Master Forge 2518-3, 8823 Owner's Manual

ITEM #0097709

4-BURNER GAS GRILL

Master Forge & M Design® is a

registered trademark of LF, LLC.

All rights reserved.

WARNING

!

Improper installation,

adjustment, alteration, service

or maintenance can cause injury

or property damage.

Read this instruction manual

thoroughly before installing or

servicing this equipment.

WARNING

!

1, Do not store or use gasoline

or other flammable liquids or

vapors in the vicinity of this or

any other appliance.

2, An LP tank not connected for

use should not be stored in the

vicinity of this or any other

appliance.

MODEL #1010037

!

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Open the lid.

4. If the odor continues, keep

away from the appliance and

immediately call your gas

supplier or fire department.

!

WARNING

!

For Outdoor Use Only

ATTACH YOUR RECEIPT HERE

Serial Number________________ Purchase Date_________________

Questions, problems, missing parts? Before returning to your retailer, call our

customer service department at 1-800-963-0211, 8 a.m. - 6 p.m., EST, Monday Thursday, 8 a.m. - 5 p.m., EST, Friday.

1

TABLE OF CONTENTS

Safety Information………………………………………………………………………………….3

Package Contents……………………………..…………………….…….……………………....5

Hardware Contents………………………………….……………………….…………..…….…..7

Preparation………………….…….………………………….………………….………...….….….7

Assembly Instructions……………………..………………………….……………….……..……8

Installation Instructions…………………………………………………………………………...17

Operating Instructions…………………………………………………………………………… 21

Care and Maintenance…………………………………………………………………………….24

Troubleshooting . ………………………………………………………………………………….30

Warranty………………………………………………………………………………………….…..32

Replacing Main Burner…………………………………………………………………………….33

Exploded View ……………………………………………………………………………….……34

Replacement Parts List………………………………………………………………………… 35

Converting to Natural Gas Kit #0050772……………………… ………………………….…... 37

2

!

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate

or install the product. If you have any questions regarding the product, please call

customer service at 1-800-963-0211 Monday through Thursday from 8:00 a.m. to 6:00 p.m.

EST, Friday from 8:00 a.m. to 5:00 p.m. EST.

1. The installation of this appliance must conform with local codes or, in the absence of local

codes, with either the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Natural Gas and

Propane Installation Code, CSA/CGA-B149.1.

2. This grill is intended for use outdoors and should not be used in a building, garage or any

other enclosed or covered area.

3. This outdoor grill is not intended for installation in or on recreation vehicles and/or boats.

4. A minimum clearance of 48 in. from combustible constructions to the sides of the grill

and 48 in. from the back of the grill to combustible constructions must be maintained.

This outdoor cooking gas appliance must not be placed under overhead combustible

construction.

5. The use of an electrical source requires that when installed, the grill must be electrically

grounded in accordance with local codes or, in the absence of local codes, with

ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1. Keep electrical supply cords

and the fuel supply hose away from heated surfaces.

6. Inspect the hoses before each use for excessive abrasion or wear, or cuts that may affect

safe operation of the grill. If there is evidence of excessive abrasion or wear, or the hose is

cut, it must be replaced prior to the grill being put into operation. The replacement hose

assembly must be those specified by the manufacturer.

7. Keep your grill in an area clear and free from combustible materials, gasoline and other

flammable vapors and liquids.

8. DO NOT obstruct the flow of combustion and ventilation air to this appliance.

9. Keep the ventilation openings of the tank enclosure free and clear from debris.

10. Check all gas connections for leaks with a soapy water solution and brush. Never use an

open flame to check for leaks.

11. Never use charcoal in the grill.

12. Never use the grill in windy areas.

13. Only a 20 lb. LP-gas cylinder is allowed. The cylinder must be

constructed and marked in accordance with the Specifications for

LP Gas Cylinders of the U.S. Department of Transportation

18 in.

12.2 in.

(D.O.T.) or the National Standard of Canada, CAN/CSA-B339,

Cylinders, Spheres and Tubes for Transportation of Dangerous

Goods; and Commission. A 20 lb. LP-gas cylinder dimensions

are:

14. Never use the grill without the drip tray installed and hung under the burner box. Without

the drip tray, hot grease and debris could leak downward and produce a fire hazard.

15. Use only the gas pressure regulator supplied with this appliance. This regulator is set for

an outlet pressure of 11.0 wc.

16. The cylinder used must include a collar to protect the cylinder valve.

3

8 in.

13.9 in.

!

SAFETY INFORMATION

17. Do not store a spare LP-gas cylinder under or near this appliance.

18. Never fill the cylinder beyond 80 percent full.

19. If the information in “17” and “18” is not followed exactly, a fire causing death or serious

injury may occur.

20. The natural gas grill and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in

excess of 0.5 PSI (3.5 KPa).

21. The outdoor cooking gas appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply

system at test pressures equal to or less than 0.5 PSI (3.5 KPa).

22. CALIFORNIA PROPOSITION 65 WARNING: The burning of gas cooking fuel generates

some byproducts which are on the list of substances known by the state of California to

cause cancer, reproductive harm, or other birth defects. To reduce exposure to these

substances, always operate this unit according to the use and care manual, ensuring you

provide good ventilation when cooking with gas.

IMPORTANT: We urge you to read this manual carefully and follow the

recommendations enclosed. This will ensure you receive the most enjoyable and

trouble-free operation of your new gas grill. We also advise you retain this manual for

future reference.

!

WARNING: Your grill has been designed to operate using only the gas specified by

the manufacturer on the rating plate. Do not attempt to operate your grill on other

gases. Failure to follow this warning could lead to a fire hazard and bodily harm and will

void your warranty.

!

WARNING: Make certain your LP (propane) tank is filled by a reputable propane dealer.

An incorrectly filled or an overfilled LP tank can be dangerous. The overfilled condition

combined with the warming of the LP tank (a hot summer day, tank left in the sun, etc.)

can cause LP gas to be released by the pressure relief valve on the tank since the

temperature increase causes the propane to expand. LP gas released from the tank is

flammable and can be explosive. Refer to your owner’s manual for more information

concerning filling your LP tank.

4

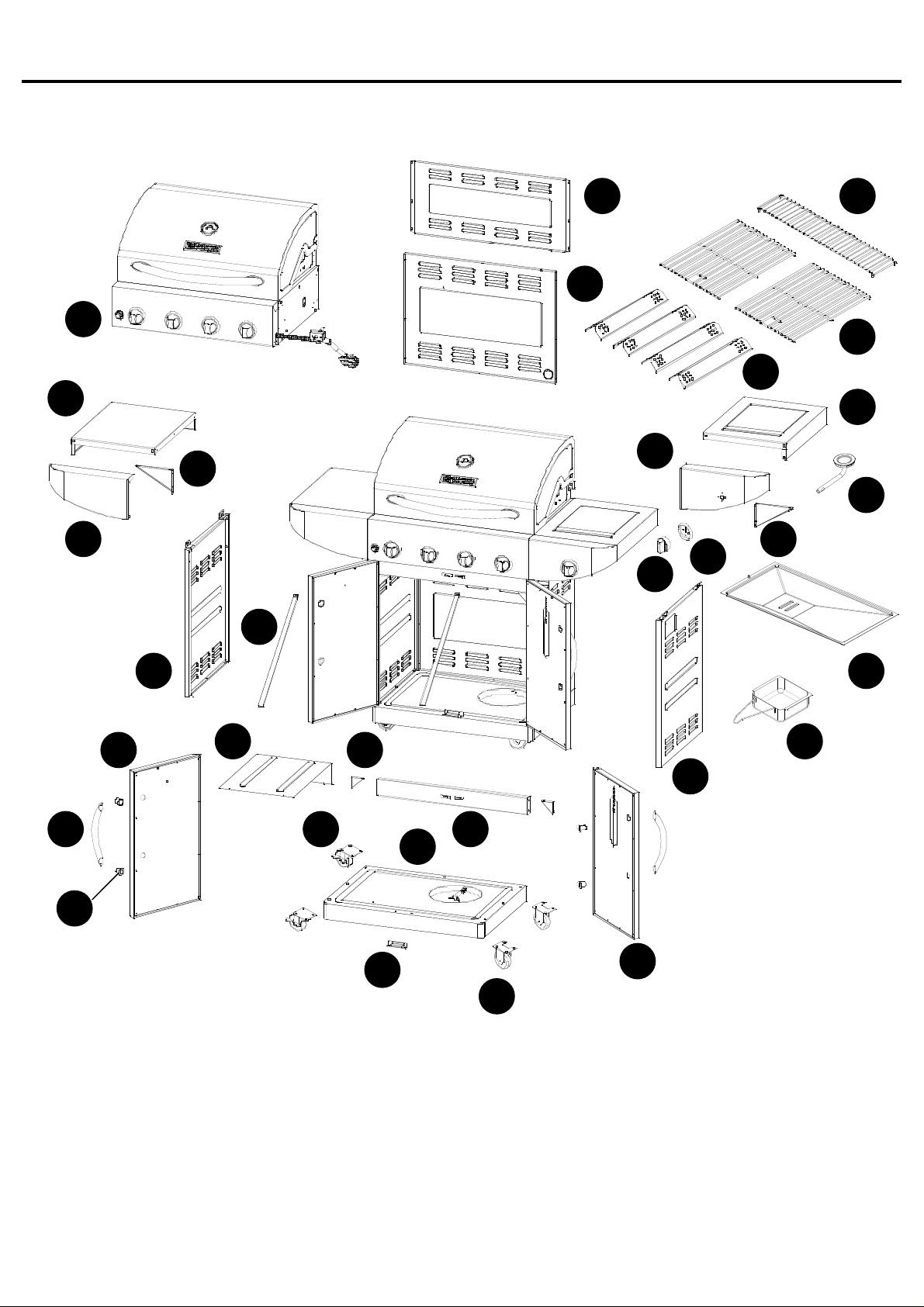

PACKAGE CONTENTS

L

K

N

M

O

J

A

I

B

C

D

E

E1

F

G

H

R

S

Q

P

T

V

U

Y

D1

C1

B1

X

W

A1

Z

5

PACKAGE CONTENTS

QuantityDescriptionPartQuantityDescriptionPart

1Left cart doorQ1Warming rackA

2Door handleR2Cooking grateB

4Door handle grommetS4Flame tamerC

1Cart heat shieldT1Right shelfD

2Cart support bracketU1Right shelf frontE

2Locking casterV1Right shelf bracketF

1Cart baseW1BezelG

1Cart support beamX1Control knobH

1Door catch plateY1Cart back panelI

2Straight casterZ1Back grill head coverJ

1Right cart doorA11Grill headK

1Right side cart panelB11Left shelfL

1Grease cupC11Left shelf bracketM

1Grease trayD11Left shelf frontN

1Side burnerE11LP tank barrier barO

1Left side cart panelP

6

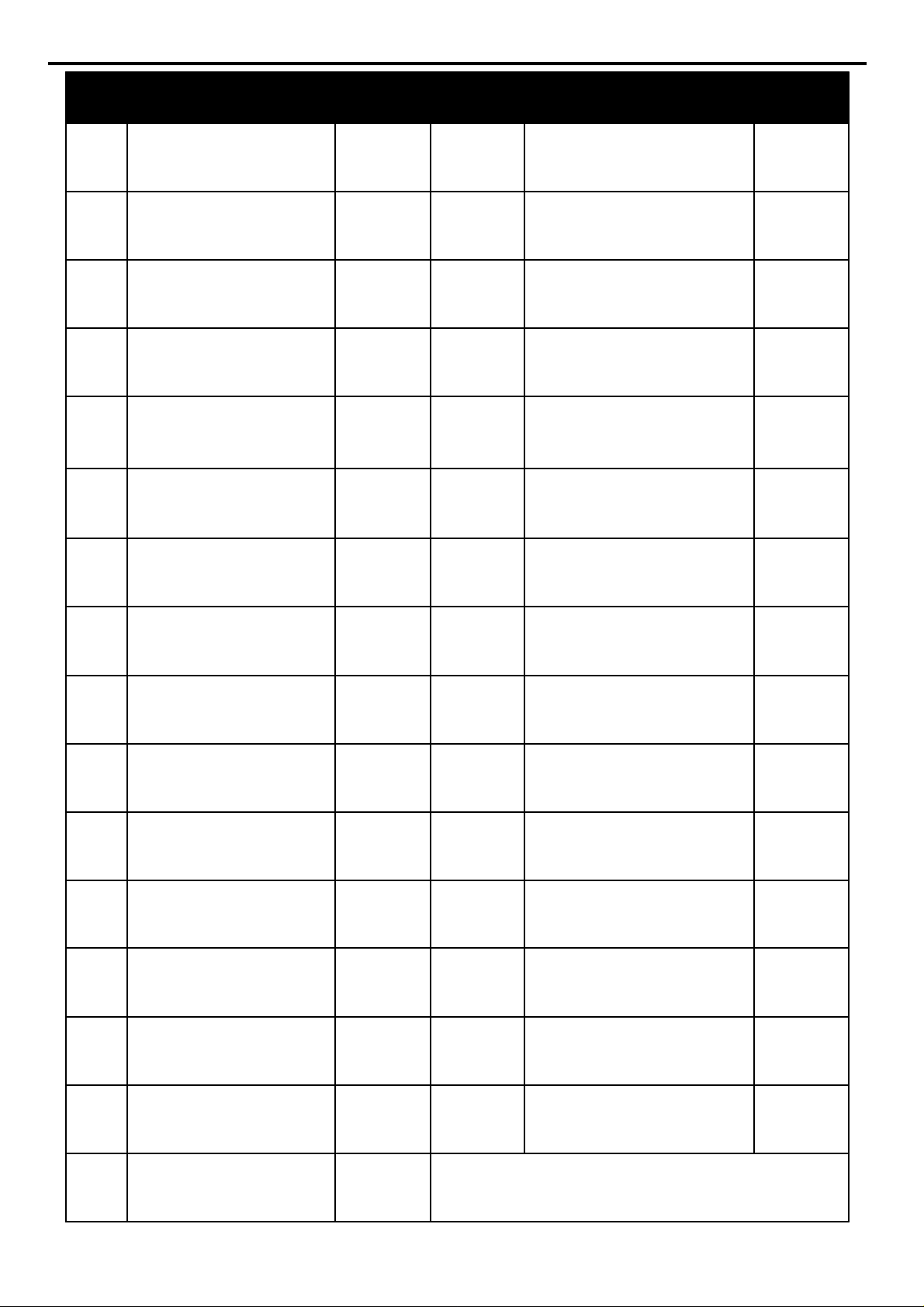

HARDWARE CONTENTS

AA BB CC DD EE

5/32-32 x 3/8 in.

Screw

Qty.16

FF

BB

1/4-20 x 1/2 in.

Screw

Qty. 26

1/4-20 x 3/8 in.

B

Screw

Qty. 23

GG

1/4-20 Lock

Washer

Qty. 22

1/4-20 x 5/16 in.

Screw

Qty.10

Allen Wrench

AA Battery

PREPARATION

Before beginning assembly of product, make sure all parts are present. Compare

parts with package contents list and hardware contents list. If any part is

missing or damaged, do not attempt to assemble the product.

Estimated Assembly Time: 40 minutes by two people

Tools Required for Assembly: Phillips Screwdriver (not included).

7

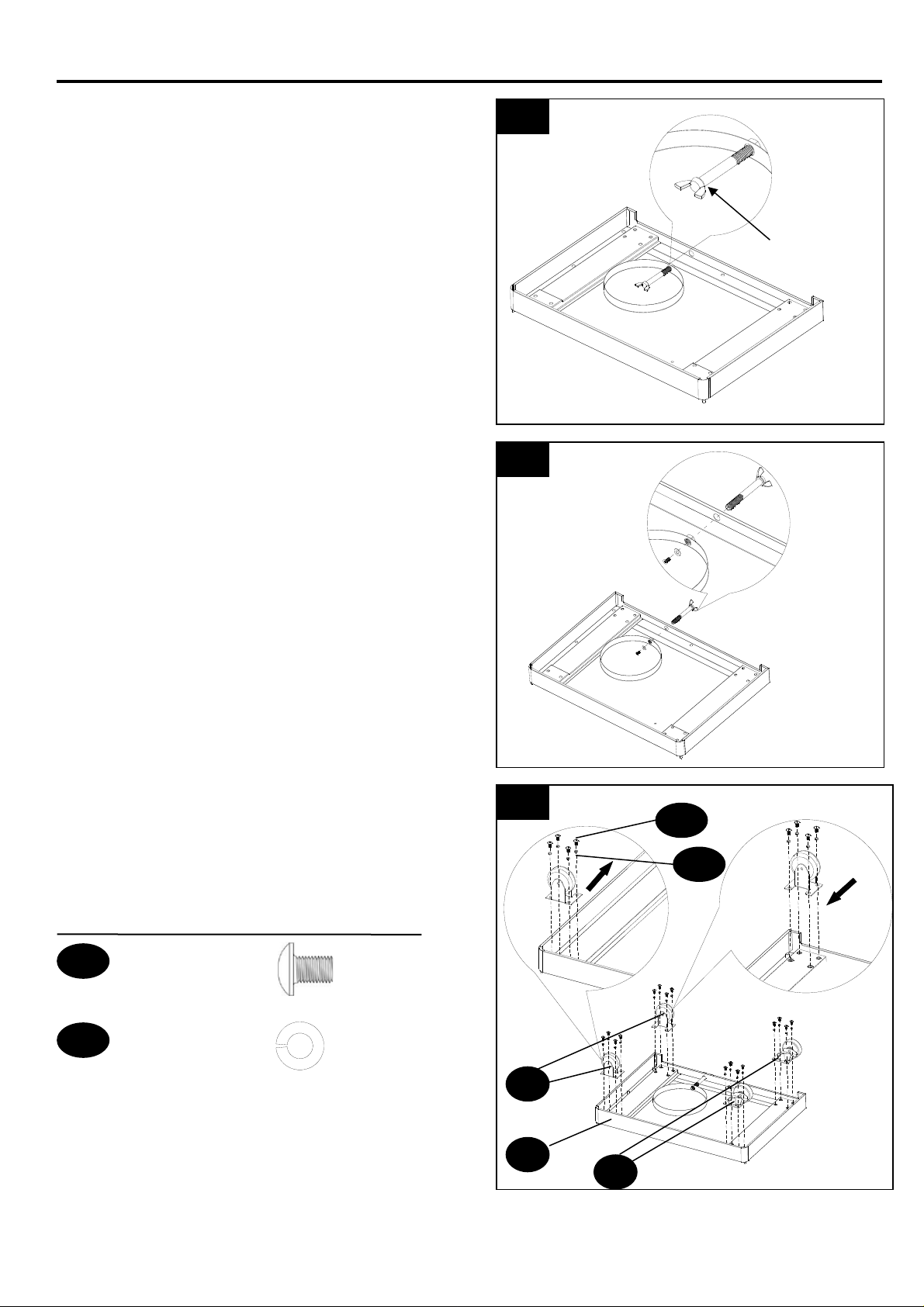

ASSEMBLY INSTRUCTIONS

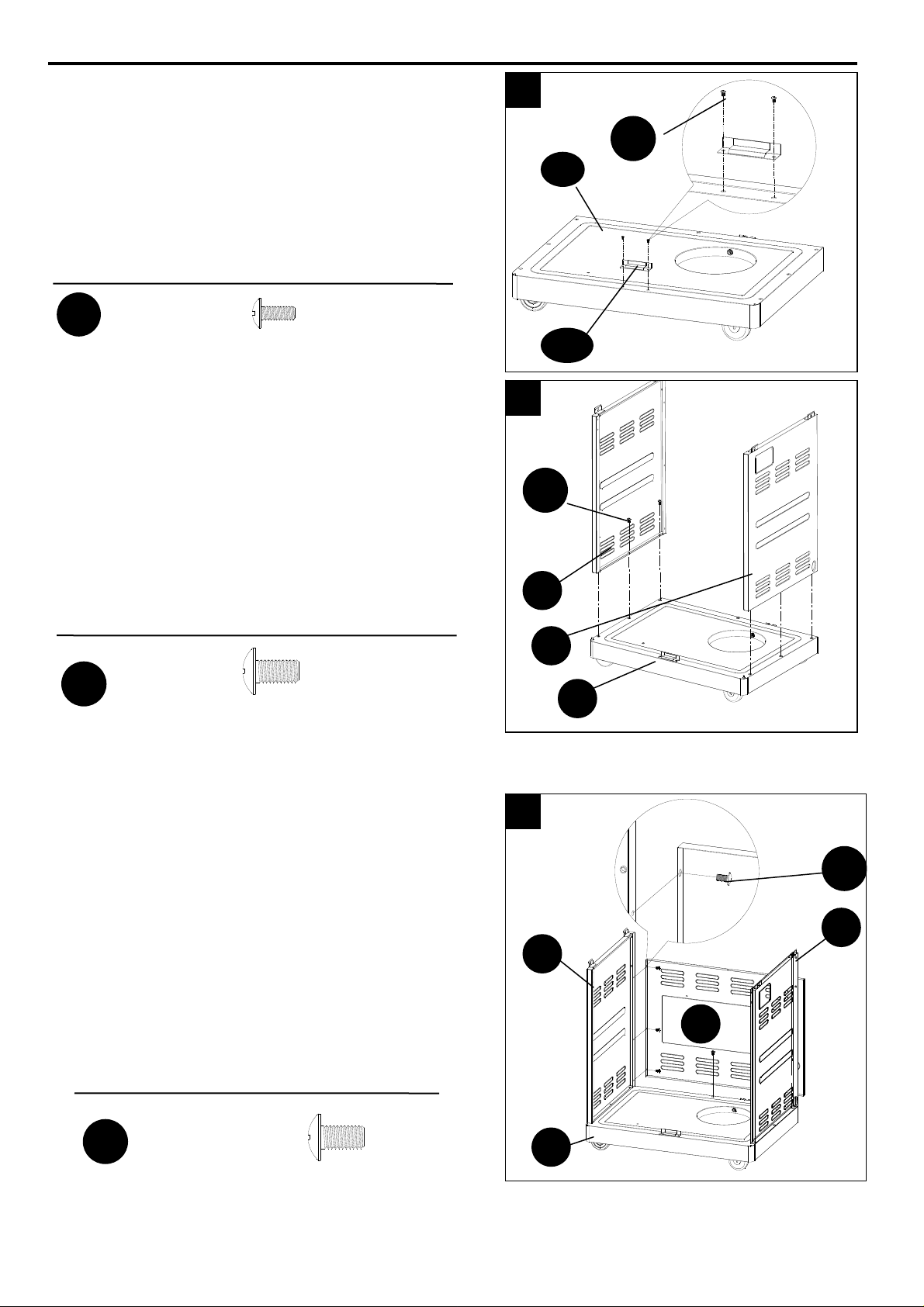

1. Fix the tank tray bolt

Remove the LP tank bolt on the cart base (W) as

shown in Fig. 1A and then reinstall as shown in

Fig. 1B.

Note: For all of the following steps, do not

tighten any screws completely until all

screws for that step have been installed.

Once all screws have been installed, then

tighten them securely.

1A

Tank tray bolt

1B

2. Install casters

a) With the cart base (W) laying as shown in Fig. 2,

attach the 2 straight casters (Z) as shown to the left

side of the cart base (W) using 8 1/4-20 x 1/2 in.

screws (BB) and 8 1/4-20 lock washers (DD). Install

all screws first and then tighten.

b) Attach the 2 locking casters (V) to the right side

of the cart base (W) using 8 1/4-20 x 1/2 in. screws

(BB) and 8 1/4-20 lock washers (DD). Install all

screws loosely first and then tighten.

Hardware Used

BB

DD

1/4-20 x 1/2 in.

Screw

1/4-20 lock

Washer

x 16

x 16

2

BB

DD

Note: For ease of assembly, lock the 2

locking casters (V) prior to proceeding to

the next steps.

Z

W

V

8

8

ASSEMBLY INSTRUCTIONS

3. Attach door catch plate

Turn the cart base (W) assembly right side up as

shown in Fig. 3.

Attach door catch plate (Y) to cart base (W)

using 2 5/32-32 x 3/8 in. screws (AA).

Hardware Used

AA

4. Install cart side panels

Attach left cart side panel (P) to cart base (W)

using 3 1/4-20 x 3/8 in. screws (CC).

Attach right cart side panel (B 1) to cart base

(W) using 3 1/4-20 x 3/8 in. screws (CC) as

shown in Fig. 4.

Hardware Used

5/32-32 x 3/8 in.

1/4-20 x 3/8 in.

CC

Screw

Screw

x 2

x 6

3

4

H

CC

P

B1

B1

W

W

AA

Y

W

5. Install cart back panel

Attach cart back panel (I) to cart base (W) using

1 1/4-20 x 3/8 in. screw (CC).

Fasten cart back panel (I) to the left side cart panel

(P) and right side cart panel (B1) using 6 1/4-20 x 3/8

in. screws (CC) as shown is Fig. 5.

Install the top screw first when assembling and

install all screws loosely first and then tighten.

CC

Hardware Used

CC

1/4-20 x 3/8 in.

Screw

x 7

5

CC

CC

B1

P

E

I

W

9

ASSEMBLY INSTRUCTIONS

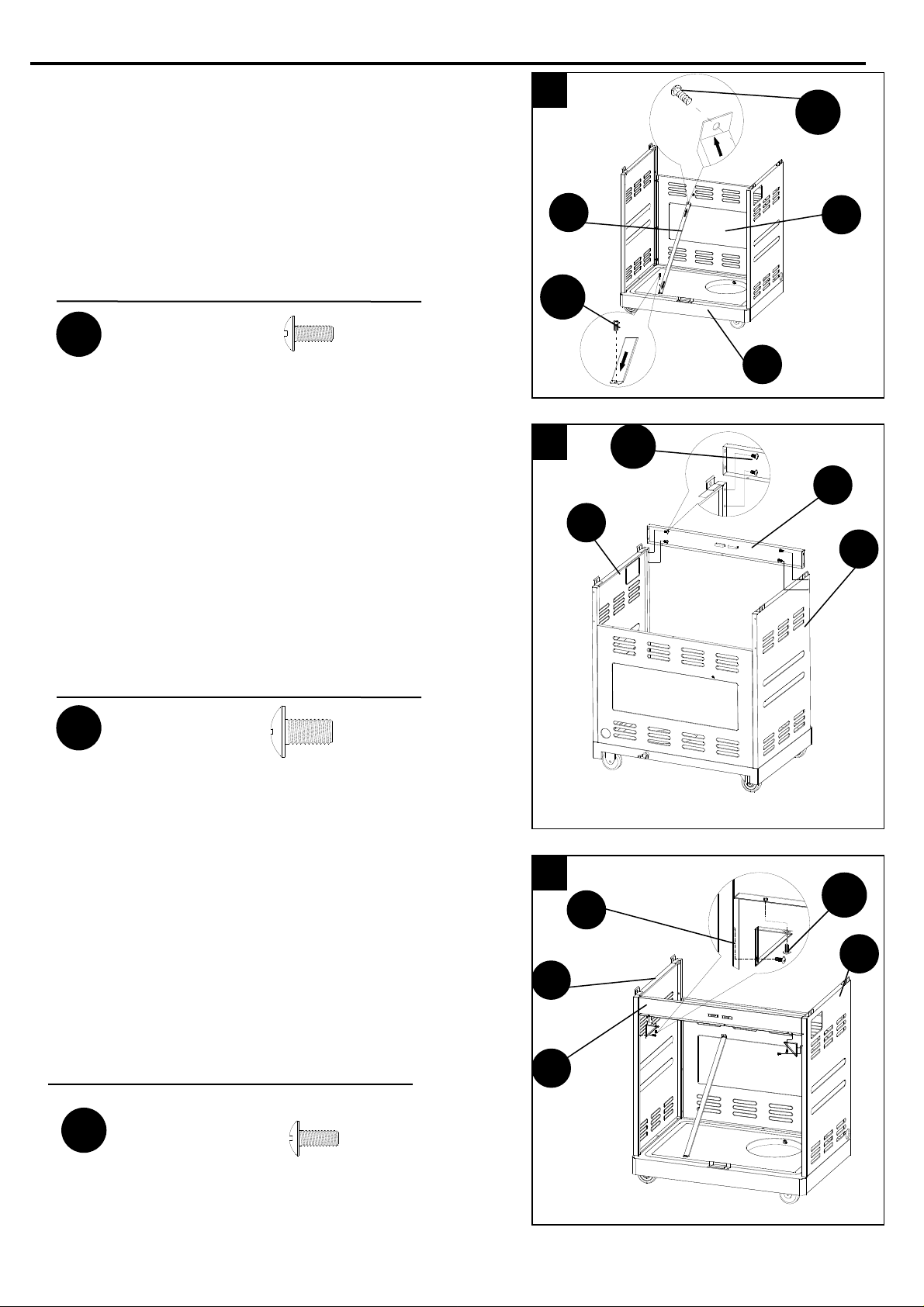

6. Install LP tank barrier bar

Attach the LP tank barrier bar (O) as the arrows indicate

to the cart back panel (I) and the cart base (W) using

2 5/32-32 x 3/8 in. screws (AA) as shown in Fig. 6. The right

install direction should be same as the indicate.

5

Hardware Used

AA

7. Install cart support beam

Attach the cart support beam (X) to the left and

right side cart panels (P and B1) using 4 1/4-20 x 3/8 in.

screws (CC) as shown in Fig. 7.

Make sure the magnets on the cart support beam (X)

face outward and the holes face downward

when assembling.

5/32-32 x 3/8 in.

BB

Screw

x 2

6

AA

7

O

AA

BB

I

W

CC

X

B1

P

Hardware Used

CC

8. Install cart support brackets

Attach the cart support brackets (U) to the cart

support beam (X) and to the left and right side

cart panels (P and B1) using 4 5/32-32 x 3/8in. screws

(AA) as shown in Fig. 8.

Install all screws loosely first and then tighten.

Hardware Used

1/4-20 x 3/8 in.

Screw

x 4

8

P

X

U

M

BB

AA

B1

AA

5/32-32 x 3/8 in.

Screw

x 4

10

ASSEMBLY INSTRUCTIONS

9. Install cart heat shield

Attach the cart heat shield (T) to the cart back

panel (I) using 2 5/32-32 x 3/8 in. screws (AA).

Note that the heat shield installs under the lip of the

cart back panel (I) as shown in Fig 9A.

Next attach the cart heat shield (T) to the cart support

beam (X) using 2 5/32-32 x 3/8 in. screws (AA) as shown

in Fig. 9B.

Note that the cart heat shield (T) installs on top of the

lip of the cart support beam (X).

Hardware Used

AA

5/32-32 x 3/8 in.

Screw

x 4

L

9

A.

T

I

10A

AA

B.

X

EE

K

10. Install grill head to cart

Caution grill head is heavy. To avoid injury, obtain

the help of an assistant for this step.

With the assistance of a helper, remove the grill head

(K) from the packaging and place on top of the grill

cart as shown in Fig. 10A.

Attach the grill head (K) to the left and right side

cart panels (P and B1) using 4 1/4-20 x 1/2 in. screws

(BB) as shown in Fig. 10B.

Hardware Used

1/4-20 x 1/2 in.

BB

x 4

Screw

K

10B

P

K

BB

V

B1

U

11

ASSEMBLY INSTRUCTIONS

11. Install grease tray

Remove the pre-installed screw from the right of the

greasy tray (D1).

From the back of the grill, slide the grease tray (D1)

onto the ledges on the left and right sides of the grill

head as shown in Fig. 11.

There are stops built into the ledges to hold the

grease tray in place. Make sure the grease tray is

slid all the way in and is resting securely between

these stops.

From the front of the grill, reinstall the screw into the

grease tray through the supporting ledge. This will

prevent the grease tray from shifting during transport.

The correct direction is shown in the picture.

12. Install grease cup

9

11

a

D1

K

12

Insert the grease cup (C1) onto the ledges of

the grease tray (D1) underneath the grill head as shown

in Fig. 12.

10

The handle of the grease cup needs to be tilted

down slightly in order for it to slide into the grease

tray ledges.

13. Install back grill head cover

Put the back grill head cover (J) into the hole on the back

panel (I) first.

Then attach the back grill head cover (J) as

shown in Fig. 13 using 6 1/4-20 x 3/8 in. screws (CC).

Install all screws loosely first and then tighten.

D1

C1

13

CC

Hardware Used

CC

1/4-20 x 3/8 in.

Screw

x 6

12

K B1

J

I

Loading...

Loading...