General Description

The DS2045W is a 1Mb reflowable nonvolatile (NV)

SRAM, which consists of a static RAM (SRAM), an NV

controller, and an internal rechargeable manganese

lithium (ML) battery. These components are encased in

a surface-mount module with a 256-ball BGA footprint.

Whenever VCCis applied to the module, it recharges the

ML battery, powers the SRAM from the external power

source, and allows the contents of the SRAM to be modified. When V

CC

is powered down or out of tolerance,

the controller write-protects the SRAM’s contents and

powers the SRAM from the battery. The DS2045W also

contains a power-supply monitor output, RST, which can

be used as a CPU supervisor for a microprocessor.

Applications

RAID Systems and Servers POS Terminals

Industrial Controllers Data-Acquisition Systems

Gaming Fire Alarms

Router/Switches PLC

Features

♦ Single-Piece, Reflowable, 27mm2PBGA Package

Footprint

♦ Internal ML Battery and Charger

♦ Unconditionally Write-Protects SRAM when V

CC

is Out-of-Tolerance

♦ Automatically Switches to Battery Supply when

V

CC

Power Failures Occur

♦ Internal Power-Supply Monitor Detects Power Fail

Below Nominal V

CC

(3.3V)

♦ Reset Output can be used as a CPU Supervisor

for a Microprocessor

♦ Industrial Temperature Range (-40°C to +85°C)

♦ UL Recognized

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

______________________________________________ Maxim Integrated Products 1

Rev 1; 1/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Ordering Information

Pin Configuration appears at end of data sheet.

PART TEMP RANGE PIN-PACKAGE

SUPPLY TOLERANCE (%)

DS2045W-100 -40°C to +85°C 256 Ball 27mm

2

BGA Module

100 3.3V ±0.3V

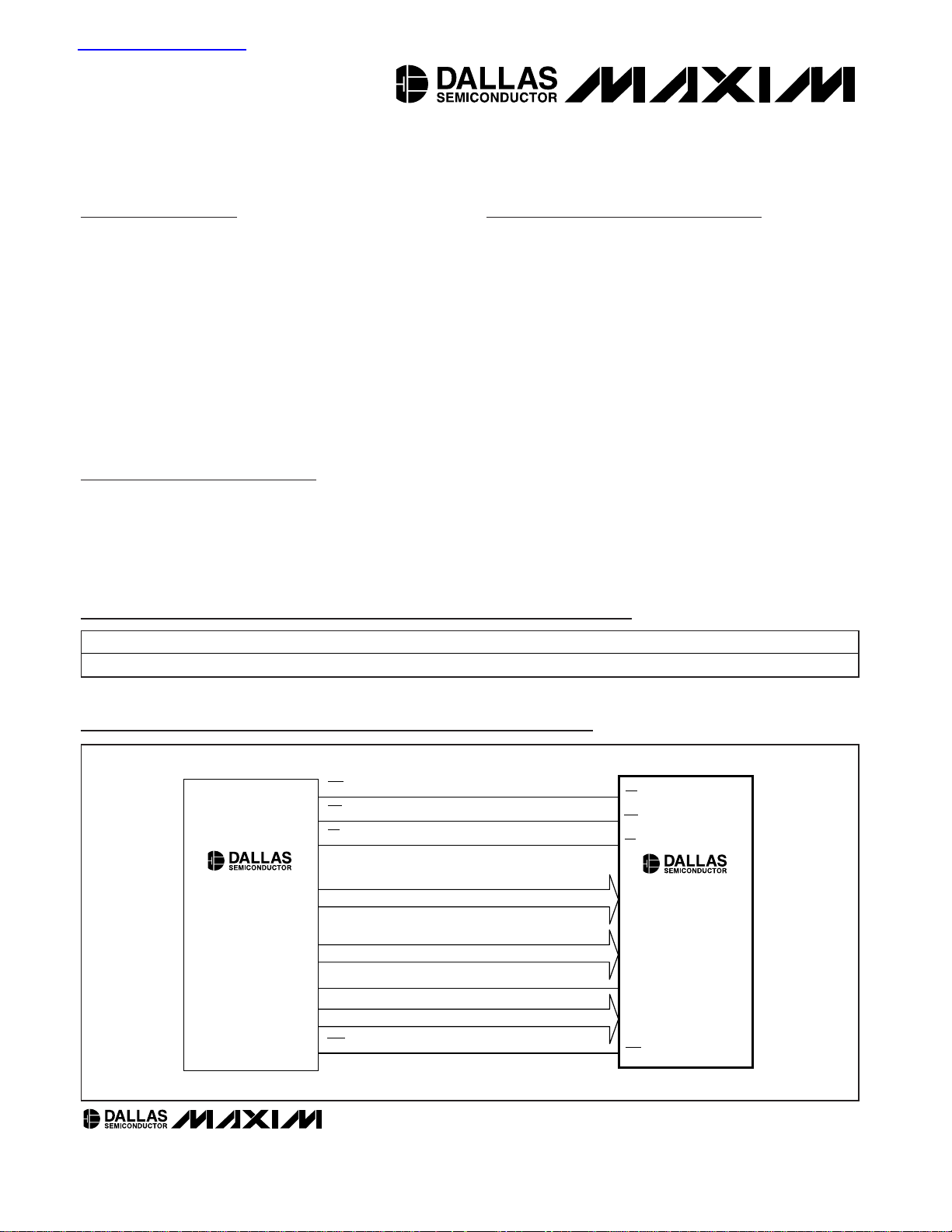

Typical Operating Circuit

P4.0

P3.6

P3.7

P1.0–7

AD0–AD7

P4.4

P2.0–7

P3.2

RST

A8–15

A0–7

A16

DQ0–7

OE

WE

CE

8 BITS

8 BITS

8 BITS

(CE0)

(INT0)

8051

MICROPROCESSOR

DS2045W

128k x 8

NV SRAM

(WR)

(RD)

查询DS2045W供应商

SPEED (ns)

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

2 _____________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

RECOMMENDED OPERATING CONDITIONS

(TA= -40°C to +85°C)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage on Any Pin Relative to Ground .................-0.3V to +4.6V

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range ...............................-40°C to +85°C

Soldering Temperature...................See IPC/JEDEC J-STD-020C

PARAMETER

CONDITIONS

Supply Voltage V

CC

3.0 3.3 3.6 V

Input Logic 1 V

IH

2.2

V

Input Logic 0 V

IL

0 0.4 V

CAPACITANCE

(TA= +25°C)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Input Capacitance C

IN

Not tested 7 pF

Input/Output Capacitance C

OUT

Not tested 7 pF

DC ELECTRICAL CHARACTERISTICS

(VCC= 3.3V ±0.3V, TA= -40°C to +85°C.)

PARAMETER

CONDITIONS

UNITS

Input Leakage Current I

IL

µA

I/O Leakage Current I

IO

CE = V

CC

µA

Output-Current High I

OH

At 2.4V

mA

Output-Current Low I

OL

At 0.4V 2.0 mA

Output-Current Low RST

At 0.4V (Note 1)

mA

I

CCS1

CE = 2.2V 0.5 7

Standby Current

I

CCS2

CE = V

CC

- 0.2V 0.2 5

mA

Operating Current I

CCO1tRC

= 200ns, outputs open 50 mA

Write Protection Voltage V

TP

2.8 2.9 3.0 V

SYMBOL

SYMBOL

MIN TYP MAX UNITS

V

CC

MIN TYP MAX

-1.0 +1.0

-1.0 +1.0

-1.0

IOL RST

10.0

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

_____________________________________________________________________ 3

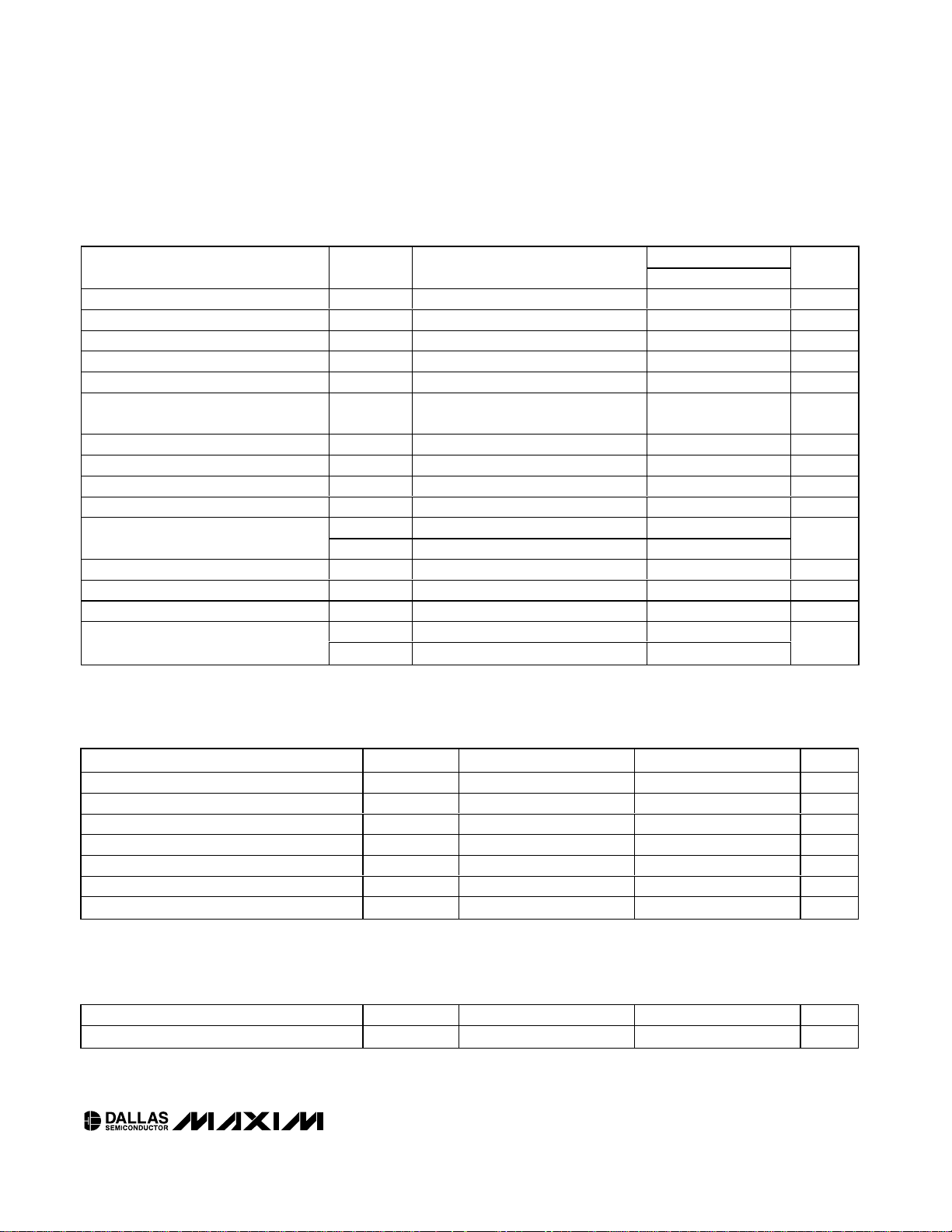

POWER-DOWN/POWER-UP TIMING

(TA= -40°C to +85°C)

PARAMETER

SYMBOL

CONDITIONS

UNITS

VCC Fail Detect to CE and WE Inactive t

PD

(Note 7) 1.5 µs

VCC Slew from VTP to 0V t

F

µs

VCC Slew from 0V to V

TP

t

R

µs

VCC Valid to CE and WE Inactive t

PU

2ms

VCC Valid to End of Write Protection t

REC

125 ms

VCC Fail Detect to RST Active t

RPD

(Note 1) 3.0 µs

VCC Valid to RST Inactive t

RPU

(Note 1)

525 ms

DATA RETENTION

(TA= +25°C)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Expected Data-Retention Time (Per Charge) t

DR

(Note 8) 2 3

years

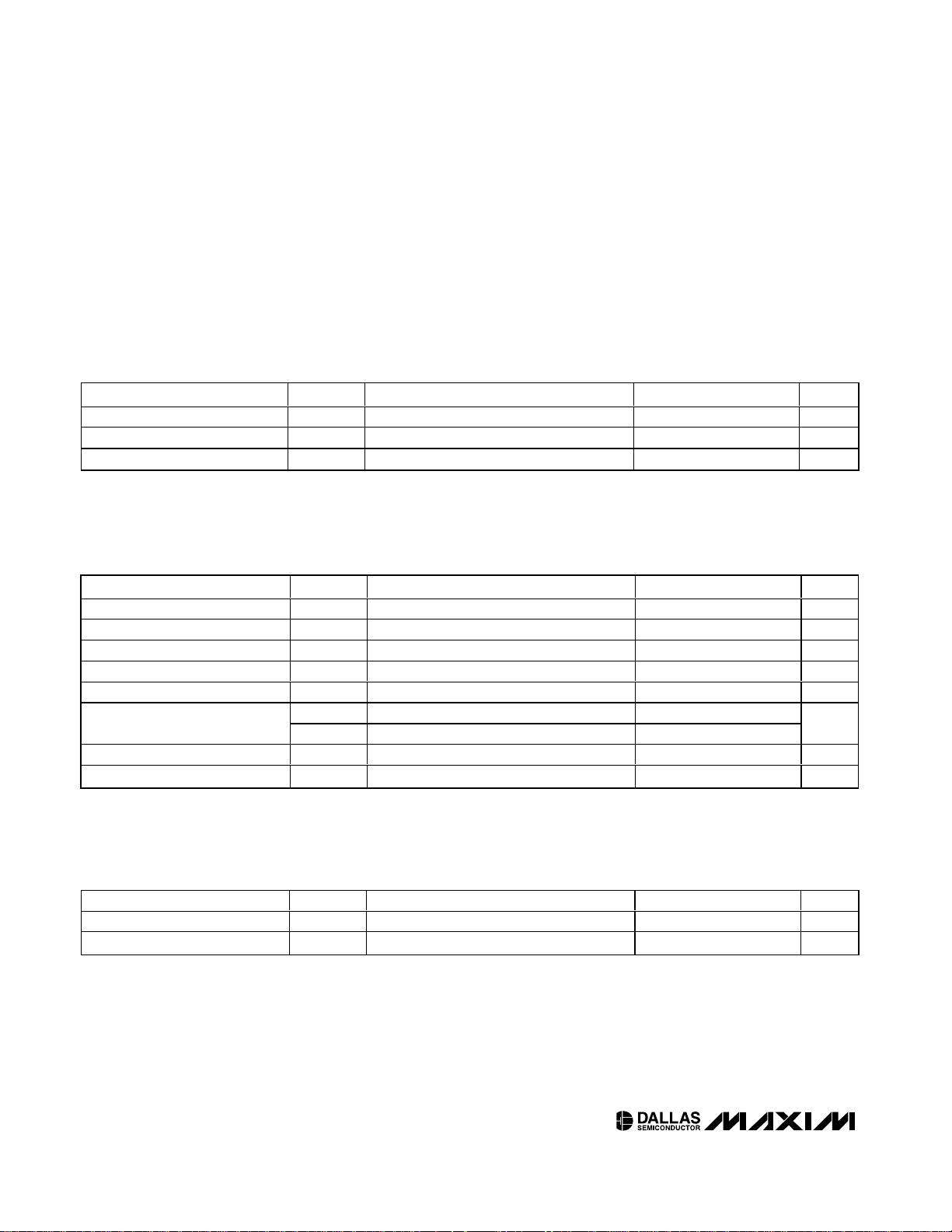

AC ELECTRICAL CHARACTERISTICS

(VCC= 3.3V ±0.3V, TA= -40°C to +85°C.)

DS2045W-100

PARAMETER

CONDITIONS

MIN MAX

UNITS

Read Cycle Time

t

RC

100 ns

Access Time

t

ACC

100 ns

OE to Output Valid

t

OE

50 ns

CE to Output Valid

t

CO

100 ns

OE or CE to Output Active

t

COE

(Note 2) 5 ns

Output High Impedance from

Deselection

t

OD

(Note 2) 35 ns

Output Hold from Address Change

t

OH

5ns

Write Cycle Time

t

WC

100 ns

Write Pulse Width

t

WP

(Note 3) 75 ns

Address Setup Time

t

AW

0ns

t

WR1

(Note 4) 5

Write Recovery Time

t

WR2

(Note 5) 20

ns

Output High Impedance from WE

t

ODW

(Note 2) 35 ns

Output Active from WE

t

OEW

(Note 2) 5 ns

Data Setup Time

t

DS

(Note 6) 40 ns

t

DH1

(Note 4) 0

Data Hold Time

t

DH2

(Note 5) 20

ns

SYMBOL

MIN TYP MAX

150

150

225 350

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

4 _____________________________________________________________________

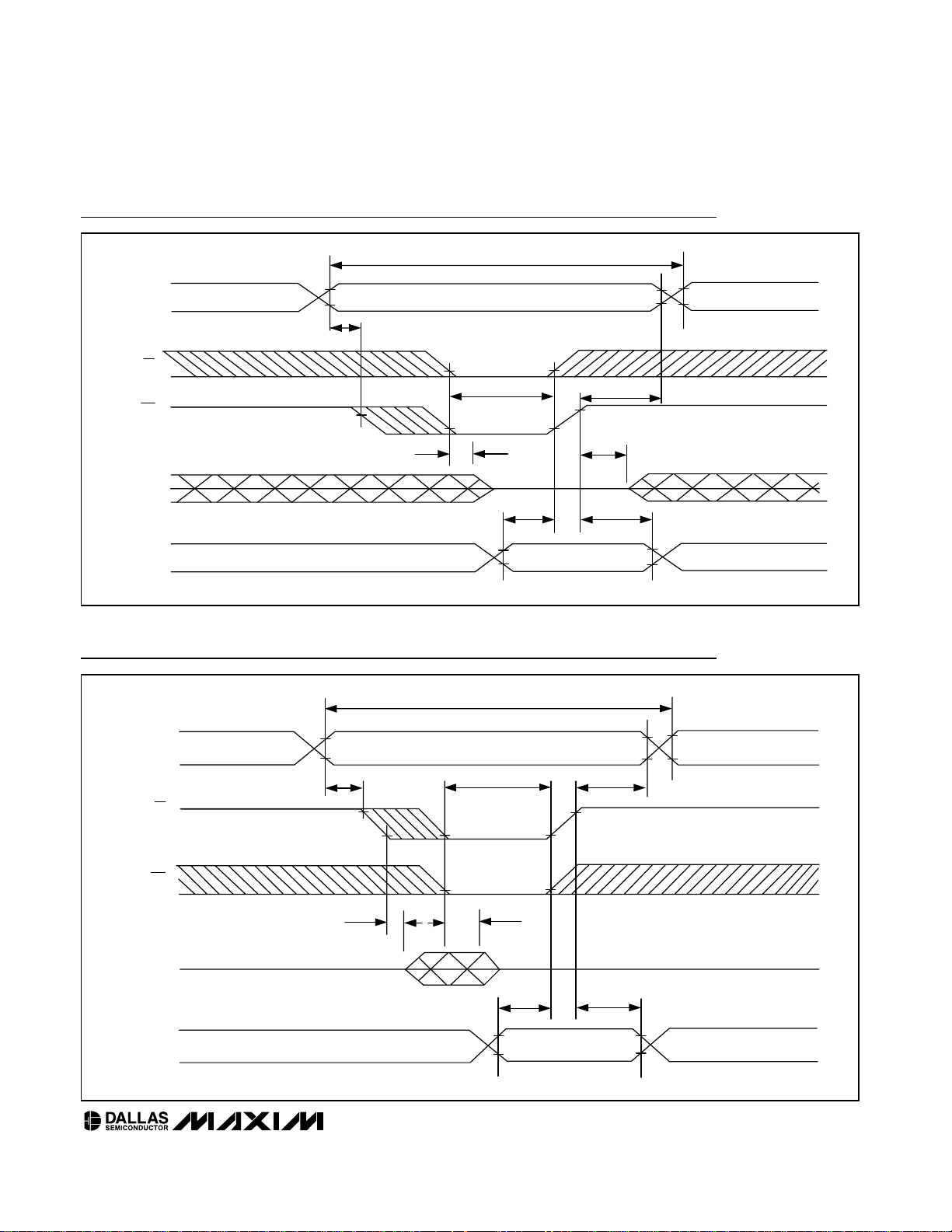

Read Cycle

OUTPUT

DATA VALID

t

RC

t

ACC

t

CO

t

OE

t

OH

t

OD

t

OD

t

COE

t

COE

V

IH

V

IH

V

IL

V

OH

V

OL

V

OH

V

OL

V

IL

V

IH

ADDRESSES

CE

OE

D

OUT

(SEE NOTE 9.)

V

IH

V

IH

V

IH

V

IH

V

IL

V

IL

V

IL

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

_____________________________________________________________________ 5

Write Cycle 1

DATA IN STABLE

ADDRESSES

CE

WE

D

OUT

D

IN

t

WC

V

IH

V

IH

V

IH

V

IH

V

IL

V

IL

V

IL

HIGH

IMPEDANCE

V

IH

V

IH

V

IL

V

IL

V

IH

V

IL

V

IL

V

IL

V

IL

t

AW

t

WP

t

OEW

t

DH1

t

DS

t

ODW

t

WR1

(SEE NOTES 2, 3, 4, 6, 10–13.)

Write Cycle 2

t

WC

t

AW

t

DH2

t

DS

t

COE

t

ODW

t

WP

t

WR2

V

IH

V

IL

V

IH

ADDRESSES

CE

WE

D

OUT

D

IN

V

IL

V

IH

V

IL

V

IH

V

IL

V

IL

V

IL

V

IL

V

IH

V

IH

V

IL

V

IH

DATA IN STABLE

V

IL

V

IH

V

IL

(SEE NOTES 2, 3, 5, 6, 10–13.)

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

6 _____________________________________________________________________

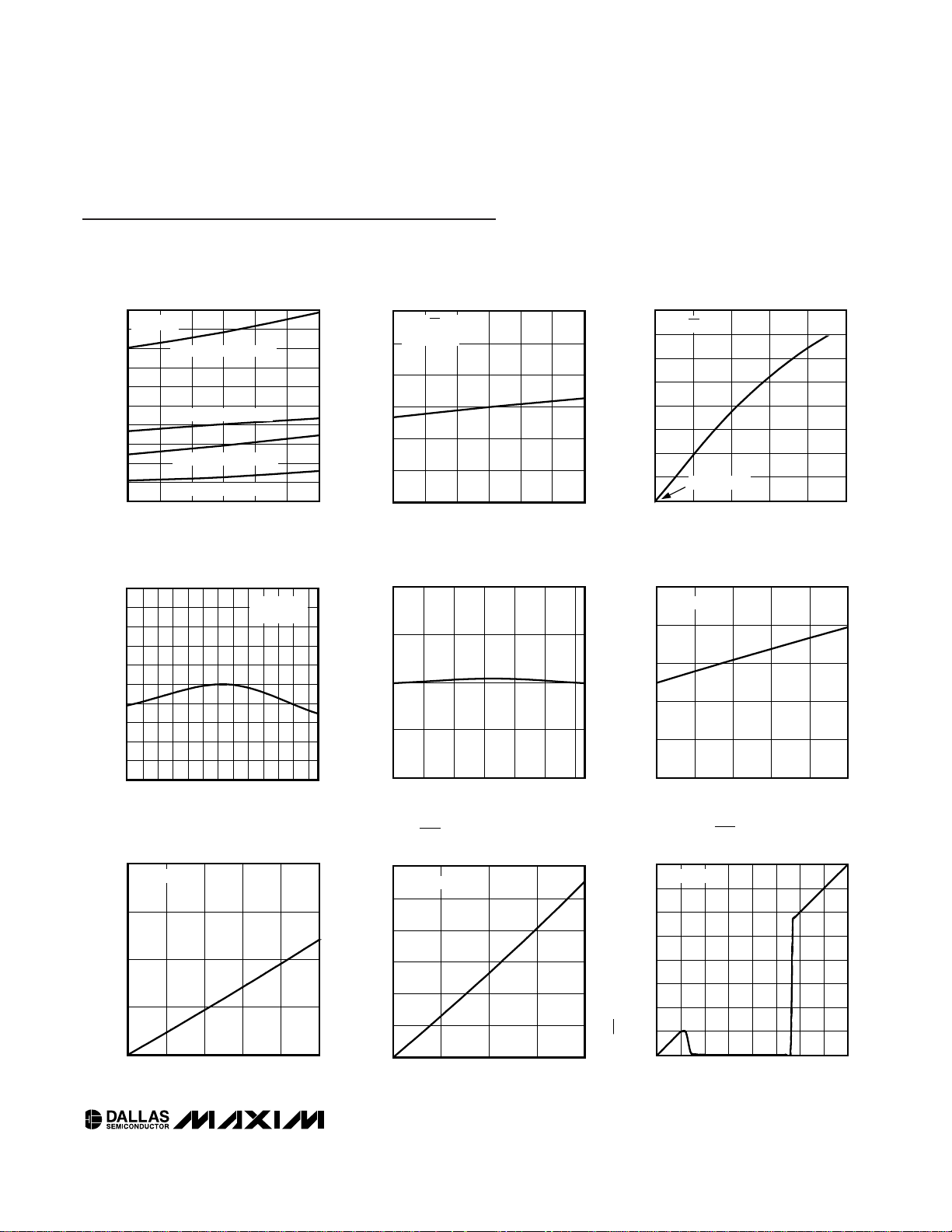

Power-Down/Power-Up Condition

t

DR

t

PU

t

F

t

PD

t

RPU

t

RPD

SLEWS WITH

V

CC

t

R

V

OL

V

IH

V

OL

t

REC

V

CC

V

TP

~2.5V

CE,

WE

RST

BACKUP CURRENT

SUPPLIED FROM

LITHIUM BATTERY

(SEE NOTES 1, 7.)

Note 1: RST is an open-drain output and cannot source current. An external pullup resistor should be connected to this pin to real-

ize a logic-high level.

Note 2: These parameters are sampled with a 5pF load and are not 100% tested.

Note 3: t

WP

is specified as the logical AND of CE and WE. tWPis measured from the latter of CE or WE going low to the earlier of

CE or WE going high.

Note 4: t

WR1

and t

DH1

are measured from WE going high.

Note 5: t

WR2

and t

DH2

are measured from CE going high.

Note 6: t

DS

is measured from the earlier of CE or WE going high.

Note 7: In a power-down condition, the voltage on any pin can not exceed the voltage on V

CC

.

Note 8: The expected t

DR

is defined as accumulative time in the absence of VCCstarting from the time power is first applied by the

user. Minimum expected data-retention time is based on a maximum of two +230°C convection solder reflow exposures,

followed by a fully charged cell. Full charge occurs with the initial application of V

CC

for a minimum of 96 hours. This para-

meter is assured by component selection, process control, and design. It is not measured directly in production testing.

Note 9: WE is high for a read cycle.

Note 10: OE = VIHor VIL. If OE = VIHduring write cycle, the output buffers remain in a high-impedance state.

Note 11: If the CE low transition occurs simultaneously with or latter than the WE low transition, the output buffers remain in a high-

impedance state during this period.

Note 12: If the CE high transition occurs prior to or simultaneously with the WE high transition, the output buffers remain in a high-

impedance state during this period.

Note 13: If WE is low or the WE low transition occurs prior to or simultaneously with the CE low transition, the output buffers remain

in a high-impedance state during this period.

Note 14: DS2045W BGA modules are recognized by Underwriters Laboratory (UL) under file E99151.

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

_____________________________________________________________________ 7

SUPPLY CURRENT

vs. OPERATING FREQUENCY

DS2045W toc01

VCC (V)

SUPPLY CURRENT (mA)

3.53.3

3.4

3.2

3.1

4

2

8

12

10

6

16

18

14

20

0

3.0 3.6

5MHz 100% DUTY CYCLE

5MHz 50% DUTY CYCLE

1MHz 100% DUTY CYCLE

1MHz 50% DUTY CYCLE

TA = +25°C

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

DS2045W toc02

VCC (V)

SUPPLY CURRENT (µA)

3.5

3.3 3.4

3.1

3.2

130

140

150

160

170

180

120

3.0 3.6

VCC = CE

V

BAT

= V

CHRG

BATTERY CHARGER CURRENT

vs. BATTERY VOLTAGE

DS2045W toc03

DELTA BELOW V

CHRG

(V)

BATTERY CHARGER CURRENT, I

CHRG

(mA)

0.6 0.80.40.2

1

2

3

4

5

6

7

8

0

01.0

VCC = CE = 3.3V

V

CHRG

= 2.86V

V

CHRG

PERCENT CHANGE

vs. TEMPERATURE

DS2045W toc04

TEMPERATURE (°C)

V

CHRG

PERCENT CHANGE FROM +25°C (%)

80705060-10 0 10 20 30 40-30-20

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

-0.5

-40

VCC = 3.3V

V

BAT

= V

CHRG

VTP vs. TEMPERATURE

DS2045W toc05

TEMPERATURE (°C)

WRITE PROTECT, V

TP

(V)

80

60

20

40

0-20

2.85

2.90

2.95

3.00

2.80

-40

DQ VOH vs. DQ I

OH

DS2045W toc06

IOH (mA)

V

OH

(V)

-1-2-3-4

2.7

2.9

3.1

3.3

3.5

2.6

-5 0

VCC = 3.3V

DQ VOL vs. DQ I

OL

DS2045W toc07

IOL (mA)

V

OL

(V)

4132

0.1

0.2

0.3

0.4

0

05

VCC = 3.3V

RST OUTPUT-VOLTAGE LOW

vs. OUTPUT-CURRENT LOW

DS2045W toc08

IOL (mA)

V

OL

(V)

15105

0.1

0.2

0.3

0.5

0.4

0.6

0

020

VCC = 2.8V

RST VOLTAGE

vs. V

CC

DURING POWER-UP

DS2045W toc09

VCC POWER-UP (V)

RST VOLTAGE W/PULLUP RESISTOR (V)

3.52.5 3.01.0 1.5

2.0

0.5

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0

0 4.0

TA = +25°C

Typical Operating Characteristics

(VCC= +3.3V, TA= +25°C, unless otherwise noted.)

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

8 _____________________________________________________________________

BALLS

NAME

DESCRIPTION

A1, A2, A3, A4

Ground

B1, B2, B3, B4 N.C. No Connection

C1, C2, C3, C4 A15 Address Input 15

D1, D2, D3, D4 A16 Address Input 16

E1, E2, E3, E4 RST

Open-Drain Reset Output

F1, F2, F3, F4 V

CC

Supply Voltage

G1, G2, G3, G4 WE Write Enable Input

H1, H2, H3, H4 OE Output Enable Input

J1, J2, J3, J4 CE Chip Enable Input

K1, K2, K3, K4 DQ7 Data Input/Output 7

L1, L2, L3, L4 DQ6 Data Input/Output 6

M1, M2, M3, M4 DQ5 Data Input/Output 5

N1, N2, N3, N4 DQ4 Data Input/Output 4

P1, P2, P3, P4 DQ3 Data Input/Output 3

R1, R2, R3, R4 DQ2 Data Input/Output 2

T1, T2, T3, T4 DQ1 Data Input/Output 1

U1, U2, U3, U4 DQ0 Data Input/Output 0

V1, V2, V3, V4

Ground

W1, W2, W3, W4

Ground

Y1, Y2, Y3, Y4

Ground

A17, A18, A19, A20

Ground

B17, B18, B19, B20 N.C. No Connection

C17, C18, C19, C20 N.C. No Connection

D17, D18, D19, D20 A14 Address Input 14

E17, E18, E19, E20 A13 Address Input 13

F17, F18, F19, F20 A12 Address Input 12

G17, G18, G19, G20 A11 Address Input 11

H17, H18, H19, H20 A10 Address Input 10

J17, J18, J19, J20 A9 Address Input 9

K17, K18, K19, K20 A8 Address Input 8

L17, L18, L19, L20 A7 Address Input 7

M17, M18, M19, M20 A6 Address Input 6

Pin Description

GND

GND

GND

GND

GND

BALLS NAME DESCRIPTION

N17, N18, N19, N20 A5 Address Input 5

P17, P18, P19, P20 A4 Address Input 4

R17, R18, R19, R20 A3 Address Input 3

T17, T18, T19, T20 A2 Address Input 2

U17, U18, U19, U20 A1 Address Input 1

V17, V18, V19, V20 A0 Address Input 0

W17, W18, W19, W20 GND Ground

Y17, Y18, Y19, Y20 GND Ground

A5, B5, C5, D5 N.C. No Connection

A6, B6, C6, D6 N.C. No Connection

A7, B7, C7, D7 N.C. No Connection

A8, B8, C8, D8 N.C. No Connection

A9, B9, C9, D9 N.C. No Connection

A10, B10, C10, D10 N.C. No Connection

A11, B11, C11, D11 N.C. No Connection

A12, B12, C12, D12 N.C. No Connection

A13, B13, C13, D13 N.C. No Connection

A14, B14, C14, D14 N.C. No Connection

A15, B15, C15, D15 N.C. No Connection

A16, B16, C16, D16 N.C. No Connection

U5, V5, W5, Y5 N.C. No Connection

U6, V6, W6, Y6 N.C. No Connection

U7, V7, W7, Y7 N.C. No Connection

U8, V8, W8, Y8 N.C. No Connection

U9, V9, W9, Y9 N.C. No Connection

U10, V10, W10, Y10 N.C. No Connection

U11, V11, W11, Y11 N.C. No Connection

U12, V12, W12, Y12 N.C. No Connection

U13, V13, W13, Y13 N.C. No Connection

U14, V14, W14, Y14 N.C. No Connection

U15, V15, W15, Y15 N.C. No Connection

U16, V16, W16, Y16 N.C. No Connection

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

_____________________________________________________________________ 9

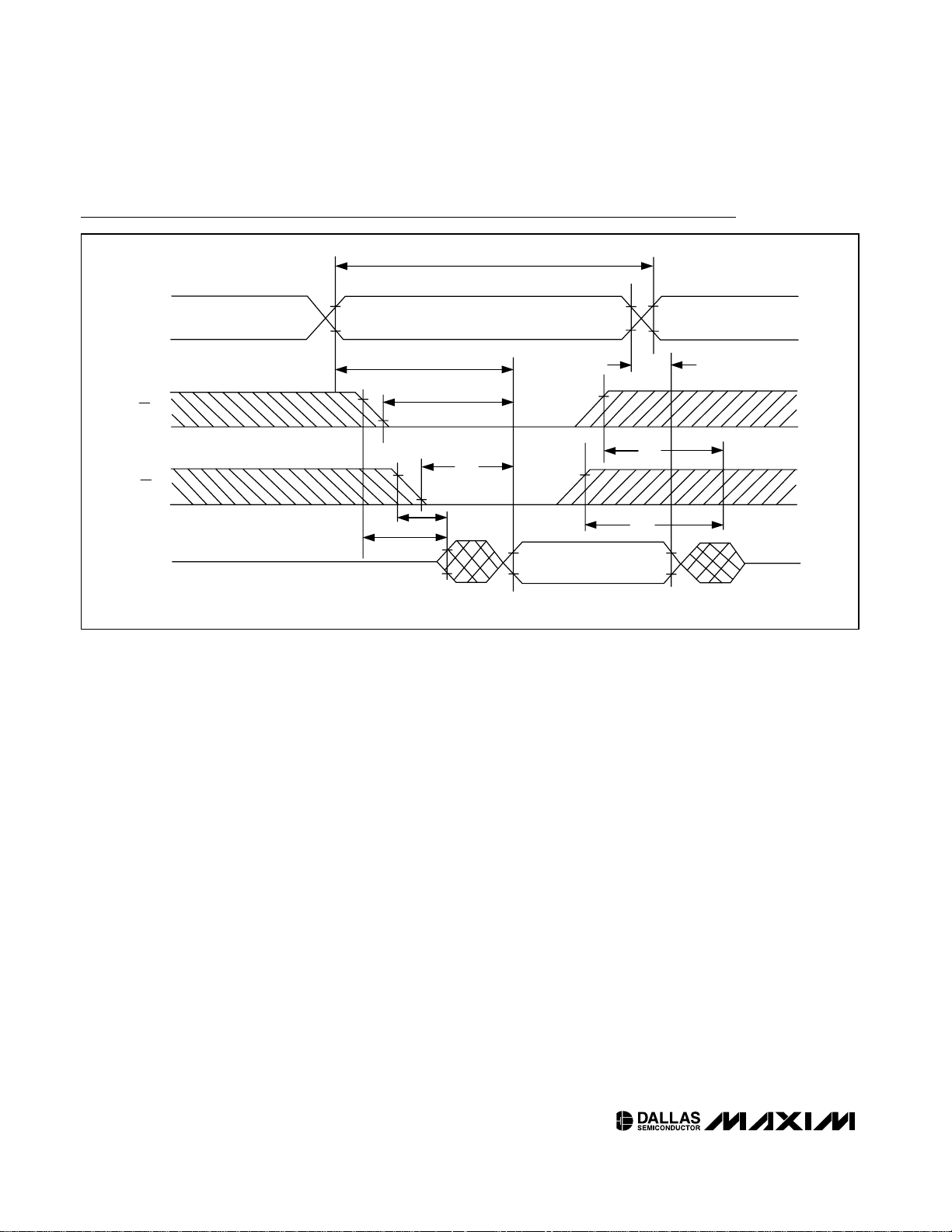

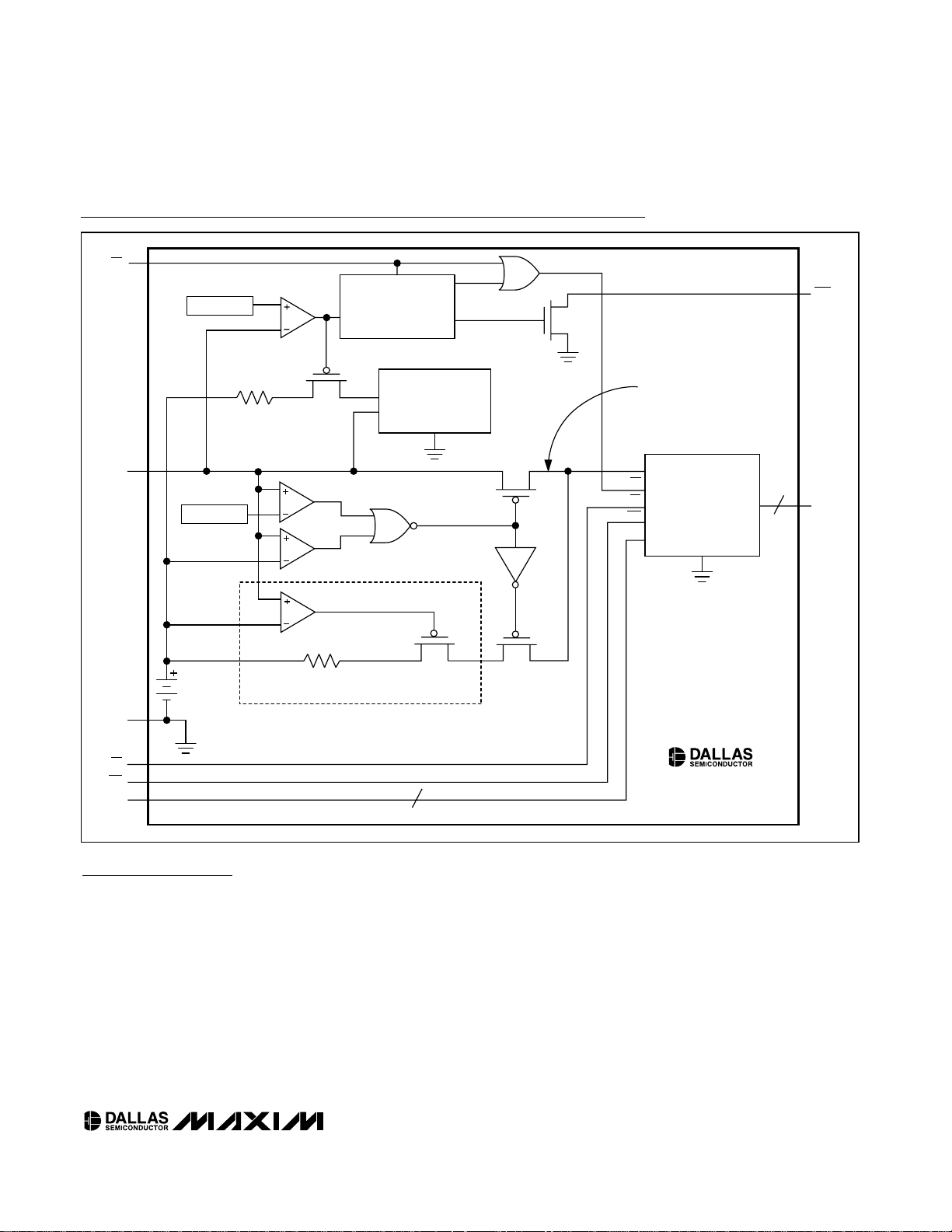

Functional Diagram

CURRENT-LIMITING

RESISTOR

BATTERY-CHARGING/SHORTING

PROTECTION CIRCUITRY (UL RECOGNIZED)

REDUNDANT LOGIC

DELAY TIMING

CIRCUITRY

CHARGER

CURRENT-LIMITING

RESISTOR

V

TP

REF

V

SW

REF

GND

ML

CE

RST

CE

REDUNDANT

SERIES FET

SRAM

DQ0–7

OE

WE

V

CC

V

CC

UNINTERRUPTED

POWER SUPPLY

FOR THE SRAM

DS2045W

OE

WE

A0–A16

Detailed Description

The DS2045W is a 1Mb (128kb x 8 bits) fully static, NV

memory similar in function and organization to the

DS1245W NV SRAM, but containing a rechargeable ML

battery. The DS2045W NV SRAM constantly monitors

VCCfor an out-of-tolerance condition. When such a condition occurs, the lithium energy source is automatically

switched on and write protection is unconditionally

enabled to prevent data corruption. There is no limit to

the number of write cycles that can be executed and no

additional support circuitry is required for microprocessor

interfacing. This device can be used in place of SRAM,

EEPROM, or flash components.

The DS2045W assembly consists of a low-power SRAM,

an ML battery, and an NV controller with a battery charger, integrated on a standard 256-ball, 27mm2BGA substrate. Unlike other surface-mount NV memory modules

that require the battery to be removable for soldering,

the internal ML battery can tolerate exposure to convection reflow soldering temperatures allowing this single-piece component to be handled with standard BGA

assembly techniques.

The DS2045W also contains a power-supply monitor

output, RST, which can be used as a CPU supervisor

for a microprocessor.

DS2045W

Read Mode

The DS2045W executes a read cycle whenever WE (write

enable) is inactive (high) and CE (chip enable) is active

(low). The unique address specified by the 17 address

inputs (A0 to A16) defines which of the 131,072 bytes of

data is to be accessed. Valid data will be available to the

eight data output drivers within t

ACC

(access time) after

the last address input signal is stable, providing that CE

and OE (output enable) access times are also satisfied. If

CE and OE access times are not satisfied, then data

access must be measured from the later occurring signal

(CE or OE) and the limiting parameter is either tCOfor CE

or tOEfor OE rather than address access.

Write Mode

The DS2045W executes a write cycle whenever the CE

and WE signals are active (low) after address inputs

are stable. The later-occurring falling edge of CE or WE

will determine the start of the write cycle. The write

cycle is terminated by the earlier rising edge of CE or

WE. All address inputs must be kept valid throughout

the write cycle. WE must return to the high state for a

minimum recovery time (t

WR

) before another cycle can

be initiated. The OE control signal should be kept inactive (high) during write cycles to avoid bus contention.

However, if the output drivers have been enabled (CE

and OE active) then WE will disable the outputs in t

ODW

from its falling edge.

Data-Retention Mode

The DS2045W provides full functional capability for V

CC

greater than 3.0V and write-protects by 2.8V. Data is

maintained in the absence of VCCwithout additional

support circuitry. The NV static RAM constantly monitors V

CC

. Should the supply voltage decay, the NV

SRAM automatically write-protects itself. All inputs

become “don’t care”, and all data outputs become high

impedance. As VCCfalls below approximately 2.5V

(VSW), the power-switching circuit connects the lithium

energy source to the RAM to retain data. During powerup, when VCCrises above VSW, the power-switching

circuit connects external VCCto the RAM and disconnects the lithium energy source. Normal RAM operation

can resume after VCCexceeds VTPfor a minimum

duration of t

REC

.

Battery Charging

When VCCis greater than VTP, an internal regulator

charges the battery. The UL-approved charger circuit

includes short-circuit protection and a temperature-stabilized voltage reference for on-demand charging of

the internal battery. Typical data-retention expectations

of 3 years per charge cycle are achievable.

A maximum of 96 hours of charging time is required to

fully charge a depleted battery.

System Power Monitoring

When the external VCCsupply falls below the selected

out-of-tolerance trip point, the output RST is forced

active (low). Once active, the RST is held active until

the VCCsupply has fallen below that of the internal battery. On power-up, the RST output is held active until

the external supply is greater than the selected trip

point and one reset timeout period (t

RPU

) has elapsed.

This is sufficiently longer than t

REC

to ensure that the

SRAM is ready for access by the microprocessor.

Freshness Seal and Shipping

The DS2045W is shipped from Dallas Semiconductor

with the lithium battery electrically disconnected, guaranteeing that no battery capacity has been consumed

during transit or storage. As shipped, the lithium battery

is ~60% charged, and no preassembly charging operations should be attempted.

When VCCis first applied at a level greater than VTP,

the lithium battery is enabled for backup operation. A

96 hour initial battery charge time is recommended for

new system installations.

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

10 ____________________________________________________________________

Memory Operation Truth Table

X = Don’t care.

WE CE OE MODE I

CC

OUTPUTS

100 Read Active Active

101 Read Active High Impedance

00XWrite Active High Impedance

X1X Standby Standby High Impedance

Recommended Cleaning Procedures

The DS2045W may be cleaned using aqueous-based

cleaning solutions. No special precautions are needed

when cleaning boards containing a DS2045W module.

Removal of the topside label violates the environmental integrity of the package and voids the warranty of

the product.

Applications Information

Power-Supply Decoupling

To achieve the best results when using the DS2045W,

decouple the power supply with a 0.1µF capacitor. Use

a high-quality, ceramic surface-mount capacitor if possible. Surface-mount components minimize lead inductance, which improves performance, while ceramic

capacitors have adequately high frequency response

for decoupling applications.

Using the Open-Drain

RST

Output

The RST output is open drain, and therefore requires a

pullup resistor to realize a high logic output level. Pullup

resistor values between 1kΩ and 10kΩ are typical.

Battery Charging/Lifetime

The DS2045W charges an ML battery to maximum

capacity in approximately 96 hours of operation when

VCCis greater than VTP. Once the battery is charged,

its lifetime depends primarily on the VCCduty cycle.

The DS2045W can maintain data from a single, initial

charge for up to 3 years. Once recharged, this deepdischarge cycle can be repeated up to 20 times, producing a worst-case service life of 60 years. More

typical duty cycles are of shorter duration, enabling the

DS2045W to be charged hundreds of times, therefore

extending the service life well beyond 60 years.

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

____________________________________________________________________ 11

Note: All temperatures refer to top side of the package, measured on the package body surface.

PROFILE FEATURE

Sn-Pb EUTECTIC

ASSEMBLY

Average ramp-up rate

(T

L

to TP)

3°C/second max

Preheat

- Temperature min (T

Smin

)

- Temperature max (T

Smax

)

- Time (min to max) (ts)

100°C

150°C

60 to 120 seconds

T

Smax

to T

L

- Ramp-up rate

Time maintained above:

-

Temperature (TL)

- Time (t

L

)

183°C

60 to 150 seconds

Peak temperature (TP) 225 +0/-5°C

Time within 5°C of actual peak

temperature (T

P

)

10 to 30 seconds

Ramp-down rate 6°C/second max

Time 25°C to peak temperature 6 minutes max

Recommended Reflow Temperature Profile

DS2045W

DS2045W 3.3V Single-Piece 1Mb

Nonvolatile SRAM

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2005 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

is a registered trademark of Dallas Semiconductor Corporation.

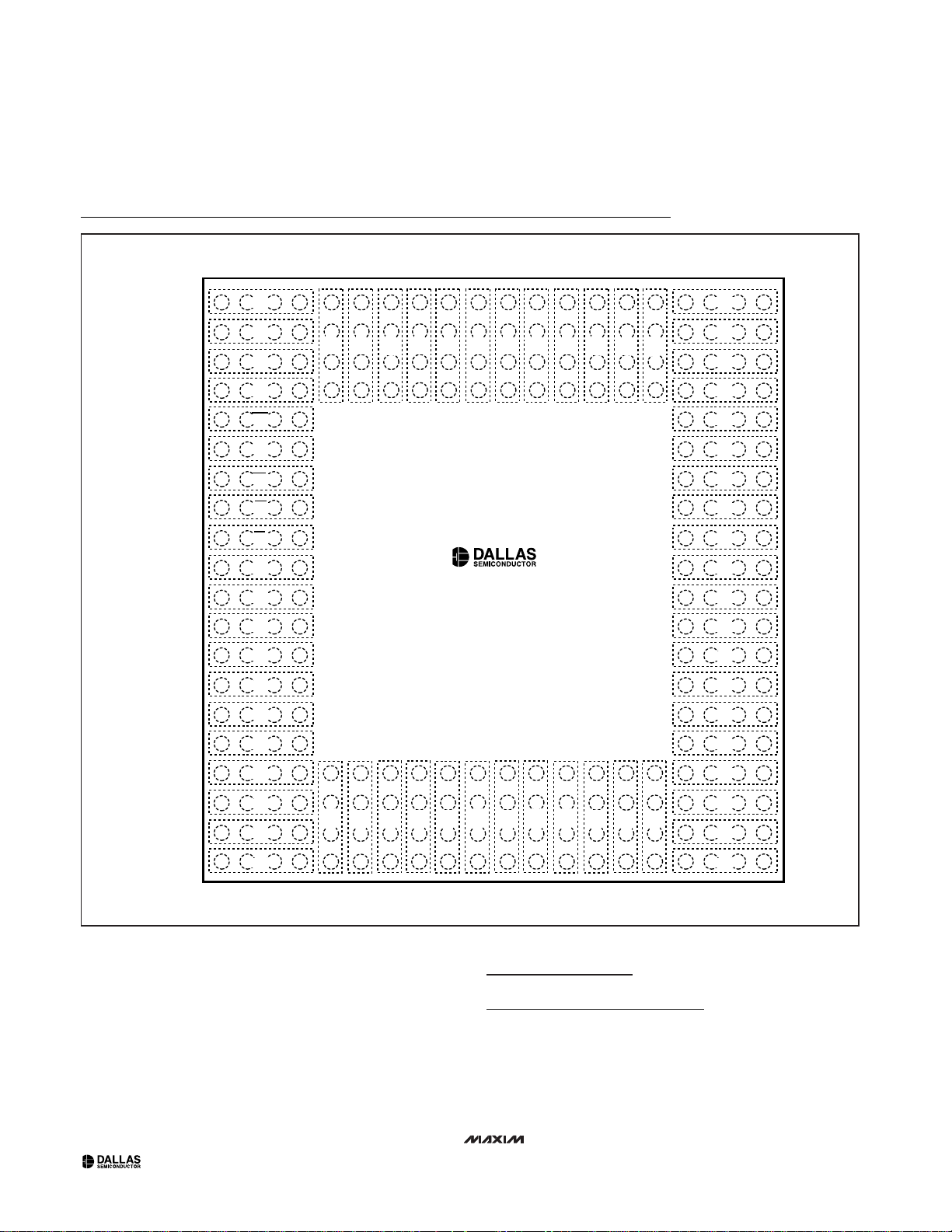

Package Information

For the latest package outline information, go to

www.maxim-ic.com/DallasPackInfo

.

Pin Configuration

A

12

34

789

0

5

6

7

8

90

1

2

34

56

1

2

34 1

1

1

2

5

678

9

1

1

1

1

1

1

1

11

1

2

1

1

1

11

1

1

7

8

9

0

0

1

2

3

4

5

6

DS2045W

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

TOP VIEW

GND

N.C.

A15

A16

RST

V

CC

WE

OE

CE

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

GND

GND

GND

GND

N.C.

N.C.

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

GND

GND

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

Loading...

Loading...