Page 1

EXA STAR Modulating Valve Series

OPERATING INSTRUCTIONS

Read these instructions carefully. Failure to follow them could

result in a re or explosion causing property damage, personal

injury, or loss of life.

Service and/or installation must be performed by a trained,

experienced service technician.

Disconnect power before installation to prevent electrical

shock, equipment or control damage.

WHAT TO DO IF YOU SMELL GAS

1. Do not operate any appliance.

2. Do not touch any electrical switch; do not use any

phone in your building.

3. Immediately evacuate the area and contact the gas

supplier. Follow the gas supplier’s instructions.

4. If you cannot reach the gas supplier, call the re

department.

PATENT PENDING

Figure 1: EXA STAR Modulating Valve Series

© 2011 Maxitrol

This control must be installed and operated strictly in accordance

with the instructions of the OEM and with all applicable government

codes and regulations, e.g. plumbing, mechanical, and electrical

codes and practices. These instructions do not supersede

OEM’s installation or operating instructions.

DESCRIPTION

The EXA STAR modulating valves are highly accurate and precise

modulating control valves (see Figure 1). EXA valves provide

repeatable process control with minimal hysteresis throughout the

entire range of modulation.

The EXA STAR modulation system’s high re setting and low re

setting are user programmable.

SPECIFICATIONS

Maximum Inlet Pressure: 5 psig

NOTE: Up to 10 psig available, consult Maxitrol Company.

Power Requirements: 24VAC/DC +/- 10% 50/60hz

NOTE: The EXA41, 51, 61 use half-wave rectiers. When using

a single transformer for powering the EXA41, 51, 61 and

devices with half-wave rectiers, the common for each must

be connected to the same leg of the transformer. Control

signal devices with full-wave bridge rectiers require a

separate transformer. See “Power Supply Compatibility”

bulletin.

Maximum Current Draw: 200mA

Temperature Limits: -40ºF to 150ºF operating

Control Signal (user selectable): 0-10VDC, 2-10VDC,

0-20mA, 4-20mA; 100KOhm Input Impedance

Mounting: Multipoise

Gases: Suitable for natural, manufactured, mixed gases,

liqueed petroleum gases, and LP gas-air mixtures.

Certications:

• EMC (EN 61000:2001)

• Immunity (EN 61000-6-2:2001)

• Emissions (EN 61000-6-4:2001)

• UL Recognized

•

Enclosure: IP40

Electrical Connection: UL310

Sizes: EXA41: 3/8”, 1/2” NPT or Rp ISO 7-1

EXA51: 1/2”, 3/4” NPT or Rp ISO 7-1

EXA61: 3/4”, 1” NPT or Rp ISO 7-1

Table 1: Capacity

Capacity @ 1” Pressure Drop - 0.64 sp. gr. gas:

EXA41 (3/8”) 190 cfh

EXA41 (1/2”) 215 cfh

EXA51 (1/2”) 385 cfh

EXA51 (3/4”) 435 cfh

EXA61 (3/4”) 670 cfh

EXA61 (1”) 780 cfh

© 2011 Maxitrol Company, All Rights Reserved.

1

Page 2

EXA STAR Modulating Valve Series

DESCRIPTION CONTINUED

The EXA STAR modulating valve series has a built-in digital

controller that provides a seamless interface with

controller.

a process

The valve has two (2) buttons and a communication LED for the

user interface. The buttons are used to set the valve for high and

low re settings (see Figure 4, page 4).

The valve has full open and full close mechanical limits. The

user can program settings that are within the valve’s mechanical

limits. This added dimension for sizing and applying the valve

is an important feature. It allows the valve to be set up for an

entirely different net output characteristic (dependent upon

supply pressure) (see Table 1, page 1).

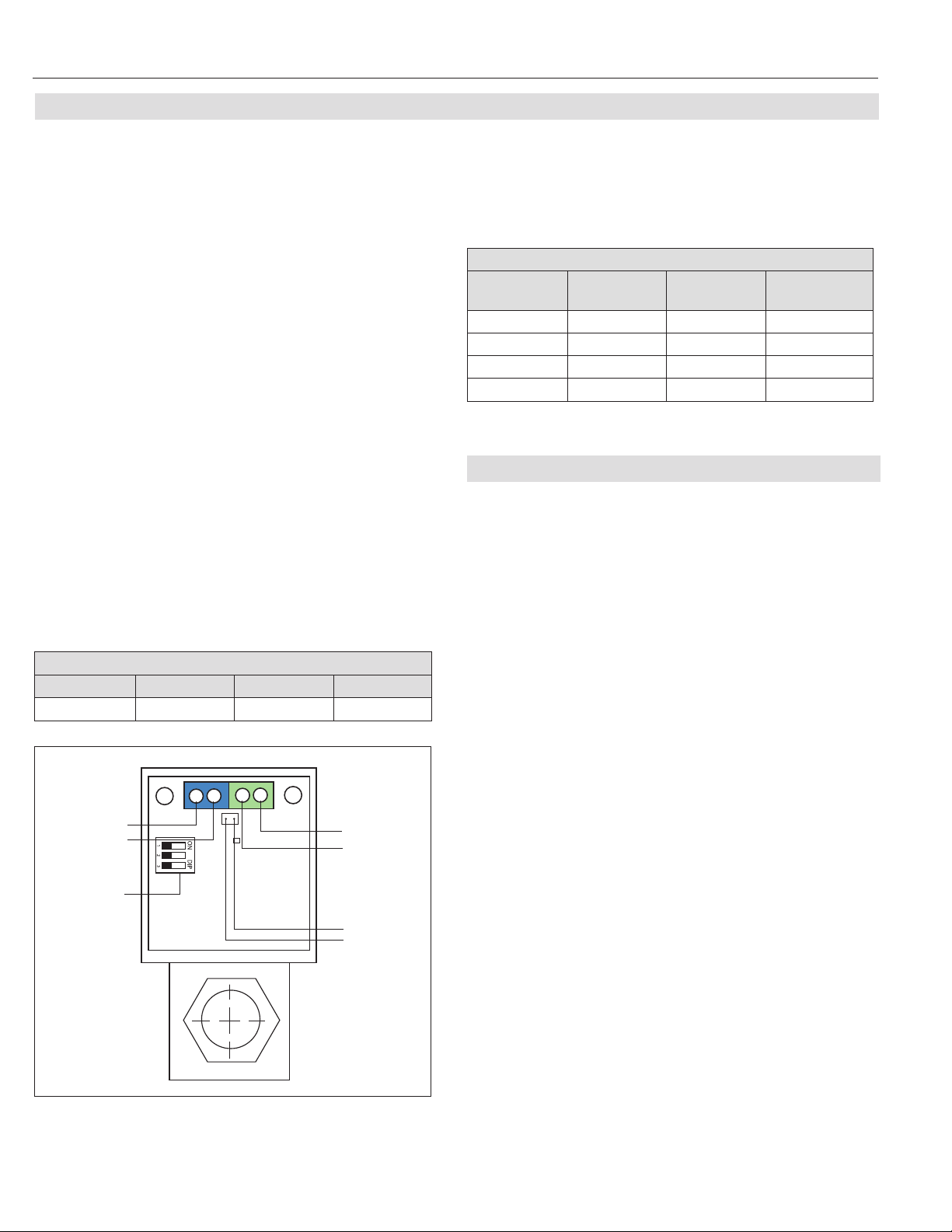

There are six (6) electrical connections on the EXA valve. Two (2)

are for power, two (2) are for the control signal, and two (2) are

for position feedback (see Figure 2).

Control Signal

The control signal indicates a position within the valve’s

programmed range of modulation.

NOTE: Control signal is polarity sensitive. Connect control

signal positive (+) to terminal 1 and control signal return

(-) to terminal 2 (see Table 2).

The control signal is “scaled” between the high and low re

setting of the valve. The minimum control signal will correspond

to the programmed low re setting, and the maximum control

signal will correspond to the programmed high re setting.

Table 2: Connection Table

Connection Table

Terminal 1 Terminal 2 Terminal 3 Terminal 4

Signal (+) Signal (-) Power (+) Power (-)

DIP Switches

A three (3) position DIP switch is located on the PCB (see Figure

2). Change the signal type and offset by changing the position of

DIP switches. (For DIP switch position and corresponding current/

voltage ranges, see Table 3).

Table 3: Dip Switch Position Table

DIP Switch Position Table

Control

Signal

SW1

Signal

SW2

Offset

SW3

Characteristic

0-10V OFF OFF OFF

2-10V OFF ON OFF

0-20 mA ON OFF OFF

4-20 mA ON ON OFF

POSITION FEEDBACK OUTPUT SPECIFICATION

The PWM output will give a feedback to correspond with the

current valve position between the programmed minimum and

maximum positions. The duty cycle range is always scaled from

the programmed minimum to the programmed maximum position.

Frequency: 200Hz ± 1Hz

Resolution: 9-bit (0.29% duty cycle)

Duty Cycle: 3% @ programmed minimum position

97% @ programmed maximum position

Output Impedance: 3.2kΩ ± 0.1kΩ

Control

Signal:

Terminal 1

Terminal 2

DIP Switches

(Table 3)

© 2011 Maxitrol

Figure 2: EXA STAR Modulating Valve Series Connections

© 2011 Maxitrol Company, All Rights Reserved.

Power:

Terminal 4

Terminal 3

Position

Feedback:

Pin 2

Pin 1

Output High Voltage: 5.0V nominal

5.25V maximum

NOTE: Output high level varies with the load current at the

PWM output.

Output Low Voltage: 0.0V + 0.01V

Pin 1: (-) negative polarity

Pin 2: (+) positive polarity

(see Figure 2)

Connection: TYCO MTA-100 or EQ.

(REF. 3-640442)

2

Page 3

EXA STAR Modulating Valve Series

C

D

B

A

F

SR

C

D

DIMENSIONS

NOTE: Dimensions are to be used only as an aid in designing clearance for the valve. Actual production dimensions may vary somewhat

from those shown (see Figure 3 and Table 4).

Table 4: Dimensions

Dimensions

inches (millimeters)

2.1

(54)

3.4

(87)

4.1

(105)

3.7

(94)

3.7

(94)

4.1

(105)

2.4

(61)

3.3

(84)

3.9

(100)

2.4

(61)

2.4

(61)

2.4

(61)

Model #

EXA41

EXA51

EXA61

Swing

Radius

(SR)

4.0

(102)

4.3

(110)

4.6

(117)

A B C D E F

4.8

(122)

5.5

(140)

6.0

(153)

1.0

(26)

1.3

(34)

1.5

(39)

SR

F

A

B

Figure 3: EXA STAR Modulating Valve Series Dimensions

D

E

C

© 2011 Maxitrol

© 2011 Maxitrol Company, All Rights Reserved.

3

Page 4

EXA STAR Modulating Valve Series

CONNECTIONS

Step 1: Remove 2 screws holding cover.

Step 2: Connect switched OFF 24V (AC/DC) power source to

terminals 3 and 4. Note polarity when using a DC

power source or if one leg of an AC transformer

secondary is externally grounded or is sharing power with

another half-wave device (see Figure 2, page 2).

Step 3: Set DIP switches to match available control signal

(see Table 3, page 2).

Step 4: Connect switched OFF control signal to terminals 1 and

2. Observe polarity.

Note that the return, or signal ground, must be connected

to terminal 2 (see Figure 2, page 2).

Step 5: Switch power and control signal ON.

Step 6: Set valve (see “Valve Setting” in section below).

Step 7: Replace cover.

VALVE SETTING

The EXA STAR modulating valve series has two (2) buttons and a

communication LED for the user interface. The buttons are used

to set the valve for high and low re settings (see Figure 4).

1. High Fire Setting (LED will be solid red)

2. Low Fire Setting (LED will be blinking red)

3. Operating Mode (LED will be OFF)

HIGH FIRE SETTING - BUTTON #1

To enter the high re setting mode, press and hold button #1 until

the LED lights solid red. Release. The valve is now in the high re

setting mode. Buttons #1 and #2 are used to set desired high re

setting.

Press or hold Button #1 to increase gas ow. Each button press

equates to the minimum available step size and will increase ow

slowly. Holding the button down auto steps and eliminates the need

to repeatedly press the button. Use this feature to rapidly increase

the ow.

Press or hold Button #2 to decrease gas ow. Each button press

equates to the minimum available step size and will decrease ow

slowly. Holding the button down auto steps and eliminates the need

to repeatedly press the button. Use this feature to rapidly decrease

the ow.

To save the high re setting, simultaneously hold Buttons #1 and #2

until the LED turns OFF.

NOTE: Controls left in any setting mode will default to the current

settings and return to normal operating mode after 5

minutes of inactivity.

LOW FIRE SETTING - BUTTON #2

To enter into the low re setting mode, press and hold button #2

until the LED light blinks red. Release. The valve is now in the low

re setting mode. Buttons #1 and #2 are used to set the desired low

re setting.

Button 1

Figure 4: EXA STAR Modulating Valve Series Adjustment Controls

Button 2

LED

© 2011 Maxitrol

Maxitrol Company

23555 Telegraph Rd., P.O. Box 2230

Southeld, MI 48037-2230 U.S.A.

EXAX1_MS_EN_08.2011

Press or hold Button #2 to decrease gas ow. Each button press

equates to the minimum available step size and will decrease ow

slowly. Holding the button down auto steps and eliminates the need

to repeatedly press the button. Use this feature to rapidly decrease

the ow.

Press or hold Button #1 to increase gas ow. Each button press

equates to the minimum available step size and will increase ow

slowly. Holding the button down auto steps and eliminates the need

to repeatedly press the button. Use this feature to rapidly increase

the ow.

To save the low re setting, simultaneously hold Buttons #1 and #2

until the blinking LED turns OFF.

NOTE: Controls left in any setting mode will default to the current

settings and return to normal operating mode after 5

minutes of inactivity.

www.maxitrol.com

© 2011 Maxitrol Company,

All Rights Reserved.

4

Loading...

Loading...