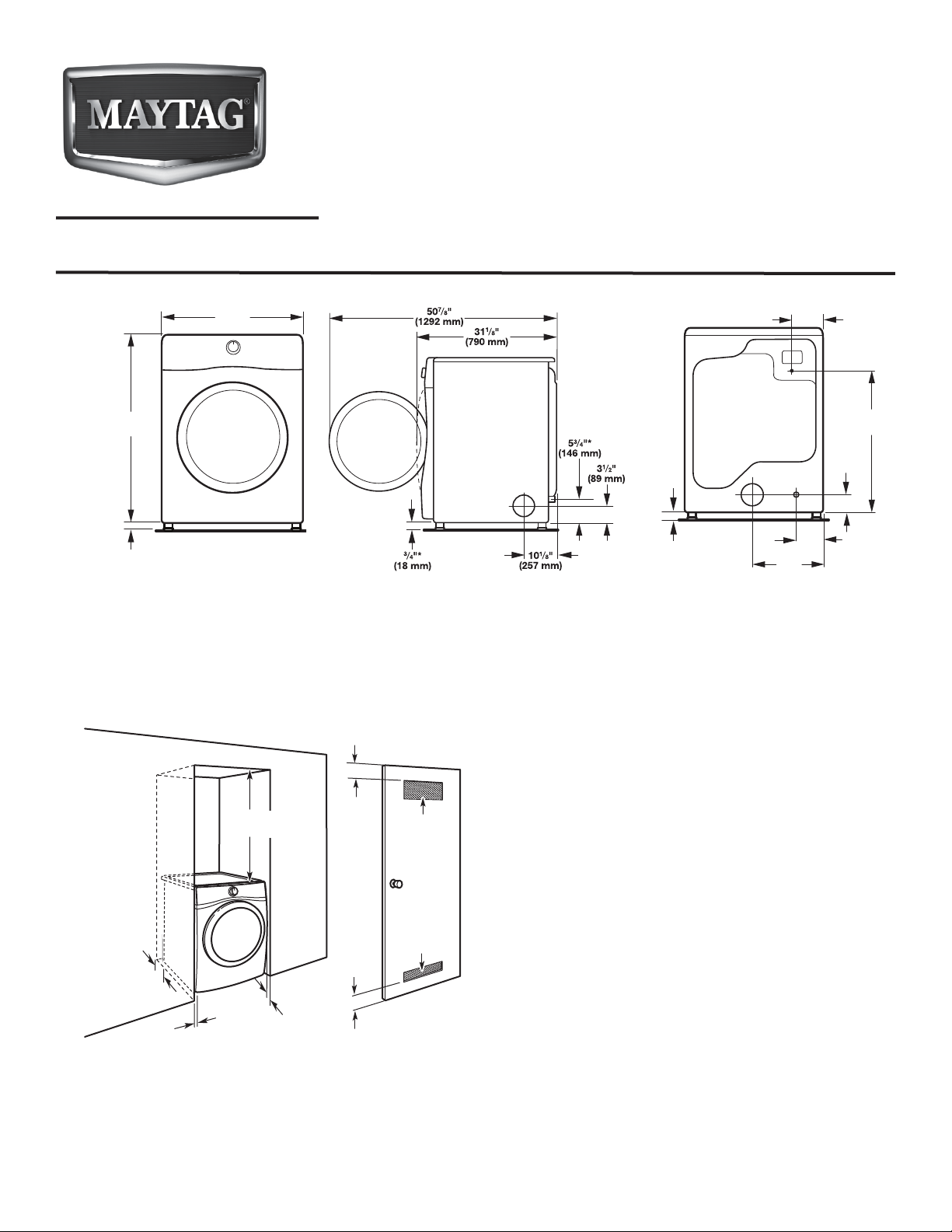

Maytag MED7000XW Dimension Guide

PRODUCT MODEL NUMBERS

(759 mm)

MED6000X, MED7000X, MED9000Y

Front view: Side view: Back view:

27"

(686 mm)

Electric Dryer

61/2"

(165 mm)

1

/8"

38

(968 mm)

3

/4"*

(18 mm)

NOTE: Most installations require a minimum of 5" (127 mm)

clearance behind dryer for exhaust vent with elbow. See

“Venting Requirements.”

Recommended Installation Spacing (Dryer Only):

3"

(76 mm)

3"

(76 mm)

48 in.2 min.

(310 cm

24 in.2 min.

(155 cm2)

5"

(127 mm)

18" min.

(457 mm)

1"

(25 mm)

1"

(25 mm)

3

/4"*

(18 mm)

Installation spacing for recessed area

or closet installation

All dimensions show recommended and minimum spacing

allowed.

■ Additional spacing should be considered for ease of

2

)

installation and servicing.

■ Additional clearances might be required for wall, door, oor

moldings, and dryer venting.

■ Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

3

14

/8"

(365 mm)

31/2"*

(89 mm)

1

6

(156 mm)

/8"*

7

29

/8"*

ELECTRICAL REQUIREMENTS

To supply the required 3 or 4 wire, single phase, 120/240 volt, 60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt electrical

supply, if specied on the serial/rating plate) on a separate 30-amp circuit, fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended. Connect to an individual branch circuit.

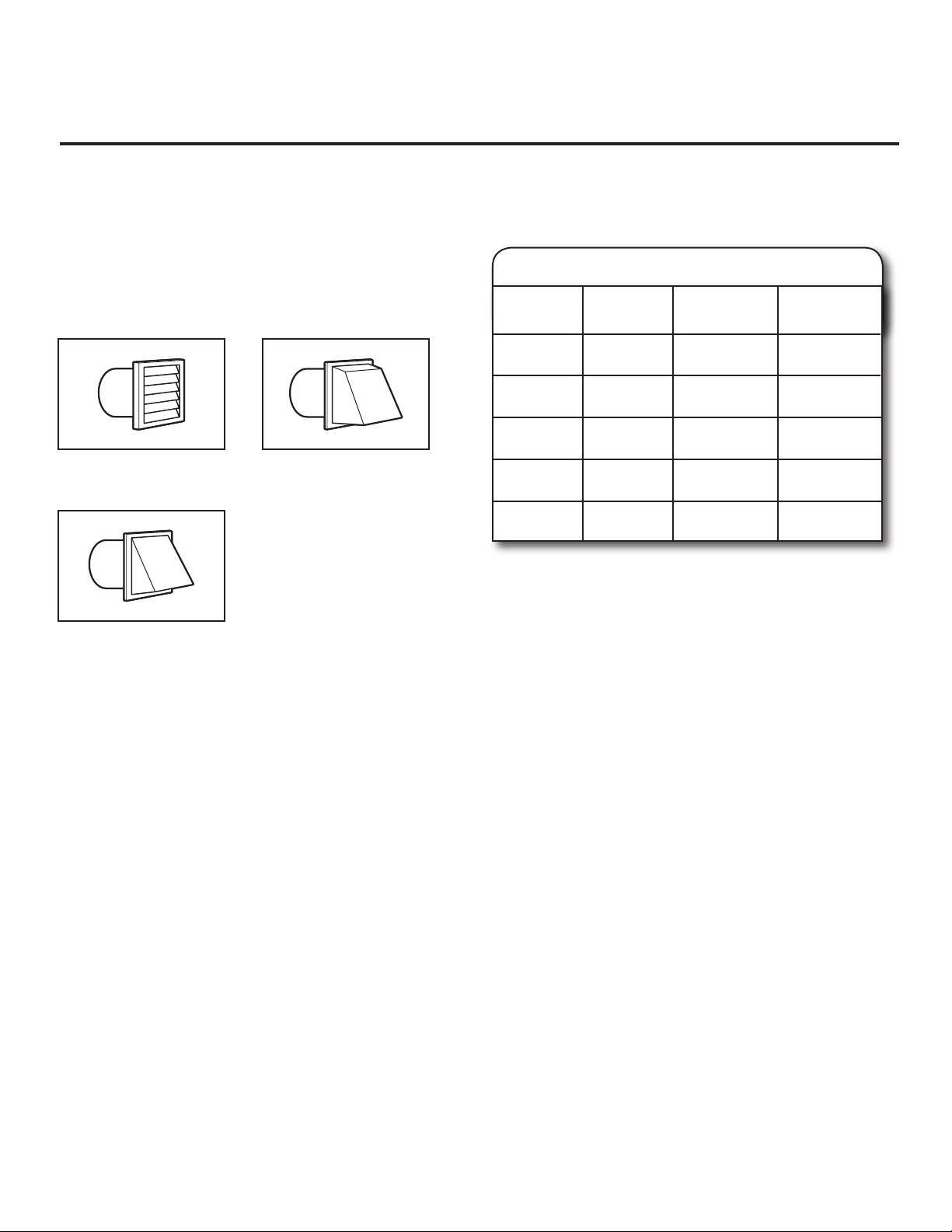

VENTING REQUIREMENTS

Exhaust venting: Exhaust your dryer to the outside. 4" (102 mm)

diameter vent is required. Rigid or exible metal exhaust vent

must be used. Do not use plastic or metal foil vet. Exhaust hood

must be at least 12" (305 mm) from the ground or any object that

may be in the path of the exhaust.

The Vent System Chart provides venting requirements that will

help achieve best drying performance.

Vent System Chart

Exhaust hoods:

Recommended Styles:

Louvered Hood

Box Hood

Acceptable Style:

Angled Hood

Determine vent path:

■ Select route that will provide straightest and most direct

path outdoors.

■ Plan installation to use fewest number of elbows and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use as few 90° turns as possible.

Number of

90° elbows

0

1

2

3

4

NOTE: Bottom exhaust installations have a 90º turn inside the

dryer. To determine maximum exhaust length, add one 90º turn

to the chart.

Type

of vent

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Box/louvered

hoods

64 ft. (20 m)

54 ft. (16.5 m)

44 ft. (13.4 m)

35 ft. (10.7 m)

27 ft. (8.2 m)

Angled

hoods

58 ft. (17.7 m)

48 ft. (14.6 m)

38 ft. (11.6 m)

29 ft. (8.8 m)

21 ft. (6.4 m)

Determine vent length and elbows needed for best

drying performance:

■ Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specied

in Vent System Chart. Exhaust systems longer than those

specied will:

■ Shorten life of dryer.

■ Reduce performance, resulting in longer drying times

and increased energy usage.

Because Whirlpool Corporation policy includes a continuous commitment to improve Dimensions are for planning purposes only. For complete details, see Installation

our products, we reserve the right to change materials and specications without notice. Instructions packed with product. Specications subject to change without notice.

W10423118A

09/2011

Loading...

Loading...