Page 1

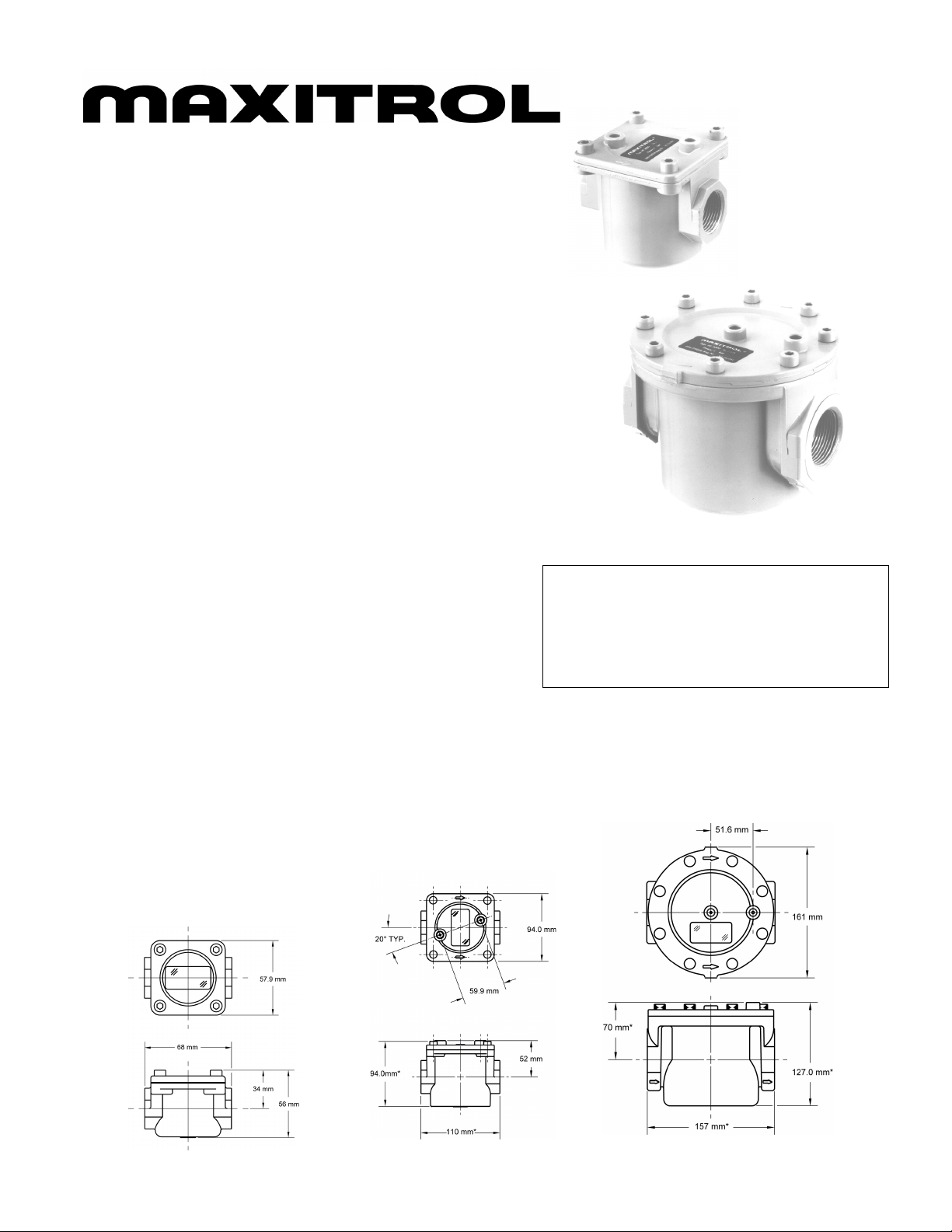

Gas Filters

and for other applications such as air

½", ¾", 1", 1¼", 1½", 2" NPT or ISO 7-1

Maxitrol filters are suitable for application in natural,

manufactured, mixed gases, liquefied petroleum gases and LP gasair mixture piping systems.

Changes to the NFPA (National Fire Protection Association) 86

Standard require a gas filter or strainer be installed in the fuel gas

supply line, on new oven and furnace installations.

The filters are tested according to DIN 3386 and have

DIN/DVGW approval. The filters are approved according to

European Gas Appliance Directive 90/396/EG, Pressure Equipment

Directive 97/23/E, the Russian GOST, and the Hungarian MBVTI

requirements. Filters with NPT threads are not covered by

European certification.

Unique filter matting effectively separates dust. The matting has

an extremely high capacity for accumulated dust due to its wide

filtering surface and depth effect. The material will not allow

particulate infiltration over 0.05mm (50 microns). The inserts are

quick and easy to replace.

The filter housing's compact size allows for easy

original equipment installation or retrofitting.

Specifications

• Housing's are made of durable cast aluminum

Pipe Size NPT Model ISO 7-1 Model

1/2" GF40-1-44 GF40M-1-44

3/4" GF60-1-66 GF60M-1-66

1" GF60-1-88 GF60M-1-88

1-1/4" GF80-1-1010 GF80M-1-1010

1-1/2" GF80-1-1212 GF80M-1-1212

2" GF80-1-1616 GF80M-1-1616

GF_MBH_EN_08.2006

Replaced Bulletin MBH2068

• Filter matting consists of polypropylene impregnated fleece

• Rp or Rc thread (parallel or taper) dimensions according to

ISO 7-1. NPT thread according to ANSI.

• Maximum operating inlet pressure: 15 psi (1 bar)

• Ambient temperature limit: 175° F (80° C)

GF60 models

GF40 models

* Dimensions (inches/millimeters) are maximums and are to be used only as an aid in designing clearance for the filter.

Actual production dimensions may vary somewhat from those shown.

© 2006, Maxitrol Company, All Rights Reserved.

GF80 models

Page 2

Installation and Service

Maxitrol filters are suitable for multipoise mounting.

(Preferably with the lid facing down or to the side.)

Install the filter properly with gas flowing as indicated

by the arrow on the casting. It is also important to

leave sufficient space above the cover to allow for

removal in order to change the filter insert.

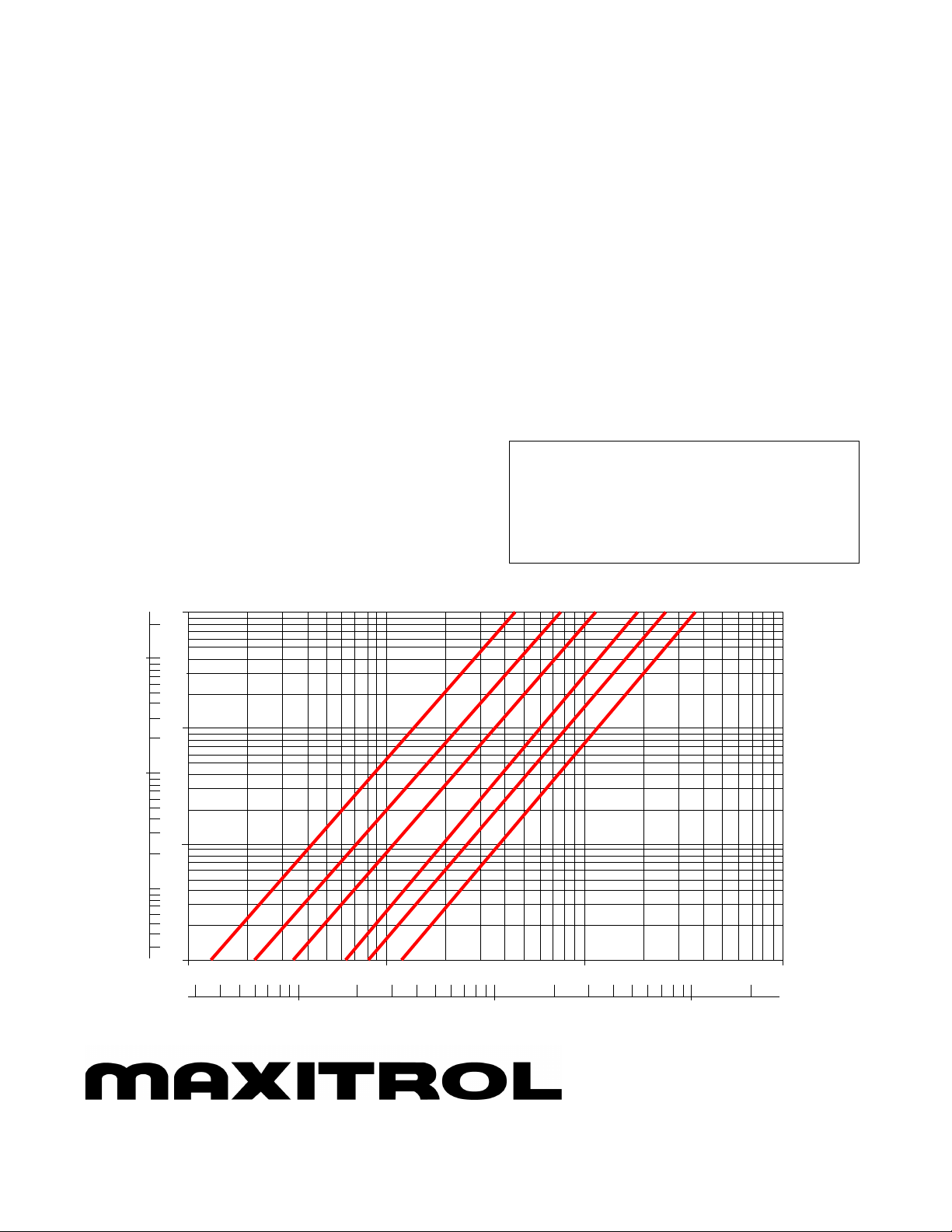

Frequency of filter insert maintenance is dependent

upon both the maximum operating pressure of your

equipment application, and the associated pressure

drop at the filter. Although, it is recommended that the

filter insert be replaced at least once a year. See the

adjoining pressure drop chart.

Shut off all gas before servicing the filter insert.

When loosening the screws secure the cover,

proceed slowly in case of any residual gas pressure.

Remove the cover and withdraw the filter insert.

Filter Replacement Material

Replacement filter matting material is available.

GF40 models - part number 101706-1

GF60 models - part number 101706-2

GF80 models - part number 101706-3

Replace the filter insert with the side imprinted

'Austritt' (outlet) facing the outlet. Inspect the o-ring and

replace if necessary. To ensure an effective seal,

place the filter insert so that it abuts correctly in relation

to the flanges and base of the housing. The filter insert

should not extend into the area between the o-ring and

cover - slightly bend down the corners of the matting to

prevent o-ring obstruction. Replace the cover and

tighten the screws.

Check carefully for gas leaks immediately after the

filter has been installed or serviced and the gas turned

on. Do this before attempting to operate the appliance

or other gas-fired device. Use a rich liquid soap

solution or other accepted leak tester on the area

between the cover and housing, and at the pipe

connections. Never use if leakage is detected.

Pipe Size NPT Model ISO 7-1 Model

1/2" GF40-1-44 GF40M-1-44

3/4" GF60-1-66 GF60M-1-66

1" GF60-1-88 GF60M-1-88

1-1/4" GF80-1-1010 GF80M-1-1010

1-1/2" GF80-1-1212 GF80M-1-1212

2" GF80-1-1616 GF80M-1-1616

Pressure Drop Curves (0.64 sp gr gas)

100

100

10

10

Pressure Drop (UP)

1

1

(inches W.C.)

(mbar)

.3

0.1

100 (cfh) 1000 10000

3 (m3/hr)

© 2006, Maxitrol Company, All Rights Reserved

10 30 100 1000 2000

GF40-1-44

GF60-1-66

Volumetric Flow Rate

FG60-1-88

GF80-1-1010

GF80-1-1212

GF80-1-1616

100000

Maxitrol Company

23555 Telegraph Rd., P.O. Box 2230

Southfield, MI 48037-2230 U.S.A.

248.356.1400 • Fax 248.356.0829

www.maxitrol.com

European Representatives

Warnstedter Strasse 3 06502 Thale, Germany

49.3947.400.0 • Fax 49.3947.400.200

Industriestrasse 1 48308 Senden, Germany

49.2597.9632.0 • Fax 49.2597.9632.99

Loading...

Loading...