Page 1

325 Series Line Pressure Regulators with Over-Pressure Protection Devices

For Piping Systems up to 5 PSI

TABLE OF CONTENTS

Description .................................................................................. 1

Specications ........................................................................... 1, 2

Capacities ................................................................................... 2

Pressure Drop ............................................................................ 3

Spring Range Selection .............................................................. 3

Dimensions ................................................................................. 4

Sizing Instructions ...................................................................... 4

DESCRIPTION

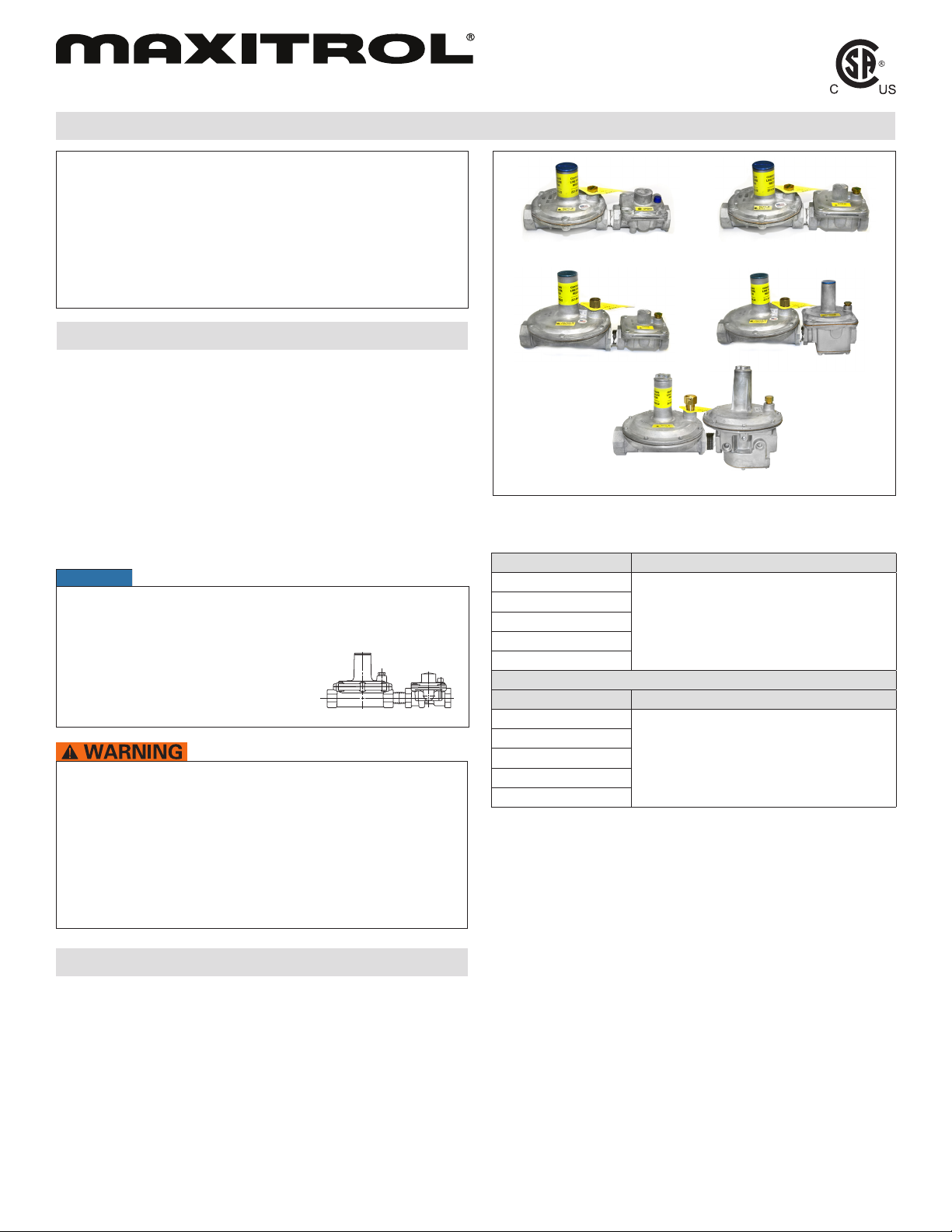

325-3L47

325-3L48

325 Series pounds to inches regulators are for use on residential,

commercial, and industrial applications.

The 325 Series with OPDs features a high leverage valve linkage

assembly to deliver positive dead-end lock-up. The regulators are

capable of precise regulating control from full ow down to pilot

ow.

B Models: Imblue Technology™ increases corrosion resistance and

provides extra protection against the elements for regulators used

in outdoor applications.

NOTE: (B) in model number designates Imblue Technology™.

NOTICE

To comply with the ANSI standard Z21.80/CSA 6.22 for Line

Pressure Regulators, installations exceeding 2 psi nominal

require a tested and approved overpressure protection device

(OPD) for use with the regulator.

Line pressure regulators with separate

overpressure protection devices shall

be factory preassembled and supplied

to the eld as a unit.

Immediately after installation and prior to operating any appliance

it is important to check the preassembled pipe connection between

the regulator and the OPD for leakage. Even though the Maxitrol

5 psi line regulator w/OPD is shipped as an assembly, installation

of the assembly can result in turning (tightening or loosening) of

the preassembled connection. If gas leakage is detected, follow

the same procedures to stop the leak as you would use with any

eld pipe connection, and repeat step 3 according to Maxitrol

Safety Warning Instructions, LPROPD_MI_EN.FR.

SPECIFICATIONS

Gases

Suitable for natural, manufactured, mixed gases, liqueed

petroleum gases, and LP gas-air mixtures.

Approvals

CSA: ANSI Z21.80/CAN 6.22

Minimum Inlet Pressure

CSA Certied...............................................................1 psi (7 kPa)

325-5AL48

325-7AL210D

Figure 1: 325 Series Line Pressure Regulators with OPDs

325-5AL600

Maximum Inlet Pressure

Model CSA Certied

325-3(B)L47

325-3(B)L48

325-5A(B)L48

325-5A(B)L600

Natural/LP

5 psi (34.5 kPa)

325-7A(B)L210D

With 12A09, 12A39, and 12A49 Installed

Model CSA Certied

325-3(B)L47

325-3(B)L48

325-5A(B)L48

325-5A(B)L600

NAT: 5 psi (34.5 kPa)

LP: 2 psi (13.8 kPa)

325-7A(B)L210D

Outlet Pressure Range

Certied Spring ............................................................ 7 - 11” w.c.

Emergency Exposure Limits

All Models (Inlet Side Only) ................................ 65 psi (450 kPa)

Maximum Individual Load/Capacity

325-3(B)L47 (3/8”, 1/2”) (w/OPD 47 attached).....125,000 Btu/hr

325-3(B)L48 (1/2”) (w/OPD 48 attached)............. 200,000 Btu/hr

325-5A(B)L48 (1/2”) (w/OPD 48 attached).............235,000 Btu/hr

325-5A(B)L48 (3/4”) (w/OPD 48 attached).............320,000 Btu/hr

325-5A(B)L600 (3/4”) (w/OPD 600 attached)........425,000 Btu/hr

325-5A(B)L600 (1”) (w/OPD 48 attached).............465,000 Btu/hr

325-7A(B)L210D (1 1/2”, 1 1/4”) (w/OPD 210D attached) ...........

.............................................................................1,250,000 Btu/hr

Ambient Temperature Limits

All Models ..................................... -40ºF to 205ºF (-40ºC to 96ºC)

© 2011 Maxitrol Company, All Rights Reserved.

1

Page 2

325 Series Line Pressure Regulators with OPDs

Mounting Position

The 325 Series is suitable for multi-poise

mounting, but when used with a vent

limiting device, the regulator must be

mounted in a horizontal upright position

(see Figure 2). Install the regulator

properly with gas owing as indicated by

the arrow on the casting. (See Maxitrol

Safety Warning Instructions, LPROPD_

MI_EN.FR.)

®

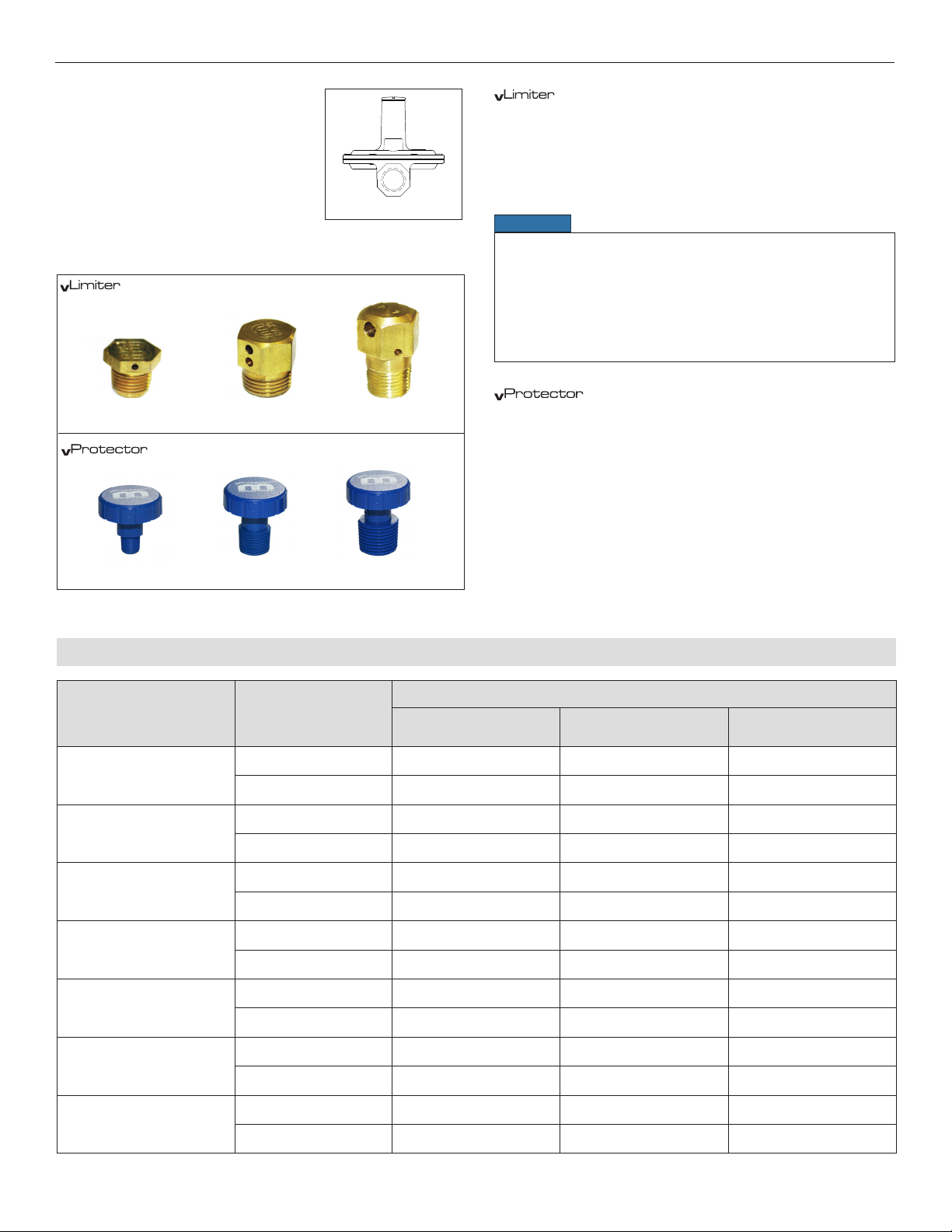

Vent Limiting Devices

12A09 (1/8” NPT)

®

Vent Protectors

12A39 (3/8” NPT)

UPRIGHT

Figure 2: 325 Regulator

in Upright Postion

12A49 (1/2” NPT)

®

Vent Limiting Devices for Indoor Applications:

325-3(B)L......................................................................12A09

325-5A(B)L..................................................................12A39

325-7A(B)L..................................................................12A49

OPD 48................................................................................12A09

OPD 600..............................................................................12A09

OPD 210D...........................................................................12A39

NOTICE

Maxitrol vent limiting devices eliminate the need to run vent

piping to the outside. Vent limiting devices are designed for

use indoors and in spaces where limiting the amount of gas

escapement due to diaphragm failure is critical. Vent limiting

devices should not be used outdoors if they are exposed

to the environment. Vent protectors are available for all

outdoor applications to ensure proper vent protection.

®

Vent Protectors for Outdoor Applications:

325-3(B)L......................................................................13A15

325-5A(B)L......................................................................13A15-5

325-7A(B)L.........................................................................13A25

OPD 48................................................................................13A15

OPD 600..............................................................................13A15

OPD 210D........................................................................13A15-5

13A15 (1/8” NPT)

Figure 3: Vent Accessories

13A25 (1/2” NPT)13A15-5 (3/8” NPT)

CAPACITIES - 0.64 sp gr gas expressed in CFH (m

Model Number

(pipe size)

325-3(B)L47 (3/8”, 1/2”)

325-3(B)L48 (1/2”)

325-5A(B)L48 (1/2”)

325-5A(B)L48 (3/4”)

325-5A(B)L600 (3/4”)

Outlet Pressure

Set Point

8.0” w.c. 110 110 110

11.0” w.c. 103 113 113

8.0” w.c. 184 184 184

11.0” w.c. 181 181 181

8.0” w.c. 229 229 229

11.0” w.c 213 220 220

8.0” w.c. 263 263 263

11.0” w.c. 237 254 254

8.0” w.c. 396 396 396

11.0” w.c. 326 355 355

3

/h)

Operating Inlet Pressure

3 psi (6.9 kPa) 4 psi (10.3 kPa) 5 psi (13.8 kPa)

325-5A(B)L600 (1”)

325-7A(B)L210D

(1 1/2”, 1 1/4”)

© 2011 Maxitrol Company, All Rights Reserved.

8.0” w.c. 413 441 441

11.0” w.c. 355 377 407

8.0” w.c. 1123 1123 1189

11.0” w.c. 1081 1107 1107

2

Page 3

325 Series Line Pressure Regulators with OPDs

PRESSURE DROP - 0.64 sp gr gas expressed in CFH (m

Model Number

7.0” w.c. (1.7 kPa) 1/2 psi (3.4 kPa) 3/4 psi (5.2 kPa) 1 psi (6.9 kPa)

3

/h) (for system pressure drop calculations)

Pressure Drop

325-3(B)L47 (3/8”) 140 198 246 283

325-3(B)L48 (1/2”) 145 204 250 289

325-5A(B)L48 (1/2”) 304 441 552 632

325-5A(B)L48 (3/4”) 315 448 568 652

325-5A(B)L600 (3/4”) 347 488 620 732

325-5A(B)L600 (1”) 362 513 644 750

325-7A(B)L210D (1 1/4”, 1 1/2”) 804 1096 1362 1624

NOTE: All Maxitrol line pressure regulators with OPDs must be installed and operated in accordance with Maxitrol’s Safety Warning

Instructions.

3

Flow Rate (m

100

@ 0.64 SG gas)

403020103 06865421

80

100 200

20

10

Pressure Drop (in. w.c.)

1

Figure 4: Pressure Drop Chart

Flow Rate (cfh @ 0.64 SG gas)

10

9

8

7

6

5

4

3

2

Pressure Drop (kPa)

1

.9

.8

00001000100101

SPRING RANGE SELECTION

Outlet Pressure Range (all models):

Certied Spring .................................................. 7 - 11” w.c.

© 2011 Maxitrol Company, All Rights Reserved.

3

Page 4

325 Series Line Pressure Regulators with OPDs

DIMENSIONS - Expressed in inches (mm)

Model Number Pipe Size* Swing Radius

A B C

Dimensions

325-3(B)L47 3/8”, 1/2” 3 (76) 3 1/2 (90) 8 (203) 4 (100)

325-3(B)L48 1/2” 3 (76) 3 1/2 (90) 8 1/2 (216) 4 (100)

325-5A(B)L48 1/2”, 3/4” 4 13/32 (112) 5 1/3 (135) 10 (254) 5 1/2 (140)

325-5A(B)L600 3/4”, 1” 4 13/32 (112) 5 1/2 (140) 11 (279) 5 1/2 (140)

325-7A(B)L210D 1 1/4”, 1 1/2” 6 3/4 (171) 7 (178) 15 3/8 (391) 9 (229)

* Standard models NPT threads

NOTE: Dimensions are to be used only as an aid in designing clearance for the regulator. Actual production dimensions may vary

somewhat from those shown.

C

A

A

B

325-3(B)L47

C

C

A

B

325-3(B)L48

C

C

B

325-5A(B)L47

A

B

325-5A(B)L600

SIZING INSTRUCTIONS

TO SELECT A REGULATOR WITH OPD OF SUFFICIENT FLOW

- ONE MUST KNOW:

1. Available inlet pressure (maximum static/minimum operating).

2. Desired outlet pressure.

3. Required maximum capacity (total load, all appliances

combined) and maximum individual load.

4. Pipe size.

Example: To select a 325 series line regulator with OPD of

sufcient capacity to handle ow...

KNOWN:

A. Required: 1/2” NPT line regulator with OPD, outlet pressure of

7” w.c., with static pressure of 5 psi, and a minimum operating

inlet pressure of 1 psi, Natural Gas.

A

B

325-7A(B)210D

B. Combined BTU rating of all appliances to be served by the

regulator: 145,000 Btu/hr.

C. Largest single appliance’s BTU rating: 90,000 Btu/hr

SOLUTION:

A. In the Capacities Table (page 2), locate 325-3L47 (1/2”) = 125

CFH, 325-3L48 (1/2”) = 200 CFH, 325-5AL48 (1/2”) = 235 CFH.

B. The total BTU load requirement cannot exceed the equivalent

CFH result from step A. The combined 145,000 Btu/hr

requirement exceeds the 325-3L47 (1/2”) capacity, but is less

than that of the 325-3L48 (1/2”), and 325-5AL48 (1/2”).

C. The 90,000 Btu/hr single largest appliance rating is below the

325-3L48 maximum individual load capacity of 200,000 Btu/hr.

D. The 325-3L48 is the correct (1/2”) line regulator with OPD for

this application.

Maxitrol Company

23555 Telegraph Rd., P.O. Box 2230

Southeld, MI 48037-2230 U.S.A.

LPROPD_MS_EN_09.2011

www.maxitrol.com

4

© 2011 Maxitrol Company,

All Rights Reserved.

Loading...

Loading...