Page 1

Line Pressure Regulators and Over-Pressure Protection Devices

For piping systems up to 5 psi

SYSTEM COMPONENTS

Maximum Inlet Pressure:

CSA Certied ............................................. 5 psi (345 mbar)

Emergency Exposure Limits:

(inlet side only) ............................................. 65 psi (4.5 bar)

Outlet Pressure Range:

Certied spring .......................................... 7 - 11 inches w.c.

Maximum Individual Load:

Largest single appliance served (regulator with OPD)

325-3L47 (3/8”, 1/2”) (w/OPD 47 attached) ... 125,000 Btu/hr

325-3L48 (1/2”) (w/OPD 48 attached) ............ 200,000 Btu/hr

325-5AL48 (1/2”) (w/OPD 48 attached) ......... 235,000 Btu/hr

325-5AL48 (3/4”) (w/OPD 48 attached) ......... 320,000 Btu/hr

325-5AL600 (3/4”) (w/OPD 600 attached) ...... 425,000 Btu/hr

325-5AL600 (1”) (w/OPD 600 attached) ......... 465,000 Btu/hr

CSA Design Certied Z21.80 / CAN 6.22

Attention: Line pressure regulators with separate

overpressure protection devices shall be factory

preassembled, and supplied to the eld as a unit.

Capacity:

Total load of all appliances combined (regulator with OPD)

325-3L47 (3/8”, 1/2”) (w/OPD 47 attached) ....125,000 Btu/hr

325-3L48 (1/2”) (w/OPD 48 attached) ........... 200,000 Btu/hr

325-5AL48 (1/2”) (w/OPD 48 attached) ......... 235,000 Btu/hr

325-5AL48 (3/4”) (w/OPD 48 attached) ......... 320,000 Btu/hr

325-5AL600 (3/4”) (w/OPD 600 attached) ...... 425,000 Btu/hr

325-5AL600 (1”) (w/OPD 600 attached) ......... 465,000 Btu/hr

Venting:

OPD 47 ................... integral vent limiting orice w/dust cap

OPD 48 (optional 12A09 vent limiter) .................... 1/8” NPT

OPD 600 (optional 12A09 vent limiter) .................... 1/8” NPT

Gases: Intended for application in natural gas piping

systems up to 5 psi.

Ambient Temperature Limits: -40° to 205°F (0° to 96°C)

Note: All Maxitrol gas appliance regulators must be installed

and operated in accordance with Maxitrol’s ‘Safety Warning’

bulletin.

The 325 Series is suitable for

limited horizontal mounting

(less than or equal to 90°

from upright). But when using

the vent limiting device, the

regulator must be mounted in

a horizontal upright position.

Upright

Install the regulator properly

with gas owing as indicated

by the arrow on the casting (also see the Safety

Warning Instructions bulletin).

NOTE: Vent limiters are designed for use indoors

and in spaces where limiting the amount of gas

escapement due to diaphragm failure is critical. Vent

limiters should not be used outdoors if they are

exposed to the environment. 13A15 vent protector

is available for outdoor use when vent protection is

required.

© 2008 Maxitrol Company, All Rights Reserved

1

Page 2

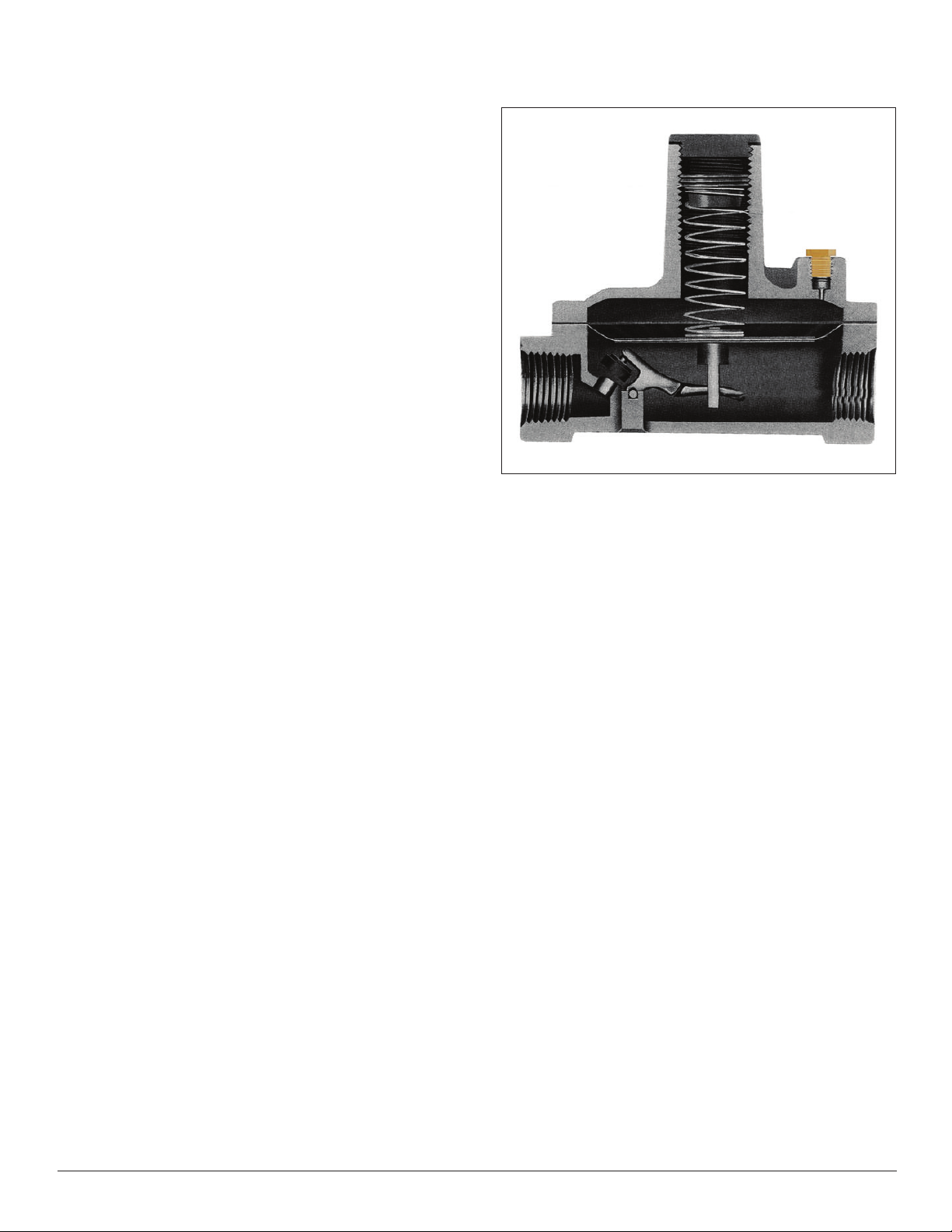

FEATURES

• CSA certied for up to 5-psi inlet pressure

• Over-pressure protection device (OPD) to limit

downstream pressure in case of regulator failure

• Maxitrol OPD approved and tested with the

regulator

• Self-aligning valve with lever action for dead end

regulator lockup

• Optional vent limiter eliminates the need to run

vent piping to an outside area

BENEFITS

• Meets ANSI standard Z21.80 for line pressure

regulators — for use on piping systems such as

CSST or semi-rigid copper tubing up to 5-psi

• OPD provides required downstream over pressure protection for supply pressures in

excess of 2-psi

• Pounds to inches regulator provides precise

control from pilot ows to full regulator capacity

• Meets many utility specications

THE NEW LINE PRESSURE REGULATOR

STANDARD - ANSI Z21.80

Although Maxitrol’s 325 Series are certied (ANSI Z21.18)

as appliance regulators (see bulletin 325LVR_MS_EN),

in the past they have often been used as line pressure

regulators. Until very recently, there was no standard for

line pressure regulators.

Z21.80 is the new ANSI standard for line pressure regulators,

intended for application in natural gas piping systems. As of

May 1, 2002, CSA requires that all line pressure regulators

above 2-psi must leave the factory pre-assembled and leak

tested. At supply pressures in excess of 2-psi, the new line

regulator standard requires a means (an over-pressure

protection device / OPD) — approved and tested with

the regulator — to limit the downstream pressure to 2-psi

maximum, in the event of regulator failure. Line pressure

regulators with separate overpressure protection

devices shall be factory preassembled, and supplied to

the eld as a unit. Maxitrol-built OPDs provide the required

downstream over-pressure protection.

As optional accessories, the regulators and OPDs offer an

automatic vent limiting device. The 12A09 or 12A39 vent

limiters eliminate the need to run vent piping to an outside

area - in the event of a diaphragm rupture, gas escapement

is limited to within the ANSI standards level. The 325 Series

are suitable for limited horizontal mounting (less than or

equal to 90° from upright) - but when using a vent limiting

device, the regulator must be mounted in a horizontal upright

position for best performance. Install the regulator properly

with gas owing as indicated by the arrow on the casting.

To deliver positive dead-end lock up, the 325 Series feature

a high leverage valve linkage assembly. Lockup pressure

can vary with the speed of the solenoid valve and its

location. The regulators are capable of precise regulating

control from full ow down to pilot ows.

The self-aligning valve is made of nitrile rubber. Housings

are durable aluminum die castings and all internal parts

are carefully selected and corrosion resistant. The

diaphragms are of high quality supported synthetic rubber

compounds.

The regulator with OPD is certied for inlet pressures up to

5-psi, and can withstand emergency exposure inlet pressure

up to 65-psi. The regulator alone provides no downstream

over-pressure protection in the event of failure.

Other 325 Series regulators will continue to be available

as CSA certied appliance regulators, as well as noncertied models for up to 10-psi inlet pressure (see bulletin

325LVR_MS_EN).

NOTE: Immediately after installation and prior to

operating any appliance: It is important to check the

preassembled pipe connection between the regulator

and OPD for leakage. Even though the Maxitrol 5 psi line

regulator with OPD is shipped as an assembly, installation

of the assembly can result in turning (tightening or

loosening) of the preassembled connection. If gas leakage

is detected, follow the same procedures to stop the leak as

you would use with any eld pipe connection, and repeat

step number 5 according to the ‘Safety Warning’ bulletin.

© 2008 Maxitrol Company, All Rights Reserved

2

Page 3

CAPACITIES AND PRESSURE DROP-

Applications above 2 psi, Regulator and OPD

Capacity:

Total load of all appliances combined (regulator & OPD)

325-3L47 (3/8”, 1/2”) (w/OPD 47) .............. 125,000 Btu/hr

325-3L48 (1/2”) (w/OPD 48) ....................... 200,000 Btu/hr

325-5AL48 (1/2”) (w/OPD 48) ..................... 235,000 Btu/hr

325-5AL48 (3/4”) (w/OPD 48) ................... 320,000 Btu/hr

325-5AL600 (3/4”) (w/OPD 600) ............... 425,000 Btu/hr

325-5AL600 (1”) (w/OPD 600) .................. 465,000 Btu/hr

Maximum Individual Load:

Largest single appliance served (regulator & OPD)

325-3L47 (3/8”, 1/2”) (w/OPD 47) ................ 125,000 Btu/hr

325-3L48 (1/2”) (w/OPD 48) .......................... 200,000 Btu/hr

325-5AL48 (1/2”) (w/OPD 48) ....................... 235,000 Btu/hr

325-5AL48 (3/4”) (w/OPD 48) ...................... 320,000 Btu/hr

325-5AL600 (3/4”) (w/OPD 600) .................. 425,000 Btu/hr

325-5AL600 (1”) (w/OPD 600) ..................... 465,000 Btu/hr

PRESSURE DROP CHART

© 2008 Maxitrol Company, All Rights Reserved

3

Page 4

DIMENSIONS AND SPRING RANGE-

A

B

C

A

B

C

A

B

C

A

C

B

Applications above 2 psi, Regulator and OPD

Attention: Line pressure regulators with separate

overpressure protection devices shall be factory

preassembled, and supplied to the eld as a unit.

Dimensions - inches (millimeters)

Model

Number

325-3L47

Pipe

Size*

3/8 x 3/8

1/2 x 1/23(76)

325-3L48 1/2 x 1/2

325-5AL48

325-5AL600

* standard models NPT threads.

1/2 x 1/2

3/4 x 3/4

3/4 x 3/4

1 x 1

Swing

Radius

3

(76)

4.4

(112)

4.4

(112)

(135)10(254)

(140)11(279)

Call Outs

A B C

3.5

(90)8(203)

3.5

(90)

8.5

(216)

5.3

5.5

325-3L47

325-3L48

3.9

(100)

3.9

(100)

5.4

(140)

5.4

(140)

325-5AL48

NOTE: Dimensions are to be used only as an aid in

designing clearance for the regulator. Actual production

dimensions may vary somewhat from those shown.

Outlet Pressure Range (all models):

Certied spring .................................... 7 - 11 inches w.c.

325-5AL600

SIZING INSTRUCTIONS

To select a line regulator of ample ow - one must know:

1. Available inlet pressure (maximum static/minimum operating).

2. Desired outlet pressure.

3. Required maximum capacity (total load, all appliances

combined), and maximum individual load.

4. Pipe size.

Example: To select a line regulator with OPD of ample capacity to handle ow. . .

KNOWN:

A. Required: 1/2” NPT line regulator with OPD, outlet pres-

sure of 7” w.c., with a static pressure of 5-psi, and a minimum operating inlet pressure of 3/4 psi.

B. Combined Btu rating of all appliances to be served by

the regulator: 145,000 Btu/hr.

C. Largest single appliance’s Btu rating: 90,000 Btu/hr.

SOLUTION:

A. In the Capacities table (page 3), locate [325-3L47 (1/2”)

= 125 CFH, 325-3L48 (1/2”) = 200 CFH, 325-5AL48

(1/2”) = 235 CFH].

B. The total Btu load requirement cannot exceed the

equivalent CFH result from step-A. The combined

145,000 Btu/hr requirement exceeds the 325-3L47

(1/2”) capacity, but is less than that of the 325-3L48

(1/2”) and 325-5AL48 (1/2”).

C. The 90,000 Btu/hr single largest appliance rating is

below the 325-3L48 maximum individual load capacity

of 200,000 Btu/hr.

D. The 325-3L48 is the smallest acceptable (1/2”) line

regulator with OPD for this application.

Maxitrol Company

23555 Telegraph Rd., PO Box 2230

Southeld, MI 48037-2230

LPROPD_MS_EN_07.2008 - Replaced Bulletin MS2076

4

www.maxitrol.com

© 2008 Maxitrol Company

All Rights Reserved

Loading...

Loading...