General Description

The MAX1407/MAX1408/MAX1409/MAX1414 are lowpower, general-purpose, multichannel data-acquisition

systems (DAS). These devices are optimized for lowpower applications. All the devices operate from a single +2.7V to +3.6V power supply and consume a

maximum of 1.15mA in Run mode and only 2.5µA in

Sleep mode.

The MAX1407/MAX1408/MAX1414 feature a differential

8:1 input multiplexer to the ADC, a programmable

three-state digital output, an output to shutdown an

external power supply, and a data ready output from

the ADC. The MAX1408 has eight auxiliary analog

inputs, while the MAX1407/MAX1414 include four auxiliary analog inputs and two 10-bit force/sense DACs.

The MAX1414 features a 50mV trip threshold for the

signal-detect comparator while the others have a 0mV

trip threshold. The MAX1409 is a 20-pin version of the

DAS family with a differential 4:1 input multiplexer to the

ADC, one auxiliary analog input, and one 10-bit

force/sense DAC.

The MAX1407/MAX1408/MAX1414 are available in

space-saving 28-pin SSOP packages, while the

MAX1409 is available in a 20-pin SSOP package.

Applications

Medical Instruments

Industrial Control Systems

Portable Equipment

Data-Acquisition System

Automatic Testing

Robotics

Features

♦ +2.7V to +3.6V Supply Voltage Range in Standby,

Idle, and Run Mode (Down to 1.8V in Sleep Mode)

♦ 1.15mA Run Mode Supply Current

♦ 2.5µA Sleep Mode Supply Current (Wake-Up, RTC,

and Voltage Monitor Active)

♦ Multichannel 16-Bit Sigma-Delta ADC

±1.5 LSB (typ) Integral Nonlinearity

30Hz or 60Hz Continuous Conversion Rate

Buffered or Unbuffered Mode

Gain of +1/3, +1, or +2V/V

Unipolar or Bipolar Mode

On-Chip Offset Calibration

♦ 10-Bit Force/Sense DACs

♦ Buffered 1.25V, 18ppm/°C (typ) Bandgap

Reference Output

♦ SPI™/QSPI™ or MICROWIRE™-Compatible Serial

Interface

♦ System Support Functions

RTC (Valid til 9999) and Alarm

High-Frequency PLL Clock Output (2.4576MHz)

+1.8V and +2.7V RESET and Power-Supply

Voltage Monitors

Signal Detect Comparator

Interrupt Generator (INT and DRDY)

Three-State Digital Output

Wake-Up Circuitry

♦ 28-Pin SSOP (MAX1407/MAX1408/MAX1414),

20-Pin SSOP (MAX1409)

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

________________________________________________________________ Maxim Integrated Products 1

19-2229; Rev 0; 10/01

Pin Configurations continued at end of data sheet.

Typical Operating Circuit appears at end of data sheet.

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

Ordering Information

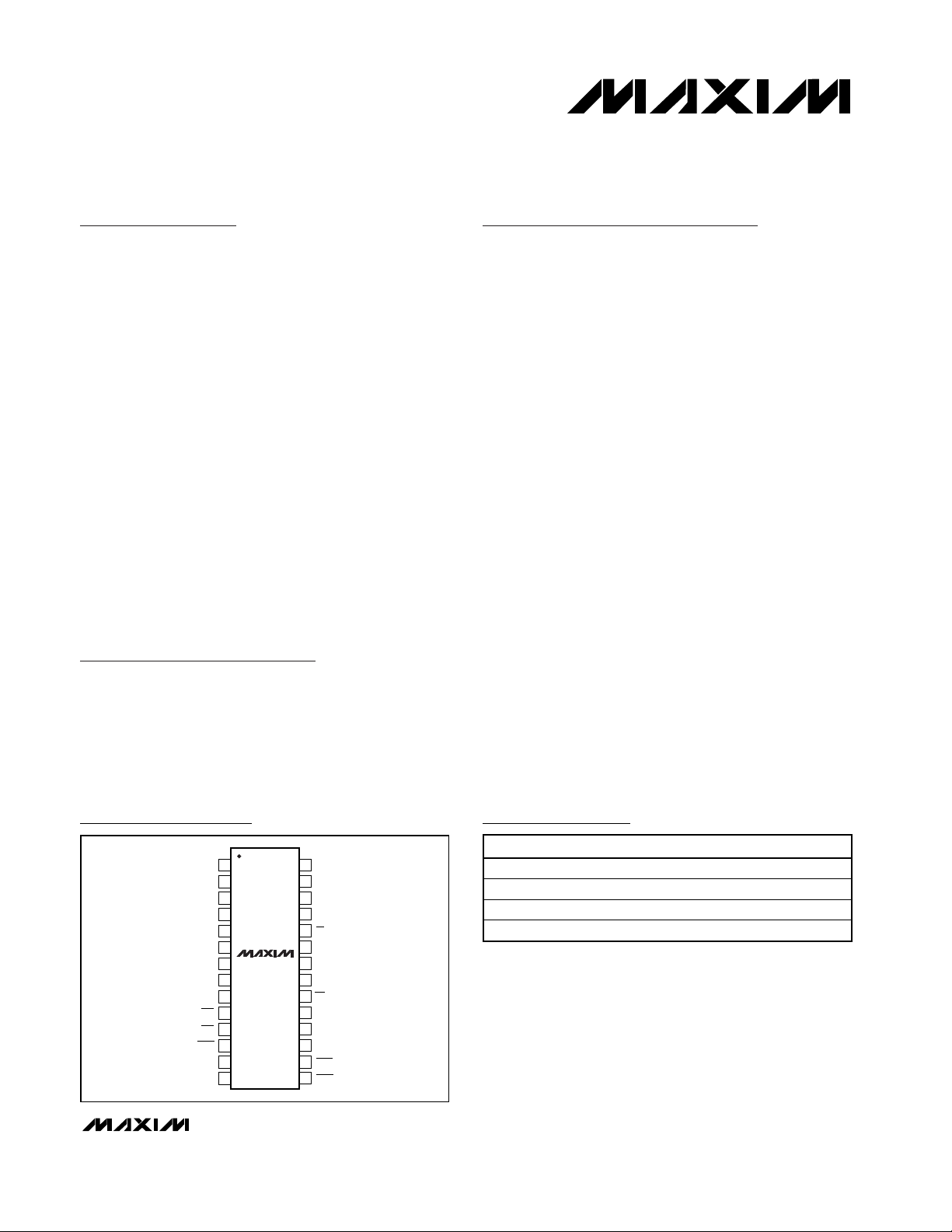

Pin Configurations

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

TOP VIEW

FB2

FB1

OUT1

REF

AGND

AV

CPLL

WU1

WU2

RESET

1

2

DO

3

4

5

IN0

6

7

MAX1407

MAX1414

8

DD

9

10

11

12

13

IN1

14

IN2

28

OUT2

27

IN3

26

DV

DD

25

DGND

24

CS

23

SCLK

22

DIN

21

DOUT

20

INT

19

CLKIN

18

CLKOUT

17

FOUT

16

DRDY

15

SHDN

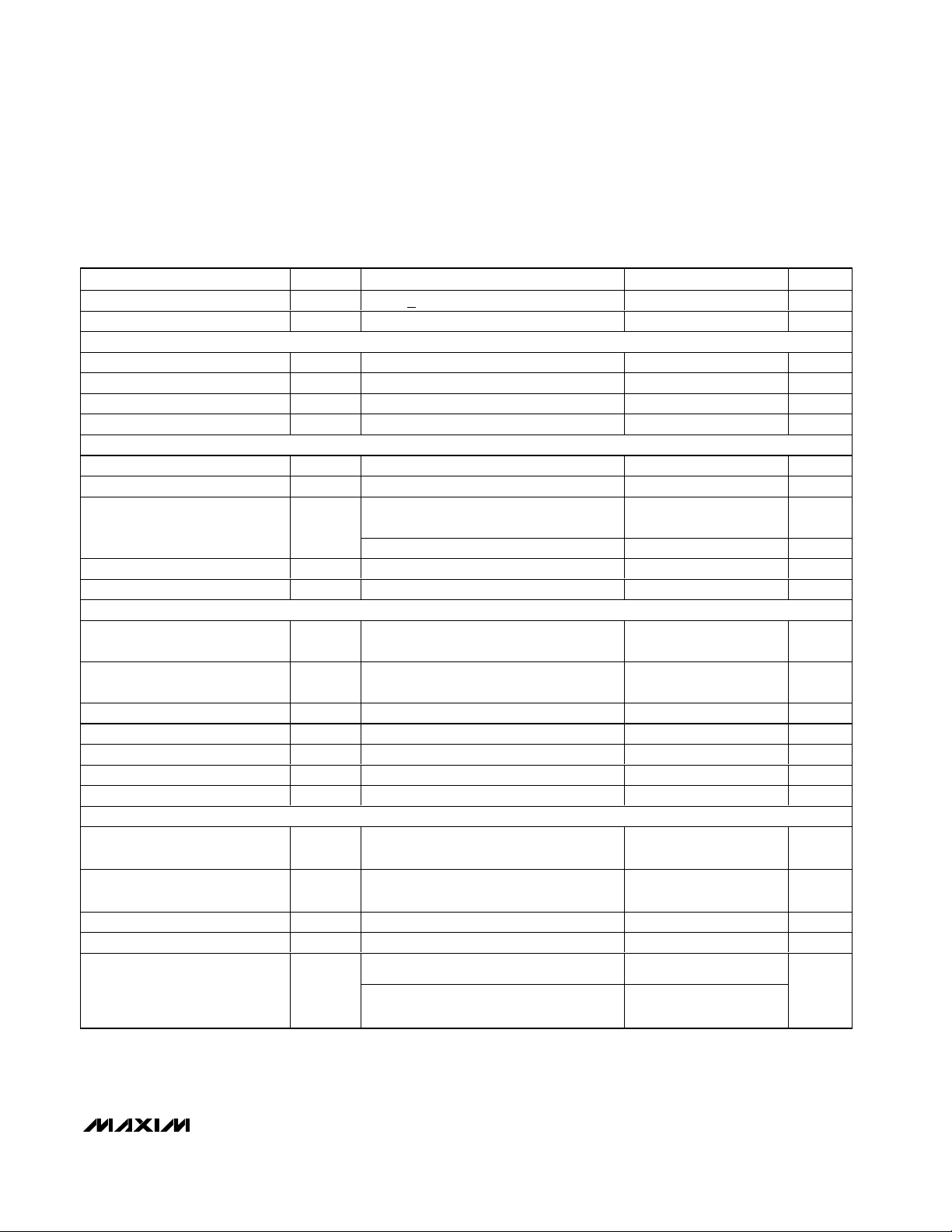

PART TEMP. RANGE PIN-PACKAGE

MAX1407CAI 0°C to +70°C 28 SSOP

MAX1408CAI 0°C to +70°C 28 SSOP

MAX1409CAP 0°C to +70°C 20 SSOP

MAX1414CAI 0°C to +70°C 28 SSOP

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVDDto AGND .........................................................-0.3V to +6V

AV

DD

to DVDD...................................................... -0.3V to +0.3V

Analog Inputs to AGND .........................-0.3V to +(AV

DD

+ 0.3V)

Digital Inputs to DGND.............................................-0.3V to +6V

Maximum Current Input Into Any Pin ..................................50mA

Continuous Power Dissipation (T

A

= +70°C)

20-Pin SSOP (derate 8.0mW/°C above +70°C) ...........640mW

28-Pin SSOP (derate 9.52mW/°C above +70°C) .........762mW

DV

DD

to DGND.........................................................-0.3V to +6V

AGND to DGND.....................................................-0.3V to +0.3V

Analog Outputs to AGND ......................-0.3V to +(AV

DD

+ 0.3V)

Digital Outputs to DGND .......................-0.3V to +(AV

DD

+ 0.3V)

REF to AGND.........................................-0.3V to +(AV

DD

+ 0.3V)

Operating Temperature Range:

MAX14__CA_ ......................................................0°C to +70°C

MAX14__EA_ ...................................................-40°C to +85°C

Lead Temperature (soldering, 10s) ................................+300 °C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

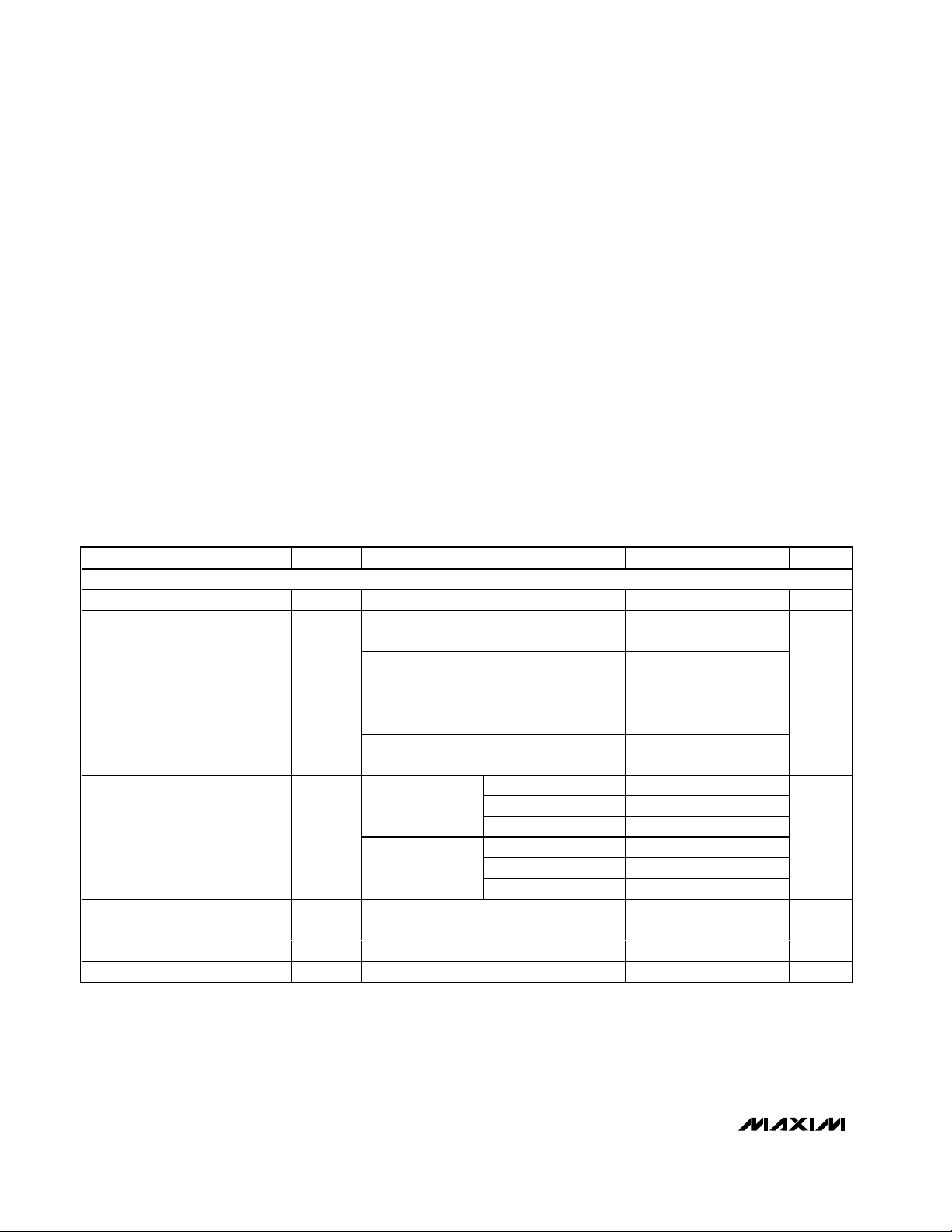

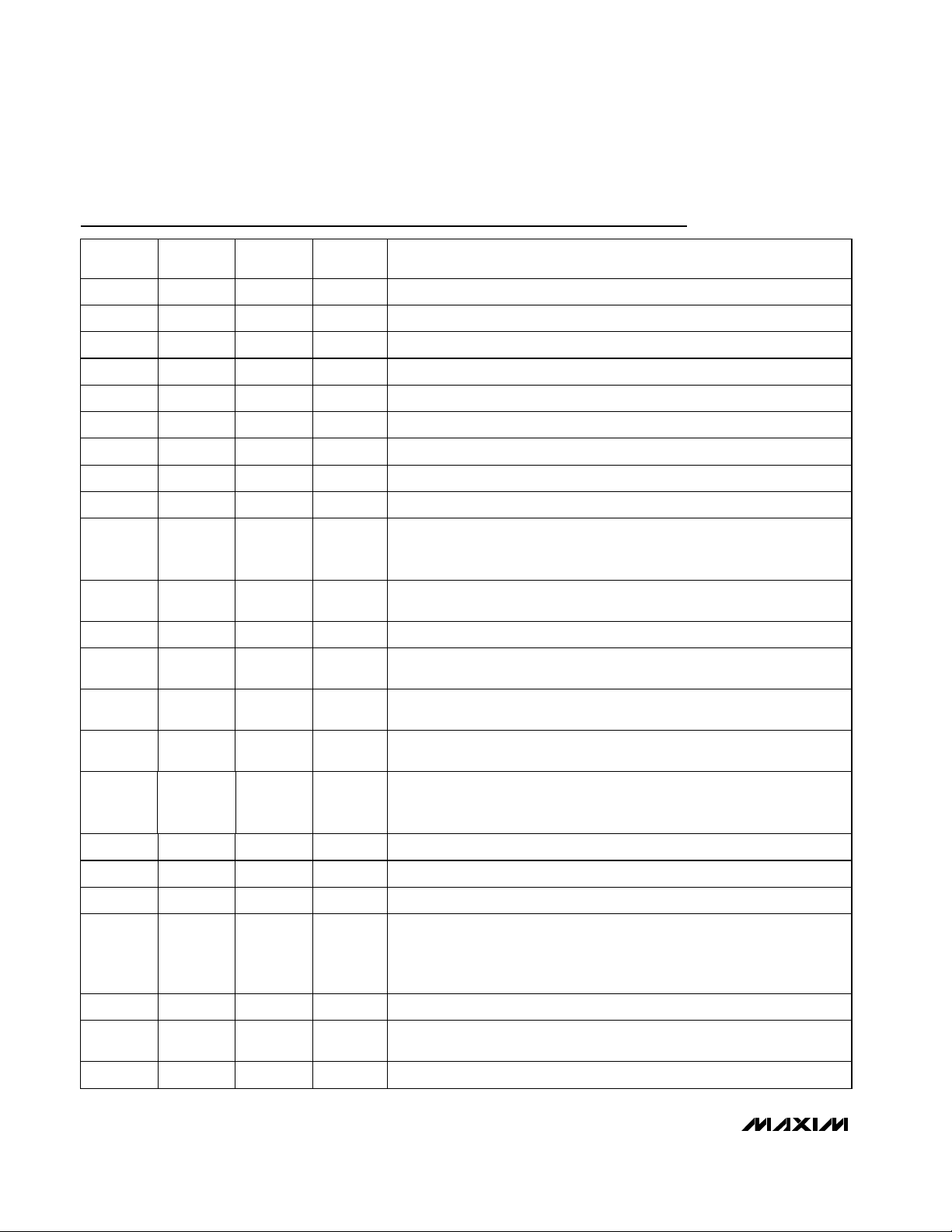

ELECTRICAL CHARACTERISTICS

(DVDD= AVDD= +2.7V to 3.6V, 4.7µF at REF, internal V

REF

, 18nF between CPLL and AVDD, 32.768kHz crystal across CLKIN and

CLKOUT, T

A

= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

ADC ACCURACY

Resolution (No Missing Codes) RES 16 Bits

Integral Nonlinearity INL

Output RMS Noise (Note 1)

Offset Error On-chip calibration removes this error ±1 % of FS R

Offset Drift ±0.5 µV/°C

Gain Error Excludes offset and reference errors ±1 % of FS R

Gain Drift Excludes offset and reference errors ±1 p p m /° C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX U N I T S

Unbuffered mode, Unipolar mode, gain = 1,

V

NEG

U nb uffer ed m od e, U ni p ol ar m od e, g ai n = 2,

V

N E G

Unbuffered mode, Bipolar mode, gain = 1,

V

NEG

Buffered mode, Bipolar mode, gain = 2,

V

NEG

Unipolar

Bipolar Mode

= 0.2V, fully differential input (Note 7)

= 0.625V , p seud o- d i ffer enti al i np ut

= 0.625V, fully differential input

= 0.625V, fully differential input

1.5 3.5

1.75

1.70

2.50

Gain = 2 ±5

Gain = 1 ±10

Gain = 1/3 ±30

Gain = 2 ±8

Gain = 1 ±16.5

Gain = 1/3 ±48.5

LSB

µV

RMS

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

_______________________________________________________________________________________ 3

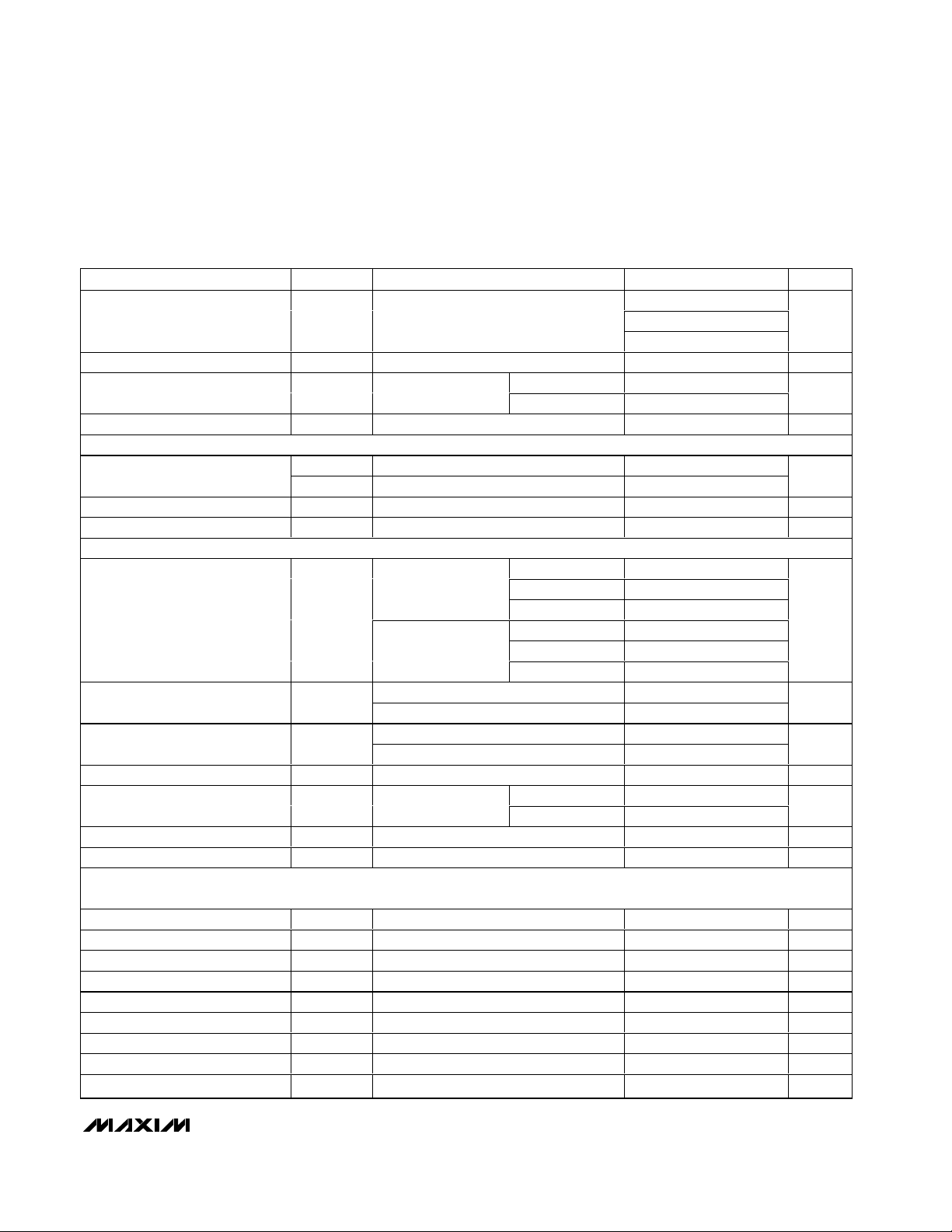

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to 3.6V, 4.7µF at REF, internal V

REF

, 18nF between CPLL and AVDD, 32.768kHz crystal across CLKIN and

CLKOUT, T

A

= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Power-Supply Rejection Ratio Gain = 1, unipolar and buffered mode 70 dB

Output Update Rate

Turn-On Time Excluding reference 50 µs

SIGNAL DETECT COMPARATOR

Differential Input-Detection

Threshold Voltage

Common-Mode Input Voltage

Turn-On Time 10 µs

ANALOG INPUTS

Differential Input Voltage Range

Absolute Input Voltage Range

Common-Mode Input Voltage

Range

Common-Mode Rejection Ratio Gain = 1, unipolar and buffered mode 90 dB

Input Sampling Rate FOUT = 2.4576MHz

Input Current Buffered mode ±0.5 nA

Input Capacitance 15 pF

F O R C E- SEN SE D A C ( al l m easur em ents m ad e w i th FB1( 2) shor ted to O U T1( 2) , unl ess other w i se noted ) .

( M AX 1407/M AX 1409/M AX 1414 onl y)

Resolution 10 Bits

Differential Nonlinearity Guaranteed monotonic (Note 2) ±1.0 LSB

Integral Nonlinearity (Note 2) ±1.0 LSB

Offset Error (Note 3) ±20 mV

Offset Drift ±5 µV/°C

Gain Error Excludes offset and reference drift 3.6 mV

Gain Drift Excludes offset and reference drift 10 ppm/°C

Line Regulation 190 µV/V

Current into FB1(2) ±0.5 nA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX U N I T S

Continuous

conversion

MAX1407/MAX1408/MAX1409 -10 0 10

MAX1414 44 50 56

Unipolar mode

Bipolar mode

Unbuffered -0.05 AV

Buffered 0.05 1.40

Unbuffered AGND AV

Buffered 0.05 1.40

1/3

1PGA Gain See PGA Gain section

2

RATE bit = 0 30

RATE bit = 1 60

0 0.8 V

ADC gain = 1 0 V

ADC gain = 2 0 V

ADC gain = 1/3 0 AV

ADC gain = 1 -V

ADC gain = 2 -V

ADC gain = 1/3 -AV

30Hz data rate 15.360

60Hz data rate 30.720

REF

REF/2

DD

REF/2

V

V

REF/2

AV

REF

DD

REF

DD

DD

DD

kHz

V/V

Hz

mV

V

V

V

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

4 _______________________________________________________________________________________

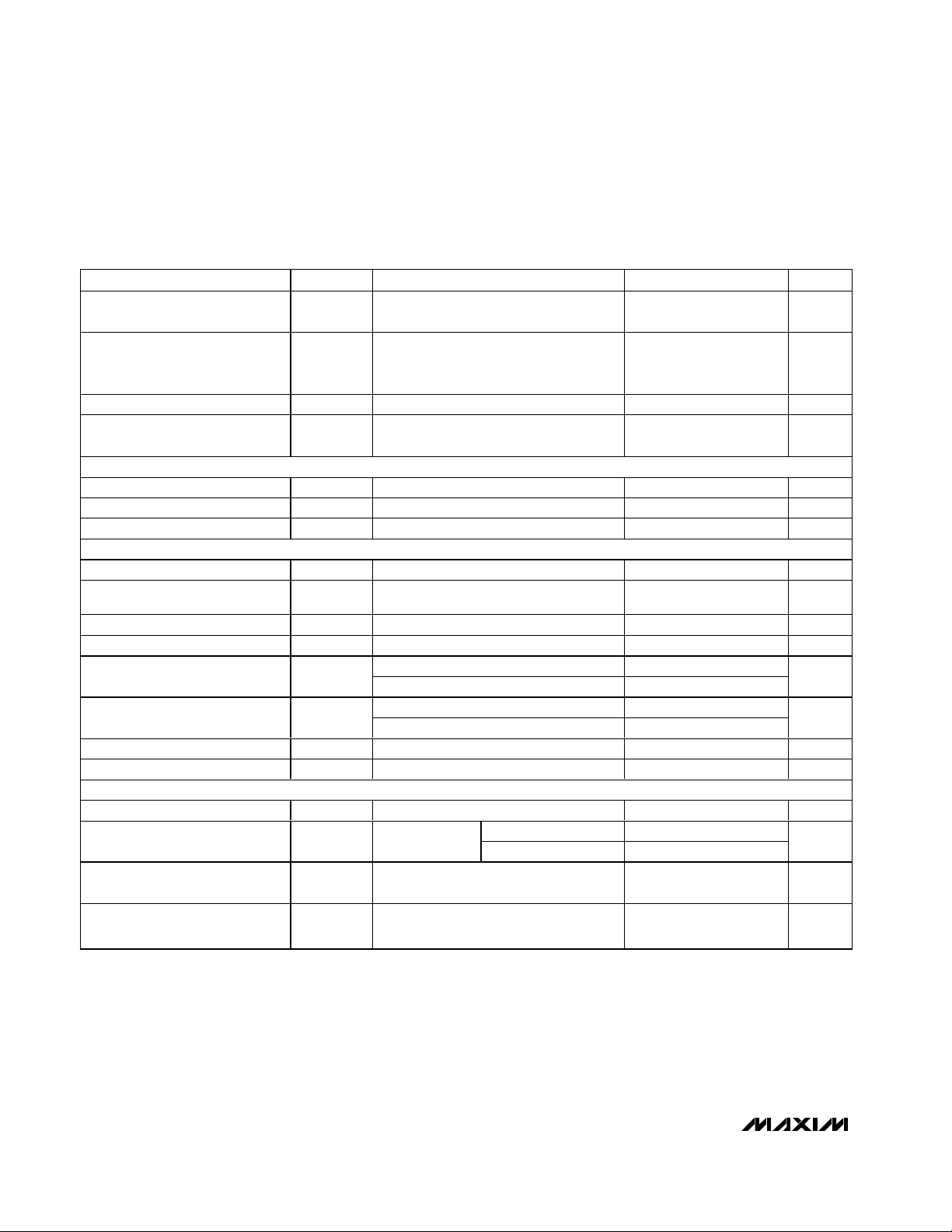

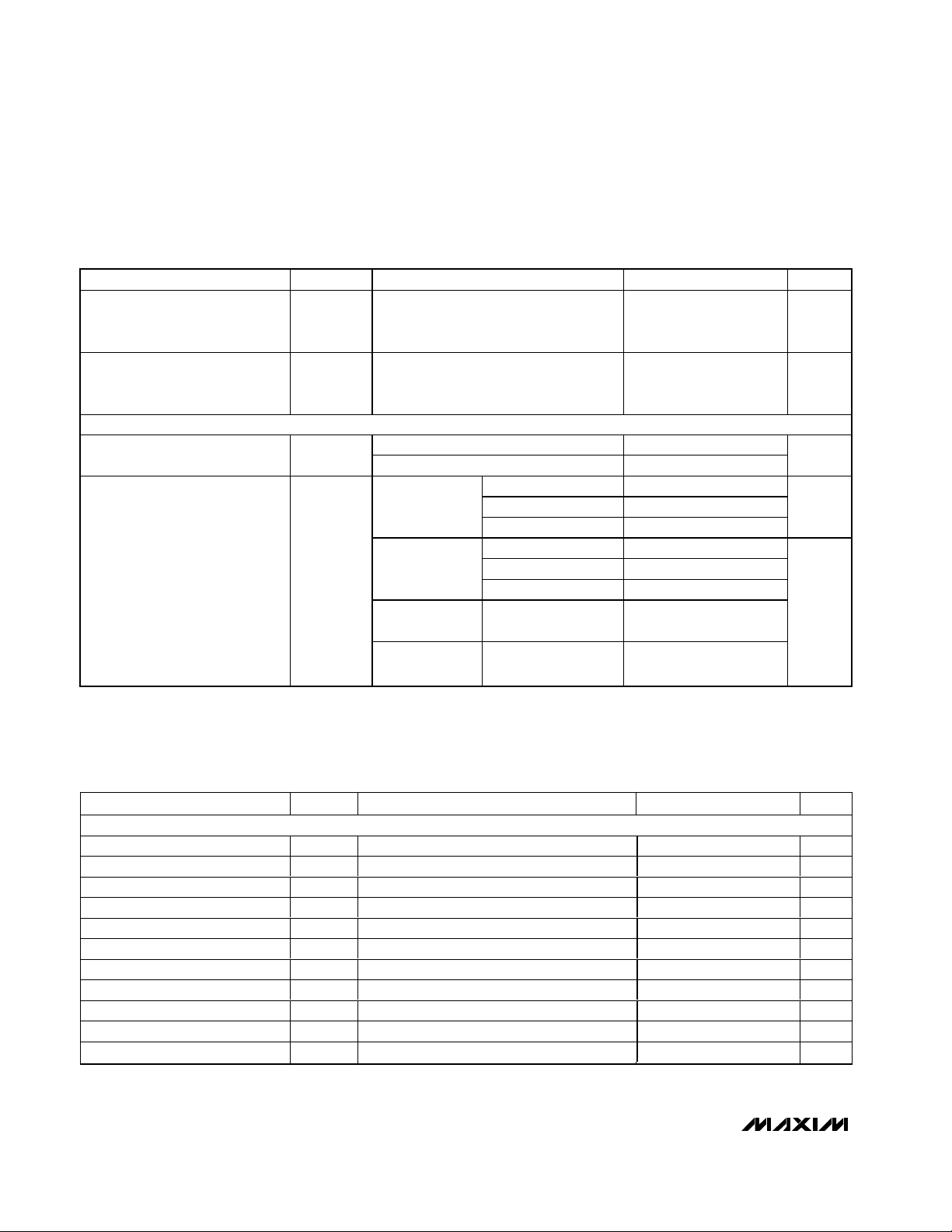

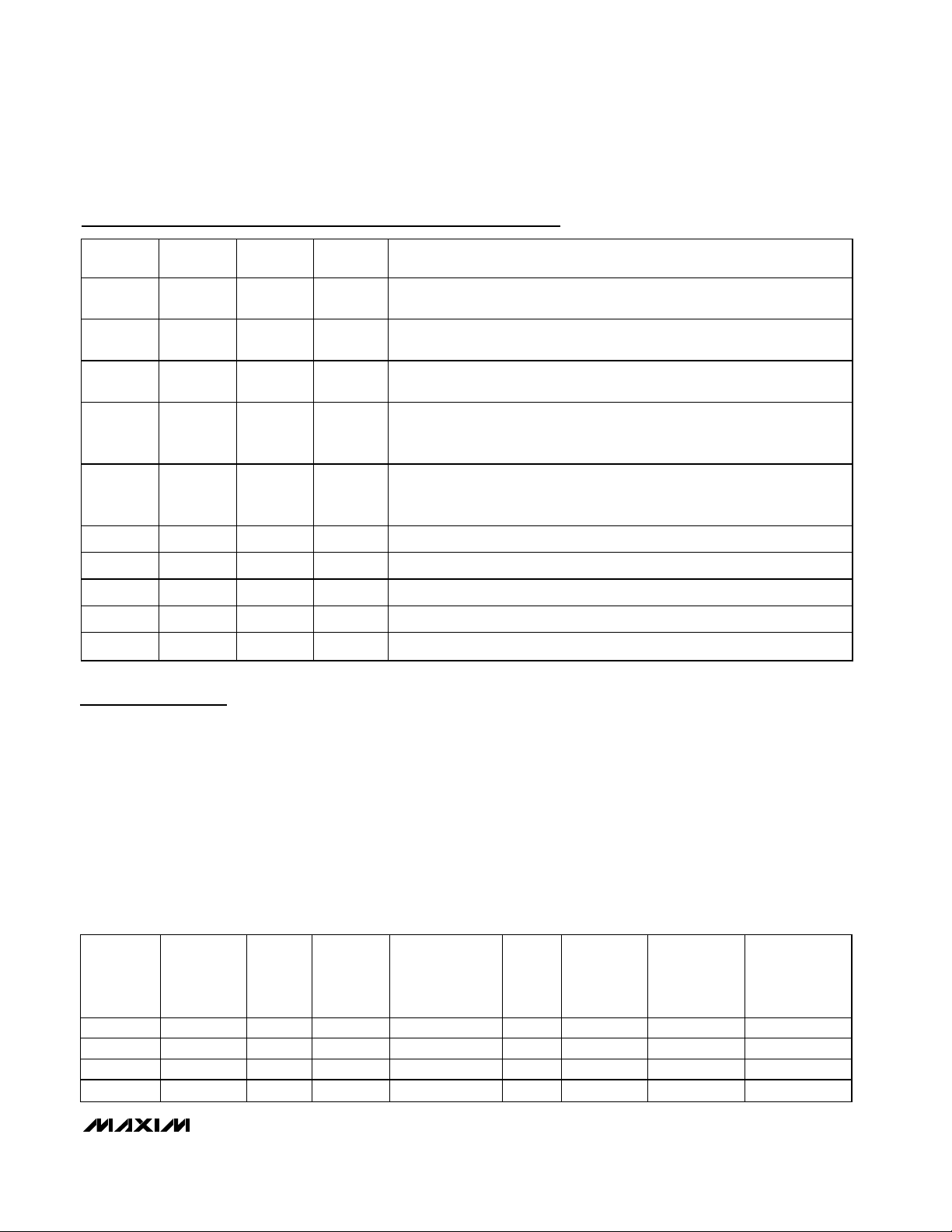

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to 3.6V, 4.7µF at REF, internal V

REF

, 18nF between CPLL and AVDD, 32.768kHz crystal across CLKIN and

CLKOUT, T

A

= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

Output Slew Rate

Output Settling Time

Turn-On Time 100 µs

OUT1, OUT2 Output Range No Load (Note 4) 0.05

EXTERNAL REFERENCE (internal reference powered down)

Input Voltage Range 1.25 ±0.10 V

Input Resistance 540 kΩ

Input Current 2.3 µA

INTERNAL REFERENCE (AVDD = 3V, unless otherwise noted)

Output Voltage TA = +25°C 1.225 1.25 1.275 V

Output Voltage Temperature

Coefficient

Output Short-Circuit Current 3.4 mA

Line Regulation ∆V

Load Regulation

Noise Voltage e

Power-Supply Rejection Ratio ±100mV, f = 120Hz 70 dB

Turn-On Time 3ms

µP RESET

Supply Voltage Range For valid RESET 1 3.6 V

RESET Trip Threshold Low V

Low AVDD Trip Threshold

RESET Output Low Voltage

(Open-Drain Output)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX U N I T S

010hex to 3FFhex and 3FFhex to 010hex

cod e sw i ng , R

To ±1/2 LSB (at 10-bit accuracy) of fullscale with code transition from 010hex

to 3FFhex, R

/∆V DD2.7<AVDD<3.6V 80 µV/V

RE F

I

SOURCE

I

SINK

OUT

TH

0.1Hz to 10Hz 40

10Hz to 10kHz 400

AVDD falling

For Normal, Idle, and Standby modes,

AV

I

SINK

= 12kΩ , C L = 200p F

L

= 12kΩ, CL = 200pF

L

= 0µA to 500µA, TA = +25°C1

= 0µA to 50µA, TA = +25°C2

Bit VM = 1 1.800 1.865 1.930

Bit VM = 0 2.70 2.75 2.80

falling

DD

= 1mA, AVDD = 1.8V 0.4 V

2.70 2.75 2.80 V

18.0 V/ms

65 µs

AV

DD

- 0.2

18 p p m /° C

V

µV/µA

µVp-p

V

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to 3.6V, 4.7µF at REF, internal V

REF

, 18nF between CPLL and AVDD, 32.768kHz crystal across CLKIN and

CLKOUT, T

A

= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

RESET Output Leakage AVDD > VTH, RESET deasserted 0.002 0.1 µA

Turn-On Time 2ms

CRYSTAL OSCILLATOR

Crystal Frequency AVDD = +3V 32.768 kHz

Crystal Load Capacitance 6pF

Oscillator Stability AV

Oscillator Startup Time 1.5 s

PLL

FOUT Frequency AVDD = +3V 2.4576 MHz

Absolute Clock Jitter Cycle-to-cycle 10 ns

Frequency Tolerance/Stability

FOUT Rise/Fall Time 20% to 80% waveform, CL = 30pF 15 30 ns

Duty Cycle 40 50 60 %

DIGITAL INPUTS (DIN, SCLK, CS, WU1, WU2)

Input High Voltage DVDD = +1.8V to +3.6V

Input Low Voltage DVDD = +1.8V to +3.6V

Input Hysteresis DVDD = +3V 200 mV

DIN, SCLK, CS, Input Current VIN = 0 or VIN = DV

WU1, WU2 Input Current VIN = AV

WU1, WU2 Pullup Current VIN = 0 10 µA

Input Capacitance 10 pF

DIGITAL OUTPUTS (DOUT, FOUT, INT, DRDY, SHDN, D0)

DOUT, FOUT, DRDY, INT

Output Low Voltage

DOUT, FOUT, DRDY, INT,

SHDN Output High Voltage

DOUT Three-State Leakage ±0.01 ±10 µA

DOUT Three-State Capacitance 15 pF

SHDN Output Low Voltage

(MAX1407/MAX1408/MAX1414

only)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX U N I T S

D D

Overtemperature excluding crystal,

T

= T

A

Over supp l y vol tag e, + 2.7V < AV

V

OL

V

OH

I

SINK

I

SOURCE

I

SINK

I

SINK

= + 1.8V to + 3.6V , excl ud i ng cr ystal 0 ppm/V

to T

MIN

MAX

< +3.6V 0 p p m /m V

D D

0.7 x

DV

DD

DD

DD

= 1mA, DVDD = +1.8V to +3.6V 0.4 V

= 0.2mA, DVDD = +1.8V to +3.6V 0.8 x DV

= 1mA, DVDD = +1.8V to +3.6V 0.4

= 50µA, DVDD = +1.8V to +3.6V

0p p m /° C

0.3 x

DV

DD

±0.01 ±10 µA

0.01 10 µA

DD

0.04 x

DV

DD

V

V

V

V

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= AVDD= +2.7V to 3.6V, 4.7µF at REF, internal V

REF

, 18nF between CPLL and AVDD, 32.768kHz crystal across CLKIN and

CLKOUT, T

A

= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.)

TIMING CHARACTERISTICS

(MAX1407/MAX1408/MAX1409/MAX1414: AV

DD

= DV

DD

= 2.7V to 3.6V, TA = T

MIN

to T

MAX,

unless otherwise noted.)

D0 Output Low Voltage

(MAX1407/MAX1408/MAX1414

only)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX U N I T S

I

SINK

= 200µA, DVDD = +2.7V to +3.6V 0.7 mV

D0 Output High Voltage

(MAX1407/MAX1408/MAX1414

only)

POWER REQUIREMENTS

Supply Voltage Range V

Supply Current (Note 5) I

DD

DD

= 2m A, D V

I

S OU RC E

Run, Idle, and Standby mode 2.7 3.6

Sleep mode 1.8 3.6

Run mode

Standby mode

Sleep mode

V

= 2.7V

DD

= + 2.7V to + 3.6V

D D

MAX1407/MAX1414 1.15

MAX1408 1.03

MAX1409 1.09

MAX1407/MAX1414 650

MAX1408 530Idle mode

MAX1409 590

MAX1407/MAX1408/

MAX1409/MAX1414

MAX1407/MAX1408/

MAX1409/MAX1414

DV

- 0.1

DD

TIMING PARAMETERS

SCLK Operating Frequency f

SCLK Cycle Time t

SCLK Pulse Width High t

SCLK Pulse Width Low t

DIN to SCLK Setup t

DIN to SCLK Hold t

SCLK Fall to Output Data Valid t

CS Fall to Output Enable t

CS Rise to Output Disable t

CS to SCLK Rise Setup t

CS to SCLK Rise Hold t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCLK

CYC

CSS

CSH

CH

CL

DS

DH

DO

DV

TR

CL = 50pF (see load circuit) 200 ns

CL = 50pF (see load circuit) 240 ns

CL = 50pF (see load circuit) 240 ns

476 ns

190 ns

190 ns

100 ns

0ns

100 ns

0ns

330

1.7 2.5

V

V

mA

µA

2.1 MHz

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

_______________________________________________________________________________________ 7

Note 1: Single conversion.

Note 2: DNL and INL are measured between code 010hex and 3FFhex.

Note 3: Offset error is referenced to code 010hex.

Note 4: Output swing is a function of external gain-setting feedback resistors and REF voltage.

Note 5: Measured with no load on FOUT, DOUT, and the DAC amplifiers. SCLK is idle, and all digital inputs are at DGND or DV

DD

.

Note 6: SHDN stays high if the PLL is on.

Note 7: Actual worst-case performance is ±2.5LSB. Guaranteed limit of ±3.5LSB is due to production test limitation.

Note 8: Guaranteed by design. Not production tested.

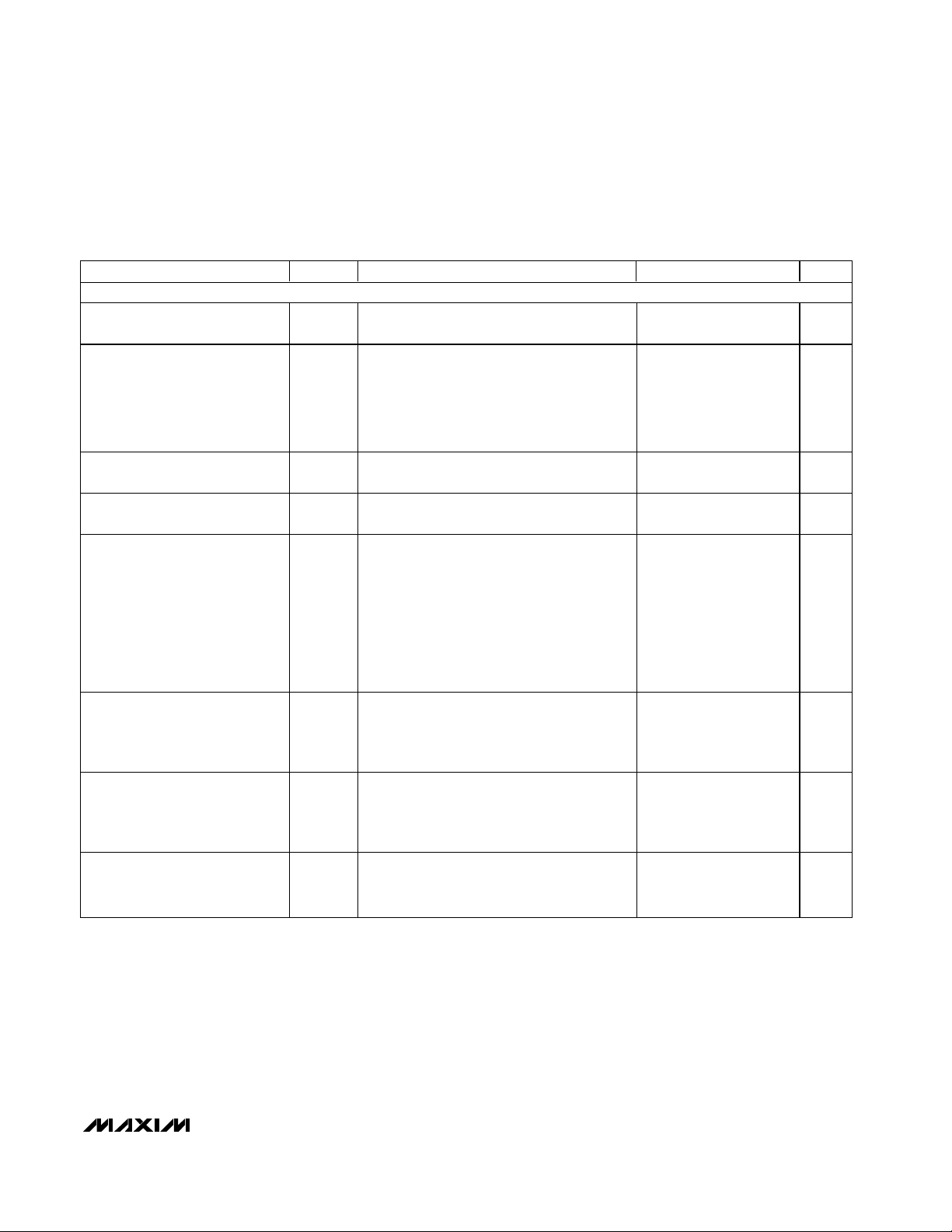

TIMING CHARACTERISTICS (continued)

(MAX1407/MAX1408/MAX1409/MAX1414: AV

DD

= DV

DD

= 2.7V to 3.6V, TA = T

MIN

to T

MAX,

unless otherwise noted.)

TYPICAL TIMING PARAMETERS

OUT1/OUT2 Turn-Off Time

Sleep Voltage Monitor Timeout

Period

WU1 or WU2 Pulse Width t

Shutdown Deassert Delay t

FOUT Turn-On Time t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

t

DSLP

WU

DPU

DFON

Input impedance > 1MΩ

(MAX1407/MAX1409/MAX1414 only)

The delay for the sleep voltage monitor

output, RESET, to go high after AV

above the reset threshold (+1.8V when bit

VM = 1 and +2.7V, when bit VM = 0); this is

largely driven by the startup of the 32kHz

oscillator

Minimum pulse width required to detect a

wake-up event

The delay for SHDN to go high after a valid

wake-up event

The turn-on time for the high-frequency

clock; it is gated by an AND function with

three signals—the RESET signal, the internal

low voltage V

assertion of the PLL; the time delay is timed

from when the low-voltage monitor trips or

the RESET going high, whichever happens

later; FOUT always starts in the low state

monitor signal, and the

DD

DD

rises

100 µs

1.54 s

1µs

1µs

31.25 ms

The delay for INT to go low after the FOUT

INT Delay t

FOUT Disable Delay t

SHDN Assertion Delay t

DFI

DFOF

DPD

clock output has been enabled; INT is used

as an interrupt signal to inform the µP the

high-frequency clock has started

The delay after a shutdown command has

asserted and before FOUT is disabled; this

gives the microcontroller time to clean up

and go into Sleep mode properly

The delay after a shutdown command has

asserted and before SHDN is pulled low

(turning off the DC-DC converter) (Note 6)

7.82 ms

1.95 ms

2.93 ms

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

8 _______________________________________________________________________________________

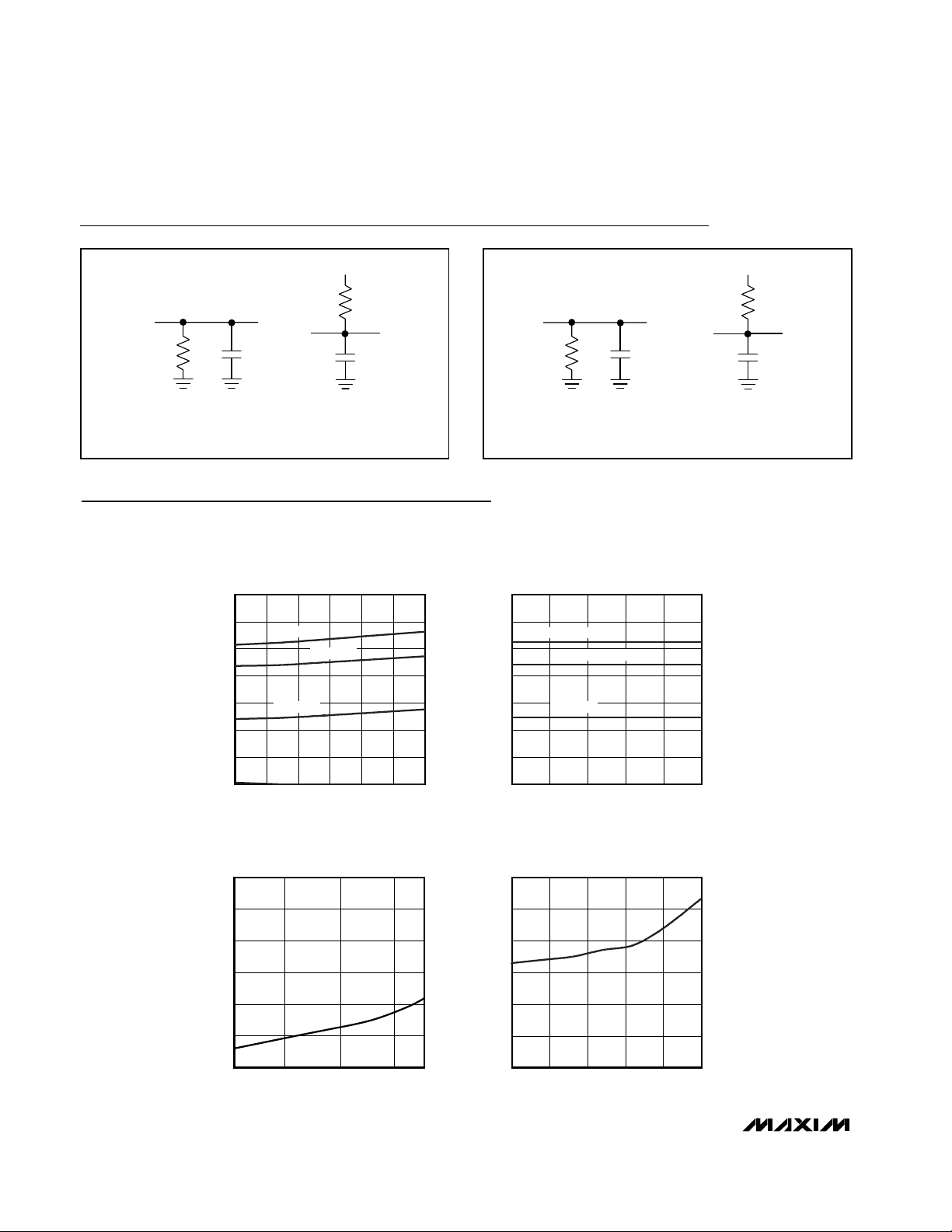

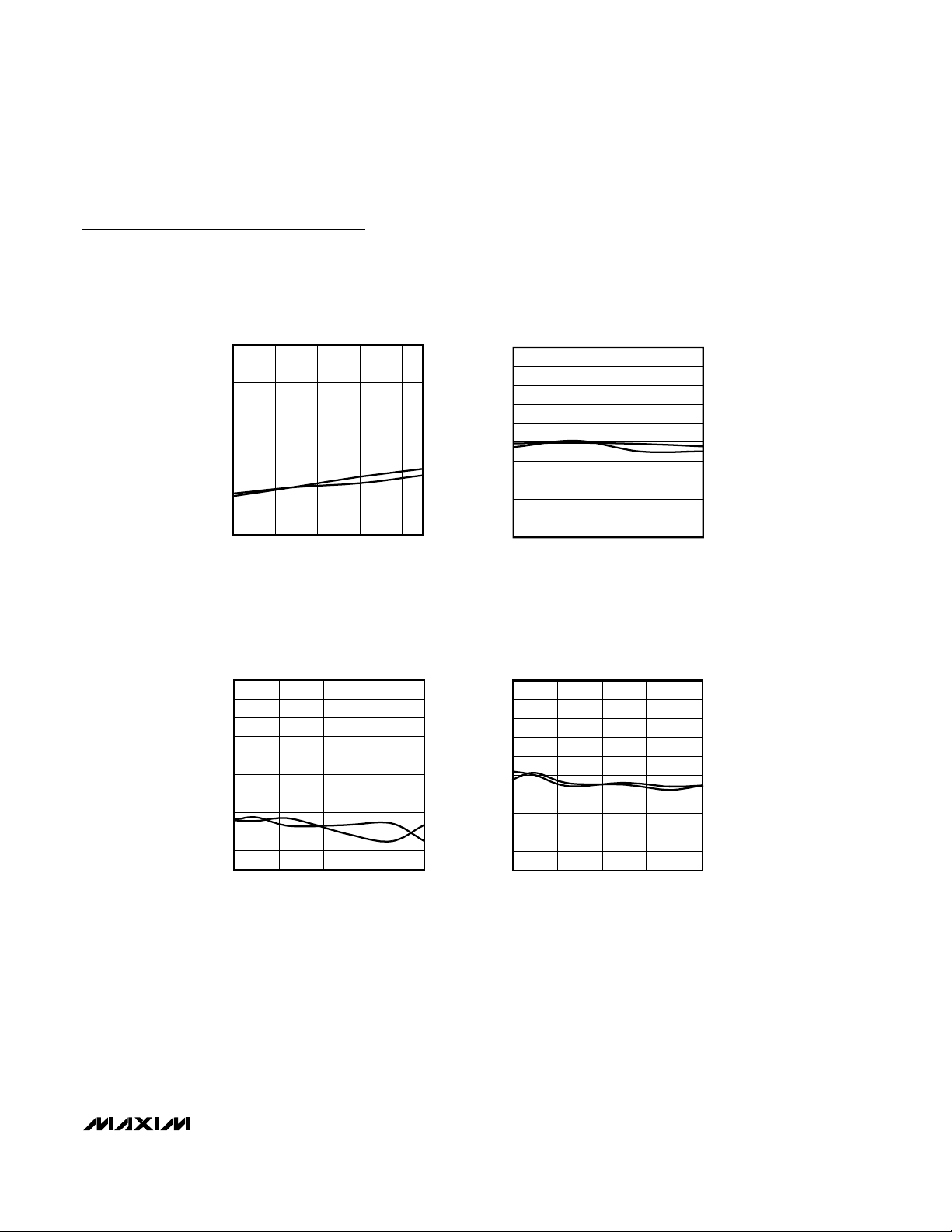

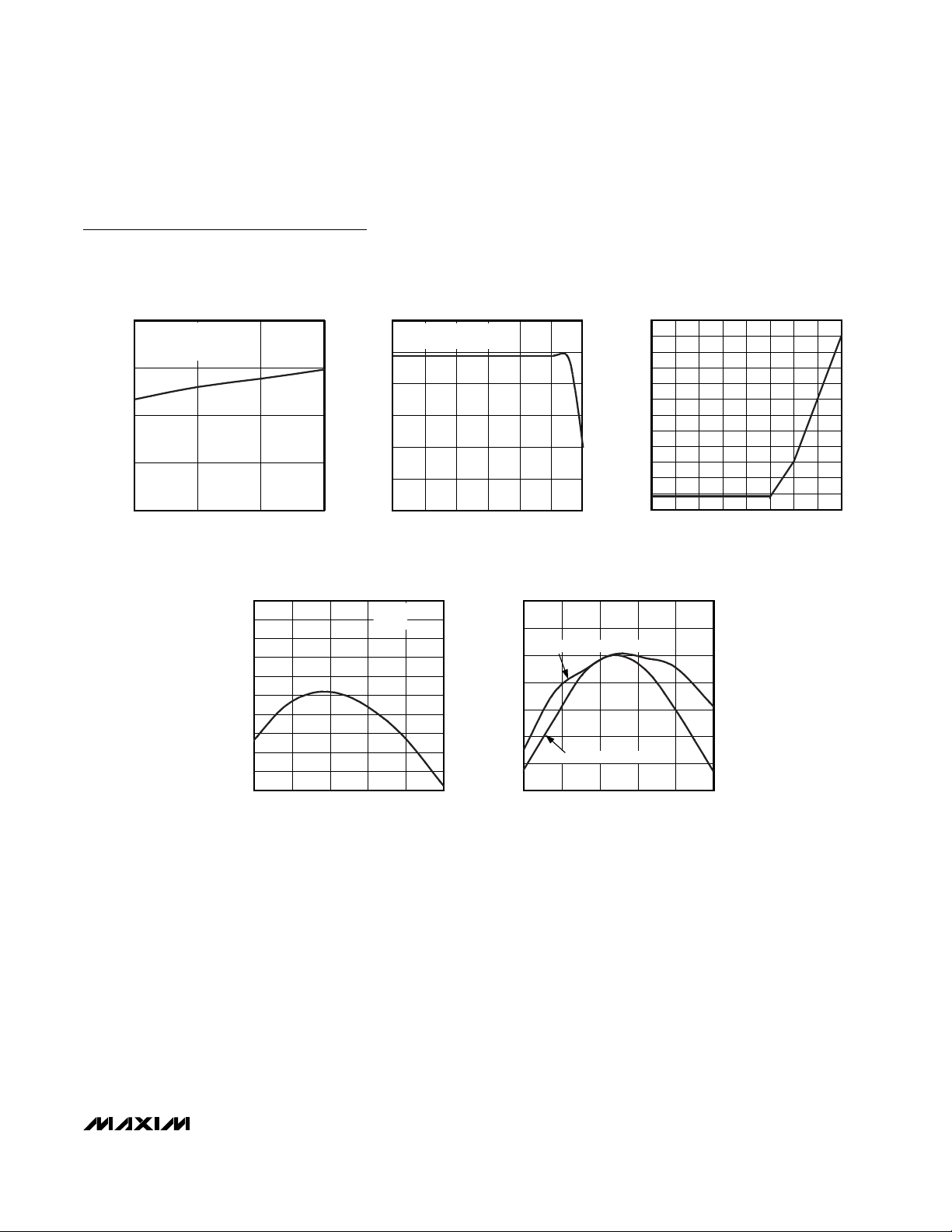

Typical Operating Characteristics

(A

VDD

= D

VDD

= 3V, MAX1407 used, TA = +25°C, unless otherwise noted.)

0

200

100

400

300

600

500

700

2.70 3.00 3.152.85 3.30 3.45 3.60

SUPPLY CURRENT vs.

SUPPLY VOLTAGE

MAX1407 toc01

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (µA)

RUN MODE

IDLE MODE

STANDBY

0

200

100

400

300

600

500

700

-40

10 35-15 60 85

SUPPLY CURRENT vs.

TEMPERATURE

MAX1407 toc02

TEMPERATURE (°C)

SUPPLY CURRENT (µA)

STANDBY

IDLE MODE

RUN MODE

1.0

2.0

1.5

3.0

2.5

3.5

4.0

1.80 2.802.30 3.30

SLEEP CURRENT vs. FALLING V

DD

MAX1407 toc03

SUPLLY VOLTAGE (V)

SLEEP CURRENT (µA)

0

1.0

0.5

2.0

1.5

2.5

3.0

-40 10-15 35 60 85

SLEEP MODE SUPPLY CURRENT

vs. TEMPERATURE

MAX1407 toc04

TEMPERATURE (°C)

SUPPLY CURRENT (µA)

Load Circuits

DV

DD

DV

DD

DOUT

6kΩ

DOUT

C

6kΩ

DGND

a) VOH TO HIGH-Z

LOAD

50pF

b) V

LOAD CIRCUITS FOR DISABLE TIME

TO HIGH-Z

OL

C

LOAD

50pF

DGND

6kΩ

DOUT

6kΩ

DGND

a) HIGH-Z TO VOH AND VOL TO V

LOAD CIRCUITS FOR ENABLE TIME

C

50pF

DOUT

LOAD

b) HIGH-Z TO VOL AND VOH TO V

OH

C

LOAD

50pF

DGND

OL

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

_______________________________________________________________________________________ 9

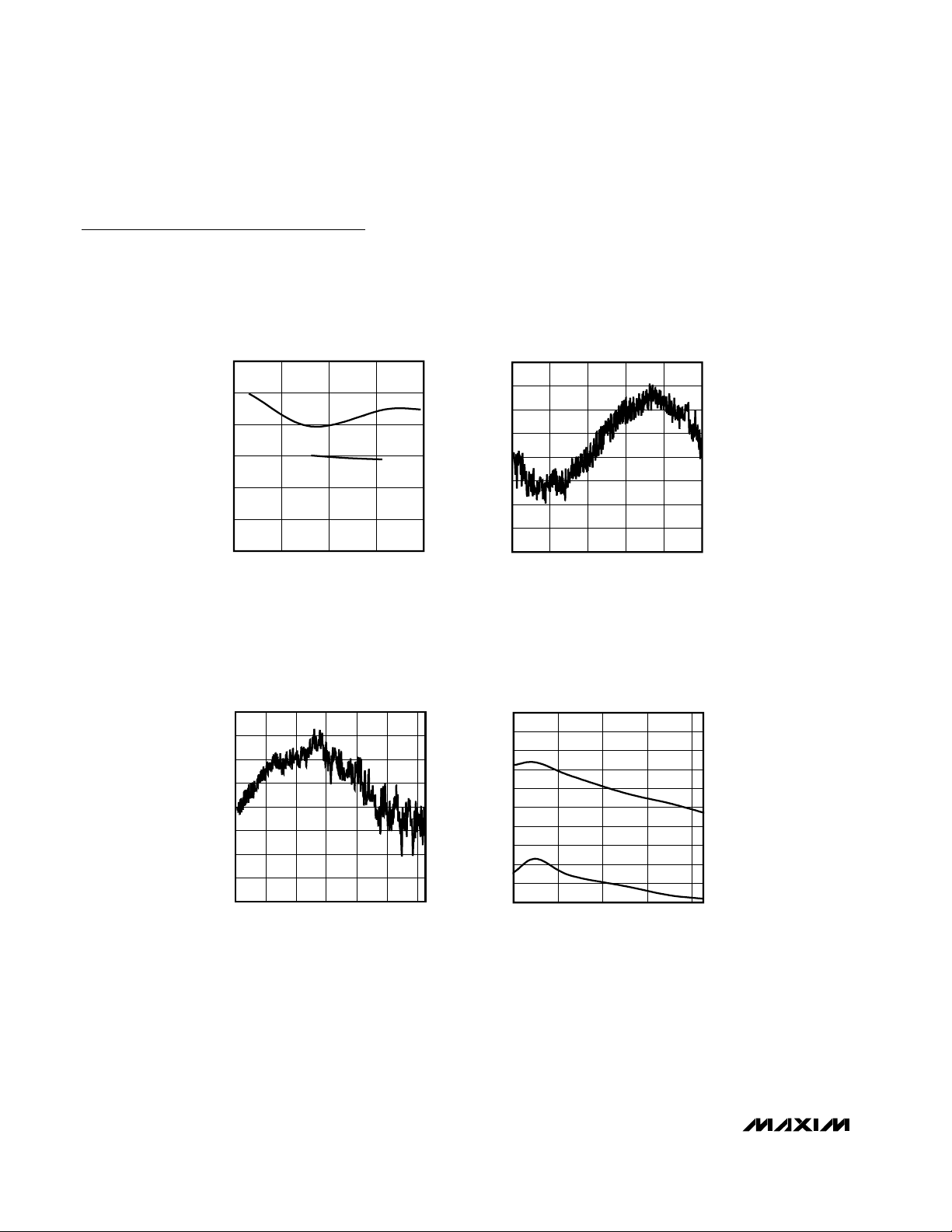

Typical Operating Characteristics (continued)

(A

VDD

= D

VDD

= 3V, MAX1407 used, TA = +25°C, unless otherwise noted.)

0

1

3

2

4

5

2.7 3.12.9 3.3 3.5

MAXIMUM INL vs. V

DD

(UNIPOLAR MODE, T = +25°C,

PSEUDO-DIFFERENTIAL INPUT)

MAX1407 toc05

VDD (V)

MAXIMUM INL (LSB)

A

B

A: GAIN = 1, UNBUFFERED MODE, 60sps

B: GAIN = 1, UNBUFFERED MODE, 30sps

0

1.5

1.0

0.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

2.7 3.12.9 3.3 3.5

MAXIMUM INL vs. V

DD

(BIPOLAR MODE, T = +25°C,

FULLY DIFFERENTIAL INPUT)

MAX1407 toc06

VDD (V)

MAXIMUM INL (LSB)

A

B

A: GAIN = 2, BUFFERED MODE, 60sps

B: GAIN = 2, BUFFERED MODE, 30sps

0

1.5

1.0

0.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

04020 60 80

MAXIMUM INL vs. TEMPERATURE

(UNIPOLAR MODE, V

DD

= 3V,

PSEUDO-DIFFERENTIAL INPUT)

MAX1407 toc07

TEMPERATURE (°C)

MAXIMUM INL (LSB)

A

B

A: GAIN = 1, UNBUFFERED MODE, 60sps

B: GAIN = 1, UNBUFFERED MODE, 30sps

0

1.5

1.0

0.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

04020 60 80

MAXIMUM INL vs. TEMPERATURE

(BIPOLAR MODE, V

DD

= 3V,

FULLY DIFFERENTIAL INPUT)

MAX1407 toc08

TEMPERATURE (°C)

MAXIMUM INL (LSB)

A

B

A: GAIN = 2, BUFFERED MODE, 60sps

B: GAIN = 2, BUFFERED MODE, 30sps

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

10 ______________________________________________________________________________________

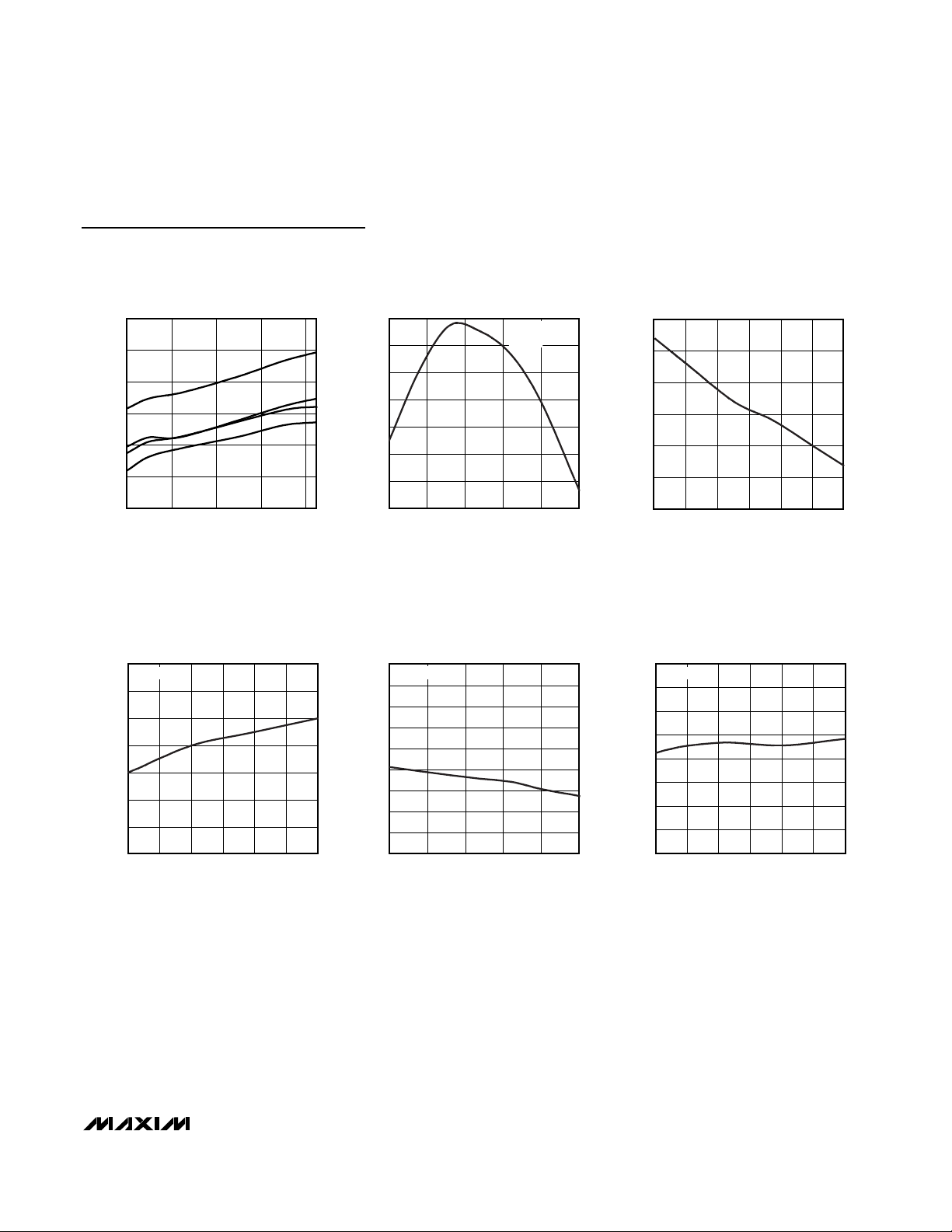

Typical Operating Characteristics (continued)

(A

VDD

= D

VDD

= 3V, MAX1407 used, TA = +25°C, unless otherwise noted.)

0

1.0

0.5

2.0

1.5

2.5

3.0

0.3 0.70.5 0.9 1.1

MAXIMUM INL vs. COMMON-MODE

INPUT VOLTAGE (BIPOLAR MODE,

BUFFERED MODE, V

DD

= 2.7V, 30sps,

FULLY DIFFERENTIAL INPUT, T = +25°C)

MAX1407 toc09

COMMON-MODE INPUT VOLTAGE (V)

MAXIMUM INL (LSB)

A: GAIN = 1

B: GAIN = 2

A

B

-2.0

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

-1.25 -0.75 -0.25 0.25 0.75 1.25

INL vs. FULLY DIFFERENTIAL

INPUT VOLTAGE (BIPOLAR MODE,

GAIN = 1, UNBUFFERED MODE,

V

CM

= 0.625V, VDD = 3V, T = +25°C)

MAX1407 toc10

DIFFERENTIAL INPUT VOLTAGE (V)

INL (LSB)

-2.0

-1.5

-1.0

-0.5

0

0.5

1.0

1.5

2.0

0 0.2 0.4 0.8 1.0

INL vs. PSEUDO-DIFFERENTIAL INPUT

VOLTAGE RANGE (UNIPOLAR MODE,

GAIN = 1, UNBUFFERED MODE,

V

NEG

= 0, VDD = 3V, T = +25°C)

MAX1407 toc11

DIFFERENTIAL VOLTAGE (V)

INL (LSB)

1.20.6

0

1.5

1.0

0.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

04020 60 80

UNCORRECTED OFFSET ERROR

vs. TEMPERATURE

(UNBUFFERED MODE, V

DD

= 3V)

MAX1407 toc12

TEMPERATURE (°C)

OFFSET ERROR (LSB)

A

B

A: GAIN = 1, UNIPOLAR MODE

B: GAIN = 2, BIPOLAR MODE

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 11

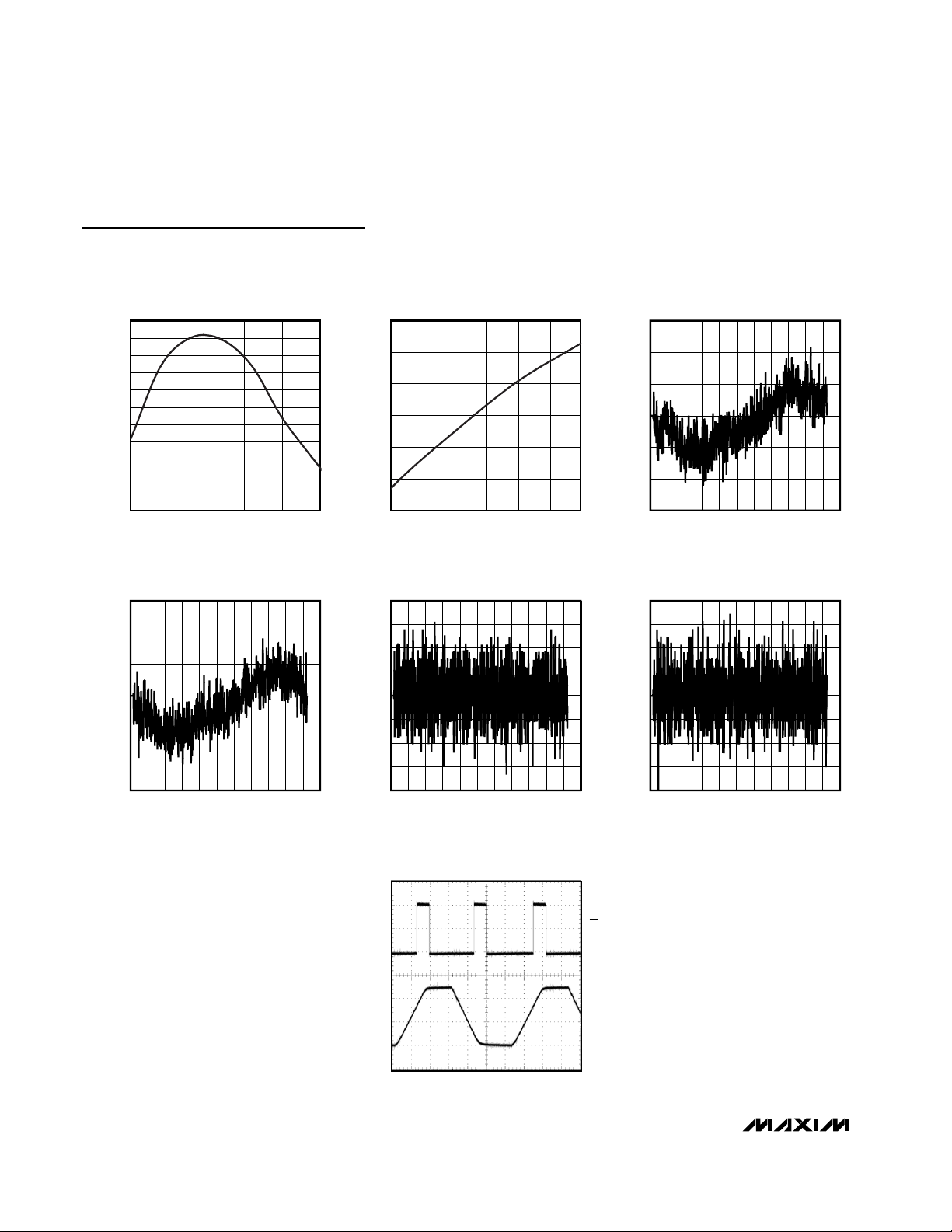

REFERENCE

VOLTAGE

(V)

Typical Operating Characteristics (continued)

(A

VDD

= D

VDD

= 3V, MAX1407 used, TA = +25°C, unless otherwise noted.)

GAIN ERROR vs. TEMPERATURE

0.12

VDD = 3V

0.11

0.10

0.09

GAIN ERROR (%)

0.08

C

0.07

0.06

0

A: GAIN = 1, UNIPOLAR MODE, UNBUFFERED MODE

B: GAIN = 1, BIPOLAR MODE, UNBUFFERED MODE

C: GAIN = 2, UNIPOLAR MODE, BUFFERED MODE

D: GAIN = 2, BIPOLAR MODE, BUFFERED MODE

4020 60 80

TEMPERATURE (°C)

REFERENCE VOLTAGE vs.

SUPPLY VOLTAGE

1.24412

NO LOAD

1.24410

1.24408

1.24406

1.24404

1.24402

REFERENCE VOLTAGE (V)

1.24400

1.24398

2.70 3.00 3.152.85 3.30 3.45 3.60

SUPPLY VOLTAGE (V)

REFERENCE VOLTAGE vs.

TEMPERATURE

0.02

B

MAX1407 toc13

D

A

0

-0.02

-0.04

-0.06

% DEVIATION

-0.08

-0.10

-0.12

-40 10-15 35 60 85

TEMPERATURE (°C)

V

REF

= 0

I

REF

= 1.24406V

MAX1407 toc14

1.24410

1.24405

1.24400

1.24395

1.24390

1.24385

1.24380

DAC OFFSET ERROR vs.

TEMPERATURE

MAX1407 toc16

OFFSET ERROR (mV)

-3.4

IDLE MODE

-3.6

-3.8

-4.0

-4.2

-4.4

-4.6

-4.8

-5.0

-5.2

-40 10-15 35 60 85

TEMPERATURE (°C)

-4.400

-4.425

MAX1407 toc17

-4.450

-4.475

-4.500

-4.525

OFFSET ERROR (mV)

-4.550

-4.575

-4.600

REFERENCE VOLTAGE vs.

OUTPUT SOURCE CURRENT

MAX1407 toc15

0 400 600200 800 1000 1200

SOURCE CURRENT (µA)

DAC OFFSET ERROR vs.

SUPPLY VOLTAGE

IDLE MODE

MAX1407 toc18

2.70 3.002.85 3.15 3.30 3.45 3.60

SUPPLY VOLTAGE (V)

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

12 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(A

VDD

= D

VDD

= 3V, MAX1407 used, TA = +25°C, unless otherwise noted.)

-1.50

-1.20

-1.35

-0.60

-0.75

-1.05

0

-0.30

-0.45

0.15

-40 10-15 35 60 85

DAC GAIN ERROR vs.

TEMPERATURE

MAX1407 toc19

TEMPERATURE (°C)

GAIN ERROR (LSB)

-0.15

-0.90

IDLE MODE

INTERNAL REF USED

-0.20

-0.10

-0.15

0

-0.05

0.05

0.10

2.70 3.00 3.152.85 3.30 3.45 3.60

DAC GAIN ERROR vs.

SUPPLY VOLTAGE

MAX1407 toc20

SUPPLY VOLTAGE (V)

GAIN ERROR (LSB)

IDLE MODE

INTERNAL REF USED

-0.15

-0.05

-0.10

0.05

0

0.10

0.15

0 200 300 400100 500 600 700 800 9001000 1100

DAC INTEGRAL NONLINEARITY

vs. DIGITAL CODE (AV

DD

= 2.7V)

MAX1407 toc21

CODE

INL (LSB)

-0.15

-0.05

-0.10

0.05

0

0.10

0.15

0 200 300 400100 500 600 700 800 9001000 1100

DAC INTEGRAL NONLINEARITY

vs. DIGITAL CODE (AV

DD

= 3.6V)

MAX1407 toc22

CODE

INL (LSB)

-0.100

-0.075

0.075

-0.025

-0.050

0

0.025

0.050

0.100

0 200 300 400100 500 600 900800 1000700 1100

DAC DIFFERENTIAL NONLINEARITY

vs. DIGITAL CODE (AV

DD

= 2.7V)

MAX1407 toc23

CODE

DNL (LSB)

-0.100

-0.075

0.075

-0.025

-0.050

0

0.025

0.050

0.100

0 200 300 400100 500 600 900800 1000700 1100

DAC DIFFERENTIAL NONLINEARITY

vs. DIGITAL CODE (AV

DD

= 3.6V)

MAX1407 toc24

CODE

DNL (LSB)

DAC LARGE-SIGNAL OUTPUT

STEP RESPONSE

V

REF

= 1.25V, AVDD = 3.0V, RL = 0

MAX1407 toc25

OUT_

500mV/DIV

CS

2V/DIV

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 13

Typical Operating Characteristics (continued)

(A

VDD

= D

VDD

= 3V, MAX1407 used, TA = +25°C, unless otherwise noted.)

1.2450

1.2445

1.2440

1.2435

1.2430

2.7 3.0 3.3 3.6

DAC OUTPUT VOLTAGE

vs. SUPPLY VOLTAGE

MAX1407 toc26

SUPPLY VOLTAGE (V)

DAC OUTPUT VOLTAGE (V)

OUTPUT AT FULL SCALE

NO LOAD

DAC BUFFER IN UNITY GAIN

1.00

1.10

1.05

1.20

1.15

1.25

1.30

0231 456

DAC OUTPUT VOLTAGE

vs. SOURCE CURRENT

MAX1407 toc27

LOAD CURRENT (mA)

DAC OUTPUT VOLTAGE (V)

OUTPUT AT FULL SCALE

DAC BUFFER IN UNITY GAIN

015

10520253530

40

1.20

1.30

1.35

1.25

1.40

1.45

1.50

1.55

1.60

1.65

1.70

1.75

1.80

DAC OUTPUT VOLTAGE

vs. SINK CURRENT

MAX1407 toc28

SINK CURRENT (µA)

DAC OUTPUT VOLTAGE (V)

-0.15

-0.06

-0.09

-0.12

-0.03

0

0.03

0.06

0.09

0.12

0.15

-40 10-15 35 60 85

DAC OUTPUT VOLTAGE vs.

TEMPERATURE

MAX1407 toc29

TEMPERATURE (°C)

DAC OUTPUT VOLTAGE (%)

V

REF

= 1.24406V

I

REF

= 0

-0.25

-0.15

-0.20

-0.05

-0.10

0.05

0

0.10

-40 10-15 35 60 85

VOLTAGE MONITOR THRESHOLD

vs. TEMPERATURE

MAX1407 toc30

TEMPERATURE (°C)

% DEVIATION

V

1.8V_THRESHOLD

= 1.865V

V

2.7V_THRESHOLD

= 2.75V

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

14 ______________________________________________________________________________________

Pin Description

MAX1407

MAX1414

1 ——FB2 Force/Sense DAC2 Feedback Input

— 1 — IN7 Analog Input. Analog input to the negative mux only.

—— 1 FB1 Force/Sense DAC1 Feedback Input

22— D0 Digital Output. Three-state general-purpose digital output.

3 ——FB1 Force/Sense DAC1 Feedback Input

— 3 — IN6 Analog Input. Analog input to the negative mux only.

4 — 2 OUT1 Force/Sense DAC1 Output

— 4 — IN4 Analog Input. Analog input to the positive mux only.

5 5 3 IN0 Analog Input. Analog input to both the positive and negative mux.

6 6 4 REF

7 7 5 AGND

886AVDDAnalog Supply Voltage

9 9 7 CPLL

10 10 8 WU1

11 11 9 WU2

MAX1408 MAX1409 PIN FUNCTION

1.25V Reference Buffer Output/External Reference Input. Reference voltage

for the ADC and the DAC. Connect a 4.7µF capacitor to REF between REF

and AGND.

Analog Ground. Reference point for the analog circuitry. AGND connects to

the IC substrate.

PLL Capacitor Connection Pin. Connect an 18nF ceramic capacitor between

CPLL and AV

Active-Low Wake-Up Input. Internally pulled up. The device will wake-up from

Sleep mode to Standby mode when WU1 is asserted.

Active-Low Wake-Up Input. Internally pulled up. The device will wake-up from

Sleep mode to Standby mode when WU2 is asserted.

DD

.

Active-Low RESET Output. It remains low while AV

12 12 10 RESET

13 13 — IN1 Analog Input. Analog input to both the positive and negative mux.

14 14 — IN2 Analog Input. Analog input to both the positive and negative mux.

15 15 — SHDN Programmable Shutdown Output. Goes low in Sleep mode.

16 16 — DRDY

17 17 11 FOUT 2.4576MHz Clock Output. FOUT can be used to drive the input clock of a µP.

18 18 12 CLKOUT

19 19 13 CLKIN 32kHz Crystal Input. Connect a 32kHz crystal between CLKIN and CLKOUT.

and stays low for a timeout period after AV

RESET is an open-drain output.

Active-Low Data Ready Output. A logic low indicates that a new conversion

result is available in the Data register. DRDY returns high upon completion of

a full output word read operation. DRDY also signals the end of an ADC

offset-calibration.

32kHz Crystal Output. Connect a 32kHz crystal between CLKIN and

CLKOUT.

rises above the threshold.

DD

is below the threshold

DD

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 15

Detailed Information

The MAX1407/MAX1408/MAX1409/MAX1414 are lowpower, general-purpose, multichannel DAS featuring a

multiplexed fully differential 16-bit ∑∆ analog-to-digital

converter (ADC), 10-bit force/sense digital-to-analog

converters (DAC), a real-time clock (RTC) with an

alarm, a bandgap voltage reference, a signal detect

comparator, two power-supply voltage monitors, wakeup control circuitry, and a high-frequency phase-locked

loop (PLL) clock output all controlled by a 3-wire serial

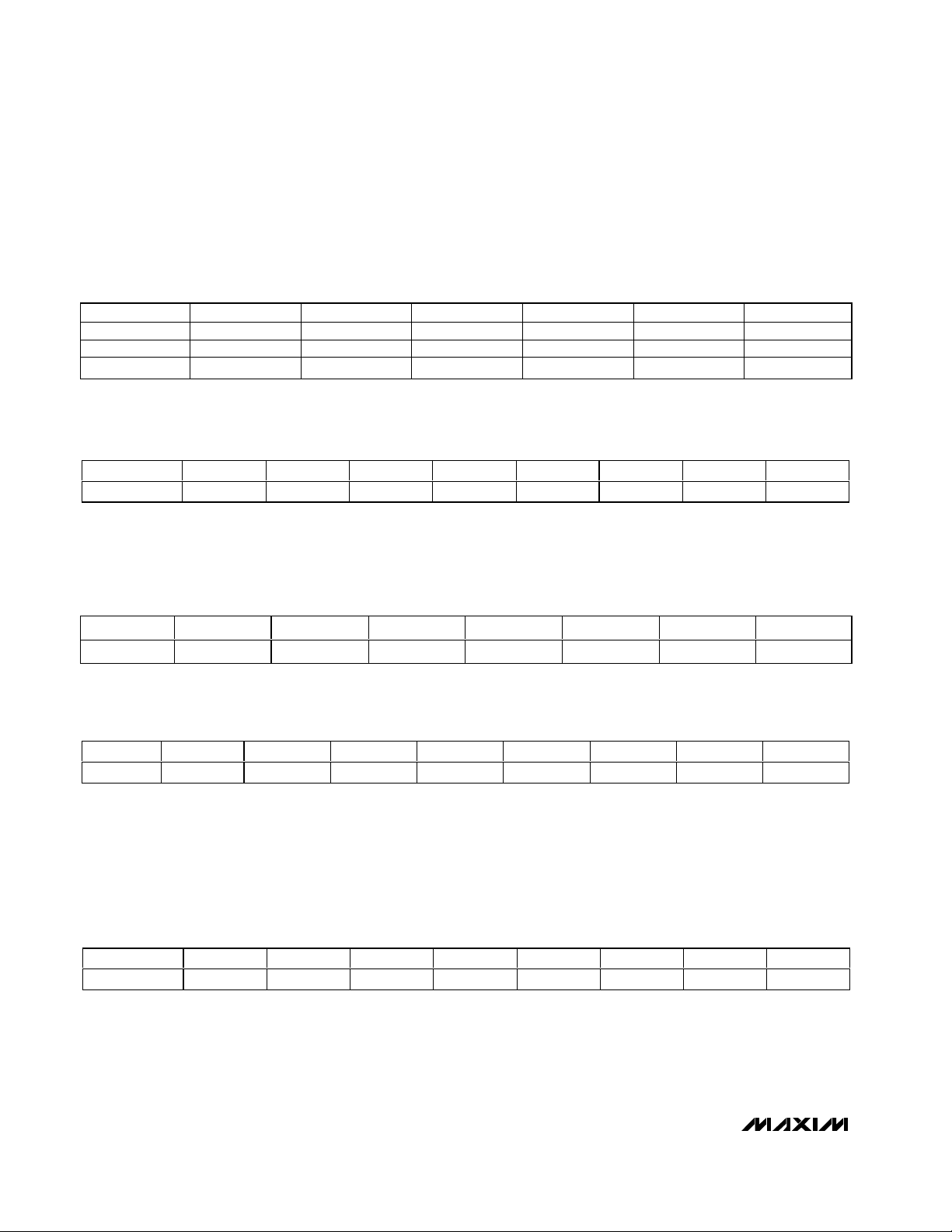

interface. (See Table 1 for the MAX1407/MAX1408/

MAX1409/MAX1414 feature sets and Figures 1, 2, 3 for

the Functional Diagrams). These DAS directly interface

to various sensor outputs and once configured provide

the stimulus, conditioning, and data conversion, as well

as microprocessor support. Figure 4 is a Typical

Application Circuit for the MAX1407/MAX1414.

The 16-bit ∑∆ ADC is capable of programmable continuous conversion rates of 30Hz or 60Hz and gains of

1/3, 1, and 2V/V to suit applications with different power

and dynamic range constraints. The force/sense DACs

provide 10-bit linearity for precise sensor applications.

Pin Description (continued)

Table 1. MAX1407/MAX1408/MAX1409/MAX1414 Feature Sets

MAX1407

MAX1414

20 20 14 INT

21 21 15 DOUT

22 22 16 DIN

23 23 17 SCLK

24 24 18 CS

25 25 19 DGND Digital Ground. Reference point for digital circuitry.

26 26 20 DV

27 27 — IN3 Analog Input. Analog input to both the positive and negative mux.

28 ——OUT2 Force/Sense DAC2 Output

— 28 — IN5 Analog Input. Analog input to the positive mux only.

MAX1408 MAX1409 PIN FUNCTION

Active-Low Interrupt Output. INT goes low when the PLL output is ready,

when the signal-detect comparator is tripped, or when the alarm is triggered.

Serial Data Output. DOUT outputs serial data from the internal shift register

on SCLK’s falling edge. When CS is high, DOUT is three-stated.

Serial Data Input. Data on DIN is written to the input shift register and is

clocked in at SCLK’s rising edge when CS is low.

Serial Clock Input. Apply an external serial clock to transfer data to and from

the device. This serial clock can be continuous, with data transmitted in a

train of pulses, or intermittent while CS is low.

Active-Low Chip-Select Input. CS is used to select the active device in

systems with more than one device on the serial bus. Data will not be

clocked into DIN unless CS is low. When CS is high, DOUT is three-stated.

DD

Digital Supply Voltage

ADC

PART

MAX1407 4 2 Yes 0 Yes Yes Yes 8

MAX1414 4 2 Yes 50 Yes Yes Yes 8

MAX1408 8 0 Yes 0 Yes Yes Yes 8

MAX1409 1 1 No 0 Yes No No 4

AUXILIARY

ANALOG

INPUTS

FORCE/

SENSE

DAC

THREE-

STATE

DIGITAL

OUTPUT

COMPARATOR

THRESHOLD

(mV)

EXTERNAL

RTC

ADC DATA

READY

(DRDY)

POWERSUPPLY

SHUTDOWN

CONTROL

DIFFERENTIAL

INPUT MUX

ADC

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

16 ______________________________________________________________________________________

With the use of two external resistors, the DAC output

can go from 0.05V to AVDD- 0.2V. The ADCs and

DACs both utilize a precise low-drift 1.25V internal

bandgap reference for conversions and setting of the

full-scale range. For applications that require increased

accuracy, power-down the internal reference and connect an external reference at REF. The RTC is leap year

compensated until 9999 and provides an alarm function

that can be used to wake-up the system or cause an

interrupt at a predefined time. The power-supply voltage monitors detect when AV

DD

falls below a trip

threshold voltage at either +1.8V or +2.7V causing the

reset to be asserted. The 4-wire serial interface is used

to communicate directly between SPI, QSPI, and

MICROWIRE devices for system configuration and

readback functions.

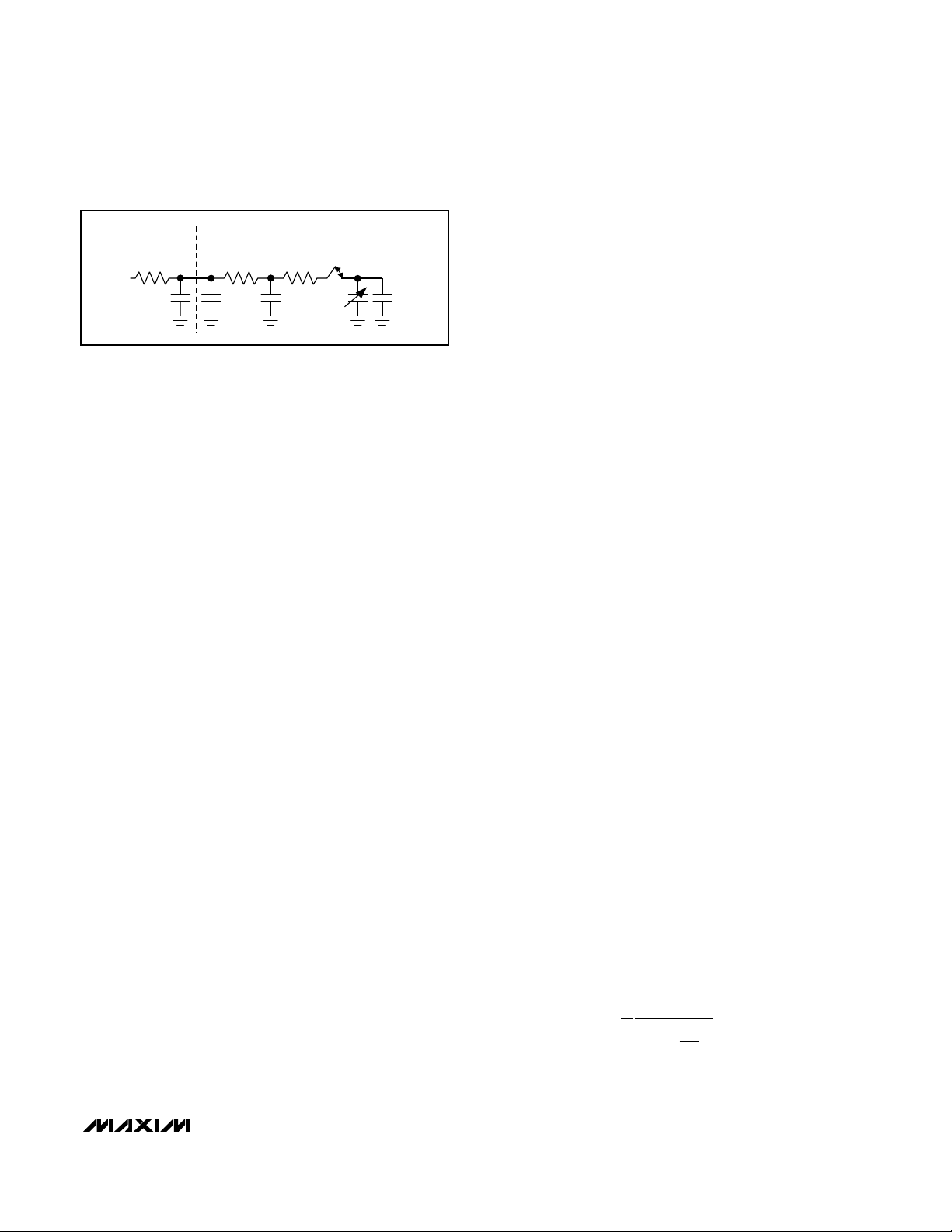

Analog Input Protection

Internal protection diodes clamp the analog input to

AVDDand AGND, which allow the channel input pins to

swing from AGND - 0.3V to AVDD+ 0.3V without damage. However, for accurate conversions near full scale,

the inputs must not exceed AVDDby more than 50mV

or be lower than AGND by 50mV.

Analog Mux

The MAX1407/MAX1408/MAX1414 include a dual 8 to 1

multiplexer for the positive and negative inputs of the

ADC. The MAX1409 has a dual 4 to 1 multiplexer at the

inputs of the ADC. Figures 1, 2, and 3 illustrate which

signals are present at the inputs of each multiplexer for

the MAX1407/MAX1408/MAX1409/MAX1414. The

MUXP and MUXN bits of the MUX register choose

which inputs will be seen at the input to the ADC

(Tables 4 and 5) and the signal-detect comparator. See

the MUX Register description under the On-Chip

Registers section for multiplexer functionality.

Input Buffers

The MAX1407/MAX1408/MAX1409/MAX1414 provide

input buffers to isolate the analog inputs from the capacitive load presented by the ADC modulator (Figure 5 and

6). The buffers are chopper stabilized to reduce the effect

of their DC offsets and low-frequency noise. Since the

buffers can represent more than 25% of the total analog

power dissipation (typically 220µA), they may be shut

down in applications where minimum power dissipation is

required and the capacitive input load is not a concern

(see ADC and Power1 Registers). Disable the buffers in

applications where the inputs must operate close to

AGND or above +1.4V. The buffers are individually

enabled or disabled.

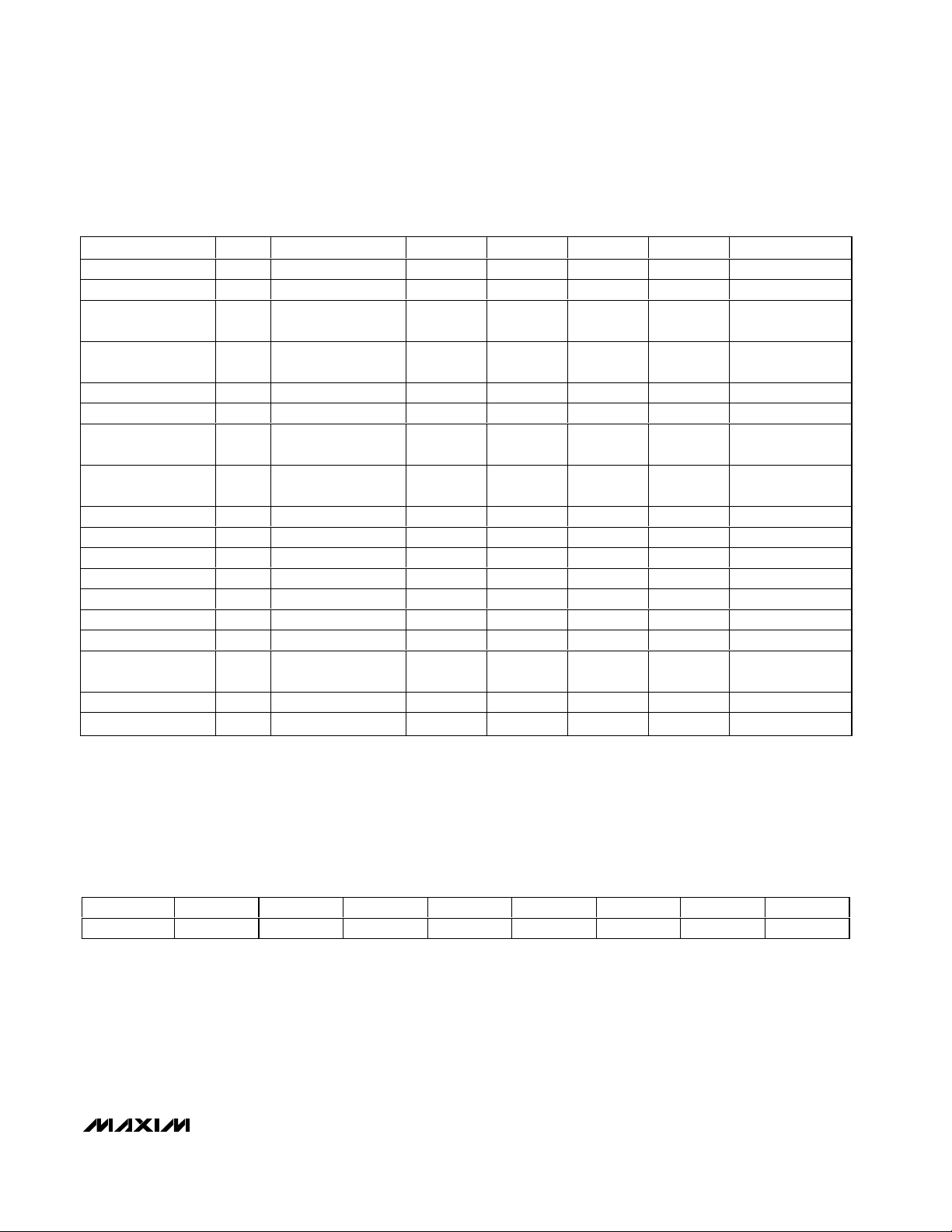

Figure 1. MAX1407/MAX1414 Functional Diagram

CPLL FOUT CLKIN CLKOUT

AV

DD

DV

DD

CS

SCLK

DIN

DOUT

IN3

IN2

IN1

IN0

*MAX1414 HAS A +50mV SIGNAL-DETECT COMPARATOR THRESHOLD.

OUT2

OUT1

REF

AV

FB2

FB1

REF

AGND

IN3

IN2

IN1

IN0

DD

SERIAL

INTERFACE

8:1

INPUT

MUX

8:1

INPUT

MUX

AGND

2.4576MHz

PLL

1.8V/2.7V

SUPERVISORS

GENERATOR

RESET

RESET

BUF

BUF

µP

32.768kHz

OSCILLATOR

COMPARATOR

1.25V

BANDGAP

REFERENCE

RTC AND

ALARM

MAX1407/MAX1414

16-BIT ADC

PGA

BUF

REF

10-BIT DAC

10-BIT DAC

WAKE-UP

LOGIC

INTERRUPT

GENERATOR

DIGITAL

OUTPUT

DGND

WU2

WU1

SHDN

INT

DRDY

D0

OUT1

FB1

OUT2

FB2

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 17

Figure 3. MAX1409 Functional Diagram

Figure 2. MAX1408 Functional Diagram

CS

SCLK

DIN

DOUT

IN5

IN4

IN3

IN2

IN1

IN0

REF

AV

DD

IN7

IN6

REF

AGND

IN3

IN2

IN1

IN0

AV

DD

SERIAL

INTERFACE

8:1

INPUT

MUX

8:1

INPUT

MUX

AGND

CPLL FOUT CLKIN CLKOUT

BUF

BUF

µP

RESET

RESET

32.768kHz

OSCILLATOR

COMPARATOR

1.25V

BANDGAP

REFERENCE

PGA

BUF

REF

2.4576MHz

PLL

1.8V/2.7V

SUPERVISORS

GENERATOR

RTC AND

ALARM

16-BIT ADC

INTERRUPT

GENERATOR

MAX1408

DV

DD

WAKE-UP

LOGIC

DIGITAL

OUTPUT

DGND

WU2

WU1

SHDN

INT

DRDY

D0

CS

SCLK

DIN

DOUT

OUT1

IN0

REF

AV

DD

FB1

IN0

REF

AGND

AV

DD

SERIAL

INTERFACE

4:1

INPUT

MUX

4:1

INPUT

MUX

AGND

CPLL FOUT CLKIN CLKOUT

BUF

BUF

µP

32.768kHz

OSCILLATOR

COMPARATOR

1.25V

BANDGAP

REFERENCE

PGA

BUF

REF

2.4576MHz

PLL

1.8V/2.7V

SUPERVISORS

GENERATOR

RESET

RESET

RTC AND

ALARM

16-BIT ADC

10-BIT DAC

GENERATOR

MAX1409

DV

DD

WAKE-UP

LOGIC

INTERRUPT

DGND

WU2

WU1

INT

OUT1

FB1

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

18 ______________________________________________________________________________________

Buffered Mode

When used in buffered mode, the buffers isolate the

inputs from the sampling capacitors. The samplingrelated gain error is dramatically reduced since only a

small dynamic load is present from the chopper. The

multiplexer exhibits an input leakage current of 0.5nA

(typ). With high-source resistances, this leakage current may result in a large DC offset error.

Figure 4. MAX1407/MAX1414 Typical Application Circuit

Figure 5. Analog Input—Buffered Mode

= 3.3V OR V

V

LX

LX

MAX1833

OUT

RST

DD

10µF

18nF

BAT

0.1µF 0.1µF

0.1µF

10µF

SENSOR

GND

4.7µF

SHDN

CPLL

SHDN

IN0

REF

R

L

IN1

R

T

OUT1

R

F

FB1

WE

RE

CE

FB2

OUT2

BATT

V

BAT

AV

DD

MAX1407

MAX1414

AGND DGND

DV

DD

RESET

CLKIN

CLKOUT

FOUT

CS

SCLK

DIN

DOUT

INT

DRDY

WU1 I/O

WU2 I/O

32.768kHz

RESET

CLKIN

OUTPUT

SCK

MOSI

MISO

INPUT

INPUT

V

DD

µP/µC

V

SS

R

EXT

C

EXT

R

MUX

C

PIN

R

IN

C

ST

C

AMP

C

SAMPLE

C

C

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 19

Unbuffered Mode

When used in unbuffered mode, the switched capacitor

sampling front end of the modulator presents a dynamic load to the driving circuitry. The size of the internal

sampling capacitor and the input sampling frequency

(Figure 6) determines the dynamic load (see Dynamic

Input Impedance section). As the gain increases, the

input sampling capacitance also increases. Since the

MAX1407/MAX1408/MAX1409/MAX1414 sample at a

constant rate for all gain settings, the dynamic load presented by the inputs varies with the gain setting.

PGA Gain

An integrated programmable-gain amplifier (PGA) provides three user-selectable gains: +1/3V/V, +1V/V, and

+2V/V to maximize the dynamic range of the ADC. Bits

GAIN1 and GAIN0 set the desired gain (see ADC

Register). The gain of +1/3V/V allows the direct measurement of the supply voltage through an internal multiplexer input or through an auxillary input.

ADC Modulator

The MAX1407/MAX1408/MAX1409/MAX1414 perform

analog-to-digital conversions using a single-bit, second-order, switched-capacitor delta-sigma modulator.

The delta-sigma modulation converts the input signal

into a digital pulse train whose average duty cycle represents the digitized signal information. The pulse train

is then processed by a digital decimation filter.

The modulator provides 2nd-order frequency shaping

of the quantization noise resulting from the single bit

quantizer. The modulator is fully differential for maximum signal-to-noise ratio and minimum susceptibility to

power-supply noise. The modulator operates at one of

two different sampling rates resulting in an output data

rate of either 30Hz or 60Hz (see ADC Register).

ADC Offset Calibration

The MAX1407/MAX1408/MAX1409/MAX1414 are capable of performing digital offset correction to eliminate

changes due to power-supply voltage or system temperature. At the end of a calibration cycle, a 16-bit calibration value is stored in the Offset register in two’s

compliment format. After completing a conversion, the

MAX1407/MAX1408/MAX1409/MAX1414 subtract the

calibration value from the ADC conversion result and

write the offset compensated data to the Data register

(see Offset Register section). Either a positive or nega-

tive offset can be calibrated. During offset calibration,

DRDY will go high. DRDY goes low after calibration is

complete. The offset register can be programmed to

skew the ADC offset with a maximum range from -215to

(+215- 1)LSBs, e.g., if the programmed 2’s complement

value is +2LSB (-2LSB), this translates to a -2LSB

(+2LSB) shift in bipolar mode or a -4LSB (+4LSB) shift in

unipolar mode.To maintain optimum performance, recalibrate the ADC if the temperature changes by more than

20°C. Offset calibration should also be performed after

any changes in PGA gain, bipolar/unipolar input range,

buffered/unbuffered mode, or conversion speed. During

calibration, the two mulitplexers will be disabled and the

inputs to the ADC will internally be shorted to a common-mode voltage.

ADC Digital Filter

The on-chip digital filter processes the 1-bit data

stream from the modulator using a SINC3filter function.

The SINC3filters settle in three data word periods. The

settling time is 3/60Hz or 50ms (for RATE bit in ADC

register set to 1) and 3/30Hz or 100ms (for RATE bit set

to “0”).

ADC Digital Filter Characteristics

The transfer function for a SINC3filter function is that of

three cascaded SINC1filters. This can be described in

the Z-domain by:

and in the frequency domain by:

where N, the decimation factor, is the ratio of the modulator frequency f

M

to the output frequency fN.

Figure 6. Analog Input—Unbuffered Mode

R

EXT

C

EXT

R

MUX

C

PIN

R

SW

CSTC

SAMPLE

C

C

H ƒ

Hz

()

=

()

1

−

()

1

=

N

1

()

sin

1

N

sinππ

3

−

N

z

1

−

−

z

3

ƒ

N

ƒ

M

ƒ

ƒ

M

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

20 ______________________________________________________________________________________

Figure 7 shows the filter frequency response. The

SINC3characteristic cutoff frequency is 0.262 times the

first notch frequency. This results in a cutoff frequency

of 15.72Hz for a first filter notch frequency of 60Hz (output data rate of 60Hz). The response shown in Figure 7

is repeated at either side of the digital filter’s sample

frequency (fM) (fM= 15.36kHz for 30Hz and fM=

30.72kHz for 60Hz) and at either side of the related har-

monics (2fM, 3fM,....).

The output data rate for the digital filter corresponds

with the positioning of the first notch of the filter’s frequency response. Therefore, for the plot of Figure 7

where the first notch of the filter is at 60Hz, the output

data rate is 60Hz. The notches of this (sinx/x)3 filter are

repeated at multiples of the first notch frequency. The

SINC3filter provides an attenuation of better than

100dB at these notches.

For step changes at the input, enough settling time

must be allowed before valid data can be read. The

settling time depends upon the output data rate chosen

for the filter. The settling time of the SINC3filter to a fullscale step input can be up to four times the output data

period, or three times if the step change is synchrozied

with FSYNC.

Force/Sense DAC

(MAX1407/MAX1409/MAX1414)

The MAX1407/MAX1414 incorporate two 10-bit force/

sense DACs while the MAX1409 has one. The DACs

use a precise 1.25V internal bandgap reference for setting the full-scale range. Program the DAC1 and DAC2

registers through the serial interface to set the output

voltages of the DACs seen at OUT1 and OUT2.

Shorting FB1(2) and OUT1(2) configures the DAC in a

unity-gain setting. Connecting resistors in a voltagedivider configuration between OUT1(2), FB1(2), and

GND sets a different closed-loop gain for the output

amplifier (see the Applications Information section).

The DAC output amplifier typically settles to ±

1

/

2

LSB

from a full-scale transition within 65µs, when it is connected in unity gain and loaded with 12kΩ in parallel

with 200pF. Loads less than 2kΩ may degrade performance. See the Typical Operating Characteristics section for the source-and-sink capabilty of the DAC

output.

The MAX1407/MAX1409/MAX1414 feature a softwareprogrammable shutdown mode for the DACs that

reduce the total power consumption when they are not

used. The two DACs can be powered-down independently or simultaneously by clearing the DA1E and

DA2E bits (see Power1 Register). DAC outputs OUT1

and OUT2 go high impedance when powered down.

The DACs are automatically powered up and ready for

a conversion when Idle or Run mode is entered.

Voltage Monitors

The MAX1407/MAX1408/MAX1409/MAX1414 include

two on-board voltage monitors. When AVDDis below

the RESET trip threshold, RESET goes low and the RST

bit of the Status register is set to “1”. When AV

DD

is

below the Low VDDtrip threshold, the LVD bit of the

Status register is set to 1.

RESET

Voltage Monitor

The RESET voltage monitor is powered up at all times

(provided that VM = 0 and LVDE = 1 or VM = 1 and

LSDE = 1). A threshold voltage of either +1.8V or +2.7V

may be selected for the RESET voltage monitor (see

Power2 Register). At initial power-up, the RESET trip

threshold is set to 2.7V. If the RESET voltage monitor is

tripped, the RST bit of the status register is set to “1”

and RESET goes low. RESET is held low for 1.54

seconds (typ) after AV

DD

rises above the RESET voltage

monitor threshold. If AVDDis no longer below the RESET

threshold, reading the Status register will clear RST.

Low VDDVoltage Monitor

When the device is operating in Run, Idle, or Standby

mode (see Power Modes) and AVDDgoes below +2.7V,

the low V

DD

monitor trips, indicating that the supply voltage is below the safe minimum for proper operation.

When tripped, the Low V

DD

Voltage Monitor sets the LVD

bit of the Status register to 1. If AV

DD

is no longer below

+2.7V, reading the Status register will clear LVD. The low

VDDmonitor is powered down in Sleep mode. When it is

powered down, the LVD bit stays unchanged. The LVD is

cleared if it is read in Sleep mode.

Figure 7. Frequency Response of the SINC3Filter (Notch at

60Hz)

0

-20

-40

-60

-80

GAIN (dB)

-100

-120

-140

-160

0 40608020 100 120 140 160 180 200

FREQUENCY (Hz)

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 21

Internal/External Reference

The MAX1407/MAX1408/MAX1409/MAX1414 have an

internal low-drift +1.25V reference used for both ADC

and DAC conversion. The buffered reference output

can be used as a reference source for other devices in

the system. The internal reference requires a 4.7µF lowESR ceramic capacitor or tantalum capacitor connected between REF and AGND. For applications that

require increased accuracy, power-down the internal

reference by writing a 0 to the REFE bit of the Power1

register and connect an external reference source to

REF. The valid external reference voltage range is

1.25V ±100mV.

Crystal Oscillator

The on-chip oscillator requires an external crystal (or

resonator) connected between CLKIN and CLKOUT

with an operating frequency of 32.768kHz. This oscillator is used for the RTC, alarm, signal-detect comparator, and PLL. The oscillator is operational down to 1.8V.

In any crystal-based oscillator circuit, the oscillator frequency is based on the characteristics of the crystal. It

is important to select a crystal that meets the design

requirements, especially the capacitive load (CL) that

must be placed across the crystal pins in order for the

crystal to oscillate at its specified frequency. CLis the

capacitance that the crystal needs to “see” from the

oscillator circuit; it is not the capacitance of the crystal

itself. The MAX1407/MAX1408/MAX1409/MAX1414

have 6pF of capacitance across the CLKIN and CLKOUT pins. Choose a crystal with a 32.768kHz oscillation

frequency and a 6pF capacitive load such as the C002RX32-E from Epson Crystal. Using a crystal with a

C

L

that is larger than the load capacitance of the oscillator circuit will cause the oscillator to run faster than

the specified nominal frequency of the crystal.

Conversely, using a crystal with a C

L

that is smaller

than the load capacitance of the oscillator circuit will

cause the oscillator to run slower than the specified

nominal frequency of the crystal.

Phase-Locked Loop (PLL) and FOUT

An on-board phase-locked loop generates a

2.4576MHz clock at FOUT from the 32.768kHz crystal

oscillator. FOUT can be used to clock a µP or other digital circuitry. Connect an 18nF ceramic capacitor from

CPLL to AVDDto create the 2.4576MHz clock signal at

FOUT. To power down the PLL, clear PLLE in the

Power2 register (see Power2 Register) or write to the

Sleep register. FOUT will be active for 1.95ms (t

DFOF

)

after receiving either power-down command and then

go low. This provides extra clock signals to the µP to

complete a shutdown sequence. The PLL is active in all

modes except the sleep mode (see Power Modes). To

reactivate the PLL, the following conditions must be

met: AV

DD

is greater than the low VDDvoltage monitor

threshold, RESET is deasserted, and the PLLE bit is

equal to “1”. FOUT is enabled 31.25ms (t

DFON

) after

the PLL is activated. At initial power-up, the PLL is

enabled. If RESET is asserted while the PLL is running,

the PLL does not shut down.

Real-Time Clock (RTC)

The integrated RTC provides the current second,

minute, hour, date, month, day, year, century, and millenium information. An internally generated reference

clock of 1.024kHz (derived from the 32.768kHz crystal)

drives the RTC. The RTC operates in either 24-hour or

12-hour format with an AM/PM indicator (see RTC_Hour

Register). An internal calendar compensates for months

with less than 31 days and includes leap year correction through the year 9999. The RTC operates from a

supply voltage of +1.8V to +3.6V and consumes less

than 1µA current.

Time of Day Alarm

The MAX1407/MAX1408/MAX1409/MAX1414 offer a time

of day alarm which generates an interrupt when the RTC

reaches a preset combination of seconds, minutes,

hours, and day (see Alarm Registers). In addition to setting a “single-shot” alarm, the Time of Day Alarm can

also be programmed to generate an alarm every second, minute, hour, day, or week. “Don’t care” states can

be inserted into one or more fields if it is desired for them

to be ignored for the alarm condition. The Time of Day

Alarm wakes up the device into Standby mode if it is in

Sleep mode. The Time of Day Alarm operates from a

supply voltage of +1.8V to +3.6V.

Interrupt (

IINNTT

)

INT indicates one of three conditions. After receiving a

valid interrupt (INT goes low), read the Status register

and the Al_Status register (if the alarm is enabled) to

identify the source of the interrupt. The three sources of

interrupts are from the CLK, SDC, and ALIRQ bits.

PLL Ready

On power-up, INT is high. 7.82ms (t

DFI

) after the PLL

output appears on FOUT, INT goes low (see Figure 15).

The CLK bit of the Status register is set to “1” after

FOUT is enabled. Reading the Status register clears the

CLK bit. INT remains low until the device detects a start

bit through the serial interface from the µP. The purpose

of this interrupt is to inform the µP that the FOUT clock

signal is present.

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

22 ______________________________________________________________________________________

Signal Detect

The INT pin will also go low and stay low when the differential voltage on the selected analog inputs exceeds

the signal-detect comparator trip threshold (0mV for the

MAX1407/MAX1408/MAX1409 and 50mV for the

MAX1414). This will latch the SDC bit of the Status register to one. Additional signal detect interrupts cannot

be generated unless the SDC bit is cleared. To clear

the SDC bit, the Status register must be read and the

input must be below the signal-detect threshold.

Powering down the signal detect-comparator without

reading the Status register will also clear the SDC bit.

Similar to the power-up case, INT goes high when the

device detects a start bit through the serial interface

from the µP.

Time of Day Alarm

If the device is in Sleep mode, the alarm will wake up

the device and set the ALIRQ bit. INT is asserted when

the PLL is turned on. If an alarm occurs while the

device is awake (BIASE = 1), the ALIRQ bit will be set

and INT will go low. INT remains low until the device

detects a start bit through the serial interface from the

µP. ALIRQ is reset to 0 when any alarm register is read

or written to.

Shutdown (

SSHHDDNN

)

SHDN is an active-low output that can be used to control an external power supply. Powering up the PLL

(PLLE = 1) or writing a “1” to the SHDE bit of the

Power2 register causes SHDN to go high. SHDN goes

low when the SHDE bit is set to 0 only if the PLL is powered down (PLLE = 0). The SHDN output stays high for

2.93ms (t

DPD

) after receiving a power-down command,

allowing the external power supply to stay alive so that

the µP can properly complete a shutdown sequence.

SHDN is not available on the MAX1409. Note: Entering

Sleep mode automatically sets PLLE and SHDE to 0.

Any wake-up event will cause SHDN to go high. (See

Wake-Up section.)

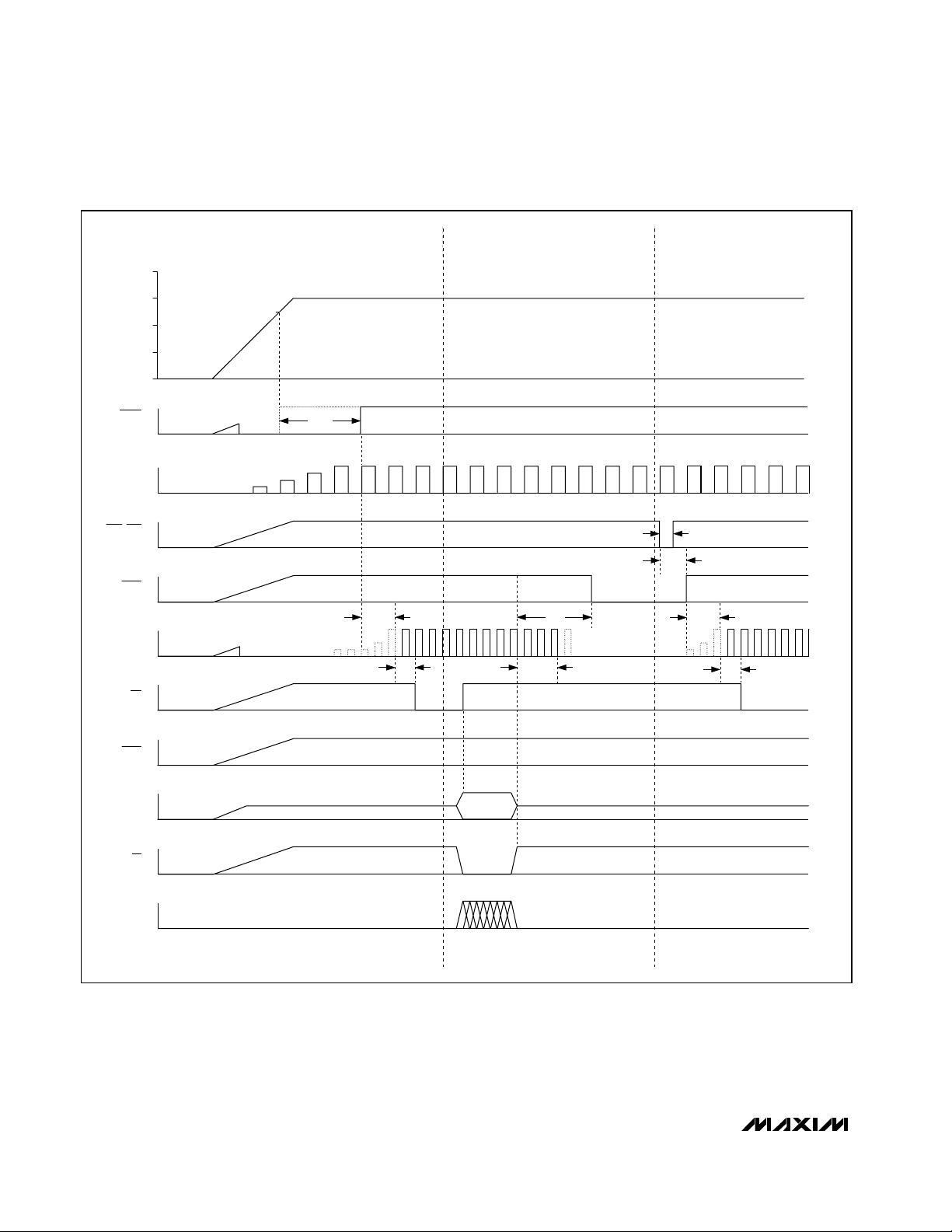

Data Ready (

DDRRDDYY

)

This pin will go low and stay low upon completion of an

ADC conversion or end of an ADC calibration. This signals the µP that a valid conversion or calibration result

has been written to the DATA or the OFFSET register.

The DRDY pin goes high either when the µP has finished reading the conversion/calibration result on the

last rising edge of SCLK (see Figure 8), or when the

next conversion result is about to be written to the

DATA register. When no read operation is performed,

DRDY pulses at 60Hz with a pulse high time of

162.76µs (or 30Hz with a pulse high time of 325.52µs)

DRDY is not available on the MAX1409. To see when

the ADC has completed a normal conversion or a calibration conversion for the MAX1409, check the status

of the ADD bit in the Status register.

Serial Digital Interface

The SPI/QSPI/MICROWIRE-serial interface consists of

chip select (CS), serial clock (SCLK), data in (DIN), and

data out (DOUT) (See Figure 9). The serial interface

provides access to 29 on-chip registers, allowing control to all the power modes and functional blocks,

including the ADCs, DACs, and RTC. Table 2 lists the

address and read/write accessibility of all the registers.

A logic high on CS three-states DOUT and causes the

MAX1407/MAX1408/MAX1409/MAX1414 to ignore any

signals on SCLK and DIN. To clock data into or out of

the internal shift register, drive CS low. SCLK synchronizes the data transfer. The rising edge of SCLK clocks

DIN into the shift register, and the falling edge of SCLK

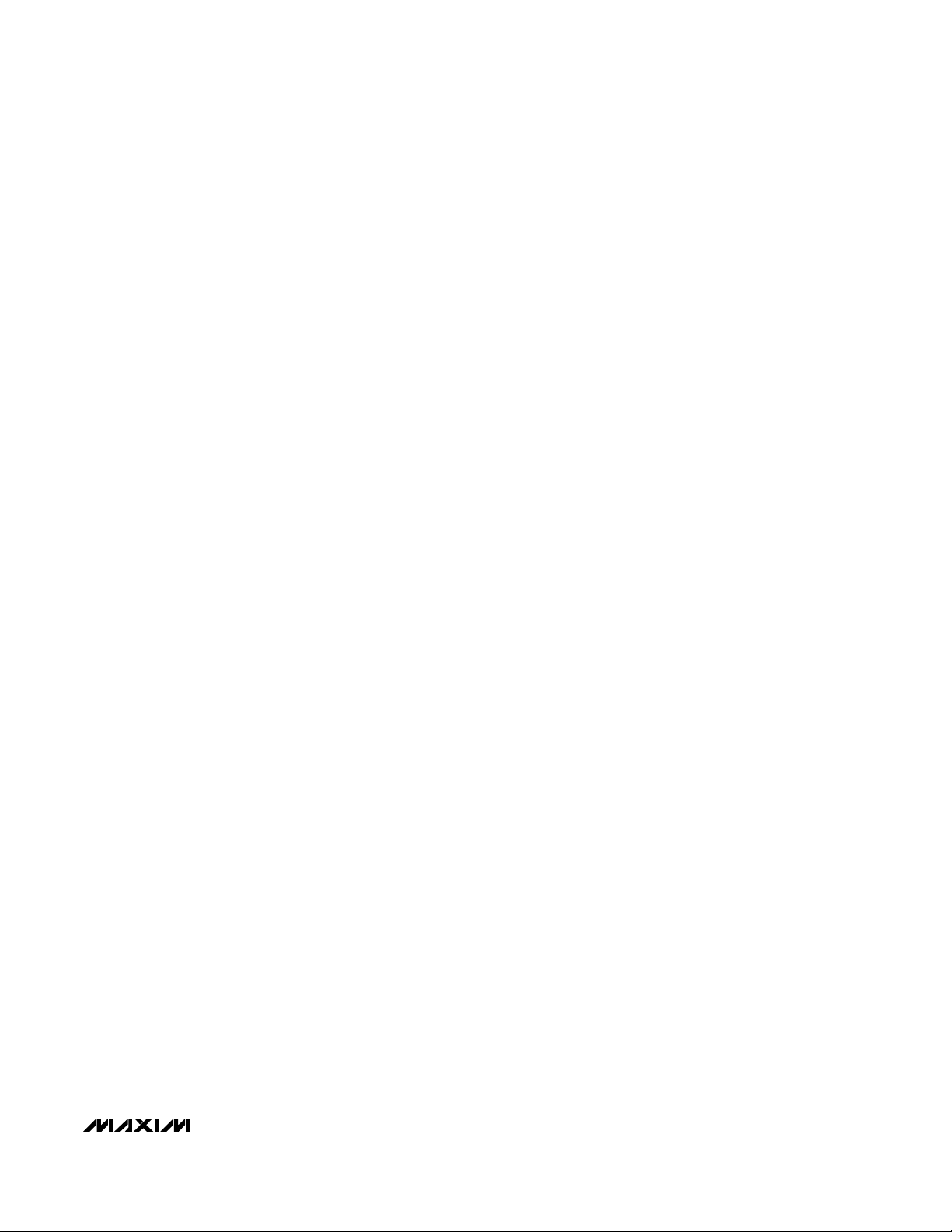

Figure 8. ADC Conversion Timing Diagram

CS

SCLK

DIN

DOUT

DRDY

1 0 A4 A3 A2 A1 A0 x 1 1 A4 A3 A2 A1 A0 x

D7 D6 D5 D4 D3 D2 D1 D0

ADC

CONV

D15 D14 D13 D12 D11 D10

D7 D6 D5 D4 D3 D2 D1 D0D8D9

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 23

clocks DOUT out of the shift register. DIN and DOUT are

transferred as MSB first (data is left justified). Figure 10

shows detailed serial interface timing.

All communication with the MAX1407/MAX1408/

MAX1409/MAX1414 begins with a command byte on

DIN, where the first logic 1 on DIN will be recognized as

the START bit (MSB) for the command byte (Table 3).

The following seven clock cycles load the command into

a shift register. These seven bits specify which of the

registers will be accessed, whether a read or write operation will take place, and the length of the subsequent

data (0-bit, 8-bit, 16-bit, or burst mode). Idle DIN low

between writes to the MAX1407/MAX1408/MAX1409/

MAX1414. Figures 11–14 show the read and write timing

for 8- and 16-bit data. Data is updated on the last rising

edge of the SCLK in the command word. CS should not

go high between data transfers. If CS is toggled before

the end of a write or read operation, the device can

enter an incorrect mode. Clock in 72 zeros to clear this

state and re-arm the serial interface.

After loading the command byte into the shift register,

additional clocks shift out data on DOUT for a read and

shift in data on DIN for a write operation.

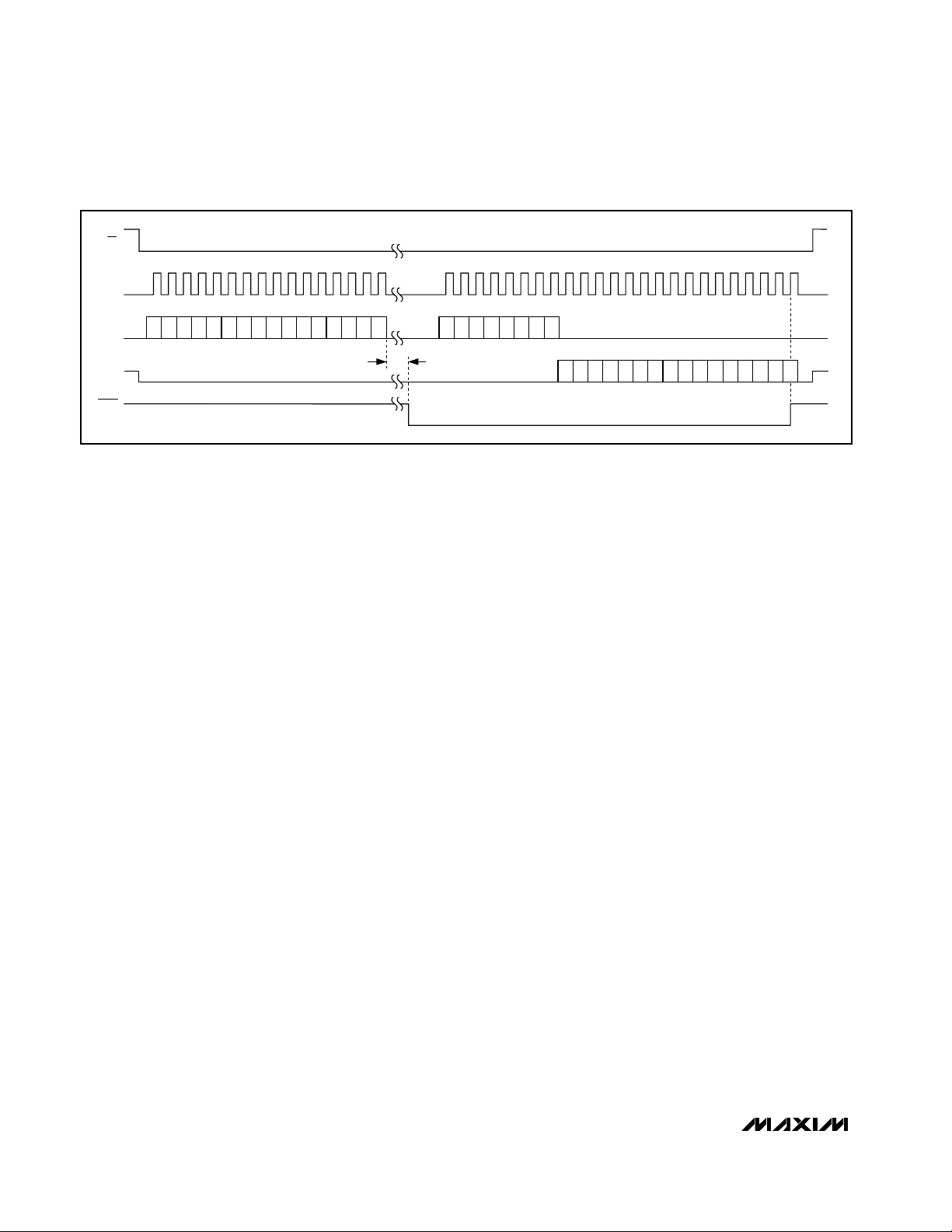

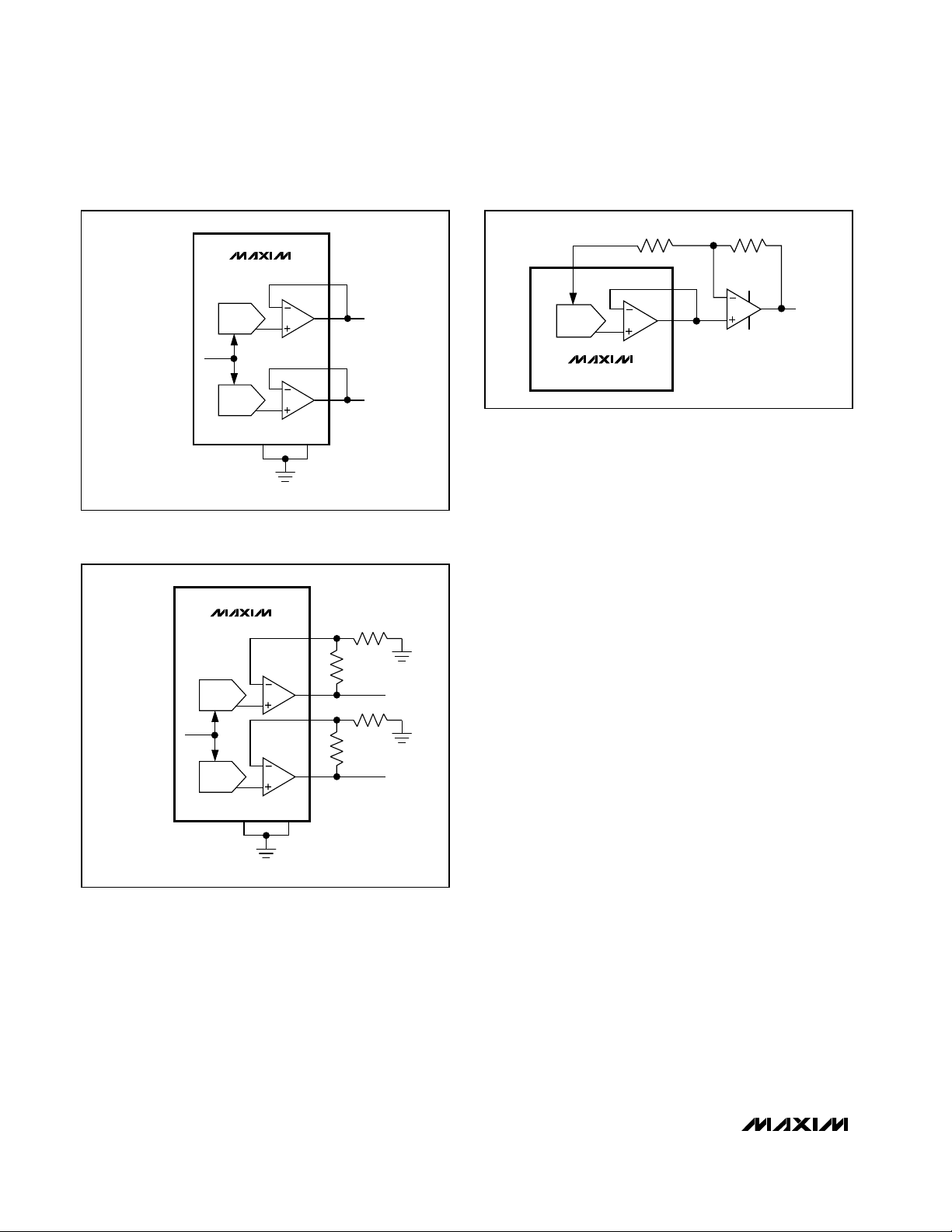

Figure 9. SPI/QSPI Interface Connections

Figure 10. Detailed Serial Interface Timing

CLKOUT

MAX1407

MAX1408

MAX1409

MAX1414

CLKIN

32.768kHz

FOUT

RESET

CS

SCLK

DIN

DOUT

INT

DRDY

WU1 I/O

WU2 I/O

µP/µC

CLKIN

RESET

OUTPUT

SCK

MOSI

MISO

INPUT

INPUT

CS

t

CSS

t

DS

t

DH

t

DV

SCLK

DIN

DOUT

t

CSH

DRDY NOT AVAILABLE ON MAX1409

t

CYC

t

CL

t

CH

• • •

• • •

• • •

• • •

t

CSH

t

DO

t

TR

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

24 ______________________________________________________________________________________

CS allows the SCLK, DIN, and DOUT signals to be

shared among several devices. When short on processor I/O pins, connect CS to DGND, and operate the serial digital interface in CPOL = 1, CPHA = 1 or CPOL = 0,

CPHA = 0 modes using SCLK, DIN, and DOUT.

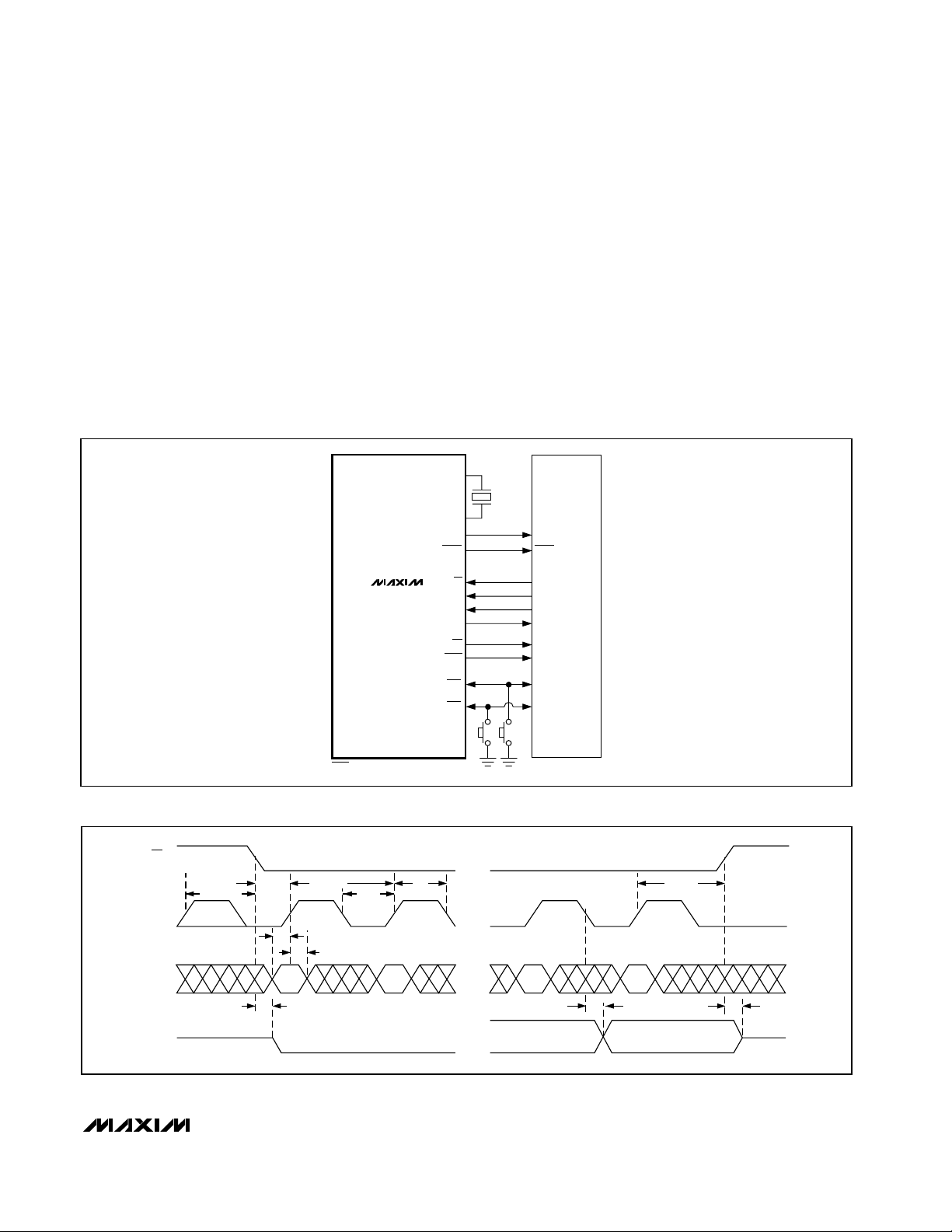

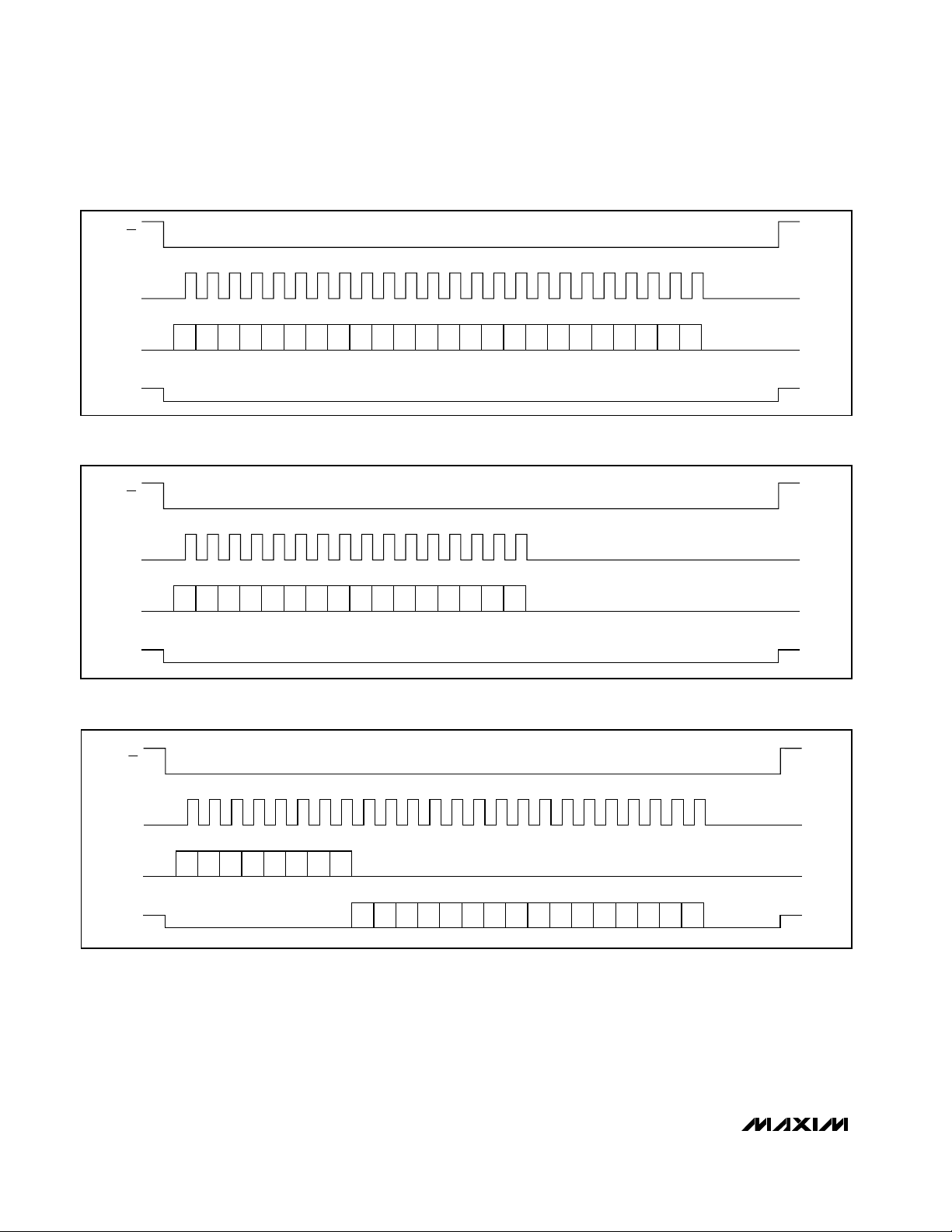

Figure 11. Serial Interface 16-Bit Write Timing Diagram

Figure 12. Serial Interface 8-Bit Write Timing Diagram

Figure 13. Serial Interface 16-Bit Read Timing Diagram

CS

SCLK

DIN

DOUT

CS

SCLK

DIN

DOUT

CS

1 0 A4 A3 A2 A1 D7 D6 D5 D4 D3 D2 D1 D0D8D9A0 x D15 D14 D13 D12 D11 D10

1 0 A4 A3 A2 A1 D7 D6 D5 D4 D3 D2 D1 D0A0 x

SCLK

DIN

DOUT

1 1 A4 A3 A2 A1 A0 x

D7 D6 D5 D4 D3 D2 D1 D0D8D9D15 D14 D13 D12 D11 D10

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 25

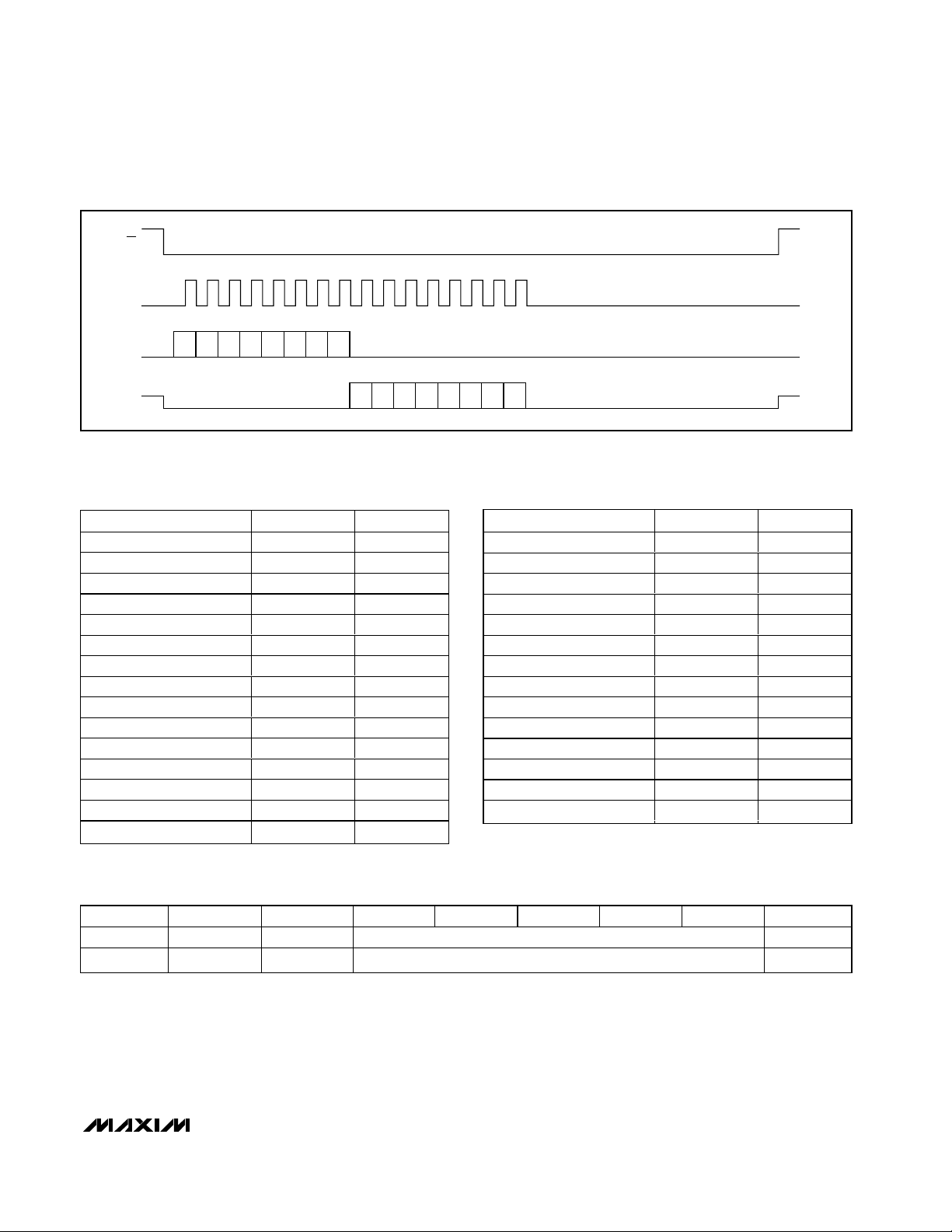

Figure 14. Serial Interface 8-Bit Read Timing Diagram

Table 2. Register Summary and Addressing

Table 3. Command Byte Format

CS

SCLK

DIN

DOUT

TARGET REGISTER R/W ACCESS ADD4:ADD0

ADC Register R/W 00000

MUX Register R/W 00001

Data Register R 00010

Offset Register R/W 00011

DAC1 Register R/W 00100

DAC2 Register R/W 00101

Status Register R 00110

Al_Burst Register R/W 01000

Al_Sec Register R/W 01001

Al_Min Register R/W 01010

Al_Hour Register R/W 01011

Al_Day Register R/W 01100

Al_Status Register R 01101

Al ar m /Cl ock_C trl Reg i ster R/W 01110

RTC_Burst Register R/W 01111

1 1 A4 A3 A2 A1 A0 x

D7 D6 D5 D4 D3 D2 D1 D0

TARGET REGISTER R/W ACCESS ADD4:ADD0

RTC_Sec Register R/W 10000

RTC_Min Register R/W 10001

RTC_Hour Register R/W 10010

RTC_Date Register R/W 10011

RTC_Month Register R/W 10100

RTC_Day Register R/W 10101

RTC_Year Register R/W 10110

RTC_Century Register R/W 10111

Power1 Register R/W 11000

Power2 Register R/W 11001

Sleep Register W 11010

Standby Register W 11011

Idle Register W 11100

Run Register W 11101

COMMAND BIT 7 (MSB) BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0 (LSB)

Write 1 0 ADD4:ADD0 (see Table 2) X

Read 1 1 ADD4:ADD0 (see Table 2) X

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

26 ______________________________________________________________________________________

MODE: Conversion Mode bit. A logic zero selects a

normal ADC conversion, while a logic 1 selects an offset

calibration conversion. After completing a calibration

conversion, MODE automatically resets to zero.

RATE: Conversion Rate bit. A logic zero selects a 30Hz

conversion rate while a logic 1 selects a 60Hz conversion rate.

GAIN1, GAIN0: Gain bits. The Gain bits select the PGA

gain. For an ADC gain of +1/3, +1, and 2V/V, [GAIN1

GAIN0] are 00, 01, and 10, respectively.

BUFP: Positive Buffer bit. When this bit is 0, the positive

input buffer is bypassed and powered down. When this

bit is 1 and the BUFE bit in the Power1 register is 1, the

positive input buffer drives the ADC input sampling

capacitors.

BUFN: Negative Buffer bit. When this bit is 0, the negative input buffer is bypassed and powered-down. When

this bit is 1 and the BUFE bit in the Power1 register is 1,

the negative input buffer drives the ADC input sampling

capacitors.

BIP: Unipolar/Bipolar bit. A logic zero selects unipolar

mode while a logic 1 selects bipolar mode.

STA1: Start bit. Setting STA1 to a logic 1 resets the registers inside the ADC filter, updates the ADC configuration according to the ADC register, and initiates an

analog-to-digital conversion or offset calibration. The

initial conversion requires three cycles for valid output

data, and each subsequent conversion cycle will output

valid data. After completing the intial conversion, STA1

automatically resets to 0; however, the ADC will continue to do conversions until it is powered down.

Writing to the ADC register with STA1 set to 0 updates

the ADC register without changing the ADC configuration and allows the ADC to continue conversions uninterrupted. This allows the ADC and MUX configuration

to be updated simultaneously. See STA2 bit of the MUX

register.

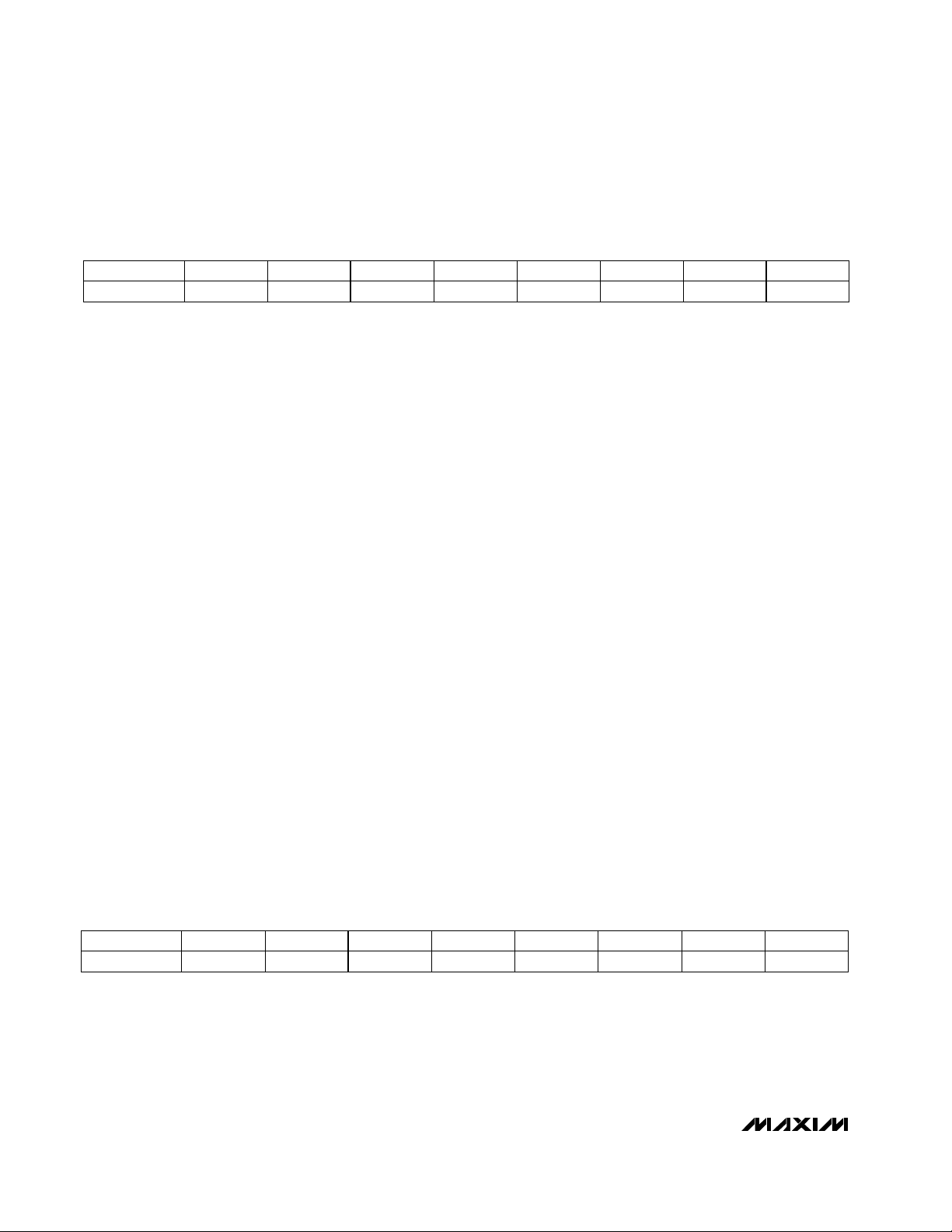

ADC REGISTER (00000)

On-Chip Registers

MUXP2, MUXP1, MUXP0: Positive Multiplexer bits.

MUXP[2:0] direct one-of-eight positive inputs to the

positive input of the ADC. Table 4 relates the MUXP bits

to the positive multiplexer inputs.

MUXN2, MUXN1, MUXN0: Negative Multiplexer bits.

MUXN[2:0] direct one-of-eight (one-of-four for the

MAX1409) negative inputs to the negative input of the

ADC. Table 5 relates the MUXN bits to the negative

multiplexer inputs.

DBIT: Digital Output bit. This bit controls the output

state of D0. When the output buffer is enabled, D0 is

low if Dbit is equal to 0, and high if Dbit is equal to 1.

D0 is enabled by the D0E bit of the Power2 register.

STA2: Start bit. Setting STA2 to a logic 1 updates the

mux selection, resets the registers inside the ADC filter,

updates the ADC configuration according to the ADC

register, and initiates an analog-to-digital conversion.

The initial conversion requires three cycles for valid output data, and each subsequent conversion cycle will

output valid data. STA2 automatically resets to 0 after

the initial conversion completes. The ADC will continue

to do conversions until it is powered down. Writing to

the MUX register with the STA2 bit set to 0, updates the

MUX register and selection, but leaves the ADC configuration unchanged. The MUX input can be switched

with the ADC continuously converting without the digital

filter resetting.

MUX REGISTER (00001)

FIRST BIT (MSB) (LSB)

NAME MODE RATE GAIN1 GAIN0 BUFP BUFN BIP STA1

DEFAULTS 00000000

FIRST BIT (MSB) (LSB)

NAME MUXP2 MUXP1 MUXP0 MUXN2 MUXN1 MUXN0 DBIT STA2

DEFAULTS 00000000

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

______________________________________________________________________________________ 27

The Data register contains the 16-bit result from the

most recently completed ADC conversion. The data format is binary for unipolar mode and two’s complement

for bipolar mode. After power-up, the DATA register

contains all zeros.

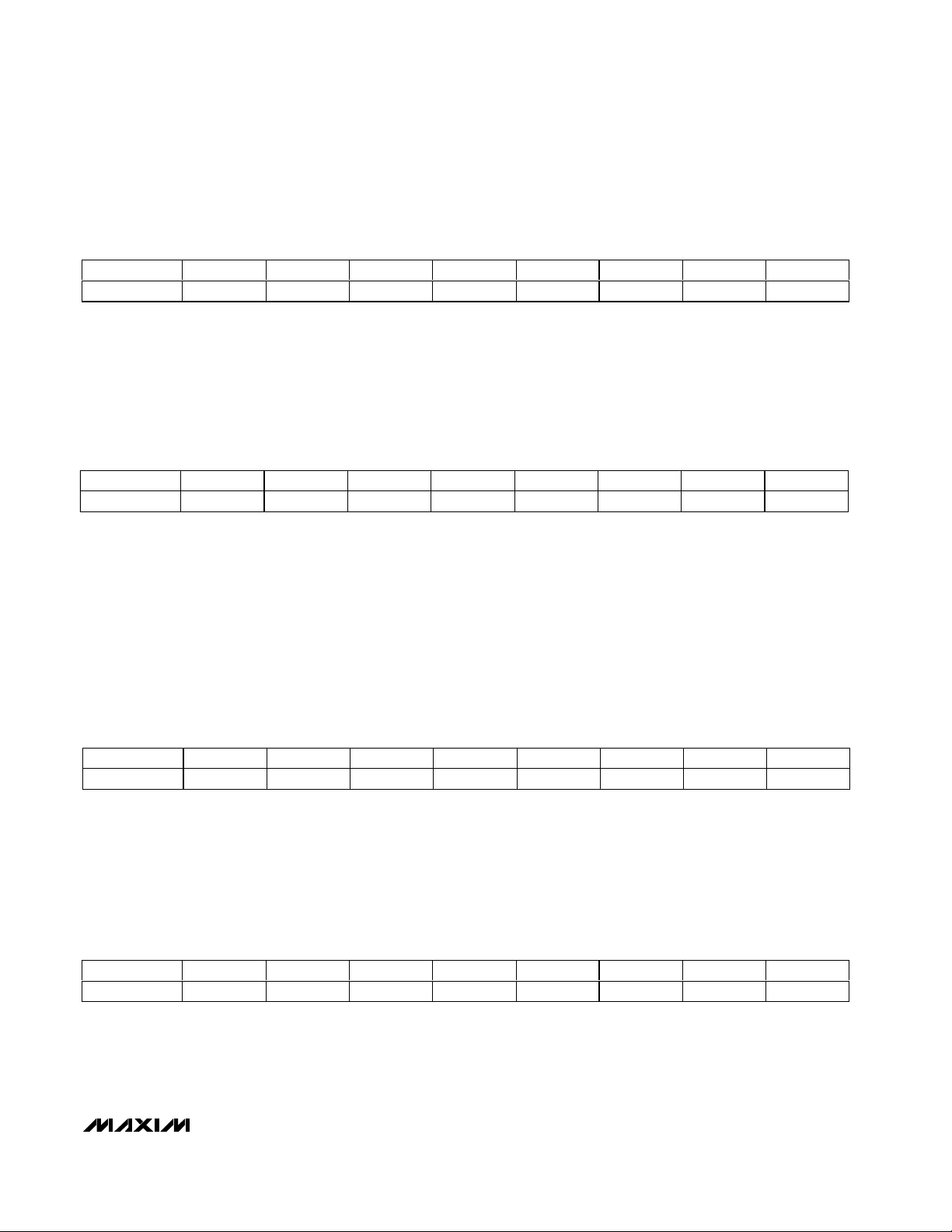

Table 4. Positive Mux Decoding

Table 5. Negative Mux Decoding

DATA REGISTER—Read-Only (00010)

MAX1407/MAX1414

AV

DD

REF REF REF 0 0 1

OUT1 IN4 OUT1 0 1 0

IN0 IN0 IN0 0 1 1

IN1 IN1 — 100

IN2 IN2 — 101

IN3 IN3 — 110

OUT2 IN5 — 111

MAX1407/MAX1414

AGND AGND AGND 0 0 0

REF REF REF 0 0 1

FB1 IN6 FB1 0 1 0

IN0 IN0 IN0 0 1 1

IN1 IN1 — 100

IN2 IN2 — 101

IN3 IN3 — 110

FB2 IN7 — 111

POSITIVE MUX INPUT

MAX1408 MAX1409

AV

DD

NEGATIVE MUX INPUT

MAX1408 MAX1409

AV

DD

MUXP2 MUXP1 MUXP0

000

MUXN2 MUXN1 MUXN0

FIRST BIT (MSB)

ADC15 ADC14 ADC13 ADC12 ADC11 ADC10 ADC9 ADC8

ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0

(LSB)

MAX1407/MAX1408/MAX1409/MAX1414

Low-Power, 16-Bit Multichannel DAS with

Internal Reference,10-Bit DACs, and RTC

28 ______________________________________________________________________________________

The Offset register contains the 16-bit result from the

most recently completed ADC offset calibration. The

data format is two’s complement and is subtracted from

the filter output before writing to the Data register. After

power-up, the Offset register contains all zeros.

Each change in ambient operating condition (power

supply and temperature), PGA gain, bipolar/unipolar

input range, buffered/unbuffered mode, or conversion

speed requires an offset calibration. The offset for a

given ADC configuration can be read and stored by the

µP to avoid ADC recalibration. When returning to an

ADC configuration where the offset was stored, write

back the stored offset to the Offset register. The stored

offset stays valid as long as the ambient operating condition remains unchanged (within ±20°C).

Force Sense DAC Registers

(MAX1407/MAX1409/MAX1414 only)

Writing to the DAC1 register updates the output of

DAC1. Writing to the DAC2 register updates the output

of DAC2. The DAC data is 10-bit long and left justified.

Follow the timing diagrams of Figure 11 and Figure 13

to program these registers. Writing a logic 0 to the

DA1E or DA2E bit in the POWER2 register disables

DAC1 or DAC2, respectively. At power-up, DAC1 and

DAC2 are disabled.

OFFSET REGISTER (00011)

DAC2 REGISTER (00101)

Writing to the DAC1 register will update the DAC1 output

(OUT1). The output voltage in a unity gain configuration is

V

REF

x N/(210), where N is the integer value of DAC1[9:0]

(0 to 1023), and V

REF

is the reference voltage for the

DAC. The DAC1 data is 10-bit long and left justified. After

power-up, the DAC1 register contains all zeros.

DAC1 REGISTER (00100)

Writing to the DAC2 register will update the DAC2 output

(OUT2). The output voltage in a unity-gain configuration is

V

REF

x N/(210), where N is the integer value of DAC2[9:0]

(0 to 1023), and V

REF

is the reference voltage for the

DAC. The DAC2 data is 10-bit long and left justified. After

power-up, the DAC2 register contains all zeros.

FIRST BIT (MSB)

OFF15 OFF14 OFF13 OFF12 OFF11 OFF10 OFF9 OFF8

OFF7 OFF6 OFF5 OFF4 OFF3 OFF2 OFF1 OFF0

FIRST BIT (MSB)

DAC1[9] DAC1[8] DAC1[7] DAC1[6] DAC1[5] DAC1[4] DAC1[3] DAC1[2]

DAC1[1] DAC1[0] x xxxxx

(LSB)

(LSB)