Page 1

INSTALLATION INSTRUCTIONS

AUTOMATIC DRYER

PLEASE READ ALL INSTALLATION

INSTRUCTIONS AND REQUIREMENTS

BEFORE INSTALLING

A WARNING

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors or liquids in the

vicinity of this or any other appliance.

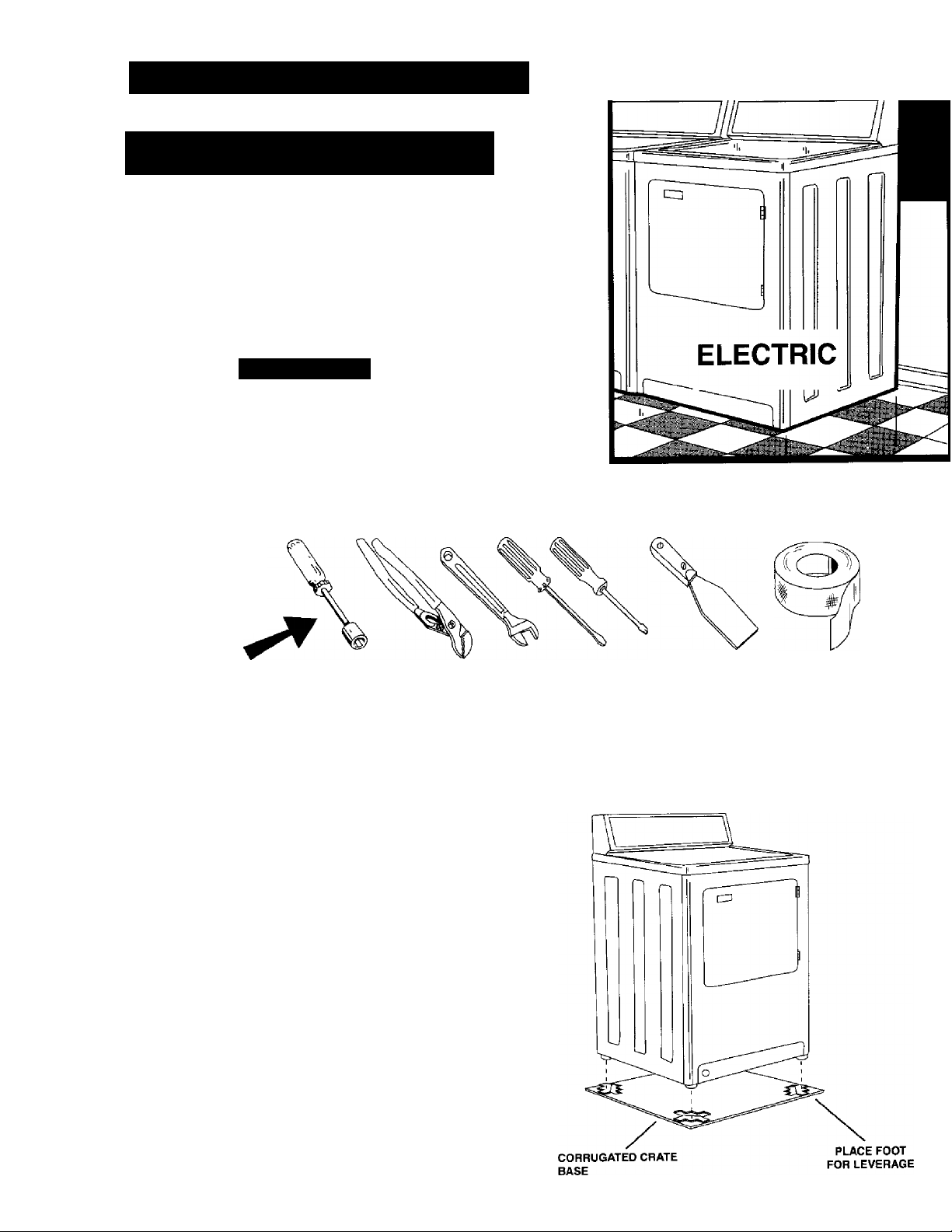

-TOOLS REQUIRED-

V DEEP WELL DRIVER

V;’ DRIVER

INSTALLING YOUR NEW DRYER

FOR YOUR SAFETY AND THE PROPER OPERA

TION OF YOUR NEW DRYER, THE DRYER

MUST BE INSTALLED IN ACCORDANCE WITH

ALL THE INSTALLATION REQUIREMENTS.

CHANNEL LOCK PLIERS

OR ADJUSTABLE WRENCH

All literature should be removed from inside dryer and

saved for future reference.

NOTE; DO NOT RAISE OR LOWER THE DRYER BY

THE BACKGUARD.

1. To remove the corrugated crate base, place your

foot on the base close to a leveling foot. Pushing

down firmly with your foot, tilt the dryer away from

you.

2. Repeat process with all leveling feet (4). Remove

excess base by hand.

SCREWDRIVER

(BLADE & TORX)

PUTTY KNIFE DUCT TAPE

BACKGUARD

P/N 53-3442

Page 2

INSTALLATION REQUIREMENTS

PLe/^SE read All Installation Instructions and Requirements Before Installing Power Cord.

rr IS RECOMMENDED THAT A QUALIRED ELECTRI

CIAN OR SERVICETECHNICIAN INSTALL YOUR DRYER.

LOCATION

This clothes dryer is designed so that it can be

installed in most locations in the home. The dryer may

even be installed in an unheated indoor location, such

as a utility room or building. However, with models hav

ing automatic dry cycles, the TIME DRY SETTING

SHOULD BE USED WHEN THE ROOM TEMPERA

TURE DROPS BELOW 50 DEGREES FAHRENHEIT

OR (10 DEGREES C.), AS THE AUTOMATIC CYCLE

MAY NOT SHUT OFF.

DO NOT INSTALL THE DRYER ON A CARPETED FLOOR.

DO NOT INSTALL OR STORE THE DRYER WHERE

IT MAY BE EXPOSED TO THE WEATHER OR DRIP

PING WATER. IF IT IS EVER EXPOSED TO WATER,

HAVE A QUALIFIED TECHNICIAN CHECK IT

BEFORE USING.

THE INSTALLATION MUST BE MADE WITH ADEQUATE CLEARANCE TO PERMIT SERVICING.

In ordinary installations enough air will be available for prop

er operation of the dryer. However, if the dryer is installed in

a mobile home, a closet or a tightly sealed room, provisions

should be made for at least 18 square inches of ventilation

area. Air openings measuring a minimum 3 in. by 3 in. should

be provided at the top and bottom of the closet door.

Ordinarily, louvered doors will satisfy the ventilation require

ments. Dryers installed in a bedroom, bathroom , or closet

must be exhausted outdoors.

Dryers installed in manufactured (mobile) homes must be

connected with 4 conductor type 3RD or SRDT cord to a 3

pole, 4 wire grounding type receptacle; by metal-clad cable;

or suitable conductors enclosed in flexible metal conduit. If

using metal-clad cable or flexible conduit, leave at least 3

feet tree to permit moving the dryer.

Where permitted by local codes, a flexible power cord (pig

tail) may be connected to the dryer. A receptacle should be

installed in a separate circuit connected to the main service

entrance panel for this type of installation. See Figure #3.

Use only a 3 or 4 wire power cord kit, including strain relief,

listed by U L for use with dryers. The power cord must have

a rating of 30 amperes, 120/240 volts AC minimum and be

terminated in closed loop or open spade lugs with upturned

ends. The attachment plug of the power cord and the recep

tacle to which it will be connected must have a minimum cur

rent rating of 30 amps and have matching configurations.

Typical 30 ampere configurations are illustrated in figure #3.

GROUNDING INSTRUCTIONS

This appliance MUST BE CONNECTED TO A GROUNDED

METAL PERMANENT WIRING SYSTEM; or an equipment

grounding conductor must be run with the circuit conductors

and connected to the equipment-grounding terminal or lead

on the appliance.

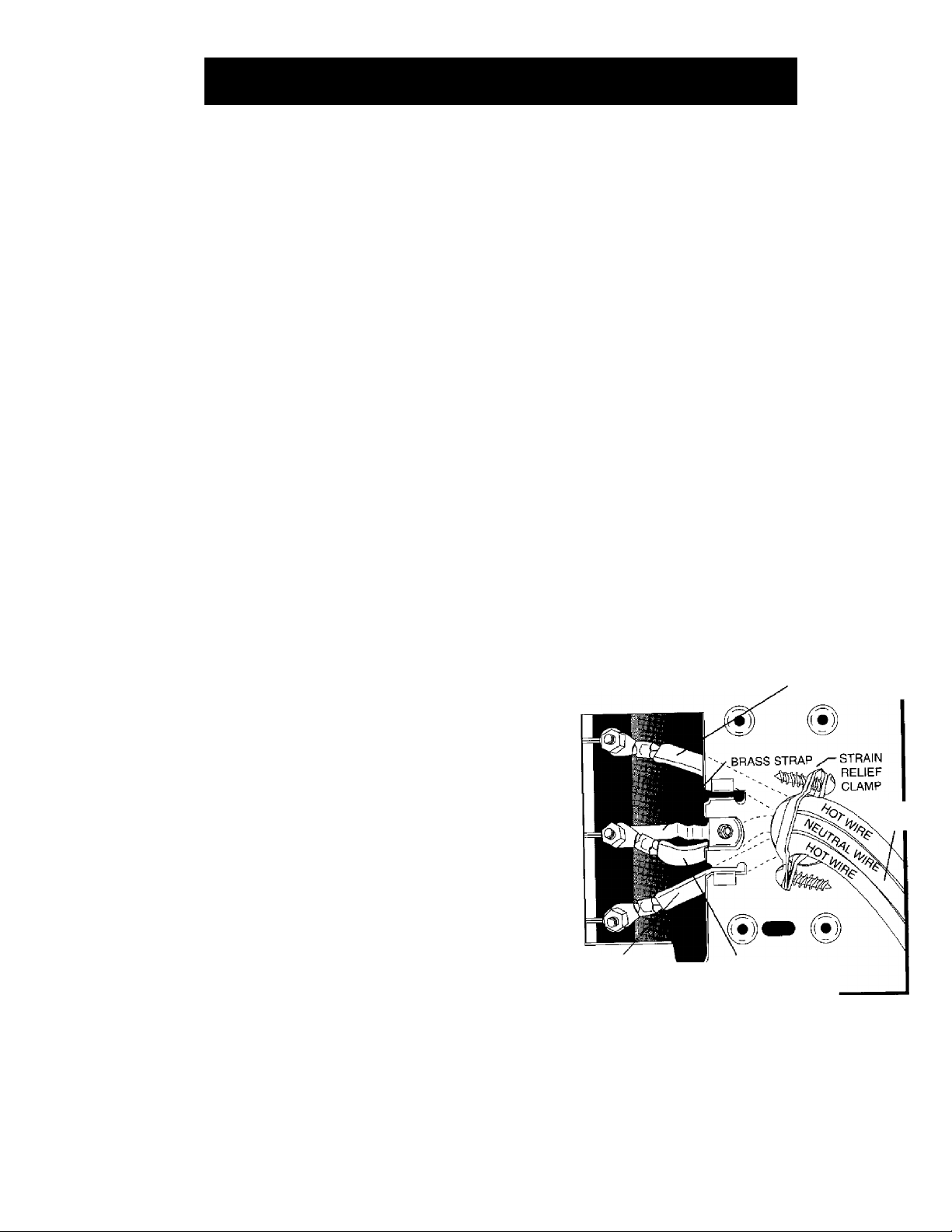

CONNECTING THE DRYER

FIG.#1 -3WIRE

LINE 1

(BLACK)

HOTWIRE ROUTED

ABOVE BRASS STRAP

1

ELECTRICAL REQUIREMENTS

This phase of the installation should be done by a qualified

service technician or electrician in accordance with the

National Electrical Code and all local codes and ordinances.

A separate circuit must be provided from the main service

entrance panel {fuse box) to the dryer. The circuit must be a 3

or 4 wire, 120/240 volt, 60 Hz, single phase, AC circuit. Each

of the 120 volt line wires (line 1 and 2) of this circuit must be

protected by 30 ampere time delay fuses or circuit breakers.

Do not fuse the neutral line or the ground line (if provided).

All wires (including neutral and ground if provided) of the

dryer circuit must be No. 10 gauge copper wire for up to 40

ft lengths and No. 8 gauge copper wire for up to 60 ft

lengths. NEVER USE A TWO WIRE CABLE WITH AN

UNINSULATED GROUND WIRE TO CONNECT THE

DRYER.

The National Electric Code requires that a means to discon

nect all ungrounded conductors (line 1 and line 2) to the

dryer be provided for service. If a power cord and receptacle

are provided this requirement is met. It other means are

used a suitable switch or circuit breaker must be installed

within sight of the dryer.

POWER

NEUTRAL

(WHITE)

LINE 2

(RED)

HOTWIRE ROUTED

BELOW BRASS STRAP

NEUTRAL WIRE

ROUTED BELOW

BRASS STRAP

THE NATIONAL ELECTRICAL CODE AND ALL

LOCAL CODES AND ORDINANCES MUST BE

OBSERVED WHEN CONNECTING THIS DRYER.

1. To gain access to the terminal block, remove the supply

cord cover plate attached to the rear of the dryer.

2. Install a suitable strain relief clamp or connector in the

strain relief hole located adjacent to the terminal block.

CORD

Page 3

3, Route the power cord (pigtail) or cable conductors through

the strain relief clamp.

FIG. #2-4 WIRE

TERMINAL BLOCK

A CAUTION - The conductors should not extend into

the dryer more than necessary to make the electrical

connections-

4. Refer to the Typical Electrical connections listed below

and make the electrical connections as instructed. We

recommend that a qualified service technician or electri

cian be consulted before connecting the dryer.

NOTE; DO NOT REMOVE THE INTERNAL GROUND WIRE

OR BRASS STRAP EXCEPT WHERE INSTRUCTED AND

REQUIRED BY LOCAL CODES AND ORDINANCES OF

YOUR AREA.

5. Check to be certain all conductors are correctly installed.

Then securely tighten all terminal nuts and the ground

screw.

6. Tighten the strain relief clamp.

7. Replace the supply cord cover plate.

8. Complete the dryer installation.

TYPICAL ELECTRICAL CONNECTIONS

LINE 1

(BLACK)

NEUTRAL

(WHITE)

LINE 2

(RED)

GREEN

GROUND WIRE

GROUND

SCREW

3-WIRE SYSTEM WITH GROUNDED NEUTRAL -

Connect power cord conductors to the line 1, neutral,

and line 2 terminals of the terminal block as shown in

Figure #1.

NOTE: Some 3-wire flat type power cords are not color

coded. When using this type of power cord, connect the

center conductor to the Neutral, connect one of the out

side conductors to line 1, and connect the other outside

conductor to line 2.

3-WIRE SYSTEM WITH GROUNDED METAL CLAD

CABLE OR RIGID METAL CONDUIT - Remove the

internal green ground wire or brass strap from the

Neutral terminal and the ground screw. Connect the

power cable conductors to the line 1, Neutral, and line

2 terminals as shown in Figure #2.

NOTE: An approved grounding type strain relief clamp

or conduit connector must be installed for this type of

installation.

4-WIRE SYSTEM - Remove internal green ground wire

or brass strap from the Neutral terminal and the ground

screw. Connect the power cord green grounding con

ductor to the ground screw. Connect the remaining

power cord conductors to the line 1, Neutral, and line 2

terminals as shown in Figure #2.

A BEFORE OPERATING YOUR DRYER READ

ALL SAFETY PRECAUTIONS LISTED IN THE

OPERATING INSTRUCTIONS.

Page 4

2. STABILITY

Place dryer in the location where it will

be used. Check, by rocking dryer with

hands on opposite corners, that all

four (4) feet are in firm contact with the

floor. If it rocks, adjust as needed.

3A. OUTSIDE WALL

VENT HOOD

OUTSIDE WALL

Attach dryer vent pipe to outside

exhaust vent. Outside exhaust vent

should fit over dryer vent pipe to avoid

catching lint. Tape all joints with heat

duct tape.

3D. INDOOR EXHAUSTING

(NOT RECOMMENDED unless

conditions on page 6 are met.)

3B. BASEMENT WALL

BASEMENT WINDOW,

90° ELBOW 4” DIA—

BASEMENT

WALL

In basements, the exhaust can be ele

vated by installing elbows to raise the

vent hood above the ground level.

4. ELECTRICAL CONNECTION

3C. FLOOR EXHAUSTING

If space permits, a 4” dia. elbow point

ed downward through the floor may be

used. If not possible, the dryer may be

exhausted through the bottom as illus

trated later in this manual.

INSTALLATION WITH

POWER CORD (PIGTAIL).

When exhausting indoors, use the

indoor exhaust kit and maintain a mini

mum clearance of 6 inches between the

rear of the dryer and any adjacent wall.

Read further instructions in this manual.

Page 6.____________________________

FLEXIBLE

POWER CORD

Ó

WALL

RECEPTACLE

MAIN SERVICE

ENTRANCE PANEL

This appliance must be connected to a grounded metal, permanent wiring

system; or an equipment - grounding conductor must be run with the cir

cuit conductors and connected to the equipment - grounding terminal or

lead on the appliance.

Page 5

EXHAUST VENTING REQUIREMENTS

A WARNING

FIRE HAZARD

NEVER EXHAUST INTO A CHIMNEY, DUCT, GAS

VENT, WALL, CEILING, ATTIC, CONFINED SPACE,

BEDROOM, OR UNDER A BUILDING.

DO NOT USE VINYL, PLASTIC, CLOTH OR OTHER

NONMETALIC DUCT TO EXHAUST THE DRYER.

MULTIPLE INSTALLATIONS REQUIRE INDIVIDUAL

EXHAUST SYSTEMS.

DRYERS INSTALLED IN A MANUFACTURED

(MOBILE) HOME MUST BE VENTED OUTDOORS.

PERIODICALLY CLEAN LINT FROM VENT SYSTEM.

CLEAN FREQUENTLY IF USING MAXIMUM

LENGTH OF VENT.

Exhausting can be accomplished directly from the rear of

the cabinet, through right side of the cabinet, or down

ward through the cabinet base. If your existing ductwork is

plastic, nonmetal, or combustible, replace it with METAL.

Standard four inch diameter galvanized or aluminum pipe

should be used. DO NOT use any pipe which may be sus

ceptible to rust or COMBUSTION. To avoid catching lint

the crimped end of each pipe section should face away

from the dryer. Do not use screws or other fasteners that

extend into the exhaust pipe or duct.

Number of

90° Turns

Separated by

at least 4 ft.

of Straight Run

0

f

2

■ \ .. ^

-----

VENT HOOD TYPE

— I I— 4"

OPENING

45 feet

35 feet

25 feet

____________

— I I—

OPENING

30 feet

20 feet

10 feet

K

Vent should never exceed 0.6 inches water column back

pressure, fluff empty dryer.

BOTTOM EXHAUSTING

If space permits behind the dryer, a 4” elbow pointed down

ward may be used to pass the exhaust system through the

floor. If this is not possible, the dryer may be exhausted

through the bottom as illustrated in FIG. #7. When exhaust

ing in this manner, the installation should be made accord

ing to the following steps:

1. Disconnect electric cord.

2. Raise the top of the dryer by pressing in with a putty knife

on the top panel retaining clips. FIG. #5.

Flexible 4” diameter metal tubing may be used for

exhausting the dryer. However, the convolutions create a

greater restriction than pipe and serious blockage can

result if the tubing is bent too sharply. If clearance to the

wall is less than 8 inches, use a 4” sheet metal elbow at

the rear of the dryer to avoid a sharp bend in the tubing.

Do not use over 8 feet (2.5 m.) of flexible metallic tubing

between the elbow and the vent hood.

VENT HOOD

The use of a vent hood

on the outside is recom

mended.

When the dryer stops the damper automatically closes to

prevent drafts and the entrance of insects and rodents. To

avoid restricting the outlet, maintain a minimum 8 inch

clearance between the hood and the ground or other

obstruction.

FIG. #4-

CORRECT

LENGTH OF VENT

PIPE CONNECTION

EXHAUST FLOW EXHAUST FLOW

_______________

Maximum Length of 4” Rigid Duct

INCORRECT

_______

Remove front panel by removing two VT screws inside top

corners of front panel. Disconnect door switch wires.

NOTE position of front seal before removing front panel.

Remove the cylinder as follows:

a. Force idler pulley to the right and remove cylinder belt

from idler and motor pulleys. See FIG. #6.

b. Lift up and turn cylinder to clear the roller supports.

c. Lift out of cabinet.

5. Remove tape and screw securing dryer vent pipe.

6. Remove the 4” dryer vent pipe and shorten to a suitable

length. Length depends on type of elbow purchased.

7. Remove knockout from dryer base.

8. Place dryer in position and mark duct location on floor.

Check floor joist location before sawing hole in floor.

Page 6

9. Saw a AT hole in floor and position dryer.

10. Secure the shortened pipe to the blower housing with a

screw at the top and seal all joints with tape or silicone

bathtub caulk.

11. install a 4” 90 degree elbow as shown.

When exhausting from the side, the installation should be

made according to the steps described in BOTTOM

EXHAUSTING and as noted above.

INDOOR EXHAUSTING

Step #3D shows a typical installation with indoor exhausting.

Indoor exhausting is not recommended unless the laundry

room is large and sufficient cross ventilation is available by

opening two windows, or a door and a window, or where an

exhaust fan is located in the laundry room.

When exhausting indoors, use the Indoor Exhausting Kit and

maintain a minimum clearance of 6 inches between the rear

of the dryer and any adjacent wall. The indoor Exhausting Kit

is available from your dealer under Part No. 53-0298.

SPECIAL REQUIREMENTS FOR MANUFACTURED

(MOBILE) HOME INSTALLATIONS

12. Seal rear opening of cabinet with the cover plate provid

ed with your dryer. Located with literature. Attach cover

plate to rear of the cabinet with #8 sheet metal screws

or duct tape. (Not supplied)

13. Place cylinder belt around cylinder with grooved side

toward cylinder. FIG. #6.

14. Reinstall cylinder by pushing and turning until rollers are

snapped in cylinder grooves and cylinder turns freely.

15. Position cylinder belt with grooved side around motor

pulley. Pull idler pulley right until smooth side of belt can

be routed around left side of idler pulley. FIG. #6.

16. Rotate cylinder counter-clockwise to position belt..

17. Replace dryer front and reconnect door switch wires.

Make sure the front seal is in the original position.

18. Complete exhaust system to outdoors.

SIDE EXHAUSTING

Figure #8 illustrates side exhaust venting pipe connections

inside the dryer cabinet. When venting the dryer from the

side, the cabinet knockout must be removed. A 4” metal

exhaust pipe must be purchased. The rear exhaust pipe

inside the dryer must then be shortened. (Length will depend

on type of elbow purchased.) Secure the shortened pipe to

the Blower Housing with a screw at the top, attach elbow and

metal exhaust pipe, and seal all joints with tape or silicone

bathtub caulk.

Follow steps outlined for installation with these exceptions:

When installed in a manufactured (mobile) home.

1. THE DRYER INSTALLATION must conform to the

Manufactured Home Construction and Safety, Title 24,

HUD (Part 280, 1975).

2. THE DRYER must be attached to the manufactured

(mobile) home structure as follows:

a. Dismantle the dryer as described in bottom exhaust

ing.

b. Buy two #10 1 'k" round head wood screws. Drive them

through the attachment screw holes of the base into

the floor. See FIG. #8 for location.

c. Reassemble the dryer.

2. THE EXHAUST DUCT must be exhausted to the outside

using metal ducting. It should not terminate beneath the

manufactured (mobile) home.

3. THE VENT HOOD must be securely fastened to the

manufactured (mobile) home structure.

THIS DRYER IS NOT SUITABLE FOR USE IN RECRE

ATION VEHICLES SUCH AS TRAVEL TRAILERS,

CAMPERS, OR MOTOR HOMES.

FINAL CHECK OUT

1. Plug dryer in.

2. Following your operating instructions, operate the

dryer briefly on all control settings. A slight odor

may be noticed with a new machine.

3. Allow empty dryer to operate on highest heat

setting for a few minutes.

4. Stop dryer and wipe inside of cylinder with a clean

cloth.

5. Wipe fingerprints and dirt from outside of dryer with

soft cloth.

6. A protective plastic film may cover the control

panel, this should be removed.

Loading...

Loading...