Page 1

Gas Pressure reGulators

CataloG

rd

3

edition

Page 2

Service and installation must be performed by a trained/experienced service technician.

All products used with combustible gas must be installed and used strictly in accordance

with the instructions of the Original Equipment Manufacturer (OEM) and with all

applicable government codes and regulations, e.g. plumbing, mechanical, and electrical

codes and practices. Maxitrol products should be installed and operated in accordance

with Maxitrol Safety Warning Instructions.

Maxitrol Company is NOT responsible for any errors or omissions in reliance by anyone of

any information set forth in this catalog without additional reference to local requirements

and applicable ordinances or codes.

Other worldwide approvals and certifications available upon inquiry.

2

®

C

US

UA.TR.012-13

© 2017, Maxitrol Company. All Rights Reserved.

Page 3

Gas Pr essure reGul a tor Ca t aloG

Appliance Regulators

RV Series Appliance Regulators: Rubber Seat Poppet Design.....................................................4-9

RV Series Appliance Regulators: Straight-Thru-Flow Design...................................................10-13

325 Series Appliance Regulators: Lever Acting Design..........................................................14-17

R/RS Series Appliance Regulators: Balanced Valve Design......................................................18-21

210 Series Appliance Regulators: Balanced Valve Design....................................................22-31

RZ and 210Z Series Appliance Regulators: Zero Governor Design.........................................32-37

220 Series Appliance Regulators: Pilot Loaded Design..........................................................38-41

SR Series Appliance Regulators: Two-Stage Design..............................................................42-45

Line Regulators

325L Series Line Regulators for 2PSI: Lever Acting Design.....................................................46-49

325L Series Line Regulators for 5PSI: Lever Acting Design.....................................................50-55

Spring Selection Chart .............................................................................................................56-57

Sizing a Regulator .......................................................................................................................58-59

Accessories

Pressure Tap Connector...........................................................................................................61

Dust Cap................................................................................................................................61

Tamper Proof Seals..................................................................................................................61

Choosing a Vent Accessory.....................................................................................................62

Venting.......................................................................................................................60-61

Definitions .....................................................................................................................................63

Gas and Air Filters ...................................................................................................................64-67

3

Page 4

RV SERIES

Rubber Seat Poppet Design

The compact RV poppet regulators are designed primarily for main

burner and pilot load applications. Typical applications include

residential and commercial cooking appliances, barbecues, hearth

products, and pilot lines. Maxitrol rubber seat poppet models offer

the ultimate in design features and performance capabilities to

meet your specific appliance or utility requirements.

RV47

Specications

Pipe Sizes .....................................1/8” thru 3/4” threaded connections with NPT or ISO7-1 threads.

(Other connections available, please consult Maxitrol Company.)

Housing Material ..................... RV12, RV20, RV47, RV48, CV47: aluminum.

Mounting ................................. All models, with the exception of “D” sufx models, are suitable for multi-positional mounting.

Other than upright position will result in a slight difference in outlet pressure. “D” sufx

models are to be mounted upright only. If ball check vent limiting device is installed, mount in

an upright position only.

NOTE: All Maxitrol gas pressure regulators should be installed and operated in accordance

with Maxitrol Safety Warning Instructions (see GPR_MI_EN.ES or GPR_CSA_MI_EN.FR).

Certications ........................... RV Series: ANSI Z21.18/CSA 6.3 Gas Appliance Pressure Regulators.

CV47 Series: ANSI Z21.78/CSA 6.20 Combination Gas Controls for Gas Appliances.

Gas Types (RV Series) ............... Suitable for natural, manufactured, mixed gases, liqueed petroleum gases, and

LP gas-air mixtures.

Gas Types (CV47 Series) ........... Suitable for natural or liqueed petroleum gases.

Rated Inlet Pressure ................. 1/2 psi (3.4 kPa)

Emergency Exposure Limits ...... 2.5 psi (17.2 kPa)

Ambient Temperature Ranges ... RV20, RV47, RV48, CV47: 32° to 225°F (0° to 107°C)

RV12: -40° to 225°F (-40° to 107°C)

RV12T: -40° to 275°F (-40° to 135°C)

RV20T: -40° to 300°F (-40° to 148°C)

RV48T: 32° to 275°F (0° to 135°C)

Minimum Regulation ................ Suitable for pilot ow applications. (Circle P) (0.15 CFH NG), (Delta P)

(0.50 CFH NG), None (1.5 CFH NG), N Models (3 CFH NG).

4

© 2017, Maxitrol Company. All Rights Reserved.

Page 5

APPLIANCE REGULATORS

C

US

®

UA.TR.012-13

Model Designations

Models having a sufx letter or a combination of sufx letters listed below indicates the design modications described.

A ............Limited spring adjustment (RV47A & CV47A**, short stack*).

C ............Convertible regulators***; preset to deliver outlet pressures for either natural or LP gases.

(RV20, RV47, RV48, CV47)

D ............Integral ball check limiting device; permits higher maximum individual load.

(see Capacities and Pressure Drop, page 6)

E .............Excessive pressure rated.

F .............Factory-set; xed/non-adjustable regulator.

I .............Left side integral manual valve; outlet faces main inlet (CV47).

L .............Integral vent limiting orice as the breather hole - with dust cap.

M ...........B.S.P. - PL parallel thread - conforms to ISO 7-1, where pressure tight joints are made on the threads.

N ............Internal by-pass orice to prevent lockup. Main burner only (RV20, RV47, RV48, CV47).

R ............Right side+ integral manual valve; outlet faces main outlet (CV47).

SR ...........Side pressure tap; right side+ 1/8” NPT (RV20, RV47, RV48, CV47I).

S .............Side pressure tap; left side+ 1/8” NPT (RV20, RV47, RV48, CV47R).

T.............Higher ambient temperature range.

V ............Threaded vent connector, 5/16-24 for 1/8” tubing connection (RV20) - with dust cap.

* Short stack models have an adjustment range of less than 2” w.c. (0.5 kPa); these models are advantageous

where installation must be made in a limited space.

** CV47 is best described as a RV47 with an extra regulated outlet. This outlet contains an integral manual valve

located on the valve body’s side.

*** Convertible regulators are designed to deliver either of two xed outlet pressures for natural or LP gases.

RV20C: NAT GAS: 4.0” w.c. (1.0 kPa); LP: 10” w.c. (2.5 kPa)

RV47C, RV48C, CV47C: NAT GAS: 4.0”, 5.0” or 6.0” w.c. (1.0, 1.3, or 1.5 kPa); LP: 10” or 11” w.c. (2.5 or

2.8 kPa)

+ Left and right is determined when viewing regulator from outlet side with stack up.

NOTE: The RV48 model may be used with either a 12A04 ball check device, or a 12A06 xed orice vent limiting device.

See page 62 for vent accessory options.

5

Page 6

RV SERIES

Rubber Seat Poppet Design

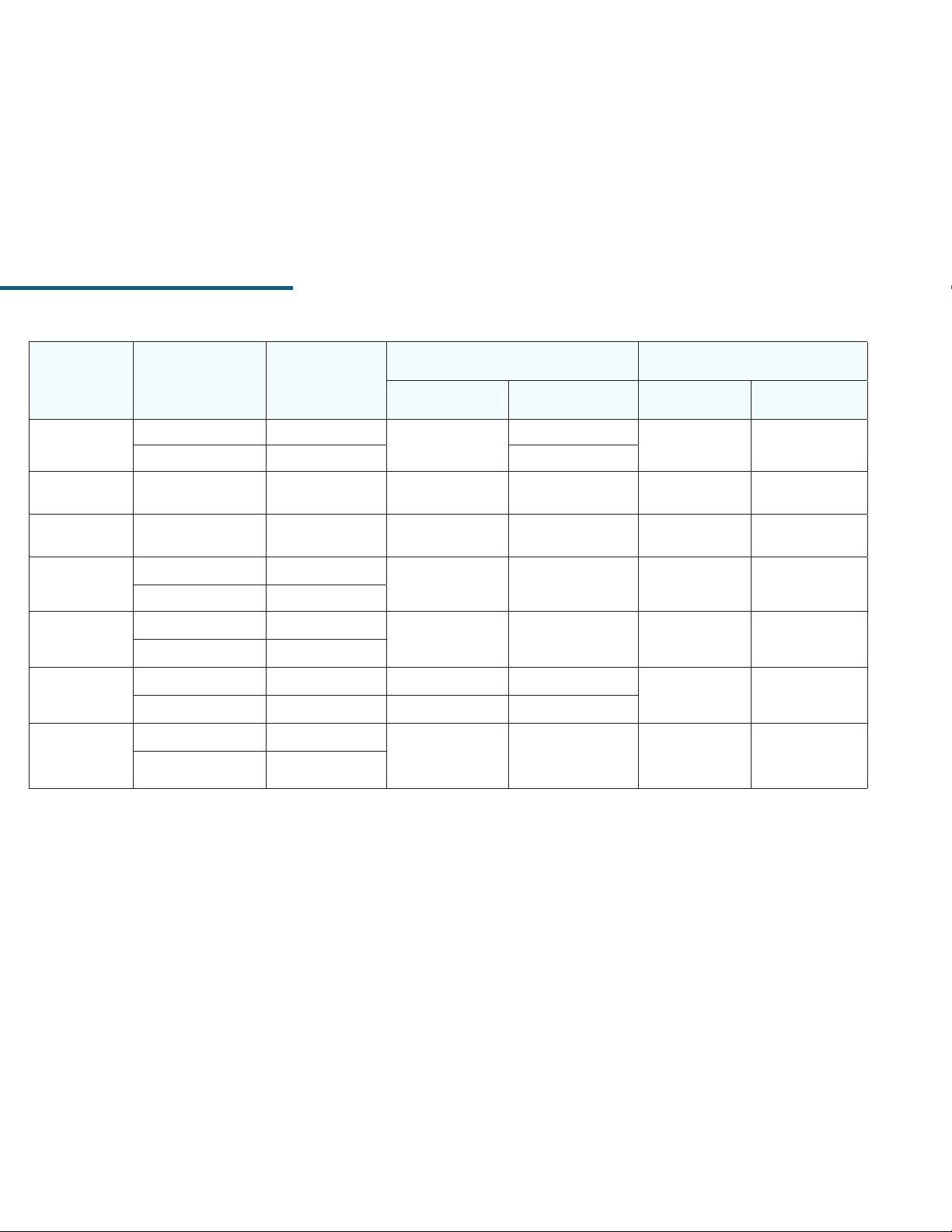

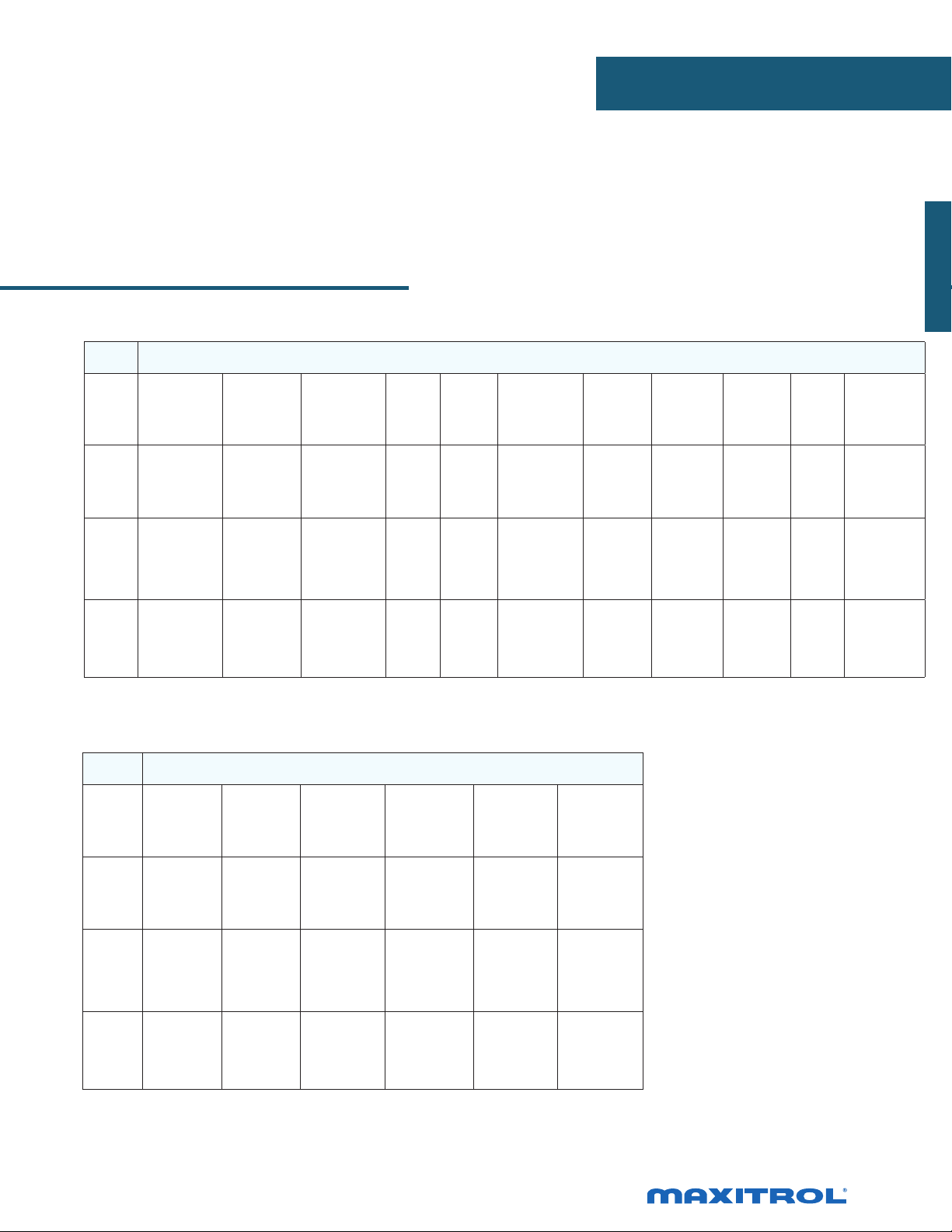

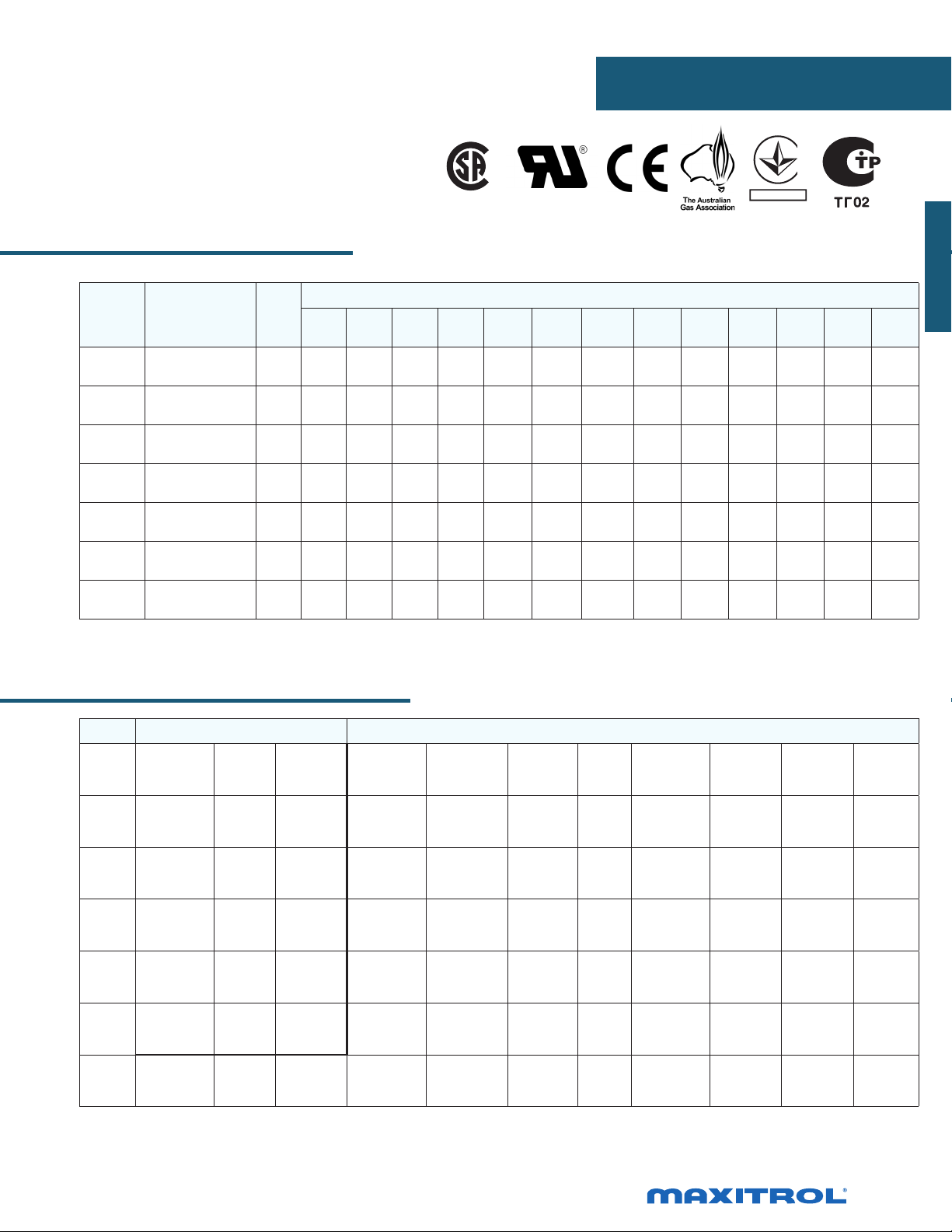

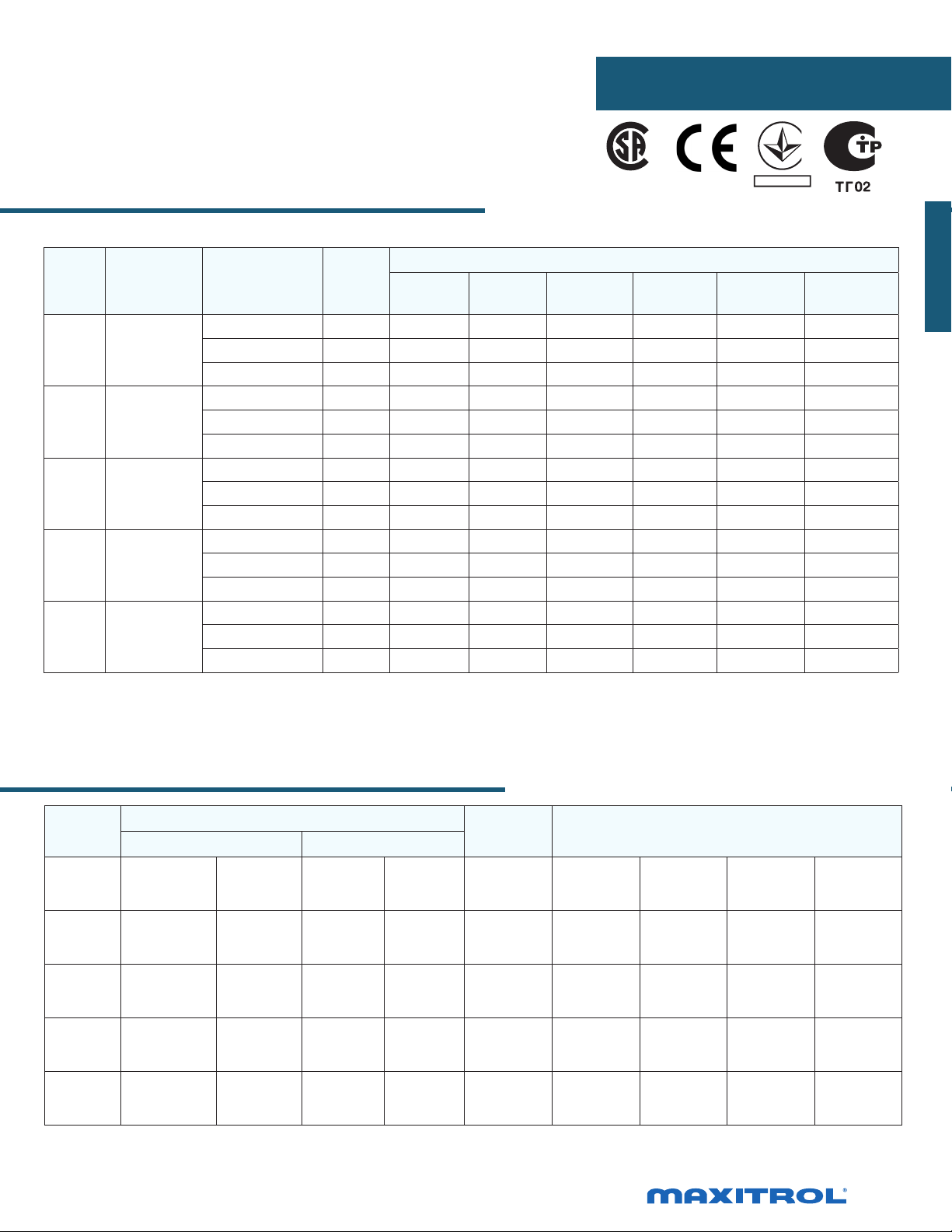

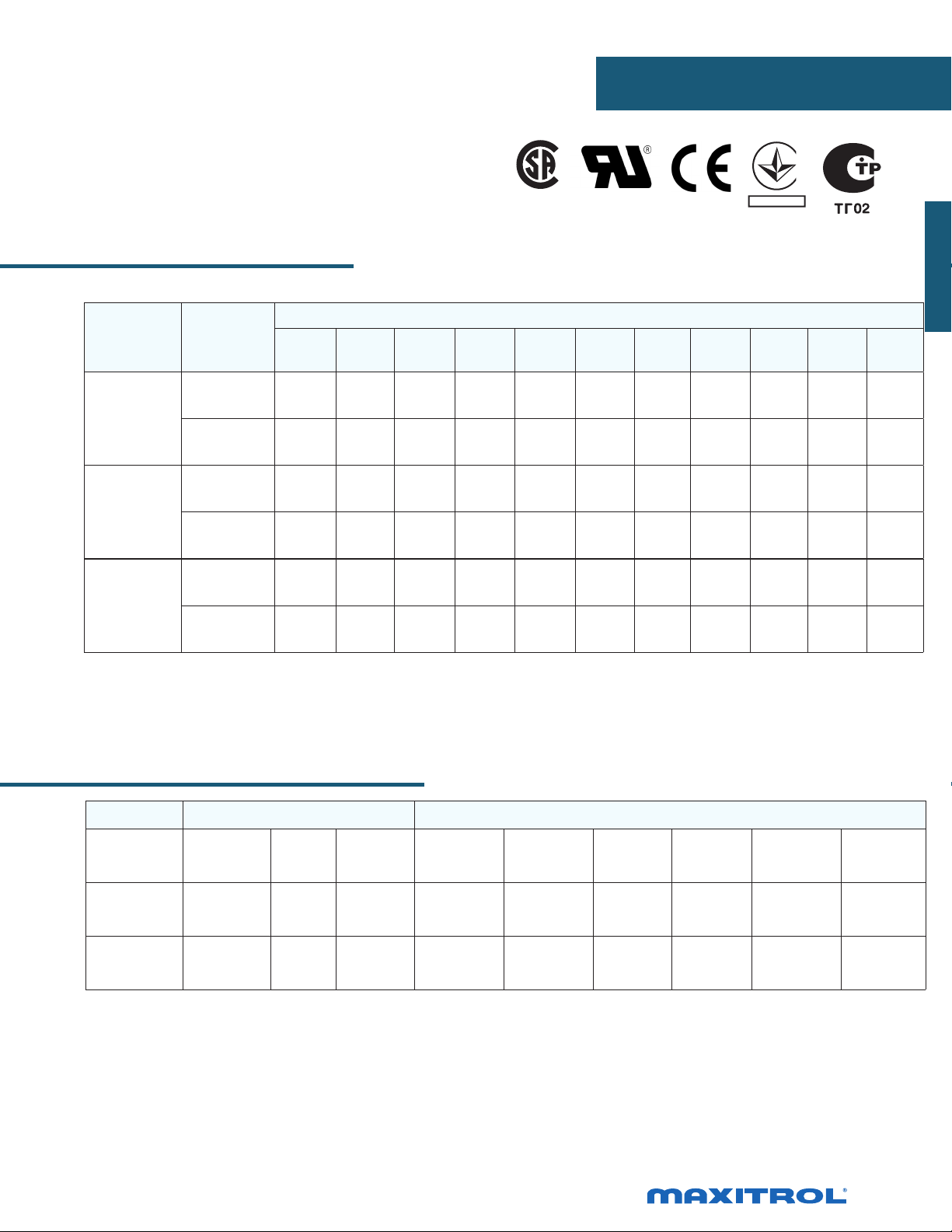

Capacities and Pressure Drop

Capacities expressed in Btu/h (m3/h) @ 0.64 sp gr gas

Range of Regulation Individual Load

Main Burner

30,000 (0.85)

125,000 (3.5) 90,000 (2.5) 40,000 (1.1) 125,000 (3.5)

125,000 (3.5) 125,000 (3.5) 40,000 (1.1) 125,000 (3.5)

400,000 (11.3)

Main Burner

& Pilot

25,000 (0.71)

275,000

275,000

(7.8) Nat

(3.1) LP

Fixed Orice

20,000 (0.56) ---

40,000 (1.1) 160,000 (4.5)

40,000 (1.1) 160,000 (4.5)

Ball Check

Device

Model Pipe Size

RV12

RV20

RV20C

CV47

RV47

CV47A or C

RV47A or C

RV48

RV48C

1/8” x 1/8”* 14,800 (0.42)

3/16” x 3/16”Loxit 8,800 (0.25) 15,000 (0.43)

1/4” x 1/4”

3/8” x 3/8”*

1/4” x 1/4”

3/8” x 3/8”

3/8”x 3/8” 55,000 (1.5)

1/2” x 1/2”* 60,000 (1.7)

3/8” x 3/8” 55,000 (1.5)

1/2” x 1/2” 60,000 (1.7)

1/2” x 1/2” 130,000 (3.7) 230,000 (6.5) 230,000 (6.5)

3/4” x 3/4” 150,000 (4.2) 250,000 (7.1) 250,000 (7.1)

1/2” x 1/2” 130,000 (3.7)

3/4” x 3/4” 150,000 (4.2)

Pressure Drop

@ 0.3” w.c.

or (0.07 kPa)

30,000 (0.85) 65,000 (1.84) 50,000 (1.4) 30,000 (0.85) ---

30,000 (0.85) 75,000 (2.11) 50,000 (1.4) 15,000 (0.42) ---

*Also available as Loxit connection.

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

Minimum main burner regulation capacity for all models (except “N”) is 150 Btu/hr (0.0042 m3/h). See pages 58-59

for Regulator Sizing Requirements and Examples.

6

© 2017, Maxitrol Company. All Rights Reserved.

Page 7

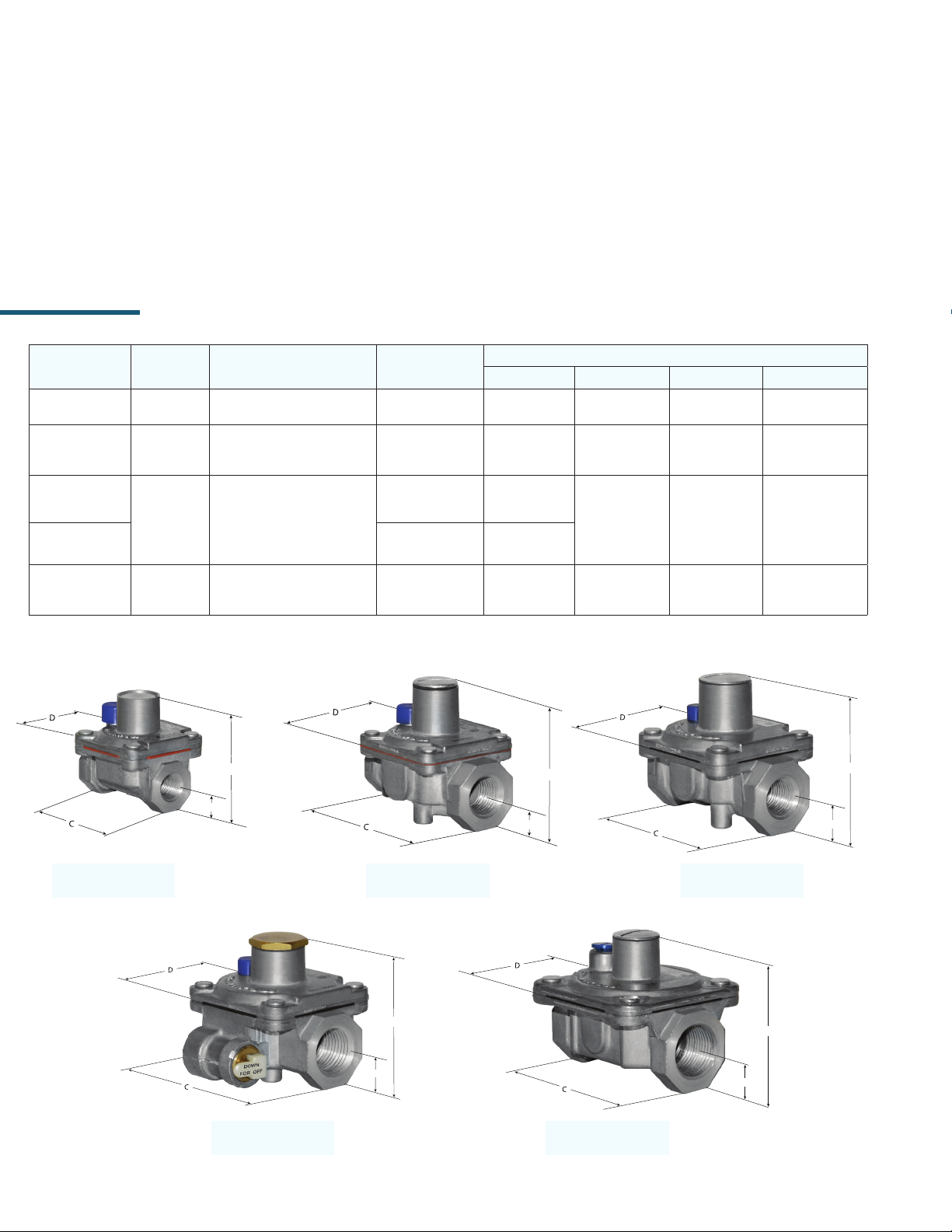

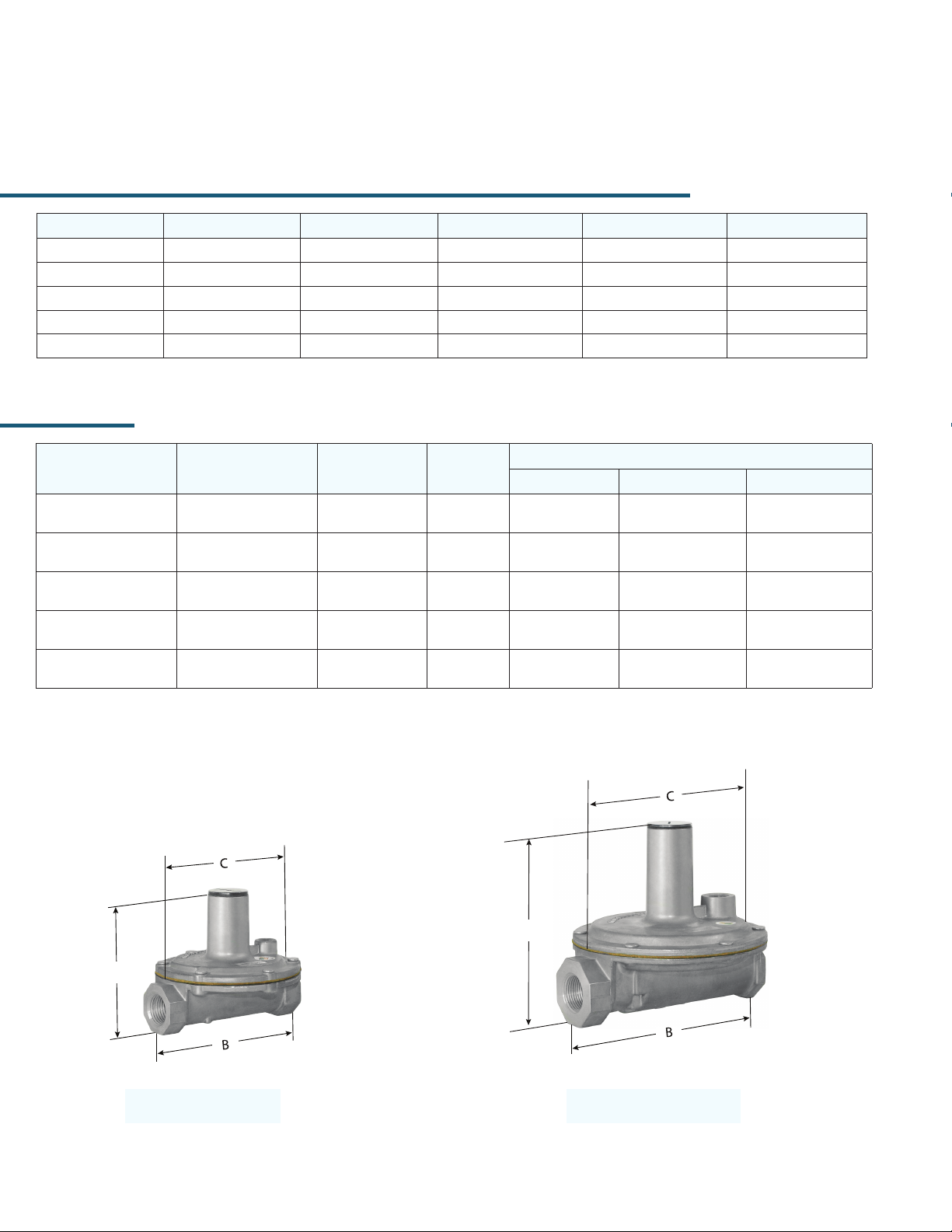

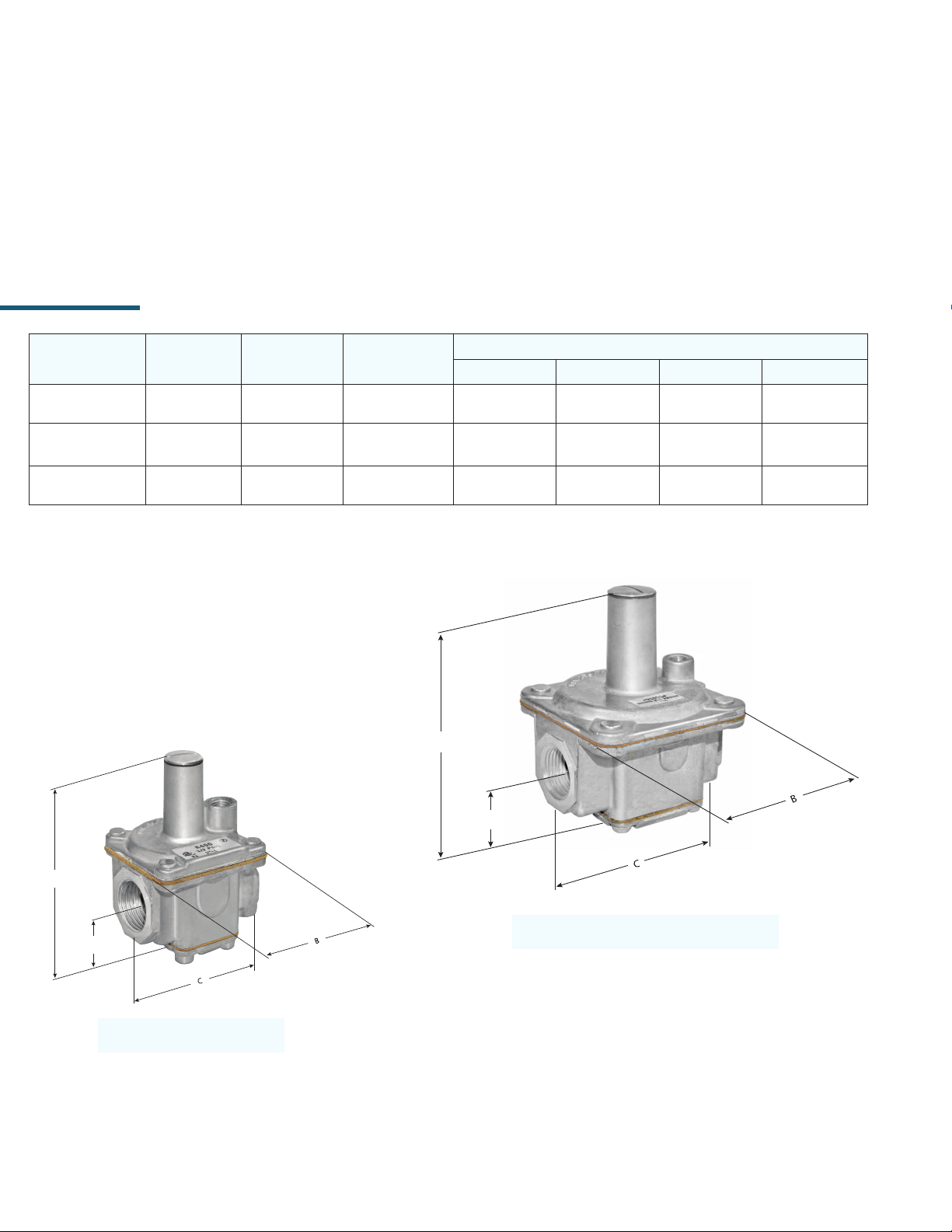

Spring Selection Chart: inches w.c. (kPa)

Model Available Springs

APPLIANCE REGULATORS

RV12

RV20

RV47

CV47

RV48

1.5 to 3*

(0.37 to 0.75)

Brown

1 to 3.5*

(0.25 to 0.9)

Brown

1 to 3.5*

(0.25 to 0.9)

Brown

1 to 3.5*

(0.25 to 0.9)

Brown

2.8 to 5.2

(0.69 to 1.3)

Plated

2.8 to 5.2

(0.69 to 1.3)

Plated

2.8 to 5.2

(0.69 to 1.3)

Plated

3.0 to 6.0

(0.75 to 1.5)

Plated

---

---

3.8 to 4.3

(0.95 to 1.08)

Black

---

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

*Uncertied Spring

**Certied at inlet pressure of 2 psi

Model Available Springs

RV20CL

4 / 10

(1 / 2.5)

--- --- --- --- ---

--- --- --- ---

--- --- --- ---

4 to 12*

(1 to 3)

Violet

--- ---

4.7 to 5.3

(1.18 to 1.33)

Green

---

5 to 12

(1.25 to 3)

Blue

5.6 to 6.4

(1.4 to 1.6)

Red

---

6 to 10

(1.5 to 2.5)

Red

6 to 10

(1.5 to 2.5)

Red

6 to 10

(1.5 to 2.5)

Red

6 to 10

(1.5 to 2.5)

Red

8 to 12

(2 to 3)

Blue

8 to 12

(2 to 3)

Blue

8 to 12

(2 to 3)

(2.42 to 2.83)

Blue

--- ---

---

9 to 12**

(2.25 to 3)

Plated

9.7 to 11.3

Plated

RV47CL

CV47CL

RV48C

4 / 10

(1 / 2.5)

4 / 10

(1 / 2.5)

4 / 10

(1 / 2.5)

4 / 11

(1 / 2.75)

4 / 11

(1 / 2.75)

4 / 11

(1 / 2.75)

5 / 10

(1.25 / 2.5)

5 / 10

(1.25 / 2.5)

5 / 10

(1.25 / 2.5)

5 / 11

(1.25 / 2.75)

5 / 11

(1.25 / 2.75)

5 / 11

(1.25 / 2.75)

NOTE: See pages 56-57 for complete Spring Selection Chart.

6 / 10

(1.5 / 2.5)

6 / 10

(1.5 / 2.5)

6 / 10

(1.5 / 2.5)

6 / 11

(1.5 / 2.75)

6 / 11

(1.5 / 2.75)

6 / 11

(1.5 / 2.75)

7

Page 8

RV SERIES

Rubber Seat Poppet Design

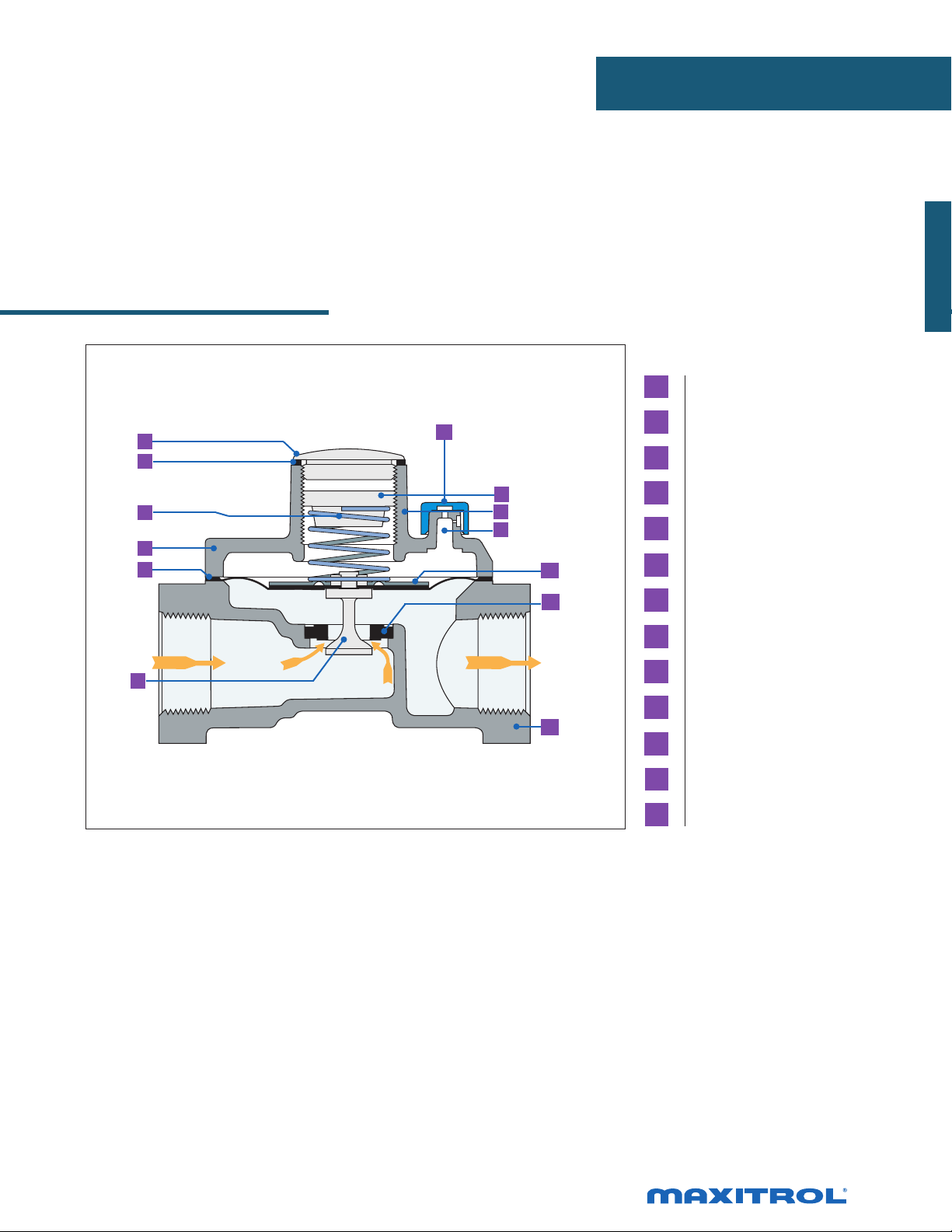

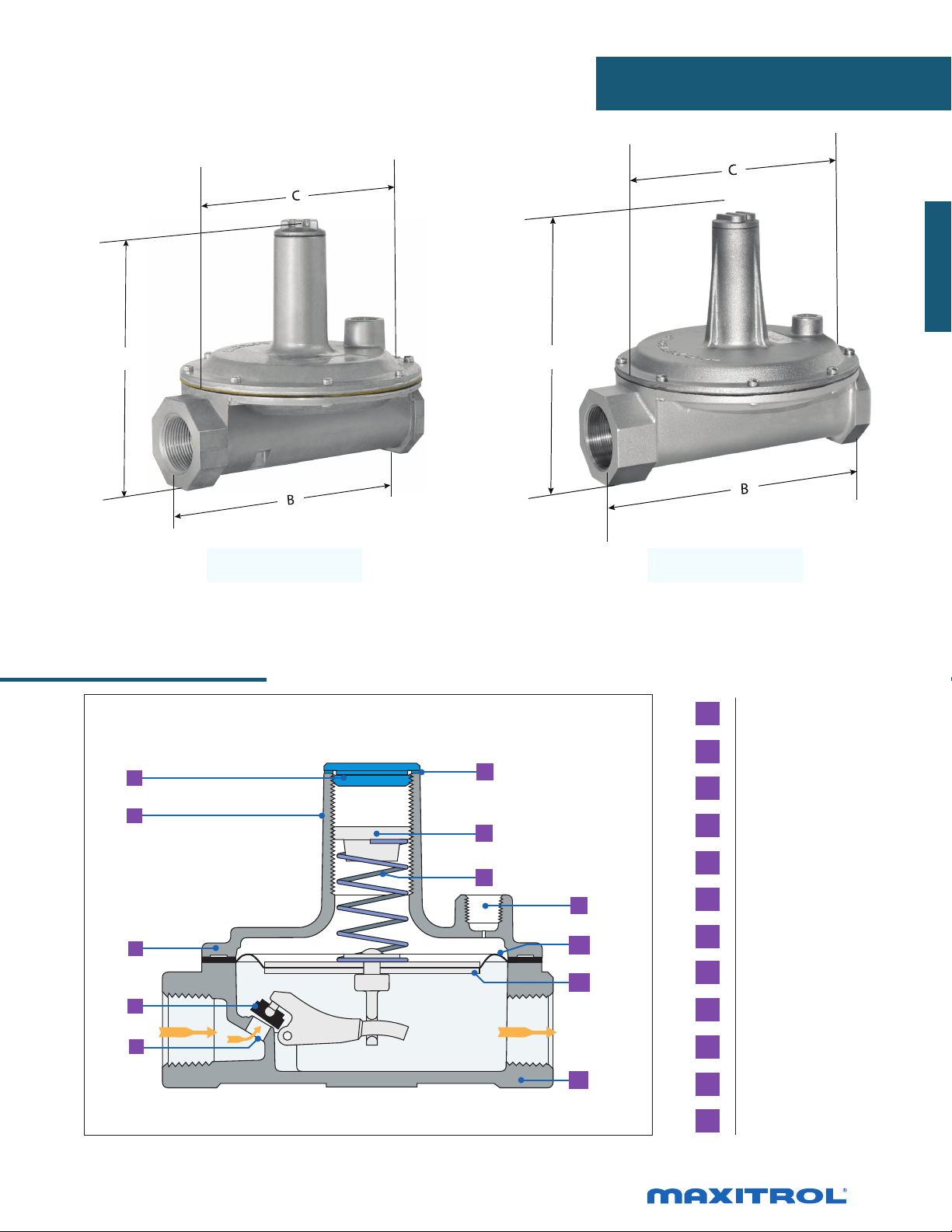

Dimensions

0.4”

(10 mm)

0.5”

(13 mm)

0.6”

(16 mm)

0.8”

(19 mm)

Dimensions

(43 mm)

(61 mm)

(75 mm)

(86 mm)

Model Pipe Size Vent Swing Radius

RV12

RV20 1/4”, 3/8”

RV47

CV47

RV47A

CV47A

RV48 1/2”, 3/4”

1/8”

3/16”Loxit

3/8”, 1/2”

12A04 or 12A06 vent limiting

Integral Vent

Limiting Orice “L”

Integral Vent

Limiting Orice “L”

or 5/16-24 “V”

Integral Vent

Limiting Orice “D” or “L”

sufx

Integral “L” or 1/8” NPT,

device

1.4”

(35 mm)

1.6”

(41 mm)

1.9”

(48 mm)

1.6”

(41 mm)

2”

(51 mm)

A B C D

1.7”

(43 mm)

2.1”

(54 mm)

2.5”

(64 mm)

2.3”

(57 mm)

2.8”

(70 mm)

NOTE: Dimensions are maximums and to be used only as an aid in designing clearance for the valve.

Actual production dimensions may vary somewhat from those shown.

A

B

A

B

1.7”

2.4“

2.9”

3.4”

1.4”

(35 mm)

1.8”

(45 mm)

2.3”

(57 mm)

3”

(76 mm)

A

B

8

RV12

RV20 RV47, RV47A

A

B

CV47, CV47A RV48

A

B

© 2017, Maxitrol Company. All Rights Reserved.

Page 9

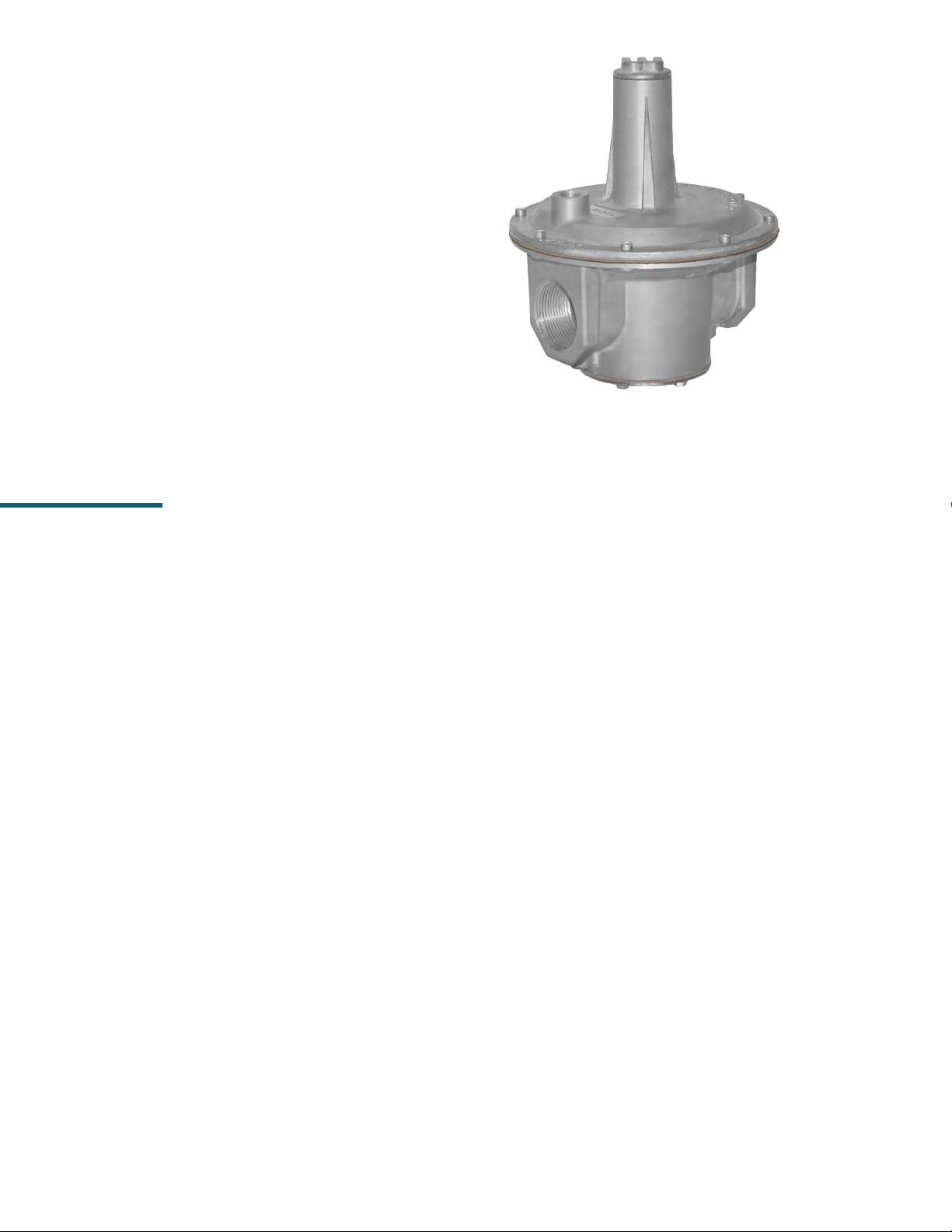

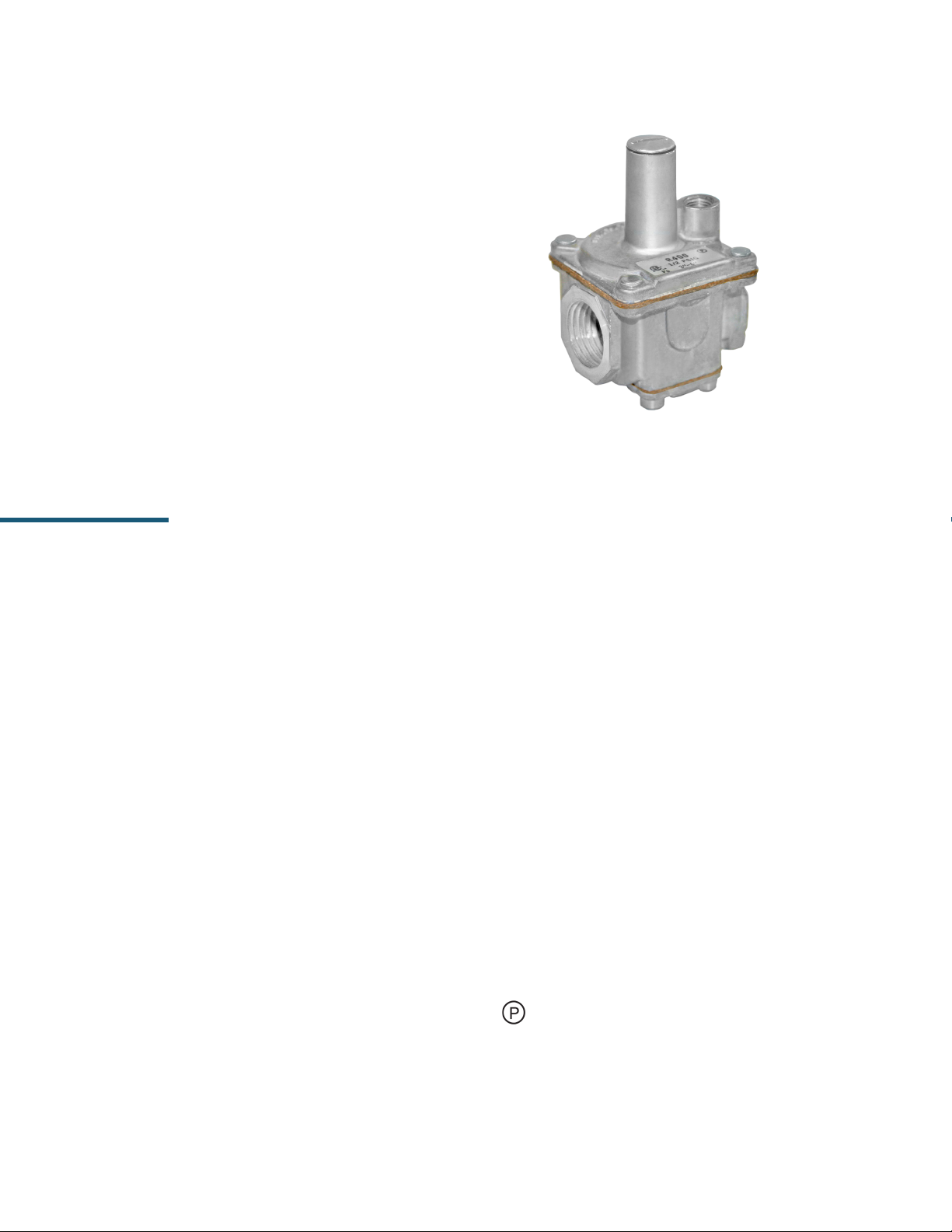

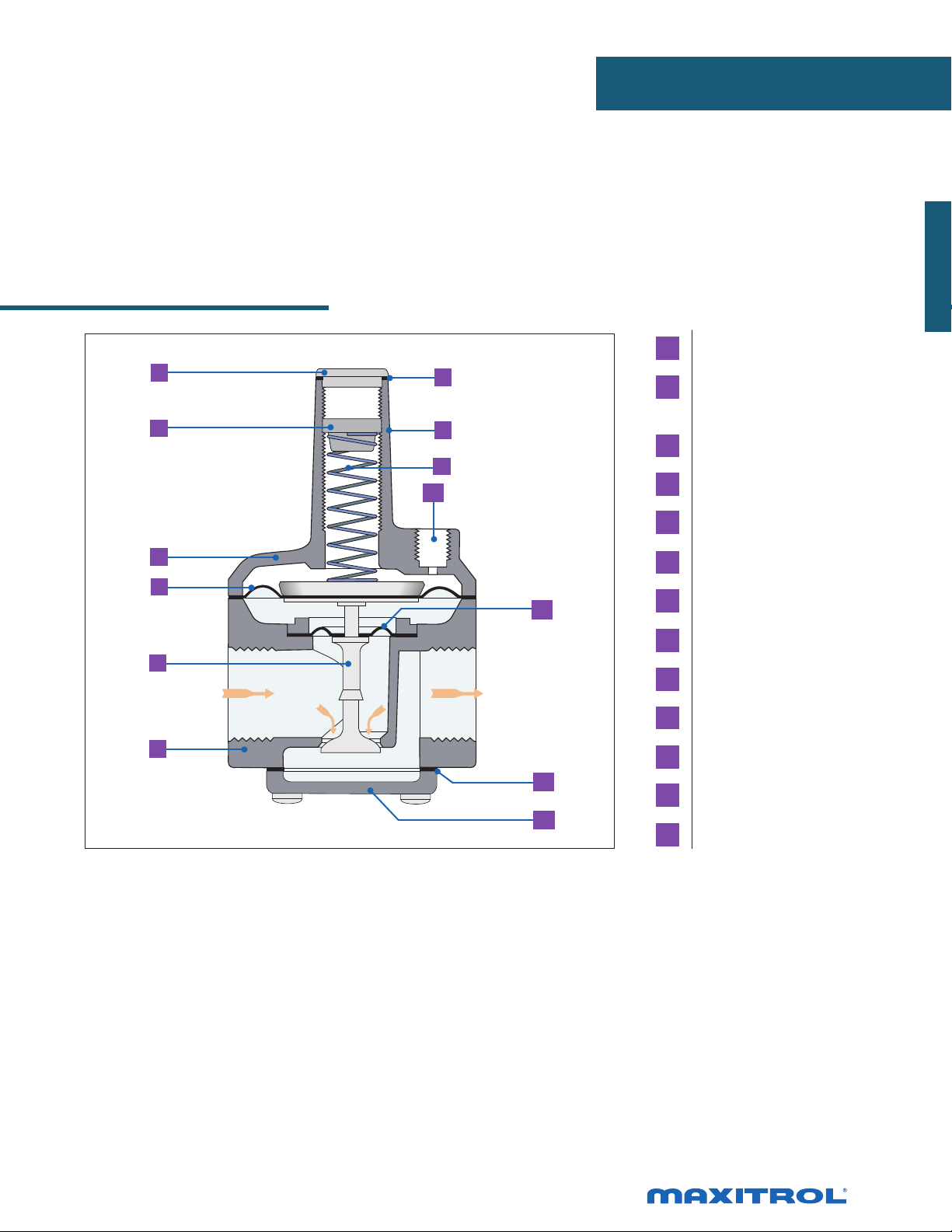

Rubber Seat Poppet Design

APPLIANCE REGULATORS

1 Seal Cap

1

2

3

4

5

13

7

8

9

10

11

2 Seal Cap Gasket

3 Spring

4 Top Housing

5 Diaphragm

6 Stem & Valve

7 Adjusting Screw

8 Stack

6

9 Vent

10 Diaphragm Plate

12

11 Rubber Seat

12 Bottom Housing

13 Dust Cap

NOTE: Diagrams are graphical representations only and may differ from actual product.

9

Page 10

RV SERIES

Straight-Thru-Flow Design

Maxitrol’s original straight-thru-ow (STF) design regulators

are non-lockup type regulators for high capacities at low inlet

pressures. The difference between STF design and other type

regulators is the conical valve. The cone principal permits gas to

ow straight through the regulator without changing directions.

Frictional ow resistance is reduced, resulting in greater

capacity. An improved ow pattern provides accurate, sensitive

regulation at extremely low pressure differentials. Typical

applications include residential, commercial, and industrial

gas-red appliances and equipment used on low or medium

pressure gas supplies.

Specications

Pipe Sizes ................................. 1/2” to 3” threaded connections with NPT or ISO7-1 threads. 4” 150lb. ange (RV131 only).

RV81

Housing Material .....................RV52, RV53, RV61, RV81, RV91, RV111: aluminum; RV131: cast iron.

Mounting .................................RV52, RV53, RV61 are suitable for multi-positional mounting. If ball check vent limiting

device is installed, mount in an upright position only. RV81, RV91, RV111, RV131, upright

position only.

NOTE: All Maxitrol gas pressure regulators should be installed and operated in accordance

with Maxitrol Safety Warning Instructions (see GPR_MI_EN.ES or GPR_CSA_MI_EN.FR).

Certications ...........................RV52, RV53, RV61, RV81, RV91, RV111: ANSI Z21.18/CSA6.3 Gas Appliance Pressure

Regulators.

Gas Types .................................Suitable for natural, manufactured, mixed gases, liqueed petroleum gases, and LP gas-air

mixtures.

Rated Inlet Pressure .................CSA Certied: RV52, RV53, RV61, RV81, RV91, RV111: 1/2 psi (3.4 kPa)

Maxitrol Tested* .......................RV52, RV53: 1/2 psi (3.4 kPa)

RV61, RV81, RV91, RV111: 1 psi (6.9 kPa)

RV131: 2 psi (13.8 kPa)

*Do not use if inlet pressure is more than 10 times desired outlet pressure.

Emergency Exposure Limits ......RV52, RV53: 3 psi (21 kPa)

RV61, RV81, RV91, RV111: 5 psi (34 kPa)

RV131: 15 psi (103 kPa)

Gas Containment Limits ........... RV52, RV53: 15 psi (103 kPa)

RV61, RV81, RV91, RV111, RV131: 25 psi (172 kPa)

NOTE: Internal damage may occur when exposed to these pressures.

Ambient Temperature Ranges ...RV52, RV53, RV61, RV81, RV91, RV111: -40° to 205°F (-40° to 96°C)

RV131: -40° to 125°F (-40° to 52°C)

Minimum Regulation ................RV52, RV53: 20 CFH; RV61: 25 CFH; RV81, RV91: 50 CFH; RV111, RV131: 250 CFH.

Expressed in CFH @ 0.64 sp gr gas.

10

© 2017, Maxitrol Company. All Rights Reserved.

Page 11

Capacities and Pressure Drop

C

US

®

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model

RV52

RV53

RV61

RV81

RV91

RV111

RV131 4” x 4” ---

Pipe

Size

1/2” x 1/2”

3/4” x 3/4”

3/4” x 3/4”

1” x 1”

1” x 1”

1 1/4” x 1 1/4”

1 1/4” x 1 1/4”

1 1/2” x 1 1/2”

2” x 2”

2 1/2” x 2 1/2”

2 1/2” x 2 1/2”

3” x 3”

CSA

MAX

450

(12.7)

690

(19.5)

900

(24.5)

2500

(70.8)

3275

(92.7)

7500

(212)

0.1

(0.02)

151

(4.2)

217

(6.1)

379

(10.7)

780

(22.1)

1212

(34.3)

2742

(78.0)

4734

(134)

0.2

(0.04)

214

(6.1)

306

(8.6)

536

(15.1)

1102

(31.2)

1714

(48.5)

3878

(110)

6695

(190)

0.3

(0.07)

262

(7.4)

375

(10.6)

675

(19.1)

1350

(38.2)

2100

(59.4)

4750

(134)

8200

(232)

0.4

(0.10)

302

(8.5)

433

(12.2)

759

(21.5)

1559

(44.1)

2424

(68.6)

5485

(155)

9468

(268)

APPLIANCE REGULATORS

Pressure Drop - inches w.c. (kPa)

0.5

(0.12)

338

(9.5)

484

(13.7)

848

(24.0)

1743

(49.5)

2711

(76.7)

6132

(175)

10586

(300)

0.6

(0.15)

370

(10.5)

530

(15)

929

(26.3)

1909

(54.0)

2969

(84.1)

6718

(190)

11596

(328)

0.7

(0.17)

400

(11.3)

573

(16.2)

1004

(28.4)

2062

(58.4)

3208

(90.8)

7256

(205)

12525

(354)

0.8

(0.20)

427

(12.1)

612

(17.3)

1073

(30.4)

2204

(62.4)

3429

(97.1)

7757

(219)

13390

(380)

0.9

(0.22)

453

(12.8)

650

(18.4)

1138

(32.2)

2339

(66.2)

3637

(103)

8227

(233)

14202

(402)

1.0

(0.25)

478

(13.5)

684

(19.3)

1200

(34.0)

2465

(69.8)

3834

(108)

8572

(243)

14971

(424)

UA.TR.012-13

(19.1)

(27.4)

(49.3)

(98.7)

12134

21172

2.0

(0.5)

676

968

1742

3485

5422

(153)

(343)

(600)

3.0

(0.75)

828

(23.4)

1185

(33.5)

2134

(60.4)

4269

(120)

6640

(188)

14862

(420)

25930

(734)

4.0

(1.0)

956

(27.1)

1369

(38.7)

2464

(69.8)

4929

(139)

7668

(217)

17161

(486)

29942

(848)

NOTE: See pages 58-59 for Regulator Sizing Requirements and Examples.

Spring Selection Chart: inches w.c. (kPa)

Model CSA Certied Springs Other Springs Available

RV52

RV53

RV61

RV81

RV91

RV111

RV131

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

---

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

---

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

2 to 5*

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated)

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

--- ---

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

(1.25 to 3.7)

(1.25 to 3.7)

(1.25 to 3.7)

--- --- --- ---

--- --- --- ---

5 to 15

Green

5 to 15

Green

5 to 15

Green

---

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

--- ---

--- ---

--- ---

--- ---

15 to 30

(3.7 to 7.5)

Yellow

20 to 42

(5 to 10.5)

Black

NOTE: The area within the heavy line indicates CSA certied springs. See pages 56-57 for complete Spring Selection Chart.

* The 2 to 5 inches w.c. (0.5 to 1.25 kPa) spring is also CSA certied for the RV61

11

Page 12

RV SERIES

Straight-Thru-Flow Design

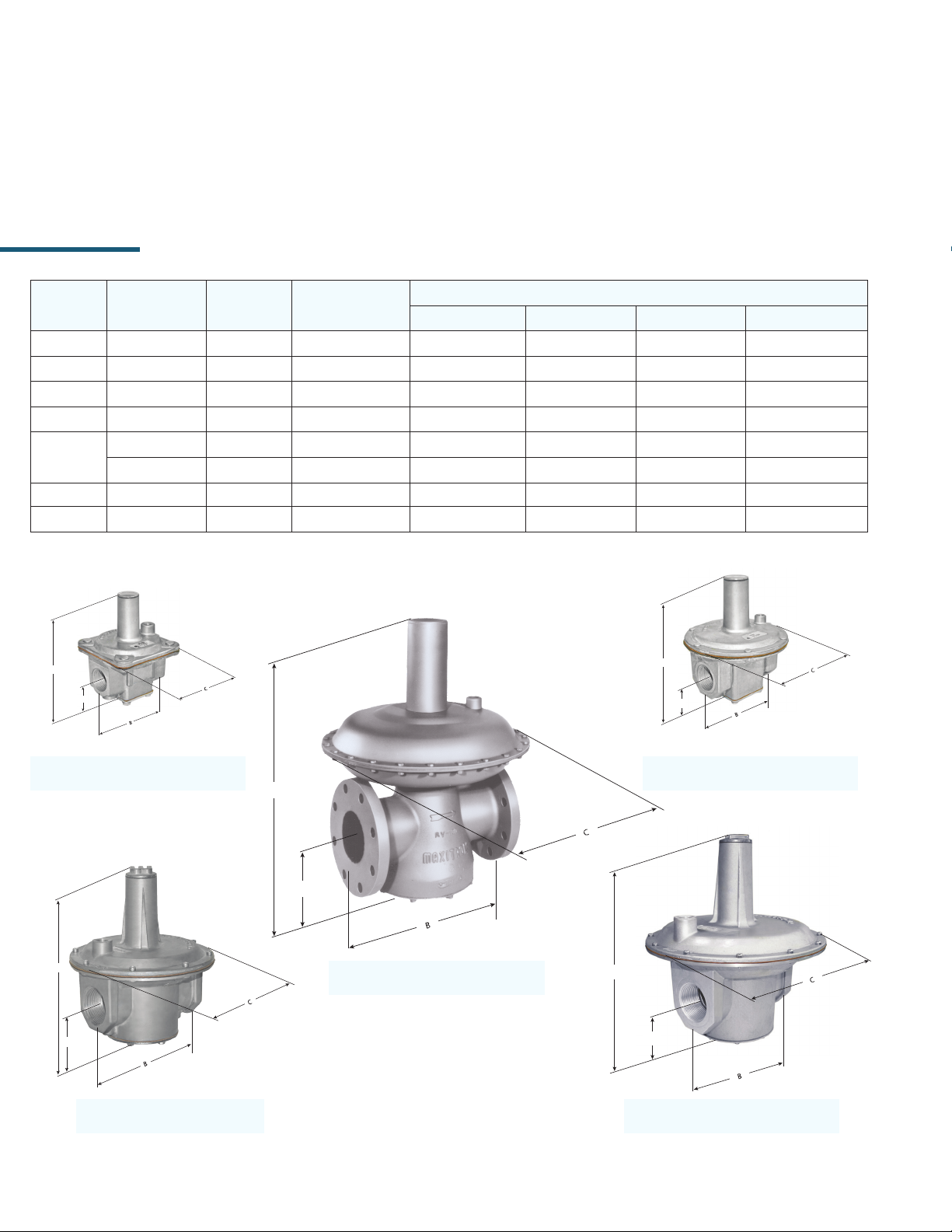

Dimensions

Model Pipe Size

RV52 1/2”, 3/4” 1/8” NPT 3.6” (91 mm) 4.9” (124 mm) 3.2” (81 mm) 3.3” (83 mm) 1.3” (32 mm)

RV53 3/4”, 1” 1/8” NPT 3.9” (99 mm) 5.2” (132 mm) 3.8” (95 mm) 3.9” (99 mm) 1.3” (33 mm)

RV61 1”, 1 1/4” 1/8” NPT 4.8” (122 mm) 6.4” (164 mm) 4.4” (111 mm) 5.4” (138 mm) 1.6” (41 mm)

RV81 1 1/4”, 1 1/2” 3/8” NPT 6.4” (162 mm) 8.4” (213 mm) 6” (153 mm) 7” (178 mm) 2” (51 mm)

2” 1/2” NPT 8.5” (216 mm) 10.8” (275 mm) 6.5” (165 mm) 9.1” (232 mm) 2.3” (60 mm)

RV91

2 1/2” 1/4” NPT 8.3” (212 mm) 10.5” (267 mm) 7.1” (181 mm) 9.1” (232 mm) 2.4” (62 mm)

RV111 2 1/2”, 3” 3/4” NPT 11.5” (284 mm) 15.1” (373 mm) 9” (229 mm) 13.4” (324 mm) 3.5” (89 mm)

RV131 4” 3/4” NPT 18.2” (462 mm) 23.3” (592 mm) 13.9” (353 mm) 18” (457 mm) 5.1” (130 mm)

Vent

Connection

Swing Radius

A B C D

Dimensions

NOTE: Dimensions are maximums and to be used only as an aid in designing clearance for the valve.

Actual production dimensions may vary somewhat from those shown.

A

D

A

D

12

A

RV61RV52, RV53

D

A

RV131

D

RV81, RV91

A

D

RV111

© 2017, Maxitrol Company. All Rights Reserved.

Page 13

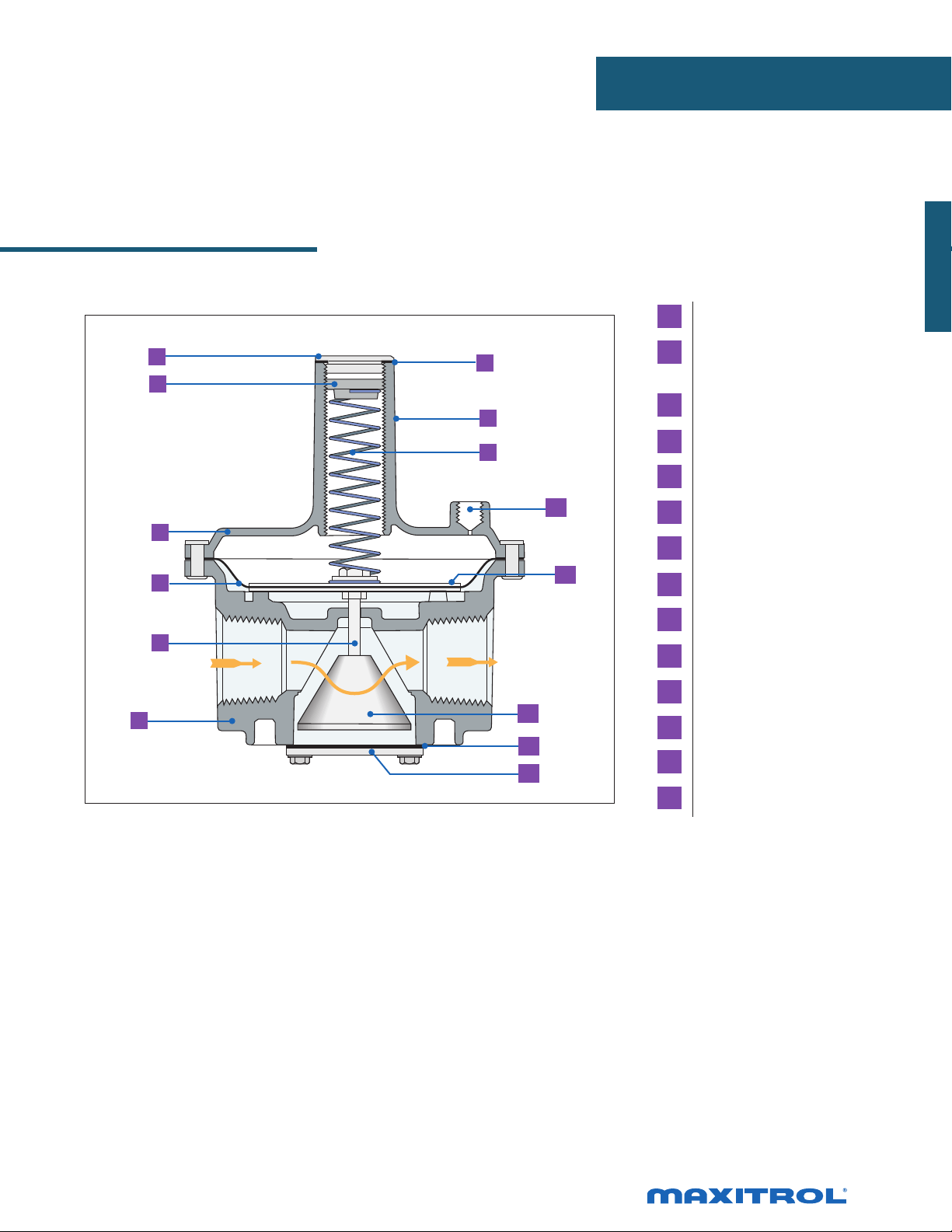

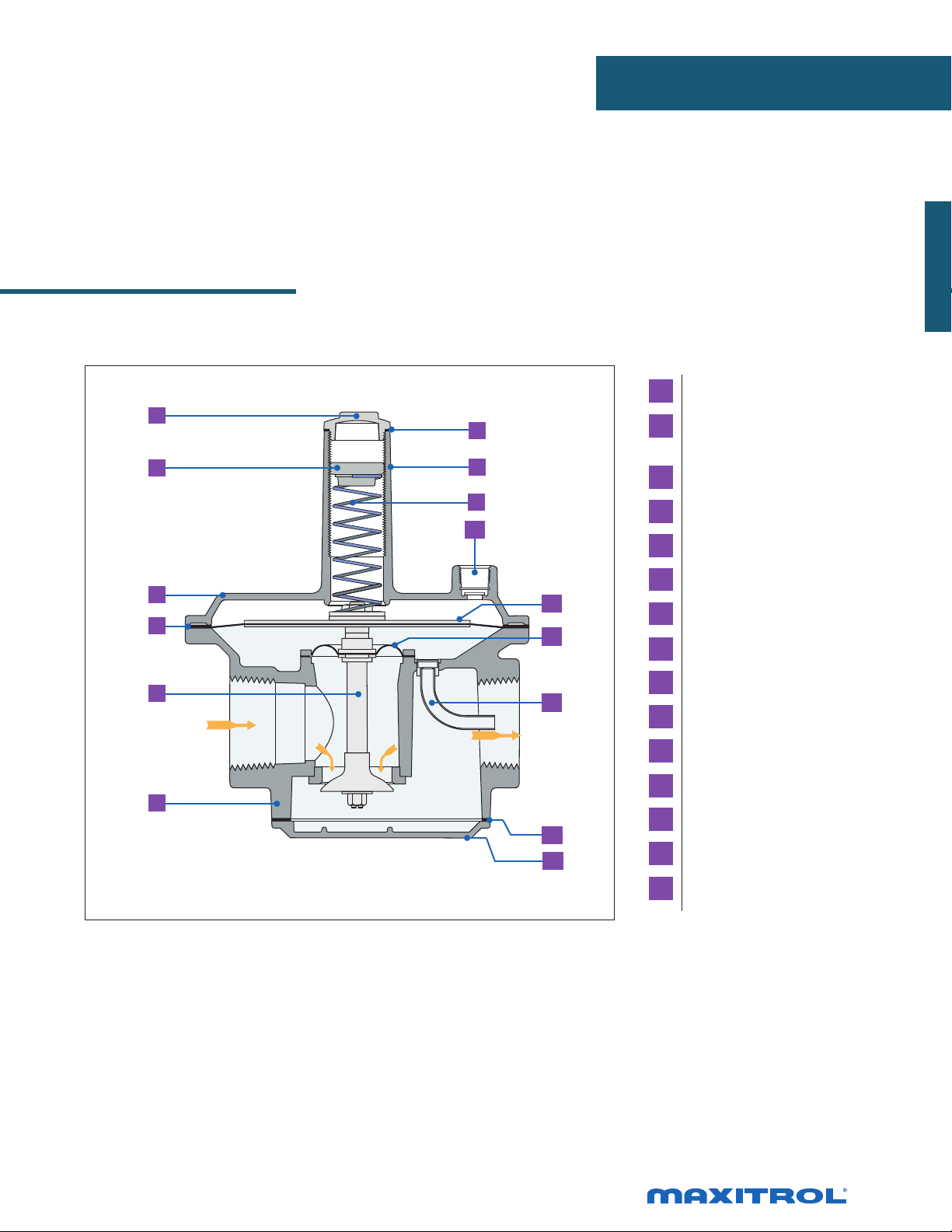

Straight-Thru-Flow Design

APPLIANCE REGULATORS

1 Welch Plug/Seal Cap

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2 Vibration Resistant

Adjusting Screw

3 Top Housing

4 Diaphragm

5 Stem

6 Bottom Housing

7 Seal Cap Gasket

8 Stack

9 Spring

10 Vent Connection

11 Diaphragm Plates

12 Valve

13 Bottom Plate Gasket

14 Bottom Plate

NOTE: Diagrams are graphical representations only and may differ from actual product.

13

Page 14

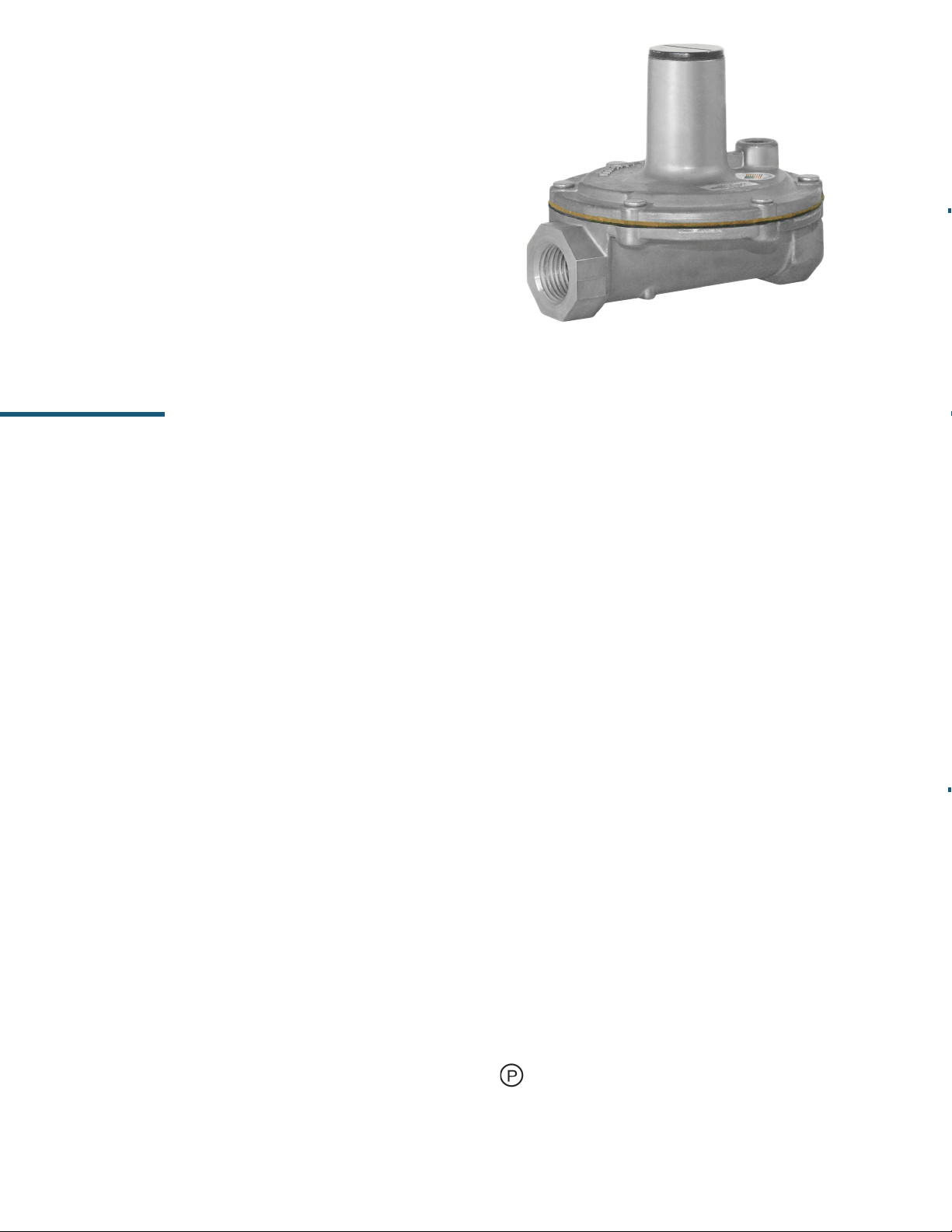

325 SERIES

Lever Acting Design

Maxitrol’s 325 Series pounds to inches regulators are for use on

residential, commercial, and industrial applications.

The 325 Series features a high leverage valve linkage assembly

to deliver positive dead-end lockup. The regulators are capable

of precise control from full ow down to pilot ow.

325-3

Specications

Pipe Sizes ..................................... 3/8” to 2” threaded connections with NPT or ISO7-1 threads.

Housing Material ......................... 325-3, 325-5, 325-7A, 325-9, 325-11: aluminum.

Mounting ..................................... Suitable for multi-positional mounting. If ball check vent limiting device is installed, mount

in an upright position only.

NOTE: All Maxitrol gas pressure regulators should be installed and operated in accordance

with Maxitrol Safety Warning Instructions (see GPR_MI_EN.ES or GPR_CSA_MI_EN.FR).

Certications ............................... 325-3, 325-5: ANSI Z21.18/CSA 6.3 Gas Appliance Pressure Regulators.

Gas Types ..................................... Suitable for natural, manufactured, mixed gases, liqueed petroleum gases, and LP gas-air

mixtures.

Rated Inlet Pressure ..................... CSA Certied: 325-3, 325-5: 2 psi (13.8 kPa), 5 psi (34.5 kPa)

Maxitrol Tested ............................ 325-3, 325-5, 325-7A, 325-9: 10 psi (69 kPa)

With Vent Limiter 12A09, 12A39, or 12A49 Installed:

325-3, 325-5, 325-7A, 325-9: 5 psi (34.5 kPa) - Natural, 2 psi (13.8 kPa) - LP

Emergency Exposure Limits .......... 65 psi (450 kPa) (inlet side only)

Maximum Individual Load ........... Largest single appliance served by the regulator: 325-3: 100,000 Btu/h;

325-5: 325,000 Btu/h; 325-7A: 1,250,000 Btu/h, 325-9: 2,250,000 Btu/h; 325-11:

4,500,000 Btu/h

Capacity ......................................Total load of multiple appliances combined: 325-3: 150,000 Btu/h;

..................................................... 325-5: 325,000 Btu/h; 325-7A: 1,250,000 Btu/h; 325-9: 2,250,000 Btu/h;

325-11: 4,500,000 Btu/h

NOTE: Capacities are used to determine the maximum multiple appliance load. The

largest single appliance served by the regulator should not exceed the maximum

individual load specied above.

Ambient Temperature Ranges .......-40 to 205°F (-40 to 96°C)

Minimum Regulation .................... Suitable for pilot ow applications. (Circle P) (0.15 CFH NG), None (1.5 CFH NG).

14

© 2017, Maxitrol Company. All Rights Reserved.

Page 15

APPLIANCE REGULATORS

C

US

®

UA.TR.012-13

Capacities: based on 1” w.c. pressure drop, from set point**

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model Pipe Size

325-3

325-5

325-7A

325-9

325-11

NOTE: Maximum Individual Load: 325-3(B) is 100 CFH (2.8 m3/h); 325-5(B) is 325 CFH (9.2 m3/h); 325-7A(B) is 1250 CFH (35.4 m3/h); 325-9(B) is 2250 CFH (63.7).

Approval based on use as an appliance regulator. **Set points (in CFH): 325-3(B) = 50; 325-5(B) = 150; 325-7A(B) = 500; 325-9(B) = 1000; 325-11(B) = 2000.

See pages 58-59 for Regulator Sizing Requirements and Examples.

3/8” x 3/8”

1/2” x 1/2”

1/2” x 1/2”

3/4” x 3/4”

1” x 1”

1 1/4” x 1 1/4”

1 1/2” x 1 1/2”

1 1/2” x 1 1/2”

2” x 2”

1 1/2” x 1 1/2”

2” x 2”

Outlet Pressure

Set Point

4.0” w.c. (1.0 kPa) 150 (4.2) 160 (4.5) 190 (5.4) 220 (6.2) 220 (6.2) 300 (8.5) 320 (9.1)

7.0” w.c. (1.7 kPa) 150 (4.2) 120 (3.4) 150 (4.2) 180 (5.1) 220 (6.2) 290 (8.2) 320 (9.1)

10.0” w.c. (2.5 kPa) 150 (4.2) 100 (2.8) 120 (3.4) 150 (4.2) 220 (6.2) 280 (7.9) 320 (9.1)

4.0” w.c. (1.0 kPa) 325 (9.2) 340 (9.6) 390 (11.0) 450 (12.7) 560 (15.9) 680 (19.3) 750 (21.2)

7.0” w.c. (1.7 kPa) 325 (9.2) 260 (7.4) 360 (10.2) 410 (11.6) 530 (15.0) 680 (19.3) 750 (21.2)

10.0” w.c. (2.5 kPa) 325 (9.2) 240 (6.8) 320 (9.1) 360 (10.2) 500 (8.5) 650 (18.4) 750 (21.2)

4.0” w.c. (1.0 kPa) — 850 (24.0) 1060 (30.0) 1190 (33.7) 1600 (45.3) 2090 (59.2) 2190 (62.0)

7.0” w.c. (1.7 kPa) — 780 (22.0) 950 (26.9) 1060 (30.0) 1500 (42.5) 1860 (52.7) 2060 (58.3)

10.0” w.c. (2.5 kPa) — 650 (18.4) 860 (24.4) 990 (28.0) 1300 (36.8) 1620 (45.9) 2060 (58.3)

4.0” w.c. (1.0 kPa) — 1815 (51.4) 2075 (58.8) 2250 (63.7) 2660 (75.3) 3550 (100.5) 3750 (106.2)

7.0” w.c. (1.7 kPa) — 1430 (40.5) 1660 (47.0) 1960 (55.5) 2570 (72.8) 3420 (96.8) 3750 (106.2)

10.0” w.c. (2.5 kPa) — 1275 (36.1) 1450 (41.1) 1720 (48.7) 2160 (61.2) 3150 (89.2) 3750 (106.2)

4.0” w.c. (1.0 kPa) — 2650 (75.0) 3400 (96.3) 4020 (113.8) 5370 (152.1) 7950 (225.1) 11900 (337.0)

7.0” w.c. (1.7 kPa) — 1800 (51.0) 2770 (78.4) 3460 (98.0) 5040 (142.7) 7700 (218.0) 11600 (328.5)

10.0” w.c. (2.5 kPa) — 1450 (41.1) 2400 (68.0) 3190 (90.3) 4800 (135.9) 7500 (212.4) 11400 (322.8)

CSA

MAX

CFH

0.5 psi

(3.4 kPa)

0.75 psi

(5.2 kPa)

Operating Inlet Pressure

1 psi

(6.9 kPa)

2 psi

(13.8 kPa)

5 psi

(34.5 kPa)

10 psi

(69.0 kPa)

Spring Selection Chart: inches w.c. (kPa) unless noted

Model

Number

325-3

325-5

325-7A — — — —

325-9 — — — —

325-11 — — — —

2 psi (13.8 kPa) 5 psi (34.5 kPa)

5 to 9

(1.25 to 2.25)

Plated

5 to 9

(1.25 to 2.25)

Plated

NOTE: See pages 56-57 for complete Spring Selection Chart.

CSA Certied

7 to 11

(1.7 to 2.7)

White

7 to 11

(1.7 to 2.7)

White

6 to 10

(1.5 to 2.5)

Plated

6 to 10

(1.5 to 2.5)

Plated

7 to 11

(1.7 to 2.7)

White

7 to 11

(1.7 to 2.7)

White

Standard

Spring

4 to 12

(1.0 to 3.0)

Violet

4 to 12

(1.0 to 3.0)

Violet

4 to 12

(1.0 to 3.0)

Violet

4 to 12

(1.0 to 3.0)

Violet

4 to 12

(1.0 to 3.0)

Violet

2 to 6

(0.5 to 1.5)

Plated

2 to 6

(0.5 to 1.5)

Plated

2 to 5

(0.5 to 1.5)

Plated

2 to 5

(0.5 to 1.5)

Plated

2 to 5

(0.5 to 1.5)

Plated

Other Springs Available

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

1 to 2 psi

(6.9 to 13.9)

Tagged

1 to 2 psi

(6.9 to 13.9)

Tagged

20 to 42

(5.0 to 10.4)

Black

20 to 42

(5.0 to 10.4)

Black

20 to 42

(5.0 to 10.4)

Black

15

Page 16

325 SERIES

Lever Acting Design

Pressure Drop: 0.64 sp gr gas expressed in CFH (m

Model 7.0” w.c. (1.7 kPa) 0.5 psi (3.4 kPa) 0.75 psi (5.2 kPa) 1 psi (6.9 kPa) 2 psi (13.8 kPa)

325-3 145 (4.0) 204 (5.8) 250 (7.0) 289 (8.2) —

325-5 400 (11.3) 550 (15.6) 670 (19.0) 770 (21.8) —

325-7A 815 (23.1) 1149 (32.5) 1405 (39.8) 1624 (46.0) 2305 (65.3)

325-9 1360 (38.5) 2113 (59.8) 2557 (72.4) 2949 (83.5) 4059 (114.8)

325-11 3000 (85.0) 4220 (119.5) 5170 (146.4) 6000 (170.0) 8485 (240.3)

Dimensions

Model Pipe Size

325-3 3/8”, 1/2” 1/8” NPT

325-5 1/2”, 3/4”, 1” 3/8” NPT

325-7A 1 1/4”, 1 1/2” 1/2” NPT

325-9 1 1/2”, 2” 1/2” NPT

325-11 2”, 2 1/2” 3/4” NPT

Vent

Connection

3

/h) (for system pressure drop calculations)

Swing

Radius

3”

(76 mm)

4.9”

(124 mm)

6.1”

(156 mm)

7.8”

(198 mm)

11.0”

(279 mm)

A B C

3.5”

(89 mm)

5.3”

(133 mm)

7.3”

(184 mm)

9.4”

(239 mm)

13.1”

(333 mm)

Dimensions

(108 mm)

(149 mm)

(203 mm)

(274 mm)

(409 mm)

4.2”

5.9”

8”

10.8”

16.1”

3.9”

(98 mm)

5.4”

(138 mm)

7”

(178 mm)

9.1”

(231 mm)

13.5”

(343 mm)

NOTE: Dimensions are maximums and to be used only as an aid in designing clearance for the valve.

Actual production dimensions may vary somewhat from those shown.

A

A

325-3 325-5

16

© 2017, Maxitrol Company. All Rights Reserved.

Page 17

APPLIANCE REGULATORS

A

Lever Acting Design

1

A

325-7A 325-9

1 Seal Cap

2 Stack

6

3 Top Housing

2

7

8

9

3

4

5

NOTE: Diagrams are graphical representations only and may differ from actual product.

10

11

12

4 Rubber Valve

5 Valve Seat

6 Seal Cap Gasket

7 Adjusting Screw

8 Spring

9 Vent Connection

10 Diaphragm

11 Diaphragm Plates

12 Bottom Housing

17

Page 18

R/RS SERIES

Balanced Valve Design

The R & RS series’ double diaphragm balanced valve design

makes it possible to maintain steady outlet pressure control

with widely varying inlet pressures. The regulator is physically

small yet has exceptional capacity characteristics. R & RS series

regulators are intended for use with both main burner and pilot

load applications. They are ideally suited for use with infrared

heaters and pilot lines on large industrial heaters and boilers.

Specications

R400

Pipe Sizes ..................................... 3/8” to 1” threaded connections with NPT or ISO7-1 threads.

Housing Material ......................... R400(S), R500(S), R600(S): aluminum.

Mounting ..................................... Suitable for multi-positional mounting. If ball check vent limiting device is installed, mount

in an upright position only.

NOTE: All Maxitrol gas pressure regulators should be installed and operated in accordance

with Maxitrol Safety Warning Instructions (see GPR_MI_EN.ES or GPR_CSA_MI_EN.FR).

Certications .................................. R400(S), R500(S), R600(S): ANSI Z21.18/CSA 6.3 Gas Appliance Pressure Regulators.

Gas Types ........................................ Suitable for natural, manufactured, mixed gases, liqueed petroleum gases, and LP gas-air

mixtures.

Rated Inlet Pressure ........................ CSA Certied: R400(S), R500(S), R600(S): 1/2 psi (3.4 kPa)

Maxitrol Tested: .............................. R400, R500, R600: 1 psi (6.9 kPa);

R400S, R500S, R600S: 5 psi (34.5 kPa)

Emergency Exposure Limits ............R400, R500, R600: 2 psi (13.8 kPa)

R400S, R500S, R600S: 12.5 psi (86.2)

Ambient Temperature Ranges ........ R400(S), R500(S), R600(S): -40° to 205°F (-40° to 96°C)

Zero Governor Models ...................Please refer to pages 32-37 for RZ model information.

Minimum Regulation .................... Suitable for pilot ow applications. (Circle P) (0.15 CFH NG), None (1.5 CFH NG).

NOTE: These R/RS regulators are not suitable for dead-end lockup service. They are capable of controlling pressure

at very low ows such as standing pilots, but should not be used as a line pressure regulator for appliances

equipped with electronic ignition unless the automatic control valve can open against line pressure.

18

© 2017, Maxitrol Company. All Rights Reserved.

Page 19

Capacities and Pressure Drop

C

US

®

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model Pipe Size

0.2

(0.05)

0.4

(0.10)

0.6

(0.15)

Pressure Drop - inches w.c. (kPa)

0.8

(0.20)

1.0

(0.25)

1.5

(0.37)

APPLIANCE REGULATORS

UA.TR.012-13

2.0

(0.50)

2.5

(0.62)

3.0

(0.75)

3.5

(0.87)

4.0

(1.0)

R400(S)

R500(S)

R600(S)

3/8” x 3/8”

1/2” x 1/2”

1/2” x 1/2”

3/4” x 3/4”

3/4” x 3/4”

1” x 1”

77

(2.3)

86

(2.4)

163

(4.6)

196

(5.5)

298

(8.3)

330

(9.2)

110

(3.1)

121

(3.4)

231

(6.5)

277

(7.8)

421

(11.8)

468

(13.1)

134

(3.8)

148

(4.1)

283

(7.9)

340

(9.5)

516

(14.5)

572

(16.2)

155

(4.3)

172

(4.82)

327

(9.2)

392

(11.0)

595

(16.7)

661

(18.2)

174

(4.9)

192

(5.4)

366

(10.3)

438

(12.3)

666

(18.7)

739

(20.7)

212

(5.9)

235

(6.6)

447

(12.5)

537

(15.0)

816

(22.9)

906

(25.4)

245

(6.9)

271

(7.6)

516

(14.6)

620

(17.4)

942

(26.4)

1046

(29.3)

274

(7.7)

303

(8.5)

577

(16.2)

693

(19.4)

1054

(29.5)

1169

(32.7)

--- --- ---

--- --- ---

635

(17.9)

760

(21.3)

1150

(32.2)

1280

(35.8)

685

(19.2)

820

(23.0)

1245

(34.86)

1380

(38.64)

730

(20.44)

876

(24.53)

1335

(37.38)

1480

(41.44)

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

Spring Selection Chart: inches w.c. (kPa)

Model CSA Certied Springs Other Springs Available

R400(S)

R500(S)

R600(S)

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

---

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

---

---

15 to 30

(3.7 to 7.5)

Yellow

NOTE: See pages 56-57 for complete Spring Selection Chart.

19

Page 20

A

D

R/RS SERIES

Balanced Valve Design

Dimensions

2”

(51 mm)

3.1”

(79 mm)

3.9”

(99 mm)

Dimensions

(51 mm)

(76 mm)

(103 mm)

Model Pipe Size

R400(S) 3/8”, 1/2” 1/8” NPT

R500(S) 1/2”, 3/4” 1/8” NPT

R600(S) 3/4”, 1” 1/8” NPT

Vent

Connection

Swing Radius

2.4”

(60 mm)

3.6”

(90 mm)

4.3”

(110 mm)

A B C D

3.3”

(83 mm)

4.7”

(119 mm)

5.7”

(145 mm)

NOTE: Dimensions are maximums and to be used only as an aid in designing clearance for the valve.

Actual production dimensions may vary somewhat from those shown.

2”

3”

4”

0.9”

(24 mm)

1.2”

(30 mm)

1.5”

(38 mm)

A

D

R500(S), R600(S)

R400(S)

20

© 2017, Maxitrol Company. All Rights Reserved.

Page 21

R/RS Balanced Valve Design

1

2

10

APPLIANCE REGULATORS

1 Welch Plug/Seal Cap

7

8

9

2 Vibration Resistant

Adjusting Screw

3 Top Housing

4 Regulating Diaphragm

5 Stem & Valve

3

4

11

5

6

12

13

NOTE: Diagrams are graphical representations only and may differ from actual product.

6 Bottom Housing

7 Seal Cap Gasket

8 Stack

9 Spring

10 Vent Connection

11 Balancing Diaphragm

12 Bottom Plate Gasket

13 Bottom Plate

21

Page 22

210 SERIES

Balanced Valve Design

The 210 series is a lockup type regulator. The balanced valve

design makes it possible to maintain steady outlet pressure

control with widely varying inlet pressures. The regulator has

an integrated dampening mechanism in the breather outlet

and the sensing tube to improve regulating stability and reduce

hunting tendencies. The 210 series provides precise regulation

over a wide range of pressures and ow rates. Applications

include gas-red boilers, steam generators, industrial furnaces,

and ovens.

Specications

21OE

Pipe Sizes ..................................1” to 3” threaded connections with NPT or ISO7-1 threads. 4” 125 lb. ange (210J only).

Housing Material ...................... 210D, 210E, 210G, 210J: aluminum.

Mounting ................................... Mount in an upright position only.

NOTE: All Maxitrol gas pressure regulators should be installed and operated in accordance

with Maxitrol Safety Warning Instructions (see GPR_MI_EN.ES or GPR_CSA_MI_EN.FR).

Certications ............................. 210D, 210E, 210G: ANSI Z21.18/CSA 6.3 Gas Appliance Pressure Regulators.

Gas Types ................................... Suitable for natural, manufactured, mixed gases, liqueed petroleum gases, and LP gas-air

Maximum Inlet Pressure ............ CSA Certied: 210D, 210E, 210G: 10 psi (69 kPa)

Maxitrol Tested........................... 210J: 10 psi (69 kPa)

Emergency Exposure Limits ....... 210D, 210E, 210G, 210J: 25 psi (172 kPa)

Ambient Temperature Ranges .... -40° to 200°F (-40° to 93°C)

Sensing Taps .............................. Convenient tap locations are available for downstream sensing, cross connections, and

Remote Sensing ......................... 210D, 210E, 210G models may be ordered with remote sensing. The internal sensing tube is

omitted and external sensing taps are provided. Add sufx letter “R” to model number when

ordering.

mixtures.

differential control. Four locations can be tapped and plugged for measuring pressure.

Zero Governor Models .............. Please refer to pages 32-37 for 210Z model information.

Minimum Regulation ................. 210D: 25 CFH; 210E, 210G: 50 CFH; 210J: 100 CFH.

22

© 2017, Maxitrol Company. All Rights Reserved.

Page 23

Capacities

C

US

®

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

APPLIANCE REGULATORS

UA.TR.012-13

Model Pipe Size

210D 1” x 1”

Inlet

Pressure

8.0” w.c.

0.5 psi

0.75 psi

1 psi

1.5 psi

2 psi

3 psi

5 psi

7.5 psi

10 psi

2.0

(0.5)

2400

(68.0)

3400

(96.3)

3500

(99.1)

3500

(99.1)

3500

(99.1)

3500

(99.1)

3500

(99.1)

3500

(99.1)

3500

(99.1)

3500

(99.1)

4.0

(1.0)

1900

(53.8)

3100

(87.8)

4000

(113)

4000

(113)

4000

(113)

4000

(113)

4000

(113)

4000

(113)

4000

(113)

4000

(113)

Outlet Pressure - inches w.c. (kPa)

6.0

(1.5)

1300

(36.8)

2700

(76.5)

3800

(108)

4500

(127)

4500

(127)

4500

(127)

4500

(127)

4500

(127)

4500

(127)

4500

(127)

9.0

(2.25)

--- --- --- --- --- ---

2200

(62.3)

3400

(96.3)

4300

(122)

4800

(136)

4800

(136)

4800

(136)

4800

(136)

4800

(136)

4800

(136)

12

(3.0)

--- --- --- --- ---

2900

(82.1)

3900

(110)

4800

(136)

4800

(136)

4800

(136)

4800

(136)

4800

(136)

4800

(136)

16

(4.0)

2200

(62.3)

3400

(96.3)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

20

(5.0)

--- --- ---

2700

(76.5)

4600

(130)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

24

(6.0)

1900

(53.8)

4100

(116)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

28

(7.0)

---

3600

(102)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

5000

(142)

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

23

Page 24

210 SERIES

Balanced Valve Design

Capacities

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model Pipe Size

210D

1 1/4”

x

1 1/4”

Inlet

Pressure

8.0” w.c.

0.5 psi

0.75 psi

1 psi

1.5 psi

2 psi

3 psi

5 psi

7.5 psi

10 psi

2.0

(0.5)

3000 (84.9) 2400 (68.0) 1700 (48.1) --- --- --- --- --- ---

4000 (113) 3905 (111) 3400 (96.3) 2700 (76.5) --- --- --- --- ---

4000 (113) 5000 (142) 4700 (133) 4200 (119) 3700 (105) 2700 (76.5) --- --- ---

4000 (113) 5000 (142) 5000 (142) 5300 (150) 4900 (139) 4200 (119) 3400 (96.3) 2400 (68.0) ---

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6000 (170) 5700 (161) 5200 (147) 4600 (130)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184)

4.0

(1.0)

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model Pipe Size

Inlet

Pressure

2.0

(0.5)

4.0

(1.0)

6.0

(1.5)

6.0

(1.5)

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

12

(3.0)

12

(3.0)

16

(4.0)

16

(4.0)

20

(5.0)

20

(5.0)

24

(6.0)

24

(6.0)

28

(7.0)

28

(7.0)

3100 (87.8) 2500 (70.8) 1800 (51.0) --- --- --- --- --- ---

0.5 psi

1.5 psi

7.5 psi

4000 (113) 4000 (113) 3600 (102) 2800 (79.3) --- --- --- --- ---

4000 (113) 5000 (142) 5000 (142) 4400 (125) 3800 (108) 2800 (79.3) --- --- ---

4000 (113) 5000 (142) 5000 (142) 5600 (159) 5100 (144) 4400 (125) 3600 (102) 2500 (70.8) ---

1 psi

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6500 (184) 6000 (170) 5400 (153) 4800 (136)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184) 6500 (184)

2 psi

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184) 6500 (184)

3 psi

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184) 6500 (184)

5 psi

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184) 6500 (184)

4000 (113) 5000 (142) 5000 (142) 6000 (170) 6000 (170) 6500 (184) 6500 (184) 6500 (184) 6500 (184)

10 psi

210D

8.0” w.c.

0.75 psi

1 1/2”

x

1 1/2”

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

24

© 2017, Maxitrol Company. All Rights Reserved.

Page 25

Capacities

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

APPLIANCE REGULATORS

Model Pipe Size

210E

1 1/2”

x

1 1/2”

Inlet

Pressure

8.0” w.c.

0.5 psi

0.75 psi

1 psi

1.5 psi

2 psi

3 psi

5 psi

7.5 psi

10 psi

2.0

(0.5)

4450 (126) 3650 (103) 2550 (72.2) --- --- --- --- --- ---

6300 (178) 5750 (163) 5150 (146) 4050 (115) --- --- --- --- ---

7000 (198) 7500 (212) 7050 (200) 6300 (178) 5450 (154) 4050 (115) --- --- ---

7000 (198) 8800 (249) 8500 (241) 7950 (225) 7250 (205) 6300 (178) 5150 (146) 3650 (103) ---

7000 (198) 8800 (249) 8800 (249) 10450 (296) 9950 (282) 9250 (262) 8550 (242) 7700 (218) 6800 (193)

7000 (198) 8800 (249) 8800 (249) 10500 (297) 10500 (297) 10500 (297) 10500 (297) 10250 (290) 9600 (272)

7000 (198) 8800 (249) 8800 (249) 10500 (297) 10500 (297) 10500 (297) 10500 (297) 10500 (297) 10500 (297)

7000 (198) 8800 (249) 8800 (249) 10500 (297) 10500 (297) 10500 (297) 10500 (297) 10250 (290) 10500 (297)

7000 (198) 8800 (249) 8800 (249) 10500 (297) 10500 (297) 10500 (297) 10500 (297) 10250 (290) 10500 (297)

7000 (198) 8800 (249) 8800 (249) 10500 (297) 10500 (297) 10500 (297) 10500 (297) 10250 (290) 10500 (297)

4.0

(1.0)

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model Pipe Size

Inlet

Pressure

2.0

(0.5)

4.0

(1.0)

6.0

(1.5)

6.0

(1.5)

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

12

(3.0)

16

(4.0)

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

12

(3.0)

16

(4.0)

20

(5.0)

20

(5.0)

24

(6.0)

24

(6.0)

28

(7.0)

28

(7.0)

8.0” w.c.

0.75 psi

210E 2” x 2”

5150 (146) 4200 (119) 2950 (83.5) --- --- --- --- --- ---

7250 (205) 6650 (188) 5950 (168) 4700 (133) --- --- --- --- ---

0.5 psi

8000 (226) 8650 (245) 8150 (231) 7250 (205) 6300 (178) 4700 (133) --- --- ---

8000 (226) 10000 (283) 9850 (279) 9150 (259) 8400 (238) 7250 (205) 5950 (168) 4200 (119) ---

1 psi

8000 (226) 10000 (283) 10000 (283) 12000 (340) 11500 (326) 10700 (303) 9850 (279) 8900 (252) 7850 (222)

1.5 psi

8000 (226) 10000 (283) 10000 (283) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 11850 (335) 11000 (311)

2 psi

8000 (226) 10000 (283) 10000 (283) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340)

3 psi

8000 (226) 10000 (283) 10000 (283) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340)

5 psi

8000 (226) 10000 (283) 10000 (283) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340)

7.5 psi

8000 (226) 10000 (283) 10000 (283) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340) 12000 (340)

10 psi

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

25

Page 26

210 SERIES

Balanced Valve Design

Capacities

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model

210G

Pipe

Size

2 1/2”

x

2 1/2”

Inlet

Pressure

8.0” w.c.

0.5 psi

0.75 psi

1 psi

1.5 psi

2 psi

3 psi

5 psi

7.5 psi

10 psi

2.0

(0.5)

10400 (294) 8500 (241) 6000 (170) --- --- --- --- --- ---

14700 (416) 13410 (380) 12000 (340) 9500 (269) --- --- --- --- ---

16000 (453) 17500 (495) 16400 (464) 14700 (416) 12750 (361) 9500 (269) --- --- ---

16000 (453) 20000 (566) 19900 (563) 18500 (524) 16950 (480) 14700 (416) 12000 (340) 8500 (241) ---

16000 (453) 20000 (566) 20000 (566) 24000 (680) 23250 (658) 21600 (612) 19900 (563) 18000 (510) 15850 (449)

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 22450 (636)

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680)

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680)

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680)

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680) 24000 (680)

4.0

(1.0)

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model

Pipe

Size

Inlet

Pressure

2.0

(0.5)

4.0

(1.0)

6.0

(1.5)

6.0

(1.5)

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

12

(3.0)

12

(3.0)

16

(4.0)

16

(4.0)

20

(5.0)

20

(5.0)

24

(6.0)

24

(6.0)

28

(7.0)

28

(7.0)

8.0” w.c.

0.75 psi

210G 3” x 3”

11500 (325) 9400 (266) 6600 (187) --- --- --- --- --- ---

16000 (453) 14800 (416) 13200 (374) 10450 (296) --- --- --- --- ---

0.5 psi

16000 (453) 19300 (546) 18100 (516) 16200 (459) 14000 (396) 10450 (296) --- --- ---

16000 (453) 20000 (566) 20000 (566) 20350 (576) 18700 (529) 16200 (459) 13200 (374) 9350 (265) ---

1 psi

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 23800 (674) 21900 (620) 19800 (561) 17450 (494)

1.5 psi

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 27000 (765) 27000 (765) 26400 (748) 24700 (699)

2 psi

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 27000 (765) 27000 (765) 27000 (765) 27000 (765)

3 psi

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 27000 (765) 27000 (765) 27000 (765) 27000 (765)

5 psi

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 27000 (765) 27000 (765) 27000 (765) 27000 (765)

7.5 psi

16000 (453) 20000 (566) 20000 (566) 24000 (680) 24000 (680) 27000 (765) 27000 (765) 27000 (765) 27000 (765)

10 psi

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

26

© 2017, Maxitrol Company. All Rights Reserved.

Page 27

Capacities

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model

Pipe

Size

Inlet

Pressure

2.0

(0.5)

4.0

(1.0)

6.0

(1.5)

APPLIANCE REGULATORS

Outlet Pressure - inches w.c. (kPa)

9.0

(2.25)

12

(3.0)

16

(4.0)

20

(5.0)

24

(6.0)

28

(7.0)

210J 4” x 4”

8.0” w.c.

0.5 psi

0.75 psi

1 psi

1.5 psi

2 psi

3 psi

5 psi

7.5 psi

10 psi

20800

(589)

29500

(835)

32000

(906)

32000

(906)

32000

(906)

32000

(906)

32000

(906)

32000

(906)

32000

(906)

32000

(906)

17000

(481)

27000

(764)

35000

(991)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

12000

(339)

24000

(680)

33000

(934)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

40000

(1132)

--- --- --- --- --- ---

19000

(538)

29420

(833)

37000

(1048)

48000

(1359)

48000

(1359)

48000

(1359)

48000

(1359)

48000

(1359)

48000

(1359)

--- --- --- --- ---

25500

(722)

34000

(963)

47000

(1331)

48000

(1359)

48000

(1359)

48000

(1359)

48000

(1359)

48000

(1359)

19000

(538)

29420

(833)

43350

(1227)

50000

(1416)

50000

(1416)

50000

(1416)

50000

(1416)

50000

(1416)

--- --- ---

24000

(680)

39700

(1124)

50000

(1416)

50000

(1416)

50000

(1416)

50000

(1416)

50000

(1416)

17000

(481)

36000

(1019)

48000

(1359)

50000

(1416)

50000

(1416)

50000

(1416)

50000

(1416)

---

31800

(900)

45000

(1274)

50000

(1416)

50000

(1416)

50000

(1416)

50000

(1416)

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

27

Page 28

210 SERIES

Balanced Valve Design

Pressure Drop: inches w.c. (kPa)

Flow Rate

CFH (m3/h)

500 (14.2) 0.23 (0.06) 0.15 (0.04) 0.14 (0.03) --- --- --- --- --1000 (28.3) 0.92 (0.23) 0.59 (0.15) 0.54 (0.13) 0.27 (0.07) 0.20 (0.05) 0.05 (0.01) 0.04 (0.009) 0.01 (0.002)

1500 (42.5) 2.08 (0.52) 1.33 (0.33) 1.22 (0.30) --- --- --- --- --2000 (56.6) 3.07 (0.76) 2.37 (0.59) 2.16 (0.54) 1.09 (0.27) 0.82 (0.20) 0.20 (0.05) 0.17 (0.04) 0.05 (0.01)

2500 (70.8) 5.78 (1.44) 3.70 (0.92) 3.38 (0.84) --- --- --- --- --3000 (85.0) 8.32 (2.07) 5.33 (1.33) 4.87 (1.21) 2.46 (0.61) 1.84 (0.46) 0.45 (0.11) 0.37 (0.09) 0.12 (0.03)

3500 (99.1) 11.33 (2.82) 7.25 (1.81) 6.62 (1.65) --- --- --- --- --4000 (113) 14.79 (3.68) 9.47 (2.36) 8.65 (2.15) 4.37 (1.09) 3.28 (0.82) 0.80 (0.20) 0.66 (0.16) 0.21 (0.05)

4500 (127) 18.72 (4.66) 11.98 (2.98) 10.95 (2.73) --- --- --- --- --5000 (142) 23.11 (5.76) 14.79 (3.68) 13.52 (3.37) 6.82 (1.70) 5.12 (1.28) 1.25 (0.31) 1.03 (0.26) 0.34 (0.08)

5500 (156) 27.97 (6.97) 17.90 (4.46) 16.35 (4.07) --- --- --- --- --6000 (170) 33.28 (8.29) 21.30 (5.30) 19.46 (4.85) 9.82 (2.45) 7.37 (1.84) 1.80 (0.45) 1.48 (0.37) 0.49 (0.12)

6500 (184) --- 25.00 (6.23) 22.84 (5.69) --- --- --- --- --7000 (198) --- 28.99 (7.22) 26.49 (6.60) 13.36 (3.33) 10.05 (2.50) 2.45 (0.61) 2.02 (0.50) 0.66 (0.16)

7500 (212) --- --- 30.41 (7.57) --- --- --- --- --8000 (226) --- --- --- 17.45 (4.35) 13.10 (3.26) 3.20 (0.80) 2.64 (0.66) 0.87 (0.22)

8500 (241) --- --- --- --- --- --- --- --9000 (255) --- --- --- 22.10 (5.50) 16.60 (4.13) 4.05 (1.01) 3.35 (0.83) 1.10 (0.27)

9500 (269) --- --- --- --- --- --- --- ---

10000 (283) --- --- --- 27.30 (6.80) 20.50 (5.11) 5.00 (1.24) 4.15 (1.03) 1.35 (0.34)

11000 (311) --- --- --- 33.00 (8.22) 24.80 (6.18) 6.05 (1.51) 5.00 (1.24) --12000 (340) --- --- --- 39.30 (9.79) 29.50 (7.35) 7.20 (1.79) 5.95 (1.48) 1.95 (0.48)

13000 (368) --- --- --- --- 34.60 (8.62) 8.50 (2.12) 7.00 (1.74) --14000 (369) --- --- --- --- 40.15 (10.00) 9.85 (2.45) 8.10 (2.01) 2.68 (0.67)

15000 (425) --- --- --- --- --- 11.30 (2.81) 9.30 (2.32) --16000 (453) --- --- --- --- --- 12.85 (3.20) 10.60 (2.64) 3.47 (0.86)

17000 (481) --- --- --- --- --- 14.50 (3.61) 11.95 (2.98) --18000 (510) --- --- --- --- --- 16.25 (4.05) 13.40 (3.34) 4.40 (1.09)

19000 (538) --- --- --- --- --- 18.10 (4.51) 14.90 (3.71) --20000 (566) --- --- --- --- --- 20.05 (4.99) 16.50 (4.11) 5.42 (1.35)

22000 (623) --- --- --- --- --- 24.25 (6.40) 20.00 (4.98) 6.56 (1.63)

24000 (680) --- --- --- --- --- 28.85 (7.19) 23.80 (5.93) 7.81 (1.94)

26000 (736) --- --- --- --- --- 33.85 (8.43) 27.90 (6.95) 9.06 (2.26)

28000 (793) --- --- --- --- --- 39.25 (9.78) 32.40 (8.07) 10.62 (2.64)

30000 (849) --- --- --- --- --- --- 37.20 (9.27) 12.41 (3.09)

32000 (906) --- --- --- --- --- --- --- 13.90 (3.46)

34000 (963) --- --- --- --- --- --- --- 15.69 (3.91)

36000 (1019) --- --- --- --- --- --- --- 17.60 (4.38)

38000 (1076) --- --- --- --- --- --- --- 19.60 (4.88)

40000 (1133) --- --- --- --- --- --- --- 21.70 (5.40)

45000 (1274) --- --- --- --- --- --- --- 27.40 (6.82)

50000 (1416) --- --- --- --- --- --- --- 33.80 (8.42)

55000 (1557) --- --- --- --- --- --- --- 41.00 (10.21)

1” 1 1/4” 1 1/2” 1 1/2” 2” 2 1/2” 3” 4”

210D 210E 210G 210J

NOTE: The maximum capacities for the different models listed on the capacity charts and represented by the heavy line on the

pressure drop are values at which these controls have been certied by CSA (except for the 210J). See pages 58-59 for

Regulator Sizing Requirements and Examples.

28

© 2017, Maxitrol Company. All Rights Reserved.

Page 29

Spring Selection Chart: inches w.c. (kPa)

APPLIANCE REGULATORS

Model CSA Certied Springs

210D

210E

210G

210J

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

1 to 3.5

(0.25 to 0.9)

Brown

---

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

2 to 5

(0.5 to 1.25)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 6

(0.75 to 1.5)

Plated

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

3 to 8

(0.75 to 2)

Pink

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

4 to 8

(1 to 2)

Orange

---

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

4 to 12

(1 to 3)

Violet

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 12

(1.25 to 3)

Blue

5 to 15

(1.25 to 3.7)

Green

5 to 15

(1.25 to 3.7)

Green

5 to 15

(1.25 to 3.7)

Green

---

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

10 to 22

(2.5 to 5.5)

Red

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

15 to 30

(3.7 to 7.5)

Yellow

Other

Springs

20 to 42

(5 to 10.5)

Black

20 to 42

(5 to 10.5)

Black

20 to 42

(5 to 10.5)

Black

20 to 42

(5 to 10.5)

Black

NOTE: The area within the heavy line indicates CSA certied springs. See pages 56-57 for complete Spring Selection Chart.

29

Page 30

210 SERIES

Balanced Valve Design

Dimensions

7”

(178 mm)

9.1”

(232 mm)

13.5”

(343 mm)

18”

(457 mm)

Dimensions

(152 mm)

(203 mm)

11.8”

(300 mm)

13.8”

(349 mm)

Model Pipe Size

210D 1”, 1 1/4”, 1 1/2” 3/8” NPT

210E 1 1/2”, 2” 1/2” NPT

210G 2 1/2”, 3” 3/4” NPT

210J 4” 3/4” NPT

Vent

Connection

Swing Radius

5.4”

(138 mm)

8.3”

(211 mm)

11.9”

(302 mm)

18.4”

(467 mm)

A B C D

9”

(228 mm)

11.3”

(286 mm)

16.5”

(419 mm)

24.3”

(616 mm)

NOTE: Dimensions are maximums and to be used only as an aid in designing clearance for the valve.

Actual production dimensions may vary somewhat from those shown.

6”

8”

2.4”

(60 mm)

2.9”

(75 mm)

4.6”

(116 mm)

5.4”

(138 mm)

30

A

A

D

D

210J210D, 210E, 210G

© 2017, Maxitrol Company. All Rights Reserved.

Page 31

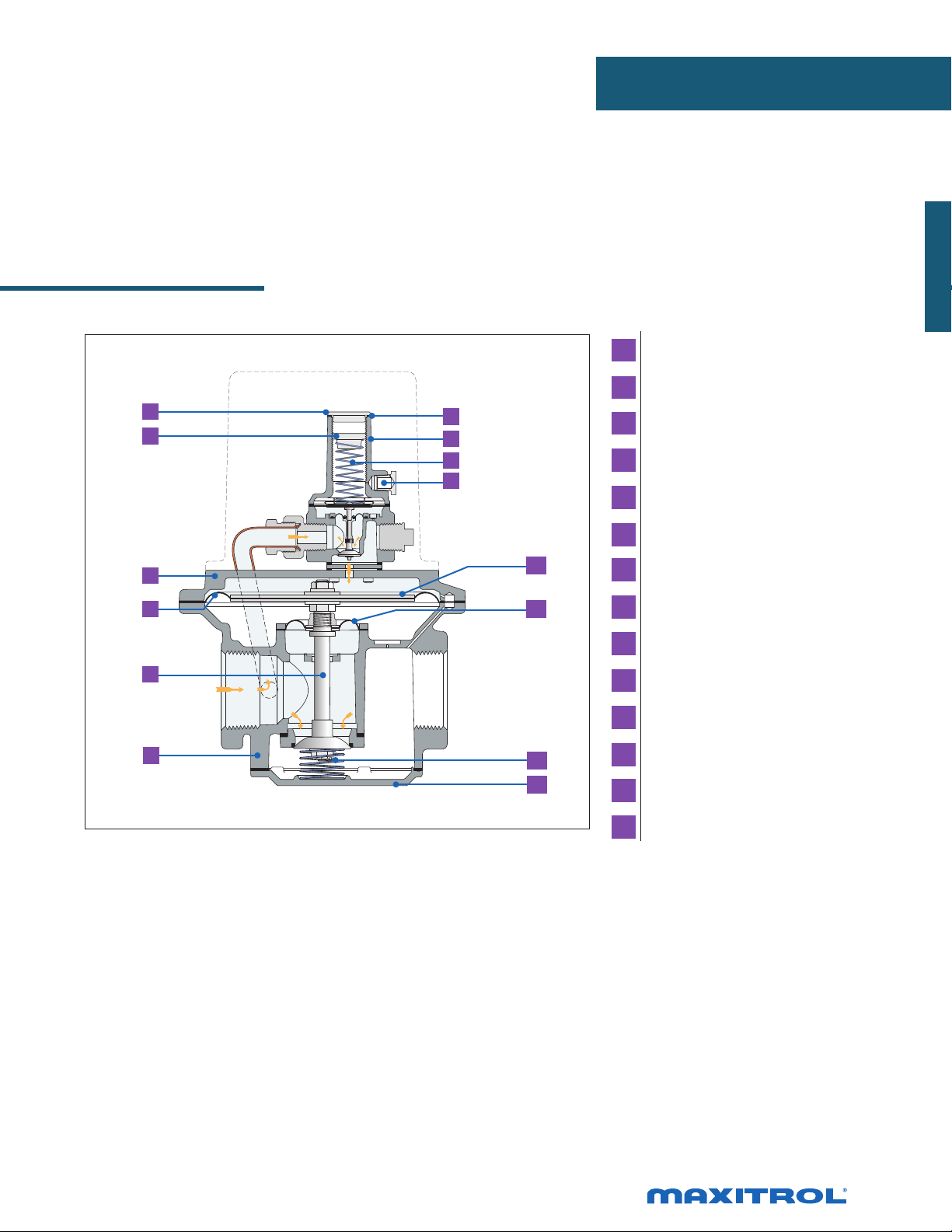

210 Balanced Valve Design

1

2

10

APPLIANCE REGULATORS

1 Welch Plug/Seal Cap

7

8

9

2 Vibration Resistant

Adjusting Screw

3 Top Housing

4 Regulating Diaphragm

5 Stem & Valve

3

4

5

6

NOTE: Diagrams are graphical representations only and may differ from actual product.

11

12

13

14

15

6 Bottom Housing

7 Seal Cap Gasket

8 Stack

9 Spring

10 Vent Connection

11 Diaphragm Plates

12 Balancing Diaphragm

13 Sensing Tube

14 Bottom Plate Gasket

15 Bottom Plate

31

Page 32

RZ and 210Z

Zero Governor Design

Both the RZ and 210Z series are adaptable for air-gas mixing

applications. Because of the balanced valve construction,

Z-models offer superior performance at an economical price

compared with other types of atmospheric regulators.

Maxitrol’s RZ and 210Z Zero Governor model regulators are

used for ow control of burners, nozzel mixers, mixing tees and

proportional premixers.

210EZ

Specications

Pipe Sizes .................................. RZ Models: 3/8” to 1” threaded connections with NPT or ISO7-1 threads.

210Z Models: 1” to 3” threaded connections with NPT or ISO7-1 threads.

4” 125 lb. ange (210JZ only).

Housing Material ......................R400Z, R500Z, R600Z, 210DZ, 210EZ, 210GZ, 210JZ: aluminum.

Mounting ..................................R400Z, 210DZ, 210EZ, 210GZ, 210JZ mount in an upright position only. R500Z, R600Z

suitable for multi-positional mounting. If ball check vent limiting device is installed, mount in

an upright position only.

NOTE: All Maxitrol gas pressure regulators should be installed and operated in accordance

with Maxitrol Safety Warning Instructions (see GPR_MI_EN.ES or GPR_CSA_MI_EN.FR).

Certications ..............................R400Z, R500Z, 210DZ, 210EZ, 210GZ: ANSI Z21.18/CSA 6.3 Gas Appl iance Press ure Regulat ors.

Gas Types .................................... Suitable for natural, manufactured, mixed gases, liqueed petroleum gases, and LP gas-air

mixtures.

Rated Inlet Pressure ....................CSA Certied: R400Z, R500Z: 1/2 psi (3.4 kPa); 210DZ, 210EZ, 210GZ: 5 psi (34.5 kPa)

Maxitrol Tested............................R400Z, R500Z, R600Z: 1 psi (6.9 kPa); 210JZ: 5 psi (34.5 kPa)

Emergency Exposure Limits ........R400Z, R500Z, R600Z: 2 psi (13.8 kPa)

210DZ, 210EZ, 210GZ, 210JZ: 25 psi (172 kPa)

Ambient Temperature Ranges ..... R400Z, R600Z: -40° to 205°F (-40° to 96°C)

R500Z: 32° to 205°F (0° to 96°C)

210DZ, 210EZ, 210GZ, 210JZ: -40° to 200°F (-40° to 93°C)

Sensing Taps ..................................210Z Models have convenient tap locations available for downstream sensing, cross connections,

and differential control. Four locations can be tapped and plugged for measuring pressure.

Remote Sensing ......................... 210DZ, 210EZ, 210GZ models may be ordered with remote sensing. The internal sensing

tube is omitted and external sensing taps are provided. Add sufx letter “R” to model number

when ordering.

Minimum Regulation .................R400Z: Suitable for pilot ow applications. (Circle P) (0.15 CFH NG), R500Z, R600Z: 10

CFH.

32

© 2017, Maxitrol Company. All Rights Reserved.

Page 33

Capacities and Pressure Drop

C

US

®

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

APPLIANCE REGULATORS

UA.TR.012-13

Pressure Drop - inches w.c. (kPa)

Model Number Pipe Size

3/8” x 3/8”

R400Z

1/2” x 1/2”

1/2” x 1/2”

R500Z

3/4” x 3/4”

3/4” x 3/4”

R600Z

1” x 1”

0.2

(0.05)

77

(2.16)

86

(2.41)

163

(4.56)

196

(5.49)

298

(8.34)

330

(9.24)

0.4

(0.10)

110

(3.08)

121

(3.39)

231

(6.47)

277

(7.76)

421

(11.8)

468

(13.1)

0.6

(0.15)

134

(3.75)

148

(4.14)

283

(7.92)

340

(9.52)

516

(14.5)

572

(16.0)

0.8

(0.20)

155

(4.34)

172

(4.82)

327

(9.16)

392

(11.0)

595

(16.7)

661

(18.2)

1.0

(0.25)

174

(4.87)

192

(5.38)

366

(10.3)

438

(12.3)

666

(18.7)

739

(20.7)

1.5

(0.37)

212

(5.94)

235

(6.58)

447

(12.5)

537

(15.0)

816

(22.9)

906

(25.4)

2.0

(0.50)

245

(6.86)

271

(7.59)

516

(14.6)

620

(17.4)

942

(26.4)

1046

(29.3)

2.5

(0.62)

274

(7.67)

303

(8.48)

577

(16.2)

693

(19.4)

1054

(29.5)

1169

(32.7)

3.0

(0.75)

-- -- --

-- -- --

635

(17.8)

760

(21.3)

1150

(32.2)

1280

(35.8)

3.5

(0.87)

685

(19.2)

820

(22.7)

1245

(34.9)

1380

(38.6)

4.0

(1.0)

730

(20.4)

876

(24.5)

1335

(37.4)

1480

(41.4)

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

33

Page 34

RZ and 210Z

Zero Governor Design

Capacities and Pressure Drop

Capacities expressed in CFH (m3/h) @ 0.64 sp gr gas

Model

Number

210DZ

210EZ

210GZ

Pipe Size

1” x 1” -- -- --

1 1/4”

x

1 1/4”

1 1/2”

x

1 1/2”

1 1/2”

x

1 1/2”

2” x 2” --

2 1/2”

x

2 1/2”

3” x 3”

0.1

(0.025)

-- -- --

-- -- --

--

1410

(39.5)

1555

(43.5)

0.3

(0.075)

1050

(29.4)

1210

(33.9)

2450

(68.6)

2695

(75.5)

0.5

(0.125)

1350

(37.8)

1560

(43.7)

3160

(88.5)

3475

(97.3)

Pressure Drop - inches w.c. (kPa) unless noted

1.0

(0.25)

900

(25.2)

1100

(30.8)

1200

(33.6)

1915

(53.6)

2210

(61.9)

4470

(125)

4920

(138)

3.0

(0.75)

1600

(44.8)

1900

(53.2)

2100

(58.8)

3315

(92.8)

3825

(107)

7740

(217)

8520

(239)

5.0

(1.25)

2000

(56.0)

2500

(70.0)

2700

(75.6)

4280

(120)

4940

(139)

9995

(280)

11000

(308)

7.0

(1.74)

2400

(67.2)

2900

(81.2)

3200

(89.6)

5065

(142)

5845

(164)

11825

(331)

13020

(365)

0.5 psi

(3.45)

3300

(92.4)

4100

(115)

4500

(126)

7125

(199)

8225

(230)

16635

(466)

18310

(513)

0.75 psi

(5.17)

4100

(115)

5000

(140)

5500

(154)

8725

(244)

10070

(282)

20370

(570)

22425

(628)

1 psi

(6.89)

4750

(133)

5850

(164)

6350

(176)

10075

(282)

11630

(326)

23525

(659)

25890

(725)

1.5 psi

(10.34)

5800

(162)

7150

(200)

7750

(217)

12340

(345)

14245

(399)

28810

(807)

31710

(888)

210JZ 4” x 4”

2700

(75.6)

4700

(132)

6000

(168)

8600

(241)

15000

(420)

19000

(532)

23000

(644)

32000

(896)

40000

(1120)

45500

(1274)

55700

(1560)

NOTE: CSA maximum capacities vary with spring range and pipe size. Please contact Maxitrol directly for CSA maximums.

See pages 58-59 for Regulator Sizing Requirements and Examples.

34

© 2017, Maxitrol Company. All Rights Reserved.

Page 35

Spring Selection: inches w.c (kPa)

Model Outlet Pressure Range

APPLIANCE REGULATORS

R400Z

R500Z

R600Z

Model Outlet Pressure Range

210DZ

210EZ

210GZ

-1.5 to 1.0

(-0.37 to 0.25)

-1.0 to 2.5

(-0.25 to 0.62)

-1.0 to 1.5

(-0.25 to 0.37)

-1.0 to 1.5

(-0.25 to 0.37)

-1.0 to 1.5

(-0.25 to 0.37)

-1.0 to 1.5

(-0.25 to 0.37)

210JZ

NOTE: See pages 56-57 for complete Spring Selection Chart.

-1.0 to 1.5

(-0.25 to 0.37)

35

Page 36

RZ and 210Z

Zero Governor Design

Dimensions

2”

(51 mm)

3.1”

(79 mm)

3.9”

(98 mm)

7”

(178 mm)

9.1”

(232 mm)

13.5”

(343 mm)

18”

(457 mm)

Dimensions

2”

(51 mm)

3”

(79 mm)

4”

(102 mm)

6”

(152 mm)

8”

(203 mm)

11.8”

(300 mm)

13.8”

(349 mm)

Model Pipe Size

R400Z 3/8”, 1/2” 1/8” NPT

R500Z 1/2”, 3/4” 1/8” NPT

R600Z 3/4”, 1” 1/8” NPT

210DZ 1”, 1 1/4”, 1 1/2” 3/8” NPT

210EZ 1 1/2”, 2” 1/2” NPT

210GZ 2 1/2”, 3” 3/4” NPT

210JZ 4” 3/4” NPT

Vent

Connection

Swing Radius

2.4”

(60 mm)

3.6”

(90 mm)

4.3”

(109 mm)

5.4”

(138 mm)

8.3”

(211 mm)

11.9”

(302 mm)

18.4”

(467 mm)

A B C D

3.3”

(83 mm)

4.7”

(119 mm)

5.7”

(144 mm)

9”

(229 mm)

11.3”

(286 mm)

16.5”