Page 1

Cantilever GPC X1

Operator`s Manual

Liftgate

Series

GPC 22 X1

Lift CORP.

11921 Slauson Avenue.

Santa Fe Springs, CA 90670

(800) 227 - 4116

Document no.: S 20 909 946

Version 2011

© Sörensen Hydraulik GmbH

Page 2

Page 3

Lift CORP.

General

You have chosen a lift gate of the highest quality. The lift gate is a low maintenance unit. It is

equipped with maintenance-free, grease-free bearings and does not require greasing

throughout its entire lifetime.

The lift gate may only be used for the raising and lowering of loads, which must be loaded in

accordance

The lift may be operated, maintained and serviced only by persons who have received

appropriate

its operation.

The accident prevention regulations, must be observed. If they are not, the manufacturer

cannot accept any liabilit

with the loa

training and

These operating instructions are valid for following lift gates :

d diagram.

who have been specifically instructed of the dangers associated with

y for resultant damage or injury.

Model Capacity kg Capacity pounds

GPC 22 X1

1000 kg 2200 pounds

Daily verifications :

• Check for correct and normal operation

• Legibility of all operating and information labels

• Check for weld cracks and make sure all bolts and nuts are tight

• Check for leaks on hoses, valves and hydraulic cylinders

• If platform has warning lights please

check for fu

nction

The driver should report any incorrect operation or obvious damage

to his maintenance department. All damages are to be mended

immediately. The lift gate owner is responsible for the repairs of

detected damages.

The operating instructions are to be carried in the vehicle at all

times.

Operator`s handbook Series GPC 22 X1

Document no.: S 20 909 946

1

Version: 2011

Page 4

Lift CORP.

Yearly check

The lift gate must be checked for damages at least once a year by trained personnel. The

results of this verification must be written down in the maintenance book.

Battery capacity

Lift capacity

Battery size

For use in short-haul traffic the next step up should always be selected.

Heavy-duty alternators are strongly recommended.

The operator is resp onsible for the battery capacity and the c harge status of the

battery.

The electric motor

You can avoid damages to the motor or the power relais if you ensure that you have the right

voltage at all times. If the motor has trouble with a load that is normally lifted without a

problem, stop the lifting operation immediately and charge the batteries.

If, in your opinion, the batteries are empty too fast, have the batteries and the power cables

checked by a specialist.It could be

batteries have to be repaired or changed.

Up to 2200 lbs

12V : 1 x 12V 88 Ah

24V : 2 x 12V 66 Ah

Group 31

possible th

at the cables, the mass connection or the

Operator`s handbook

Document no.: S 20 909 946

2

Series GPC 22 X1

Version: 2011

Page 5

Lift CORP.

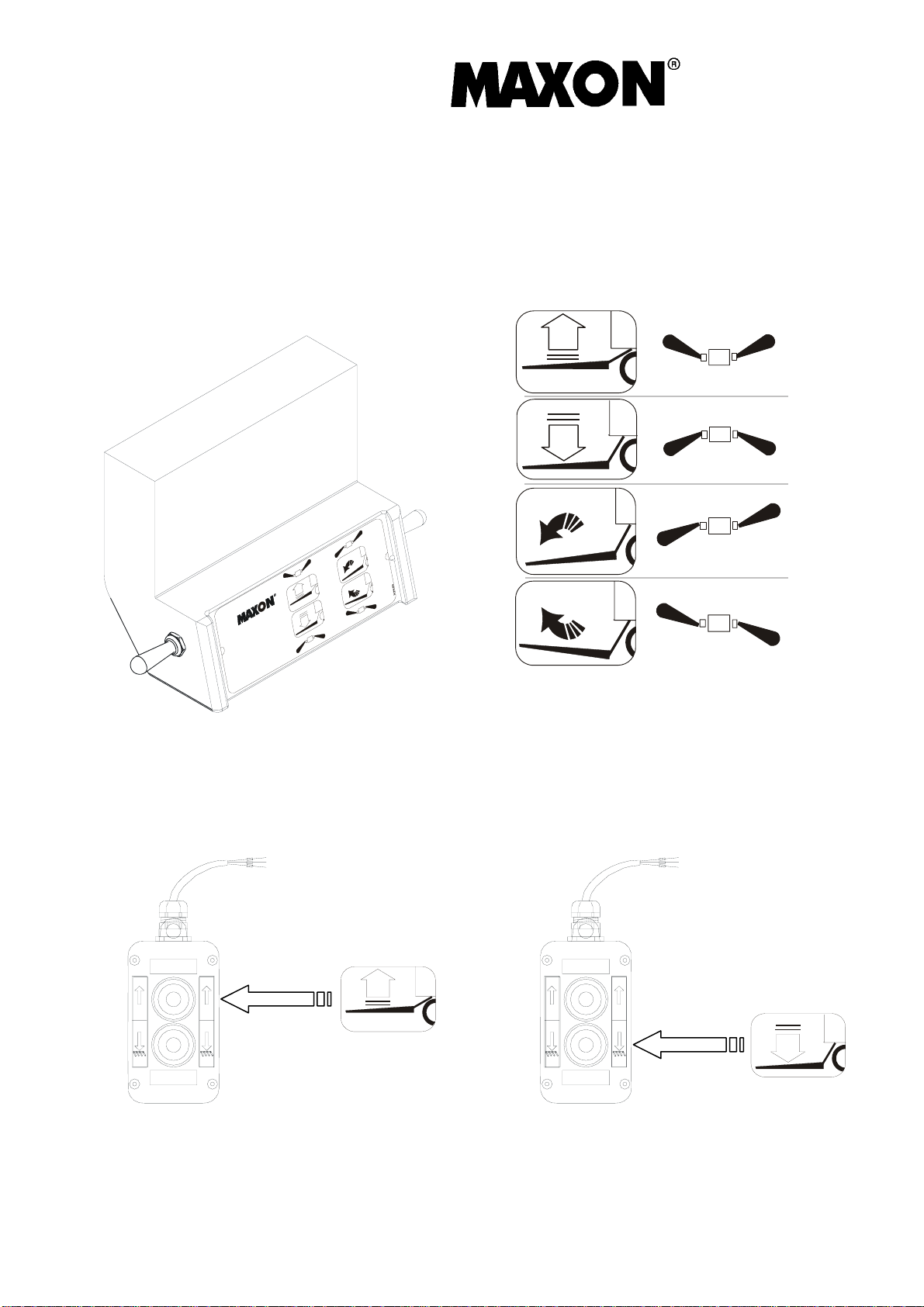

Switching on the lift gate

Switch the lift gate on with the push button located in the cabin. When the red lamp lits, the

lift is ready for operation

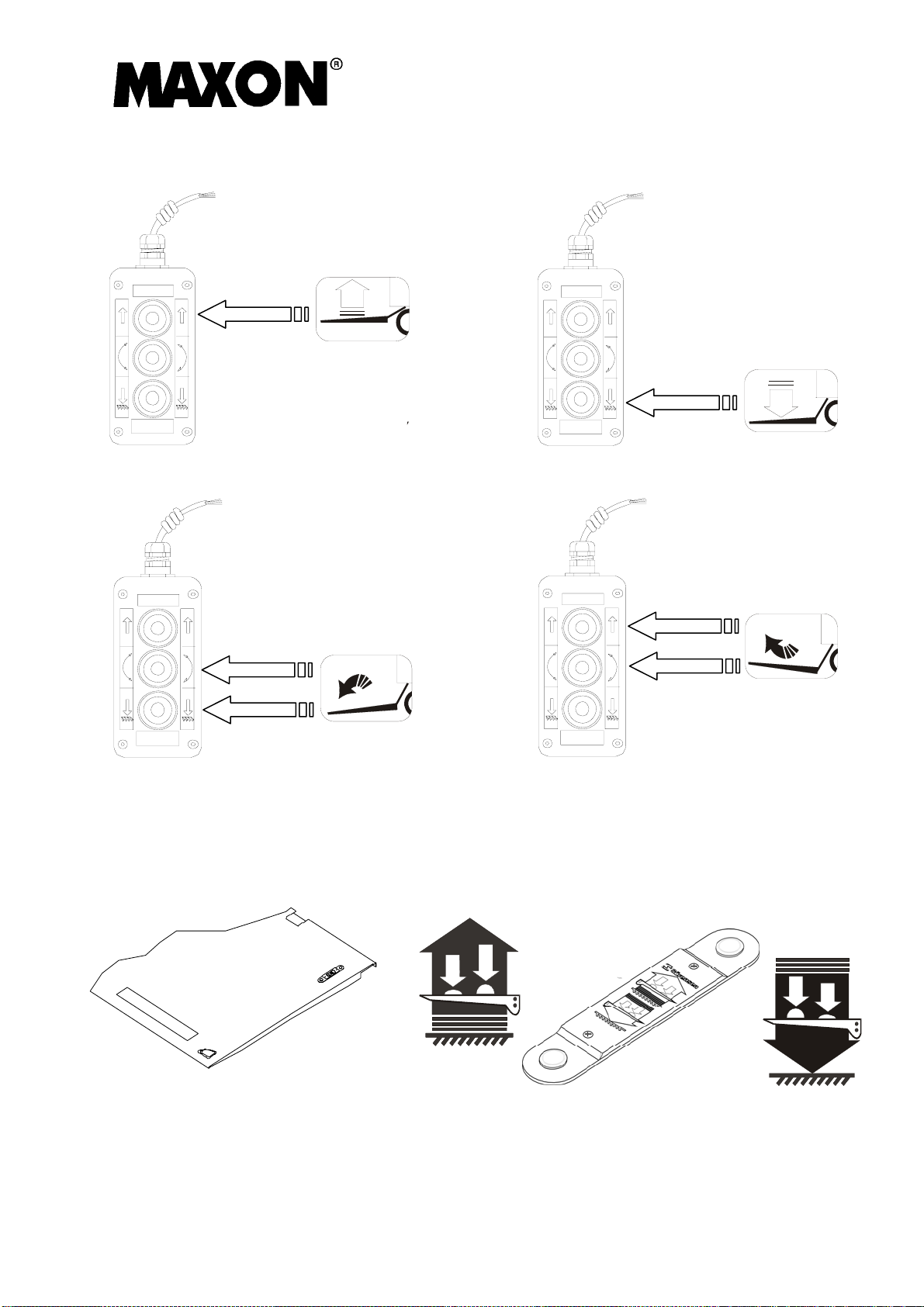

Description of the controls

Hand control box

All functions must be operated with two hands by switching the toggle switches located at the

side of the hand control

Hand control box 2 Buttons

box

Lift

Lower

Open / tilt down

Close / tilt up

Lift

Operator`s handbook

Document no.: S 20 909 946

Lower

3

Series GPC 22 X1

Version: 2011

Page 6

Lift CORP.

Hand control box 3 Buttons

Open / tilt down

Foot Controls (Optional version)

The foot controls are connected so that they only work when pushed in a specific order.

To lift and tilt up

Step 1 - activate foot control button for lowering

Step 2 - activate foot control button for lifting

Close / tilt up

Operator`s handbook

Document no.: S 20 909 946

To lower and tilt down

Step 1 - activate foot control button for lifting

Step 2 - activate foot control button for lowering

4

Series GPC 22 X1

Version: 2011

Page 7

Lift CORP.

General Information

Standing on the platform when it is moving

As it is only allowed for the operator to stand on the platform, he must ensure that no other

person (especially children) are standing inside the danger zone.

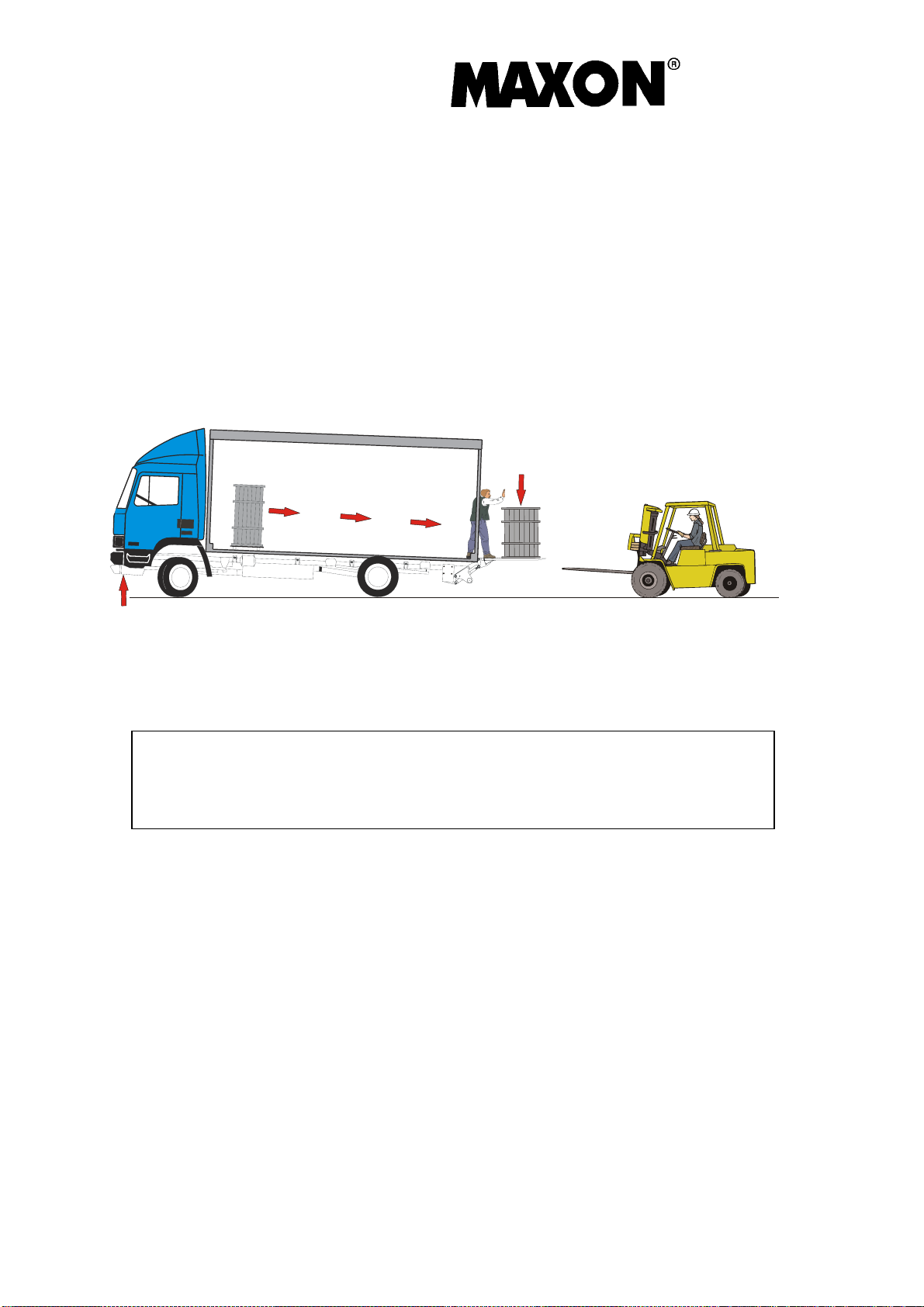

Hazard information for unsecured loads

Under certain circumstances, there is a possibility that the front axle of the vehicle lifts while

unloading. On this inclination, unsecure loads may start to slip and create a danger for the

operator.

You can purchase a warning sticker

CAUTION ! Secure the load against

moving or use mechanical supports

Operator`s handbook

Document no.: S 20 909 946

5

Series GPC 22 X1

Version: 2011

Page 8

Lift CORP.

Description of the Safety Installations

Hose Rupture Valves

If a hose, a pipe or a screw connection should burst, the lift gate lowers or inclines in a

controlled manner at the

permitted speed, as lon

control units (hand held remote controls, foot controls or hand control box). If such control

unit is not activated, or ceases to be activated, the lift gate stops automatically.

Safety Valve

The lift gate is protected by the factory-set safety valve from raising loads which are heavier

than the spe

ified carrying capacity. This valve may only be adjusted by an expert using a

c

test weight and a manometer.

Fuses

Defective fuses may only be replaced by fuses which correspond to the values specified in

the wiring diagram and on the distributor plate.

malfunctions, which could lead to cables catching fire.

Roll-off Safety Devices

If roller containers are being used, the lift gate should be equipped with roll-off safety

devices. Th

eir operation

is impaired by dirt; the operator should keep the roll-off safety

devices clean at all times.

Warning Flags

The flags can be seen until the platform is on the ground. Both safety installations should be

kept clean a

nd in perfect

condition at all times.

(Optional version)

Warning Lights

The lights flash as soon as the platform has opened a few degrees.

g as a function is connected via one of the

Larger fuses may not be

blown in the event of

Operator`s handbook

Document no.: S 20 909 946

6

Series GPC 22 X1

Version: 2011

Page 9

Lift CORP.

Standing on the platform when it is moving

When loading the platform, please ensure that you leave enough space for the operator to

securely operate the lift gate.

Securing of Loads

Rolling and sliding loads must be secured on the platform. Lift gates come optionally

equipped with cart stops, securing rolling loads with the maximum efficiency (wheels with

maximum diameter 4” )

Operator`s handbook

Document no.: S 20 909 946

7

Caster diameter max. 4“

Series GPC 22 X1

Version: 2011

Page 10

Lift CORP.

Safety guide for the operation of the lift gate

Secure the load against toppling over and sliding

Operator`s handbook

Document no.: S 20 909 946

8

Series GPC 22 X1

Version: 2011

Page 11

Lift CORP.

Permissible Loading

Apart from being included in these operating instructions, the load diagram is also shown on

the lift gate identification

nearest to the vehicle floor as possible, with the heaviest part of the load toward the vehicle.

No part of any load should be allowed to extend over the edges of the Platform. Do not place

unstable loads on the Platform. Do not allow any load to exceed the rated capacity for the

unit. If standing on the Platform, do not allow your feet to protrude beyond the edges. The

greater the distance of the load from the vehicle floor, the lower the loading capacity. The

maximum loading capacity specified in the load diagram must not be exceeded. The platform

may not be used with any load greater than the maximum permitted carrying capacity.

plate. All loads must be placed as close to the edge of the Platform

LBS

LBS

2500

2000

1500

1000

500

0

78 3/8 70 7/8 63 55 1/8 47 1/4 39 3/4 31 1/2 23 5/8 15 3/4 7 7/8

inch

The maximum weight indicated in the loading diagram must not be

exceeded. When the platform sits on the ground, it can be overrolled

only with the maximum load indicated.

GPC 22 X1

Operator`s handbook

Document no.: S 20 909 946

9

Series GPC 22 X1

Version: 2011

Page 12

Lift CORP.

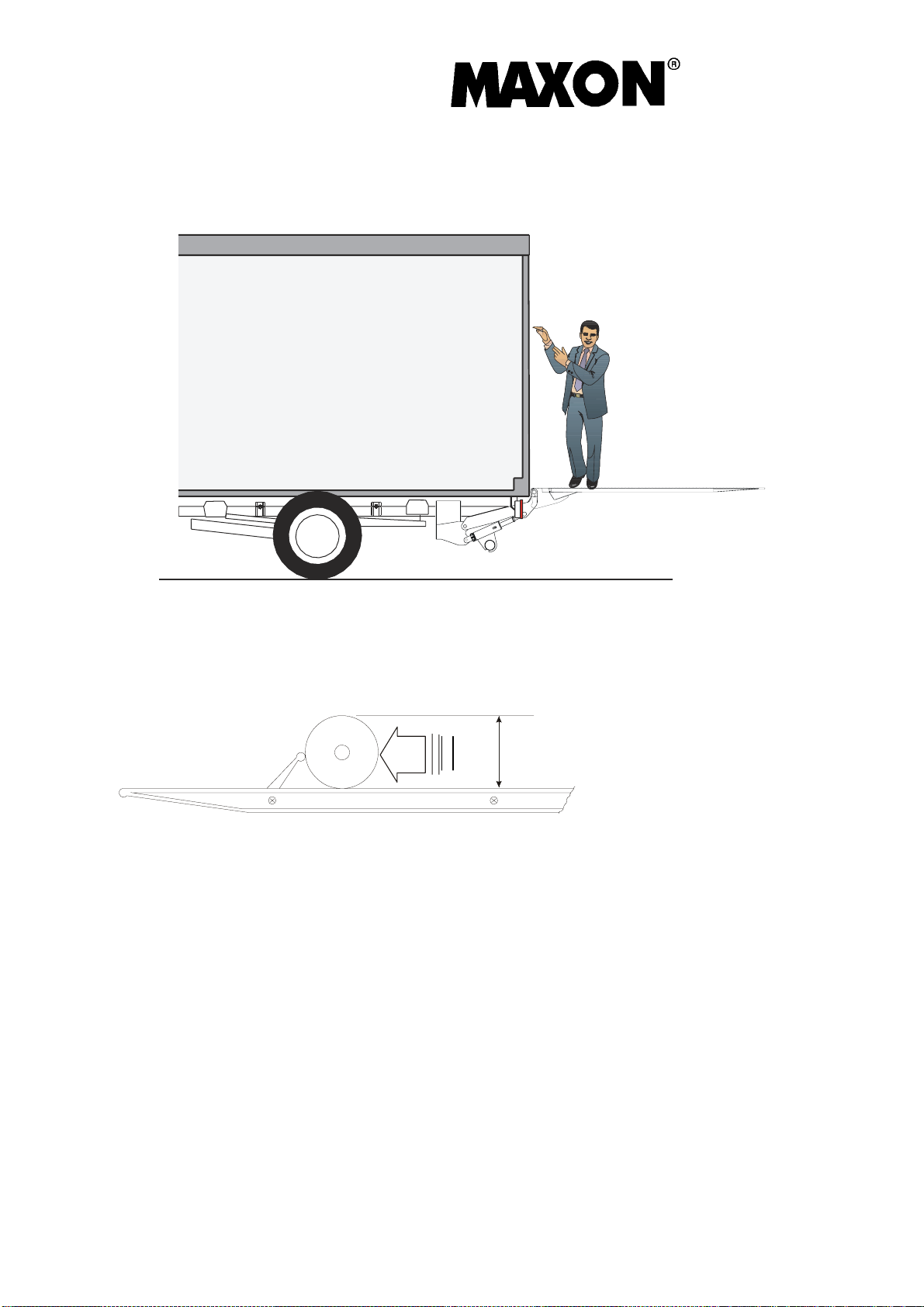

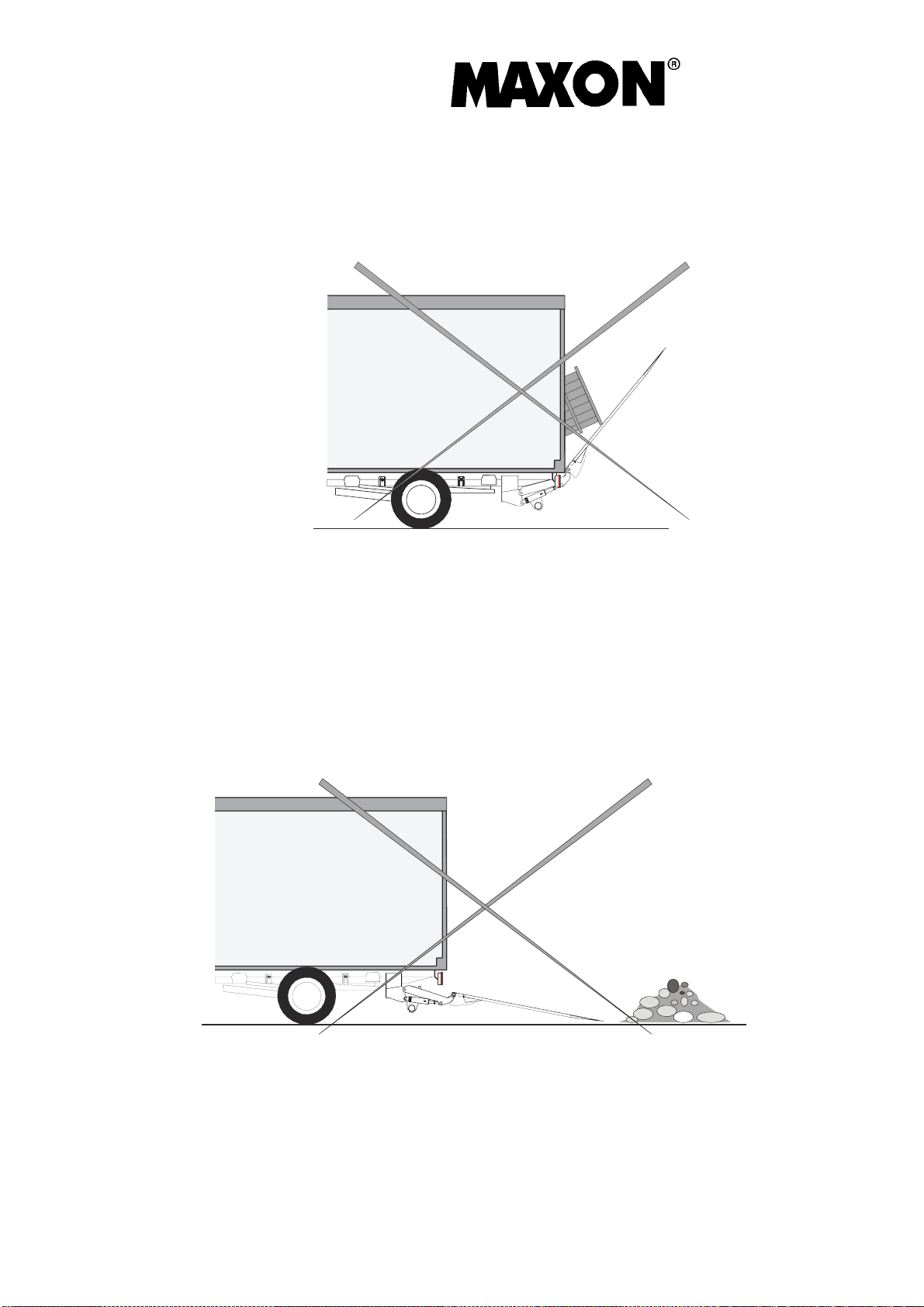

Platform, bridge and ramp

Never sit the ramp on the platform, always use the platform as a ramp !

Operator`s handbook

Document no.: S 20 909 946

10

Series GPC 22 X1

Version: 2011

Page 13

Lift CORP.

Load and unload at a ramp

Loading and unloading at a ramp is only possible if the platform tip sits firmly on the dock.

Please note

that the vehicle might lift

while unloading, and that the platform will lift from the

ground. To prevent accidents, the platform tilt must always be compensated, so that the tip

sits firmly on the dock at all times.

Operator`s handbook

Document no.: S 20 909 946

11

Series GPC 22 X1

Version: 2011

Page 14

Lift CORP.

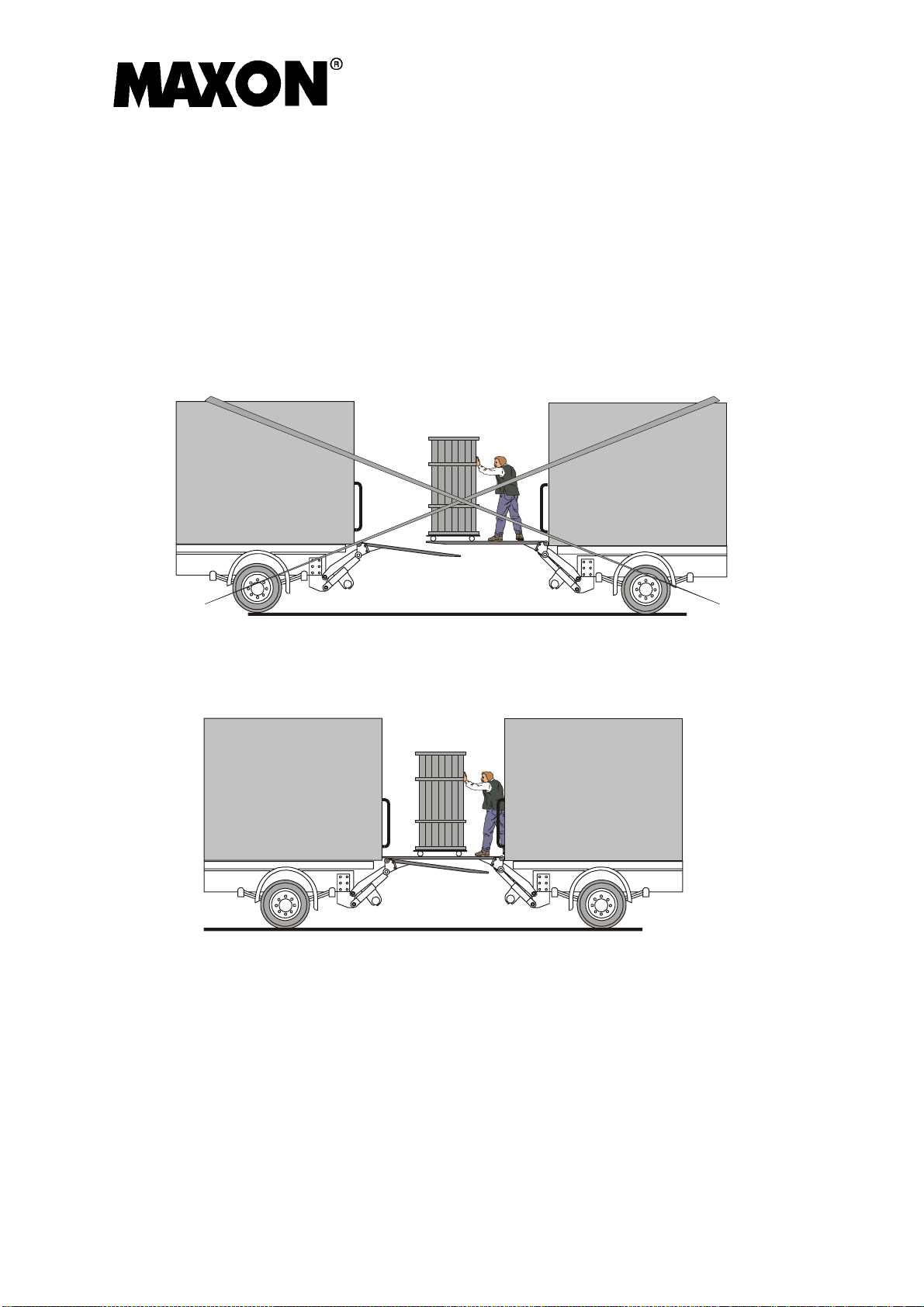

Transferring Loads from Vehicle to Vehicle

When transferring loads, it should be ensured that only one of the two platforms is being

used as a d

ock. The pla

or it may lead to the lift gate becoming overloaded.

tform being used as a dock must lie firmly on the vehicle opposite,

Wrong

Right

Operator`s handbook

Document no.: S 20 909 946

12

Series GPC 22 X1

Version: 2011

Page 15

Lift CORP.

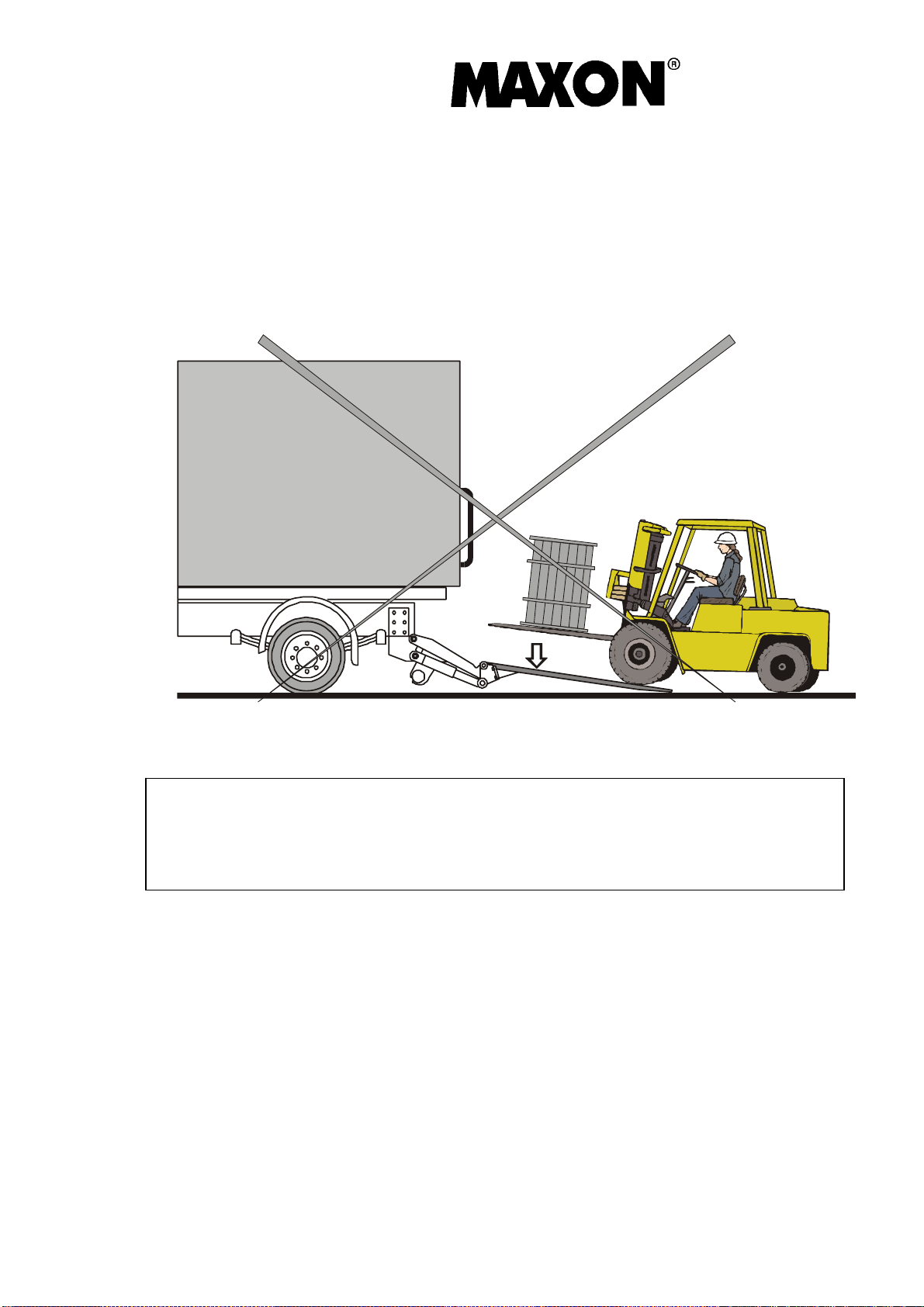

Loading with a Fork-Lift Truck

Driving over the platform with a fork-lift truck is not allowed if the weight of the fork-lift plus

the weight of the load to be transport

The platform must lie firmly on the floor.

ed is greater than the carrying capacity of the lift gate.

When performing any kind of loading or unloading

operation, the vehicle must be secured against

unexpected movement. Use handbrake or wedges

Operator`s handbook

Document no.: S 20 909 946

13

Series GPC 22 X1

Version: 2011

Page 16

Lift CORP.

Securing of Load

The use of the platform or any other parts of the lift gate as a means of securing a load is not

permitted.

Only close the platform after the lift arms have

circumstances close

the platform on the floor or in an intermediate position. This will destroy

cylinders, cables and mechanical parts.

moved firmly against the bodywork. Under no

Operator`s handbook

Document no.: S 20 909 946

14

Series GPC 22 X1

Version: 2011

Page 17

Lift gate as lifting device

Do not hand any loads on the platform

Lift gate as pushing device

Do not use the lift gate as a pushing device

Lift CORP.

Operator`s handbook

Document no.: S 20 909 946

15

Series GPC 22 X1

Version: 2011

Page 18

Lift CORP.

Care, Maintenance, Testing and Repairs

Before the start of maintenance work, the lift gate must be secured against unforeseen

movement.

The lift gate is very undemanding. It should, however, be included in the regular servicing

work on the vehicle.

Check that all screw connections are tight. Check that cables and hoses are able to move

freely. Corre

ct shearing

damaged hydraulic hoses with ones of the same quality. Note the replacement in the

inspection records.

During cleaning it should be ensured that no moisture penetrates the power pack or the

control box. The bearing

this may allow dirt and moisture to penetrate the bearing.

Check the hydraulic unit for leaks. With the lift gate lowered, check the oil level with the

platform lowered to the ground in th

The maximum oil level has been reached when the dipstick dips approx. one centimetre into

the oil.

Carry out an annual oil change and clean the suction filter. Carry out the oil change before

any period of frost, in ord

Hydraulic oil – recommendations

ISO 32 HYDRAULIC OIL ISO 15 HYDRAULIC OIL ISO-10 OR MIL-H-5606

Hydraulic Oil

AMSOIL AWH-05 AMSOIL AWF-05 AMSOIL N/A

CHEVRON HIPERSYN 32 CHEVRON FLUID A, AW-MV-

KENDALL GOLDEN MV KENDALL GLACIAL BLU KENDALL GLACIAL BLU

SHELL TELLUS T-32 SHELL TELLUS T-15 SHELL AEROSHELL FLUID-

EXXON UNIVIS N-32 EXXON UNIVIS HVI-1

MOBIL DTE-13M, DTE-24,

HYDRAULIC OIL-13

and chafing points on cables and hoses. Immediately replace

areas should not be cleaned with high pressure

or steam jets, as

e unit's tank (dipstick on the oil filler neck cover).

er to prevent the hydraulic unit from f

15

MOBIL DTE-11M MOBIL AERO HFA

reezing up.

CHEVRON FLUID A, FLUID G

41

EXXON UNIVIS HVI-13

With normal temperatures from 15 to 85 degree Fahrenheit it is recommended to use ISO 15

Hydraulic oil. For general colder climate use ISO 10, and warmer climate use ISO 32.

Oil fill up or change

1. lower

2. tilt down

3. oil fill up

1

3

Series GPC 22 X1

Version: 2011

Operator`s handbook

Document no.: S 20 909 946

2

16

Page 19

Lift CORP.

Repairs to Load-Bearing Components

Repairs to load-bearing components are only to be carried out in an authorized repair shop

and are to b

e tested by a competent person and

For any malfunctioning, first check voltage level

Troubleshooting

The 2 diodes in the front of the control box lits when the GPC

are switched on. If not

Problem possible cause

1. Motor of pump box

does not work

Battery cable or ground cable not connected or defective or

empty battery

Main fuse defective

Fuse in power pack defective

The power relay is defective and doesn't switch

Motor defective

2. Motor does not work

on one function only

Toggleswitch on hand control box defective

Cable from hand control box to pump box defective

entered in the inspection records.

- check the fuse in the battery cable.

Wiring inside pump box defective

Switch relay defective (Starter Solenoid)

3. Platform tilts down

alone without operating

Solenoid valves on tilting cylinder defective

Cylinder defective

that function.

4. Platform does not tilt

Cable to pressure switch defective

down when touching the

ground.

Pressure switch defective

5. Lift gate does not lift

Pump box does not work

Lack of oil in the tank

Voltage insufficient (low Battery)

6. Lift gate does not lift

Load is placed in excess of permitted loading distance

rated capacity

Weight of load too high

Overload security valve not set properly

Operator`s handbook

Document no.: S 20 909 946

17

Series GPC 22 X1

Version: 2011

Page 20

Lift CORP.

Voltage insufficient (low Battery)

7. Lift gate does not tilt up

from ground when unloaded

Mercury switch S2 defective or not set properly

Pump defective

Toggle switch does not operate

8. Lift gate does not tilt up

Load is placed in excess of permitted loading distance

from ground when loaded.

Weight of load too high

Overload security valve not set properly

9. Lift gate tilts from ground

Mercury switch S2 defective or not set properly

above horizontal

Where the electrical motor runs continuously (the lift gate will not switch off)

disconnect the positive cable from the battery b

y disconnecting the main switch or

throwing the main fuse.

In an emergency call our Customer Service Department or the nearest authorized repair

shop. On request, we shall be plea

sed to send

you an up-to-date list of Customer Service

repair shops authorised by us.

Operator`s handbook

Document no.: S 20 909 946

18

Series GPC 22 X1

Version: 2011

Page 21

Lift CORP.

In an Emergency

If, in an emergency, the lift gate is raised or closed manually or by mechanical means instead

of hydraulically, the hydraulic cylinders are

operational in this case. This means that removal of any rope, chain or other means being

used to hold lift in the raised position can be extremely dangerous and even fatal, as the lift

gate will freefall to the floor without any braking mechanism.

In such a case secure the lift gate by means of ropes or chains and attach a clear notice to it:

Caution ! Life danger ! The Lift gate is unsecured and must be operated

only by trained personnel !

Operation failure

In case of failure, please contact our customers service or the next authorized service dealer.

We will provide an up-to-date list of service dealers on request

Contact Maxon Technical Service at 1-800-227-4116 or by fax 888-771-7713

Warranty

LIFT CORP.

11921 Slauson Ave.

Santa Fe Springs, CA. 90670

CUSTOMER SERVICE:

(562) 464-0099

(800) 227-4116

FAX: (888) 771-7713

TECHNICAL SERVICE:

(800) 8-MAXTEK (862-9835)

WARRANTY POLICY & PROCEDURE

NEW LIFT GATE WARRANTY

Term of Warranty: 2 Years from Date of In-Service

Type of Warranty: Full Parts and Labor

MAXON agrees to replace any components which are found to be defective during the first

2 years of service, and will reimburse for labor based on Maxon’s Lift gate Warranty Flat

Rate

Labor Schedule.

All claims for warranty must be received within 30 Days of the repair date, and include the

following information:

1. Lift gate Model Number

2. Lift gate Serial Number

3. Description of Problem

4. Corrective Action Taken, and Date of Repair.

5. Parts used for Repair, Including MAXON Part Number(s).

6. MAXON R.G.A. # and/or Authorization # if applicable (see below).

7. Person contacted at MAXON if applicable.

PURCHASE PART WARRANTY

Term of Warranty: 1 Year from Date of Purchase Type of Warranty: Part Replacement and

Replacement Labor

MAXON will guarantee all returned genuine replacement parts upon receipt, and inspection

of parts and invoice. All Warranty repairs must be performed by an authorized MAXON

warranty station.

For major repairs, Maxon’s Warranty Department must be notified, and an “Authorization

filled with air. The safety valves are not

Operator`s handbook

Document no.: S 20 909 946

19

Series GPC 22 X1

Version: 2011

Page 22

Lift CORP.

Number” received. Major repairs would generally be considered repairs made to the

structural assembly of the lift gate and/or repairs not outlined in the Maxon Slidelift Waranty

Flat Rate Schedule.

Major components (i.e. hydraulic pumps, cylinders, valves, or failed structural parts) must

be returned, freight pre-paid, prior to the claim being processed. To ensure timely processing

of these warranty claims, an R.G.A. (Returned Goods Authorization) number must be

obtained from

Maxon’s Warranty Department prior to the return of any defective part. Defective Parts must

be returned within 60 da

Warranty Dapartment, MAXON Lift Corp.

16205 Distribution Way, Cerritos, California. 90703

Maxon’s warranty policy does not include the reimbursement for travel time; towing;

vehicle rental; service calls; fabrication of parts

due to misuse or abuse; loss of income due to downtime.

Maxon’s Flat Rate Labor Schedule times takes into consideration time required for diagnosis

of problem.

Warranty and Technical Information is available by calling Maxon’s Customer Service

Department.

NOTE:

Check with Customer Service Department for updat

annual basis.

Liability exclusions

Our liability excludes : damages assigned to wrong installation or operation of the slidelift,

overloading, unproper use, insuff

to ground contact (e.g. rough terrain at building sites)

ys of the claim date for consideration

which are a

to:

vailable from MAXON; oil; defects

ed versions of Manuals on an

nt battery charge or capacity, accidents or damages due

icie

Operator`s handbook

Document no.: S 20 909 946

20

Series GPC 22 X1

Version: 2011

Page 23

Decals

These Decals should be read and completely

understood before operating the unit. They should

also be kept clean and readable at all times. If

any decals should become detached from the

vehicles, or defaced, it must be replaced. Free

replacement are available from: MAXON Lift Corp.,

Parts Department.

Same distance bothsides

Ground level loaded

max. bed hight

GPC 22 X1 - max. bed hight 46” 7/16 - Liftarm 26” 9/16

min 17” 5/16

Ground level unloaded

Always as near max. as possible

max 26” 6/16

*

max 20” 1/16

min 32” 1/4 - inch

max 46” 7/16 - inch

Lift CORP.

Apply grease to bearings

located in arms prior

assembly

Caution!

Do not power pack

with hands, ropes or chains.

Do not use pry bars.

assemble o-rings

to arms as shown

lift on

Operator`s handbook

Document no.: S 20 909 946

21

Series GPC 22 X1

Version: 2011

Page 24

Lift CORP.

GPC 22 X1

THE MAXIMUM CAPACITY OF

THIS LIFT IS

2200 POUNDS

Diagnostic Lamp

Lift CORP.

11921 Slauson Avenue.

Santa Fe Springs, CA

90670

All liftgate warning, capacity, and caution decals

should be affixed to the truck body in plain view

of the operator near the main lift gate Control Station.

Note: The main liftgate Control Station is normally

mounted on right rear corner of the truck body.

®

Diagnostic Lamp

20 904 654

STAND CLEAR

WHEN OPERATING

WARNING

TIL T THE PLATFORM TO

LEVEL POSITION PRIOR

TO RAISING

50092

Improper operation of this Lift can result in serious personal injury. Do

not operate unless you have been properly instructed and have read, and

are familiar with the operat ing instructions. If you do not have a copy of

the instructions, please obtain them from your employer, distributor, or

lessor, before you attempt to operate Lift

Be certain that the vehicle is properly and securely braked beforeusing

the Lift

Always inspect this Lift for maintenance or damage before using it. If

there are signs of improper maintenance, damage to vital parts, or

slippery Platform surface, do not use the Lift until these problems have

been corrected

Do not overload the Lift. The load limit is based on evenly distributed

cargo over the entire Platform surface. If you are using a pallet jack, be

sure it can be maneuvered safely. Do not operate a forklift on the

Platform or travel with the platform in an open position at any time.

Load should be placed in a stable position close to the edge of the

Platform nearest the truck. The heaviest portion of the load should never

be placed beyond the center of the Platform away from the truck.

Never allow yourself, a helper, or bystander to stand in a position

where a falling load could land on either of you. Also do not allow any

part of yours or your helper body to be placed under, within, or around

any portion of the moving liftgate, or it`s mechanisms, or in a position

that would trap them between the platform and the ground or truck when

the liftgate is operated.

If a helper is riding the Platform with you, make sure you are both

doing so safely and that you are not in danger of coming in contact with

any moving or potentially moving obstacles. USE GOOD COMMON

SENSE. If load appears to be unsafe, do not lift or lower it.

MAXON LIFT CORP.

WARNING

READ CAREFULLY

PART NO.

264081

Operator`s handbook

Document no.: S 20 909 946

22

Series GPC 22 X1

Version: 2011

Page 25

Page 26

X

X

XXXX

XX

X

X

YA

KM

X

X

*

S4S2S1

Y3

Y1

XX

X

XX

X

X

X

Y1

KM

Th

SERVICE-SWITCH

KM

Y1

YA

31

YA

30

YA

KM

30

Y3

Y3

Y1

KM

30

YA

Y1

Y3

31

30

DATUM:

control-unit

gez.:

No.:

W.Bassen SOE28050

29.01.2008

20 908 356

gr/ye

123 6 5

No 30

20 905 547

20 906 387

20 905 109

X

250 cm

test up,down

lamp +

lamp +

test S2,S4

HANDHELD CONTROLBOX

DOWN

UP

CONTROL-LAMP

20 907 162 CONTROL-UNIT 12 V

30 - batteryplus

31 - batteryminus

KM - motorrelay

YA - solenoid in power-pack

Y1 - solenoid tilt-cylinder

Y3 - solenoid lift-cylinder

S1 - mercury-switch

S2 - mercury-switch lift

S4 - pressure-switch tilt down

Th - motor-thermoswtich

ON/OFF - Switch

POWER-PACK

FUSE 6A

motor-relay

FUSE 250 A

Please connect behind

the fuse

platform-cable

tilt-cylinder

TILT-DOWN

LOWER

TILT-UP

LIFT

TILT DOWN

TILT-UP

LOWER

LIFT

HANDHELD

CONTROL CONTROLBOX

right lamp is out, if switch "up" or "down" is pressed on handheld

controlbox.

left lamp is out also, if "down" is pressed and

S4 switched if platform is on ground (lift-cylinder is without pressure).

left lamp is out, if "up" is pressed and

S2 switched at horizontal platform position.

STANDARD 12V GPC 22 X1

OPTION:

®

TILT

white (30)

brown (+)

red (30)

blue

viol.

green

1 - 1 - S4

2 - 2 - S4

3 - 3 - Y3

4 - gr/ge - Y3

1 -

2 - brown - S2

3 -

4 - black - S2

5 - grey - S1

6 - gr/ye - S1

Hg - switch

S1 + S2

mercury

S1

grey

gr/ye

S2

black

brown

platform

1 - 1 - +

2 - 2 - FH

3 - 3 - FS

4 - 4 - S2

5 - 5 - S1

6 - gr/ye - 31

plug no.

cable no.

signal

Y3

P

S4

lift-cylinder

pressure-

swtich

blue

brown

1

23

gr/ye

plug no.

cable no.

1 - 1 - 30

2 - 2 - YA

3 - 3 - KM

4 - 5 - Y1

5 - 6 - Y3

6 -gr/ye - 31

plug no.

cable no.

7G1.5

grey

blue

gr/ye

brown

+

31

1

2

3

gr/ye

black

cable no.

cable color.

red

blue

grey

U

T

D

brown

450 cm 7G0.75

60 cm 4G0.75

60 cm 7G1.5

120 cm 5G0.75

50 cm FLKK

*S1 signal is lead to ground

22 905 768 REPLACEMENT

Page 27

Page 28

Page 29

Loading...

Loading...