Page 1

®

OPERATING MANUAL:

PUMP SYSTEM

MANUEL DE LʼUTILISATEUR :

SYSTEME DE POMPAGE

BEDIENUNGSANLEITUNG:

PUMPENSYSTEM

MANUAL DE OPERACIÓN:

SISTEMA DE BOMBAS

MANUALE dI ISTRUZIONI:

SISTEMA POMPANTE

The MASTERFLEX®C/L®Pump Systems are small peristaltic

pumps with integral drive motors and are intended for use with

a series of tubing sizes that provide flow rates in the range of

2.2 μL/min to 12.3 mL/min.

77120-32

77120-42

77120-52

77120-62

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

A-1299-1039B

Edition 05

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

E-mail: techinfo@coleparmer.com

www.masterflex.com • www.coleparmer.com

Page 2

SAFETY PRECAUTIONS

WARNING: Tubing breakage may result in fluid being sprayed from pump. Use appropriate measures

to protect operator and equipment.

CAUTION: Tubing for use with the MASTERFLEX®C/L®Pump Systems is Microbore Autoanalysis Tubing.

See Appendix A for specifics. Use of tubing other than that specified will result in poor pumping

performance and/or pump system damage and voiding of applicable warranty.

WARNING: PRODUCT USE LIMITATION

These products are not designed for, nor intended for use in patient connected applications; including,

but not limited to, medical and dental use, and accordingly have not been submitted for FDA approval.

TABLE OF CONTENTS

Title Page

SAFETY PRECAUTIONS ........................................................2

INTRODUCTION .....................................................................3

GENERAL DESCRIPTION...................................................4-5

SETUP..................................................................................5-6

Selecting Tubing Size........................................................5

Installing Tubing in Pump Head ........................................5

Installing Panel Mount Mounting Brackets ........................6

Installing Rubber Feet.......................................................6

Connecting Primary Power ...............................................6

Backup Battery Connection ..............................................6

Remote Start/Stop Connection .........................................6

OPERATION ............................................................................7

Turning Pump System On and Selecting Direction of

Operation ..........................................................................7

Setting Pump Speed.........................................................7

Priming Pump System ......................................................7

MAINTENANCE ......................................................................7

Cleaning............................................................................7

Replacement Parts and Accessories................................7

SPECIFICATIONS ...................................................................8

WARRANTY ............................................................................9

PRODUCT RETURN ...............................................................9

TECHNICAL ASSISTANCE.....................................................9

APPENDIX A MASTERFLEX

®

C/L

®

PUMP SYSTEM TUBING FLOW RATES .......................10

2

®

NORYL — Reg TM General Electric Company

PHARMED, TYGON — Reg TM Saint-Gobain Performance Plastics Corp.

VITON — Reg TM E.I. duPont DeNemours & Co.

Trademarks bearing the ® symbol in this publication are registered in the U.S.

and in other countries.

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

Page 3

3

®

INTRODUCTION

The MASTERFLEX®C/L®Pump System is designed to pump

fluid through Microbore tubing by means of peristaltic action

at very low flow rates. It is ideal for sanitizers, reagent

dispensing, analyzers, printing systems, controlled feeding

and non-human infusion procedures.

Page 4

4

®

PWR

MAX

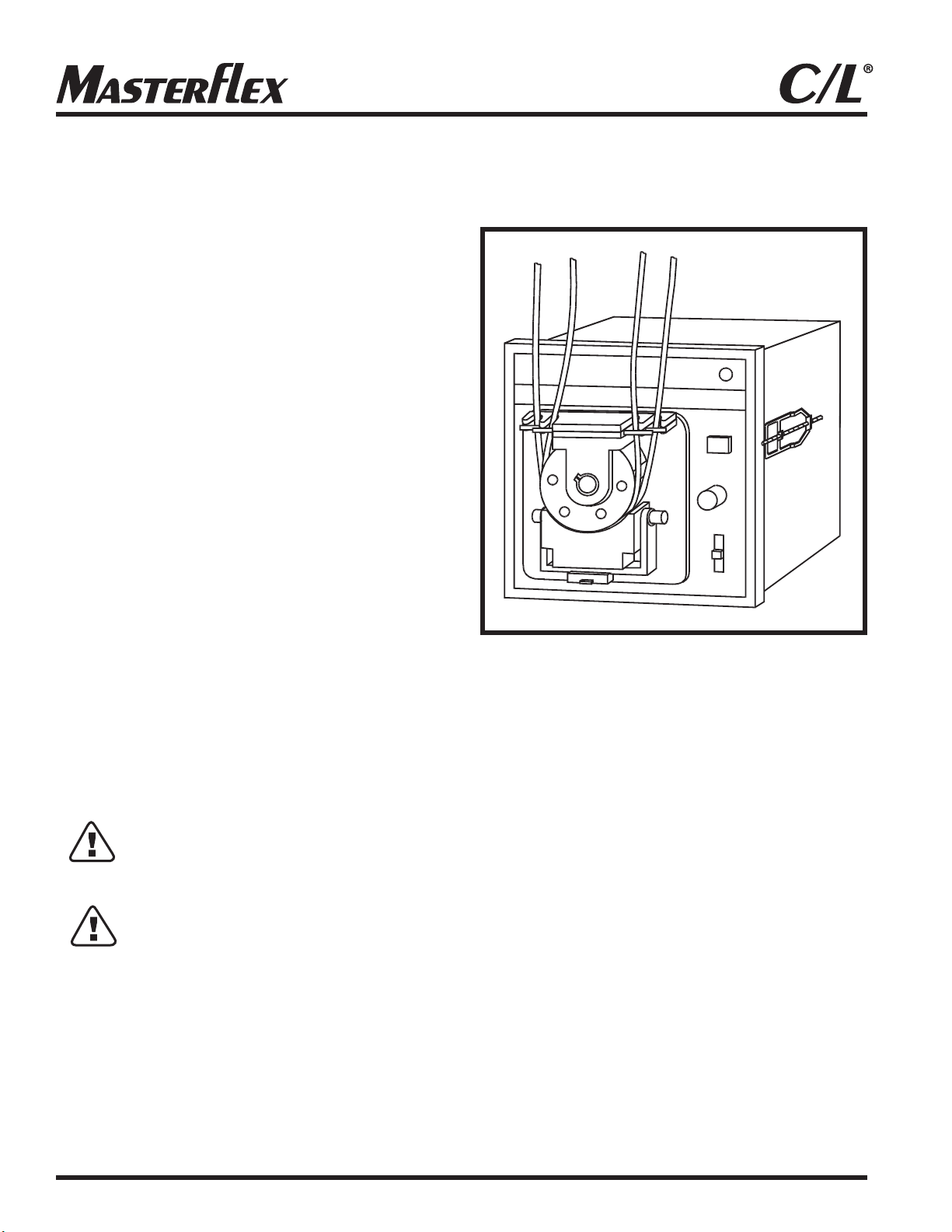

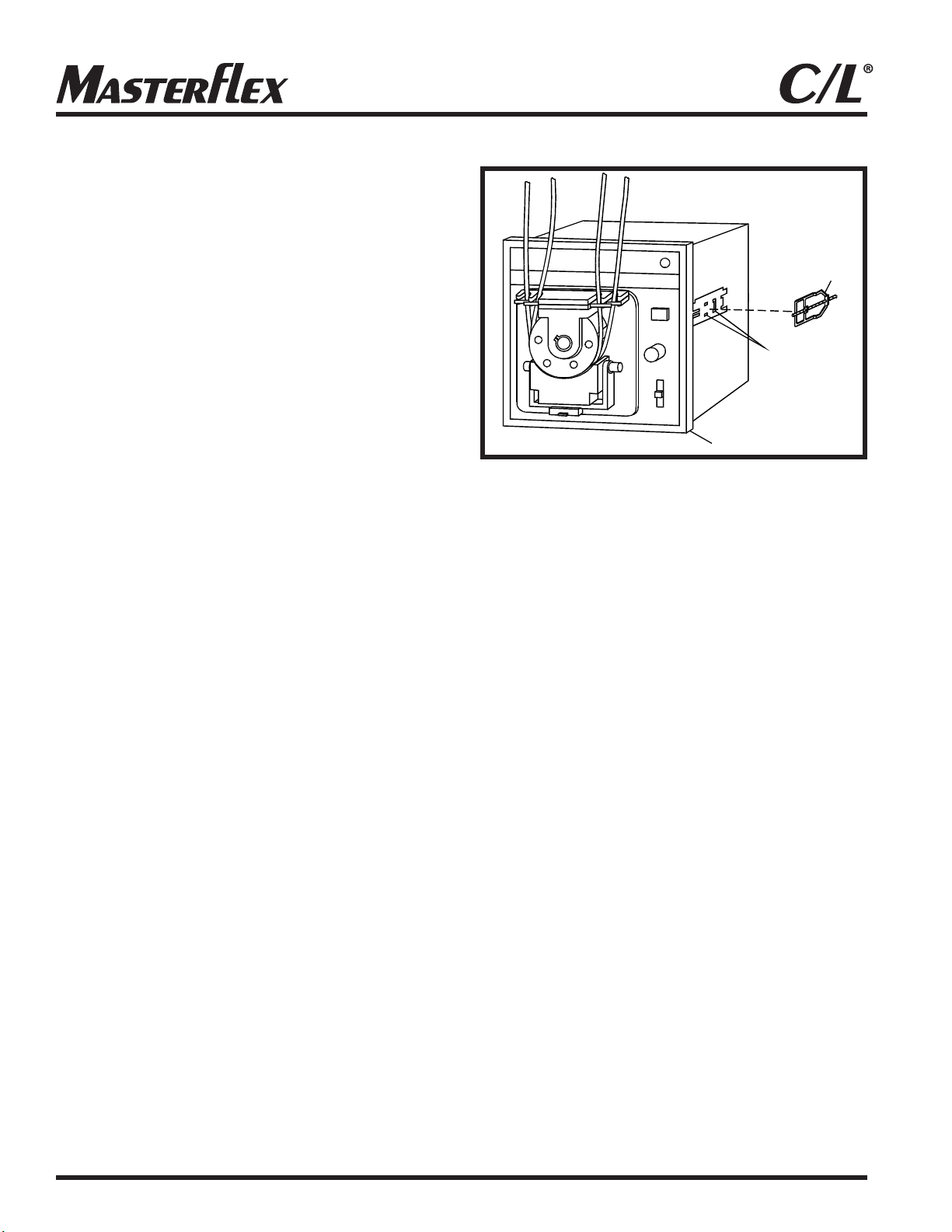

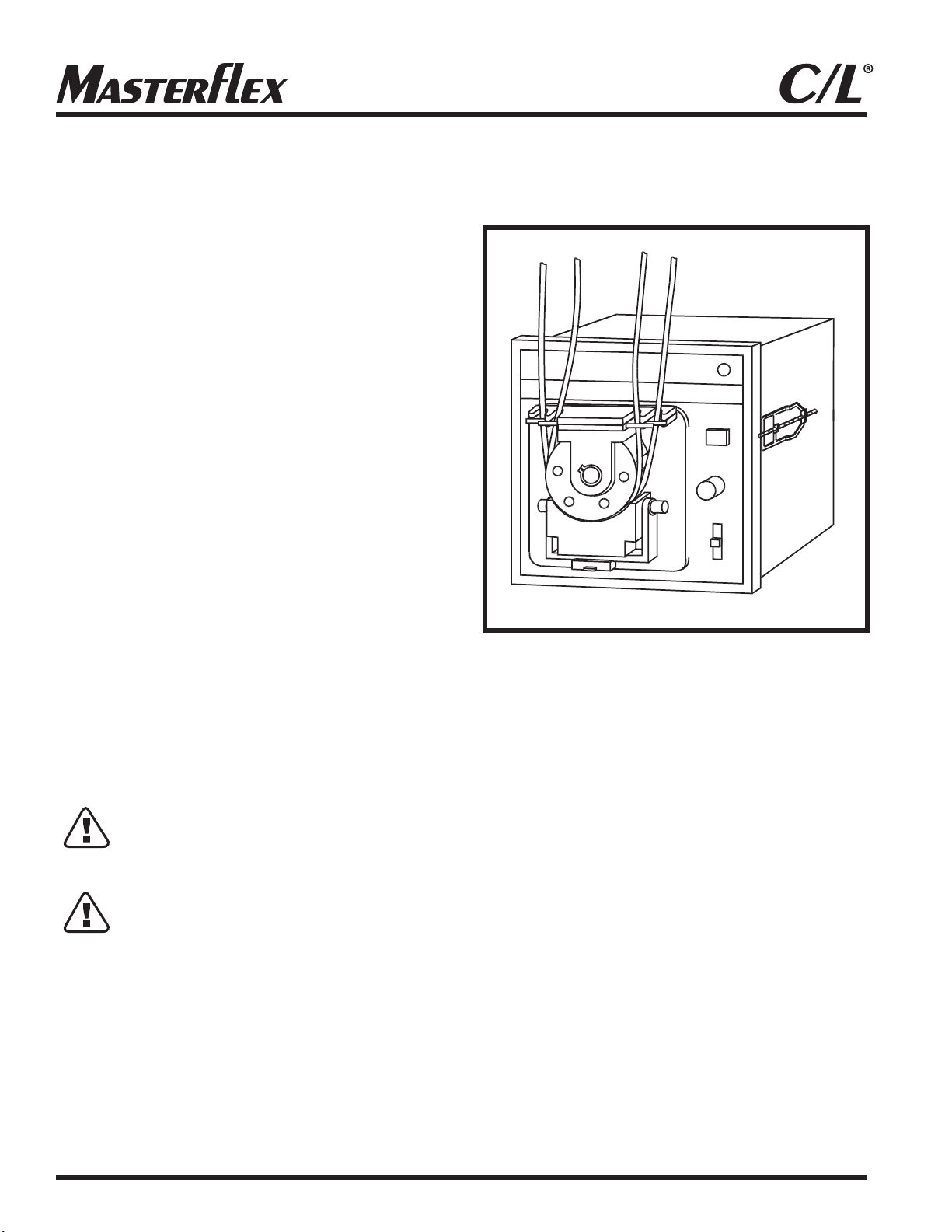

The MASTERFLEX®C/L®Pump System,

Figure 1, is enclosed in a plastic 1/4 DIN

Case. The enclosure allows panel mounting

using optional Mounting Brackets (see

Accessory Section). Rubber Feet, supplied

with the unit, can be attached to the bottom of

the Case for operating on a bench or other flat

surface.

The Pump System can accommodate two

tubes simultaneously for the 6 and 60 rpm

systems at controlled speeds as low as 1 rpm.

Tubing is held in place by spring-clip Tubing

Retainers. For a list of tubing sizes for use with

the Pump System, refer to Appendix A.

The latching Occlusion Bed allows quick

loading or changing of tubing. The Pump Head

Rotor contains six rollers for minimum

pulsation. All units operate from an External

DC Power Supply. The AC models are

supplied with a Universal Power Supply, which

provides a DC output for

connection to the Pump Drive.

The single-turn, adjustable Speed Control,

Figure 2, provides variable flow -operation.

The green PWR On indicator lights whenever

the pump is operating. The Power

On/Direction Switch turns power on when

either clockwise or counterclockwise pump

rotor direction is selected. The MAX Button

is used for priming and purging and operates

the pump at maximum speed while depressed.

Figure 2. Pump — Front Panel

GENERAL DESCRIPTION

Figure 1. MASTERFLEX®C/L®Pump System

Tubing

retainers

Tubing

retainers

PWR On

Indicator

MAX: Press and hold to

prime or purge pump.

Speed Control: Provides

variable flow adjustment

Power On/Direction

Switch

Occlusion Bed Latch: Press

down to release occlusion

bed for changing tubing

Bezel

1/4 DIN Case

Mounting

Bracket

(not Supplied)

Universal

Power Supply

Occlusion Bed

Latch

Page 5

5

®

SETUP

Use only Microbore Autoanalysis tubing with

MASTERFLEX®C/L®pumps to ensure optimum

performance. Use of other tubing may void

applicable warranties.

Selecting Tubing Size

Appendix A provides a list of tubing sizes which will work

efficiently with the MASTERFLEX

®

C/L®Pump System. This

list includes tubing diameters, flow rates in µL/min and the

maximum flow rates at 6 rpm and 60 rpm. Tubing is listed by

part number. For best results, when using two tubes, select

tubes that provide flow rates within a 10:1 range.

(Tube diameter ratios should be within approximately 3.5:1.)

Silicone tubing should not be used with TYGON

®

or

NORPRENE

®

.

Installing Tubing in Pump Head

WARNING: Be sure the Pump Drive is turned off

before proceeding. Loose clothing

could be caught in the rollers.

1. Place the Power On/Direction Switch, Figure 2, in the

center (Off) position.

2. Press down on the Occlusion Bed Latch, Figure 4, to

release the Occlusion Bed from the rotor.

3. Gently stretch the tubing and insert the tubing into the

spring-loaded left rear Retainer.

4. While maintaining the slight amount of stretching, wrap the

selected tubing around the lower Rollers and secure the

tubing in the right rear spring-loaded Retainer. If a second

tubing is to be installed, secure the tubing in the same

manner using the front spring-loaded Retainers.

5. Lift up on the outer edge of the Occlusion Bed until it locks

in position holding the tubing against the bottom Rollers.

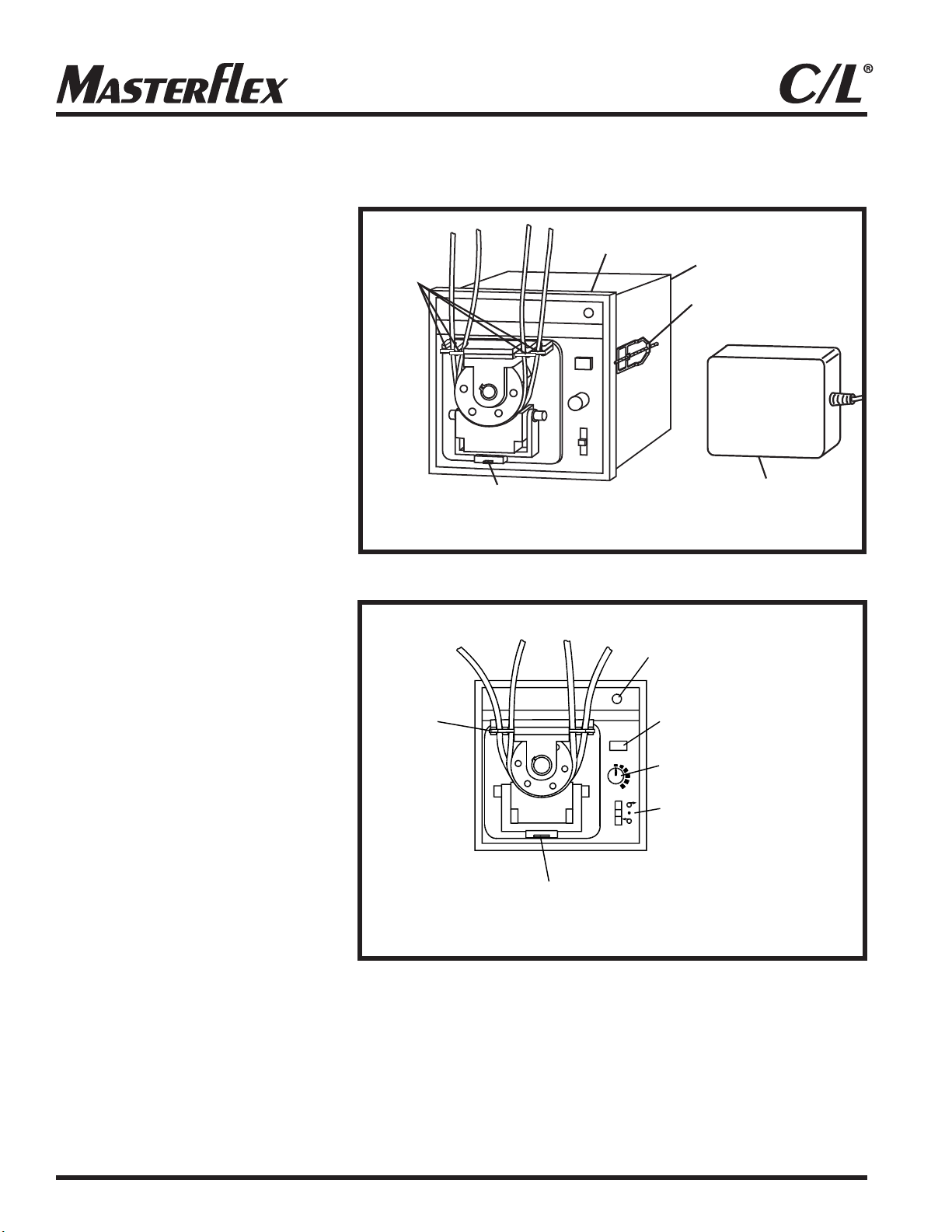

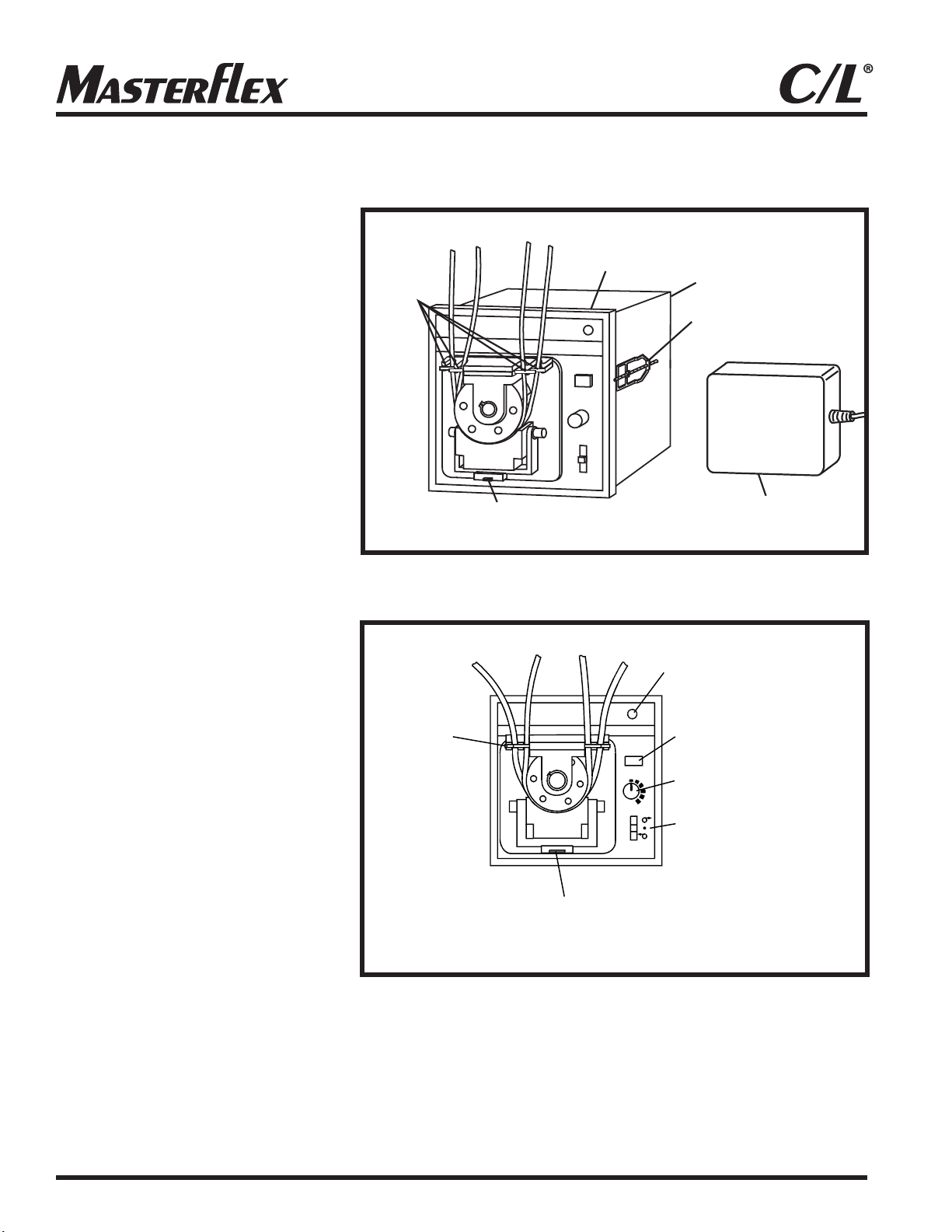

Figure 3. Pump — Rear Panel

DC

Power Input,

2.5 mm Coaxial Receptacle

Backup

DC

Input

Remote

Start/Stop

Input

Rear Tube

Retainer

Rear Tube

Retainer

Front Tube

Retainers

Occlusion Bed in Unlatched

(Tube Loading) Position

Shorting Bar

The rear panel, Figure 3, contains a DC power input jack for

connection of primary power and a 4-terminal barrier strip for

connection of remote start/stop and for a DC backup supply.

Figure 4. Occlusion Bed in Unlatched Tube Loading Position

Page 6

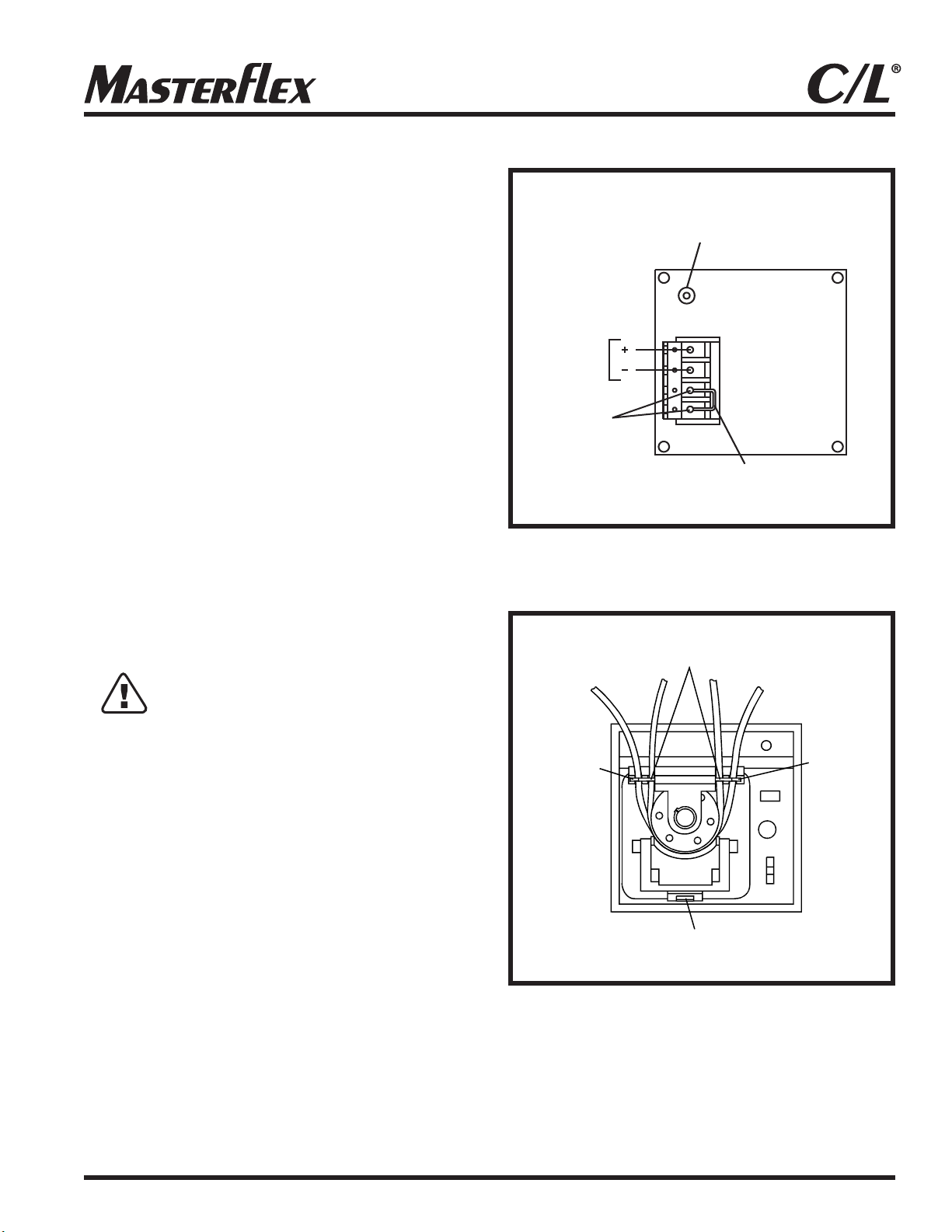

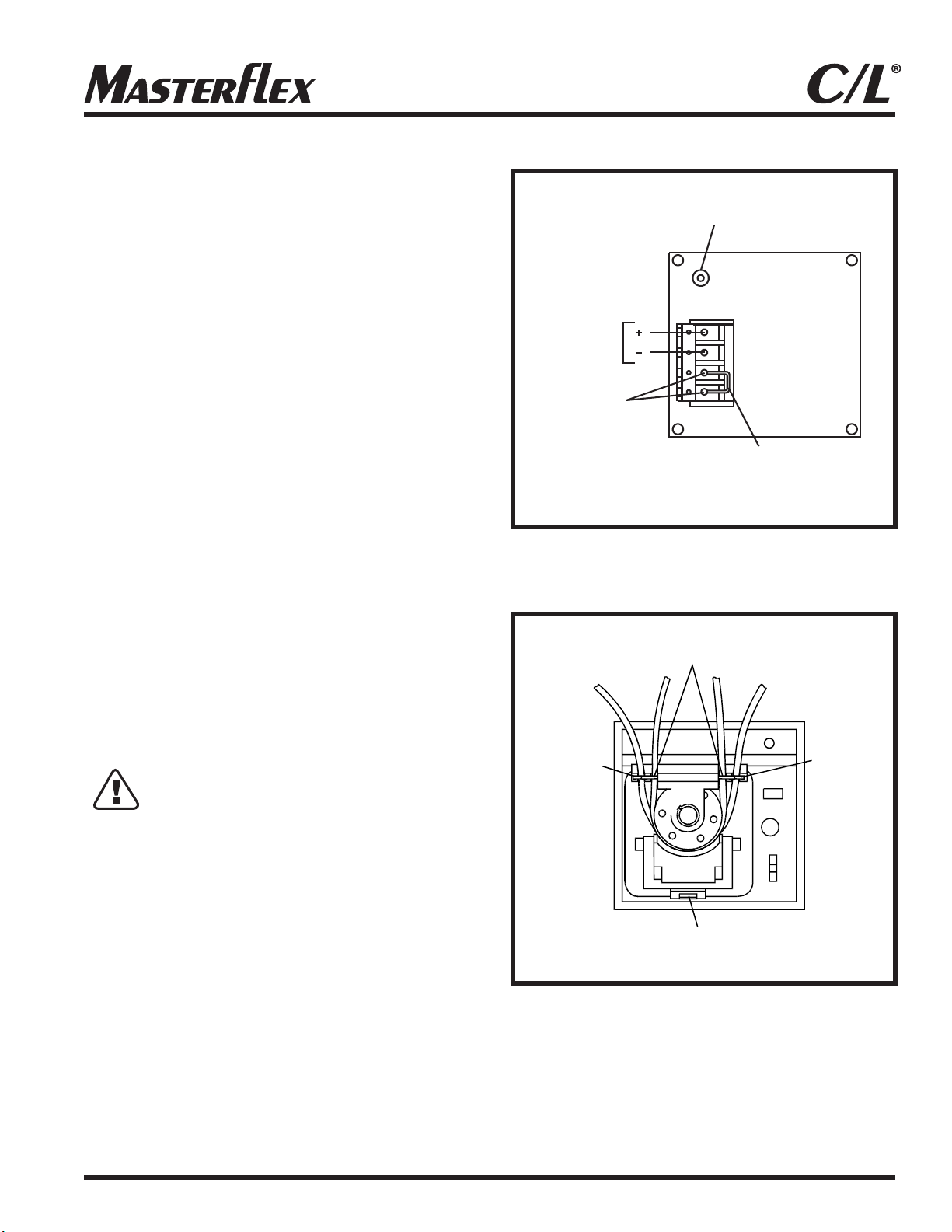

Installing Panel Mount

Mounting Brackets

The optional Mounting Brackets are used to attach the 1/4 DIN

Case to a Mounting Rack. Use Mounting Brackets Part No.

77120-03, (2/set).

1. Be sure the panel bezel is on the pump, then slide the pump

system through the front of the mounting rack.

2. Place a Mounting Bracket, Figure 5, between the grooved

bracket retainers on one side of the Case and slide the

Mounting Bracket back to lock into the retainer grooves.

3. Tighten the bracket screw against the back of the rack to

hold the Pump System in place.

4. Repeat steps 2 and 3 for the second Mounting Bracket

on the opposite side.

Installing Rubber Feet

Four rubber feet are provided for operating the Pump System

on a bench or other flat surface. The feet should be installed at

the four corners on the bottom of the unit. Remove the

protective paper from the adhesive surface of each foot

and press the foot firmly on the bottom surface about

one-eighth inch in from and parallel to the outer edges.

Connecting Primary Power

Depending on the Pump System model, primary power may

be 100-240V AC, 12V DC. The DC models can be connected

to any DC* supply and are not supplied with a Universal

Power Supply unit. Connect the External Power Supply to

the applicable input voltage source and the output of the

External Power Supply to the DC input connector on the pump

unit.

*Refer to Specifications for current supply voltage.

NOTE: The Power Supply output connection is center

positive (+).

6

®

Backup Battery Connection

Terminals 1 and 2 on the rear panel Barrier Terminal Strip,

Figure 3, provide a means for connecting a backup DC power

source. The positive (+) terminal is terminal 1. The negative

(–) terminal is terminal 2. Connection to these terminals would

usually be made only for emergency type operation in

conjunction with an External Power Supply, or a stand-alone

operation for the DC models.

NOTE: Input voltage must not exceed 16V DC or equipment

may be damaged. A minimum of 11.5V DC is required for

proper operation.

Remote Start/Stop Connection

Terminals 3 and 4 on the rear panel Terminal Strip, Figure 3,

are used for remote start/stop operation. Pump direction and

speed are not remotely controllable. In non-remote operation,

these terminals are connected together by a Shorting Bar.

For remote control by switch closure, remove the Shorting Bar

and connect the two terminals of the remote control switch to

terminals 3 and 4. A closure of the remote control switch

contacts will start the Pump System. Opening the

contact will stop the Pump System.

Figure 5. Mounting Bracket Installation

Mounting

Bracket

Bracket

Retainers

Bezel

Page 7

This section describes the procedures for obtaining desired

performance. Flow rate is determined by the drive speed and

the tubing size.

WARNING: Tubing breakage may result in fluid

being sprayed from pump. Use

appropriate measures to protect

operator and equipment.

Turning Pump System On and

Selecting Direction of Operation

The Pump System can be set to operate in either a clockwise

or a counterclockwise direction. The same control used to

select direction also turns power on or off. Select direction of

pump operation desired. PWR indicator should light.

Setting Pump Speed

Pump speed is controlled by the variable Speed Control.

Turning the control clockwise increases the speed. Tube life is

decreased with increased operating speed.

Priming Pump System

The MAX Push Button is used for priming and purging the

Pump System. When MAX is depressed, the pump operates

at maximum speed in the selected direction until the button is

released. Approximately two feet of tubing length can be filled

or emptied per minute using the MAX Push Button on the 6

rpm units.

7

®

OPERATION

Cleaning

Clean exterior surfaces of case, control panel and pump

rollers using dry or damp cloth. Never immerse nor use

excessive fluid.

Replacement Parts and Accessories

Item Part No.

Rubber Feet (4 ea.) A-1390-0001

Shorting Bar A-4402

Accessory Part No.

Mounting Brackets (2/set) 77120-03

Universal Power Supply, 100-240V AC 77120-11

MAINTENANCE

Page 8

8

®

Output:

Operating Speed:

Models 77120-32, 1 to 6 rpm

and 77120-52

Models 77120-42, 10 to 60 rpm

and 77120-62

Maximum No. of Tubes: 2

Direction of rotation: Clockwise and

Counterclockwise

Input:

Supply Voltage/Frequency:

Models 77120-32 115V AC nominal, 50/60 Hz

(90–130V AC) @110 mA AC

230V AC nominal, 50/60 Hz

(190–260V AC) @75 mA AC

Models 77120-42 115V AC nominal, 50/60 Hz

(90–130V AC) @175 mA AC

230V AC nominal, 50/60 Hz

(190–260V AC) @108 mA AC

Models 77120-52 and 77120-62 12V DC nominal

(11.5–16.0V DC) @ 1.0 A DC

Power Input:

For 6 and 60 rpm models 11.5–16.0V DC to terminals

1 and 2 of terminal strip or

External Power Supply

Installation Category:

77120-32, -42 Category II per IEC664

(Local level—appliances,

portable equipment, etc.)

77120-52, -62 Category I per IEC664

(Signal Level)

Remote Start/Stop: Contact Closure connection

at terminal strip contacts 3

and 4

Construction:

Dimensions (L × W × H): 5.3 in × 3.5 in × 3.5 in

(13.5 cm × 8.9 cm × 8.9 cm)

Weight: 2 pounds (0.91 kg)

Color: Black

Material:

Pump Head: PPS, polypropylene

and stainless steel

Case: NORYL

®

Enclosure Rating: IP22 per IEC529

Environment:

Operating Temperature: 32°F to 105°F (0°C to 40°C)

Storage Temperature: –49°F to 149°F (–45°C to 65°C)

Humidity (Non-cond): 10% to 90%

Altitude: Less than 6600 ft (2000 m)

Pollution Degree: Pollution Degree 2 per IEC664

(Indoor usage — lab, office)

Noise level: <70dBa @ 1 meter

Compliance (For CE Mark):

EN61326-1/A2: 2001 (EMC Directive)

EN809 (Machinery Directive)

SPECIFICATIONS

Page 9

WARRANTY

Use only Microbore Autoanalysis tubing with

MASTERFLEX®C/L®pumps to ensure optimum

performance. Use of other tubing may void

applicable warranties.

The Manufacturer warrants this product to be free from

significant deviations from published specifications. If repair or

adjustment is necessary within the warranty period, the

problem will be corrected at no charge if it is not due to misuse

or abuse on your part, as determined by the Manufacturer.

Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is one (1) year from

the date of purchase.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer

for authorization and shipping instructions before returning the

product, either within or outside of the warranty period. When

returning the product, please state the reason for the return.

For your protection, pack the product carefully and insure it

against possible damage or loss.

Any damages resulting from improper packaging are your

responsibility.

TECHNICAL

ASSISTANCE

If you have any questions about the use of this product,

contact the Manufacturer or authorized seller.

9

®

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

www.masterflex.com • www.coleparmer.com

E-mail: techinfo@coleparmer.com

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010

Page 10

APPENDIX A

CAUTION: Tubing for use with the MASTERFLEX®C/L®Pump Systems is Microbore Autoanalysis Tubing.

Use of tubing other than that specified will result in poor pumping performance and/or

pump system damage and voiding of applicable warranty.

Available Microbore Autoanalysis Tubing

TYGON — Catalog prefix number 06460-XX available

in sizes 10 through 48.

TYGON E-LFL — Catalog prefix number 06449-XX available

in sizes -10 ,-12, -18, -26, -30, -34, -42 and -48.

Silicone (peroxide-cured) — Catalog prefix number

07625-XX available in sizes 22 through 48.

Silicone (platinum-cured) — Catalog prefix number

95590-XX available in sizes 18 through 48.

PHARMED

®

BPT — Catalog prefix number 95809-XX

available in sizes -12, -18, -26, -32, -36, -40, -44 and -48.

VITON

®

fluoroelastomer — Catalog prefix number

97632-XX available in sizes -26, -30, -34, -38, -42, -46 and -48.

C-Flex

®

— Catalog prefix number 95718-XX available in

sizes-10 through 48.

Solvent/Hydrocarbon – Catalog prefix number 95712-XX

available in sizes 10 through 48.

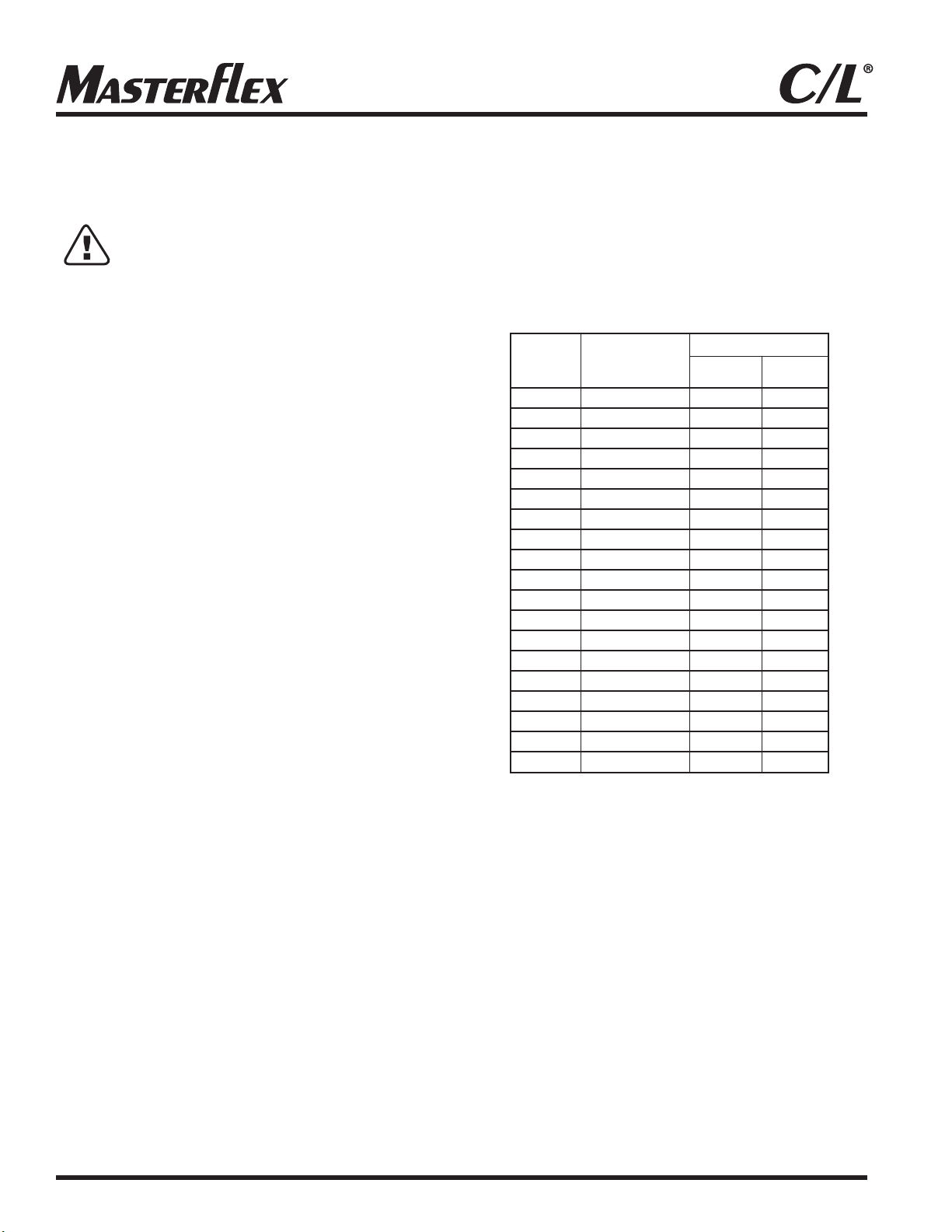

See the following table for Tubing size versus ID and

flow rates. Flow rates are for water pumped at room

temperature and 0 psi. Flow rates for silicone tubing

are approximately 25%–50% less than listed.

Flow rate is determined by drive, speed, tubing size

and material.

10

®

Tubing Tubing Flow Rate

Suffix. ID 60 rpm 6 rpm

in (mm) (µL/min) (µL/min)

-10 0.008 (0.19) 128 13

-12 0.010 (0.25) 178 17

-14 0.015 (0.38) 378 45

-16 0.017 (0.44) 490 55

-18 0.020 (0.51) 698 70

-22 0.025 (0.64) 1110 105

-24 0.030 (0.76) 1580 150

-26 0.035 (0.89) 2110 205

-28 0.040 (1.02) 2680 270

-30 0.045 (1.14) 3290 335

-32 0.051 (1.30) 4130 420

-34 0.056 (1.42) 4900 495

-36 0.060 (1.52) 5510 555

-38 0.065 (1.65) 6330 630

-40 0.073 (1.85) 7650 750

-42 0.081 (2.06) 8910 875

-44 0.090 (2.29) 10160 1015

-46 0.100 (2.54) 11340 1170

-48 0.110 (2.79) 12340 1330

All flow rates based on pumping water @ 0 psig 70°F (21°C).

Printed in U.S.A.

Page 11

®

OPERATING MANUAL:

PUMP SYSTEM

MANUEL DE LʼUTILISATEUR :

SYSTEME DE POMPAGE

BEDIENUNGSANLEITUNG:

PUMPENSYSTEM

MANUAL DE OPERACIÓN:

SISTEMA DE BOMBAS

MANUALE DI ISTRUZIONI:

SISTEMA POMPANTE

Les systèmes de Pompage MASTERFLEX®C/L®sont de petites

pompes péristaltiques avec moteurs d'entrainement intègres

conçues pour être utilisées avec toute une gamme de tailles

de tuyaux afin de fournir des débits allant de 2.2 μL/min

à 12.3 mL/min.

77120-32

77120-42

77120-52

77120-62

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

11

A-1299-1039B

Édition 05

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

E-mail: techinfo@coleparmer.com

www.masterflex.com • www.coleparmer.com

Page 12

®

CONSIGNES DE SECURITE

AVERTISSEMENT: La rupture dʼun tuyau peut entraîner une pulvérisation du liquide refoulé par la pompe.

Prendre des mesures appropriées pour protéger l'opérateur et les appareils.

MISE EN GARDE: Le tuyau des systèmes de pompage MASTERFLEX®C/L®est un tuyau Microbore

Autoanalysis. Voir lʼannexe A pour de plus amples informations. Lʼemploi dʼun tuyau

non spécifié entraînerait de mauvaises performances de pompage et/ou une

détérioration du système de pompage, et annulerait la garantie.

AVERTISSEMENT:

LIMITES DʼUTILISATION DES PRODUITS

Ces produits ne sont pas conçus pour être utilisés dans des applications avec patients, y compris, entre

autres, les applications médicales et dentaires, et ne sont pas destinés à cet effet. Ils nʼont par conséquent

pas été soumis à lʼagrément de la FDA.

TABLE DES MATIERES

Titre Page

CONSIGNES DE SECURITE ................................................12

INTRODUCTION ...................................................................13

DESCRIPTION GENERALE ............................................14-15

INSTALLATION ................................................................15-16

Sélection de la taille de tuyau .........................................15

Installation du tuyau dans la tête de pompe ..................15

Installation des supports de fixation sur panneau...........16

Installation des pieds en caoutchouc..............................16

Connexion de l’alimentation principale ...........................16

Connexion de la batterie auxiliaire..................................16

Connexion de la commande de marche/

arrêt à distance ...............................................................16

FONCTIONNEMENT.............................................................17

Démarrage du système de pompage et sélection

du sens de fonctionnement.............................................17

Réglage de la vitesse de la pompe.................................17

Amorçage de la pompe...................................................17

ENTRETIEN...........................................................................17

Nettoyage........................................................................17

Pièces et accessoires de rechange ................................17

CARACTERISTIQUES TECHNIQUES..................................18

GARANTIE.............................................................................19

RETOUR DE MARCHANDISES ...........................................19

ASSISTANCE TECHNIQUE ..................................................19

ANNEXE A MASTERFLEX

®

C/L

®

DEBIT DES TUYAUX DU SYSTEME DE POMPAGE.....20

12

NORYL — Marque déposée de General Electric Company

PHARMED, TYGON — Marque déposée de Saint-Gobain Performance Plastics Corp.

VITON — Marque déposée de E.I. duPont DeNemours & Co.

Les marques de commerce accompagnees du symbole ® dans cette

publication sont des marques deposees aux États-Unis et dans d'autres pays.

POMPE POUR LIQUIDES

TRADUCTION DU MODE

D’EMPLOI ORIGINAL

Page 13

®

13

INTRODUCTION

Le système de pompage MASTERFLEX®C/L®est conçu pour

pomper de manière péristaltique des liquides par le biais

d’un microtuyau à des débits très lents. Il est idéal pour les

désinfectants, la distribution de réactif, les analyseurs,

les systèmes d'impression, l'alimentation contrôlée et les

procédures de perfusion non effectuées sur les humains.

Page 14

®

14

PWR

MAX

Le système de pompage MASTERFLEX

®

C/L®(figure 1) est contenu dans un boîtier

en plastique 1/4 DIN. Il peut être monté sur

panneau au moyen des supports de fixation

(voir la section sur les accessoires). Les

pieds en caoutchouc fournis avec l’appareil

peuvent être fixés au fond du boîtier pour

fonctionnement sur plan de travail ou sur

toute autre surface plane.

Le système de pompage peut recevoir

simultanément deux tuyaux pour les

systèmes de 6 et 60 tr/min à des vitesses

contrôlées aussi basses que 1 tr/min. Le

tuyau est maintenu en place par des brides

à ressort. Consulter l’annexe A pour une liste

des tailles de tuyaux compatibles avec le

système de pompage.

La surface d’occlusion à verrouillage permet

un chargement ou un changement rapide de

tuyau. Le rotor de la tête de pompe contient

six rouleaux pour des pulsations minimales.

Tous les appareils fonctionnent sur un bloc

d'alimentation externe en courant continu.

Les modèles de c.a. sont fournis avec un

bloc d’alimentation externe qui produit une

sortie de courant continu pour alimenter

l’entraînement de la pompe.

La commande de vitesse réglable à un

seul tour (voir figure 2) permet d'obtenir un

débit variable. Le témoin vert de marche

s’allume lorsque la pompe fonctionne.

L’interrupteur de marche et de sens permet

d’allumer la pompe lorsque le sens horaire

ou antihoraire du rotor est sélectionné. Le

bouton MAX sert à l'amorçage et à la purge,

et permet de faire fonctionner la pompe à la

vitesse maximale lorsqu'il est enfoncé.

Figure 2. Pompe — Panneau avant

DESCRIPTION GENERALE

Figure 1. Système de pompage MASTERFLEX®C/L

®

Boîtier à

cadran 1/4 DIN

Support de fixation

(non fourni)

Dispositifs

de

retenue

des

tuyaux

Cadran

Dispositif de blocage de

la surface d’occlusion

Bloc

d’alimentation

externe

Dispositifs

de retenue

des tuyaux

Témoin de

marche

MAX : maintenir ce

bouton appuyé pour

amorcer ou purger

la pompe.

Contrôle de la vitesse :

permet de régler des

débits variables.

Interrupteur de marche /

sens de la pompe

Dispositif de blocage de la surface

d’occlusion : appuyer pour relâcher la

surface d’occlusion lors du

changement de tuyau.

Page 15

®

15

INSTALLATION

Utiliser uniquement des tuyaux Microbore

Autoanalysis avec les pompes MASTERFLEX®C/L

®

pour garantir des performances optimales.

Lʼusage dʼautres tuyaux pourrait annuler les

garanties en vigueur.

Sélection de la taille de tuyau

L'annexe A fournit une liste des tailles de tuyaux qui

permettent un fonctionnement efficace du système de

pompage MASTERFLEX

®

C/L®. Cette liste indique les

diamètres de tuyaux, les débits en µL/min et les débits

maximum à 6 et 60 tr/min. Les tuyaux sont répertoriés par

numéro de référence. Pour des résultats optimaux lors

de l’utilisation de deux tuyaux, sélectionner des tuyaux qui

fournissent des débits dans une plage de 10/1. (Les rapports

de diamètre des tuyaux doivent être d’environ 3,5/1.) Les

tuyaux de silicone ne doivent pas être utilisés avec TYGON

®

ou NORPRENE®.

Installation du tuyau dans la tête de

pompe

AVERTISSEMENT: Vérifier si lʼentraînement de la

pompe est éteint avant de

commencer. Les vêtements

lâches pourraient être happés

par les rouleaux.

1. Placer l’interrupteur de marche/sens de la pompe (figure 2)

en position centrale (sur « Off »).

2. Appuyer sur le dispositif de blocage de la surface

d’occlusion (figure 4) pour dégager celle-ci du rotor.

3. Étirer délicatement le tuyau et l’insérer dans le dispositif

de retenue à ressort à gauche à l'arrière.

4. Tout en maintenant le tuyau choisi légèrement étiré,

l’enrouler autour des rouleaux inférieurs et le fixer au niveau

du dispositif de retenue à ressort, à droite à l’arrière. Si un

deuxième tuyau doit être installé, le fixer de la même manière

en utilisant les dispositifs de retenue à ressort de l’avant.

5. Soulever le bord externe de la surface d'occlusion jusqu'à

ce qu'elle se bloque en place et maintienne le tuyau contre

les rouleaux du bas.

Figure 3. Pompe — Panneau arrière

Le panneau arrière, figure 3, contient une prise d’entrée

d’alimentation en courant continu pour branchement de

l’alimentation principale et un bornier à cloison à quatre

bornes pour branchement d’un dispositif de marche / arrêt à

distance et d’une alimentation auxiliaire en courant continu.

Figure 4. Surface d’occlusion en position débloquée de

chargement du tuyau

Entrée de courant continu,

prise coaxiale de 2,5 mm

Entrée

auxiliaire

de courant

continu

Entrée de

marche / arrêt

à distance

Tige de

court-circuit

Dispositif

de retenue

de tuyau

arrière

Dispositif

de retenue

de tuyau

arrière

Dispositifs de retenue

de tuyau avant

Surface d’occlusion en position

débloquée (chargement du tuyau)

Page 16

®

Installation des supports de

fixation sur panneau

Les supports de fixation en option permettent de fixer le

boîtier 1/4 DIN sur un bâti. Utiliser les supports de fixation réf.

77120-03 (2/paquet).

1. Vérifier si le cadran du panneau est sur la pompe, puis faire

glisser le système de pompage par l'avant du bâti.

2. Placer un supports de fixation (figure 5) entre les dispositifs

de retenue à fentes d’un côté du boîtier et faire glisser le

support de fixation vers l’arrière pour se bloquer dans les

fentes.

3. Serrer la vis du support contre l’arrière du bâti pour

maintenir le système de pompage en place.

4. Répéter les points 2 et 3 pour le deuxième support de

fixation du côté opposé.

Installation des pieds en caoutchouc

Quatre pieds en caoutchouc sont fournis pour le

fonctionnement du système de pompage sur un plan de

travail ou toute autre surface plane. Les pieds doivent être

installés aux quatre coins, sous l’appareil. Retirer la protection

en papier de la surface adhésive de chaque pied et les

presser fermement sur le dessous, parallèlement au contour

et à environ 3 mm des bords.

Connexion de lʼalimentation

principale

En fonction du modèle du système de pompage, l’alimentation

principale peut être du 100–140 V c.a., ou du 12 V c.c. Les

modèles fonctionnant sur courant continu peuvent être

branchés sur tout bloc d’alimentation en courant continu* et ne

sont pas fournis avec un bloc d’alimentation externe. Brancher

le bloc d’alimentation électrique sur une source de tension

correcte et sur le connecteur d’entrée de courant continu de la

pompe.

*Se reporter à la section Caractéristiques techniques pour la tension

d'alimentation.

REMARQUE: Le branchement de sortie du bloc

d’alimentation est positif au centre (+).

16

Connexion de la batterie auxiliaire

Les bornes 1 et 2 du bornier à cloisons du panneau arrière

(figure 3) permettent de brancher une source auxiliaire

d’alimentation en courant continu. La borne positive (+)

correspond à la borne 1. La borne négative (–) correspond à

la borne 2. Le branchement sur ces bornes sert normalement

pour un fonctionnement en cas d’urgence avec une source

d'alimentation externe ou pour un fonctionnement autonome

pour les modèles fonctionnant sur courant continu.

REMARQUE: La tension d’entrée ne doit pas dépasser 16 V

c.c. sans quoi l’équipement risquerait d’être endommagé. Un

minimum de 11,5 V c.c. est nécessaire au fonctionnement

correct.

Connexion de la commande de

marche/arrêt à distance

Les bornes 3 et 4 du bornier du panneau arrière (figure 3) sont

utilisées pour une commande de marche/arrêt à distance. Le

sens et la vitesse de la pompe ne peuvent être contrôlés à

distance. En fonctionnement sur place, ces bornes sont reliées

ensemble par une tige de court-circuit. En fonctionnement à

distance par fermeture de commutateur, retirer la tige de courtcircuit et brancher les deux bornes du commutateur

de commande à distance aux bornes 3 et 4. La fermeture

des contacts du commutateur fera démarrer le système de

pompage. Par contre, l’ouverture du contact arrêtera la pompe.

Figure 5. Installation des supports de fixation

Support de

fixation

Dispositifs

de retenue

Cadran

Page 17

®

Cette section décrit comment obtenir le fonctionnement

désiré. Le débit est déterminé par la vitesse d’entraînement et

la taille du tuyau.

AVERTISSEMENT: La rupture dʼun tuyau peut

entraîner une pulvérisation du

liquide refoulé par la pompe.

Prendre des mesures

appropriées pour protéger

l'opérateur et les appareils.

Démarrage du système de

pompage et sélection du sens

de fonctionnement

Le système de pompage peut fonctionner dans le sens des

aiguilles d’une montre ou dans le sens contraire. La commande

employée pour sélectionner le sens permet également de

couper ou d’allumer le contact. Sélectionner le sens de

fonctionnement désiré. Le témoin d’alimentation devrait

s’allumer.

Réglage de la vitesse de la pompe

La vitesse de la pompe est contrôlée par la commande de

vitesse variable. Elle augmente lorsque le bouton est tourné

dans le sens horaire. La durée de vie du tuyau est réduite par

une vitesse de fonctionnement accrue.

Amorçage de la pompe

Le bouton poussoir MAX permet d'amorcer et de purger le

système de pompage. Lorsqu’il est enfoncé, la pompe

fonctionne à la vitesse maximale dans le sens sélectionné

jusqu’au relâchement du bouton. Avec les appareils de

6 tr/min, le bouton MAX permet de remplir ou de vider une

soixantaine de centimètres de tuyau par minute.

17

FONCTIONNEMENT

Nettoyage

Nettoyer les surfaces externes du boîtier, le panneau de

commande et les rouleaux de pompage avec un chiffon sec

ou humide. Ne jamais plonger l’appareil dans un liquide ni

utiliser trop de liquide.

Pièces et accessoires de rechange

Article Référence

Pieds en caoutchouc (par lots de 4) A-1390-0001

Tige de court-circuit A-4402

Accessoire Référence

Supports de fixation (2/paquet) 77120-03

Bloc d’alimentation universel, 100–240 V c.a. 77120-11

ENTRETIEN

Page 18

®

18

Sortie:

Vitesse de fonctionnement:

Modèles 77120-32, 1 à 6 tr/min

et 77120-52

Modèles 77120-42, 10 à 60 tr/min

et 77120-62

Nb de tuyaux maximum: 2

Sens de rotation: Sens horaire et anti-horaire

Entrée:

Tension / Fréquence d’alimentation:

Modèles 77120-32 115 V c.a. nominale, 50/60 Hz

(90–130 V c.a.) à 110 mA c.a.

230 V c.a. nominale, 50/60 Hz

(190–260 V c.a.) à 75 mA c.a.

Modèles 77120-42 115 V c.a. nominale, 50/60 Hz

(90–130 V c.a.) à 175 mA c.a.

230 V c.a. nominale, 50/60 Hz

(190–260 V c.a.) à 108 mA c.a.

Modèles 77120-52 et 77120-62 12 V c.c. nominale

(11,5–16 V c.c.) à 1 A c.c.

Entrée d’alimentation :

Pour les modèles de 11,5–16 V c.c. aux bornes

6 et 60 tr/min 1et 2 du bornier ou bloc

d’alimentation externe

Catégorie d’installation:

77120-32, -42 Catégorie II conformément à la

norme CEI664 (Niveau local—

appareils, équipement portatif,

etc.)

77120-52, -62 Catégorie I, conformément à la

norme CEI664 (niveau de signal)

Commande de marche/ Connexion de la fermeture du

arrêt à distance: contact aux bornes 3 et 4

Construction:

Dimensions (L × l × H) : 13,5 × 8,9 × 8,9 cm

(5,3 × 3,5 × 3,5 po)

Poids: 0,91 kg

Couleur : Noir

Matériau:

Tête de la pompe: PPS, polypropylène et

acier inoxydable

Boîtier: NORYL

®

Homologation de

l’enveloppe: IP22, conformément à la

norme CEI529

Environnement:

Température de

fonctionnement: 0 à 40 ºC (32 à 105 °F)

Température de stockage: –45 à 65 ºC (–49 à 149 °F

Humidité (sans

condensation): 10 à 90 %

Altitude: Moins de 2 000 m (6 600 pi)

Degré de pollution: Degré de pollution 2, conformément

à CEI664 (Utilisation à l’intérieur –

laboratoire, bureau)

Niveau sonore : <70dB à 1 mètre

Conformité (pour marque CE):

EN61326-1/A2: 2001

EN809 (Directive « Machines » CE)

CARACTERISTIQUES TECHNIQUES

Page 19

®

GARANTIE

Utiliser uniquement des tuyaux Microbore

Autoanalysis avec les pompes MASTERFLEX®C/L

®

pour garantir des performances optimales. Lʼusage

dʼautres tuyaux pourrait annuler les garanties en

vigueur.

Le fabricant garantit ce produit contre tout écart significatif par

rapport aux spécifications publiées. Si des réparations ou des

réglages s’avèrent nécessaires pendant la période de

garantie, le problème sera résolu gratuitement s’il ne provient

pas, de l’avis du fabricant, d’un usage incorrect ou abusif par

l’utilisateur. Les frais de réparations effectuées en dehors de la

période de garantie, ou liées à un usage incorrect ou abusif du

produit, seront à la charge du client.

La durée de garantie de ce produit est à un (1) an à

compter de la date dʼachat.

RETOUR DE

MARCHANDISES

Afin de limiter les frais et les délais, il convient de contacter

le vendeur ou le fabricant pour obtenir une autorisation

préalable et des instructions d’expédition avant de renvoyer le

produit, qu’il soit ou non couvert par la garantie. La raison du

retour doit être mentionnée pour tout produit renvoyé. Afin de

se protéger, le produit doit être emballé soigneusement et

assuré contre les risques de dommages ou de perte. Toute

détérioration provenant d’un emballage incorrect incombe au

client.

ASSISTANCE

TECHNIQUE

Pour toute question concernant l’utilisation de ce produit,

contacter le fabricant ou le revendeur agréé.

19

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

www.masterflex.com • www.coleparmer.com

E-mail: techinfo@coleparmer.com

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010

Page 20

®

ANNEXE A

MISE EN GARDE: Le tuyau des systèmes de pompage MASTERFLEX®C/L®est un tuyau Microbore

Autoanalysis. Lʼemploi dʼun tuyau non spécifié entraînerait de mauvaises performances de

pompage et/ou une détérioration du système de pompage, et annulerait la garantie.

Suffixe

Diamètre Débit

du tuyau

interne du 60 tr/min 6 tr/min

tuyau mm (po) (µL/min) (µL/min)

-10 0.19 (0.008) 128 13

-12 0.25 (0.010) 178 17

-14 0.38 (0.015) 378 45

-16 0.44 (0.017) 490 55

-18 0.51 (0.020) 698 70

-22 0.64 (0.025) 1110 105

-24 0.76 (0.030) 1580 150

-26 0.89 (0.035) 2110 205

-28 1.02 (0.040) 2680 270

-30 1.14 (0.045) 3290 335

-32 1.30 (0.051) 4130 420

-34 1.42 (0.056) 4900 495

-36 1.52 (0.060) 5510 555

-38 1.65 (0.065) 6330 630

-40 1.85 (0.073) 7650 750

-42 2.06 (0.081) 8910 875

-44 2.29 (0.090) 10160 1015

-46 2.54 (0.100) 11340 1170

-48 2.79 (0.110) 12340 1330

Tous les débits sont basés sur le pompage d’eau à 0 psig et 21 ºC.

20

Imprimé aux États-Unis

Tuyaux Microbore Autoanalysis

disponibles

TYGON — Préfixe de catalogue 06460-XX, disponible en

tailles 10 à 48.

TYGON E-LFL — Préfixe de catalogue 06449-XX, disponible

en tailles -10 ,-12, -18, -26, -30, -34, -42 et -48.

Silicone (durci au peroxyde) — Préfixe de catalogue

07625-XX, disponible en tailles 22 à 48.

Silicone (durci au platine) — Préfixe de catalogue 95590XX, disponible en tailles 18 à 48.

PHARMED

®

BPT — Préfixe de catalogue 95809-XX,

disponible en tailles 12, -18, -26, -32, -36, -40, -44 et -48.

Fluoroélastomère VITON

®

— Préfixe de catalogue 97632-XX

disponible en tailles -26, -30, -34, -38, -42, -46 et -48.

C-Flex

®

— Prèfixe du Catalogue 95718-XX disponibles

en tailles 10 à 48.

Hydrocarbure/Solvant — Préfixe du catalogue 95712-XX,

disponible en tailles 10 à 48.

Se référer au tableau suivant pour les tailles de tuyau par

rapport aux diamètres internes et aux débits. Les débits sont

indiqués pour de l’eau pompée à température ambiante,

à 0 psi. Les débits des tuyaux en silicone sont environ 25

à 50 % inférieurs à ceux indiqués.

Le débit est fonction de l'entraînement, de la vitesse,

de la taille du tuyau et du matériau.

Page 21

®

OPERATING MANUAL:

PUMP SYSTEM

MANUEL DE LʼUTILISATEUR :

SYSTEME DE POMPAGE

BEDIENUNGSANLEITUNG:

PUMPENSYSTEM

MANUAL DE OPERACIÓN:

SISTEMA DE BOMBAS

MANUALE dI ISTRUZIONI:

SISTEMA POMPANTE

BEI DEN MASTERFLEX®C/L®PUMPENSYSTEMEN HANDELT

ES SICH UM KLEINE PERISTALTIKPUMPEN MIT INTEGRALEN

ANTRIEBSMOTOREN, DIE ZUR VERWENDUNG MIT EINER

REIHE VON SCHLAUCHGRÖSSEN FÜR FÖRDERMENGEN VON

2,2 μL/MIN BIS 12,3 ML/MIN VORGESEHEN SIND.

77120-32

77120-42

77120-52

77120-62

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

21

A-1299-1039B

Ausgabe 05

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

E-mail: techinfo@coleparmer.com

www.masterflex.com • www.coleparmer.com

Page 22

®

SICHERHEITSMASSNAHMEN

ACHTUNG: Wenn ein Schlauch reißt, wird möglicherweise Flüssigkeit von der Pumpe versprüht.

Geeignete Maßnahmen zum Schutz von Bediener und Geräten ergreifen.

VORSICHT: Schläuche, die zur Verwendung mit den MASTERFLEX®C/L®Pumpensystemen geeignet sind:

Microbore Autoanalysis Tubing. Einzelheiten siehe Anhang A. Die Verwendung von anderen als den

angegebenen Schläuchen führt zu mangelhafter Pumpleistung und/oder Beschädigung des

Pumpensystems und macht die Garantie hinfällig.

ACHTUNG! ANWENDUNGSEINSCHRÄNKUNGEN

Diese Geräte sind nicht für den Einsatz am Patienten vorgesehen und auch nicht für diesen Zweck bestimmt

(z.B. medizinischen oder zahnmedizinischen Bereich) und entsprechen demgemäß auch keinen FDA (Food &

Drug Administration) Normen.

INHALTSVERZEICHNIS

Titel Seite

SICHERHEITSMASSNAHMEN ............................................22

EINFÜHRUNG.......................................................................23

ALLGEMEINE BESCHREIBUNG ....................................24-25

MONTAGE........................................................................25-26

Wahl der Schlauchgröße ................................................25

Schlauchmontage im Pumpenkopf .................................25

Installierung der Befestigungsschellen an der

Frontkonsole .................................................................26

Installierung der Gummifüße ........................................26

Anschließen des Primärstroms.......................................26

Anschließen der Reservebatterie ...................................26

Anschließen der Start-/Stopp-Fernbedienung ................26

BETRIEB ...............................................................................27

Einschalten des Pumpensystems und Wahl der

Betriebsrichtung..............................................................27

Einstellen der Pumpgeschwindigkeit ..............................27

Füllen des Pumpensystems............................................27

WARTUNG.............................................................................27

Reinigung........................................................................27

Ersatzteile und Zubehör..................................................27

TECHNISCHE DATEN ..........................................................28

GARANTIE.............................................................................29

WARENRÜCKSENDUNGEN ................................................29

TECHNISCHE BERATUNG...................................................29

ANHANG A MASTERFLEX

®

C/L

®

FÖRDERMENGE BEI

PUMPENSYSTEMSCHLÄUCHEN A-1 ..........................30

22

NORYL — Reg TM General Electric Company

PHARMED, TYGON — Reg TM Saint-Gobain Performance Plastics Corp.

VITON — Reg TM E.I. duPont DeNemours & Co.

WARENZEICHEN, DIE IN DIESER PUBLIKATION MIT DEM SYMBOL ®

VERSEHEN SIND, SIND IN DEN USA UND ANDEREN LÄNDERN

EINGETRAGEN.

PUMPE FÜR FLÜSSIGKEITEN

ÜBERSETZUNG DER

ORIGINAL-ANWEISUNGEN

Page 23

®

23

EINFÜHRUNG

Das MASTERFLEX®C/L®Pumpensystem ist zum Pumpen

von Flüssigkeit durch Microbore-Schläuche mit Hilfe von

Peristaltik bei sehr niedrigen Fördermengen vorgesehen.

Es ist ideal geeignet für Hygienemittel, Reagenzverteilung,

Analysegeräte, Drucksysteme, kontrollierte Zuführung und

Infusionen außerhalb von Menschen.

Page 24

®

24

PWR

MAX

Das MASTERFLEX®C/L®Pumpensystem,

Abbildung 1, ist in einem 1/4-DINKunststoffgehäuse untergebracht.

Das Gehäuse ermöglicht die

Frontkonsolemontage mit Hilfe optionaler

Befestigungsschellen (siehe ZubehörAbschnitt). Die im Lieferumfang enthaltenen

Gummifüße können unten am Gehäuse

befestigt werden, um das Gerät auf einer

Werkbank oder sonstigen ebenen Fläche

aufzustellen.

Bei Systemen mit 6 und 60 U/min können

an das Pumpensystem für kontrollierte

Drehzahlen bis zu nur 1 U/min zwei

Schläuche gleichzeitig angeschlossen

werden. Der Schlauch wird durch gefederte

Befestigungsschellen festgehalten.

Auf Anhang A stent eine Liste, die für das

Pumpensystem geeigneten Schlauchgrößen

zeigt.

Das Okklusionsbett mit Verriegelung

ermöglicht das rasche Befestigen und

Auswechseln von Schläuchen. Der

Pumpenkopfrotor enthält sechs Rollen,

die für minimales Pulsieren sorgen. Alle

Einheiten werden von einem externen

Gleichstromversorgungsgerät betrieben.

Die Wechselstrommodelle sind mit

einem externen Stromversorgungsgerät

ausgestattet, das eine Gleichstromausgabe

für die Verbindung mit dem Pumpenantrieb

aufweist.

Der um eine Drehung einstellbare

Geschwindigkeitsregler, Abbildung 2, bietet

variablen Förderbetrieb. Die grüne PWRAnzeige leuchtet, wenn die Pumpe

eingeschaltet ist. Der Ein-/Richtungsschalter

ermöglicht die Versorgung mit Strom,

wobei es keine Rolle spielt, ob sich der

Pumpenrotor rechts oder links herum dreht.

Die MAX-Taste dient zum Füllen und

Entleeren und betreibt die Pumpe bei

maximaler Geschwindigkeit, solange diese

Taste gedrückt wird.

Abbildung 2. Pumpe — Frontkonsole

ALLGEMEINE BESCHREIBUNG

Abbildung 1. MASTERFLEX ®C/L®Pumpensystem

Schlauch-

halter

Okklusionsbettverriegelung

Fase

1/4-DIN-Gehäuse

Befestigungsschelle

(separat erhältlich)

Einschaltanzeige

MAX: Zum Füllen oder

Entleeren der Pumpe

gedrückt halten.

Geschwindigkeitskontrolle:

Für die variable

Fördermengeneinstellung.

Ein-/Richtungsschalter

Okklusionsbettverriegelung: Zum Loslassen des Okklusionsbetts

beim Schlauchwechsel nach unten drücken.

Schlauchhalter

Externes

Stromversorgungsgerät

Page 25

®

25

MONTAGE

Um optimale Anwendungsergebnisse zu

gewährleisten, sind für MASTERFLEX®C/L®Pumpen

ausschließlich Microbore Autoanalysis-Schläuche

zu verwenden.

Der Einsatz anderer Schläuche kann eine

Verweigerung der Garantieleistung nach sich

ziehen.

Wahl der Schlauchgröße

In Anhang A ist eine Liste der für das MASTERFLEX®C/L

®

Pumpensystem geeigneten Schlauchgrößen enthalten. Die

Liste umfasst Schlauchdurchmesser, Fördermengen µL/min

die maximalen Fördermengen bei 6 U/min und 60 U/min. Die

Schläuche sind nach Artikelnummer aufgelistet. Um bei der

Verwendung von zwei Schläuchen die besten Ergebnisse zu

erzielen, Schläuche für Fördermengen im Bereich 1:10

wählen. (Das Schlauchdurchmesserverhältnis sollte im

Bereich von ca. 3,5:1 liegen.) Für TYGON

®

oder NORPRENE

®

sollten keine Silikonschläuche verwendet

werden.

Schlauchmontage im Pumpenkopf

ACHTUNG! Vor dem Weitermachen sicherstellen,

dass der Pumpenantrieb ausgeschaltet

ist. Es besteht Gefahr, dass sich lose

Bekleidung in den Rollen verfängt.

1. Ein-/Richtungsschalter, Abbildung 2, auf mittlere Position

(aus) stellen.

2. Zum Lösen des Okklusionsbetts vom Rotor die Okklusions-

bettverriegelung nach unten drücken, Abbildung 4.

3. Den Schlauch vorsichtig dehnen und in den gefederten

Schlauchhalter hinten links anschließen.

4. Während der Schlauch leicht gedehnt wird, den gewählten

Schlauch um die unteren Rollen wickeln und mit dem

gefederten Schlauchhalter hinten rechts befestigen.

Wenn ein zweiter Schlauch installiert wird, den Schlauch

auf gleiche Weise mit den vorderen gefederten

Schlauchhaltern befestigen.

5. Die äußere Kante des Okklusionsbetts anheben, bis sie

einrastet; hierbei den Schlauch gegen die unteren Rollen

halten.

Abbildung 3. Pumpe — Rückwandkonsole

Abbildung 4. Okklusionsbett in ungesperrter

Schlauchlade-Position

Rückseitenkonsole, Abbildung 3, enthält einen

Gleichstromeingang zum Anschließen des Primärstroms

und eine 4-polige Klemmleiste zum Anschließen der

Start/Stopp-Fernbedienung und eines ReserveGleichstromversorgungsgeräts.

Gleichstromeingang

2,5-mm-Koaxialbuchse

Schlauchhalter vorn

Schlauchhalter

hinten

Schlauchhalter

hinten

Okklusionsbett in ungesperrter

(Schlauchlade-)Position

Kurzschlussbrücke

Reserve-

Gleichstromeingang

Start-/Stopp-

Fernbedienungseingang

Page 26

®

Installierung der

Befestigungsschellen

an der Frontkonsole

Die optionalen Befestigungsschellen dienen zum Befestigen

des 1/4-DIN-Gehäuses am Montagegestell. Verwendung der

Befestigungsschellen Artikel-Nr. 77120-03, (2/Satz).

1. Sicherstellen, dass sich die Konsolenfase an der Pumpe

befindet, dann das Pumpensystem vorn ins Montagegestell

schieben.

2. Zwischen den gerillten Schellenhaltern auf einer Seite des

Gehäuses eine Befestigungsschelle anbringen (Abbildung

5) und die Befestigungsschelle nach hinten schieben,

damit sie in den Rillen der Halter festgehalten wird.

3. Die Schraube der Schelle hinten am Gestell festziehen,

damit das Pumpensystem gut festgehalten wird.

4. Die Schritte 2 und 3 für die zweite Befestigungsschelle an

der gegenüberliegenden Seite wiederholen.

Installierung der Gummifüße

Im Lieferumfang sind vier Gummifüße für das Betreiben des

Pumpensystems auf einer Werkbank oder sonstigen ebenen

Fläche enthalten. Die Füße sollten an den vier Ecken an der

Unterseite der Pumpe befestigt werden. Das Schutzpapier von

den Klebeflächen abziehen und die Gummifüße ca. 3 mm von

den Außenkanten entfernt in den Ecken an der Unterseite der

Pumpe festdrücken.

Anschließen des Primärstroms

Je nach Pumpensystemmodell kann der Primärstrom

100–240 V~, 12 V Gleichstrom sein. Die Gleichstrommodelle

können an ein beliebiges Gleichstromversorgungsgerät

angeschlossen werden; externe Stromversorgungseinheiten

sind separat erhältlich. Das externe Stromversorgungsgerät

an eine Steckdose mit der entsprechenden Stromspannung

und den Ausgang des externen Stromversorgungsgeräts mit

der Gleichstromeingangsbuchse der Pumpeneinheit

verbinden.

*Siehe hierzu die Spezifikationen des verwendeten Versorgungsstroms.

HINWEIS: Der Ausgangsanschluss des

Stromversorgungsgeräts in der Mitte ist positiv (+).

26

Anschließen der Reservebatterie

An die Pole 1 und 2 der Klemmleiste auf der

Rückwandkonsole, Abbildung 3, kann ein ReserveGleichstromversorgungsgerät angeschlossen werden. Pol 1

ist der positive (+) Pol. Pol 2 ist der negative (-) Pol. Der

Anschluss hieran erfolgt normalerweise nur für Notfalleinsätze

in Verbindung mit einem externen Stromversorgungsgerät

oder bei alleinstehendem Gebrauch der Gleichstrommodelle.

HINWEIS: Darf die Eingangsspannung 16 V Gleichstrom nicht

übersteigen, sonst besteht Gefahr von Sachbeschädigung.

Für den ordnungsgemäßen Betrieb

sind mindestens 11,5 V Gleichstrom erforderlich.

Anschließen der Start-/StoppFernbedienung

Die Pole 3 und 4 der Klemmleiste an der Rückwandkonsole,

Abbildung 3, sind für die Start-/Stopp-Fernbedienung

vorgesehen. Die Pumpenrichtung und die Geschwindigkeit

können nicht fernbedient werden. Beim Einsatz ohne

Fernbedienung werden diese Anschlüsse mit einer Brücke

kurzgeschlossen.

Für Fernbedienung bei Schalterschluss die

Kurzschlussbrücke entfernen und die beiden Anschlüsse des

Fernbedienungsschalters mit den Anschlüssen 3 und 4

verbinden. Durch Schließen der Fernbedienungskontakte wird

das Pumpensystem gestartet. Beim Öffnen der

Kontakte wird das Pumpensystem gestoppt.

Abbildung 5. Installation der Befestigungsschelle

Fase

Schellenhalter

Befestigungsschelle

Page 27

®

In diesem Abschnitt wird erläutert, wie sich die gewünschte

Leistung erzielen lässt. Die Fördermenge hängt von der

Antriebsgeschwindigkeit und der Schlauchgröße ab.

ACHTUNG! Wenn ein Schlauch reißt, wird

möglicherweise Flüssigkeit von der

Pumpe versprüht. Geeignete

Maßnahmen zum Schutz von Bediener

und Geräten ergreifen.

Einschalten des Pumpensystems

und Wahl der Betriebsrichtung

Das Pumpenystem kann entweder auf Betriebsrichtung im

Uhrzeigersinn (rechts herum) oder gegen den Uhrzeigersinn

(links herum) eingestellt werden. Derselbe Regler, mit dem die

Richtung gewählt wird, dient auch zum Ein- und Ausschalten

des Stroms. Die gewünschte Pumpenbetriebsrichtung wählen.

Nun müsste die PWR-Anzeige leuchten.

Einstellen der Pumpgeschwindigkeit

Die Pumpgeschwindigkeit wird mit dem variablen

Geschwindigkeitsregler kontrolliert. Durch Drehen des Reglers

im Uhrzeigersinn wird die Geschwindigkeit erhöht. Bei

erhöhter Betriebsgeschwindigkeit verringert sich die

Schlauchlebensdauer.

Füllen des Pumpensystems

Die MAX-Drucktaste dient zum Füllen und Entleeren des

Pumpensystems. Wenn die MAX-Taste gedrückt wird, arbeitet

die Pumpe bei maximaler Geschwindigkeit in der gewählten

Richtung, bis die Taste losgelassen wird. Mit der MAXDrucktaste können bei den 6-U/min-Einheiten pro Minute ca.

60 cm Schlauchleitung gefüllt oder entleert werden.

27

BETRIEB

Reinigung

Die Außenflächen des Gehäuses, der Kontrollkonsole und

der Pumpenrollen mit einem trockenen oder feuchten Tuch

reinigen. Nicht in Flüssigkeit tauchen und nicht zu viel

Flüssigkeit verwenden.

Ersatzteile und Zubehör

Produkt Artikel-Nr.

Gummifüße (je 4) A-1390-0001

Kurzschlussbrücke A-4402

Zubehör Artikel-Nr.

Befestigungsschellen (2/Satz) 77120-03

Universell Stromversorgungsgerät, 100-240 V~ 77120-11

WARTUNG

Page 28

®

28

Ausgangsleistung:

Drehzahl bei Betrieb:

Modelle 77120-32

und 77120-52 1 bis 6 U/min

Modelle 7712042

und 77120-62 10 bis 60 U/min

Höchstzahl von

Schläuchen: 2

Drehrichtung: Uhrzeigerrichtung (rechts herum)

und gegen die Uhrzeigerrichtung

(links herum)

Eingang:

Versorgungsspannung/Frequenz:

Modelle 77120-32 115 V~ nominal, 50/60 Hz

(90 – 130 V~) bei 110 mA

Wechselstrom

230 V~ nominal, 50/60 Hz

(190 – 260 V~) bei 75 mA

Wechselstrom

Modelle 77120-42 115 V~ nominal, 50/60 Hz

(90 – 130 V~) bei 175 mA

Wechselstrom

230 V~ nominal, 50/60 Hz

(190 – 260 V~) bei 108 mA

Wechselstrom

Modelle 77120-52 und 77120-62 12 V Gleichstrom nominal

(11,5 – 16,0 V Gleichstrom)

bei 1,0 A Gleichstrom

Leistungseingang:

Für Modelle mit 6 und 60 U/min 11,5 – 16,0 V Gleichstrom

zu den Polen 1 und 2 der

Klemmleiste oder zur

externen Stromversorgung

Installationskategorie:

77120-32, -42 Kategorie II nach IEC664

(Lokalebene — Geräte,

portable Geräte usw.)

77120-52, -62 Kategorie I nach IEC664

(Signalebene)

Externer Start/Stopp: Kontaktschlussschaltung

an Klemmleistenkontakten

3 und 4

Konstruktion:

Abmessungen (L × B × H): 13,5 cm × 8,9 cm × 8,9 cm

Gewicht: 0,91 kg

Farbe: Schwarz

Material:

Pumpenkopf: PPS, Polypropylen und

Edelstahl

Gehäuse: NORYL®

Gehäusering: IP22 nach IEC529

Umweltbedingungen:

Betriebstemperatur: 0 °C bis 40 °C

Lagertemperatur: –45 °C bis 65 °C

Feuchtigkeit

(nicht kondensierend): 10 % bis 90 %

Höhe Unter 2000 m

Umweltverschmutzungsgrad: Umweltverschmutzungsgrad

2 nach IEC664 (Verwendung in

Innenräumen — Labor, Praxis)

Geräuschpegel: <70dBa bei 1 Meter

Einhaltung der Normen

(für CE-Zeichen):

EN61326-1/A2: 2001(EMV-Richtlinie)

EN809 (EU Maschinen-Richtlinie)

TECHNISCHE DATEN

Page 29

®

GARANTIE

Um optimale Anwendungsergebnisse zu

gewährleisten, sind für MASTERFLEX

®

C/L®Pumpen

ausschließlich Microbore Autoanalysis-Schläuche

zu verwenden. Der Einsatz anderer Schläuche kann

eine Verweigerung der Garantieleistung nach sich

ziehen.

Der Hersteller garantiert, dass dieses Produkt keine

nennenswerten Abweichungen von den veröffentlichten

Spezifikationen aufweist. Falls während der Garantiezeit

eine Reparatur oder Nachbesserung erforderlich werden

sollte, wird diese kostenlos vorgenommen, Falls

es kein vom Hersteller feststellbarer fehlerhafter oder

unsachgemäßer Einsatz seitens des Kunden vor gibt.

Reparaturkosten außerhalb der Garantiezeit oder aufgrund

von fehlerhaftem oder unsachgemäßem Gebrauch des

Produktes werden dem Kunden in Rechnung gestellt.

Die Garantie gilt für einen Zeitraum von ein (1) Jahr nach

dem Kaufdatum.

WARENRÜCKSENDUNGEN

Um Kosten und Verzögerungen so gering wie möglich zu

halten, lassen Sie sich in jedem Fall von Ihrem Fachhändler

oder dem Hersteller eine Rücksendegenehmigung und die

Versandanweisungen geben, bevor Sie Ware zurückschicken.

Geben Sie bitte den Rücksendegrund mit an. Verpacken Sie

die Ware sorgfältig und versichern Sie die Sendung gegen

Beschädigung bzw. Verlust. Für Transportschäden aufgrund

unsachgemäßer Verpackung haften Sie.

TECHNISCHE BERATUNG

Wenn Sie Fragen zur Anwendung dieses Produktes haben,

wenden Sie sich bitte an den Hersteller oder autorisierten

Fachhändler.

29

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

www.masterflex.com • www.coleparmer.com

E-mail: techinfo@coleparmer.com

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010

Page 30

®

ANHANG A

ANHANG! Schläuche, die zur Verwendung mit den MASTERFLEX® C/L® Pumpensystemen geeignet sind:

Microbore Autoanalysis Tubing. Die Verwendung von anderen als den angegebenen Schläuchen

führt zu mangelhafter Pumpleistung und/oder Beschädigung des Pumpensystems und macht die

Garantie hinfällig

Verfügbare Microbore Autoanalysis-Schläuche

TYGON — Der Katalognummer voranzustellende Ziffern:

06460-XX, erhältlich in den Größen 10 bis 48.

TYGON E-LFL — Der Katalognummer voranzustellende Ziffern:

06449-XX, erhältlich in den Größen -10 ,-12, -18, -26, -30, -34,

-42 und -48.

Silikon (Peroxid-behandelt) — Der Katalognummer

voranzustellende Ziffern: 07625-XX, erhältlich in den Größen

22 bis 48.

Silikon (Platin-behandelt) — Der Katalognummer

voranzustellende Ziffern: 95590-XX, erhältlich in den

Größen 18 bis 48.

PHARMED

®

BPT — Der Katalognummer voranzustellende Ziffern:

95809-XX, erhältlich in den Größen -12, -18, -26, -32, -36,

-40, -44 und -48.

VITON

®

fluoroelastomer — Der Katalognummer

voranzustellende Ziffern: 97632-XX, erhältlich in den

Größen -26, -30, -34, -38, -42, -46 und -48.

C-Flex

®

— Katalognummern mit Präfix 95718-XX lieferbar

in Größe 10 bis 48.

Löslicher/Wasserstoff — Katalognummern beginnend mit

95712-XX sind in Größen 10 bis 48 lieferbar.

Die Tabelle zeigt die Schlauchgrößen im Vergleich zu

Innendurchmesser und Fördermengen. Die Fördermengen

gelten für bei Zimmertemperatur und 0 psi gepumptes

Wasser. Die Fördermengen liegen bei Silikonschläuchen

ca. 25 % - 50 % niedriger als angegeben.

Die Fördermenge hängt vom Antrieb, Material,

der Geschwindigkeit und Schlauchgröße ab.

Alle Fördermengen basieren auf bei 0 psig und 21 °C gepumptem Wasser.

Gedruckt in den USA

Voranzustellende Schlauchinnen- Fördermenge

Ziffern für durchmesser 60 U/min 6 U/min

Schläuche in mm (µL/min) (µL/min)

-10 0.008 (0.19) 128 13

-12 0.010 (0.25) 178 17

-14 0.015 (0.38) 378 45

-16 0.017 (0.44) 490 55

-18 0.020 (0.51) 698 70

-22 0.025 (0.64) 1110 105

-24 0.030 (0.76) 1580 150

-26 0.035 (0.89) 2110 205

-28 0.040 (1.02) 2680 270

-30 0.045 (1.14) 3290 335

-32 0.051 (1.30) 4130 420

-34 0.056 (1.42) 4900 495

-36 0.060 (1.52) 5510 555

-38 0.065 (1.65) 6330 630

-40 0.073 (1.85) 7650 750

-42 0.081 (2.06) 8910 875

-44 0.090 (2.29) 10160 1015

-46 0.100 (2.54) 11340 1170

-48 0.110 (2.79) 12340 1330

30

Page 31

®

OPERATING MANUAL:

PUMP SYSTEM

MANUEL DE LʼUTILISATEUR :

SYSTEME DE POMPAGE

BEDIENUNGSANLEITUNG:

PUMPENSYSTEM

MANUAL DE OPERACIÓN:

SISTEMA DE BOMBAS

MANUALE dI ISTRUZIONI:

SISTEMA POMPANTE

LOS SISTEMAS DE BOMBAS MASTERFLEX® C/L® SON BOMBAS

PERISTÁLTICAS PEQUEÑAS CON MOTORES DE ACCIONAMIENTO

INTEGRALES Y ESTÁN DISEÑADOS PARA SU USO CON TUBOS

DE UNA SERIE DE TAMAÑOS QUE DESCARGAN CAUDALES

EN LA GAMA DE 2,2 μL/MIN A 12,3 ML/MIN.

77120-32

77120-42

77120-52

77120-62

Model No.

Nº de modèle

Modellnummern

Modelo No.

Modello No.

31

A-1299-1039B

Edición 05

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

E-mail: techinfo@coleparmer.com

www.masterflex.com • www.coleparmer.com

Page 32

®

PRECAUCIONES DE SEGURIDAD

ADVERTENCIA: La rotura de las mangueras puede derramar el fluido de la bomba.

Tomar las medidas apropiadas para proteger al operador y el equipo.

PRECAUCIÓN: Con el sistema de bombas MASTERFLEX®C/L®han de usarse únicamente

mangueras Microbore Autoanalysis. Ver el Apéndice A para obtener más detalles. El uso de

mangueras diferentes a los especificados tendrá como resultado un bajo rendimiento de bombeo

y/o daños en el sistema de bombas, además de la anulación de la garantía correspondiente.

ADVERTENCIA: LIMITACIÓN DE USO

DEL PRODUCTO

Estos productos no están diseñados ni destinados para ser utilizados en aplicaciones conectadas a un

paciente, incluyendo las aplicaciones médicas y dentales, pero sin limitarse a las mismas, y por lo tanto no

se ha solicitado su aprobación a la FDA.

CONTENIDO

Título Página

PRECAUCIONES DE SEGURIDAD......................................32

INTRODUCCIÓN...................................................................33

DESCRIPCIÓN GENERAL ..............................................34-35

CONFIGURACIÓN...........................................................35-36

Selección del tamaño de mangueras..............................35

Instalación de la manguera en el cabezal de la bomba..35

Instalación de las consolas para montaje para la

colocación en panel ........................................................36

Instalación de las patas de goma ...................................36

Conexión de la energía eléctrica primaria ......................36

Conexión de la batería de reserva..................................36

Conexión del control remoto de inicio/parada.................36

OPERACIÓN .........................................................................37

Encendido del sistema de bombas y selección

del sentido de la operación.............................................37

Ajuste de la velocidad de la bomba ................................37

Cebado del sistema de bombas .....................................37

MANTENIMIENTO ................................................................37

Limpieza .........................................................................37

Piezas de repuesto y accesorios ....................................37

ESPECIFICACIONES............................................................38

GARANTÍA ............................................................................39

DEVOLUCIÓN DEL PRODUCTO .........................................39

ASISTENCIA TÉCNICA ........................................................39

APÉNDICE A MASTERFLEX

®

C/L

®

Valores de flujo del sistema de mangueras ....................40

32

NORYL — Marca registrada de General Electric Company

PHARMED, TYGON — Marca registrada de Saint-Gobain Performance Plastics Corp.

VITON — Marca registrada de E.I. duPont DeNemours & Co.

LAS MARCAS REGISTRADAS QUE LLEVAN EL SÍMBOLO ® EN ESTA

PUBLICACIÓN ESTÁN REGISTRADAS EN ESTADOS UNIDOS DE AMÉRICA

Y EN OTROS PAÍSES.

BOMBA PARA LÍQUIDOS

TRADUCCIÓN DE LAS

INSTRUCCIONES

ORIGINALES

Page 33

®

33

INTRODUCCIÓN

El sistema de bombas MASTERFLEX®C/L®está diseñado

para bombear fluidos a través de mangueras Microbore

Autoanalysis por medio de una acción peristáltica en

flujos muy bajos. Es ideal para estirilizadores, distribución de

reactivos, analizadores, sistemas de impresión,

alimentación controlada y procedimientos de infusión

que no sean para humanos.

Page 34

®

34

PWR

MAX

El sistema de bombas MASTERFLEX

®

C/L®, figura 1, está encerrado en una caja

de plástico de 1/4 DIN. La caja permite la

colocación en panel utilizando las consolas

para montaje opcionales (ver la sección

Accesorios). Las patas de goma, que se

suministran con la unidad, pueden

acoplarse en la parte inferior de la caja

para utilizar el equipo sobre una plataforma

u otra superficie plana.

El sistema de bombas puede acomodar

simultáneamente dos tubos para los

sistemas de 6 y 60 rpm a velocidades

controladas que pueden ser de hasta 1 rpm.

La misma se sujeta en su lugar con

retenedores de chavetas para mangueras.

Para obtener una lista de las mangueras de

los tubos para su uso con el sistema de

bombas, consultar el Apéndice A.

El enganche de bancada por oclusión

permite cargar o cambiar rápidamente el

tubo. El rotor del cabezal de la bomba

contiene seis rodillos para que la pulsación

sea mínima. Todas las unidades funcionan

con un suministro de energía de CC

externo. Los modelos de CA se envían con

un suministro de energía externo, que

proporciona una corriente de salida de CC

para la conexión con el propulsor de la

bomba.

El control de velocidad ajustable y de

una sola espira, figura 2, proporciona una

operación de caudal variable. Siempre que

la bomba está en funcionamiento se

enciende el indicador verde de activación

(PWR On). El interruptor de activación/

sentido (Power On/Direction) activa la

potencia cuando se selecciona el sentido

del rotor de la bomba bien sea a favor o en

contra de las manecillas del reloj. El botón

MAX se utiliza para el cebado y purga, y

cuando está pulsado la bomba opera a la

velocidad máxima.

Figura 2. Bomba — Panel delantero

DESCRIPCIÓN GENERAL

Figura 1. Sistema de bombas MASTERFLEX®C/L

®

Retenedores

para

mangueras

Enganche de

bancada por

oclusión

Enganche de bancada por oclusión:

Apretar para soltar la bancada por

oclusión a fin de cambiar el tubo.

Retenedores

para

mangueras

Indicador de

activación

MAX: Pulsar y

mantener pulsado

para cebar o purgar

la bomba.

Control de velocidad:

Proporciona un ajuste

de caudal variable.

Interruptor de activación/sentido

Bisel

Suministro de

energía externo

Consola para montaje

(no se suministra)

Caja de 1/4 DIN

con bisel

Page 35

®

35

CONFIGURACIÓN

Usar solamente mangueras Microbore Autoanalysis

con las bombas MASTERFLEX®C/L®para asegurar

el máximo rendimiento. El uso de otras mangueras

puede anular las garantías correspondientes.

Selección del tamaño de la

manquera

En el Apéndice A se ofrece una lista de los tamaños de

mangueras, que funcionarán eficazmente con el sistema de

bombas MASTERFLEX

®

C/L®. Esta lista incluye los diámetros

de las mismas, los caudales en µL/min y los caudales

máximos a 6 rpm y 60 rpm. Las mangueras se listan por

número de pieza. Para obtener el mejor resultado posible,

cuando se utilicen dos mangueras, seleccionar aquellas que

proporcionen caudales que estén dentro de la gama de 10:1.

(La proporción del diámetro la maguera debe ser

aproximadamente de 3.5:1.) No deben utilizarse mangueras

de silicona con TYGON

®

o NORPRENE®.

Instalación de mangueras en

el cabezal de la bomba

ADVERTENCIA:

Antes de seguir, asegurarse de que el

propulsor de la bomba esté apagado.

La ropa suelta puede engancharse

en los rodillos.

1. Colocar el interruptor de activación/sentido, figura 2,

en la posición del centro (apagado).

2. Apretar el enganche de bancada por oclusión, figura 4,

para soltar la bancada por oclusión del rotor.

3. Estirar ligeramente la manguera e insertarla en el

retenedor cargado por resorte izquierdo trasero.

4. Mientras se mantiene la manguera ligeramente estirada,

enrollarla seleccionado en los rodillos inferiores y

fijarla en el retenedor cargado por resorte derecho trasero.

Si ha de instalarse un una segunda manguera, fijarla de la

misma manera utilizando los retenedores cargados por

resorte delanteros.

5. Levantar el borde exterior de la bancada por oclusión hasta

que se trabe en posición sujetando la manguera en los

rodillos inferiores.

Figura 3. Bomba — Panel trasero

El panel trasero, figura 3, contiene un enchufe de potencia

de entrada de CC para la conexión de la energía eléctrica

primaria y una regleta de barrera de 4 conexiones para la

conexión del control remoto de inicio/parada y un suministro

de CC auxiliar.

Figura 4. Bancada por oclusión en posición desenganchada

para la carga del tubo

Potencia de entrada de CC,

receptáculo coaxial de 2,5 mm

Entrada de

CC auxiliar

Entrada del

control

remoto de

inicio/parada

Barra de

corto circuitar

Retenedores delanteros

para manguera

Bancada por oclusión en posición

desenganchada (carga de tubo)

Retenedor

trasero

para

manguera

Retenedor

trasero

para

manguera

Page 36

®

Instalación de las consolas para

montaje para la colocación

en panel

Las consolas para montaje opcionales se utilizan para acoplar

la caja de 1/4 DIN a un soporte de montaje. Utilizar las

consolas para montaje nº de pieza 77120-03, (juego de 2).

1. Asegurarse de que el bisel del panel esté sobre la bomba

y deslizar el sistema sobre la parte delantera del soporte de

montaje.

2. Colocar un soporte de montaje, figura 5, entre los

retenedores de consola ranurados en un lado de la caja

y deslizarlo hacia atrás para trabarlo en las ranuras de los

retenedores.

3. Apretar el tornillo de la consola contra la parte trasera del

soporte para sujetar la unidad en su lugar.

4. Repetir los pasos 2 y 3 para la segunda consola

para montaje en el lado opuesto.

Instalación de las patas de goma

El sistema de bombas se suministra con cuatro patas de

goma para su uso sobre una plataforma u otra superficie

plana. Las patas deben instalarse en las cuatro esquinas de la

parte inferior de la unidad. Quitar el papel protector de la

superficie adhesiva de la pata y presionar firmemente la pata

en la superficie inferior aproximadamente a un octavo de

pulgada de y paralela a los bordes exteriores.

Conexión de la energía eléctrica primaria

Dependiendo del modelo del sistema de bombas, la energía

eléctrica primaria puede ser de 100–240V CA, 12V CC. Los

modelos de CC pueden conectarse a cualquier suministro de

CC* y no se envían con una unidad de suministro de energía

externo. Conectar el suministro de energía externo a la fuente

de voltaje de entrada correspondiente y la corriente de salida

del suministro de energía externo al conector de entrada de

CC en la unidad de la bomba.

*Consultar las Especificaciones para obtener información sobre el voltaje de

corriente de entrada.

NOTA: La conexión de salida de suministro de energía es de

centro positivo (+).

36

Conexión de la batería de reserva

Las terminales 1 y 2 en la regleta de conexiones del panel

trasero, figura 3, proporcionan un medio para la conexión de

una fuente de energía de CC de reserva. La terminal 1 es la

terminal positiva (+). La terminal 2 es la terminal negativa (–).

La conexión a estas terminales se hace generalmente

solamente para las operaciones de emergencia

conjuntamente con un suministro de energía externo o una

operación independiente para los modelos de CC.

Nota: El voltaje de entrada no debe sobrepasar de 16V CC,

ya que de lo contrario puede dañarse el equipo. Para el

funcionamiento correcto se requiere un mínimo de 11,5V CC.

Conexión del control remoto

de inicio/parada

Las terminales 3 y 4 en la regleta de conexiones del panel

trasero, figura 3, se utilizan para la operación de inicio/parada

por control remoto. El sentido de rotación de la bomba y la

velocidad no pueden controlarse a distancia. Cuando la unidad

funciona en un modo que no es por control remoto, estas

terminales se conectan juntas con una barra de cortocircuitar.

Para controlar la unidad a distancia por medio del cierre del

interruptor, quitar la barra de cortocircuitar y conectar las dos

terminales del interruptor de control remoto a las terminales

3 y 4. El cierre de los contactos del interruptor de control

remoto pone en marcha el sistema de bombas. La apertura de

los contactos detiene el sistema de bombas.

Figura 5. Instalación de la consola para montaje

suporte de

montaje

Retenedores

de consola

Bisel

Page 37

®

Esta sección describe los procedimientos para obtener el

rendimiento deseado. El caudal está determinado por la

velocidad del propulsor y el tamaño del tubo.

ADVERTENCIA:

La rotura de las mangueras puede

derramar el fluido de la bomba. Tomar

las medidas apropiadas para proteger al

operador y el equipo.

Encendido del sistema de bombas y

selección del sentido de rotación de

la operación