Page 1

Write down the modeland serial numbers before installing washer.

Both numbersare listed on themodel/serial rating plate located

under the lid.

Model# _______________________________

Serial #_______________________________

Date of Purchase _______________________

Prendrenote des numérosdemodèleetdesérie avant d'installer

la laveuse.

Les deux numéros sont indiqués surla plaquesignalétique sous

le couvercle.

Numéro de modèle_______________________________

Numéro de série_________________________________

Date d’achat____________________________________

W10135312B

www.maytagcommerciallaundry.com

INSTALLATION INSTRUCTIONS

COMMERCIAL WASHER

120-volt, 60-Hz Models

INSTRUCTIONS D’INSTALLATION DE LA

LA VEUSE COMMERCIALE

Modèles 120V,60Hz

Page 2

2

You can be killed or seriously injured if you don't immediately

You can be killedor seriously injured if you don't

follow

Allsafetymessages will tell you what the potential hazardis, tell you how to reducethe chanceofinjury, and tell youwhat can

happenifthe instructions are not followed.

Your safetyand the safetyofothers are very important.

We haveprovided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is thesafety alert symbol.

This symbol alerts youto potential hazards that cankill or hurt you and others.

Allsafetymessages will follow thesafety alertsymbol and either the word “DANGER” or “WARNING.”

These words mean:

followinstructions.

instructions.

DANGER

WARNING

TableofContents

WASHER SAFETY ........................................................................ 2

INSTALLATION REQUIREMENTS .............................................. 3

Tools and Parts ...........................................................................3

Location Requirements.............................................................. 3

Drain System.............................................................................. 4

ElectricalRequirements ............................................................ 5

INSTALLATION INSTRUCTIONS ............................................ 6

Remove Shipping Strap ............................................................6

Connect the Hoses ....................................................................6

Levelthe Washer ...................................................................... 7

Complete Installation ................................................................8

ELECTRONIC CONTROLS SETUP ..........................................10

WARRANTY ................................................................................14

Table des matières

SÉCURITÉ DE LA LAVEUSE .................................................... 15

EXIGENCESD’INSTALLATION ................................................ 16

Outillage et pièces ..................................................................16

Exigences d’emplacement ...................................................... 16

Systèmedevidange ................................................................17

Spécifications électriques........................................................ 18

INSTRUCTIONS D’INSTALLATION........................................ 19

Enleverlasangled'expédition ................................................ 19

Raccordement des tuyaux ......................................................19

Réglage de l’aplombdela laveuse ........................................ 20

Achever l’installation ................................................................21

RÉGLAGE DE LA COMMANDE ÉLECTRONIQUE..................23

GARANTIE....................................................................................27

WASHER SAFETY

Page 3

3

Location Requirements

IMPORTANT : Do not installorstore the washer whereit will be

exposed to the weather.Donot storeor operate the washerin

temperaturesator below 32°F(0°C). Some water can remainin

the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

INSTALLATION REQUIREMENTS

Toolsand Parts

Gather the required tools and parts before starting installation.

Toolsneeded

Level

Utility knife

Scissors

8" or 10" adjustable wrench

Flat-bladescrewdriver

Pliers

Bucket

Partssupplied

Remove parts bag from washer .Check that all parts were

included.

1 hose clamp

2 inlet hoses

4flat waterhosewashers

2front-leveling legs with nuts

1drain hose

Youwill need:

Awater heaterset to deliver 120°F(49°C) water to the washer.

Agrounded electrical outlet located within 4ft (1.2 m) of where

the power cord is attached to thebackof the washer.

See“Electrical Requirements.”

Hot and cold water faucets located within 4ft(1.2m)ofthe

backof the washer, and providewater pressure of 10-100 psi

(69-690kPa). Apressurereduction valve should be used in

the supply line whereinlet pressure entering the building

exceeds 100 psi (690 kPa) to prevent damage to the washer

mixing valve.

Alevel floor with amaximum slopeof1"(25 mm) under entire

washer.

Asturdyfloor to support the washer weight (washer, water,

and load) of 315lbs (143 kgs).

A 12" (300 mm)minimum risertoprovide an air cushionand

prevent noise and damage to valves forasingle washer

installation.

Afloor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water supply

lines and drain facilities should be used only where local

codes permit.

NOTE: Front access to the pumpareais available by removing

2No. T20 TORX

®

†

security screwsand then removing the front

panel.

®TORXisaregistered trademark of AcumentIntellectual Properties, LLC.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Read all instructions beforeusing the washer.

Do not washarticles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable, or explosive

substances as they giveoff vapors that could igniteor

explode.

Do notadd gasoline, dry-cleaning solvents, or other

flammable, or explosive substances to the wash water.

Thesesubstances giveoff vaporsthat could igniteor

explode.

Under certain conditions,hydrogen gas maybe

producedinahot water system that has not been used

for2weeksormore. HYDROGENGAS IS

EXPLOSIVE. If the hot water system has not been

used forsuchaperiod, beforeusing thewashing

machine, turn on all hot water faucets and let the water

flow from eachfor severalminutes.This will release

any accumulated hydrogen gas.Asthe gas is

flammable, do not smoke or usean open flame during

this time.

Do notallow children to play on or in the washer. Close

supervision of children is necessary when thewasher is used

near children.

Before the washer is removed from service or discarded,

remove the door or lid.

Do notreach into thewasher if the drum, tub or agitator is

moving.

Do not install or store the washer where it will be exposed to

the weather.

Do nottamper with controls.

Do notrepair or replace any partofthe washer or attempt any

servicing unlessspecifically recommended in this manual or in

published user-repair instructions that you understand and

havethe skills to carry out.

See “Electrical Requirements” for grounding instructions.

WARNING: To reducethe risk of fire, electric shock, or injury to persons when using the washer, follow basic precautions,

including thefollowing:

†

Page 4

4

DrainSystem

Standpipe Drain System

The standpipedrain requires aminimum diameter standpipe of

2" (50 mm). The minimum carry-away capacity canbeno less

than 17 gal. (64L) per minute.

Thetop of thestandpipe must be at least39" (990 mm) high and

no higher than 72" (1.8m)fromthe bottom of the washer.

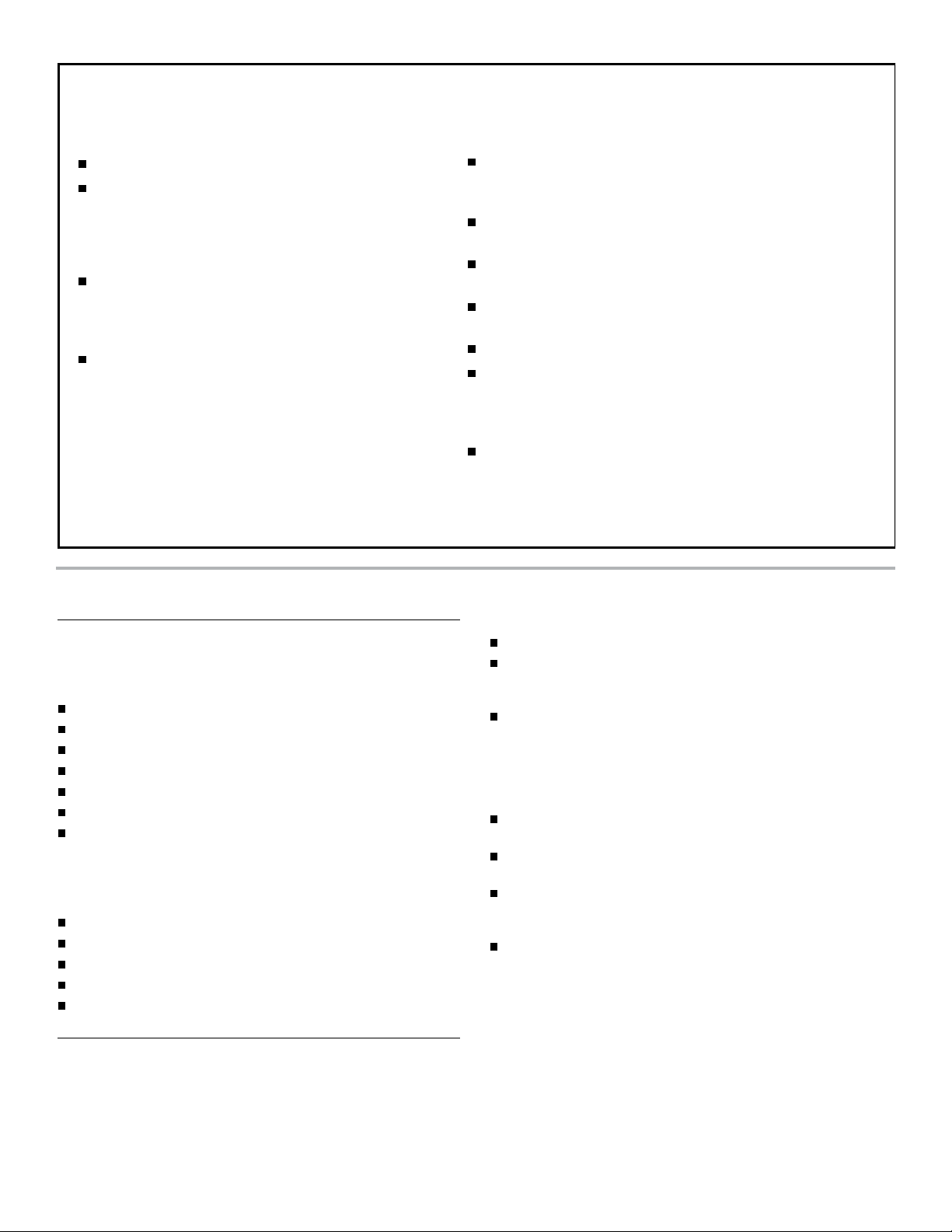

Recessed Area and Closet InstallationInstructions

This washer may be installed inarecessed area or closet.

The installation spacing shown is in inches and is the minimum

allowable. Additional spacing should be considered for ease of

installation, servicing, and compliance with local codes and

ordinances.

If closetdoor is installed, theminimum unobstructed air openings

in the top and bottom arerequired. Louvered doors with

equivalent air openingsare acceptable.

Recessed front view Closet sideview

Minimum Installation Clearances

Closet

door

Front view

3" (76 mm)

3" (76mm)

24"

2

(1,55m2)*

48"

2

(3,10m2)*

24"

2

(1,55m2)*

48"

2

(3,10m2)*

*Openingis the minimum for acloset door.

Louvereddoorswithequivalent air openingsare acceptable.

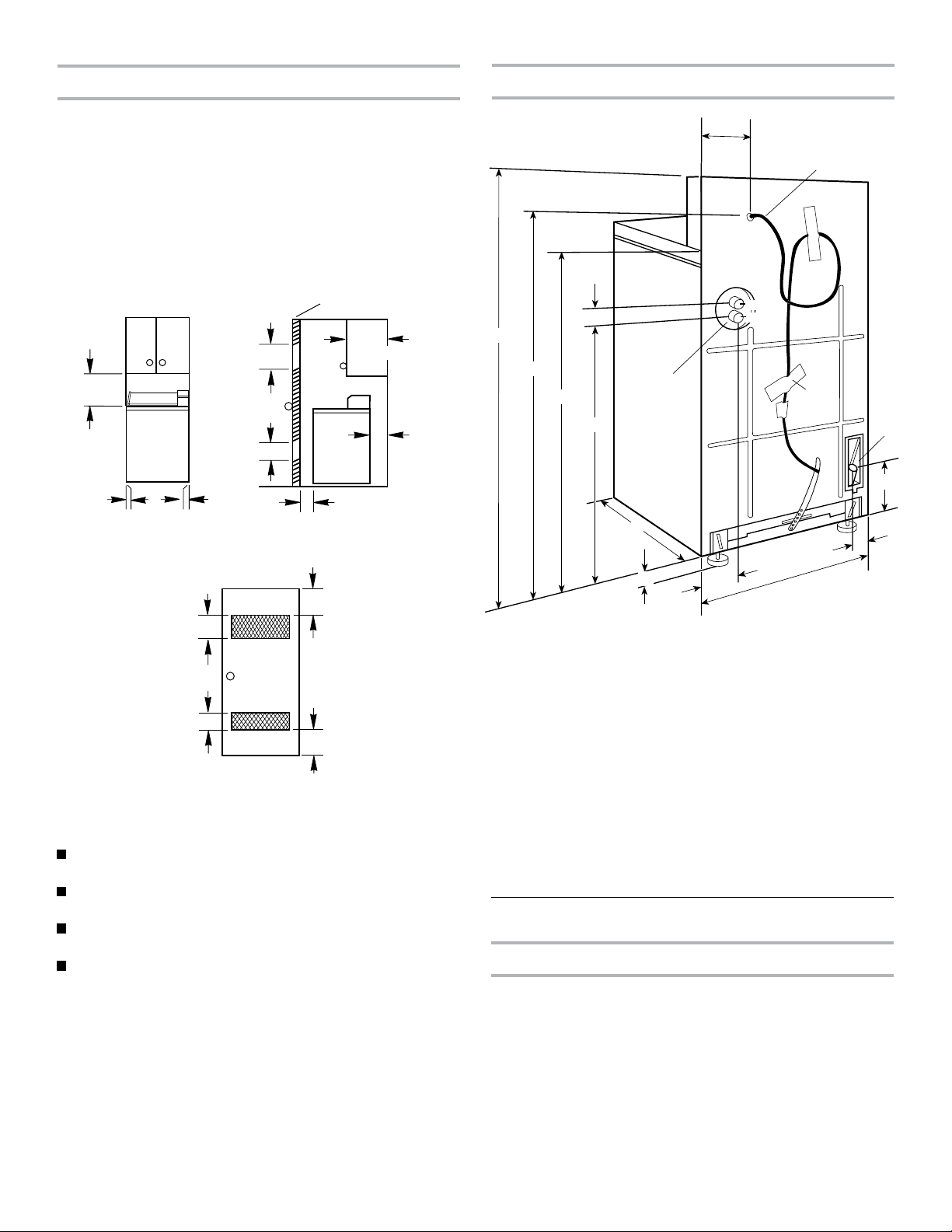

ProductDimensions

0"

(0 mm)

0"

(0 mm)

Closet door

17"

(432 mm)

14"

(356 mm)

max.

4"

(102 mm)

min.

1" (25 mm)

min.

Cold

Hot

A

B

C

E

D

F

G

I

J

K

L

M

H

43" (1090 mm)

38¹⁄8"(970mm)

35" (890 mm)

1¹⁄2"(38 mm)

27¹⁄

4" (705 mm)

25¹⁄

2" (650 mm)

Waterinlets

7" (180 mm)

Power supply cord

Drainhose connector

Label

27"(685 mm)

5¹⁄

4"(133 mm)

1" (25 mm)

5" (127 mm)

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

M.

N.

O.

Additional spacing shouldbe considered for the ease of

installation and servicing.

Additional clearances may be required forwall, door, and floor

moldings.

Additional spacing of 1" (25 mm)onall sides of the washer is

recommended to reduce noise transfer.

Companion spacing shouldalsobe considered.

N

O

H

Page 5

5

Electrical Requirements

IMPORTANT : The washermustbe electricallygrounded in

accordance with local codes and ordinances or,inthe absenceof

local codes,with the National Electrical Code, ANSI/NFPA 70,

latest edition.

If codes permit andaseparate ground wireis used, it is

recommended that aqualified electrical installer determine

thatthe ground path is adequate.

Do not ground to a gas pipe.

Do not have a fuse in the neutral or ground circuit.

Acopyof the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park,Quincy, MA 02269

A 120 volt,60 Hz, AC only, 15- or 20-amp, fused electrical

circuit is required.Atime-delay fuse or circuit breakeris

recommended. It is recommended that a separate circuit

serving only this washer be provided.

The washer is equipped with a power supply cordhavinga

3prong grounding plug.

To minimize possible shock hazard, the cord must be plugged

into a mating, 3prong, grounding-type outlet, grounded in

accordance with local codes andordinances. If amating

outlet is not available, it is the personalresponsibility and

obligationof the customer to have the properly grounded

outlet installed by aqualified electrician.

Electrical ShockHazard

Plug into agrounded3prong outlet.

Do not remove ground prong.

Do not useanadapter.

Do not usean extension cord.

Failure to followthese instructions canresult in death,

fire, or electrical shock.

WA RNING

RecommendedGround Method

The washer,when installed,mustbeelectrically grounded in

accordance with local codes, or in theabsence of local codes,

with the National ElectricalCode, ANSI/NFPA70, latest edition,

and alllocal codes andordinances.

Page 6

6

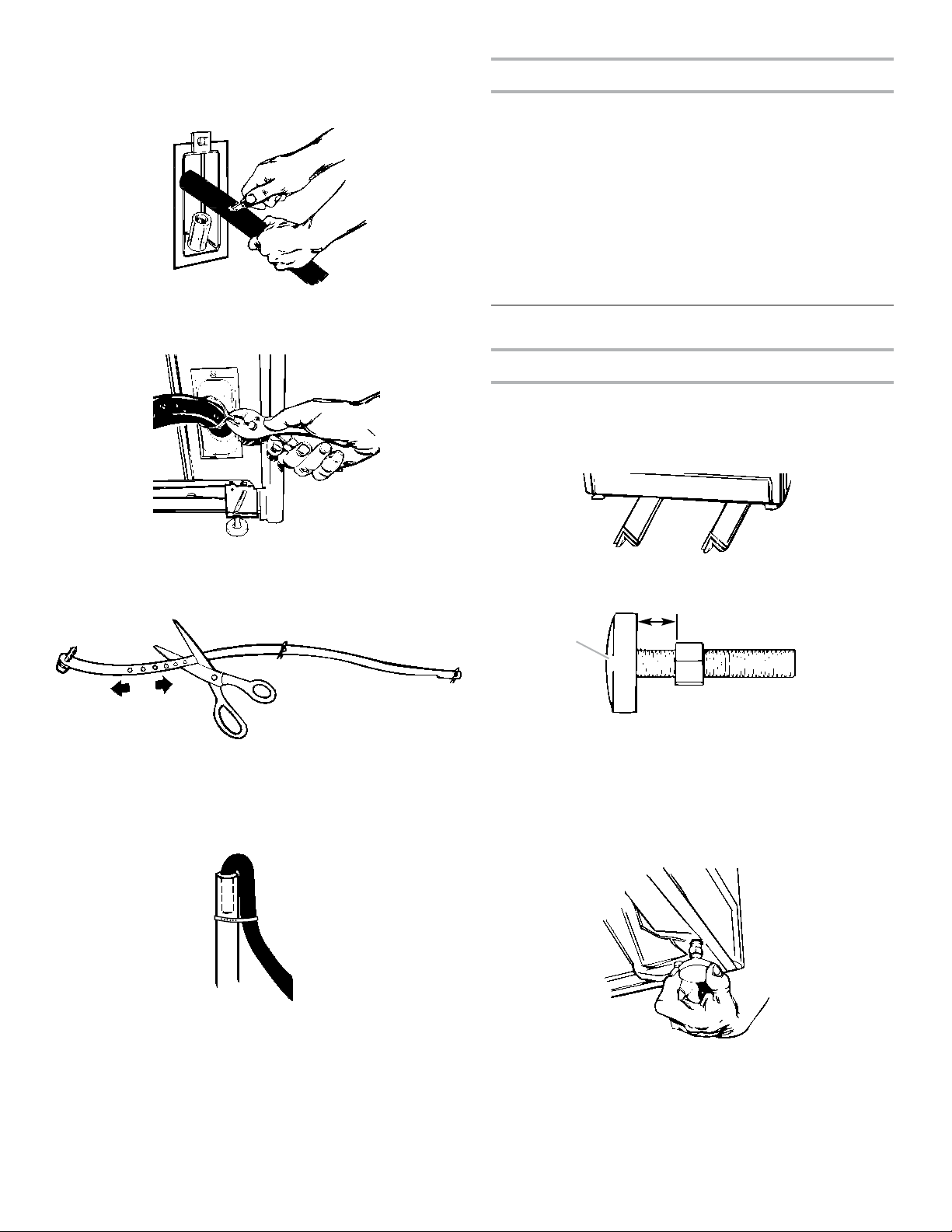

Connect thedrain hose

NOTE: Slide washer onto cardboardor hardboard before

moving across floor.

1. Move washer closeto final position.

2. Put“hook” endof drain hose into laundry tubor standpipe.

3. Estimate the lengthofdrain hose needed when washer is in

finalposition. Hose must be cut exactly to lengthso“hook”

end is heldtightly over edge of standpipe.

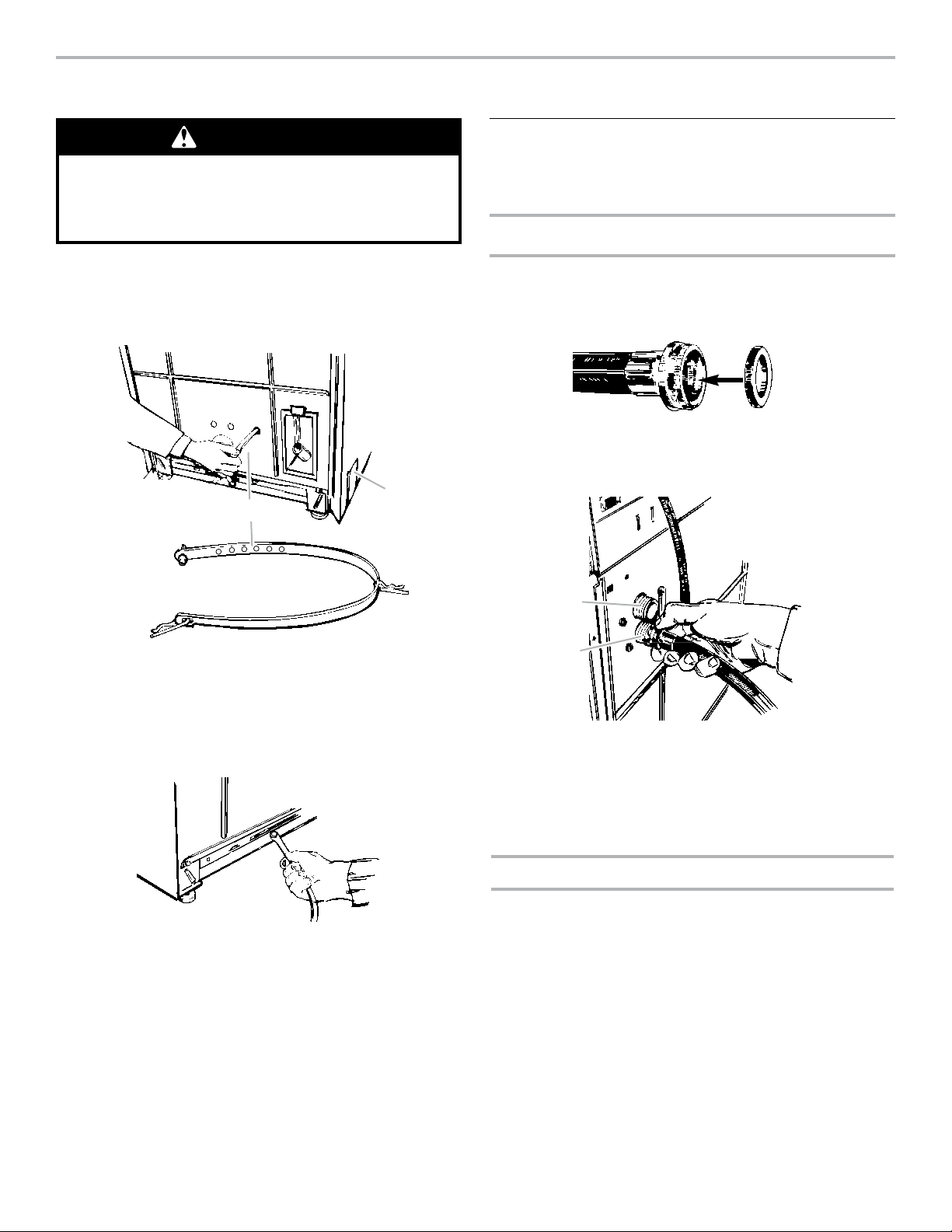

Remove Shipping Strap

1. Remove tape that covers shippingstrap. Pull to completely

remove the shipping strap with 2 cotter pins from the inside of

the washer.

2. Pull firmly to remove the end of shipping strap from the back

of the washer. The shipping strapplug must be completely

removed from the washer forthe self-leveling legs to be

released.

Save the shipping strap for later use.

INSTALLATION INSTRUCTIONS

WARNING

Excessive Weight Hazard

Use twoormorepeople to move and install washer.

Failuretodoso can result in back or other injury.

A

B

A. Shipping tape

B. Shipping strap

A

B

A. Coupling

B. Washer

Connectthe Hoses

Proper connection of the drain hose avoids damage to your oors

dueto water leakage. Read and follow these

instructions.

Connect the inlet hosestothe washer

1. The washer must be connected to the water faucets using

thenew inlet hoses. Do not use old hoses. Insert new flat

washers (supplied) into each end of the inlet hoses. Firmly

seat the washers in the couplings.

2. Attach hose to bottom inlet valve opening first.

3. Attach second hose to top inlet. Tighten couplings by hand;

then use pliers to makean additional two-thirds turn.

NOTE: Inlet valve threads are plastic. Do not strip or crossthread.

A

B

A. Cold water inlet valve

B. Hot water inletvalve

Page 7

7

Connect the inlethoses to the water faucets

1. Beforeattaching water inlethoses,run water through both

faucets into abucket. This will get rid of particlesin the water

lines that might clog hoses. Mark which is the hot water

faucet.

2. Attach bottom hose (inlet marked “H”) to hotwater faucet.

Tighten coupling to faucet by hand.

3. Attach top hose (inletmarked“C”)tocold water faucet.

Tightencouplingtofaucetbyhand.

4. Usepliers to make an additional two-thirds turn to each

coupling.

Levelthe Washer

Installthe front leveling feet

1. Stack twocorner posts on top of each other. Tilt washer

backward andinsertcornerposts 3" (76 mm) in from oneside

of washer,asshown. Repeat with other corner posts on other

side of washer.

2. Usethe leveling legs and nuts from theparts package. Screw

nut downtowithin 1/2"(13 mm) of base.

3. Insert legs into correct holes at each frontcorner of washer

until nuts touchwasher.Do not tighten nuts until the washer

is leveled.

4. Tilt washer backward andremove corner posts. Gently lower

washer to floor.

5. Move washer to its permanentlocation. Remove cardboardor

hardboardfrom under washer .

If drain hoseistoo long, cut straight endofhose. (Donot cut

the “hook” shaped end of the drainhose.)

NOTE: Do not force excess lengthofdrain hose down the

standpipe. This could cause siphoning.

A

B

C

A. 1/2"(13mm)

B. Base

C. Nut

4. Place the hoseclamp over thewasherdrain connector . Push

the drain hose onto the washer connector. Use pliers to open

clamp andslide clamp over drainhose. Check for good fit.

5. Measure and mark a point approximately 16"(406mm) from

the plug end of the shipping strap. Cut theshipping strap at

this point.

16"

(406 mm)

6. Check that hose is not twistedorkinked and is securely in

place.

7. Put “hook” end of drain hoseintostandpipe. Tightly wrap the

shipping strap around the standpipe. Push plug into the

nearest hole in the shipping strap.

Page 8

8

6. Plug power supply cord intoagrounded 3prong outlet.

NOTE: On somemodels, during factory testing, thetimer is

advanced partially into the cycle causing the start button to be

depressed.Allow timer to advance to the end of the cycle.

When the cycle is complete, the timer will reset and the start

button will return to the start position. If the timer is not allowed

to advance to the end of the first cycle and reset, the wash load

will notbe completed.

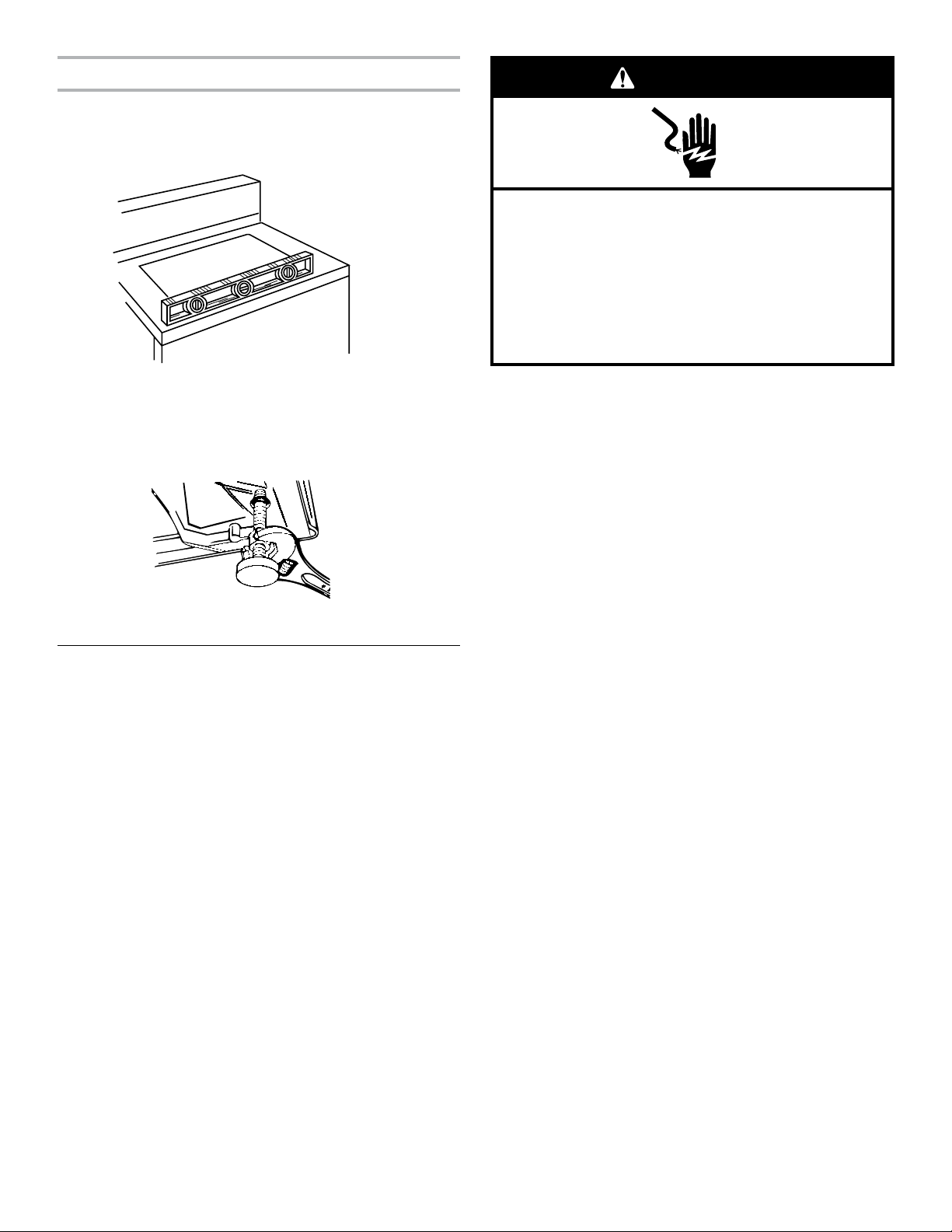

1. Tilt washer forward raising back legs 1" (25 mm)off of floor,to

adjustrear self-leveling legs. Gently lower washerto floor.

2. Check levelness of the washer by placing a carpenter’s level

on top of the washer, first side to side; thenfront to back.

3. If washer is not level, adjust thefront legs up or down. Make

final check with level.

4. When washer is level, use awrench to turn the nutsonfront

legsup tightly against the washer base.If nuts are not tight

against washer base, the washer mayvibrate.

Level the washer

CompleteInstallation

1. Check the electrical requirements. Be sure that you have the

correctelectrical supply and therecommendedgrounding

method.

2. Check to be sure allpartsare nowinstalled. If thereisan

extra part, go back through the stepsto see whichstep was

skipped.

3. Turn on water faucets andcheck for leaks. Tighten

couplingsifthere is leaking. Do not overtighten; this could

cause damage to faucets.

4. Check to be sureyou have allof your tools.

5. Checkthatthe shipping strapwas removedfrom the back of

the washerand used to securethe drain hose. If entire strap

is notremoved, washer may vibrateand be noisy.

Electrical Shock Hazard

Plug into agrounded3prong outlet.

Do not remove ground prong.

Do not useanadapter.

Do not usean extension cord.

Failure to followthese instructions canresult in death,

fire, or electricalshock.

WARNING

Page 9

9

Checklist for washer operation:

Check the following if the washer is not operatingproperly:

1. Power supply cordisplugged in.

2. Circuitbreaker is not tripped or fuse is not blown.

3. Timer has been advanced to start of acycle.

4. Water faucets are turned on.

5. Inlet and drain hoses are not kinked.

6. Washer lidis closed.

7. Inletvalveis not frozen if not protected from the weather .

8. Suds level.Excess suds will slow the spin and cause poor

rinsing. Operate the washer throughacomplete cycle with no

detergent. Use less detergent or acontrolled sudstype

detergent in future loads.

If you need assistance:

The Maytag Consumer Interaction Center will answer any

questions about operating or maintainingyourwasher not

coveredin the Installation Instructions. The Maytag Consumer

InteractionCenter is open 24 hours aday,7days a week. Just

dial 1-800 NO BELTS (1-800-662-3587) -the call is free.

When you call,you will need the washer model number and serial

number. Both numbers canbefound on the serial-ratingplate

locatedon your washer.

WARNING

Electrical Shock Hazard

Disconnect powerbefore servicing.

Replace allpartsand panels before operating.

Failuretodoso can result in death or electrical shock.

It is recommended that fiberglass itemsnot be washed in coinoperated washers. If these itemsare washedin the washer ,run

thewasher throughacomplete cycle to rinse anyresidue away

that might be leftinthe washer .

WARNING

Fire

Never place items in the washer that are dampened

with

No washer can

Do notdry anything that has ever had any type of oil on

it

Doingsocan result

Removethe front legs from the base of thewasher.

Place both rear leveling legs in theupper position and tape

securely.

Apply tape to thesideand bottom of the cabinet near the

rear .

Open washer lid, wedge ablanket between the tub ring and

thecabinet toprestricting the tub movement.

Handle washer gently.Donot drop washer while using hand

truck.

Load Type Loading

Suggestion

Load Type Loading

Suggestion

MixedLoad 3doublesheets

4pillowcases

6pairshorts

8T-shirts

2shirts

2blouses

8handkerchiefs

HeavyWork

Clothes

3pairpants

3shirts

1coverall

4pairjeans

1overall

Permanent

Press

2doubleor

1kingsize sheet

1tablecloth

1dress

1blouse

2slacks

3shirts

2pillowcases

Knits 3blouses

4slacks

6shirts

4tops

4dresses

Operating Tips

Moving theWashertoaNew Location

Typical full load sizes

Rear

legs

Tape 2sides

Front legs

If you need assistance:

Contact your authorized Maytag® Commercial Laundry

distributor. To locate your authorized Maytag

Laundry distributor, or for web inquiries, visit

www.MaytagCommercialLaundry.com.

If you cannot locate your distributor, the Commercial Laundry

Support Center will answer any questions about operating

or maintaining your washer not covered in the Installation

Instructions.

Just dial 1-800 NO BELTS (1-800-662-3587)—the call is free.

When you call, you will need the washer model number and serial

number. Both numbers can be found on the serial-rating plate

located on your appliance.

®

Commercial

Page 10

10

IMPORTANT

Electrostatic Discharge(ESD)

SensitiveElectronics

ESD problemsare present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is finished,

but failure may occur at alater date due to ESD stress.

Usean anti-static wrist strap. Connect wrist strap to green

ground connection point or unpainted metal in the washer.

-ORTo uchyourfinger repeatedlytoagreengroundconnection point

or unpaintedmetal in thewasher.

Before removing the partfromits package, touch the

anti-static bag to agreen ground connection pointor

unpainted metal in the washer.

Avoid touching electronic parts or terminal contacts; handle

electronic control assemblyby edges only.

Whenrepackaging failed electronic control assembly in

anti-static bag, observe above instructions.

BASIC OPERATION OF COMMERCIAL WASHER

For additional information,

see www.MaytagCommercialLaundry.com.

This techsheet is notvalid formodelsprior to series MAT14.

GENERAL USER INFORMAT ION

Blank Display

This condition indicate the washer is inoperative. Enter set-up mode

to view diagnostic code.

‘0 Minutes’ showing in display

Thiscondition indicates the washer cannot be operated. Coins

droppedordebit inputs during this condition will be stored in escrow

butcannot be useduntil normaloperation is restored by opening

andclosing thedoor. If adoor switch fails,itmust be replaced before

normal operation can be restored.

Cold Start (initial first use)

Washer is programmed at the factory as follows:

11 minute washperiod

1 rinses and2minutesofrinse agitation

$1.75 wash price (PD models)

$0.00 wash price (PR models)

Warm Start (after power failure)

After a delay of up to 8 seconds, the washer is restored to the

state that existed at timeof the power failure.

Free Cycles

This is established by settingthe cycle pricetozero. When this

happens, ‘SELECTCYCLE’willappearratherthanacycle price.

DebitCard Ready

This washer is debit card ‘cable’ready.Itwillacceptavariety

of debitcardsystems, but does NOT comewith a debitcardreader.

Refer to thedebit card reader manufacturer forproper washer

set-up.In modelsconvertedtoaGeneration 1debit card system,

debit pulsesrepresent theequivalentofone coin (coin 1).

Display

Afterthe washer has been installed andplugged in, the displaywill

show ‘0 MINUTES’. Once thewasher has been plugged in and the

washer door opened andclosed, the display willshowthe price.In

washersset forfreecycles, the display will flash‘SELECT CYCLE’.

MINUTES

0

PRICE

2.00

ELECTRONIC CONTROLS SETUP

Page 11

CONTROLSET -UPPROCEDURES

IMPORTANT: Read allinstructions before operating.

The lower fabric setting key pads and the digital display are used

to setup the controls. The display can contain 4 numbers and/or

letters and a decimal point. These are used to indicate the set-up

codes and related code values available for use in programming

the washer .

Howto use the key padstoprogram the controls

1. The LOWER LEFT key pad is used to adjust the values

associated with set-up codes. Pressing the key pad will

increment the value.

Rapid adjustment is possibleby holding the key pad down.

2. The LOWER MIDDLE key pad will advance you through the

set-up codes. Pressing the key padwill advance you to the

next available set-up code. Holding the key pad down will

automatically advance through the set-up codes at a rate of

one (1) per second.

3. The LOWER RIGHT key pad is used to select or deselect options.

Start Operating Set-Up

�

PD Models: Insert access door key , turn, and lift to remove access door.

�

PR Models: Once the debit cardreader is installed (according to the

reader manufacturer’s instructions), the set-up mode can be entered

by inserting a set-up card (supplied by the reader manufacturer) into

the cardslot. If amanual set-up cardisnot available, manual set-up

mode can be entered by removing connector AA1 on the circuit

board.

IMPORTANT: The console must not be opened unless poweris first

removed from the washer.To access connector AA1:

Unplug washer or disconnect power.

�

Open console, disconnect plug on AA1, close console.

�

Plug in washer or reconnect power.

�

The washer is now in the set-up mode.

Before proceeding,itis worth noting that, despite all of the options

available, an owner can simply choose to uncrate a new commercial

washer, hookit up, plug it in, and have a unit that operates.

SET- UP CODES

�

The LOWER MIDDLEkey pad will advance from code to code.

�

The LOWER LEFT key pad will change the code value.

�

The LOWER RIGHT key pad will select or deselect options.

FORPR MODELS: The set-up codes are the same as for the ‘PD’

models except where noted.

Theset-up code is indicated by the one or two left-hand characters. The

set-up code valueisindicated by the twoorthree right-hand characters.

CODE EXPLANA TION

607

607

Press theLOWER MIDDLE key pad oncetoadvance to next code.

�

REGULAR CYCLEPRICE

Represents the numberofquarters (coin 1);may adjust from 0-39.

(See VALUE OF COIN 1.)Advance from 0-39bypressing the LOWER

LEFT key pad. Factorypreset for 7quarters = $1.75.

PR MODELS ONLY:Factory preset for 0 quarters.

CODE EXPLANATION

711

711

Press the LOWER MIDDLE keypad once to advance to next code.

�

821

821

Press the LOWER MIDDLE keypad once to advance to next code.

�

900

900

90

Press the LOWER MIDDLE keypad once to advance to next code.

�

1. 00

1. 00

1. 0

1.C0

Press the LOWER MIDDLE keypad once to advance to next code.

�

2. 00

2. 00

2.

SP

If SPECIAL PRICINGOPTIONisselected,you have access to codes ‘3.’

through ‘9.’ .

Press the LOWER MIDDLE keypad once to advance to next code.

�

3. 07

3. 07

Pressthe LOWER MIDDLE keypad once to advance to next code.

�

WASH LENGTH

This is thenumber of minutesfor WASH.

Choose from 8-20 minutesbypressing the LOWER LEFTkey pad.

RINSECYCLES

This is thelength and total numberof rinses. Each rinse agitation is

1-4minutes, withachoiceof1or 2rinses. The middle digit is the

lengthof rinseagitationand the right digit is the number of rinses.

The number is changed in the followingsequence (11, 21, 31, 41,

12, 22, 32, 42) by pressing the LOWER LEFT key pad.

Pressthe LOWER MIDDLE keypad once to advance to next code.

The DELICA TES &KNITScycle hasafixed rinse agitation length

of oneminute.

CYCLECOUNTER OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’ and not able to be deselected.

C

Press the LOWER RIGHTkey pad3consecutive times

to select ‘ON’. Once selected ‘ON’ it cannot be deselected.

MONEY COUNTEROPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’.

C

Press the LOWER RIGHTkey pad3consecutive times

to select ‘ON’ and3consecutive times to remove

(Not Selected ‘OFF’.) Counter resets by going from ‘OFF’to‘ON’.

Selected ‘ON’and notable to be deselected.

To select ‘ON’ andnot able to be deselected, first select ‘ON’, then

withintwo seconds pressthe LOWER RIGHT key pad twice, the

LOWER LEFT key pad once, and exit the set-up mode.

SPECIAL PRICING OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Pressthe LOWER RIGHTkey pad once

forthis selection.

OPTIONSTO USE IF SPECIAL PRICINGISSELECTED:

SPECIAL CYCLE PRICE

Representsthe numberof quarters (coin 1): may adjust

from 0-39. (SeeVALUE OF COIN 1.) Advance from 0-39 by

pressing theLOWER LEFT keypad.Factory preset

for7quarters=$1.75.

PR MODELS ONLY:Factory preset for0quarters.

11

Page 12

12

CODE EXPLANATION

OPTIONSTO USE IF SPECIALPRICING IS SELECTED (cont.):

TIME-OF-DAY CLOCK, MINUTES

This is theTIME-OF-DAY CLOCK, minute setting;

select 0-59 minutesbypressing the LOWER LEFT key pad.

�

Press the LOWERMIDDLEkey pad oncetoadvance to next code.

TIME-OF-DAY CLOCK, HOURS

NOTE: Usesmilitarytimeor24hr. clock.

This is theTIME-OF-DAY CLOCK, hour setting; select 0-23 hours

by pressingthe LOWER LEFTkey pad.

�

Press the LOWERMIDDLEkey pad oncetoadvance to next code.

SPECIAL PRICE STAR T HOUR

NOTE: Usesmilitarytimeor24hr. clock.

This is thestart hour; 0-23hours.SelectSTART HOURbypressing

theLOWER LEFT key pad.

Press theLOWER MIDDLE key pad oncetoadvance to next code.

�

Press the LOWERMIDDLEkey pad oncetoadvance to next code.

SPECIAL PRICE STOP HOUR

NOTE: Usesmilitarytimeor24hr. clock.

This is thestophour; 0-23 hours.Select STOP HOURbypressing

theLOWER LEFT key pad.

�

Press the LOWERMIDDLEkey pad oncetoadvance to next code.

SPECIAL PRICEDAY

This represents theday of the weekand whether special pricing

is selected forthatday.Anumber followed by ‘0’ indicates no

selectionthatparticular day (9.10). A number followedbyan ‘S’

indicatesselected for that day (9.1S).

Days of the week (1-7) can be chosen by pressing the LOWER

LEFT keypad. Press theLOWER LEFTkey pad once to select

.special pricing for each daychosen.

When exiting set-up code ‘9’, the display must show current day

of week:

DISPLAYDAY OF WEEK CODE (selected)

10 Day1=Sunday1S

20 Day2=Monday2S

30 Day3=Tuesday3S

40 Day4=Wednesday 4S

50 Day5=Thursday 5S

60 Day6=Friday6S

70 Day7=Saturday7S

�

Press theLOWER MIDDLE keypad once to advance to next code.

8. 00

8. 00

9. 10

9. 10

VAULTVIEWING OPTION

This option is eitherSELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press theLOWER RIGHT key pad once for

this selection.Whenselected, the money and/or cycle counts

will be viewable (if counting is selected) when the coin

boxis removed.

�

Press theLOWER MIDDLE key pad oncetoadvance to next code.

VALUEOFCOIN 1

This represents thevalue of coin 1in number of nickels:

05 = $0.25.

By pressing theLOWER LEFTkey pad, youhave the option

of 1-199 nickels.

�

Press theLOWER MIDDLE key pad oncetoadvance to next code.

A.

00

A.

00

6. 05

6. 05

A.SC

5. 00

5.00

6. 00

6.00

7. 00

7. 00

CODE EXPLANATION

VALUEOFCOIN2

This represents the valueofcoin2in numberof nickels:

20 =$1.00.

PR MODELS ONLY:Factory presetfor $0.25.

By pressingthe PERMANENTPRESS keypad, you have the option

of 1-199 nickels.

�

Press the LOWER LEFTkey padoncetoadvance to next code.

COIN SLIDE OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Pressthe LOWER RIGHTkey pad 3consecutive

times forthis selection.

Whencoin slide mode is selected, set‘b.’ equal to valueof slide

in nickels. Setstep 6 (regular cycle price) and step 3 (specialcycle

price)tonumber of slideoperations.Ifthe installer sets up ‘CS’

onacoin drop model, it will not register coins.

�

Press the LOWER MIDDLE keypad once to advance to next code.

ADDCOINS OPTION

This option is either SELECTED ‘ON’ or NOT SELECTED ‘OFF’. This

optioncauses thecustomer display to show the number of coins

(coin1)toenter, rather than the dollars-and-cents amount.

Not Selected ‘OFF’.

Selected ‘ON’. Pressthe LOWER RIGHTkey pad

3consecutivetimes for thisselection.

�

Press the LOWER MIDDLE keypad once to advance to next code.

ENHANCEDPRICING OPTION

Not Selected ‘OFF’.

Cycle-Based pricing enabled. This optionallows configuration

of different pricesfor cold, warm, and hotwater cycles. Press the

LOWER RIGHT key padfor this selection.

Super Cycle pricing enabled. This optionallows customers

to upgrade cycles by depositing extra money. Set-up codes

‘H.’ and‘h.’willbe displayedonly when this option is enabled.

Press the LOWER RIGHTkey pad for this selection.

�

Press the LOWER MIDDLE keypad once to advance to next code.

SUPER CYCLE UPGRADE PRICE

(SkippedunlessSuper Cyclepricing is enabled.)

This represents the numberofcoin 1 required to upgrade a

basecycle to asuper cycle. Advance from 0-39 by pressing

theLOWER LEFTkey pad.

�

Press the LOWER MIDDLE keypad once to advance to next code.

SUPER CYCLE TYPE

(SkippedunlessSuper Cyclepricing is enabled.)

This represents the Super Cycle upgrade option. Press the

LOWER LEFT key padto step through upgrade options1

through 3asfollows:

01 -enhanced wash,extra 3 minutesof wash tumble in addition

to theprogrammed wash time.

02 -extra rinsefor allcycles.

03 -both01and 02.

�

Pressthe LOWER MIDDLE keypad once to advance to next code.

8.00

E

.00

E

.00

E.AC

8.00

8.

CS

F

.00

F

.00

F.CP

F.S

8

H

.0 1

H

.0 1

H

.0 1

H

.0 1

C

.20

C

.20

Page 13

13

CODE EXPLANATION

COIN/DEBIT OPTION

Both coin & debit selected.

Coinsselected, debitdisabled. Press the LOWER RIGHT key pad

forthisselection.

DebitCard selected,coins disabled. Press the LOWER RIGHT key

padfor this selection.

Enhanced Debit is self-selected whenaGeneration2card reader

is installed in thewasher. The Ed optioncannot be manually

selectedor deselected.

�

Pressthe LOWERMIDDLEkey padonceto advance to next code.

PRICESUPPRESSION OPTION

This option causesthe customerdisplayto show ‘ADD’ or

‘AVAILABLE’ratherthan the amountofmoney to add. (Used

mainly in debitinstallations.)

NotSelected ‘OFF’.

Selected ‘ON’. Press theLOWER RIGHT keypad once

for this selection.

�

Pressthe LOWERMIDDLEkey padonceto advance to next code.

CLEAR ESCROW OPTION

When selected, money held in escrow for30 minutes without

further escroworcycle activity will be cleared.

Selected ‘ON’.

Not selected ‘OFF’.Press the LOWER RIGHT key pad once to deselect

thisselection.

�

Pressthe LOWERMIDDLEkey padonceto advance to next code.

PENNY INCREMENT OFFSET

This represents thepenny increment priceoffset usedin

Generation 2(Enhanced Debit) PR models. Choose from 0-4

penniesbypressing the LOWER LEFT key pad.

�

Pressthe LOWERMIDDLEkey padonceto advance to next code.

If cyclecounter(90C) is selected, the following is true:

100 Represents the numberof cycles in HUNDREDS. 102

= 200

200 Represents the numberof cycles in ONES.225 = 225

TOT AL CYCLES=225

This is “VIEW ONL Y” andcannotbecleared.

Pressthe LOWER MIDDLEkey pad once to advance

to nextcode.

If money counter (1.0C or 1.C0)is selected, the following is true:

300Number of dollars in HUNDREDS.301

= $100.00

400 Numberofdollars in ONES. 468

=$168.00

500NumberofCENTS.575 =$100.75

TOTAL=$168.75

ENDOFSET -UP PROCEDURES

EXIT FROM SET- UP MODE

�

PD Models:Reinstall access door.

�

PR Models:

�

Unplug washeror disconnect power.

�

Open console,reinsert plugintoAA1,closeconsole.

�

Plug in washer or reconnectpower.

Page 14

MAYTAG® COMMERCIAL SINGLE-LOAD AND VENDED

MULTI-LOAD WASHER AND DRYER

WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTA BILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STAT E OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

3/10

For written correspondence:

Maytag

®

Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

10. Repairs made by a non-Whirlpool authorized service technician.

14

Page 15

15

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

CONSERVEZ CESINSTRUCTIONS

Liretoutes les instructions avant d’utiliser la laveuse.

Ne pas laver des articles qui ont été nettoyésou lavés

avec de l’essenceouimbibés d’essence, solvantsde

nettoyage àsec,ou autressubstances inflammables

ou explosives;ces substances peuvent émettre des

vapeurssusceptibles de s’enflammerou d’exploser.

Ne pas ajouter d’essence, solvant de nettoyage à sec ou

autre produitinflammableouexplosif dans l’eau de

lavage.Ces substances peuvent émettre des vapeurs

susceptibles de s’enflammeroud’exploser.

Dans certaines conditions,de l’hydrogène gazeux peut

se former dans un circuit d’eau chaude qui n’a pas été

utilisé pendant 2semaines ou plus.LEGAZ

HYDROGÈNE EST EXPLOSIBLE.Si le circuit d’eau

chaude n’a pas étéutilisé pendant une telle période,

avant d’utiliser la laveuse, ouvrirtous les robinets

d’eau chaude et laisser l’eau s’écouler pendant

plusieursminutes par chaque robinet. Ceci permettra

l’évacuation de l’hydrogène gazeux accumulé. Comme

ce gaz est inflammable, ne pas fumerouutiliser une

flamme nue au coursdecette période.

Ne pas laisserdes enfants jouer sur ou à l’intérieur de la

laveuse. Bien surveiller les enfants lorsque la laveuse est

utilisée àproximité d’enfants.

Avant de mettre la laveuse au rebut ou hors de service, enlever

la porte ou le couvercle.

Ne pas tenter d’atteindre un article à l’intérieur de la cuve de la

laveuse lorsque le tambour,lacuveoul’agitateur est en

mouvement.

Ne pas installer ou remisercette laveuse à un endroit où elle

serait exposée aux intempéries.

Ne pas modifier les organes de commande.

Ne pas réparer ou remplacer un composant quelconque de la

laveuse, ni entreprendre une opération de service, si ce n’est

spécifiquementrecommandé dans ce manuel ou dans un

manuel d’instructions de réparations destiné à l’utilisateur; il est

alorsessentiel quela personne concernéecomprenne ces

instructions et soit compétente pour les exécuter.

Voir “Spécifications électriques” pour les instructions de liaison

àlaterre.

AVERTISSEMENT:Pour réduire les risques d’incendie, de choc électrique ou de blessures lors de l’utilisationdela

laveuse, suivre les précautions fondamentales dont les suivantes:

Risque possiblededécès ou de blessure grave si

vous ne suivez pasimmédiatement les instructions.

Risque possiblededécès ou de blessure grave si

vous ne suivez pasles instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure

et ce qui peut se produireencas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreuxmessages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous

de toujours liretous les messagesdesécuritéetdevous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous et à

d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

SÉCURITÉ DE LA LAVEUSE

Page 16

16

EXIGENCESD’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant d'entreprendre

l’installation.

Outils nécessaires

Niveau

Couteau utilitaire

Ciseaux

Cléàmollette de 8" ou 10"

Tournevis àlame plate

Pince

Seau

Pièces fournies

Retirerles pièces de la laveuse.Vérifierlaprésencede toutes les

pièces.

1bride de fixation

2 tuyaux d'arrivée d'eau

4rondelles plates de tuyau d'arrivée d'eau

2pieds de nivellement avant avec écrous

1 tuyau de vidange

Exigencesd’emplacement

IMPORTANT:Ne pas installer ou remiser la laveuse dans un

endroitoùellesera exposée aux intempéries.Nepas remiser

ou fairefonctionner la laveuseàdes températures inférieures

ou égalesà0°C (32°F). Unequantitéd'eau peut demeurerdans

la laveuseetcauser des dommagesàdes températures basses.

C’estàl’utilisateurqu’incombelaresponsabilité de réaliser une

installationcorrecte.

Il vous faudra :

Un chauffe-eau pour fournirde l'eau à49°C(120°F)àla

laveuse.

Uneprise électrique reliée àla terre située àmoins de

1,2 m(4pi) de la priseducordonélectriquesetrouvantà

l'arrièredelalaveuse.

Voir “Spécificationsélectriques”.

Desrobinets d'eau chaudeetd'eau froide situés à1,2 m(4pi)

de l’arrièredelalaveuse,et une pression d’eaude69à690

kPa(10 à100 lb/po

2

). Lorsquelapressiond'alimentationà

l'entrée du bâtiment est supérieureà690kPa (100 lb/po

2

),

on devrait installer unevanne de réductiondelapressionpour

éviter uneéventuelle détériorationdelavanne de mixagede

la laveuse.

Un plancher de niveau ayantune pentemaximalede

25 mm (1") sous l’ensembledela laveuse.

Un plancher robustepour supporter la laveuse dont le poids

total (laveuse,eau et charge) est de 143 kg (315 lb).

Une colonne montante d’au moins300 mm (12") destinéeà

fourniruncoussin d’air et àempêcher l’émission de bruit et

la détérioration des électrovannes lors de l’installation d’une

seulemachine.

Un siphon de plancher devrait être disponible sous la cloison.

On devrautiliserune cloisonpréfabriquée avec prisesde

courant, canalisations d’eauet canalisations d’évacuation

seulement lorsque le code local le permet.

REMARQUE:La zone de la pompe est accessible à l’avant

après dépose du panneau avant (maintenuen place par2vis

TORX

®†

n° T20).

†®TORX estune marque déposée de AcumentIntellecual Properties,LLC.

Page 17

17

Système de vidange

Système de vidange avectuyau de rejetàl'égout

Le systèmederejet àl'égout nécessite un tuyaudediamètre

minimumde50mm(2"). La capacité minimumdevidange ne

peut pasêtreinférieureà64 L(17 gal.) par minute.

Le sommet du tuyauderejet à l'égout doit êtreaumoins à

990mm(39")dehauteur et au maximum à 1,8 m(72") de

la basedelalaveuse.

Instructions d’installation dans un encastrement ou

un placard

Cette laveuse peut être installée dans un encastrement ou un

placard.

Lesdimensions d’installation illustrées sont en centimètres et

constituent le minimum applicable. Un espace supplémentaire

peut être nécessaire pour faciliterl’installation, l’entretien et pour

observerles codes et règlements locaux en vigueur.

Si une portedeplacardest installée, des ouvertures d’évacuation

de l’air minimales sont nécessairesdans les parties supérieureet

inférieure. Les portes àclaire-voieoffrant des ouvertures

équivalentes sont acceptables.

Dégagements de séparationminimums àrespecter

Un espace supplémentairepeut êtrenécessaire pour faciliter

l’installation et l’entretien.

Un espace supplémentairepeut êtrerequispour les moulures

de porte et de plancheret pour les plinthes.

Un espace supplémentairede25mm(1")detousles côtés

de la laveuseest recommandé pour réduireletransfert du

bruit.

Il faut aussi prendre en comptel’espace requis entre les

appareilsvoisins.

Dimensionsduproduit

Froid

Chaud

A

B

C

E

D

F

G

I

J

K

L

M

H

N

O

H

Vue encastrée de

face du placard

Vuelatéraledu

placard

Portede

placard

Vuedeface

76 mm (3")

76 mm (3")

1,55m

2

(24"2)*

3,10m

2

(48"2)*

1,55m

2

(24"2)*

3,10 m

2

(48"2)*

*Dimension minimale pour une portedeplacard.

Lesportesàclaire-voie offrantdes ouvertures équivalentes sont acceptables.

0mm

(0")

0mm

(0")

Portedeplacard

432mm

(17")

356mm

(14")max.

102mm

(4") min.

25 mm (1")

min.

A. 1090 mm (43")

B. 970 mm (38-1/8")

C. 890 mm (35")

D. 38 mm (1-1/2")

E. 705 mm (27-3/4")

F. 650 mm (25-1/2")

G. Arrivéesd’eau

H. 180 mm (7")

I. Cordon d’alimentation électrique

J. Étiquette

K. 685mm (27")

L. 133 mm (5-1/4")

M. 25 mm (1")

N. Tuyau de vidange

O. 127 mm (5")

Page 18

18

Spécifications électriques

IMPORTANT : La laveuse doit être correctement reliée àlaterre

en conformité avec les codes et règlements locaux en vigueur ou,

en l'absence de tels codes, avec le NationalElectrical Code,

ANSI/NFP A70-dernièreédition.

Si les codes le permettentetsion utilise un conducteur

distinctdeliaison àlaterre,il est recommandé qu’un

électricien qualifié vérifiela qualitédelaliaison àla terre.

Ne pas utiliser une tuyauteriedegaz pour le raccordement à

la terre.

Ne pas installer un fusible dans le conducteur neutreoule

conducteur de liaison àlaterre.

Pour obtenir un exemplairedela normedes codes ci-dessus,

contacter :

National Fire Protection Association

One Batterymarch Park, Quincy,MA02269

L’appareil doit êtrealimenté parun circuitde 120 V, CA

seulement, 60 Hz, 15 ou 20 A, protégé parunfusible. On

recommande d’utiliser un fusibleouundisjoncteur temporisé.

Il estrecommandé de raccorder la laveusesur un circuit

distinct exclusif à cet appareil.

Cette laveuse comporte un cordon d’alimentation électrique à

troisbroches pour liaison àla terre.

Pour minimiser les risquesdechocélectrique, on doit

brancherle cordon sur une prise de courant de configuration

correspondante, à3alvéoles, reliée àlaterre et installée

conformément à tous les codes et règlements locaux en

vigueur.Si une prise de courant de configuration

correspondante n’est pas disponible, le client ala

responsabilité et l’obligationde faire installer par un électricien

qualifié une prise de courant correctementreliée àla terre.

Risque de choc électrique

Branchersur uneprise à3alvéolesreliéeàlaterre.

Ne pasenlever la broche de liaison à la terre.

Ne pasutiliser un adaptateur.

Ne pasutiliser un câble de rallonge.

Le non-respect de ces instructionspeut causer un

décès, un incendie ou un choc électrique.

A VERTISS EM ENT

INSTRUCTIONSDE LIAISON À LA TERRE

Pour une laveuse reliée à la terre et connectée par

un cordon :

Cette laveuse doit être reliée la terre. En cas d’anomalie de

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courantélectrique un

itinéraire d’évacuation de moindre résistance. Cette laveuse

estalimentée par un cordon électrique comportant un

conducteur relié à la terre et une fiche de branchement

munie d’une broche de liaison à la terre. La fiche doit être

branchée surune prisedecourant appropriée qui est bien

installée et reliée la terre conformément à tous les codes et

règlements locaux.

AVERTISSEMENT :

Le raccordement incorrect de cet

appareilauconducteur de liaison la terre peut susciter un

risque de choc électrique. En cas de doute quant à la qualité

de la liaison la terre de l’appareil, consulter un électricien ou

technicien d’entretien qualifié.

Ne pasmodifier la fiche de branchement fournie avec

l’appareilsilafiche ne correspond pasàla configuration de

la prise de courant, demander à un électricien qualifié

d’installer une prise de courantconvenable.

Pour une laveuse raccordée en permanence :

Cette laveuse doit être raccordée à un système de câblage

permanent en métalrelié à la terre ou un conducteur relié à

la terre doit être en fonction avec les conducteurs de circuit

et raccordés à la bornede liaison la terre ou la borne sur

l’appareilménager.

Méthoderecommandée de miseàlaterre

La laveusedoitêtrecorrectementreliée àla terreenconformité

avec les codes et règlements locaux en vigueur ou, en l'absence

de tels codes,avecle National Electrical Code, ANSI/NFPA70dernière édition, et aux codes et règlements locaux.

Page 19

19

Connecter le tuyau de vidange

REMARQUE : Faireglisser la laveuse sur un carton ou une

plaque de contreplaqué avant de la déplacer sur le plancher.

1. Placer la laveuse près de son emplacement d'installation final.

2. Mettre l'extrémitéencrochet du tuyau de vidange dans

l'évier de buanderieou dans le tuyau de rejet à l'égout.

3. Estimerlalongueurdetuyau de vidangenécessairelorsque la

laveuseest àson emplacement d'installation final. Il faut que

le tuyausoitcoupé àla longueur exacte quipermettra à

l’extrémitéencrochet d’être fermement retenuedans

l’embouchure du tuyauderejet àl’égout.

Enleverla sangle d’expédition

1. Enleverle ruban adhésifqui recouvrela sangle d’expédition.

Tirer pour extraire complètement la sangle et les2goupilles

quisetrouvent àl’intérieur de la laveuse.

2. Tirer fermement pour extrairel’extrémité de la sangle

d’expédition de l’arrièredelalaveuse.Pourla libérer les pieds

de réglagedel’aplomb, il faut que la sangle d’expédition soit

complètement extraite de la machine.

Conserver la sangle d’expédition pour réutilisation éventuelle.

INSTRUCTIONS D'INSTALLATION

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installerlalaveuse.

Le non-respect de cette instruction peut causer une

blessureau dos ou d'autre blessure.

A

A. Rubanadhésif pour expédition

B. Sangle d’expédition

Raccordement des tuyaux

Le bon acheminementdutuyau de vidange évite d’endommage

r

imputables à une fuite d’eau.

Lireetsuivre

ces instructions.

Connecterles tuyaux d'alimentation àlalaveuse

1. La laveuse doitêtre connectée auxrobinetsd'eau àl'aide

des nouveaux tuyaux d'arrivéed'eau.Nepas utiliser de tuyaux

usagés.Insérer lesrondelles plates neuves (fournies) dans

chaqueextrémité destuyauxd'arrivée d'eau. Insérer fermement

lesrondelles dans les raccords.

2. Fixerd'abord le tuyauàla valve d'arrivée d'eauinférieure.

3. Fixer le second tuyau àla valve d’arrivée d’eau supérieure.

Serrer les raccordsàla main, puis utiliser une pince et serrer

de deux tiers de touren plus.

REMARQUE : Les fils des valves de tuyau d’arrivée d’eau sont

en plastique. Veiller àne pas détériorer les filetages des

raccords.

A

B

A. Valvedutuyau d'alimentation d'eau froide

B. Valvedutuyau d'alimentation d'eauchaude

A

B

A. Raccord

B. Rondelle

B

vos planchers

Page 20

20

Connecter lestuyauxd'alimentation aux

robinets d'eau

1. Avantdefixer les tuyaux d’alimentation,faire s'écouler l'eau

desdeuxrobinets dans un seau. Ceci éliminerales particules

se trouvant dans lescanalisations d'eauqui pourraient

obstruer les tuyaux. Marquer le robinet d’eauchaude.

2. Fixer le tuyau d’alimentation inférieur (marqué “H”) au

robinet d’eau chaude.

Serrer àlamainles raccords au robinet.

3. Fixer le tuyau d’alimentation supérieur (marqué“C”)aurobinet

d’eau froide.

Serreràla main lesraccords auxrobinets.

4. Utiliser une pinceet tourner chaque raccordde deux tiersde

tour en plus.

Réglage de l'aplomb de la laveuse

Installation des pieds de réglage de l’aplomb avant

1. Superposer deux cornièresdecarton d’emballage. Incliner la

laveuseversl’arrièreetinsérer les cornières sous la laveuseà

76 mm (3") de chaque côté –voirl’illustration.

2. Trouver lespieds de réglage de l’aplombetles écrous dans

le sachet de pièces. Visser l’écrou jusqu’à moins de 13 mm

(1/2") de la base.

3. Insérer un pied dans le trou appropriédanschaqueangle

avantdelalaveuse jusqu’à ce que l’écrou soit au contact

de la base de la laveuse. Ne passerrerles écrous avant

quel’aplomb de la laveuse n’aitété établi.

4. Incliner la laveusevers l’arrièreetretirer les cornières de

carton.Abaisser doucement la laveuse pour la reposer au sol.

5. Déplacerlalaveuse jusqu’à son emplacement définitif. Retirer

le cartonoulaplaque de contreplaqué de dessous la laveuse.

Si le tuyau de vidange est trop long, couper l’extrémitédroite

pour le raccourcir. (Nejamaiscouper l’extrémité recourbéedu

tuyau de vidange.)

REMARQUE:Ne pas forcer une sectionexcessive du tuyau

de vidange à pénétrer dans le tuyau de rejetàl’égout, ceci

pourraitprovoquerunsiphonnage.

4. Placer la bridede tuyau sur le raccordde vidange de la

laveuse. Pousser le tuyau de vidange pour l’engagersur le

raccordde connexion de la laveuse. Utiliserune pince pour

ouvrir la bridede tuyau et la placer àl’emplacement approprié

sur le tuyau de vidange. Vérifier que la bride est correctement

placée et serrée.

5. Mesurer et marquer un pointàapproximativement

406 mm (16") de l’extrémité avec piton de la sangle

d’expédition. Couper la sangle à cet endroit.

6. Vérifier que le tuyau n’est pas vrillé ou déformé et qu’il est

fermement maintenu en place.

7. Introduire l’extrémité recourbée du tuyau de vidange dans le

tuyau de rejet àl’égout. Enlacer lesdeux tuyaux avec la

sangle d’expédition. Introduire le piton dans le trou le plus

proche de la sangle.

A

B

C

A. 13 mm (1/2")

B. Base

C. Écrou

16"

(40.6 cm)

406 mm

(16")

Page 21

6. Brancher le cordon électriquedans une prise à3alvéoles

reliée àla terre.

REMARQUE : Sur certains modèles, lors des tests à l’usine,le

bouton de la minuterie est engagé (exécution partielle d’un

programme)etle bouton de miseenmarche est enfoncé.

Laisser la minuterie provoquer la poursuite du programme

jusqu’à la fin. Lorsqueleprogramme est terminé, la minuterie se

réarmeetlebouton reprend sa position de mise en marche. Si

on ne laisse paslaminuterie commander le déroulement du

programme jusqu’à la fin et le réarmement, le lavage de la

première charge ne sera pas exécuté correctement.

1. Incliner la laveuse vers l’avant pour soulever les pieds arrière

de 2,5 mm (1") pour l’ajustement des pieds arrièrederéglage

automatique de l’aplomb. Abaisser doucementlalaveuse

jusqu’au sol.

2. Utiliser un niveau pour contrôler l’aplomb de la machine dans

les deux directions, transversalementetavant-arrière.

3. Si la laveuse n’estpas d’aplomb,réglerlalongueur de

déploiement des pieds avant. Utiliser le niveau pour un

contrôlefinal.

4. Lorsquelalaveuseest d’aplomb, utiliser une clé pour serrer

chaque écrouaucontact de la base de la laveuse. Si les

écrous ne sont passuffisammentserrés contrela base, la

laveuse pourrait vibrer.

Réglage de l’aplomb de la laveuse

Acheverl'installation

1. Consulter lesspécifications électriques.Vérifier que la tension

électrique disponibleest correcte et que la prise de courant

est convenablement reliée àlaterre.

2. Vérifier que toutes les piècessontmaintenant installées. S’il

reste une pièce, passerenrevue lesdifférentesétapes pour

découvrir laquelle aurait été oubliée.

3. Ouvrir les robinets d’eau et vérifier s’il yades fuites. Serrer les

raccords en cas de fuites. Ne passerrer excessivement, ceci

pourrait endommager les robinets.

4. S’assurer d’avoir récupéré tous vos outils.

5. Vérifier que la sangled’expéditionaété retirée àl’arrièredela

laveuse et qu’elle a été utilisée pour l’arrimage du tuyau de

vidange. Si la sangle n’a pasété totalement retirée, la laveuse

peut vibrer et êtrebruyante.

Risque de choc électrique

Brancher sur une priseà3alvéolesreliéeàla terre.

Ne pasenlever la broche de liaison à la terre.

Ne pasutiliser un adaptateur.

Ne pasutiliser un câble de rallonge.

Le non-respect de ces instructions peut causer un

décès, un incendie ou un choc électrique.

AVERTISSEMENT

Listede contrôle pour le fonctionnement de la laveuse :

Si la laveusenefonctionne pas correctement, vérifiercequi suit :

1. Le cordon d’alimentation est branché.

2. Le disjoncteur ne s’est pas déclenchéou aucun fusible

n’est grillé.

3. La minuterie a été avancée pour commencer un programme.

4. Lesrobinets d’eau chaudeet d’eau froide sont ouverts.

5. Les tuyaux d’arrivée d’eau et de vidange ne sont pas

déformés.

6. Le couvercledela laveuse estfermé.

7. La valve d’arrivée d’eau n’est pas geléesielle n’estpas

protégée des intempéries.

8. Niveau de mousse. Unequantitéexcessive de mousse

ralentira l’essorage et produira un rinçage médiocre.Exécuter

un programme complet sans utiliser de détergent. Utiliser

moins de détergent ou un détergent au niveau de mousse

contrôlé pour les prochaines charges.

AVERTISSEMENT

Risque de choc électrique

Déconnecter la source de courantélectrique avant

l’entretien.

Replacer pièces et panneaux avant de faire la remise

en marche.

Le non-respect de ces instructions peut causer un

décèsouunchoc électrique.

On déconseillele lavage d’articles de fibrede verre dans une

laveusecommandée par piècedemonnaie. Si de tels articles ont

étélavés dans la machine, commander l’exécution d’un

programme complet pour l’éliminationde toutrésiduqui pourrait

encore se trouverdansla machine.

Taillesdecharges complètesclassiques

Type de

charge

Suggestion de

chargement

Type de

charge

Suggestion de

chargement

Charge

mixte

3draps à2places

4taies d’oreiller

Vêtements

de travail

3pantalons

3chemises

Conseils de fonctionnement

21

Page 22

On déconseillele lavage d’articles de fibrede verre dans une

laveusecommandée par piècedemonnaie. Si de tels articles ont

étélavés dans la machine, commander l’exécution d’un

programme complet pour l’éliminationde toutrésiduqui pourrait

encore se trouverdansla machine.

Taillesdecharges complètesclassiques

Type de

charge

Suggestion de

chargement

Type de

charge

Suggestion de

chargement

Charge

mixte

3draps à2places

4taies d’oreiller

6 shorts

8tee-shirts

2 chemises

2 chemisiers

8 mouchoirs

Vêtements

de travail

épais

3pantalons

3chemises

1salopette

4jeans

1 ensemble

Pressage

permanent

2draps à2places

ou 1drapdetrès

grande taille

1nappe

1robe

1chemisier

2pantalons toutaller

3chemises

2taies d’oreiller

Tricots 3chemisiers

4pantalons toutaller

6 chemises

4hauts

4robes

Conseils de fonctionnement

En cas de déplacement de la laveuse

àunnouvel emplacement

Retirer les pieds avant de la base de la laveuse.

Placer les deux pieds de nivellement arrièreenpositionélevée

et fixer àl’aide de ruban adhésif.

Appliquer du ruban adhésifsur les côtés et le bas du placard

àl'arrière de celui-ci.

Ouvrirlecouvercle de la laveuse; insérerune couverture entre

la couronne de la cuve et le sommet de la caissepour limiter

lesmouvements de la cuve.

Pieds

Piedsavant

Si vous avez besoin d’assistance :

On déconseillele lavage d’articles de fibrede verre dans une

laveusecommandée par piècedemonnaie. Si de tels articles ont

étélavés dans la machine, commander l’exécution d’un

programme complet pour l’éliminationde toutrésiduqui pourrait

encore se trouverdansla machine.

Conseils de fonctionnement

Ouvrirlecouvercle de la laveuse; insérerune couverture entre

la couronne de la cuve et le sommet de la caissepour limiter

lesmouvements de la cuve.

Manipulerdoucement la laveuse. Faire attention de ne pas

laissertomberlalaveuse en casd’utilisation d’un chariotà

bras.

Pieds

arrière

Ruban adhésifdouble face

Piedsavant

22

Listede contrôle pour le fonctionnement de la laveuse :

Si la laveusenefonctionne pas correctement, vérifiercequi suit :

1. Le cordon d’alimentation est branché.

2. Le disjoncteur ne s’est pas déclenchéou aucun fusible

n’est grillé.

3. La minuterie a été avancée pour commencer un programme.

4. Lesrobinets d’eau chaudeet d’eau froide sont ouverts.

5. Les tuyaux d’arrivée d’eau et de vidange ne sont pas

déformés.

6. Le couvercledela laveuse estfermé.

7. La valve d’arrivée d’eau n’est pas geléesielle n’estpas

protégée des intempéries.

8. Niveau de mousse. Unequantitéexcessive de mousse

ralentira l’essorage et produira un rinçage médiocre.Exécuter

un programme complet sans utiliser de détergent. Utiliser

moins de détergent ou un détergent au niveau de mousse

contrôlé pour les prochaines charges.

Si vous avez besoin d’assistance :

Le Centred’intéraction avec le consommateur Maytag répondra à

toutes vos questions concernantlefonctionnementou l’entretien

de la laveuse non traitées dans les Instructionsd'installation. Le

Centre d’intéraction avec le consommateur Maytag est ouvert 24

heures par jour,7jours par semaine. Composer le 1-800 NO

BELTS (1-800-662-3587) - appel sans frais.

Lorsde l’appel,vous aurez besoin des numérosde modèle et de

série de la laveuse. Les deux numéros sont indiqués sur la plaque

signalétique de la laveuse.

AVERTISSEMENT

Risque de choc électrique

Déconnecter la source de courantélectrique avant

l’entretien.

Replacer pièces et panneaux avant de faire la remise

en marche.

Le non-respect de ces instructions peut causer un

décèsouunchoc électrique.

On déconseillele lavage d’articles de fibrede verre dans une

laveusecommandée par piècedemonnaie. Si de tels articles ont

étélavés dans la machine, commander l’exécution d’un

programme complet pour l’éliminationde toutrésiduqui pourrait

encore se trouverdansla machine.

Taillesdecharges complètesclassiques

Type de

charge

Suggestion de

chargement

Type de

charge

Suggestion de

chargement

Charge

mixte

3draps à2places

4taies d’oreiller

6 shorts

8tee-shirts

2 chemises

2 chemisiers

8 mouchoirs

Vêtements

de travail

épais

3pantalons

3chemises

1salopette

4jeans

1 ensemble

Pressage

permanent

2draps à2places

ou 1drapdetrès

grande taille

1nappe

1robe

1chemisier

2pantalons tout-

aller

3chemises

2taies d’oreiller

Tricots 3chemisiers

4pantalons tout-

aller

6 chemises

4hauts

4robes

Conseils de fonctionnement

Communiquer avec votre distributeur d’ensemble de buanderie

®

Maytag

de buanderie Maytag

de renseignements sur Internet, visitez le site Web

www.MaytagCommercialLaundry.com.

Si vous ne pouvez pas localiser votre distributeur, le Centre

d’assistance d’appareils de buanderie commerciaux répondra à

toute question concernant le fonctionnement et l’entretien de la

laveuse non abordée dans les instructions d’installation.

Il suft de composer le 1-800 NO BELTS (1-800-662-3587).

La communication est gratuite.

Lors de l’appel, vous aurez besoin des numéros de modèle et de

série de la laveuse. Les deux numéros sont indiqués sur la plaque

signalétique de l’appareil.

autorisé. Pour localiser votre distributeur d’ensemble

®

autorisé, ou pour des demandes

Page 23

AVERTISSEMENT

Risquedechoc électrique

Déconnecter la sourcede courant électrique avant

l’entretien.

Replacer piècesetpanneaux avant de fairela

remise en marche.

Le non-respect de ces instructions peut causer un

décès ou un choc électrique.

IMPORTANT

Circuits électroniques sensibles

aux décharges électrostatiques

Le risque de décharge électrostatique estpermanent.Une décharge électrostatique peut

endommager ou affaiblir les composants électroniques. La nouvelle cartepeutdonner

l’impression qu’elle fonctionne correctement aprèslaréparation, mais une décharge

électrostatique peut lui avoirfaitsubir desdommages quiprovoqueront une défaillance

plus tard.

Utiliser un bracelet de déchargeélectrostatique.Connecter le bracelet àla vis vertede

liaisonàlaterre ou sur une surface métallique non peintedel’appareil

-OUToucher plusieurs fois du doigt la vis vertedeliaison àlaterre ou une surface

métalliquenon peinte de la laveuse.

Avant de retirerla pièce de son sachet, placer le sachet antistatique en contact avec

la vis vertede liaison àla terre ou une surfacemétallique nonpeinte de la laveuse.

Éviter de toucher les composants électroniquesoules broches de contact; tenir la

carte de circuits électroniquespar lesbordsseulement lors des manipulations.

Lors du réemballage d’une cartedecircuits électroniquesdéfaillante dans le sachet

antistatique, observer les instructionsci-dessus.

LAVEUSE COMMERCIALE -OPÉRATIONSDE BASE

Pour d’autresrenseignements, consulter www.MaytagCommercialLaundry.com.

Cet fiche technique n’est pas valable pour les modèles antérieursaux modèlessériesMAT14.

INFORMATION GÉNÉRALE POUR L’UTILISATEUR

Afficheur vierge

Cette situation indique que la laveuse n’est pas opérationnelle. Accéder au modede

configuration pour voir le code de diagnostic.

Affichage de ‘0 Minute’

Ceci indique qu’il n’est pas possible de faire fonctionner la laveuse. L’information surles

pièces inséréesoules entrées de débit sera mémorisée mais ne peut être utilisée avant le

rétablissement du fonctionnement normal par unemanœuvre d’ouverture/fermeture du

couvercle. En cas de défaillance du contacteur du couvercle, on doit le remplacer pour pouvoir

rétablir le fonctionnement normal.

Mise en marche pour la première utilisation

La laveuseaété programmé à l’usine comme suit :

Périodedelavage de 11 minutes

1 rinçage et 2minutes d’agitation (rinçage)

Prix du lavage:1,75 $ (modèlesPD)

Prix du lavage:0,00 $ (modèlesPR)

Remiseenmarche après une interruption de l’alimentation

A

près un délai quipeut atteindre 8 secondes, l’étatinitial de la laveuse (au moment

de l’interruption de l’alimentation) est restaurée.

Prix de l’utilisation

Après l’ouverture du couvercle à l’achèvement d’un programme, l’afficheur présente

le prix d’utilisation (sauf si l’appareil est réglé pour l’utilisation gratuite). Lors de

l’enregistrement de l’introductiondepièces ou d’un débit, l’information affichée

change et guidel’utilisateur pour le lancement d’un programme.

Programmes gratuits

Pour ceci, on règlele prix de l’utilisation à zéro; l’afficheur présentealors

‘SELECT CYCLE’ (sélectionner le programme) plutôt queleprixd’une utilisation.

MINUTES

0

PRICE

2.00

Prêt pour cartede débit

Cette laveuse est pré-configurée pour l’utilisation des cartes de débit; il est compatib

l

avec une variétédesystèmesdepaiement parcarte de débit, mais il n’est PAS

fourni avec un lecteur de cartede débit.Pour le réglage approprié de la machine,

voir lesinstructionsfournies parle fabricant du lecteur de carte de débit. Pour un

modèle converti pour l’utilisation d’une cartededébit Génération 1, les impulsions

de débitsont équivalentesàl’insertion d’une pièce (pièce 1).

Afficheur

Après l’installationinitialeetlebranchementdel’appareil,l’afficheur présente

‘0 MINUTES’.Après le branchement de la laveuseetl’ouverture du couvercle,

l’afficheur présente le prix.Silalaveuse est régléepour l’utilisationgratuite,

l’afficheur présente ‘SELECTCYCLE’ (sélectionner le programme) avec clignotement.

PROCÉDURES DE RÉGLAGE DES SYSTÈMES

DE COMMANDE

IMPORTANT : Lirelatotalité des instructions avant l’utilisation.

Pour le réglage des systèmes de commande, on utilise les touchesderéglage

inférieures (tissu)etl’afficheur numérique. L’afficheur peut présenter 4 chiffres

et/oulettres et un point décimal,qui indiquent les codesdeparamétrage et des

valeurs connexes disponibles pourlaprogrammation de la laveuse.

Utilisationdes touches pour la programmation des

systèmes de commande

1. La touche INFÉRIEURE DE GAUCHEpermetlasélection des valeursassociées

auxcodes de paramétrage.Une pression sur la touche faitaugmenterla valeur;

si on maintientlapression surlatouche, la valeur affichée augmente rapidement.

2. La touche INFÉRIEURECENTRALE commandela progression parmi les codesde

paramétrage.Une pression sur la touche provoque le passage au code de

paramétrage suivant; une pression constante surlatouche commandele

défilementautomatique des codes àraisondeun code par seconde.

3. La touche INFÉRIEUREDEDROITE permet de sélectionner/désélectionner

les options.

RÉGLAGE DE LA COMMANDE ÉLECTRONIQUE

23

Ouvrirlecouvercle de la laveuse; insérerune couverture entre

la couronne de la cuve et le sommet de la caissepour limiter

lesmouvements de la cuve.

Manipulerdoucement la laveuse. Faire attention de ne pas

laissertomberlalaveuse en casd’utilisation d’un chariotà

bras.

Pieds

arrière

Ruban adhésifdouble face

Piedsavant

Page 24

Paramétrage pour mise en marche

ModèlePD:Insérer la clé de la ported’accès; tourner et soulever pour enlever

la ported’accès.

Modèle PR:Après installation du lecteur de cartededébit (conformément aux

instructions du fabricant du lecteur de carte), pour accéder au mode de

paramétrage, insérer la carte de paramétrage manuel (fourniepar le fabricant du

lecteur de carte) dans le lecteur de carte.Siune cartede paramétrage manuel

n’est pas disponible, on peut égalementenlever le connecteurAA1 surlacarte

des circuits pour accéder au mode de paramétragemanuel.

IMPORTANT: Ne pasouvrir la console avantd’avoir déconnecté l’appareildetoute

source d’énergie. Pour accéderauconnecteur AA1:

Débrancher la laveuse ou déconnecterla source de courant électrique.

Ouvrir la console, débrancherleconnecteur AA1; refermer la console.

Brancher la laveuse ou reconnecterlasourcede courant électrique.

L’appareil est maintenant au modedeparamétrage.

Avant de poursuivre, noter que malgré le grand nombre d’options disponibles,

le propriétairede l’appareil peut déciderdesimplement déballer sa nouvelle machine

commerciale, la brancheretlaraccorder; elle sera alors parfaitement opérationnelle.

CODES DE PARAMÉTRAGE

La touche INFÉRIEURE CENTRALEpermetdepasserdecodeencode.

La touche INFÉRIEURE DE GAUCHE permet de changer la valeur du code.

La touche INFÉRIEURE DE DROITE permet de sélectionner ou désélectionner les options.

POUR LES MODÈLES PR :Les codes de paramétrage sontidentiquesaumodèle PD,sauf

quand spécifié.