15

Initialization Menu ......................................................... 18

Wash Program Creation and Adjustment .....................20

CYCLE PROGRAMMING ................................................ 21

Program Menu .............................................................. 21

Program Functions ....................................................... 21

Program Step Function ................................................ 22

Program the Wash Cycle ............................................. 23

Program the Drain Step ................................................ 33

OPERATION ..................................................................... 36

Start a Laundry Load .....................................................36

Cycle Options ................................................................36

Program End and Unloading ........................................ 37

Messages During the Wash Cycle ............................... 37

Special Function Keypad ............................................. 38

PROGRAMMED CYCLES ............................................... 39

Legend .......................................................................... 39

WASH PROGRAMS ......................................................... 40

TROUBLESHOOTING ..................................................... 47

Display Messages ........................................................ 47

Fault Code Overview .................................................... 49

Service Menu ................................................................ 52

Problem Check List ...................................................... 57

Error Message Explanation .......................................... 58

SERVICE INFORMATION ............................................... 83

Replacing the Electronic Board and Keypad ............... 84

Installing New Software ................................................ 84

Washer Specications .................................................. 85

APPENDIX ........................................................................ 86

Table A-1: Conversion Between

Celsius and Fahrenheit ................................................. 86

Table A-2: Conversion Between

Kilograms and Pounds ................................................. 86

Table A-3: Machine Conversion ................................... 86

Table A-4: Maximum, Minimum, and

Normal Water Setting Values ....................................... 87

Table A-5: Programmable Water Level Units

Related to the Amount of Water in the Tub ................. 88

Table A-6: Washer Wash and Spin Speeds ................ 91

2

Page 3

WASHER SAFETY

3

Page 4

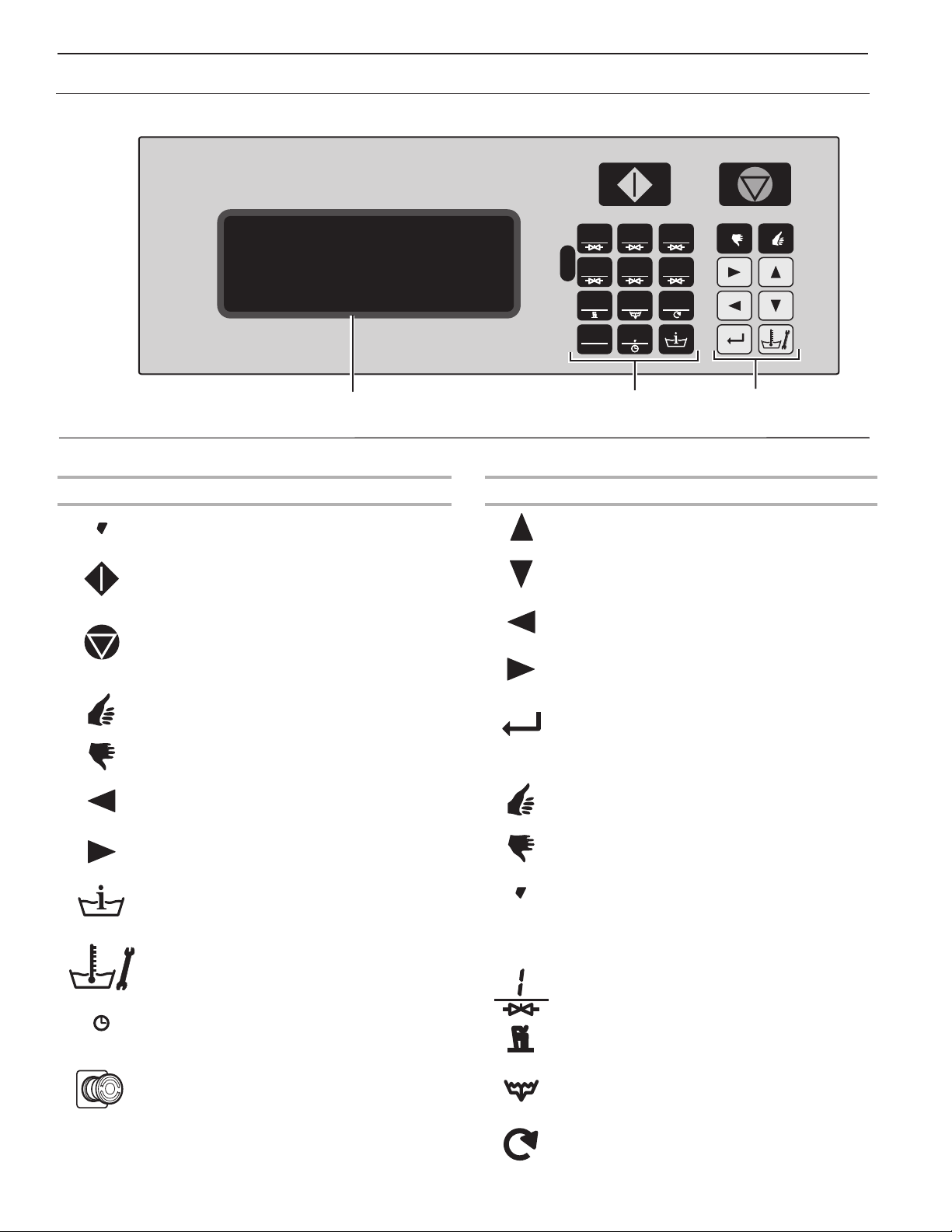

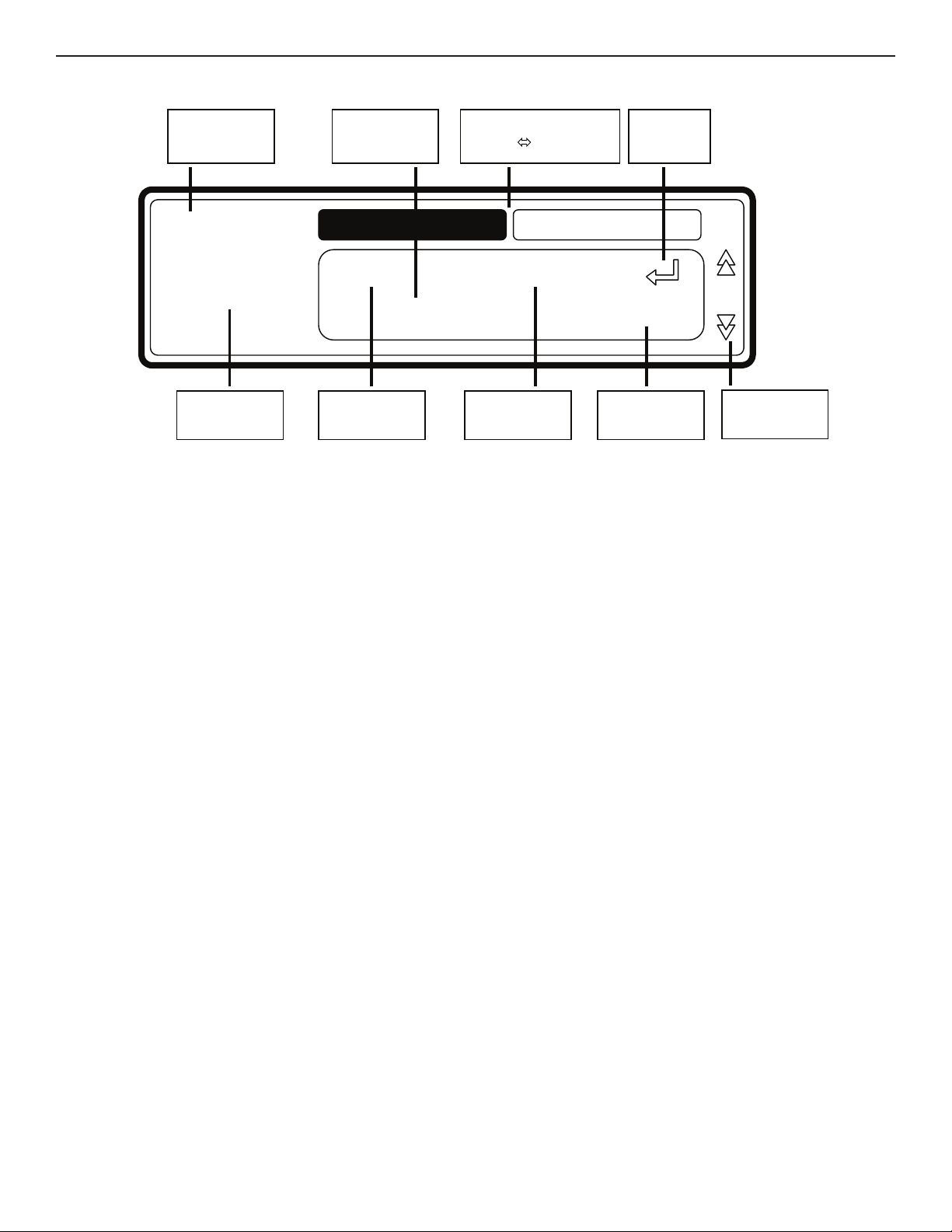

CONTROL PANEL

Control Panel Overview

0

321

654

987

LCD Display

Operation

Keypads

KEYPAD

Operation Keypads Program Keypads

n 1 2 3 4 5 6 7 8 9 0

- Program number selection keypads

n START

- Starts a program

- Advances the program step by step

n STOP

- Interrupts a program

- Ends a program

n YES

- Select displayed option

n NO

- Do not select displayed option

n ARROW LEFT

- Decreases the sequence time

n ARROW RIGHT

- Increases the sequence time

n ARROW UP

- Selects the previous menu item

n ARROW DOWN

- Selects the next menu item

n LEFT ARROW

- Selects the previous element of a menu item

n RIGHT ARROW

- Selects the next element of a menu item

n ENTER

- Selects a new menu

- Conrms a new value or list element and

continues to the next menu item

n YES

- Select displayed option

n NO

- Do not select displayed option

Program

Keypads

n INFO

- Shows all available wash programs, program

steps and functions

n SERVICE/STATUS

- Shows the status and total number

of washer cycles

n 1 2 3 4 5 6 7 8 9 0

- Numeric values

- Decimal point

SPECIAL FUNCTION KEYPADS

n INLET 1 2 3 ( 4 5 6 )

- Opens the inlet valve

n DELAY TIME

- Activates the time delay function

n HEAT

- Activate the heat (if equipped)

EMERGENCY STOP SWITCH

This emergency stop switch is used on non-coin

washer-extractors. Located on the control panel

n DRAIN

- opens the drain valve

just left of the LCD Display

n SPEED ADJUST

- Adjusts the spin speed in a cycle

4

Page 5

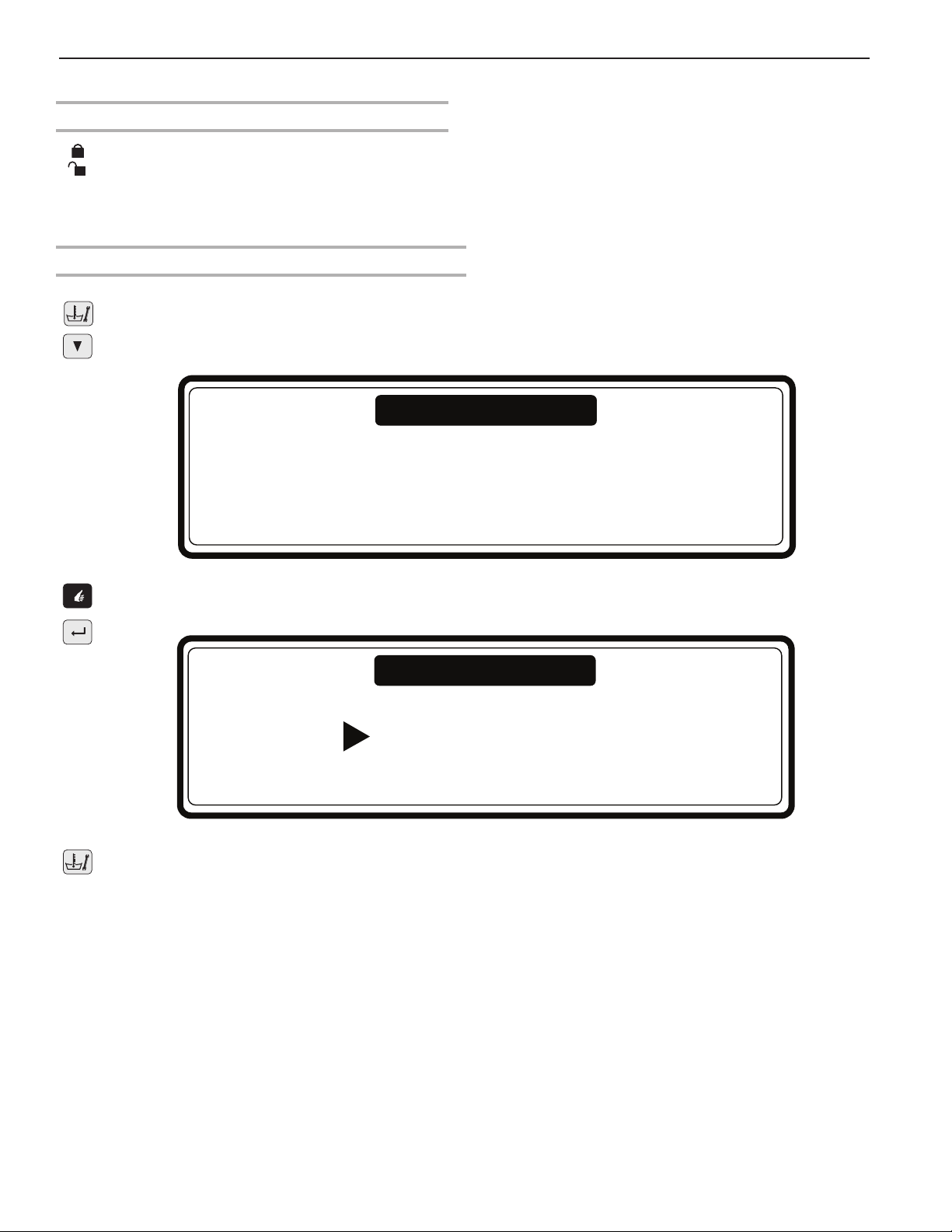

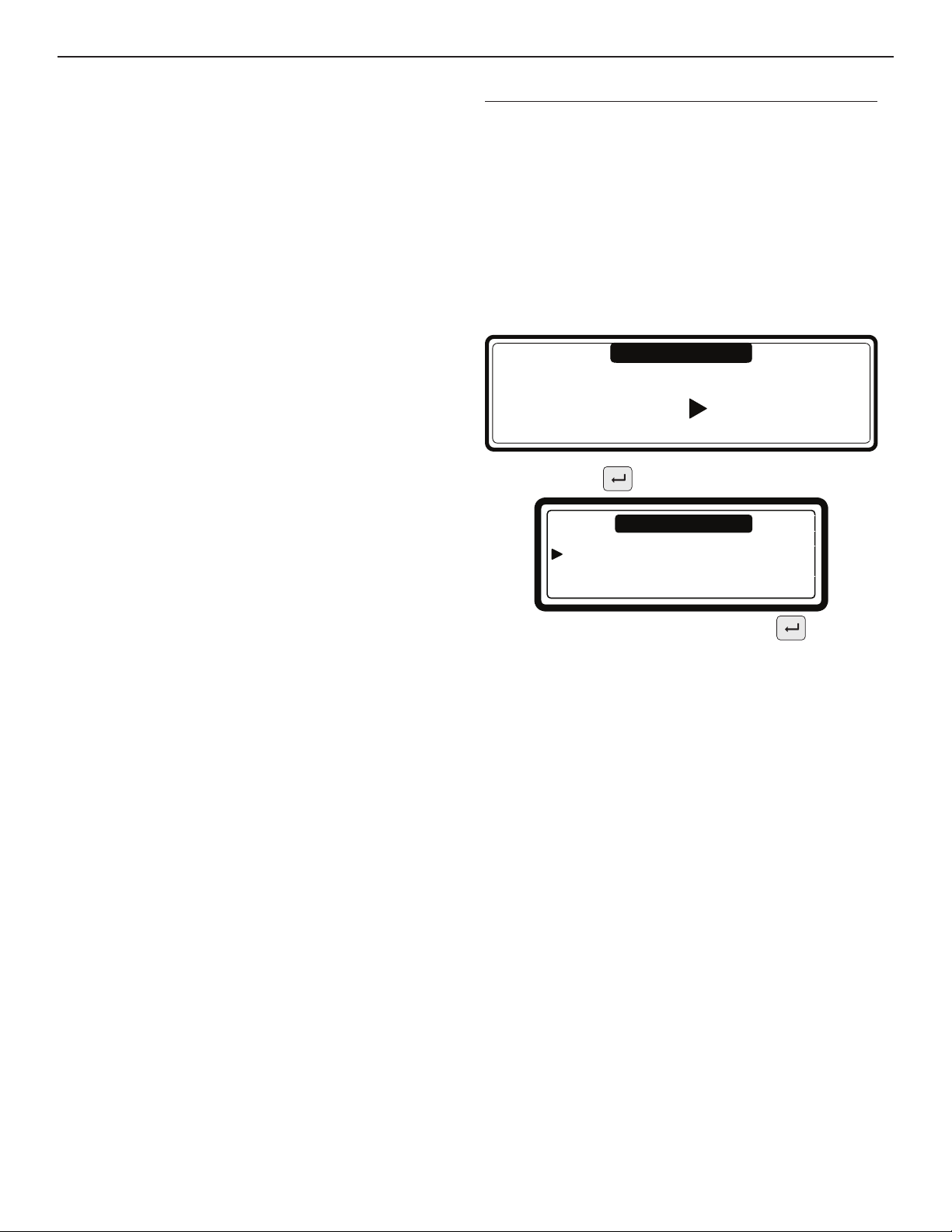

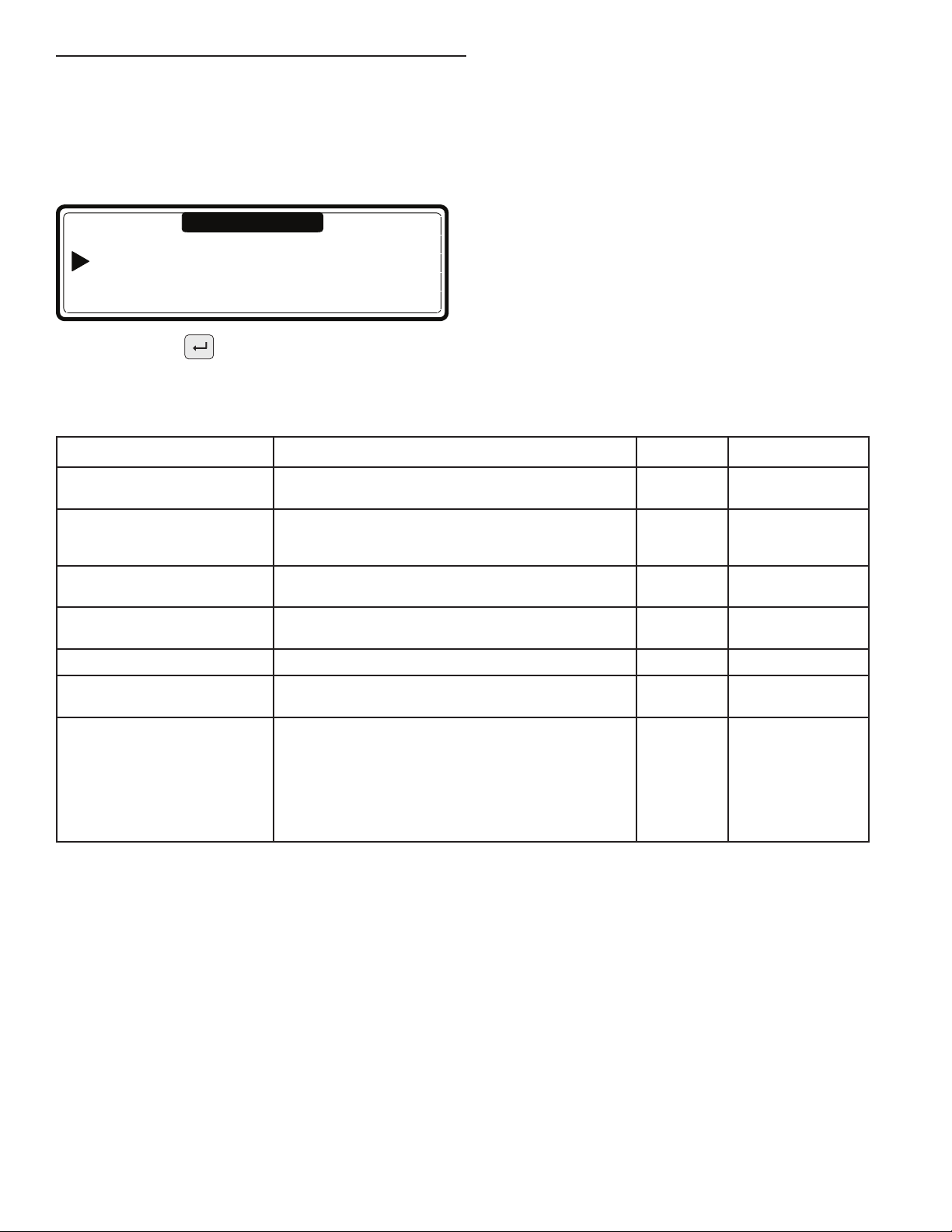

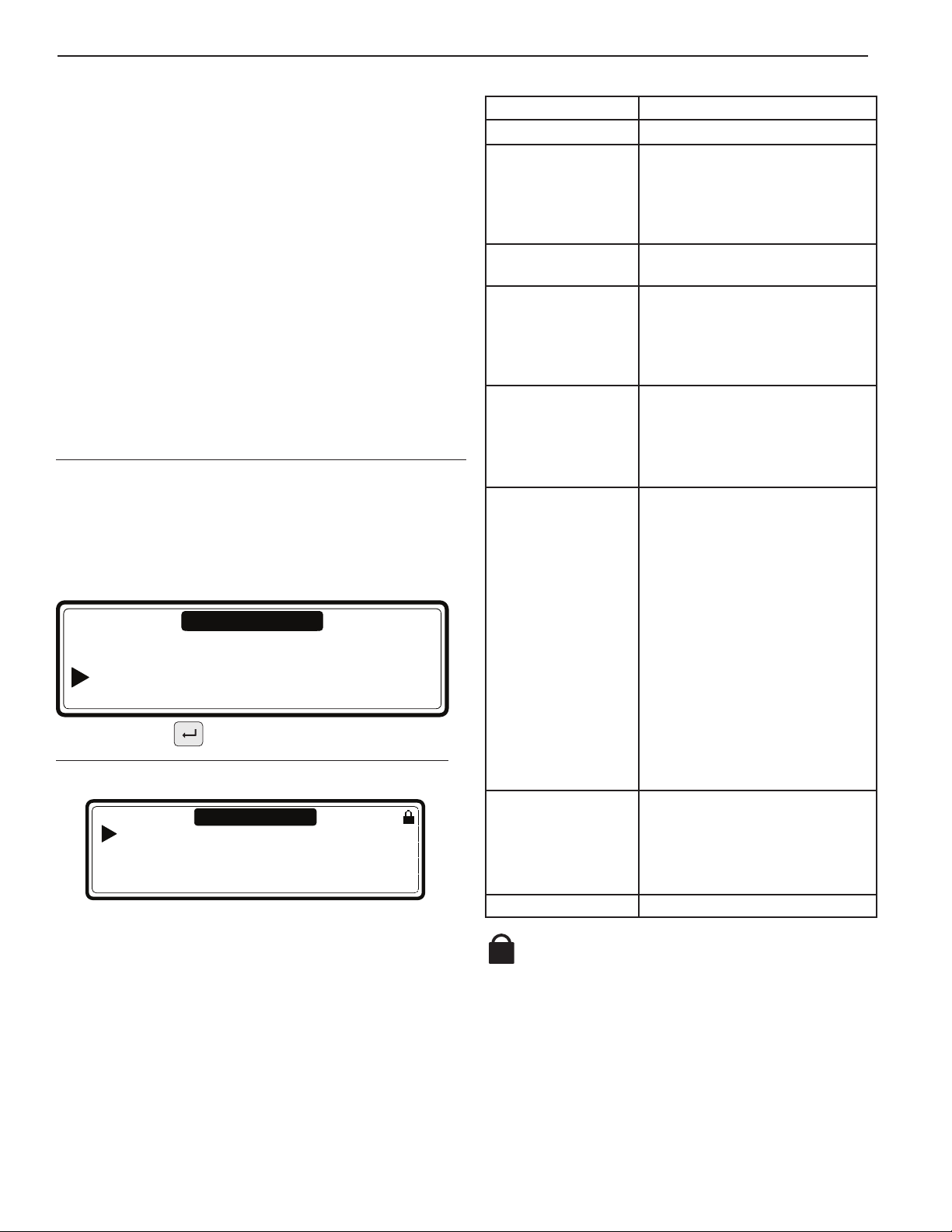

How To Enter Program Mode

To Enter With Keyswitch

KEYSWITCH

The key switch may be mounted on the front panel, the rear panel, or in the control area of the washer.

With the key switch you can select “Run Mode” or “Program Mode”

– RUN MODE: For normal washer wash operation.

– PROGRAM MODE: For changing the wash programs and washer settings.

To Enter With Program Keypads

1. Press Service/Status.

2. Press Arrow Down several times until you see the screen with the menu selection “To Program

Mode No/Yes.”

Status Menu

To Program Mode No/Yes

3. Select “Yes” by pressing ENTER. You will see the Main Menu Screen. If a password was enabled, rst you have to

enter the correct password.

To Program Mode

Password ....

To leave the To Program Mode:

When the “Main Menu” screen is shown:

Press Service/Status. You will return to “Run Mode” and “SELECT CYCLE” is displayed.

5

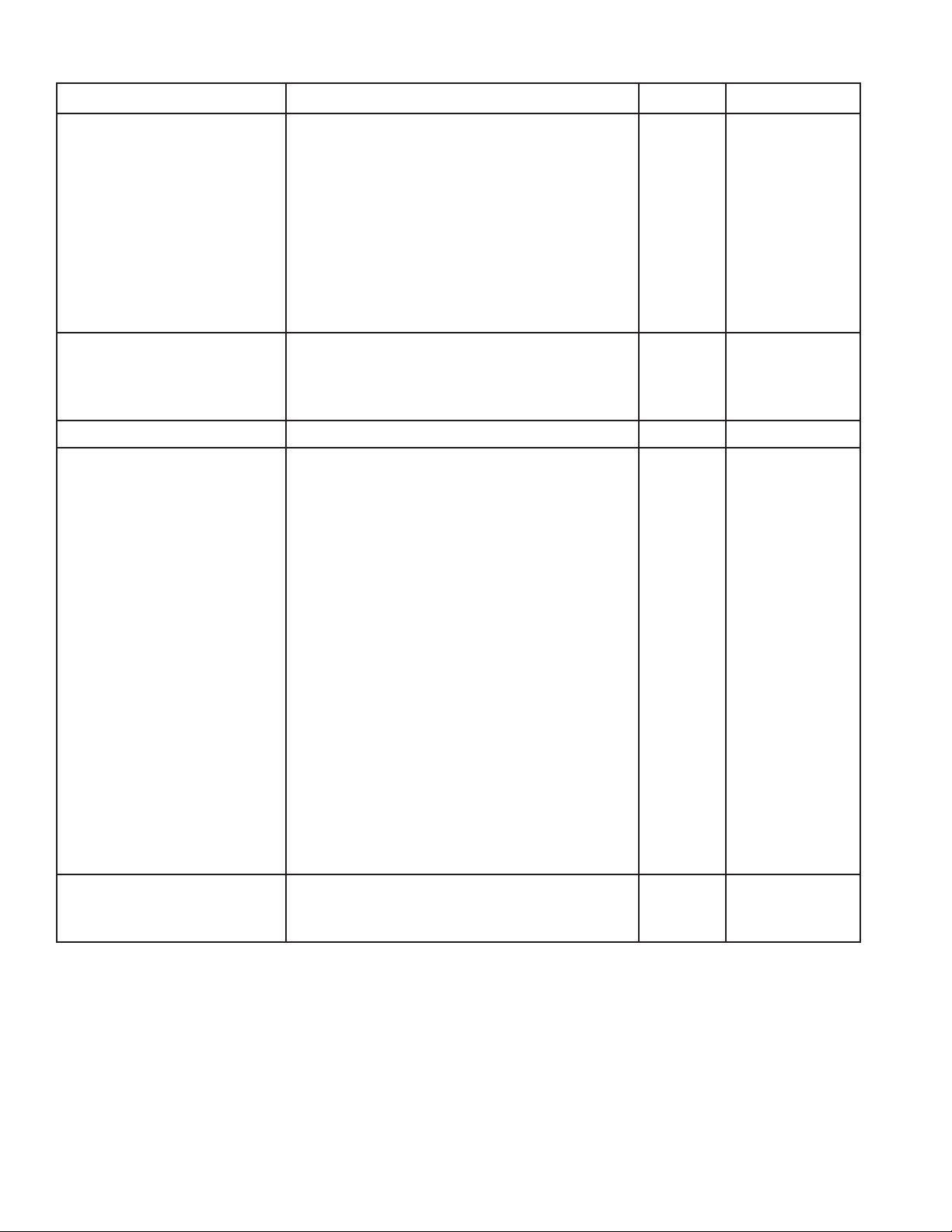

Page 6

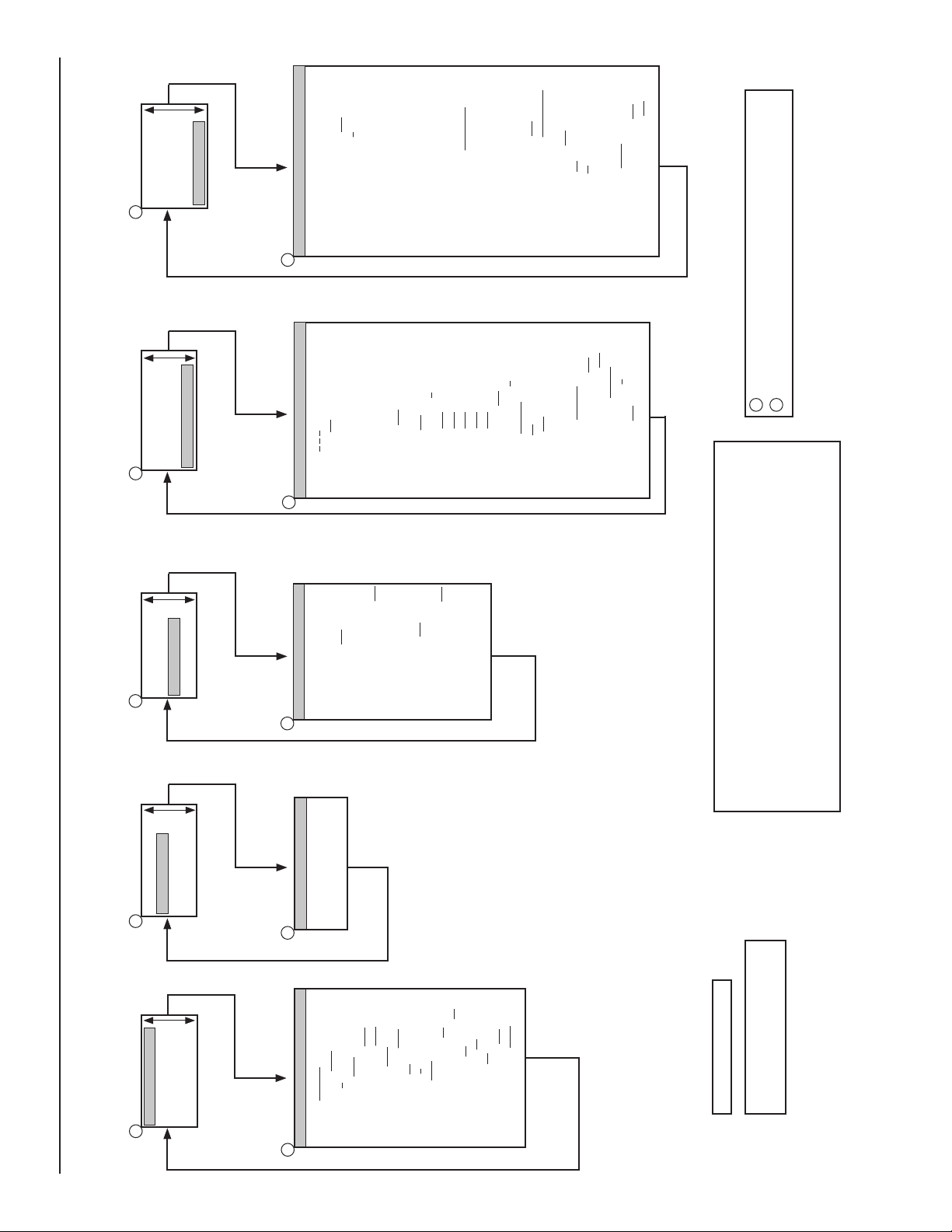

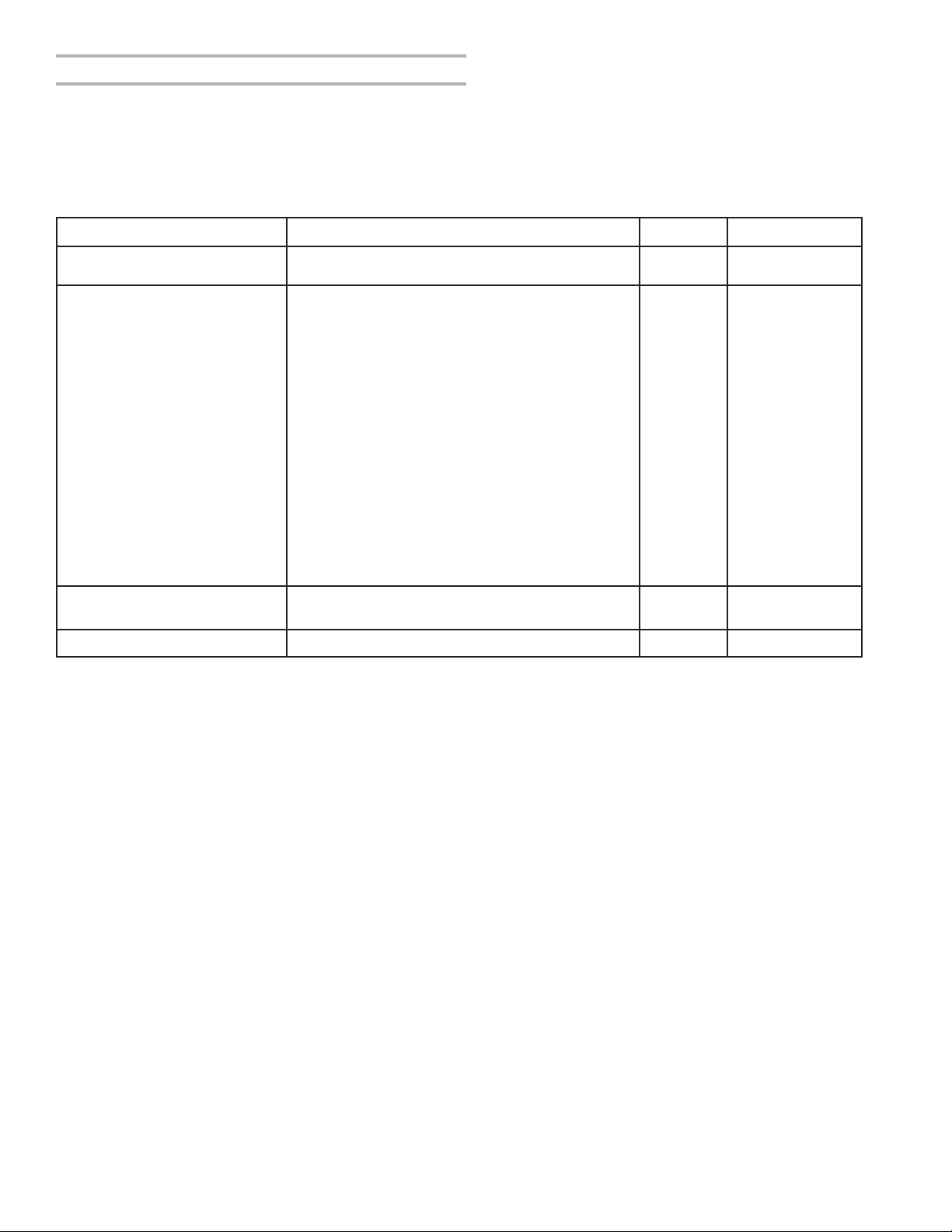

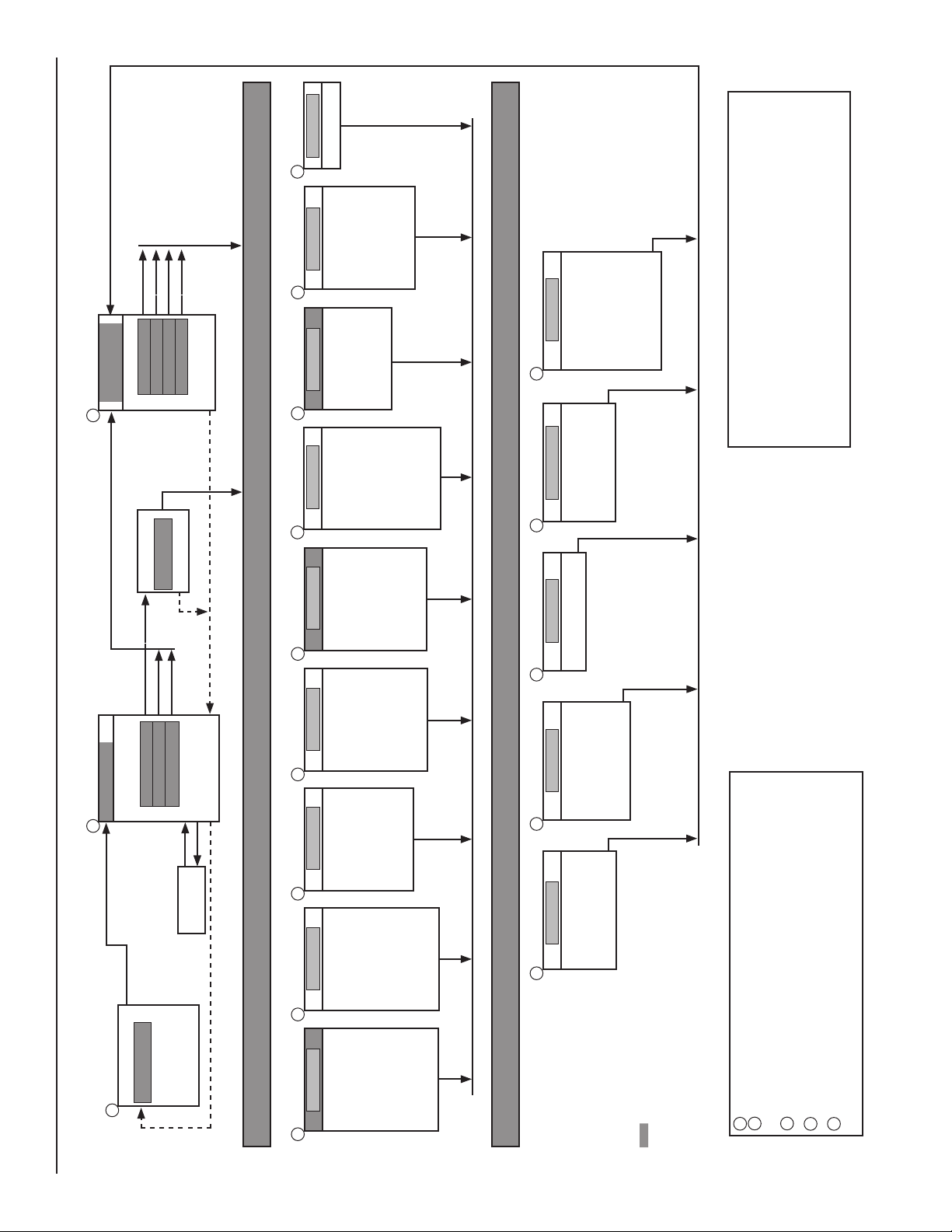

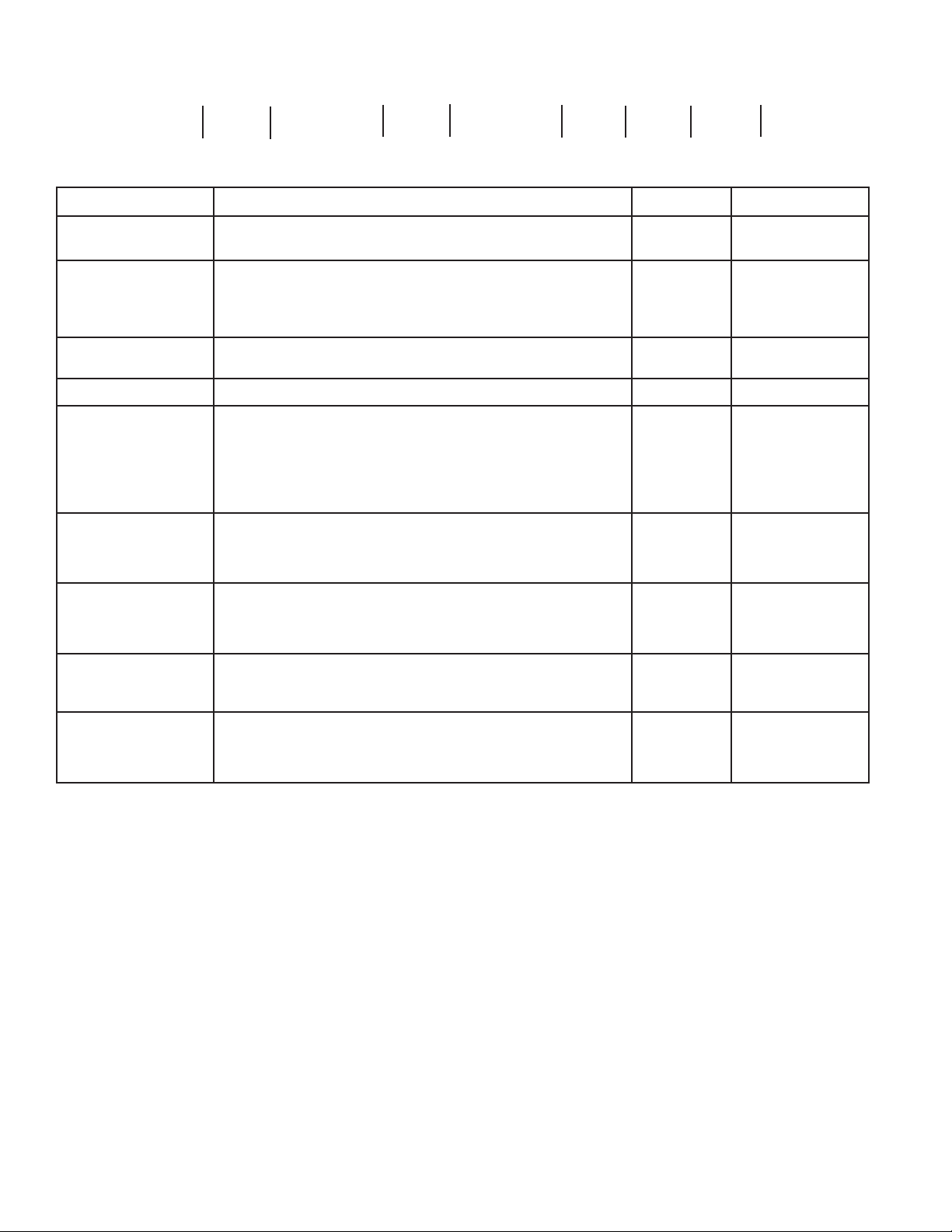

8

Initialization Menu

Program Menu

Service Menu

1.

1.

Conguration Menu

Initialization Menu

Program Menu

Service Menu

Conguration Menu

8 8 8

Advanced Menu

Advanced Menu

Data Acquisition Mem

Hygienic Cycle

Strict Temp. Control: NO

Temp. Calib. Offset: 0

Program Mode Lock

Conguration Menu

Machine Type R6 tu

Reset Defaults ?

Brightness Display: 12

Inverter Menu

Password 3 2 1

2.

Password

Edit Password

New Password

Old Password

Supply Volt: 3x380-415V+N tu

Load Param

Steam Connect: NO

Total N of Inlets: 2 tu

No Password

Program Lock

Password

Programs

Drain Valve 2: NO

(Water Recycle Inlets: 0) tu

Supply Sign A: Box tu

Supply Sign B: Box tu

Program 1 Unlocked tu

Edit Password

New Password

Old Password

Supply Sign C: Box tu

Supply Sign D: Box tu

Supply Sign E: Box tu

Liquid Soap Supply: NO

No Password

Traceability:

Enable Traceability: NO

Traceability Report: Store DAQ tu

Weighing

Min. Level Start Supply: 0

Temperature: Celsius tu

Full Heating: 67

Wet Cleaning: NO

Erase All Wash Program

Weighing System: NO

Main Units: kg

Help Units: %

Load Cell Calibration

Expected Free Weight: XXXX

Water Level: Units

Automatic Level Adjust: NO

(Automatic Soap Adjust.: NO)

Advance Menu Exit

Load Standard Programs

Language: English tu

Load Program 1 - 15? NO

Load Program 16 - 52? NO

Advanced Menu: NO

Conguration Menu Exit

Communication Type: RS485 tu

Communication Address: 1

Change the Settings at the Menu items.

Select the Initialization, Program, Service or Conguration Menu.

1.

8

2.

MAIN MENU

Initialization Menu

1.

Initialization Menu

1.

Program Menu

Service Menu

Conguration Menu

8

Program Menu

Service Menu

Conguration Menu

8

Service Menu

Software Y Y Y Version: X.XX

Diagnostic Program

Start Cycle: NO

Faults

2.

View Fault Messages

8

Program Menu

See Corresponding owchart

How to Create and Adjust

2.

a Wash Program

View Fault Messages: NO

View Fault Statistics

Toolbox

View Input States

Invert Power: Off

Pulley Ratio: XX

Reset Service Counts: NO

8

(RTC Time: XX: YY: ZZ)

(RTC Date: AA: BB: CC)

(Adjust Clock)

Service Menu Exit

8

p Selecting the Menu item: Press UP or DOWN.qtu Selecting list: Press LEFT or RIGHT.

8 Selecting a new program Sub-menu and go to the next item: ENTER.

8 Conrming a menu item and go to the next menu item: ENTER.

-- Insert a value or Select another List element.

Attention !!!

Depending the Machine Type,

Initialization Menu

Program Menu

Service Menu

1.

Conguration Menu

Initialization Menu

Language English tu

Service Interval: 3000

Buzzer time: 5 sec

2. 2.

Allow Advance: YES

Automatic Cool Down: YES

Wait for Temperature: YES

Manual Override: YES

Temperature balance: YES

Motor On Time: 12 sec

Motor Off Time: 3 sec

Smart Motion: YES

Hot Water Heater temp. 60 °C

Keyswitch: Program

Temp Overshoot Protection: -00%

Max, Heating Time: 60 Min

Max, WaterFill Time: 10 Min

Overll Detection: 10 Units

External Wait Control: NO

Main Water Pressure: High tu

Initialization Menu Exit

some items will not be displayed.

6

Page 7

GENERAL CONTROL DESCRIPTION

Control Features

The control offers:

n 99 programmable cycles

n 15 pre-programmed cycles and 37 dedicated programs

n Signal voltage control for external pumps or liquid supply

dispensers

n Redistribution of garments, if needed, to reduce vibration

during extraction

n Automatic temperature control during the water ll process

n Wash options and conguration setting

n Language (English, French, or Spanish)

Information displayed during operation:

n Program selected

n The active wash step

n The remaining program time

n Wash cycle progression bar

n The name of the sequence

n Indication of wait for heat (if selected)

n Symbol for water lling

n Symbol for heating

n The water level and temperature can be viewed

n Diagnostic messages

Operation Menu:

n Manually shorten, extend, or stop a cycle

n Pause a cycle

n Special function keypads allow direct operation of

selected components (water valves, etc.)

n Program overview

n Service information

THE HARDWARE AND SOFTWARE OF THE FULL

CONTROL WASHER CONTROLLER:

n Easy operation using a comprehensive keypad

n The hardware contains 1 electronic board

n The MCG FC washer controller with Graphic LCD display

n Washer control software is stored as Flash memory

that is easily replaced

n Washer programs are stored as EEPROM memory

(non-volatile memory)

Menu Functions

The PROGRAM Menu allows you to:

n Create and name wash programs

n Edit existing wash programs

n Modify wash programs

n Copy wash programs

n Delete wash programs

n Inspect wash programs with the VIEW function

The CONFIGURATION Menu allows you to:

n Select the Machine Type

n Load the default factory settings into the CONFIGURATION

and INITIALIZATION Menu

n Select the display brightness

n Select the power supply voltage of the washer

n Load the Frequency Inverter Parameters

n Erase all the programmed wash programs

(reset Wash program in EEPROM memory)

n Load the standard wash programs

n Select the number of washer water supply inlets

n Select a second drain valve for water recycling

n Select Soap Box or liquid supply

n External liquid pump setup (if connected)

n Select the temperature display (Celsius or Fahrenheit)

n Select full heating

n Low water pressure setting

n Select wet cleaning option

n Select the minimum water level for chemical supply to start

The INITIALIZATION Menu allows you to:

n Select display language

n Program the Service due cycle count

n Set buzzer time interval

n Select/deselect the Advance function

n Select/deselect the Wait for temperature function

n Select/deselect allow manual override of a step or

function

n Select/deselect the Temperature balance function

n Select/deselect the default speed and reset time of wash

cycle action

n Select/deselect the Automatic Cool Down function

n Select/deselect the Show Economic function

n Program the hot water supply temperature

n Program the Temperature Overshoot Protection

temperature

n Program the Maximum Heating Time

n Program the Maximum Fill time

n Programming the Maximum Level Overll value

The SERVICE Menu allows you to:

n Inspect the error messages log register and statistics

n Activate the power of the Frequency Inverter

n Determine the functionality of the electric input signals

n Reset the Cycle counter

The DIAGNOSTIC Menu runs a diagnostic cycle to detect

problems with the washer

The ADVANCED Menu is designated for special optional

applications and is available on Model MFS55 and larger

models.

7

Page 8

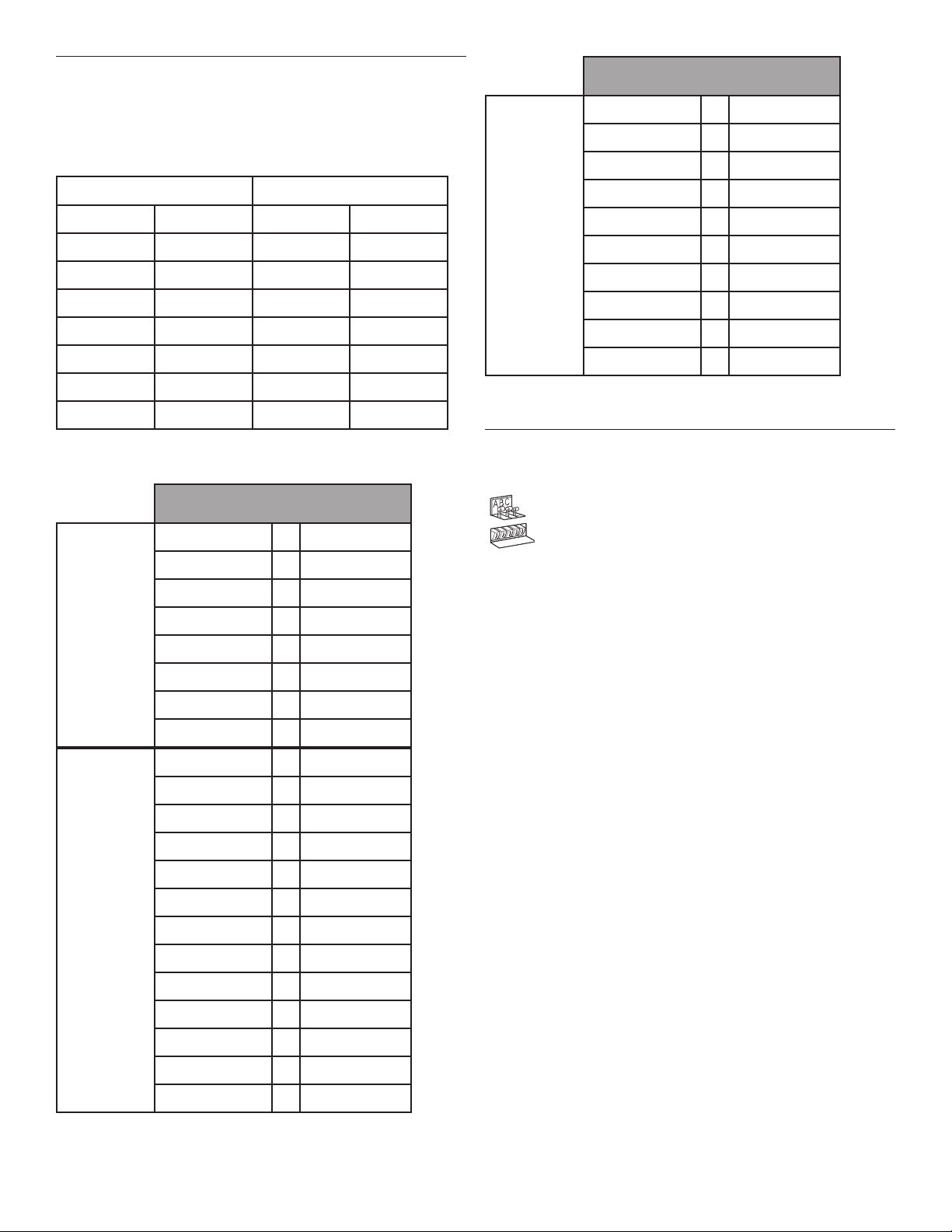

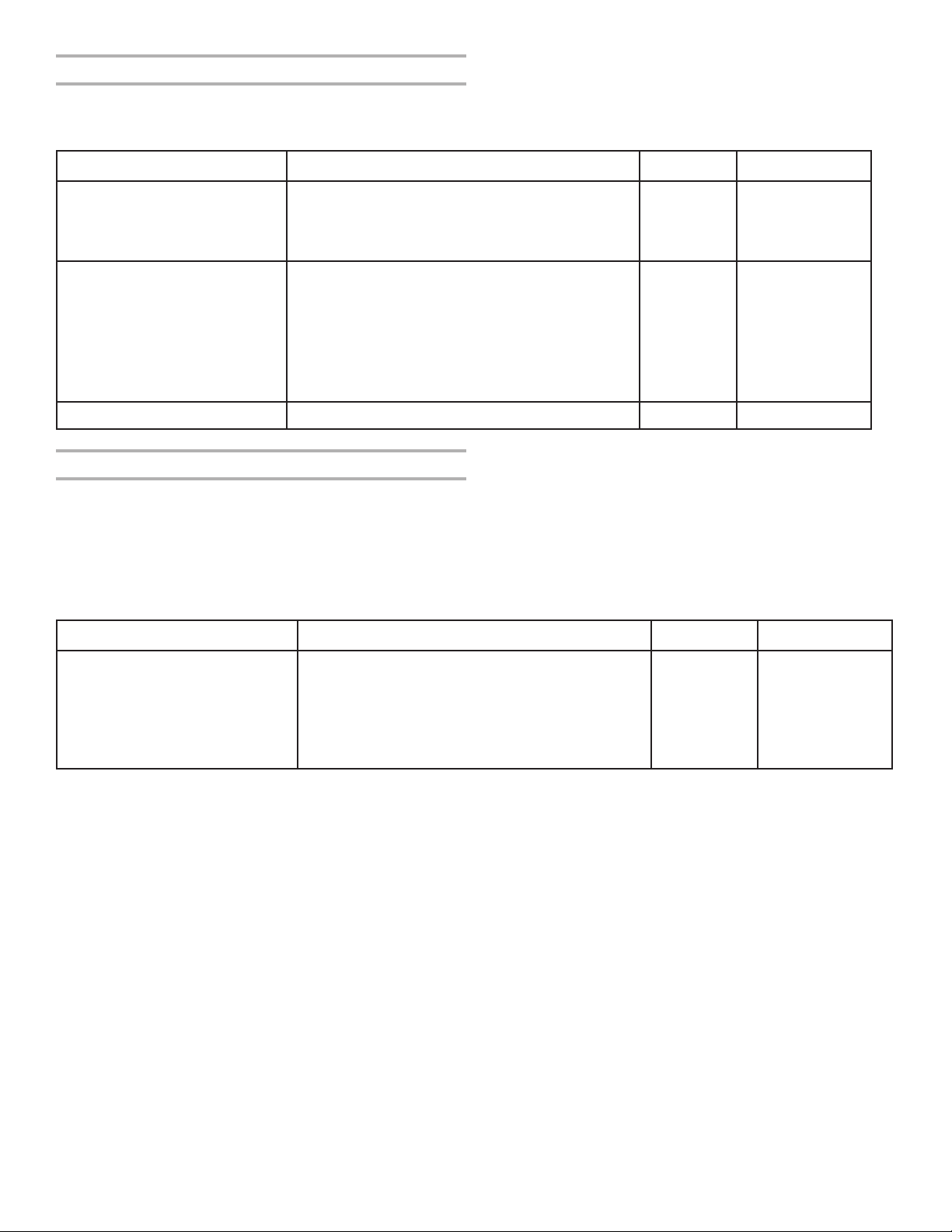

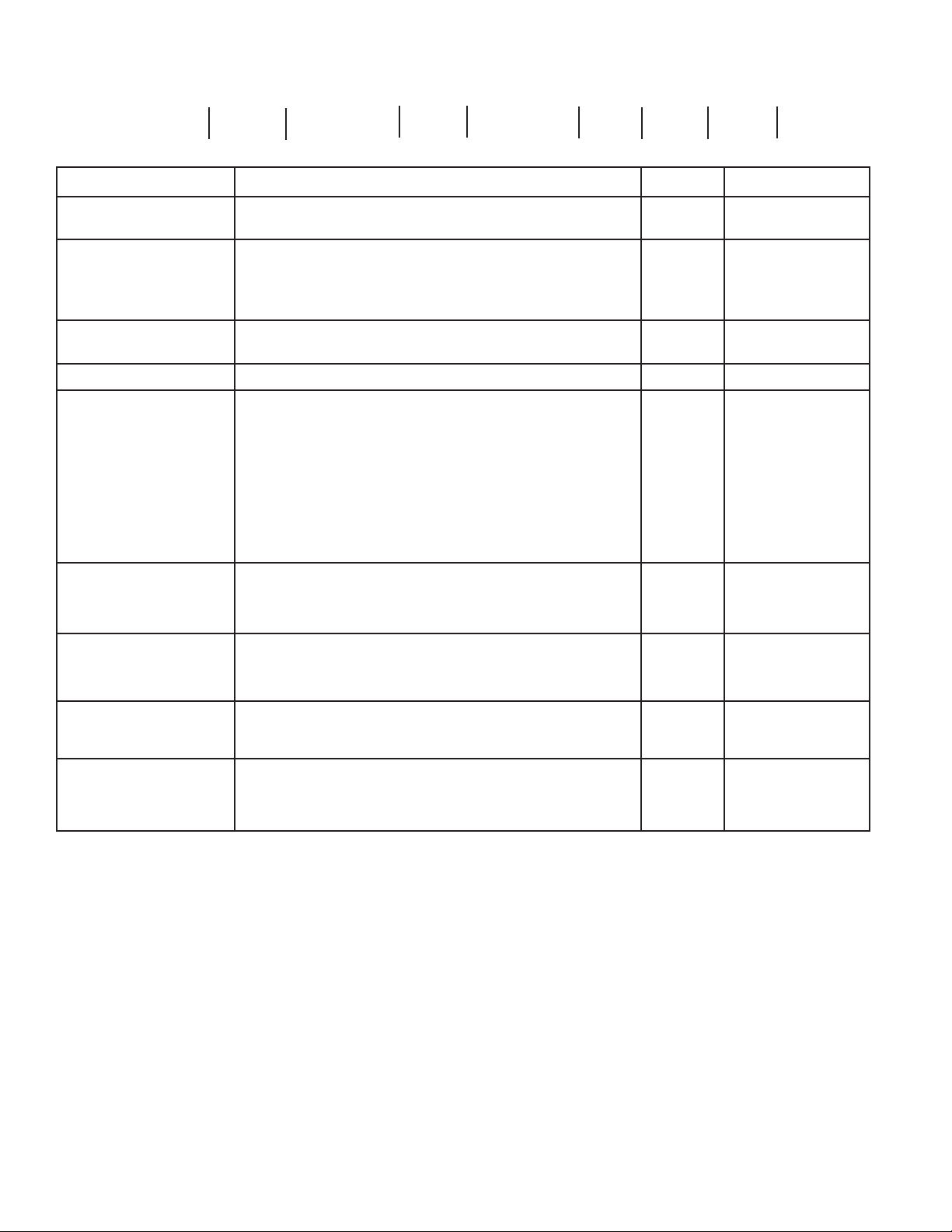

Machine Types

This programming guide uses Machine Types for references to

the tables and text. Refer to the table below for Machine Types

for your washer.

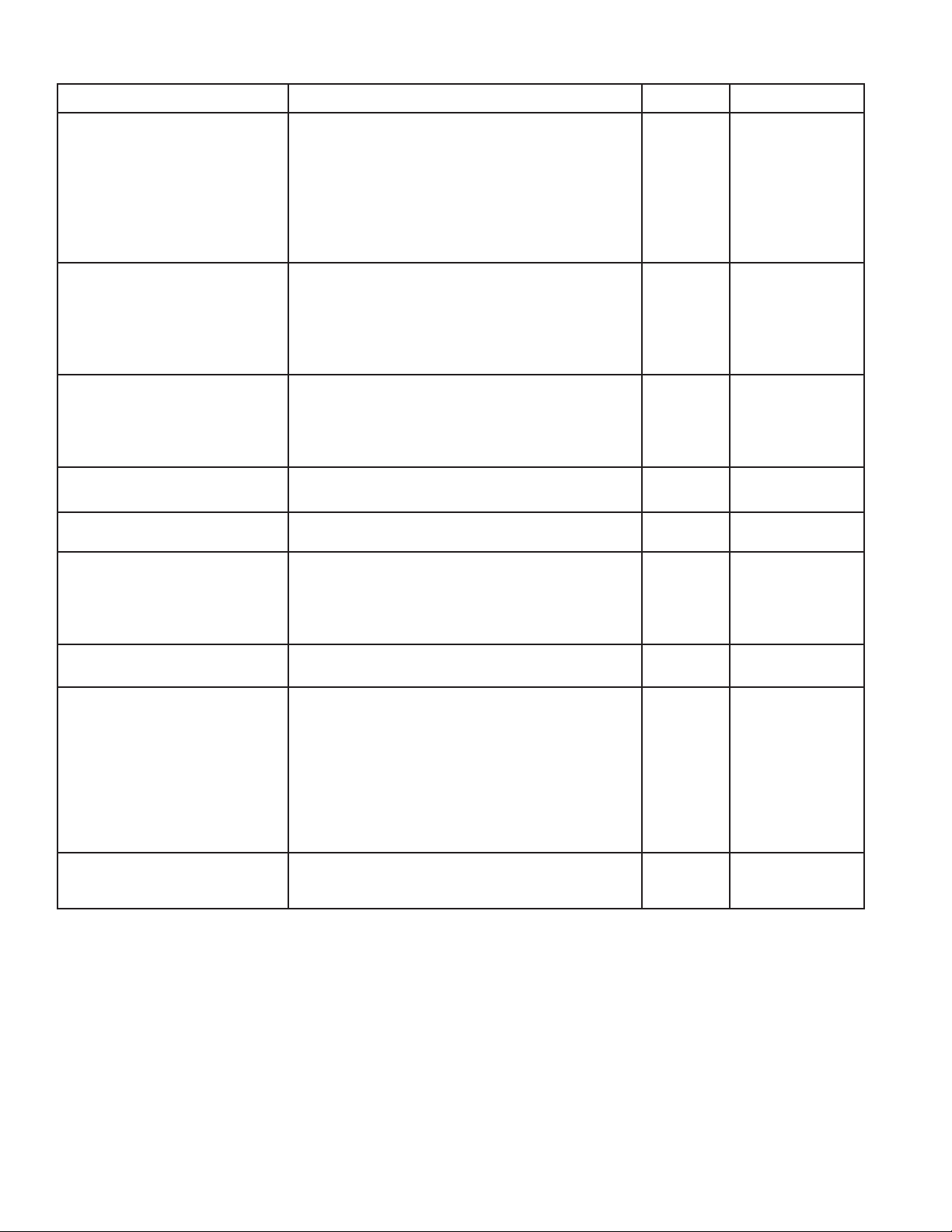

Machine Types Used for Commercial Washers

Rigid Mount Washers Soft Mount Washers

Model Machine Type Model Machine Type

MFR30PNCTS R 13 MFS25PNFTS F 10

MFR40PNCTS R 18 MFS35PNFTS F 16

MFR60PNCTS R 27 MFS55PNAVS F 23/3

MFR80PNCTS R 35 MFS50PNFVS F 22

- - MFS80PNFVS F 33

- - MFS100PFVS F 40

- - MFS125PFVS F 55

Machine Type Selection for Commercial Washers

Dry load “Machine Type”

capacity selection

6 kg / 15 lbs => R6

7 kg / 18 lbs => R7

Rigid

mounted

industrial

washer

extractors

Soft Mount

industrial

washer

extractors

10 kg / 25 lbs => R10

13 kg / 30 lbs => R13

18 kg / 40 lbs => R18

22 kg / 50 lbs => R22

27 kg / 60 lbs => R27

35 kg / 80 lbs => R35

6 kg / 15 lbs => F6

7 kg / 18 lbs => F7

10 kg / 25 lbs => F10

13 kg / 30 lbs => F13

16 kg / 35 lbs => F16

22 kg / 50 lbs => F23/3*

22 kg / 50 lbs => F23/4**

33 kg / 80 lbs => F33

40 kg / 100 lbs => F40

55 kg / 125 lbs => F55

80 kg / 180 lbs => F800

100 kg / 225 lbs => F1000

120 kg / 275 lbs => F1200

Dry load “Machine Type”

capacity selection

16 kg / 35 lbs => MB16

26 kg / 60 lbs => MB26

33 kg / 80 lbs => MB33

Soft Mount

hygienic

44 kg / 110 lbs => MB44

66 kg / 150 lbs => MB66

barrier

washer

extractors

70 kg / 160 lbs => MB70

90 kg / 200 lbs => MB90

110 kg / 245 lbs => MB110

140 kg / 310 lbs => MB140

180 kg / 400 lbs => MB180

NOTE: Other Machine Types appear in the software, but do

not correspond to current Maytag brands.

Create a Wash Program

n The Full Control washer controller is designated for:

Washers with a top dispensers.

Washers with front/side dispensers.

E

D

C

B

A

n Wash programs are built step-by-step.

n Each step consists of a Wash Sequence and a

Drain/Extraction sequence.

n 99 wash programs with 99 steps is programmable.

Programming the Wash Sequence:

n First choose the type of Wash Sequence.

Washer with

Top Soap Dispenser

n Prewash

n Wash

n Cool Down

n Rinse

n Final Rinse

n Flush

n Soak

n Spray

n No Wash

Front/Side Soap Dispenser

n Wash

n Cool Down

n Rinse

n Soak

n Spray

n No Wash

Then program all the related functions of the sequence.

The available functions are:

n Temperature

n Water Level

n Water Inlet Valves

n Wash Speed

n Reversing Interval times

n Supplies

n Sequence Time (length of step)

n Drain Valve 1–2

n Pause Signal

Each step has default settings. Many new programs will

not require changes from the suggested values.

Washer with

* Washers with plastic soap dispenser

** Washers with stainless steel soap dispenser

8

Page 9

Programming the Drain sequence:

After programming the Wash Sequence, program the

Drain/Extraction sequence.

n Drain, or

n Extraction, or

n No Drain, or

n Static Drain, or

n Reversing Drain.

Then program all related functions of the Drain/Extraction

sequence. The available functions are:

n Sequence Time (length of step)

n Speed

n Drain valve 1–2

It is also possible to skip a sequence between two other

sequences by programming No Wash or No Drain.

Example: The No Drain sequence should be programmed

between a Wash and a Cool Down Sequence.

NOTE: See Programming for more information on sequences.

Tumble Sequence:

n The wash cycle always ends with a Tumble Sequence.

n The Tumble sequence takes 30 seconds, then the program is

nished and the door can be opened.

n The Tumble sequence cannot be skipped.

Program Functions

Limits:

n To ensure the correct operation of the washer, values must be

within certain limits.

n Programming functions into a washer that does not have the

associated function will cause error codes during operation.

n If a programmed value is outside the programmed limits, the

default program value will override the programmed value.

The hot water inlet valves

Inlet Valve 4 Corresponds with Soap Box B (Wash).

Inlet Valve 3 Is a direct inlet valve and speeds up the

water ll process.

See the schematic diagram supplied with the washer for

additional information on inlet valves.

How to Select Inlet Valves:

EXAMPLE:

n For a Prewash: Programmable temperature: 34–113°F

(1–45°C)

Inlet Valve 2 (cold) Soap Box A

+ Inlet Valve 3 (hot)

and/or 6 (cold) Direct Inlets

n For a Wash: Programmable temperature: 34–198°F

(1–92°C)

Inlet Valve 4 (hot)

and/or 5 (cold) Soap Box B

+ Inlet Valve 3 (hot)

and/or 6 (cold) Direct Inlets

n For a Rinse: Inlet Valves 2 + 5 + 6 (cold) No Soap

n For a Final Rinse: Inlet Valve 1 (cold hard)

(or cold soft) Soap Box C

+ Inlet Valve 6 (cold soft) only if No

NOTES:

n Water inlets 3 or 6 must be used for washers with laundry

product supply pumps because the liquid is added at the

direct water inlet channel.

n Depending on the washer, cold water can be used with water

Inlet Valve 1.

n If the water recycling feature is used, the water recycling

supply must be connected to Inlet Valve 2 or 5.

Programming the Water Temperature:

– Minimum value: 34°F (1°C)

– Maximum value: 113°F (45°C) for PREWASH and SOAK,

and 196°F (92°C) for the WASH Sequence.

– For RINSE, FINAL RINSE, FLUSH, and SPRAY, no

temperature can be programmed.

Programming the Water Inlet Valves:

n Depending on the programmed temperature the water inlet

valves are suggested.

n While the tub is lling with water, the computer controls the

water temperature by switching on and off the hot and cold

water inlet valves.

n For washers with a Top Soap Dispenser, you must consider

that by programming the water inlet valves, you are also

selecting the Soap Box at which the soap must be added.

n If you want to program a Wash Sequence with:

– Cold water: Only cold inlet valves must be programmed.

– Warm or hot water: Cold and hot inlet valves must be

programmed.

Top Soap Dispenser washers:

The cold water inlet valves

Inlet Valve 2 Corresponds with Soap Box A (Prewash).

Inlet Valve 5 Corresponds with Soap Box B (Wash).

Inlet Valve 1 Corresponds with Soap Box C (Final Rinse).

Inlet Valve 6 Is a direct inlet valve and speeds up the

water ll process.

9

Page 10

Front/Side Soap Dispenser washers:

The cold water inlet valves

Inlet Valve 1 Cold Hard Water or Recycled Water

Inlet Valve 2 Cold Soft Water

The hot water inlet valves

Inlet Valve 3 Warm Soft Water

NOTE: To add soap to a Front/Side Soap Dispenser washer,

the supplies must be programmed.

Programming the Water Level:

Water level Limits

n See “Water Setting Values for Different Washers” because

these values are different for each Machine Type.

n The minimum value is above the heating elements and the

temperature sensor

n The maximum value is below the overow outlet

Normal Low Level, Normal High Level

n The Normal Low Level is recommended for the PREWASH,

WASH, and SOAK sequences.

n The Normal High Level is recommended for the RINSE and

FINAL RINSE Sequences.

n At the FLUSH sequence, you can’t program a water level

because the water will escape through the overow opening.

n At the Cool Down sequence, the Full Control washer

controller makes use of a low water level and is draining

the water automatically.

n At the Spray sequence, the Drain valve stays open.

Economic Water Level

n If you prefer a wash cycle with an economic water level:

You can select “Show ECONOMIC” in the Initialization

Menu to use the standard setting.

n ECONOMIC function. At the start of each wash cycle,

the question ECONOMIC? will be displayed. If you select

ECONOMIC, the program will function with 20% units less

water.

– or you may make dedicated programs with a water level

20% units below the normal water level.

Wet Cleaning selection Conguration Menu

n It is possible to program a level below default minimum

programmable level. (See table on page 87).

n The heating will not be functional for a water level below

the standard minimum programmable water level.

NOTES:

n Normal high water level is recommended for woolens

and delicate linens.

n The economic function should only be used for small,

lightly soiled wash loads.

Programming the Wash Speed:

n Standard reversing Wash Speed is between 40 and 50 RPM

(See table on page 91).

n For some special applications the drum should only turn very

slowly.

Speed Limits:

n The minimum programmable Wash Speed is 10 RPM.

n The maximum programmable Wash Speed is 40 - 60 RPM,

depending on washer size.

Programming Extraction Speed:

n See Table A-5 for maximum and minimum spin speeds. The

limits differ depending on the maximum allowed g-force at

high spin for each Machine Type.

n An Intermediate spin between two sequences should be about

1/2 the maximum spin.

Programming Supplies:

n Up to 4 supplies can be programmed at the same time in a

sequence.

n For Front/Side Soap Dispenser washers, supplies A, B,

C, D, and E have to be programmed to inject the soap by

compartment.

n If liquid soap pumps were installed on the washer, these

pumps will be activated by programming a time value for the

corresponding supply signal 1, 2, 3, 4, 5, 6, 7, or 8.

n The maximum programmable time is 99 seconds per

sequence.

n If the time is 0 seconds then the supply will NOT be

activated during the wash process.

NOTE: If more than 4 supplies are needed in the same step, run

the step twice with half the water volume in each step. Use the

NO DRAIN sequence between the steps so the water does not

drain out.

Programming the Motor On and Off Times

for Reversing

n The default Reversing Motor On and Off Times at Wash Speed

is 12 seconds on and 3 seconds off.

n For Delicates and Woolens, it is recommended to program a

Gentle Wash action with a On time of 3 seconds and an Off

Time of 12 seconds.

Programming the Sequence Time

n The sequence time starts running after the programmed

water level is reached.

n If the Wait for Temperature feature is selected, the

sequence time begins only after the programmed

temperature is reached.

NOTE: The Wait for Temperature feature must be Off unless

there is an auxiliary heat source on the washer.

n For a Cool Down Sequence, the programmed time

corresponds with the time for decreasing the water

temperature.

TIP: A cool down of 3 minutes must be programmed. To avoid

garment shrinkage, it is recommended to program the time

so that the temperature will decrease with about 5°F (3°C)

for each minute.

Buzzer

n The Buzzer should be programmed when a running wash

cycle needs to be interrupted.

n The Buzzer will be activated to alert the operator.

n In most cases, the operator interrupts a program to ll

the Soap Box an additional time.

n The program interruption will always occur at the end of

a step.

10

Page 11

WASHER STARTUP

Perform washer startup after the washer is installed. See the

Installation Instructions for your washer. Startup consists of

three steps:

n Select the washer specic settings in the Conguration

Menu.

n Select the operator specic settings in the Initialization

Menu.

n Adjust default programs or create new programs at the

Program Menu.

Initial conguration and initialization settings were done at

the factory.

IMPORTANT:

n Read this manual thoroughly before making changes to

the Conguration or Initialization Menus.

n Write down current settings before changing any setting.

n The default washer setups are used for a wide variety of

models and applications. Some program modications

may be necessary to achieve optimum performance for

your application.

Configuration Menu

The Conguration Menu allows you to choose individual

washer specic settings. The Conguration Menu can only be

accessed when the washer is in standby mode.

IMPORTANT: Only a qualied technician should perform

conguration setup. Incorrect conguration setting could

cause serious washer damage.

1. Make sure power is ON and no program is running.

2. Turn the key switch to PROGRAM MODE or enter through

the Program Mode setup with the keypad sequence outlined on page 6. The Main Menu will be displayed.

3. Press 5 or 6 to select the Conguration Menu.

Main Menu

Initialization Menu …

Program Menu … Configuration Menu …

Service Menu … Advanced Menu …

4. Press ENTER.

The password screen will appear.

Configuration Menu

Password _ _ _

5. Enter the password “3-2-1”. Press ENTER.

6. Press 5 or 6 to select the menu items individually.

11

Page 12

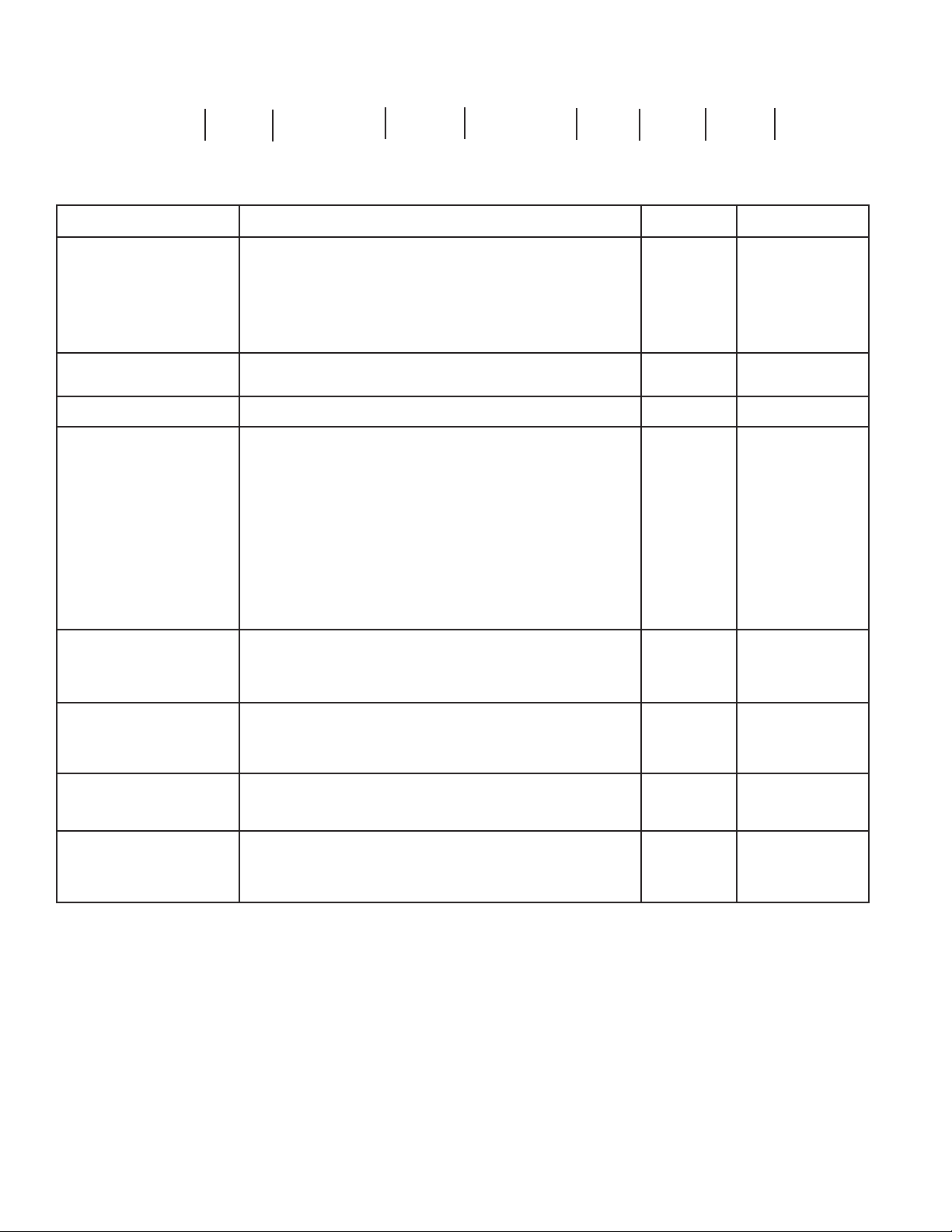

Conguration Menu Options and Defaults

Menu Item Description Default Range

Machine Type

Are You Sure ?

Reset Defaults ?

Are You Sure ?

Brightness Display Change the display brightness for best viewing. 12 1–20

Inverter Menu…

Select the Machine Type. The Machine Type is on

the Name Plate at the rear of the washer.

Conrm that you want to change the Machine Type.

(F23/3 = Top Soap Dispenser)

(F23/4 & F22/5 = Front/Side Soap Dispenser)

NOTES:

Changing the Machine Type does not change wash

programs stored in EEPROM memory. Erase all

program memory and the standard wash programs

again after changing the Machine Type because

wash programs settings differ for each washer.

To ensure proper operation, make certain the

Machine Type is correct. See table on page 86.

Resets Initialization and Conguration Menu settings

to the default factory settings.

Only used at SETUP of a new washer controller.

Conrm that you want to Reset Defaults.

Loads the Inverter Menu.

NOTES:

The washer can only perform properly if the Inverter

Parameters are correct. Make certain the Inverter

Type and supply voltage are correct.

Not for washers R6, R7, R10.

R6

No

No

No

List

No/Yes

No/Yes

No/Yes

Supply Voltage XXXXXXX

(Inverter Type)

Load Param…

Are You Sure ?

Steam Connect Not valid for washers MFS18 to MFS35, MFR18 to

* Choices vary by model.

Select the correct supply voltage as indicated by

the washer nameplate.

NOTE: Loading parameters is only required after

Inverter replacement or if there are problems with

the drive system.

n Conrm that you want to load the Inverter

Parameters.

If yes:

– Door must be closed.

– Check if the SETUP is correct.

• Parameter List Version

• Machine Type, Software Version

– Check status screen while parameters are

loaded.

• Sending Param.: 0–100%

• Inverter Software Version: YYYY

• Verify Parameters: 0–100%

• Inverter Type: XXXX

MFR80 (except MFR60)

Kit for steam heat is only available on the

MFS models 55 and larger.

Select from

available choices

in menu*

No

No No/Yes

No/Yes

12

Page 13

Conguration Menu Options and Defaults (continued)

Menu Item Description Default Range

Total Number of Inlets Washers have 2 or 3 water inlets:

2 main:

– hot water

– cold water

3 main:

– soft warm water

– soft cold water

– hard or recycled cold water

NOTE: This input changes program choices.

Drain Valve 2 Second drain destination could include recycled

water. Not all washers have a second drain valve.

NOTES:

If drain 2 is a normally closed drain valve,

then select “yes.”

Select “No” for single drain destination.

Water Recycle Inlets Front/Side Soap Dispenser washers only: If water

recycling is employed, select the Inlet Valve number

that recycled water will ow into the washer form.

NOTE: All washers require additional equipment to

recycle water. Call customer service.

Supply Signals A through E Front/Side Soap Dispenser washers only: Select

“box” for dispenser box.

Liquid Soap Supply Select “Yes” if external liquid laundry supply pumps

will be used.

Minimum Level Start Supply Enter the water level at which the liquid supply

pump(s) begin pumping. Refer to “Minimum,

Normal, and Maximum Water Setting Values.”

NOTE: The default water level for front dispenser

washers is 10 units.

3 2/3

No No/Yes

0 0–3

Box Box/Liquid

No No/Yes

0 units

(top)

10 units

(front)

0 – Minimum

program level

Temperature Select the units temperature will be displayed in. Celsius Celsius /

Fahrenheit

Full Heating This function controls the percent of wash time

supplementary heat is used during the wash

sequence to reduce energy consumption.

100%: Target temperature is maintained

throughout the wash sequence.

0%: Supplemental heat turns off after the

target temperature is reached.

67%: Target temperature is maintained 2/3 of

the way through the wash sequence.

Wet Cleaning Select Wet Cleaning to program water levels

below the Minimum Water level. Refer to “Minimum,

Normal, and Maximum Water Setting Values.”

67% 0–100%

No No/Yes

13

Page 14

Conguration Menu Options and Defaults (continued)

Menu Item Description Default Limits

Erase All Wash Prog ?

Are You Sure ?

Load Standard Programs ?

Language

Load Program 1 - 15 ?

Load Program 16-52 ?

Communication Type The washer controller supports RS485 and

This function erases all existing wash programs stored

in memory. It should be performed when installing a

new washer controller to make certain no old programs

are stored in the memory.

Allows you to load 15 factory-set programs

and 37 additional default programs. It also allows you

to select the language for the user program.

Select display language*

Loads factory set cycles

Loads additional default programs

NOTE: Always re-load standard programs in memory

after selecting a different Machine Type.

Infrared (IRDA) ports; it only supports one type of

communication at a time.

The RS485 port allows hard-wire connection to a

network or computer.

The IRDA window is next to the “4” on the touch pad

and allows communication with a infrared device.

NOTE: Some handheld computers emit a weak signal.

It will be necessary to hold the device next to the IRDA

window. See Trace-Tech Manual (Part Number

W10243988) for more information.

No

No

No

English

No

No

RS485 RS485/IRDA

No/Yes

No/Yes

No/Yes

List

No/Yes

No/Yes

Communication Addr. Assigns a unique address for communication with a

network or computer through a RS485 cable.

NOTE: No two washers or other devices can have the

same communication address in a network.

Advanced Menu Displays the Advanced Menu on the Main Menu. No No/Yes

Exit Return to Main Menu.

* Call Customer Service for language availability.

255 1–255

14

Page 15

Advanced Menu

Water

The Advanced Menu contains special, optional, and infrequently

used applications. Only factory trained personnel should modify

items in this menu.

1. Make sure power is ON and no program is running.

2. Enter the PROGRAM MODE. The Main Menu will be

displayed. To get access to the Advance Menu, select “YES”

for “Advanced Menu” listed in the Conguration Menu.

3. Press 5 or 6 to select the Advanced Menu.

Main Menu

Initialization Menu …

Program Menu … Configuration Menu …

Service Menu … Advanced Menu …

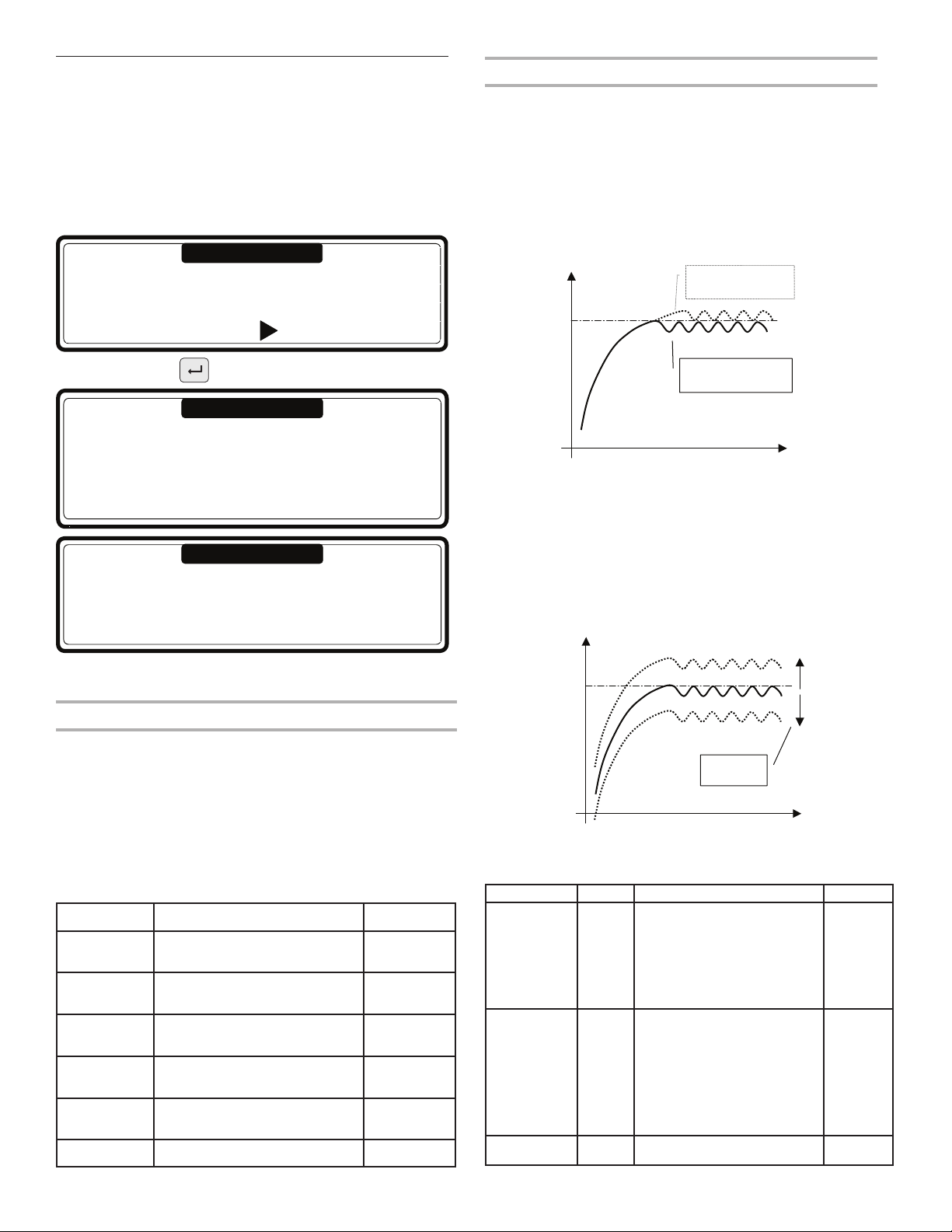

Hygienic Cycle Menu

The Hygienic Cycle Menu contains the Strict Temperature

Control and Temperature Calibration Offset functions. Both

programs act on temperature control and require accessory

heat to function properly.

n Strict Temperature Control may be turned on or off.

When it is turned on, the target wash temperature is the

minimum temperature during the wash cycle. When this

function is off, accessory heat turns off when the water

reaches target temperature (see illustration below).

Water

Temperature

2 : Strict Temperat ure

Control

Target

4. Press ENTER.

Advanced Menu

1 DAQ Memory …

2 Hygienic Cycle …

3 Program Mode Lock …

4 Program Lock …

5 Traceability …

Advanced Menu

6Weighing …

7 Exit

5. The Advanced Menu contains 7 items on two screens.

Press 5 or 6 to select the desired menu item.

DAQ Memory Menu

The Data Acquisition (DAQ) memory stores information about

the use prole and functionality of the washer. This information

is usually applied in conjunction with Trace-Tech software.

n The DAQ memory collects information whenever the washer

is on. It does not collect information when the washer is off.

n The DAQ Storage Memory can be reset at the Conguration

Menu by the Reset Defaults function. All data stored in the

DAQ Memory will be lost.

DAQ Memory Menu Variables

Menu Item Description Limits

All Memory

Segments

Statistics

Segment

Traceability

Segment

Trace-Tech

Settings

Log

Segment

Exit Return to Advanced Menu.

Turns on all memory

segments.

Stores statistical information

about washer utilization.

Contains Traceability

information from the washer.

Stores setup information from

the Trace-Tech PC software

Contains the event log for

the washer.

On/Off

On/Off

On/Off

On/Off

On/Off

1 : Normal Temperature

Control

Strict Temperature Control

n Temperature Control Offset allows calibration with an

Time

external measurement device. The offset control is

adjustable between 23° and 41°F (-5° and +5° C)

(see illustration below).

NOTE: Calibration is only necessary to assure a minimum

temperature is attained during a hygienic cycle. It is not

required for normal washer use.

Temperature

Target

Offset

adjustment

Temperature Calibration Offset

+ 5

- 5

Time

Temperature Calibration Offset Variables

Menu Item Default Information Limits

Strict

Temperature

Control

No

The Strict Temperature

Control of the wash

computer ensures laundry is

No/Yes

washed at the programmed

target temperature.

Temperature

Calibration

Offset

0

By changing the

Temperature Calibration

Offset setting,

23/32/41°F

(-5/0/5°C)

the water temperature sensor

setting is equalized with the

external reference

temperature sensor.

Exit Return to Advanced Menu.

15

Page 16

Program Mode Lock Menu

The access to the Program Mode can be locked by a password.

It means that without password you can’t have access to the

Main Menu Screen.

Menu Item Description Default Limits

Password . . . Enter a 4 digit value for the Password and press

Edit Password …

New Password ….

No Password …

Old Password …

Exit Return to Advanced Menu

ENTER.

NOTE: The password will not be requested if it has

not been set.

Insert a 4 digit numeric value to create a new

password.

Select the menu item “No password” if you want to

get rid of the password.

To change the Password enter old password, create

a new password.

None 0000–99999

Program Lock Menu

Each wash program can be locked individually.

When the program is locked, it means no settings can be

changed anymore.

It avoids that programs once created get changed by somebody

else.

To get access to this menu a password is needed if it has been

set.

Menu Item Description Default Limits

Programs …

1 HOT WASH Unlocked

2 WARM WASH Locked

…

99 Program 99 Unlocked

EXIT

Each program can be locked - unlocked individually.

When the program is locked, it means Program

settings can no longer be changed.

This helps avoid created programs being changed

by another.

Unlocked

16

Page 17

Traceability Menu

The Traceability Menu allows information collection regarding

cycle parameters. This information can be used to verify that any

wash cycle meets given requirements. For further information

on the collection and management of this information see the

Traceability Management Manual W10243988.

Traceability Menu Options and Defaults

Menu Item Description Default Limits

Enable Traceability First you have to select Traceability to obtain the

Traceability Report

Stored Cycles …

Start Print Last Report

Disability Traceability Errors Err 81 and Err 82 can be switched off if they are

Exit Return to Advanced Menu.

other menu items.

A report can be created for each wash cycle.

A printer or PC can be connected to the washer by

Serial RS485 communication bus.

• “Store DAQ”: stores all wash process data in the

DAQ memory. When the PC is connected to the

washer, the data is sent and stored on the PC.

• “Store PC”: sends continuously all wash cycle data

to the PC, where it is stored.

• “Print Last” sends the report directly to a printer.

The command is given by “Start Print Last Report.”

• “Print All” sends the report in real time to a printer.

If Store DAQ is selected, the display shows the

number of wash cycles stored in DAQ memory.

If Print Last is selected, the menu item “Start Printing

the Last Stored Report” is displayed.

interfering with the wash cycle.

No No/Yes

Store DAQ

XX%

No

No No/Yes

Store DAQ

Store PC

Print Last

Print All

No/Yes

17

Page 18

Initialization Menu

Initialization Menu allows you to choose standard default

program settings for your application.

1. Make sure power is ON and no program is running.

2. Enter PROGRAM MODE. The Main Menu will be displayed.

3. Press 5 or 6 to select the Initialization Menu.

Main Menu

Initialization Menu …

Program Menu … Configuration Menu …

Service Menu … Advanced Menu …

4. Press ENTER.

Initialization Menu Selections and Defaults

Menu Item Description Default Range

Language Language selection for Program Mode: English,

Spanish, or French

Service Interval Number of cycles at which maintenance is required.

3000: Top Soap Dispenser washers

9999: Front/Side Soap Dispenser washers

Buzzer Time The time the Buzzer beeps at end of wash

cycle while “Unload” is displayed.

Allow Advance The Advance function allows the user to skip a

sequence or change sequence duration.

Automatic Cool Down Automatic cool down selection*. Yes No/Yes

Wait for Temp Wash Process time is put on hold until the

programmed temperature is reached.

English List

3000

9999

5 sec 0–99

Yes No/Yes

Yes No/Yes

1–9999

Manual Override Activates the Special Function keys on the touch

pad. The operator can directly operate the water inlet,

drain, heating, and spin speed functions.

NOTE: It is not possible to manually direct the washer

to perform an unsafe sequence of functions.

Example: If there is no water in the drum, the

HEATING special function keypad can’t be activated.

*Automatic Cool Down

n To avoid mechanical temperature shock and to extend the life time of your washer, after a hot wash, cold water is injected bit

by bit. As a result at the end of the hot wash, the temperature will be lowered to about 65°C (150°F).

n The automatic cool down function will only be functional if a hot wash with a temperature above 65°C (150°F) has been

programmed and if a cold water inlet valve is programmed in the next step. When a Cool down sequence has been

programmed, the automatic cool down will not function.

n The automatic cool down differs from a normal cool down sequence. The purpose of a normal cool down sequence is to

avoid the shrinking of the garments. (Takes more time).

Yes No/Yes

18

Page 19

Initialization Menu Selections and Defaults (continued)

Menu Item Description Default Range

Temperature Balance Temperature balance, controls water temperature

by regulating the cold and hot water valves. (Some

wash temperatures may require additional heat.)

Motor On Time Normal wash action, drum turns for 12 seconds.

Recommended 3 sec for Gentle wash action.

(= suggested values for the Program Menu)

Motor Off Time Drum is stopped for 3 seconds for normal action.

12 sec recommended for Gentle wash action.

Smart Motion This option decreases the drum RPM during water

lling; therefore, the laundry absorbs water more

quickly and washing efciency increases.

Hot Water Heater Temp. The water heater temperature should be the same

as the temperature of the hot water supply.

Temp. Overshoot Prot. This is the % below the target temperature heat is

switched off to avoid overshoot. Heating will begin

after 30 seconds if the target temperature is not

reached.

Max. Heating Time Generates an error message if the target water

temperature is not reached within the Maximum

Heating time (Err 14).

If 99 is entered, no error message will display.

The washer will continue heating until the target

water temperature is reached.

Max. Water Fill Time Generates an error message if the target water level

is not reached within the Max. Water Fill Time (Err 11).

If 99 is entered, no error message will display. The

washer will continue lling until the target water level

is reached.

Overll Detection An error message is generated if the water level

exceeds the programmed water level by more than

the programmed number of units (Err 12). If the

washer uses steam heating, the steam installation

should have adequate power to quickly heat the

water. Slow heating will raise the water level and

also cause increased energy and laundry product

consumption. Reduce the programmed water

temperature to the minimum level necessary to

achieve satisfactory results.

Yes No/Yes

12 sec 1–99 sec

3 sec 1–99 sec

Yes No/Yes

140°F

(60°C)

00 % 0–30 %

60 min 10–90 min

10 min 5–99 min

10 units 10–25 units

122–176°F

(50–80°C)

99

External Wait Control Liquid soap supply system:

Selection for a washer connected to a central liquid

soap supply system.

The central pump system is able to Pause the washer,

before continuing the wash process, until the central

pump system is free to pump the liquid soap supply

into the washer.

Heating, (for installations with limited power supply):

You can disable the heating system of the washer

with an external signal.

The heating will switch on again, and the wash

process will continue, as soon as the external signal

is switched off.

Main Water Pressure Front/Side Soap Dispenser washers only: The laundry

product containers may not fall during the water

intake sequence if the water pressure is too low. Set

to “Low” if the water pressure is weak or if the water

supply pressure decreases notably during delivery.

Exit Return to Main Menu

No No/Yes

High Low/High

19

Page 20

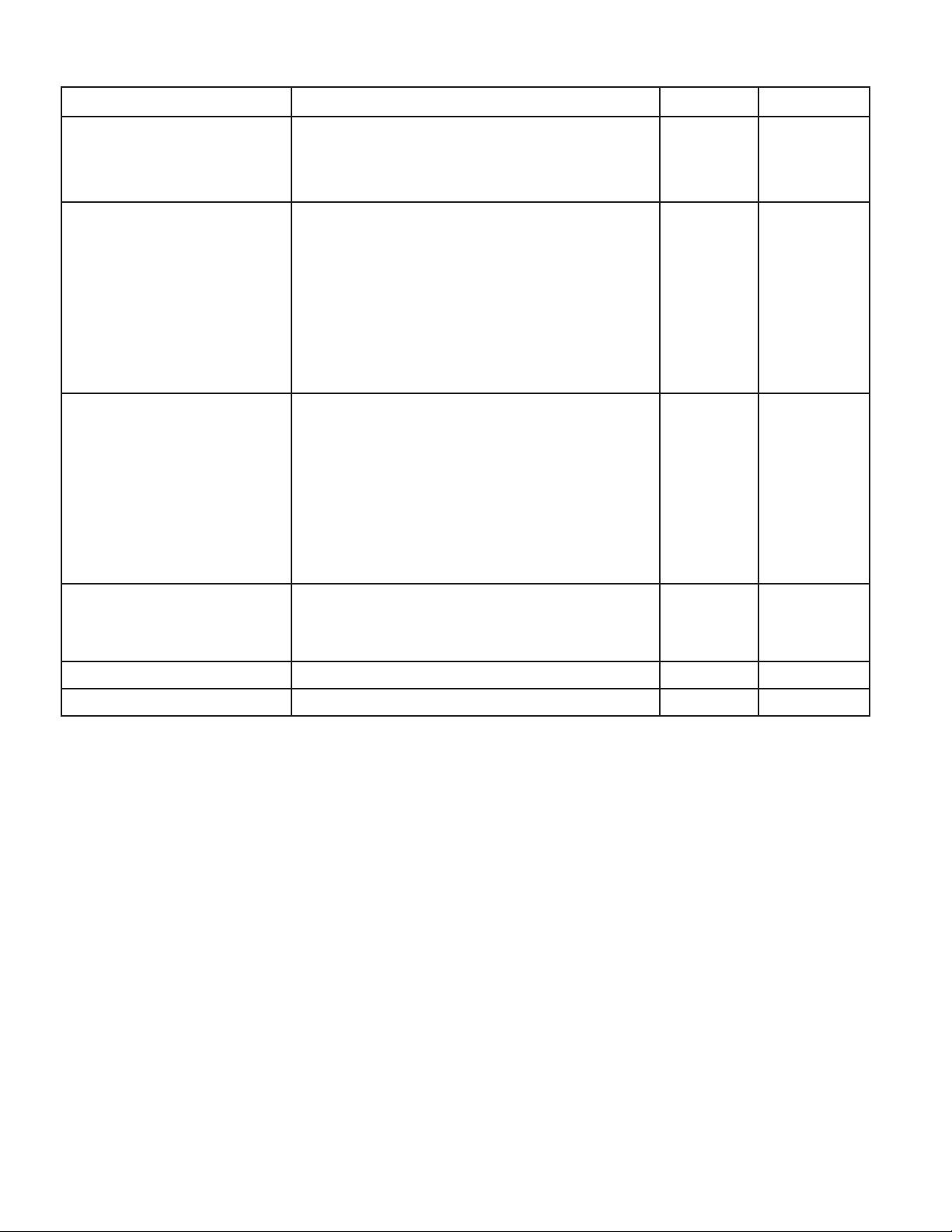

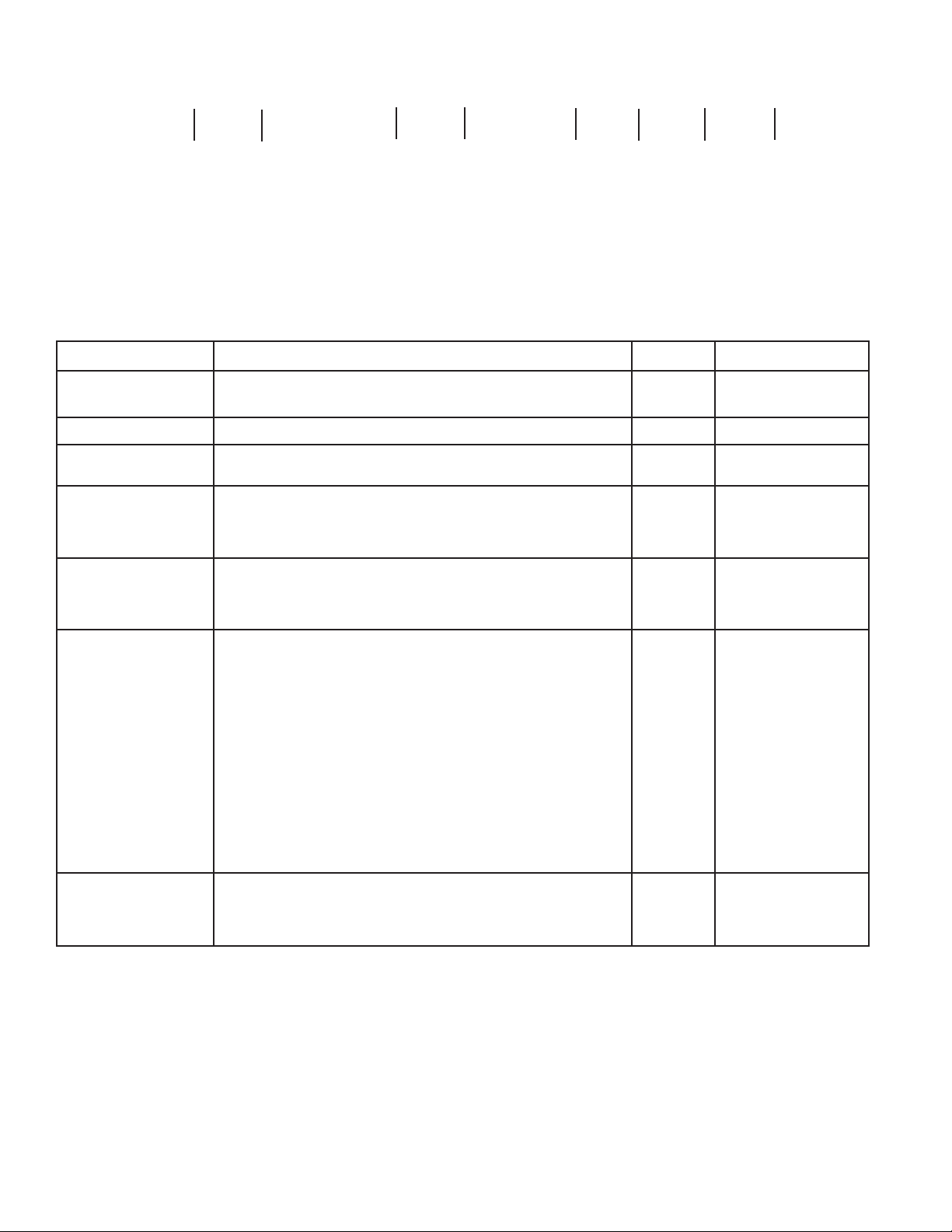

Edit Step

Menu

_

o

Select Step N

Add Step...

Edit Step...

Insert Step...

:

o

Select Step N

View Step . .

View Step...

Delete Step...

Step Menu Exit

Exit

4.

4.

4.

4.

No WashSpray

tu

tu

Flush

tu

Soak

tu

RPM _

RPM

C

o

Temp _

Drain Valve 1 tu

Supply A _”

Spray 1

Spray 2

On Time _ Sec

Off Time _ Sec

Time _ Min

Signal No

Inlet _

Level _

RPM _

Detergents Menu...

Time _ Min

Signal No

On Time _ Sec

Off Time _ Sec

Time _ Hour

Signal No

Drain

tu

Static Drain

5. 5.

tu

RPM

On Time _ Sec

Off Time _ Sec

Drain Valve 1 tu

Drain Valve 1 tu

Time _ Min

Time _ Min

Step Exit

Step Exit

Legend:

Select a new program Sub-menu and go to the next item: ENTER.

p Select the Menu item: Press UP or DOWN. qtu Select list: Press LEFT or RIGHT.

8

-- Insert a value or Select another List element.

or

Conrm a menu item and go to the next menu item: ENTER.

_

o

Program Menu

Select Program N

Name XXXX

View...

Edit...

New...

Copy...

Delete...

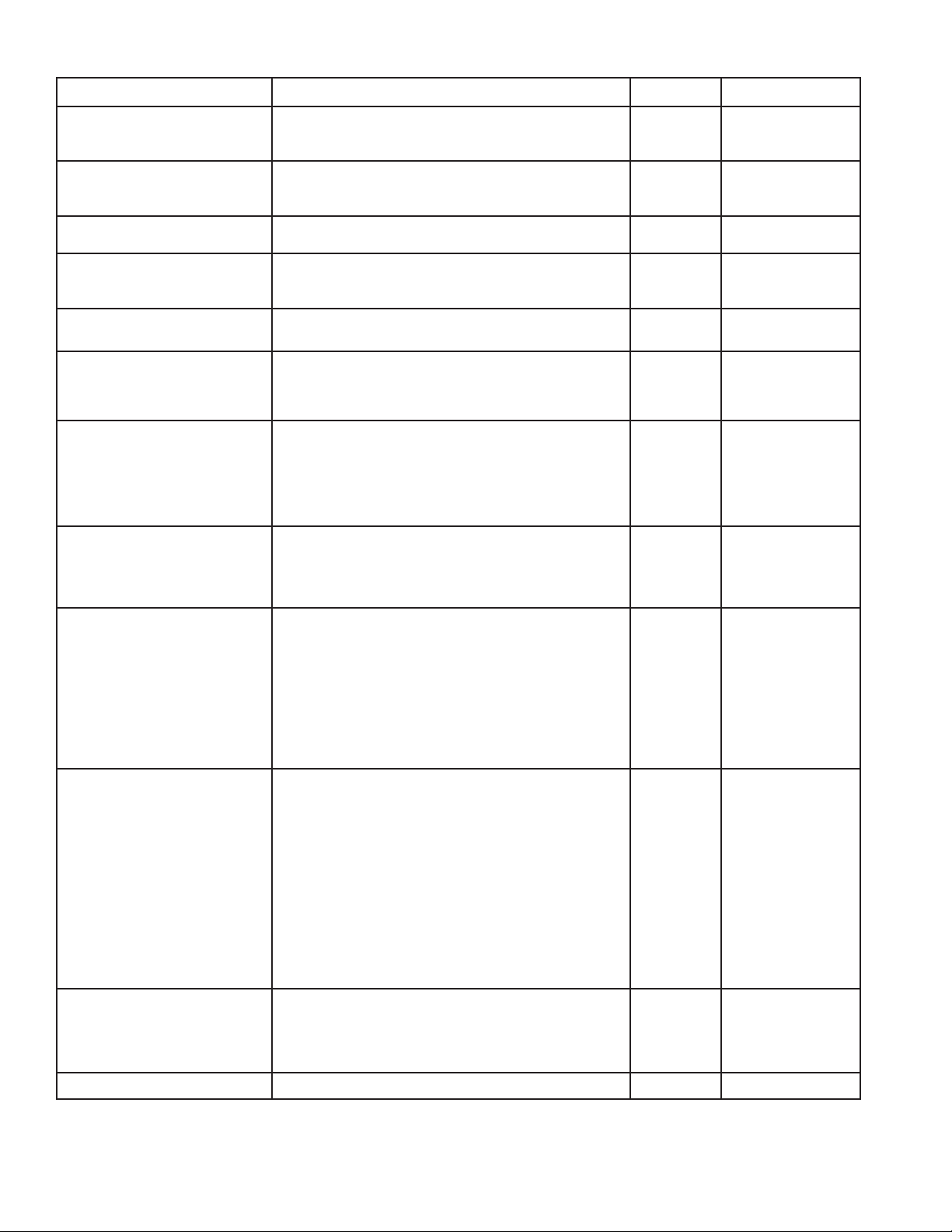

Wash Program Creation and Adjustment

2. 3.

Program Menu Exit

Program

Copy From

8

Final Rinse

Inlet _

Level _

RPM _

Detergents Menu...

On Time _ Sec

Off Time _ Sec

Time _ Min

4.

tu

Program Wash Part Step

Rinse

4.

tu

Cool Down

4.

tu

Wash

4.

tu

Inlet _

Level _

C

o

Temp _

RPM _

C

o

Temp _

Inlet _

RPM _

Drain Valve 1 tu

Level _

Detergents Menu...

On Time _ Sec

RPM _

Signal No

On Time _ Sec

Off Time _ Sec

Time _ Min

Signal No

Off Time _ Sec

Time _ Min

Signal No

Detergents Menu...

On Time _ Sec

Off Time _ Sec

Time _ Min

u

Signal No

No Drain

Step Exit

5.

tu

Program Drain Step

Spin

Drain Valve 1 tu

RPM _

Time _ Min

5.

tu

Drain

5.

Step Exit

Drain Valve 1 tu

Time _ Min

Step Exit

Keyswitch: Program

NOTE: Depending on the washer conguration and

initialization, some menu items will not be displayed.

20

Initialization Menu

Program Menu

Service Menu

1.

Diagnostic Menu

Conguration Menu

Pre Wash

4.

C

o

Temp _

Inlet _

Level _

RPM _

Detergents Menu...

On Time _ Sec

Off Time _ Sec

Time _ Min

Signal No

= Only for washers with Top Soap Dispenser

1. Select the Program Menu.

2. Enter the desired Program Number.

For a new program enter the program name.

Select Program View, Edit, Insert, New, Copy or Delete.

3. Select the appropriate Step Function: Add, Edit, Insert, View, or Delete.

Enter the desired Step Number.

4. Select the appropriate Wash Step Function.

Enter the appropriate Step Function settings.

5. Select the appropriate Drain Function.

Enter the appropriate Step Function settings.

Exit the Step Menu.

Page 21

CYCLE PROGRAMMING

Press the ENTER button to confirm your selection.

Go to

5.3. STEP : PROGRAM FUNCTIONS

Specic functions have been implemented in the Full Control

washer controller to allow for a detailed programming.

Functions for the Complete Program:

n Program Number: Select the wash program.

n Name: Insert or modify the name for the program.

n View: Inspect the program settings without making changes.

n Edit: Make changes to a program.

n New: Create a new program.

n Copy: Make a copy of an existing program.

n Delete: Erase a program.

n Exit: Leave the Program Menu.

Functions for the Program Steps:

n Step Number: Select the program step.

n Add: Add a program step at the end of the program.

n Edit: Adjust a program step.

n Insert: Add a program step between two other steps.

n View: Inspect the step settings without making changes.

n Delete: Delete a step.

n Exit: Leave the program step menu.

Follow the owchart on the proceeding page step-by-step.

Program Menu

Initialization allows you to choose standard default program

settings for your application.

1. Make sure power is ON and no program is running.

2. Enter PROGRAM MODE. The Main Menu will be displayed.

3. Press 5 or 6 to select the Program Menu.

Main Menu

Initialization Menu …

Program Menu … Configuration Menu …

Service Menu … Advanced Menu …

4. Press ENTER.

Program Functions

Program Menu

Select Program N°: 1

Name: HOT WASH

View … New … Delete …

Edit … Copy … Exit

Menu Item Description

Select Program N: Select program 1 to 99.

Name: _ _ _ _ _ _ _ _ _ The Program Name describes the

wash cycle. Press ENTER when the

cycle name is complete. Select the

Character with the 5 and 6 arrows.

Select the character position with

the 3 and 4 arrows.

View Allows you to see the Program

Settings without changing them.

Edit Allows you to change a program

by selecting new sequences from a

menu or by changing values in an

existing step. You can also add,

insert or delete sequences from

an existing program.

New To create a new program, you

have to make use of the add step

function. By adding steps the

program will grow step by step.

A conrmation is asked rst to

delete the old program.

Copy

HINT: To create a new program,

with minor changes from an existing

program, it is easier to copy an

existing program than to make

changes.

Insert the desired program number

Copy From

Program N°: XXX

from which you want to copy the

program.

The standard programs can be

selected at the program numbers

101–115.

Program number 101 corresponds

with program 1.

Program number 102 corresponds

with program 2.

Program number 115 corresponds

with program 15.

A conrmation is asked rst to

delete the old program.

Delete a Program To get rid of an existing program,

use the delete program function.

The complete program will be

erased at once.

A conrmation is asked rst to

delete the old program.

Exit Return to Main Menu

: Program Lock Symbol

In the Advanced Menu, it is possible to lock/unlock each wash

program individually. The wash program cannot be changed

when the Program Lock Symbol is displayed. Only the View

function will be operational, all others will be disabled until

unlocked.

21

Page 22

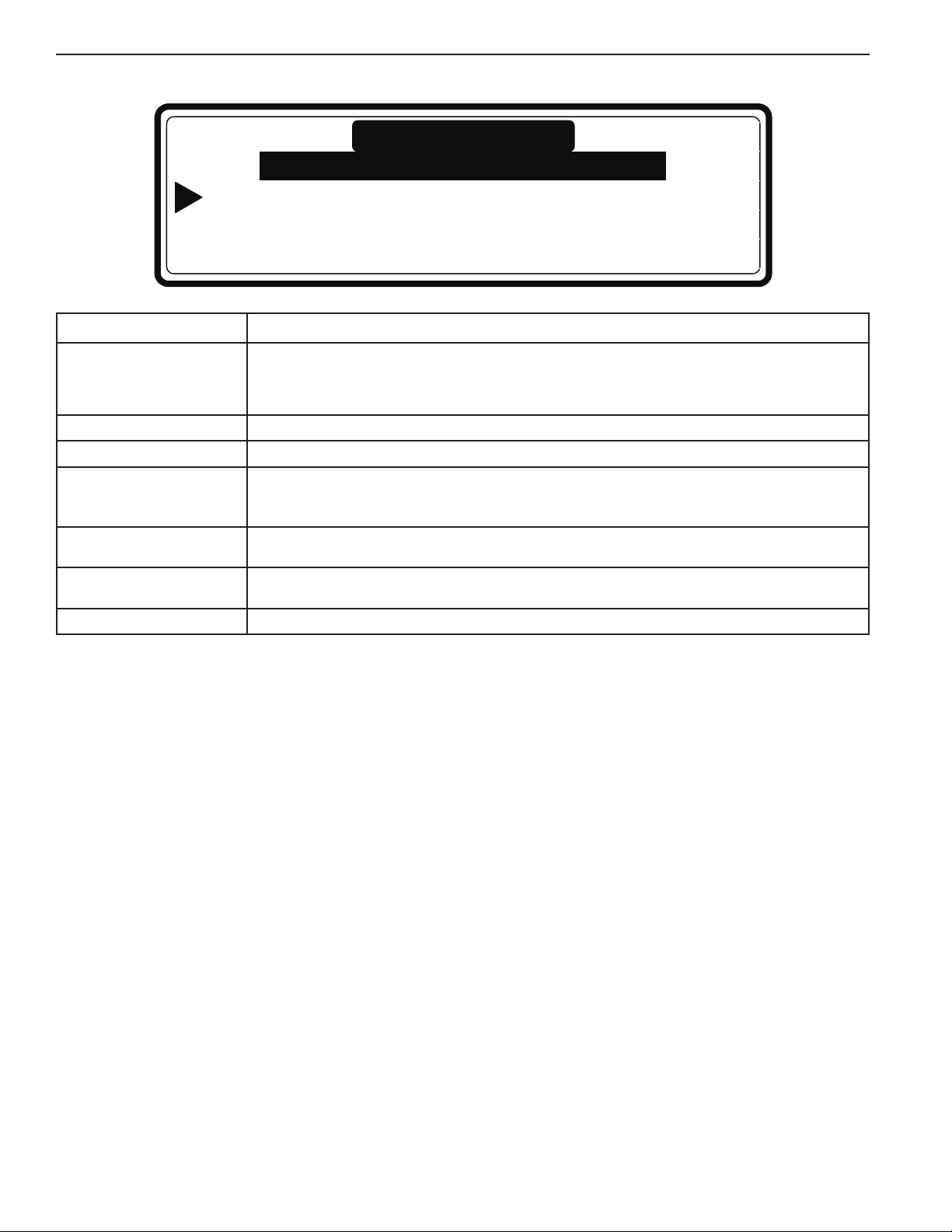

Program Step Function

5.4. STEP : PROGRAM STEP FUNCTION

Edit Step Menu

Program 1: Hot Wash

Select Step N°: 1

Add step … Insert Step … Delete Step …

Edit Step … View Step … Exit

Menu Item Description

Select Step N°: 1 Insert the desired step number.

Add Step To create new programs, a new extra step should be added at the end of the program.

Edit Step To change values and list elements from an existing step.

Insert Step A new step is inserted between two existing steps.

View Step Before making changes in a wash program, it is recommended to have a look at the actual

Delete Step An existing Step in the program disappears when it is deleted. A conrmation is asked

Exit Return to Program Menu

Step 1 to 99 can be selected.

If the number is not accepted, this means that the step is not available.

No Step number must be entered for “Add Step” function.

If the number is not accepted, this means there is no step with a step number that is equal to a

selected step number minus one. A new step can only be inserted between two available steps.

settings in the view function. No changes can be made in the View Step function.

before deleting the Old Step.

22

Page 23

Program the Wash Cycle

5.5. STEP : PROGRAMMING THE WASH PART

Program

Number

Prog 1

Original

Value

Wash

STEP

Wash

Spin part

Spin

Info

Action

Time: 8.0 Min

STEP 2

5

8.0 [4.0-20.0]

Step

Number

This section provides a detailed explanation about programming the Wash Sequences.

n Each program step contains a Wash segment and a Drain/Spin segment.

n First, the Wash segment must be selected; each item can be programmed.

n Next the Drain/Spin segment must be selected, each item can be programmed.

n Without making changes you can see item by item, by pressing ARROW DOWN or UP.

n If you want to make changes:

– Insert a new value.

– Enable or disable a setting by pressing YES or NO.

– Select a list element by pressing LEFT ARROW or RIGHT ARROW.

NOTE: You must press ENTER to conrm each selection.

n Default values were pre-programmed into each step to make programming easier.

See WASH PROGRAMS for a general explanation of creating wash programs.

n See each list element by using the LEFT ARROW or RIGHT ARROW symbols at the right side of the display.

n The arrow down symbol on the display points to the last Menu Item: EXIT.

Menu Value

Item

Menu Item

Limits

Menu Item

Position

Menu Item

23

Page 24

Selecting the wash cycle

If Add Step, Edit Step, or Insert Step, are selected,

choose the wash sequence now.

Depending on the machine type, with top or front soap

dispenser, you have more or less sequences available.

Selecting the wash cycle

If Add Step, Edit Step, or Insert Step, are selected, choose the

Prog XX

Step YY

Pre-Wash

Type: Pre-Wash

Extract

z

Wash Sequence now.

The number of available sequences depends on the Machine

Type and whether it is equipped with top or Front/Side Soap

Dispensers.

For Washers with Top Soap Dispenser:

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

For Washers with Front/Side Soap Dispenser:

Wash Cool Down Rinse Soak Flush Spray No Wash

For a new step, as a default, the rst displayed function is the Wash Sequence.

n Press LEFT ARROW or RIGHT ARROW to choose the desired sequence.

n Press ENTER to conrm.

n Use ARROW DOWN if you accept the pre-programmed default value.

24

Page 25

The Prewash Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

Only for washers with Top Soap Dispensers.

Menu Item Description Default Limits

Temperature The water temperature. 104°F

(40°C)

Inlet The suggested Inlet Valves are related to the temperature and

Level The suggested water level depends on the Machine Type. Normal

RPM The suggested RPM depends on the Machine Type. – See Table A-6

Detergents Menu...

Supply 1, ..., 8

On Time The wash action, motor On Time.

Off Time The wash action, motor Off Time.

Time The Prewash Sequence Time.

the Soap Box to be used.

If you insert other Inlet Valves than suggested, problems

can occur at the water ll process.

Time selection for external liquid soap supplies. You can

program up to 4 supplies at the same time, attempting

to program more than 4 supplies will generate an error

message. Only 4 non-zero supplies per step are accepted.

(Liquid soap supplies must be switched on at the Conguration

Menu.)

Gentle wash action: 3 seconds

(The suggested default values can be adjusted in the

Initialization Menu)

Gentle wash action: 12 seconds

(The suggested default values can be adjusted in the

Initialization Menu)

(for 0 minutes the Prewash sequence will be skipped

(programmable in steps of 0.5 minutes)

2–3 1–6

Low

0 sec 0–99 sec

12 sec 1–99 sec

3 sec 1–99 sec

4 min 0–99.5 min

33.8–113°F

(1–45°C)

See Table A-4

Signal When a signal is programmed, a pause will be introduced at

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

No No/Yes

25

Page 26

The Wash Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

Menu Item Description Default Limits

Temperature The water temperature. 140°F

(60°C)

Inlet (Top Soap

Dispenser)

(Front/Side Soap

Dispenser)

Level The suggested water level depends on the Machine Type. Normal

RPM The suggested RPM depends on the Machine Type. – See Table A-6

Detergents Menu. . .

Box A, B, C, D, E

Supply 1, ..., 8

On Time The wash action, motor On Time.

Off Time The wash action, motor Off Time.

Time The Wash Sequence Time.

Signal When a signal is programmed, a pause will be introduced

The suggested Inlet Valves are related to the temperature

and the Soap Box to be used.

NOTE: If you insert other Inlet Valves than the suggested

ones, problems can occur at the water ll process.

Time selection for Soap Boxes (hopper) and external liquid

soap supplies. You can program up to 4 supplies at the

same time, attempting to program more then 4 supplies

will generate an error message.

Reset the time of the supplies back to 0. Only 4 non-zero

times values can be programmed.

- Liquid soap supplies must be switched on in the

Conguration Menu.

- Box A, B, C, D, and E are only available on Front/Side Soap

Dispenser washers.

Gentle wash action: 3 seconds

(The suggested default values can be adjusted in the

Initialization Menu)

Gentle wash action: 12 seconds

(The suggested default values can be adjusted in the

Initialization Menu)

(for 0 minutes the Wash Sequence will be skipped)

(programmable in steps of 0.5 minutes)

at the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

3, 4, 5

2, 3

Low

0 sec

0 sec

12 sec 1–99 sec

3 sec 1–99 sec

7 min 0–99.5 min

No No/Yes

33.8–197.6°F

(1–92°C)

1–6

1–3

See Table A-4

0–9 sec

26

Page 27

The Cool Down Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

n After a hot wash you can program a Cool Down Sequence to avoid temperature shock and shrinking

of the garments.

n The drain step after the hot wash must be put on NO DRAIN.

n No inlets are programmable:

– For Top Soap Dispenser washers: inlet 6 is the standard inlet.

– For Front/Side Soap Dispenser washers: inlet 2 is the standard inlet.

n The water level cannot be programmed as the process of adding and draining water does not allow this.

IMPORTANT: Do not program a drain sequence before a cool down sequence.

Menu Item Description Default Limits

Temperature The water temperature 140°F

(60°C)

RPM The suggested RPM depends on the Machine Type. –

Drain Valve Only available on washers with both a normal Open and

normal Closed Drain valve.

On Time The wash action, motor On Time.

Gentle wash action: 3 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

Off Time The wash action, motor Off Time.

Gentle wash action: 12 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

Time The programmed time = time needed to decrease the

water temperature.

Once the programmed temperature has been reached,

the next Sequence will be started.

(for 0 minutes the Cool Down sequence will be skipped)

(programmable in steps of 0.5 minutes)

IMPORTANT: If a short time is programmed, the water

temperature will decrease fast.

Recommendation: Program 1 minute for each 37.4°F (3°C)

temperature drop.

Example: For a hot wash of 194°F (90°C) and a Cool Down

Sequence of 140°F (60°C) a time of about 86°F (30°C)/37.4°F

(3°C) = 10 minutes should be programmed for the Cool Down

Sequence.

1 1–2

12 sec 1–99 sec

3 sec 1–99 sec

7 min 0–99.5 sec

33.8–140°F

(1–60°C)

Signal When a signal is programmed, a pause will be introduced at

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

No No/Yes

27

Page 28

The Rinse Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

n No temperature can be programmed because a Rinse is only possible with cold water.

Menu Item Description Default Limits

Inlet (Top Soap

Dispenser)

(Front/Side Soap

Dispenser)

Level The suggested water level depends on the Machine Type. Normal

RPM The suggested RPM depends on the Machine Type. – See Table A-6

Detergents Menu…

Box A, B, C, D, E

Supply 1, …, 8

On Time The wash action, motor On Time.

3 Inlets can be programmed.

The suggested Inlet Valves are related to the

temperature and the Soap Box to be used.

IMPORTANT: If you insert other Inlet Valves than the

suggested ones, problems can occur at the water ll

process.

Time selection for Soap Boxes (hopper) and external liquid

soap supplies.

You can program up to 4 supplies at the same time. If you

have programmed more then 4 supplies an error message

will be generated.

Reset the time of the supplies back to 0. Only 4 non-zero

times values can be programmed.

– Liquid soap supplies must be switched on in the

Conguration Menu.

– Box A, B, C, D, and E are only available on Front/Side

Soap Dispenser washers.

Gentle wash action: 3 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

2, 5, 6

2

High

0 sec

0 sec

12 sec 1–99 sec

1, 2, 5, 6

1, 2

See Table A-4

0–99 sec

Off Time The wash action, motor Off Time.

Gentle wash action: 12 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

Time The Rinse Sequence Time.

(for 0 minutes the Rinse sequence will be skipped)

(programmable in steps of 0.5 minutes)

Signal When a signal is programmed, a pause will be introduced at

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

3 sec 0–99 sec

2 min 0–99.5 min

No No/Yes

28

Page 29

The Final Rinse Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

n Only for top dispenser washers.

n No temperature can be programmed because a Final Rinse is only possible with cold water.

Menu Item Description Default Limits

Inlet (Top Soap

Dispenser)

Level The suggested water level depends on the Machine Type. Normal

RPM The suggested RPM depends on the Machine Type. – See Table A-6

Detergents Menu…

Supply 1, …, 8

On Time The wash action, motor On Time.

Off Time The wash action, motor Off Time.

3 Inlets can be programmed.

The suggested Inlet Valves are related to the temperature

and the Soap Box to be used.

IMPORTANT: If you insert other Inlet Valves than the

suggested ones, problems can occur at the water ll

process.

Time selection for external liquid soap supplies.

You can program up to 4 supplies at the same time. If you

have programmed more then 4 supplies an error message

will be generated.

Reset the time of the supplies back to 0. Only 4 non-zero

times values can be programmed.

– Liquid soap supplies must be switched on in the

Conguration Menu.

Gentle wash action: 3 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

Gentle wash action: 12 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

1

1, 6

High

0 sec

0 sec

12 sec 1–99 sec

3 sec 0–99 sec

1, 2, 5, 6

See Table A-4

0–99 sec

Time The Final Rinse Sequence Time.

(for 0 minutes the Final Rinse sequence will be skipped)

(programmable in steps of 0.5 minutes)

Signal When a signal is programmed, a pause will be introduced at

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

2 min 0–99.5 min

No No/Yes

29

Page 30

The Soak Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

Menu Item Description Default Limits

Temperature The water temperature 104°F

Inlet

(Top Soap Dispenser)

(Front/Side Soap

Dispenser)

Level The suggested water level depends on the Machine Type. Normal

RPM The suggested RPM depends on the Machine Type. – See Table A-6

Detergents Menu…

Box A, B, C, D, E

Supply 1, …, 8

On Time The wash action, motor On Time.

Off Time The wash action, motor Off Time.

Time The Soak Sequence Time.

Signal When a signal is programmed, a pause will be introduced at

The suggested Inlet Valves are related to the

temperature and the Soap Box to be used.

IMPORTANT: If you insert other Inlet Valves than the

suggested ones, problems can occur at the water ll

process.

Time selection for Soap Boxes (hopper) and external

liquid soap supplies.

You can program up to 4 supplies at the same time.

If you have programmed more then 4 supplies an error

message will be generated.

Reset the time of the supplies back to 0. Only 4 non-zero

times values can be programmed.

– Liquid soap supplies must be switched on in the

Conguration Menu.

– Box A, B, C, D, and E are only available on Front/Side

Soap Dispenser washers.

(The suggested default values can be adjusted at the

Initialization Menu)

(The suggested default values can be adjusted at the

Initialization Menu)

(for 0 minutes the Soak Sequence will be skipped)

(programmable in steps of 0.5 minutes)

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

(40°C)

2, 3

2, 3

Low

0 sec

0 sec

12 sec 1–99 sec

10 min 1–99 min

1 hour 0–25.5 hour

No No/Yes

33.8–113°F

(1–45°C)

1–6

1, 2, 3

See Table A-4

0–99 sec

30

Page 31

The Flush Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

Only for Top Soap Dispenser washers.

n No water level can be programmed as the water will raise and escape by the overow hole.

n No water inlets can be programmed as only cold water from water inlet 6 is used.

n No supplies can be programmed.

Menu Item Description Default Limits

RPM The suggested RPM depends on the Machine Type. – See Table A-6

On Time The wash action, motor On Time.

Gentle wash action: 3 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

Off Time The wash action, motor Off Time.

Gentle wash action: 12 sec.

(The suggested default values can be adjusted in the

Initialization Menu)

Time The Flush Sequence Time.

(for 0 minutes the Flush sequence will be skipped)

(programmable in steps of 0.5 minutes)

Signal When a signal is programmed, a pause will be introduced at

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

12 sec 1–99 sec

3 sec 1–99 min

10 min 0–99.5 min

No No/Yes

31

Page 32

The Spray Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

n Water or Liquid is injected at Distribution or Low Spin Speed

n No standard water inlets can be programmed in this function.

n The liquid will be injected based on soap supply programming.

Menu Item Description Default Limits

RPM The suggested RPM depends on the Machine Type. – See Table A-6

Drain Valve Only available on washers with both:

Detergents Menu…

Box A, B, C, D, E

Supply 1, …, 8

Signal When a signal is programmed, a pause will be introduced at

a normal Open and normal Closed Drain valve.

Time selection for Soap Boxes (hopper) and external

liquid soap supplies.

You can program up to 4 supplies at the same time.

If you have programmed more then 4 supplies an error

message will be generated.

Reset the time of the supplies back to 0. Only 4 non-zero

times values can be programmed.

– Liquid soap supplies must be switched on in the

Conguration Menu.

– Box A, B, C, D, and E are only available on Front/Side

Soap Dispenser washers.

the end of the Wash Step. This allows the operator to add

soap for the next step. A buzzer signal warns the operator

that the cycle has been interrupted.

No Wash Sequence

Prewash Wash Cool Down Rinse Final Rinse Soak Flush Spray No Wash

1 1–2

0–99 sec

0 sec

0 sec

No No/Yes

In case of a No Wash Sequence, the wash function of the programmed step is skipped.

32

Page 33

Program the Drain Step

A Drain/Extraction step is required after each wash step.

NOTE: You do not need to program a drain sequence before an

extraction sequence because the water will automatically drain

during the extraction sequence.

SELECTING THE DRAIN/EXTRACTION STEP

The number of drain functions and options depends on

the Machine Type.

n For a new step, the rst sequence that is displayed is the

Drain sequence (default).

n Select the desired Drain step sequence from the list by

pressing LEFT ARROW or RIGHT ARROW.

n Press ENTER to conrm your selection.

n You can also use ARROW DOWN if you

accept the pre-programmed default value.

Prog XX

Step YY

Wash

Type: Drain

Drain

z

Drain Sequence

Drain Extract No Drain Static Drain Reversing Drain

Menu Item Description Default Limits

Drain Valve Only available on washers with both a normal Open and

normal Closed Drain valve.

Time The Drain Sequence Time.

(for 0 minutes the Drain sequence will be skipped)

(programmable in steps of 0.5 minutes)

Exit Return to Edit Program Menu.

1 1–2

0.5 min 0–9.5 min

33

Page 34

The Extract Sequence

Drain Extract No Drain Static Drain Reversing Drain

Menu Item Description Default Limits

Drain Valve Only available on washers with both a normal Open and

normal Closed Drain valve.

RPM The suggested RPM depends on the Machine Type. See Table A-6

Time The Extract Sequence Time.

(for 0 minutes the Extract sequence will be skipped)

(programmable in steps of 0.5 minutes)

Exit Return to Edit Program Menu.

1 1–2

4.5 min 0–9.5 min

The No Drain Sequence

Drain Extract No Drain Static Drain Reversing Drain

• The Drain/Extraction part of the programmed step is skipped.

IMPORTANT: For some specic functions “No Drain” must be programmed.

Example: If you want to program a Cool Down Sequence, then “No Drain” must be programmed between the Hot Wash and the

Cool Down Sequence.

Menu Item Description Default Limits

Exit Return to Edit Program Menu.

Static Drain Sequence

Drain Extract No Drain Static Drain Reversing Drain

The drum is at standstill while the water is drained.