Maytag MDG9520BWW, MDG9316AWW, MDG9316AXW, MDG9316AWQ, MDG9206AWW Installation Guide

...

MDG (ALL)

INSTALLATION

INSTRUCTIONS

PLEASE READ ALL INSTALLATION INSTRUCTIONS AND REQUIREMENTS BEFORE INSTALLING.

AWARNING: For your safety the information in this

manual must be followed to minimize the risk of fire

or explosion or to prevent property damage, personal

injury or loss of life.

• Do not store or use gasoline or other flammable

vapors and liquids in the vicini'(y of this or any

other appliance.

WHAT T.O DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neigh-

bor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

INSTALLING YOUR NEW DRYER

FOR YOUR SAFETY AND THE PROPER OPERATION

OF YOUR NEW DRYER, THE DRYER MUST BE IN-

STALLED IN ACCORDANCE WITH ALL THE INSTAL-

LATION REQUIREMENTS.

_ATTENTION: Pour votre s_curit6, suivre les indi-

cations donn6es dans ce manuel afin de r_duire les

risques d'incendie ou d'explosion et d'_viter dom-

mages materiels, blessures et d6c_s.

- Ne pas entreposer ni utiliser d'essence ou autres

produits et vapeurs inflammables & proximit6 de

cette s_cheuse ou de tout autre appareil _lectrome-

nager.

- QUE FAIRE S'IL Y A UNE ODEUR DE GAZ

• N'allumer aucun appareit.

• Ne toucher aucun commutateur _lectrique; ne pas

utiliser le t616phone dans votre maison ou votre

immeuble.

• Faire sortir tousles occupants de la piece, du to-

gement ou immeuble, ou de la vicinit6.

• Appeler la compagnie de gas imm_diatement en

utilisant le t_l_phone d'un voisin. Suivre les in-

structions de la compagnie de gaz.

• En cas d'impossibilit_ de joindre la compagnie de

gaz, appeler les pompiers.

Le montage et les r_parations doivent _tre faits par

un technicien qualifi_, un prestataire de services ou la

compagnie de gaz.

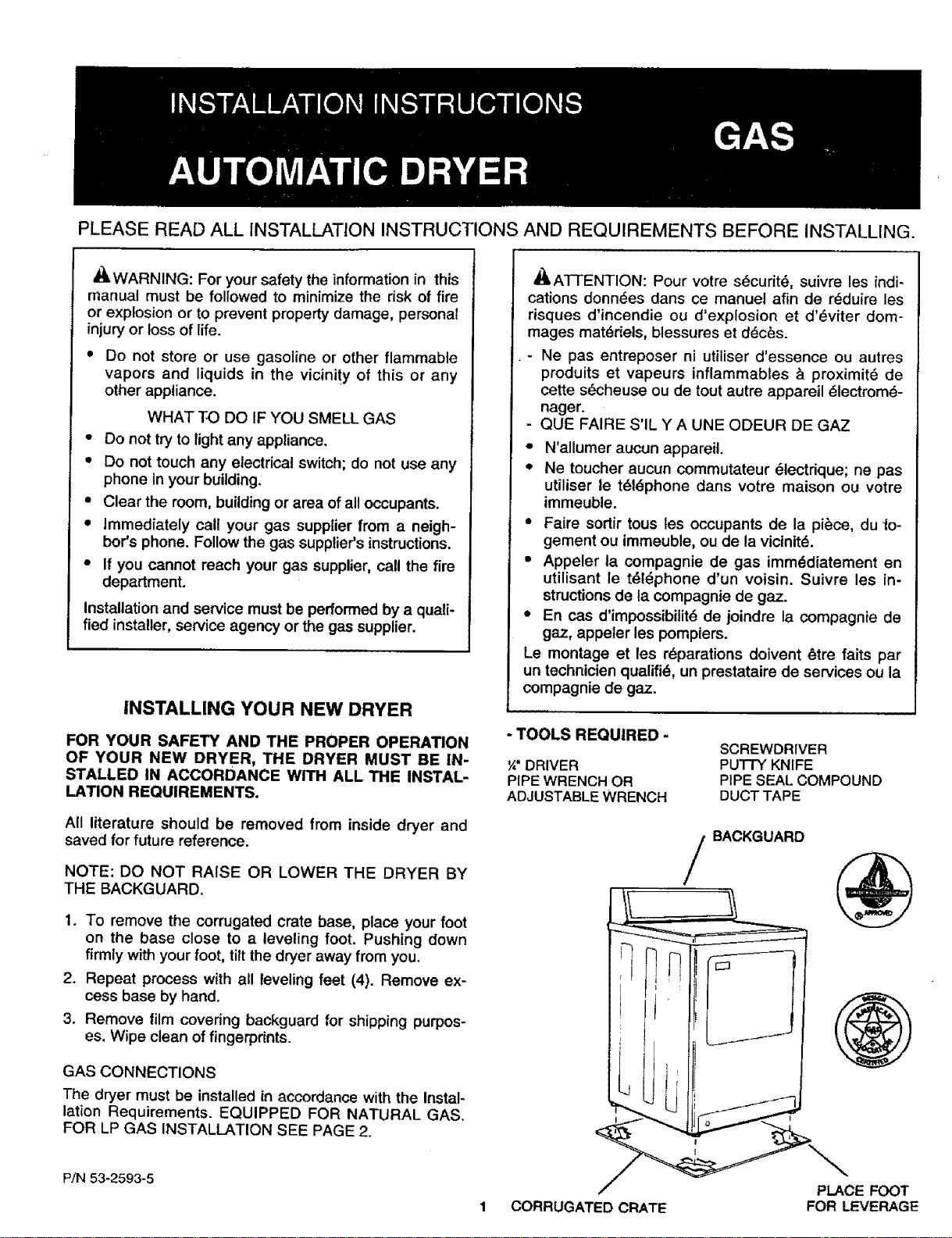

- TOOLS REQUIRED -

'/," DRIVER

PIPE WRENCH OR

ADJUSTABLE WRENCH

SCREWDRIVER

PUTTY KNIFE

PIPE SEAL COMPOUND

DUCT TAPE

All literature should be removed from inside dryer and

saved for future reference.

NOTE: DO NOT RAISE OR LOWER THE DRYER BY

THE BACKGUARD.

1. To remove the corrugated crate base, place your foot

on the base close to a leveling foot. Pushing down

firmly with your foot, tilt the dryer away from you.

2. Repeat process with all leveling feet (4). Remove ex-

cess base by hand.

3. Remove film covering backguard for shipping purpos-

es. Wipe clean of fingerprints.

GAS CONNECTIONS

The dryer must be installed in accordance with the Instal-

lation Requirements. EQUIPPED FOR NATURAL GAS.

FOR LP GAS INSTALLATION SEE PAGE 2.

PiN 53-2593-5

/ BACKGUARD

_ PLAICE FOOT

CORRUGATED CRATE FOR LEVERAGE

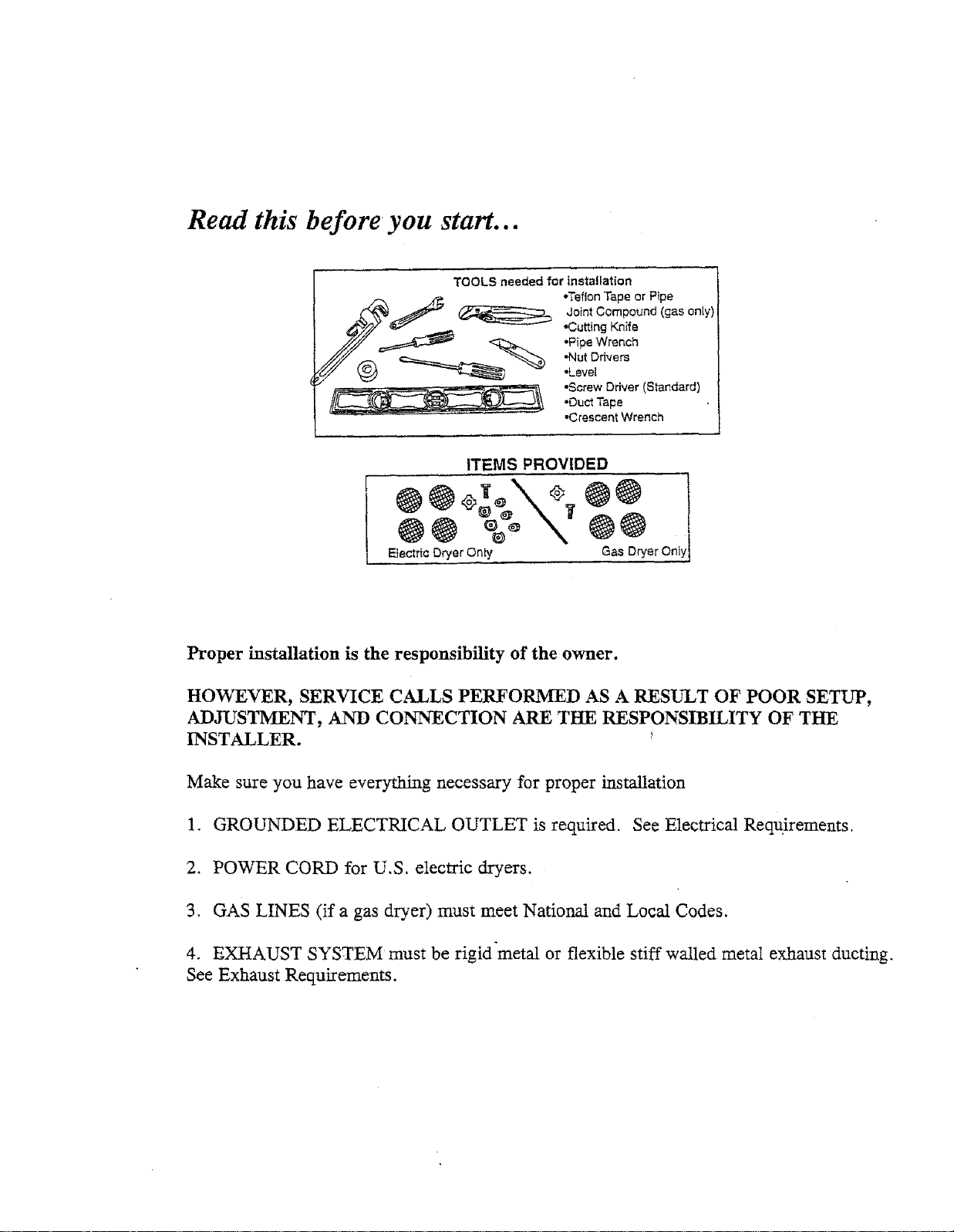

Read this before you start...

TOOLS needed for installation

Joint Compound (gas on_y)

•Cutting Knife

S( _= <_ .Pipe Wrench

•Nut Drivers

*Level

•Screw Driver (Standard)

•Duct Tape

•Crescent Wrench

ITEMS PROVIDED

@@ X @@

Electric Dryer OnLy Gas Dryer Oniy

Proper installation is the responsibility of the owner.

HOWEVER, SERVICE CALLS PERFORMED AS A RESULT OF POOR SETUP,

ADJUSTMENT, AND CONNECTION ARE THE RESPONSIBILITY OF THE

INSTALLER.

Make sure you have everything necessary for proper installation

!. GROUNDED ELECTRICAL OUTLET is required. See Electrical Requirements.

2. POWER CORD for U.S. electric dryers.

3. GAS LINES (if a gas dryer) must meet National and Local Codes.

4. EXHAUST SYSTEM must be rigid'metal or flexible stiff walled metal exhaus_ ducting.

See Exhaust Requirements.

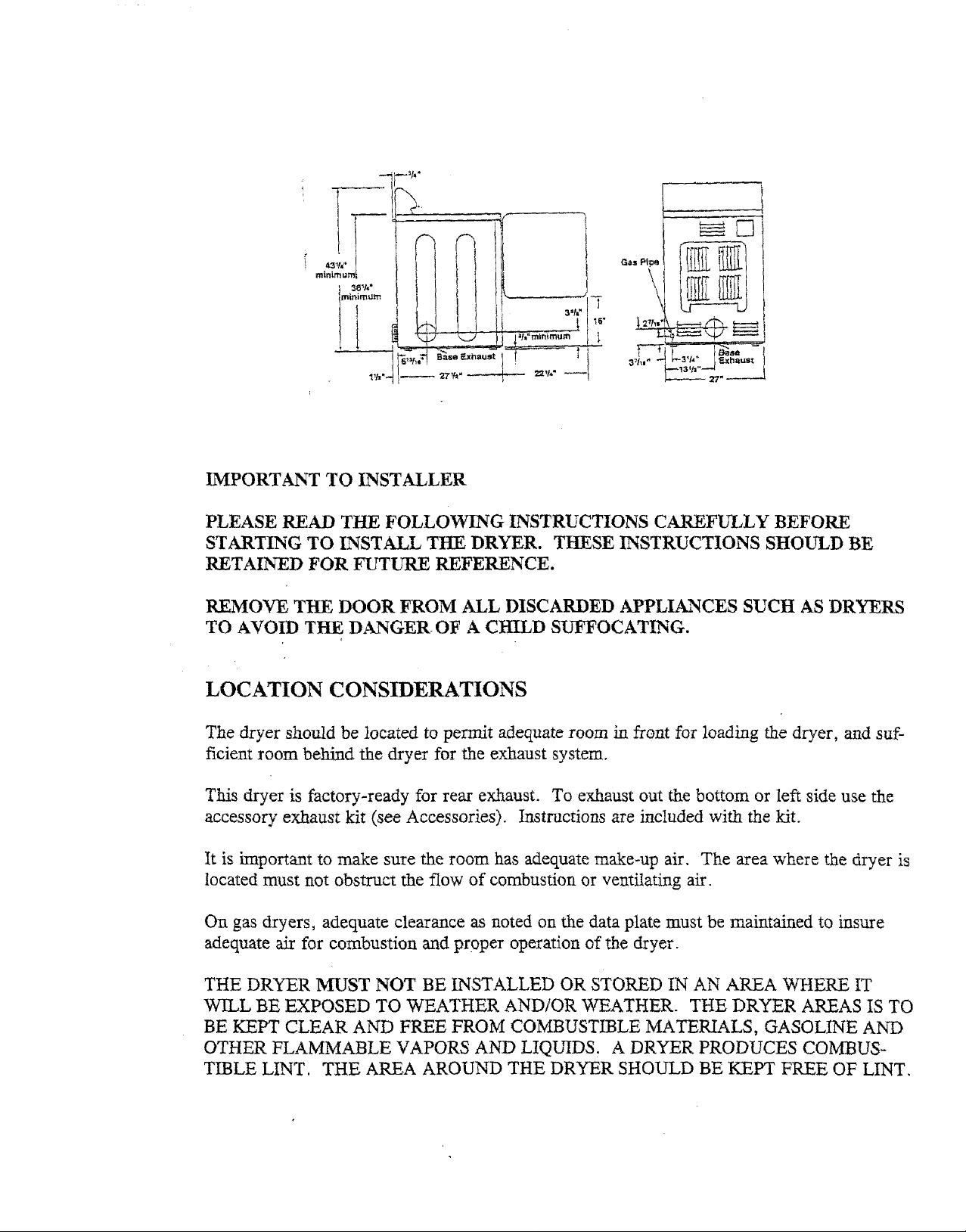

mt mum

-T

_!=_minimum

i_._ Base Exhaust

,l,

IMPORTANT TO INSTALLER

PLEASE READ TIlE FOLLOWING INSTRUCTIONS CARSEFUT._LY BEFORE

STARTING TO INSTALL TI_ DRYER. THESE INSTRUCTIONS SHOL_LD BE

RETAINED FOR FUTURE REFERENCE.

REMOVE THE DOOR FROM ALL DISCARDED APPLIANCES SUCH AS DRYERS

TO AVOID THE DANGER OF A CHILD SUFFOCATING.

LOCATION CONSIDERATIONS

The dryer should be located to permit adequate room in front for loading the dryer, and suf-

ficient room behind the dryer for the exhaust system.

This dryer is factory-ready for rear exhaust. To exhaust out the bottom or left side use the

accessory exhaust kit (see Accessories). Instructions are included win the kit.

It is important to make sure the room has adequate make-up air. The area where the dryer is

located must not obstruct the flow of combustion or ventilating air.

On gas dryers, adequate clearance as noted on the data plate must be maintained to insure

adequate air for combustion and proper operation of the dryer.

THE DRYER MUST NOT BE INSTALLED OR STORED IN AN AREA WHERE IT

WILL BE EXPOSED TO WEATHER AND/OR WEATHER. THE DRYER AREAS IS TO

BE KEPT CLEAR AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE AND

OTHER FLAMMABLE VAPORS AND LIQUIDS. A DRYER PRODUCES COMBUS-

TIBLE LINT, THE AREA AROUND THE DRYER SHOULD BE KEPT FREE OF LINT.

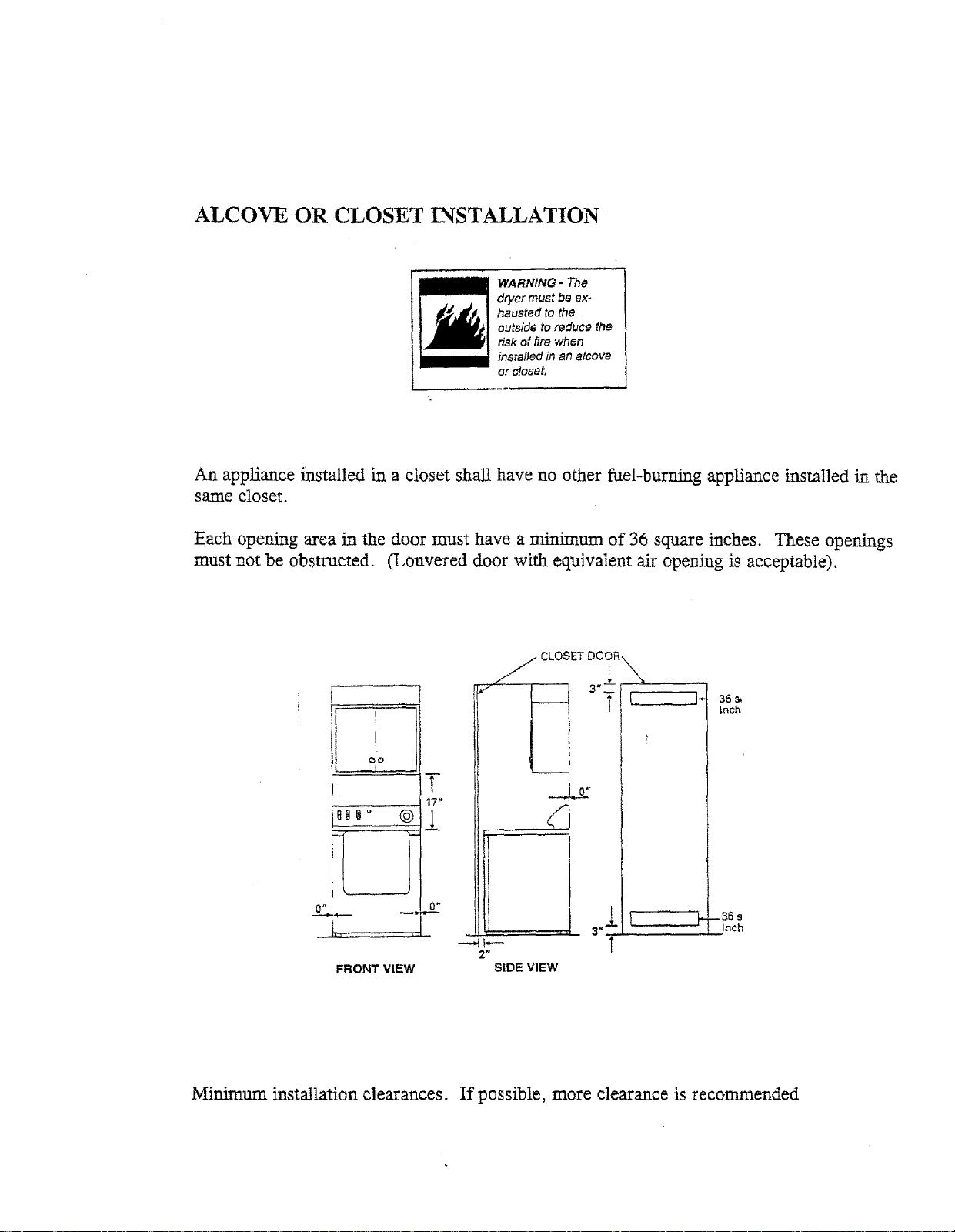

ALCOVE OR CLOSET INSTALLATION

WARNING - The

dryer must be ex-

hausted to the

outside to reduce the

risk of fire when

installed in an alcove

or closet.

An appliance installed in a closet shall have no other fuel-burning appliance installed in the

same closet.

Each opening area in the door must have a minimum of 36 square inches. These openings

must not be obstructed. (Louvered door with equivalent air opemng is acceptable).

CLOSET DO_R_

]÷ --36 S_

inch

olo

L

-f

17"

8°_° ©_k

o2.

L,

FRONT VIEW

Minimum installation clearances. If possible, more clearance is recommended

_2

0"

2"

SIDE VIEW

--36 s

Inch

MOBILE HOME INSTALLATION

The installation of the dryer in mobile homes must conform to the Manufactured Home

Construction and Safety Standard Title 24 CFR, Part 32-80 (formerly the Federal Standard

for Mobile Home Construction and Safety, TNe 24 HUD (Part 280), 1975 for the United

States), or CSA Standards Z240 (for Canada).

When installing a dryer in a mobile home, provisions for anchoring the dryer to the floor

must be made. An anchor bracket kit is available with instructions (see Accessories).

Locate in an area that has adequate makeup air. A minimum of 25 square inches of unob-

structed opening is required.

All mobile home installations must be exhausted to the outside with the exhaust duct termi-

nation securely fastened to the mobile home structure, using materials that will not support

combustion. The exhaust duct may not terminate beneath the mobile home. See the section

on exhausting for more information.

EXHAUSTING

Exhausting the dryer to the outside will prevem large amounts of tint and moisture from

being blown into the room.

In the United States:

- all gas dryers must be exhausted to the outside

- electric dryers located in a confined area such as a bedroom, bathroom, or closet must be

exhausted to the outside.

- electric dryers not located in a confined area may be exhausted to the inside (see

nonexhausted installations).

In Canada:

- all gas and electric dryers must be exhausted to the outside.

NON METAL FLEXIBLE DUCT.

If your existing ductwork is p_astio,

nonmetal or combustible, reptace

it with metal. Use onty metal

exhaust duct that wilt not support

combustion to insure the cantain-

merit of exhaust air, heat and iint.

WARNING -

plastic or nonmetal

ftexibte duct pre-

sents a potential fire

hazard.

NEVER USE PLASTIC

Plastic flexible duct can kink, sag, be punctured, reduce airflow, extend drying times,

and affect dryer operation.

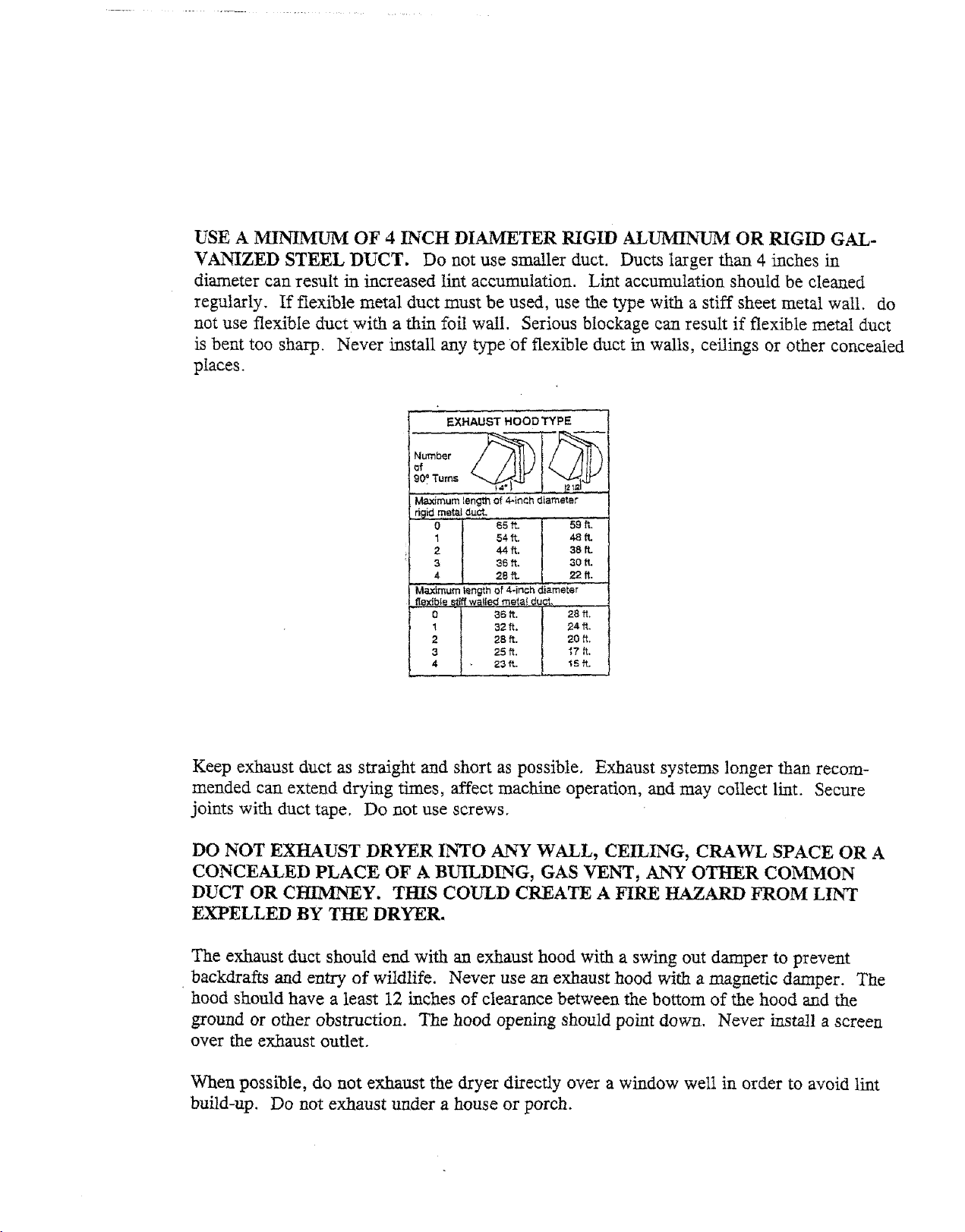

USE A MIN/MUM OF 4 INCH DIAMETER RIGID ALUM!NqJM OR RIGID GAL-

VANIZED STEEL DUCT. Do not use smaller duct. Ducts larger than 4 inches in

diameter can result in increased lint accumulation. Lint accumulation should be cleaned

regularly. If flexible metal duct must be used, use the type with a stiff sheet metal wall. do

not use flexibIe duct with a thin foiI wall. Serious blockage can result if flexible metal duct

is bent too sharp. Never install any type of flexible duct in walls, ceilings or other concealed

places.

EXHAUST HOOD"?YPE

90* Turns

i"'M_Lximumlengm of 4qnch diameter

rigid metal duct.

0 BSff- 59ft.

1 54ft 48ft,

2 44ft. 38ft

3 36 ft, 30 ft.

4 28f!', 22ft.

Maximum length of 4-inch diameter

flexfbte stiff waited merci _uct,

0 36ft. 28ft,

1 32_t. 24_.

2 28ft. 20ft.

3 25ft. 17ff.

4 23fL 15ft.

Keep exhaust duct as straight and short as possible. Exhaust systems longer than recom-

mended can extend drying times, affect machine operation, and may collect lint. Secure

joints with duct tape. Do not use screws.

DO NOT EXHAUST DRYER INTO ANY WALL, CEILING, CRAWL SPACE OR A

CONCEALED PLACE OF A BUILDING, GAS VENT, ANY OTHER COMMON

DUCT OR CtIIMNEY. THIS COULD CREATE A FIRE HAZARD FROM LINT

EXPELLED BY THE DRYER.

The exhaust duct should end with an exhaust hood with a swing out damper to prevent

backdrafts and entry of wildlife. Never use an exhaust hood with a magnetic damper. The

hood should have a least 12 inches of clearance between the bottom of the hood and the

ground or other obstruction. The hood opening should point down. Never install a screen

over the exhaust outlet.

Wqaen possible, do not exhaust the dryer directly over a window welt in order to avoid tint

build-up. Do not exhaust under a house or porch.

Loading...

Loading...