Page 1

HIGH-EFFICIENCY WASHER INSTALLATION INSTRUCTIONS

MACHINE À LAVER HAUTE EFFICACITÉ

GUIDE DE MISE EN SERVICE

INSTRUCCIONES PARA LA INSTALACIÓN

DE LA LAVADORA DE ALTA EFICIENCIA

LEAVE THESE INSTRUCTIONS WITH THE OWNER

LAISSER CE GUIDE DE MISE EN SERVICE AU PROPRIÉTAIRE

DEJAR ESTAS INSTRUCCIONES CON EL PROPIETARIO

DC68-02032B-01

Page 2

ELECTRICAL

Refer to serial plate for specific

electrical requirements. For

more detailed information refer

to section on Electrical

Requirements.

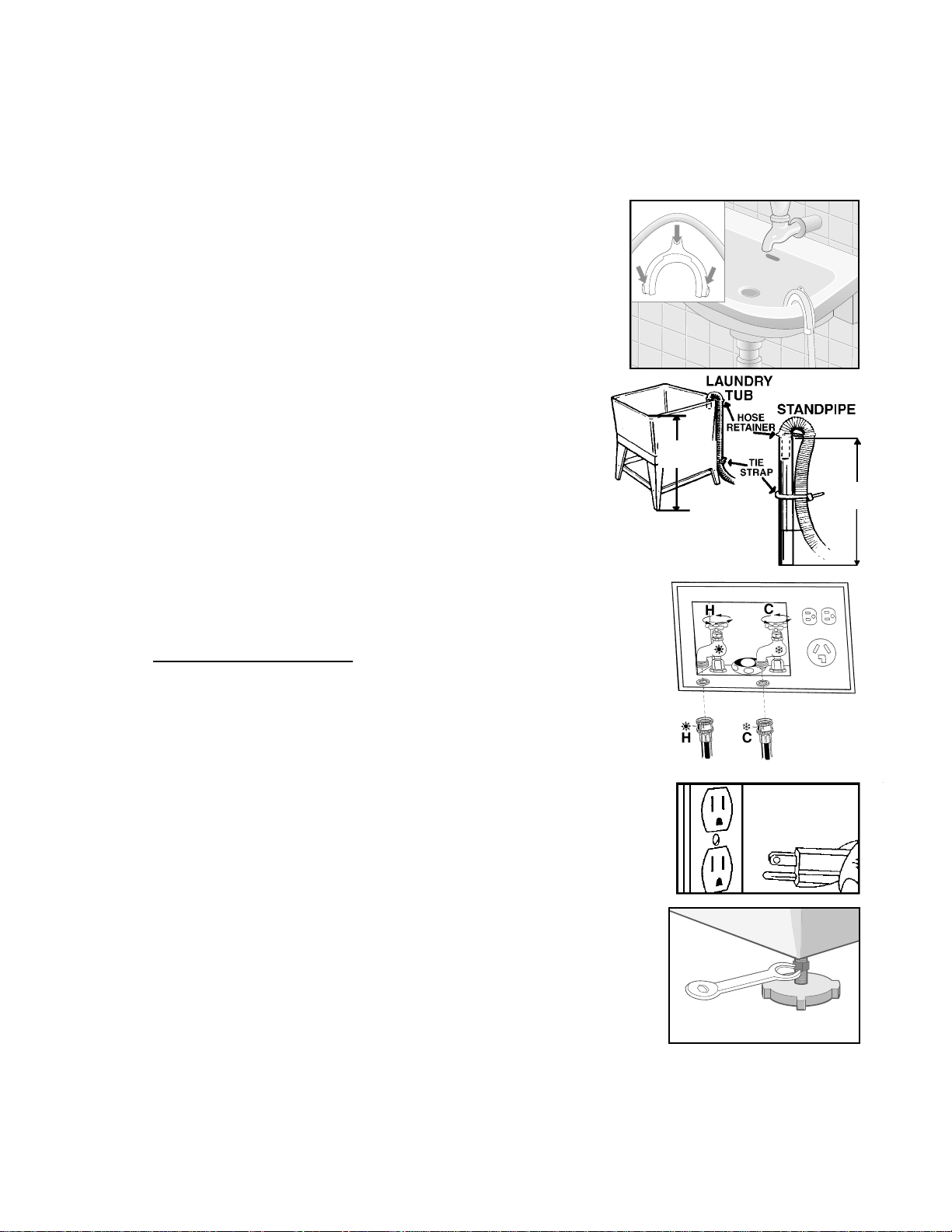

WATER

Washer needs two standard

3/4 inch water supply faucets

with a pressure between

20–120 pounds per square inch.

For more detailed information

refer to section on Water

Requirements.

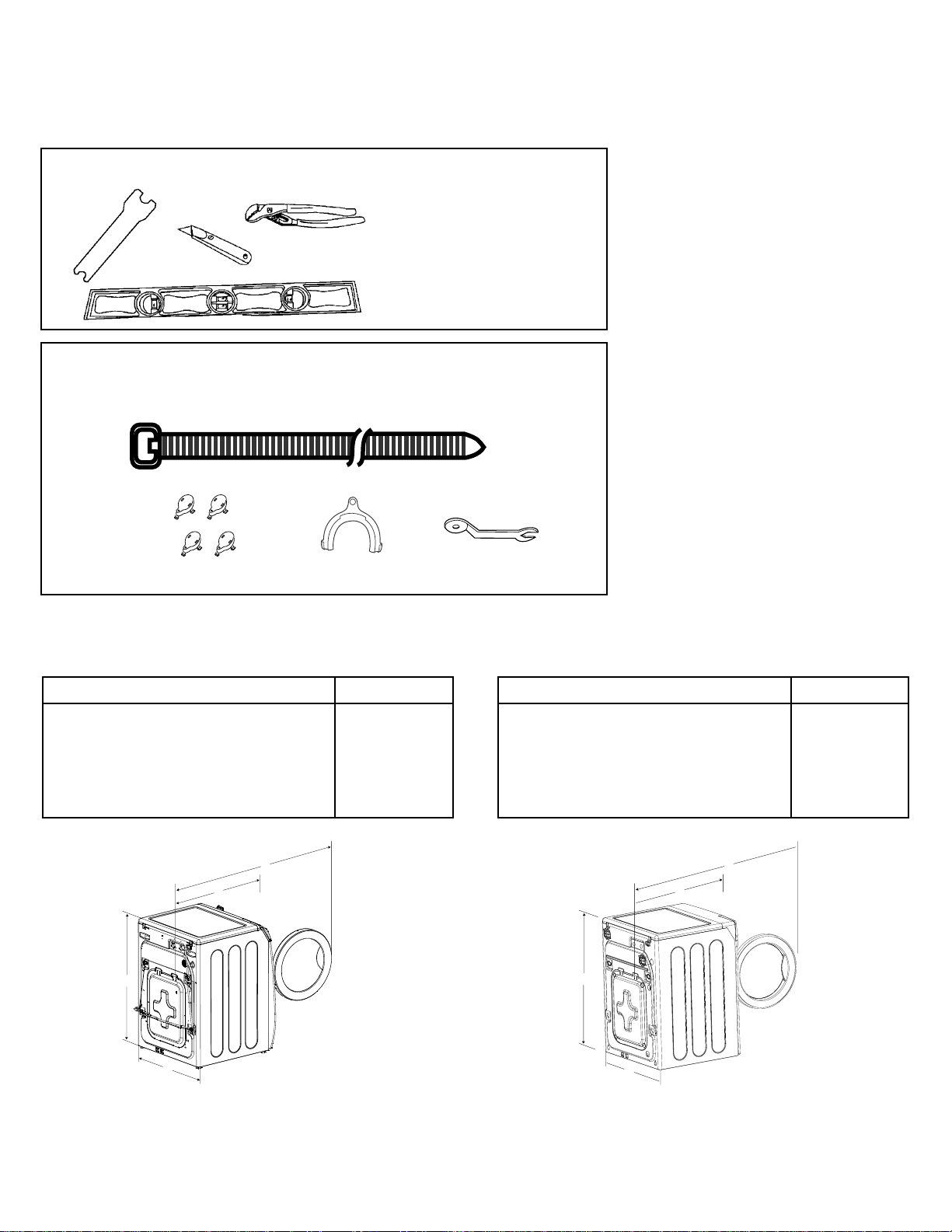

PARTS supplied for installation:

Cable tie to secure drain hose to standpipe, inlet hose or laundry tub

• Multi wrench

• Utility knife

• Channel lock

• Level

READ THIS BEFORE YOU START…

Tools needed for installation:

CABINET DIMENSIONS

Note:

The height of the washer from top to floor is 38" this includes the leveling leg screwed all the way in. The customer can

unscrew the leg out an additional 7\8" for a total overall height of 38 7\8".

2

Hose guideBolt hole covers Wrench

A

C

B

D

A

C

B

D

9700/8700 series INCH(CM)

A. Height-Overall 38” (96.5)

B. Width 27” (68.6)

C. Depth-With Washer Door Open 90 50-7/8” (129.2)

Degrees

D. Depth 30-3/4” (78.1)

6700 series INCH(CM)

A. Height-Overall 38” (96.5)

B. Width 27” (68.6)

C. Depth-With Washer Door Open 90 49” (124.5)

Degrees

D. Depth 28” (71.0)

Page 3

BASIC LOCATION REQUIREMENTS:

• Improper connection of the equipment-grounding conductor can result in a risk of electrical

shock. Check with a qualified electrician or serviceman if you are in doubt as to whether

the appliance is properly grounded. Do not modify the plug provided with the appliance – if

it will not fit the outlet, have a proper outlet installed by a qualified electrician.

IMPORTANT SAFETY PRECAUTIONS

• To prevent unnecessary risk of fire, electrical shock or personal injury, all wiring and

grounding must be done in accordance with the National Electrical Code ANSI/FNPA, No.

70-Latest Revision and local codes and ordinances. It is the personal responsibility and

obligation of the appliance owner to provide adequate electrical service for this appliance.

3

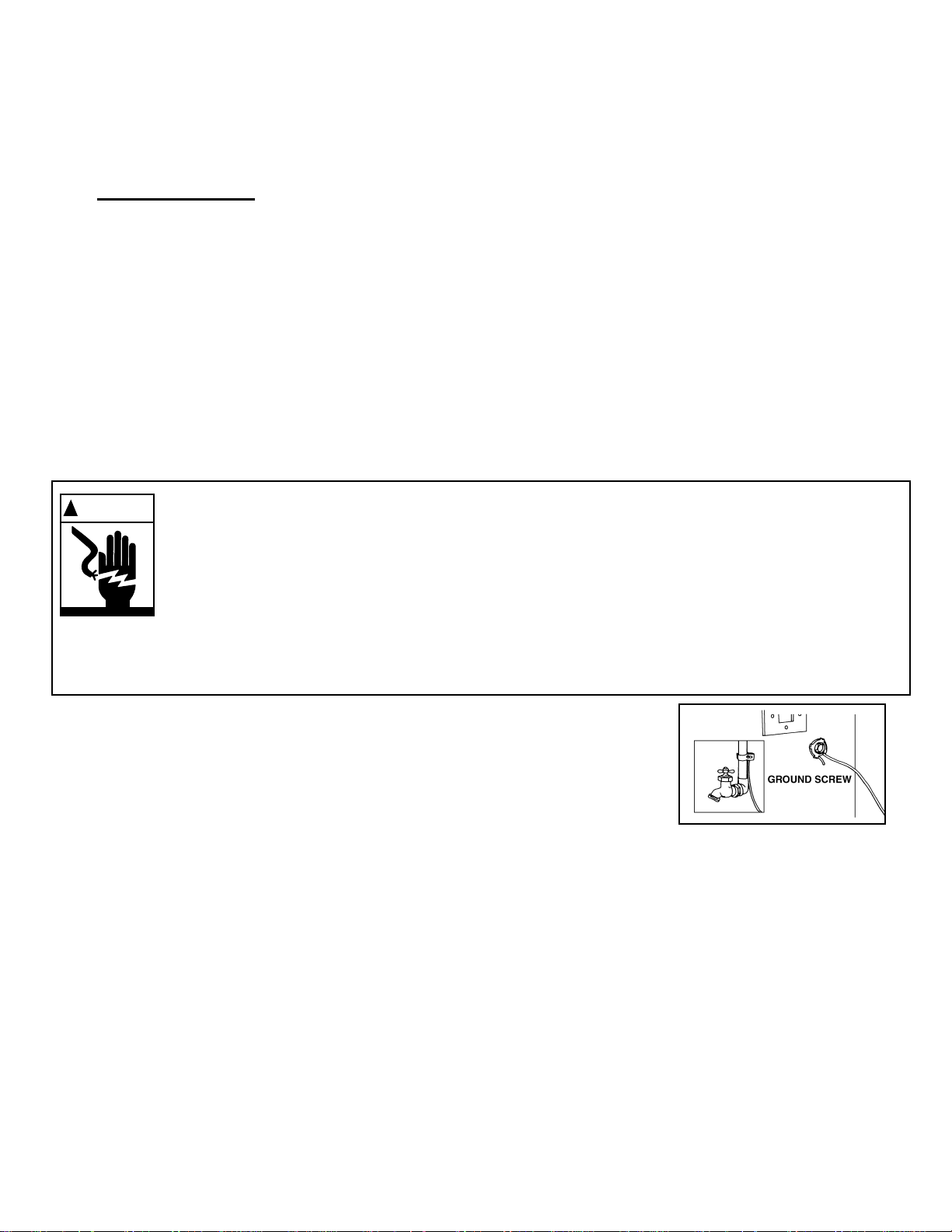

GROUNDING

ELECTRICAL GROUND IS REQUIRED ON THIS APPLIANCE.

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance for electric current. This appliance is equipped

with a power cord having a 3-prong grounding plug for use in a properly installed and grounded outlet.

ADDITIONAL GROUNDING CONNECTIONS

A grounding kit (Part No. 12001875) is available. It contains the ground wire,

clamp, ground screw and washer. Connect the ground wire to back of unit

with the cabinet ground screw and washer. Secure the other end of ground

wire to a grounded COLD metal water pipe.

NEVER CONNECT GROUND WIRE TO PLASTIC PLUMBING LINES, GAS LINES OR HOT WATER

PIPES.

WATER

To correctly fill the washer in the proper amount of time, Water pressure of 20 to 120 p.s.i. is required.

Water pressure less than 20 psi may cause a failure in the water valve and may not allow the water

valve to shut off completely. Or may extend the fill time beyond what the washer controls will normally

allow and result in the washer turning off. A time limit is built into the controls in the event of an internal

hose becoming loose and avoids a flooded home.

The water valve Hot and Cold water faucets must be within 4 feet of the back of the washer for inlet

hoses provided with the washer. NOTE: Accessory inlet hoses are available in various lengths up to

10 feet for faucets more than 4 feet from the back of the washer.

ELECTRICAL

• 120 Volt 60 Hz 15 AMP Fuse or Circuit Breaker

• Individual branch circuit serving only the washer is recommended.

• The washer is equipped with a power cord.

NEVER USE AN EXTENSION CORD.

!

WARNING

Page 4

4

DRAIN FACILITY

Recommended height of the standpipe is 18”. The drain hose must be routed through the drain hose clip

to the standpipe. Standpipe must be large enough to accept the outside diameter of the drain hose. The

drain hose is attached at the factory.

FLOORING

For best performance the washer must be installed on a solidly constructed floor. Wood floors may need

to be reinforced to minimize vibration and/or unbalanced load situations. Carpeting and soft tile surfaces

are contributing factors in vibration and/or tendency for a washer to move slightly during the spin cycle.

Never install the washer on a platform or weakly supported structure.

LOCATION CONSIDERATIONS

It is recommended the washer never be installed in areas where water may freeze since the washer will

always maintain some water in the water valve, pump and hose areas. This can cause damage to belts,

pump, hoses and other components. Operating temperature should be above 60°F.

ALCOVE OR CLOSET INSTALLATION

MINIMUM CLEARANCES FOR CLOSET AND ALCOVE INSTALLATIONS:

Sides – 0 in / 0 mm Rear – 2-3/8 in / 60 mm

Top – 17 in / 432 mm Closet Front – 2 in / 51 mm

The closet front must have a total unobstructed air opening of 72 in2. / 465 cm2minimum, if both washer

and dryer are installed together. A louvered door with equivalent air opening is acceptable. Washer alone

does not require specific air opening.

T

o Avoid The Possibility Of W

ater Damage:

• Have Water Faucets Easily Accessible

• Turn Off Faucets When Washer Is Not In Use.

Page 5

5

MAYTAG INTERNATIONAL, INC.

1475 East Woodfield Road

Schaumburg, Illinois 60173

Phone: 847-273-3100

ADDITIONAL INFORMATION

50-HERTZ OPERATION

This Maytag appliance is manufactured for operation on 60 Hz AC approved electrical service. This

model is not designed for use on 50 Hz AC electrical services and conversion of the product from 60 to

50 Hz operations is not recommended. For additional information on 50 Hz products, write:

FOR TECHNICAL ASSISTANCE, REPLACEMENT PARTS AND ACCESSORIES

For technical assistance or if your washer requires replacement parts or accessories, contact Maytag

Customer Service, toll-free 1-888-4-Maytag for information on the nearest authorized Maytag Parts

Distributor.

Proper installation is the responsibility of the owner; Service Calls Performed As A Result Of Improper

Set-up, Adjustment And/Or Connection Are The Responsibility Of The Installer.

UNPACKING THE WASHING MACHINE

Unpack your washing machine and inspect it for shipping damage and have you have received

all of the items shown on page 2. If the washing machine was damaged during shipping or you

do not have all of the items, contact your Maytag dealer immediately.

Page 6

6

IMPORTANT TO INSTALLER

Please Read The Following Instructions Carefully Before Installing The

Washing Machine.

These Instructions Should Be Retained For Future Reference.

Remove The Door From All Discarded Appliances To Avoid The Danger Of

A Child Suffocating.

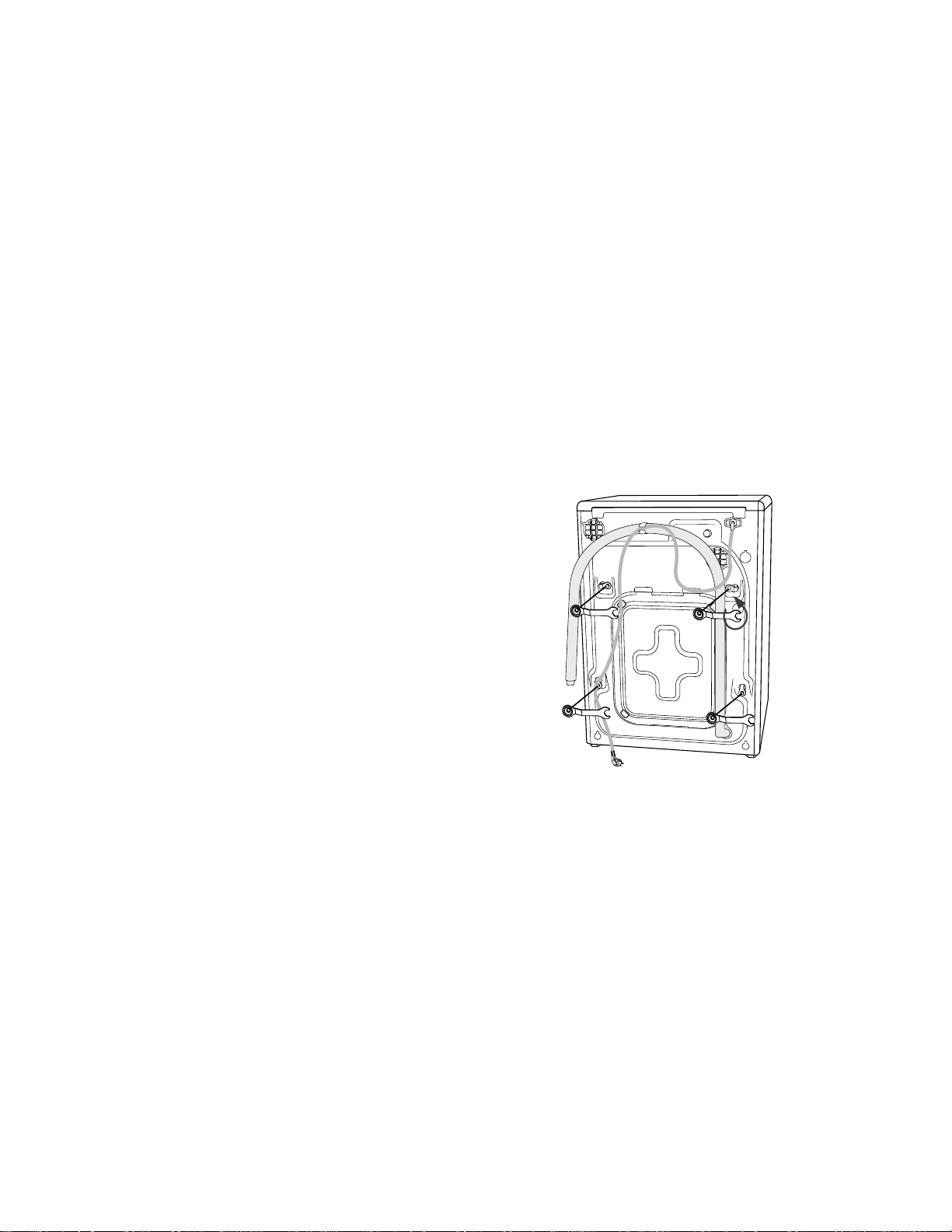

STEP 1

PREPARE WASHER

Removing The Shipping Bolts

Before using the washing machine, you must remove the four shipping bolts

from the back of the unit.

1. Loosen all bolts with the supplied wrench before

removing them.

2. Slide the bolt and spacer up and remove the bolt

with spacer through the hole in the rear wall of the

washer. Repeat for each bolt.

3. Fill the holes with the supplied plastic covers.

4. Keep the shipping bolts and spacers for future use.

STEP 2

INSTALLING THE WASHING MACHINE

Selecting a location

Before you install the washing machine, select a location with the following characteristics:

• Ahard, level surface (if the surface is uneven, see “Adjusting the leveling feet,”

below)

• Locate away from direct sunlight.

• Adequate ventilation

• Room temperature that will not fall below 32°F or 0°C.

• Away from sources of heat such as coal or gas

• Make sure that the washing machine does not stand on its power cord.

• Carpeting must not obstruct ventilation openings when the washing machine is

installed on a carpeted floor.

Page 7

96” MAX.

18” MIN.

96” MAX.

18” MIN.

7

STEP 3

INSTALL THE WASHER

1. Place the drain hose in the drain facility. Be sure an airtight

connection is NOT made between the drain hose and the

standpipe. Standpipe must be at least 18” high.

NOTE: If drain standpipe is in excess of 5 feet above floor level, a

drain hose extension kit (Part #12002482) will need to be installed.

If drain standpipe is in excess of 10 feet above floor level, a pump

accessory kit (Part #12001674) may need to be installed.

NOTE: Caution must always be exercised to avoid collapsing or

damaging the drain hose. For best performance the drain hose

should not be restricted in any way, through elbows, couplings or

excessive lengths.

For installations where the drain hose cannot be conveniently

elevated to at least 18”, the drain hose must be supported.

2. Check the inlet hose to ensure a washer is inside of each fill

hose. Thread the inlet hoses to the HOT and COLD faucet connections. On the other end of the hose, check for one rubber

washer per hose and install each fill hose to the water valve.

Make sure the hose marked “HOT”is attached to the HOT

faucet. Tighten by hand until snug and the 2/3 of a turn with

pliers. DO NOT OVER

TIGHTEN.

NOTE: For the right use of water, connect both HOT and COLD water

valve. If one is not connected, “nF”(No fill) Error can occur.

3. Turn on “HOT” and “COLD” water supply and check all

connections at the water valve and the faucet for leaks.

NOTE:Accessory inlet hoses are available in various lengths up to 10

feet.

4. Plug power cord into a grounded 120 volt 60 Hz approved

electrical service protected by a 15-amp fuse or comparable circuit

breaker. This washer is grounded through the third prong of the

power cord when plugged into a three prong grounded receptacle.

5. Slide washer into position.

6. Level washer by turning the leveling legs in or out as necessary

by hand. When the washer is level, tighten the leveling leg lock

nuts up against the base of the washer using the wrench

supplied with the washer. NOTE: The washer must be leveled

on all 4 sides. Acarpenter’s level should be used on all 4

corners of the washer. It’s a good idea after the first dozen

washes to recheck the levelness of the washer.

Page 8

8

NOTE: Keep the leg extension at a minimum to prevent excessive vibration. The farther out the legs are extended the more the washer will ibrate

and possibly walk.

FINAL INSTALLATION CHECKLIST

Instruction and Installation Kit have been removed from tub.

Shipping bolts and spacers have been removed.

Washer is plugged into electrical outlet and is properly grounded.

Water hoses are connected to the faucets with inlet screens and washers.

Water is turned on and checked for leaks at faucet and water valve connections on back of washer.

Drain hose is properly located into drain facility and is not collapsed or damaged.

Washer has been properly leveled. All legs should be firmly on the floor and leveling leg lock nuts tight-

ened up against the bottom of the washer base frame.

Washer fills properly on all temperature selections.

Test for proper operation by running the washer through a complete cycle.

COLD WEATHER STORAGE

The following precautions should be taken if a washer is to be stored, after use, where it would be subject

to freezing conditions.

1. Turn off the water supply, then remove the inlet hoses from the facets.

2. Place the end of the inlet hoses into a bucket or container. Select a fill cycle and energize the water valve

by selecting a warm water setting. Afew seconds of fill is sufficient to empty the inlet hoses.

3. Disconnect from electrical supply.

4. Lower the drain hose to floor level and tilt washer backwards to remove water from the drain hose and

pump.

❏

❏

❏

❏

❏

❏

❏

❏

❏

Page 9

9

ÉLECTRICITÉ

Reportez-vous à la plaque signalétique pour obtenir les exigences

spécifiques sur l’alimentation électrique. Pour de plus amples détails,

reportez-vous à la section sur

l’Alimentation électrique.

EAU

DEUX ROBINETS STANDARD DE

19 MM (3/4 PO) SONT NÉCESSAIRES POUR ALIMENTER LA

LAVEUSE EN EAU. LA PRESSION

DOIT ÊTRE ENTRE 138 ET 828

KPA (20 ET 120 LB/PO2). POUR

DES INFORMATIONS PLUS PRÉCISES, REPORTEZ-VOUS À LA

SECTION SUR L’ALIMENTATION

EN EAU.

PIÈCES FOURNIES POUR L’INSTALLATION :

Attache de câble pour fixer le tuyau d’évacuation au tuyau vertical,

tuyau d’arrivée ou au bac à laver.

• Clé multiple

• Couteau utilitaire

• Pince multiprise

• Niveau

LISEZ AVANT DE COMMENCER …

Outils nécessaires pour l’installation :

DIMENSIONS DE LA CAISSE

Remarque :

La hauteur de la laveuse, du dessus au sol, est de 96,5 cm (38 po). Cette dimension comprend le ou les pieds de mise à niveau

complètement vissés. Le client peut dévisser le pied de 22 mm (7/8 po) pour donner une hauteur totale de 98,7 cm (38 7/8 po).

Clé

Obturateurs de

trou de boulon

Guide pour tuyau

9700/8700 série cm (po)

A. Hauteur générale 96,5 (38)

B. Largeur 68,6 (27)

C. Profondeur – porte ouverte à 90 129,2 (50 7/8)

degrés

D. Profondeur 78,1 (30 3/4)

6700 série cm (po)

A. Hauteur générale 96,5 (38)

B. Largeur 68,6 (27)

C. Profondeur – porte ouverte à 90 124,5 (49 7/8)

degrés

D. Profondeur 71,0 (28 3/4)

A

C

B

D

A

C

B

D

Page 10

RACCORDEMENTS SUPPLÉMENTAIRES POUR MISE À LA TERRE

Un nécessaire de mise à la terre (pièce n° 12001875) est disponible. Il comporte le

fil de mise à la terre, un serre-câble, une vis de mise à la terre et une rondelle.

Raccordez le fil de mise à la terre à l’arrière de l’appareil en utilisant la rondelle et la

vis de mise à la terre sur la caisse. Fixez l’autre extrémité du fil de mise à la terre à

un tuyau d’eau FROIDE en métal, mis à la terre.

NE RACCORDEZ JAMAIS LE FIL DE MISE À LA TERRE À DE LA TUYAUTERIE EN PLASTIQUE, CANALISATION DE GAZ OU À UN TUYAU D’EAU CHAUDE.

ALIMENTATION EN EAU

Pour remplir correctement la laveuse et ce au cours de la durée appropriée, la pression de l’eau doit être située

entre 138 et 828 kPa (20 et 120 lb/po2).Une pression d’eau inférieure à 138 kPa (20 lb/po2) peut entraîner un

mauvais fonctionnement de l’électrovanne et peut faire que l’électrovanne ne se ferme pas complètement. Cette

pression inférieure peut aussi prolonger la durée de remplissage au-delà de ce que les commandes permettent

normalement en entraînant l’arrêt de la laveuse. Une limite de durée est intégrée aux commandes au cas où un

tuyau interne se déferait et cela pour éviter une inondation dans la maison.

Les robinets d’eau froide et d’eau chaude doivent se trouver à moins de 1,2 m (4 pi) de l’arrière de la laveuse

dans le cas des tuyaux d’arrivée fournis avec la laveuse. REMARQUE : Des tuyaux d’arrivée fournis en accessoires sont disponibles en longueurs variables jusqu’à 3 m (10 pi) dans le cas des robinets se trouvant à plus de

1,2 m (4 pi) de l’arrière de laveuse.

• Le raccordement incorrect du conducteur de mise à la terre de l’équipement peut entraîner

un risque de décharge électrique. Vérifiez avec un électricien ou un réparateur qualifié si

vous avez des doutes quant à la mise à la terre de l’appareil. Ne modifiez pas la prise

fournie avec l’appareil – si elle ne convient pas à la prise, faites-la changer par un électricien

qualifié.

IMPORTANTES MESURES DE SÉCURITÉ

• Pour éviter un risque inutile d’incendie, de décharge électrique ou de blessure, tout le

câblage et la mise à la terre doivent être exécutés selon la dernière révision de la norme n°

70 du Code électrique national ANSI/NFPA, et conformément à tous les codes et règlements

locaux. Il revient au propriétaire de l’appareil de fournir une alimentation électrique adéquate

pour cet appareil.

10

EXIGENCES DE BASE SUR L’EMPLACEMENT :

ALIMENTATION ÉLECTRIQUE

• 120 volts, fusible ou disjoncteur de 15 A, 60 Hz

• Circuit indépendant ne desservant que la laveuse : recommandé

• La laveuse est dotée d’un cordon d’alimentation.

N’UTILISEZ JAMAIS UN CORDON PROLONGATEUR.

MISE À LA TERRE

UNE MISE À LA TERRE ÉLECTRIQUE EST NÉCESSAIRE POUR CET APPAREIL

Cet appareil doit être fondé. En cas de la mauvaise fonctionnement ou en cas de la défaillance,

fonder réduira le risque de décharge électrique en fournant un chemin de moins de résistance pour le

courant électrique. Cet appareil est équipé avec un cordon d'alimentation ayant un de 3 broches fondant le bouchon pour l'usage dans une sortie convenablement installée et fondé.

VIS DE MISE

À LA TERRE

Mise En

!

Garde

Page 11

11

Pour éviter le risque de dommage par l’eau :

•Les robinets d’eau doivent être facilement accessibles.

•Fermez les robinets quand la laveuse n’est pas utilisée.

INSTALLATION D’ÉVACUATION

La hauteur recommandée pour le tuyau vertical est de 46 cm (18 po). Le tuyau d’évacuation doit passer

dans l’attache prévue pour ce tuyau, pour ensuite arriver au tuyau vertical. Le tuyau vertical doit être

d’un diamètre suffisant pour recevoir le tuyau d’évacuation. Le tuyau d’évacuation est raccordé à l’usine.

PLANCHER/SOL

Pour les meilleures performances de la laveuse, celle-ci doit être installée sur un plancher ou sol solide.

Les planchers en bois peuvent nécessiter un renforcement afin de minimiser les vibrations ou le

déséquilibre de la laveuse. Les revêtements en moquette ou en carreaux souples peuvent contribuer

aux vibrations ou à une tendance de la laveuse à se déplacer légèrement pendant l’essorage.

N’installez jamais la laveuse sur une plate-forme ou une surface portante insuffisamment solide.

EMPLACEMENT

Il est recommandé de ne jamais installer la laveuse dans des endroits où l’eau peut geler parce qu’il y a

toujours de l’eau dans la laveuse au niveau de l’électrovanne, de la pompe et des tuyaux. Ceci peut

endommager les courroies, la pompe, les tuyaux et les autres éléments de l’appareil. La température

de fonctionnement doit être au-dessus de 15,5 °C (60 °F).

INSTALLATION DANS UNE ALCÔVE OU UN PLACARD

DÉGAGEMENTS MINIMAUX POUR INSTALLATION DANS UNE ALCÔVE OU UN PLACARD :

Côtés – 0 mm / 0 po Arrière – 60 mm / 2-3/8 po

Dessus – 432 mm / 17 po (placard) Devant – 51 mm / 2 po

Le devant de l’armoire doit avoir une ouverture d’air non fermée de 465 cm

2

/ 72 po2minimum, si la

laveuse et la sécheuse sont installées ensemble. Une porte à persienne avec des ouvertures d’air

équivalentes est acceptable. Pour la laveuse seule, il n’est pas nécessaire d’avoir une ouverture d’air

particulière.

Page 12

12

INFORMATIONS SUPPLÉMENTAIRES

FONCTIONNEMENT 50 HERTZ

Cet appareil Maytag est fabriqué pour fonctionner sur une alimentation électrique approuvée de 60 Hz,

CA. Ce produit n’est pas prévu pour un fonctionnement sur 50 Hz et il n’est pas recommandé de le

convertir, du 60 Hz en 50 Hz. Pour des renseignements supplémentaires sur les produits prévus pour

50 Hz, écrivez à :

MAYTAG INTERNATIONAL, INC.

1475 East Woodfield Road

Schaumburg, Illinois 60173

Téléphone : 847-273-3100

POUR UNE ASSISTANCE TECHNIQUE, PIÈCES DE RECHANGE ET ACCESSOIRES

Pour une assistance technique ou si votre laveuse a besoin de pièces de rechange ou d’accessoires,

prenez contact avec le service à la clientèle de Maytag, au numéro sans frais 1-888-4-Maytag pour

obtenir de l’information sur le distributeur de pièces Maytag autorisé le plus proche de chez vous.

Le propriétaire est responsable de la bonne installation de l’appareil; les appels de service qui sont le

résultat d’une installation, d’un réglage ou d’un raccordement inappropriés, sont à la charge de

l’installateur.

DÉBALLAGE DE LA LAVEUSE

Déballez votre laveuse et inspectez-la pour voir si elle n’a pas été endommagée pendant l’expédition et

si vous avez bien reçu tous les articles illustrés à la page 2. Si la laveuse a été endommagée au cours

de l’envoi ou que vous n’ayez pas tous les articles, prenez contact immédiatement avec le détaillant

Maytag.

Page 13

CONSIGNE IMPORTANTE POUR L’INSTALLATEUR

Veuillez lire attentivement les instructions suivantes avant d’installer la laveuse.

Conservez ces instructions pour vous y reporter ultérieurement.

Enlevez la porte de tous les appareils que vous mettez au rebut afin d’éviter qu’un enfant ne s’y

retrouve étouffé.

ÉTAPE 1

PRÉPARATION DE LA LAVEUSE

Enlevez les boulons d’expédition

Avant d’utiliser la laveuse, vous devez enlever les quatre boulons d’expédition de l’arrière de l’appareil.

1. Desserrez tous les boulons avec la clé fournie avant de les

retirer.

2. Coulissez chaque boulon et chaque entretoise vers le haut

et faites-les passer par le trou de la paroi arrière de la

laveuse.

3. Fermez les trous avec les obturateurs en plastique fournis.

4. Conservez les boulons d’expédition et les entretoises pour

une utilisation ultérieure.

ÉTAPE 2

INSTALLATION DE LA LAVEUSE

Choix de l’emplacement

Avant d’installer la laveuse, choisissez un emplacement présentant les caractéristiques suivantes :

• Une surface à niveau, solide (si la surface est inégale, voyez ci-après comment régler les pieds

de mise à niveau)

• Non exposé aux rayons directs du soleil

• Présentant une aération appropriée

• Température ambiante ne descendant pas en dessous de 0 °C (32 °F)

• Éloigné des sources de chaleur comme le gaz ou le charbon

• Assurez-vous que la laveuse ne se trouve pas sur son cordon d’alimentation

• La moquette ne doit pas gêner les ouvertures d’aération lorsque la laveuse est installée sur de la

moquette.

13

Page 14

14

ÉTAPE 3

INSTALLATION DE LA LAVEUSE

1.Disposez le tuyau d’évacuation dans le dispositif prévu. Le raccordement

NE doit PAS être hermétique à l’air entre le tuyau d’évacuation et le tuyau

vertical. Le tuyau vertical doit avoir au moins 30 cm (18 po) de hauteur.

REMARQUE : si le tuyau vertical est à plus de 1,5 m (5 pi) au-dessus du

niveau du sol, un nécessaire de rallonge de tuyau d’évacuation (pièce n°

12002482) devra être installé. Si le tuyau vertical est de plus de

3 m (10 pi) au-dessus du niveau du sol, un nécessaire d’accessoire avec pompe (pièce n° 12001674) pourra devoir être installé.

REMARQUE : il faut toujours prendre les mesures nécessaires

pour éviter d’écraser le tuyau d’évacuation. Pour les meilleures

performances, le tuyau d’évacuation ne doit en aucune façon

être comprimé, au niveau des coudes et raccords et ne doit pas

être d’une longueur excessive.

Pour les installations où le tuyau d’évacuation ne peut être commodément placé à au moins 46 cm (18 po) de hauteur, il faut

prévoir un support.

2.Vérifiez le tuyau d’arrivée pour vous assurer qu’une rondelle se trouve à l’intérieur de chacune des extrémités des tuyaux de remplissage. Vissez les

tuyaux d’arrivée aux raccords des robinets d’eau CHAUDE et d’eau

FROIDE. À l’autre extrémité des tuyaux, vérifiez qu’il y a une rondelle en

caoutchouc par tuyau et insérez chaque tuyau de remplissage à l’électrovanne. Assurez-vous que le tuyau marqué « HOT » (CHAUD) est raccordé au robinet d’eau CHAUDE. Serrez bien à la main puis de 2/3 de tour

à l’aide de pince. NE SERREZ P

AS TROP

FORT.

REMARQUE : Pour utiliser correctement la machine ‡ laver, raccorder les

robinets d eau chaude « CHAUDE » et froide « FROIDE ». Si l un des robinets n est pas raccordÈ, une erreur de type « nF »(No Fill - ucun remplissage) peut survenir.

3.Ouvrez l’eau « CHAUDE » et l’eau « FROIDE » et vérifiez tous les raccordements au niveau des robinets et de l’électrovanne pour vous assurer qu’il n’y

a pas de fuite. REMARQUE : Des tuyaux sont disponibles en accessoires,

en longueurs variables allant jusqu’à 3 m (10 pi).

4.Branchez le cordon d’alimentation dans une prise de 120 volts, 60 Hz

approuvée, mise à la terre et protégée par un disjoncteur ou fusible de 15 A.

cette laveuse est mise à la terre par l’intermédiaire de la troisième broche du

cordon lorsqu’il est branché dans une prise à trois alvéoles mise à la terre.

5.Poussez la laveuse en place.

6.Mettez la laveuse à niveau en tournant les pieds de mise à niveau dans un

sens ou dans l’autre à la main, selon le besoin. Lorsque la laveuse est de

niveau, serrez les contre-écrous des pieds de mise à niveau contre la base

de la laveuse avec la clé fournie avec l’appareil. REMARQUE : la laveuse

doit être de niveau sur ses quatre côtés. Utilisez un niveau de charpentier

aux quatre angles de la laveuse. Il est conseillé de revérifier le niveau de

la laveuse après les douze premiers lavages.

244 cm (96 po) MAX

46 cm (18 po) MIN.

BAC À LAVER

TUYAU

VERTICAL

RETENUE

DE TUYAU

ATT ACHE

244 cm (96 po) MAX

46 cm (18 po) MIN.

Page 15

15

REMARQUE : Dévissez les pieds au minimum afin d’éviter un excès de

vibration. Plus les pieds sont dévissés, plus la laveuse vibrera et éventuellement se déplacera.

VÉRIFICATION FINALE DE L’INSTALLATION

❏ Les instructions et le nécessaire d’installation ont été enlevés de la cuve.

❏ Les boulons d’expédition et les entretoises ont été enlevés.

❏ La laveuse est branchée dans une prise électrique et est correctement mise à la terre.

❏ Les tuyaux d’eau sont raccordés aux robinets munis de rondelles et de tamis.

❏ L’eau est ouverte et une vérification des fuites a été faite au niveau des robinets et de l’électrovanne

à l’arrière de l’appareil.

❏ Le tuyau d’évacuation est correctement disposé au niveau de l’évacuation et n’est pas écrasé ni

endommagé.

❏ La laveuse a été correctement mise à niveau. Tous les pieds reposent fermement sur le sol et les

contre-écrous des pieds de mise à niveau, bien serrés, contre le bas du cadre de la laveuse.

❏ La laveuse se remplit correctement à toutes les températures choisies.

❏ Vérifiez le bon fonctionnement en faisant faire un cycle complet à la laveuse.

ENTREPOSAGE PAR TEMPS FROID

Prenez les précautions suivantes si vous devez remiser la laveuse après l’avoir utilisée à un endroit

pouvant être soumis à des conditions de gel.

1. Coupez l’arrivée d’eau, puis débranchez les tuyaux d’arrivée au niveau des robinets.

2. Placez l’extrémité des tuyaux d’arrivée dans un seau ou un contenant. Choisissez un cycle de rem-

plissage et faites fonctionner l’électrovanne en choisissant un réglage d’eau tiède. Quelques secondes de remplissage sont nécessaires pour vider les tuyaux d’arrivée.

3. Débranchez la laveuse de l’alimentation électrique.

4. Baissez le tuyau d’évacuation au niveau du sol et inclinez la laveuse vers l’arrière pour enlever l’eau

de la pompe et du tuyau d’évacuation.

Page 16

16

INFORMACIÓN

ELÉCTRICA

Consulte la placa de serie para

obtener los requerimientos eléctricos específicos. Para obtener

información más detallada, consulte la sección sobre los requer-

imientos eléctricos.

INFORMACIÓN

SOBRE EL AGUA

La lavadora necesita dos llaves de

suministro de agua estándares de

3/4" (1,91 cm) con presión entre

las 20 y las 120 libras por pulgada

cuadrada. Para obtener información más detallada, consulte la

sección sobre los requerimientos

de agua.

PIEZAS suministradas para la instalación:

Amarre de cable para fijar la manguera de desagüe al tubo vertical,

a la manguera de admisión o a la tina del lavadero

• Llave múltiple

• Cuchillo multiuso

• Llave inglesa

• Nivel

LEA ESTO ANTES DE COMENZAR...

Herramientas necesarias para la instalación:

DIMENSIONES DEL GABINETE

Nota:

La altura de la lavadora desde la superficie del piso es 38" (96,52 cm). Esto incluye las patas niveladoras completamente

atornilladas. El cliente puede destornillar las patas 7/8" (2,22 cm) para una altura total de 38-7/8" (98,74 cm).

Llave

Tapas para agujeros

de perno

Guía de

manguera

9700/8700 serie PULG. (CM)

A. Altura general 38” (96,5)

B. Ancho 27” (68,6)

C. Profundidad con la puerta 50-7/8” (129.2)

de la lavadora abierta a 90°

D. Profundidad 30-3/4” (78.1)

6700 serie PULG. (CM)

A. Altura general 38” (96,5)

B. Ancho 27” (68,6)

C. Profundidad con la puerta 49-7/8” (124.5)

de la lavadora abierta a 90°

D. Profundidad 28-3/4” (71.0)

A

C

B

D

A

C

B

D

Page 17

17

CONEXIONES ADICIONALES A TIERRA

Puede adquirir un kit de puesta a tierra adicional (pieza Nº 12001875). El mismo

contiene el cable de puesta a tierra, la abrazadera, el tornillo de puesta a tierra y la

arandela. Conecte el cable de puesta a tierra a la parte trasera del electrodoméstico

usando el tornillo de puesta a tierra y la arandela. Fije el otro extremo del cable de

puesta a tierra a una tubería de agua FRÍA de metal.

NUNCA CONECTE EL CABLE DE PUESTA A TIERRA A TUBERÍAS DE AGUA DE PLÁSTICO, A

TUBERÍAS DE GAS O A TUBERÍAS DE AGUA CALIENTE.

REQUERIMIENTOS DE AGUA

Para llenar correctamente la lavadora en la cantidad de tiempo adecuado, se requiere una presión de agua de

20 a 120 psi. Si la presión es menor de 20 psi, puede ocurrir una falla en la válvula de agua y evitar que la

válvula de agua se cierre completamente. Esto también puede provocar que el tiempo de llenado se extienda

más allá del control de la lavadora, lo que hará que la lavadora se apague. Los controles cuentan con un límite

de tiempo incorporado en caso de que una manguera interna se suelte y así evitar una inundación en el hogar.

La válvula de agua y las llaves de agua fría y caliente deben estar a menos de 4 pies (1,2 m) de la parte trasera

de la lavadora para las mangueras de admisión proporcionadas con la lavadora. NOTA: Puede adquirir

mangueras de admisión adicionales en diferentes tamaños de hasta 10 pies (3 m) para las llaves de agua que

se encuentren a más de 4 pies (1,2 m) de la parte trasera de la lavadora.

• La conexión inadecuada del conductor de puesta a tierra del equipo puede causar un

choque eléctrico. Si no está seguro de que el electrodoméstico esté debidamente conectado

a tierra, consulte a un electricista o técnico de servicio. No modifique el enchufe proporcionado con el electrodoméstico – si el enchufe no cabe en el tomacorriente, haga que un

electricista calificado instale un tomacorriente adecuado.

PRECAUCIONES IMPORTANTES DE SEGURIDAD

• Para evitar riesgos innecesarios de incendio, choque eléctrico o lesiones personales, todo el cableado y la

puesta a tierra deben ser llevados a cabo de acuerdo con el Código Nacional de Electricidad ANSI/FNPA,

Nº 70, última edición, y de acuerdo con los códigos y leyes locales. Es responsabilidad y obligación personal del propietario proporcionar un suministro eléctrico adecuado para este electrodoméstico.

REQUERIMIENTOS BÁSICOS DE UBICACIÓN:

REQUERIMIENTOS ELÉCTRICOS

• Suministro de 120 V, 60 Hz, 15 A con fusible o disyuntor.

• Se recomienda un circuito individual exclusivo para la lavadora.

• La lavadora viene equipada con un cordón eléctrico.

NUNCA USE UN CORDÓN DE EXTENSIÓN.

PUESTA A TIERRA

SE REQUIERE UNA CONEXIÓN ELÉCTRICA A TIERRA PARA ESTE ELECTRODOMÉSTICO.

Este aparato se debe moler. En caso del funcionamiento defectuoso o la avería, molió reducirá el riesgo de calambre proporcionando un sendero de menos resistencia para la corriente eléctrica. Este

aparato se equipa con una cuerda del poder que tiene un de 3 puntas molió tapón para el uso en un

apropiadamente instalado y molido salida. .

TORNILLO DE

PUESTAA

TIERRA

!

ADVERTENCIA

Page 18

18

Para evitar el riesgo de daños por inundación:

• Facilite el acceso a las llaves de agua.

• Cierre las llaves cuando la lavadora no esté en uso.

INSTALACIONES DE DESAGÜE

La altura recomendada del tubo vertical es de 18" (45,72 cm). La manguera de desagüe debe ser

dirigida a través del gancho para dicha manguera y hacia el tubo vertical. El tubo vertical debe ser lo

suficientemente grande para acomodar el diámetro exterior de la manguera de desagüe. La manguera

de desagüe viene instalada de la fábrica.

PISO

Para obtener el mejor rendimiento, la lavadora debe ser instalada sobre un piso de construcción firme.

Los pisos de madera pueden requerir ser reforzados para minimizar la vibración y/o las situaciones de

carga desbalanceada. Las superficies alfombradas y de baldosa suave aumentan la vibración y/o la

tendencia de que la lavadora se mueva levemente durante el ciclo de centrifugado. Nunca instale la

lavadora sobre una plataforma o sobre una estructura con soportes endebles.

CONSIDERACIONES DE UBICACIÓN

Se recomienda que la lavadora nunca se instale en áreas donde el agua pueda congelarse, ya que la

lavadora siempre mantendrá cierta cantidad de agua en la válvula, en la bomba y en las mangueras.

Esto puede causar daños a las correas, a la bomba, a las mangueras y a otras piezas. La temperatura

de funcionamiento debe estar sobre los 60°F (16°C).

INSTALACIÓN EN UN NICHO O ARMARIO

DESPEJES MÍNIMOS PARA INSTALACIONES EN NICHOS O ARMARIOS:

Costados – 0 pulg./0 mm Parte trasera – 2-3/8 pulg./ 60 mm

Parte superior – 17 pulg./432mm en un armario Parte delantera – 2 pulg./51 mm

La parte delantera del armario debe presentar una abertura de aire sin obstrucciones de 72 pulg.

2

(465

cm

2

) como mínimo si se instalan la lavadora y la secadora juntas. Se puede usar una puerta persiana

con una abertura de ventilación equivalente. La lavadora sola no tiene requerimientos específicos de

aberturas de ventilación.

Page 19

19

INFORMACIÓN ADICIONAL

FUNCIONAMIENTO A 50 HERTZ

Este electrodoméstico Maytag fue fabricado para funcionar con un suministro eléctrico aprobado de 60 Hz

CA. Este modelo no fue diseñado para usar un suministro eléctrico de 50 Hz CA, y no se recomienda su

conversión de 60 Hz a 50 Hz. Para obtener información adicional sobre productos de 50 Hz, escriba a:

MAYTAG INTERNATIONAL, INC.

1475 East Woodfield Road

Schaumburg, Illinois 60173

Tel.: 847-273-3100

PARA OBTENER ASISTENCIA TÉCNICA, PIEZAS DE REPUESTO Y ACCESORIOS

Para obtener asistencia técnica o si su lavadora requiere piezas de repuesto o accesorios, póngase en

contacto con Atención al cliente Maytag por la línea gratuita 1-888-4-Maytag para obtener información sobre el distribuidor de piezas Maytag autorizado más cercano.

La instalación adecuada es responsabilidad del propietario. Las llamadas de servicio generadas por

la instalación, ajuste y/o conexión inadecuados son responsabilidad del instalador.

DESEMPAQUE DE LA LAVADORA

Desempaque la lavadora e inspecciónela para verificar que no tenga daños por el envío y que haya

recibido todos los artículos que se muestran en la página 2. Si la lavadora sufrió daños durante el

envío o si no tiene todos los artículos, póngase en contacto con su distribuidor Maytag inmediatamente.

Page 20

20

NOTA IMPORTANTE PARA EL INSTALADOR

Por favor lea cuidadosamente las siguientes instrucciones antes de instalar la lavadora.

Guarde estas instrucciones para referencia futura.

Retire la puerta de todos los electrodomésticos desechados para evitar el sofocamiento de

niños.

PASO 1

PREPARE LA LAVADORA

Remoción de los pernos de envío de la parte trasera de la unidad.

Antes de usar la lavadora, debe retirar los cuatro pernos de envío.

1. Afloje todos los pernos con la llave provista antes de retirarlos.

2. Deslice el perno y el espaciador hacia arriba y retírelos

juntos a través del agujero en la pared trasera de la

lavadora. Repita el proceso para cada perno.

3. Cubra los agujeros con las tapas para agujeros de pernos.

4. Guarde los pernos y espaciadores para uso futuro.

PASO 2

INSTALLATION DE LA LAVEUSE

Selección de una ubicación

Antes de instalar la lavadora, seleccione una ubicación con las siguientes características:

• Superficie dura y nivelada (si la superficie no está nivelada, vea la sección "Ajuste de las patas

niveladoras" abajo).

• Instale el electrodoméstico alejado de la luz directa del sol.

• Ventilación adecuada.

• Temperatura ambiental que no caiga por debajo de los 32°F o 0°C.

• Instale el electrodoméstico alejado de fuentes de calor tales como carbón o gas.

• Asegúrese de que el cordón eléctrico no quede atrapado debajo de la lavadora.

• La alfombra no debe obstruir las aberturas de ventilación cuando la lavadora sea instalada sobre

piso alfombrado.

Page 21

21

PASO 3

INSTALE LA LAVADORA

1.Coloque la manguera de desagüe en la instalación de desagüe. Asegúrese

de que NO se cree una conexión hermética entre la manguera de desagüe

y el tubo vertical. El tubo vertical debe ser de por lo menos 18" (45,72 cm)

de alto.

NOTA: Si el tubo vertical se extiende 5 pies (1,5 m) sobre el nivel del piso,

deberá instalar un kit de extensión de manguera de desagüe (pieza Nº

12002482). Si el tubo vertical se extiende 10 pies (3,1 m) sobre

el nivel del piso, deberá instalar un kit de accesorio de bomba

(pieza Nº 12001674).

NOTA: Siempre tenga cuidado de evitar colapsar o dañar la

manguera de desagüe. Para obtener el mejor rendimiento, la

manguera de desagüe no debe estar obstruida de ninguna

manera con el uso de codos, acopladores o largo excesivo.

Para las instalaciones donde la manguera de desagüe no

pueda ser elevada de manera conveniente sobre las 18" (45,72

cm), se deberá apoyar la manguera de desagüe.

2.Verifique la manguera de admisión para asegurar que haya una arandela en

cada manguera de llenado. Enrosque las mangueras de admisión en las

llaves de agua CALIENTE y FRÍA. En el otro extremo de la manguera, verifique que haya una arandela de goma en cada manguera y conecte cada

manguera de llenado a la válvula de agua.

Asegúrese de que la manguera marcada como "HOT" (caliente) esté conectada a la llave de agua CALIENTE. Apriete completamente a mano y luego

gire 2/3 de vuelta adicional con un alicate. NO APRIETE DEMASIADO.

NOTA: Para el uso correcto de la lavadora, conecte la válvula de agua

CALIENTE y la de agua FRÍA. Si una de las dos no está conectada, puede

producirse un error "nF"(No Llenado)

3.Abra el suministro de agua CALIENTE y FRÍA y verifique todas las conexiones en la válvula de agua y las llaves para asegurarse de que no haya

escapes. NOTA: Puede adquirir accesorios de mangueras de admisión de

varias longitudes hasta 10 pies (3,1 m).

4.Enchufe el cordón eléctrico en un suministro eléctrico puesto a tierra de 120

V, 60 Hz protegido por un fusible de 15 A o un disyuntor equivalente. Esta

lavadora es puesta a tierra a través de la tercera clavija del cordón eléctrico

cuando se enchufa en un tomacorriente de 3 alvéolos puesto a tierra.

5.Deslice la lavadora a su lugar definitivo.

6.Nivele la lavadora girando con la mano las patas niveladoras hacia adentro

o hacia afuera como sea necesario. Cuando la lavadora haya sido nivelada,

apriete las tuercas de bloqueo de las patas niveladoras contra la base de la

lavadora usando la llave provista. NOTA: La lavadora debe ser nivelada en

los 4 costados. Use un nivel de carpintero en las 4 esquinas de la lavadora.

Se recomienda verificar el nivel de la lavadora después de la primera

docena de lavadas.

MÁX. 96" (243 cm)

MÍN. 18" (45,72 cm)

TINA DE LAVADO

TUBO

VERTICAL

SOPORTE

DE LA

MANGUERA

AMARRE

MÁX. 96" (243 cm)

MÍN. 18" (45,72 cm)

Page 22

22

NOTA: Mantenga la extensión de las patas a un mínimo para evitar vibración

excesiva. Mientras más extendidas estén las patas, más vibrará la lavadora y

la misma podría hasta "caminar".

LISTA DE VERIFICACIÓN FINAL

❏ Se sacaron las instrucciones y el kit de instalación de la tina de lavado.

❏ Se retiraron los pernos de envío y los espaciadores.

❏ La lavadora está enchufada en un tomacorriente debidamente puesto a tierra.

❏ Las mangueras de agua están conectadas a las llaves de agua con las mallas de admisión y las

arandelas.

❏ El agua está abierta y se realizó la verificación de escapes en las conexiones de las llaves y de la

válvula de agua en la parte trasera de la lavadora.

❏ La manguera de desagüe está debidamente ubicada en la instalación de desagüe y no está colap-

sada o dañada.

❏ La lavadora ha sido debidamente nivelada. Todas las patas deben estar apoyadas firmemente sobre

el piso y las tuercas de bloqueo de las patas niveladoras están apretadas contra la parte inferior del

marco de la base de la lavadora.

❏ La lavadora se llena adecuadamente en todas los ajustes de temperatura.

❏ Pruebe el funcionamiento adecuado haciendo funcionar la lavadora por un ciclo completo.

ALMACENAMIENTO EN AMBIENTES FRÍOS

Siga las siguientes precauciones si, después de haberla usado, va a almacenar la lavadora en un

ambiente donde la temperatura baje del punto de congelación.

1. Cierre el suministro de agua y retire las mangueras de admisión de las llaves de agua.

2. Coloque el extremo de las mangueras de admisión en un cubo o contenedor. Seleccione un ciclo de

llenado y active la válvula de agua programando un ajuste de agua tibia. Unos pocos segundos en

la etapa de llenado es suficiente para vaciar las mangueras de admisión.

3. Desenchufe el electrodoméstico.

4. Baje la manguera de desagüe hasta el nivel del piso e incline la lavadora hacia atrás para sacar el

agua de la manguera de desagüe y de la bomba.

Loading...

Loading...