Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

Commercial

Top Load

Washer

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

MAT12PDA

MAT12PDB

MAT12PDC

MAT12PDD

MAT12PDS

MAT12PRA

MAT12PRB

MAT12PRD

MAT12PRS

MAT12PSA

MAT12PSB

MAT12PSD

MAT12CSA

MAT12CSD

MAT13MNA

MAT13MND

MAT13PNA

MAT13PND

16022842

Revision 0

December 2003

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however, that during

its lifetime a product may require service. Products should be serviced only by a qualified service technician who is

familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO REVIEW ALL

APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

!

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the distributor from whom you purchased this

product. For further assistance:

Contact your local commercial product distributor or visit Web site www.maytagcommerciallaundry.com

Recognize Safety Symbols, Words, and Labels

DANGER

!

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

!

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

WARNING

!

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

2 16022842 Rev. 0 ©2003 Maytag Appliances Company

Table of Contents

Important Information .................................................... 2

Important Safety Information ......................................... 4

General Information

Model Identification .................................................... 7

Model Nomenclature .................................................. 7

How It Works ............................................................. 8

Tools For Servicing ................................................... 10

Troubleshooting Procedures

Mechanical Troubleshooting ..................................... 11

Drive Lug Adjustment .............................................12

Damper Pad Noise ................................................ 12

Pump Belt Adjustment...........................................12

Electrical Troubleshooting ........................................ 13

Component Testing ................................................ 14

Motor Testing .........................................................14

Disassembly Procedures ............................................. 16

Control Panel ............................................................16

MN (Manual) Timer ................................................... 16

CS (Coin Slide) Timer ...............................................16

Control Board (Microprocessor) ................................ 16

Touch Pad ................................................................ 17

Cycle Selector Switch .............................................. 17

Transformer .............................................................. 17

Motor Run Relay .......................................................17

Reversing Motor Relay .............................................. 18

Indicator Light ........................................................... 18

Lid Switch Assembly (Prior series 15) ...................... 18

Lid Switch Assembly (After series 15) ...................... 18

Unbalance Lever and Plunger Assembly ................... 19

Disassembly Procedures(continued) ...............................

Pressure Switch ....................................................... 19

Air Dome .................................................................. 19

Water Valve .............................................................. 20

Meter Case ...............................................................20

Coin Slide .................................................................20

Coin Drop Acceptor................................................... 20

Coin Sensor ..............................................................21

Service Door Switch ..................................................21

Coin Vault Switch ..................................................... 21

Lid ............................................................................ 21

Front Panel ...............................................................22

Top Cover .................................................................. 22

Tub Cover ................................................................. 22

Balance Ring ............................................................ 22

Agitator .....................................................................23

Access Plug ............................................................. 23

Inner Tub .................................................................. 23

Mounting Stem .........................................................24

Outer Tub ................................................................. 24

Tub Bearing .............................................................. 24

Transmission ............................................................ 25

Lip Seal .................................................................... 26

Damper Assembly .................................................... 27

Brake Package and Radial Bearing .......................... 27

Belts .........................................................................28

Drive Pulley and Rotor Bearing ................................. 28

Pump ........................................................................29

Drive Motor and Motor Base ..................................... 29

©2003 Maytag Appliances Company 16022842 Rev. 0 3

Important Safety Information

WARNING

!

To reduce the risk of fire, electric shock, serious injury

or death to persons when using your washer, follow

these basic precautions:

• Read all instructions before using the washer.

• Refer to the Grounding Instructions in the Installation

Manual for the proper grounding of the washer.

• Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

• Do not add gasoline, dry-cleaning solvents, or other

flammable or explosive substances to the wash

water. These substances give off vapors that could

ignite or explode.

• Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. Hydrogen gas is

explosive. If the hot water system has not been used

for such a period, before using a washing machine or

combination washer-dryer, turn on all hot water

faucets and let the water flow from each for several

minutes. This will release any accumulated hydrogen

gas. The gas is flammable, do not smoke or use an

open flame during this time.

• Do not allow children to play on or in the washer.

Close supervision of children is necessary when the

washer is used near children. This is a safety rule for

all appliances.

• Before the washer is removed from service or

discarded, remove the lid to the washing

compartment.

• Do not reach into the washer if the wash tub is

moving.

• Do not install or store the washer where it will be

exposed to water and/or weather.

• Do not tamper with the controls.

• Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the User-Maintenance instructions

or in published user-repair instructions that you

understand and have the skills to carry out.

• To reduce the risk of an electric shock or fire, do not

use an extension cord or an adapter to connect the

washer to the electrical power source.

• Use your washer only for its intended purpose,

washing clothes.

• Always disconnect the washer from electrical supply

before attempting any service. Disconnect the power

cord by grasping the plug, not the cord.

• Install the washer according to the Installation

Instructions. All connections for water, drain,

electrical power and grounding must comply with

local codes and be made by licensed personnel

when required. Do not do it yourself unless you know

how!

• To reduce the risk of fire, clothes which have traces

of any flammable substances such as vegetable oil,

cooking oil, machine oil, flammable chemicals,

thinner, etc. or anything containing wax or chemicals

such as in mops and cleaning cloths, must not be

put into the washer. These flammable substances

may cause the fabric to catch on fire by itself.

• Do not use fabric softeners or products to eliminate

static unless recommended by the manufacturer of

the fabric softener or product.

• Keep your washer in good condition. Bumping or

dropping the washer can damage safety features. If

this occurs, have your washer checked by a qualified

service person.

• Replace worn power cords and/or loose plugs.

• Be sure water connections have a shut-off valve and

that fill hose connections are tight. Close the shut-off

valves at the end of each wash day.

• Loading lid must be closed any time the washer is in

operational fill, tumble, or spin. Do not attempt to

bypass the loading lid switch by permitting the

washer to operate with the loading lid open.

• Always read and follow manufacturer’s instructions

on packages of laundry and cleaning aids. Heed all

warnings or precautions. To reduce the risk of

poisoning or chemical burns, keep them out of the

reach of children at all times (preferably in a locked

cabinet).

• Always follow the fabric care instructions supplied by

the garment manufacturer.

• Never operate the washer with any guards and/or

panels removed.

• Do not operate the washer with missing or broken

parts.

• Do not bypass any safety devices.

• Failure to install, maintain, and/or operate this

washer according to the manufacturer’s instructions

may result in conditions which can produce bodily

injury and/or property damage.

NOTE: The Warnings and Important Safety Instructions

appearing in this manual are not meant to cover

all possible conditions and situations that may

occur. Common sense, caution and care must

be exercised when installing, maintaining, or

operating the washer.

Always contact your dealer, distributor, service agent or

the manufacturer about any problems or conditions you

do not understand.

4 16022842 Rev. 0 ©2003 Maytag Appliances Company

Important Safety Information

WARNING

!

To avoid personal injury or death from improper

servicing, make sure you read and understand the

descriptions and meaning of various safety symbols,

words and labels used in this manual, before

attempting any procedures described in the manual.

Failure to understand and comply with safety

information may result in severe personal injury or

death.

General Information

This Service Manual describes the operation,

disassembly, troubleshooting, and repair of Maytag

washing machines. It is intended for use by authorized

technicians who troubleshoot and repair these units.

NOTE: It is assumed that users of this manual are

familiar with the use of tools and equipment used

to troubleshoot and repair electrical, and

mechanical systems; and understand the

terminology used to describe and discuss them.

®

About Ground Wires

In the event of an electrical short circuit, a ground wire

reduces the risk of electric shock by providing an escape

wire for the electric current.

Standard accepted color coding for ground wires is green

or green with a yellow stripe.

Grounding wires and wires colored like grounding wires

are NOT to be used as current carrying conductors.

WARNING

!

To reduce the risk of fire, electric shock, serious injury

or death, all wiring and grounding must conform with

the latest edition of the National Electric Code, ANSI/

NFPA 70, or the Canadian Electrical Code, CSA

C22.1, and such local regulations as might apply. It is

the customer’s responsibility to have the wiring and

fuses checked by a qualified electrician to make sure

your home has adequate electrical power to operate

the washer.

WARNING

!

Related Publications

This is a base service manual, covering a range of similar

models. It is intended to be used in conjunction with the

Parts Manual and Technical Sheet covering the specific

model being serviced.

Electrical Service Information

Proper Grounding and Polarization of

120 Volts Wall Outlets

For the safety of our customers and the Service

Technician ALL appliances have a three–prong power cord

and MUST be connected to a properly polarized AND

grounded wall outlet.

This information was written for those who do not

understand grounding and polarization of a wall outlet.

A 120 volt wall outlet must always be wired as shown

below.

Ground

Neutral

0

V.A.C.

Neutral

side

L1

115±12

V.A.C.

To avoid risk of personal injury or death due to

electrical shock:

• Observe all local codes and ordinances.

• Disconnect electrical power to unit before servicing.

• Ground appliance properly.

• Check with a qualified electrician if you are not sure

this appliance is properly grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water pipe if pipe is

interrupted by plastic, nonmetallic gaskets, or other

insulating (nonconducting) materials.

• DO NOT modify plug on power cord. If plug does not

fit electrical outlet, have proper outlet installed

by qualified electrician.

• DO NOT have a fuse in the neutral or ground circuit.

A fuse in the neutral or ground circuit could result in

an electrical shock.

• DO NOT use an extension cord with this appliance.

• DO NOT use an adapter plug with this appliance.

• DO NOT pinch power cord.

Round

grounding

prong

©2003 Maytag Appliances Company 16022842 Rev. 0 5

115±12

V.A.C.

Important Safety Information

Explanation

Polarization–This means that the larger slot must be

neutral and the small slot must be at line voltage.

Mispolarized–The outlet is incorrectly wires so that the

larger slot is at line voltage and the smaller slot is neutral.

Grounded–This means the round hole connection is connected to earth ground through a connection to the main

power panel.

Ungrounded–The round hole connection is not complete to

earth ground and/or the main power panel.

Grounding Instructions

WARNING

!

• To avoid the risk of electrical shock or death, do not

alter the plug.

• Do not remove grounding prong when installing

grounded appliance in a home that does not have

three wire grounding receptacle. Under no condition

is grounding prong to be cut off or removed. It is the

personal responsibility of the consumer to contact a

qualified electrician and have properly grounded three

prong wall receptacle installed in accordance with

appropriate electrical codes

• To avoid the risk of electrical shock or death, this

equipment must be grounded.

This equipment MUST be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric

current. This unit is equipped with a cord having a

grounding wire with a grounding plug. The plug must be

plugged into an outlet that is properly installed and

grounded.

Consult a qualified electrician or technician if grounding

instructions are not completely understood, or if doubt

exists as to whether the equipment is properly grounded.

Do not use an extension cord. If the product power cord

is too short, have a qualified electrician install a three-slot

receptacle. This unit should be plugged into a separate 60

hertz circuit with the electrical rating as shown in the

appropriate drawing. Models operate with a supply voltage

of 120 Volts.

6 16022842 Rev. 0 ©2003 Maytag Appliances Company

General Information

Model Identification

Model and serial number is located on the back of the

console and cabinet. It is important that you keep a

record for future reference.

• For Maytag product call your distributor or visit the

Web Site at www.maytagcommerciallaundry.com

When contacting provide product information located on

rating plate. Record the following:

Model Number: ___________________

Serial or S/N Number: ___________________

Date of purchase: ___________________

Distributor name and address: ___________________

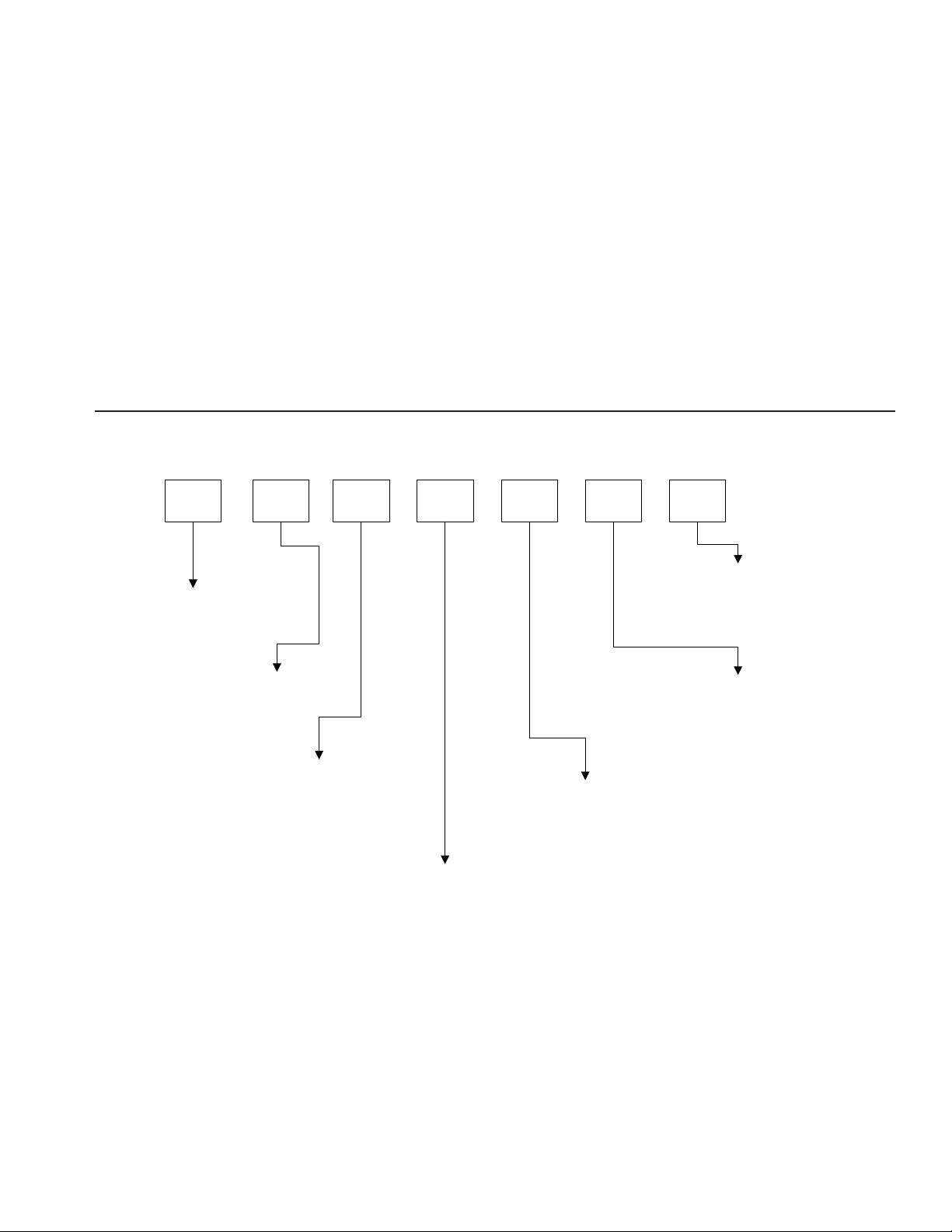

Commercial Washer Nomeclature

M AT WAAPD12

Service

Keep a copy of sales receipt for future reference or in

case warranty service is required. To locate an authorized

distributor:

• For Maytag product call your distributor or visit the

Web Site at www.maytagcommerciallaundry.com.

Service should be performed by qualified service

technicians. We also recommend contacting an

authorized distributor, if service is required.

Parts and Accessories

Purchase replacement parts and accessories over the

phone. To order accessories for your product call:

• or Maytag product call your distributor or visit the Web

Site at www.maytagcommerciallaundry.com.

Only factory approved replacement parts should be used.

Brand

M - Commercial Maytag

Product Type

AT - Automatic Vertical

12 - Top Load Regular Tub

13 - Top Load Deep Tub

Model Number

This identifies which

version of production

the unit is

Control Type

CS - Mechanical coin slide ready

MN - Mechanical non-coin

PD - Microprocessor with coin drop

PN - Microprocessor non-coin

PR - Microprocessor debit reader ready

PS - Microprocessor coin slide ready

Color Code

W - White

Q - Bisque

Voltage Code

A - 120V 60Hz

B - 120V 60Hz (Canada)

G - 220 / 240V 50Hz (Generic Europe)

E - 220 / 240 50Hz (U.K. Export)

Marketing Code

©2003 Maytag Appliances Company 16022842 Rev. 0 7

General Information

is important to understand that water pressure is the

operation force in the water valve.

HOW IT WORKS

The cycles are made up of three basic operations Fill,

agitate and drain/spin. These operations are sequenced

by the controls (timer or microprocessor board) to provide

a proper cleaning cycle for each of several different

fabrics.

FILL

Pressurized hot and cold water supplies are required.

The dynamic, or flow pressure should be between 30 lbs.

per square inch and 80 lbs. per square inch (p.s.i.).

Pressure below 20 lbs p.s.i. may cause water line

hammering.

Hot water is describe to be 140° F and cold water

temperature should be 75° F. A 50-50 mix of hot water

and cold should result in warm temperature between

100° F and 105° F.

The components involved in a fill operation are the water

valve assembly, the water level control and the timer or

control board. The control board or timer along with the

selector switch tell the valve whether to allow hot, cold or

both (warm) into the washer. The water level control

(a.k.a. pressure switch) controls the level of the water in

the washer. It should be at the top row of holes

(perforations) in the washer basket plus or minus 1/4 inch.

When the valve operating solenoid is energized, a

magnetic field is produced that lifts the plunger away from

the pressure release hole in the center of the diaphragm.

The pressure in the guide tube area is released through

the hole allowing the inlet pressure to lift the diaphragm off

of the outlet seat. Water flows under the diaphragm and

out through the valve outlet.

Because the bleed holes cannot allow water into the

guide tube area as rapidly as it can escape out through

the pressure release hole, the diaphragm will remain in

the open position as long as the plunger is held away

from the release hole.

When the plunger is released (solenoid coil de-energized),

it again blocks the release hole allowing pressure entering

though the bleed holes to again force the diaphragm back

against the outlet seat, stopping the flow of water. A

nozzle arrangement at the center of the diaphragm

causes the valve closure to be gradual and smooth to

reduce the chances of water hammer as the valve closes.

Water Level Control (Pressure Switch)

The water level switch is a single pole-double throw switch

which is activated by air pressure increase against a

sealed diaphragm. An air hose is connected to a spout at

the bottom of the outer water container (outer tub) and to

an inlet spout at the water level control body.

Water Valve (Non-Thermostatic)

The water valve used on the top load washers is designed

to operate with in a pressure range of 30-120 p.s.i.. Flow

pressure cannot fall below 20 p.s.i. or valves may fail to

close when solenoids are de-energized.

Water from source enters valve at inlet and pushes up on

diaphragm. The solenoid plunger and the plunger spring

are not strong enough to hold the diaphragm in a closed

position. The diaphragm lifted and some water will flow

under the diaphragm and into the outlet.

Some water also flows through bleeder holes in the

diaphragm and into the guide tube area behind the

diaphragm. With the solenoid not energized, the plunger

would block the pressure release hole allowing the guide

tube to pressurize to source pressure. This causes the

diaphragm to be pushed against the valve seat blocking

the valve seat and closing the outlet.

While there is equal pressure (source pressure) on both

sides of the diaphragm, the pressure in the guide tube

area covers a greater surface area of the diaphragm. The

center (outlet area) on the bottom side of the diaphragm is

at atmospheric pressure so the valve remains closed. It

As water enters the tubs and the water level raises, air is

trapped in the air dome at the bottom of the pressure

switch hoses. As the water level increases, this air is

pushed up the hose and against the diaphragm in the

water level control body.

The control is designed to cause the contact points to

switch when the water level in the wash basket (and the

outer container) reach a particular level. At that point the

fill circuits are disconnected and the motor circuit is

energized. This corresponds to empty = fill and full = run.

Air leaks at the hose connections cannot be tolerated for

proper operation of the water level control.

In timer models, a bypass circuit is provided by the timer

and selector switch to continue power to the motor in spin

operations. Without the bypass, the drive motor would

stop when sufficient water had been pumped out of the

washbasket to cause the pressure switch to reset to the

”empty” position. Microprocessor models do not need the

bypass circuit.

8 16022842 Rev. 0 ©2003 Maytag Appliances Company

General Information

DRIVE MOTOR

When the water level/pressure switch is satisfied circuits

are completed to the main drive motor. The drive motor is

a special high torque split-phase, four pole motor. Two

windings are used. The run winding is designed for full

time use in wash and spin. A second winding, called the

auxiliary or “start” winding is used to provide starting

torque and determine direction of rotation. A centrifugal

switch is mounted to the upper end bell of the motor and

serves to disconnect the start winding as the motor

reaches running speed.

Contact sets in a timer or in a motor reversing relay

provide proper connection to the motor to cause it to run

clockwise in agitate and counterclockwise in spin (viewed

from the top).

The motor drives the power unit by means of a special

design “V” belt. The belt has a “slip factor” designed to

act as a slip clutch.

rotates down the shaft, a lug on the pulley comes against

a drive lug which is splined to the helical drive shaft. At

this point the drive shaft turns with the pulley. The pulley

bearing which merely resting on top of the pulley also

rotates with the pulley, drive lug and helical drive shaft.

At the top of the drive shaft is a spined gear. As it rotates

it drives a series of gears causing the agitator to move

back and forth in an arc creating the water action for the

wash.

The tub and transmission are locked in place and cannot

turn because the brake rotor and brake shoe (which is

splined to the transmission ) is being held down against

the brake drum by the brake spring.

SPIN

When the motor reverses, the pulley will turn in a

clockwise (viewed from the bottom). This causes the

pulley and bearing to turn. The pulley climbs the threads

on the helical drive shaft overcoming the force of the brake

spring to lift the brake rotor and brake shoe off the brake

drum.

TRANSMISSION

The helical drive shaft drives a pinion gear (which is

splined to the top of the drive shaft) at approximately 618

r.p.m. This drives the bevel gear at approximately 150

r.p.m.

The pivot pin of the yoke portion of the torque block and

yoke assembly is driven in a circular motion (orbit) around

an imaginary center point of the bevel gear center axis.

The yoke drives the torque block back and forth through

an arc of approximately 97 degrees at the rate of about

150 times per minute. Because this is a continuous

motion, the drive provides very smooth operation. The low

number of parts results in improved dependability. This

gear case can be serviced without removing it from the

washer.

HELICAL DRIVE

The helical drive mechanism used in the washer is simple

- not requiring a special device or linkage to shift the

washer from agitation to spin.

The drive mechanism utilizes a reversible motor and

helical (threaded) drive shaft. A pulley which is threaded

to the helical drive shaft moves either up or down the shaft

dependent upon the direction it is turned by the drive

motor by means of a drive belt.

As the pulley climbs the shaft and overcomes the force of

the brake spring, there is a downward pull on the shaft.

Within the transmission there are two washers which act

as a spin clutch. This is a friction clutch consisting of a

bronze washer which is splined to and turns the drive

shaft. Between this washer and the pinion gear is a steel

washer which is locked to the transmission case.

As the helical shaft is pulled downward, the two clutch

washers under the pinion are forced together. This is

done rapidly and slippage occurs only during the first two

or three revolutions, until the film of oil between the two

clutch washers is forced out.

The drive occurs when the washers are forced together

and the pulley has climbed the shaft as far as it can. The

driving force has locked the pulley, brake rotor, drive tube

and gear case together and all will turn as a unit in the

same direction as the pulley is turning, causing the tube

to spin is a counterclockwise direction (as viewed from

the top).

Spin cycle completed:

When the washer reaches the end of the spin cycle, the

drive force is removed. Thus, there is no force supplied to

lock the components together or to compress the brake

spring. Therefore, the downward force of the brake spring

and the momentum of the spinning washbasket effectively

reverse all the actions outlined above.

AGITATION

When the pulley is turning counterclockwise (viewed from

the bottom) it moves down the helical drive shaft. As it

©2003 Maytag Appliances Company 16022842 Rev. 0 9

General Information

WARNING

!

To avoid risk of electrical shock, personal injury or death from improper servicing, make sure you understand the

proper procedures and usage of tools listed, before attempting any procedures described in the manual. Failure to

understand and comply with safety information may result in severe personal injury or death.

TOOLS FOR SERVICING

The following is a list of tools used to service the

commercial top load washer.

Part Number Description

Test Meters

Appliance Test Meter (AC-DC voltage and Ohmmeter)

Clamp-On Ammeter

038138 Motor Test Cord

20000021 Lip Seal Tool

22038313 Tub Nut spanner Wrench

038315 Brake Package Wrench

038323 Agitator Puller

038327 Motor Pulley Puller

038555 Center Shaft Installation Tool

20001028 T-15 Torx bit

038227 T20H Torx bit

20001052 T25H Torx bit

20001025 #3 Pozi-Drive bit

038184 Water Hardness Test Kit

038195 Rust Test Capsules

056080 Transmission Oil

055978 Rubber Adhesive (yellow)

204999 Silicone Grease

-- RTV Sealant Maytag

-- ¼” nut driver or socket

-- 5/16” nut driver or socket

-- 3/8” nut driver or socket

-- 7/16” socket

-- ½” socket

-- #2 “stubby” Phillips screwdriver

-- #2 Pozi-Drive screwdriver

10 16022842 Rev. 0 ©2003 Maytag Appliances Company

Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

Mechanical Troubleshooting

There are a number of factors which can contribute to noisy or improper washer operation. Some of these are listed

below along with areas to check for possible corrections.

Condition Possible Cause

1. Vibration Noise

2. Operation Noise

3. Water Leaks

4. Oil Leaks

5. Failure To Agitate Or Spin

6. Poor Spin Out

7. Spins And Agitates At Same Time

8. Freewheeling Inner Tub

9. Timer Shaft Hard to Pull Out (MN Models)

10. Warm Water Temperature Too Cold

11. Slow Fill

12. Water Siphoning Out Of Washer

©2003 Maytag Appliances Company 16022842 Rev. 0 11

• Control cover loose

• Front panel loose

•

Entire washer

o weak floor construction (reinforce)

o inner Tub not centered

o damper pads dry

• Noise during agitation

o check rotor bearing

• Noise during spin

o check tub bearing

o check radial bearing

• Water valve

• Fill hoses

• Hose clamps

• Injector housing

• Poly pump

• Boot seal

• Tub cover loose

• Clear oil around inside of cabinet; excess oil from

tub bearing. Wipe off and wait to see if more

develops.

• Oil under base; wipe off and wait to see if more

develops. It is probably excess oil from brake

package.

• Excess oil on helical shaft and in rubber dust cap.

Replace lip seal in transmission.

•

Belt broken or off pulley

• Motor pulley off or loose

• Transmission

• Brake package loose

• Belt off or broken

• Dry or dirty motor base

• Kinked drain hose

• Clothing article between tubs

• Pump belt too tight

•

Drive lug adjustment

• Clutch washer in transmission

• Rotor bearing in upside down

• Brake liner loose

• Tub nut loose

•

Oil shaft where it goes into timer housing and work

in and out until it loosens up (rust).

•

Increase temperature at hot water heater.

• Clean inlet screen in host water hose

• Adjust hot and cold faucets to compensate

• Plugged inlet screens in fill hoses and water valve

• Inadequate water pressure (should be 30 – 120

p.s.i.)

•

Drain hose not 36” from floor

o Raise drain hose to 365”

o Install siphon break

Troubleshooting Procedures

Pulley

Drive

!

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

Drive Lug Adjustment

1. Disconnect power supply to unit.

2. Turn the drive pulley onto the shaft clockwise until all

play is taken up.

3. Holding the pulley in this position, the distance

between drive and pulley lugs should be 3/8”.

4. Turn pulley counterclockwise and check to see that

the drive lug and pulley are making contact.

Note: There should always be clearance between the

bottom of the pulley and the top of the stop lug to

prevent the drive pulley from dragging on the drive

lug, forcing it off the shaft.

WARNING

3/8”

Lug

Lug

Damper Pad Noise

Dry or poorly lubricated damper pads can result in a rubbing noise during the beginning and end of the spin cycle. If

this condition is encountered, the damper pads should be lubricated or replaced. See “Damper Assembly” in

Disassembly Procedures Section of this manual.

Pump Belt Adjustment

1. Disconnect power supply to unit.

2. Pull motor forward so drive belt is tight.

3. With washer in an upright position, grasp the pump

belt in the middle and flex. With the belt flexed, it

should be tightened so that there is approximately 1/

4” between the inside surfaces of the pump belt before

movement of the motor is felt.

4. If necessary, tilt washer and loosen screws holding

pump to base frame and position pump to attain the

proper 1/4” dimension.

1/4”

12 16022842 Rev. 0 ©2003 Maytag Appliances Company

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

ELECTRICAL TROUBLESHOOTING

The malfunction of an electrical circuit cannot easily be

diagnosed unless you first understand how it functions

when operating normally. The electrical schematic and

wiring diagram includes a cycle sequence chart keyed to

the contacts in the timer, relay and/or control switches.

!

CAUTION

Resistance or continuity testing is done with the product

disconnected from power. Failure to do so can result in

damage to your meter.

For the most part, we will only be concerned with

continuity. Is there a path or not? References are made

between a “closed” (Continuity) reading and an “open (No

continuity) reading. One note, when you get and “open”

reading, try a higher resistance range (setting). A very

high resistance appears as an “open” on the lower ranges.

For best accuracy always “rezero” meter when changing

ranges and/or the physical position of the meter.

WARNING

Continuity test of “load” devices will show varying levels of

resistance from very low for some transformer and motor

windings to very high for some timer motors and

components on control boards. Usually it is more

important to know if there is a path for current flow through

a device (continuity ) that to know the exact resistance

(ohms) of the device.

Continuity tests of switches will show virtually no

resistance across a closed contacts. Resistance, even

low values indicate burned or dirty contacts in a switch.

When checking components or circuit paths for continuity,

external wiring should be disconnected to eliminate false

readings through external paths. Isolate what you want to

test.

Continuity testing, as related to an electrical component,

is the check of a part for an “open” or closed” circuit.

Electrical components fall into two general categories.

1. Loads - Devices that use or consume electricity.

Examples would include drive motor, timer and

solenoid coils.

2. Switches - Devices that control the supply of

electricity to the load or loads in a circuit.

Examples include lid switches, timer contacts

selector switch and relay contacts.

©2003 Maytag Appliances Company 16022842 Rev. 0 13

Troubleshooting Procedures

!

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

WARNING

requires power.

COMPONENT TESTING

Illustration Component Test Procedure Results

Pressure Switch Disconnect wire terminals from switch.

Measure resistance across the

following terminals:

Empty (Filling) 20 to 15--------------------

Full (Run) 20 to 15 -------------------------

Water Valve Measure resistance across the

terminals of each coil on the valve.

Motor Type of Motor:

Single speed (Split phase)

Resistance above 2 Ω indicates dirty

switch contacts.

Closed circuit

Open circuit

Approximately 850-950 Ω

See “Motor” Testing section for

correct wiring contact

Pump Verify drain pump is not clogged or

damaged

Transmission Type of transmission (orbital):

618 r.p.m. Spin

150 o.p.m. Agitate

Check wattage with full tub of water

only (Use Wattage Meter)

Belts Check belt for excessive wear or being

burnt and cracking

1) Remove clog and verify proper

operation

2) Replace drain pump if damaged

See “Transmission” Disassembly

Procedures section.

380 to 420 watts

Replace if belt if damaged

MOTOR TESTING

A motor test cord may be used to electrically check operation of the various electrical components without removing

them from the unit. Testing in this manner merely determines whether or not part will function independently of other

electrical components. In order to make accurate test, proper connection of the motor test cord is important.

All four leads of the test cord are required to test the washer drive motor. The following drawing shows installation of

the test cord on washer drive motor. Reversing the motor from agitation to spin is accomplished by reversing the test

cord wires B and C.

14 16022842 Rev. 0 ©2003 Maytag Appliances Company

Troubleshooting Procedures

tionSpi

n

!

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing, unless testing

requires power.

WARNING

Agita

Windings Wiring Harness Connections Readings

Run Winding Red to White or Black

Start Winding Yellow to Blue

Over-load White to Black

Note: Export Motors-run windings 4.9Ω, start windings 20.5Ω,

over-load 0 Ω.

©2003 Maytag Appliances Company 16022842 Rev. 0 15

1.5Ω

3Ω

0 Ω

Disassembly Procedures

!

WARNING

Control Panel

1. Disconnect power supply to unit.

2. Remove top two T-20H Torx screws located on the

front of the control panel.

3. Carefully lay the control panel forwards.

Note: Use a protective cloth to minimize the chance

of scratching the panel on the control console.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

5. Squeeze tabs to remove connectors from timer.

MN (Manual) Model Timer

1. Disconnect power supply to unit.

2. Carefully pry the timer knob center cap out of the

knob.

3. Slip the retainer clip off of the timer shaft.

Control Board (Microprocessor)

1. Disconnect power supply to unit.

2. Remove Control Panel.

3. Remove four 5/16” nuts from backup plate mounting

studs.

4. Pull the knob, spring and dial off of the timer shaft.

5. Remove screws securing Timer to Control Panel.

6. Remove Control Panel.

CS (Coin Slide) Model Timer

1. Disconnect power supply to unit.

2. Use key to gain access through service door.

3. Remove screw securing timer bracket to meter case.

4. Lift timer and bracket up and forward from the meter

case.

Note: Extra wire (slack) can be fed from the left.

16 16022842 Rev. 0 ©2003 Maytag Appliances Company

4. Lift board from studs and tilt forward. Don’t lose the

spacers.

5. Disconnect touch pad ribbon. Grasp touch pad “tail”

between your thumbs and forefinger. Ribbon can be

pulled out of receptacle.

Disassembly Procedures

!

WARNING

Touch pad

1. Disconnect power supply to unit.

2. Remove all four T-20H Torx screws securing control

panel facia.

3. Remove Control Panel.

4. Remove Control Board.

5. Remove two Pozi-drive screws securing touch pad to

Control panel.

Cycle Selector Switch

1. Disconnect power supply to unit.

2. Remove all four T-20H Torx screws securing control

panel facia.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

5. Lay control panel forward.

6. Remove wires from switch (note switch position) and

remove switch.

Note: When replacing switch, note the position of “top”

on the switch.

Transformer

1. Disconnect power supply to unit.

2. Remove Control Panel.

3. Remove two screws securing transformer and

disconnect wire harness.

Motor Run Relay

3. Pull selector switch knob off switch shaft.

4. Remove two screws holding switch to control panel.

©2003 Maytag Appliances Company 16022842 Rev. 0 17

1. Disconnect power supply to unit.

2. Remove Control Panel.

3. Disconnect wires from Motor Relay.

4. Remove screw securing relay to Control Panel.

Disassembly Procedures

!

WARNING

Reversing Motor Relay

1. Disconnection power supply to unit.

2. Remove all four T-20H Torx screws securing control

panel facia.

3. Disconnect all wires attached to Reversing Motor

Relay.

4. Remove single screw securing relay.

Note: Notice the positioning tab for ease in mounting

and locating relay onto the Control Panel.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Lid Switch Assembly (After series 15)

1. Disconnect power supply to unit.

2. Remove Control Panel

3. Remove wire connector attached to the switch.

Indicator Light (Timer models)

1. Disconnect power supply to unit.

2. Remove Control Panel.

3. Compress tab on the end of the Indicator Light and

remove from back side of Control Panel.

4. Remove wires from assembly.

Lid Switch Assembly (Prior series 15)

1. Disconnect power supply to unit.

2. Remove Control Panel.

3. Remove wires attached to switches and fuse.

4. Remove adjusting screw securing lid switch bracket

to the top cover.

4. Lift tab and move switch forward and out.

Lift Tab

18 16022842 Rev. 0 ©2003 Maytag Appliances Company

Disassembly Procedures

!

WARNING

Reinstalling Lid Switch

1. Insert the lid switch assembly in the Top Cover (Push

the switch assembly straight down and back until it

locks in place).

WRONG!

Top

Front Of

Machine

Cover

RIGHT!

Front Of

Machine

Top

Cover

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Pressure Switch

1. Disconnect power supply to unit.

2. Remove Control Panel.

3. Disconnect wires attached to the switch.

4. Remove clamp securing Air Dome Hose.

5. Remove two screws securing Pressure Switch to the

Top Cover.

Unbalance Lever and Plunger Assembly

1. Disconnect power supply to unit.

2. Remove Lid and tilt the Top cover backwards.

3. Remove two screws securing the plunger assembly to

the Top Cover.

Plunger Assembly

Air Dome

1. Disconnect power supply to unit.

2. Remove Control Panel and rear access service plate.

3. Remove clamp securing rubber hose to the Pressure

Switch.

4. Remove clamp securing Air Dome to the Outer Tub

spout.

5. Disconnect rubber air tube secured to the cabinet.

Unbalance

Lever

©2003 Maytag Appliances Company 16022842 Rev. 0 19

6. Remove the air dome hose through the rear access

opening.

Disassembly Procedures

!

WARNING

Water Valve

1. Disconnect power supply to unit.

2. Remove screw holding Valve Bracket to back panel.

3. Pivot out until flange clears back and lift up to

disengage the bracket from the slot on the back

panel.

4. Remove two screws holding Water Valve to mounting

bracket.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

5. Remove Control Panel.

6. Remove screws securing console to meter case.

7. Remove two nuts (one inside coin box area and inside

service access door compartment.).

Coin Slide

1. Disconnect power supply to unit.

2. Unlock and remove service access door.

3. Loosen the locking bolt from inside the meter case.

4. Pull the coin slide out of the Meter Case.

Note: The timer Actuator can be adjusted once the

Coin slide is removed. The holes on the actuator

are slotted to allow proper length adjustments

(the actuator must be adjusted for the particular

coin slide to advance the timer into the cycle).

Coin Drop Acceptor

1. Disconnect power supply to unit.

5. Disconnect wires from terminals.

6. Remove injector hose.

Meter Case

1. Disconnect power supply to unit.

2. Remove Service Access Door.

3. Remove coin box.

4. Remove timer or disconnect wires to Service and Vault

Switches.

2. Unlock service access door.

3. Loose the two locking bolts from inside the meter

case.

4. Remove Coin Drop Acceptor.

5. Remove screw securing Coin Sensor to the rear of the

Coin Drop Acceptor.

20 16022842 Rev. 0 ©2003 Maytag Appliances Company

Disassembly Procedures

!

WARNING

Coin Sensor

1. Disconnect power supply to unit.

2. Remove Control Panel and disconnect Coin Sensor

connector plug on the Control Board.

3. Unlock service access door.

4. Remove Coin Drop Acceptor.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Lid

1. Disconnect power supply to unit.

2. Raise the lid where it is at a 45 degree angle.

3. With the left hand, grasp the left side of the lid toward

the back. With the right hand, grasp the right side of

the lid at the front right corner.

4. Taking care to watch the right hinge ball, pull towards

you with the right hand. When the lid is disengaged

from the right side of the top cover, catch the right

hinge ball, remove the lid and catch the left hinge ball.

Service Door Switch

1. Disconnect power supply to unit.

2. Remove Service Access Door.

3. Remove the screw securing the switch mounting

bracket and lift the switch from inside the Meter Case.

4. Disconnect wires from the switch, and squeeze tabs

on switch to remove from bracket.

Coin Vault Switch

1. Disconnect power supply to unit.

2. Remove Service Access Door and Coin Box.

3. Disconnect wires from the switch.

4. Squeeze the two tabs on the switch and push the

switch through towards the front.

©2003 Maytag Appliances Company 16022842 Rev. 0 21

Reinstalling the Lid

1. Place a hinge ball in the recess of the left side of the

top cover. Holding it in position, place the lid over the

ball so the ball is in the recess on the left side of the

lid.

2. Hold the lid with the left hand as shown, keeping

sufficient pressure against the left side to ensure the

hinge ball will remain wedged between the lid and the

top cover.

3. With the right hand , place a hinge ball in the right

side of the Top Cover recess.

4. Push the lid down against the hinge ball on the right

side and with the right thumb. Press down sharply to

engaged the lid with the hinge ball on the right side.

Disassembly Procedures

!

WARNING

Note: If the fit between the right hinge ball and the lid is

so tight you cannot press it into position with the

right thumb, carefully strike the right corner of the

lid with the palm of the hand to snap it into

position.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Tub Cover

1. Disconnect power supply to unit.

2. Secure Lid to the Top cover.

3. Remove Front Panel.

4. Remove screw securing Top cover to the cabinet.

5. Tilt Top backwards.

6. Remove tub cover by unsnapping the tabs securing

Tub Cover to the Outer Tub.

Front Panel

1. Disconnect power supply to unit.

2. Remove two T-25H Torx screws securing front panel.

3. Pull front panel up and away from the bottom.

Top Cover

1. Disconnect power supply to unit.

2. Remove Front Panel.

3. Remove two top cover bolts and tilt Top Cover back.

Note: Hold lid closed or tape lid to the Top Cover to

prevent it from striking the Control Panel.

Balance Ring

1. Disconnect power supply to unit.

2. Remove Tub Cover.

3. Insert a pencil or other small pin through the three

small holes in the outer tub depressing the tabs on

the Balance Ring.

22 16022842 Rev. 0 ©2003 Maytag Appliances Company

Disassembly Procedures

!

WARNING

Note: Try using a thin piece of cardboard to place

between the tab and outer tub once you have

inserted the pencil through the hole to depress

the tabs. This will allow you to work on the other

tabs for easy removal.

Agitator

1. Disconnect power supply to unit.

2. Loosen 1/4” hex head screw and lift Agitator up.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

4. Remove Tub Cover.

5. Remove Agitator.

6. Use spanner wrench to remove clamping nut.

Note: This is a left hand thread so it must be turned

clockwise. A mallet will be required to loosen the

nut. Use care when striking wrench to prevent

chipping the tub.

7. Remove clamping nut washer.

Access Plug

1. Disconnect power supply to unit.

2. Remove Agitator.

3. Pry out Access Plug.

Note: Grasp plug in the center on the long side. Lift

up and push in at the same time to remove plug.

Inner Tub

1. Disconnect power supply to unit.

2. Remove Front Panel.

3. Raise Top Cover.

8. Lift Inner Tub Out. (Inner tub is lighter if Balance Ring

has been removed.)

Note: When reinstalling Inner Tub. Rock Inner Tub

back and forth on the mounting stem to make

sure it is seated properly. Use care when

tightening clamping nut, not to chip Tub.

Tub Centering

1. Place a 1/2 lb. weight in the tub.

2. Allow the washer to reach full spin speed.

3. When washer reaches full spin speed, turn off power

to the washer and allow the tub to come to a complete

stop before opening lid. The opening in the tub cover

should be centered with the opening in the top cover,

but with a small portion of the tub cover visible at the

back. This visible portion of the tub cover should not

exceed 1/4”.

©2003 Maytag Appliances Company 16022842 Rev. 0 23

Disassembly Procedures

!

WARNING

4. If the proper amount of the tub cover is not visible at the

back or the tub is off center on either side, tighten the

opposite damper spring and recheck as outlined in

previous steps.

Mounting Stem

1. Disconnect power supply to unit

2. Remove Inner Tub.

3. Remove T-20H Torx set screw in the Mounting Stem.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Outer Tub

1. Disconnect power supply to unit.

2. Remove Inner Tub.

3. Remove Mounting Stem.

4. Loosen clamps and remove Drain Hose and Air Dome

Hose from Outer Tub.

4. Use spanner wrench to remove Mounting Stem.

Note: This is a left hand thread so it must be turned

clockwise. A mallet will be required to loosen.

5. When the Mounting Stem is lifted off you have access

to the Boot Seal.

6. Remove Boot Seal by twisting clock wise.

Reinstalling Mounting Stem

1. Center seal grease may be used on the mounting

stem threads. When the Mounting Stem has been

reinstalled and hand tighten to seat. Tap the spanner

wrench a couple of times with the mallet to seat.

2. Before inserting the set screw into the Mounting stem,

lubricate the hole in the mounting stem with Maytag

grease. Be sure to tighten the screw securely.

Note: Set screw must not be in a water relief groove.

5. Remove three bolts that hold the Outer Tub to the tub

braces. To facilitate removal of Tub Bolts, remove

outside nuts, lock and Retaining Washers and push

tub Bolts through into the Tub.

6. Lift Outer Tub off transmission.

Note: When replacing tub bolt and nuts, just get them

started. Do not tighten them until you have the

front bolt also started. Use the brake package

tool, you can hook the front brace to apply

pressure to move the brace against the tub. This

makes it easier to get the lock washer and the

nut on the front bolt.

Note: The two rear bolts are longer than the front bolt.

DO NOT use a long tub bolt in the front position.

Tub Bearing

1. Disconnect power supply to unit.

2. Remove Outer Tub.

3. Because of the porcelain tub and molded retainer, it is

not practical to drive the tub bearing from the tub. To

remove the bearing from the tub, elevate the tub so

that the porcelain drain tube clear the floor. This could

be done by placing 2 X 4 under the tub.

4. Apply pressure on the bearing pushing it from the tub.

This can be done by standing on the bearing.

24 16022842 Rev. 0 ©2003 Maytag Appliances Company

Disassembly Procedures

!

WARNING

Reinstalling tub bearing

1. Turn tub over, starting bearing into outer tub.

Note: Caution should be exercised to see that the tub

bearing is started into the tub straight to prevent

egg-shaping when sealed in the tub.

2. Press bearing into place by apply pressure. This may

be done with a rubber mallet.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

8. Remove cover plate (it may be necessary to pry the

plate off with a screwdriver). Carefully rotate the

transmission, dumping oil into your catch pan.

9. Remove Plastic Keeper on the top of the Agitator

shaft.

Note: Prior to Series 22, a spring Retaining Clip was

used. This clip can be removed by pulling it out

and off the agitator shaft. Care should be taken

when removing.

Note: Beginning with Series 22, a Plastic Keeper is

used.

Transmission

1. Disconnect power supply to unit.

2. Remove Mounting Stem.

Note: Prior to Series 22, proceed onto Step 3.

Note: Beginning with Series 22, The Mounting Stem

must be removed if work must be performed on

Agitator shaft, before proceeding.

3. Place Tub Block in the Tub.

4. Remove Front Panel.

5. Lay the washer on its back and remove Belts.

6. Place an oil catch pan (Motor Cover will do) under the

center hub of the Transmission (take used oil to your

local oil recycling center for proper disposal).

7. Remove the 7/16” bolts from the transmission cover.

Note: Be sure the bolts heads are facing up. This will

insure that you will not get oil all over the back of

the washer should the cover come loose. Cut

around the cover to separate silicon sealer used

as a gasket.

10. Remove the Plastic Keeper and Center Shaft Collar.

Note: Early models used a Collar secured with a Pin

(remove with a 3/16” Allen wrench).

Note: Later version used the Plastic Keeper and Center

Shaft collar

©2003 Maytag Appliances Company 16022842 Rev. 0 25

Disassembly Procedures

!

WARNING

11. Grasp the drive pulley and slowly pull the center shaft

out. Only a small amount of force will be needed to

remove the shaft.

Note: Be careful not to damage the Lip Seal at the

bottom of the Transmission.

12. Pull the Agitator Shaft out through the Tub.

Note: You may have to pull hard on this as the oil in

the Torque Block forms a suction.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Note: At this point, all components to be reassembled

should be cleaned. Also, clean any silastic from

the Transmission housing and cover before

reassembling. Apply a thin film of oil on the

center stud before installing Bevel Gear.

Lip Seal

1. Disconnect power supply to unit.

2. Tip washer to gain access to bottom of pulley.

Remove #2 Phillips screw and lock washer from

bottom of Drive Shaft.

3. Pry drive Lug off Drive Shaft.

4. Spin drive Pulley off shaft (counterclockwise from

bottom).

13. With the Agitator and Drive Shafts removed, simply lift

out the Pinion Gear, followed by the steel Clutch Plate

and copper Spined Washer which are located under

the Pinion Gear.

Note: Pay close attention as to the order in which the

Clutch Plate and Spline Washer are Removed.

14. The Torque Block and Yoke can now be removed as

can the Bevel Gear. Underneath the Bevel Gear is a

spacer Washer.

5. Use the Lip Seal Tool to remove the Lip Seal from

Center Tube.

Note: This tool is screwed into the Lip Seal and the Lip

Seal is removed by turning the bolt against the

Center shaft.

Reinstalling Lip Seal

1. Clean Lip Seal recess in the center tube with choke

cleaner to remove any oil. Make sure area is clean

and dry.

2. Press new Lip Seal over the Seal-Protector. The SealProtector is designed to protect the seal area of the

Lip Seal from rolling over or tearing as the seal is

26 16022842 Rev. 0 ©2003 Maytag Appliances Company

Disassembly Procedures

!

WARNING

pressed into the center tube of the transmission.

3. Slide assembly over square thread of center shaft until

the Lip Seal starts into the center tube bore.

4. Turn Drive Pulley onto the center shaft and against

Seal -protector. Tighten pulley to press Lip Seal into /

center tube bore. Back pulley off and check to make

sure Lip Seal is pressed into position (flange of Lip

Seal should be against end of center tube).

5. Remove Pulley.

6. Using the loops, remove Seal -Protector and discard.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

6. Set washer down on top of the wood block.

7. The complete assembly of the Tubs and Damper

should be pushed up from the base far enough to get

to the damper pads.

8. Scrape old pads from base.

9. Use a degreasing agent such as alcohol to remove

any grease from the area.

10.Apply rubber adhesive to area where old pads were

removed.

11. Apply pads to base and let dry. The top surface of the

pad should be located 3/32” below center opening in

base. The distance between pads should be about

5/8”.

7. Replace pulley and belts. Be sure rotor bearing is on

drive pulley correctly with “cup” of bearing over hub of

pulley.

8. Place washer in upright Position. Replace front panel

and remove tub block.

Note: Connect washer and check for proper operation.

Damper Assembly

1. Disconnect power supply to unit.

2. Remove two bolts holding Top Cover and raise.

Note: Tape Lid to prevent it from striking the Control

Panel.

3. Remove nut from three eyebolts. The position of the

nuts on the eyebolts can be marked by placing strips

of electrical tape around bolts above nuts before

loosening.

4. Remove Drive Belts.

5. Tip washer back and lay 4” X 4” wood block under

drive pulley.

Brake Package and Radial Bearing

1. Disconnect power supply to unit.

2. Put Tub Block in Tub and lay washer back far enough

to get to the Pulley and Brake Package.

3. Remove Bolt and Retainer Clip in Damper holding the

brake package.

Note: Bolt and Retainer Clip must be removed before

the brake package.

©2003 Maytag Appliances Company 16022842 Rev. 0 27

Disassembly Procedures

!

WARNING

4. Use the Brake Tool to unscrew the Brake Package

assembly from the Damper. When the Brake

Package is free, pull out to disengage it from the

spline surface of the drive tube.

5. Use a hammer to remove the Brake Package.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

Drive Pulley and Rotor Bearing

1. Disconnect power supply to unit.

2. Remove Drive and Pump Belts and Dust Cap covering

hub of Pulley.

3. Remove screw and washer from bottom of Drive Shaft.

4. Remove the splined Drive Lug from the Drive shaft.

5. Turn pulley counterclockwise to remove it from the

Helical Shaft. The Rotor Bearing is located above the

drive pulley.

Note: There is a top and bottom to the rotor bearing.

When it is positioned correctly, the top of the

Bearing and the Pulley hub will be about even

(the concave side against Pulley hub).

WARNING

!

To reduce the risk of serious injury or death to persons

when using your washer, make sure the Rotor Bearing

is not put on upside down. You will have no Brake.

6. After Brake Package has been removed, the Radial

Bearing may be removed from top of Brake package.

Belts

1. Disconnect power supply to unit.

2. Remove front Panel.

3. Tilt machine backwards.

4. Roll Pump Belt than Drive Belt off pulleys.

Note: When the drive Pulley is replaced, the Drive Lug

must be properly positioned.

28 16022842 Rev. 0 ©2003 Maytag Appliances Company

Disassembly Procedures

!

WARNING

Pump

1. Disconnect power supply to unit.

2. Remove Front Panel.

3. Disconnect hoses from pump.

4. Tape washer lid to Top Cover.

5. Tilt washer and remove Pump Belt.

6. Remove three screws from bottom of base holding

pump to base. The mounting holes for the pump on

the base frame are slotted for adjustment of the Pump

Belts.

Note: Mark the general position of pump before

removing.

To avoid risk of electrical shock, personal injury or death;

disconnect power to unit before servicing.

3. Remove Motor Cover.

4. Remove main wiring harness from motor terminals.

Note: DO NOT remove the wires going from motor

switch to motor.

5. Remove Belts.

6. Remove three screws holding motor base to base

frame.

7. Tilt pump and lift through access hole in base frame.

Drive Motor and Motor Base

1. Disconnect power supply to unit.

2. Remove Front Panel.

©2003 Maytag Appliances Company 16022842 Rev. 0 29

7. Remove Motor and Motor Base.

8. Remove Pulley from Motor.

9. Disengage tension springs and remove mounting nuts.

Note: To remove two of the nuts, align upper and lower

sections and insert wrench through the slots into

lower section.

10. Lift Motor Base off Motor.

Note: With Motor removed, carriage and slides are

accessible for service.

Loading...

Loading...