Maytag MED6200KW Service Manual

FOR SERVICE TECHNICIAN’S USE ONLY

DANGER

Only authorized technicians should

perform diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can

result in death or electrical shock.

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Ƀ

Verify the controls are in the off position so that the appliance does not start when energized.

Ƀ

Allow enough space to perform the voltage measurements without obstructions.

Ƀ

Keep other people a safe distance away from the appliance to prevent potential injury.

Ƀ

Always use the proper testing equipment.

Ƀ

After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at approximately 3000 V. It takes as

little as 10 V to destroy, damage, or weaken the main control assembly. The new main control assembly may appear to

work well after repair is finished, but a malfunction may occur at a later date due to ESD stress.

Ƀ

Use an anti-static wrist strap. Connect wrist strap to green earth connection point or unpainted metal in the

appliance.

– OR –

Touch your finger repeatedly to a green ground connection point or unpainted metal in the appliance.

Ƀ

Before removing the part from its package, touch the anti-static bag to a green ground connection point or unpainted

metal in the appliance.

Ƀ

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

Ƀ

When repackaging main control assembly in anti-static bag, observe above instructions.

IMPORTANT SAFETY NOTICE — “For Technicians only”

This service data sheet is intended for use by persons having electrical, electronic, and mechanical experience and

knowledge at a level generally considered acceptable in the appliance repair trade. Any attempt to repair a major

appliance may result in personal injury and property damage. The manufacturer or seller cannot be responsible, nor

assume any liability for injury or damage of any kind arising from the use of this data sheet.

W11411589B

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

Contents

General Information .............................................................................. 3-8

Dryer safety .............................................................................................. 4

Product specifications ............................................................................... 5

Model number nomenclature ..................................................................... 7

Model number and serial number label location ......................................... 7

Tech sheet location ................................................................................... 8

Diagnostic Guide ................................................................................. 9-14

Diagnostic guide ..................................................................................... 10

Service diagnostic mode ......................................................................... 10

Button activation & encoder test .............................................................. 11

Service test mode ................................................................................... 11

Service test mode chart .......................................................................... 12

Software version display ......................................................................... 13

Service fault/error codes ......................................................................... 14

Troubleshooting ................................................................................15-29

Troubleshooting guide ............................................................................. 16

Troubleshooting tests .............................................................................. 17

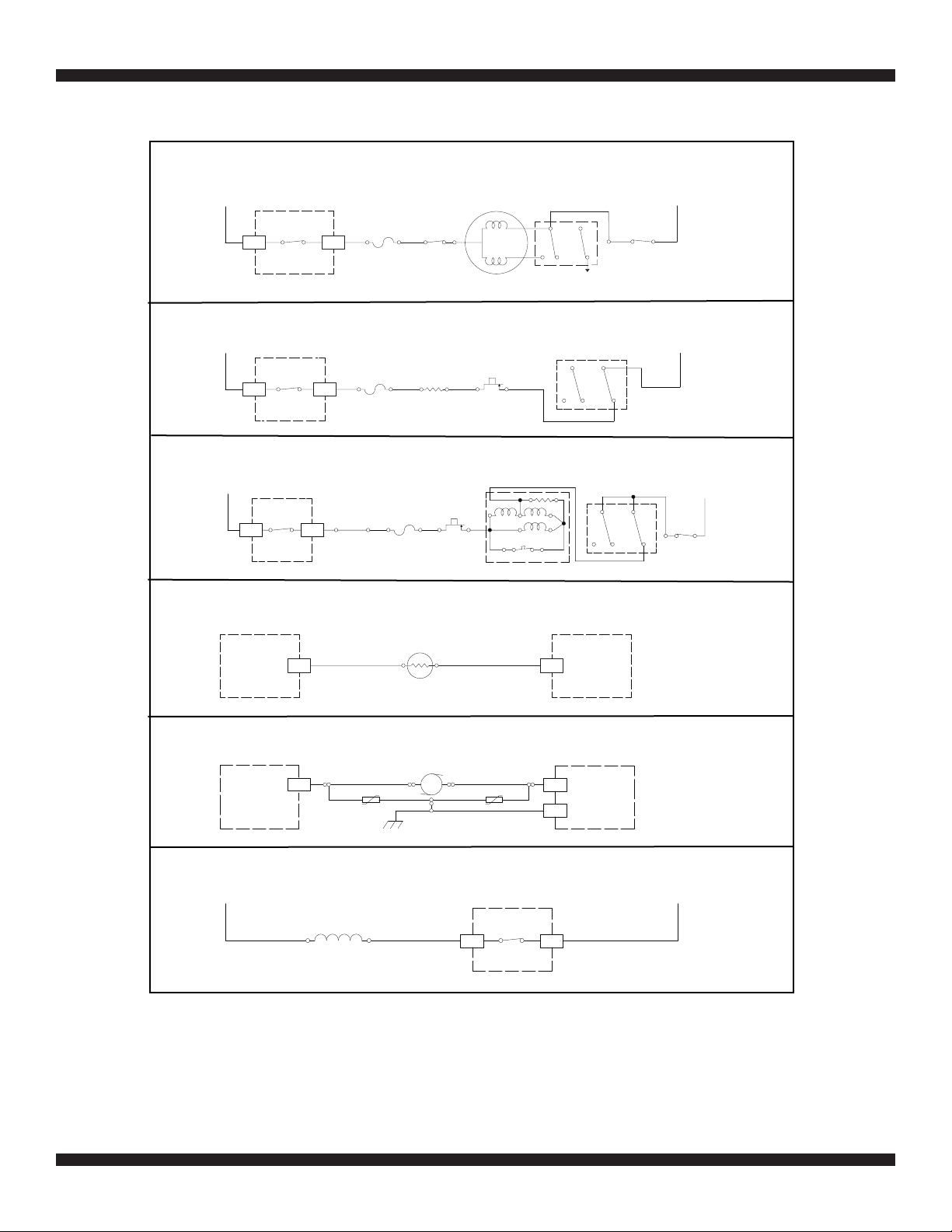

Strip circuits ........................................................................................... 25

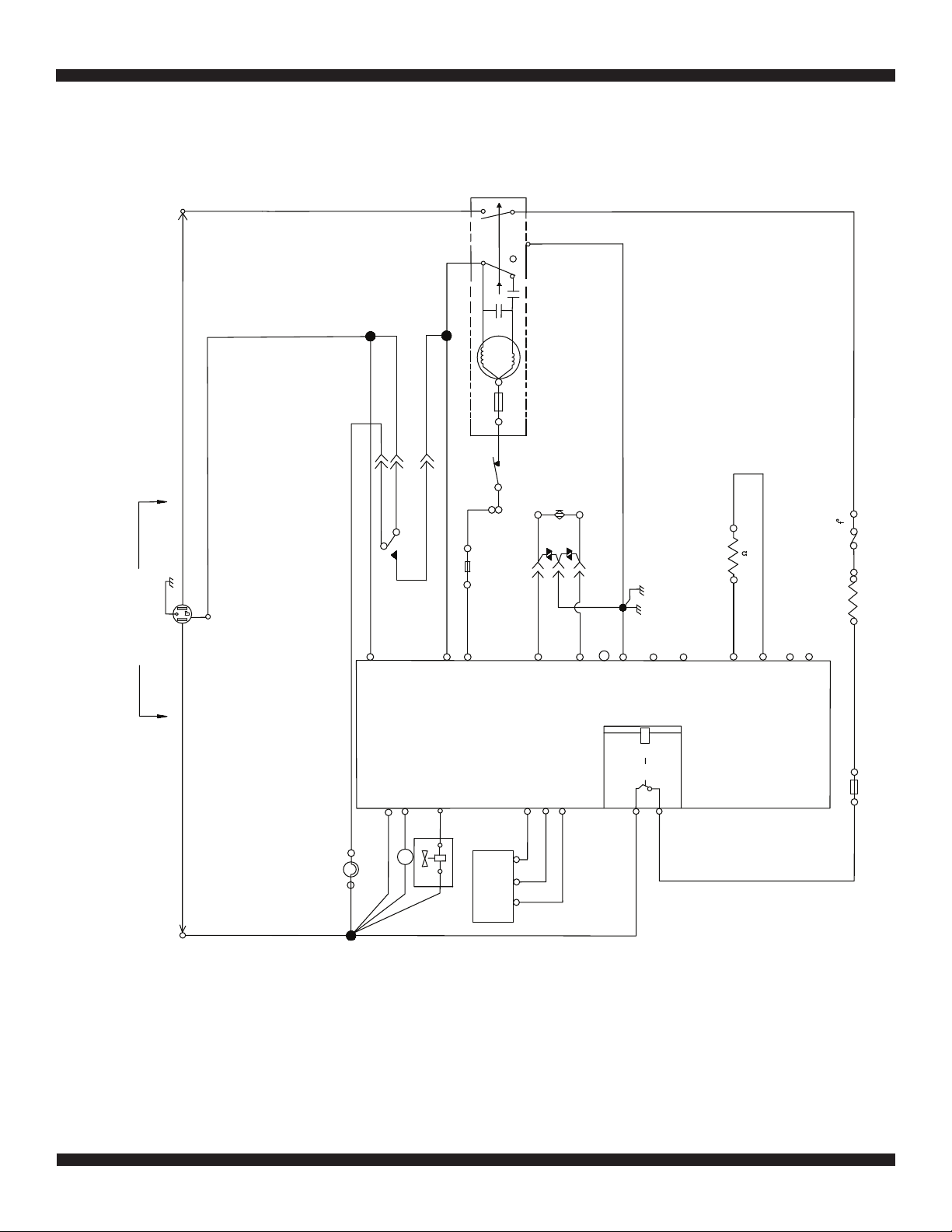

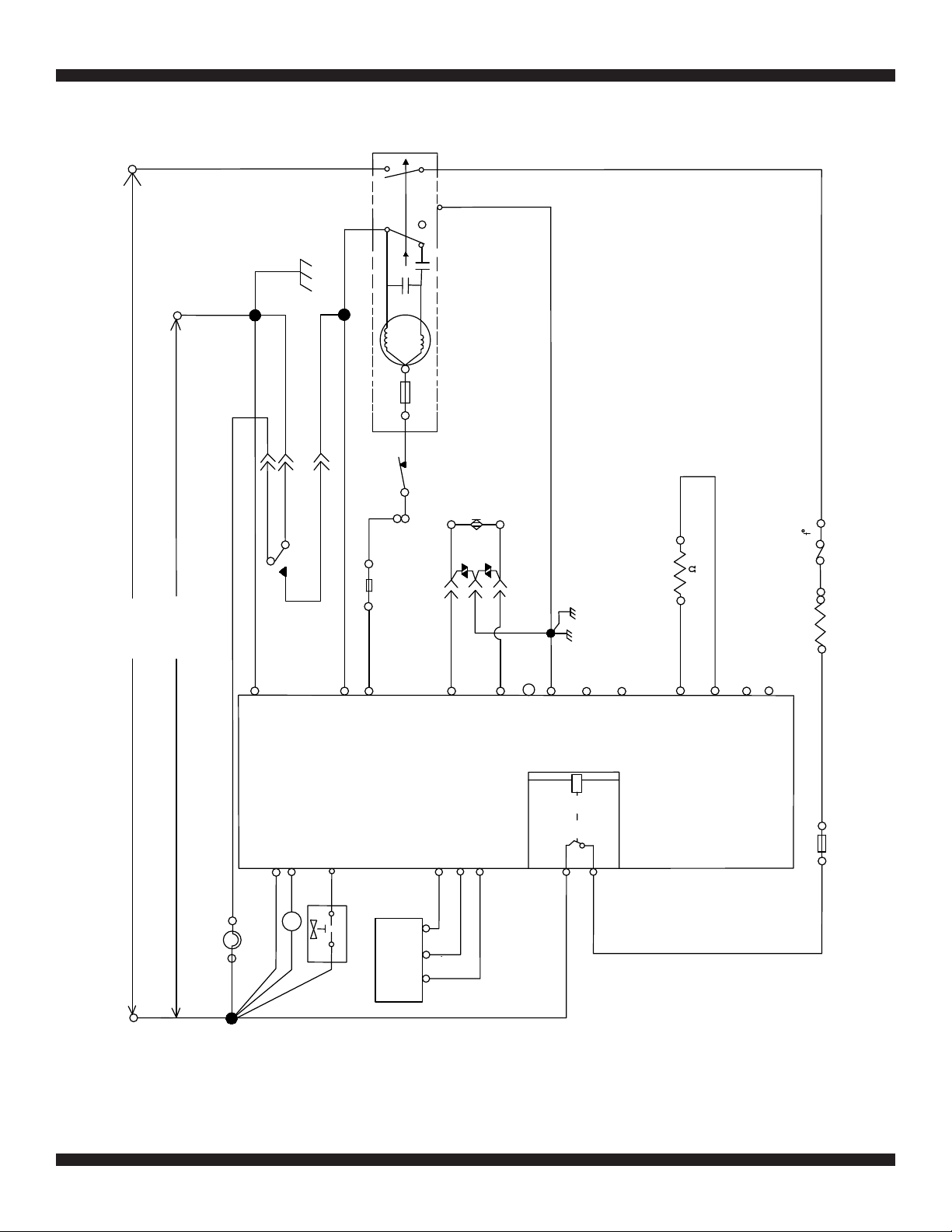

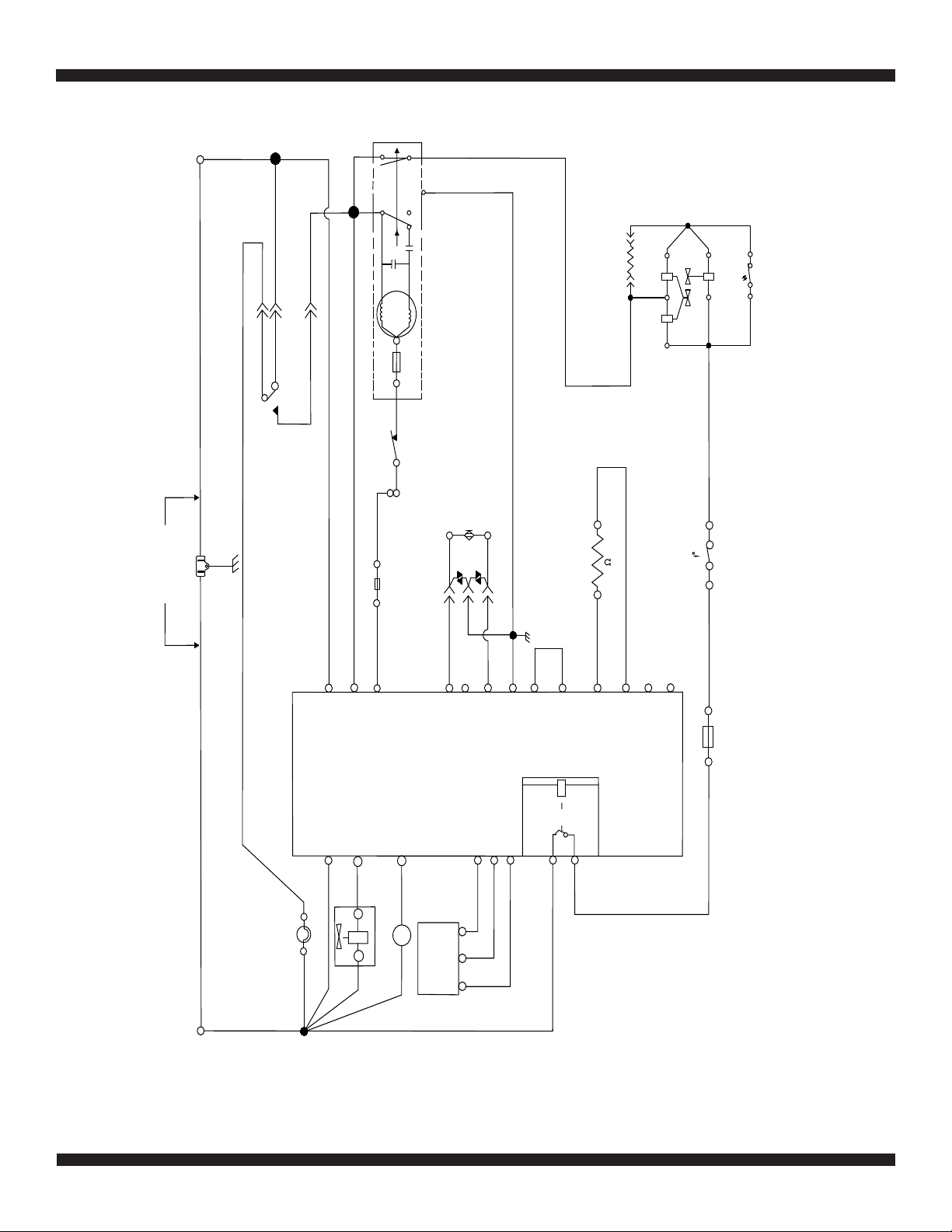

Wiring diagram........................................................................................ 26

Component locations .............................................................................. 29

Component Access ......................................................................... 30-44

Removing the door assembly .................................................................31

Removing the console/HMI and top panel ...............................................31

Removing the appliance control unit (ACU) .............................................32

Removing the door switch and front panel ..............................................34

Removing the drum and front panel bearings ..........................................35

Removing the belt, drum, and rear rollers ...............................................35

Removing the drive motor ......................................................................36

Removing the thermal fuse and exhaust thermistor .................................37

Removing the rear panel, high-limit thermostat, and

Thermal cutoff (TCO) (gas models only) .................................................38

Removing the thermal cutoff (TCO), heater, and inlet thermistor

(Electric models only) ............................................................................39

Removing the flame sensor and gas burner assembly

(Gas models only) ..................................................................................40

Removing the moisture sensor and metal oxide varistors (MOV)

..............................................................................................................41

Removing the drum light assembly. ........................................................42

2

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

Section 1: GENERAL INFORMATION

This section provides general safety, parts, and information for the “Maytag® 7.0 cu. ft. Electric/Gas Dryer.”

Ƀ

Dryer Safety

Ƀ

Product Specifications

Ƀ

Product Features

Ƀ

Model Number Nomenclature

Ƀ

Model Number and Serial Number Label Location

Ƀ

Tech Sheet Location.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

3

FOR SERVICE TECHNICIAN’S USE ONLY

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

follow instructions.

You can be killed or seriously injured if you don't

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

instructions.

follow

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using your appliance, follow basic precautions, including the following:

Ƀ

Read all instructions before using the appliance.

Ƀ

Do not dry articles that have been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry-cleaning solvents, or other

flammable or explosive substances, as they give off vapors that could

ignite or explode.

Ƀ

Do not allow children to play on or in the appliance. Close supervision

of children is necessary when the appliance is used near children.

Ƀ

Before the appliance is removed from service or discarded, remove

the door to the drying compartment.

Ƀ

Do not reach into the appliance if the drum is moving.

Ƀ

Do not install or store this appliance where it will be exposed to the

weather.

Ƀ

Do not tamper with controls.

Ƀ

Do not repair or replace any part of the appliance or attempt any

servicing unless specifically recommended in the user maintenance

instructions or in published user-repair instructions that you

understand and have the skills to carryout.

Ƀ

Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturer of the fabric softener or product.

Ƀ

Do not use heat to dry articles containing foam rubber or similarly

textured rubber-like materials.

Ƀ

Clean lint screen before or after each load.

Ƀ

Keep area around the exhaust opening and adjacent surrounding areas

free from the accumulation of lint, dust, and dirt.

Ƀ

The interior of the appliance and exhaust duct should be cleaned

periodically by qualified service personnel.

Ƀ

Do not place items exposed to cooking oils in your dryer. Items

contaminated with cooking oils may contribute to a chemical reaction

that could cause a load to catch fire. To reduce the risk of fire due

to contaminated loads, the final part of a tumble dryer cycle occurs

without heat (cool down period). Avoid stopping a tumble dryer before

the end of the drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated.

Ƀ

Do not use replacement parts that have not been recommended by the

manufacturer (e.g. parts made at home using a 3D printer).

Ƀ

See the Installation Instructions for grounding requirements and

installation.

4

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

SAVE THESE INSTRUCTIONS

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

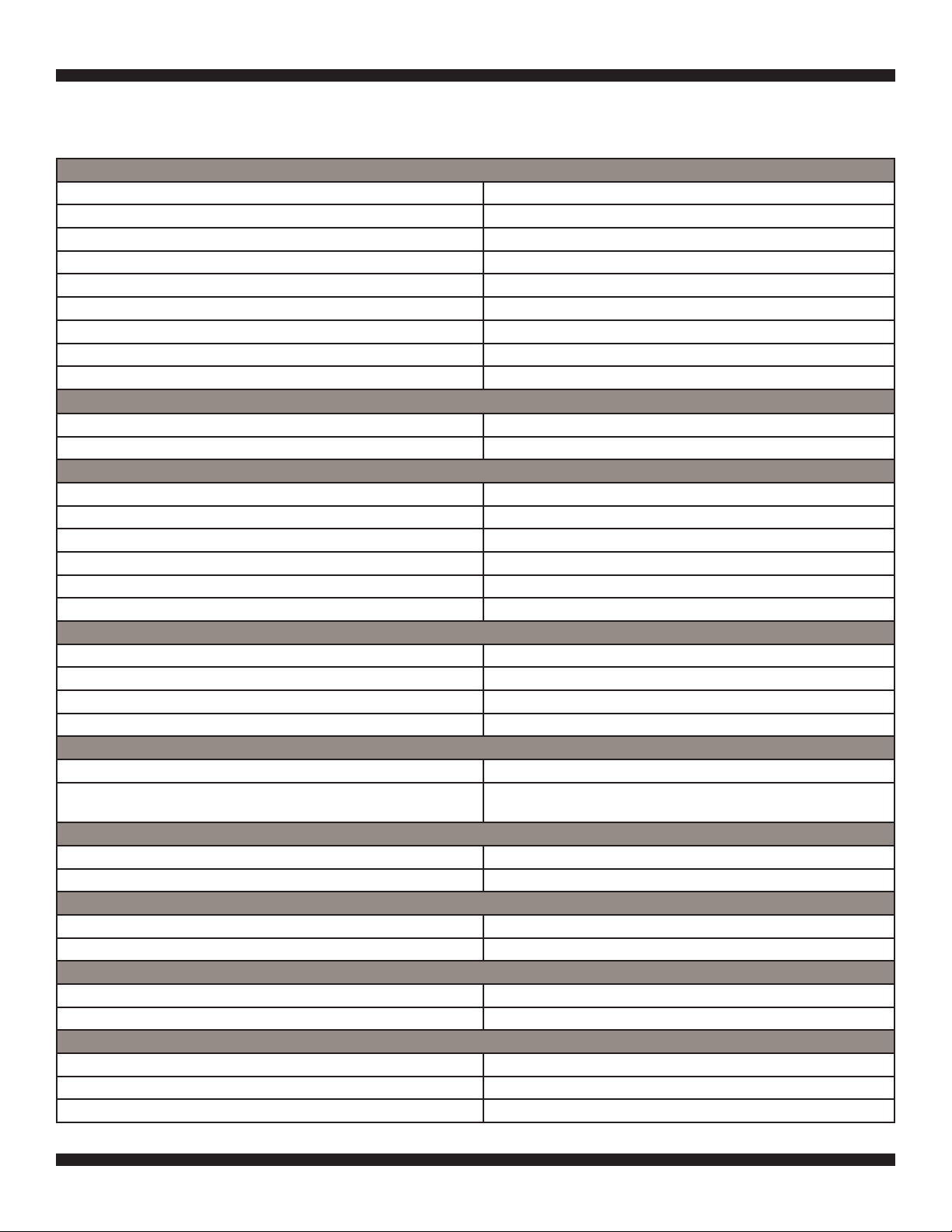

PRODUCT SPECIFICATIONS

Maytag® 7.0 cu. ft. Electric/Gas Dryer

Dimensions

Capacity IEC CAN (cu. ft.) 7

Capacity (cu. ft.) 7

Depth With Door Open 90 Degree (IN, inches) 5011/

Depth (IN, inches) 283/

Height to Top Of Cabinet (IN, inches) 367/

Height (IN, inches) 4011/

Maximum Height (IN, inches) 425/

Minimum Height (IN, inches) 4011/

Width (IN, inches) 29

Exterior

Door Style Side Swing

Reversible Door Yes

Controls

Automatic Temperature Controls Yes

Control Location Rear Console

Control Type Knob and Button

Electronic Display Type LED

Feedback-Status Indicators Cool, Done, Sensing, Wet

End of Cycle Signal Yes

Features

Automatic Dry Control Yes

LP Convertible Yes

Moisture Sensor Yes

Sound Package No

Cycles

Number of Dryer Cycles 11

Selection of Drying Cycles Air Dry, Bulky Items, Delicates, Heavy Duty, Less Dry, More Dry, Normal,

Options

Dryer Option Selections Cycle Signal, Temperature, Timed Dry, Wrinkle Prevent

Number of Dryer Options 4

Temperature Settings

Number of Temperatures 4

Temperature Selection High, Low, Extra Low, Medium

Modifiers

Number of Dryness Levels 3

Selection of Drying Levels More, Less, Normal

Installation Considerations

Maximum Vent Length (ft.) 64

Venting Direction Rear Only

Ventless NA

16

8

8

16

16

16

Quick Dry, Timed Dry, Towels, Wrinkle Control

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

5

FOR SERVICE TECHNICIAN’S USE ONLY

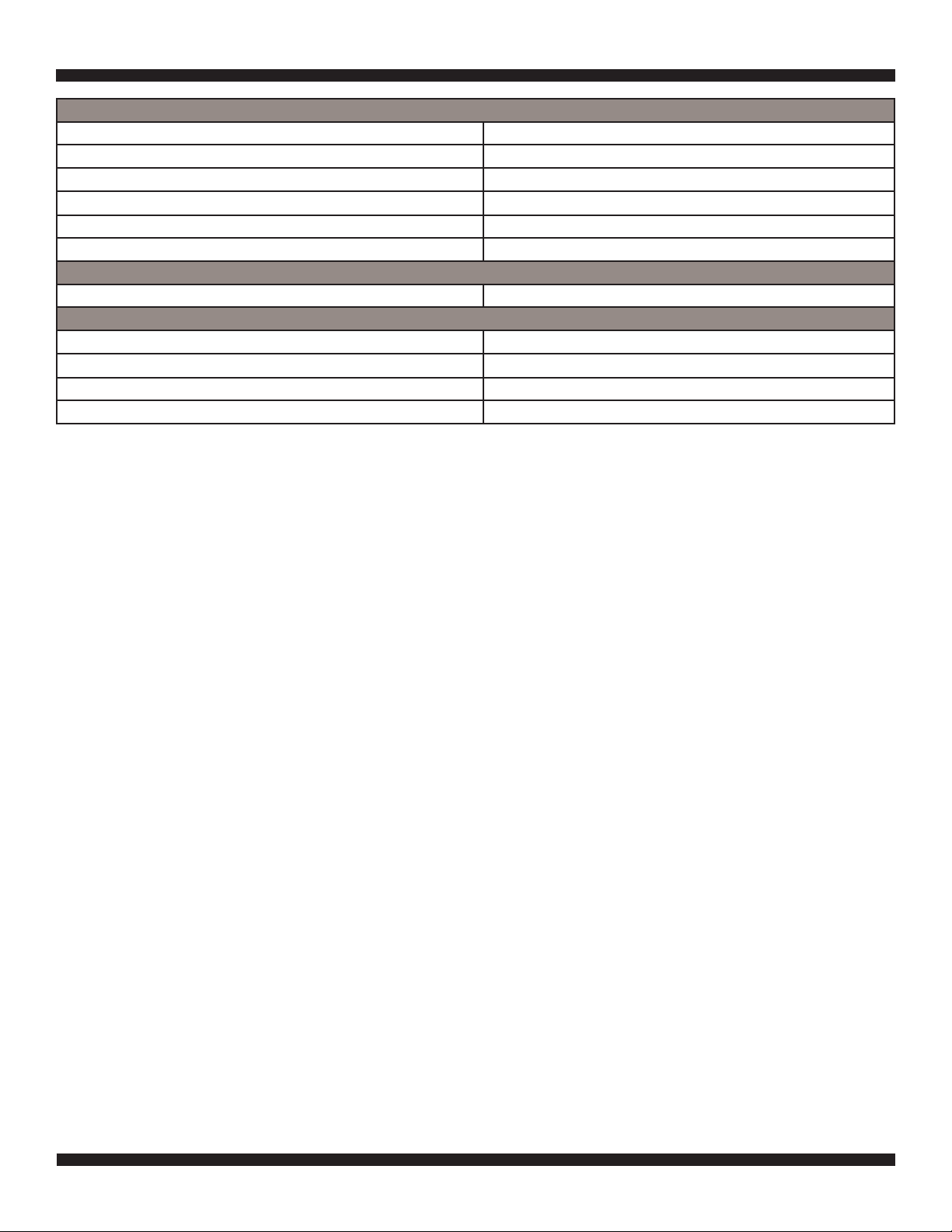

Details

Drum Material Powder Coat

Heating Burner (BTU) (for Gas Dryer Only) 22000

Interior Light Yes

Lint Screen Location Top

Motor Horsepower 1/3 HP

Hoses Included (for Gas Dryer Only) No

Description

Fuel Type Electric or Gas

Electrical

Ampere 15 or 30 A

Frequency (Hz) 60 Hz

Power Cord Included Yes

Voltage 120 or 240 VAC Only

6

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

MODEL NUMBER NOMENCLATURE

Maytag® Model Number Nomenclature

MODEL NUMBER M E D 6200 K W

Brand

M = Maytag

Fuel

E = Electric

G = Gas

Product Type

D = Dryer

W = Washer

Feature Set

6200 = Higher the number more features

are available

Year of Launch

J = 2019

K = 2020

Color Code

W = White

C = Metallic Slate

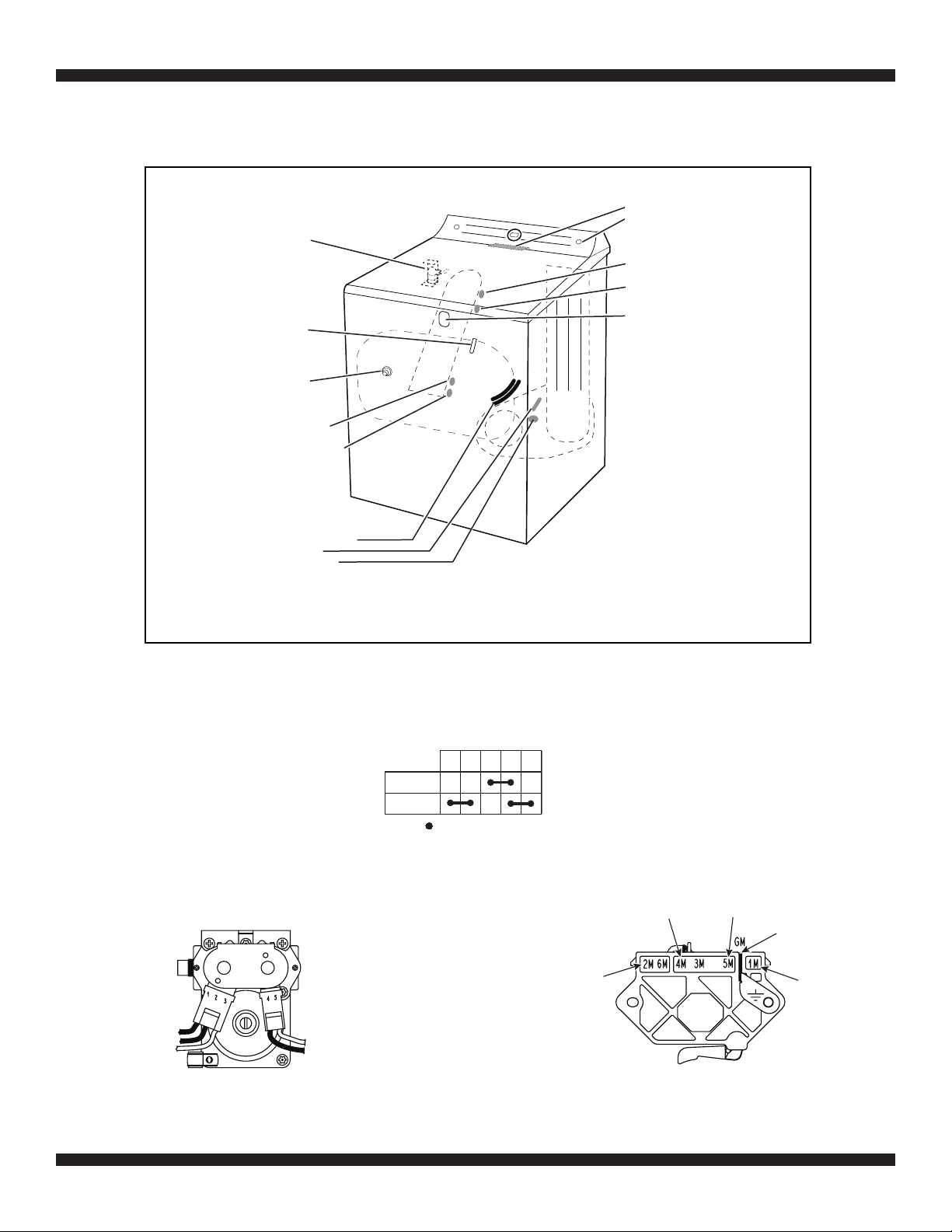

MODEL NUMBER AND SERIAL NUMBER LABEL LOCATION

Model Number and Serial Number

Label Location

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

7

TECH SHEET LOCATION

FOR SERVICE TECHNICIAN’S USE ONLY

Tech Sheet

Location

8

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

Section 2: DIAGNOSTIC GUIDE

This section provides Diagnostic guide for the “Maytag® 7.0 cu. ft. Electric/Gas Dryer.”

Ƀ

Diagnostic Guide

Ƀ

Service Diagnostic Mode

Ƀ

Button Activation & Encoder Test

Ƀ

Service Test Mode

Ƀ

Service Test Mode Chart

Ƀ

Software Version Display

Ƀ

Service Fault/Error Codes.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

9

FOR SERVICE TECHNICIAN’S USE ONLY

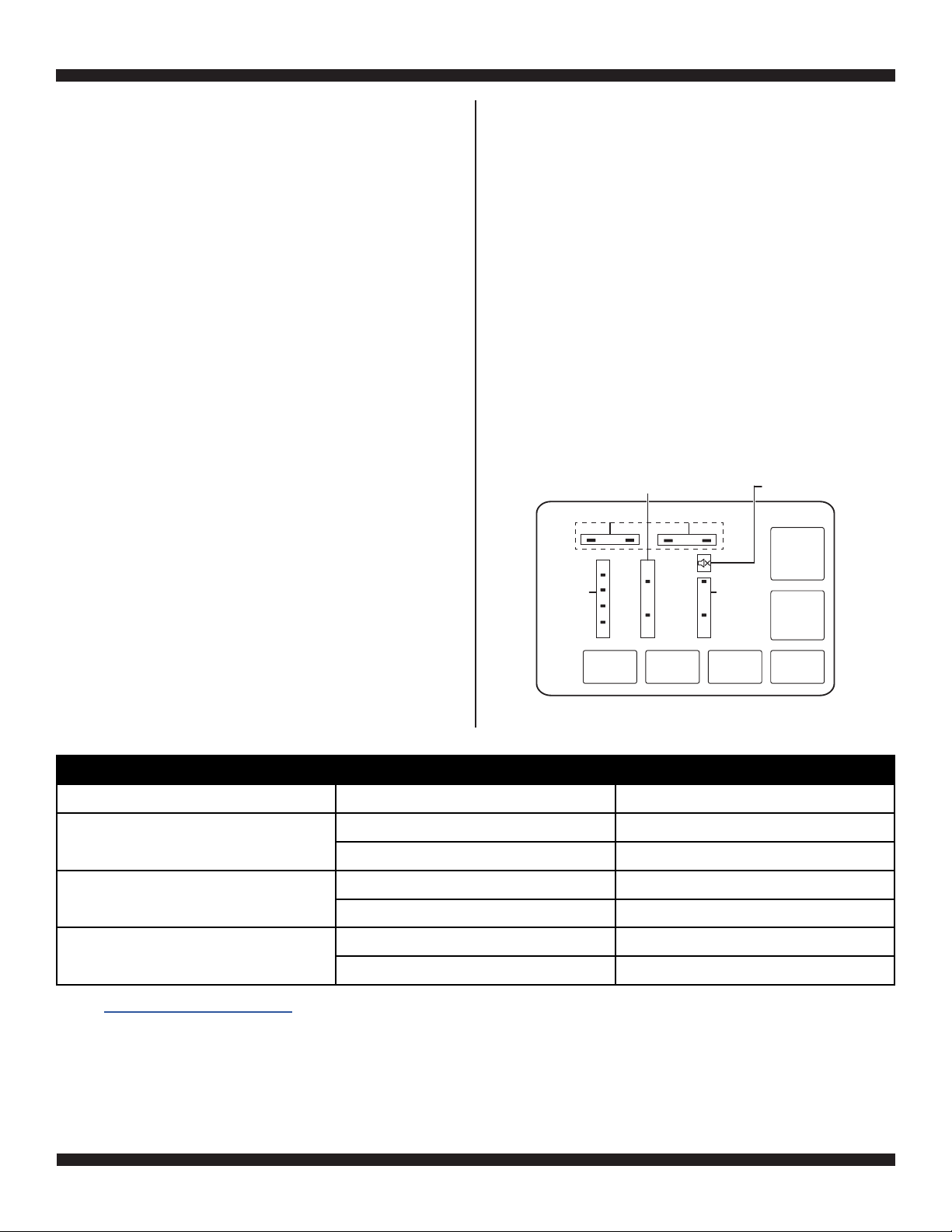

LED group 4

DIAGNOSTIC GUIDE

Before servicing, check the following:

Ƀ

Make sure there is power at the wall outlet.

Ƀ

Has a household fuse blown or circuit breaker tripped? Was a regular

fuse used? Inform customer that a time-delay fuse is required.

Ƀ

Make sure the dryer vent and lint screen are clear of lint and

obstructions.

Ƀ

All tests/checks should be made with a VOM (volt-ohm-milliammeter)

or DVM (digital-voltmeter) having a sensitivity of 20,000 Ω per VDC or

greater.

Ƀ

Resistance checks must be made with dryer unplugged or power

disconnected.

Ƀ

IMPORTANT: Avoid using large diameter probes when checking harness

connectors as the probes may damage the connectors upon insertion.

Ƀ

Check all harnesses and connections before replacing components. Look

for connectors not fully seated, broken or loose wires and terminals, pin

insertion, or wires not pressed into connectors far enough to engage

metal barbs.

Ƀ

A potential cause of a control not functioning is corrosion or

contamination on connections. Use an ohmmeter to check for continuity

across suspected connections.

Ƀ

To properly check voltage, complete the following steps:

1. Unplug the dryer or disconnect power.

2. Attach voltage measurement equipment to proper connectors.

3. Plug in dryer or reconnect power and verify voltage reading.

4. Always unplug dryer or disconnect power after completing voltage

measurements.

SERVICE DIAGNOSTIC MODE

These tests allow service personnel to test and verify all inputs to the

machine control electronics. You may want to do a quick and overall

checkup of the dryer with these tests before going to specific

troubleshooting tests.

ACTIVATING SERVICE DIAGNOSTIC MODE

1. Be sure the dryer is in standby mode (plugged in with all LEDs off).

2. Select any three (3) buttons (except POWER & START) and follow the

steps below, using the same buttons (remember the buttons and the

order that the buttons were pressed):

Within 8 seconds,

• Press and Release the 1st selected button,

• Press and Release the 2nd selected button,

• Press and Release the 3rd selected button,

• Repeat this 3 button sequence 2 more times.

3. If this test mode has been entered successfully, all indicators on the HMI

will be illuminated for 1 second then will be turned OFF. After this, If there

are no saved fault codes, the STATUS indicators (Sense, Soak, Wash and

Done) will blink two times and then all the indicators will be turned OFF.

NOTE: The Service Diagnostic mode will time out after 5 minutes of user

inactivity, or shutdown if the power supply is removed from the dryer.

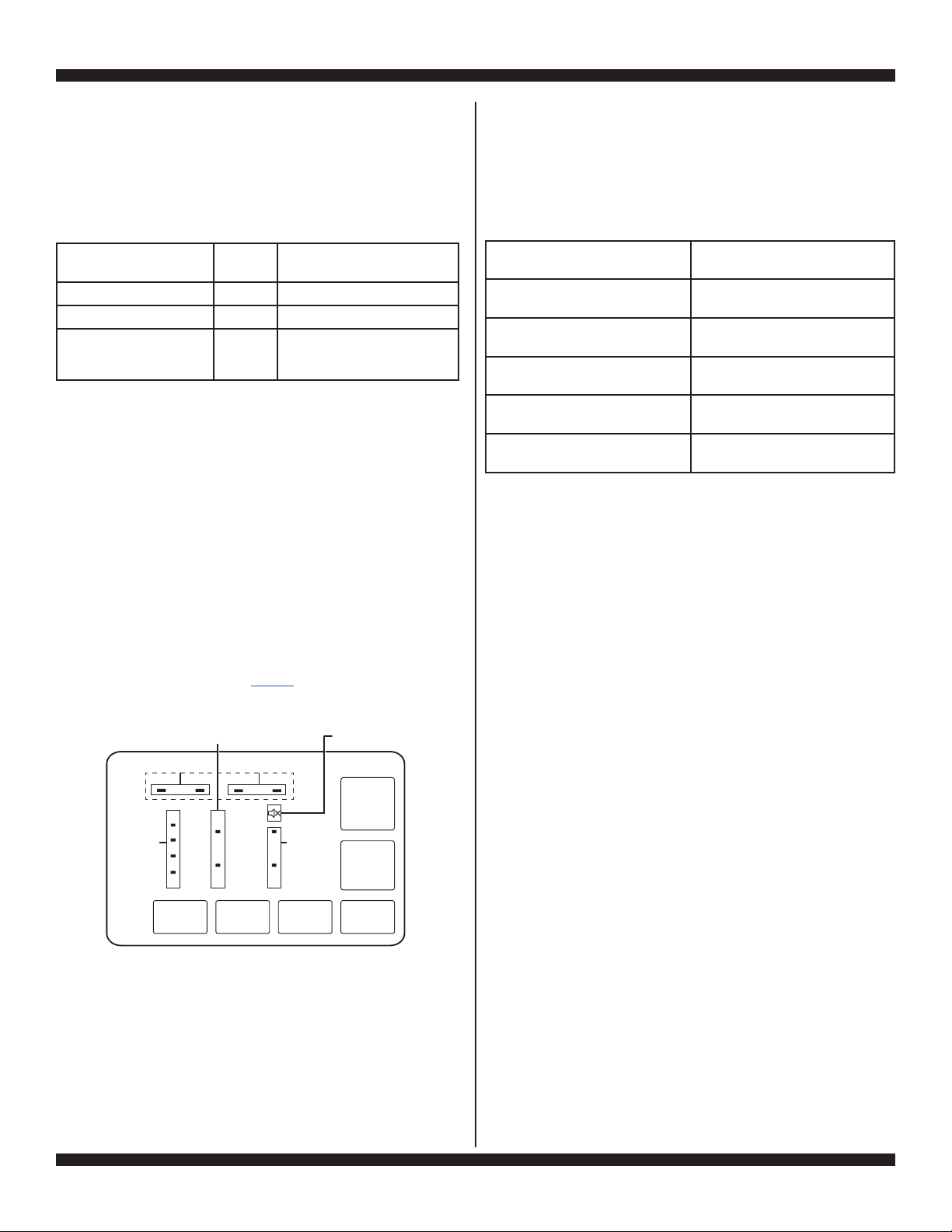

LED group 2

Status

LED group 5

Indicator

LED group 6

Key 6 /

POWER

LED group 1 LED group 3

Key 5/

START

Key 1

Key 2 Key 3 Key 4

SERVICE DIAGNOSTIC MENU TABLE

Button Press Function Behavior

1st Button - Momentary press - Enter Button Activation & Encoder test

- Press and hold for 5 seconds. - Exits Service Diagnostics

2nd Button - Momentary press - Activates Service Test Mode

- Press and hold for 5 seconds. - Software Version Display

3rd Button - Momentary press - Displays Next Error Code

- Press and hold for 5 seconds. - Clears the Error Codes

dz See “Activating Service Diagnostic Mode” to activate these buttons.

10

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

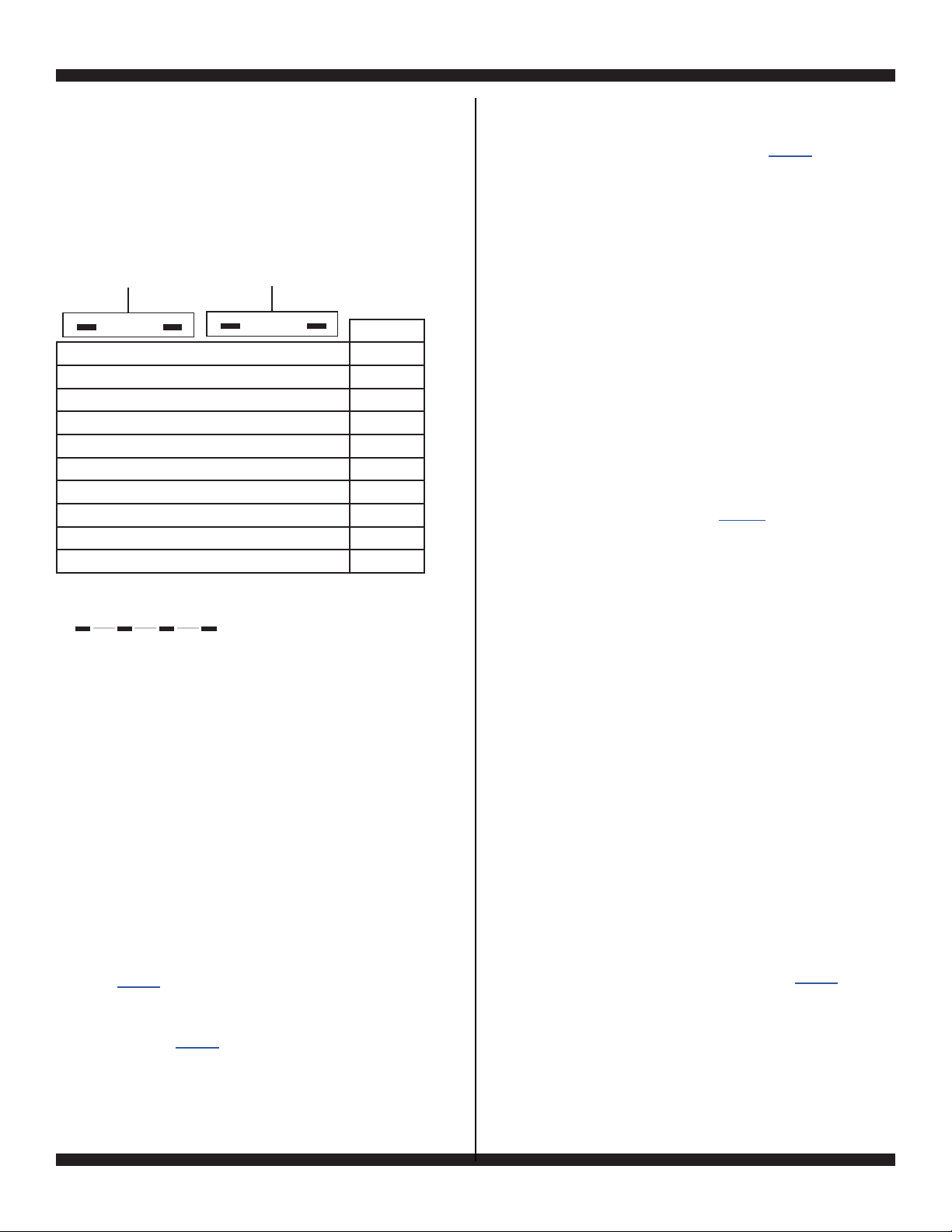

READING BINARY CODES

dz LED ON means 1.

dz LED OFF means 0.

dz The status bar will blink 2x, to display a FxEx code.

dz The first LEDs blinking will represent the F-number, and the

MUTE LED/LED 4 will be ON.

dz The Second LEDs blinking will represent the E-number, and the

MUTE LED/LED4 will be OFF.

LED group 5

0 0 0 0 0

0 0 0 1 1

0 0 1 0 2

0 0 1 1 3

0 1 0 0 4

0 1 0 1 5

0 1 1 0 6

0 1 1 1 7

1 0 0 0 8

1 0 0 1 9

LED group 6

Value

BUTTON ACTIVATION & ENCODER TEST

NOTE: The Service Diagnostic mode must be activated before entering the

Button Activation & Encoder Test; see procedure on page 10.

Entry Procedure

Press and release the 1st button used to activate Service Diagnostic mode.

The following test will be available:

DIAGNOSTIC: Button Activation & Encoder Test

The Encoder Test will be active immediately after successfully entering into

the Button Activation & Encoder Test:

➢

When the Encoder Test starts, the WET LED will be turned ON.

➢

Rotate the knob CW/CCW from the current position until a full knob

rotation is completed. Notice that the LEDs will turn ON/OFF while the

knob is rotated. After the Encoder Test is completed, all the LEDs will be

turned ON and the Button Activation test will be active. Pressing each

button will toggle ON/OFF its corresponding LEDs:

➢

Temperature LEDs will toggle ON/OFF with TEMP button.

➢

Time LEDs will toggle ON/OFF with TIME button.

➢

Static Reduce (in some models only) and Wrinkle Shield LEDs will toggle

ON/OFF with OPTIONS button.

➢

SENSE LED will toggle ON/OFF with MUTE button.

➢

WET and COOL LEDs will toggle ON/OFF with START button.

➢

DONE and MUTE LEDs will toggle ON/OFF with POWER button.

➢

If LEDs do not toggle ON/OFF after pressing buttons and rotating the

cycle selector knob go to Test #6: HMI, page 23.

Exit Procedure

To exit Button Activation & Encoder test, press and hold the 1st used to activate

Service Diagnostic mode.

Sense Soak Wash Done

Example: F3E2

1. Wash and Done are ON

2. All are OFF

3. Wash is ON

4. All are OFF

5. Back to step 1.

Unsuccessful Activation

If entry into Diagnostic mode is unsuccessful, refer to the following

indications and actions:

Indication: None of the LEDs will turn on.

Action: Turn on the appliance by pressing the POWER button or rotating the

knob and select any cycle.

➢

If LEDs turn on after pressing the POWER button or turning the knob,

then try to enter Service mode again: be sure to complete the three

key entry method within 8 seconds. Alternatively, you can try using 3

different keys to enter (excluding POWER and START). If these re-entry

procedures fail to enter into Diagnostic mode, there is likely a faulty

button in the HMI. Replace the HMI.

➢

If no LEDs come on after selecting the cycle, go to TEST #1, ACU Power

Check, page 17.

Activation with Saved Fault Codes

If there is a saved fault code, it will be flashing in the display. Review the Fault/

Error Codes table on page 14 for the recommended procedure. If there is no

saved fault code. All LEDs will turn OFF.

SERVICE TEST MODE

NOTE: The Service Diagnostic mode must be activated before entering Service

Test Mode; see procedure on page 10.

NOTE: If, at any point, the user presses the POWER button or opens the door

when not requested by the test sequence during Service test mode, the dryer

exits to standby mode.

NOTE: Door must be closed to perform test. Dryer must be cool before test

to run correctly.

Active Fault Code Display in Service Test Mode

If the display begins flashing while in Service test mode, it is displaying an

active fault code. Active fault codes are codes that are currently detected. Only

one active fault code can be displayed at a time.

Entry Procedure

To enter Service Test Mode, press and release the 2nd button used to

activate the Service Diagnostic mode then press and release the START

button. All LEDs will turn ON indicating that the Service Test Mode entry

was successful.

Perform All Tests: Run all tests indicated in the chart on page 12.

Exit Procedure

When the test is complete, press the POWER button to exit Service test mode

and return to Standby mode.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

11

FOR SERVICE TECHNICIAN’S USE ONLY

SERVICE TEST MODE CHART

Step# Action Component HMI response

1 User enters Service test mode through

Service Diagnostics by pressing

releasing the 2nd button used in entry

sequence

2 Press and release START button to

begin the test

3 All LEDs ON test starts

automatically

4 Single Button Actuation test starts

automatically

dz Press and release TEMPERATURE

button.

5 Heater/gas valve test starts

automatically

1. Press and release TEMPERATURE

button.

2. After the TEMPERATURE button is

pressed, the heater or gas valve will

be turned OFF.

6 Door test starts automatically

1. Open the door.

2. After door is opened all loads will be

turned OFF. Drum light will be turned

ON.

Door must be closed All LEDs are OFF and machine is waiting for START

button to be pressed.

Motor ON

Heater /gas valve ON

Water valve On (Steam models

only)

Motor ON

Heater /gas valve ON

Water valve On (Steam models

only)

Motor ON

Heater /gas valve ON

Water valve On (Steam models

only)

Motor ON

Heater /gas valve ON

Water valve On (Steam models

only)

Motor ON

Water valve On (Steam models

only)

-

1. All LEDs are ON.

1. All LEDs are ON at HMI and machine is waiting for the

TEMPERATURE button to be pressed.

2. After the TEMPERATURE button is pressed, all LEDs

in the HMI are turned OFF.

1. The SENSING LED is turnd ON at HMI and machine is

waiting for the TEMPERATURE button to be pressed.

2. After the TEMPERATURE button is pressed the WET

LED is turned ON.

1. The SENSING and WET LEDs are turned ON at HMI

and the machine is waiting for the user to open the

door.

2. After the door is opened, the COOL LED is turned ON.

7 Moisture strips test starts automatically

8 Service test finishes - If all sequence is completed the HMI will turn ON Sense,

NOTE: Electric dryer performance is optimized for 2-phase, 240 VAC service. If complaint is made regarding electric dryer performance and the

L1 to L2 voltage is ~208 VAC, dryer may be connected to a 3-phase service with reduced wattage that will decrease dryer performance.

If a fault is detected at anytime in the test cycle, the service test cycle will stop and display the corresponding error code.

12

DO NOT REMOVE OR DESTROY

dz User touches the front moisture

strips for 5 seconds.

10-Sep-2020 08:59:44 EDT | RELEASED

Door open 1. The SENSING and WET and COOL LEDs are turned

ON at HMI and the machine is waiting for the user to

touch the moisture strips.

Wet , Cool, Done, 90, 60, 30 and 15 minute LEDs and

the end of cycle sound is played.

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

LED group 4

SOFTWARE VERSION DISPLAY

NOTE: The Software Version Display mode will time out after 5 minutes of user

inactivity and return to standby mode.

Entry Procedure

To enter Software Version Display, press and hold the 2nd button used to

activate the Service Diagnostic mode for 5 seconds. Upon entry, the display

will automatically cycle through the following information:

Component Identi-

fier

ACU Application Firmware 1 XX:YY:ZZ

HMI Application Firmware 2 XX:YY:ZZ

Setting FIle 3 PN1:PN2:PN3:PN4:PN5:PN6:

Ƀ

Where XX.YY.ZZ corresponds to the 3 sets of 2 digit numbers that

describe a software version and PN1.PN2.PN3.PN4.PN5.PN6.PN7.PN8

is the 8 digit settings file part number.

Ƀ

The ACU, HMI and Settings file information will be displayed in the LEDs

(SENSE, SOAK, WASH, and DONE) in binary format. Consider SENSE

LED the most significant bit.

Ƀ

The identifier value of the component information will be displayed in the

TEMPERATURE LEDs in binary format. Consider HOT LED from top as

the most significant bit.

(For example: Cold LED blinks, then the Identifier is 1. Cold and Cool LED

blinks, then the Identifier is 3)

Ƀ

LED ON = 1, LED OFF = 0.

Exit Procedure

Pressing the POWER button will exit Software Version Display and return dryer

to Standby mode.

Value display

PN7:PN8

Ƀ

When the F# digits are displayed, the MUTE LED will be turned ON.

Ƀ

When the E# digits are displayed, the MUTE LED will be turned OFF.

Up to five Fault/Error codes may be stored. Additional presses of the 3rd

button will cause the system to display the next fault code. If there are no

fault codes saved, the LEDs will blink two times for each 3rd button press.

Advancing Through Saved Fault/Error Codes

Procedure for advancing through saved fault codes:

Press and release 3rd button used

to activate service diagnostics

Most recent fault code is

displayed.

Repeat Second most recent fault code is

displayed.

Repeat Third most recent fault code is

displayed.

Repeat Fourth most recent fault code is

displayed.

Repeat Fifth most recent fault code is

displayed.

Repeat Back to the most recent fault

code.

Clearing Fault Codes

To clear stored fault codes, enter Service Diagnostic mode. Then press and

hold the 3rd button used to enter Service Diagnostic mode for 5 seconds. Once

the stored fault codes are successfully erased, the LEDs will blink two times.

EXITING SERVICE DIAGNOSTIC MODE

Use below method to exit Diagnostic mode.

dz Pressing the POWER button once.

FAULT/ERROR CODES

Refer to service fault/error codes on page 14.

Fault/Error Code Display Method

LED group 2

Status

LED group 5

Indicator

LED group 1 LED group 3

Key 1

Ƀ

Fault codes are composed by a F# and an E#. The F# has two digits

LED group 6

Key 6 /

POWER

Key 5/

START

Key 2 Key 3 Key 4

and indicates the suspect System/Category. The E# has two digits and

indicates the suspect Component system.

Ƀ

The fault codes are displayed in binary format at the LEDs (SENSE,

SOAK, WASH, and DONE). When the LED is ON it represents a binary 1

and when the LED is OFF it represents a binary 0.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

13

FOR SERVICE TECHNICIAN’S USE ONLY

SERVICE FAULT/ERROR CODES

CODE DESCRIPTION EXPLANATION AND RECOMMENDED PROCEDURE

F1E1 Main Control (ACU) Fault Indicates an ACU problem.

F2E1 HMI stuck button Indicates a stuck button (depressed for over 20 seconds).

dz Replace the ACU.

See Test #6: HMI, page 23.

F3E1 Exhaust Thermistor

Open/Shorted

F3E2 Moisture Sensor

Open/Shorted

F6E1 Communication Error: HMI and ACU Communication between the ACU and HMI has not been detected.

Indicates that the exhaust thermistor is open or shorted. If the Open/Shorted temperature

drops below 18°F (-8°C) (> 50k ohms), the exhaust thermistor is open. If the temperature

is above 250°F (121°C) (< 500 ohms), the exhaust thermistor has shorted. May occur

if the J14 connector is not plugged into the ACU. See TEST #4a: Thermistor, page 21.

Indicates the moisture sensor strip is open or shorted. This fault code will only appear

when in the Service Diagnostic mode. See TEST #5: Moisture Sensor, page 22.

dz Unplug dryer or disconnect power.

dz Check the harness continuity and connections between the ACU and HMI.

dz Check AC and DC supplies. Test #1: ACU Power Check, page 17.

dz Replace the HMI.

dz Replace the ACU.

14

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

Section 3: TROUBLESHOOTING

This section provides Troubleshooting guide for the “Maytag® 7.0 cu. ft. Electric/Gas Dryer.”

Ƀ

Troubleshooting Guide

Ƀ

Troubleshooting Tests

Ƀ

Strip Circuits

Ƀ

Wiring Diagram

Ƀ

Component Locations.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

15

FOR SERVICE TECHNICIAN’S USE ONLY

TROUBLESHOOTING GUIDE

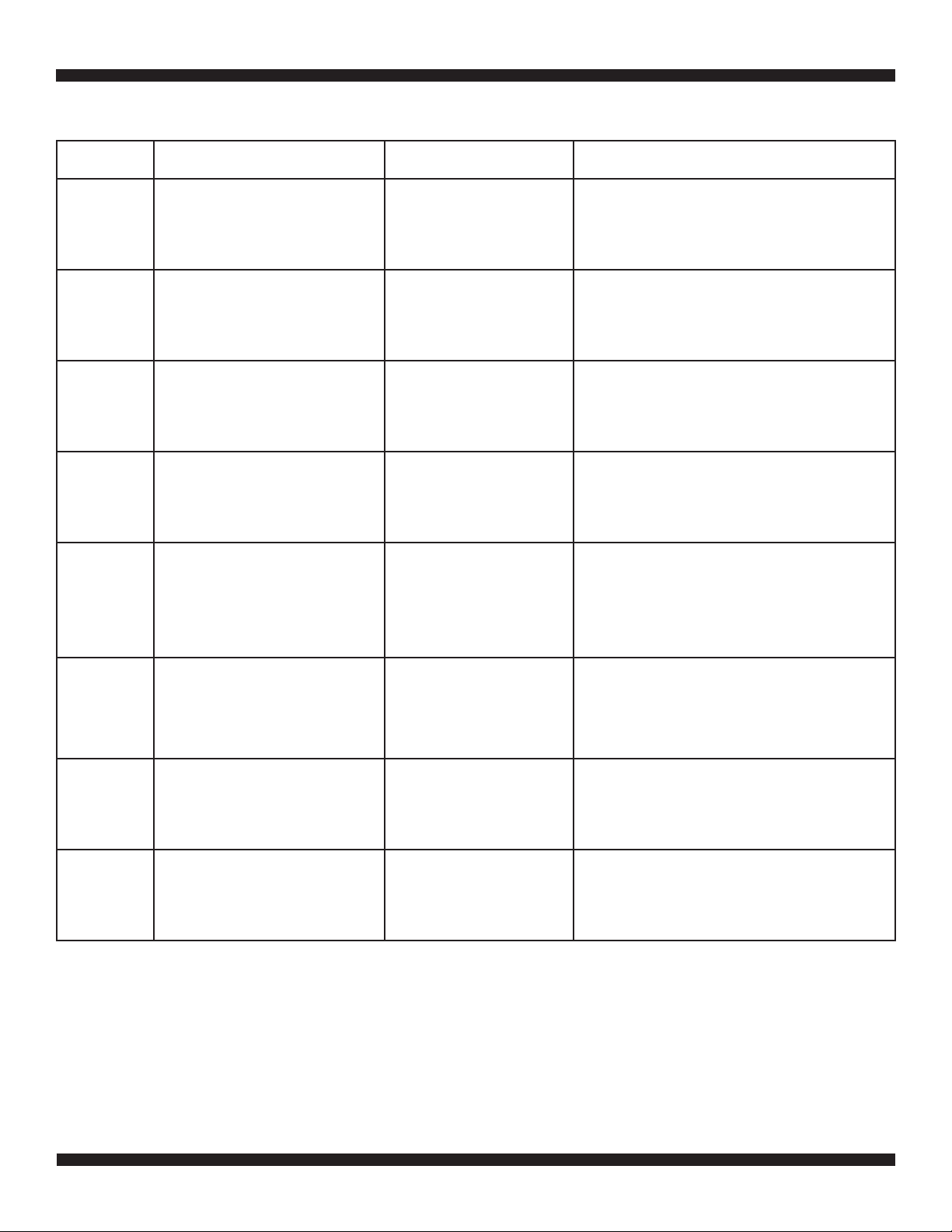

PROBLEM POSSIBLE CAUSE CHECKS & TESTS

WILL NOT POWER UP

- No operation

- No button response

- No LED’s or display

WILL NOT START CYCLE

(No response when Start button

is pressed.)

WILL NOT SHUT OFF

WHEN EXPECTED

CONSOLE WON’T ACCEPT

SELECTIONS

DRUM WILL NOT SPIN Drive Belt or Belt Switch problem See Test #3: Motor Circuit, page 19.

WILL NOT HEAT Check installation. Verify proper dryer installation.

No power to dryer. Check power at outlet, check circuit breaker, fuses, or junction box connec-

tions.

Connection problem between AC plug and dryer. See Test #2: Supply Connections, page 18.

Connection problem between ACU and HMI. Check connections and harness continuity between ACU and HMI.

Power supplies not present at machine electronics. Test #1: ACU Power Check, page 17.

HMI problem. See Test #6: HMI, page 23.

Door not fully closed or striking the door latch. Be sure the door is completely closed, then press and hold the START button.

Door Switch problem. See Test #7: Door Switch, page 23.

Drive Belt problem. See Test #3: Motor Circuit, page 19.

Thermal Fuse / Motor problem. See Test #3: Motor Circuit, page 19.

HMI problem See Test #6: HMI, page 23.

ACU problem. Test #1: ACU Power Check, page 17.

Poor airflow. Check lint screen and exhaust vent. Clean if necessary.

Check the Start/Pause button. Perform button Activation & Encoder Test.

Moisture Sensor problem. See Test #5: Moisture Sensor, page 22.

Thermistor problem. See Test #4a: Thermistor, page 21.

HMI problem. See Test #6: HMI, page 23.

ACU problem. Test #1: ACU Power Check, page 17.

User selected invalid option. Refer customer to “Use and Care Guide.”

HMI problem. See Test #6: HMI, page 23.

Thermal Fuse. See Test #4b: Thermal Fuse, page 22.

Door switch problem. See Test #7: Door Switch, page 23.

Motor problem. See Test #3: Motor Circuit, page 19.

ACU problem. Test #1: ACU Power Check, page 17.

Check for L1 and L2. See Test#2: Supply Connections, page 18.

Heater system malfunction or open heater coil. See Test #4: Heat System, page 20.

ACU problem. Test #1: ACU Power Check, page 17.

HEATS IN AIR CYCLE Heater coil shorted. See Test #4: Heat System, page 20.

Heater relay shorted. See Test #4: Heat System, page 20.

Heater system problem. See Test #4: Heat System, page 20.

SHUTS OFF BEFORE CLOTHES

ARE DRY

WATER VALVE NOT DISPENSING

(ON SOME MODELS)

(Water valve is activated intermittently during the steam cycle.)

WATER LEAKING FROM DRYER

(ON SOME MODELS)

(Too much water being dispensed

during steam cycles)

16

DO NOT REMOVE OR DESTROY

Dry Cycle selection. Select More Dry cycle to increase dryness level in the Auto cycle. Increase

Lint screen full. Clean if necessary. Refer customer to “Use and Care Guide.”

Heater vent clogged. Clean if necessary. Refer customer to “Use and Care Guide.”

Moisture Sensor problem. See Test #5: Moisture Sensor, page 22.

Steam cycle not selected. Refer customer to “Use and Care Guide”.

No water to valve. Verify water supply is turned on.

No water from valve. See Test #8: Water Valve, page 23.

Residue buildup on water nozzle opening. Unscrew nozzle and clean if necessary.

10-Sep-2020 08:59:44 EDT | RELEASED

Temperature and Time for timed cycles.

Refer customer to “Use and Care Guide.”

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

CDV5+( SUB NIW – 2J

J9 – MOTOR/L1

MOISTURE SENSOR

MOISTURE SENSOR

J8

TROUBLESHOOTING TESTS

IMPORTANT: The following procedures may require the use of needle probes

to measure voltage. Failure to use needle probes will damage the connectors.

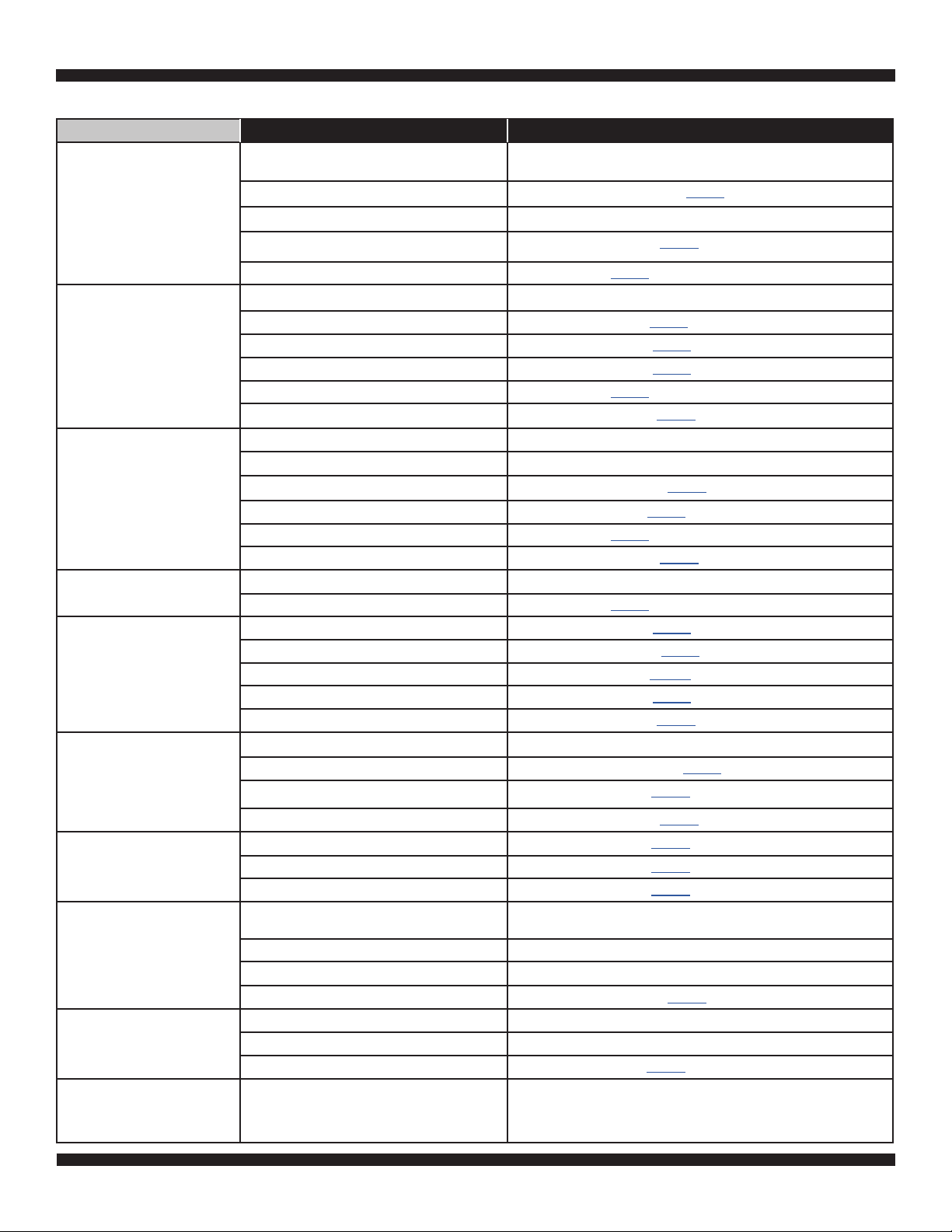

TEST #1: ACU Power Check

This test is used to determine if power is present at the machine control

electronics. This test assumes that proper voltage is present at the outlet.

1. Verify that the green LED on the ACU is lit and blinking when the dryer is

turned on.

2. Unplug dryer or disconnect power.

3. Check for appropriate line voltage at the outlet: 240 VAC

(electric 2-phase), 208 VAC(electric 3-phase), or 120 VAC (gas).

➢

If line voltage is present, go to step 4.

➢

If line voltage is not present, check for tripped circuit breaker or blown

household fuse. If CB (circuit breaker) is not tripped, have customer

check with qualified electrician.

4. Remove console to access the machine electronics.

5. ACU VAC – With voltmeter set to AC, connect black probe to ACU

J8-3 (N) and red probe to J9-2 (L1). (See Figure 1.) Plug in dryer or

reconnect power.

➢

If 120 VAC is present, unplug dryer or disconnect power and go to

step 6.

➢

If 120 VAC is not present, unplug dryer or disconnect power and perform

TEST #2: Supply Connections, page 18.

6. ACU +5 VDC – With voltmeter set to DC, unplug connector J2 from the

ACU and connect black probe to ACU J2-3 (ground) and red probe to

J2-1 (+5 VDC). Plug in dryer or reconnect power.

➢

If +5 VDC is present, unplug dryer or disconnect power and go to

step 9.

➢

If +5 VDC is not present, go to step 7.

7. Unplug dryer or disconnect power. Unplug J14 from the ACU. Plug in

dryer or reconnect power and repeat step 6.

➢

If +5 VDC returns, the thermistor has shorted. To diagnose

thermistor,see TEST #4a, page 21.

➢

If +5 VDC is not present, go to step 8.

8. Unplug dryer or disconnect power. Reconnect J14 to the ACU and

unplug J2 from the ACU. Plug in dryer or reconnect power and repeat

step 6. Perform voltage check inside header J2 on ACU, between

pins 2 & 4—DO NOT SHORT PINS TOGETHER.

➢

If +5 VDC is still missing, unplug dryer or disconnect power and replace

the ACU.

➢

If +5 VDC returns, unplug dryer or disconnect power and check

harnesses and connections between the ACU and HMI. If acceptable,

replace the HMI.

9. ACU +12 VDC – with voltmeter set to DC, connect black probe to

ACU J2-4 (ground) and red probe to J2-1 (+12 VDC). Plug in dryer or

reconnect power.

➢

If +12 VDC is present, go to step 11.

➢

If +12 VDC is not present, go to step 10.

10. Unplug dryer or disconnect power. Unplug connector J2 from the ACU.

Perform voltage check inside heater J2 on ACU, between pins 1 & 4 DO NOT SHORT PINS TOGETHER.

➢

If +12.7 VDC is still missing, unplug dryer or disconnect power and

replace the ACU.

➢

If +12.7 VDC returns, unplug dryer or disconnect power and check

harnesses and connections between the ACU and HMI. If acceptable,

replace the HMI.

11. Unplug dryer or disconnect power.

12. Reassemble all parts and panels.

13. Perform steps under “Service Test Mode”, page 11, to verify repair.

and +12.7 VDC)

J2-1 RED +12.7 VDC

2 1

J2-2 NC +5 VDC

J2

3

J2-3 YEL DATA

4

J2-4 BLK GND

J8 – MYST VALVE/DOOR SWITCH/AC BUZZER

J8-5 TAN AC BUZZER

4 5

J8-4 TAN DOOR SWITCH

J8

J8-3 WHT NEUTRAL

2 3

J8-2 G/Y CHASSIS GND

1

J8-1 BLK MYST VALVE

(ON SOME MODELS)

J14-3 R/W OUTLET THERMISTOR

J14-2 OPEN

J14-1 OPEN

Heater Relay #1

(Gas & Electric)

Heater - VT

= Pin 1

L1-BLK

K2

K3

J14 – THERMISTORS

J14

6

3

J14-6 R/W OUTLET THERMISTOR

2 5

1 4

J14-4 OPEN

Motor Relay

J9

K1

2

J9-2 BLK L1

J9

1

J9-1 LT BLU MOTOR

J13 – MOISTURE SENSOR

1

J13-1 BLK

J13

2

J13-2 RED

OPENJ14-5

J13

J6

J23

J2

J14

Figure 1 - ACU Connectors and Pinouts

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

17

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

J9

TEST #2: Supply Connections

This test assumes that proper voltage is present at the outlet, and for U.S.

installations, a visual inspection indicates that the power cord is securely

fastened to the terminal block (electric dryer) or wire harness connection

(gas dryer).

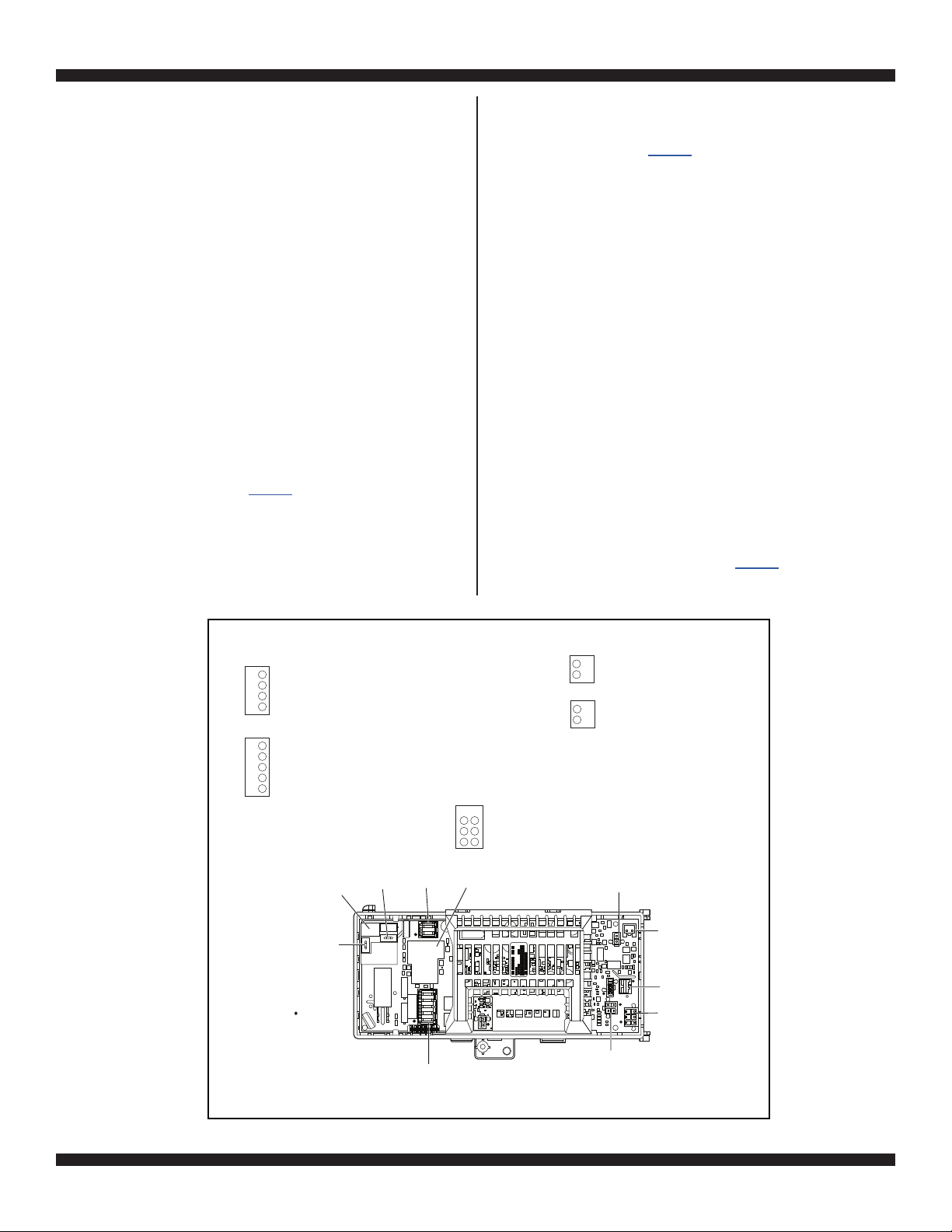

ELECTRIC DRYER (U.S. Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top center portion of the back of the

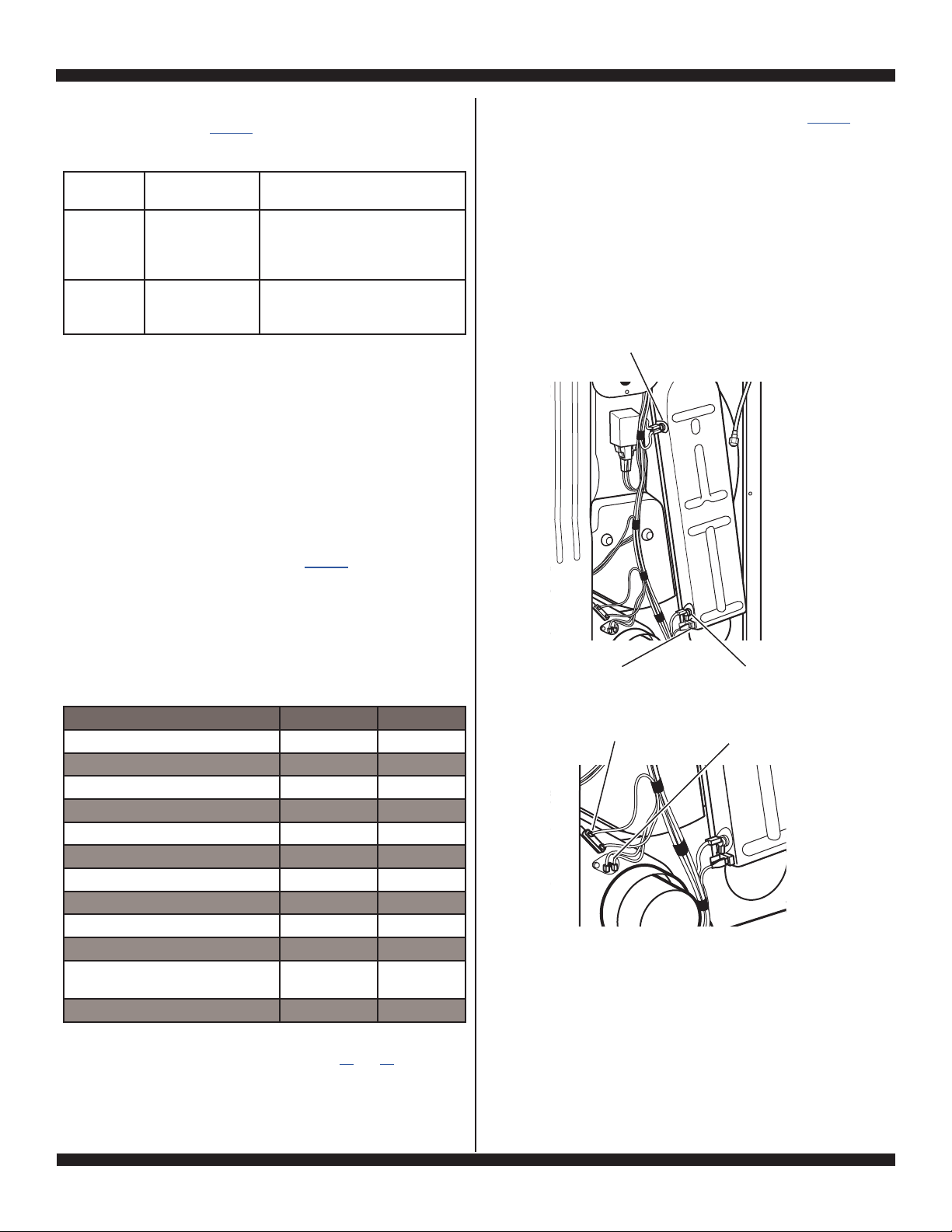

dryer. See figure 2.

3. With an ohmmeter, check for continuity between the neutral (N) terminal

of the plug and the center contact on the terminal block. See figure 3a.

➢

If there is no continuity, replace the power cord and test the dryer.

➢

If there is continuity, go to step 4.

4. In a similar way, check which terminal of the plug is connected to the

left-most contact on the terminal block and make a note of it. This will be

L1 (black wire) in the wiring diagram. See figure 3a.

➢

When this is found, go to step 5.

➢

If neither of the plug terminals have continuity with the left-most contact

of the terminal block, replace the power cord and retest dryer.

Cover Plate

Figure 2 - Remove the cover plate.

Power Cord

N

Plug

COM

Terminal Block

L1

Remove screw

9. Check the wiring and continuity from the L2 terminal of the terminal block

and the 2M terminal in the white connector from the Motor, see figure 7

on page 19. Also, locate these measurement points by referring to the

appropriate wiring diagram (Electric) on page 27.

➢

If there is continuity, go to step 10.

➢

If there is no continuity, check that wires to the terminal block are

mechanically secure. If so, replace the main wire harness and test the

dryer.

10. Visually check that ALL connectors are fully inserted into the ACU.

11. Visually check that ALL connectors are fully inserted into the HMI.

12. Reassemble all parts and panels.

13. Plug in dryer or reconnect power.

14. Perform steps under “Service Test Mode”, page 11, to verify repair.

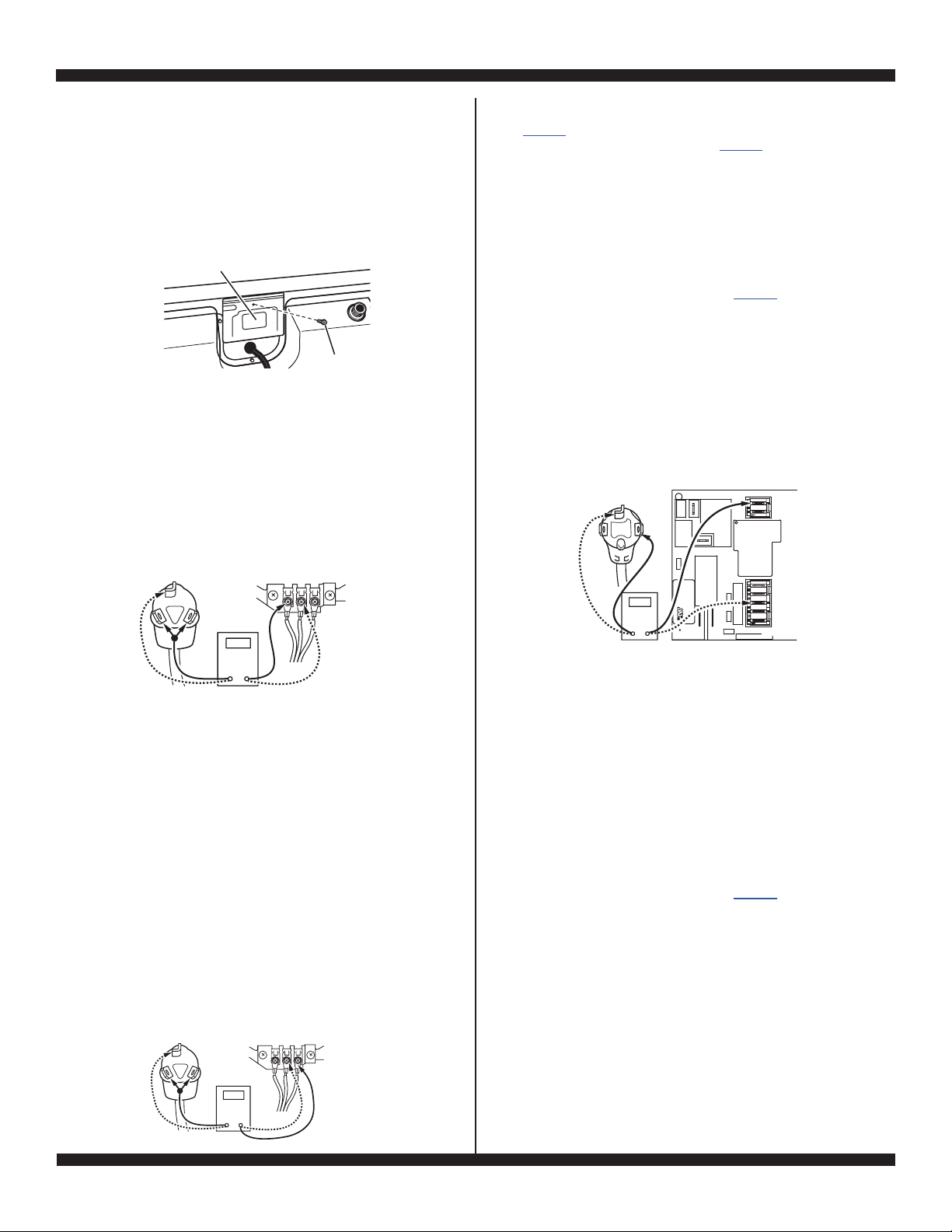

ELECTRIC DRYER (Canadian Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top center portion of the back of the

dryer. See figure 2.

3. Access the machine electronics without disconnecting any wiring to the

ACU.

4. With an ohmmeter, check the continuity from L1 and N plug terminals of

the power cord to the terminals for L1 and N on the ACU. See figure 3c.

Power Cord

Neu

N

Plug

COM

L1

Date Code YDDD-xx

MADE IN COO

XXXX-XXX

P/N XXXXXX Rev X

1

ACU

L1

5

N

Neu

1

J8

Figure 3c - Plug-to-terminal connections

for electric dryer.

Figure 3a - Plug-to-terminal connections for electric dryer.

5. Access the machine electronics without disconnecting any wiring to the

ACU.

6. With an ohmmeter, check for continuity between the L1 terminal of the

plug (found in step 4) and J9-2 (black wire) on the ACU.

➢

If there is continuity, go to step 7.

➢

If there is no continuity, check that wires to the terminal block are

mechanically secure. If so, replace the main wire harness and test the

dryer.

7. Check for continuity between the neutral (N) terminal of the plug and

J8-3 (white wire) on the ACU.

➢

If there is continuity, go to step 8.

➢

If there is no continuity, and the mechanical connections of the wire are

secure, replace the main wire harness.

8. With an Ohmmeter, check which terminal of the plug is connected to the

right-most contact on the terminal block and make a note of it. This will

be L2 (Red wire) in the wiring diagram. See figure 3b.

➢

When this is found, go to step 9.

➢

If neither of the plug terminals have continuity with the right-most contact

of the terminal block, replace the power cord and retest dryer.

COM

ACU

L2

N

Power Cord

Plug

Figure 3b - Plug-to-terminal connections for electric dryer.

➢

If continuity exists for both connections, go to step 6.

➢

If an open circuit is found, check the integrity of the connections of the

power cord to the harness in the dryer; harness to the ACU; and the

integrity of the power cord itself.

5. If it is necessary to replace the power cord, remove the retaining clip that

secures the cord to the back panel. Disconnect the cord from the main

harness and the ground wire from the rear panel, then pull out the power

cord.

6. Visually check that ALL connectors are fully inserted into the ACU.

7. Visually check that ALL connectors are fully inserted into the HMI.

8. Reassemble all parts and panels.

9. Plug in dryer or reconnect power.

10. Perform steps under “Service Test Mode”, page 11, to verify repair.

18

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

GAS DRYER (U.S. and Canadian Installations):

1. Unplug dryer or disconnect power.

2. Remove the cover plate from the top center portion of the back of the

dryer. See figure 2.

3. Check that the power cord is firmly connected to the dryer’s wire

harness. See figure 4.

Power Cord

Wire Harness

Figure 4 - Power cord-to-wire harness

connection for gas dryer.

4. Access the machine electronics without disconnecting any wiring to the

ACU.

5. With an ohmmeter, check for continuity between the neutral (N) terminal

of the plug and J8-3 (white wire) on the ACU. The left-hand side of figure

6 shows the position of the neutral terminal (N) on the power cord plug.

Also see figure 1, page 17.

➢

If there is continuity, go to step 6.

➢

If there is no continuity, disconnect the white wire of the main harness

from the power cord at the location illustrated in figure 4. Test the

continuity of the power cord neutral wire as illustrated in figure 5. If an

open circuit is found, replace the power cord. Otherwise, go to step 6.

N

L1

G

Masse

Neu

Power Cord

Plug

COM

N

Neu

G

Masse

L1

Figure 5 - Power cord terminals, gas dryer.

6. In a similar way, check for continuity between the L1 terminal of the plug

and J9-2 (black wire) on the ACU.

➢

If there is continuity, go to step 7.

➢

If there is no continuity, check the continuity of the power cord in a

similar way to that illustrated in figure 6, but for power cord’s L1 wire.

➢

If an open circuit is found, replace the power cord. Otherwise, replace the

main harness.

7. Visually check that ALL connectors are fully inserted into the ACU.

8. Visually check that ALL connectors are fully inserted into the HMI.

9. Reassemble all parts and panels.

10. Plug in dryer or reconnect power.

11. Perform steps under “Service Test Mode”, page 11, to verify repair.

TEST #3: Motor Circuit

This test will check the wiring to the motor and the motor itself. The

following items are part of this motor system:

Part of Motor

Electric Dryer Gas Dryer

System

Drum belt 3 3

Door switch 3 3

Harness/connection 3 3

Thermal fuse 3 3

Drive motor 3 3

Centrifugal switch 3 3

Part of Motor System Electric Dryer Gas Dryer

Machine control

3 3

electronics

Belt switch 3 3

NOTE: Refer to strip circuit on page 25 to diagnose drive motor.

1. Unplug dryer or disconnect power.

2. Remove console to access the machine electronics.

3. Check for loose, worn, or damaged drum belt—repair as necessary.

4. Door Switch problems can be uncovered by following procedure under

TEST #7: Door Switch, page 23; however, if this was not done, the

following can be performed without applying power to the dryer. Connect

an ohmmeter across ACU J8-3 (neutral, white wire) and J8-4

(door, tan wire).

➢

With the door properly closed, the ohmmeter should indicate a closed

circuit (0–2 Ω).

➢

If not, check harnesses and connections between ACU and door switch.

If good, replace the door switch assembly.

5. Motor Circuit Check - Access the ACU and measure the resistance

across J8-4 and J9-1.

➢

If resistance across J8-4 and J9-1 is inthe range of 1 to 6 Ω, the motor

circuit is acceptable. Replace the ACU.

➢

Otherwise, continue to step 6.

6. Check the wiring and components in the path between these

measurement points by referring to the appropriate wiring diagram (gas

or electric) on pages 26 or 27 or 28.

NOTE: To access motor system components, remove the front panel.

Check the thermal fuse. See TEST #4b: Thermal Fuse, page 22.

ALL DRYERS: Continue with step 7 below to test the remaining components

in the motor circuit.

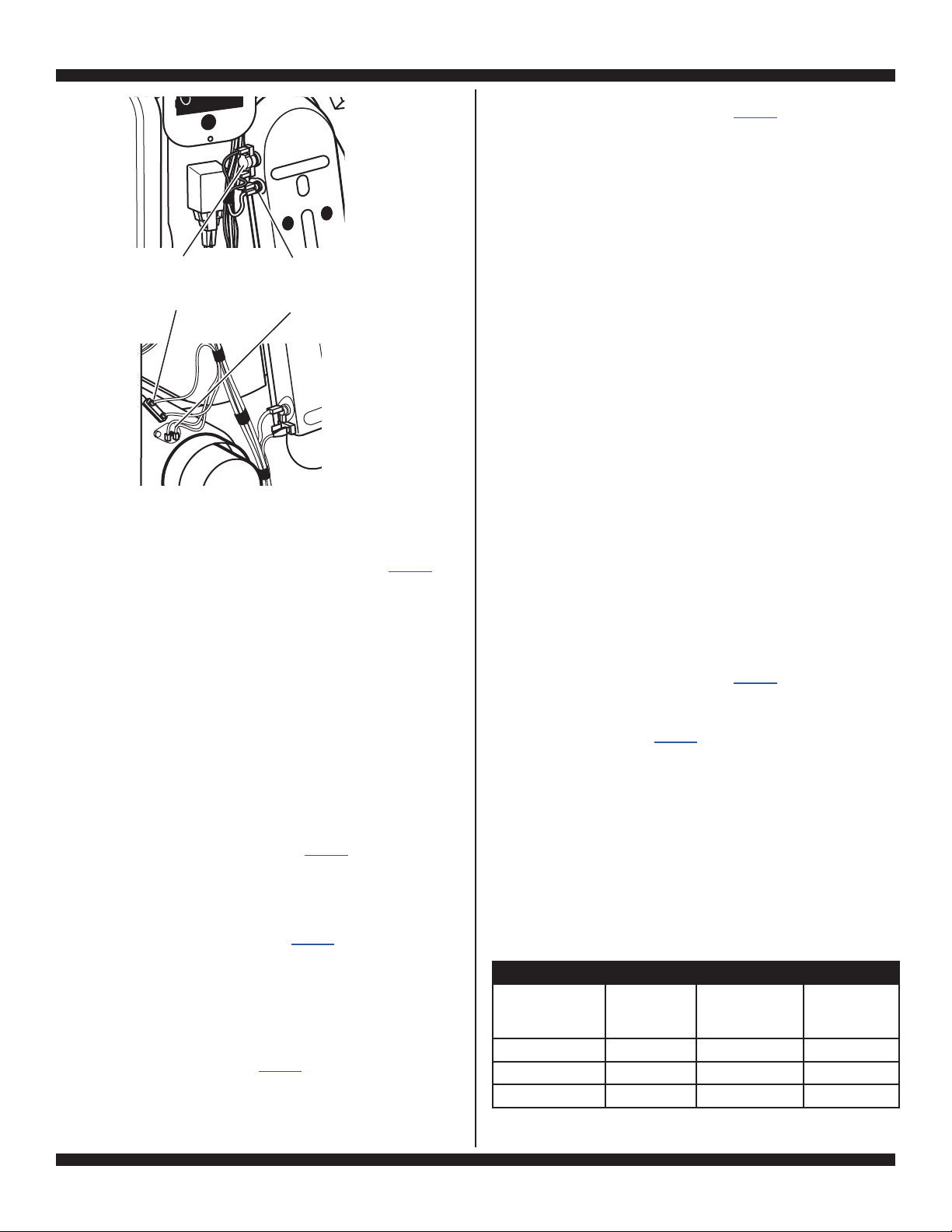

7. Check the drive motor. Slowly remove the drum belt from the springloaded pulley, gently letting the pulley down. See figure 6.

Pulley

Belt

Figure 6 - Slowly remove drum belt.

8. Remove the white connector from the drive motor switch. See figure 7.

Connector.

Figure 7 - Remove connector.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

19

FOR SERVICE TECHNICIAN’S USE ONLY

9. Remove the bare copper wire terminal from pin 5 of black drive motor

switch.

10. Using the strip circuit on page 25, check for the resistance values of the

motor’s Main and Start winding coils as shown in the following table.

NOTE: Main and Start winding coils must be checked at the motor.

Winding

MAIN 3.3–3.6 Lt. blue wire in back at pin 4 and

START 2.7–3.0 Lt. blue wire in back at pin 4 and

➢

If the resistance at the motor is correct, there is an open circuit between

the motor and ACU. Check and repair the main wiring harness as needed.

➢

If the Main or Start winding resistance is much greater or less than the

values listed in the table above, replace the motor.

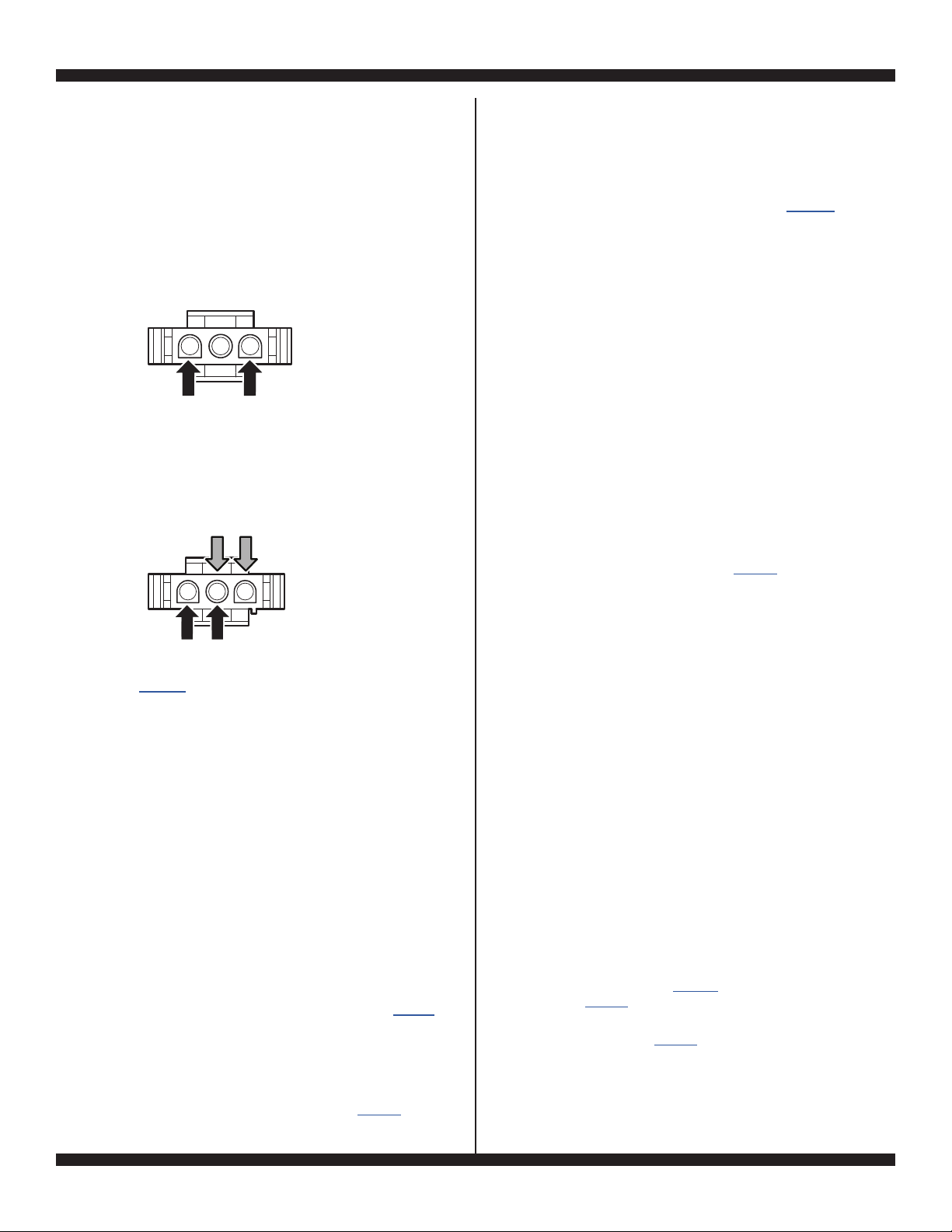

11. Check the belt switch by measuring resistance between the two light blue

wires in the belt switch connector block while pushing up the belt switch

pulley.

➢

If the resistance reading goes from open to a few ohms as pulley arm

closes the switch, belt switch is good. If not, replace the belt switch.

➢

If belt switch is good and there is still an open circuit, check and repair

the main wiring harness.

12. Reassemble all parts and panels.

13. Plug in dryer or reconnect power.

14. Perform steps under “Service Test Mode”, page 11, to verify repair.

Resistance in

ohms

Contact Points of Measurement

bare copper wire terminal removed

from pin 5 of black drive motor

switch.

bare copper wire terminal on pin 3

of black drive motor switch.

ELECTRIC DRYER ONLY:

dz Quick Check: Perform steps under “Service Test Mode”, page 11, to test

the machine capability to turn ON and OFF the Heater in the Load test.

dz If Heater relay can be turned ON and OFF by the ACU during the Service

Test, then verify that L1 and L2 are present by executing Test #2: Supply

Connections. Also check for appropriate line voltages at the outlet:

240 VAC (electric 2-phase) and 208 VAC (electric 3-phase).

1. Unplug dryer or disconnect power.

2. Remove the back panel to access thermal components.

3. Check Heater—on the ACU, use an ohmmeter to measure the resistance

from the violet wire terminal at the thermal cut-off to the red-white wire

terminal at the High Limit.

➢

If the resistance is about 10 Ω, go to step 5.

➢

If an open circuit is detected, go to step 4.

Thermal Cut-Off

TEST #4: Heat System

This test is performed when either of the following situations occurs:

3 Dryer does not heat.

3 Heat will not shut off.

This test checks the components making up the heating circuit. The following

items are part of this system:

Part of heating System Electric Dryer Gas Dryer

Harness/connection 3 3

Heater relay 3 3

Thermal cut-off 3 3

Thermal fuse no no

High limit thermostat 3 3

Heat element assembly 3 no

Gas valve assembly no 3

Centrifugal switch 3 3

Outlet thermistor 3 3

Machine control electronics 3 3

Console electronics and housing

assembly

Gas supply no 3

Dryer does not heat:

Locate the components using figures 8 and 9, page 20 and 21. To access

heater system components, remove the back panel.

3 3

Heater

Element

Thermal Fuse

Figure 8 - Thermal components,

electric dryer.

High Limit

Thermostat

Outlet Thermistor

20

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

High Limit Thermostat

Thermal Fuse Outlet Thermistor

Figure 9 - Thermal components, gas dryer.

4. Visually check the wire connections to the thermal cut-off, high limit

thermostat, and heater. If the connections look good, check for continuity

across each of these components. Refer to strip circuit on page 25.

➢

Replace the heater if it is electrically open.

➢

Replace both the thermal cut-off and high limit thermostat if either the

thermal cut-off or the high limit thermostat is electrically open.

5. If no open circuit is detected, remove the J14 connector from the ACU

and measure the outlet thermistor resistance between J14-3 and J14-6

at the connector. Refer to “Outlet Thermistor Resistance” table for

temperatures and their associated values.

➢

If the resistance corresponds to the temperature, the outlet thermistor is

good. Go to step 6.

➢

If the thermistor resistance does not agree with the table, replace the

outlet thermistor.

6. If the preceding steps did not correct the problem and L1 and L2 were

both detected, replace the ACU. If L2 was not detected, inspect the

centrifugal switch before replacing the ACU. If the centrifugal switch is

damaged then change the motor.

7. Reassemble all parts and panels.

8. Plug in dryer or reconnect power.

9. Perform steps under “Service Test Mode”, page 11, to verify repair.

GAS DRYER ONLY:

1. Verify the gas supply to the dryer is turned on.

2. Unplug dryer or disconnect power.

3. Perform TEST #4c: Thermal Cut-Off on page 22. If the thermal cut-off is

OK, go to step 4.

4. Locate the high limit thermostat (see figure 9). Measure the continuity

through it by connecting the meter probes to the black and light blue wire

terminals.

➢

If there is an open circuit, replace both the high limit thermostat and the

thermal cut-off.

➢

Otherwise, go to step 5.

5. Perform TEST #4d: Gas Valve on page 22. If the gas valve is OK, go to

step 6.

6. If the preceding steps did not correct the problem, suspect the centrifugal

switch before replacing the ACU.

7. Reassemble all parts and panels.

Thermal Cut-Off

8. Plug in dryer or reconnect power.

9. Perform steps under “Service Test Mode”, page 11, to verify repair.

Heat will not shut off:

ALL DRYERS:

1. Unplug dryer or disconnect power.

2. Remove console to access the machine electronics.

3. Remove connector J14 from the ACU and measure the resistance

between J14-3 and J14-6 at the connector. Refer to “Outlet Thermistor

Resistance” table for temperatures and their associated values.

➢

If the resistance corresponds to the temperature, the outlet thermistor is

good.

➢

If the thermistor resistance does not agree with the table, replace the

outlet thermistor.

4. Check heater coil for a short to ground (usually inside the heater box).

Repair or replace if necessary.

5. Check heater relay output on the ACU with a voltmeter set to AC, connect

voltmeter to terminals 1 & 2 of heater relay. Plug in dryer or reconnect

power.

6. Perform steps under “Service Test Mode”. When reaching Service Test

step 5, measure the voltage across terminals 1 & 2.

➢

If little or no voltage is present, the relay is closed and heater is activated,

go to step 7.

➢

If voltage is present (~240 VAC for electric, ~120 VAC for gas), the

relay is open an not working when commanded by the ACU. Replace

ACU.

7. Under “Service Test Mode” go to Service test step 6, measure the

voltage across terminals 1 & 2.

➢

If voltage is present (~240 VAC for electric, ~120 VAC for gas), the

relay is open and working when commanded by the ACU. Go to step 8.

➢

If little or no voltage is present, the relay is closed and heater is activated

without being commanded by the ACU. Replace ACU.

8. Unplug dryer or disconnect power.

9. Reassemble all parts and panels.

10. Plug in dryer or reconnect power.

11. Perform steps under “Service Test Mode”, page 11, to verify repair.

TEST #4a: Thermistor

NOTE: Refer to strip circuit on page 25 to diagnose outlet temperature

thermistor.

Outlet (Exhaust) Thermistor

The ACU monitors the exhaust temperature using the outlet thermistor,

and cycles the heater relay on and off to maintain the desired temperature.

NOTE: Begin with an empty dryer and a clean lint screen.

1. Unplug dryer or disconnect power.

2. Remove console to access the machine electronics.

3. Remove connector J14 from the ACU and measure the resistance

between J14-3 and J14-6 at the connector. The following table gives

temperatures and their associated resistance values.

NOTE: All thermistor resistance measurements must be made while dryer

is unplugged and connector removed from ACU.

OUTLET THERMISTOR RESISTANCE

TEMPERATURE

°F (°C)

50° (10°) 19.0–22.0 80° (27°) 8.5–10.5

60° (16°) 14.8–16.8 90° (32°) 6.8–8.8

70° (21°) 11.5–13.5 100° (38°) 5.0–7.0

➢

If the resistance is OK, the outlet thermistor is good. Proceed to step 4.

RESISTANCE

RANGE

k ohms

TEMPERATURE

°F (°C)

RESISTANCE

RANGE

k ohms

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

21

FOR SERVICE TECHNICIAN’S USE ONLY

➢

If the thermistor resistance does not agree with the table, replace the

outlet thermistor.

4. Check J14-3 and J14-6 to dryer cabinet ground. If either pin indicates

continuity to ground (short), replace wiring harness;otherwise, proceed

to step 5.

5. If the preceding steps did not correct the problem, replace the ACU.

Temperature Levels Incorrect – If no error code is displayed and the

connections to the thermistor are good, check the exhaust temperature

value at any or all of the temperature levels in question, using the

Timed Dry cycle.

1. Remove load from dryer and disconnect external vent.

2. Plug in dryer or reconnect power.

3. Run a TIMED DRY cycle with 15 minutes in duration and select a

temperature setting using heat.

4. Using a calibrated temperature probe, take a temperature measurement

in the center of the exhaust outlet. The correct exhaust temperatures are

as follows:

EXHAUST TEMPERATURES

TEMPERATURE

SETTING

High 150° ± 5° (65° ± 3°) 10°–15° (6°–8°)

Medium 143° ± 5° (62° ± 3°)

Low 137° ± 5° (58° ± 3°)

Ex Low 125° ± 5° (52° ± 3°)

➢

If the temperature is not reached within ~7 minutes, check voltage level

and vent blockage, and then retest.

➢

If the temperature probe does not agree with temperature setting, replace

the outlet thermistor.

➢

If the temperature probe confirms the temperature setting, retest at a

different temperature setting.

5. If the preceding steps did not correct the problem, replace the ACU.

TEST #4b: Thermal Fuse

The thermal fuse is wired in series with the dryer drive motor.

ALL DRYERS:

1. Unplug dryer or disconnect power.

2. Remove the back panel to access the thermal fuse.

3. Using an ohmmeter, check the continuity across the thermal fuse.

➢

If the ohmmeter indicates an open circuit, replace the thermal fuse.

TEST #4c: Thermal Cut-Off

If the dryer does not produce heat, check the status of the thermal cut-off.

1. Unplug dryer or disconnect power.

2. Access the thermal cut-off by removing the back panel.

3. Using an ohmmeter, check the continuity across the thermal cut-off. See

figures 8 and 9, pages 20 and 21 for location.

4. If the ohmmeter indicates an open circuit, perform the following:

ALL DRYERS: Replace both the thermal cut-off and high limit thermostat.

In addition, check for blocked or improper exhaust system, and, on electric

dryers, for heat element malfunction.

TEST #4d: Gas Valve (Gas Dryer)

1. Unplug dryer or disconnect power.

2. Access the gas valve, by removing the front panel.

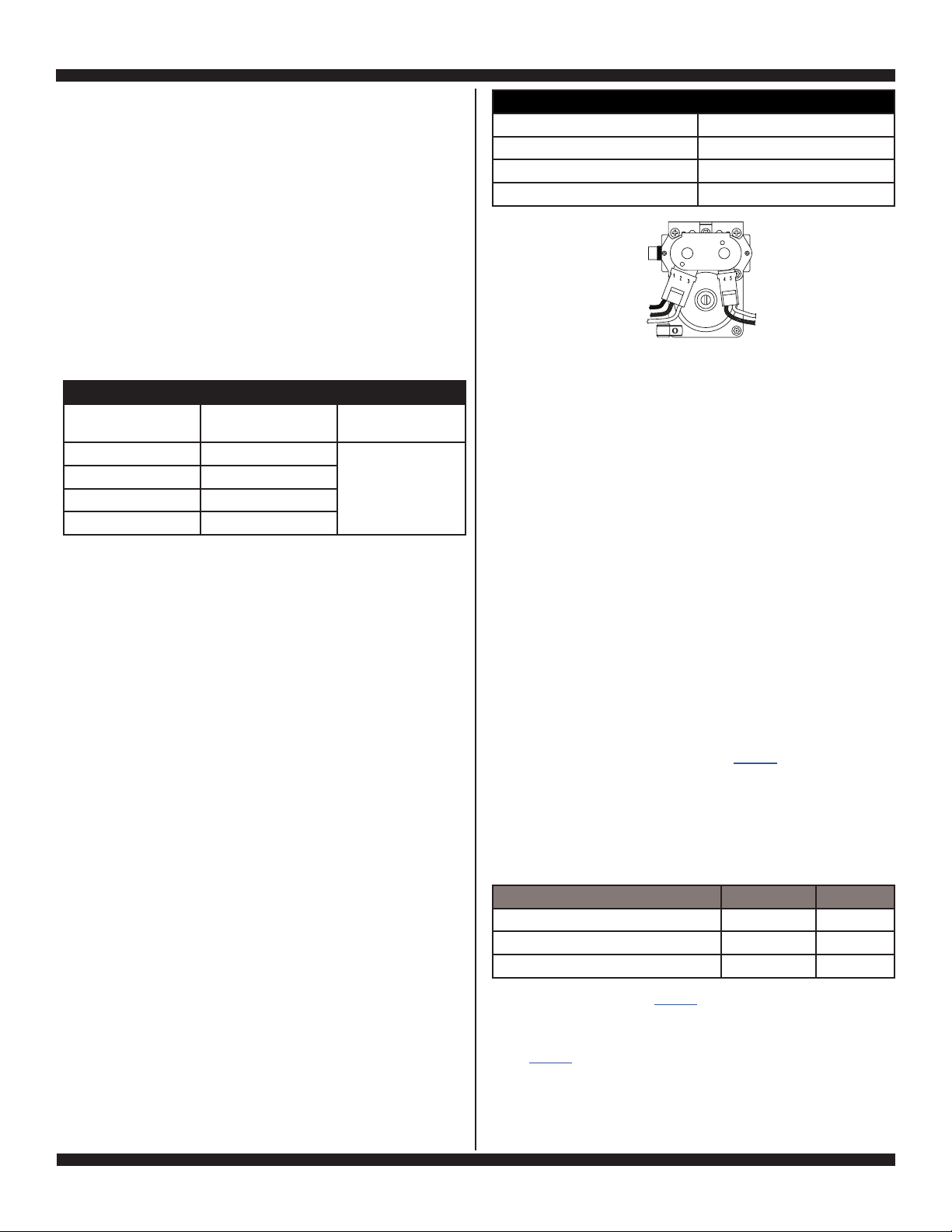

3. Use an ohmmeter to determine if a gas valve coil has malfunctioned.

Remove harness plugs. Measure resistance across the terminals

(see figure 10). Readings should match those shown in the following

chart; if not, replace coils.

HEAT TURNS OFF

°F (°C)

HEAT TURNS ON

°F (°C)

below the

heat turn off

temperature

GAS VALVE RESISTANCE

Terminals Resistance in ohms

1 to 2 1400 ± 70

1 to 3 570 ± 28.5

4 to 5 1300 ± 65

Black

Light Blue

White

Figure 10 - Measuring gas valve resistance.

4. Disconnect the ignitor plug from the burner. Using an ohmmeter, measure

the resistance across the ignitor’s 2-pin connector. Resistance should be

50-500 Ω.

➢

If resistance readings are outside the range or open, replace the ignitor.

➢

If resistance readings are within range, reconnect the ignitor plug and

continue to step 5.

5. Disconnect the wires going to the flame sensor terminals. Using an

ohmmeter, measure across the two sensor terminals for continuity.

➢

If there is continuity, reconnect the sensor wires and continue to step 6.

➢

If the reading is open, the flame sensor needs replacing.

6. Reassemble all parts and panels before reconnecting power.

7. Plug in dryer or reconnect power.

8. Run a high-temp TIMED DRY cycle 15 minutes in duration.

9. Watch the ignitor for a couple of minutes through the “peek window” in

the side. If the ignitor stays red hot and the gas does not come out and

ignite, the flame sensor needs replacing.

NOTE: If ignitor does not come on, line voltage may not be present at the

gas burner. The motor centrifugal switch may be suspect.

IMPORTANT: To avoid damage to the gas burner wire harness, ensure

the harness is routed exactly as it was prior to service.

10. Unplug dryer or disconnect power.

11. Reassemble all parts and panels.

12. Plug in dryer or reconnect power.

13. Perform steps under “Service Test Mode”, page 11, to verify repair.

White

Light Blue

TEST #5: Moisture Sensor

This test is performed when an automatic cycle stops too soon, or runs much

longer than expected.

NOTE: Dryer will shut down automatically after 2½ hours.

The following items are part of this system:

Part of Moisture System Electric Dryer Gas Dryer

Harness/connection 3 3

Metal sensor strips 3 3

Machine control electronics 3 3

NOTE: Refer to strip circuit on page 25 to diagnose moisture sensor.

NOTE: Over-drying may be caused by a short circuit in the sensor system.

1. Perform steps under “Service Test Mode” up to the Service Test step 6.

See page 11.

2. Open the door. Using a wet cloth or one finger, jointly touch both sensor

strips.

➢

If the test is completed successfully the End of Cycle signal will play. This

means that the moisture sensor has passed the test. Go to step 9.

22

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

FOR SERVICE TECHNICIAN’S USE ONLY

➢

If the test doesn’t complete by touching the front moisture sensor,

continue with step 3.

3. Unplug dryer or disconnect power.

4. Remove console to access the machine electronics.

5. Access the moisture sensor wires and disconnect the 3-wire moisture

sensor connector.

6. Access the ACU and remove connector J13 from the circuit board.

Check the wire harness for continuity between J13 and the moisture

sensor connector.

➢

If there is continuity, go to step 7.

➢

If there is no continuity, replace the main harness.

7. Measure the resistance across the outermost contacts of the connector

that includes the two MOVs.

➢

If a small resistance is measured, clean the two metal moisture strips

inside the drum.

➢

If a small resistance is measured after cleaning, replace the sensor

harness.

➢

If a small resistance is not measured, go to step 8.

8. Measure the resistance across each of the outermost contacts and the

center terminal (ground connection).

Some buttons do not respond:

1. Unplug dryer or disconnect power.

2. Remove console to access the ACU and HMI.

3. Replace the HMI.

4. Reassemble all parts and panels.

5. Plug in dryer or reconnect power.

6. Perform the “Button Activation & Encoder Test” (see page 11) to verify

repair.

No beep sound is heard:

1. Verify that the MUTE option is OFF.

2. Unplug dryer or disconnect power.

3. Remove console to access the ACU and HMI.

4. Visually check that ALL ACU connectors are inserted all the way into the

ACU.

5. Visually check that ALL HMI connectors are inserted all the way into the

HMI.

6. Verify that the AC Buzzer connector is inserted all the way in.

7. Check the wire continuity between terminal J8-5 at the ACU and the AC

Buzzer.

➢

If there is continuity go to step 8.

➢

If there is no continuity replace main harness.

8. Check the wire continuity between terminal J9-2 at the ACU and the AC

Buzzer.

➢

If there is continuity go to step 9.

➢

If there is no continuity replace main harness.

9. Reassemble all parts and panels.

10. Plug in dryer or reconnect power.

11. Perform steps under “Service Test Mode”, page 11, to verify repair.

12. If the problem is still present, replace the AC Buzzer and verify

functionality.

13. If after replacing the AC Buzzer the issue is still present, replace the ACU.

➢

If a resistance less than infinity is measured, replace the sensor harness.

9. If the moisture sensor diagnostic test passes, check the outlet thermistor:

TEST #4a, page 21.

10. If the preceding steps did not correct the problem, replace the ACU.

TEST #6: HMI

This test is performed when any of the following situations occurs during the

“Button Activation & Encoder Test” or no sound is heard after the End of the

Cycle and MUTE option is OFF.

3 None of the LEDs turn on.

3 Some buttons do not respond.

3 No beep sound is heard.

None of the LEDs turn on:

1. Unplug dryer or disconnect power.

2. Remove console to access the ACU and HMI.

3. Visually check that ALL ACU connectors are inserted all the way into the

ACU.

4. Visually check that ALL HMI connectors are inserted all the way into the

HMI.

5. If all visual checks pass, perform Test #1: ACU Power Check, page 17, to

verify supply voltages.

➢

If supply voltages are present, replace the HMI.

➢

If supply voltages are not present, replace the ACU.

6. Reassemble all parts and panels.

7. Plug in dryer or reconnect power.

8. Perform the “Button Activation & Encoder Test” (see page 11) to verify

repair.

TEST #7: Door Switch

Functionality is verified when opening the door turns on the drum light.

Closing the door should turn off the drum light.

If the preceding conditions are not met:

1. Unplug dryer or disconnect power.

2. Remove console to access the machine electronics.

3. Check that the wires between the door switch and ACU are connected.

(Refer to wiring diagrams on pages 26, 27 and 28).

➢

If the connections are good, replace the wire and door switch assembly

and retest.

➢

If wire and door switch assembly have been replaced and dryer still does

not start, replace the ACU.

4. Reassemble all parts and panels.

5. Plug in dryer or reconnect power.

6. Verify that the dryer will start with the door closed, and that it stops when

the door opens.

TEST #8: Water Valve

(on some models)

Activate Service Test Mode (see page 11). Skip to Step 3 in Service Test

Mode Chart (see page 12). Verify that water is being sprayed into the drum.

See figure 11.

NOTE: Refer to strip circuit on page 25 to diagnose water valve.

If water leaks from the dryer/too much water being sprayed into the drum:

1. Inside the drum, unscrew the water nozzle.

2. Inspect nozzle opening for residue buildup;clean and replace it.

➢

If no water is sprayed in the drum:

1. Verify that water is connected and turned on.

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

23

FOR SERVICE TECHNICIAN’S USE ONLY

2. Unplug dryer or disconnect power.

3. Remove console to access the machine electronics.

4. Verify that the black wire coming from the water valve is connected to the

ACU, J8-1. Refer to wiring diagrams on pages 26, 27 and 28.

Water Valve Assembly

Figure 11 - Water System Components.

5. Check Water Valve & Harness—using an ohmmeter, measure the

resistance between the ACU J8-1 (black wire) and J9-2 (black wire).

➢

If the resistance is 1300 Ω (±5%), go to step 6; if not, replace the water

valve.

➢

If an open circuit is detected, go to step 7.

6. Inside the drum, unscrew and replace the water nozzle using a 7/16"

wrench or socket. Retest water valve.

➢

If water does not dispense, go to step 7.

7. Access the water valve by removing the back panel.

➢

Check that the hose and wires are connected to the water valve assembly

(see figure 11).

➢

Check that the water valve assembly hose is connected to the nozzle.

8. If everything is connected and the water still does not dispense:

➢

Unplug dryer or disconnect power.

➢

Replace the valve assembly and retest.

9. If the preceding steps did not correct the problem, replace the ACU.

24

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

STRIP CIRCUITS

N

ACU

ACU

CHASSIS GND

FOR SERVICE TECHNICIAN’S USE ONLY

MOTOR CIRCUIT

L1

BK

HEATER (ELECTRIC)

L1

BK

HEATER (GAS)

L1

BK

P9-2

N.O. 1

N.O. 1

ACU

K1

MOTOR RELAY

ACU

K2

HEATER RELAY 1

ACU

K2

HEATER RELAY 1

COM 1

COM 1

P9-1

R

V

LBU

THERMAL

FUSE

THERMAL

CUT-OFF

R

LBU

RD

THERMAL

CUT-OFF

4M

HEATER

N.C.

BK LBU

HIGH LIMIT

THERMOSTAT

DRIVE MOTOR

1/3 HP

MAIN

2.4-3.6 Ω

2.4-3.8

START

N.C.

HIGH LIMIT

THERMOSTAT

2

LBU

LBU

Ω

R-W

BK

BK

BK

1

SPLIT COIL

1 2

MAIN COIL

FS1

FLAME SENSOR

CENTRIFUGAL

SWITCH

5M

3M 6M

CENTRIFUGAL SWITCH

Motor

Circuit

3M5M6M

IGNITOR

120 Ω

W

3

W

W

FS2

W

2M

1M

See Heater Circuit

See

CENTRIFUGAL SWITCH

See

Motor

Circuit

3M5M6M

BU

N.O.

DOOR

SWITCH

W

BU

L2

N

2M

R

1M

N

RBU

2M

LBU

W

DOOR

1M

SWITCH

OUTLET (EXHAUST) THERMISTOR

ACU

OUTLET (EXHAUST)

THERMISTOR

P14-3

R- RW -W

OUTLET TEMP (EXHAUST) THERMISTOR

10K Ω

MOISTURE SENSOR

MOISTURE SENSOR

MOV MOV

G-Y G-Y

MOISTURE SENSOR

P13-1

BK

Y-R

WATER VALVE CIRCUIT (ON SOME MODELS)

L1

BK BK

WATER VALVE

Figure 12 - Strip circuits.

P8-1

G-Y

ACU

K4

VALVE RELAY

BK R

P14-6

P13-2

P8-2

P8-3

OUTLET (EXHAUST)

ACU

THERMISTOR RTN

MOISTURE SENSOR RTN

CHASSIS GND

W

DO NOT REMOVE OR DESTROY

10-Sep-2020 08:59:44 EDT | RELEASED

In some European factories the letter "W" of the part code mentioned herein will be automatically

25

replaced by the number "4000" (e.g. "W12345678" becomes "400012345678")

WIRING DIAGRAM

RD

LINE L2-RD

GROUND - GN-YLNEMA® 14-30P

AC

SUPPLY

NEUTRAL N - WH

230

FOR SERVICE TECHNICIAN’S USE ONLY

RD

2M5M

SWITCH

GM

CENTRIFUGAL

6M 1M

BK-WH GN-YL RD-WH

3M

START CAP

RUN

CAP

WH

SPLICE N

TN

D2

J8-3 WH

BU

SPLICE B

BU

WH

D3

D1

DOOR SWITCH

J8-4 TN

MAIN

PRINCIPAL