Page 1

General Description

The MAX105 evaluation kit (EV kit) is a fully assembled

and tested circuit board that contains all the components necessary to evaluate the performance of the

MAX105, dual channel, 6-bit (800Msps), or the

MAX107, dual channel, 6-bit (400Msps) high-speed

analog-to-digital converter (ADC). The MAX105 ADC is

able to process differential or single-ended analog

inputs. The EV kit allows the user to evaluate the ADC

with either type of signals. The digital output produced

by the ADC can be easily sampled with a user-provided high-speed logic analyzer or data-acquisition system. The EV kit comes with the MAX105 installed. To

evaluate the MAX107, replace the MAX105 with the

MAX107.

Features

♦ Two Matched 6-Bit, 800 Msps ADCs

♦ 0.8V

p-p

Input Signal Range

♦ Demultiplexed Differential LVDS Outputs

♦ Square-Pin Headers for Easy Connection of Logic

Analyzer to Digital Outputs

♦ Four-layer PC Board with Separate Analog and

Digital Power and Ground Connections

♦ Fully Assembled and Tested with MAX105

Installed

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

________________________________________________________________ Maxim Integrated Products 1

19-2055; Rev 0; 5/01

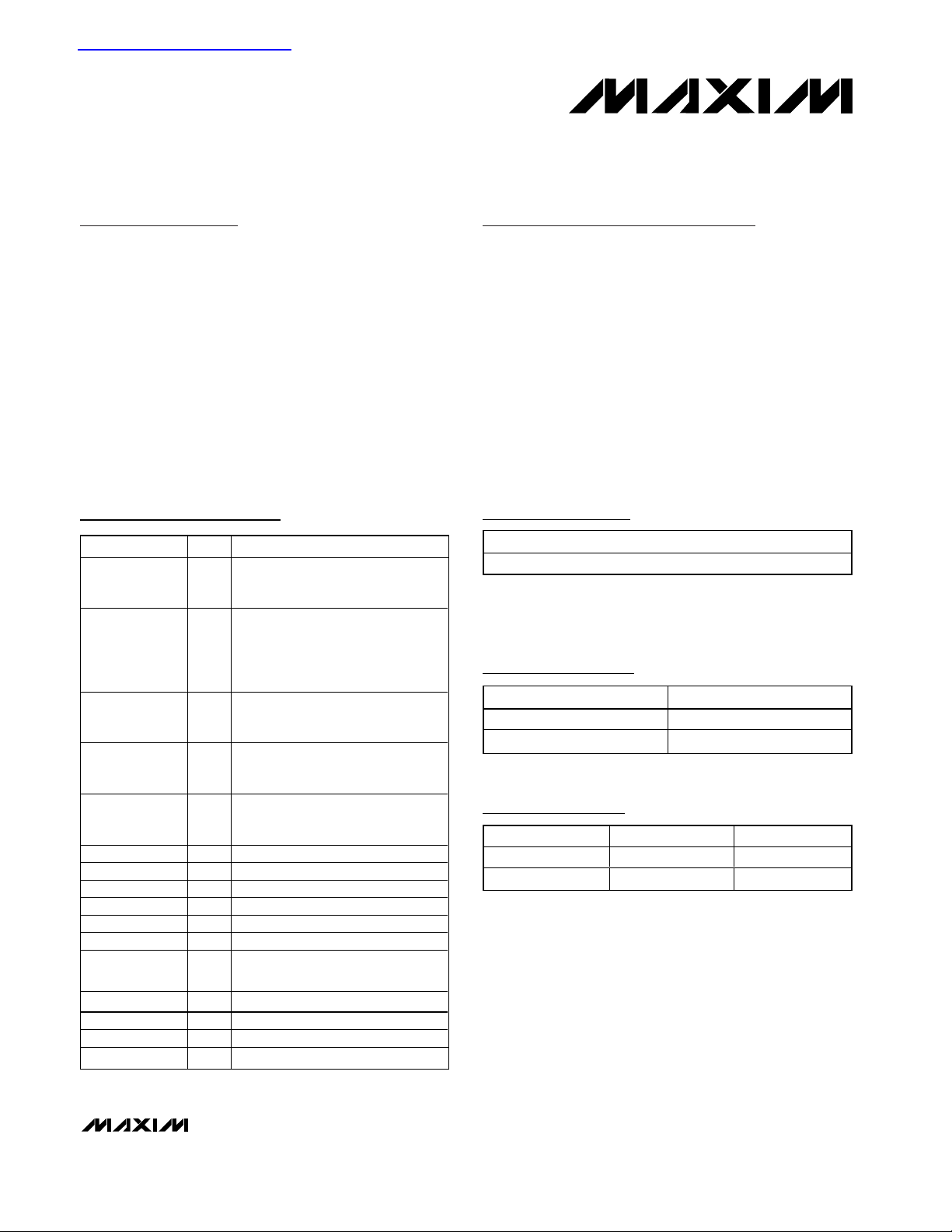

ADC Selection Table

Ordering Information

Component List

Component Suppliers

*Exposed pad

Note: Please indicate that you are using the MAX105 when contacting these component suppliers.

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

查询MAX105EVKIT供应商

DESIGNATION QTY DESCRIPTION

C1, C5, C9,

C13, C16,

C18, C20, C22

C2, C6, C10,

C14, C15,

C17, C19,

C21,

C24–C28, C30

C3, C4, C7,

C8, C11, C12

C23, C29 2

L1–L4 4

R1–R6 6 51.1Ω ±1% resistors (0402)

R7–R32 26 100Ω ±1% resistors (0402)

J1–J6 6 SMA connectors (edge-mounted)

JU1, JU2 0 Not installed 2-pin headers

JU4–JU55 52 2-pin headers

JU3 0 Not installed 3-pin header

AVCC, AGND,

OVCC, OGND

U1 1 MAX105ECS (80-pin TQFP-EP)

None 1 MAX105 PC board

None 1 MAX105 data sheet

None 1 MAX105 EV kit data sheet

47pF ±10%, +50V COG ceramic

8

capacitors (0402)

Murata GRM36COG470K050AD

0.01µF ±10%, +16V X7R ceramic

capacitors (0402)

14

Murata GRM36X7R103K016AD

100pF ±5%, +50V COG ceramic

6

capacitors (0402)

Murata GRM36COG101J050AD

10µF ±10%, +25V tantalum

capacitors (CASE D)

AVX TAJD106K025R

Ferrite beads 600Ω at 100MHz,

500mA , 0.3Ω DCR

Murata BLM21A601R

4 Test point hooks

MAX105EVKIT 0°C to 70°C 80 TQFP-EP*

MAX105ECS 800

MAX107ECS 400

AVX 803-946-0690 803-626-3123

Murata 814-237-1431 814-238-0490

PART TEMP. RANGE IC PACKAGE

PART SPEED (Msps)

SUPPLIER PHONE FAX

Page 2

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

2 _______________________________________________________________________________________

Quick Start

Test Equipment Required

• DC power supplies:

Digital +3.3V, 510mA

Analog +5.0V, 350mA

• Generator with low phase-noise for clock input

(e.g., HP8662A, HP8663A, or equivalent)

• Two signal generators for analog signal inputs (e.g.,

HP8662A, HP8663A, or equivalent)

• Logic analyzer or data-acquisition system (e.g.,

HP16500C series, HP16517A 1.25Gbps state

module for single-ended evaluation.

• User-selected analog bandpass filters (e.g., TTE

Elliptical Bandpass Filter, or equivalent)

• Digital Voltmeter

• Baluns (e.g., MA/COM H-9-SMA)

•50Ω terminators with SMA connectors

The MAX105 EV kit is a fully assembled and tested surface-mount board. Follow the steps below for board

operation. Do not turn on power supplies or enable

function generators until all connections are

completed.

1) Connect a signal generator with low phase-jitter to

the clock inputs CLK- and CLK+ through a balun

(Figure 1). For a single-ended clock input (Figure

2), connect a 500mV (354mV

RMS

, +4dBm) amplitude from the signal generator to the CLK+ input

and terminate the unused CLK- input with a 50Ω

termination resistor to AGND.

2) For differential operation, connect a ±380mV

270mV

RMS

(approximately -0.5dB FS) sine-wave

test signal to connector A of the balun. Terminate

connector B of the balun with a 50Ω terminator.

Attach connector C of the balun to the analog input

VINI+ (VINQ+). Attach connector D of the balun to

the analog input VINI- (Figure 1). For single-ended

operation, apply the test signal to either VINI+

(VINQ+) or VINI- (VINQ-) and terminate the unused

input with a 50Ω resistor to AGND (Figure 2). For

best results, use a narrow bandpass filter designed

for the frequency of interest to reduce the harmonic

distortion of the signal generator.

3) Phase-lock both the VINI and/or VINQ signal generators with the clock generator.

4) Connect a logic analyzer, such as the HP16500 with

the HP16517 plug-in module to monitor the I or Q

channel of the MAX105. Note that the podlets are

single-ended to ground and you may need to

remove the 100Ω termination resistors R7–R32 to

increase the logic signal swing. Reflections are

absorbed by the back-terminated LVDS drivers.

Note: Two state modules are required to monitor

both I and Q channel simultaneously.

5) Connect the logic analyzer clock to the DREADY+

output on the EV kit and set the logic analyzer to

trigger on the falling edge of the DREADY+ signal.

6) Connect a +5V power supply to the pad marked

AV

CC

. Connect the supply’s ground to the pad

marked AGND.

Note: MAX105 has separate AV

CC

I and AVCCQ

supply pins.

7) Connect a +3.3V power supply to the pad marked

OV

CC

. Connect the supply’s ground to the pad

marked OGND. Tie AGND and OGND together at

the power supplies.

Note: MAX105 has separate OV

CC

I and OVCCQ

supply pins.

8) Turn on both power supplies, then the signal

sources. Capture the digitized outputs from the

MAX105 with the logic analyzer and transfer the

digital record to a PC for data analysis.

Detailed Description

The MAX105 EV kit evaluates the performance of the

MAX105 dual channel, 6-bit ADC at a maximum clock

frequency of 800MHz (400MHz for MAX107). The

MAX105 ADC can process differential or single-ended

analog and clock inputs. The user may apply baluns to

generate differential signals from a single-ended analog signal to the EV kit.

The EV kit’s PC board incorporates a four-layer board

design to optimize the performance of the MAX105 in a

50Ω environment. Separate analog and digital ground

planes minimize noise coupling between analog and

digital signals. The EV kit requires a +5.0V power supply applied to the analog power plane, and a +3.3V

power supply applied to the digital power plane.

Access to the outputs is provided through the two-pin

headers (Table 1) all around the edge of the board. A

silkscreen on the PC board’s top layer indicates reference designations.

Page 3

Power Supplies

The MAX105 EV kit requires separate analog and digital power supplies for best performance. A +3.3V ±10%

power supply is used to power the digital portion

(OVCC) of the ADC. A separate +5.0V ±5% power supply is used to power the analog portion (AVCC) of the

ADC. Ferrite beads are used to filter out high-frequency

noise at the analog power supply. At 100MHz, the ferrite beads have an impedance of 600Ω.

Clock

The clock signals CLK± are AC-coupled from the SMA

connectors J3 and J4. The DC-biasing level is internally

set to the reference voltage. The MAX105’s clock input

resistance is 5kΩ. However, the EV kit’s clock input

resistance is set by an external resistor to 50Ω. An ACcoupled, differential sine-wave signal may be applied

to the CLK± SMA connectors (Figure 3). The signal

must not exceed a magnitude of 1.4V

RMS

. The typical

clock frequency should be 800MHz for MAX105

(400MHz for MAX107).

I/Q Input Signals

The input signals are AC-coupled. The DC biasing level

is internally set to the reference voltage V

REF

. The

MAX105’s analog input resistance is 2kΩ per input.

However, the EV kit’s I/Q input resistance is set to 50Ω

by an external resistor. For single-ended operation,

apply a signal to one of the analog inputs and terminate

the opposite complimentary input with a 50Ω resistor to

ground.

Note: When a differential signal is applied to the ADC,

the positive and negative input pins of the ADC each

receive half of the input signal supplied to the balun. A

common mode voltage of +2.5V is established within

the part and blocked by the AC-coupling capacitors.

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

_______________________________________________________________________________________ 3

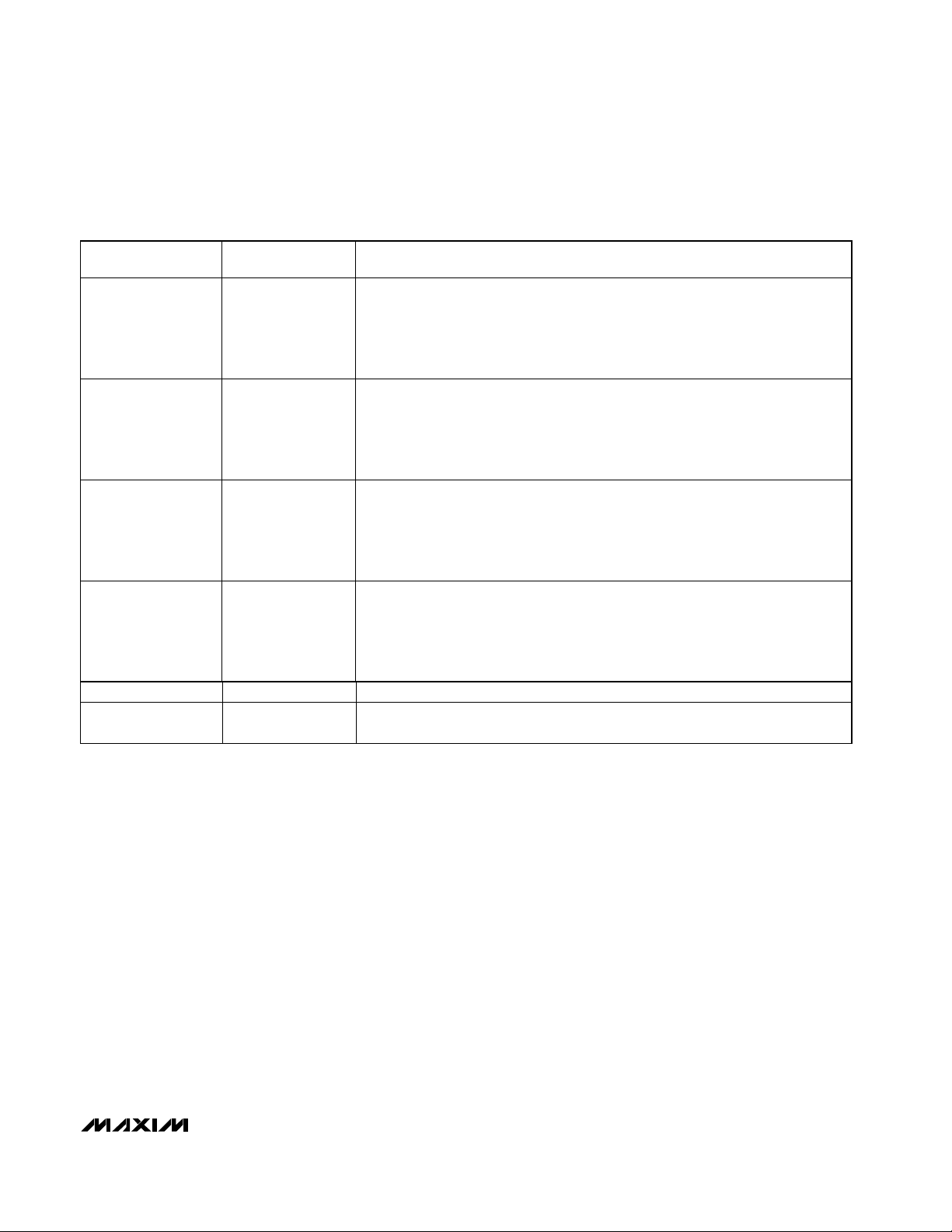

Table 1. LVDS Outputs and Functional Description

LVDS OUTPUT

SIGNALS

P5I+, P5I- (MSB)

P4I+, P4IP3I+, P3IP2I+, P2IP1I+, P1IP0I+, P0I- (LSB)

A5I+, A5I- (MSB)

A4I+, A4IA3I+, A3IA2I+, A2IA1I+, A1IA0I+, A0I- (LSB)

P5Q+, P5Q- (MSB)

P4Q+, P4QP3Q+, P3QP2Q+, P2QP1Q+, P1QP0Q+, P0Q- (LSB)

A5Q+, A5Q- (MSB)

A4Q+, A4QA3Q+, A3QA2Q+, A2QA1Q+, A1QA0Q+, A0Q- (LSB)

DOR+, DOR- JU33, JU32 Out-of-range signal’s true and complementary outputs

DREADY+,

DREADY-

EV KIT HEADER

LOCATION

JU52, JU53

JU48, JU49

JU44, JU45

JU12, JU13

JU40, JU41

JU36, JU37

JU54, JU55

JU50, JU51

JU46, JU47

JU18, JU19

JU42, JU43

JU38, JU39

JU6, JU7

JU10, JU11

JU16, JU17

JU22, JU23

JU27, JU26

JU31, JU30

JU4, JU5

JU8, JU9

JU14, JU15

JU20, JU21

JU25, JU24

JU29, JU28

JU34, JU35

FUNCTIONAL DESCRIPTION

Primary in-phase differential outputs from MSB to LSB. “+” indicates the true value,

“-” denotes the complementary outputs

Auxiliary in-phase differential outputs from MSB to LSB. “+” indicates the true

value, “-” denotes the complementary outputs

Primary quadrature differential outputs from MSB to LSB. “+” indicates the true

value, “-” denotes the complementary outputs

Auxiliary quadrature differential outputs from MSB to LSB. “+” indicates the true

value, “-” denotes the complementary outputs

Data Ready LVDS output latch clock. Output data changes on the rising edge of

DREADY+

Page 4

Evaluates: MAX105/MAX107

Reference

An on-chip reference is provided with a nominal +2.5V

output. This voltage is then processed to drive the

resistor ladder in the ADC core. A buffered reference

voltage is also used as the DC-bias voltage for the analog input.

Demultiplexing and LVDS Outputs

Each ADC provides six differential outputs (two’s complement code) at 800MHz, which fan out to 12 differential outputs at 400MHz after the on-chip demultiplexer.

To interface with lower supply CMOS DSP chips, all

outputs provide LVDS-compatible voltage levels. The

LVDS outputs will have approximately ±270mV swing

differential with a common mode around 1.25V. The differential output impedance is roughly 100Ω. For details,

refer to IEEE standard 1596.3.

*Note: To boost the output signal swing for singleended data capture with the HP16500C and HP16517A

high-speed state module, all 100Ω termination resistors (R7–R32) should be removed.

Out-of-Range (DOR) Signal

The out-of-range signal (DOR+, DOR-) flags high when

either the I or Q input is below -FS or above +FS. The

out-of-range signal has the same latency as the ADC

output data or is demultiplexed the same way. For an

800MHz system DOR+ and DOR- are clocked at

400MHz.

Data Ready (DREADY) Output

In single-ended data capture mode the clock interface

of the logic analyzer should be connected to the

DREADY output at headers JU34 or JU35 on the EV kit.

Since both the primary and auxiliary outputs change on

the rising edge of DREADY, set the logic analyzer to

trigger on the falling edge. DREADY and the data outputs are internally time aligned, which places the falling

edge of DREADY in the approximate center of the valid

data window, resulting in the maximum setup and hold

time for the logic analyzer.

Board Layout

The MAX105 EV kit is a four-layer PC board design

(Figure 4), optimized for high-speed signals. The board

is constructed from low-loss GETek core material which

has a relative dielectric constant of 3.9 (

ε

R

= 3.9). The

GETek material used in the MAX105 EV kit board offers

improved high frequency and thermal properties over

standard FR4 board material. All high-speed signals

are routed with differential microstrip transmission lines.

Special Layout Considerations

Special effort was made in the board layout to separate

the analog and digital portions of the circuit. 50Ω

microstrip transmission lines are used for analog and

clock inputs, as well as for all digital LVDS outputs. The

power plane is separated into strips to provide isolation

between different sections of the circuit (e.g., AV

CC

I and

AVCCQ or OVCCI and OVCCQ). All differential outputs are

properly terminated with 100Ω termination resistors

between true and complementary digital outputs.

The PC board comes in a circular shape to ensure the

best possible trace length matching for the 50Ω

microstrip lines. The electrical lengths of the 50Ω

microstrip lines are matched to within a few picoseconds to minimize layout-dependent delays. The propagation delay on the MAX105 EV kit board is about

130ps/inch.

The line width for a differential microstrip is 2.5mils with

a ground plane height of 14mils which is a standard

GETek core thickness. Table 2 shows PC board layers

of the EV kit.

MAX105 Evaluation Kit

4 _______________________________________________________________________________________

Table 2. MAX105 EV kit Layers

Layer I, Top Layer

Layer II, Ground

Plane

Layer III, Power

Plane

Layer IV, Bottom

Layer

LAYER DESCRIPTION

Components, Headers, Connectors,

Test Pads, AV

OGND, Analog 50Ω microstrip lines.

100Ω Termination Resistors

AGND, AGNDI, AGNDQ, AGNDR,

OGND, OGNDI, OGNDQ

AVCC, AVCCI, AVCCQ, AVCCR, OVCC,

OV

I, OVCCQ

CC

AGND, Components

, OVCC, AGND,

CC

Page 5

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

_______________________________________________________________________________________ 5

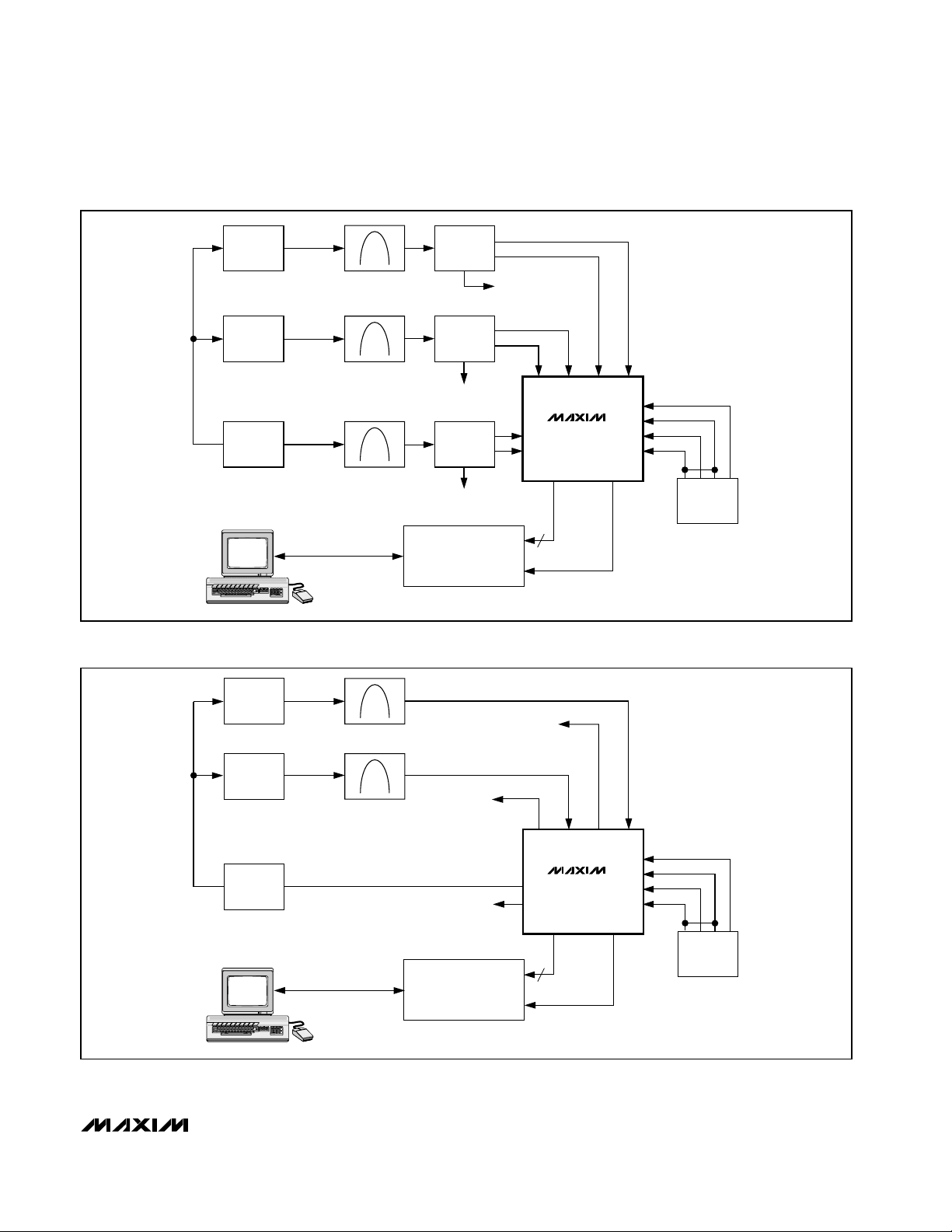

Figure 1. Typical Evaluation Setup with Differential Analog Inputs, Differential Clock Drive, and Single-Ended Data Capture

HP8662A/3A

SINE-WAVE

SOURCE

EXTERNAL 50Ω

TERMINATION TO AGND

BPF

HP8662A/3A

SINE-WAVE

SOURCE

BPF

VINI-

CLK+

CLK-

AV

CC

+5V ANALOG

AGND

+3.3V DIGITAL

DGND

AGND

OV

CC

DGND

V

IN

I+

OUTPUTS DREADY

VINQ- VINQ+

HP8662A/3A

SINE-WAVE

SOURCE

EXTERNAL 50Ω

TERMINATION TO

AGND

EXTERNAL 50Ω

TERMINATION TO

AGND

HP16500C

LOGIC ANALYZER

WITH HP16517A

1.25Gbps STATE MODULE

POWER

SUPPLIES

800MHz

+4dBm

GBIP

24 DATA

DREADY+

OR DREADY-

PHASELOCKED

PC

MAX105EVKIT

Figure 2. Typical Evaluation Setup with Single-Ended Analog Inputs, Single-Ended Clock Drive, and Single-Ended Data Capture

PHASELOCKED

HP8662A/3A

SINE-WAVE

SOURCE

HP8662A/3A

SINE-WAVE

SOURCE

HP8662A/3A

SINE-WAVE

SOURCE

PC

800MHz

+4dBm

GBIP

BPF

BPF

BPF

EXTERNAL 50Ω

TERMINATION TO AGND

EXTERNAL 50Ω

TERMINATION TO AGND

LOGIC ANALYZER

WITH HP16517A

1.25Gbps STATE MODULE

BALUN

A

BALUN

A

BALUN

A

HP16500C

C

BD

C

BD

C

BD

EXTERNAL 50Ω

TERMINATION TO

AGND

V

I-

IN

MAX105EVKIT

CLK+

CLK-

OUTPUTS DREADY

24 DATA

DREADY+

OR DREADY-

V

IN

I+

VINQ- VINQ+

AV

AGND

OV

DGND

CC

CC

+5V ANALOG

AGND

+3.3V DIGITAL

DGND

POWER

SUPPLIES

Page 6

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

6 _______________________________________________________________________________________

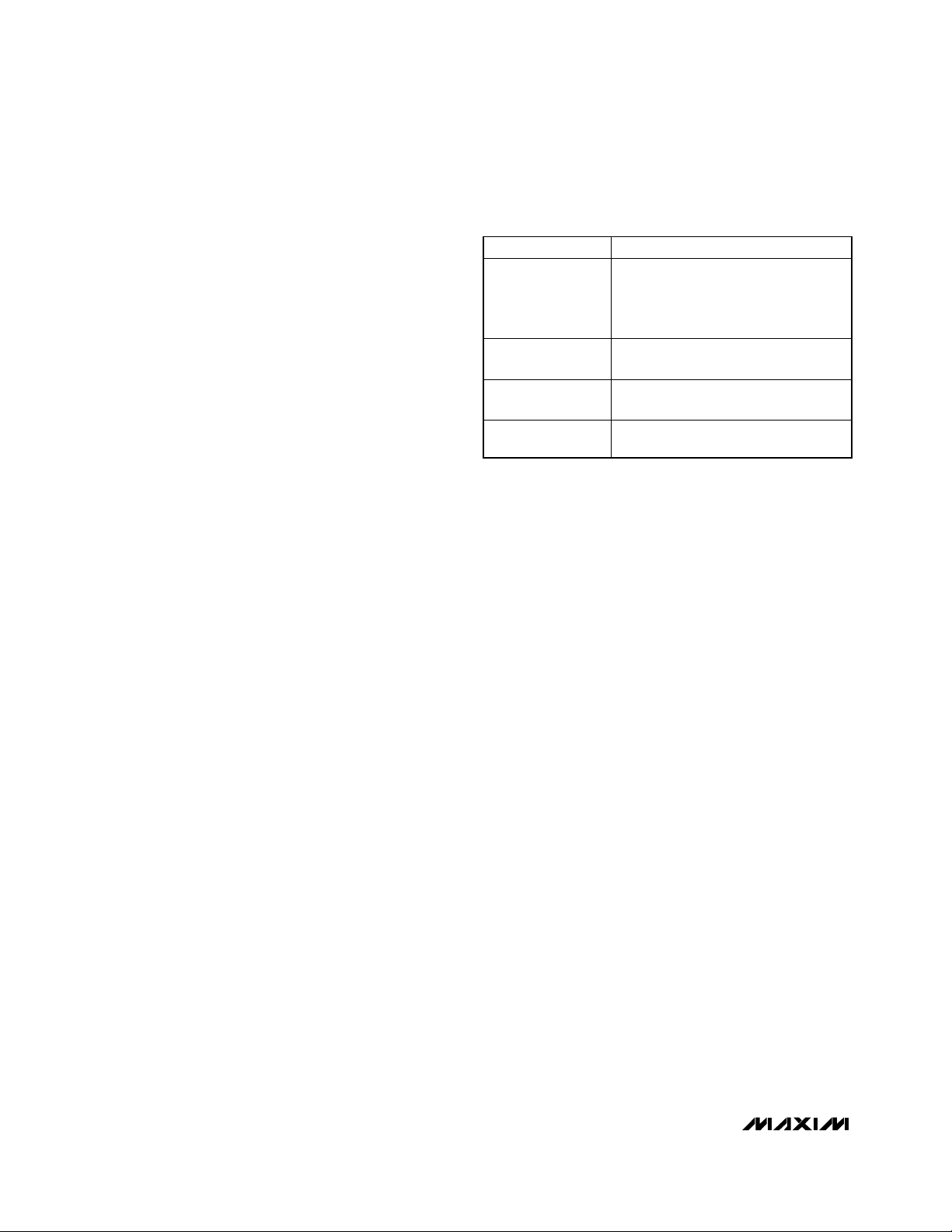

Figure 3. AC-Coupled, Differential Clock Drive

25mils

50Ω

50Ω

25mils

LAYER NO. 1 (TOP)

LAYER NO. 2

LAYER NO. 3

LAYER NO. 4 (BOTTOM)

1oz. Cu

14mils GETek CORE

14mils GETek CORE

GETek PREPREG AS NEEDED

Figure 4. PC Board Stacking

D

SIGNAL

SOURCE

50Ω

180°

A

0°

CONNECTION

0°

B

0°

C

AGND

EXTERNAL

50Ω

SMA

SMA

50Ω

50Ω

AGND

MAX105EVkit

AGND

TO ADC

CLK-

100pF

TO ADC

CLK+

100pF

Page 7

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

_______________________________________________________________________________________ 7

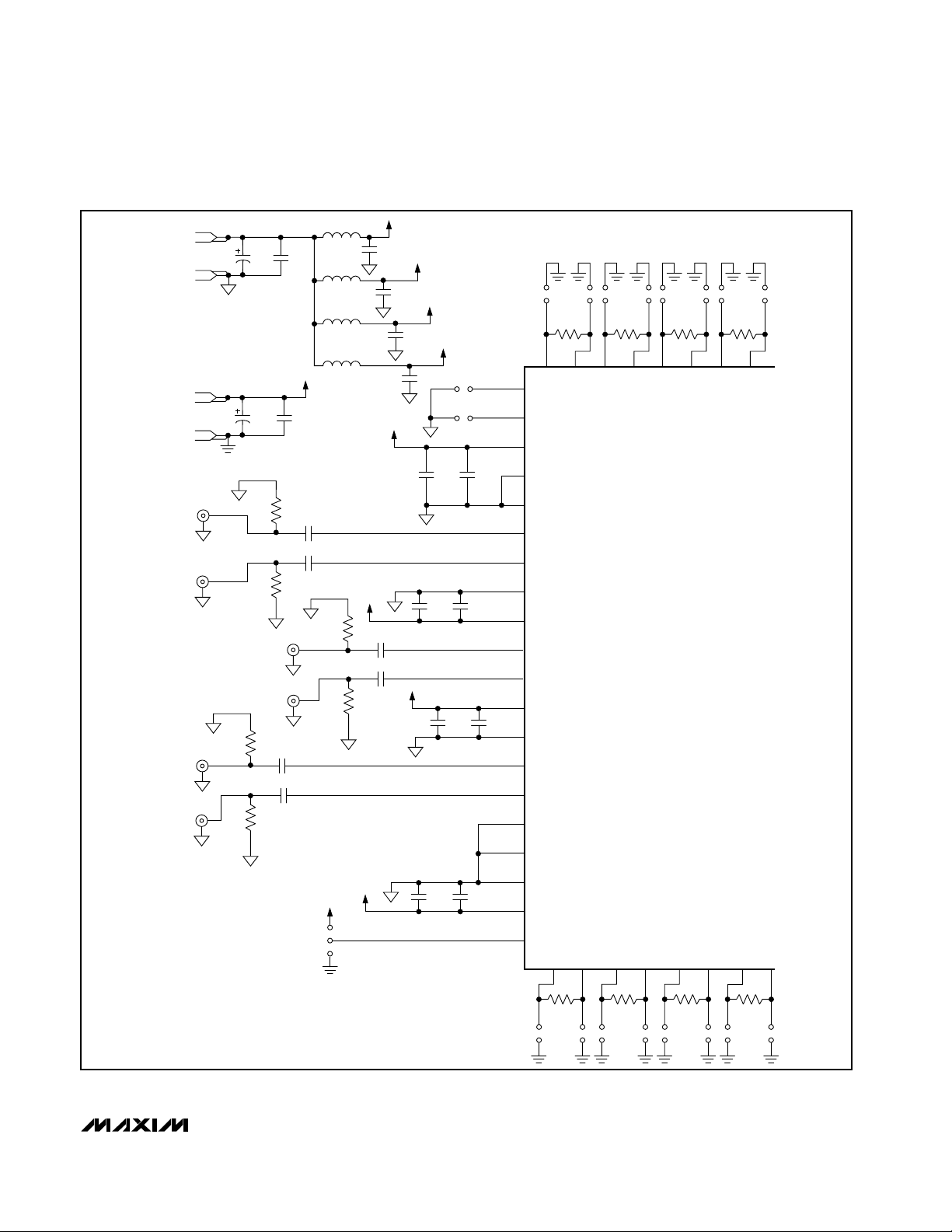

J7

Figure 5a. MAX105 EV Kit Schematic

J8

J9

J10

J1

AGND

AGND

J5

AGND

J6

AGND

J2

AGND

AGND

AGND

AGND

C23

10µF

C29

10µF

R5

51.1Ω

R6

51.1Ω

AGND

J3

J4

C24

0.01µF

R1

51.1Ω

R2

51.1Ω

AGND

AGND

C12

100pF

C11

100pF

OVCC

C30

0.01µF

AGND

JU3

C4

100pF

C3

100pF

OVCC

IND1

IND1

IND1

IND1

L1

L2

L3

L4

AGND

AVCCI

R3

51.1Ω

R4

51.1Ω

AVCC

AVCCR

C25

0.01µF

AVCCR

AGND

C8

100pF

C7

100pF

AGND

C26

0.01µF

AVCCI

C27

0.01µF

AVCCQ

AGND

AVCCQ

C28

0.01µF

AGND

AVCC

C2

0.01µF

C6

0.01µF

C14

0.01µF

C10

0.01µF

JU54 JU55

R32

100Ω

80 73747576777879

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

A5I+ P4I-P4I+A4I-A4I+P5I-P5I+A5I-

TEMPS

REF

R

AV

CC

AGNDR

AGNDI

V

-

INI

+

V

INI

AGNDI

I

AV

CC

CLK+

CLK-

Q

AV

CC

AGNDQ

V

Q+

IN

Q-

V

IN

AGNDQ

SUB

AGND

AV

CC

TESTB

A5Q+ P4Q-P4Q+A4Q-A4Q+P5Q-P5Q+A5Q-

21 28272625242322

JU1

JU2

C1

47pF

C5

47pF

C9

47pF

C13

47pF

JU52 JU53

R31

100Ω

JU50 JU51

R30

100Ω

JU48 JU49

R29

100Ω

R7

100Ω

JU4 JU5

R8

100Ω

JU6 JU7

R9

100Ω

JU8 JU9

R10

100Ω

JU10 JU11

Page 8

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

8 _______________________________________________________________________________________

Figure 5b. MAX105 EV Kit Schematic (continued)

OVCC

C22

47pF

C21

0.01µF

U1

JU46 JU47

R28

100Ω

JU44 JU45

R27

100Ω

C20

OVCC

47pF

JU18 JU19

C19

0.01µF

IOGNDIP3I-P3I+A3I-A3I+OGNDIOVCCI P2I-

CC

MAX105

QP3Q-P3Q+A3Q-A3Q+OGNDQOVCCQ P2Q-

CC

R14

100Ω

JU12 JU13

100Ω

6263646566676869707172 61

P2I+A2I-A2I+OV

P2Q+A2Q-A2Q+OGNDQOV

3938373635343332313029 40

R11

A1I+

A1I-

P1I+

P1I-

A0I+

A0I-

P0I+

P0I-

DREADY+

DREADY-

D0R-

D0R+

P0Q-

P0Q+

A0Q-

A0Q+

P1Q-

P1Q+

A1Q-

A1Q+

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

R26

100Ω

R25

100Ω

R24

100Ω

R23

100Ω

R22

100Ω

R21

100Ω

R20

100Ω

R19

100Ω

R18

100Ω

R17

100Ω

JU42

JU43

JU40

JU41

JU38

JU39

JU36

JU37

JU34

JU35

JU32

JU33

JU30

JU31

JU28

JU29

JU26

JU27

JU24

JU25

X1

MTHOLE

X2

MTHOLE

X3

MTHOLE

X4

MTHOLE

X5

LOGO

1

1

1

1

1

C16

OVCC OVCC

47pF

C15

0.01µF

R12

100Ω

JU14 JU15

R13

100Ω

JU16 JU17

C18

47pF

C17

0.01µF

R15

100Ω

JU20 JU21

R16

100Ω

JU22 JU23

Page 9

________________________________________________________________________________________________ 9

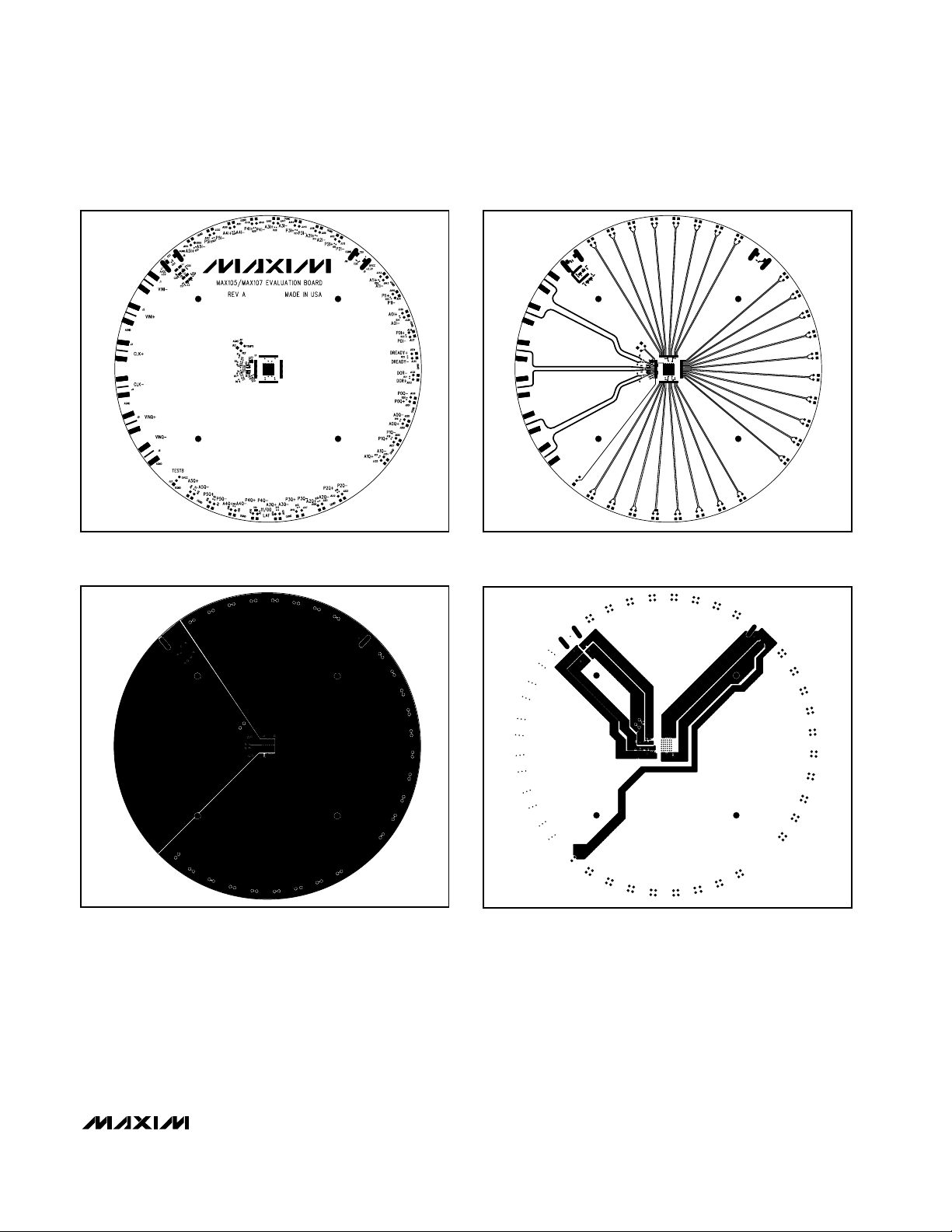

Figure 6. MAX105 EV Kit Component Placement Guide—

Component Side

Figure 7. MAX105 EV Kit PC Board Layout—Component Side

Figure 8. MAX105 EV Kit PC Board Layout—Inner Layer,

Ground Plane

MAX105 Evaluation Kit

Evaluates: MAX105/MAX107

Figure 9. MAX105 EV Kit PC Board Layout—Inner Layer,

Power Plane

Page 10

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

10 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2001 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Evaluates: MAX105/MAX107

MAX105 Evaluation Kit

Figure 10. MAX105 EV Kit PC Board Layout—Solder Side

Figure 11. MAX105 EV Kit Component Placement Guide—

Solder Side

Loading...

Loading...