Page 1

查询MAX1626供应商

19-1075; Rev 0; 6/96

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

High-Efficiency, Step-Down DC-DC Controllers

_______________General Description

The MAX1626/MAX1627 step-down DC-DC switching

controllers provide high efficiency over loads ranging

from 1mA to more than 2A. A unique current-limited,

pulse-frequency-modulated (PFM) control scheme

operates with up to a 100% duty cycle, resulting in very

low dropout voltages. This control scheme eliminates

minimum load requirements and reduces the supply

current under light loads to 90µA (versus 2mA to 10mA

for common pulse-width modulation controllers).

These step-down controllers drive an external P-channel MOSFET, allowing design flexibility for applications

to 12W or higher. Soft-start reduces current surges during start-up. A high switching frequency (up to 300kHz)

and operation in continuous-conduction mode allow the

use of tiny surface-mount inductors. Output capacitor

requirements are also reduced, minimizing PC board

area and system costs.

The output voltage is preset at 5V or 3.3V for the

MAX1626 and adjustable for the MAX1627. Input voltages can be up to 16.5V. The MAX1626/MAX1627 are

functional upgrades for the MAX1649/MAX1651.

________________________Applications

PCMCIA Power Supplies

Personal Digital Assistants

Hand-Held Computers

Portable Terminals

Low-Cost Notebook Computer Supplies

5V to 3.3V Green PC Applications

High-Efficiency Step-Down Regulation

Minimum-Component DC-DC Converters

Battery-Powered Applications

__________________Pin Configuration

TOP VIEW

3/5 (FB)

SHDN

( ) ARE FOR MAX1627

5V/3.3V or Adjustable, 100% Duty-Cycle,

____________________________Features

♦ Low Dropout Voltage

♦ 100% Maximum Duty Cycle

♦ Soft-Start Limits Start-Up Current

♦ Efficiency >90% (3mA to 2A Loads)

♦ Output Power >12.5W

♦ 90µA Max Quiescent Current

♦ 1µA Max Shutdown Current

♦ Up to 300kHz Switching Frequency

♦ 16.5V Max Input Voltage

♦ Output Voltage: 5V/3.3V (MAX1626)

Adjustable (MAX1627)

♦ Current-Limited Control Scheme

______________Ordering Information

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

-40°C to +85°C

0°C to +70°C

V+

MAX1626

CSSHDN

P

3/5

REF

GND

EXT

OUT

Dice*

8 SO

Dice*

OUTPUT

3.3V

OUT

REF

1

2

3

4

MAX1626

MAX1627

SO

PART

MAX1626C/D

MAX1626ESA

MAX1627C/D

MAX1627ESA -40°C to +85°C 8 SO

* Dice are tested at TA= +25°C.

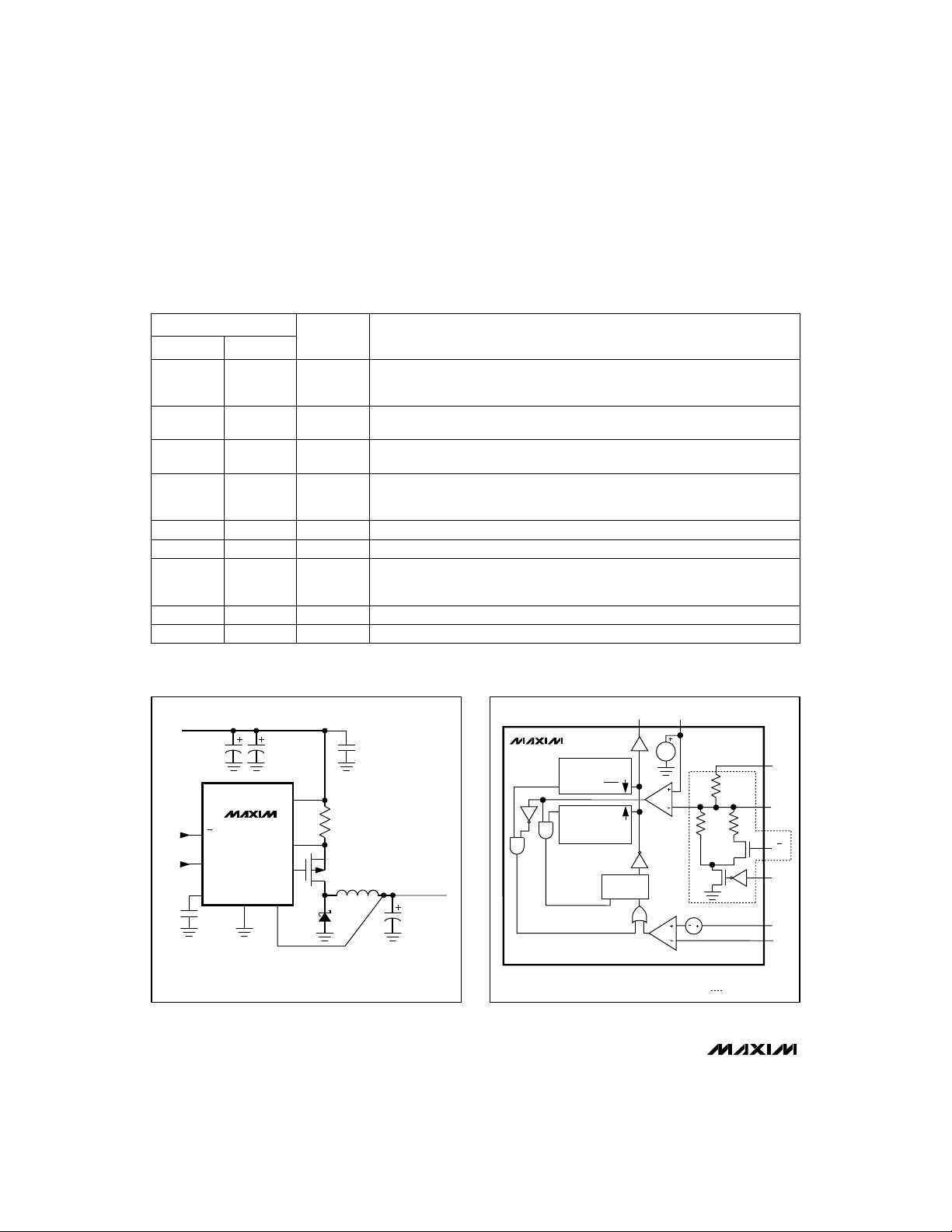

__________Typical Operating Circuit

INPUT

3.3V to 16.5V

8

GND

EXT

7

CS

6

5

V+

ON/OFF

MAX1626/MAX1627

________________________________________________________________

Maxim Integrated Products

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Page 2

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, V+ to GND.......................................-0.3V, +17V

OUT, FB, 3/5, SHDN, REF, CS, EXT to GND...-0.3V, (V+ + 0.3V)

Maximum Current at REF (I

Maximum Current at EXT (I

Continuous Power Dissipation (T

SO (derate 5.88mW/°C above +70°C)..........................471mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

)..........................................15mA

REF

) ..........................................50mA

EXT

= +70°C)

A

ELECTRICAL CHARACTERISTICS

(V+ = +3V to +16.5V, SHDN = 3/5 = 0V, TA= 0°C to +85°C, unless otherwise noted.)

Operating, no load

V

I+Supply Current into V+

V+ = SHDN = 16.5V (shutdown)

Circuit of Figure 1, 3/5 = V+ (Note 1)

OUT

Circuit of Figure 1, 3/5 = 0V (Note 1)

MAX1626, 3/5 = V+, output forced to 5V

OUT

MAX1627, includes hysteresis

MAX1627

CS

SHDN = 0V or V+

3/5 = 0V or V+

V+ = 5V

Output forced to 0V

Output in regulation

6.0V < V+ < 12.0V, I

30mA < I

LOAD

I

= 0µA

LOAD

REF

REF

≤ 100µA

0µA ≤ I

V+ = 3V to 16.5V, I

MAX1626/MAX1627

Output Voltage

OUT Input Current

CS Threshold Voltage

3/5 Input Voltage High

3/5 Input Voltage Low

3/5 Leakage Current

Minimum EXT Off Time

Reference Voltage

Operating Temperature Range

MAX1626ESA/MAX1627ESA............................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

CONDITIONS

70 90

4.85 5.00 5.15

3.20 3.30 3.40

81012

1.5 2.0 2.5

= 1A

LOAD

< 2.0A, V+ = 8V

= 0µA µV/V10 100REF Line Regulation

LOAD

UNITSMIN TYP MAXSYMBOLPARAMETER

1

V3.0 16.5V+Input Voltage Range

µA

V2.7 2.8Undervoltage Lockout

V

µA24 37 50I

V1.27 1.30 1.33FB Threshold Voltage

nA035FB Leakage Current

µA010CS Input Current

mV85 100 115V

V1.6SHDN Input Voltage High

V0.4SHDN Input Voltage Low

µA±1SHDN Input Current

VV+ - 0.5

V0.5

µA±1

Ω10EXT Resistance

µs

%100EXT Duty-Cycle Limit

mV/V5Line Regulation

mV/A15Load Regulation

V1.27 1.30 1.33V

mV410REF Load Regulation

2 _______________________________________________________________________________________

Page 3

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

ELECTRICAL CHARACTERISTICS

(V+ = +3V to +16.5V, SHDN = 3/5 = 0V, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

CONDITIONS

Operating, no load

Supply Current into V+

Output Voltage

OUT Input Current

I

V

OUT

V+ = SHDN = 16.5V (shutdown)

Circuit of Figure 1, 3/5 = V+

OUT

Circuit of Figure 1, 3/5 = 0V

MAX1626, 3/5 = V+, output forced to 5V

OUT

MAX1627, includes hysteresis

MAX1627

I

= 0µA

LOAD

Note 1: V+ must exceed V

Note 2: Specifications from 0°C to -40°C are guaranteed by design, not production tested.

to maintain regulation.

OUT

4.80 5.20

3.16 3.44

100

2

MAX1626/MAX1627

UNITSMIN TYP MAXSYMBOLPARAMETER

V3.0 16.5V+Input Voltage

µA

V2.9Undervoltage Lockout

V

µA24 50I

V1.25 1.35FB Threshold Voltage

nA050FB Leakage Current

mV80 120CS Threshold Voltage

V1.25 1.35Reference

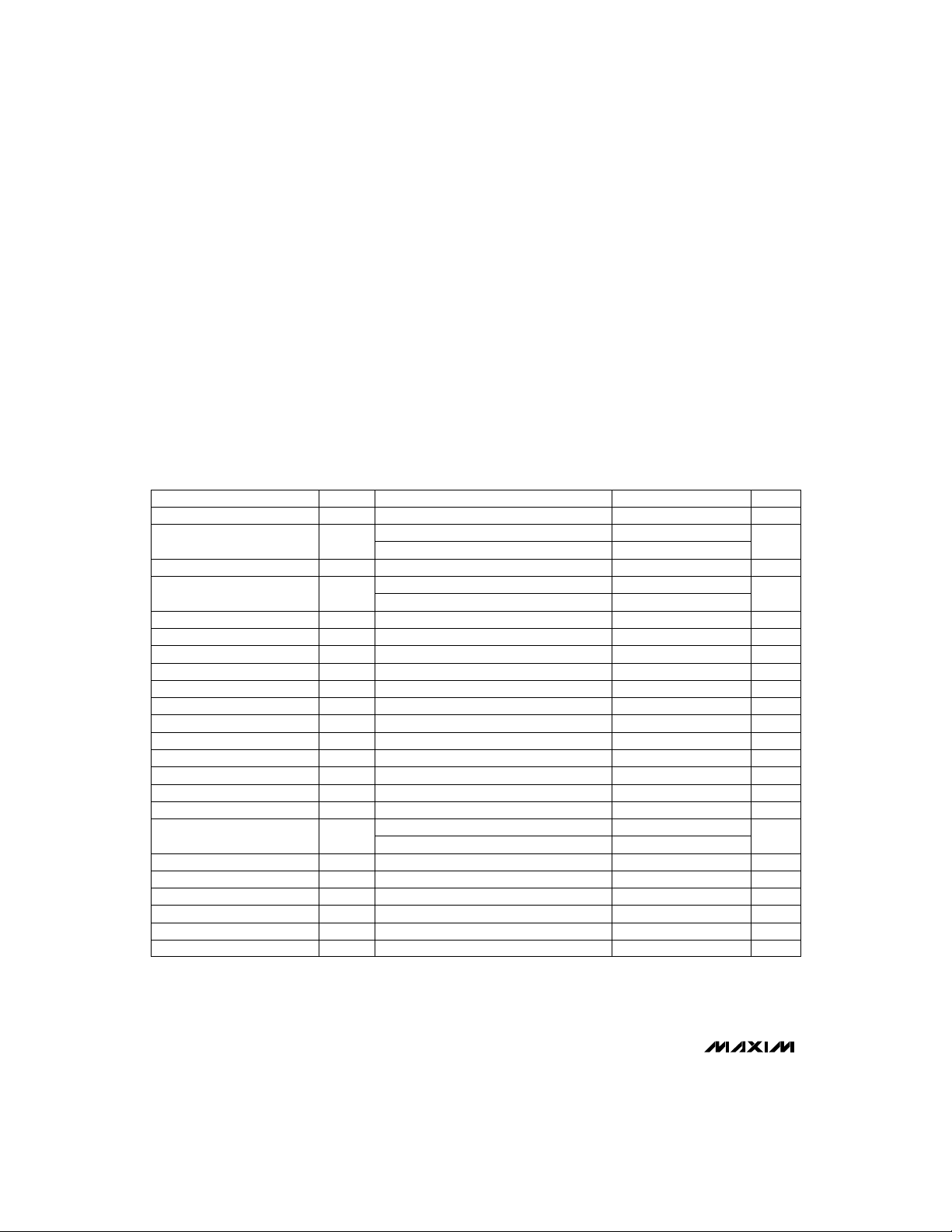

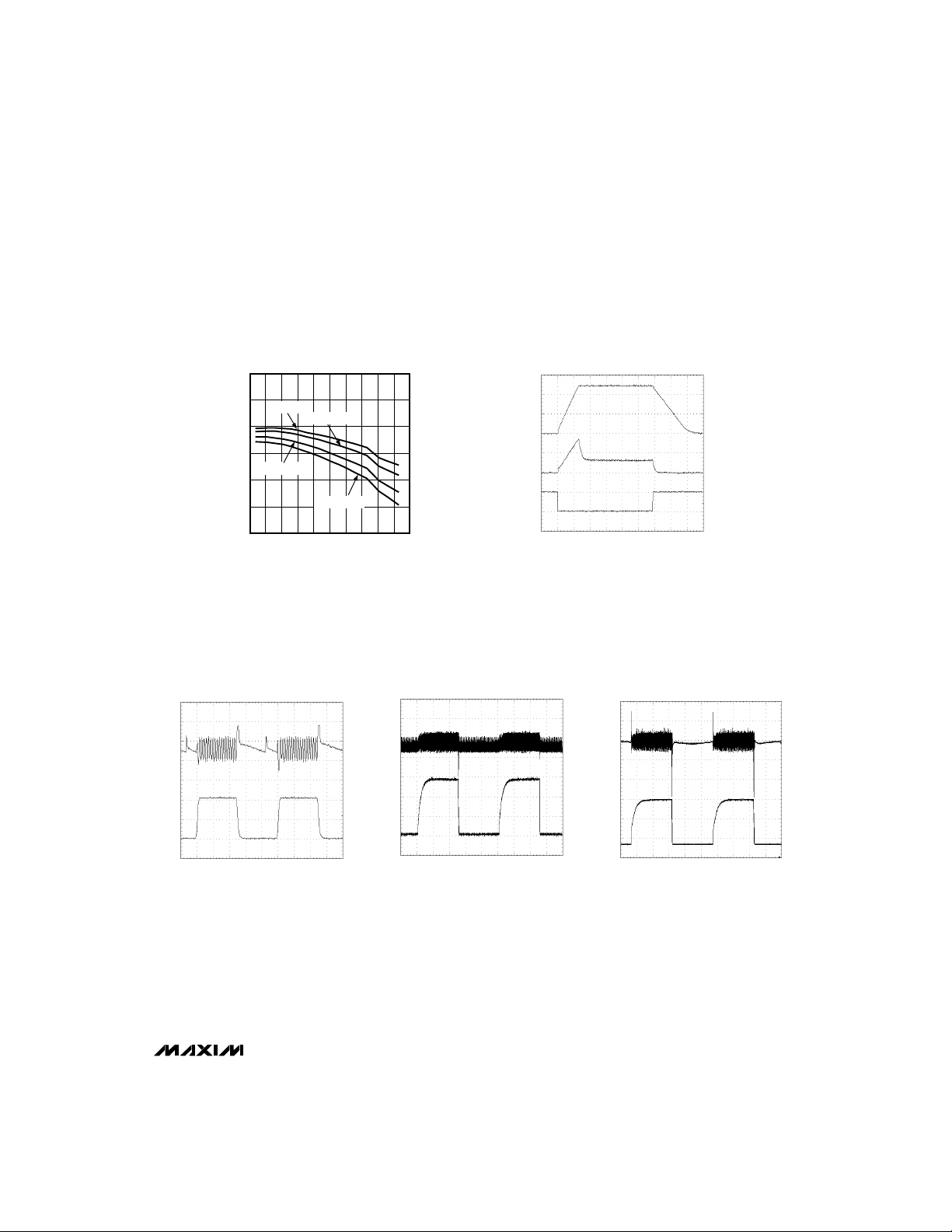

__________________________________________Typical Operating Characteristics

(Circuit of Figure 1, TA= +25°C, unless otherwise noted.)

DROPOUT VOLTAGE

0.45

0.40

0.35

0.30

0.25

0.20

0.15

DROPOUT VOLTAGE (V)

0.10

0.05

0

vs. LOAD CURRENT

3.3V SETTING

= +3.17V

V

OUT

0 0.5 1.0 1.5 2.0 2.5

LOAD (A)

_______________________________________________________________________________________ 3

5V SETTING

= +4.8V

V

OUT

MAX1626-11

EFFICIENCY vs. LOAD CURRENT

(V

= +3.3V)

100

90

A

80

70

60

50

40

EFFICIENCY (%)

30

20

10

CIRCUIT OF FIGURE 1

0

0.1m 100m 11m 10m 10

C

B

LOAD CURRENT (A)

OUT

D E F

A: V+ = +4.3V

B: V+ = +5V

C: V+ = +8V

D: V+ = +10V

E: V+ = +12V

F: V+ = +15V

MAX1626-05

EFFICIENCY (%)

EFFICIENCY vs. LOAD CURRENT

(V

= +5V)

100

90

A

80

70

60

50

40

30

20

10

CIRCUIT OF FIGURE 1

0

0.1m 100m 11m 10m 10

OUT

C

B

LOAD CURRENT (A)

D

E

A: V+ = +6V

B: V+ = +8V

C: V+ = +10V

D: V+ = +12V

E: V+ = +15V

MAX1626-03

Page 4

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

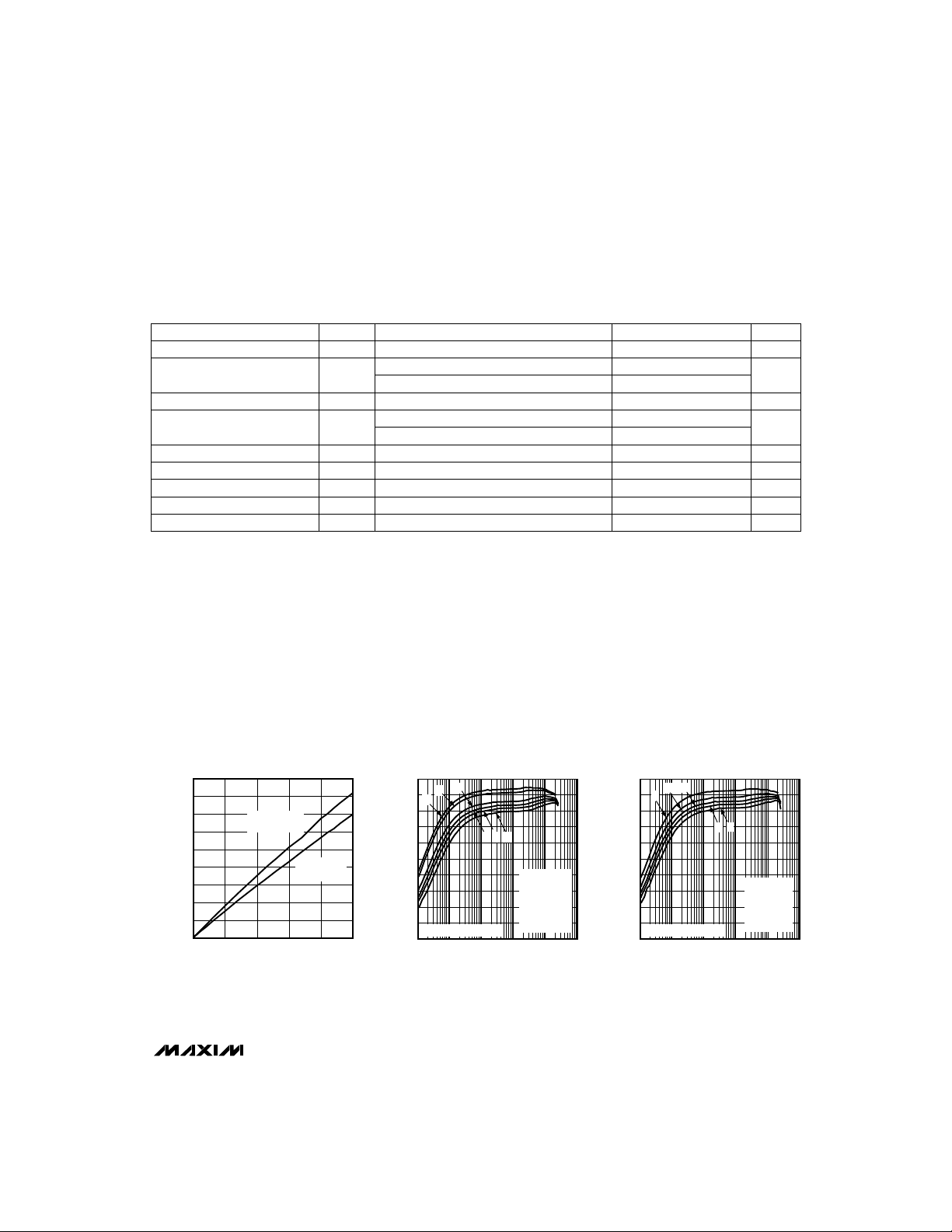

____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, TA= +25°C, unless otherwise noted.)

MAX1626 SHUTDOWN CURRENT

0.8

0.7

0.6

0.5

0.4

0.3

0.2

SHUTDOWN CURRENT (µA)

0.1

0

-60

MAX1626/MAX1627

vs. TEMPERATURE

APPLICATION CIRCUIT

SHUTDOWN CURRENT:

A: V+ = +15V

B: V+ = +10V

C: V+ = +4V

MAX1626 SHUTDOWN

CURRENT:

D: V+ = +16V

E: V+ = +4V

-20 0 204060 80 100120

-40

TEMPERATURE (°C)

A

MAX1626-04

B

C

D

EXT OFF TIME (µs)

E

140

MAX1626 EXT OFF TIME

vs. OUTPUT VOLTAGE

12

10

8

6

4

2

0

012345

3/5 = V+

3/5 = GND

OUTPUT VOLTAGE (V)

V+ = +5V

MAX1626-02

12

10

8

6

4

EXT OFF TIME (µs)

2

MAX1627 EXT OFF TIME

vs. FB PIN VOLTAGE

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

FB PIN VOLTAGE (V)

V+ = +5V

MAX1626-03

EXT RISE AND FALL TIMES

50

45

40

35

(ns)

30

FALL

25

AND t

20

RISE

t

15

10

5

0

-60 -40 -20 40 60 140

vs. TEMPERATURE

t

, V+ = +5V

FALL

t

RISE

C

= 1nF

EXT

3/5 = 0V

OUT = 50kHz, 0.3Vp-p

0

20 80

TEMPERATURE (°C)

t

RISE

, t

FALL

3.3V

,

, V+ = +5V

, V+ = +15V

DC

100 120

MAX1626-09

400

350

300

(ns)

250

FALL

200

AND t

150

RISE

t

100

50

EXT RISE AND FALL TIMES

vs. CAPACITANCE

t

, V+ = +15V

RISE

, V+ = +5V

t

FALL

t

, V+ = +5V

RISE

, V+ = +15V

t

0

0 2000 4000

CAPACITANCE (pF)

FALL

MAX1626

V+ QUIESCENT CURRENT

72

70

68

66

(µA)

Q

I

64

62

60

-60

vs. TEMPERATURE

V+ = +16V

V+ = +10V

V+ = +4V

3/5 = 0V

OUT FORCED TO 3.4V

-20 0 204060 80 100120

-40

TEMPERATURE (°C)

MAX1626-01

140

CS TRIP LEVEL vs. TEMPERATURE

115

OUT = 0V

110

105

100

95

CS TRIP LEVEL (mV)

90

85

-60 -40 -20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

4 _______________________________________________________________________________________

MAX1626-10

MAX1626-12

Page 5

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

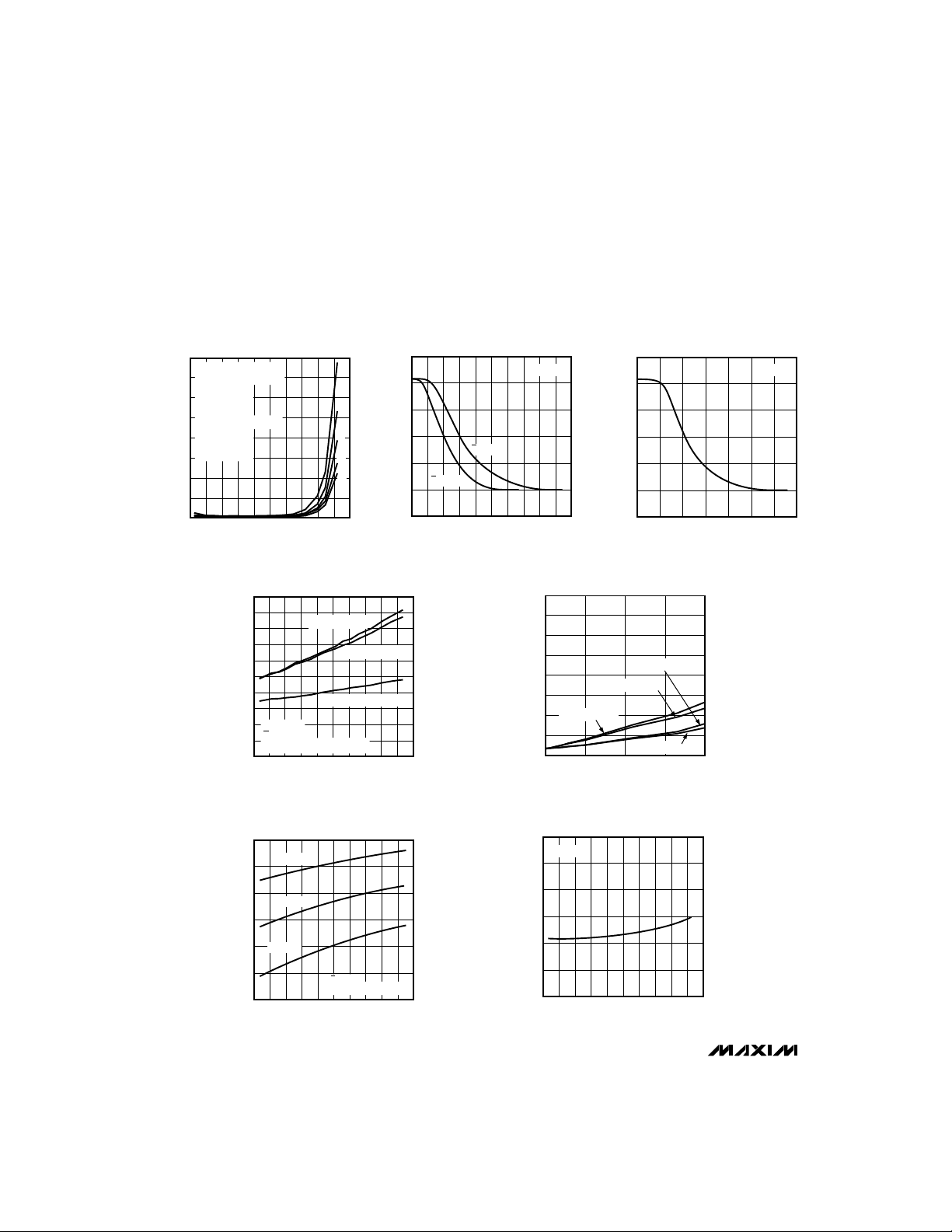

____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, TA= +25°C, unless otherwise noted.)

MAX1626/MAX1627

REFERENCE OUTPUT VOLTAGE

vs. TEMPERATURE

1.310

1.305

1.300

1.295

1.290

1.285

REFERENCE OUTPUT VOLTAGE (V)

1.280

I

= 0µA

REF

= 50µA

I

REF

-60 -40 -20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

MAX1626 LOAD-TRANSIENT RESPONSE

A

I

REF

= 10µA

I

REF

= 100µA

MAX1626-15

MAX1626-13

MAX1626 LINE-TRANSIENT RESPONSE

A

MAX1626 SHUTDOWN RESPONSE TIME

AND SUPPLY CURRENT

A

B

C

V+ = 8V, V

A: OUT, 2V/div

B: SUPPLY CURRENT, 1A/div

C: SHDN, 5V/div

500µs/div

= 5V, LOAD = 1A

OUT

LINE-TRANSIENT RESPONSE

FROM 100% DUTY CYCLE

MAX1626-16

A

MAX1626-14

MAX1626-17

B

V+ = 8V, V

A: OUT, 50mV/div, 3.3V DC OFFSET

B: LOAD CURRENT, 1A/div

100µs/div

= 3.3V, LOAD = 30mA to 2A

OUT

_______________________________________________________________________________________

B

V

= 5V, LOAD = 1A, CIN = 33µF

OUT

A: OUT, 100mV/div, 5V DC OFFSET

B: V+ 6V to 12V, 2V/div

5ms/div

B

V

= 3.3V, LOAD = 1A, CIN = 47µF

OUT

A: OUT, 100mV/div, 3.3V DC OFFSET

B: V+ 3.3V to 15V, 5V/div

5ms/div

5

Page 6

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

______________________________________________________________Pin Description

MAX1626

PIN

MAX1627

NAME

Sense input for fixed 5V or 3.3V output operation. OUT is internally connected to an

11

OUT

on-chip voltage divider (MAX1626). It does not supply current. Leave OUT unconnected during adjustable-output operation (MAX1627).

2—

—2

FB

3/5

Feedback Input for adjustable-output operation. Connect to an external voltage

divider between the output and GND (see the

3.3V or 5V Selection. Output voltage is set to 3.3V when this pin is low or 5V when it

is high.

Active-High Shutdown Input. Device is placed in shutdown when SHDN is driven

33

SHDN

high. In shutdown mode, the reference, output, and external MOSFET are turned off.

Connect to GND for normal operation.

MAX1626/MAX1627

V+

REF

1.3V Reference Output. Can source 100µA. Bypass with 0.1µF.44

Positive Supply Input. Bypass with 0.47µF.55

Current-Sense Input. Connect current-sense resistor between V+ and CS. External

66

CS

MOSFET is turned off when the voltage across the resistor equals the current-limit

trip level (around 100mV).

Gate Drive for External P-Channel MOSFET. EXT swings between V+ and GND.77

Ground88

C5

0.47µF

R

SENSE

0.04Ω

U1

LOGIC-LEVEL MOSFET

L1

22µH, 3A

L1: SUMIDA CDRH125-220

D1: NIHON NSQ03A03

U1: MORTOLA MMSF3PO2HD

INPUT

68µF LOW-ESR

TANTALUM

C4

0.1µF

C2

3/5

SHDN

REF

MAX1626

GND

C3

68µF LOW-ESR

TANTALUM

V+

CS

EXT

OUT

D1

EXT

GND

P

Figure 1. MAX1626 Typical Operating Circuit

OUTPUT

C1

220µF

LOW-ESR

TANTALUM

FUNCTION

Setting the Output Voltage

EXT REF

1.5V

MAX1626

MAX1627

MINIMUM ON-TIME

ONE-SHOT

TRIG

Q

Q

TRIG

MINIMUM OFF-TIME

ONE-SHOT

S

CURRENT-SENSE

COMPARATOR

REF

Q

R

Figure 2. Simplified Functional Diagram

ERROR

COMPARATOR

R2

R1

( ) MAX1627 ONLY

MAX1626 ONLY

section).

OUT

(FB)

R3

3/5

SHDN

V+

CS

6 _______________________________________________________________________________________

Page 7

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

_______________Detailed Description

The MAX1626/MAX1627 are step-down DC-DC controllers designed primarily for use in portable computers and battery-powered devices. Using an external

MOSFET and current-sense resistor allows design flexibility and the improved efficiencies associated with

high-performance P-channel MOSFETs. A unique, current-limited, pulse-frequency-modulated (PFM) control

scheme gives these devices excellent efficiency over

load ranges up to three decades, while drawing around

90µA under no load. This wide dynamic range optimizes the MAX1626/MAX1627 for battery-powered

applications, where load currents can vary considerably as individual circuit blocks are turned on and off to

conserve energy. Operation to a 100% duty cycle

allows the lowest possible dropout voltage, extending

battery life. High switching frequencies and a simple

circuit topology minimize PC board area and component costs. Figure 1 shows a typical operating circuit

for the MAX1626.

PFM Control Scheme

The MAX1626/MAX1627 use a proprietary, third-generation, current-limited PFM control scheme. Improvements

include a reduced current-sense threshold and operation

to a 100% duty cycle. These devices pulse only as needed to maintain regulation, resulting in a variable switching

frequency that increases with the load. This eliminates the

current drain associated with constant-frequency pulsewidth-modulation (PWM) controllers, caused by switching

the MOSFET unnecessarily.

When the output voltage is too low, the error comparator sets a flip-flop, which turns on the external P-channel MOSFET and begins a switching cycle (Figures 1

and 2). As shown in Figure 3, current through the

inductor ramps up linearly, storing energy in a magnetic field while dumping charge into an output capacitor

and servicing the load. When the MOSFET is turned off,

the magnetic field collapses, diode D1 turns on, and

the current through the inductor ramps back down,

transferring the stored energy to the output capacitor

and load. The output capacitor stores energy when the

inductor current is high and releases it when the inductor current is low.

The MAX1626/MAX1627 use a unique feedback and

control system to govern each pulse. When the output

voltage is too low, the error comparator sets a flip-flop,

which turns on the external P-channel MOSFET. The

MOSFET turns off when the current-sense threshold is

exceeded or when the output voltage is in regulation. A

one-shot enforces a 2µs minimum on-time, except in

current limit. The flip-flop resets when the MOSFET

turns off. Otherwise the MOSFET remains on, allowing a

duty cycle of up to 100%. This feature ensures the lowest possible dropout. Once the MOSFET is turned off,

the minimum off-time comparator keeps it off. The minimum off-time is normally 2µs, except when the output is

significantly out of regulation. If the output is low by

30% or more, the minimum off-time increases, allowing

soft-start. The error comparator has 0.5% hysteresis for

improved noise immunity.

In the MAX1626, the 3/5 pin selects the output voltage

(Figure 2). In the MAX1627, external feedback resistors

at FB adjust the output.

Operating Modes

When delivering low and medium output currents, the

MAX1626/MAX1627 operate in discontinuous-conduction mode. Current through the inductor starts at zero,

rises as high as the peak current limit set by the current- sense resistor, then ramps down to zero during

each cycle (Figure 3). Although efficiency is still excellent, output ripple increases and the switch waveform

exhibits ringing. This ringing occurs at the resonant frequency of the inductor and stray capacitance, due to

residual energy trapped in the core when the commutation diode (D1 in Figure 1) turns off. It is normal and

poses no operational problems.

When delivering high output currents, the MAX1626/

MAX1627 operate in continuous-conduction mode

(Figure 4). In this mode, current always flows through

the inductor and never ramps to zero. The control circuit adjusts the switch duty cycle to maintain regulation

without exceeding the peak switching current set by

the current-sense resistor. This provides reduced output ripple and high efficiency.

100% Duty Cycle and Dropout

The MAX1626/MAX1627 operate with a duty cycle up

to 100%. This feature extends usable battery life by

turning the MOSFET on continuously when the supply

voltage approaches the output voltage. This services

the load when conventional switching regulators with

less than 100% duty cycle would fail. Dropout voltage

is defined as the difference between the input and output voltages when the input is low enough for the output to drop out of regulation. Dropout depends on the

MOSFET drain-to-source on-resistance, current-sense

resistor, and inductor series resistance, and is proportional to the load current:

Dropout Voltage=

I x R + R + R

OUT DS(ON) SENSE INDUCTOR

[]

MAX1626/MAX1627

_______________________________________________________________________________________ 7

Page 8

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

A

B

C

0A

CIRCUIT OF FIGURE 1, V+ = 8V, V

A: MOSFET DRAIN, 5V/div

B: OUT, 50mV/div, 5V DC OFFSET

MAX1626/MAX1627

Figure 3. Discontinuous-Conduction Mode, Light-Load-Current

Waveform

C: INDUCTOR CURRENT, 1A/div

10µs/div

= 5V, LOAD = 100mA

OUT

EXT Drive Voltage Range

EXT swings from V+ to GND and provides the gate

drive for an external P-channel power MOSFET. A higher supply voltage increases the gate drive to the

MOSFET and reduces on-resistance (R

External Switching Transistor

section.

DS(ON)

Quiescent Current

The device’s typical quiescent current is 70µA.

However, actual applications draw additional current to

supply MOSFET switching currents, OUT pin current, or

external feedback resistors (if used), and both the diode

and capacitor leakage currents. For example, in the circuit of Figure 1, with V+ at 7V and V

at 5V, typical

OUT

no-load supply current for the entire circuit is 84µA.

When designing a circuit for high-temperature operation, select a Schottky diode with low reverse leakage.

Shutdown Mode

When SHDN is high, the device enters shutdown mode.

In this mode, the feedback and control circuit, reference,

and internal biasing circuitry are turned off. EXT goes

high, turning off the external MOSFET. The shutdown

supply current drops to less than 1µA. SHDN is a logiclevel input. Connect SHDN to GND for normal operation.

Reference

The 1.3V reference is suitable for driving external loads,

such as an analog-to-digital converter. It has a guaranteed 10mV maximum load regulation while sourcing load

currents up to 100µA. The reference is turned off during

). See

A

B

C

0A

CIRCUIT OF FIGURE 1, V+ = 8V, V

A: MOSFET DRAIN, 5V/div

B: OUT, 50mV/div, 5V DC OFFSET

C: INDUCTOR CURRENT, 1A/div

Figure 4. Continuous-Conduction Mode, Heavy-Load-Current

Waveform

10µs/div

= 5V, LOAD = 1.5A

OUT

shutdown. Bypass the reference with 0.1µF for normal

operation. Place the bypass capacitor within 0.2 inches

(5mm) of REF, with a direct trace to GND (Figure 7).

Soft-Start

Soft-start reduces stress and transient voltage slumps

on the power source. When the output voltage is near

ground, the minimum off-time is lengthened to limit peak

switching current. This compensates for reduced negative inductor current slope due to low output voltages.

________________Design Information

The MAX1626’s output voltage can be selected to 3.3V

or 5V under logic control by using the 3/5 pin. The 3/5

pin requires less than 0.5V to ensure a 3.3V output, or

more than (V+ - 0.5)V to guarantee a 5V output. The

voltage sense pin (OUT) must be connected to the output for the MAX1626.

The MAX1627’s output voltage is set using two resistors, R2 and R3 (Figure 5), which form a voltage divider

between the output and GND. R2 is given by:

where V

REF

has a maximum value of 50nA, large values (10kΩ to

200kΩ) can be used for R3 with no significant accuracy

loss. For 1% error, the current through R2 should be at

Setting the Output Voltage

R2= R3 x

V

V

OUT

REF

−

1

= 1.3V. Since the input bias current at FB

8 _______________________________________________________________________________________

Page 9

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

least 100 times FB’s input bias current. Capacitor C

is used to compensate the MAX1627 for even switching. Values between 0pF and 330pF work for many

applications. See the

Compensation

Stability and MAX1627 Feedback

section for details.

Current-Sense-Resistor Selection

The current-sense comparator limits the peak switching

current to VCS/R

SENSE

, where R

SENSE

is the value of

the current-sense resistor and VCSis the current-sense

threshold. VCSis typically 100mV, but can range from

85mV to 115mV. Minimizing the peak switching current

will increase efficiency and reduce the size and cost of

external components. However, since available output

current is a function of the peak switching current, the

peak current limit must not be set too low.

Set the peak current limit above 1.3 times the maximum

load current by setting the current-sense resistor to:

V

R =

CS

1.3 x I

CS(MIN)

OUT(MAX)

Alternatively, select the current-sense resistor for 5V

and 3.3V output applications using the current-sense

resistor graphs in Figures 6a and 6b. The current-sense

resistor’s power rating should be 20% higher than:

2

V

R =

POWER RATING (W)

CS MAX()

R

CS

Standard wire-wound resistors have an inductance

high enough to degrade performance, and are not recommended. Surface-mount (chip) resistors have very

little inductance and are well suited for use as current-

3.5

V

= 5V

OUT

3.0

2.5

2.0

1.5

1.0

MAXIMUM OUTPUT CURRENT (A)

0.5

0

4.5 5.55.0 6.0 1210 14 16

R

SENSE

R

SENSE

R

SENSE

R

SENSE

INPUT VOLTAGE (V)

= 0.03Ω

= 0.04Ω

= 0.05Ω

= 0.1Ω

R2

C

R2

FROM

OUTPUT

R2

TO FB

R3

Figure 5. Adjustable-Output Operation Using the MAX1627

sense resistors. Power metal-strip resistors feature

1/2W and 1W power dissipation, 1% tolerance, and

inductance below 5nH. Resistance values between

10mΩ and 500mΩ are available.

Inductor Selection

The essential parameters for inductor selection are

inductance and current rating. The MAX1626/MAX1627

operate with a wide range of inductance values. In many

applications, values between 10µH and 68µH take best

advantage of the controller’s high switching frequency.

Calculate the minimum inductance value as follows:

V+ - V

()

L =

(MIN)

(MAX) OUT

V

()

CS MIN

R

CS

where 2µs is the minimum on-time. Inductor values

between two and six times L

3.5

V

= 3.3V

OUT

3.0

2.5

2.0

1.5

1.0

MAXIMUM OUTPUT CURRENT (A)

0.5

0

3.0 4.03.5 4.5 1210 14 16

INPUT VOLTAGE (V)

are recommended.

(MIN)

R

= 0.03Ω

SENSE

R

= 0.04Ω

SENSE

R

= 0.05Ω

SENSE

R

= 0.1Ω

SENSE

xs

2µ

MAX1626/MAX1627

Figure 6a. MAX1626 5V-Operation Current-Sense Resistor

Graph

_______________________________________________________________________________________ 9

Figure 6b. MAX1626 3.3V-Operation Current-Sense Resistor

Graph

Page 10

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

With high inductor values, the MAX1626/MAX1627 will

begin continuous-conduction operation at a lower fraction of the full load (see

Detailed Description

). Low-value

inductors may be smaller and less expensive, but they

result in greater peak current overshoot due to currentsense comparator propagation delay. Peak-current

overshoot reduces efficiency and could cause the external components’ current ratings to be exceeded.

The inductor’s saturation and heating current ratings

must be greater than the peak switching current to prevent overheating and core saturation. Saturation occurs

when the inductor’s magnetic flux density reaches the

maximum level the core can support, and inductance

starts to fall. The heating current rating is the maximum

DC current the inductor can sustain without overheating.

The peak switching current is the sum of the current limit

set by the current-sense resistor and overshoot during

current-sense comparator propagation delay.

MAX1626/MAX1627

I =

PEAK

V

CS

R

CS

+−

VV 1s

()

+

OUT

L

×µ

1µs is the worst-case current-sense comparator propagation delay.

Inductors with a core of ferrite, Kool Mu™, METGLAS™,

or equivalent, are recommended. Powder iron cores

are not recommended for use with high switching

frequencies. For optimum efficiency, the inductor windings’ resistance should be on the order of the currentsense resistance. If necessary, use a toroid, pot-core,

KOOL Mu is a trademark of Magnetics.

METGLAS is a trademark of Allied Signal.

or shielded-core inductor to minimize radiated noise.

Table 1 lists inductor types and suppliers for various

applications.

External Switching Transistor

The MAX1626/MAX1627 drive P-channel enhancementmode MOSFETs. The EXT output swings from GND to

the voltage at V+. To ensure the MOSFET is fully on,

use logic-level or low-threshold MOSFETs when the

input voltage is less than 8V. Tables 1 and 2 list recommended suppliers of switching transistors.

Four important parameters for selecting a P-channel

MOSFET are drain-to-source breakdown voltage, current rating, total gate charge (Qg), and R

drain-to-source breakdown voltage rating should be at

least a few volts higher than V+. Choose a MOSFET

with a maximum continuous drain current rating higher

than the peak current limit:

V

CS MAX

I

D(MAX LIM MAX

I

≥=

)()

()

R

SENSE

The Qg specification should be less than 100nC to

ensure fast drain voltage rise and fall times, and reduce

power losses during transition through the linear region.

Qgspecifies all of the capacitances associated with

charging the MOSFET gate. EXT pin rise and fall times

vary with different capacitive loads, as shown in the

Typical Operating Characteristics

. R

DS(ON)

as low as practical to reduce power losses while the

MOSFET is on. It should be equal to or less than the

current-sense resistor.

DS(ON)

should be

. The

Table 1. Component Selection Guide

PRODUCTION

METHOD

Surface Mount

Miniature

Through-Hole

Low-Cost

Through-Hole

10 ______________________________________________________________________________________

INDUCTORS CAPACITORS DIODES

Sumida

CDRH125-470 (1.8A)

CDRH125-220 (2.2A)

CoilCraft

DO3316-473 (1.6A)

DO3340-473 (3.8A)

Sumida

RCH875-470M (1.3A)

CoilCraft

PCH-45-473 (3.4A)

AVX

TPS series

Sprague

595D series

Sanyo

OS-CON series

low-ESR organic

semiconductor

Nichicon

PL series

low-ESR electrolytics

United Chemi-Con

LXF series

Motorola

MBRS340T3

Nihon

NSQ series

Motorola

1N5817 to

1N5823

CURRENT-SENSE

RESISTORS

Dale

WSL series

IRC

LRC series

IRC

OAR series

Siliconix

Little Foot series

Motorola

medium-power

surface-mount products

Motorola

Motorola

TMOS power MOSFETs

MOSFETS

Page 11

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

Table 2. Component Suppliers

COMPANY PHONE FAX

AVX USA or (803) 626-3123

Coilcraft USA (847) 639-6400 (847) 639-1469

Coiltronics USA (516) 241-7876 (516) 241-9339

Dale USA (605) 668-4131 (605) 665-1627

International

Rectifier

IRC USA (512) 992-7900 (512) 992-3377

Motorola USA (602) 303-5454 (602) 994-6430

Nichicon USA (847) 843-7500 (847) 843-2798

Nihon USA (805) 867-2555 (805) 867-2698

Sanyo USA (619) 661-6835 (619) 661-1055

Siliconix USA or (408) 970-3950

Sprague USA (603) 224-1961 (603) 224-1430

Sumida USA (847) 956-0666 (847) 956-0702

United

Chemi-Con

USA (310) 322-3331 (310) 322-3332

Japan 81-7-5231-8461 81-7-5256-4158

Japan 81-3-3494-7411 81-3-3494-7414

Japan 81-7-2070-6306 81-7-2070-1174

Japan 81-3-3607-5111 81-3-3607-5144

USA (714) 255-9500 (714) 255-9400

The MAX1626/MAX1627’s high switching frequency

demands a high-speed rectifier. Schottky diodes, such

as the 1N5817–1N5822 family or surface-mount equivalents, are recommended. Ultra-high-speed rectifiers

with reverse recovery times around 50ns or faster, such

as the MUR series, are acceptable. Make sure that the

diode’s peak current rating exceeds the peak current

limit set by R

SENSE

exceeds V+. Schottky diodes are preferred for heavy

loads due to their low forward voltage, especially in

low-voltage applications. For high-temperature applications, some Schottky diodes may be inadequate due to

their high leakage currents. In such cases, ultra-highspeed rectifiers are recommended, although a Schottky

diode with a higher reverse voltage rating can often

provide acceptable performance.

Choose filter capacitors to service input and output

peak currents with acceptable voltage ripple.

Equivalent series resistance (ESR) in the capacitor is a

major contributor to output ripple, so low-ESR capacitors are recommended. Sanyo OS-CON capacitors are

(803) 946-0690

(800) 282-4975

(408) 988-8000

(800) 554-5565

Diode Selection

, and that its breakdown voltage

Capacitor Selection

best, and low-ESR tantalum capacitors are second

best. Low-ESR aluminum electrolytic capacitors are tolerable, but do not use standard aluminum electrolytic

capacitors.

Voltage ripple is the sum of contributions from ESR and

the capacitor value:

V

≈+

RIPPLE

VV

,,

RIPPLE ESR RIPPLE C

To simplify selection, assume initially that two-thirds of

the ripple results from ESR and one-third results from

capacitor value. Voltage ripple as a consequence of

ESR is approximated by:

V

RIPPLE,ESR

≈ ()()R

ESRIPEAK

Estimate input and output capacitor values for given

voltage ripple as follows:

2

1

LI

∆

L

2

=

VV

,

RIPPLE CIN IN

=

VV

RIPPLE COUT OUTININ OUT

2

1

LI

∆

L

2

,

V

−

VV

is the change in inductor current (around

under moderate loads).

where I

0.5I

PEAK

C

IN

C

OUT

∆L

These equations are suitable for initial capacitor selection; final values should be set by testing a prototype or

evaluation kit. When using tantalum capacitors, use

good soldering practices to prevent excessive heat

from damaging the devices and increasing their ESR.

Also, ensure that the tantalum capacitors’ surge-current

ratings exceed the start-up inrush and peak switching

currents.

Pursuing output ripple lower than the error comparator’s hysteresis (0.5% of the output voltage) is not practical, since the MAX1626/MAX1627 will switch as

needed, until the output voltage crosses the hysteresis

threshold. Choose an output capacitor with a working

voltage rating higher than the output voltage.

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on V+ and CS, caused by the circuit’s switching

action. Use a low-ESR capacitor. Two smaller-value

low-ESR capacitors can be connected in parallel for

lower cost. Choose input capacitors with working voltage ratings higher than the maximum input voltage.

Place a surface-mount ceramic capacitor very close to

V+ and GND, as shown in Figure 7. This capacitor

bypasses the MAX1626/MAX1627, and prevents spikes

and ringing on the power source from obscuring the

MAX1626/MAX1627

______________________________________________________________________________________ 11

Page 12

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

current feedback signal and causing jitter. 0.47µF is

recommended. Increase the value as necessary in

high-power applications.

Bypass REF with 0.1µF. This capacitor should be

placed within 0.2 inches (5mm) of the IC, next to REF,

with a direct trace to GND (Figure 7).

Layout Considerations

High-frequency switching regulators are sensitive to PC

board layout. Poor layout introduces switching noise into

the current and voltage feedback signals, resulting in jitter, instability, or degraded performance. The currentsense resistor must be placed within 0.2 inches (5mm)

of the controller IC, directly between V+ and CS. Place

voltage feedback resistors (MAX1627) next to the FB pin

(no more than 0.2") rather than near the output. Place

the 0.47µF input and 0.1µF reference bypass capacitors

within 0.2 inches (5mm) of V+ and REF, and route

directly to GND. Figure 7 shows the recommended lay-

MAX1626/MAX1627

out and routing for these components.

High-power traces, highlighted in the

Circuit

(Figure 1), should be as short and as wide as

possible. The supply-current loop (formed by C2, C3,

R

, U1, L1, and C1) and commutation-current loop

SENSE

(D1, L1, and C1) should be as tight as possible to

reduce radiated noise. Place the anode of the commutation diode (D1) and the ground pins of the input and

output filter capacitors close together, and route them to

a common “star-ground” point. Place components and

route ground paths so as to prevent high currents from

causing large voltage gradients between the ground pin

of the output filter capacitor, the controller IC, and the

reference bypass capacitor. Keep the extra copper on

the component and solder sides of the PC board, rather

than etching it away, and connect it to ground for use as

a pseudo-ground plane. Refer to the MAX1626

Evaluation Kit manual for a two-layer PC board example.

Typical Operating

Stability and MAX1627 Feedback

Compensation

Use proper PC board layout and recommended external components to ensure stable operation. In oneshot, sequenced PFM DC-DC converters, instability is

manifested as “Motorboat Instability.” It is usually

caused by excessive noise on the current or voltage

feedback signals, ground, or reference, due to poor PC

board design or external component selection.

Motorboat instability is characterized by grouped

switching pulses with large gaps and excessive lowfrequency output ripple. It is normal to see some

grouped switching pulses during the transition from

discontinuous to continuous current mode. This effect

is associated with small gaps between pulse groups

MAX1626

4x

SCALE

C

REF

C

V+ BYPASS

Figure 7. Recommended Placement and Routing of the

Current-Sense Resistor, 0.1µF Reference, and 0.47µF Input

Bypass Capacitors

and output ripple similar to or less than that seen during no-load conditions.

Instability can also be caused by excessive stray capacitance on FB when using the MAX1627. Compensate for

this by adding a 0pF to 330pF feed-forward capacitor

across the upper feedback resistor (R2 in Figure 5).

MAX1626/MAX1627 vs.

MAX1649/MAX1651 vs.

MAX649/MAX651

The MAX1626/MAX1627 are specialized, third-generation upgrades to the MAX649/MAX651 step-down controllers. They feature improved efficiency, a reduced

current-sense threshold (100mV), soft-start, and a

100% duty cycle for lowest dropout. The MAX649/

MAX651 have a two-step (210mV/110mV) currentsense threshold. The MAX1649/MAX1651 are secondgeneration upgrades with a 96.5% maximum duty cycle

for improved dropout performance and a reduced current-sense threshold (110mV) for higher efficiency,

especially at low input voltages. The MAX1649/

MAX1651 are preferable for special applications where

a 100% duty cycle is undesirable, such as flyback and

SEPIC circuits.

Since the MAX1626’s pinout is similar to those of the

MAX649 and MAX1649 family parts, the MAX1626 can

be substituted (with minor external component value

changes) into fixed-output mode applications, provided

the PC board layout is adequate. The MAX1627 can

also be substituted when MAX649 or MAX1649 family

parts are used in adjustable mode, but the feedback

resistor values must be changed, since the MAX1627

has a lower reference voltage (1.3V vs. 1.5V). Reduce

the current-sense resistor value by 50% when substituting for the MAX649 or MAX651.

R

SENSE

12 ______________________________________________________________________________________

Page 13

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

INPUT

68µF LOW-ESR

TANTALUM

C2

68µF LOW-ESR

TANTALUM

C3

C5

0.47µF

INPUT

68µF LOW-ESR

TANTALUM

C2

C3

0.47µF

MAX1626/MAX1627

V+

R

SENSE

0.15Ω

U1

LOGIC-LEVEL MOSFET

P

22µH, 3A

D1

L1: SUMIDA CDRH125-220

D1: NIHON NSQ03A03

C

R2

U1: MOTOROLA MMSF3P02HD

L1

ADJUSTABLE

OUTPUT

C1

220µF

LOW-ESR

TANTALUM

0.1µF

C4

N.C.

MAX1627

OUT

SHDN

REF

GND FB

CS

EXT

R3 R2

Figure 8. MAX1627 Typical Operating Circuit

________________________Applications

The MAX1626/MAX1627 typical operating circuits

(Figures 1 and 8) are designed to output 2A at a 5V

output voltage. The following circuits provide examples

and guidance for other applications.

When designing a low-power, battery-based application, choose an external MOSFET with low gate capacitance (to minimize switching losses), and use a low

peak current limit to reduce I2R losses. The circuit in

Figure 9 is optimized for 0.5A.

The circuit in Figure 10 outputs 6A at 2.5V from a 5V or

3.3V input. High-current design is difficult, and board

layout is critical due to radiated noise, switching transients, and voltage gradients on the PC board traces.

Figure 11 is a recommended PC board design. Choose

the external MOSFET to minimize R

gate-charge factor below the MAX1626/MAX1627’s

drive capability (see Ext Rise and Fall Times vs.

Capacitance graph in the

Characteristics

and fall times will contribute to efficiency losses. For

higher efficiencies, especially at low output voltages,

the MAX796 family of step-down controllers with synchronous rectification is recommended.

Micropower Step-Down Converter

High-Current Step-Down Converter

. Keep the

DS(ON)

Typical Operating

). Otherwise, increased MOSFET rise

V+

MAX1626

0.1µF

3/5

SHDN

REF

C4

GND

CS

EXT

OUT

D1

Figure 9. 0.5A Step-Down Converter

3V TO 6V

INPUT

MAX1627

GND

21.5k, 1%

R3

100µF

C5

C6

0.1µF

V+

CS

EXT

FB

Q1

LOGIC-LEVEL MOSFET

P

2.7µH >8A

D1

R2

20k, 1%

C1–C3: SANYO OS-CON 220µF, 6.3V

C

R2

C4, C5: SANYO OS-CON 100

220pF

RCS1, RCS2: 0.025Ω DALE WSL-2512

Q1: MOTOROLA MTB50PO3HDL

D1: NIEC C10T04Q

L1: SUMIDA CDRH127-2R7NC

C10

0.1µF

100µF

N.C.

C4

OUT

SHDN

REF

Figure 10. 6A Step-Down Converter

R

SENSE

0.15Ω

U1

LOGIC-LEVEL MOSFET

P

L1

68µH, 0.7A

L1: SUMIDA CDR1053-680

D1: MOTOROLA MBRS130T3

U1: MOTOROLA MMSF3P02HD

C8

C7

1.0µF

0.1µF

R

, R

CS1

CS2

0.025Ω

L1

C2

C1

220µF

220µF

OUTPUT

C1

100µF

LOW-ESR

TANTALUM

C9

1.0µF

OUTPUT

2.5V, 6A

C3

220µF

µF, 20V

______________________________________________________________________________________ 13

Page 14

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

VIA

VIAS

MAX1626/MAX1627

VIA

COMPONENT PLACEMENT GUIDE—COMPONENT SIDE

COPPER ROUTING—BACK SIDE

COPPER ROUTING—FRONT SIDE

Figure 11. Recommended PC Board Design for 6A Step-Down Converter

14 ______________________________________________________________________________________

Page 15

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

___________________Chip Topography

GNDGNDOUT

EXT

3/5

(FB)

0.105"

(2.63mm)

MAX1626/MAX1627

SHDN

REF

0.081"

(2.06mm)

( ) ARE FOR MAX1627

TRANSISTOR COUNT: 375

SUBSTRATE CONNECTED TO V+

CS

V

CC

______________________________________________________________________________________ 15

Page 16

5V/3.3V or Adjustable, 100% Duty-Cycle,

High-Efficiency, Step-Down DC-DC Controllers

________________________________________________________Package Information

INCHES MILLIMETERS

DIM

D

A

0.101mm

e

A1

B

MAX1626/MAX1627

0.004in.

HE

C

L

Narrow SO

SMALL-OUTLINE

PACKAGE

(0.150 in.)

0°-8°

A1

DIM

D

D

D

A

B

C

E

e

H

L

PINS

MAX

MIN

0.069

0.053

0.010

0.004

0.019

0.014

0.010

0.007

0.157

0.150

0.228

0.016

8

14

16

0.244

0.050

INCHES MILLIMETERS

MIN

MAX

0.189

0.197

0.337

0.344

0.386

0.394

MIN

1.35

0.10

0.35

0.19

3.80

5.80

0.40

MIN

4.80

8.55

9.80

1.270.050

MAX

1.75

0.25

0.49

0.25

4.00

6.20

1.27

MAX

5.00

8.75

10.00

21-0041A

16 ______________________________________________________________________________________

Page 17

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...