Page 1

Instruction 16026908

2206860

Sheet

Description: LP Gas Conversion Kit

Repair Part Number: 649P3

Kit includes:

Quantity Part number Description

1-----------------------------------------------40097101 --------------------------------------- Block – Open Plug

1 -----------------------------------------------40097301 --------------------------------------- Burner Orifice Spud (1.45 mm)

1 -----------------------------------------------40097004 --------------------------------------- Conversion Plate

1 -----------------------------------------------40096701 --------------------------------------- Valve Converted to

L.P. Gas Sticker (English)

1 -----------------------------------------------40096901 --------------------------------------- Valve Converted to

L.P. Gas Sticker (French)

1 -----------------------------------------------40096801 --------------------------------------- Valve Converted to

L.P. Gas Sticker (Spanish)

2 -----------------------------------------------40096602 --------------------------------------- L.P. Gas Stickers (English)

2 -----------------------------------------------40096606 --------------------------------------- L.P. Gas Stickers (French)

1-----------------------------------------------40096604 --------------------------------------- L.P. Gas Sticker (Spanish)

1 -----------------------------------------------16026908 --------------------------------------- Instructions

m

m

5

4

.

1

Block - Open Plug Burner Orifice Spud

!

This conversion kit shall be installed by a qualified service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements of the authority having jurisdiction. The information in

these instructions must be followed to minimize the risk of fire or explosion or to prevent property damage,

personal injury or death. The qualified service agency is responsible for the proper installation of this kit. The

installation is not proper and complete until the operation of the converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

THE CONVERSION SHALL BE CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS OF THE

PROVINCIAL AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH THE REQUIREMENTS OF

THE CSA-B149.1 INSTALLATION CODE.

!

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer before servicing.

• Close equipment shut-off valve to gas dryer before servicing.

• Never start the dryer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be reconnected to ensure that

the dryer is properly grounded.

WARNING

WARNING

16026908 © 2006 Maytag Services Page 1 of 5

3/2/2006

Page 2

Important Note:

For proper operation at elevations above 4500 feet (1370 m) one of the following orifice sizes must be used to

ensure complete combustion. These parts are not included in standard kits. See Table below for proper orifice size.

Altitude Orifice Size Part Number

Feet m Number Inches mm

3000 915 55 0.0520 1.32

8000 2440 56 0.0465 1.18 40098001

GAS Input − 22,500 BTU/HR

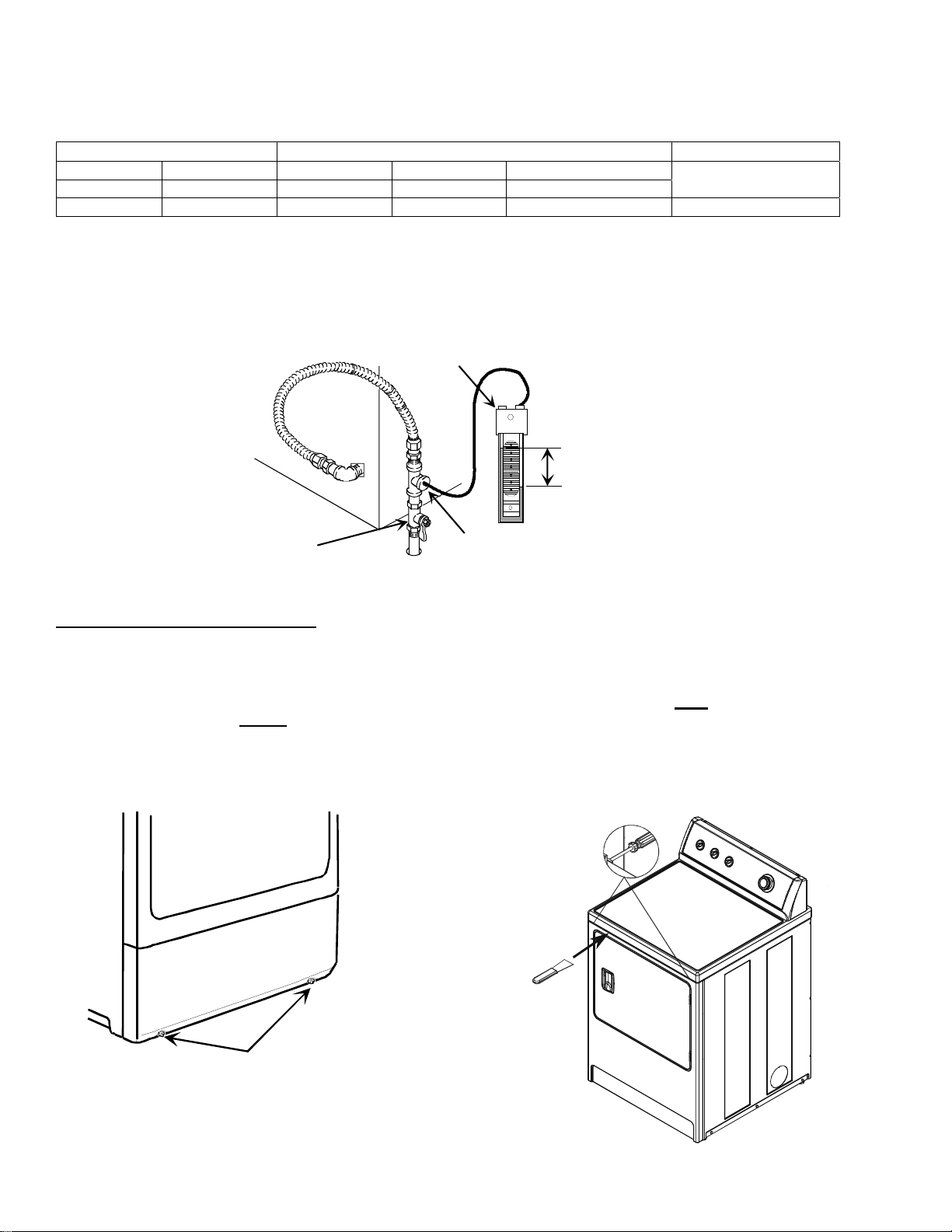

• When converting the dryer gas valve to L.P. gas, be sure the incoming gas supply line is equipped with a

pressure regulator (located ahead of the dryer) that will maintain the gas supply to the dryer at 10 ± 1.5 inches

(25.4 ± 3.81 cm) water column pressure. Remove pressure tap pipe plug and check gas pressure by connecting

a “U” tube manometer (or similar pressure gauge) to the pressure tap.

40097201

Manometer

10 + 1.5"

(25.4 + 3.81 cm)

Equipment

shut-off valve

within 6' (1.8 m) of dryer.

Install the No. 649P3 Kit as follows:

1. Disconnect electrical power to the machine.

2. Turn the equipment shut-off valve handle to the closed position (if so equipped). If shut-off valve is not present,

turn off dryer gas supply at the appliance.

(For models built before

3. Remove service access panel by removing two

access panel screws.

JULY 2005)

1/8" NPT pipe plug

(for checking inlet

gas pressure)

(For models built after

3(a) Use a plastic putty knife to depress the locking

clips between the Top Cover and Front Panel.

Repeat for both sides, and then lift Top Cover.

3(b) Disconnect wiring from the Door Switch.

3(c) Remove two screws (1 each side) from the back

flange of the front panel.

JULY 2005)

Front Panel

Access screws

Page 2 of 5

Service Access Panel

screws

© 2006 Maytag Services 16026908

3/2/2006

Page 3

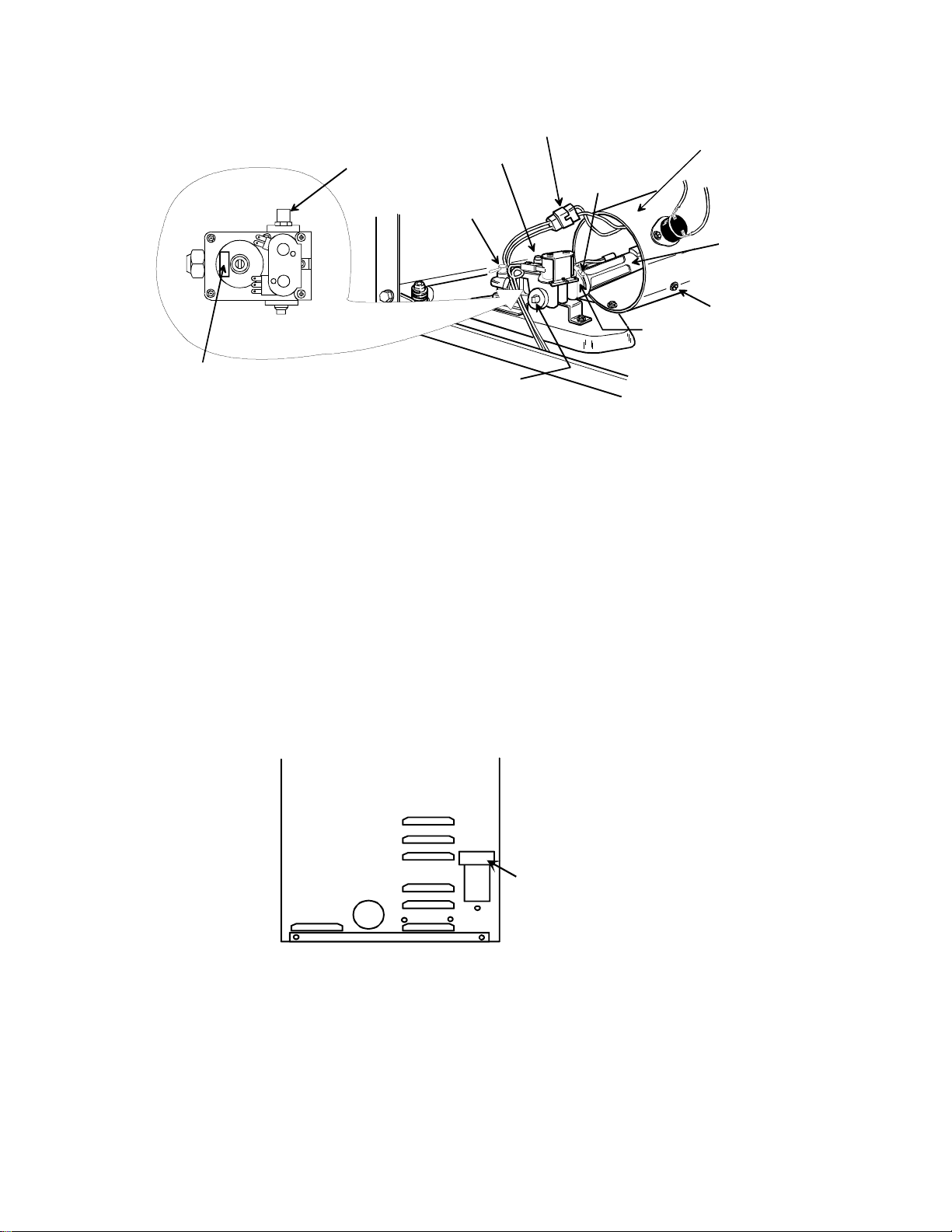

4. Disconnect igniter wires at quick disconnect blocks.

Burner Orifice

Spud

Shut-Off

Valve

4

5

1 - 3

Ignitor Quick

Disconnect

Block

Vent Screw

Air Shutter

Adjustment

Screw

Burner Housing

Burner Tube

Hex Head Screw

Air Shutter

Apply No. 40096701 Valve

Converted Sticker Here

1/ 8" Pipe Plug

(For checking manifold pressure)

5. Remove hex head screw holding burner tube and igniter in place.

6. Carefully move burner tube toward rear of dryer, far enough to permit removal of burner orifice spud from gas

valve.

NOTE: Tab on burner tube may have to be removed from slot in burner housing to obtain enough clearance.

7. Turn the burner orifice spud out of gas valve and install No. 40097301 L.P. Burner Orifice Spud

(metal stamped 1.45 mm). Torque new burner orifice spud to 30 inch-pounds (3.4 N-m).

8. Reinstall burner tube, tighten hex head screw firmly and reconnect igniter leads.

9. Remove the vent screw, and install No. 40097101 Block-Open Plug.

10. Install No. 40096701 “Valve Converted to L.P. Gas” Sticker to top side of gas valve, so it covers the gas valve

part number.

11. In Canada, early models (with access door) do not need to use the two 40096602 L.P. Gas Stickers.

Sign and date each of the two No. 40096602 L.P. Gas Stickers. Install one of the 40096602 L.P. Gas Stickers

over the top three lines of the old sticker on rear of cabinet, then place the second sticker over the top three lines

of the old sticker located on backside of access door or lower access panel.

Apply No. 40096602

L.P. Sticker Here

16026908 © 2006 Maytag Services Page 3 of 5

3/2/2006

Page 4

12. Apply the No. 40097002 Conversion Plate to the inside of the loading door opening, or over the top of any

previously applied conversion plate.

Nameplate

Apply No.

40097002

conversion

plate here

13. Turn the equipment shut-off valve handle to the open position, and connect electrical service.

14. Check gas valve pressure as follows:

a. Remove pressure tap pipe plug.

b. Connect a “U” tube manometer (or similar pressure gauge) to the pressure tap.

Air Shutter

Adjustment

Screw

Shut-Off

Valve

Manometer

10 + 1.5"

Air Shutter

1/ 8" Pipe Plug

(For checking manifold pressure)

c. Start dryer, pressure should be 10 ± 1.5 inches.

d. Stop dryer and remove “U” tube and reinstall the pressure tap pipe plug.

!

To reduce the risk of fire or explosion, check pipe connection for gas leaks by using a soapy solution.

DO NOT USE AN OPEN FLAME TO CHECK FOR GAS LEAKS!

15. Check the gas line connection for gas leaks with a non-corrosive leak detection fluid.

16. Make sure the dryer conversion has been completed. Recheck the following:

⎯ Installed correct orifice spud (40097301, 1.45 mm, for standard installation), see Step 7.

⎯ Installed block-open plug, see Step 9.

⎯ Gas valve pressure must be 10 ± 1.5 inches (25.4 ± 3.8 cm), see Step 14.

⎯ Installed four stickers, see Steps 10, 11, and 12.

WARNING

(25.4 + 3.81 cm)

Page 4 of 5

© 2006 Maytag Services 16026908

3/2/2006

Page 5

17. For models built before

obtain a soft, uniform blue flame. (A lazy, yellow tipped flame indicates lack of air. A harsh, roaring, very blue

flame indicates too much air.)

Adjust the air shutter as follows:

⎯ Loosen the air shutter lockscrew.

⎯ Turn the air shutter to the left to get a luminous yellow tipped flame, then turn it back slowly to the right to

obtain a steady soft blue flame. The air shutter should be adjusted to a gap of approximately 5/16 inches (8

mm) to 3/8 inches (9.5 mm).

⎯ After the air shutter is adjusted for the proper flame, tighten the air shutter lockscrew securely.

⎯ Be sure and observe at least two complete ignition and burn cycles before reinstalling the access door or

lower access panel.

⎯ Reinstall the access door or lower access panel.

JULY 2005: Start the dryer and observe the burner flame. Adjust the air shutter to

For models built after

Adjust the air shutter as follows:

⎯ Loosen the air shutter lockscrew.

⎯ The air shutter should be adjusted to a gap of approximately 5/16 inches (8 mm) to 3/8 inches (9.5 mm).

⎯ Tighten the air shutter lockscrew securely.

⎯ Reinstall the access door or lower access panel.

For personal safety, access door or lower access panel must be in place during normal operation.

JULY 2005): The dryer cannot be run with the front panel removed.

!

WARNING

16026908 © 2006 Maytag Services Page 5 of 5

3/2/2006

Page 6

Feuille 16026908

A

A

r

2206860

d’instructions

Description : Trousse de conversion au GPL

Pièce de rechange numéro : 649P3

La trousse inclut :

Quantité Numéro de pièce Description

1-----------------------------------------------40097101 --------------------------------------- Bloc – Bouchon ouvert

1 -----------------------------------------------40097301 --------------------------------------- Tête d’injecteur à filetage

extérieur du brûleur (1,45 mm)

1 -----------------------------------------------40097004 --------------------------------------- Plaque de conversion

1 -----------------------------------------------40096701 --------------------------------------- Soupape convertie vers

Autocollant de GPL (Anglais)

1 -----------------------------------------------40096901 --------------------------------------- Soupape convertie vers

Autocollant de GPL (Français)

1 -----------------------------------------------40096801 --------------------------------------- Soupape convertie vers

Autocollant de GPL (Espagnol)

2 -----------------------------------------------40096602 --------------------------------------- Autocollants de GPL (Anglais)

2 -----------------------------------------------40096606 --------------------------------------- Autocollants de GPL (Français)

1-----------------------------------------------40096604 --------------------------------------- Autocollant de GPL (Espagnol)

1 -----------------------------------------------16026908 --------------------------------------- Instructions

m

m

5

4

.

1

Bloc – Bouchon ouvert

Block - Open Plug Burner Orifice Spud

!

Cette trousse de conversion doit être installée par une agence de service qualifiée, selon les instructions fournies

par le fabricant et en respectant les codes et exigences des autorités compétentes. Les informations données

dans ces instructions doivent être respectées afin de réduire les risques d’incendie ou d’explosion

ou pour éviter des dommages à la propriété, des blessures ou la mort. L’agence de service qualifiée est

responsable de l’installation adéquate de cette trousse. L’installation n’est pas correcte et complète tant que

le fonctionnement de l’appareil converti n'est pas vérifié tel qu’il est spécifié dans les instructions du fabricant

fournies avec la trousse.

EFFECTUER LA CONVERSION SELON LES EXIGENCES DES AUTORITÉS PROVINCIALES COMPÉTENTES

ET SELON LES EXIGENCES DES PARTIES CSA-B149.1 DU CODE D’INSTALLATION.

!

Afin de réduire les risques de décharge électrique, d’incendie, d'explosion, de blessures graves ou de mort :

• Débrancher l’alimentation électrique de la sécheuse, avant d'effectuer l’entretien.

• Fermer le robinet d’arrêt de l'équipement vers la sécheuse au gaz avant d'effectuer l'entretien.

• Ne jamais démarrer la sécheuse si toute protection ou tout panneau a été enlevé.

• Si des prises de terre sont enlevées pendant l’entretien, elles doivent être rebranchées pour assurer la mise à

la terre correcte de la sécheuse.

Tête d’injecteur à filetage extérieur du brûleu

VERTISSEMENT

WARNING

VERTISSEMENT

WARNING

16026908 © 2006 Maytag Services Page 1 de 5

3/2/2006

Page 7

Remarque importante :

Pour obtenir un fonctionnement adéquat à plus de 1370 m (4500 pi), utiliser une des tailles d’orifice suivantes afin

d’assurer une combustion complète. Ces pièces ne sont pas incluses dans les trousses standard. Voir le tableau

ci-dessous pour connaître les tailles d’orifice qui conviennent.

Altitude Taille d’orifice Numéro de pièce

Pieds m Numéro Pouces mm

3000 915 55 0,0520 1,32

8000 2440 56 0,0465 1,18 40098001

Entrée de GAZ – 22 500 BTU/H

• Lors de la conversion d'une soupape à gaz pour sécheuse vers le GPL, s’assurer que l'alimentation de la

conduite de gaz est équipée d'un régulateur de pression (situé à l’avant la sécheuse) qui maintiendra

l’alimentation de colonne de pression d'eau de 25,4 cm ±3,81 cm (10 ±1,5 po) vers la sécheuse. Enlever le

bouchon du tuyau du robinet de pression et vérifier la pression du gaz en connectant un manomètre avec tube

en « U » (ou autre manomètre semblable) au robinet de pression.

40097201

25,4 ±3,81 cm

(10 ±1,5 po)

o

Installer la trousse n

1. Débrancher l’alimentation électrique de la machine.

2. Tourner la poignée du robinet d'arrêt à la position fermée (le cas échéant). Si aucun robinet d’arrêt n’est présent,

couper l’alimentation en gaz au niveau de l’appareil.

(Seulement pour les modèles

construits avant

3. Enlever le panneau d'accès de service en

dévissant les deux vis du panneau d’accès.

649P3 comme suit :

JUILLET 2005)

(Seulement pour les modèles

construits après

3(a). Utiliser un couteau à mastic en plastique pour

enfoncer les attaches de verrouillage entre le

dessus et le panneau avant.

3(b). Débrancher le câblage du contacteur de porte.

3(c). Enlever les deux vis (1 de chaque côté) du

rebord arrière du panneau avant.

Vis d’accès du

panneau avant

Front Panel

Access screws

JUILLET 2005)

Service Access Panel

Vis du panneau d’accès

screws

Page 2 de 5 © 2006 Maytag Services 16026908

de service

3/2/2006

Page 8

4. Débrancher les fils de l’allumeur électrique au niveau des blocs de débranchement rapide.

5. Enlever les vis à tête hexagonale qui maintiennent le tube du brûleur et de l'allumeur électrique.

6. Déplacer avec précaution le tube du brûleur vers l'arrière de la sécheuse, à une distance suffisante pour pouvoir

enlever de la soupape à gaz la tête d’injecteur à filetage extérieur du brûleur.

REMARQUE : L’onglet du tube du brûleur pourrait avoir été enlevé de la fente de l’enveloppe du brûleur pour obtenir

un dégagement suffisant.

7. Dévisser la tête d’injecteur à filetage extérieur du brûleur de la soupape de gaz et installer la tête d’injecteur à

filetage extérieur du brûleur n

o

40097301 PL (métal marqué à 1,45 mm). Serrer la nouvelle tête d’injecteur à

filetage extérieur à 3,4 Nm (30 po/lb).

8. Réinstaller le tube du brûleur, serrer fermement la vis à tête hexagonale et rebrancher les fils de l’allumeur

électrique.

9. Enlever les vis de l’évent et installer le bloc - bouchon ouvert n

10. Apposer l’autocollant n

o

40096701 « Soupape convertie au GPL » sur le côté supérieur de la soupape de gaz,

o

40097101.

de manière à recouvrir son numéro de série.

11. Au Canada, les premiers modèles (avec porte d’accès) n’ont pas besoin des deux autocollants pour le gaz

40096602 GPL. Signer et dater chaque autocollant pour le gaz n

o

40096602 GPL. Installer un des autocollants

pour le gaz 40096602 GPL par-dessus les trois lignes supérieures de l'ancien autocollant, situé à l'arrière de

l'armoire, et placer le deuxième autocollant par-dessus les trois lignes supérieures de l'ancien autocollant situé

à l'arrière de la porte d'accès ou du panneau d'accès inférieur.

Appliquer l’autocollant

o

40096602 GPL ici

n

16026908 © 2006 Maytag Services Page 3 de 5

3/2/2006

Page 9

12. Apposer la plaque de conversion n

A

dessus toute plaque de conversion apposée précédemment.

13. Tourner la poignée du robinet d'arrêt à la position ouverte et brancher l’alimentation électrique.

14. Vérifier comme suit la pression de la soupape de gaz :

a. Enlever le bouchon du tuyau du robinet de pression.

b. Raccorder un manomètre à tube en « U » (ou une jauge similaire) au robinet de pression.

Bouchon pour tuyau de 1/8 po

(pour la vérification de la pression du collecteur)

c. Démarrer la sécheuse, la pression devrait être de 10 ±1,5 po.

d. Arrêter la sécheuse, enlever le tube en « U » et réinstaller le bouchon du tuyau du robinet de pression.

Robinet

d’arrêt

o

40097002 à l’intérieur de l’ouverture de la porte de chargement, ou par-

Plaque-marque

Appliquer la plaque

de conversion

no 40097002 ici

Vis de réglage

du registre

Registre

Manomètre

25,4 ±3,81 cm

(10 ±1,5 po)

VERTISSEMENT

!

Afin de réduire les risques d'incendie ou d'explosion, utiliser une solution savonneuse pour vérifier que le raccord

du tuyau ne présente aucune fuite de gaz.

NE PAS UTILISER UNE FLAMME NUE POUR VÉRIFIER LA PRÉSENCE DE FUITES DE GAZ!

15. Utiliser un fluide non corrosif de détection de fuite pour vérifier que les raccords de conduite de gaz ne

présentent pas de fuites.

16. S’assurer que la conversion de la sécheuse est bien terminée. Vérifier encore une fois ce qui suit :

⎯ Installation de la bonne tête d’injecteur à filetage extérieur (40097301, 1,45 mm, pour installation standard),

voir l’étape 7.

⎯ Installation du bloc - bouchon ouvert, voir l'étape 9.

⎯ La pression de la soupape de gaz doit être de 25,4 ±3,81 cm (10 ±1,5 po), voir l’étape 14.

⎯ Installation des quatre autocollants, voir les étapes 10, 11 et 12.

Page 4 de 5 © 2006 Maytag Services 16026908

WARNING

3/2/2006

Page 10

17 Seulement pour les modèles construits avant

A

du brûleur. Ajuster le registre pour obtenir une flamme douce et uniforme. (Une flamme molle aux embouts

jaunes indique un manque d'air. Une flamme rude et rugissante, très bleue, indique un surplus d'air.)

Ajuster le registre comme suit:

⎯ Desserrer la vis de calage du registre.

⎯ Fermer le registre sur la gauche pour obtenir une flamme lumineuse au bout jaune, puis tourner pour obtenir

une flamme bleue et stable.

⎯ Après avoir réglé le registre pour obtenir la flamme voulue, bien resserrer la vis de calage du registre.

⎯ Effectuer et observer au moins deux cycle complets d'allumage et de brûlage avant de réinstaller la porte

d'accès ou le panneau d'accès inférieur.

⎯ Réinstaller la porte d’accès ou le panneau d’accès inférieur.

Seulement pour les modèles construits après

panneau avant est enlevé.

Ajuster le registre comme suit:

⎯ Desserrer la vis de calage du registre.

⎯ Le registre doit être ajusté pour un écart d’environ 12,5 mm (1/2 po).

⎯ Bien resserrer la vis de calage du registre.

⎯ Réinstaller la porte d’accès ou le panneau d’accès inférieur.

JUILLET 2005: Démarrer la sécheuse et observer la flamme

JUILLET 2005: La sécheuse ne peut fonctionner lorsque son

!

Pour des raisons de sécurité personnelle, la porte d’accès ou le panneau d’accès inférieur doivent être en place

lors d’une utilisation normale.

WARNING

VERTISSEMENT

16026908 © 2006 Maytag Services Page 5 de 5

3/2/2006

Loading...

Loading...