Maytag MED6630HW, WED8620HC, WED560LHW, WED8620HW, WED6620HC Owners Manual

...

ELECTRIC DRYER OWNER’S MANUAL

GUIDE D’UTILISATION DE LA SÉCHEUSE ÉLECTRIQUE

Table of Contents

Dryer Safety

Dryer Safety

Dryer Maintenance and Care

Cleaning the Dryer Location

Cleaning the Dryer Interior

Removing Accumulated Lint

Cleaning the Lint Screen.............. ....................... 5

Changing the Drum Light (on some models).........6

Check Your Vent System for Good Airflow

Maintain Good Airflow

Nonuse, Storage, and Moving Care

Special Instructions for Steam Models

Installation Instructions

Requirements............................................. ............7

Tools and Parts

Location Requirements....................................... 8

Electrical Requirements – U.S.A.......................... 9

Electric Requirements – Canada ....................... 10

Installation

Install Leveling Legs

Electrical Installation – U.S.A.

Venting Requirements

Plan Vent System

Install Vent System..................... ...................... 19

Connect Inlet Hoses ......................................... 19

Connect Vent (Vented Models Only)

Level Dryer ...................................................... 21

Complete Installation Checklist.......................... 21

......................................................... ..2

.......................................................2

..................................5

................................5

..................................5

................................5

............ 6

......................................... 6

.....................6

.................7

..........................................7

..................................................7

....................................................... .... 11

......................................... 11

............................ 11

...................................... 17

............................................. 17

.................. 20

Table des matières

Sécurité de la sécheuse .. ..................................... 22

Sécurité de la sécheuse

Entretien et réparation de la sécheuse ................. 25

Nettoyage de l’emplacement de la

sécheuse

Nettoyage de l’intérieur de la sécheuse.............. 25

Retrait de la charpie accumulée ........................ 25

Nettoyage du filtre à charpie.............................. 25

Changement de l’ampoule d’éclairage du

tambour (sur certains modèles)

Vérification d’une circulation d’air adéquate

pour le système d’évacuation

Pour maintenir une bonne circulation d’air .......... 26

Précautions à prendre lorsque l’appareil

n’est pas utilisé, est entreposé ou

déménagé

Instructions spécifiques pour les modèles

vapeur

Instructions d’installation

Spécifications

Outils et pièces ..... ........................................... 28

Exigences d’emplacement ................................ 29

Spécifications électriques – É.-U. ...................... 30

Spécifications électriques – Canada .................. 31

L’installation

Installation des pieds de nivellement.................. 32

Installation Électrique - U.S.A ............................ 32

Exigences concernant l'évacuation

Planification des circuits de conduits

Installation du conduit d’évacuation

Raccordement des tuyaux d’alimentation

Raccorder le conduit d’évacuation (sur les

modèles avec conduit seulement)

Réglage de l’aplomb de la sécheuse.......... ........ 43

Liste de vérification pour installation

terminée

......................................................... 25

....................................................... 27

............................................................. 27

...................................................... 28

....................................................... .. 32

......................................................... . 43

.................................... 22

......................... 26

............................ 26

..................................... 28

.................... 38

.................. 39

................... 41

........... 41

...................... 42

W11364660A

W11364661A-SP

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These

words mean:

You can be killed or seriously injured if you don't

DANGER

immediately follow instructions.

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

You can be killed or seriously injured if you don’t follow

instructions.

WARNING — “Risk of Fire”

− Clothes dryer installation must be performed by a qualified installer.

− Install the clothes dryer according to the manufacturer's instructions and local codes.

− Do not install a clothes dryer with flexible plastic venting materials or flexible metal (foil

type) duct. If flexible metal duct is installed, it must be of a specific type identified by the

appliance manufacturer as suitable for use with clothes dryers. Flexible venting materials

are known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

− To reduce the risk of severe injury or death, follow all installation instructions.

− Save these instructions.

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic precautions,

including the following:

n Read all instructions before using the appliance.

n Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-cleaning

solvents, or other flammable or explosive substances, as

they give off vapors that could ignite or explode.

n Do not allow children to play on or in the appliance. Close

supervision of children is necessary when the appliance is

used near children.

n Before the appliance is removed from service or discarded,

remove the door to the drying compartment.

n Do not reach into the appliance if the drum is moving.

n Do not install or store this appliance where it will be

exposed to the weather.

n Do not tamper with controls.

n Do not repair or replace any part of the appliance or attempt

any servicing unless specifically recommended in the usermaintenance instructions or in published user-repair

instructions that you understand and have the skills to carry

out.

n Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

n Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

n Clean lint screen before or after each load.

n Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

n The interior of the appliance and exhaust duct should be

cleaned periodically by qualified service personnel.

n Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch fire. To

reduce the risk of fire due to contaminated loads, the final

part of a tumble dryer cycle occurs without heat (cool down

period). Avoid stopping a tumble dryer before the end of the

drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated.

n Do not use replacement parts that have not been

recommended by the manufacturer (e.g. parts made at

home using a 3D printer).

n See the Installation Instructions for grounding requirements

and installation.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WHEN DISCARDING OR STORING YOUR OLD CLOTHES DRYER, REMOVE THE DOOR.

SAVE THESE INSTRUCTIONS

3

Internet Connectivity Guide for Connected Appliances Only

IMPORTANT: Proper installation of your appliance prior to use is your responsibility. Be sure to read and follow the installation

instructions that came with your appliance.

Connectivity requires Wi-Fi and account creation. App features and functionality are subject to change. Data rates may apply. Once

installed, launch the app. You will be guided through the steps to set up a user account and to connect your appliance.

You Will Need:

n A home wireless router supporting Wi-Fi, 2.4Ghz with WPA2 security. If you are unsure of your router’s capabilities, refer to the router

manufacturer’s instructions.

n The router to be on and have a live internet connection.

n The 10–character SAID code for your appliance. The SAID code is either printed on a label on the appliance or found on the LCD

screen.

Federal Communications Commission (FCC) Compliance Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

Industry Canada (IC) Compliance Notice

This Device complies with Industry Canada License-exempt RSS standard(s). Operation is subject to the following two conditions:

1. This device may not cause interference.

2. This device must accept any interference, including interference that may cause undesired operation of the device.

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain

should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful

communication.

To comply with FCC and Industry Canada RF radiation exposure limits for general population, antenna(s) used for this transmitter must

be installed such that a minimum separation distance of 20 cm is maintained between the radiator (antenna) and all persons at all times

and must not be co-located or operating in conjunction with any other antenna or transmitter.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one of the following measures:

n Reorient or relocate the receiving antenna.

n Increase the separation between the equipment and receiver.

n Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

n Consult the dealer or an experienced radio/TV technician for help.

4

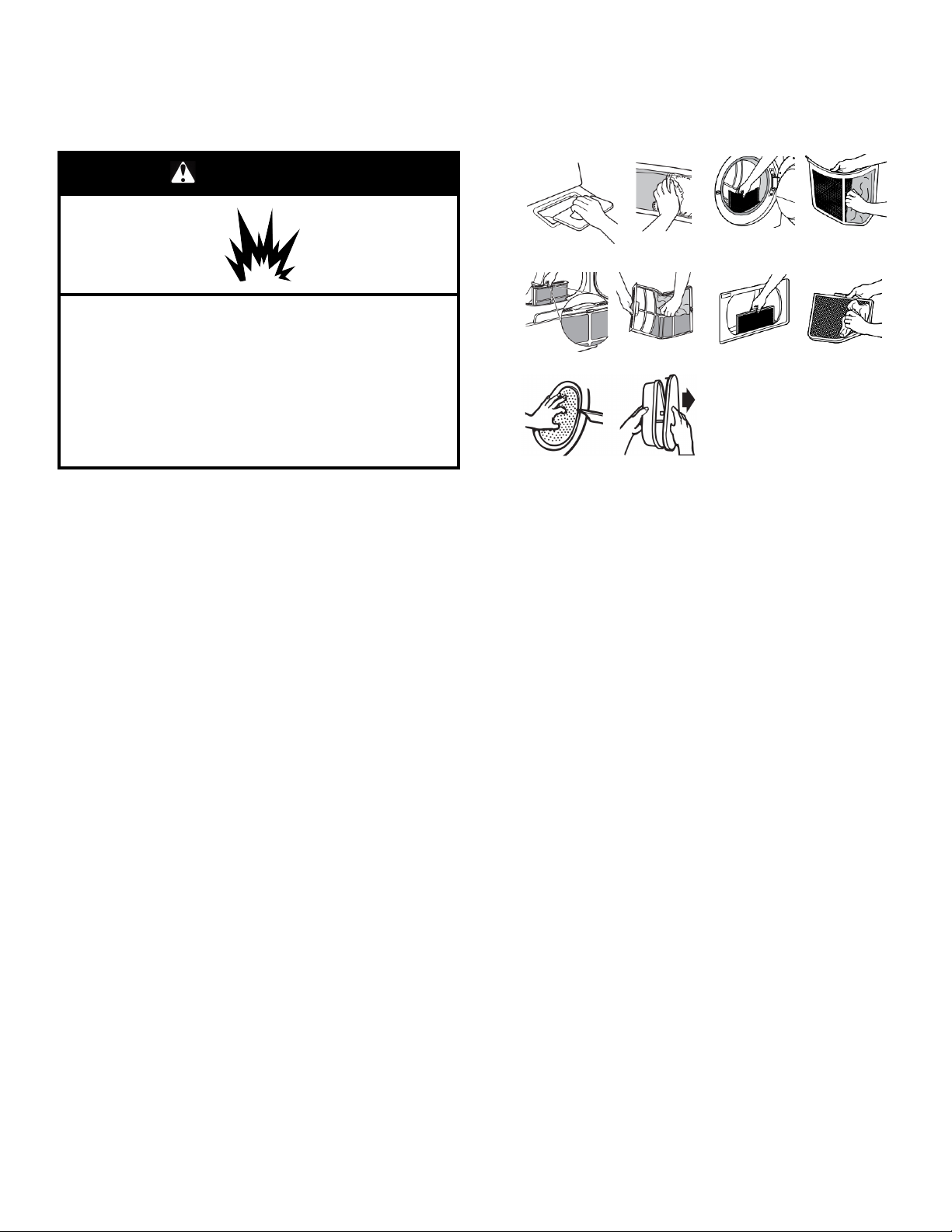

DRYER MAINTENANCE AND CARE

Cleaning the Dryer Location

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Place dryer at least 18 inches (460 mm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

Keep dryer area clear and free from items that would block the

airflow for proper dryer operation. This includes clearing piles of

laundry in front of the dryer.

Cleaning the Dryer Interior

To clean dryer drum:

1. Use nonflammable cleaner or a mild hand dish detergent

mixed at a low concentration with very warm water, and rub

with a soft cloth.

n Rinse well with a wet sponge or towel.

n Tumble a load of clean clothes or towels to dry drum.

OR

2. Use a microfiber cloth and hot water in a spray bottle to clean

the drum and a second microfiber towel to dry.

NOTE: Garments that contain unstable dyes, such as denim blue

jeans or brightly colored cotton items, may discolor the rear of the

dryer interior. These stains are not harmful to your dryer and will

not stain future loads of clothes. Dry unstable dye items inside out

to avoid transfer of dye.

Removing Accumulated Lint

From inside the dryer cabinet:

Lint should be removed every 2 years, or more often, depending

on dryer usage. Cleaning should be done by a qualified appliance

service or ventilation system cleaner.

From the exhaust vent:

Lint should be removed every 2 years, or more often, depending

on dryer usage.

To clean:

1. Remove the lint screen. If necessary, press the tab to release

and open the lint screen. Roll lint off the screen with your

fingers. Do not rinse or wash screen to remove lint. Wet lint is

hard to remove.

2. Push the lint screen firmly back into place.

IMPORTANT:

n Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

n If lint falls off the screen into the dryer during removal, check

the exhaust hood and remove the lint. See “Venting

Requirements” in the Installation Instructions.

n Clean space where lint screen is located, as needed. Using a

vacuum, gently remove any lint that has accumulated outside

of the lint screen.

As-needed cleaning:

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off while the screen

is in the dryer. Clean the lint screen with a nylon brush every 6

months, or more frequently, if it becomes clogged due to a residue

buildup.

To wash:

1. Roll lint off the screen with your fingers.

2. Wet both sides of lint screen with hot water.

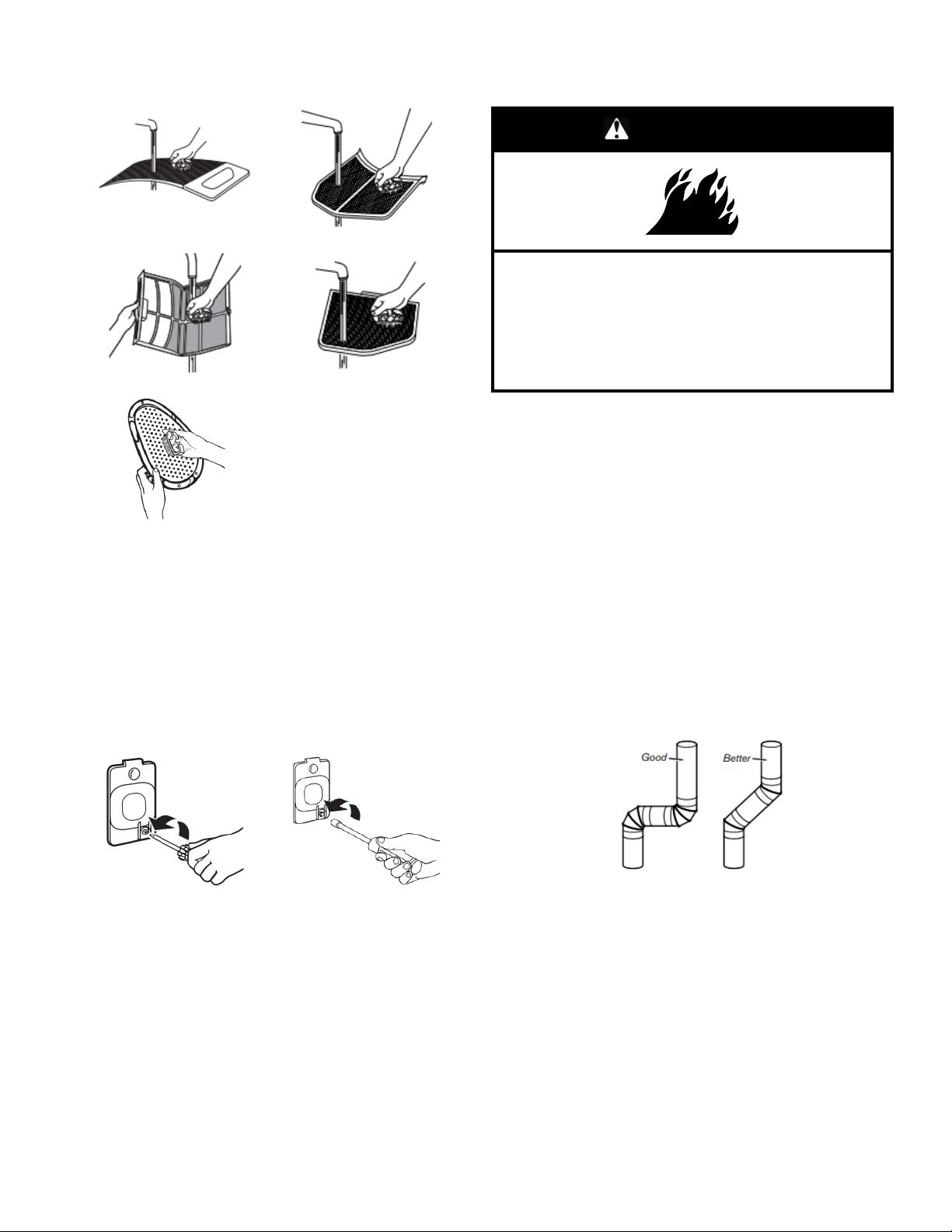

Cleaning the Lint Screen

Every load cleaning:

The lint screen may be located either in the door opening or the

top of the dryer depending on model. A screen blocked by lint can

increase drying time.

5

3. Wet a nylon brush with hot water and liquid detergent. Scrub

lint screen with the brush to remove residue buildup.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Reinstall screen

in dryer.

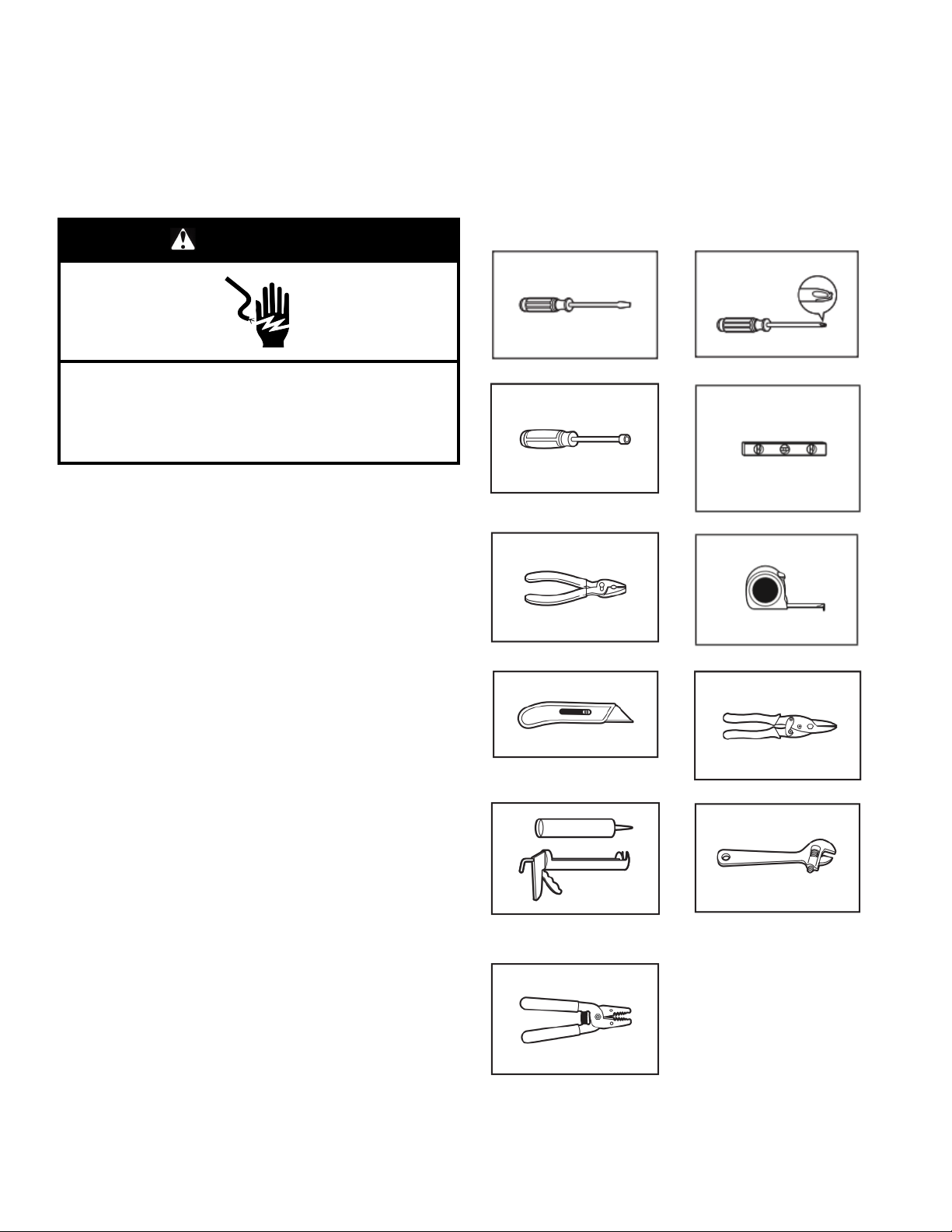

Check Your Vent System for Good Airflow

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death or

fire.

Good Airflow

Along with heat, dryers require good airflow to efficiently dry

laundry. Proper venting will reduce your drying times and improve

your energy savings. See Installation Instructions.

The venting system attached to the dryer plays a big role in good

airflow. Blocked or crushed vents as well as improper venting

installation will reduce air flow and dryer performance.

Service calls caused by improper venting are not covered by the

warranty and will be paid by the customer, regardless of who

installed the dryer. To clean or repair venting, contact a venting

specialist.

Changing the Drum Light (on some models)

1. Unplug dryer or disconnect power.

2. Open the dryer door. Locate the light bulb cover on the back

wall of the dryer. Using a Phillips-head screwdriver or 1/4"

(6.35 mm) nut driver or socket wrench, remove the screw

located in the lower right-hand corner of the cover. Remove

the cover.

3. Turn bulb counterclockwise. Replace the bulb with a 10 W

appliance bulb only. Replace the cover and secure with the

screw.

4. Plug in dryer or reconnect power.

Accessories and replacement parts are available for your model.

For ordering and contact information, please reference your Quick

Start Guide.

Maintain Good Airflow

n Cleaning your lint screen before each load.

n Replace plastic or foil vent material with 4" (102 mm) diameter

heavy, rigid vent material.

n Use the shortest length of vent possible.

n Use no more than four 90° elbows in a vent system; each bend

and curve reduces airflow.

n Remove lint and debris from the exhaust hood.

n Remove lint from the entire length of the vent system at least

every 2 years. When cleaning is complete, be sure to follow

the Installation Instructions for final product check.

n Clear away items from the front of the dryer.

Nonuse, Storage, and Moving Care

Nonuse or Storage Care

If you will be on vacation or not using your dryer for an extended

period of time, you should:

1. Unplug dryer or disconnect power.

2. Clean lint screen. See “Cleaning the Lint Screen.”

3. Turn off the water supply to the dryer. This helps to avoid

unintended flooding (due to a water pressure surge) while you

are away.

6

Moving Care

For power supply cord-connected dryers:

1. Unplug the power supply cord.

2. Steam models only: Shut off water faucet. Disconnect the

water inlet hose from faucet; then drain the hose. Transport

hose separately.

3. Make sure leveling legs are secure in dryer base.

4. Use tape to secure dryer door.

For direct-wired dryers:

WARNING

INSTALLATION INSTRUCTIONS

REQUIREMENTS

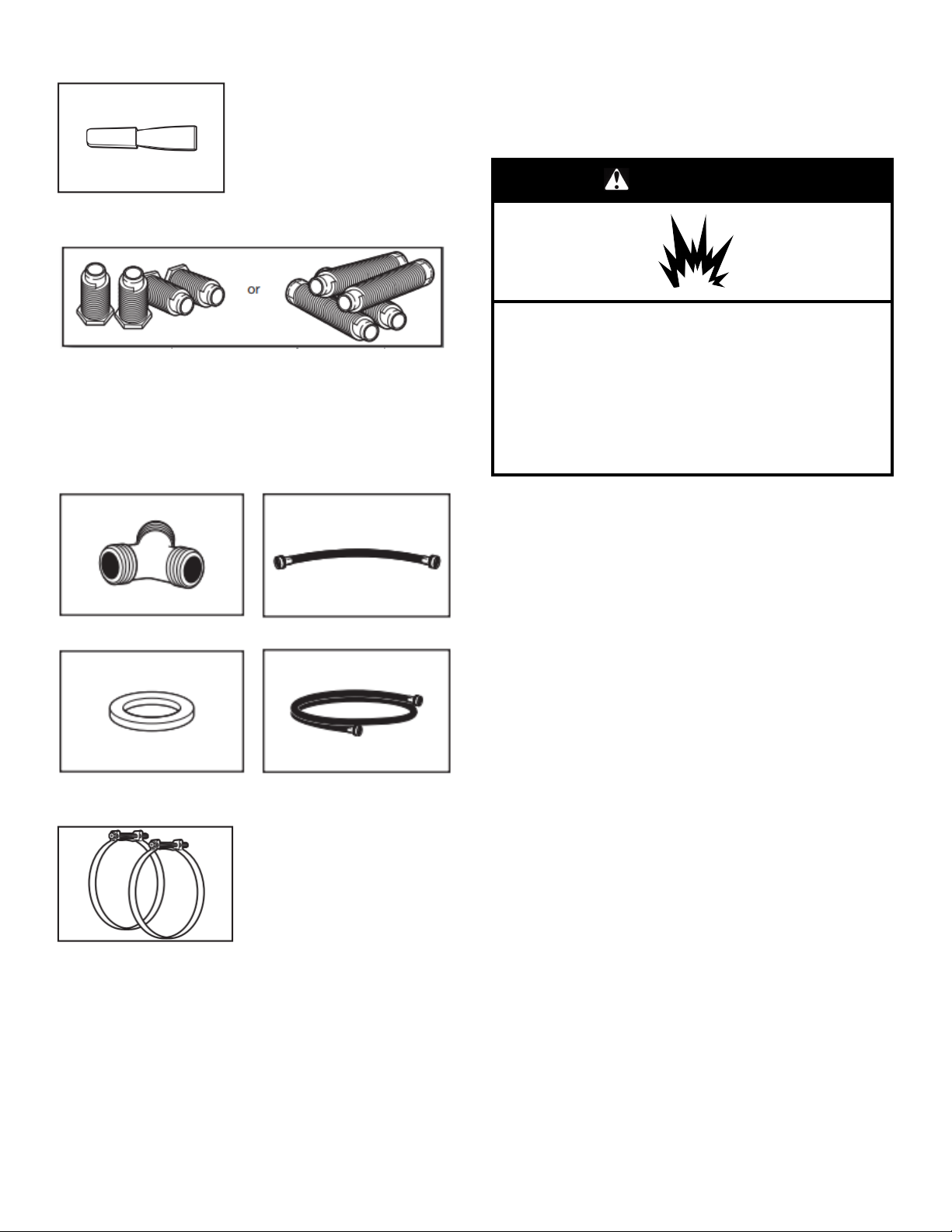

Tools and Parts

NOTE: Install the clothes dryer according to the manufacturer’s

instructions and local codes.

Gather required tools and parts before starting installation. Read

and follow the instructions provided with any tools listed here.

Tools Needed for All Installations:

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Turn off power at fuse or breaker box.

2. Disconnect wiring.

3. Steam models only: Shut off water faucet.

4. Steam models only: Disconnect the water inlet hose from

faucet; then drain the hose. Transport hose separately.

5. Make sure leveling legs are secure in dryer base.

6. Use tape to secure dryer door.

Special Instructions for Steam Models

Install and store your dryer where it will not freeze. Because some

water may stay in the hose, freezing can damage your dryer. If

storing or moving your dryer during freezing weather, winterize it.

Water inlet hose

Replace inlet hose and hose screen after 5 years of use to reduce

the risk of hose failure. Periodically inspect and replace inlet hose

if bulges, kinks, cuts, wear, or leaks are found.

When replacing your inlet hose, record the date of replacement.

To winterize the dryer:

1. Unplug dryer or disconnect power.

2. Shut off water faucet.

3. Disconnect water inlet hose from faucet and drain.

To use the dryer again:

1. Flush water pipes. Reconnect water inlet hose to faucet. Turn

on water faucet.

2. Plug in dryer or reconnect power as described in the

Installation Instructions.

Reinstalling the Dryer

Follow the Installation Instructions to locate, level, and connect the

dryer.

Flat-blade screwdriver

1/4” Nut driver

Pliers

Utility knife

Caulking gun and compound

#2 Phillips screwdriver

Level

Tape measure

Tin snips

Adjustable wrench that opens

to 1” (25 mm) or hex-head

socket wrench

Wire stripper

7

Additional Tools Needed (on some models):

Putty knife

Parts Supplied (all models):

Leveling legs (4) (Length and appearance of legs may vary

according to model)

Parts package is located in dryer drum. Check that all parts are

included.

NOTE: Do not use leveling legs supplied with dryer if installing

with a pedestal or stack kit.

Parts Needed (steam models):

“Y” connector

Rubber washer

2' (0.6 m) inlet hose

5' (1.52 m) inlet hose

Vented Models:

Vent Clamps, elbows, and vent work

Parts Needed (all models):

Additional parts may be required, depending on your installation.

Check local codes. Check existing electrical supply and venting.

Read “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please refer to the Quick Start

Guide for service contact information.

Available Accessories:

Refer to your Quick Start Guide for contact and ordering

information.

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as gasoline,

away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Place dryer at least 18 inches (460 mm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

Check code requirements. Some codes limit, or do not permit,

installing dryer in garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspector.

You will need:

n For vented models: A location allowing for proper exhaust

installation. See “Venting Requirements.”

n A separate 30 A circuit for electric dryers.

n If you are using power supply cord, a grounded electrical outlet

located within 2 ft. (610 mm) of either side of dryer. See

“Electrical Requirements.”

n A sturdy floor to support dryer weight of 200 lbs. (90.7 kg).

Also, consider the combined weight of the companion

appliance.

n For steam dryers: Cold water faucets located within 4 ft. (1.2

m) of the water fill valves, and water pressure of 20–120 psi

(138–827 kPa). You may use the water supply for your washer

using the necessary parts as noted (which you may need to

purchase).

n Level floor with a maximum slope of 1" (25 mm) under the

entire dryer. If the slope is greater than 1" (25 mm), install

Extended Dryer Feet Kit. If not level, clothes may not tumble

properly and automatic sensor cycles may not operate

correctly.

n For garage installation, place dryer at least 18" (460 mm)

above the floor. If using a pedestal, you will need 18" (460 mm)

to bottom of the dryer.

n The dryer must not be installed or stored in an area where it

will be exposed to water and/or weather.

IMPORTANT: Do not operate dryer at temperatures below 45°F

(7°C). Lower temperatures may cause dryer not to shut off at end

of automatic sensor cycles, resulting in longer drying times.

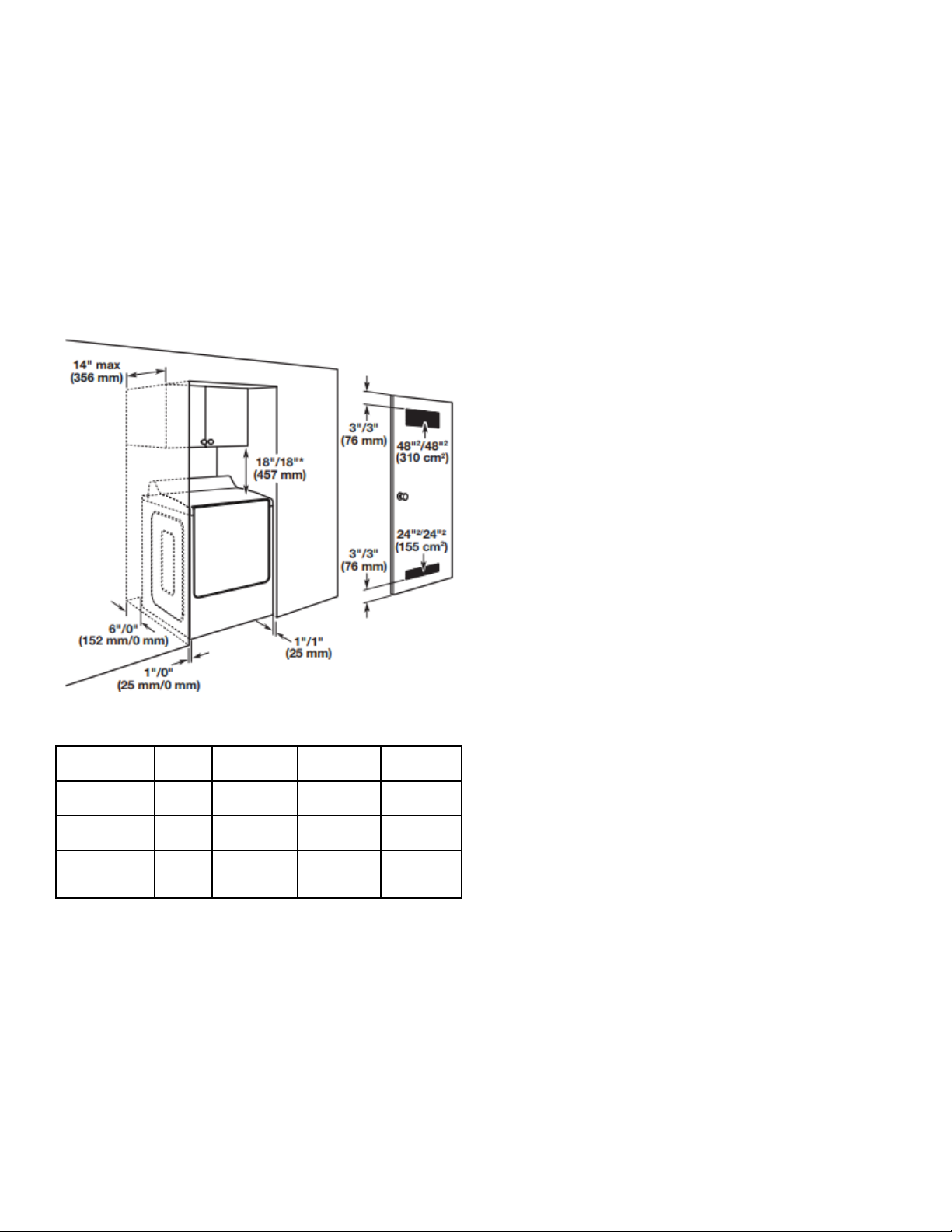

Installation clearances:

For each arrangement, consider allowing more space for ease of

installation and servicing, spacing for companion appliances, and

clearances for walls, doors, and floor moldings. Space must be

large enough to allow the dryer door to fully open. Add spacing on

all sides of the dryer to reduce noise transfer. If a closet door or

louvered door is installed, top and bottom air openings in the door

are required.

8

Installation spacing for a recessed area or closet installation

All dimensions show recommended and minimum spacing

allowed.

n Additional spacing should be considered for ease of

installation and servicing.

n Additional clearances might be required for wall, door, floor,

moldings, dryer venting, and drain system.

n Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

n For closet installation with a door, minimum ventilation

openings in the top and bottom of the door are required for

vented models. Louvered doors with equivalent ventilation

openings are acceptable.

n Companion appliance spacing should also be considered.

Recommended installation clearances (dryer

only):

*Additional spacing recommended.

Minimum installation clearances (dryer only):

Front Sides Rear Top

Recessed NA 0" (0 mm) 0" (0 mm) 0" (0 mm)

Closet NA 0" (0 mm) 0" (0 mm) 0" (0 mm)

Under

Counter

0" (0 mm) rear spacing is allowed for straight-back venting only.

For steam models only, inlet hose must not be kinked.

NA 1" (25 mm) 0" (0 mm) 0" (0 mm)

Mobile Home – Additional installation

requirements

This dryer is suitable for mobile home installations. The

installation must conform to the Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280 (formerly the

Federal Standard for Mobile Home Construction and Safety, Title

24, HUD Part 280) or the Standard for Mobile Homes, CAN/CSAZ240 MH.

Mobile home installations require:

n Metal exhaust system hardware, which is available for

purchase from your dealer.

n Special provisions must be made in mobile homes to introduce

outside air into the dryer. The opening (such as a nearby

window) should be at least twice as large as the dryer exhaust

opening.

Electrical Requirements – U.S.A.

It is your responsibility:

n To contact a qualified electrical installer.

n To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/ NFPA

70 – latest edition and all local codes and ordinances. The

National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved in

remodeling after 1996, and all mobile home installations. A

copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02169–7471.

n To supply the required 3- or 4-wire, single-phase, 120/240 V,

60 Hz, AC-only electrical supply (or 3- or 4-wire, 120/208 V

electrical supply, if specified on the serial/rating plate) on a

separate 30 A circuit, fused on both sides of the line. Connect

to an individual branch circuit. Do not have a fuse in the neutral

or grounding circuit.

n Do not use an extension cord.

n If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

n This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground conductor must be

removed from the external ground connector (green screw),

and secured under the neutral terminal (center or white wire)

of the terminal block. When the neutral ground conductor is

secured under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor. The green ground wire of the 4-wire power cord

must be secured to the dryer cabinet with the green ground

screw

n If local codes do not permit the connection of a neutral ground

wire to the neutral wire, see “Optional 3-Wire Connection.”

n A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral conductor is prohibited for (1) new branch-circuit

installations after 1996, (2) mobile homes, (3) recreational

vehicles, and (4) areas where local codes prohibit grounding

through the neutral conductors.

If using a power supply cord:

Use a UL-listed power supply cord kit marked for use with clothes

dryers. The kit should contain:

n A UL-listed 30 A power supply cord, rated 120/240 V

minimum. The cord should be type SRD or SRDT and be at

least 4 ft. (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

n A UL-listed strain relief.

9

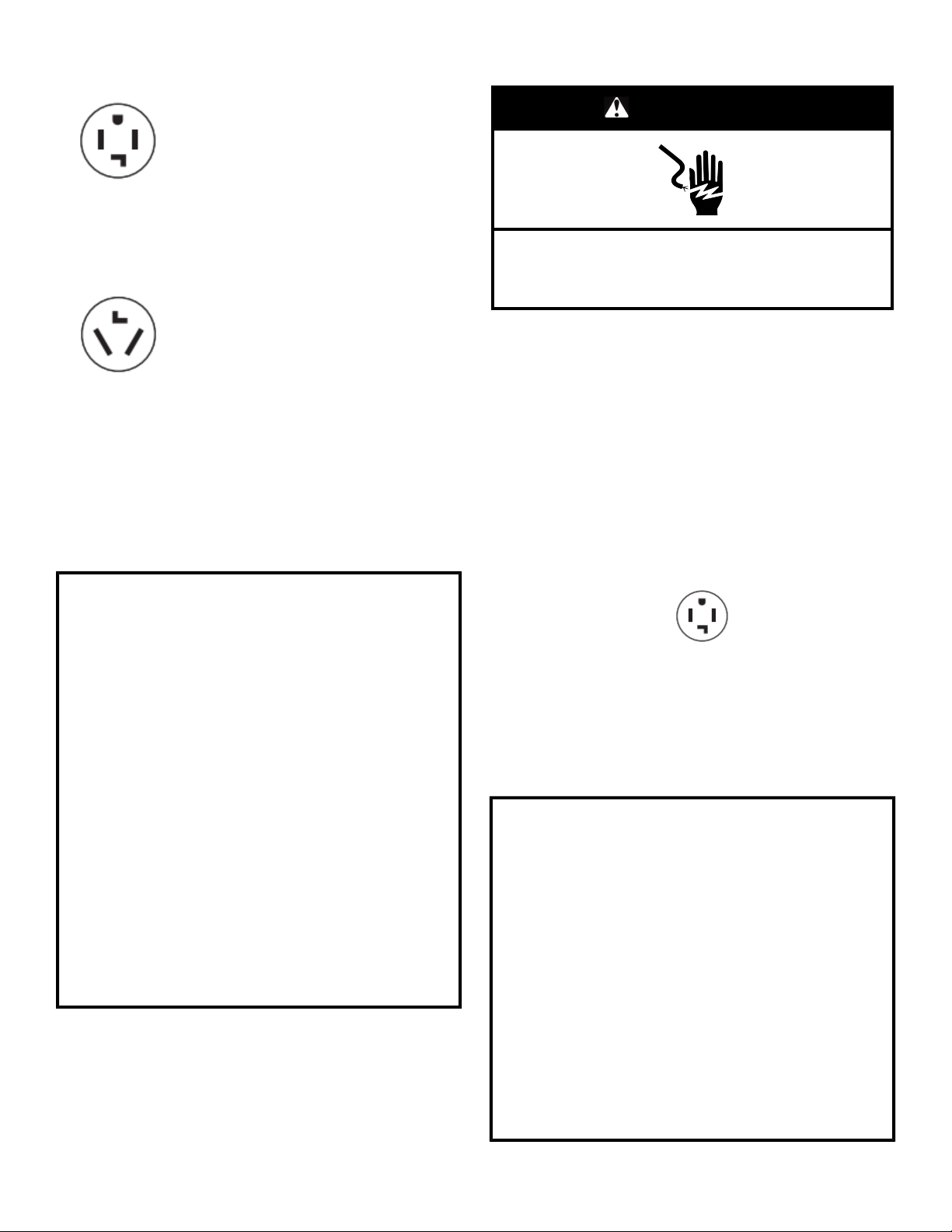

If your outlet looks like this:

Electric Requirements – Canada

Then choose a 4-wire power supply cord

with ring or spade terminals and UL-listed

strain relief. The 4-wire power supply cord,

at least 4 ft. (1.22 m) long, must have four

10-gauge copper wires and match a 4-wire

receptacle of NEMA Type 14-30 R. The

4-wire receptacle

(14-30R)

If your outlet looks like this:

3-wire receptacle

(10-30R)

ground wire (ground conductor) may be

either green or bare. The neutral

conductor must be identified by a white

cover.

Then choose a 3-wire power supply cord

with ring or spade terminals and UL-listed

strain relief. The 3-wire power supply cord,

at least 4 ft. (1.22 m) long, must have three

10-gauge copper wires and match a 3-wire

receptacle of NEMA Type 10-30R.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with flexible metallic conduit. All

current-carrying wires must be insulated.

10-gauge solid copper wire (do not use aluminum) at least 5 ft.

(1.52 m) long.

GROUNDING INSTRUCTIONS

WARNING

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

It is your responsibility:

To contact a qualified electrical installer.

To be sure that the electrical connection is adequate and in

conformance with Canadian Electrical Code, C22.1 – latest

edition and all local codes. A copy of above codes standard

may be obtained from: Canadian Standards Association, 178

Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

To supply the required 4-wire, single-phase, 120/240 V, 60 Hz,

AC-only electrical supply on a separate 30 A circuit, fused on

both sides of the line. A time-delay fuse or circuit breaker is

recommended. Connect to an individual branch circuit.

This dryer is equipped with a UL-listed and/or CSA

International Certified Power Cord intended to be plugged into

a standard 14-30R wall receptacle. The cord is 5 ft. (1.52 m)

long. Be sure wall receptacle is within reach of dryer’s final

location.

For a grounded, cord-connected appliance:

This appliance must be grounded. In the event of a

malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This appliance is equipped with a cord having

an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative if

you are in doubt as to whether the appliance is properly

grounded. Do not modify the plug provided with the

appliance: If it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

For a permanently connected appliance:

This appliance must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

SAVE THESE INSTRUCTIONS

If codes permit and a separate ground wire is used, it is

4-wire receptacle (14-30R)

recommended that a qualified electrician determine that the

ground path is adequate.

Do not use an extension cord.

For further information, or to obtain a Power Supply Cord

Replacement (Part Number W11095079), please reference the

contact information listed on your Quick Start Guide.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected appliance:

This appliance must be grounded. In the event of a

malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This appliance is equipped with a cord having

an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative if

you are in doubt as to whether the appliance is properly

grounded. Do not modify the plug provided with the

appliance: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

10

INSTALLATION

Electrical Installation – U.S.A.

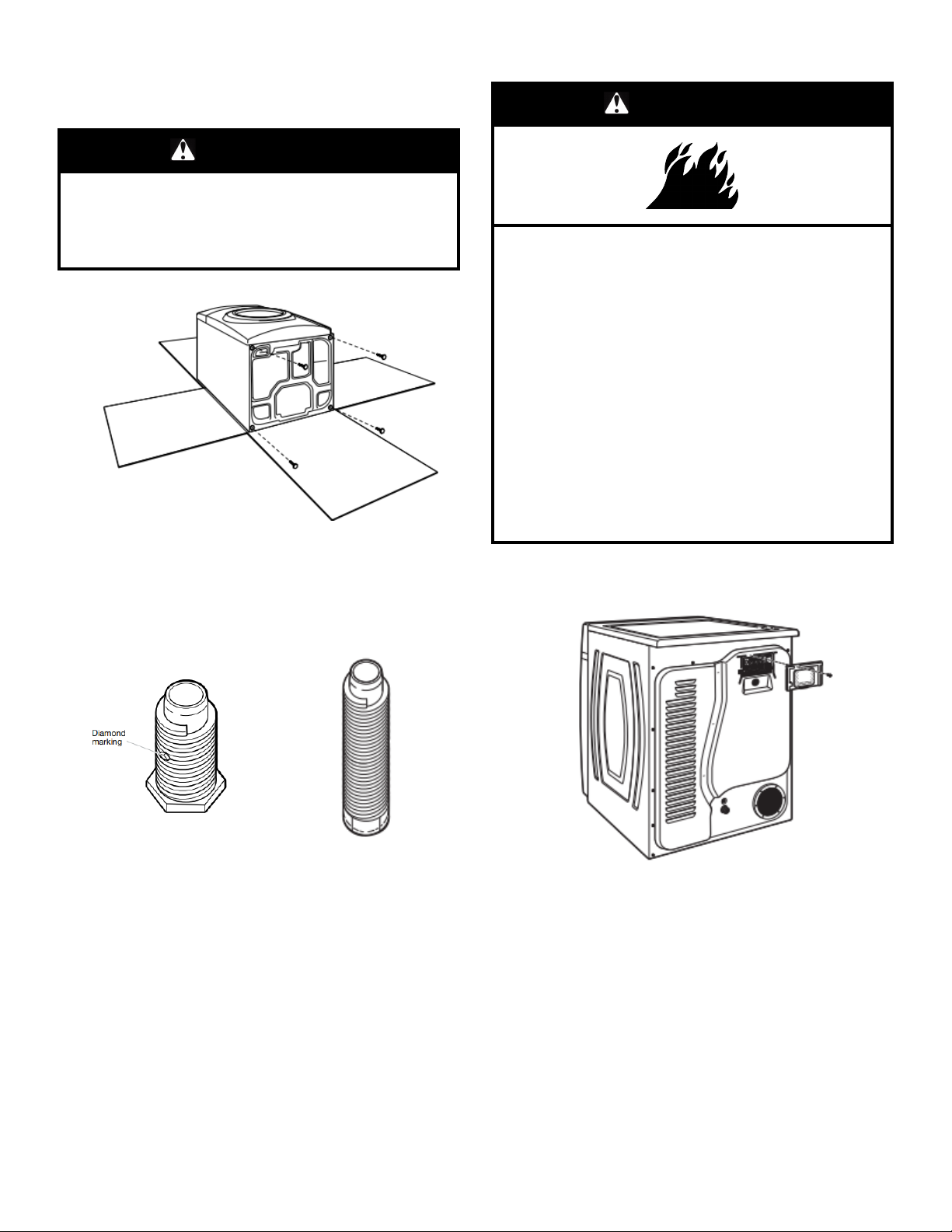

Install Leveling Legs

WARNING

Excessive Weight Hazard

Use two or more people to move and install or uninstall

appliance.

Failure to do so can result in back or other injury.

1. Prepare dryer for leveling legs

To avoid damaging floor, use a large flat piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

NOTE: Residual water from factory testing may drain when

dryer is laying on its side.

2. Screw in leveling legs

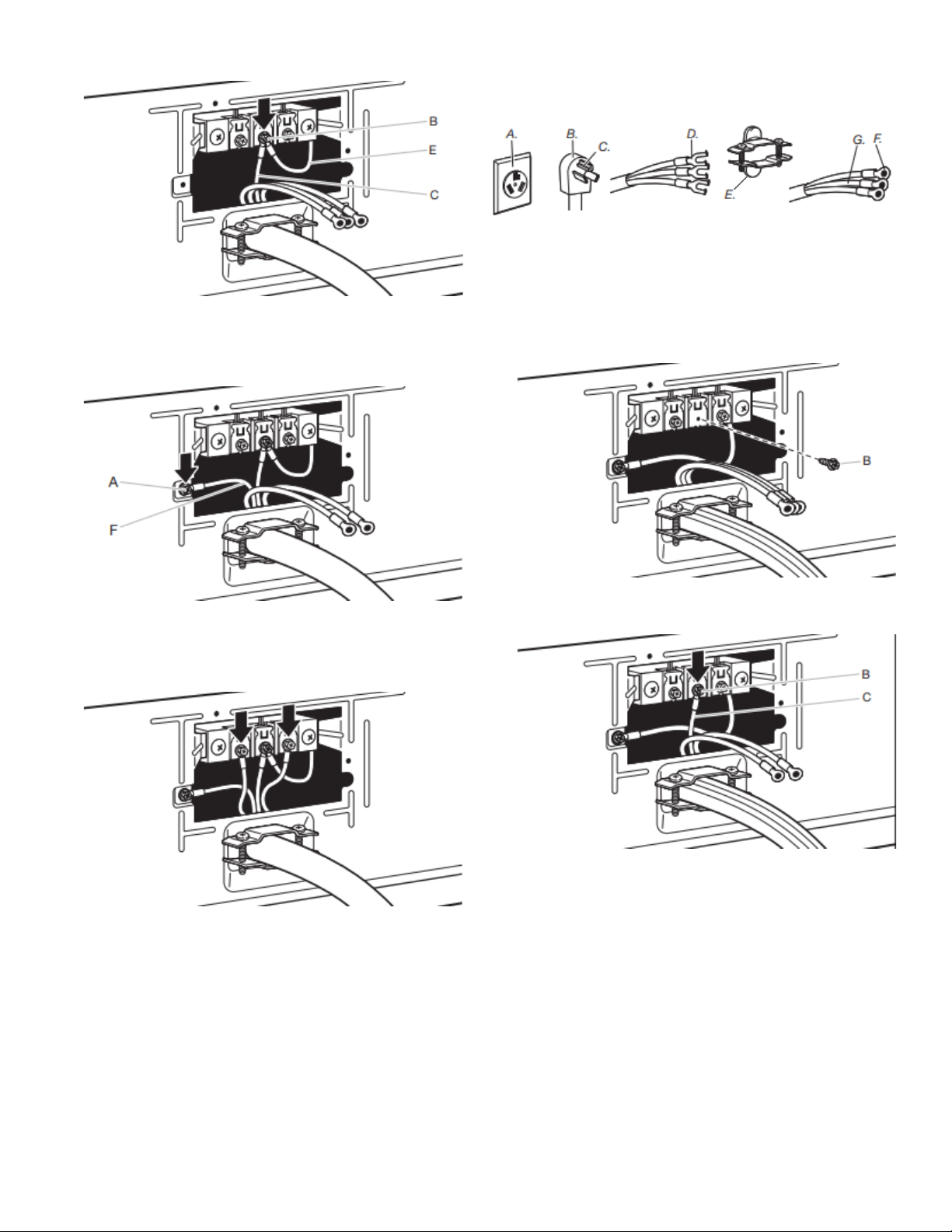

WARNING

Fire Hazard

For power supply cord, use a new UL listed 30 A power

supply cord.

For direct wire, use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Connect ground wire (green or bare wire) to green

ground connector.

Connect remaining 2 supply wires to remaining 2

terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or electrical

shock.

1. Disconnect power

2. Remove terminal block cover

Leveling leg with diamond

marking.

Using a wrench and tape measure, screw leveling legs into

leg holes until bottom of foot is approximately 1/2" (13 mm) to

1 1/2" (38 mm) from bottom of the dryer.

For leveling legs with the diamond marking:

Screw legs into leg holes by hand. Use a wrench to finish

turning legs until diamond marking is no longer visible.

Place a carton corner post from dryer packaging under each

of the two dryer back corners. Stand the dryer up. Slide the

dryer on the corner posts until it is close to its final location.

Leave enough room to connect the exhaust vent.

Leveling leg without diamond

marking

Remove hold-down screw and terminal block cover.

11

3. Choose electrical connection type

Power supply cord 4-wire receptacle

(NEMA Type 14-30R): Go to “4-Wire Power

Supply Cord Connection.” Then, go to

“Venting Requirements.”

Power supply cord 3-wire receptacle

(NEMA Type 10-30R): Go to “3-Wire Power

Supply Cord Connection.” Then, go to

“Venting Requirements.”

4-wire direct connection: Go to “Direct Wire

Strain Relief,” then “4-Wire Direct Wire

Connection,” then, go to “Venting

Requirements.”

3-wire direct connection: Go to “Direct Wire

Strain Relief”, then “3-Wire Direct Wire

Connection,” then, go to “Venting

Requirements.”

NOTE: If local codes do not permit connection of a cabinetground conductor to neutral wire, go to “Optional 3-wire

Connection.” This connection may be used with either a

power supply cord or a direct wire connection.

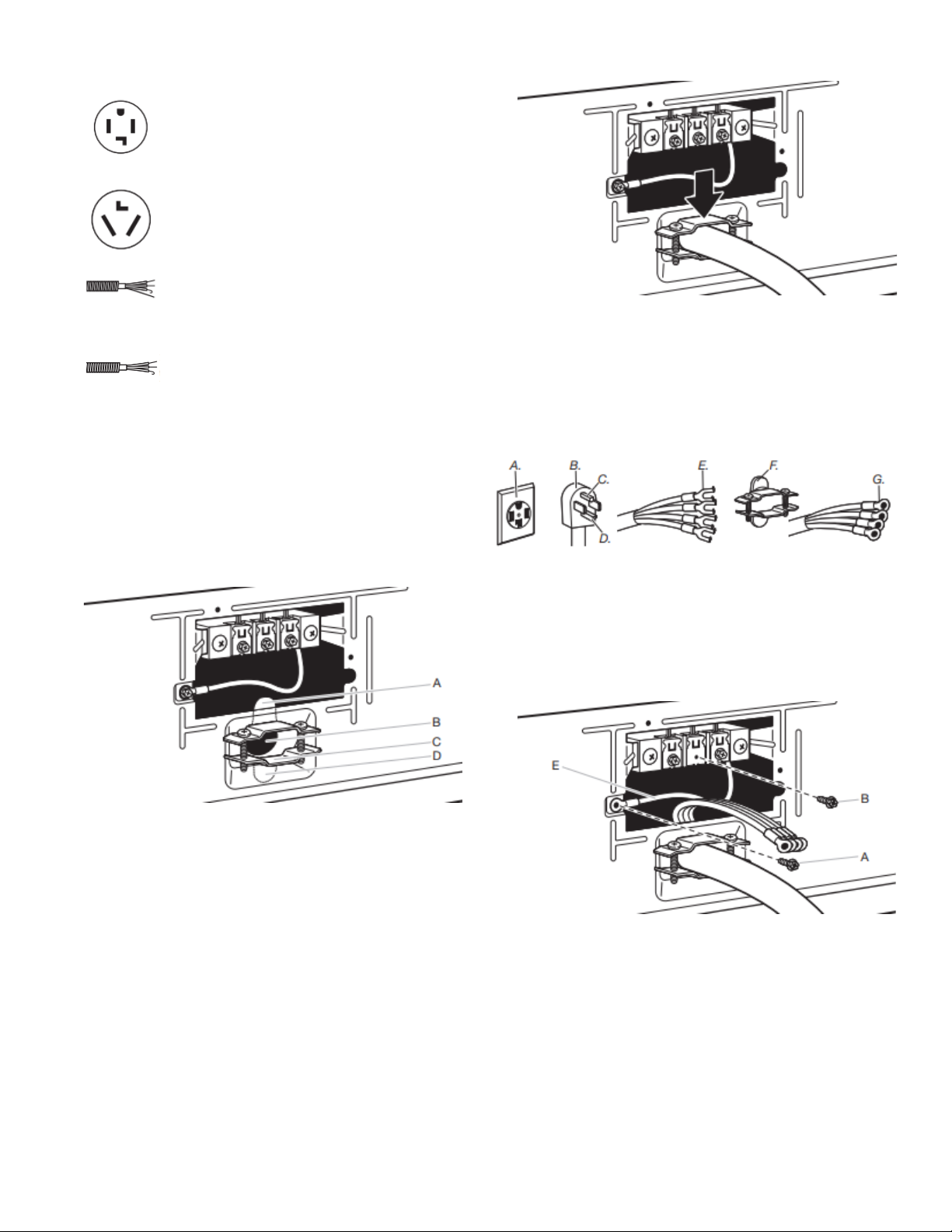

2. Attach power supply cord to strain relief

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the

strain relief. The strain relief should have a tight fit with the

dryer cabinet and be in a horizontal position. Do not further

tighten strain relief screws at this point.

4-Wire Power Supply Cord Connection

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

Power Supply Cord Connection

Power Supply Cord Strain Relief

1. Attach power supply cord strain relief

Remove the screws from a 3/4" (19 mm) UL-listed strain relief

(UL marking on strain relief). Put the tabs of the two clamp

sections (C) into the hole below the terminal block opening

(B) so that one tab is pointing up (A) and the other is pointing

down (D), and hold in place. Tighten strain relief screws just

enough to hold the two clamp sections (C) together.

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned ends

F. 3/4" (19 mm) UL-listed strain relief

G. Ring terminals

3. Prepare to connect neutral ground wire and

neutral wire

Remove center terminal block screw (B). Remove neutral

ground wire (E) from green external ground conductor screw

(A).

12

4. Connect neutral ground wire and neutral wire

Connect neutral ground wire (E) and neutral wire (white or

center) (C) of power supply cord under center terminal block

screw (B). Tighten screw.

5. Connect ground wire

3-Wire Power Supply Cord Connection

IMPORTANT: Use where local codes permit connecting cabinet-

ground conductor to neutral wire.

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with upturned ends

E. 3/4" (19 mm) UL-listed strain relief

F. Ring terminals

G. Neutral (white or center wire)

3. Remove center screw

Connect ground wire (F) (green or bare) of power supply cord

under green external ground conductor screw (A). Tighten

screw.

6. Connect remaining wires

Connect remaining wires under outer terminal block screws.

Tighten screws. Insert tab of terminal block cover into slot of

dryer rear panel. Secure cover with hold-down screw. Now,

go to “Venting Requirements.”

Remove center terminal block screw (B).

4. Connect neutral wire

Connect neutral wire (white or center) (C) of power supply

cord under center terminal block screw (B). Tighten screw.

13

Loading...

Loading...