Page 1

SERIES 44 INSTALLATION INSTRUCTIONS

and field service checklist

Table of Contents

Page 2 Introduction and Dimensions

Page 3 Specifications

Installation of Components

Typical Gas Trains

Page 4 & 5 Field Service Checklist

Page 6 Wiring Diagrams

Valve Adjustments

Page 7 Preliminary Circuit Analysis

Page 8 Temperature Calibration

Low Fire Start Time Adjustment

Sensitivity Adjustment

A1044L1 Amplifier

Selectrastat

Valve

Temp. Sensor

A1044 Amplifier

Temp. Selector

Mixing Tube and Sensor

BULLETIN MI2047-06/04

REPLACED MI1079

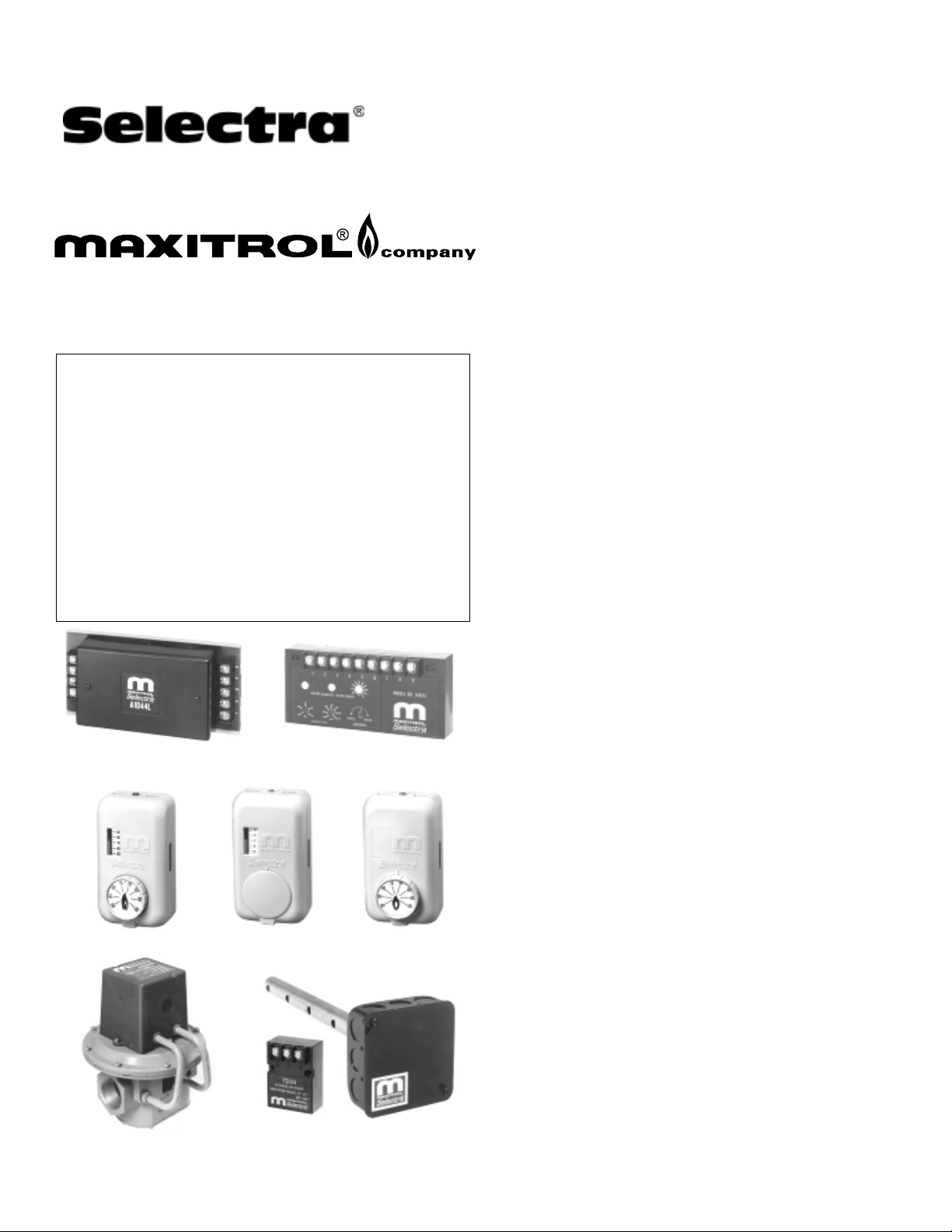

System Components

Amplifiers:

A1044 (min. 40° to 80° F/ max. 80° to 140° F)

A1044C (min. 20° to 60° F/ max. 80° to 140° F)

A1044D (min. 20° to 60° F/ max. 35° to 75° F)

A1044E (min. 20° to 60° F/ max. 60° to 120° F)

A1044L1, A1044CL1, A1044DL1, A1044EL1, A1044FL1 above ranges with adjustable low fire start duration

NOTE: Amplifier and Discharge Temperature Sensor must

have same temperature range to be compatible.

Discharge Temperature Sensors: use with Mixing Tube

TS144 (min. 40° to 80° F/max. 80° to 140° F)

TS144C (min. 20° to 60° F/max. 80° to 140° F)

TS144D (min. 20° to 60° F/max. 35° to 75° F)

TS144E (min. 20° to 60° F/max. 60° to 120° F)

TS144F (min. 40° to 60° F/max. 60° to 95° F)

Mixing Tubes: used with Sensors

MT1-9 or MT2-9 (9" length)

MT1-12 or MT2-12 (12" length)

MT1-23 or MT2-23 (23" length)

MT1-28 or MT2-28 (28" length)

MT1-57 (57" length)

Valves:

M411 (3/8" & 1/2" pipe size)

M511 (1/2" & 3/4" pipe size)

M611 (3/4" & 1" pipe size)

MR212D (1", 1¼", 1½ pipe size)

MR212E (1½" & 2" pipe size)

MR212G (2½" & 3" pipe size)

MR212J (4" flanged)

MR212D-2, E-2, G-2 & J-2 (same pipe sizes as MR212D-J

except used for 2-speed blower or dual fuel operation)

NOTE: M (Modulator) valve requires an upstream pressure

regulator for low fire & high fire settings.

MR (Modulator/Regulator) valve requires no

upstream pressure regulator up to 5 psi inlet.

Selectrastat (Senses & Selects):

T244 (55° to 90° F)

T244A (40° to 80° F)

or optional pair to replace Selectrastat:

Space Temperature Selector:

TD244 (wall mount 55° to 90° F)

TD244A (wall mount 40° to 80° F)

TD244P (panel mount 55° to 90° F)

TD244AP (panel mount 40° to 80° F)

Space Temperature Sensor:

TS244 (55° to 90° F)

TS244A (40° to 80° F)

NOTE: Space Temperature Selector and Space

Temperature Sensor must have same

temperature range to be compatible.

Page 2

Introduction and Dimensions

Selectra SERIES 44 electronic gas flame modulation

systems are designed primarily for space heating, as

components of direct fired equipment. They may be

field installed on existing equipment or specified for new

equipment installation. All fuel gases are compatible.

The systems utilize Modulator or Modulator-Regulator

valves to control gas pressure. Amplifiers are available

with adjustable low-fire start duration.

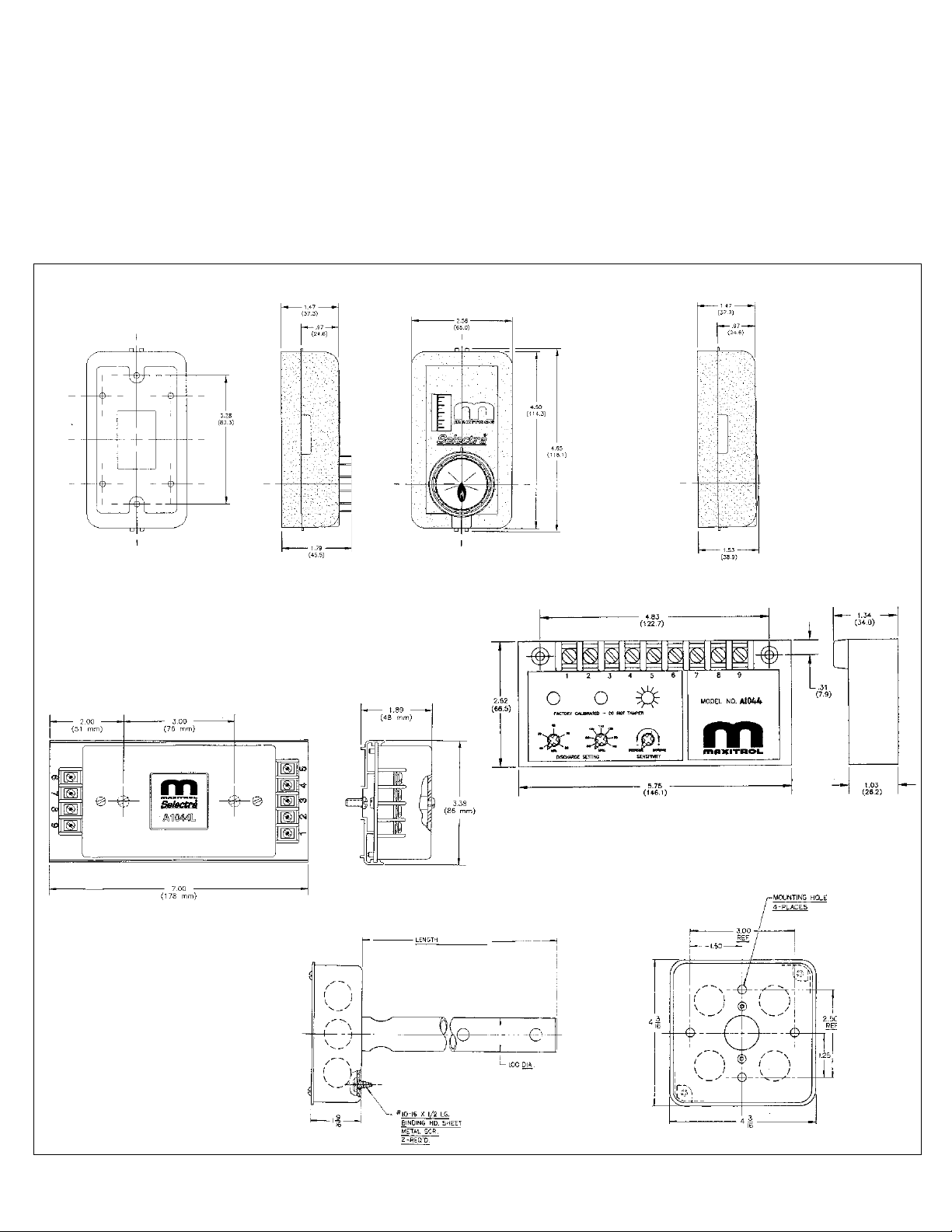

SELECTRASTAT, TEMP. SELECTOR, SPACE TEMP. SENSOR

A discharge air temperature sensor (and mixing tube) is a

means of limiting the minimum and maximum discharge air

temperature. The amplifier supplies output voltage to the

modulating valve. A wall mounted Selectrastat senses

space temperature and has an integral selector with either

a 55° to 90° F or 40° to 80° F range. Optionally, a remote

Temperature Sensor paired with a separate Temperature

Selector can be substituted for the Selectrastat.

(Space Temperature Selector dimensions same)

A1044 AMPLIFIER

A1044L1 AMPLIFIER

(Space Temperature Sensor dimensions same except without front dial)

MIXING TUBE (TS144 attaches internally)

(SEE PAGE 1)

2

Page 3

Specifications

Pressure Adjustment Ranges: (Maximum Fire)

Standard (MR212) ................. 2" to 5" w.c. / 5 to 12 mbar

Standard (MR212-2) .............. 2" to 5" w.c. / 5 to 12 mbar

reduced 0" to 3" w.c. / 0 to 7.5 mbar

Vent: Model M411, M511, M611-vertical vent outlet 1/8"

NPT—12A06 installed.

MR212—two vents located in upper housing, both

equipped with vent limiting means.

Ambient Limits:

Operating -40° to 125° F / -40° to 52° C

Non-Operating -50° to 185° F / -46° to 85° C

Power Requirements: 24 Volts, NEC Class ll

transformer 20 VA

NOTE: Transformer secondary must not be grounded

in any portion of the circuit external to a Maxitrol

amplifier. If existing transformer is grounded, a

separate isolated transformer must be used. Electrical

Installation of Components

Wiring Run: Control wires connected to the Selectrastat,

Discharge Air Sensor, Remote Temperature Selector/

Sensor, Amplifier or Valve must not be run close to or

inside conduit with power or ignition wires. Doing so

may cause the unit to function erratically or may

destroy the amplifier. If shielded wires are used, shield

must be insulated and grounded at the amplifier location

only.

Amplifier: Install in any convenient location that is

protected from the weather and contaminated

atmosphere.

interference may effect performance and/or damage

equipment.

Gases: All fuel gases

Pressure Limits:

Maximum M411, M511, M611 Outlet Pressure: 7.0" w.c.

/17 mbar

MR212 Outlet Pressure Springs: 1" to 3.5" w.c. / 2.5 to 9

mbar, 2" to 5" w.c. / 5 to 12 mbar, and 3" to 8" w.c. / 7

to 20 mbar

Static Pressure Rating (M411, M511, M611 ) ..... 5.0 psi

/345 mbar

Maximum Operating Inlet Pressure (MR212) ...... 5.0 psi

/345 mbar

Maximum Emergency Exposure *(MR212)...... 12.5 psi

/862 mbar

*May not function properly at this pressure, but will suffer

no internal damage.

Selectrastat: This component selects and senses space

temperature. Remove cover to mount in heated area

where representative space temperature can be sensed.

Optional:

Remote Temperature Selector: Not temperature

sensitive (selects space temperature). Remove cover to

mount in any convenient location. Note: Temperature

selector and sensor must have same temperature range to

be compatible.

Remote Temperature Sensor: Senses space

temperature. Remove cover to mount in area where

representative space temperature is to be sensed.

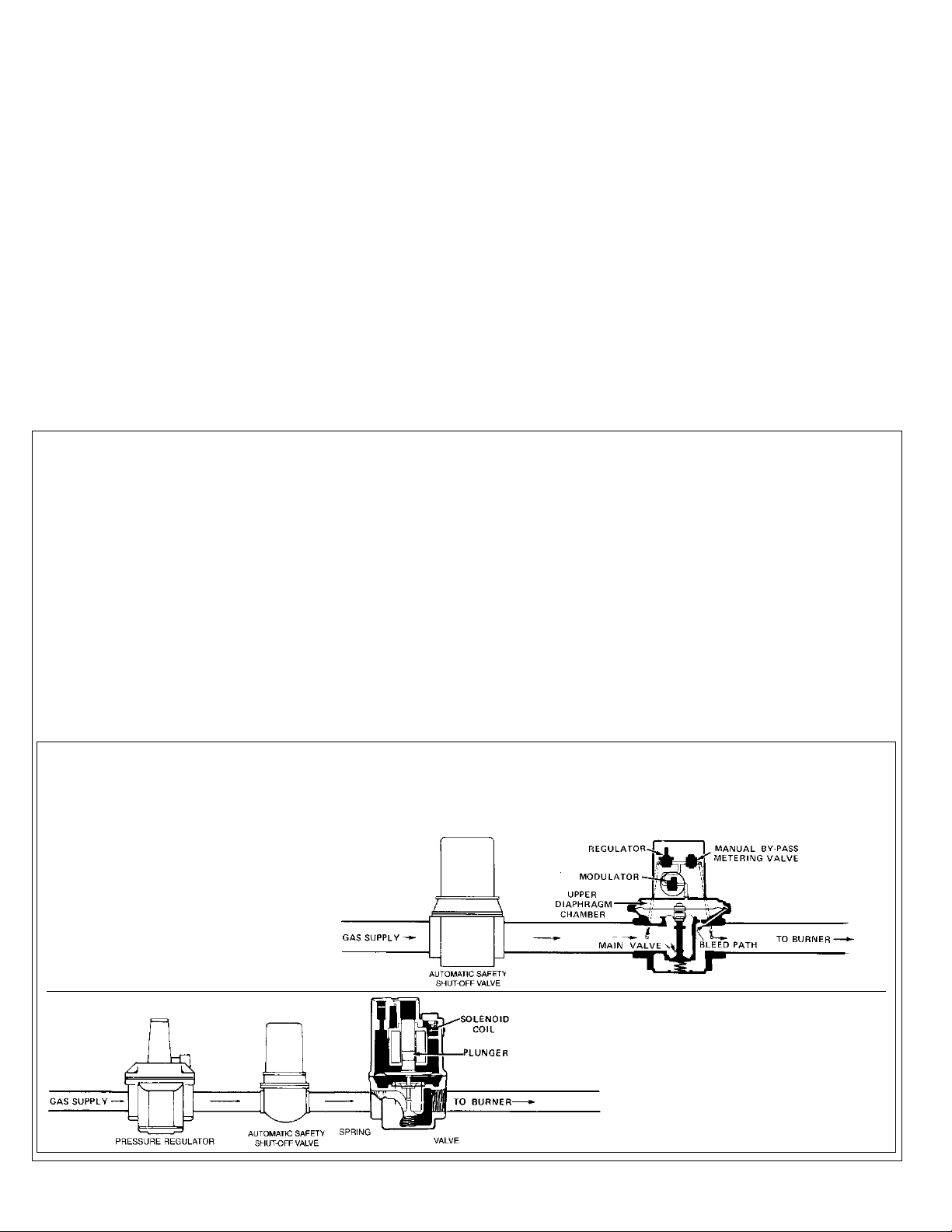

Typical Gas Trains

Modulator (M) or Modulator-Regulator (MR) Valve: Mount in upright position in horizontal run of pipe, downstream of

other controls - a separate gas pressure regulator must be used with any modulator (M) valve.

MR Valve: Modulator-regulator valve

M Valve: Regulator upstream of modulator valve

3

Page 4

head or repair wiring.

REMEDY

1. Install properly.

1. Arrow on side of valve should point in direction of gas flow.

on page 3).

2. If proper resistance values are not observed, replace modulator

3. Clean or replace plunger if necessary and install (as in figures

4. Replace diaphragm if ruptured.

MR212 (60-80 ohms), M611 (45-55 ohms).

solenoid sleeve.

2. Remove wires connected to amplifier terminals 6 & 7 and measure resistance.

3. Inspect - plunger should be installed (as in figures on page 3) and operate freely in

4. Disassemble valve for inspection of internal parts.

head or repair wiring.

5. Provide 24V AC to amplifier. Refer to item 24.

6. If proper resistance values are not observed, replace modulator

7. If readings are incorrect, replace the TS144 or repair wiring.

8. If power source and modulator coil check ot (items 5 & 6) but

wires 1 & 3, then 2 & 3. Meter should read greater than 2500 ohms.

5. Check for 24V AC at amplifier terminals 8 & 9.

6. Measure resistance per item 2.

7. Remove wires connected to amplifier terminals 1, 2, & 3. Measure resistance across

8. Follow precedures outlined in "PRELIMINARY CIRCUIT ANALYSIS" (Sections I & II).

proper modulating voltages cannot be obtained, then amplifier may

be assumed at fault. Install replacement amplifier.

filters & other inlet air restrictions. For other solutions, consult Maxitrol.

9. Adjust to proper low fire.

10. If greater than 1.5" negative pressure, check equipment for clogged

operating. Should be less than 1.5" w.c. negative pressure

9. See Valve Adjustments - Page 6.

10. Close main gas supply and measure manifold pressure with blower

repair wiring.

necessary - Pg. 8.

11. If amplifier is proven at fault, install replacement amplifier.

12. If reading is incorrect, replace the T244, TS244/TD244 or

13. If proper action is obtained, first check item 12. Recalibrate if

+ 1000 (T244).

+ 1000 (TS244) and 2100

+ 150 (TD244).

setting. Measure resistance across wires. Meter should read 6000 ohms

If TS244/TD244 are used, mete should read 4500 ohms

ohms

11. Follow precedures outlined in "PRELIMINARY CIRCUIT ANALYSIS" (Sections I & II).

12. Remove wires connected to amplifier terminals 4 & 5. Set T244 or TD244 to maximum

13. Follow procedures outlined in "PRELIMINARY CIRCUIT ANALYSIS" (Sections IV).

Temperature calibration procedures - Page 8.

14. Move TS144 to location where average temperature can be sensed.

15. If proper temperatures are not observed, refer to Discharge Air

14. Compare sensed temperature reading at TS144 with average discharge air temperature.

15. Follow precedures outlined in "PRELIMINARY CIRCUIT ANALYSIS" (Sections IV).

Consult Maxitrol about possibility of using special spring to

reduce pressure drop on selected installations.

19. Increase inlet pressure if possible or change to larger valve.

16. Clean, replace valve and/or seat if necessary.

16. Remove bottom Plate and inspect valve and seat

18. If readings are incorrect, replace the TS144 or repair wiring.

17. Clean, or if necessary, replace plunger.

18. Measure resistance per item 7.

17. Inspect - plunger should be smooth and clean and operate freely in solenoid sleeve.

20. See valve adjustments - page 6.

Pressure should be at least equal to the sum of: outlet pressure setting and pressure

drop of the valve (See Maxitrol Capacity Chart Bulletin) plus 1.0" w.c.

equipment manufacturer.

19. Read inlet pressure at valve, using a manomete with heater operating at full fire.

20. Read outlet pressure using manomete and compare with recommendation of

repair wiring.

necessary - page 8.

repair wiring.

21. If amplifier is proven at fault, install replacement ampifier.

22. If reading is incorrect, replace the T244, TS244/TD244 or

23. If proper aciton is obtained, first check item 22. Recalibrate if

24. If proper resistances are not observed, replace modulator head or

21. Follow precedure outlined in "PRELIMINARY CIRCUIT ANALYSIS" (Sections I & II).

22. Measure resistance per item 12.

23. Follow precedures outlined in "PRELIMINARY CIRCUIT ANALYSIS" (Section IV).

24. Measure resistance per item 2.

25. If desired temperature is not reached, increase maximum

25. Check to see if heater is delivering air at maximum discharge air setting.

dischage air temperature setting.

discharge air temperature setting.

fire, it may be indersized. Consult equipment manufacturer.

recalibrate if necessary.

26. If desired space temperatue is not reached, decrease minimum

27. If desired space temperature is not reached with heater at high

28. If temperature reading is incorrect, check items 25, 26 & 27, then

reading with T244 or TD244 dial setting.

26. Check to see if heater is delivering air at minimum discharge air setting.

27. Check to see if heater is operating at high fire.

28. Place thermometer next to T244 or TS244. Compare space temperature

POSSIBLE CAUSE FIELD TEST

1. Valve improperly installed.

2. Open circuit in modulator coil.

3. Plunger missing, jammed or improperly installed.

4. Ruptured main or balancing diaphragm.

Continuous low fire

(electronics OK).

No gas flow.

SYMPTOM

A.

Field Service Checklist

B.

5. No voltage to the amplifier.

6. Short in modulator coil circuit.

7. Short in TS144 circuit.

8. Faulty amplifier

Continuous Low Fire

(electronics problem).

C.

14. Improper TS144 location.

10. Excessive negative burner pressure.

Incorrect Low Fire. 9. Incorrect by-pass metering valve adjustment.

D.

11. Faulty amplifier.

12. Short in T244 or TS244/TD244 circuit.

13. Incorrect space temperature calibration.

Continuous

Minimum Discharge Air

Temperature.

E.

15. Incorrect discharge air temperature calibrations.

Incorrect Max. or Min.

Discharge Air Temperature.

F.

4

16. Foreign material holding valve open.

Continuous High Fire.

G.

18. Open circuit in TS144.

17. Plunger jammed.

(electronics OK)

Continuous High Fire.

H.

19. Inlet pressure too low.

20. Incorrect outlet pressure adjustment.

Incorrect High Fire.

(electronics problem)

I.

21. Faulty amplifier.

22. Open circuit in T244 or TS244/TD244.

23. Incorrect space temperature calibration.

Discharge Air Temperature.

J. Continuous Maximum

24. Short in modulator coil circuit.

K. Burned out Transfromer. No

25. Incorrect maximum discharge air temperature

Voltage to Amplifier.

L. Incorrect Space

setting A1044).

setting (A1044).

26. Incorrect minimum discharge air temperature

27. Insufficient burner capacity.

28. Incorrect space temperature calibration.

Temperature.

*Control circuits external to the Series 44 can cause burner malfunction. Always check manual valve to be certain gas is on, and check limit controls for normal operation.

Page 5

Amplifier with Selectrastat

Wiring Diagrams

Amplifier with remote temperature sensor and

separate temperature selector

TS144

MT1-12

TS144

MT1-12

VALVE

TRANS.

T244

TS244

TD244

TRANS.

VALVE

(Terminal locations shown for A1044 [and C, D, E] model amplifiers.

A1044L1 [and CL1, DL1, EL1] model terminal blocks 1-5 and 6-9 are at opposite ends of the board)

Valve Adjustments

(See bulletin MT2035 for additional M/MR valve information)

NOTE: Low fire adjustment should be checked whenever the high fire adjustment is changed.

MR 212 VALVE

M411, 511, 611 VALVE

High Fire Manifold Adjustments:

1. Disconnect wires from amplifier terminal #2 & #4.

This causes the valve to go to continuous high fire.

2. Remove seal cap (A), and turn

regulator pressure adjusting

screw to obtain desired manifold

pressure. (Clockwise rotation

increases pressure.)

3. Reconnect the wires to amplifier

terminal #2 & #4.

NOTE: If low fire bypass is on

maximum, the desired high fire

outlet pressure may not be

achieved.

Low Fire or Bypass Adjustments:

1. Disconnect wire from amplifier terminal

#8, this causes valve to go to continuous low fire.

2. Remove cap (B), and loosen lock screw (C). Turn (D)

to desired low fire adjustment. (Clockwise rotation

reduces minimum flow rate.)

3. Tighten set screw (C), replace cap (B) and reconnect

wire to amplifier terminal #8.

High Fire Manifold Adjustments:

1. Disconnect wires from amplifier terminal #2 & #4, this

causes the valve to go to continuous high fire.

2. Adjust the upstream pressure regulator to obtain the

desired manifold

pressure

(7" w.c. maximum).

3. Reconnect the wires

to amplifier terminal

#2 & #4.

B

Low Fire or Bypass

Adjustments:

1. Disconnect wire from

amplifier terminal #8,

this causes the valve

A

to go to continuous low fire.

2. Remove cap (A), and turn adjusting screw (B) to

desired low fire adjustment. (Clockwise rotation

reduces minimum flow rate.)

3. Replace cap (A), and reconnect wire to amplifier

terminal #8.

5

Page 6

Preliminary Circuit Analysis

This Preliminary Circuit Analysis will provide identification

of faulty components, improper wiring or calibration, and

other difficulties when used with the tabulated Field

Service Checklist (pages 4 & 5).

Note: All voltages and resistance readings are

approximate.

Section I

1. Wire the system (per Figure 1 below).

2. Connect a DC voltmeter to amplifier terminals #6 & #7.

3. Turn the Test-Potentiometer to minimum resistance.

(2,000 ohms). The DC voltage should read 0 volts.

4. Turn the Test-Potentiometer slowly to maximum

resistance (12,000 ohms). The DC voltage should

gradually increase to at least 18 volts.

If proper voltages are observed continue on with

Section II.

If proper voltages are not observed, the problem is

identified with the Amplifier, the 24-volt AC power

supply, or the circuit connected to terminals #6 & #7.

Section II

1. Turn power OFF, wire system (per Figure 2 below), turn

power ON.

2. Turn Test-Potentiometer to minimum resistance, the

voltage should be 0 volts.

3. Turn Test-Potentiometer slowly to maximum

resistance, the DC voltage should gradually increase to

at least 18 volts.

If proper voltages are observed in both Sections I & II,

the amplifier is satisfactory.

If proper voltages are not observed, continue testing to

identify the difficulty. Faults may be identified with the

amplifier, the 24V power supply, or the circuit

connected to terminals #6 & #7. See Field Service

Checklist.

Section III

1. Observe burner flames and/or burner pressure as Test-

Potentiometer is turned through full range. Note: From

0-5 volts, heater should be at by-pass or low, 5-15 volts,

heater should respond with various input rates; beyond

15 volts, heater is at maximum input.

If proper operation is observed, continue procedure to

check operation of sensing and selecting components.

If proper operation is not observed, see Field Service

Checklist to test M or MR valves and connecting wiring.

Section IV

1. With proper voltages observed thus far and modulator

responding correctly, wire the system (see Figure 1

below), except have TS144 connected in place of

jumper. Set MIN temperature selector at least 10° F

above outdoor temperature. Set MAX

temperature selector

at mid-range. Heater

is now under control

by the

(or)

TS144 Discharge Air Monitor.

2. Turn Test-Potentiometer to maximum resistance,

delivered air temperature should be per MAX

temperature setting. Turn Test-Potentiometer to

minimum resistance, delivered air temperature

should be per MIN temperature setting.

If proper delivered air temperatures are observed,

the problem is identified with the space

Model

A1044L1

temperature sensing and/or temperature

selecting components and circuits. See Field Service

Checklist.

If proper delivered air temperatures are not observed,

check calibration. See Field Service Checklist.

Section V

1. After test, remove all test equipment and reconnect all

components.

2K

RESISTOR

JUMPER

MT1-12/TS144

10K TEST

POT

VALVE

24V20VA

TRANS.

10K TEST POT

2K

RESISTOR

JUMPER

VALVE

14V20VA

TRANS.

(Terminal locations shown for A1044 [and C, D, E] model amplifiers.

A1044L1 [and CL1, DL1, EL1] model terminal blocks 1-5 and 6-9 are at opposite ends of the board)

6

Figure 2Figure 1

Page 7

Temperature Calibration

Note: All electronic components are pre-calibrated to a base

resistance. This permits field replacement without upsetting

system calibration.

Minimum Discharge Air Temperature

1. Install a thermometer or other temperature measuring

device at a point adjacent to the tip

of the TS144.

2. Connect a wire jumper between

terminals #4 and #5. Be sure

minimum temperature setting is at

least ten degrees higher than outdoor

temperature.

3. Turn the calibrating potentiometer

(A) until the reading of the

thermometer adjacent to the

TS144 agrees with the minimum

setting of the Discharge Air

Temperature Selector. Clockwise

rotation increases temperature

(A1044L model adjusted from blue

side).

4. Remove jumper.

Maximum Discharge Air Temperature

1. Install a thermometer or other temperature measuring

device at a point adjacent to the tip of the TS144.

2. Disconnect wires from terminals #4 & #5. Connect 12K

resistor across terminals #4 & #5.

Low Fire Start Time Adjustment

On A1044L1 (CL1, DL1, EL1) amplifiers, the low fire start

duration is adjustable from approximately 0-30 seconds,

and begins timing after the amplifier has been energized.

High fire is delayed, and the M/MR valve remains in the

low fire setting position during the delay time period.

Use a small screwdriver to adjust the time delay

potentiometer.

Turn clockwise (+) to increase low fire start duration, and

counter-clockwise (-) to decrease low fire start duration.

Time delay

potentiometer

A1044L1 (CL1, DL1, EL1)

cover removed

Sensitivity adjustment

3. Turn the calibrating potentiometer (B), until the reading

of the thermometer adjacent to the TS144 agrees with

the maximum setting of the Discharge Air Temperature

Selector. Clockwise rotation increases temperature

(A1044L1 model adjusted from blue side). Be sure

temperature setting does not exceed the design

temperature rise of the heater.

4. Remove resistor and reconnect

wires.

Space Temperature

1. Install a thermometer or other

temperature measuring device at a

point adjacent to the T244 or the

TS244. Set the T244 or the TD244

(whichever is used) for the desired

room temperature. Because of the

large space being heated, wait at

least one half hour* to make certain

adjustment is needed.

2. If the temperature reading is

different from the temperature setting,

turn (C) clockwise for an increase in

space temperature and counterclockwise for a decrease in

temperature. Each increment on adjustment C is

approximately 2.5 degrees (A1044L1 model adjusted from

blue side). After an adjustment has been made, give the

room temperature at least one half hour* to settle out

before rechecking.

* One half hour is only a time estimate. Longer or shorter

periods may be required for the temperature to stabilize.

Be sure space temperature is stabilized before attempting

calibration!

Sensitivity Adjustment

The sensitivity control will allow the user to control the

response of the system. Caution should be exercised in

the use of this adjustment. Under normal usage the

pointer should be located on the mark of the label.

If hunting is encountered (rapid oscillation), rotating the

sensitivity control counterclockwise may dampen the

oscillation, stabilizing the flame.

DO NOT adjust unless

A1044 (C, D, E)

model amplifier

necessary, because

decreasing the sensitivity will

increase the temperature

"DROOP" of the system.

7

Page 8

A copyrighted publication of

www.maxitrol.com

23555 Telegraph Rd., P.O. Box 2230

Maxitrol Company

Southfield, MI 48037-2230 U.S.A.

248.356.1400 • Fax 248.356.0829

European Representatives

Warnstedter Strasse 3 06502 Thale, Germany

49.3947.400.0 • Fax 49.3947.400.200

Industriestrasse 1 48308 Senden, Germany

49.2597.9632.0 • Fax 49.2597.9632.99

Loading...

Loading...