For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

General Description

The MAX1652–MAX1655 are high-efficiency, pulsewidth-modulated (PWM), step-down DC-DC controllers

in small QSOP packages. The MAX1653/MAX1655 also

come in 16-pin narrow SO packages that are pincompatible upgrades to the popular MAX797. Improvements include higher duty-cycle operation for better

dropout, lower quiescent supply currents for better

light-load efficiency, and an output voltage down to 1V

(MAX1655).

The MAX1652–MAX1655 achieve up to 96% efficiency

and deliver up to 10A using a unique Idle Mode™ synchronous-rectified PWM control scheme. These devices

automatically switch between PWM operation at heavy

loads and pulse-frequency-modulated (PFM) operation

at light loads to optimize efficiency over the entire output current range. The MAX1653/MAX1655 also feature

logic-controlled, forced PWM operation for noise-sensitive applications.

All devices operate with a selectable 150kHz/300kHz

switching frequency, which can also be synchronized

to an external clock signal. Both external power switches are inexpensive N-channel MOSFETs, which provide

low resistance while saving space and reducing cost.

The MAX1652 and MAX1654 have an additional feedback pin that permits regulation of a low-cost second

output tapped from a transformer winding. The

MAX1652 provides an additional positive output. The

MAX1654 provides an additional negative output.

The MAX1652–MAX1655 have a 4.5V to 30V input voltage range. The MAX1652/MAX1653/MAX1654’s output

range is 2.5V to 5.5V while the MAX1655’s output range

extends down to 1V. An evaluation kit (MAX1653EVKIT)

is available to speed designs.

Applications

Notebook Computers

PDAs

Cellular Phones

Hand-Held Computers

Handy-Terminals

Mobile Communicators

Distributed Power

____________________________Features

♦ 96% Efficiency

♦ Small, 16-Pin QSOP Package

(half the size of a 16-pin narrow SO)

♦ Pin-Compatible with MAX797 (MAX1653/MAX1655)

♦ Output Voltage Down to 1V (MAX1655)

♦ 4.5V to 30V Input Range

♦ 99% Duty Cycle for Lower Dropout

♦ 170µA Quiescent Supply Current

♦ 3µA Logic-Controlled Shutdown

♦ Dual, N-Channel, Synchronous-Rectified Control

♦ Fixed 150kHz/300kHz PWM Switching,

or Synchronized from 190kHz to 340kHz

♦ Programmable Soft Start

♦ Low-Cost Secondary Outputs (MAX1652/MAX1654)

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

________________________________________________________________

Maxim Integrated Products

1

19-1357; Rev 1; 7/98

EVALUATION KIT

AVAILABLE

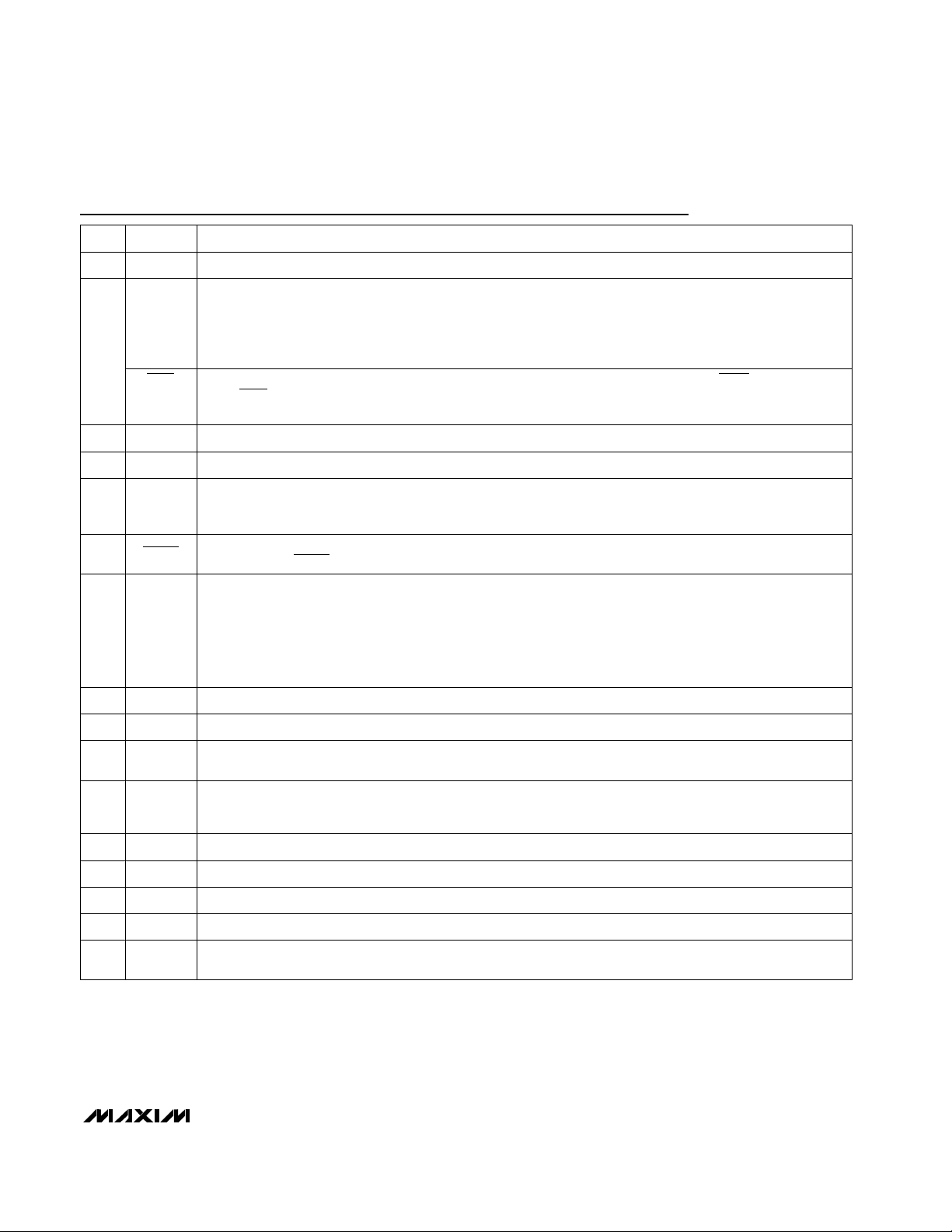

Ordering Information

Selection Guide

Pin Configurations appear at end of data sheet.

Idle Mode is a trademark of Maxim Integrated Products.

PART

FEEDBACK

VOLTAGE (V)

SPECIAL

FEATURE

COMPATIBILITY

MAX1652 2.5

Regulates positive

secondary voltage

(such as +12V)

Same pin order

as MAX796, but

smaller package

MAX1653 2.5

Logic-controlled,

low-noise mode

Pin-compatible

with MAX797

MAX1654 2.5

Regulates negative

secondary voltage

(such as -5V)

Same pin order

as MAX799, but

smaller package

MAX1655 1

Low output voltages (1V to 5.5V);

logic-controlled,

low-noise mode

Pin compatible

with MAX797

(except for feedback voltage)

PART

MAX1652EEE

-40°C to +85°C

TEMP. RANGE PIN-PACKAGE

16 QSOP

MAX1653EEE -40°C to +85°C 16 QSOP

MAX1654EEE

-40°C to +85°C 16 QSOP

MAX1653ESE

-40°C to +85°C 16 Narrow SO

MAX1655ESE

-40°C to +85°C 16 Narrow SO

MAX1655EEE -40°C to +85°C 16 QSOP

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V+ = +15V, GND = PGND = 0V, SYNC = REF, IVL= I

REF

= 0A, TA= 0°C to +85°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

V+ to GND..............................................................-0.3V to +36V

GND to PGND .......................................................-0.3V to +0.3V

VL to GND ................................................................-0.3V to +6V

BST to GND............................................................-0.3V to +36V

DH to LX.....................................................-0.3V to (BST + 0.3V)

LX to BST..................................................................-6V to +0.3V

SHDN to GND...............................................-0.3V to (V+ + 0.3V)

SYNC, SS, REF, SECFB, SKIP, FB to GND...-0.3V to (VL + 0.3V)

DL to PGND..................................................-0.3V to (VL + 0.3V)

CSH, CSL to GND ....................................................-0.3V to +6V

VL Short Circuit to GND..............................................Momentary

REF Short Circuit to GND...........................................Continuous

VL Output Current...............................................+50mA to -1mA

REF Output Current...............................................+5mA to -1mA

Continuous Power Dissipation (T

A

= +70°C)

SO (derate 8.70mW/°C above +70°C) .......................696mW

QSOP (derate 8.3mW/°C above +70°C) ....................667mW

Operating Temperature Range

MAX165_E_E ..................................................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

Rising edge, falling edge hysteresis = 60mV

Rising edge, falling edge hysteresis = 50mV

SHDN = 2V, 0 < IVL< 25mA, 5.5V < V+ < 30V

Rising edge, falling edge, hysteresis = 22mV (MAX1654)

CSH - CSL, negative

CSH - CSL, positive

Falling edge, rising edge, hysteresis = 22mV (MAX1652)

6V < V+ < 30V

25mV < (CSH - CSL) < 80mV

0 < (CSH - CSL) < 80mV, FB = VL, 6V < V+ < 30V,

includes line and load regulation

External resistor divider

VSS= 4V

0 < (CSH - CSL) < 80mV

VSS= 0V

CONDITIONS

V4.2 4.5 4.7VL/CSL Switchover Voltage

V3.8 3.9 4.0VL Fault Lockout Voltage

V4.7 5.0 5.3VL Output Voltage

-0.05 0 0.05

V

2.45 2.50 2.55

SECFB Regulation Setpoint

mA2.0SS Fault Sink Current

µA2.5 4.0 6.5SS Source Current

V4.5 30Input Supply Range

-50 -100 -160

mV

80 100 120

Current-Limit Voltage

%/V0.03 0.06Line Regulation

1.2

V4.85 5.06 5.255V Output Voltage (CSL)

V

1 5.5

Nominal Adjustable Output

Voltage Range

%

2

Load Regulation

UNITSMIN TYP MAXPARAMETER

0 < (CSH - CSL) < 80mV, FB = 0V, 4.5V < V+ < 30V,

includes line and load regulation

V3.20 3.34 3.463.3V Output Voltage (CSL)

2.5 5.5

MAX1655

MAX1652/MAX1653/

MAX1654

2.43 2.50 2.57

MAX1652/MAX1653/

MAX1654

CSH - CSL = 0V, CSL = FB,

SKIP = 0V, 4.5V < V+ < 30V

MAX1655

V

0.97 1.00 1.03

Feedback Voltage

3.3V AND 5V STEP-DOWN CONTROLLERS

FLYBACK/PWM CONTROLLER

INTERNAL REGULATOR AND REFERENCE

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

_______________________________________________________________________________________ 3

Note 1: Since the reference uses VL as its supply, V+ line-regulation error is insignificant.

Note 2: At very low input voltages, quiescent supply current may increase due to excessive PNP base current in the VL linear

regulator. This occurs if V+ falls below the preset VL regulation point (5V nominal).

ELECTRICAL CHARACTERISTICS (continued)

(V+ = +15V, GND = PGND = 0V, SYNC = REF, IVL= I

REF

= 0A, TA= 0°C to +85°C, unless otherwise noted.)

SECFB, 0 or 4V

SHDN, 0 or 30V

SHDN, SKIP

SYNC

SYNC = 0 or 5V

SYNC = REF

Guaranteed by design, not tested

CSH = CSL = 5.5V

V+ = 4.5V, CSH = CSL = 4.0V (Note 2)

SYNC = 0 or 5V

Falling edge

0 < I

REF

< 100µA

SYNC = REF

SHDN = 0V, CSL = 5.5V, CSH = 5.5V, V+ = 0 or 30V,

VL = 0V

CONDITIONS

0.1

µA

3.0

No external load (Note 1)

Input Current

2.0

V

VL - 0.5

Input High Voltage

%

98 99

97 98

Dropout-Mode Maximum Duty

Cycle

kHz190 340Oscillator Sync Range

ns200SYNC Rise/Fall Time

ns200SYNC Low Pulse Width

ns200SYNC High Pulse Width

125 150 175

kHz

270 300 330

Oscillator Frequency

2.46 2.50 2.54

1 2Quiescent Power Consumption

1 8Dropout Power Consumption

5 15

V+ Shutdown Current

V2.0 2.4Reference Fault Lockout Voltage

mV15Reference Load Regulation

µA0.1 1

CSL, CSH Shutdown Leakage

Current

UNITSMIN TYP MAXPARAMETER

SHDN = 0V, V+ = 30V, CSL = 0 or 5.5V

FB = CSH = CSL = 5.5V, VL switched over to CSLV+ Off-State Leakage Current

DL forced to 2V

FB, FB = REF

CSH, CSL, CSH = CSL ≤ 4V

SYNC, SKIP

A1DL Sink/Source Current

±0.1

70

1.0

SHDN, SKIP

SYNC

0.5

V

0.8

Input Low Voltage

DH forced to 2V, BST - LX = 4.5V A1DH Sink/Source Current

High or low, BST - LX = 4.5V

High or low

Ω1.5 5DH On-Resistance

Ω1.5 5DL On-Resistance

Reference Output Voltage V

OSCILLATOR AND INPUTS/OUTPUTS

3 7

5 15

µA

µA

mW

mW

V

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V+ = +15V, GND = PGND = 0V, SYNC = REF, IVL= I

REF

= 0A, TA= -40°C to +85°C, unless otherwise noted.) (Note 3)

Note 3: Specifications from 0°C to -40°C are guaranteed by design, not production tested.

0 < (CSH - CSL) < 70mV, FB = VL, 4.5V < V+ < 30V,

includes line and load regulation

0 < (CSH - CSL) < 70mV, FB = VL, 6V < V+ < 30V,

includes line and load regulation

CONDITIONS

V3.16 3.503.3V Output Voltage (CSL)

V4.5 30Input Supply Range

V4.80 5.305V Output Voltage (CSL)

UNITSMIN TYP MAXPARAMETER

CSH - CSL, negative

CSH - CSL, positive

-40 -160

Current-Limit Voltage

V

0.96 1.04

Feedback Voltage

2.40 2.60

mV

70 130

FB = CSH = CSL = 5.5V, VL switched over to CSL

SHDN = 0V, V+ = 30V, CSL = 0 or 5.5V

Rising edge, hysteresis = 60mV

No external load (Note 1)

0 < I

REF

< 100µA

µA15V+ Off-State Leakage Current

µA10V+ Shutdown Current

V

Rising edge, hysteresis = 50mV

SHDN = 2V, 0 < IVL< 25mA, 5.5V < V+ < 30V

4.2 4.7VL/CSL Switchover Voltage

V2.43 2.57Reference Output Voltage

Falling edge, hysteresis = 22mV (MAX1652)

Falling edge, hysteresis = 22mV (MAX1654)

mV15Reference Load Regulation

V3.75 4.05VL Fault Lockout Voltage

V4.7 5.3VL Output Voltage

2.40 2.60

V

-0.08 0.08

SECFB Regulation Setpoint

SYNC = REF

SYNC = 0 or 5V

97

kHz210 320Oscillator Sync Range

kHz

SYNC = REF

120 180

Oscillator Frequency

ns250SYNC High Pulse Width

ns250SYNC Low Pulse Width

250 350

mW2Quiescent Power Consumption

High or low, BST - LX = 4.5V

High or low

SYNC = 0 or 5V

Ω5DH On-Resistance

Ω5DL On-Resistance

%

98

Maximum Duty Cycle

CSH - CSL = 0V, 5V < V+ < 30V,

CSL = FB, SKIP = 0V

6V < V+ < 30V %/V0.06Line Regulation

3.3V and 5V STEP-DOWN CONTROLLERS

FLYBACK/PWM CONTROLLER

INTERNAL REGULATOR AND REFERENCE

OSCILLATOR AND INPUTS/OUTPUTS

MAX1652/MAX1653/

MAX1654

MAX1655

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

_______________________________________________________________________________________ 5

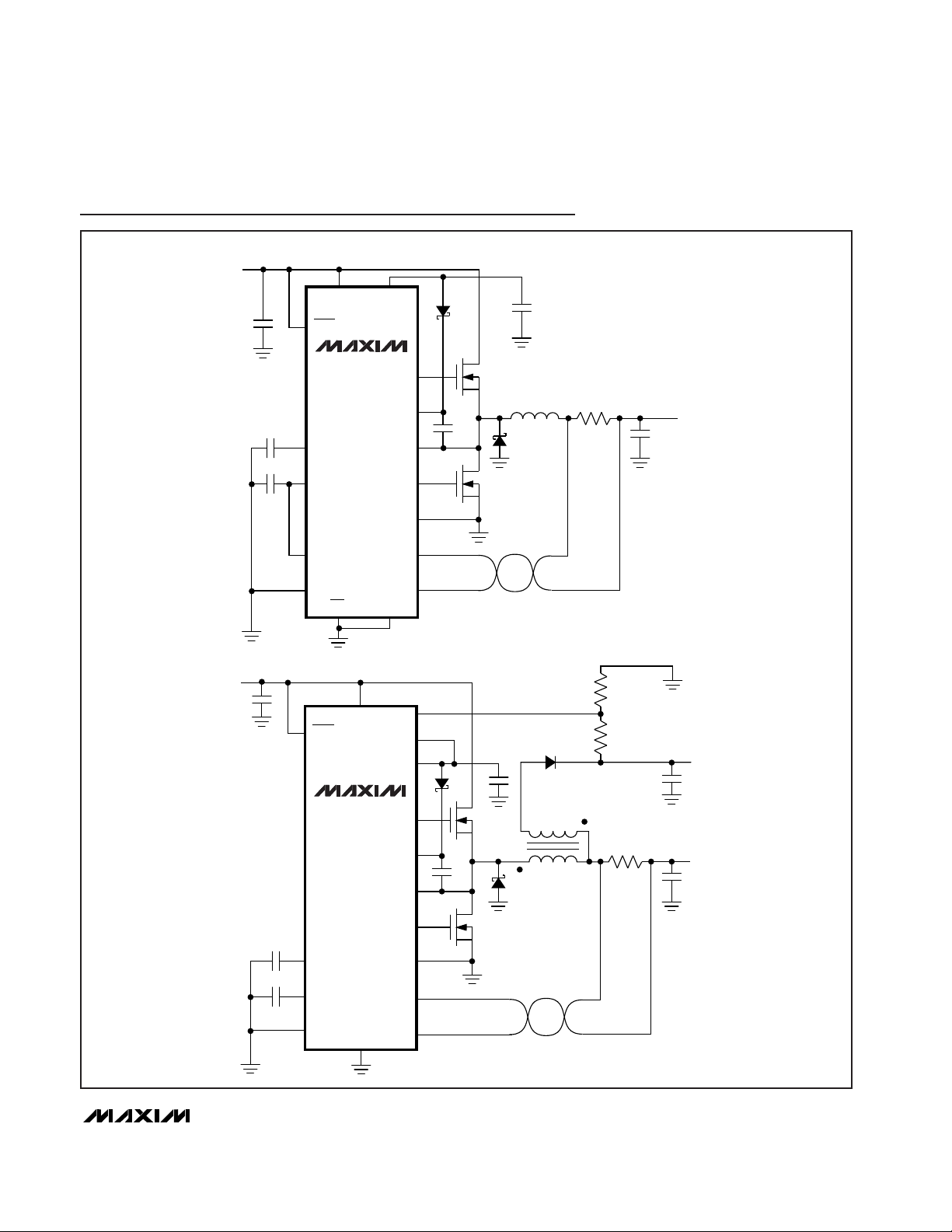

SHDN

DH

+12V

OUTPUT

+5V

OUTPUT

INPUT

6V TO 30V

BST

LX

DL

PGND

CSH

CSL

SS

REF

SYNC

GND

V+

VL

FB

SECFB

MAX1652

MAX1653

MAX1655

SHDN

DH

+3.3V

OUTPUT

INPUT

4.5V TO 30V

BST

LX

DL

PGND

CSH

CSL

SS

REF

SYNC

GND

SKIP FB

V+ VL

Typical Operating Circuits

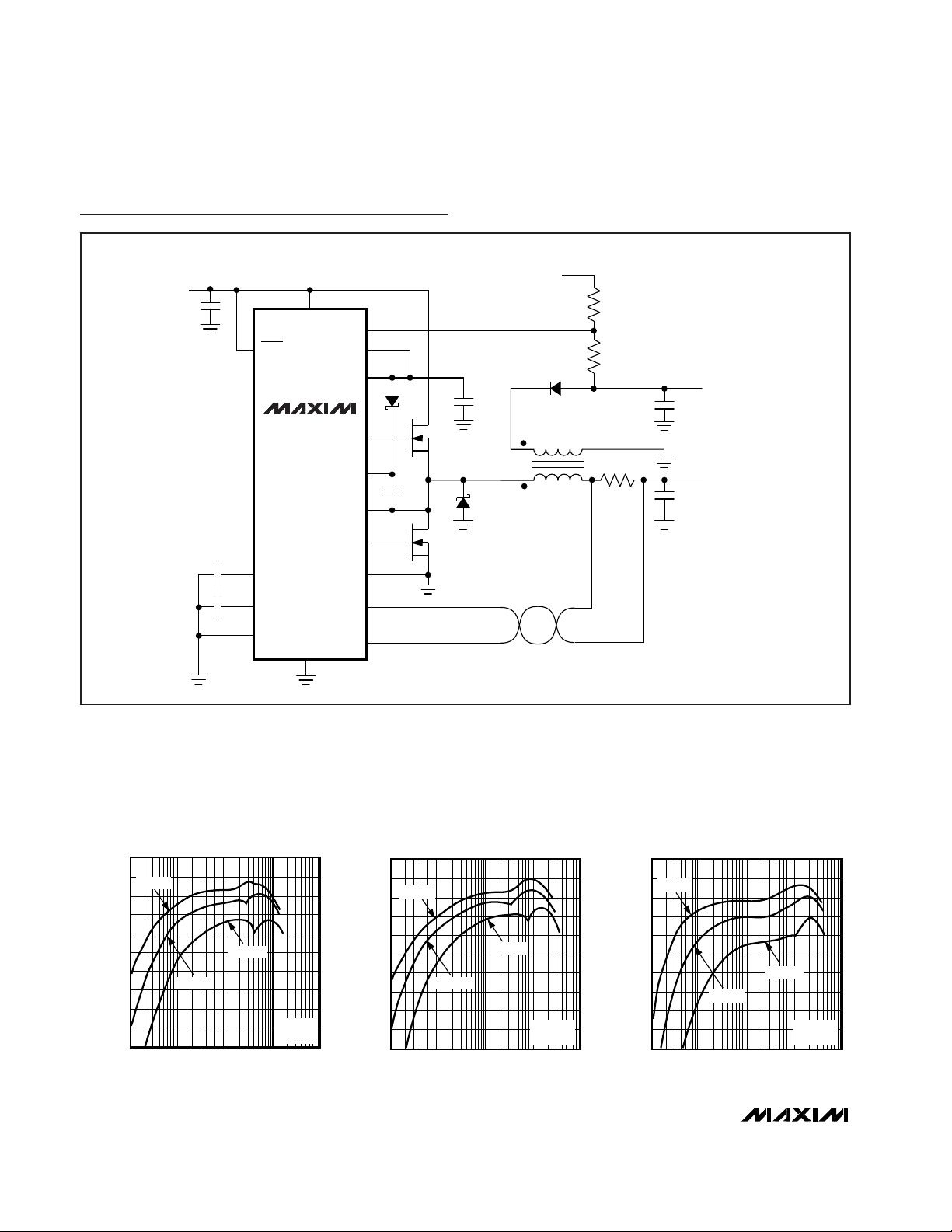

__________________________________________Typical Operating Characteristics

(Circuit of Figure 1, SKIP = GND, TA = +25°C, unless otherwise noted.)

100

50

0.001 0.1 10.01 10

EFFICIENCY vs.

LOAD CURRENT (3.3V/1A CIRCUIT)

60

MAX1652 toc01

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

V+ = 6V

MAX1653

f = 300kHz

V+ = 28V

V+ = 12V

100

50

0.001 0.1 10.01 10

EFFICIENCY vs.

LOAD CURRENT (3.3V/2A CIRCUIT)

60

MAX1652 toc02

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

V+ = 6V

V+ = 28V

V+ = 12V

MAX1653

f = 300kHz

100

50

0.001 0.1 10.01 10

EFFICIENCY vs.

LOAD CURRENT (3.3V/3A CIRCUIT)

60

MAX1652 toc03

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

V+ = 6V

V+ = 28V

V+ = 12V

MAX1653

f = 300kHz

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

6 _______________________________________________________________________________________

MAX1654

SHDN

DH

-5V

OUTPUT

+5V

OUTPUT

INPUT

6V TO 30V

BST

LX

DL

PGND

CSH

CSL

SS

REF

FROM

REF

SYNC

GND

V+

VL

FB

SECFB

Typical Operating Circuits (continued)

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

_______________________________________________________________________________________

7

100

50

0.001 0.1 10.01 10

EFFICIENCY vs.

LOAD CURRENT (5V/3A CIRCUIT)

60

MAX1652 toc04a

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

V+ = 28V

V+ = 6V

V+ = 12V

MAX1653

f = 300kHz

____________________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, SKIP = GND, TA = +25°C, unless otherwise noted.)

100

50

0.001 0.1 10.01 10

EFFICIENCY vs.

LOAD CURRENT (3.3V/5A CIRCUIT)

60

MAX1652 toc04

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

V+ = 6V

V+ = 28V

V+ = 12V

MAX1653

f = 300kHz

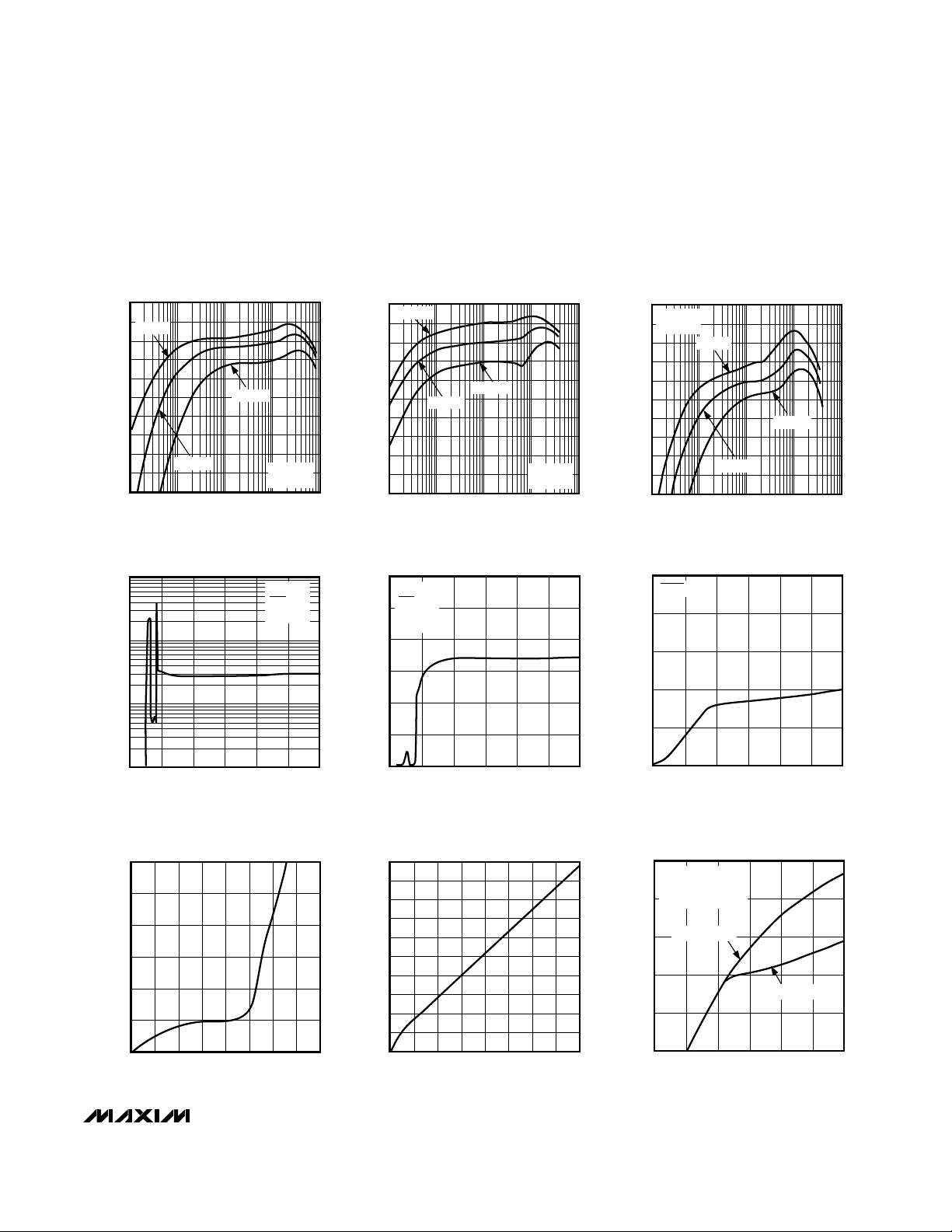

0

10

5

20

15

25

30

0 10 155 20 25 30

PWM-MODE SUPPLY CURRENT vs.

INPUT VOLTAGE (3.3V/3A CIRCUIT)

MAX1652 toc07

INPUT VOLTAGE (V)

SUPPLY CURRENT (mA)

MAX1653

SKIP = VL

f = 300kHz

NO LOAD

100

50

0.001 0.1 10.01 10

EFFICIENCY vs.

LOAD CURRENT (1.8V/2.5A CIRCUIT)

60

MAX1652 toc05

LOAD CURRENT (A)

EFFICIENCY (%)

70

80

90

V+ = 6V

V+ = 24V

V+ = 12V

MAX1655

f = 300kHz

0.01

0 302010 25155

IDLE-MODE SUPPLY CURRENT vs.

INPUT VOLTAGE (3.3V/3A CIRCUIT)

0.1

1

10

MAX1652 toc06

INPUT VOLTAGE (V)

SUPPLY CURRENT (mA)

MAX1653

SKIP = 0

NO LOAD

0

4

2

6

8

10

0 10 155 20 25 30

SHUTDOWN SUPPLY CURRENT

vs. INPUT VOLTAGE

MAX1652 toc08

INPUT VOLTAGE (V)

SUPPLY CURRENT (µA)

SHDN = 0V

0

10

5

20

15

25

30

0 100 15050 200 250 300 350 400

REF LOAD-REGULATION ERROR

vs. REF LOAD CURRENT

MAX1652 toc010

LOAD CURRENT (µA)

LOAD REGULATION ∆V (mV)

0

300

900

600

1200

1500

0 10 155 20 25 30

MAX1652 MAXIMUM SECONDARY OUTPUT

CURRENT vs. SUPPLY VOLTAGE

MAX1652 toc12

SUPPLY VOLTAGE (V)

MAXIMUM SECONDARY CURRENT (mA)

V

SEC

> 12.75V,

+5V OUTPUT > 4.75V,

CIRCUIT OF FIGURE 9

+5V LOAD = 0A

+5V LOAD = 3A

0

10

5

20

15

25

50

45

40

35

30

0 20 3010 40 50 60 70 80

VL LOAD-REGULATION ERROR

vs. VL LOAD CURRENT

MAX1652 toc011

LOAD CURRENT (mA)

LOAD REGULATION ∆V (mV)

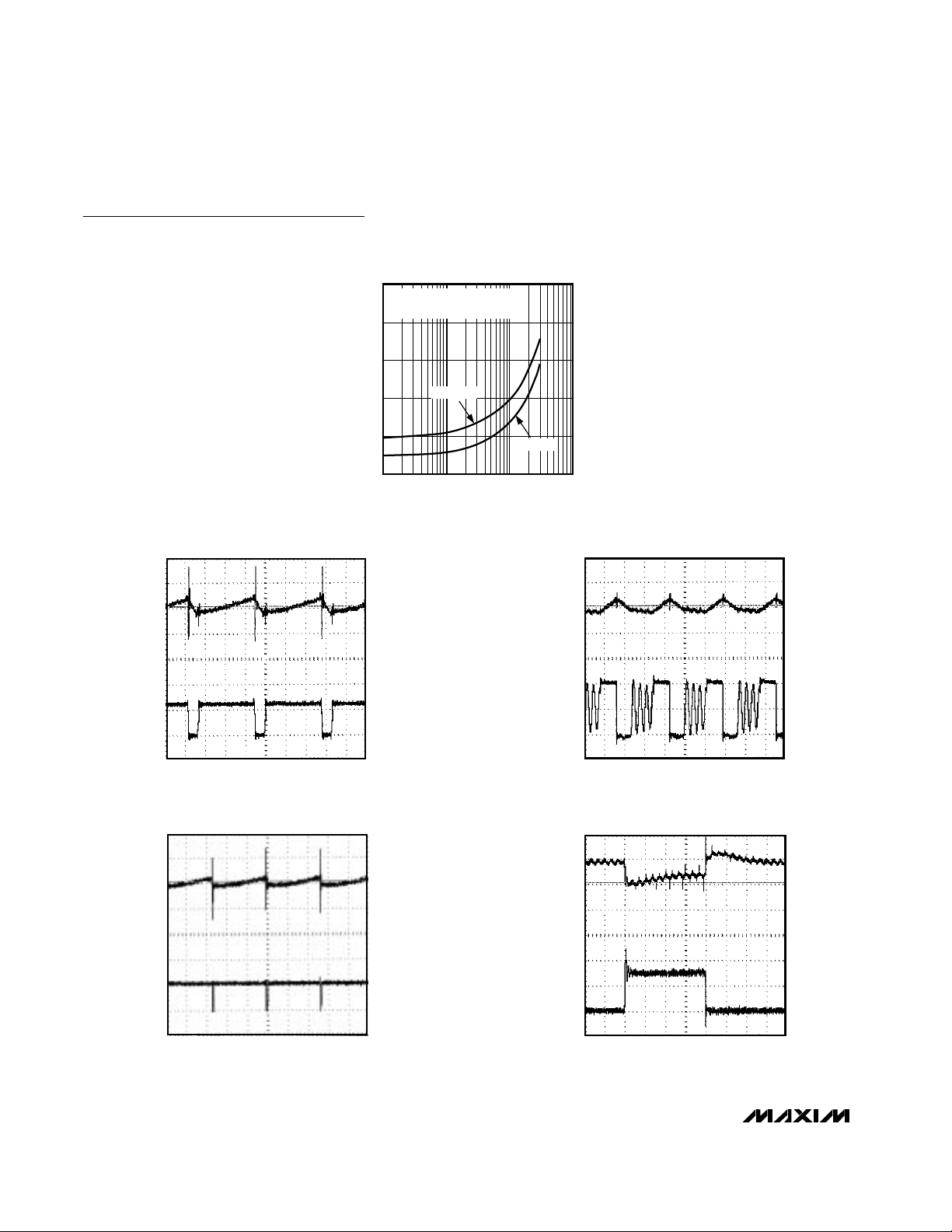

OUTPUT

VOLTAGE

LOAD

CURRENT

100mV/div,

AC

2A/div

TIME (10µs)

V

IN

= 15V, 3.3V/3A CIRCUIT

LOAD-TRANSIENT RESPONSE

MAX1652-16

OUTPUT

VOLTAGE

LX

VOLTAGE

10mV/div,

AC

5V/div

TIME (5µs)

V

IN

= 5.1V, NO LOAD, 3.3V/3A CIRCUIT,

SET TO 5V OUTPUT (FB = VL)

DROPOUT WAVEFORMS

MAX1652-15

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

8 _______________________________________________________________________________________

OUTPUT

VOLTAGE

LX

VOLTAGE

10mV/div,

AC

5V/div

TIME (1µs)

V

IN

= 6V, 3.3V/3A CIRCUIT

PULSE-WIDTH-MODULATION

MODE WAVEFORMS

MAX1652-13

OUTPUT

VOLTAGE

LX

VOLTAGE

50mV/div,

AC

5V/div

TIME (2.5µs)

I

LOAD

= 300mA, VIN = 10V, 3.3V/3A CIRCUIT

IDLE-MODE WAVEFORMS

MAX1652-14

Typical Operating Characteristics (continued)

(Circuit of Figure 1, SKIP = GND, TA = +25°C, unless otherwise noted.)

0

0.01 1010.1

DROPOUT VOLTAGE vs.

LOAD CURRENT (3.3V/3A CIRCUIT)

100

300

400

200

500

MAX1652 toc09

LOAD CURRENT (A)

DROPOUT VOLTAGE (mV)

OUTPUT SET FOR 5V (FB = VL)

V

OUT

> 4.85V

f = 150kHz

f = 300kHz

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

_______________________________________________________________________________________ 9

Pin Description

Dual Mode is a trademark of Maxim Integrated Products.

SKIP

(MAX1653/

MAX1655)

Disables pulse-skipping mode when high. Connect to GND for normal use. Don’t leave SKIP unconnected.

With SKIP

grounded, the device will

automatically

change from pulse-skipping operation to full PWM opera-

tion when the load current exceeds approximately 30% of maximum (Table 3).

16 DH

High-Side Gate-Drive Output. Normally drives the main buck switch. DH is a floating driver output that swings

from LX to BST, riding on the LX switching-node voltage.

15 LX Switching Node (inductor) Connection. Can swing 2V below ground without hazard.

14 BST Boost Capacitor Connection for High-Side Gate Drive (0.1µF)

13 DL Low-Side Gate-Drive Output. Normally drives the synchronous-rectifier MOSFET. Swings from 0V to VL.

NAME FUNCTION

1 SS Soft-Start Timing Capacitor Connection. Ramp time to full current limit is approximately 1ms/nF.

2

SECFB

(MAX1652/

MAX1654)

Secondary Winding Feedback Input. Normally connected to a resistor divider from an auxiliary output.

Don’t leave SECFB unconnected.

• MAX1652: SECFB regulates at VSECFB = 2.50V. Tie to VL if not used.

• MAX1654: SECFB regulates at VSECFB = 0V. Tie to a negative voltage through a high-value current-

limiting resistor (I

MAX

= 100µA) if not used.

PIN

3 REF Reference Voltage Output. Bypass to GND with 0.33µF minimum.

7 FB

Feedback Input. Regulates at the feedback voltage in adjustable mode. FB is a Dual ModeTMinput that also

selects the fixed output voltage settings as follows:

• Connect to GND for 3.3V operation.

• Connect to VL for 5V operation.

• Connect FB to a resistor divider for adjustable mode. FB can be driven with +5V CMOS logic in order to

change the output voltage under system control.

6 SHDN

Shutdown Control Input, active low. Logic threshold is set at approximately 1V (VTHof an internal N-channel

MOSFET). Tie SHDN to V+ for automatic start-up.

5 SYNC

Oscillator Synchronization and Frequency Select. Tie to GND or VL for 150kHz operation; tie to REF for

300kHz operation. A high-to-low transition begins a new cycle. Drive SYNC with 0 to 5V logic levels (see the

Electrical Characteristics

table for VIHand VILspecifications). SYNC capture range is 190kHz to 340kHz.

4 GND Low-Noise Analog Ground and Feedback Reference Point

12 PGND Power Ground

11 VL

5V Internal Linear-Regulator Output. VL is also the supply voltage rail for the chip. VL is switched to the output voltage via CSL (V

CSL

> 4.5V) for automatic bootstrapping. Bypass to GND with 4.7µF. VL can supply up

to 5mA for external loads.

10 V+

Battery Voltage Input (4.5V to 30V). Bypass V+ to PGND close to the IC with a 0.1µF capacitor. Connects to a

linear regulator that powers VL.

9 CSL Current-Sense Input, low side. Also serves as the feedback input in fixed-output modes.

8 CSH Current-Sense Input, high side. Current-limit level is 100mV referred to CSL.

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

10 ______________________________________________________________________________________

Standard Application Circuits

It’s easy to adapt the basic MAX1653 single-output 3.3V

buck converter (Figure 1) to meet a wide range of applications with inputs up to 30V (limited by choice of external MOSFET). Simply substitute the appropriate

components from Table 1 (candidate suppliers are provided in Table 2). These circuits represent a good set of

trade-offs among cost, size, and efficiency while staying

within the worst-case specification limits for stress-related parameters such as capacitor ripple current.

Don’t change the frequency of these circuits without

first recalculating component values (particularly inductance value at maximum battery voltage).

For a discussion of dual-output circuits using the

MAX1652 and MAX1654, see Figure 9 and the

Secondary Feedback-Regulation Loop

section.

Detailed Description

The MAX1652 family are BiCMOS, switch-mode powersupply controllers designed primarily for buck-topology

regulators in battery-powered applications where high

efficiency and low quiescent supply current are critical.

The parts also work well in other topologies such as

boost, inverting, and Cuk due to the flexibility of their

floating high-speed gate driver. Light-load efficiency is

enhanced by automatic idle-mode operation—a variable-frequency pulse-skipping mode that reduces

losses due to MOSFET gate charge. The step-down

power-switching circuit consists of two N-channel

MOSFETs, a rectifier, and an LC output filter. The output voltage is the average of the AC voltage at the

switching node, which is adjusted and regulated by

changing the duty cycle of the MOSFET switches. The

gate-drive signal to the N-channel high-side MOSFET

must exceed the battery voltage and is provided by a

flying capacitor boost circuit that uses a 100nF capacitor connected to BST.

MAX1653

CSL

CSH

VL

SYNC

FB

V+

10 11

57

14

Q1

Q2

16

15

13

D2

CMPSH-3

J1

150kHz/300kHz

JUMPER

NOTE: KEEP CURRENT-SENSE

LINES SHORT AND CLOSE

TOGETHER. SEE FIGURE 8.

D1

12

8

9

REF

3

GND

4

+5V AT

5mA

+3.3V

OUTPUT

GND

OUT

BST

DH

LX

DL

2

1

LOW-NOISE

CONTROL

PGND

SKIP

SS

6

ON/OFF

CONTROL

SHDN

INPUT

REF OUTPUT

+2.5V AT 100µA

C5

0.33µF

C4

4.7µF

C7

0.1µF

C6

0.01µF

(OPTIONAL)

C1

C2

C3

0.1µF

R1

L1

Figure 1. Standard 3.3V Application Circuit (see Table 1 for Component Values)

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 11

Table 1. Component Selection for Standard Applications

COMPONENT 3.3V at 1A 3.3V at 2A 5V/3.3V at 3A 3.3V at 5A 1.8V at 2.5A

Frequency 300kHz

300kHz 300kHz 300kHz 150kHz

Q1 High-Side

MOSFET

International Rectifier

1/2 IRF7101

International Rectifier

1/2 IRF7303 or

Fairchild

Semiconductor

1/2 NDS8936

International Rectifier

IRF7403 or

Fairchild

Semiconductor

NDS 8410A

Fairchild

Semiconductor

FDS6680

International Rectifier

1/2 IRF7303 or

Fairchild

Semiconductor

1/2 NDS8936

Q2 Low-Side

MOSFET

International Rectifier

1/2 IRF7101

International Rectifier

1/2 IRF7303 or

Fairchild

Semiconductor

1/2 NDS8936

International Rectifier

IRF7403 or

Fairchild

Semiconductor

NDS 8410A

Fairchild

Semiconductor

FDS6680

International Rectifier

1/2 IRF7303 or

Fairchild

Semiconductor

1/2 NDS8936

C1 Input

Capacitor

10µF, 35V

AVX

TPSD106M035R0300

22µF, 35V

AVX

TPSE226M035R0300

(2) 22µF, 35V

AVX

TPSE226M035R0300

(3) 22µF, 35V

AVX

TPSE226M035R0300

10µF, 25V ceramic

Taiyo Yuden

TMK325F106Z

C2 Output

Capacitor

100µF, 6.3V

AVX TPSC107M006R

220µF, 10V

AVX

TPSE227M010R0100

or Sprague

594D227X001002T

470µF, 6V (for 3.3V)

Kemet

T510X477M006AS

or

(2) 220µF, 10V (for 5V)

AVX

TPSE227M010R011

(3) 330µF, 10V

Sprague

594D337X0010R2T

or

(2) 470µF, 6V

Kemet

T510X477M006AS

470µF, 4V

Sprague

594D477X0004R2T

or

470µF, 6V

Kemet

T510X477M006AS

D1 Rectifier

1N5819 or Motorola

MBR0520L

1N5819 or Motorola

MBRS130LT3

1N5819 or Motorola

MBRS130LT3

1N5821 or Motorola

MBRS340T3

1N5817 or Motorola

MBRS130LT3

R1 Sense

Resistor

70mΩ

Dale WSL-1206-R070F

or IRC LR2010-01-R070

33mΩ

Dale WSL-2010-R033F

or IRC LR2010-01-R033

25mΩ

Dale WSL-2010-R025F

or IRC LR2010-01-R025

12mΩ

Dale WSL-2512-R012F

30mΩ

Dale WSL-2010-R030F

or IRC LR2010-01-R030

L1 Inductor

33µH

Sumida CDR74B-330

15µH

Sumida CDR105B-150

10µH

Sumida CDRH125-100

4.7µH

Sumida CDRH127-4R7

15µH

Sumida CDRH125-150

Table 2. Component Suppliers

*

Distributor

[1] 602-994-6430602-303-5454Motorola

[1] 408-986-1442408-986-0424Kemet

[1] 512-992-3377512-992-7900IRC

[1] 408-721-1635408-822-2181Fairchild

[1] 605-665-1627605-668-4131Dale

[1] 561-241-9339561-241-7876Coiltronics

[1] 847-639-1469847-639-6400Coilcraft

[1] 516-435-1824516-435-1110Central Semiconductor

[1] 803-626-3123803-946-0690AVX

FACTORY FAX

[Country Code]

USA PHONEMANUFACTURER

Input Range 4.75V to 28V

4.75V to 28V 4.75V to 28V 4.75V to 28V 4.75V to 22V

[1] 408-573-4159408-573-4150Taiyo Yuden

[81] 3-3607-5144847-956-0666Sumida

[1] 603-224-1430603-224-1961Sprague

[1] 408-970-3950

408-988-8000

800-554-5565

Siliconix

[81] 7-2070-1174619-661-6835Sanyo

[81] 3-3494-7414805-867-2555*NIEC

[1] 814-238-0490

814-237-1431

800-831-9172

Murata

FACTORY FAX

[Country Code]

USA PHONEMANUFACTURER

[1] 702-831-3521702-831-0140Transpower Technologies

[1] 714-960-6492714-969-2491Matsuo

[1] 310-322-3332310-322-3331International Rectifier

[1] 847-390-4405847-390-4461TDK

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

12 ______________________________________________________________________________________

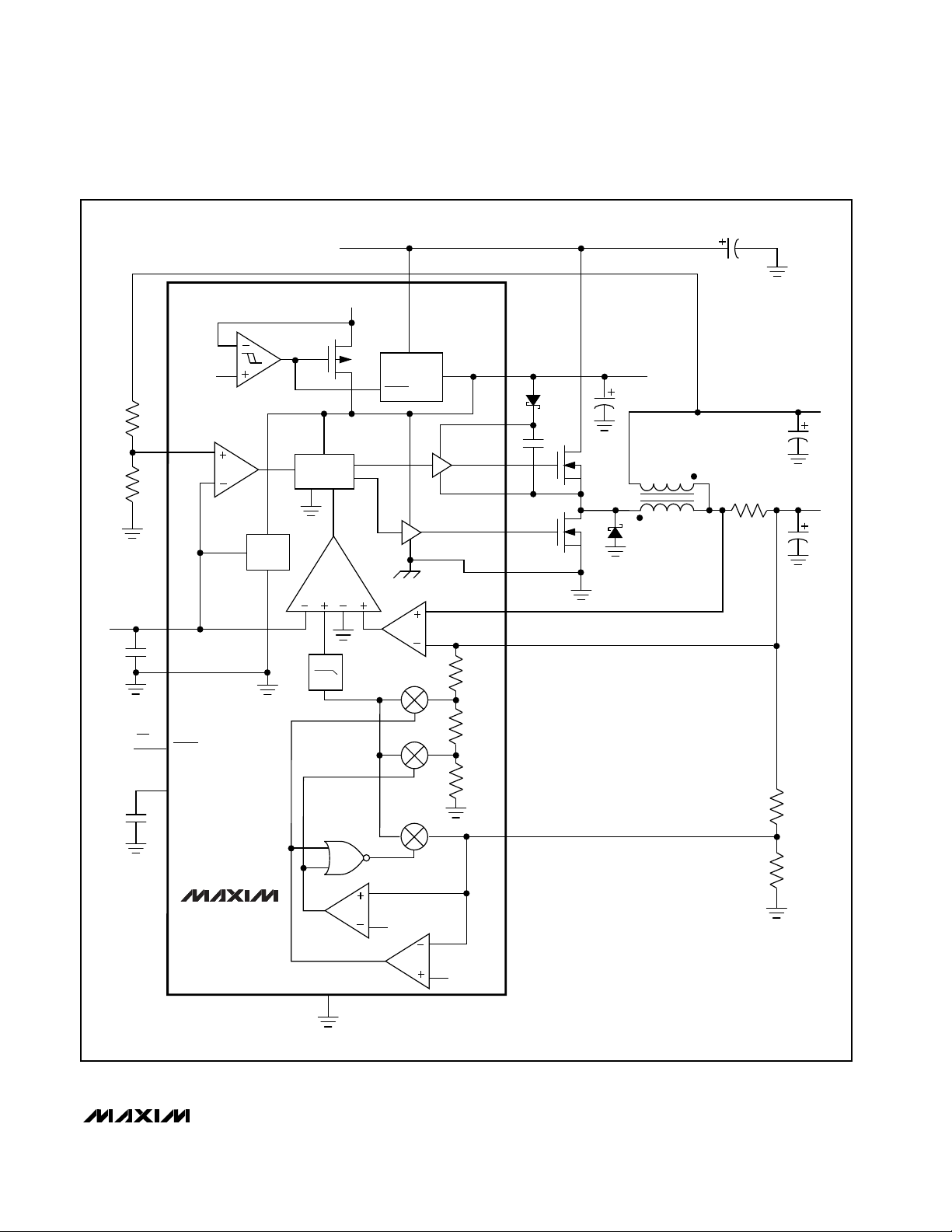

The MAX1652–MAX1655 contain nine major circuit

blocks, which are shown in Figure 2:

PWM Controller Blocks:

• Multi-Input PWM Comparator

• Current-Sense Circuit

• PWM Logic Block

• Dual-Mode Internal Feedback Mux

• Gate-Driver Outputs

• Secondary Feedback Comparator

Bias Generator Blocks:

• +5V Linear Regulator

• Automatic Bootstrap Switchover Circuit

• +2.50V Reference

These internal IC blocks aren’t powered directly from

the battery. Instead, a +5V linear regulator steps down

the battery voltage to supply both the IC internal rail (VL

pin) as well as the gate drivers. The synchronousswitch gate driver is directly powered from +5V VL,

while the high-side-switch gate driver is indirectly powered from VL via an external diode-capacitor boost circuit. An automatic bootstrap circuit turns off the +5V

linear regulator and powers the IC from its output voltage if the output is above 4.5V.

PWM Controller Block

The heart of the current-mode PWM controller is a

multi-input open-loop comparator that sums three signals: output voltage error signal with respect to the reference voltage, current-sense signal, and slope

compensation ramp (Figure 3). The PWM controller is a

direct summing type, lacking a traditional error amplifier and the phase shift associated with it. This directsumming configuration approaches the ideal of

cycle-by-cycle control over the output voltage.

Under heavy loads, the controller operates in full PWM

mode. Each pulse from the oscillator sets the main

PWM latch that turns on the high-side switch for a period determined by the duty factor (approximately

V

OUT/VIN

). As the high-side switch turns off, the synchronous rectifier latch is set. 60ns later the low-side

switch turns on, and stays on until the beginning of the

next clock cycle (in continuous mode) or until the

inductor current crosses zero (in discontinuous mode).

Under fault conditions where the inductor current

exceeds the 100mV current-limit threshold, the highside latch resets and the high-side switch turns off.

If the load is light in Idle Mode (SKIP = low), the inductor current does not exceed the 25mV threshold set by

the Idle Mode comparator. When this occurs, the controller skips most of the oscillator pulses in order to

reduce the switching frequency and cut back gate-

charge losses. The oscillator is effectively gated off at

light loads because the Idle Mode comparator immediately resets the high-side latch at the beginning of each

cycle, unless the feedback signal falls below the reference voltage level.

When in PWM mode, the controller operates as a fixedfrequency current-mode controller where the duty ratio

is set by the input/output voltage ratio. The currentmode feedback system regulates the peak inductor

current as a function of the output voltage error signal.

Since the average inductor current is nearly the same

as the peak current, the circuit acts as a switch-mode

transconductance amplifier and pushes the second output LC filter pole, normally found in a duty-factorcontrolled (voltage-mode) PWM, to a higher frequency.

To preserve inner-loop stability and eliminate regenerative inductor current “staircasing,” a slope-compensation ramp is summed into the main PWM comparator to

reduce the apparent duty factor to less than 50%.

The relative gains of the voltage- and current-sense

inputs are weighted by the values of current sources

that bias three differential input stages in the main PWM

comparator (Figure 4). The relative gain of the voltage

comparator to the current comparator is internally fixed

at K = 2:1. The resulting loop gain (which is relatively

low) determines the 2% typical load regulation error.

The low loop-gain value helps reduce output filter

capacitor size and cost by shifting the unity-gain

crossover to a lower frequency.

The output filter capacitor C2 sets a dominant pole in

the feedback loop. This pole must roll off the loop gain

to unity before the zero introduced by the output

capacitor’s parasitic resistance (ESR) is encountered

(see

Design Procedure

section). A 12kHz pole-zero

cancellation filter provides additional rolloff above the

unity-gain crossover. This internal 12kHz lowpass compensation filter cancels the zero due to the filter capacitor’s ESR. The 12kHz filter is included in the loop in

both fixed- and adjustable-output modes.

Synchronous-Rectifier Driver (DL Pin)

Synchronous rectification reduces conduction losses in

the rectifier by shunting the normal Schottky diode with

a low-resistance MOSFET switch. The synchronous rectifier also ensures proper start-up of the boost-gate driver circuit. If you must omit the synchronous power

MOSFET for cost or other reasons, replace it with a

small-signal MOSFET such as a 2N7002.

If the circuit is operating in continuous-conduction mode,

the DL drive waveform is simply the complement of the

DH high-side drive waveform (with controlled dead

time to prevent cross-conduction or “shoot-through”).

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 13

MAX1652

MAX1653

MAX1654

MAX1655

1V

CSL

CSH

REF

GND

4V

FB

ADJ FB

5V FB

3.3V FB

SYNC

LPF

12kHz

PWM

COMPARATOR

OUT

V+

BATTERY VOLTAGE

4.5V

VL

TO

CSL

+5V AT 5mA

BST

DH

LX

DL

PGND

SECFB

MAIN

OUTPUT

AUXILIARY

OUTPUT

SHDN

PWM

LOGIC

SHDN

SS

ON/OFF

+2.50V

AT 100µA

+5V LINEAR

REGULATOR

+2.50V

REF

Figure 2. MAX1652–MAX1655 Functional Diagram

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

14 ______________________________________________________________________________________

SHOOTTHROUGH

CONTROL

R

Q

25mV

R

Q

LEVEL

SHIFT

1µs

SINGLE-SHOT

MAIN PWM

COMPARATOR

OSC

LEVEL

SHIFT

CURRENT

LIMIT

VL

24R

1R

2.5V

4µA

SYNCHRONOUS-

RECTIFIER CONTROL

2.5V (1V, MAX1655)

SS

SHDN

-100mV

(NOTE 1)

COMPARATOR

CSH

CSL

FROM

FEEDBACK

DIVIDER

BST

DH

LX

VL

DL

PGND

S

S

SLOPE COMP

IDLE MODE

COMPARATOR

N

SKIP

(MAX1653/

MAX1655

ONLY)

REF (MAX1652)

GND (MAX1654)

MAX1652, MAX1654 ONLY

SECFB

NOTE 1: COMPARATOR INPUT POLARITIES

ARE REVERSED FOR THE MAX1654.

Figure 3. PWM Controller Detailed Block Diagram

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 15

In discontinuous (light-load) mode, the synchronous

switch is turned off as the inductor current falls through

zero. The synchronous rectifier works under all operating conditions, including idle mode. The synchronousswitch timing is further controlled by the secondary

feedback (SECFB) signal in order to improve multipleoutput cross-regulation (see

Secondary Feedback-

Regulation Loop

section).

Internal VL and REF Supplies

An internal regulator produces the 5V supply (VL) that

powers the PWM controller, logic, reference, and other

blocks. This +5V low-dropout linear regulator can supply up to 5mA for external loads, with a reserve of

20mA for gate-drive power. Bypass VL to GND with

4.7µF. Important: VL must not be allowed to exceed

5.5V. Measure VL with the main output fully loaded. If

VL is being pumped up above 5.5V, the probable

cause is either excessive boost-diode capacitance or

excessive ripple at V+. Use only small-signal diodes for

D2 (10mA to 100mA Schottky or 1N4148 are preferred)

and bypass V+ to PGND with 0.1µF directly at the

package pins.

The 2.5V reference (REF) is accurate to ±1.6% over

temperature, making REF useful as a precision system

reference. Bypass REF to GND with 0.33µF minimum.

REF can supply up to 1mA for external loads. However,

if tight-accuracy specs for either V

OUT

or REF are

essential, avoid loading REF with more than 100µA.

Loading REF reduces the main output voltage slightly,

according to the reference-voltage load regulation

error. In MAX1654 applications, ensure that the SECFB

divider doesn’t load REF heavily.

When the main output voltage is above 4.5V, an internal

P-channel MOSFET switch connects CSL to VL while

simultaneously shutting down the VL linear regulator.

This action bootstraps the IC, powering the internal circuitry from the output voltage, rather than through a linear regulator from the battery. Bootstrapping reduces

power dissipation caused by gate-charge and quiescent losses by providing that power from a 90%-efficient switch-mode source, rather than from a less

efficient linear regulator.

It’s often possible to achieve a bootstrap-like effect,

even for circuits that are set to V

OUT

< 4.5V, by powering VL from an external-system +5V supply. To achieve

this pseudo-bootstrap, add a Schottky diode between

the external +5V source and VL, with the cathode to the

VL side. This circuit provides a 1% to 2% efficiency

boost and also extends the minimum battery input to

less than 4V. The external source must be in the range

of 4.8V to 5.5V.

Boost High-Side

Gate-Driver Supply (BST Pin)

Gate-drive voltage for the high-side N-channel switch is

generated by a flying-capacitor boost circuit as shown

in Figure 5. The capacitor is alternately charged from

the VL supply and placed in parallel with the high-side

MOSFET’s gate-source terminals.

On start-up, the synchronous rectifier (low-side MOSFET) forces LX to 0V and charges the BST capacitor to

5V. On the second half-cycle, the PWM turns on the

high-side MOSFET by closing an internal switch

between BST and DH. This provides the necessary

enhancement voltage to turn on the high-side switch,

FB

REF

CSH

CSL

SLOPE COMPENSATION

VL

I1

R1 R2

TO PWM

LOGIC

OUTPUT DRIVER

UNCOMPENSATED

HIGH-SPEED

LEVEL TRANSLATOR

AND BUFFER

I2 I3

Figure 4. Main PWM Comparator Block Diagram

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

16 ______________________________________________________________________________________

an action that “boosts” the 5V gate-drive signal above

the battery voltage.

Ringing seen at the high-side MOSFET gate (DH) in

discontinuous-conduction mode (light loads) is a natural operating condition caused by the residual energy in

the tank circuit formed by the inductor and stray capacitance at the switching node LX. The gate-driver negative rail is referred to LX, so any ringing there is directly

coupled to the gate-drive output.

Current-Limiting and

Current-Sense Inputs (CSH and CSL)

The current-limit circuit resets the main PWM latch and

turns off the high-side MOSFET switch whenever the

voltage difference between CSH and CSL exceeds

100mV. This limiting is effective for both current flow

directions, putting the threshold limit at ±100mV. The

tolerance on the positive current limit is ±20%, so the

external low-value sense resistor must be sized for

80mV/R1 to guarantee enough load capability, while

components must be designed to withstand continuous

current stresses of 120mV/R1.

For breadboarding purposes or very-high-current applications, it may be useful to wire the current-sense inputs

with a twisted pair rather than PC traces.

Oscillator Frequency and

Synchronization (SYNC Pin)

The SYNC input controls the oscillator frequency.

Connecting SYNC to GND or to VL selects 150kHz

operation; connecting SYNC to REF selects 300kHz.

SYNC can also be used to synchronize with an external

5V CMOS clock generator. SYNC has a guaranteed

190kHz to 340kHz capture range.

300kHz operation optimizes the application circuit for

component size and cost. 150kHz operation provides

increased efficiency and improved low-duty factor

operation (see

Dropout Operation

section).

Dropout Operation

Dropout (low input-output differential operation) is enhanced by stretching the clock pulse width to increase

the maximum duty factor. The algorithm follows: if the output voltage (V

OUT

) drops out of regulation without the

current limit having been reached, the controller skips an

off-time period (extending the on-time). At the end of the

cycle, if the output is still out of regulation, another off-time

period is skipped. This action can continue until three offtime periods are skipped, effectively dividing the clock

frequency by as much as four.

The typical PWM minimum off-time is 300ns, regardless

of the operating frequency. Lowering the operating frequency raises the maximum duty factor above 98%.

Low-Noise Mode (SKIP Pin)

The low-noise mode (SKIP = high) is useful for minimizing RF and audio interference in noise-sensitive applications such as audio-equipped systems, cellular

phones, RF communicating computers, and electromagnetic pen-entry systems. See the summary of operating modes in Table 3. SKIP can be driven from an

external logic signal.

The MAX1653 and MAX1655 can reduce interference

due to switching noise by ensuring a constant switching frequency regardless of load and line conditions,

thus concentrating the emissions at a known frequency

outside the system audio or IF bands. Choose an oscillator frequency where harmonics of the switching frequency don’t overlap a sensitive frequency band. If

necessary, synchronize the oscillator to a tight-tolerance external clock generator.

The low-noise mode (SKIP = high) forces two changes

upon the PWM controller. First, it ensures fixed-frequency operation by disabling the minimum-current comparator and ensuring that the PWM latch is set at the

beginning of each cycle, even if the output is in regulation. Second, it ensures continuous inductor current

MAX1652

MAX1653

MAX1654

MAX1655

BST

VL

+5V

VL SUPPLY

BATTERY

INPUT

VL

VL

DH

LX

DL

PWM

LEVEL

TRANSLATOR

Figure 5. Boost Supply for Gate Drivers

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 17

flow, and thereby suppresses discontinuous-mode

inductor ringing by changing the reverse current-limit

detection threshold from 0 to -100mV, allowing the

inductor current to reverse at very light loads.

In most applications, SKIP should be tied to GND in

order to minimize quiescent supply current. Supply current with SKIP high is typically 10mA to 20mA, depending on external MOSFET gate capacitance and

switching losses.

Forced continuous conduction via SKIP can improve

cross regulation of transformer-coupled multiple-output

supplies. This second function of the SKIP pin produces

a result that is similar to the method of adding secondary regulation via the SECFB feedback pin, but with

much higher quiescent supply current. Still, improving

cross regulation by enabling SKIP instead of building in

SECFB feedback can be useful in noise-sensitive applications, since SECFB and SKIP are mutually exclusive

pins/functions in the MAX1652 family.

Adjustable-Output Feedback

(Dual-Mode FB Pin)

The MAX1652–MAX1655 family has both fixed and

adjustable output voltage modes. For fixed mode, connect FB to GND for a 3.3V output and to VLfor a 5V out-

put. Adjusting the main output voltage with external

resistors is easy for any of the devices in this family, via

the circuit of Figure 6. The feedback voltage is nominally 2.5 for all family members except the MAX1655,

which has a nominal FB voltage of 1V. The output voltage (given by the formula in Figure 6) should be set

approximately 2% high in order to make up for the

MAX1652’s load-regulation error. For example, if

designing for a 3.0V output, use a resistor ratio that

results in a nominal output voltage of 3.06V. This slight

offsetting gives the best possible accuracy.

Recommended normal values for R5 range from 5kΩ to

100kΩ.

Remote sensing of the output voltage, while not possible in fixed-output mode due to the combined nature of

the voltage- and current-sense input (CSL), is easy to

achieve in adjustable mode by using the top of the

external resistor divider as the remote sense point.

Duty-Factor Limitations for

Low V

OUT/VIN

Ratios

The MAX1652/MAX1653/MAX1654’s output voltage is

adjustable down to 2.5V and the MAX1655’s output is

adjustable as low as 1V. However, the minimum duty

factor may limit the choice of operating frequency, high

input voltage, and low output voltage.

MAX1652

MAX1653

MAX1654

MAX1655

CSL

CSH

GND

FB

R4

R5

MAIN

OUTPUT

REMOTE

SENSE

LINES

DH

DL

V

OUT

WHERE V

REF

(NOMINAL) = 2.5V (MAX1652–MAX1654)

= 1.0V (MAX1655)

= V

REF

(1 + –––)

R4

R5

V+

Figure 6. Adjusting the Main Output Voltage

SHDN SKIP

LOAD

CURRENT

MODE

NAME

DESCRIPTION

Low X X Shutdown

All circuit blocks

turned off; supply

current = 3µA typ

High Low

Low,

<10%

Idle

Pulse-skipping;

supply current =

300µA typ at VIN=

10V; discontinuous

inductor current

High Low

Medium,

<30%

Idle

Pulse-skipping;

continuous inductor

current

High Low

High,

>30%

PWM

Constant-frequency

PWM; continuous

inductor current

High High X

Low Noise*

(PWM)

Constant-frequency

PWM regardless of

load; continuous

inductor current

even at no load

Table 3. Operating-Mode Truth Table

*

MAX1652/MAX1654 have no SKIP pin and therefore can’t go

into low-noise mode.

X = Don’t care

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

18 ______________________________________________________________________________________

With high input voltages, the required duty factor is

approximately (V

OUT

+ VQ2)/ VIN, where VQ2is the voltage drop across the synchronous rectifier. The

MAX1652’s minimum duty factor is determined by

delays through the feedback network, error comparator,

internal logic gate drivers, and the external MOSFETs,

which typically total 400ns. This delay is about 12% of

the switching period at 300kHz and 6% at 150kHz, limiting the typical minimum duty factor to these values.

Even if the circuit can not attain the required duty factor

dictated by the input and output voltages, the output

voltage will remain in regulation. However, there may be

intermittent or continuous half-frequency operation. This

can cause a factor-of-two increase in output voltage ripple and current ripple, which will increase noise and

reduce efficiency. Choose 150kHz operation for highinput-voltage/low-output-voltage circuits.

Secondary Feedback-Regulation Loop

(SECFB Pin)

A flyback winding control loop regulates a secondary

winding output (MAX1652/MAX1654 only), improving

cross-regulation when the primary is lightly loaded

or when there is a low input-output differential voltage.

If SECFB crosses its regulation threshold, a 1µs oneshot is triggered that extends the low-side switch’s

on-time beyond the point where the inductor current

crosses zero (in discontinuous mode). This causes the

inductor (primary) current to reverse, which in turn pulls

current out of the output filter capacitor and causes the

flyback transformer to operate in the forward mode. The

low impedance presented by the transformer secondary

in the forward mode dumps current into the secondary

output, charging up the secondary capacitor and bringing SECFB back into regulation. The SECFB feedback

loop does not improve secondary output accuracy in

normal flyback mode, where the main (primary) output is

heavily loaded. In this mode, secondary output accuracy is determined (as usual) by the secondary rectifier

drop, turns ratio, and accuracy of the main output voltage. Hence, a linear post-regulator may still be needed

in order to meet tight output accuracy specifications.

The secondary output voltage-regulation point is determined by an external resistor-divider at SECFB. For negative output voltages, the SECFB comparator is

referenced to GND (MAX1654); for positive output voltages, SECFB regulates at the 2.50V reference

(MAX1652). As a result, output resistor-divider connections and design equations for the two device types differ slightly (Figure 7). Ordinarily, the secondary

regulation point is set 5% to 10% below the voltage normally produced by the flyback effect. For example, if the

MAX1654

NEGATIVE

SECONDARY

OUTPUT

MAIN

OUTPUT

DH

V+

SECFB

R3

R2

1-SHOT

TRIG

DL

0.33µF

REF

MAX1652

POSITIVE

SECONDARY

OUTPUT

MAIN

OUTPUT

DH

V+

SECFB

2.5V REF

R3

R2

1-SHOT

TRIG

DL

+V

TRIP

WHERE V

REF

(NOMINAL) = 2.5V= V

REF

(1 + –––)

R2

R3

-V

TRIP

R3 = 100kΩ (RECOMMENDED)= -V

REF

(–––)

R2

R3

Figure 7. Secondary-Output Feedback Dividers

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 19

output voltage as determined by the turns ratio is +15V,

the feedback resistor ratio should be set to produce

about +13.5V; otherwise, the SECFB one-shot might be

triggered unintentionally, causing an unnecessary

increase in supply current and output noise. In negativeoutput (MAX1654) applications, the resistor-divider acts

as a load on the internal reference, which in turn can

cause errors at the main output. Avoid overloading REF

(see the Reference Load-Regulation Error vs. Load

Current graph in the

Typical Operating Characteristics

).

100kΩ is a good value for R3 in MAX1654 circuits.

Output current on secondary winding applications is

limited at low input voltages. See the MAX1652

Maximum Secondary Output Current vs. Supply Voltage

graph in the Typical Operating Characteristics for data

from the application circuit of Figure 8.

Soft-Start Circuit (SS)

Soft-start allows a gradual increase of the internal current-limit level at start-up for the purpose of reducing

input surge currents, and perhaps for power-supply

sequencing. In shutdown mode, the soft-start circuit

holds the SS capacitor discharged to ground. When

SHDN goes high, a 4µA current source charges the SS

capacitor up to 3.2V. The resulting linear ramp waveform causes the internal current-limit level to increase

proportionally from 0 to 100mV. The main output capacitor thus charges up relatively slowly, depending on the

SS capacitor value. The exact time of the output rise

depends on output capacitance and load current and is

typically 1ms per nanofarad of soft-start capacitance.

With no SS capacitor connected, maximum current limit

is reached within 10µs.

Shutdown

Shutdown mode (SHDN = 0V) reduces the V+ supply

current to typically 3µA. In this mode, the reference and

VL are inactive. SHDN is a logic-level input, but it can

be safely driven to the full V+ range. Connect SHDN to

V+ for automatic start-up. Do not allow slow transitions

(slower than 0.02V/µs) on SHDN.

MAX1652

FB

GND

REF

SYNC

SECFB VL 10

2

11

7

35

14

Si9410

Si9410

D2

EC11FS1

T1 = TRANSPOWER TTI5870

* = OPTIONAL, MAY NOT BE NEEDED

16

15

13

D1

CMPSH

-3A

1N5819

12

8

9

V

IN

(6.5V TO 18V)

+15V AT

250mA

+5V

AT 3A

6

ON/OFF

1

CSL

CSH

BST

V+

DH

LX

DL

PGND

SHDN

SS

0.33µF

C2

4.7µF

C3

15µF

2.5V

220µF

10V

220µF

10V

0.1µF

22µF, 35V

22µF, 35V

0.01µF

20mΩ

22Ω*

4700pF*

T1

15µH

2.2:1

49.9k, 1%

210k, 1%

0.01µF

(OPTIONAL)

18V

1/4 W

C2

4.7µF

4

Figure 8. 5V/15V Dual-Output Application Circuit (MAX1652)

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

20 ______________________________________________________________________________________

__________________Design Procedure

The predesigned standard application circuits (Figure

1 and Table 1) contain ready-to-use solutions for common applications. Use the following design procedure

to optimize the basic schematic for different voltage or

current requirements. Before beginning a design, firmly

establish the following:

V

IN(MAX)

, the maximum input (battery) voltage. This

value should include the worst-case conditions, such

as no-load operation when a battery charger or AC

adapter is connected but no battery is installed.

V

IN(MAX)

must not exceed 30V. This 30V upper limit is

determined by the breakdown voltage of the BST floating gate driver to GND (36V absolute maximum).

V

IN(MIN)

, the minimum input (battery) voltage. This

should be at full-load under the lowest battery conditions. If V

IN(MIN)

is less than 4.5V, a special circuit must

be used to externally hold up VL above 4.8V. If the minimum input-output difference is less than 1V, the filter

capacitance required to maintain good AC load regulation increases.

Inductor Value

The exact inductor value isn’t critical and can be

adjusted freely in order to make trade-offs among size,

cost, and efficiency. Although lower inductor values will

minimize size and cost, they will also reduce efficiency

due to higher peak currents. To permit use of the physically smallest inductor, lower the inductance until the

circuit is operating at the border between continuous

and discontinuous modes. Reducing the inductor value

even further, below this crossover point, results in discontinuous-conduction operation even at full load. This

helps reduce output filter capacitance requirements but

causes the core energy storage requirements to

increase again. On the other hand, higher inductor values will increase efficiency, but at some point resistive

losses due to extra turns of wire will exceed the benefit

gained from lower AC current levels. Also, high inductor values affect load-transient response; see the V

SAG

equation in the

Low-Voltage Operation

section.

The following equations are given for continuous-conduction operation since the MAX1652 family is mainly intended for high-efficiency, battery-powered applications. See

Appendix A in Maxim’s

Battery Management and DC-DC

Converter Circuit Collection

for crossover point and discontinuous-mode equations. Discontinuous conduction

doesn’t affect normal Idle Mode operation.

Three key inductor parameters must be specified:

inductance value (L), peak current (I

PEAK

), and DC

resistance (RDC). The following equation includes a

constant LIR, which is the ratio of inductor peak-to-peak

AC current to DC load current. A higher value of LIR

allows smaller inductance, but results in higher losses

and ripple. A good compromise between size and losses is found at a 30% ripple current to load current ratio

(LIR = 0.3), which corresponds to a peak inductor current 1.15 times higher than the DC load current.

V

OUT(VIN(MAX)

- V

OUT

)

L = ———————————

V

IN(MAX)

x f x I

OUT

x LIR

where: f =switching frequency, normally 150kHz or

300kHz

I

OUT

=maximum DC load current

LIR =ratio of AC to DC inductor current,

typically 0.3

The peak inductor current at full load is 1.15 x I

OUT

if

the above equation is used; otherwise, the peak current

can be calculated by:

The inductor’s DC resistance is a key parameter for efficiency performance and must be ruthlessly minimized,

preferably to less than 25mΩ at I

OUT

= 3A. If a standard off-the-shelf inductor is not available, choose a

core with an LI2rating greater than L x I

PEAK

2

and wind

it with the largest diameter wire that fits the winding

area. For 300kHz applications, ferrite core material is

strongly preferred; for 150kHz applications, Kool-mu

(aluminum alloy) and even powdered iron can be

acceptable. If light-load efficiency is unimportant (in

desktop 5V-to-3V applications, for example) then lowpermeability iron-powder cores may be acceptable,

even at 300kHz. For high-current applications, shielded

core geometries (such as toroidal or pot core) help

keep noise, EMI, and switching-waveform jitter low.

Current-Sense Resistor Value

The current-sense resistor value is calculated according to the worst-case, low-current-limit threshold voltage

(from the

Electrical Characteristics

table) and the peak

inductor current. The continuous-mode peak inductorcurrent calculations that follow are also useful for sizing

the switches and specifying the inductor-current saturation ratings. In order to simplify the calculation, I

LOAD

may be used in place of I

PEAK

if the inductor value has

been set for LIR = 0.3 or less (high inductor values)

and 300kHz operation is selected. Low-inductance

resistors, such as surface-mount metal-film resistors,

are preferred.

80mV

R

SENSE

= ————

I

PEAK

I I

x f x L x V

PEAK LOAD

IN MAX

= +

( )

V (V - V )

OUT IN(MAX) OUT

2

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 21

Input Capacitor Value

Place a small ceramic capacitor (0.1µF) between V+ and

GND, close to the device. Also, connect a low-ESR bulk

capacitor directly to the drain of the high-side MOSFET.

Select the bulk input filter capacitor according to input

ripple-current requirements and voltage rating, rather

than capacitor value. Electrolytic capacitors that have

low enough effective series resistance (ESR) to meet the

ripple-current requirement invariably have more than

adequate capacitance values. Ceramic capacitors or

low-ESR aluminum-electrolytic capacitors such as Sanyo

OS-CON or Nichicon PL are preferred. Tantalum types

are also acceptable but may be less tolerant of high

input surge currents. RMS input ripple current is determined by the input voltage and load current, with the

worst possible case occurring at VIN= 2 x V

OUT

:

Output Filter Capacitor Value

The output filter capacitor values are determined by the

ESR, capacitance, and voltage rating requirements.

Electrolytic and tantalum capacitors are generally chosen by voltage rating and ESR specifications, as they

will generally have more output capacitance than is

required for AC stability. Use only specialized low-ESR

capacitors intended for switching-regulator applications,

such as AVX TPS, Sprague 595D, Sanyo OS-CON, or

Nichicon PL series. To ensure stability, the capacitor

must meet

both

minimum capacitance and maximum

ESR values as given in the following equations:

V

REF

(1 + V

OUT

/ V

IN(MIN)

)

C

OUT

> ––––––––––––––––———–––

V

OUT

x R

SENSE

x f

R

SENSE

x V

OUT

R

ESR

< ————————

V

REF

(can be multiplied by 1.5, see note below)

These equations are “worst-case” with 45 degrees of

phase margin to ensure jitter-free fixed-frequency operation and provide a nicely damped output response for

zero to full-load step changes. Some cost-conscious

designers may wish to bend these rules by using less

expensive (lower quality) capacitors, particularly if the

load lacks large step changes. This practice is tolerable if

some bench testing over temperature is done to verify

acceptable noise and transient response.

There is no well-defined boundary between stable and

unstable operation. As phase margin is reduced, the

first symptom is a bit of timing jitter, which shows up as

blurred edges in the switching waveforms where the

scope won’t quite sync up. Technically speaking, this

(usually) harmless jitter is unstable operation, since the

switching frequency is now nonconstant. As the capacitor quality is reduced, the jitter becomes more pronounced and the load-transient output voltage

waveform starts looking ragged at the edges.

Eventually, the load-transient waveform has enough

ringing on it that the peak noise levels exceed the

allowable output voltage tolerance. Note that even with

zero phase margin and gross instability present, the

output voltage noise never gets much worse than I

PEAK

x R

ESR

(under constant loads, at least).

Note: Designers of RF communicators or other noisesensitive analog equipment should be conservative

and stick to the ESR guidelines. Designers of notebook

computers and similar commercial-temperature-range

digital systems can multiply the R

ESR

value by a factor

of 1.5 without hurting stability or transient response.

The output voltage ripple is usually dominated by the

ESR of the filter capacitor and can be approximated as

I

RIPPLE

x R

ESR

. There is also a capacitive term, so the

full equation for ripple in the continuous mode is

V

NOISE(p-p)

= I

RIPPLE

x [R

ESR

+ 1 / (8 x f x C

OUT

)]. In

Idle Mode, the inductor current becomes discontinuous

with high peaks and widely spaced pulses, so the noise

can actually be higher at light load compared to full load.

In Idle Mode, the output ripple can be calculated as:

0.025 x R

ESR

V

NOISE(p-p)

= —————— +

R

SENSE

(0.025)2x L x [1 / V

OUT

+ 1 / (VIN- V

OUT

)]

———————————————————

(R

SENSE

)2x C

OUT

Transformer Design

(MAX1652/MAX1654 Only)

Buck-plus-flyback applications, sometimes called “coupled-inductor” topologies, use a transformer to generate

multiple output voltages. The basic electrical design is a

simple task of calculating turns ratios and adding the

power delivered to the secondary in order to calculate the

current-sense resistor and primary inductance. However,

extremes of low input-output differentials, widely different

output loading levels, and high turns ratios can complicate the design due to parasitic transformer parameters

such as interwinding capacitance, secondary resistance,

and leakage inductance. For examples of what is possible with real-world transformers, see the graphs of

Maximum Secondary Current vs. Input Voltage in the

Typical Operating Characteristics.

I I x

V

V

I I when V is x V

RMS LOAD

OUT VIN VOUT

IN

RMS LOAD IN OUT

/

( )

=

=

−

2 2

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

22 ______________________________________________________________________________________

Power from the main and secondary outputs is lumped

together to obtain an equivalent current referred to the

main output voltage (see

Inductor Value

section for definitions of parameters). Set the value of the currentsense resistor at 80mV / I

TOTAL

.

P

TOTAL

=the sum of the output power from

all outputs

I

TOTAL=PTOTAL

/ V

OUT

= the equivalent output

current referred to V

OUT

V

OUT(VIN(MAX)

- V

OUT

)

L(primary) = —————————————

V

IN(MAX)

x f x I

TOTAL

x LIR

V

SEC

+ V

FWD

Turns Ratio N = ——————————————

V

OUT(MIN)

+ V

RECT

+ V

SENSE

where: V

SEC

is the minimum required rectified

secondary-output voltage

V

FWD

is the forward drop across the

secondary rectifier

V

OUT(MIN)

is the

minimum

value of the main

output voltage (from the

Electrical

Characteristics

)

V

RECT

is the on-state voltage drop across the

synchronous-rectifier MOSFET

V

SENSE

is the voltage drop across the sense

resistor

In positive-output (MAX1652) applications, the transformer secondary return is often referred to the main

output voltage rather than to ground in order to reduce

the needed turns ratio. In this case, the main output

voltage must first be subtracted from the secondary

voltage to obtain V

SEC

.

______Selecting Other Components

MOSFET Switches

The two high-current N-channel MOSFETs must be

logic-level types with guaranteed on-resistance specifications at VGS= 4.5V. Lower gate threshold specs are

better (i.e., 2V max rather than 3V max). Drain-source

breakdown voltage ratings must at least equal the maximum input voltage, preferably with a 20% derating

factor. The best MOSFETs will have the lowest on-resistance per nanocoulomb of gate charge. Multiplying

R

DS(ON)

x QGprovides a meaningful figure by which to

compare various MOSFETs. Newer MOSFET process

technologies with dense cell structures generally give

the best performance. The internal gate drivers can tolerate more than 100nC total gate charge, but 70nC is a

more practical upper limit to maintain best switching

times.

In high-current applications, MOSFET package power

dissipation often becomes a dominant design factor.

I

2

R losses are distributed between Q1 and Q2 according to duty factor (see the equations below). Switching

losses affect the upper MOSFET only, since the

Schottky rectifier clamps the switching node before the

synchronous rectifier turns on. Gate-charge losses are

dissipated by the driver and don’t heat the MOSFET.

Ensure that both MOSFETs are within their maximum

junction temperature at high ambient temperature by

calculating the temperature rise according to package

thermal-resistance specifications. The worst-case dissipation for the high-side MOSFET occurs at the minimum

battery voltage, and the worst-case for the low-side

MOSFET occurs at the maximum battery voltage.

PD (upper FET) = I

LOAD

2

x R

DS(ON)

x DUTY

VINx C

RSS

+ VINx I

LOAD

x f x (––––––––––– +20ns

)

I

GATE

PD (lower FET) = I

LOAD

2

x R

DS(ON)

x (1 - DUTY)

DUTY = (V

OUT

+ VQ2) / (VIN- VQ1+ VQ2)

where the on-state voltage drop VQ_= I

LOAD

x R

DS(ON)

C

RSS

=MOSFET reverse transfer capacitance

I

GATE

=DH driver peak output current capability

(1A typically)

20ns =DH driver inherent rise/fall time

Under output short circuit, the synchronous-rectifier

MOSFET suffers extra stress and may need to be oversized if a continuous DC short circuit must be tolerated.

During short circuit, Q2’s duty factor can increase to

greater than 0.9 according to:

Q2 DUTY (short circuit) = 1 - [VQ2/ (V

IN(MAX)

- V

Q1 + VQ2

)]

where the on-state voltage drop VQ= (120mV / R

SENSE

)

x R

DS(ON).

Rectifier Diode D1

Rectifier D1 is a clamp that catches the negative inductor swing during the 60ns dead time between turning

off the high-side MOSFET and turning on the low-side.

D1 must be a Schottky type in order to prevent the

lossy parasitic MOSFET body diode from conducting. It

is acceptable to omit D1 and let the body diode clamp

the negative inductor swing, but efficiency will drop one

or two percent as a result. Use an MBR0530 (500mA

rated) type for loads up to 1.5A, a 1N5819 type for

loads up to 3A, or a 1N5822 type for loads up to 10A.

D1’s rated reverse breakdown voltage must be at least

equal to the maximum input voltage, preferably with a

20% derating factor.

MAX1652–MAX1655

High-Efficiency, PWM, Step-Down

DC-DC Controllers in 16-Pin QSOP

______________________________________________________________________________________ 23

Boost-Supply Diode D2

A 10mA to 100mA Schottky diode or signal diode such

as a 1N4148 works well for D2 in most applications. If

the input voltage can go below 6V, use a Schottky

diode for slightly improved efficiency and dropout characteristics. Don’t use large power diodes such as

1N5817 or 1N4001, since high junction capacitance

can cause VL to be pumped up to excessive voltages.

Rectifier Diode D3

(Transformer Secondary Diode)

The secondary diode in coupled-inductor applications

must withstand high flyback voltages greater than 60V,

which usually rules out most Schottky rectifiers.

Common silicon rectifiers such as the 1N4001 are also

prohibited, as they are far too slow. This often makes

fast silicon rectifiers such as the MURS120 the only

choice. The flyback voltage across the rectifier is related to the VIN-V

OUT

difference according to the trans-

former turns ratio:

V

FLYBACK

= V

SEC

+ (VIN- V

OUT

) x N

where: N is the transformer turns ratio SEC/PRI

V

SEC

is the maximum secondary DC output voltage

V

OUT

is the primary (main) output voltage

Subtract the main output voltage (V

OUT

) from V

FLYBACK

in this equation if the secondary winding is returned to

V

OUT

and not to ground. The diode reverse breakdown

rating must also accommodate any ringing due to leakage inductance. D3’s current rating should be at least

twice the DC load current on the secondary output.

_____________Low-Voltage Operation

Low input voltages and low input-output differential voltages each require some extra care in the design. Low

absolute input voltages can cause the VL linear regulator to enter dropout, and eventually shut itself off. Low

input voltages relative to the output (low VIN-V

OUT

differential) can cause bad load regulation in multi-output flyback applications. See

Transformer Design

section.

Finally, low VIN-V

OUT

differentials can also cause the

output voltage to sag when the load current changes

abruptly. The amplitude of the sag is a function of inductor value and maximum duty factor (D

MAX

an

Electrical

Characteristics

parameter, 98% guaranteed over tem-

perature at f = 150kHz) as follows:

(I

STEP

)2x L

V

SAG

= ———————————————

2 x C

OUT

x (V

IN(MIN)

x D

MAX

- V

OUT

)

The cure for low-voltage sag is to increase the value of

the output capacitor. For example, at VIN= 5.5V, V

OUT

= 5V, L = 10µH, f = 150kHz, a total capacitance of

660µF will prevent excessive sag. Note that only the

capacitance requirement is increased and the ESR

requirements don’t change. Therefore, the added

capacitance can be supplied by a low-cost bulk

capacitor in parallel with the normal low-ESR capacitor.

Table 4 summarizes low-voltage operational issues.

Table 4. Low-Voltage Troubleshooting

Supply VL from an external source other

than V

BATT

, such as the system 5V supply.

VL output is so low that it hits the

VL UVLO threshold at 4.2V max.

Low input voltage, <4.5V

Won’t start under load or

quits before battery is

completely dead

Use a small 20mA Schottky diode for

boost diode D2. Supply VL from an

external source.

VL linear regulator is going into

dropout and isn’t providing

good gate-drive levels.

Low input voltage, <5V

High supply current,

poor efficiency

Reduce f to 150kHz. Reduce secondary

impedances—use Schottky if possible.

Stack secondary winding on main output.

Not enough duty cycle left to

initiate forward-mode operation.

Small AC current in primary can’t

store energy for flyback operation.

Low VIN-V

OUT

differential,

V

IN

< 1.3 x V

OUT

(main)