Page 1

®

®

OPERATING MANUAL:

Compact Pump Drives

MANUEL DE L’UTILISATEUR :

Entrainements de

Pompes Compacts

BEDIENUNGSANLEITUNG:

Compact Pumpenantriebe

MANUAL DE OPERACIÓN:

Propulsores de Bombas

Compactos

MANUALE dI ISTRUZIONI:

Azionamenti Compatti per

Pompe

77200-12

77200-20

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

®

®®®®®®®®®

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

A12991007B

Edition 04

(US & Canada only) Toll Free 1800MASTERFLEX • 18006373739

(Outside US & Canada) 18475497600 • 18473817050

www.masterflex.com • techinfo@masterflex.com

®

Page 2

SAFETY PRECAUTIONS

CAUTION: Use of Pump Heads other than those specified will result in unsatisfactory performance,

damage to the drive unit and voiding of applicable warranties.

The drive system can only be used with one Pump Head at a time. Use of this drive unit

with multiple Pump Heads will result in unsatisfactory performance, damage to the drive unit

and voiding of applicable warranties.

When mounting the Pump Head to the drive unit, the mounting screws should only be tightened

fingertight. Excessive tightening of the mounting screws will result in binding and unsatisfactory

performance.

WARNING: Be sure the Pump Drive is turned off before proceeding. Loose clothing could be caught

in the drive.

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in patient-connected applications, including,

but not limited to, medical and dental use and, accordingly, have not been submitted for FDA approval.

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS ........................................................2

INTRODUCTION AND GENERAL DESCRIPTION.............3-4

SETUP AND DRIVE OPERATION ..........................................5

MAINTENANCE ......................................................................5

SPECIFICATIONS ...................................................................5

WARRANTY ............................................................................6

PRODUCT RETURN ...............................................................6

TECHNICAL ASSISTANCE.....................................................6

2

®

®

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

!

!

C-FLEX — Reg TM Saint-Gobain Performance Plastics Corp.

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

Page 3

3

®

®

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

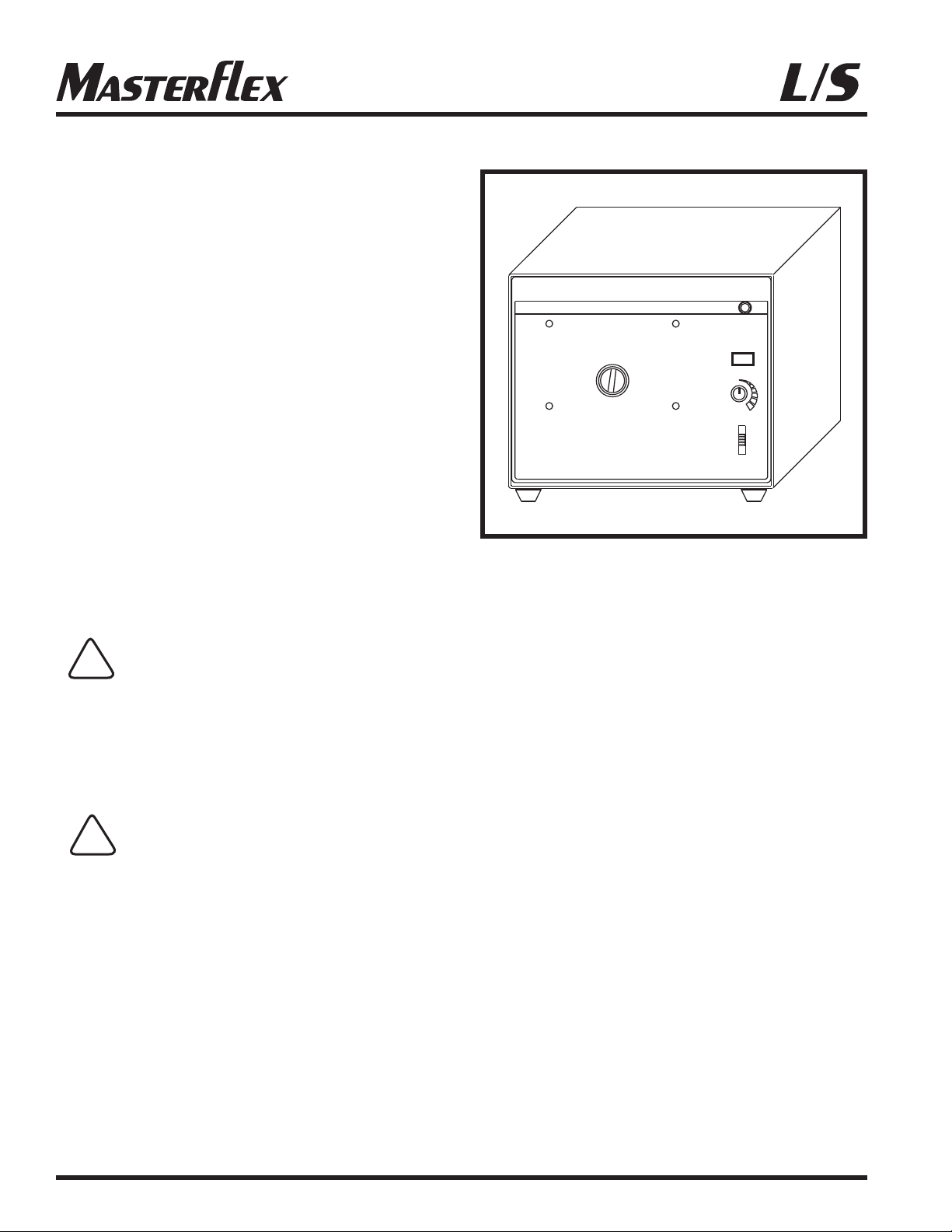

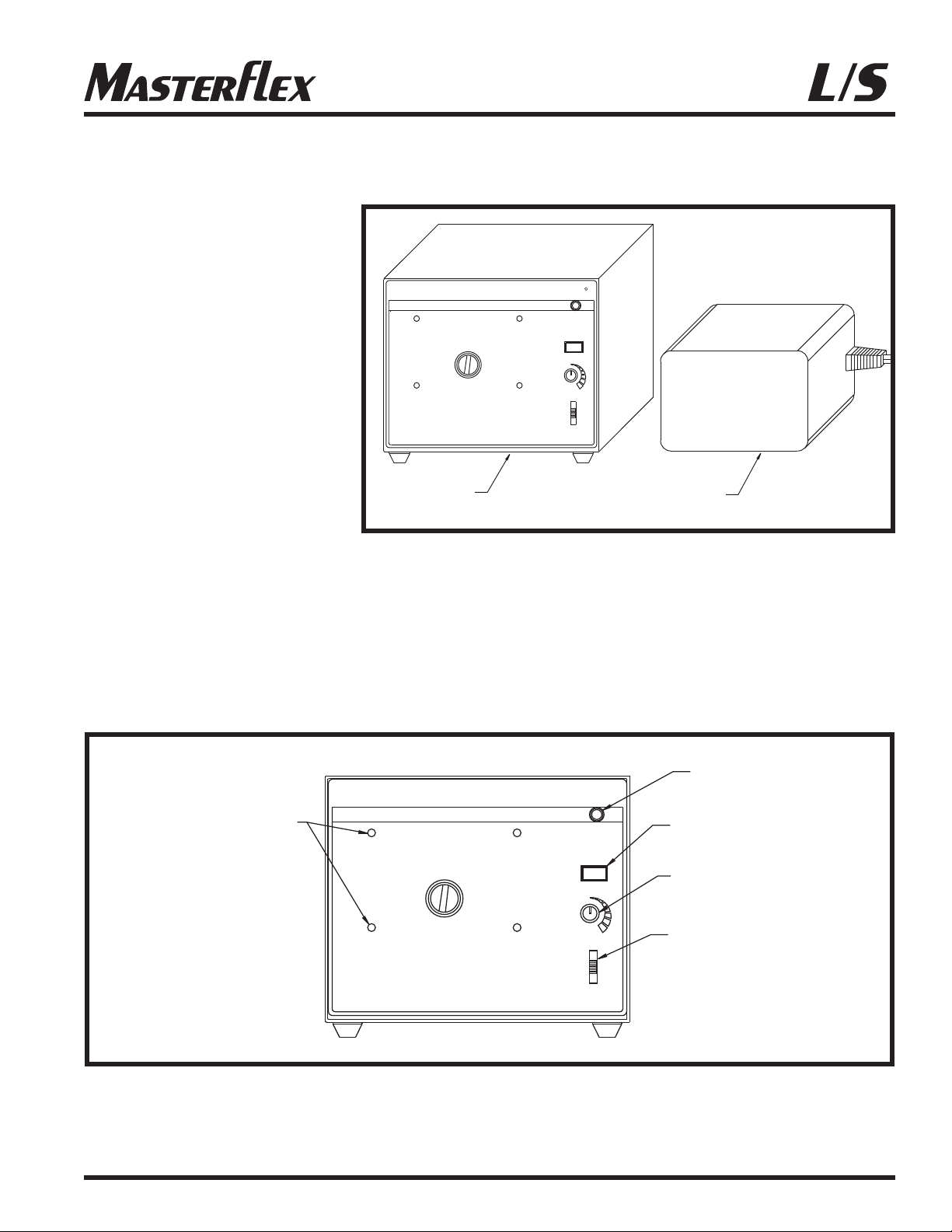

INTRODUCTION AND GENERAL DESCRIPTION

The MASTERFLEX®L/S®COMPACT

Pump Drives are designed as an

inexpensive variable speed drive

which accepts MASTERFLEX L/S

STANDARD, QUICK LOAD

®

and

EASY-LOAD

®

Pump Heads. These

200 rpm drives accommodate one Pump

Head and one tube at controlled speed

as low as 30 rpm. All units

operate from an external Power Supply.

The AC models are supplied with a

Universal Power Supply which provides

a DC output for connection to the Pump

Drive.

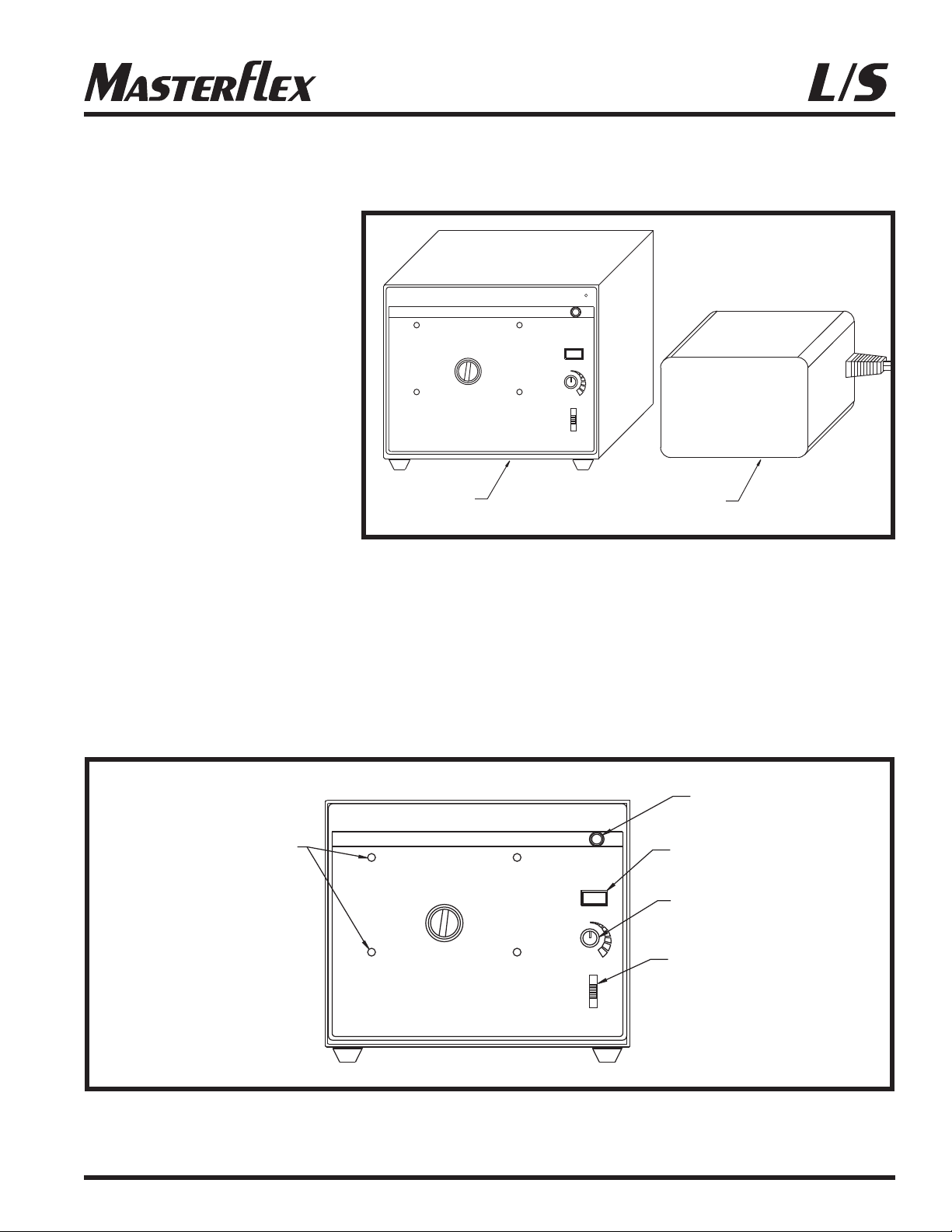

The single-turn adjustable Speed

Control, Figure 2, provides variable flow

operation. The green POWER On indicator lights whenever the pump is operating. The Power On/Direction Switch

turns power on when either clockwise or

counterclockwise pump rotor direction is

selected. The MAX Button is used for

priming and purging and operates the

pump at maximum speed while

depressed.

Pump Drive

Unit

Universal Power

Supply

Figure 1. MASTERFLEX L/S Compact Pump Drive

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

Figure 2. Pump Drive—Front Panel

Pump mounting holes,

accept all standard

8-32 pump mounting

hardware

Power On

Indicator

MAX: Press and hold to

prime or purge pump

Speed control: provides

variable flow adjustment

Power On/

direction switch

Page 4

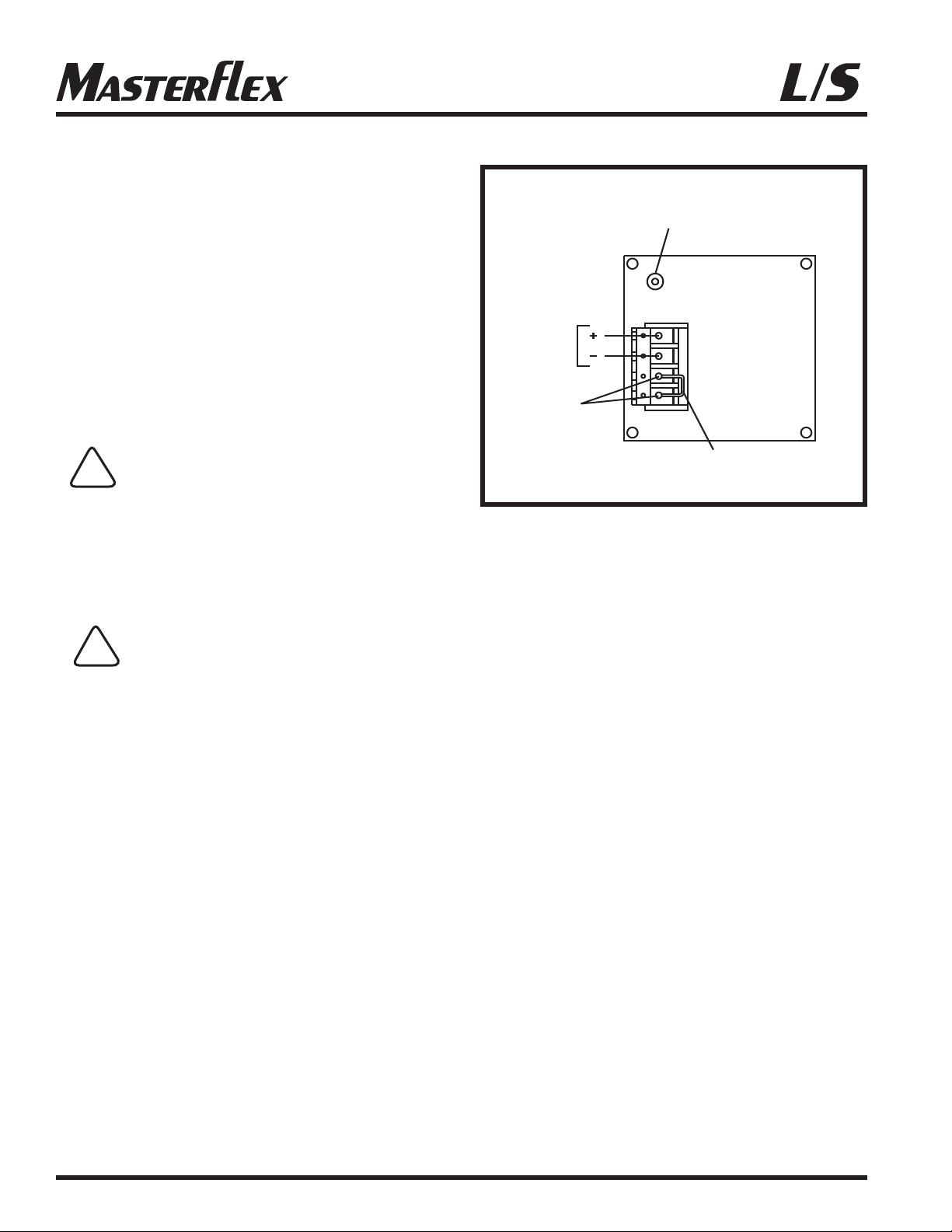

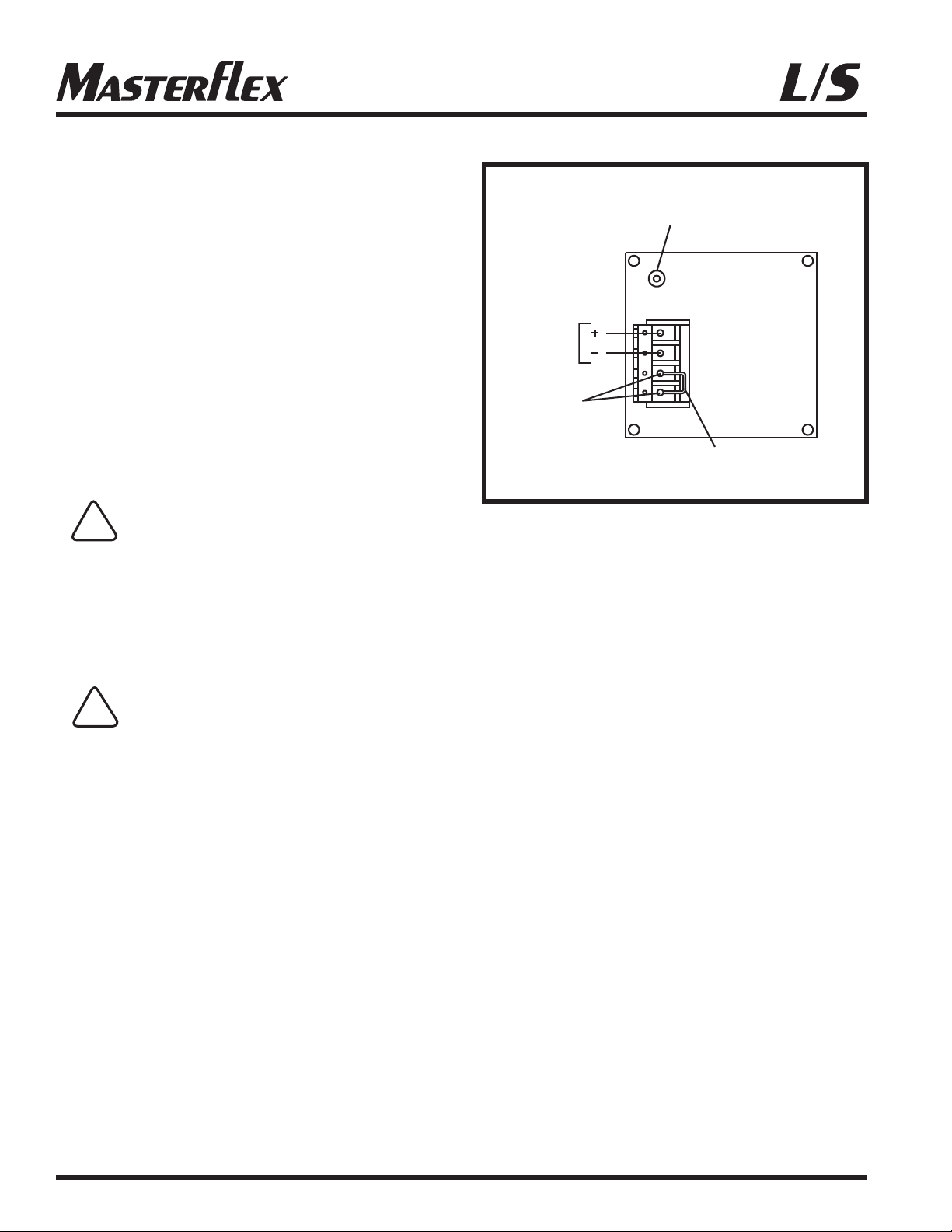

The rear panel, Figure 3, contains a DC power input jack for

connection of primary power and a 4-terminal barrier strip for

connection of remote start/stop and for a DC backup supply.

Remote Start/Stop: Terminals 3 and 4 on the rear panel

terminal strip, (Figure 3) are used for remote start/stop

operation. Pump direction and speed are not remotely

controllable. In non-remote operation, these terminals are connected together by a shorting bar. For remote control by

switch closure, remove the shorting bar and connect the two

terminals of an isolated remote control switch or relay to

terminals 3 and 4. A closure of the remote switch contacts will

turn the pump system on. Opening the contact will

turn the pump system off.

WARNING: Be sure the Pump Drive is turned off

before proceeding. Loose clothing

could be caught in the drive.

Pump Heads Accepted: Only the MASTERFLEX L/S

STANDARD, QUICK LOAD and EASY-LOAD are acceptable

for use with this pump drive. Only one Pump Head at a time

can be used with this drive unit.

CAUTIONS: Use of Pump Heads other than those

specified will result in unsatisfactory

performance, damage to the drive unit

and voiding of applicable warranties.

The drive system can only be used with

one Pump Head at a time. Use of this

drive unit with multiple Pump Heads

will result in unsatisfactory performance, damage to the drive unit and

voiding of applicable warranties.

When mounting the Pump Head to the

drive unit, the mounting screws should

only be tightened fingertight. Excessive

tightening of the mounting screws will

result in binding and unsatisfactory performance.

Tubing Accepted: The Pump Heads accepted for use with

drive can be used with MASTERFLEX precision tubing sizes

L/S

®

13, L/S®14 and L/S®16 in all formulations. For

L/S

®

17 and L/S®25 size tubing, use silicone or C-FLEX

®

formulations only.

Use only MASTERFLEX precision tubing with MASTERFLEX

pumps to ensure optimum performance. Use of other tubing

may void applicable warranties.

4

®

®

Figure 3. Pump — Rear Panel

DC Power Input,

2.5 mm Coaxial Receptacle

Shorting Bar

Remote

Start/Stop

Input

Backup

DC

Input

!

!

Page 5

5

®

®

SETUP AND DRIVE

OPERATION

1. Unpack the drive: save packaging material until proper prod-

uct operation has been verified.

2. Select and mount Pump Head and load tubing

(see Pump Head manual).

3. For 77200-20 plug in Universal Power supply and connect

to the back of the drive. (See Figure #3.)

4. For 77200-12 supply 11.0 to 15V DC to terminal strip

positions 1 and 2. (See Figure #3.)

5. The drive system can be set to operate in either a clockwise

or a counterclockwise direction. The same control used to

select direction also turns power on or off. To

operate in a clockwise direction place direction control

switch in the "up" position. The POWER indicator should

light and the fluid will flow from right to left. To operate in

a counterclockwise direction, place direction switch in the

"down" position. The POWER indicator should light and

the fluid will flow from left to right. To turn pump off, place

switch in the "center" position.

6. The pump speed is controlled by the variable speed control.

Turning the control clockwise increases the speed. Tubing

life is decreased with increased operating speed. Speed can

be controlled up to a 6:1 range.

MAINTENANCE

Cleaning: Keep the drive enclosure clean with mild

detergents. Never immerse nor use excessive fluid.

Motor/ Brush Replacement: The motor used in this

inexpensive drive is not serviceable or repairable and has

brushes which cannot be replaced. The motor is rated for

a continuous duty life of 3000 operating hours minimum.

Operation at other than continuous duty cycles will result in

longer motor life. If motor failure for whatever reason occurs,

the motor must be replaced.

Output:

Operating Speed: 35 to 200 rpm

Number of Pump Heads: 1

Torque Load: 20 oz-in, maximum

Direction of rotation: Clockwise and Counterclockwise

Input:

Operating Voltage/Frequency:

Model 77200-20 115V AC nominal, 50/60 Hz

(90–130VAC) @500 mA AC

230V AC nominal, 50/60 Hz

(190–260VAC) @300 mA AC

Model 77200-12 13.5V DC nominal

(11.0–15.0V DC) @ 2.4 A DC

Installation Category:

Model 77200-12 & -20 Category I per IEC664 (Signal Level)

Remote Start/Stop: Contact closure connection at

terminal strip contacts 3 and 4

Construction:

Dimensions (L × W × H): 5.750 in × 5.14 in × 4.14 in

(14.6 cm × 13.0 cm × 10.5 cm)

Weight: 1.88 pounds (0.85 kg)

Color: Black

Material: Painted Steel

Enclosure Rating: IP22 per IEC529

Environment:

Operating Temperature: 32°F to 104°F (0°C to 40°C)

Storage Temperature: –49°F to 149°F (–45°C to 65°C)

Humidity (Non-cond): 10% to 90%

Altitude: 6600 ft (2000 m)

Pollution Degree: Pollution Degree 2 per IEC664

(Indoor usage — lab, office)

Compliance (For CE Mark):

EN61326-1/A2: 2001 (EMC Directive)

Converter is UL listed and CSA approved.

Regulatory agency specifications not applicable to the

balance of the unit due to low voltage.

SPECIFICATIONS

Page 6

6

®

®

WARRANTY

Use only MASTERFLEX precision tubing with

MASTERFLEX pumps to ensure optimum

performance. Use of other tubing may void

applicable warranties.

The Manufacturer warrants this product to be free from

significant deviations from published specifications. If repair or

adjustment is necessary within the warranty period, the problem will be corrected at no charge, if it is not due to

misuse or abuse on your part, as determined by the

Manufacturer. Repair costs outside the warranty period,

or those resulting from product misuse or abuse, may be

invoiced to you.

The warranty period for this product is one (1) year from

the date of purchase.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer

for authorization and shipping instructions before returning the

product, either within or outside of the warranty period. When

returning the product, please state

the reason for the return. For your protection, pack the

product carefully and insure it against possible damage

or loss. Any damages resulting from improper packaging

are your responsibility.

TECHNICAL

ASSISTANCE

If you have any questions about the use of this product,

contact the Manufacturer or authorized seller.

Page 7

®

®

77200-20

77200-12

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

7

OPERATING MANUAL:

Compact Pump Drives

MANUEL DE L’UTILISATEUR :

Entrainements de

Pompes Compacts

BEDIENUNGSANLEITUNG:

Compact Pumpenantriebe

MANUAL DE OPERACIÓN:

Propulsores de Bombas

Compactos

MANUALE dI ISTRUZIONI:

Azionamenti Compatti per

Pompe

®

®®®®®®®®®

A12991007B

Édition 04

(US & Canada only) Toll Free 1800MASTERFLEX • 18006373739

(Outside US & Canada) 18475497600 • 18473817050

www.masterflex.com • techinfo@masterflex.com

®

Page 8

®

®

CONSIGNES DE SECURITE

MISES EN GARDE: l'usage de têtes de pompes autres que celles spécifiées produirait un fonctionnement

incorrect, endommagerait l’entraînement et annulerait les garanties applicables.

Le système d’entraînement peut uniquement être utilisé avec une tête de pompe

à la fois. L'usage de cet entraînement avec plusieurs têtes de pompes produirait

un fonctionnement incorrect, endommagerait l’entraînement et annulerait les garanties

applicables.

Lors du montage de la tête de pompe sur l’entraînement, les vis de fixation doivent

seulement être serrées à la main. Tout serrage excessif de ces vis provoquerait

un grippage et des performances non satisfaisantes.

AVERTISSEMENT: vérifier si l’entraînement de la pompe est éteint avant de commencer. Les vêtements

lâches pourraient être happés par l’entraînement.

AVERTISSEMENT:

LIMITES D’UTILISATION DES PRODUITS

Ces produits ne sont pas conçus pour être utilisés dans des applications avec patients, y compris, entre

autres, les applications médicales et dentaires, et ne sont pas destinés à cet effet. Ils n’ont par conséquent

pas été soumis à l’agrément de la FDA.

TABLE DES MATIERES

Titre Page

CONSIGNES DE SECURITE ..................................................8

INTRODUCTION ET DESCRIPTION GENERALE............9-10

INSTALLATION ET FONCTIONNEMENT

DE L’ENTRAINEMENT .........................................................11

ENTRETIEN...........................................................................11

CARACTERISTIQUES TECHNIQUES..................................11

GARANTIE.............................................................................12

RETOUR DE MARCHANDISES ...........................................12

ASSISTANCE TECHNIQUE ..................................................12

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

!

!

C-FLEX — Reg TM Saint-Gobain Performance Plastics Corp.

Les marques accompagnées du symbole ® qui apparaissent dans cette publication sont déposées aux États-Unis et dans d’autres pays.

8

POMPE POUR LIQUIDES

Page 9

®

®

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

INTRODUCTION ET DESCRIPTION GENERALE

Les entraînements de pompes compacts

MASTERFLEX

®

L/S®représentent des

entraînements économiques à vitesse

variable, compatibles avec les têtes

de pompe MASTERFLEX L/S

STANDARD, QUICK LOAD

®

et EASY-

LOAD

®

. Ces entraînements de 200 tr/min

reçoivent une tête de pompe et un tuyau

à une vitesse contrôlée minimale de 30

tr/min. Tous les appareils fonctionnent sur

un bloc d'alimentation externe. Les modèles de c.a. sont fournis avec un bloc

d’alimentation externe qui produit une

sortie de courant continu pour alimenter

l’entraînement de la pompe.

La commande de vitesse réglable à un

seul tour (voir figure 2) permet d'obtenir

un débit variable. Le témoin vert de

marche s’allume lorsque la pompe fonctionne. L’interrupteur de marche et de

sens permet d’allumer la pompe lorsque

le sens horaire ou antihoraire du rotor est

sélectionné. Le bouton MAX sert à

l'amorçage et à la purge, et permet de

faire fonctionner la pompe à la vitesse

maximale lorsqu'il est enfoncé.

Entraînement

de la pompe

Bloc

d’alimentation externe

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

Figure 2. Pompe — Panneau avant

Orifices de montage

de la pompe, accepte

tout le matériel de

fixation standard des

pompes 8-32.

Témoin de

marche

MAX: maintenir ce bouton

appuyé pour amorcer ou

purger la pompe.

Contrôle de la vitesse:

permet de régler des

débits variables.

Interrupteur de

marche / sens de

la pompe

9

Page 10

®

®

10

Le panneau arrière, figure 3, contient une prise d’entrée d’alimentation en courant continu pour branchement de l’alimentation principale et un bornier à cloison à quatre bornes pour

branchement d’un dispositif de marche / arrêt à distance et

d’une alimentation auxiliaire en courant continu.

La commande de marche/arrêt à distance: Les bornes 3

et 4 du bornier du panneau arrière (figure 3) sont utilisées

pour une commande de marche/arrêt à distance. Le sens et

la vitesse de la pompe ne peuvent être contrôlés à distance.

En fonctionnement sur place, ces bornes sont reliées

ensemble par une tige de court-circuit. En fonctionnement

à distance par fermeture de commutateur, retirer la tige de

court-circuit et brancher les deux bornes du commutateur de

commande à distance aux bornes 3 et 4. La fermeture des

contacts du commutateur fera démarrer le système de

pompage. Par contre, l’ouverture du contact arrêtera la pompe.

AVERTISSEMENT: Vérifier si l’entraînement de

la pompe est éteint avant de

commencer. Les vêtements

lâches pourraient être happés

par les rouleaux.

Têtes de pompes acceptées: seules les MASTERFLEX L/S

STANDARD, QUICK LOAD et EASY-LOAD peuvent être utilisées avec cet entraînement. Une seule tête de pompe

à la fois peut être employée avec cet entraînement.

MISES EN GARDE: L'usage de têtes de pompes

autres que celles spécifiées

produirait un fonctionnement

incorrect, endommagerait

l’entraînement et annulerait

les garanties applicables.

Le système d’entraînement peut

uniquement être utilisé avec

une tête de pompe à la fois.

L'usage de cet entraînement

avec plusieurs têtes de pompes

produirait un fonctionnement

incorrect, endommagerait

l’entraînement et annulerait

les garanties applicables.

Lors du montage de la tête de

pompe sur l’entraînement,

les vis de fixation doivent

seulement être serrées à la

main. Tout serrage excessif

de ces vis provoquerait un

grippage et des performances

non satisfaisantes.

Figure 3. Pompe — Panneau arrière

Entrée de courant continu,

prise coaxiale de 2,5 mm

Tige de

court-circuit

Entrée de

marche/ arrêt

à distance

Entrée

auxiliaire

de courant

continu

!

!

Tuyaux acceptés: les têtes de pompes compatibles avec

cet entraînement peuvent être employées avec les tuyaux de

précision MASTERFLEX de tailles L/S

®

13, L/S®14 et L/S

®

16 de toutes compositions. Pour les tuyaux de tailles L/S®17

et L/S

®

25, utiliser uniquement des compositions en silicone

ou C-FLEX

®

.

Utiliser uniquement des tuyaux de précision MASTERFLEX

avec les pompes MASTERFLEX pour assurer des performances optimales. L’usage d’autres tuyaux pourrait annuler

les garanties en vigueur.

Page 11

®

®

11

INSTALLATION ET FONCTIONNEMENT DE

L’ENTRAINEMENT

1. Déballer l’entraînement: conserver le matériau d’emballage

tant que le fonctionnement de l’appareil n’a pas été vérifié.

2. Sélectionner et monter la tête de pompe, puis charger le

tuyau (voir notice de la tête de pompe).

3. Pour le 77200-20, brancher le bloc d’alimentation externe et

connecter au dos de l’entraînement. (Voir figure 3.)

4. Pour le 77200-12, fournir 11 à 15 V c.c. aux bornes.

(Voir figure 3.)

5. Le système d’entraînement peut fonctionner dans le sens

horaire ou dans le sens contraire. La commande employée

pour sélectionner le sens permet également de couper ou

d’allumer le contact. Pour un fonctionnement dans le sens

horaire, placer l’interrupteur de commande de sens vers le

haut. Le témoin d’alimentation s'allume alors et le liquide

coule de la droite vers la gauche. Pour un fonctionnement

dans le sens antihoraire, placer l’interrupteur de commande

de sens vers le bas. Le témoin d’alimentation s'allume alors

et le liquide coule de la gauche vers la droite. Pour arrêter la

pompe, l'interrupteur doit être placé en position centrale.

6. La vitesse de la pompe est contrôlée par la commande

de vitesse variable. Pour l’augmenter, il suffit de tourner

ce bouton dans le sens horaire. La durée de vie du tuyau

est réduite par une vitesse de fonctionnement accrue.

La vitesse peut être contrôlée jusqu’à une plage de 6/1.

ENTRETIEN

Nettoyage: l’enveloppe de l’entrainement doit étre maintenue

propre avec des détergents doux.

Remplacement du moteurs/des balais: le moteur de cet

entraînement économique n'est pas réparable et comporte

des balais qui ne peuvent pas être remplacés. La durée de

vie minimum standard en utilisation continue du moteur est de

3 000 heures de fonctionnement. Le fonctionnement non continu entraîne un accroissement de la durée de vie. En cas de

défaillance du moteur pour quelque raison que ce soit,

il doit être remplacé.

Sortie:

Vitesse de fonctionnement: 35 à 200 tr/min

Nombre de

têtes de pompes: 1

Couple: 1440 gm-cm, maximum

Sens de rotation: Sens horaire et sens antihoraire

Entrée:

Tension/Fréquence d’alimentation :

Modèle 77200-20 115 V c.a. nominale, 50/60 Hz

(90–130 V c.a.) à 500 mA c.a.

230 V c.a. nominale, 50/60 Hz

(190–260 V c.a.) à 300 mA c.a.

Modèle 77200-12 13,5 V c.c. nominale

(11-15 V c.c.) à 2,4 A c.c.

Catégorie d’installation:

Modèle 77200-12 & -20 Catégorie I, conformément à

CEI664 (niveau de signal)

Commande de marche/

arrêt à distance : Connexion de la fermeture du

contact aux bornes 3 et 4

Construction:

Dimensions (L × l × H): 14,6 × 13 × 10,5 cm

(5,75 × 5,14 × 4,14 po)

Poids: 0,85 kg

Couleur: Noir

Matériau : Acier peint

Homologation de

l’enveloppe: IP22, conformément à

la norme CEI529

Environnement:

Température de

fonctionnement : 0 à 40 ºC (32 à 104 °C)

Température de stockage : –45 à 65 ºC (–49 à 149 °F)

Humidité

(sans condensation) : 10 à 90 %

Altitude: 2000 m (6 600 pi)

Degré de pollution : Degré de pollution 2, conformément

à CEI664 (Utilisation à l’intérieur –

laboratoire, bureau)

Conformité (pour marque CE):

EN61326-1/A2: 2001

(Directive sur la compatibilité électromagnétique européenne)

Transformateur répertorié UL et homologué CSA. Les spécifications

de l’organisme de réglementation ne sont pas applicable

à l’équilibre de l’appareil en raison de la faible tension.

CARACTERISTIQUES

TECHNIQUES

Page 12

®

®

12

GARANTIE

Utiliser uniquement des tuyaux de précision

MASTERFLEX avec les pompes MASTERFLEX

pour assurer des performances optimales. L’usage

d’autres tuyaux pourrait annuler les garanties en

vigueur.

Le fabricant garantit ce produit contre tout écart significatif par

rapport aux spécifications publiées. Si des réparations

ou des réglages s’avèrent nécessaires pendant la période de

garantie, le problème sera résolu gratuitement s’il ne provient

pas, de l’avis du fabricant, d’un usage incorrect ou abusif par

l’utilisateur. Les frais de réparations effectuées en dehors de

la période de garantie, ou liées à un usage incorrect ou abusif

du produit, seront à la charge du client.

La durée de garantie de ce produit est

à un (1) an à

compter de la date d’a chat.

RETOUR DE

MARCHANDISES

Afin de limiter les frais et les délais, il convient de contacter

le vendeur ou le fabricant pour obtenir une autorisation

préalable et des instructions d’expédition avant de renvoyer le

produit, qu’il soit ou non couvert par la garantie. La raison du

retour doit être mentionnée pour tout produit renvoyé. Afin de

se protéger, le produit doit être emballé soigneusement et

assuré contre les risques de dommages ou de perte. Toute

détérioration provenant d’un emballage incorrect incombe au

client.

ASSISTANCE

TECHNIQUE

Pour toute question concernant l’utilisation de ce produit, contacter le fabricant ou le revendeur agréé.

Page 13

®

®

77200-20

77200-12

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

13

OPERATING MANUAL:

Compact Pump Drives

MANUEL DE L’UTILISATEUR :

Entrainements de

Pompes Compacts

BEDIENUNGSANLEITUNG:

Compact Pumpenantriebe

MANUAL DE OPERACIÓN:

Propulsores de Bombas

Compactos

MANUALE dI ISTRUZIONI:

Azionamenti Compatti per

Pompe

®

®®®®®®®®®

A12991007B

Ausgabe 04

(US & Canada only) Toll Free 1800MASTERFLEX • 18006373739

(Outside US & Canada) 18475497600 • 18473817050

www.masterflex.com • techinfo@masterflex.com

®

Page 14

®

®

SICHERHEITSMASSNAHMEN

VORSICHTSHINWEISE: Bei Verwendung von anderen als den angegebenen Pumpenköpfen wird

die Leistung beeinträchtigt, die Antriebseinheit beschädigt, und die Garantie ungültig.

Das Antriebssystem kann jeweils nur für einen Pumpenkopf verwendet werden. Bei gleichzeitiger

Verwendung dieser Einheit mit mehreren Pumpenköpfen wird die Leistung beeinträchtigt, die

Antriebseinheit beschädigt und die Garantie ungültig.

Beim Anschließen des Pumpenkopfes an die Antriebseinheit sollten die Befestigungsschrauben

nur mit den Fingern festgedreht werden. Wenn die Schrauben zu stark eingedreht werden, führt

dies zum Blockieren und zu mangelhafter Leistung.

ACHTUNG!: VOR DEM WEITERMACHEN SICHERSTELLEN, DASS DER PUMPENANTRIEB

AUSGESCHALTET IST. ES BESTEHT GEFAHR, DASS SICH LOSE BEKLEIDUNG IM ANTRIEB

VERFÄNGT.

ACHTUNG! ANWENDUNGSEINSCHRÄNKUNGEN

Diese Geräte sind nicht für den Einsatz am Patienten vorgesehen und auch nicht für diesen Zweck bestimmt

(z.B. medizinischen oder zahnmedizinischen Bereich) und entsprechen demgemäß auch keinen FDA

(Food & Drug Administration) Normen.

!

!

INHALTSVERZEICHNIS

Titel Seite

SICHERHEITSMASSNAHMEN ............................................14

EINFÜHRUNG UND ALLGEMEINE BESCHREIBUNG

......15-16

MONTAGE UND BETRIEB ...................................................17

WARTUNG.............................................................................17

TECHNISCHE DATEN ..........................................................17

GARANTIE.............................................................................18

WARENRÜCKSENDUNGEN ................................................18

TECHNISCHE BERATUNG...................................................18

14

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

C-FLEX — Reg TM Saint-Gobain Performance Plastics Corp.

Warenzeichen, die in dieser Publikation mit dem Symbol ® versehen sind, sind in den USA und anderen Ländern eingetragen.

PUMPE FÜR

FLÜSSIGKEITEN

Page 15

®

®

15

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

EINFÜHRUNG und ALLGEMEINE BESCHREIBUNG

Die MASTERFLEX®L/S®COMPACT

Pumpenantriebe sind als preisgünstiger

Antrieb mit variabler Geschwindigkeit für

den Anschluss an MASTERFLEX L/S

STANDARD, QUICK LOAD

®

und EASY-

LOAD

®

Pumpenköpfe vorgesehen. An

diese Antriebe mit 200 U/min kann ein

Pumpenkopf und ein Schlauch für kontrollierte Drehzahlen bis zu nur 30 U/min

angeschlossen werden. Alle Einheiten

werden von einem externen

Stromversorgungsgerät betrieben.

Die Wechselstrommodelle sind mit

einem externen Stromversorgungsgerät

ausgestattet, das eine

Gleichstromausgabe für die Verbindung

mit dem Pumpenantrieb aufweist.

Der um eine Drehung einstellbare

Geschwindigkeitsregler, Abbildung 2,

bietet variablen Förderbetrieb. Die grüne

PWR-Anzeige leuchtet, wenn die Pumpe

eingeschaltet ist.

Der Ein-/Richtungsschalter ermöglicht die

Versorgung mit Strom, wobei es keine

Rolle spielt, ob sich der Pumpenrotor

rechts oder links herum dreht. Die MAXTaste dient zum Füllen und Entleeren und

betreibt die Pumpe bei maximaler

Geschwindigkeit, solange diese Taste

gedrückt wird.

Pumpenantriebseinheit

Externes

Stromversorgungsgerät

Abbildung 1. MASTERFLEX

®

L/S ®Compact Pumpenantrieb

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

Abbildung 2. Pumpe — Frontkonsole

Pumpenmontageöffnungen für

alle standarmäßigen 8-32

Pumpenmontageteile.

Einschaltanzeige

MAX: Zum Füllen oder Entleeren

der Pumpe gedrückt halten.

Geschwindigkeitskontrolle: Bietet

variable Fördermengeneinstellung.

Ein-/Richtungsschalter

Page 16

®

®

16

Rückseitenkonsole, Abbildung 3, enthält einen

Gleichstromeingang zum Anschließen des Primärstroms

und eine 4-polige Klemmleiste zum Anschließen der

Start/Stopp-Fernbedienung und eines ReserveGleichstromversorgungsgeräts.

Anschließen der Start-/Stopp-Fernbedienung

Die Pole 3 und 4 der Klemmleiste an der Rückwandkonsole,

Abbildung 3, sind für die Start-/Stopp-Fernbedienung

vorgesehen. Die Pumpenrichtung und die Geschwindigkeit

können nicht fernbedient werden. Beim Einsatz ohne

Fernbedienung werden diese Anschlüsse mit einer Brücke

kurzgeschlossen.

Für Fernbedienung bei Schalterschluss die Kurzschlussbrücke entfernen und die beiden Anschlüsse des

Fernbedienungsschalters mit den Anschlüssen 3 und 4

verbinden. Durch Schließen der Fernbedienungskontakte

wird das Pumpensystem gestartet. Beim Öffnen der

Kontakte wird das Pumpensystem gestoppt.

ACHTUNG!

Vor dem Weitermachen sicherstellen,

dass der Pumpenantrieb ausgeschaltet

ist. Es besteht Gefahr, dass sich lose

Bekleidung in den Rollen verfängt.

Geeignete Pumpenköpfe: Nur die MASTERFLEX L/S

STANDARD, QUICK LOAD und EASY-LOAD sind zur

Verwendung mit diesem Pumpenantrieb geeignet. Die

Antriebseinheit kann jeweils nur für einen Pumpenkopf

verwendet werden.

VORSICHTSHINWEISE: Bei Verwendung

von anderen als den angegebenen

Pumpenköpfen wird die Leistung

beeinträchtigt, die Antriebseinheit

beschädigt und die Garantie ungültig.

Das Antriebssystem kann jeweils nur

für einen Pumpenkopf verwendet

werden. Bei gleichzeitiger Verwendung

dieser Einheit mit mehreren

Pumpenköpfen wird die Leistung

beeinträchtigt, die Antriebseinheit

beschädigt und die Garantie ungültig.

Beim Anschließen des Pumpenkopfes

an die Antriebseinheit sollten die

Befestigungsschrauben nur mit den

Fingern festgedreht werden. Wenn die

Schrauben zu stark eingedreht werden,

führt dies zum Blockieren und zu

mangelhafter Leistung.

!

!

Abbildung 3. Pumpe — Rückwandkonsole

Gleichstromeingang

2,5-mm-Koaxialbuchse

Kurzschlussbrücke

Reserve-

Gleichstromeingang

Start-/Stopp-

Fernbedienungseingang

Geeignete Schläuche: Die für die Verwendung mit diesem

Antrieb geeigneten Pumpenköpfe akzeptieren den Anschluss

von MASTERFLEX Präzisionsschläuchen in den Größen L/S

®

13, L/S®14 und L/S®16 in allen Ausführungen. Für Schläuche

in den Größen L/S

®

17 und L/S®25 nur die Ausführungen in

Silikon oder C-FLEX

®

verwenden.

Um optimale Anwendungsergebnisse zu gewährleisten, sind

für MASTERFLEX Pumpen ausschließlich MASTERFLEX

Präzisionsschläuche zu verwenden. Der Einsatz anderer

Schläuche kann eine Verweigerung der Garantieleistung nach

sich ziehen.

Page 17

®

®

17

MONTAGE UND BETRIEB

1. Antrieb auspacken: Das Verpackungsmaterial aufbewahren,

bis der ordnungsgemäße Betrieb der Einheit bestätigt wird.

2. Pumpenkopf wählen und Schlauch anschließen (siehe

Bedienungsanleitung des Pumpenkopfes).

3. Bei den Modellen 77200-20 das externe

Stromversorgungsgerät an den Netzstrom anschließen

und mit der Rückseite des Antriebs verbinden.

(Siehe Abbildung Nr. 3.)

4. Bei Stromversorgungsgerät 77200-12: 11,0 bis 15 V

Gleichstrom zu Klemmleistenpositionen 1 und 2. (Siehe

Abbildung Nr. 3.)

5. Das Antriebssystem kann entweder auf Betriebsrichtung im

Uhrzeigersinn (rechts herum) oder gegen den

Uhrzeigersinn (links herum) eingestellt werden. Derselbe

Regler, mit dem die Richtung gewählt wird, dient auch zum

Ein- und Ausschalten des Stroms. Zum Betreiben des

Geräts im Uhrzeigersinn den Richtungsschalter "nach oben"

stellen. Die POWER-Anzeige müsste nun leuchten, und die

Flüssigkeit fließt von rechts nach links. Zum Betreiben des

Geräts gegen den Uhrzeigersinn den Richtungsschalter

"nach unten" stellen. Die POWER-Anzeige müßte nun

leuchten, und die Flüssigkeit fließt von links nach rechts.

Zum Ausschalten der Pumpe den Schalter auf die "mittlere"

Position stellen.

6. Die Pumpgeschwindigkeit wird mit dem variablen

Geschwindigkeitsregler kontrolliert. Durch Drehen des

Reglers im Uhrzeigersinn wird die Geschwindigkeit erhöht.

Bei erhöhter Betriebsgeschwindigkeit verringert sich die

Schlauchlebensdauer. Die Geschwindigkeit kann bis zu

einem Bereich von 6:1 reguliert werden.

WARTUNG

REINIGUNG: Das Antriebsgehäuse mit milden reinigungsmitteln sauberhalten. Nicht in Flüssigkeit tauchen und nicht zu

viel Flüssigkeit verwenden.

Auswechseln des Motors/der Kohlebürste: Der bei diesem

preisgünstigen Antrieb verwendete Motor kann nicht gewartet

oder repariert werden und ist mit Bürsten ausgestattet, die

nicht ausgewechselt werden können. Die Nennleistung des

Motors ist für eine kontinuierliche Betriebsdauer von mindestens 3000 Stunden berechnet. Der Motor lebt länger, wenn

er nicht kontinuierlich verwendet wird. Der Motor ist

auszuwechseln, wenn er aus irgendeinem Grund ausfällt.

Ausgangsleistung:

Drehzahl bei Betrieb: 35 bis 200 U/min

Anzahl der Pumpenköpfe: 1

Drehmoment: 1440 g/cm, maximal

Drehrichtung: Im Uhrzeigersinn (rechts herum)

und gegen den Uhrzeigersinn

(links herum)

Eingang:

Betriebsspannung/Frequenz:

Modell 77200-20 115 V~ nominal 50/60 Hz

(90 - 130 V~) bei 500 mA

Wechselstrom

230 V~ nominal 50/60 Hz

(190 - 260 V~) bei 300 mA

Wechselstrom

Modell 77200-12 13,5 V Gleichstrom nominal

(11,0 - 15,0 V Gleichstrom) bei 2,

4 A Gleichstrom

Installationskategorie:

Modell 77200-12 & -20 Kategorie I nach IEC664

(Signalebene)

Externer Start/Stopp: Kontaktschlussschaltung an

Klemmleisten 3 und 4

Konstruktion:

Abmessungen (L × B × H): 14,6 cm × 13,0 cm × 10,5 cm)

Gewicht: 0,85 kg

Farbe: Schwarz

Material: Lackierter Stahl

Gehäusering: IP22 nach IEC529

Umweltbedingungen:

Betriebstemperatur: 0 °C bis 40 °C

Lagertemperatur: 0 °C bis 65 °C

Feuchtigkeit

(nicht kondensierend): 10 % bis 90 %

Höhe: 2000 m

Umweltverschmutzungsgrad: Umweltverschmutzungsgrad

2 nach IEC664

(Verwendung in Innenräumen —

Labor, Praxis)

Einhaltung der Normen

(für CE-Zeichen):

EN61326-1/A2: 2001 (EMV-Richtlinie der EU)

Gleichrichter ist UL-aufgelistet und CSA-zugelassen.

Aufgrund der niedrigen Stromspannung treffen die Spezifikationen

der Aufsichtsbehörde zum Abgleichen der Einheit nicht zu.

TECHNISCHE DATEN

Page 18

®

®

18

GARANTIE

Um optimale Anwendungsergebnisse zu

gewährleisten, sind für MASTERFLEX Pumpen

ausschließlich MASTERFLEX Präzisionsschläuche

zu verwenden. Der Einsatz anderer Schläuche kann

eine Verweigerung der Garantieleistung nach sich

ziehen.

Reparaturkosten außerhalb der Garantiezeit oder aufgrund

von fehlerhaftem oder unsachgemäßem Gebrauch des

Produktes werden dem Kunden in Rechnung gestellt.

Die Garantie gilt für einen Zeitraum von ein (1) Jahr nach

dem Kaufdatum.

WARENRÜCKSENDUNGEN

Um Kosten und Verzögerungen so gering wie möglich zu

halten, lassen Sie sich in jedem Fall von Ihrem Fachhändler

oder dem Hersteller eine Rücksendegenehmigung und die

Versandanweisungen geben, bevor Sie Ware zurückschicken.

Geben Sie bitte den Rücksendegrund mit an. Verpacken Sie

die Ware sorgfältig und versichern Sie die Sendung gegen

Beschädigung bzw. Verlust. Für Transportschäden aufgrund

unsachgemäßer Verpackung haften Sie.

TECHNISCHE BERATUNG

Wenn Sie Fragen zur Anwendung dieses Produktes haben,

wenden Sie sich bitte an den Hersteller oder autorisierten

Fachhändler.

Page 19

®

®

77200-20

77200-12

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

19

OPERATING MANUAL:

Compact Pump Drives

MANUEL DE L’UTILISATEUR :

Entrainements de

Pompes Compacts

BEDIENUNGSANLEITUNG:

Compact Pumpenantriebe

MANUAL DE OPERACIÓN:

Propulsores de Bombas

Compactos

MANUALE dI ISTRUZIONI:

Azionamenti Compatti per

Pompe

®

®®®®®®®®®

A12991007B

Edición 04

(US & Canada only) Toll Free 1800MASTERFLEX • 18006373739

(Outside US & Canada) 18475497600 • 18473817050

www.masterflex.com • techinfo@masterflex.com

®

Page 20

®

®

PRECAUCIONES PARA SEGURIDAD

PRECAUCIONES:

El uso de cabezales diferentes a los especificados tendrá como resultado un rendimiento poco satisfactorio, daños a la unidad de propulsión y la anulación de las garantías correspondientes.

El sistema de propulsión solamente puede usarse con un cabezal de bomba a la vez. El uso

de esta unidad de propulsión con múltiples cabezales tendrá como resultado un rendimiento poco

satisfactorio, daños a la unidad de propulsión y la anulación de las garantías

correspondientes.

Al montar el cabezal de la bomba en la unidad de propulsión, los tornillos de montaje deben

apretarse solo a mano. Si se aprietan demasiado los tornillos de montaje se producirá un agarrotamiento y el rendimiento no será satisfactorio.

ADVERTENCIA:

ANTES DE SEGUIR, ASEGURARSE QUE EL PROPULSOR DE LA BOMBA ESTÉ APAGADO.

LA ROPA SUELTA PUEDE ENGANCHARSE EN LOS RODILLOS.

ADVERTENCIA: LIMITACIÓN DE USO DEL PRODUCTO

Estos productos no están diseñados ni destinados para ser utilizados en aplicaciones conectadas a un

paciente, incluyendo las aplicaciones médicas y dentales, pero sin limitarse a las mismas, y por lo tanto no

se ha solicitado su aprobación a la FDA.

!

!

CONTENIDO

Título Página

PRECAUCIONES PARA SEGURIDAD.................................20

INTRODUCCIÓN Y DESCRIPCIÓN GENERAL .............21-22

CONFIGURACION Y OPERACION DEL PROPULSOR ......23

MANTENIMIENTO ................................................................23

ESPECIFICACIONES............................................................23

GARANTÍA ............................................................................24

DEVOLUCIÓN DEL PRODUCTO .........................................24

ASISTENCIA TÉCNICA ........................................................24

20

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

C-FLEX — Marca registrada de Saint-Gobain Performance Plastics Corp.

Las marcas registradas que llevan el símbolo ® en esta publicación están registradas en EE.UU. y en otros países.

BOMBA PARA LIQUIDOS

Page 21

®

®

21

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

INTRODUCCIÓN Y DESCRIPCIÓN GENERAL

Las bombas de propulsión

COMPACTAS MASTERFLEX

®

L/S

®

están diseñadas con velocidad variable,

a precio reducido y aceptan cabezales

STANDARD, QUICK LOAD

®

y

EASY-LOAD

®

MASTERFLEX L/S.

Estos propulsores de 200 rpm

acomodan un cabezal y un tubo a velocidad controlada de hasta

30 rpm. Todas las unidades operan

con un suministro de energía externo.

Los modelos de CA se envían con un

suministro de energía externo, que

proporciona una salida de corriente de

CC para la conexión con el propulsor.

El control de velocidad ajustable y de

una sola espira, figura 2, proporciona

una operación de caudal variable.

Siempre que la bomba está en funcionamiento se enciende el indicador

verde de activación (PWR On). El interruptor de activación/sentido (Power

On/Direction) activa la potencia cuando

se selecciona el sentido del rotor de la

bomba bien sea en sentido de las agujas del reloj o dirección opuesta. El botón

MAX se utiliza para el cebado y purga, y

cuando está pulsado la bomba opera a

la velocidad máxima.

Unidad

bomba de propulsión

Suministro de

energía externo

Figura 1. Propulsor de bomba compacto MASTERFLEX

®

L/S

®

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

Figura 2. Bomba — Panel delantero

Orificios de montaje,

aceptan toda la

tornillería de montaje

estándar 8-32 para

bombas.

Indicador de activación

MAX: Oprimir y mantener presionado para cebar o purgar

la bomba.

Control de velocidad:

Proporciona un ajuste de

caudal variable.

Interruptor de activación/

sentido

Page 22

®

®

22

El panel trasero, figura 3, contiene un enchufe de potencia de

entrada de CC para la conexión de la energía eléctrica primaria

y una regleta de barrera de 4 conexiones para la conexión del

control remoto de inicio/parada y un suministro de CC auxiliar.

Control remoto de inicio/parada: Las terminales 3 y 4 en la

regleta de conexiones del panel trasero, figura 3, se utilizan

para la operación de inicio/parada por control remoto. El

sentido de la bomba y la velocidad no pueden controlarse a

distancia. Cuando la unidad funciona en un modo que no es

por control remoto, estas terminales se conectan juntas con

una barra de cortocircuitar.

Para controlar la unidad a distancia por medio del cierre del

interruptor, quitar la barra de cortocircuitar y conectar las

dos terminales del interruptor de control remoto a las

terminales 3 y 4. El cierre de los contactos del interruptor de

control remoto pone en marcha el sistema de bombas. La

apertura de los contactos detiene el sistema de bombas.

ADVERTENCIA:

Antes de seguir, asegurarse de que el

propulsor de la bomba esté apagado.

La ropa suelta puede engancharse en

los rodillos.

Cabezales de bomba aceptados: Cabezales de bomba

aceptados: Esta bomba de propulsión solamente acepta los

cabezales de bomba STANDARD, QUICK LOAD y EASY-

LOAD MASTERFLEX

®

L/S®. En esta unidad solo puede

usarse un cabezal a la vez.

PRECAUCIONES: El uso de cabezales

de bomba diferentes a los especificados

tendrá como resultado un rendimiento

poco satisfactorio, daños a la unidad de

propulsión y la anulación de las garantías correspondientes.

El sistema de propulsión solamente

puede usarse con un cabezal a la vez. El

uso de esta unidad de propulsión con

múltiples cabezales tendrá como resultado un rendimiento poco satisfactorio,

daños a la unidad de propulsión y la

anulación de las garantías correspondientes.

Al montar el cabezal en la bomba de

propulsión, los tornillos de montaje

deben apretarse solamente con la mano.

Si se aprietan demasiado se

producirá un agarrotamiento y el

rendimiento no será satisfactorio.

!

!

Figura 3. Propulsor de bomba — Panel trasero

Potencia de entrada de CC,

Receptáculo coaxial de 2,5 mm

Barra de cortocircuitar

Entrada

del control

remoto de

inicio/parada

Entrada

de CC

auxiliar

Mangueras aceptados: Los cabezales aceptados para su

uso con el propulsor pueden utilizarse con las manguernas de

precisión de tamaño L/S

®

13, L/S®14 y L/S®16 en todas las

formulaciones. Para manguernas de tamaño L/S

®

17 y L/S

®

25, usar formulaciones de silicona o C-FLEX®solamente.

Usar solamente manguernas de precisión MASTERFLEX con

las bombas MASTERFLEX para asegurar el máximo

rendimiento. El uso de otras manguernas puede anular las

garantías correspondientes.

Page 23

®

®

23

CONFIGURACIÓN Y

OPERACIÓN DEL

PROPULSOR

1. Desembalar el propulsor: guardar el material de embalaje

hasta que se haya verificado el funcionamiento correcto del

producto.

2. Seleccionar y montar el cabezal de la bomba y tubos de

carga (ver el manual del cabezal de la bomba).

3. Para los modelos 77200-20 enchufar en el suministro de

energía externo y conectar en la parte trasera del propulsor.

(Ver la figura nº 3.)

4. Para los modelos 77200-12 suministro de 11,0 a 15V CC

a las posiciones 1y 2 de la regleta de conexiones.

(Ver la figura nº 3.)

5.El sistema del propulsor puede fijarse para que opere tanto en

sentido de rotación del reloj u opuesto. El mismo control que

se utiliza para seleccionar el sentido también activa y desactiva la potencia. Para operar en sentido igual al reloj, colocar el

interruptor de control de sentido en la posición "up" (arriba).

Se encenderá el indicador de activación y el fluido fluirá de

derecha a izquierda. Para operar en sentido contrario,

colocar el interruptor de control de sentido en la posición

"down" (abajo). Se encenderá el indicador de activación y el

fluido fluirá de izquierda a derecha. Para apagar la bomba,

colocar el interruptor en la posición del "centro".

6. La velocidad de la bomba se controla con el control

de velocidad variable. Cuando se gira el control en el sentido

de rotación del reloj aumenta la velocidad. Una velocidad de

funcionamiento elevada reduce la duración del tubo. La velocidad puede controlarse hasta una gama de 6:1.

MANTENIMIENTO

Limpieza: Mantener la caja de la bomba limpia con

detergentes suaves.

Motor/ Cambio de escobillas: El motor que se utiliza en

esta unidad no admite mantenimiento ni reparaciones y tiene

escobillas, que no pueden cambiarse. El motor está determinado para una duración útil continua de un mínimo de 3000

horas de funcionamiento. La operación en ciclos de trabajo

que no sean continuos tendrá como resultado una duración

más prolongada del motor. Si falla el motor por cualquier

razón, debe ser reemplazado.

Salida:

Velocidad operacional: 35 a 200 rpm

Número de cabezales

de bomba: 1

Carga de par: 1440 gm-cm (20 oz-pulg.), máxima

Sentido de la rotación: Horario y antihorario

Entrada:

Voltaje de entrada /frecuencia:

Modelo 77200-20 Nominal de 115V CA 50/60 Hz

(90-130V CA) a 500mA CA

Nominal de 230V CA 50/60 Hz

(190-260V CA) a 300mA CA

Modelo 77200-12 Nominal de 13,5V CC

(11,0-15,0V CC) a 2,4A CC

Categoría de instalación:

Modelo 77200-12 & -20 Categoría I según IEC664

(Nivel de señales)

Control remoto de

inicio/parada: Conexión de cierre de contactos en

las terminales 3 y 4 de la regleta

Construcción:

Dimensiones (L × A × A): 14,6 cm × 13,0 cm × 10,5 cm

(5,750 pulg. × 5,14 pulg. × 4,14 pulg.)

Peso: 0,85 kg (1,88 libras)

Color: Negro

Material: Acero pintado

Clasificación de la caja: IP22 según IEC529

Ambiente:

Temperatura de

funcionamiento: 0 °C a 40 °C (32 °F a 104 °F)

Temperatura de

almacenamiento: -45 °C a 65°C (-49 °F a 149 °F)

Humedad

(sin condensación): 10% a 90%

Altitud: 2000 m (6600 pies)

Grado de contaminación: Grado de contaminación 2 según IEC664

(Uso en interiores — laboratorio, oficina)

Conformidad (Para marca de CE):

EN61326-1/A2: 201 (Directiva EU EMC)

El convertidor está listado en UL y aprobado por CSA.

Las especificaciones del organismo de control no aplican al equilibrio

de la unidad debido al bajo voltaje.

ESPECIFICACIONES

Page 24

®

®

24

GARANTÍA

Usar solamente mangueras de precisión

MASTERFLEX con las bombas

MASTERFLEX para asegurar el máximo

rendimiento. El uso de otros tubos puede

anular las garantías correspondientes.

El Fabricante garantiza que las especificaciones de este producto no se desvían significativamente de las especificaciones publicadas. Si es necesario hacer una reparación o un

ajuste en el período de garantía, el problema será corregido

de forma gratuita si no se debe a uso indebido o abuso por

parte del usuario, según lo determine el Fabricante. Los costos de reparación fuera del período de garantía o aquellos

resultantes del uso indebido o abuso del producto podrán cargarse al usuario.

El período de garantía de este producto es

una (1) año a

partir de la fecha de compra.

DEVOLUCIÓN DEL

PRODUCTO

Para limitar cargos y retrasos, ponerse en contacto con el

vendedor o Fabricante para recibir la autorización e instrucciones de envío con anterioridad a la devolución del producto,

bien sea dentro o fuera del período de garantía. Al devolver el

producto, indicar el motivo de la devolución. Para protección

del usuario, embalar bien el producto y asegurarlo contra

posibles daños o pérdidas. El usuario es responsable de los

daños resultantes de un embalaje incorrecto.

ASISTENCIA TÉCNICA

Si se tiene alguna duda sobre el uso de este producto, ponerse en contacto con el Fabricante o vendedor autorizado.

!

Page 25

®

®

77200-20

77200-12

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

25

OPERATING MANUAL:

Compact Pump Drives

MANUEL DE L’UTILISATEUR :

Entrainements de

Pompes Compacts

BEDIENUNGSANLEITUNG:

Compact Pumpenantriebe

MANUAL DE OPERACIÓN:

Propulsores de Bombas

Compactos

MANUALE dI ISTRUZIONI:

Azionamenti Compatti per

Pompe

®

®®®®®®®®®

A12991007B

Edizione 04

(US & Canada only) Toll Free 1800MASTERFLEX • 18006373739

(Outside US & Canada) 18475497600 • 18473817050

www.masterflex.com • techinfo@masterflex.com

®

Page 26

®

®

MISURE DI SICUREZZA

ATTENZIONE: l'uso di teste pompanti diverse da quelle specificate provoca prestazioni insoddisfacenti,

danni alla motorizzazione e l'invalidazione delle garanzie.

La motorizzazione può essere usata soltanto con una testa pompante alla volta. L’uso di

questa motorizzazione con più teste pompanti provoca prestazioni insoddisfacenti,

danneggiamenti e l'invalidazione delle garanzie.

Quando si monta la testa pompante sulla motorizzazione, le viti di montaggio devono essere

strette solo a mano. Un serraggio eccessivo provocherebbe inceppamenti e prestazioni

insoddisfacenti.

AVVERTENZA:assicurarsi che la motorizzazione della pompa sia spenta prima di procedere. I lembi sciolti

del vestiario potrebbero incastrarvisi.

AVVERTENZE: RESTRIZIONI SULL’USO DEL

PRODOTTO

Questi prodotti non sono stati progettati o realizzati per applicazioni con pazienti come, ad esempio,

applicazioni mediche od odontoiatriche. Di conseguenza, non sono stati sottoposti all’approvazione della

FDA (ente statunitense di controllo su alimenti e i farmaci).

INDICE

Titolo Pagina

MISURE DI SICUREZZA ......................................................26

INTRODUZIONE E DESCRIZIONE GENERALE ............27-28

MESSA A PUNTO E AZIONAMENTO..................................29

MANUTENZIONE..................................................................29

SPECIFICHE TECNICHE......................................................29

GARANZIA ............................................................................30

RESTITUZIONE DEL PRODOTTO.......................................30

ASSISTENZA TECNICA .......................................................30

26

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

L/

s

®®

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

Masterflex

!

!

C-FLEX – Reg TM Saint-Gobain Performance Plastics Corp.

I marchi di fabbrica recanti il simbolo ® in questa pubblicazione sono registrati negli Stati Uniti e in altri paesi.

POMPA PER LIQUIDI

Page 27

®

®

27

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

INTRODUZIONE E DESCRIZIONE GENERALE

Le motorizzazioni per pompe

MASTERFLEX

®

L/S®COMPATTE

sono state progettate al fine di realizzare

azionamenti a velocità variabile a

basso costo per le teste pompanti

MASTERFLEX L/S STANDARD, QUICK

LOAD

®

e EASY-LOAD®. Queste

motorizzazioni a 200 giri/1' operano con

una testa pompante e un tubo a velocità

controllata fino ad un minimo di 30 giri/1'.

Tutte le unità sono alimentate da un alimentatore esterno. I modelli da CA sono

alimentate da un alimentatore esterno

che fornisce una uscita a CC per

il collegamento alla motorizzazione

della pompa.

Il comando della velocità regolabile, a giro

singolo, Figura 2, consente di regolare la

portata. La spia verde PWR On (acceso),

si illumina ogni volta che la pompa è in funzione. L’interruttore Power On/Direction

(acceso/direzione) alimenta l’apparecchio

quando si seleziona il senso di rotazione

del rotore della pompa, orario o antiorario.

Il pulsante MAX serve per effettuare le

operazioni di adescamento e spurgo.

Inoltre, mentre viene tenuto premuto,

fa funzionare la pompa alla velocità

massima.

Motorizzazione

pompa

Alimentatore

esterno

Figura 1. Motorizzazione pompa MASTERFLEX

®

L/S®Compatta

MAX

POWER

Use only MASTERFLEX precision

tubing with MASTERFLEX pumps

to ensure optimum performance.

Use of other tubing may void

applicable warranties.

COMPACT DRIVE

For use with L/S 13, L/S 14, and L/S 16 size

tubing in all formulations.

For L/S 17 and L/S 25 size tubing

use silicone or C-Flex tubing only.

L/

s

®®

Masterflex

Figura 2. Pompa — Pannello anteriore

Fori di montaggio

predisposti per

bulloneria standard

per pompe 8-32.

Spia di

accensione

MAX: Tenere premuto per

innescare o eseguire lo spurgo

della pompa.

Comando velocità: permette

di regolare la portata.

Interruttore Power

On/Direction

(acceso/direzione)

Page 28

®

®

28

Il pannello posteriore, Figura 3, contiene un jack per

l’alimentazione in CC per il collegamento all’alimentazione prin-

cipale e una morsettiera a 4 terminali per il collegamento del

telecomando di avvio /arresto e per l'alimentatore in CC

di riserva.

Avvio/arresto telecomando: I terminali 3 e 4 sulla morsettiera

nel pannello posteriore, Figura 3, servono per le operazioni di

avvio/arresto con telecomando. Il senso operativo e la velocità

della pompa non possono essere comandati a distanza. Nelle

applicazioni senza l'uso del telecomando, questi terminali sono

collegati assieme tramite una barra cortocircuitante. Per il

comando a distanza per mezzo di chiusura di commutazione

occorre togliere la barra cortocircuitante e collegare i due

terminali dell’interruttore di comando a distanza ai terminali 3

e 4. La chiusura dei contatti dell’interruttore del telecomando

provoca l'avviamento del sistema pompante. L’apertura del con-

tatto provoca l'arresto del sistema pompante.

AVVERTENZA: Assicurarsi che la motorizzazione

sia spenta (Off) prima di procedere.

Fare attenzioni ai lembi degli abiti in

quanto potrebbero impigliarsi nei rulli

Teste pompanti idonee: con questa motorizzazione

si possono utilizzare soltanto le teste MASTERFLEX L/S

STANDARD, QUICK LOAD e EASY-LOAD. Con questo

tipo di motorizzazione si può usare una sola testa pom-

pante alla volta.

ATTENZIONE: l'uso di teste pompanti diverse

da quelle specificate provoca

prestazioni insoddisfacenti, danni alla

motorizzazione e l'invalidazione delle

garanzie.

La motorizzazione può essere usata

soltanto con una testa pompante alla

volta. L’uso di questa motorizzazione

con più teste pompanti provoca

prestazioni insoddisfacenti,

danneggiamenti e l'invalidazione delle

garanzie del caso.

Quando si monta la testa pompante

sulla motorizzazione, le viti di

montaggio devono essere strette solo

a mano. Un serraggio eccessivo

provocherebbe inceppamenti e

prestazioni insoddisfacenti.

Figura 3. Motorizzazione pompa — Pannello posteriore

Ingresso alimentazione CC;

Presa coassiale da 2,5 mm

Barra di messa

in corto circuito

Input

avvio/arresto

a distanza

Input in CC

di riserva

!

Tubi idonei: le teste pompanti idonee all'uso con la

motorizzazione possono essere usate con tubi di precisione

MASTERFLEX delle misure seguenti e in tutte le formulazioni:

L/S

®

13, L/S®14 ed L/S®16. Con i tubi di dimensioni L/S

®

17 ed L/S®25 , usare solo le formulazioni in silicone o in

C-FLEX

®

Per assicurare le migliori prestazioni, usare solo tubi di

precisione MASTERFLEX con le pompe MASTERFLEX.

L’uso di altri tubi potrebbe invalidare le eventuali garanzie.

!

Page 29

®

®

29

MESSA A PUNTO E

AZIONAMENTO

1. Sballare la motorizzazione: conservare l’imballaggio fino a

quando non si sia verificato il corretto funzionamento del

prodotto.

2. Selezionare e montare la testa pompante e il tubo di carico

(vedere il manuale della testa pompante).

3. Per i modelli 77200-20, inserire l’alimentatore esterno e collegarlo al retro della motorizzazione (Vedere Figure #3).

4. Per i modelli 77200-12, alimentare da 11,0 a 15V CC alle

posizioni 1 e 2 della morsettiera (vedere Figure #3).

5. La motorizzazione può essere impostata per operare in

senso orario o antiorario. Lo stesso comando usato per

scegliere il senso di rotazione serve anche per accendere

e spegnere l'apparato. Per operare in senso orario è

sufficiente posizionare il comando del senso di rotazione in

corrispondenza di "up" (in alto). La spia POWER si illumina

e il fluido scorre da destra a sinistra. Per operare in senso

antiorario è sufficiente posizionare il comando del senso di

rotazione in corrispondenza di "down" (in basso). La spia

POWER si illumina e il fluido scorre da sinistra a destra.

Per spegnere la pompa occorre posizionare l’interruttore

nella posizione centrale, "center".

6. Il comando della velocità variabile consente di selezionare

la velocità desiderata della pompa. Girando il comando in

senso orario si aumenta la velocità. Il funzionamento a

velocità elevata riduce la vita utile del tubo. La velocità

può essere controllata fino ad un range di 6:1.

MANUTENZIONE

PULIZIA: Tenere pulita la scatola della motorizzazione con

detergenti non aggressivi.

Sostituzione del motore/spazzola: il motore installato in

questo tipo di motorizzazione a basso costo non è riparabile e

le sue spazzole non sono sostituibili. Il motore ha una vita utile

nominale pari ad almeno 3.000 ore di servizio continuo.

Il funzionamento in cicli di esercizio non continui prolunga la

vita utile del motore. Il motore deve essere sostituito in caso di

guasti, a prescindere dalla causa.

Uscita:

Velocità operativa: da 35 a 200 giri/1'

Numero di teste pompanti: 1

Carico di coppia: 1440 gm-cm max. (20 once-1")

Senso di rotazione: orario ed antiorario

Entrata:

Tensione/frequenza di operativa:

Modello 77200-00 115V CA nominali 50/60 Hz

(90-130V CA) a 500mA CA

230V CA nominali 50/60 Hz

(190-260V CA) a 300mA CA

Modello 77200-12 13,5V CC nominali

(11,0-15,0V CC) a 2,4A CC

Categoria di installazione:

Modello 77200-12 & -20 Categoria I secondo norma IEC664

(intensità del segnale)

Avvio/arresto telecomandato: Connessione chiusura contatto,

ai contatti della morsettiera 3 e 4

Costruzione:

Dimensioni (L × P × H): 14,6 cm × 13,0 cm × 10,5 cm

(5,750" × 5,14" × 4,14")

Peso: 0,85 kg (1,88 lb)

Colore: Nero

Materiale: Acciaio verniciato

Rating della scatola: IP22 secondo norma IEC529

Ambiente:

Temperatura di esercizio: da 0° a 40°C (da 32°F a 104°F)

Temperatura di stoccaggio: da -45°C a 65°C (da -49°F a 149°F)

Umidità (senza condensa): dal 10% al 90%

Altitudine: 2.000 m

Grado di inquinamento: Grado di inquinamento 2 secondo

norma IEC664 (impieghi interni—

laboratori, uffici)

Conformità (al marchio CE):

EN61326-1/A2: 2001

(Direttiva UE EMC)

Il convertitore è riportato negli elenchi UL ed è approvato dal CSA.

Le specifiche dell'ente normativo (regulatory agency) non sono

applicabili al resto dell'apparato a causa della bassa tensione.

SPECIFICHE TECNICHE

Page 30

®

®

30

GARANZIA

Usare solo tubi di precisione MASTERFLEX, con le

pompe MASTERFLEX, per assicurare le migliori

prestazioni. L’uso di altri tubi potrebbe invalidare

le eventuali garanzie.

Il produttore garantisce che questo prodotto è esente da deviazioni significative rispetto alle specifiche tecniche

pubblicate. Eventuali interventi di regolazione o riparazione

verranno eseguiti gratuitamente durante il periodo di garanzia

a condizione che non siano stati causati da abuso o uso

errato dell'apparecchio da parte dell'utente, condizione che

verrà determinata dal produttore. I costi delle riparazioni che

non rientrano nel periodo di validità della garanzia, o che risultano da abuso o uso errato del prodotto, verranno

fatturati all’utente.

Il periodo di garanzia per questo prodotto è

ad un (1)

anno

dalla data di acquisto.

RESTITUZIONE DEL

PRODOTTO

Per ridurre spese e ritardi, prima di restituire il prodotto si

raccomanda di contattare il venditore o il produttore per

l’autorizzazione e le istruzioni di spedizione, sia entro che

fuori il periodo di garanzia. L'utente che restituisce il prodotto

è pregato di dichiararne il motivo. Si raccomanda di imballare

con cura il prodotto e assicurarlo contro danni o perdite.

L'utente si assume ogni responsabilità per eventuali danni

risultanti da un imballaggio inadeguato.

ASSISTENZA TECNICA

In caso di quesiti circa l’uso di questo prodotto si prega di

contattare il produttore o il rivenditore.

Page 31

31

®

®

Page 32

32

®

®

Printed in U.S.A.

US & Canada only

Toll Free 1-800-MASTERFLEX | 1-800-637-3739

Outside US & Canada

1-847-549-7600 | 1-847-381-7050

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue, Barrington, IL 60010

techinfo@masterflex.com | www.masterflex.com

Loading...

Loading...