Page 1

GPC X1-LDF liftgate

Installation Manual

for

Mercedes Benz Sprinter

Page 2

LIFT CORP.

11921 Slauson Avenue

Santa Fe Springs, CA 90670-2221

P 800.227.4116 / 562.464.0099

Date 07.2019

Page 3

Contact information

Contact information

MAXON LIFT CORP.

Corporate Office

11921 Slauson Avenue

Santa Fe Springs, CA 90670-2221

P 800.227.4116 / 562.464.0099

F 888.771.7713

Customer Service / Parts

USA/Canada

Mexico

P 800.227.4116

F 888.771.7713

P 01.664.231.6039

Page 4

Contents

IV

Contents

Contact information ................................................................................................ III

Contents ................................................................................................................... IV

1 Safety .................................................................................................................. 1

1.1 Intended use ................................................................................................ 1

1.2 Requirements for personnel ......................................................................... 1

1.3 Requirements for installation and commissioning ........................................ 2

1.4 Fundamental hazards................................................................................... 2

1.5 Emergency procedure .................................................................................. 2

1.6 Presentation of warning notices ................................................................... 3

2 Introduction ....................................................................................................... 4

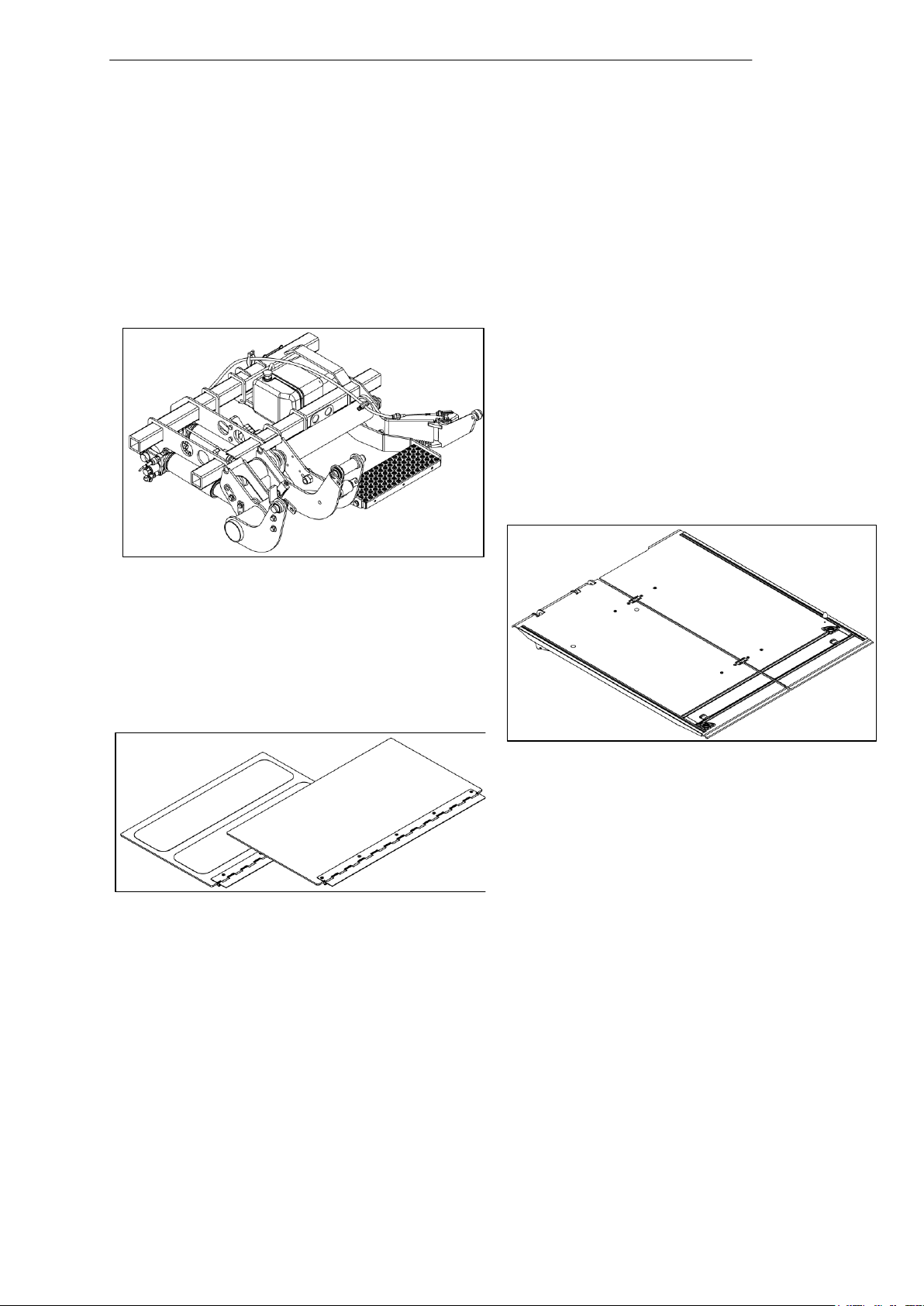

2.1 Scope of delivery .......................................................................................... 4

2.1.1 Lifting gear ........................................................................................ 4

2.1.2 Platform ............................................................................................. 4

2.1.3 Bridge plates (20 909 431) ................................................................ 4

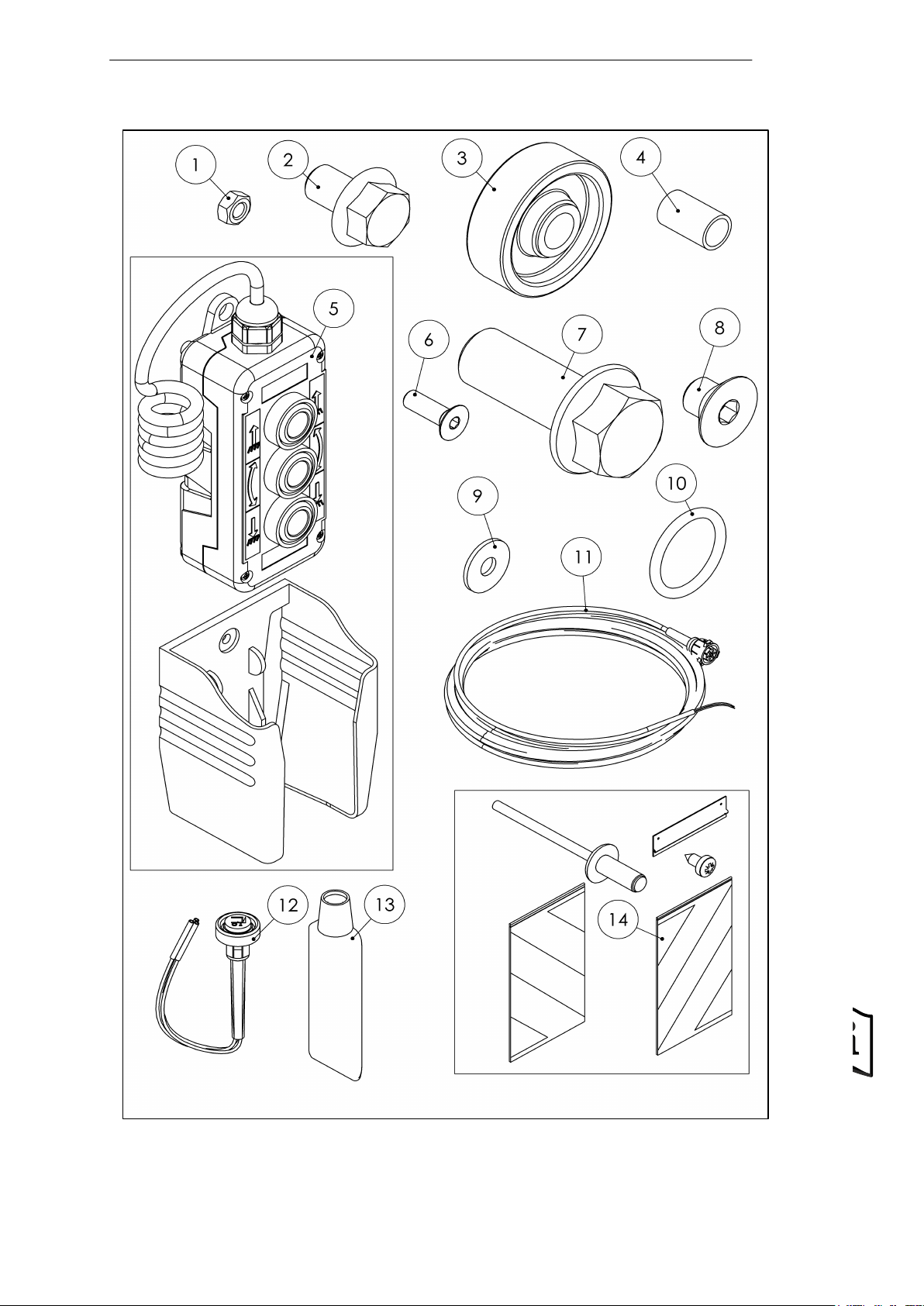

2.1.4 Accessories kit .................................................................................. 5

2.1.5 Installation adapter kit (22 911 216) .................................................. 7

2.2 Damage during transport.............................................................................. 8

3 Preparing for installation .................................................................................. 9

3.1 Requirements for installation ........................................................................ 9

3.2 Lifting the vehicle ......................................................................................... 9

3.3 Preparing the vehicle ................................................................................... 9

3.3.1 Remove spare tire ........................................................................... 10

3.3.2 Move exhaust pipe ................................................................ .......... 10

3.3.3 Mount supplementary battery .......................................................... 10

3.3.4 Install standard bumper on Mercedes Sprinter ................................ 10

3.3.5 Deactivate parking sensors ............................................................. 10

3.3.6 Remove trailer hitch or step ............................................................ 11

3.4 Unpacking the lifting gear, installation adapters, and accessories kit ......... 11

3.5 Pre-installing the installation adapters ........................................................ 11

3.6 Installing the cables/preparation ................................................................. 15

3.6.1 Cable to the platform ....................................................................... 15

3.6.2 Cable for the service switch ............................................................ 15

3.6.3 Routing the cables to the front of the vehicle .................................. 16

3.6.4 Control panel cable on the control unit ............................................ 18

3.6.5 Handheld control (optional) ............................................................. 18

3.7 Aligning the lifting gear ............................................................................... 20

3.8 Mounting holes on the vehicle .................................................................... 21

4 Installation ....................................................................................................... 22

4.1 Positioning the lifting gear .......................................................................... 22

4.2 Tightening the lifting gear fittings until hand-tight ....................................... 23

4.3 Securing the lifting gear to the vehicle........................................................ 26

4.4 Laterally aligning the lifting gear ................................................................. 27

Page 5

Contents

V

4.5 Securing the axle assemblies ..................................................................... 27

4.6 Securing the installation adapters .............................................................. 27

4.7 Connecting the cables to the lifting gear .................................................... 28

4.7.1 Installing and connecting the service switch .................................... 28

4.7.3 Installing and connecting the control panel ..................................... 29

4.7.4 Connecting the handheld control (optional) ..................................... 33

4.7.5 Mounting the bracket for the handheld control (optional) ................ 33

4.7.6 Connecting the cables (front of vehicle) .......................................... 33

4.8 Unpacking the platform .............................................................................. 36

4.9 Raising the platform ................................................................................... 36

4.10 Installing the platform ................................................................................. 37

4.11 Mounting the platform lock on the closing arm ........................................... 41

4.12 Mounting the ground rollers ........................................................................ 42

4.13 Installing supports (vehicle-dependent) ...................................................... 43

4.14 Connecting the platform to the electrical system ........................................ 43

4.14.1 Connecting the platform cable to the electrical system ................... 43

4.14.2 Connecting the license plate light .................................................... 44

4.15 Mounting the license plate holder ............................................................... 45

4.16 Mounting the bridge plates (20 909 431) .................................................... 45

4.17 Mounting the warning flags ........................................................................ 45

4.18 Affixing the danger notice sticker ............................................................... 48

5 Adjusting the liftgate ....................................................................................... 49

5.1 Setting the lift height to the vehicle floor level using the adjustable stop on

the axle assembly .............................................................................................. 49

5.2 Aligning the platform parallel to the vehicle floor ........................................ 49

5.3 Aligning the platform (foldover section) parallel to the vehicle floor ............ 50

5.4 Checking the stop on the foldover section of the platform .......................... 52

5.5 Setting the end stop for the closed platform ............................................... 53

5.6 Adjusting the stopper for fastening the platform ......................................... 55

5.7 Adjusting the support arm for the driving position using the Bowden cable 55

5.8 Programming the tilt sensor ....................................................................... 56

6 Testing the liftgate........................................................................................... 58

6.1 Function test ............................................................................................... 58

6.2 Testing the operating speed ....................................................................... 58

6.2.1 Vertical speed ................................................................................. 58

6.2.2 Closing and opening speed (90° to 10°) .......................................... 58

6.2.3 Tilting speed (10° to -10°)................................................................ 58

6.3 Load tests ................................................................................................... 59

6.3.1 Static test ........................................................................................ 59

6.3.2 Dynamic test ................................................................................... 59

6.3.3 Testing against lifting an overload ................................................... 59

6.3.4 Testing the safety devices ............................................................... 59

6.4 Explanation of diagnostic LED on the control unit ...................................... 60

6.4.1 Checking tilt sensors S1 and S2 in the platform .............................. 61

6.4.2 Checking pressure switch S4 .......................................................... 61

Page 6

Contents

VI

6.5 Entry in inspection record book .................................................................. 61

7 Recommendations and instructions regarding the liftgate ......................... 62

7.1 Hydraulic oil recommendations .................................................................. 62

7.2 Painting the lifting gear ................................................................ ............... 62

7.3 Rating plate ................................................................................................ 62

8 Useful information ........................................................................................... 63

8.1 About the service switch............................................................................. 63

8.2 Assembly drawings of installation adapters ................................................ 65

8.3 Electrical circuit diagram ............................................................................ 66

8.4 Hydraulic circuit diagram ............................................................................ 67

8.5 Torque table ............................................................................................... 68

8.6 Activating the liftgate .................................................................................. 69

8.7 Operation using the control panel .............................................................. 69

8.8 Operation using the optional handheld control ........................................... 70

Page 7

Safety

1

1 Safety

1.1 Intended use

This liftgate was specially developed for cargo vans. It may be used only on the

vehicles for which it was designed.

To determine whether the liftgate may be installed on a specific vehicle, please

contact the manufacturer or customer service.

The liftgate is used for loading and unloading the vehicle and for transferring loads.

Any other use is prohibited.

Do not exceed the maximum load carrying capacity (see rating plate). Be sure to

correctly position the load on the platform.

Do not operate the liftgate with the vehicle in motion.

Do not use the liftgate to lift any person other than the operator.

This manual is intended for the manufacturer who installs the liftgate on the vehicle. It

contains information on transport, installation, and commissioning.

Read this manual before working on or operating the liftgate.

Do not deviate from the instructions contained in this manual. By doing so, you

risk injury, damage to property, and voiding of the warranty.

Make sure that this manual always remains with the liftgate or vehicle.

IMPORTANT: For information on operation, cleaning, maintenance,

decommissioning, disassembly, and disposal, refer to the accompanying user

manual.

1.2 Requirements for personnel

The tasks described in this manual may be performed only by qualified and

trained personnel.

Use personal safety gear when performing these tasks: protective goggles, work

gloves, and protective footwear.

Perform these tasks at an appropriate working height with the body in an

appropriate position. Avoid unusual positions.

Comply with valid legal and operational guidelines, such as occupational safety

regulations and environmental regulations.

Page 8

Safety

2

1.3 Requirements for installation and commissioning

Follow the vehicle manufacturer’s current installation guidelines for the relevant

vehicle. Pay particular attention to safety instructions and warnings.

Changes to the liftgate’s axle assemblies and to the necessary installation

adapters are prohibited and invalidate approval by the German Federal Motor

Transport Authority.

Do not modify or remove safety equipment (pressure limiting valves, non-return

valves, electrical fuses, and software control routines). By doing so, you risk

serious injury.

Do not modify, cover, or remove product labels (warning labels, instructions,

rating plates).

1.4 Fundamental hazards

Electrical system with on-board voltage:

The liftgate receives electrical power from the vehicle’s on-board power supply (max.

48 V DC). The electrical system is designed using state-of-the-art technology.

Do not damage or modify electrical components or wiring.

High-pressure hydraulic system:

The liftgate’s hydraulic system operates at high pressure (max. 220 bar). The

hydraulic system is designed using state-of-the-art technology.

Do not damage or modify hydraulic components or hoses.

Moving parts with crushing points:

All parts that move in close proximity to one another can potentially crush fingers.

Watch out for the unexpected movement of moving parts.

Hinges with crushing points (on liftgate with platform foldover section):

Fingers are at risk of being crushed in the hinge area when the platform is folded and

unfolded.

Be careful when folding and unfolding the platform.

1.5 Emergency procedure

If you or another person working on or operating the liftgate experience a dangerous

situation:

Immediately stop what you’re doing and seek expert help.

Page 9

Safety

3

WARNING

Failure to heed this notice can result in death or serious

injury.

CAUTION

Failure to heed this notice can result in minor or moderate

injury.

NOTICE

Failure to heed this notice can result in damage to property

or the environment.

1.6 Presentation of warning notices

The following types of notices are used in this manual to identify hazards and

complications:

And:

IMPORTANT

Important information or useful tip for correct use.

Page 10

Introduction

4

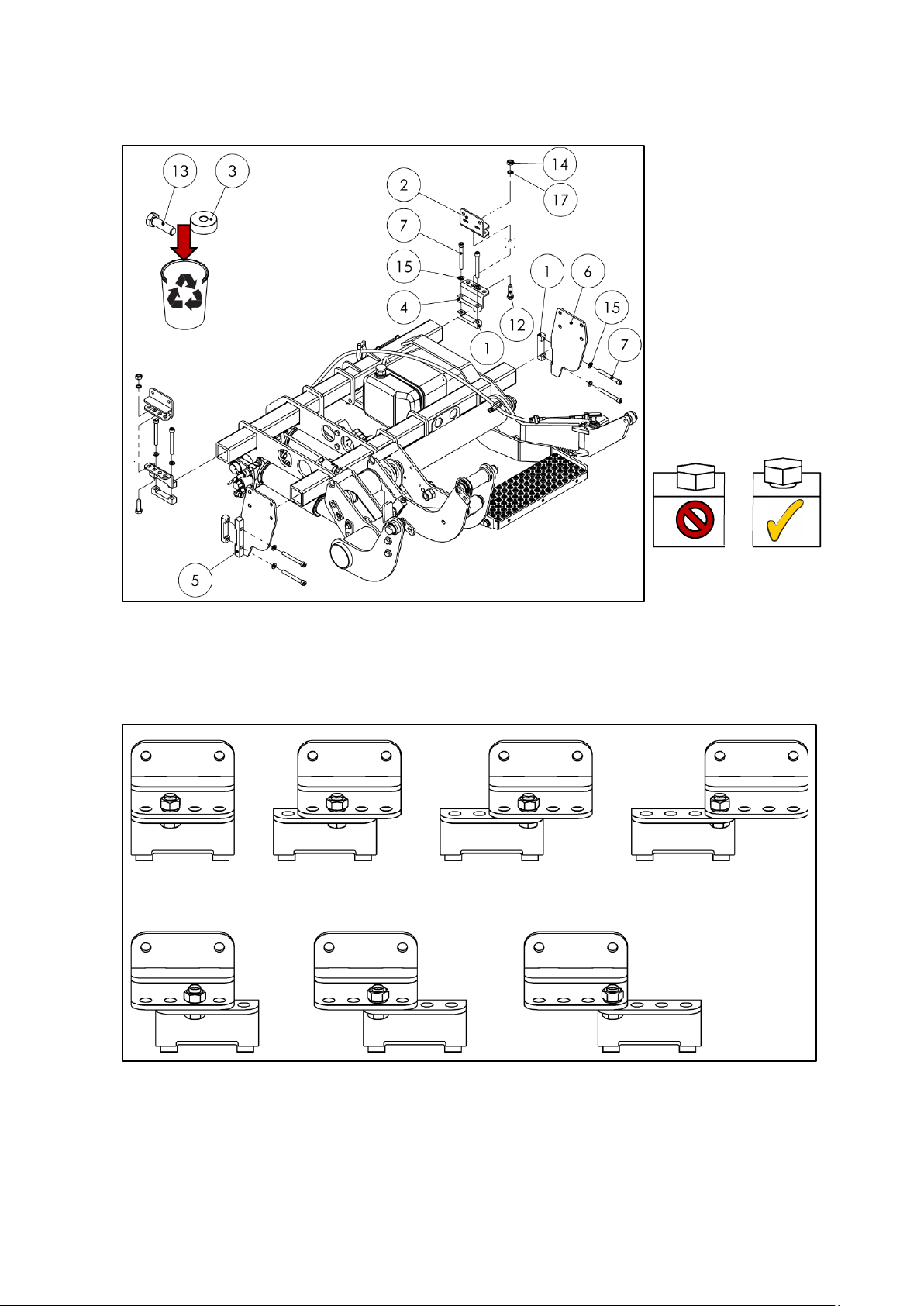

Fig. 3

Fig. 1

Fig. 2

2 Introduction

2.1 Scope of delivery

IMPORTANT: All illustrations of the lifting gear are shown without factory-installed

cables and hydraulic hoses.

2.1.1 Lifting gear

2.1.2 Platform

2.1.3 Bridge plates (20 909 431)

Page 11

Introduction

5

Fig. 4

2.1.4 Accessories kit

Page 12

Introduction

6

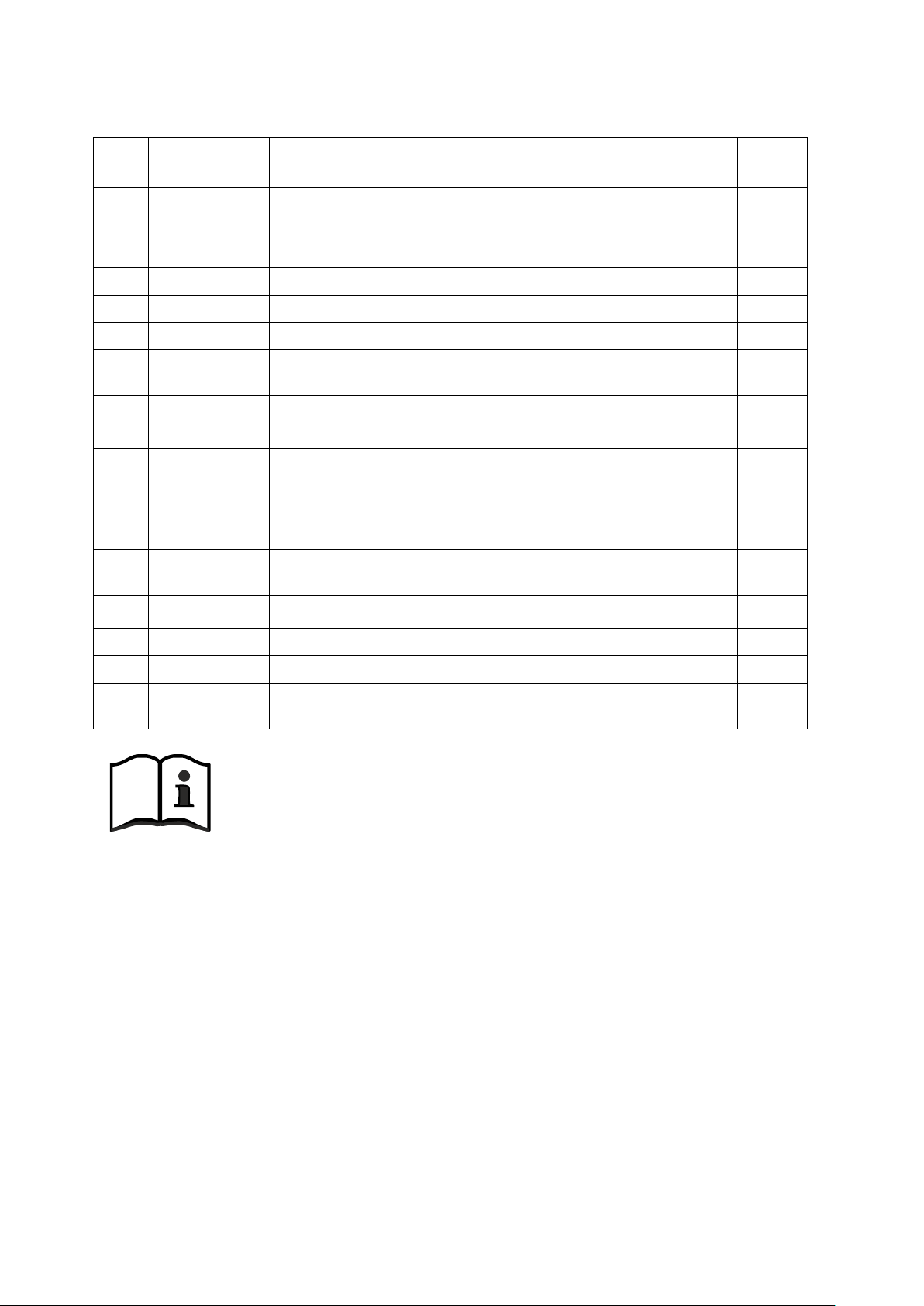

Item

No.

Part No.

Description

Standard

Qty.

1

80 000 046

Hexagon nut

DIN 934 - M5 - A2

4

2

20 908 251

Hexagon flange bolt

DIN 6921 - M10x15 - 10.9 - ZN

2

3

20 907 616

Ground roller

2 4

20 907 615

Bushing

d20/16x32

2

5

20 907 200

Handheld control

3-button

1

6

20 904 647

Countersunk screw with

hexagon socket

ISO 10642 - M5x16 - A2

4

7

20 904 600

Flange screw

W 0263 - M16x40 - 10.9 - GEO

2

8

20 901 791

Countersunk screw with

hexagon socket

DIN 7991 - M10x12 - A2

1

9

20 850 543

Washer

DIN 9021 - D5,3 - A2

4

10

20 840 117

O-ring

40.65x5.33

6

11

20 906 975

12 m cable with VEHH

connector

1

12

20 906 974

Cabin switch

1

13

20 840 405

Lubricating grease

1 14

60 710 330

Warning flag

Kit

1

15

-------------

Accompanying

documentation

6

Parts list – accessories kit

Accompanying documents:

Inspection booklet Part No. 60 700 495

Installation manual Part No. 20 912 027

User manual Part No. 20 908 422

Oil-level sticker Part No. 20 911 907

Electrical circuit diagram Part No. 20 910 824

Hydraulic circuit diagram Part No. 20 908 421

IMPORTANT: As a general rule, only existing mounting points (holes in the vehicle

chassis) may be used for installation. Different installation adapters are available for

each vehicle type as described below.

Page 13

Introduction

7

Fig. 5

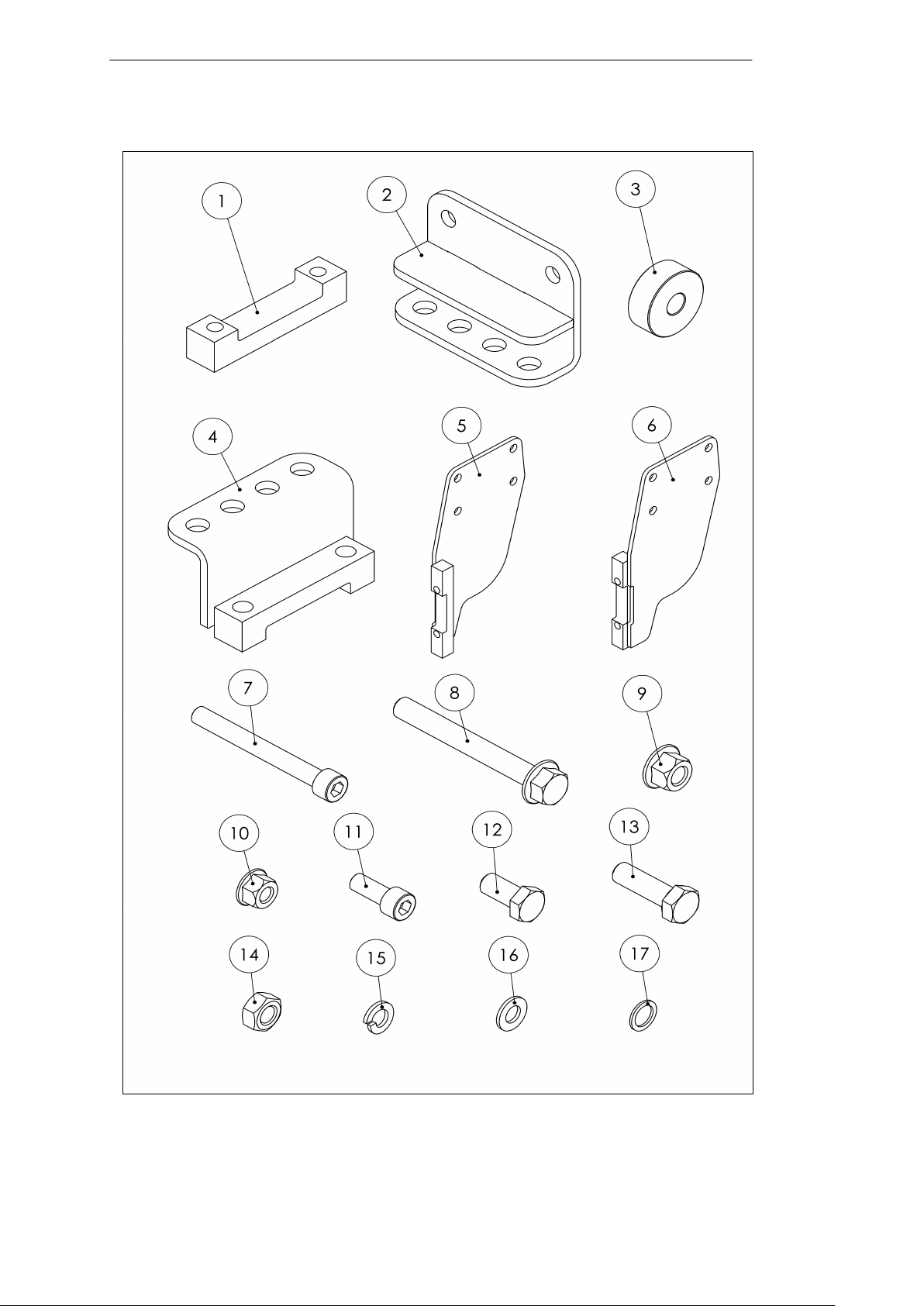

2.1.5 Installation adapter kit (22 911 216)

Page 14

Introduction

8

Item

No.

Part No.

Description

Standard

Qty.

1

20 908 103

Bracket

4

2

20 908 322

Installation adapter

2

3

20 908 395

Spacer ring

2

4

20 908 398

Installation adapter

2

5

20 908 639

Installation adapter

1

6

20 908 640

Installation adapter

1

7

20 909 327

Cheese-head screw

with hexagon socket

DIN 912 - M10x90 - 8.8 - ZN - PRE80

8

8

20 911 796

Hexagon flange bolt

MBN 10105 - M12x1.5x100 - 10.9 DBL

8

9

20 911 797

Hexagon nut with

flange and clamping

piece

MBN 13023 - M12x1.5 - 10 - DBL

8

10

20 911 864

Hexagon nut with

flange and clamping

piece

MBN 13023 - M10 - 10 - DBL

4

11

22 902 352

Cheese-head screw

with hexagon socket

ISO 4762 - M10x25 - 10.9 - ZFSHL

4

12

80 000 029

Hexagon head screw

ISO 4017 - M12x25 - 8.8 - ZFSHL

2

13

80 000 032

Hexagon head screw

DIN 933 - M12x40 - 8.8 - A2K

2

14

80 000 050

Hexagon nut

DIN 934 - M12 - 8 - A2K

2

15

80 000 061

Spring washer

DIN 127 – A – 10 - ZN

8

16

80 000 072

Washer

ISO 7089 - A - D10 - ZFSH

4

17

80 000 253

Lock washer

VS - D12 - Gal.ZN8

2

18

20 912 022

Cheese-head screw

with hexagon socket

MBN 10105 - M10x100 - 10.9 - DBL

4

Parts list – installation adapter kit (Part No. 22 911 216)

2.2 Damage during transport

After unloading, inspect the liftgate for damage. If any damage is found, record it in

writing on the shipper’s waybill so that claims can be asserted.

Page 15

Preparing for installation

9

CAUTION

Unsuitable transport equipment

When transporting and lifting heavy parts, use transport equipment (e.g. cranes,

pallet trucks, or other lifting gear) with a sufficient load carrying capacity.

Verify the correct and reliable functioning of the transport equipment.

3 Preparing for installation

3.1 Requirements for installation

The vehicle exhaust must not be located at the rear of the vehicle.

Line the vehicle floor with wood panels. For other types of flooring, verify whether

installation is possible.

The rear doors must open to a minimum angle of 180°.

A spare tire must not be located between the rear axle and rear bumper.

The liftgate cannot be installed if the rear bumper has an integrated step. In this

case, the vehicle must be fitted with a standard bumper.

A step must not be installed behind the bumper.

A supplementary battery and switching strip must be present.

For vehicles with rear parking sensors, the sensors will no longer function

correctly once the platform is installed, because the lifting gear interferes with the

sensors.

3.2 Lifting the vehicle

Lift the vehicle using a lifting platform.

IMPORTANT: Installation over a pit is also possible, in which case the vehicle must

also be raised (using winches or wedges) so that the liftgate and pallet can be

inserted under the vehicle.

3.3 Preparing the vehicle

Secure the vehicle in place to prevent unintentional movement.

Disconnect the vehicle battery. Follow the vehicle manufacturer’s instructions for

correctly handling the battery.

Be careful not to damage the vehicle. We recommend using appropriate

coverings.

Page 16

Preparing for installation

10

NOTICE

Be sure to maintain a sufficient

distance from heat-sensitive

parts. The minimum distance

from plastics and cables is

300 mm (see Fig. 7).

Fig. 6

Fig. 7

Fig. 8

Fig. 9

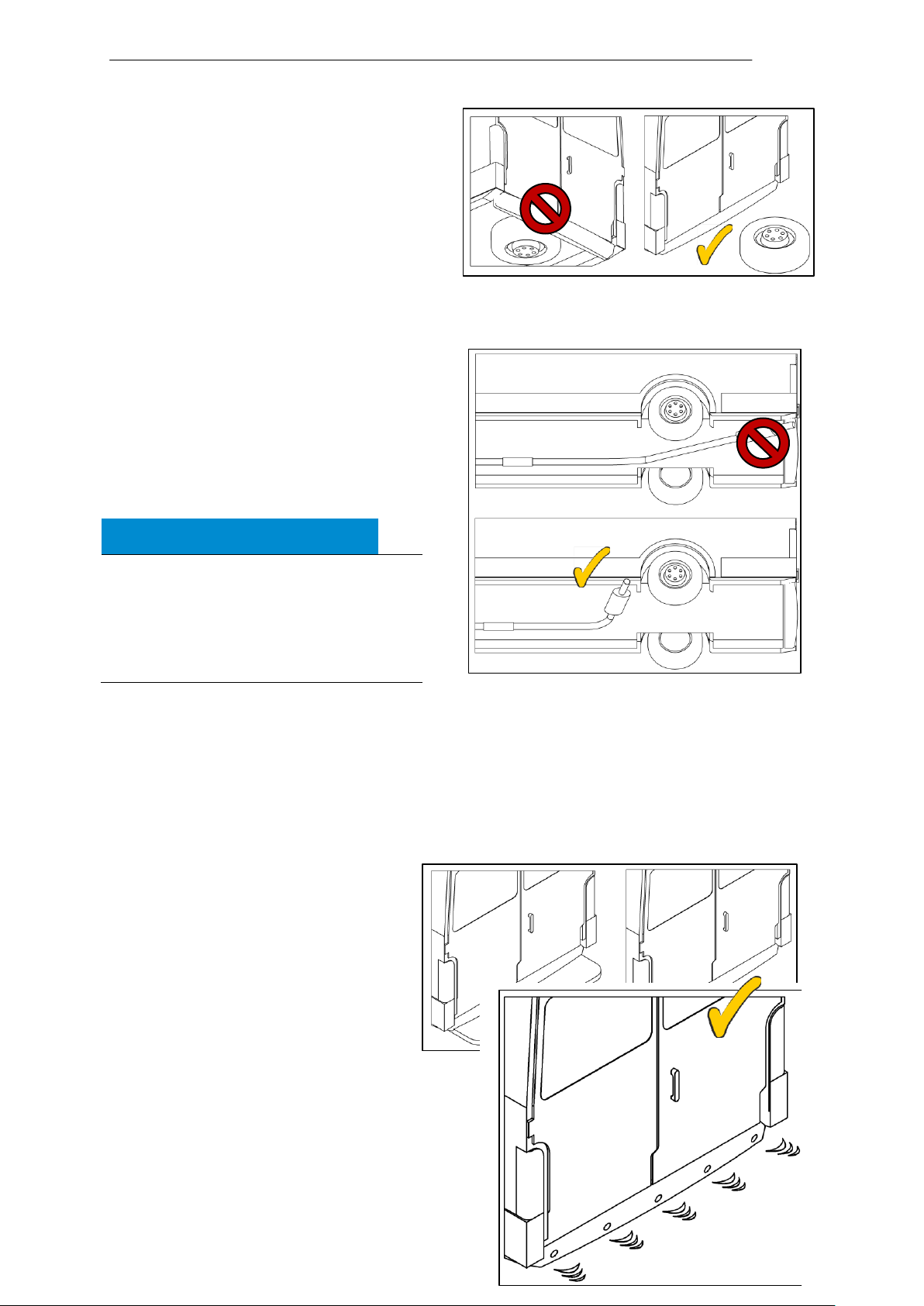

3.3.1 Remove spare tire

If the vehicle has a spare tire

between the rear axle and the rear

bumper, remove the tire

(see Fig. 6).

3.3.2 Move exhaust pipe

If the exhaust pipe is at the rear,

move it to the side.

IMPORTANT: Changes to the exhaust

system must be carried out by qualified

personnel and according to the vehicle

manufacturer’s guidelines.

3.3.3 Mount supplementary battery

If applicable, mount a supplementary battery to supply power to the liftgate.

3.3.4 Install standard bumper

on Mercedes Sprinter

If the vehicle has a bumper

with an integrated step,

replace it with a standard

bumper (see Fig. 8).

3.3.5 Deactivate parking

sensors

For vehicles with rear parking sensors,

the sensors will no longer function

correctly once the platform is installed,

Page 17

Preparing for installation

11

CAUTION

Unsecured, heavy parts

When transport locks are removed, parts may fall or tip over and the platform may tip

over. Risk of injury.

Secure loose parts. Remove transport locks carefully.

After disposing of packing materials, store all parts in a secured manner.

NOTICE

Oil leakage

Incorrect positioning of the lifting gear can result in oil leakage. Risk of environmental

damage.

Always transport the lifting gear in an upright position using suitable lifting points.

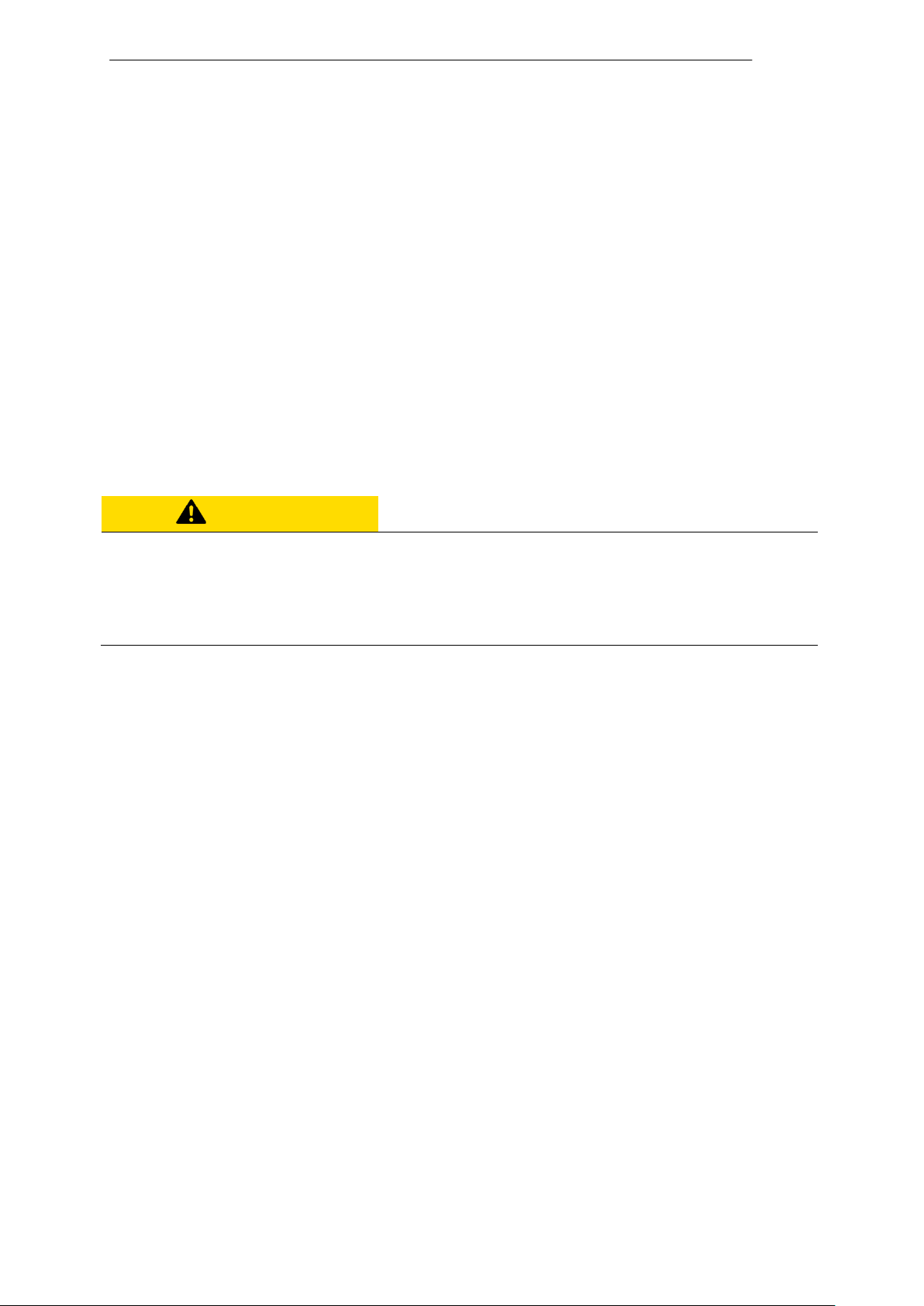

Item

No.

Part No.

Description

Standard

Qty.

1

20 908 103

Bracket

4

2

20 908 322

Installation adapter

2

Fig. 10

because the lifting gear interferes with the sensors (see Fig. 9).

3.3.6 Remove trailer hitch or step

If a trailer hitch or step is mounted

on the vehicle, remove it

(see Fig. 10).

3.4 Unpacking the lifting

gear, installation adapters, and accessories kit

Check the scope of delivery for completeness (see pages 4 – 8).

IMPORTANT: Dispose of all packing materials in accordance with environmental

regulations.

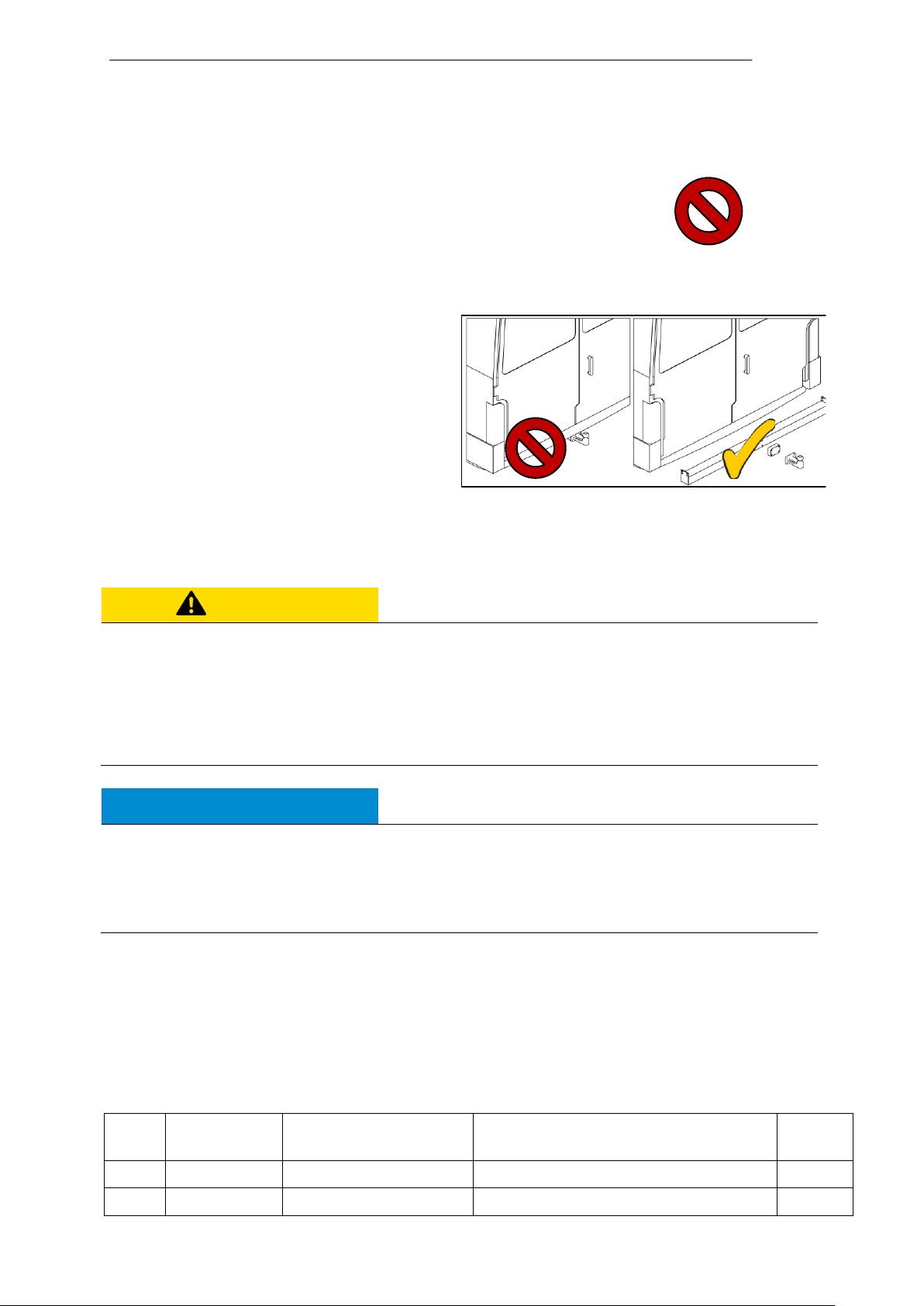

3.5 Pre-installing the installation adapters

Required material from installation adapter kit (Part No. 22 911 216)

Page 18

Preparing for installation

12

3

20 908 395

Spacer ring

2

4

20 908 398

Installation adapter

2

5

20 908 639

Installation adapter

1

6

20 908 640

Installation adapter

1

7

20 909 327

Cheese-head screw

with hexagon socket

DIN 912 - M10x90 - 8.8 - ZN PRE80

8

12

80 000 029

Hexagon head screw

ISO 4017 - M12x25 - 8.8 ZFSHL

2

13

80 000 032

Hexagon head screw

DIN 933 - M12x40 - 8.8 - A2K

2

14

80 000 050

Hexagon nut

DIN 934 - M12 - 8 - A2K

2

15

80 000 061

Spring washer

DIN 127 - A - 10 - ZN

8

Fig. 11

Pre-install the installation adapters on the liftgate’s lifting gear as shown in Fig. 11

or Fig. 13, tightening the fittings until hand-tight.

IMPORTANT: Depending on the vehicle, choose either the 3.5 ton (see Fig. 11) or 5

ton (see Fig. 13) installation version.

Vehicle with maximum authorized mass of 3.5 tons

(for 5 ton vehicles, see next page)

Page 19

Preparing for installation

13

Fig. 12

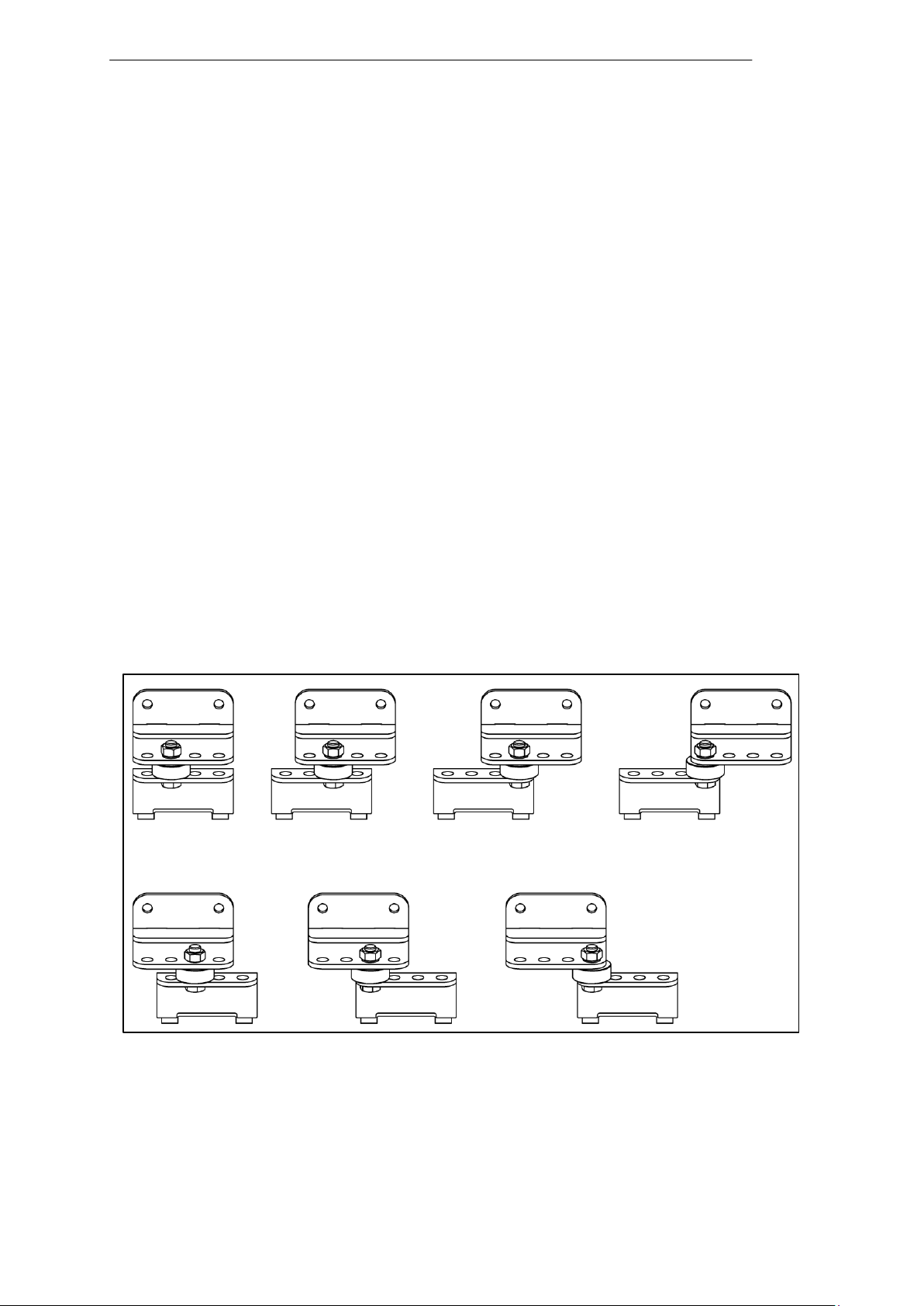

Depending on requirements, different installation options are available for the front

installation adapters (2 and 4) in the installation adapter kit (Part No. 22 911 216)

(see Fig. 12).

Page 20

Preparing for installation

14

Fig. 13

Fig. 14

Vehicle with maximum authorized mass of 5 tons

(for 3.5 ton vehicles, see previous page)

Depending on requirements, different installation options are available for the front

installation adapters (2 and 4) in the installation adapter kit (Part No. 22 911 216)

(see Fig. 14).

Page 21

Preparing for installation

15

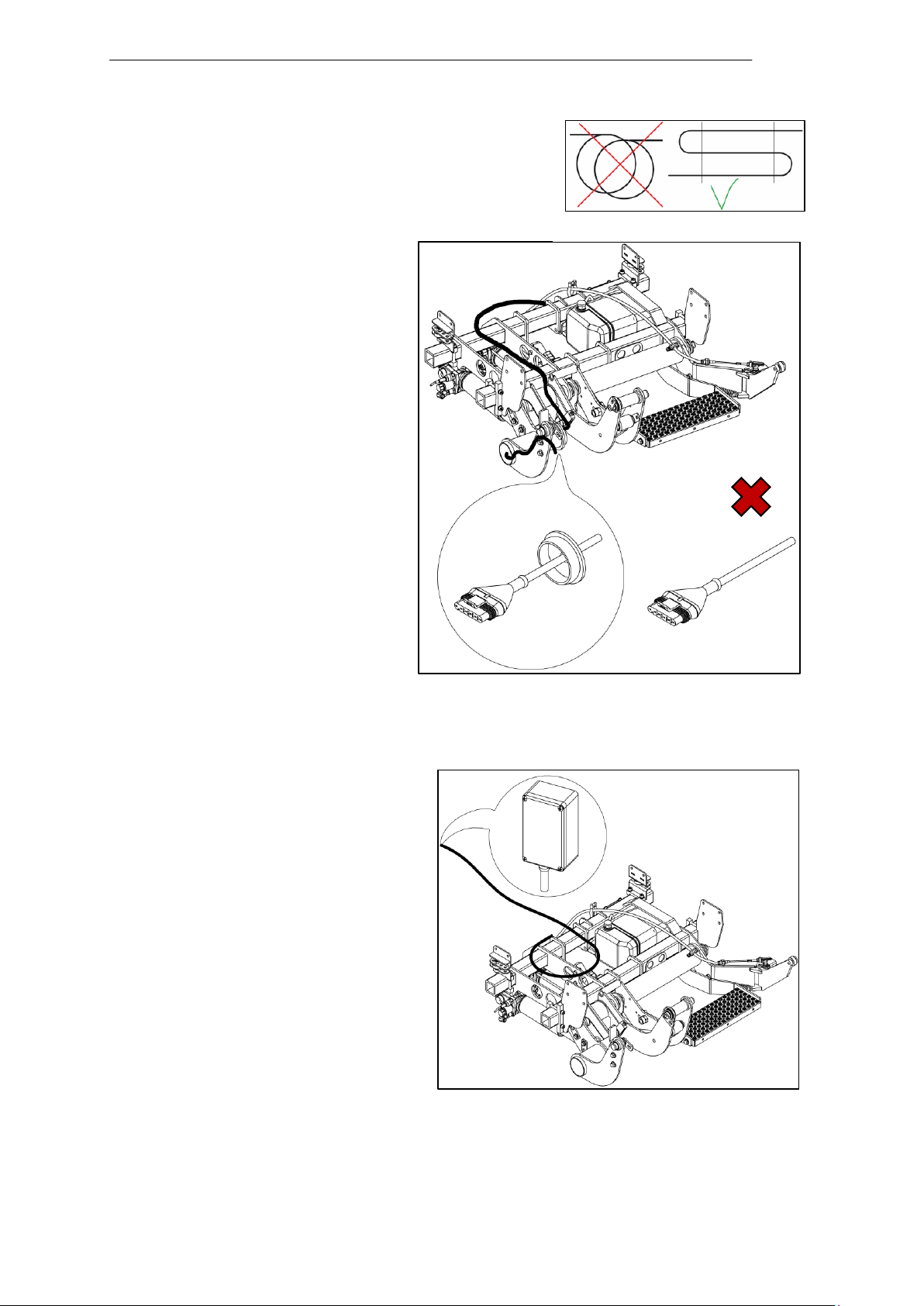

Fig. 16

Fig. 17

Fig. 15

3.6 Installing the cables/preparation

IMPORTANT: Excess cable must not be wound up

in a coil but must be placed in slings.

(Fig. 15).

3.6.1 Cable to the platform

Route the control unit cable for

platform connection (white

plastic cover) to the swing-arm

assembly in the center of the

vehicle (Fig. 16).

3.6.2 Cable for the service

switch

Route the control unit cable for

service switch connection to the

vehicle cargo area (Fig. 17).

Page 22

Preparing for installation

16

NOTICE

When installing cables, make sure they are safe from chafing.

Do not install cables near heat-dissipating components.

Fig. 18

3.6.3 Routing the cables to the front of the vehicle

For more information, look online under

http://www.taillift.org/en/electrical-vehicle-interface

IMPORTANT: Follow the vehicle manufacturer’s installation guidelines.

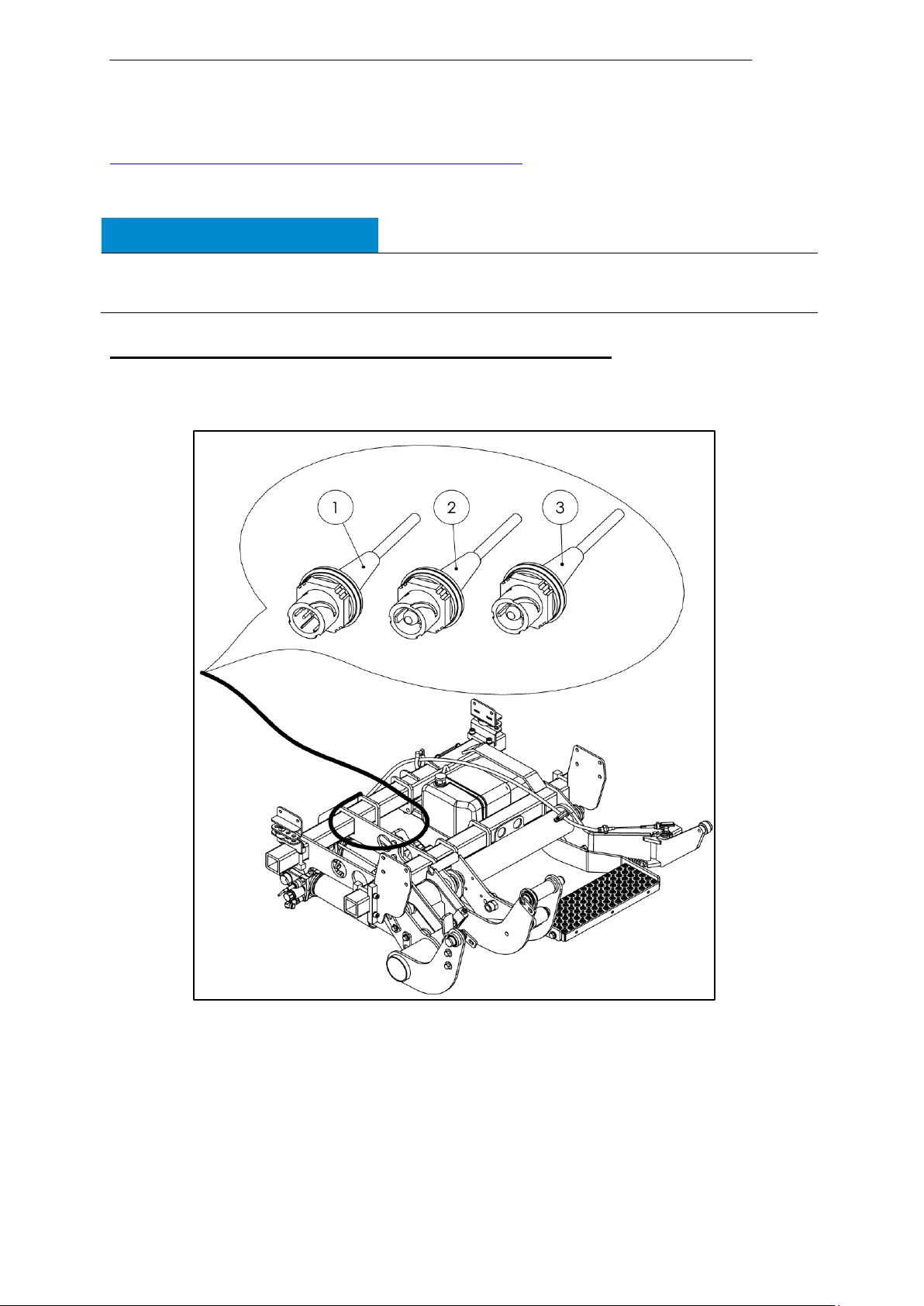

With preparation according to ETMA Code A and Code B

Route the power cable and the cable for the cabin switch unit to the junction box

provided (Fig. 18).

Legen

d:

Item 1 Connector for cabin switch unit Part No. 20 910 754

Item 2 Connector for positive cable (red) Part No. 20 907 673

Item 3 Connector for negative cable (blue) Part No. 20 907 673

Page 23

Preparing for installation

17

NOTICE

Do not yet connect the cables.

Fig. 19

Fig. 20

No preparation according to ETMA Code A and Code B

Power cable

Insert the positive cable (25 mm² red) (“power unit cable”) for the power supply

into a length of slit corrugated tubing (see Fig. 19).

Route the positive cable

(red) and negative cable

(blue) to the terminals but

do not yet connect them

(see Fig. 20).

Legend:

Item 1 Positive cable (red) Part No. 20 907 673

Item 2 Negative cable (blue) Part No. 20 907 673

Item 3 Connector for cabin switch unit Part No. 20 910 754

Page 24

Preparing for installation

18

Fig. 22

click!

Cable for cabin switch unit

Route the cabin switch cable from the accessories kit (Item No. 11) to the

driver’s cabin (see Fig. 21).

Connect the cabin switch cable to the 7-pin connector (DIN 72585) from the

control unit.

Fig. 21

Legend:

Item 1 7-pin connector (DIN 72585) from control unit

Item 2 Connector for cabin switch unit Part No. 20 910 754

3.6.4 Control panel cable on the

control unit

Route the control unit cable for

control panel connection to the

right as viewed in the forward

direction of travel (see Fig. 22).

3.6.5 Handheld control

Page 25

Preparing for installation

19

Fig. 23

Fig. 24

1

(optional)

Prepare the cable on the control unit

Sever the control unit cable (1, red

marking with cable tie) for connecting

the handheld control (see Fig. 23)

Leave the end without a cable tie

blank.

Strip the end of the control unit cable section with a red marking for connecting the

handheld control (see Fig. 24).

Page 26

Preparing for installation

20

Fig. 25

Fig. 26

Handheld control

Determine the installation

location for the handheld

control and route the cable to

the installation location

(see Fig. 25).

Find the bushing into the cargo

area.

3.7 Aligning the lifting

gear

Align the lifting gear under

the vehicle on a mounting

tool or pallet (see Fig. 26).

Page 27

Preparing for installation

21

Fig. 27

Line up the installation adapters on the lifting gear with the manufacturer’s holes

in the vehicle chassis (see Fig. 27).

3.8 Mounting holes on the vehicle

IMPORTANT: Follow the vehicle manufacturer’s installation guidelines.

Find the mounting holes on the vehicle.

Make any new mounting holes that are necessary.

If necessary, weld spacer sleeves onto the vehicle chassis.

Remove underbody coating in the area of the mounting points (contact surfaces

between vehicle and installation adapters).

Seal any areas of the vehicle body that are thus exposed (with corrosion

protection).

Page 28

Installation

22

Fig. 28

4 Installation

4.1 Positioning the lifting gear

Place the prepared lifting gear (on a pallet) under the vehicle using a suitable

means of transport, e.g. pallet truck, forklift, etc. (see Fig. 28).

Page 29

Installation

23

WARNING

Installation at crushing and shearing points

Fingers are at risk of being crushed or sheared when the lifting gear is installed on

the vehicle.

Be careful at the connecting points between the lifting gear and vehicle.

NOTICE

Do not damage cables.

Item

No.

Part No.

Description

Standard

Qty.

8

20 911 796

Hexagon flange bolt

MBN 10105 - M12x1.5x100 - 10.9 DBL

8

9

20 911 797

Hexagon nut with

flange and clamping

piece

MBN 13023 - M12x1.5 - 10 - DBL

8

Fig. 29

4.2 Tightening the lifting gear fittings until hand-tight

Raise the lifting gear. Insert the rear bolts (installation adapter kit – Part No. 22

911 216) as viewed in the forward direction of travel and tighten until hand-tight

as shown in Fig. 29.

Excerpt from parts list: Installation adapter kit (Part No. 22 911 216)

Page 30

Installation

24

NOTICE

Do not damage cables.

Item

No.

Part No.

Description

Standard

Qty.

10

20 911 864

Hexagon nut with flange

and clamping piece

MBN 13023 - M10 - 10 - DBL

4

11

22 902 352

Cheese-head screw with

hexagon socket

ISO 4762 - M10x25 - 10.9 ZFSHL

4

16

80 000 072

Washer

ISO 7089 - A - D10 - ZFSH

4

Fig. 30

Insert the front bolts (installation adapter kit – Part No. 22 911 216) as viewed

in the forward direction of travel and tighten until hand-tight as shown in Fig. 30.

Excerpt from parts list: Installation adapter kit (Part No. 22 911 216)

Page 31

Installation

25

NOTICE

Do not damage cables

Item

No.

Part No.

Description

Standard

Qty.

10

20 911 864

Hexagon nut with flange

and clamping piece

MBN 13023 - M10 - 10 - DBL

4

18

20 912 022

Cheese-head screw with

hexagon socket

ISO 4762 - M10x - 10.9 ZFSHL

4

Fig. 31

Optional: Insert the front bolts (installation adapter kit – Part No. 22 911 216) as

viewed in the forward direction of travel and tighten until hand-tight as shown in Fig. 31.

Legend:

a Welded-on bushing as per manufacturer’s installation guidelines

Excerpt from parts list: Installation adapter kit (Part No. 22 911 216)

Page 32

Installation

26

Fig. 32

4.3 Securing the lifting gear to the vehicle

Secure the lifting gear (with adapters) to the vehicle and tighten to a torque of

115 Nm in the rear and 70 Nm in front (see Fig. 32).

Page 33

Installation

27

Fig. 34

Fig. 33

Fig. 35

4.4 Laterally

aligning the

lifting gear

Shift the lifting gear to

the left so that the

brand emblem on the

rear door does not

collide with the platform

(see Fig. 33).

4.5 Securing the axle

assemblies

Secure the installation adapters to the

lifting gear and tighten to the specified

torque of 53 Nm (see Fig. 34).

4.6 Securing the installation

adapters

Secure the front installation adapters

to the lifting gear and tighten to a

torque of 70 Nm (see Fig. 35).

Page 34

Installation

28

Fig. 36

4.7 Connecting the cables to the lifting gear

4.7.1 Installing and connecting the service switch

Disconnect the service switch box from the cable by loosening the screw

terminals in the housing (see Fig. 36).

Legend:

Terminal 30 Black cable

Terminal Y1 Blue cable

Terminal KM Gray cable

Terminal YA Brown cable

Terminal Y3 Green/yellow cable

Route the cable to the cargo area via a bushing opening.

Reconnect the service switch to the routed cable as shown in Fig. 36.

Secure the service switch box.

Page 35

Installation

29

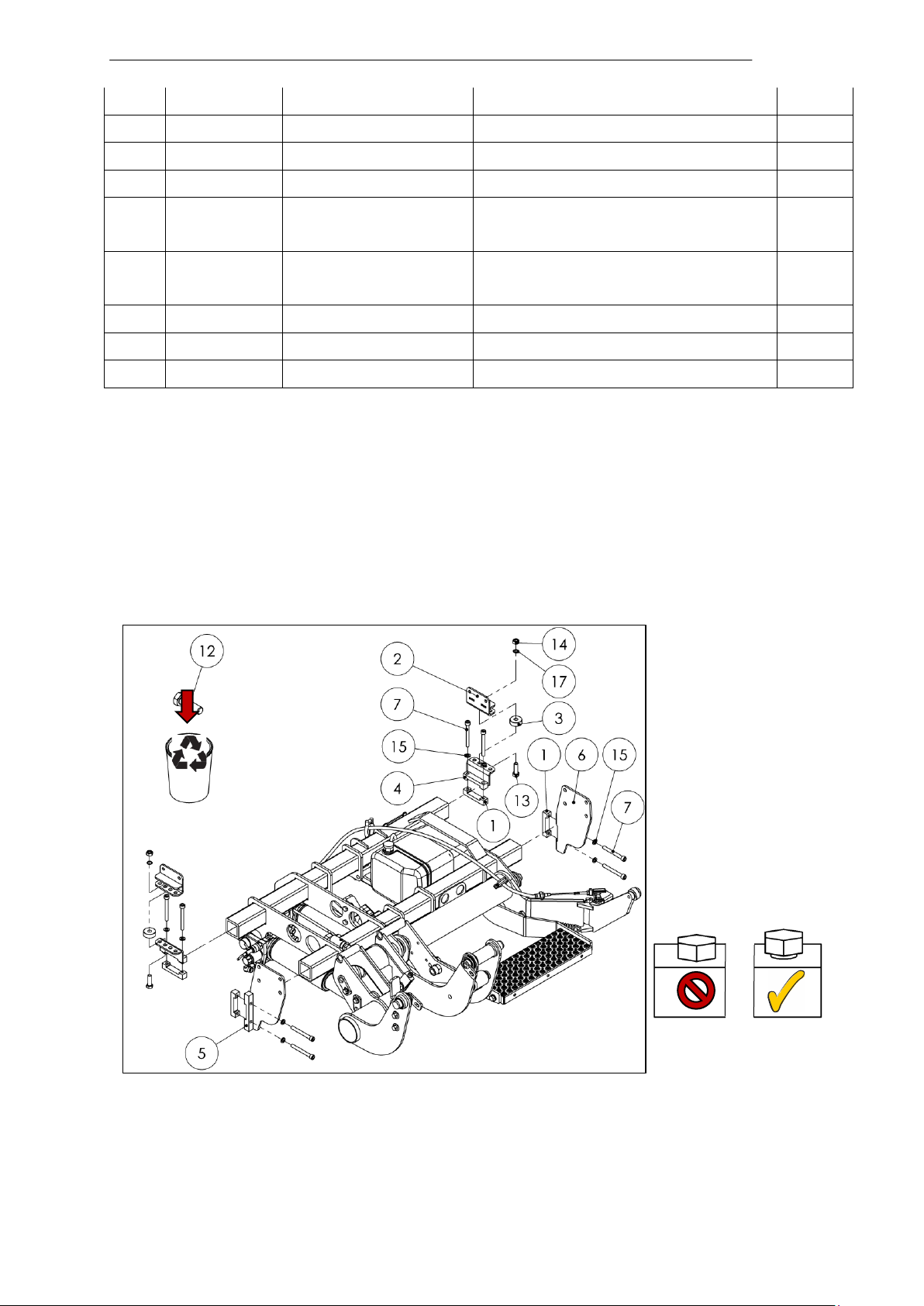

WARNING

Penetration of water

Over the long term, the improper installation of cables can result in water penetrating

the control panel and causing it to malfunction.

Risk of serious injury in subsequent operation.

Route the cable to the control panel only from below.

Fig. 37

4.7.3 Installing and connecting the control panel

Mount the control panel on door

Route the control panel cable to the cargo area so that it can be secured to the

right-hand door (a) (protect against kinks and ensure correct cable length for fully

opened door, using corrugated tubing if necessary) (see Fig. 37).

Disassemble the control panel SUPERSEAL connector and, if appropriate, the

control unit SUPERSEAL connector so that the control panel cable can be

routed to the control unit cable via openings.

Page 36

Installation

30

Control unit wires (1)

Pin No. and Wire No.

Control panel wires (2)

Black

1

Black

Brown

2

Black

Gray

3

Black

Blue

4

Black

White

5

Green/yellow

Green/yellow

6

Fig. 40

Fig. 39

Fig. 42

Fig. 44

Fig. 38

Fig. 41

Fig. 43

IMPORTANT: A release tool is required for disassembling the SUPERSEAL

connector.

IMPORTANT: When

reassembling, pay

attention to the position of

the individual wires! Return

the wires to their original

positions (see Fig. 39 for 1

and Fig. 38 for 2).

Legend:

Item 1 Socket housing

(Fig. 39) of the control unit

Item 2 Pin housing (Fig. 38) of the control panel

Using the release tool,

release the safety guard

from the socket housing

and pin housing (see

Fig. 40 and Fig. 41).

For the socket

housing, release

the latches on the

contact pins and

pull the wires out of

the back of the

housing (see

Fig. 42 and Fig. 43).

For the pin housing, first use the

release tool to pry out the safety

guard (see Fig. 44).

Page 37

Installation

31

Fig. 46

Fig. 45

For the pin housing, release the latches on the contact pins and pull the wires out

of the back of the housing (Fig. 45 and Fig. 46).

Reassemble the control panel SUPERSEAL connector and the control unit

SUPERSEAL connector.

Page 38

Installation

32

Item No.

Part No.

Description

Standard

Qty.

1

80 000 046

Hexagon nut

DIN 934 - M5 - A2

4

6

20 904 647

Countersunk screw

with hexagon socket

ISO 10642 - M5x16 - A2

4

9

20 850 543

Washer

DIN 9021 - D5,3 - A2

4

Fig. 47

click!

Fig. 48

X

Connect the control panel connector (1) to the control unit connector (2) (see

Fig. 47).

Legend:

Item 1 Connector from control

panel for connection to

control unit

Item 2 Connector from control

unit for connection to

control panel

Secure the control panel (b) to the right-hand vehicle door (a) using the fasteners

(1, 6, 9) from the accessories kit, maintaining a distance of 400 mm +/-100 mm

(15 ¾” +/- 1 15/16”) as per specifications

(see Fig. 37 und Fig. 48).

Required material from accessories kit

Legend:

Item a Right-hand vehicle door

Item b Control panel

X = distance

400 mm +/-100 mm

(15 3/4“ +/- 1 15/16“)

Page 39

Installation

33

Connection

Function

Control unit cable

Handheld control cable

+

+

Black wire

Red wire

1

Lift

Blue wire

Blue wire

2

Lower

Gray wire

Gray wire

3

Tilt up/down

Brown wire

Brown wire

4

31 (ground)

Green/yellow wire

Fig. 50

Fig. 49

4.7.4 Connecting the handheld control (optional)

Connect the cable from the handheld control (2) to the stripped control unit cable

section (1) with the red marking at the installation location (see Fig. 49).

Legend:

Item 1 Control unit

Item 2 Handheld control

4.7.5 Mounting the bracket for the handheld control (optional)

Mount the bracket (1) for the handheld control (2) on the vehicle wall (3) using, for

example, 2 screws or adhesive (see Fig. 50).

Legend:

Item 1 Bracket for handheld control

Item 2 Handheld control

Item 3 Vehicle wall

4.7.6 Connecting the cables (front of

Page 40

Installation

34

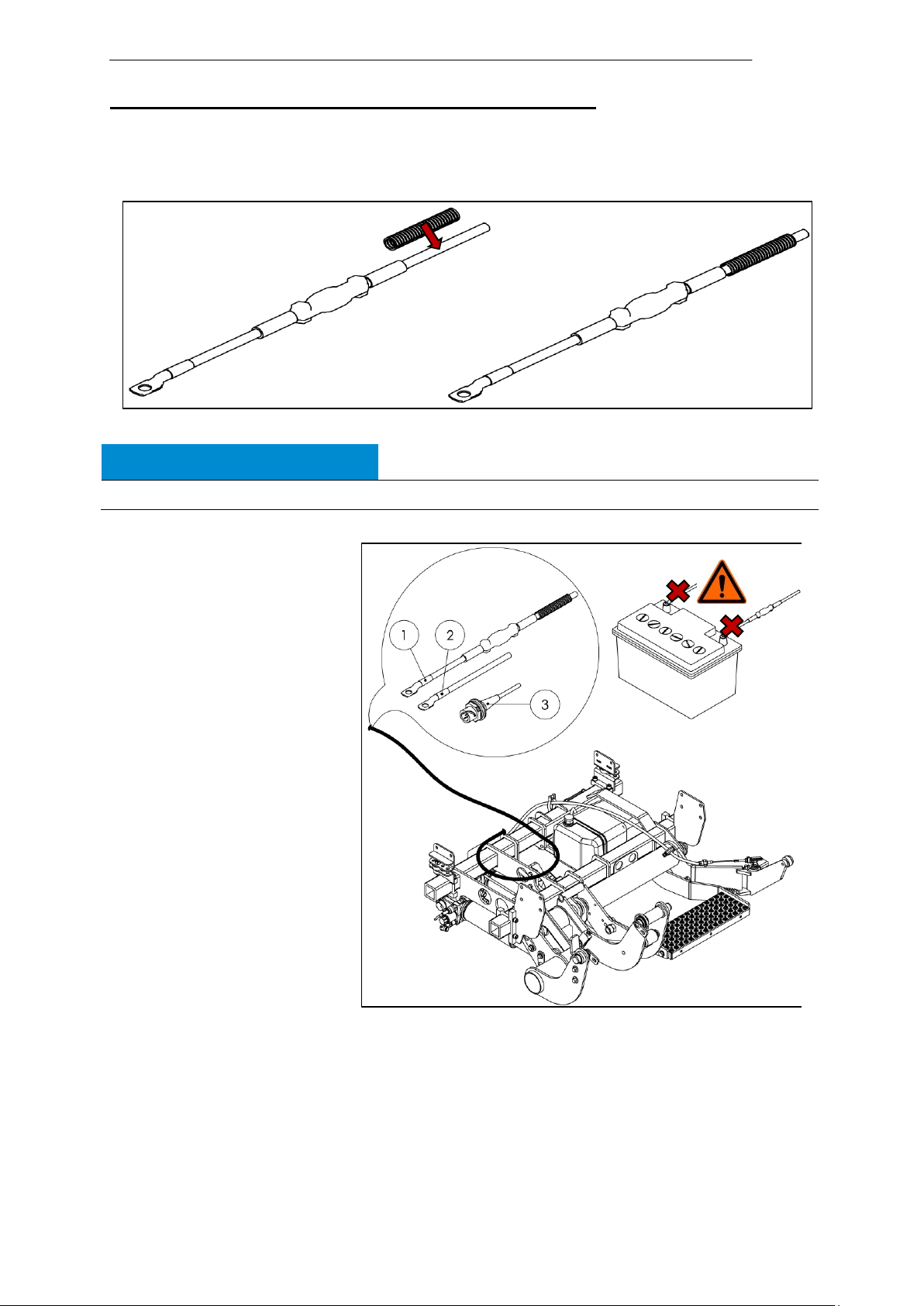

WARNING

Vehicle battery short-circuit

Improper connection of the device to the vehicle battery can cause a short-circuit

and explosion of the battery.

Risk of damage to property, fire, and injury.

Follow the vehicle manufacturer’s instructions for correctly handling the battery.

NOTICE

Connect cables only to cables of the same color.

Fig. 51

click!

click!

click!

vehicle)

With preparation according to ETMA Code A and Code B

Connect the power cable and the cable for the cabin switch unit to the sockets

provided (see Fig. 51).

Legend:

Item 1 Connector for cabin switch unit Part No. 20 910 754

Item 2 Positive cable (red) Part No. 20 907 673

Item 3 Negative cable (blue) Part No. 20 907 673

Item 4 7-pin connector (DIN 72585) from control unit

Item 5 Connector for positive cable

Item 6 Connector for negative cable

Page 41

Installation

35

Item No.

Part No.

Description

Qty.

11

20 906 975

Cabin switch unit cable 12 m with VEHH

connector

1

12

20 906 974

Cabin switch

1

Fig. 52

Fig. 53

No preparation according to ETMA Code A and Code B

Power cable

Route the “power unit cable,” positive cable, and negative cable (25 mm²) for the

power supply to the terminals provided for the battery and connect (see example

in Fig. 52).

Cabin switch unit

Drill a 16 mm dia. hole for the cabin switch (12) in a suitable location on the

dashboard.

Snap the cabin switch (12) into the hole.

Route the cabin switch unit cable (11) from the lifting gear to the front.

Connect the cabin switch unit as shown in Fig. 53.

Excerpt from parts list: accessories kit

Page 42

Installation

36

Fig. 54

4.8 Unpacking the platform

Check the scope of delivery for completeness (see pages 4f.)

IMPORTANT: Dispose of all packing materials in accordance with environmental

regulations.

4.9 Raising the platform

Lift the platform using suitable means, e.g. crane, assembly table, or pallet truck

and pallet (see Fig. 54).

Page 43

Installation

37

WARNING

Installation at crushing and shearing points

Fingers are at risk of being crushed or sheared when the platform is installed on the

lifting gear.

Be careful at the connecting points between the platform and lifting gear.

Item No.

Part No.

Description

Standard

Qty.

10

20 840 117

O-ring

40.65 x 5.33

6

Fig. 55

Fig. 56

4.10 Installing the platform

Remove the transport lock (cable tie).

R

e

m

ov

e

th

e

pi

ns

(a,

b,

c)

(s

ee

Fig. 55).

Legend:

Item a Pin Part No. 20 905 057

Item b Pin Part No. 20 840 722

Item c Pin Part No. 20 907 775

Thread 6 O-rings (accessories kit parts list – Item No. 10) onto the steel bushings

(see Fig. 56).

Exc

erp

t

fro

m

par

ts

list:

acc

ess

ori

es

kit

Page 44

Installation

38

Item No.

Part No.

Description

Standard

Qty.

13

20 840 405

Lubricating grease

1

Fig. 57

Fig. 58

Loosen the platform stop (1) and push it toward the vehicle

(see Fig. 57).

Legend:

Item 1 Platform stop

Thoroughly grease the bearing bushes with the special assembly grease

(accessories kit parts list – Item No. 13) (see Fig. 58).

Excerpt from parts list: accessories kit

Page 45

Installation

39

Item No.

Part No.

Description

Standard

Qty.

2

20 908 251

Hexagon flange

bolt

DIN 6921 - M10x15 - 10.9 - ZN

2

Fig. 59

Fig. 60

Align the top bearing points of the platform (platform attachment points) with the

swing-arm bearing points (top attachment points of the lifting gear)

(see Fig. 59).

Insert the two pins (a, b) through the top attachment points of the platform and

the attachment points of the swing-arm assembly.

IMPORTANT: Note the direction of insertion (see Fig. 60).

Mount the bolts from the accessories kit (2) to secure the pins and tighten them

to 70 Nm.

Excerpt from parts list: accessories kit

Legend:

Item a Pin Part No. 20 905 057

Item b Pin Part No. 20 840 722

Page 46

Installation

40

Item No.

Part No.

Description

Standard

Qty.

8

20 901 791

Countersunk screw with

hexagon socket

DIN 7991 - M10x12 - A2

1

Fig. 61

Fig. 62

Lift the tip of the platform until the closing-rod bearing point (attachment point for

the closing rod) is aligned with the swing-arm bearing point (bottom attachment

point on the platform) (see Fig. 61).

IMPORTANT: If necessary, slightly retract or extend the closing rod.

Insert the pin (c).

Mount the screw (8) from the accessories kit to secure the pin (Fig. 62).

Excerpt from parts list: accessories kit

Legend:

Item c Pin Part No. 20 907 775

Page 47

Installation

41

Item No.

Part No.

Description

Standard

Qty.

10

20 840 117

O-ring

40.65 x 5.33

6

Fig. 63

Fig. 64

Move the 6 pre-fitted O-rings (accessories kit parts list – Item No. 10) into their

correct positions (see Fig. 63).

IMPORTANT: All bearing points are sealed with O-rings.

Excerpt from parts list: accessories kit

4.11 Mounting the platform

lock on the closing arm

Remove and properly dispose of

the nut on the transport lock (1)

(see Fig. 64).

Legend:

Item 1 Nut Part No. 80 000 052

Page 48

Installation

42

Item No.

Part No.

Description

Standard

Qty.

3

20 907 616

Ground roller

2 4

20 907 615

Bushing

d20/16x32

2

7

20 904 600

Flange screw

W 0263 - M16x40 - 10.9 - GEO

2

Fig. 65

Fig. 66

Mount the screw (1) for the

platform lock, including the spring

washer (2), washers (3), and

sleeve (4), on the platform

bearing (see Fig. 65).

Legend:

Item 1 Hexagon head screw

Item 2 Spring washer

Item 3 Washer

Item 4 Sleeve

4.12 Mounting the ground rollers

Required material from accessories kit

Remove the flange

screws (7), bushings (4),

and ground rollers (3)

from the accessories kit

(see Fig. 66).

Page 49

Installation

43

WARNING

Shift in center of gravity and lifting up of front end of the vehicle

Unexpected movements of the vehicle can result in the severe injury or death of

bystanders.

Follow the vehicle manufacturer’s installation guidelines. If necessary, install

supports.

Fig. 67

click!

4.13 Installing supports (vehicle-dependent)

With some vehicle types and installation versions, maximum loading of the platform

can cause the front of the vehicle to lift up.

4.14 Connecting the platform to the electrical system

4.14.1 Connecting the platform cable to the electrical system

Connect the platform cable connector (1) to the control unit connector (2) (see

Fig. 67)

IMPORTANT: The control unit connector is identified by the white plastic cover on

the cable.

Legend:

Item 1 Platform connector for connection to control unit

Item 2 Control unit connector for connection to platform

Page 50

Installation

44

Fig. 69

Fig. 68

4.14.2 Connecting the

license plate light

Find the cable connection

point for the license plate

light in the C column (a)

on the Mercedes Benz

Sprinter (see Fig. 68).

Route the license plate

light cable (2) (cable

outlet from platform’s

aluminum torsion box)

along the closing arm

(see Fig. 69).

Legend:

Item b License plate light

Join the two cables (1) and (2) and connect.

IMPORTANT: Follow the vehicle manufacturer’s installation guidelines.

Page 51

Installation

45

Item

No.

Part No.

Description

Standard

Qty.

14

60 710 330

Warning flag

Kit

1

Fig. 70

Fig. 71

4.15 Mounting the license plate holder

Mount the license plate holder below the license plate light.

IMPORTANT: When positioning the holder, make sure the license plate is sufficiently

illuminated.

4.16 Mounting the bridge plates (20 909 431)

Fasten the bridge plate with the non-skid coating (2) on the right side. The non-

skid coating must face upward when the bridge plate is folded shut (see Fig. 70).

Fasten the non-coated bridge plate (1) on the left side (see Fig. 70).

Legend:

Item 1 Bridge plate

Part No. 20 911 718

Item 2 Bridge plate

Part No. 20 911 699

4.17 Mounting the warning flags

Remove the warning flag kit (14, Part No. 60 710 330) from the accessories kit

and mount it in accordance with the installation instructions below (Fig. 71,

Fig. 72, and Fig. 73).

Required material from accessories kit

IMPORTANT: Mounting specifications: Comply with

these mounting specifications (see Fig. 71):

Dimension A – Move the holder far enough away from

the tip of the platform to leave 20 mm clearance

between the holder and the ground when the platform is

lowered. The holder must not touch the ground when the

platform is lowered.

Dimension B – Position the warning flag as close as

possible to the outside platform edge.

Page 52

Installation

46

Fig. 72

Close the liftgate (place in driving position).

Align the warning flag holder (14c).

IMPORTANT: Comply with the mounting specifications.

Transfer the existing holes in the warning flag holder to the platform and pre-drill

holes for the 2 blind rivets.

Rivet the warning flag holder (14c) using 2 blind rivets (14d).

Slide the left warning flag (14a) into the slot in the warning flag holder (14c).

IMPORTANT: Identify the left warning flag (14a) by the angle of the pattern

(see Fig. 72).

Secure the warning flag using the Phillips-head screw (14e).

Legend:

Item 14a Left warning flag

Item 14b Right warning flag

Item 14c Warning flag holder

Item 14d Blind rivet

Item 14e Phillips-head screw

Page 53

Installation

47

CAUTION

Not a normal operating position

Risk of injuring yourself or damaging the vehicle or liftgate.

Fig. 73

Move the liftgate to the horizontal position.

Fold out (open) the liftgate.

Bring the open liftgate as far as necessary into the vertical position to comfortably

mount the right warning flag.

Align the warning flag holder (14c).

IMPORTANT: Comply with the mounting specifications.

Transfer the existing holes in the warning flag holder to the platform and pre-drill

holes for the 2 blind rivets.

Rivet the warning flag holder (14c) using 2 blind rivet (14d).

Slide the right warning flag (14a) into the slot in the warning flag holder (14c).

IMPORTANT: Identify right warning flag (14a) by the angle of the pattern (see

Fig. 73).

Secure the warning flag using the Phillips-head screw (14e).

Legend:

Item 14a Left warning flag

Item 14b Right warning flag

Item 14c Warning flag holder

Item 14d Blind rivet

Item 14e Phillips-head screw

Page 54

Installation

48

4.18 Affixing the danger notice sticker

Affix the danger notice sticker “Safe handling of the liftgate.”

IMPORTANT: This sticker is supplied with all new liftgates. The installing company

must place it in an easily visible location on the inside of the vehicle cargo area.

The danger notice sticker uses pictograms to indicate potential incorrect and correct

use of the liftgate.

Page 55

Adjusting the liftgate

49

NOTICE

If no readjustment is necessary, make sure that the screws (1 and 3) are securely

tightened.

Fig. 74

Fig. 75

3

5 Adjusting the liftgate

5.1 Setting the lift height to the vehicle floor level using the

adjustable stop on the axle assembly

Use the adjustment screw (1) pre-mounted on the axle assembly of the X1A

600F/GPC X1 and an appropriate tool (e.g. a ring wrench) to set the lifting gear to the

desired height with relation to the vehicle floor.

Use the adjustment screw (1)

to set the lift height

(see Fig. 74).

Rotate to left:

lower lift height

Rotate to right:

higher lift height

Legend:

Item 1 Adjustment screw

5.2 Aligning the platform parallel to the vehicle floor

To align the platform parallel to the vehicle floor, adjust the lifting gear using the

left-hand adjustment fork (adjustment screw accessible from above) (see

Fig. 75).

With the platform open,

operate the lifting gear

to the height of the

vehicle floor (not

against the stop).

Legend:

Item 1 Adjustment screw

Item 2 Adjustment fork

Item 3 Hex bolt

Page 56

Adjusting the liftgate

50

Fig. 76

Fig. 77

Loosen the hex bolt (3).

Rotate the adjustment screw (1) to the left or right.

Rotating the adjustment screw (1) to the right moves the right side of the platform

closer to the vehicle chassis. This slightly lifts the platform on the right side of the

vehicle (see Fig. 76).

Rotating the adjustment screw (1) to the left moves the right side of the platform

away from the vehicle chassis. This slightly lowers the platform on the right side

of the vehicle (see Fig. 76).

W

h

e

n

f

i

n

i

s

h

e

d

a

d

justing, tighten the bolt (3) for securing the torsion bar to 115 Nm (see torque

table on page on page 68 and see Fig. 77).

5.3 Alignin

g the

platfor

m

(foldov

er

section)

parallel

to the

vehicle

floor

Page 57

Adjusting the liftgate

51

Fig. 78

Fig. 79

If necessary, adjust the height of the foldover section on the right side of the platform

using the right-hand adjustment fork (2) (adjustment screw accessible from below)

(see Fig. 78).

Legend:

Item 1 Adjustment screw

Item 2 Adjustment fork

Item 3 Hex bolt

Item 4 Support arm

Use the adjustment screw (1) to set the support arm (4) so that the platform stop

rests on and is supported by the support arm (4).

IMPORTANT: At the same time, check the stop (Section 5.4) on the foldover

section.

Rotating the adjustment screw (1) to the right lifts the support arm (4).

Rotating the adjustment screw (1) to the left lowers the support arm (4)

(see Fig. 79).

When finished adjusting, tighten the bolt (3) for securing the torsion bar to

11

5

N

m

(se

e

tor

qu

e

tab

le

on

pa

ge

68).

Page 58

Adjusting the liftgate

52

Fig. 80

5.4 Checking the stop on the foldover section of the platform

Check the stop on the foldover section of the platform.

IMPORTANT: The roller (1) on the support arm (2) must remain against the stop (3)

throughout the entire lifting process. If necessary, loosen the stop (3) and shift it

slightly by loosening 2 cheese-head screws (4). At the same time, the stop (3) must

not be shifted too far. When the platform is folded over, the plastic spacer (5) must

hold the platform in place (see Fig. 80).

Legend:

Item 1 Roller on support arm

Item 2 Support arm (supports foldover section of platform when platform is open)

Item 3 Stop (on foldover section of platform)

Item 4 Cheese-head screw (2 pieces)

Item 5 Plastic spacer (holds platform in driving position)

Page 59

Adjusting the liftgate

53

Fig. 81

Fig. 82

3°- 4°

5.5 Setting the end stop for the closed platform

The end stop for the platform in the closed position is mounted on the closing arm.

The platform requires no additional stops on the vehicle.

IMPORTANT: Adjust the platform so that it stands vertically behind the vehicle when

closed and in the driving position.

L

o

o

s

e

n

t

h

e

2

s

c

r

e

ws (1) on the clamping plate (2) (see Fig. 81).

Hydraulically close the platform

until not quite vertical, leaving it

open 3° to 4° (see Fig. 82).

Page 60

Adjusting the liftgate

54

Fig. 84

Fig. 83

Retighten the 2 screws (1) on the clamping plate (2) on the platform stop to a

torque of 195 Nm (see Fig. 83).

When you reclose the platform, it will stand vertically behind the vehicle (see Fig. 84).

Page 61

Adjusting the liftgate

55

Fig. 85

Fig. 86

5.6 Adjusting the stopper for fastening the platform

The stopper fastens the right-hand foldover section of the closed platform and keeps

the platform from hitting the vehicle while driving.

IMPORTANT: Make the adjustment with the platform folded and closed (driving

position).

Loosen the nuts (1) and bolts (2) on the stopper (3).

Press the stopper (3) firmly against the plastic disk (4) (see Fig. 85).

Leg

end:

Item

1

Hex

agon

nut

Item

2

Scre

w

Item

3

Stopper

Item 4 Plastic disk

Tighten the nuts (1) and bolts (2) on the

stopper (3) to a torque of 80 Nm

(see Fig. 86).

5.7 Adjusting the support arm for

the driving position using the

Bowden cable

Page 62

Adjusting the liftgate

56

Adjust the support arm (1) so that it can be pulled as close to the vehicle as desired

when the platform is closed. The adjustment is made outside at the Bowden cable (2)

and, if applicable, also at the screw on the lever (3). While making the adjustment,

release the Bowden cable (2) and open the platform (see Fig. 87).

Fig. 87

Legend:

Item 1 Support arm

Item 2 Bowden cable

Item 3 Screw

5.8 Programming the tilt sensor

Platform tilt is adjusted by programming the tilt sensor. The tilt sensor is programmed

by pressing a combination of buttons on the control panel (a) (see Fig. 88).

Page 63

Adjusting the liftgate

57

Fig. 89

Fig. 88

3x

3x

1

2

a

a

Using the manual control, move the platform to a horizontal position.

On the control panel (a), press button 1 (top left) 3 times, then

On

the

con

trol

pan

el

(a),

pre

ss

butt

on

2

(top

righ

t) 3 times (see Fig. 89).

IMPORTANT: Each of the programming sequences with button 1 and then button 2

must be completed within a period of 2 seconds.

The selected position will continue to be used each time the liftgate is operated until

the sensor is reprogrammed.

Page 64

Testing the liftgate

58

CAUTION

Platform at ground level

In the fully lowered position, the platform is easily overlooked and

may cause people to trip, resulting in injury.

If leaving the platform in this position for a longer period of time,

secure the area.

WARNING

Permissible vertical speed exceeded

Risk of injury when operating the liftgate.

Contact customer service.

WARNING

Permissible angular velocity exceeded

Risk of injury when operating the

liftgate.

Contact customer service.

WARNING

Permissible angular velocity exceeded Risk of injury when operating the liftgate.

Contact customer service.

Fig. 90

6 Testing the liftgate

6.1 Function test

Test: opening, lifting, lowering, tilting down, tilting up, closing

6.2 Testing the operating speed

6.2.1 Vertical speed

Test: vertical speed (lifting and lowering)

The vertical speed must not exceed (lifting and lowering) 15 cm/sec.

6.2.2 Closing and opening speed (90° to 10°)

Test: angular velocity when opening and

closing (see Fig. 90)

The angular velocity when opening and closing

must not exceed 10°/sec.

6.2.3 Tilting speed (10° to -10°)

Test: angular velocity when tilting up and down (see Fig. 90).

The angular velocity when tilting up and down must not exceed 4°/sec.

Page 65

Testing the liftgate

59

WARNING

High loading of components

Incorrect installation or defective components may cause components to fail and

break.

Risk of injury when operating the liftgate.

Perform all the load tests specified here.

6.3 Load tests

6.3.1 Static test

Operate the horizontal platform to the height of the vehicle floor.

Place a test load weighing 125% of the rated capacity on the platform within the

loading distance.

During a test period of 15 minutes, the platform must not lower more than15 mm

and must not tilt down more than 2°.

IMPORTANT: The permissible loading distance and the rated capacity are engraved

on the liftgate’s rating plate. The loading diagram on the rating plate shows the

permissible loads when the loading distance is changed.

IMPORTANT: After the static test, the installer must inspect the liftgate for

deformation.

6.3.2 Dynamic test

Test the lifting, lowering, and tilting functions using the maximum permissible

load.

IMPORTANT: The pressure limiting valve is adjusted ex-works. A correction is

generally unnecessary. If adjustment is necessary, contact the factory.

The maximum permissible pressure is printed on the liftgate’s rating plate.

After performing the static and dynamic tests, visually inspect the hydraulics

system for tightness.

6.3.3 Testing against lifting an overload

Perform a test to guarantee that a load of more than 125% of the maximum rated

capacity cannot be lifted off the ground.

6.3.4 Testing the safety devices

Operate all the functions to their end positions until all the safety devices

respond.

Page 66

Testing the liftgate

60

LED monitoring function

Cabin switch in

driver’s cabin or

key switch

LED off

LED on

LED

flashing

Platform closed (90°)

Off

X

Platform closed

On

X

Platform open (90° to 60°)

On

X

Platform open (60° to 0°)

On

X

Platform tilted down (0° to -10°)

On

X

Switch being actuated *

On

X

x

6.4 Explanation of diagnostic LED on the control unit

Description:

90° = Platform is closed

0° = Platform is open to the horizontal position

-10° = Tip of platform is tilted down

*If a control element on the handheld control (toggle switch, remote control

pushbutton, or foot switch) is actuated, the control LED flashes (see Fig. 91).

F

ig. 91

Legend:

X Control unit LED for control function

Page 67

Testing the liftgate

61

6.4.1 Checking tilt sensors S1 and S2 in the platform

Platform closed and liftgate switched on:

LED on.

Power supply is functioning correctly.

Platform position 0 ° to approx. 60 °:

LED off

Tilt sensor S1 in switching position is functioning correctly.

Corner lights are activated.

Platform position 0° to -10° (tilted down)

LED on.

Tilt sensor S2 in switching position is functioning correctly.

The switchover occurs in the horizontal position, making it possible to set the

automatic tilt-up function.

6.4.2 Checking pressure switch S4

Begin lowering the platform using the two bottom control panel buttons.

LED flashes.

As soon as the platform reaches the ground and the pressure switch is actuated, the

flashing changes to continuous on – LED is on and the platform tilts down.

This indicates that the pressure switch was actuated. If it doesn’t occur, the pressure

switch is defective.

6.5 Entry in inspection record book

Once the liftgate has been assembled, installed on the vehicle, adjusted, and has

passed the function test, a qualified specialist must fill out and sign the section of

the inspection record book entitled “Results of test performed by specialist before

first operation.”

Page 68

Recommendations and instructions regarding the liftgate

62

7 Recommendations and instructions regarding the

liftgate

IMPORTANT:

To ensure safe operation of the liftgate read the safety instructions and

warnings in the accompanying user manual.

7.1 Hydraulic oil recommendations

HLPD 22 (ISO-VG 22) “detergent” so that free water remains emulsified (e.g. to

prevent ice formation in winter) and to improve oil film adhesion.

In colder regions, we use HLPD 10 grade hydraulic oil.

Sörensen hydraulic oil HLPD 10 Part No. 20 841 181

Sörensen hydraulic oil HLPD 22 Part No. 60 700 283

Sörensen bio oil Part No. 20 858 811

7.2 Painting the lifting gear

The lifting gear is powder-coated black ex-works. If another color is desired, painting

must be performed by the vehicle manufacturer.

IMPORTANT:

Roughen the powder-coated surface before painting.

Mask the black connecting rods before painting.

Carefully remove extra paint and masking material from the connecting rods after

painting to avoid damaging the seals and voiding the warranty.

7.3 Rating plate

The rating plate with the loading diagram and factory number is affixed to the liftgate

closing arm on the right side of the vehicle as viewed in the forward direction of

travel. A second rating plate is affixed to the power unit cover. The device number

and stamped figures are also stamped into the mounting flange on the left as viewed

in the forward direction of travel.

Page 69

Useful information

63

YA

Y3

Y1

KM

Fig. 92

8 Useful information

8.1 About the service switch

The service switch mounted in a housing enables

trained service personnel to control and test the

functioning of the liftgate directly (see Fig. 92).

If the liftgate’s handheld control malfunctions, a

trained person can operate the liftgate to any

position using the service switch (emergency

function).

Page 70

Useful information

64

Function

YA

Y1

Y3

KM

Power light green

●

Lift

●

●

Lower

● ●

Open/tilt down

● ●

●

Close/tilt up

●

●

Please follow the sequence shown. Always operate KM last.

Page 71

Useful information

65

®

GPC X1 LDF

8.2 Assembly drawings of installation adapters

Page 72

Useful information

66

8.3 Electrical circuit diagram

Page 73

Useful information

67

®

8.4 Hydraulic circuit diagram

Page 74

Useful information

68

Screw size

8.8

Tightening torque

in Nm

Thread sizes

DIN 3852

Tightening torque

in Nm

M4

2.7 ± 0.1

G1/4“

40 ± 1.2

M6

9.5 ± 0.3

G3/8“

95 ± 2.9

M8

23 ± 0.7

G1/2“

130 ± 3.9

M10

53 ± 1.6

Union nuts

M12

80 ± 2.4

M16 x 1.5

60 ± 1.8

M14

130 ± 3.9

M18 x 1.5

60 ± 1.8

M16

195 ± 5.9

Plugs

M20

385 ± 11.6

G1/8“

15 ± 0.5

10.9

G1/4“

33 ± 1

M10

70 ± 2.1

G3/8”

70 ± 2.1

M12

115 ± 3.5

M14

180 ± 5.4

M16

275 ± 8.3

M20

542 ± 16.3

Platform bearing

10.9

M12

60 ± 1.8

M16

150 ± 4.5

Serrated flange screw

M14

215 ± 6.5

M16

310 ± 9.3

8.5 Torque table

Valid torque table for all the bolts and screws supplied and installed on our liftgates

Page 75

Useful information

69

Lower

Lift

Open/tilt down

Close/tilt up

8.6 Activating the liftgate

Switch on the liftgate control unit using the pushbutton in the driver’s cabin. When the

red indicator light is illuminated, the liftgate is ready to operate.

8.7 Operation using the control panel

From the control panel, all functions are initiated by pressing two different

pushbuttons simultaneously. The diagram shows which buttons are responsible for

each individual function.

Page 76

Useful information

70

Lift

Tilt up/tilt down

Lower

8.8 Operation using the optional handheld control

The 3-button handheld control can be used to operate the lifting and lowering

functions as well as the tilting up and down functions when the platform is open.

Loading...

Loading...