Page 1

www.maxitrol.com

A1093 AMPLIFIER

TD92 TEMPERATURE DIAL

TS194Q SENSOR WITH MIXING TUBE

MODULATINING GAS VALVE

s

e

iS

r

e

11/04 MS2099

3

MODULATION

FOR USE WITH 2-STAGE BURNER SYSTEMS

Page 2

asily turn a 2-stage indirect fired furnace into

a modulating furnace with Maxitrol’s

Series 3 electronic gas modulation system.

E

mance, a comfortable work environment, and precise control of discharge air temperature are just a few of the

advantages the Series 3 system has over a conventional

system.

Maxitrol Company originally designed the Series 3 system

for use with duct furnaces - additional applications include indirect makeup air heaters and commercial furnaces.

Heaters using atmospheric indirect fired gas burners are

typically used in both large and small industrial and commercial buildings. Any of these heaters with a 2-stage gas

valve and a 2-speed combustion blower is a candidate for

a Series 3 upgrade.

You’ll be glad you did. Improved perfor-

Such furnaces typically have a turn down that is 50% of

the high fire input. Converting to Maxitrol’s Series 3 system can reduce the turn down to 25%, or lower, of the

high fire input. By controlling the switch point of a relay

connected to the gas valve and inducer we are able to create

two separate modulation ranges.

A higher turn down allows you to accurately control the

discharge air temperature and significantly reduces the cycling of the heater, resulting in a consistent room temperature. This is especially true when you’re using multiple units with a large duct system (see example).

We also eliminate problems associated with lighting the

burner at the lowest gas input by providing an adjustable

timer and adjustable VDC output to the modulating valve

on start-up.

Many of the benefits of upgrading to the Series 3 modulation system are a direct result of the system’s ability to

obtain a higher turn down on atmospheric indirect-fired

applications.

SYSTEM REQUIREMENTS

Two-stage gas combination control. Low stage (flow) set approx. 50% of High stage (flow).

Two-speed combustion blower (inducer).

PRODUCT SPECIFICATIONS

Power Requirements

Ambient Limits

A1093 Dimensions

TD92 Dimensions

Valves

Sensor

Discharge Air Temperature Range

Combustion Blower and

Gas Valve Relay

The Series 3 system is used with Maxitrol’s industry leading Selectra modulator and modulator-regulator (M/MR)

valves. These unique electronic valves provide quick reaction times & offer continuous burner pressure adjustment.

24 VAC, 50/60 Hz Class II transformer

-40°F (-40°C) to 158°F (70°C)

7.5” x 3.4” x 1.9”

4.0” x 4.0” x 2.8”

M420, M520, M620 Series (one required)

TS194Q with mixing tube

TD92-0509: 50°F (10°C) to 90°F (32.2°C)

(Other temperature control ranges configured upon request.)

Normally Open 20 AMP maximum at 25°C

es

i

r

3

Se

Burner Light Off Adjustment

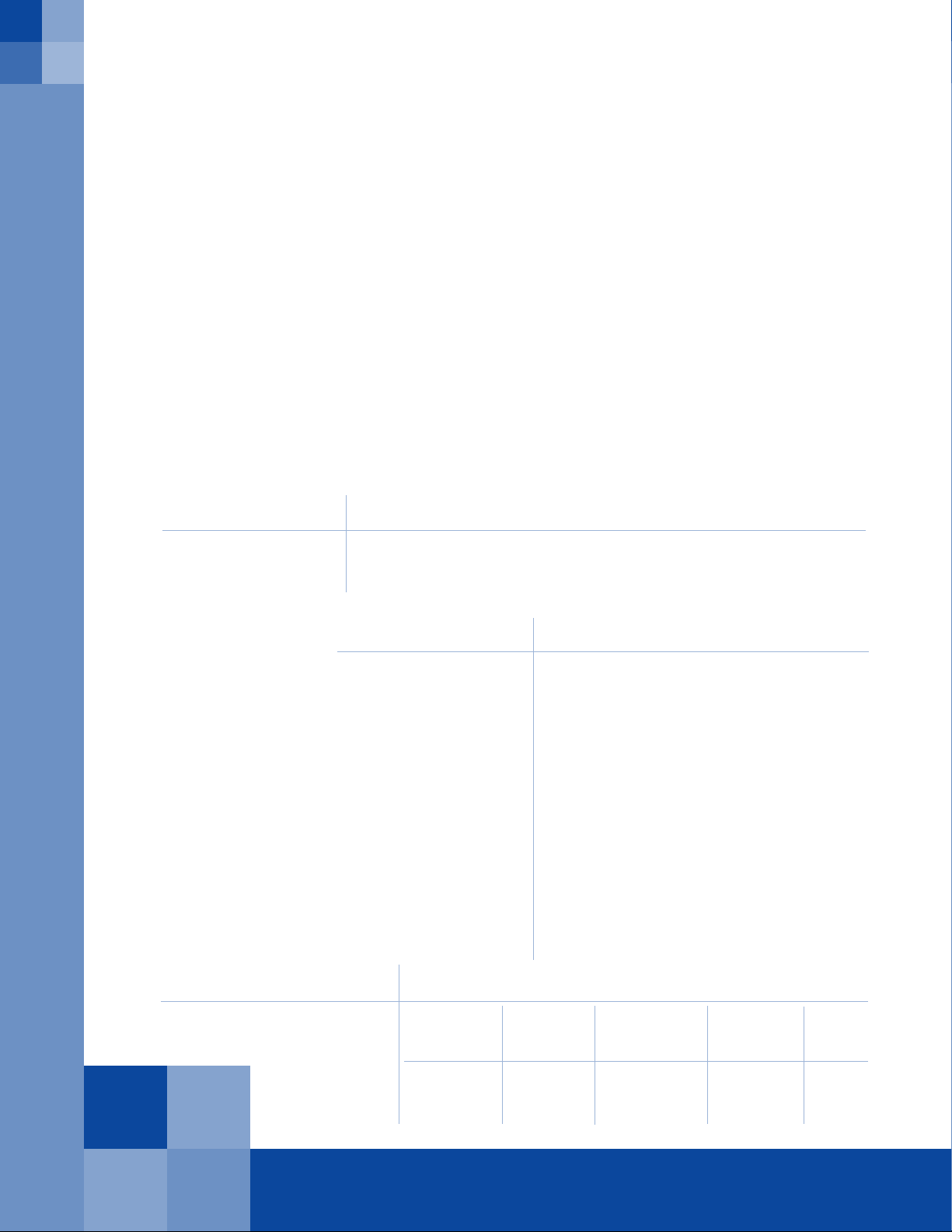

TYPICAL MANIFOLD PRESSURES

Position

High stage 2

Low stage 2

High stage 1

Low stage 1

Adjustable timer (0-30 sec) & adjustable VDC (5-15 VDC)

output to the modulating gas valve on startup.*

* Starts when power is supplied to amplifier.

Inlet

Pressure

(in. w.c.)

7”

7”

7”

7”

Outlet

Combination

Control

(in. w.c.)

3.6”

3.6”

1.0”

1.0”

Outlet

Modulator

(in. w.c.)

3.5”

0.7”

1.0”

0.2”

% of

Max

Input

100

45

55

25

www.maxitrol.com

Page 3

T

WO

-S

TAGE

M

ODULATING INDIRECT

Combination Control 2-Stage

(High Fire, Low Fire)

F

URNACE

M420

M520

M620

EXAMPLE

TYPICAL APPLICATION REQUIRING 16:1 TURNDOWN

Multiple Units

Large single duct system

4 duct furnaces each with a rated input of 400,000 BTUH

4 units total 1.6M BTUH

One unit is modulated by Series 3 resulting in a 4:1 Turn Down - 100,000 BTUH to 400,000 BTUH

The other units are staged ON/OFF using customer supplied staging control

Total turn down: 16:1

FOR USE WITH ENERGY/BUILDING MANAGEMENT SYSTEMS

SUPPLIED WITH SERIES 3

The Series 3 discharge air temperature can be set using a current

loop output from an energy/building management system.

No modification to the A1093 is required. However, the following must be observed:

The input current range should be limited from 5.0mA to 13.0mA.

This range corresponds to a set point temperature range of 50°F to

130°F (i.e. 0.1mA/°F). (The input current range for the A1093 is

not a standard 4-20mA interface.)

TYPICALLY S UPPLIED WITH FURNACE

(See Typical Wiring Diagram)

A1093 Amplifier

TD92 Temperature Dial

TS194Q with mixing tube

Modulating Gas Valve

2-stage Combination Gas Valve

2-speed Inducer

2 SPDT Relays

1 SPST Relay

Powers A1093 with separate transformer when 24 VAC is supplied

to combination gas valve.

1 N.O. SPST Timer Relay (optional)

Gives time for inducer to reach High speed position.

24 VAC 20 VA Transformer (separate, recommended)

Page 4

A1093 WITH EXTERNAL CURRENT LOOP

CURRENT LOOP INPUT

5.0 mA = 50°F

13.0 mA = 130°F

Rin = 100 ohms

(nominal)

es

i

er

S

3

Note:

Connect externally powered current loop to TB1, terminals 10 and 11 as

shown. No external connection is required to “LOOP” (TB1, terminal 9)

or (TB1, terminal 12). Connections to TB2 are not shown.

TYPICAL WIRING DIAGRAM

@ 2004, Maxitrol Company,

All Rights Reserved.

www.maxitrol.com P.O. Box 2230 Southfield, MI 48037-2230 U.S.A. tel 248.356.1400 fax 248.356.0829

Loading...

Loading...