Page 1

OPERATING MANUAL:

®

®

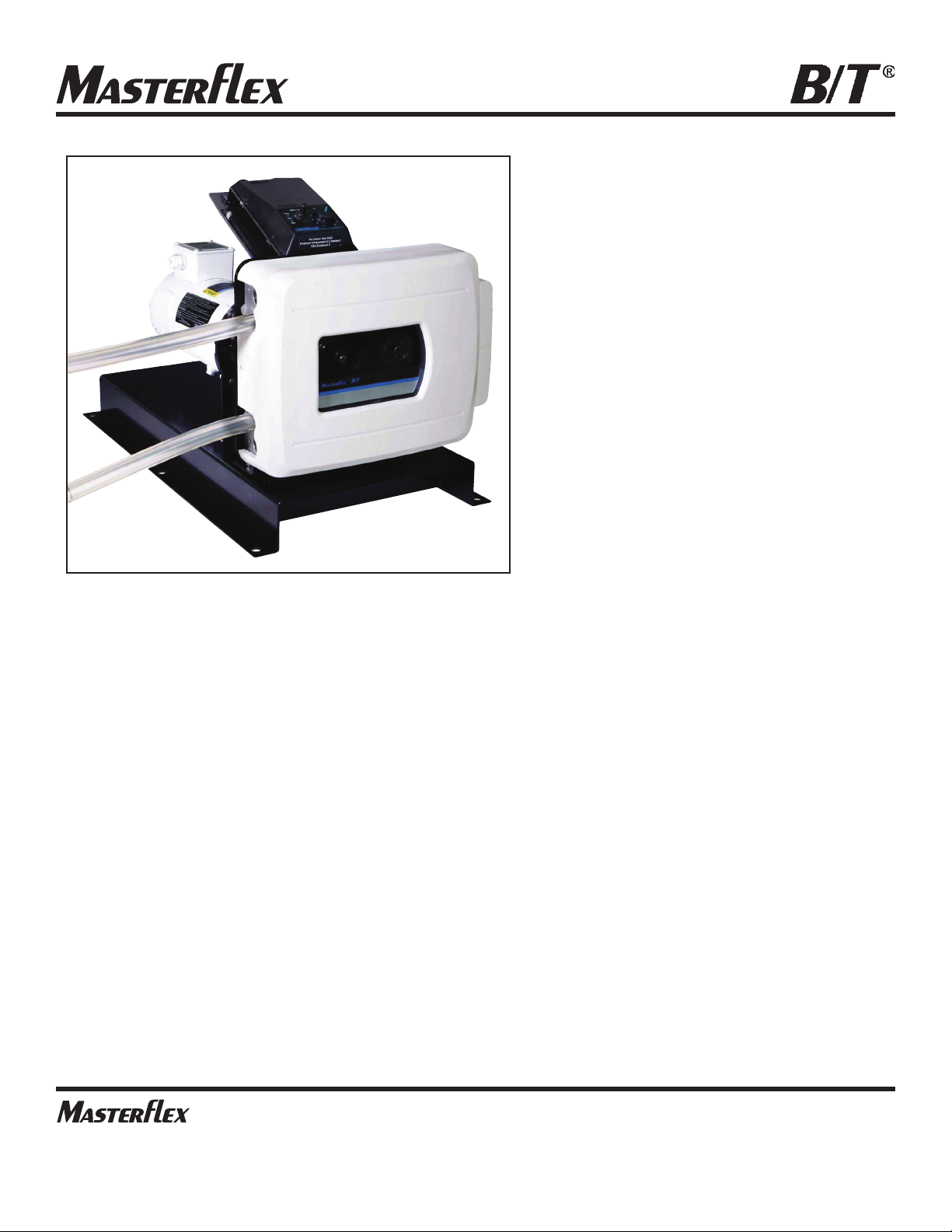

MASTERFLEX®B/T®Pump 77111-60

B/T®RAPID-LOAD

®

PERISTALTIC PUMPS

AND DRIVES

System Model Nos.

77111-10

77111-12

77111-15

77111-17

77111-30

77111-37

77111-40

77111-47

77111-50

77111-55

77111-60

77111-67

77111-80

A12995152B

Edition 04

(US & Canada only) Toll Free 1800MASTERFLEX • 18006373739

(Outside US & Canada) 18475497600 • 18473817050

www.masterflex.com • techinfo@masterflex.com

Page 2

© 2019 Cole-Parmer Instrument Company. All rights reserved.

Chem-Durance, B/T, Rapid-Load, Masterflex – Reg TM of Cole-Parmer Instrument Company

C-FLEX, NORPRENE, PHARMAPURE, PHARMED, TYGON – Reg TM Saint-Gobain Performance Plastics Corp.

Trademarks bearing the ®symbol in this publication are registered in the U.S. and in other countries.

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

Masterflexii B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual

Page 3

Preface

Safety Precautions

SAFETY

PRECAUTIONS

DANGER: High voltages exist and are accessible. Do not remove cover of

Drive or Controller. Use extreme caution when servicing internal components.

CAUTIONS: Risk of electric shock – this pump is supplied with a grounding

conductor and grounding-type attachment plug. To reduce risk of electric

shock, be certain that it is connected only to a properly grounded, groundingtype receptacle.

Electrical connections and grounding (earthing) must conform to local wiring

codes.

WARNINGS: Tubing breakage may result in fluid being sprayed from pump.

Use appropriate measures to protect operator and equipment.

To reduce the risk of injury, use hose clamps on all tubing connections. All

tubing connections, must be made outside of the pump.

To reduce risk of injury, power must be removed from pump before removing

or installing tubing. Fingers or loose clothing could get caught in drive

mechanism. Do not operate this pump without cover or interlock door properly

closed and latched. Rotating parts can cause serious injury.

To reduce risk of injury, do not pump materials hotter than 150 degrees

Fahrenheit, (65.5°C).

Explanation of

Symbols

WARNING:

Product Use

Limitation

Before permanent installation, test the equipment with the chemicals and under

the specific conditions of your application.

Verify tubing material chemical compatibility prior to use. It is the sole

responsibility of the user to determine suitability of the product for the

application

CAUTION: Risk of Danger. Consult Operator’s manual for nature of hazard and

corrective actions.

CAUTION: Risk of crushing. Keep fingers away from rotor while pump is in

operation. Stop pump before loading or unloading tubing.

CAUTION: Hot Surface. Do not touch.

CAUTION: Risk of electric shock. Consult Operator’s manual for nature of

hazard and corrective actions.

This product is not designed for, nor intended for use in, patient-connected

applications, including, but not limited to, medical and dental use, and,

accordingly, has not been submitted for FDA approval. If drive is used in a

manner not specified in this manual the protection provided by the equipment

may be impaired.

Masterflex

®

Use only MASTERFLEX

MASTERFLEX pumps to ensure optimum performance. Use of other tubing may

void applicable warranties.

PERFECTPOSITION®B/T®precision tubing with

®

RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual iii

B/T

Page 4

Page 5

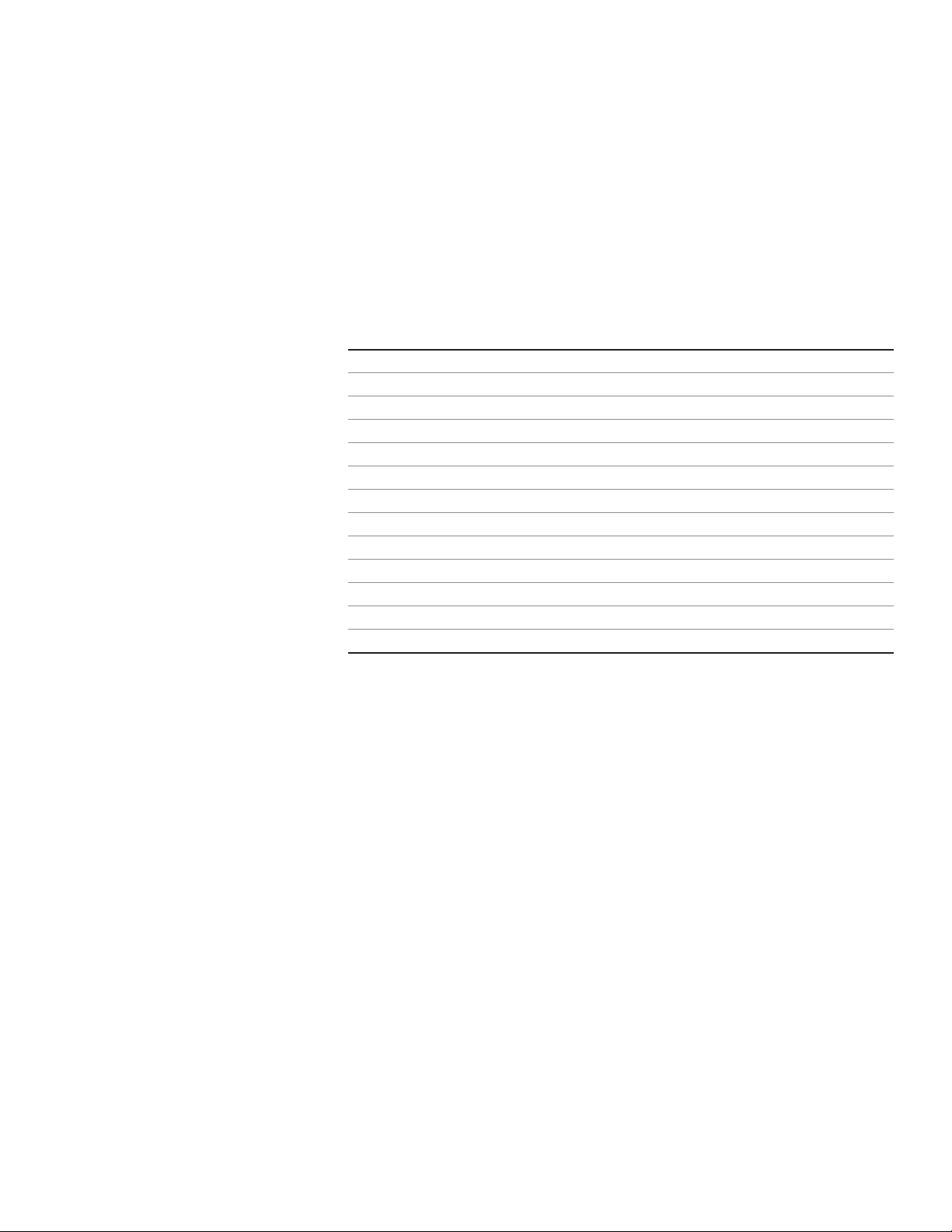

Section 1

Table of Contents

Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

APPLICATION DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Section 2

Section 3

Section 4

INSTALLATION AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

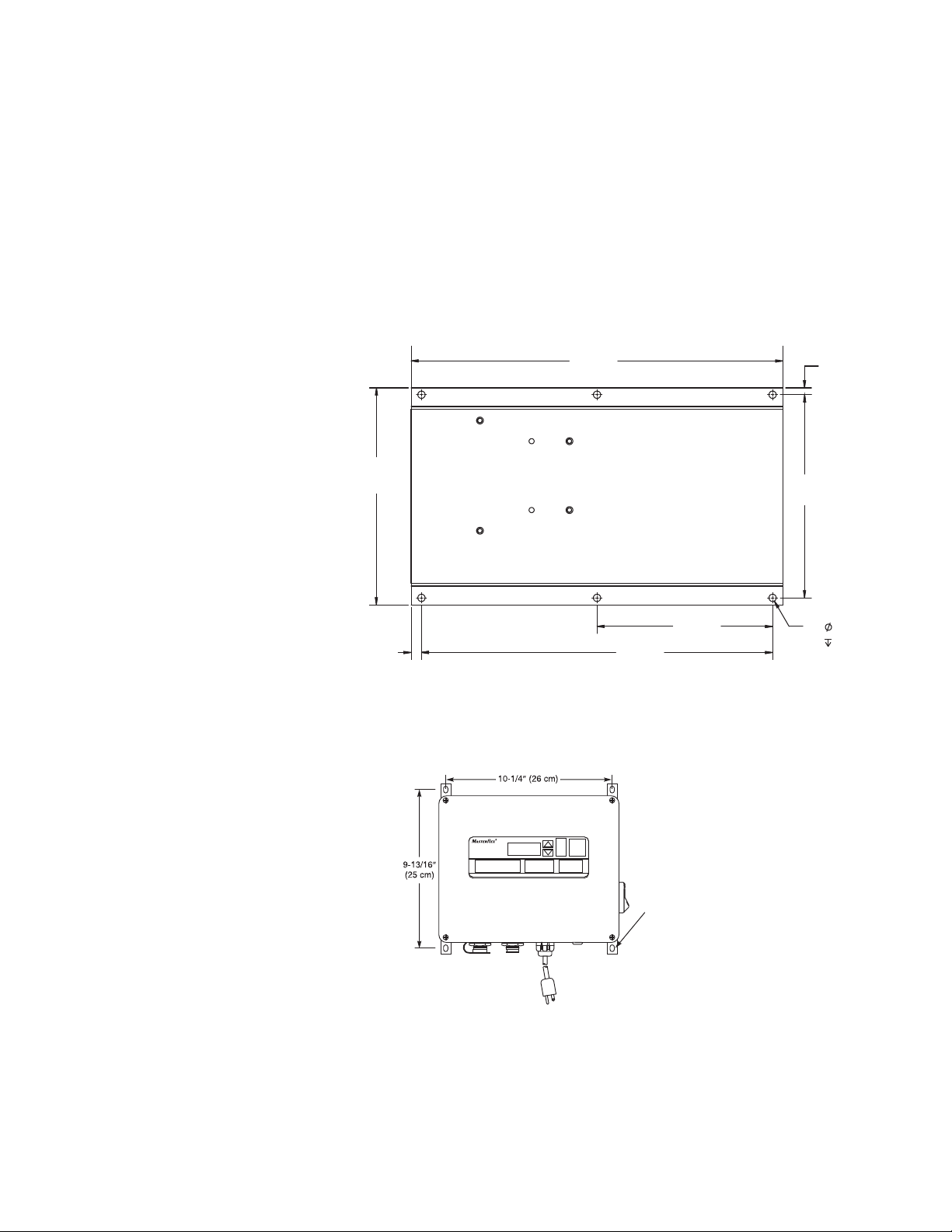

PUMP MOUNTING DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

CONTROL BOX MOUNTING DIMENSIONS (Digital Models Only) . . . . . . . . . . . . . .2-1

CONTROL BOX MOUNTING DIMENSIONS (Analog Models Only) . . . . . . . . . . . . . .2-2

MODEL 77111-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

MODEL 77111-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

MODEL 77111-55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

TUBING TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

INSTALLING THE PUMP TUBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

CONTROL DISPLAY FUNCTION MODELS 77111-10, 77111-15,

77111-40 AND 77111-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

MODELS 77111-12, AND 77111-17 CONTROLLER SETUP . . . . . . . . . . . . . . . . . . . .3-2

MODELS 77111-60 AND 77111-67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

MODEL 77111-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

MODELS 77111-30 AND 77111-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

MAINTENANCE AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

REPLACING MOTOR BRUSHES MODELS 77111-12, 77111-17, 77111-60,

77111-67, 77111-40 AND 77111-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

REPLACING ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

TROUBLESHOOTING MODELS 77111-40 AND 77111-47 . . . . . . . . . . . . . . . . . . . . .4-5

ERROR CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Section 5

Section 6

SPECIFICATIONS AND AGENCY APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

MODELS 77111-10, 77111-12, 77111-15, 77111-17,

77111-40 AND 77111-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

MODELS 77111-60 AND 77111-67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

MODEL 77111-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

MODELS 77111-30 AND 77111-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

MODELS 77111-50 AND 77111-55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

WARRANTY, PRODUCT RETURN, TECHNICAL ASSISTANCE . . . . . . . . . . . . .6-1

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

PRODUCT RETURN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

TECHNICAL ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual vMasterflex

Page 6

Page 7

Figures

Figures

Page

RAPID-LOAD Pump and Drive Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

RAPID-LOAD Pump and Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Pump Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Control Box Mounting Dimensions 77111-10, 77111-15,

77111-40 and 77111-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Control Box Mounting Dimensions 77111-60 (115V) . . . . . . . . . . . . . . . . . . .2-2

Control Box Mounting Dimensions 77111-67 (230V) . . . . . . . . . . . . . . . . . . .2-2

Air-Powered Rapid-Load Pump and Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Motor Mounting NEMA TYPE 56C Motor Fame . . . . . . . . . . . . . . . . . . . . . . .2-4

Motor Mounting IEC-72 71-14F130 Motor Frame . . . . . . . . . . . . . . . . . . . . .2-5

Tubing Retaining Pockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

PerfectPosition Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Tubing Retaining Pockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Connectors and Switch on Controller Side Panel . . . . . . . . . . . . . . . . . . . . . .3-2

Remote Control Connector Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Remote Control Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Model 77111-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Model 77111-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Motor Brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Exploded Roller Sub-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Motor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual viiMasterflex

Page 8

Page 9

Tables

Tables

Page

Tubing Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual ixMasterflex

Page 10

Page 11

Section 1 Introduction

This manual provides information for installing, operating and servicing

the following models of MASTERFLEX

Pumps and Drives.

MODEL TYPE

77111-10 Controller Only 115VAC for 77111-40

77111-12 Drive Only 115VAC for 77111-40

77111-15 Controller Only 230VAC for 77111-47

77111-17 Drive Only 230VAC for 77111-47

77111-30 Fixed Speed w/TEFC, 115V AC @ 60 Hz

77111-37 Fixed Speed w/TEFC, 230V AC @ 50 Hz

77111-40 Modular Drive , Digital 115V AC system.

77111-47 Modular Drive , Digital 230V AC system.

77111-50 Drive Only NEMA56C mount less motor

77111-55 Drive Only IEC72 mount less motor

77111-60 Modular Drive, Analog 115V AC system

77111-67 Modular Drive, Analog 230V AC system

77111-80 Air-Powered Variable Occlusion Peristaltic Pump and Drive.

B/T®RAPID-LOAD®Peristaltic

®

The unique design of these peristaltic pumps provides a greatly simplified

means for rapid loading and changing of tubing. In addition, the following

features are incorporated:

Pumps up to 11.1 GPM (42.0 LPM).

Uses continuous tubing to ensure a sanitary and non-contaminating

system.

Fluid contacts only the tubing.

Handles wide range of viscosities.

Several different sizes and formulations of tubing can be used.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 1-1Masterflex

Page 12

Section 1

Introduction

Application Data

The gentle peristaltic action of these pumps is ideal for pumping highly

viscous and shear-sensitive liquids. These pumps are also ideally suited for

use where sterile conditions and purity are required. Toxic and hazardous

fluids can be pumped with the proper selection of MASTERFLEX

PERFECTPOSITION B/T tubing since the fluid contacts only the

tubing and not the pump.

Use only MASTERFLEX®PERFECTPOSITION®B/T®precision tubing

with MASTERFLEX pumps to ensure optimum performance. Use of

other tubing may void applicable warranties.

WARNING: Tubing breakage may result in fluid being sprayed

from pump. Use appropriate measures to

protect operator and equipment.

Verify tubing material chemical compatibility prior to use. It is

the sole responsibility of the user to determine suitability of the

product for the application.

1-2 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 13

Section 1

Note:

Introduction

General Description

The RAPID-LOAD®B/T peristaltic pump (see Figure 1) is mounted on a

base and attached to a NEMA 56C frame motor or IEC-72 71-14F130

frame motor through a 5.45:1 gear head and adapter. Depending on the

model, the motor is either supplied or customer furnished and is attached

to the adapter by four bolts. A modular controller is furnished with some

models. The modular controller can be wall mounted.

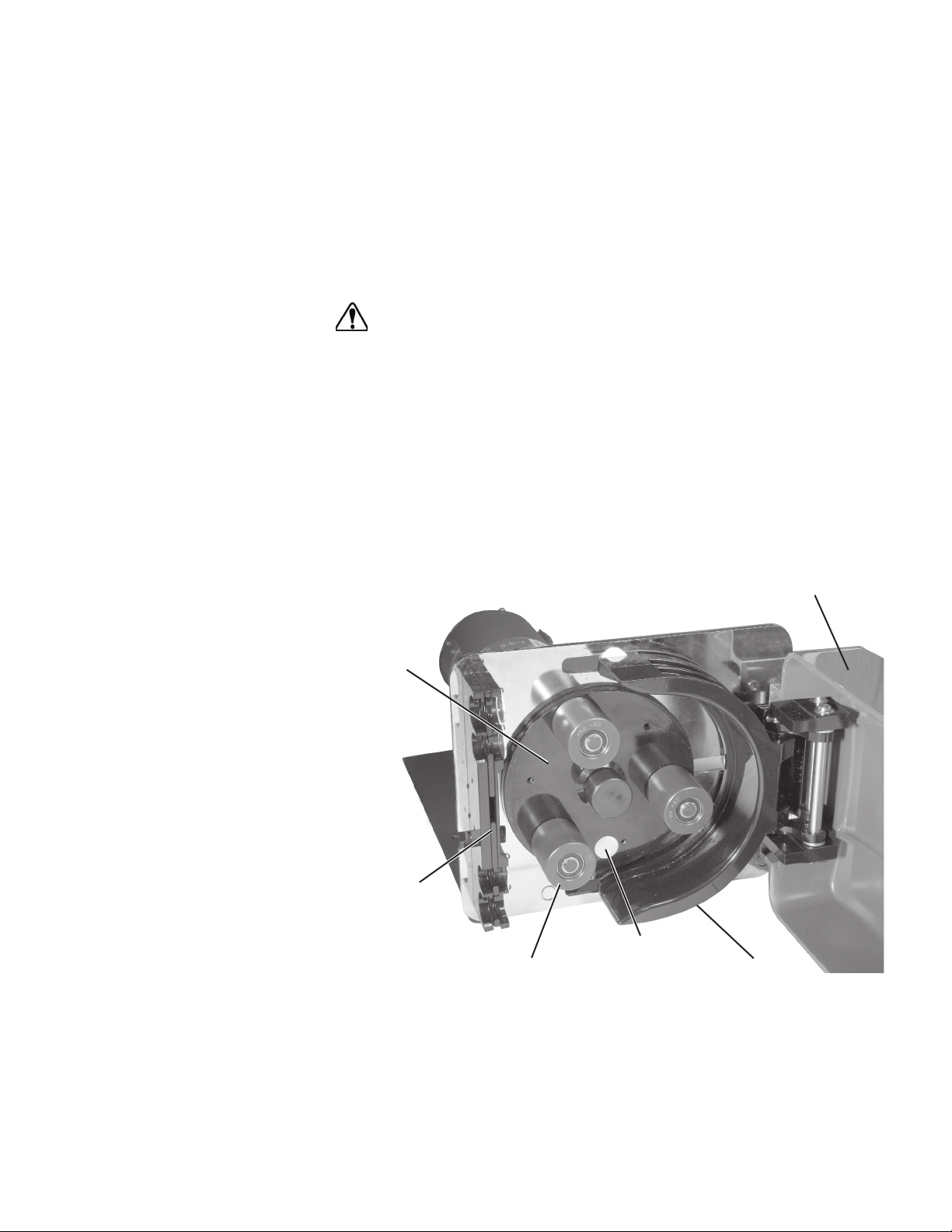

Figure 1-1. RAPID-LOAD Pump and Drive Family

Due to its unique design, different MASTERFLEX PERFECTPOSITION

B/T tubing sizes can be accommodated by this RAPID-LOAD peristaltic

pump.

For an indirect estimate of flow rate, a reflective element attached to the

rotor has been provided for use with an optical tachometer. Point

tachometer beam through front cover window and target the reflective

element.

To obtain flow rate in mL/min., multiply tachometer rpm reading times

the nominal flow per revolution value provided in TABLE 1

(N

3,785 mL = 1 U.S. liquid gallon).

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 1-3Masterflex

Page 14

Section 1

Introduction

The maximum recommended rotor speed is 321 rpm. The pump rotor can

turn either clockwise or counterclockwise. When turning clockwise (FWD)

the top connection is for suction and the bottom connection is for

discharge. The 321 rpm speed is obtained from the standard 1725 rpm

fractional horsepower motor through the 5.45:1 gear reduction. Faster

speeds will increase flow, but will also considerably shorten average tubing

life. (Manufacturer cannot be responsible for pump performance when

operated at speeds higher than 321 rpm.)

WARNING: To reduce the risk of injury, use hose clamps on all

tubing connections.

Silicone or C-FLEX®tubing, because of their highly elastic natures, can

expand very quickly if back-pressure is present and could create leakage at

the fittings if not securely retained. It is this same elastic nature, however,

that makes them such excellent materials for this peristaltic type pump.

®

NORPRENE

tubing yields longer life, especially under pressure. Refer to

Table 1 for tubing recommendations. Do not attempt to use other

materials in lieu of these, as pump performance could be severely

compromised with possible damage to the pump.

ROTOR

ASSEMBLY

RETAINER

ASSEMBLY

ROLLER

Figure 1-2. RAPID-LOAD Pump and Drive

REFLECTIVE

ELEMENT

DOOR ASSEMBLY

OCCLUSION BED

1-4 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 15

PUMP MOUNTING

27.0

(685.80)

15.8

(400.05)

.5

(12.70)

14.8

374.65

25.5

(647.70)

12.8

(323.85)

.3 (6.35)

6

X

.5 (13.49)

.8

(19.05)

DIMENSIONS

(All Models)

Section 2 Installation and Setup

These units should be placed on a flat surface such as a floor, bench or

table and should be near an electrical power source. Be sure to check data

plate for proper voltage rating(s).

CONTROL BOX

MOUNTING

DIMENSIONS

(Digital Models Only)

Figure 2-1. Pump Mounting Dimensions, applies to all Pump Systems.

CLEARANCE FOR 1/4 IN SCREW

Figure 2-2. Control Box Mounting Dimensions 77111-10, 77111-15, 77111-40

and 77111-47.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 2-1Masterflex

Page 16

Section 2

7.3

(184)

3.6

(91)

Ø .220

(6)

4 Places

5.5

(140)

5.5

(140)

TYP

5.1

(130)

TYP

3.6

(91)

Ø .165

(4)

4 Places

6.3

(160)

5.1

(130)

9.0

(228)

9.5

(240)

TYP

Installation and Setup

CONTROL BOX

MOUNTING

DIMENSIONS

(Analog Models

77111-60 and

77111-67 Only)

NOTE: The controller and bracket can be removed and located up to

10 feet away.

Figure 2-3. Control Box Mounting Dimensions 77111-60 (115V).

Figure 2-4. Control Box Mounting Dimensions 77111-67 (230V).

2-2 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 17

Section 2

Unpack the drive

Install the following components:

Installation and Setup

Model 77111-80

This unit should be placed on a flat surface such as a floor, bench, or table

and should be near a compressed air source.

and save packaging material until proper product

operation has been verified.

pressure gauge, pressure filter/regulator

and lubricator assembly, pipe nipple, elbow, and muffler. See Figure 2-5 for

proper orientation, (all items and fittings included except as noted). Use a

thread seal such as PTFE tape for all connections to reduce the possibility

of air leakage.

Connect compressed air line to the 1/4 NPT connection on the regulator

(fitting not supplied). Turn on compressed air line to start pumping.

(Maximum 100 psig inlet.)

NOTE: Pump will not run unless Door Assembly is closed.

Gear Reducer

Lubricator

Control Knob

Muffler

Door

Assembly

Elbow Pipe Nipple Pressure Gauge

Figure 2-5. Air-Powered Rapid-Load Pump and Drive

Air Motor

Filter/Regulator

Control Knob

(Speed Control)

Base

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 2-3Masterflex

Page 18

Section 2

Trim Interlock Cable to

Length and Strip Leads.

Install in Series with

Power to the Motor.

Gear Reducer

Pump

Head

Flat Washers

and Bolts

Installation and Setup

MODEL 77111-50

Install customer-supplied motors in accordance with the following procedure.

CAUTION: This product is intended for use with a motor that has

a maximum speed of 1800 rpm, @ 1.0 HP (0.75 KW). Do not use a

motor with a higher speed capacity.

WARNING: Electrical connections and grounding (earthing), must

conform to local codes. (See motor wiring diagram for motor

wiring instructions.)

Tools required: 5/16 inch Hex Key.

Model 77111-50 is designed to be installed to a customer-supplied NEMA Type

56C frame motor. To install the unit, refer to Figure 2-6 and follow these steps:

1. Using a 5/16 inch Hex Key, and the supplied hardware, bolt the motor

to the gear reducer by installing the four flat washers on the bolts and

inserting the bolts through the gear head adapter into the motor.

Torque bolts from 17 to 19 foot pounds.

2. Cutoff connector from end of interlock cable and strip outer jacket.

3. Strip individual conductors and wire in series with the power to the

motor turned off. Failure to do so will result in defeating the door

interlock, creating a potential crushing hazard.

CAUTION: Risk of crushing. Keep fingers away from rotor while

pump is in operation. Stop pump before loading or unloading tubing.

Figure 2-6. Motor Mounting NEMA TYPE 56C Motor Fame

2-4 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 19

Section 2

Trim Interlock Cable to

Length and Strip Leads.

Install in Series with

Power to the Motor.

Gear Reducer

Pump

Head

Flat Washers

and Bolts

Installation and Setup

MODEL 77111-55

Install customer-supplied motors in accordance with the following procedure.

CAUTION: This product is intended for use with a motor that has

a maximum speed of 1800 rpm, @ 1.0 HP (0.75 KW). Do not use a

motor with a higher speed capacity.

WARNING: Electrical connections and grounding (earthing), must

conform to local codes. (See motor wiring diagram for motor

wiring instructions.)

Tools required: 13 mm Wrench.

Model 77111-55 is designed to be installed to a customer-supplied

IEC-72-71-14F130 frame motor with foot mountings. To install the

unit, refer to Figure 2-7 and follow these steps:

1. Using a 13 mm wrench, and the supplied hardware, bolt the motor to

the gear reducer by installing the four flat washers on the bolts and

inserting the bolts through the gear head adapter into the motor. Torque

bolts from 1.73 to 2.00 kilogram-meters (12.5 to 14.5 foot pounds.)

2. Cutoff connector from end of interlock cable and strip outer jacket.

3. Strip individual conductors and wire in series with the power to the

motor turned off. Failure to do so will result in defeating the door

interlock, creating a potential crushing hazard.

CAUTION: Risk of crushing. Keep fingers away from rotor while pump is

in operation. Stop pump before loading or unloading tubing.

Figure 2-7. Motor Mounting IEC-72 71-14F130 Motor Frame

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 2-5Masterflex

Page 20

Section 2

Installation and Setup

TUBING TYPES

Use only MASTERFLEX

PERFECTPOSITION

B/T precision tubing with

MASTERFLEX pumps to ensure optimum performance.

Use of other tubing may void applicable warranties.

NOTE Use MASTERFLEX PERFECTPOSITION B/T tubing. These

pumps are designed to use PERFECTPOSITION B/T tubing sizes 87 and

91 only. The tubing sizes refer to the last two digits of the MASTERFLEX

PERFECTPOSITION B/T tubing model number.

Table 1. Tubing Types

Characteristics B/T 87 B/T 91

Inside Dia. in (mm) 0.5 (12.7) 0.75 (19.05)

Hose barb size in (mm) 1/2″ (12.7) 3/4″ (19.0)

Flow Range 0.17-5.0 GPM 0.37-11.1 GPM

(with 321 rpm drive) (0.010-18.9 LPM) (1.40-42.0 LPM)

Nominal Flow Per Revolution 58.88 mL 130.84 mL

Maximum Vacuum 28.5 in Hg 28.5 in Hg

Maximum Pressure 35 PSI 30 PSI

Tubing Size

All MASTERFLEX PERFECTPOSITION B/T tubing formulations in sizes

B/T 87 and B/T 91 can be used with this pump. Be sure tubing material

matches application.

WARNING: Verify tubing material chemical compatibility prior to

use. It is the sole responsibility of the user to determine suitability

of the product for the application.

PERFECTPOSITION

Silicone - 10 ft. (3.0 m), Platinum cured 96510-87 96510-91

Silicone - 10 ft. (3.0 m), Peroxide cured 96400-87 96400-91

BioPharm Plus silicone - 10 ft. (3.0 m), Platinum cured 96445-87 96445-91

C-FLEX - 10 ft. (3.0 m) 06424-87 06424-91

Puri-Flex™ 10 ft. (3.0 m) 96419-87 96419-91

Chem-Durance

PharMed®BPT - 25 ft. (7.6 m) 06508-87 06508-91

PharMed®BPT - 3 ft. (0.9 m) 95668-87 95668-91

PharmaPure®- 10 ft. (3.0 m) 06437-87 06437-91

NORPRENE®food - 25 ft. (7.6 m) 06402-87 06402-91

Pump Tubing B/T 87 B/T 91

®

BIO 25 ft. (7.6 m) 06442-87 06442-91

2-6 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 21

Section 2

Installation and Setup

INSTALLING THE

PUMP TUBING

(All Pump Models)

WARNING: Power must be removed from pump before removing

or installing tubing. Fingers or loose clothing could get caught in

drive mechanism. Do not operate this pump without cover or

interlock door properly closed and latched. Rotating parts can

cause serious injury.

1. Cut off power to the pump by disconnecting line cord or, if wired

permanently, by removing the fuse. Do not assume that turning off the

switch at the motor (or controller) is "safe enough."

2. Unlatch the door latch and open the cover.

3. Insert the tube in the appropriate upper tube retaining pocket (see

Figure 2-10). Line up the “PERFECTPOSITION” placement marks

printed on the tube with the outside edge of the retainer assembly

(see Figure 2-8).

PERFECTPOSITION

MARK

Figure 2-8. Tubing Retaining Pockets

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 2-7Masterflex

Page 22

Section 2

Installation and Setup

PERFECTPOSITION

MARKS

Figure 2-9.

PerfectPosition

Marks

4. If the new tube must be cut from a length of approved replacement

tubing, a minimum of 32 inches will be required for a new tube.

5. Going with the natural lay or curvature of the tubing, wrap the tubing

around the assembly and insert the tubing in the lower retaining pocket.

6. Close the door and insure that door latch is engaged and locked.

WARNING: Do not operate this pump without cover or interlock

door properly closed and latched. Rotating parts can cause

serious injury.

7. Restore power to the pump.

WARNING: To reduce the risk of injury, use hose clamps on all

tubing connections.

All tubing connections must be made outside of the pump.

A

TUBING RETAINING POCKETS

FOR (A) 91 AND (B) 87 TUBING

B

Figure 2-10. Tubing Retaining Pockets

2-8 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 23

Section 3 Operation

Control

Display Functions

Models 77111-10

77111-15

77111-40

77111-47

AB

L

A) DOWN ARROW (DECREMENT)—Decrease value of a flashing display.

B) UP ARROW (INCREMENT)—Increase value of a flashing display.

C) DISPENSE/COPY—Set dispense volume, copy amount, or dispense time.

D) FLOW CONTROL—Set flow rate for selected tubing size. To change flow rate, press ▲ or

▼ arrows. (If pump is running, its speed will change with new settings.)

E) CAL CONTROL—Refine built-in calibration, using a measured volume.

F) STOP/START—Stop/Start motor.

G) PRIME—Run pump at full speed to fill or clear lines.

H) DIRECTION—To change motor direction.

I) MODE SELECT—INT for internal control; mA for remote current control; V for remote voltage

control.

J) SIZE—Select tubing size and flow units, also displays maximum flow rate.

K) GALLONS—Flow and Volume units indicator.

L) LITERS—Flow and volume units indicator.

K

C

D

E

F

G

HIJ

Figure 3-1. Control Panel

Press buttons to activate function.

Use up/down (▲, ▼) arrows to correct/change a flashing display.

Press STOP/START to enter new values.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 3-1Masterflex

Page 24

Section 3

ABCDE

F

Section 3

Operation

Operation

A) EXTERNAL RECEPTACLE

B) MOTOR RECEPTACLE

C) LINE CORD

D) INTERLOCK CONNECTOR

E) T8A FUSE (115V AC); T4A FUSE (230V AC)

F) POWER SWITCH — ALL SETTINGS ARE RETAINED IN MEMORY

Controller Setup

Figure 3-2. Connectors and Switch on Controller Side Panel

1. Connect Motor Cable plug to mating receptacle on the Controller.

2. Connect Interlock Cable plug to mating receptacle on the controller.

3. Connect power cord of Controller to grounded power line outlet.

4. Turn controller on and select TUBING SIZE.

NOTE: If CAL LED is lit, that tubing size has been previously field

calibrated. If LED is not lit, the drive is operating with the built-in factory

calibration. To clear a field calibration, press and hold the CAL switch

until the CAL light goes out. This will take about 3 seconds. To recalibrate

for better accuracy, see Calibration section.

5. MODE selection (INT, mA, V).

6. Select MOTOR DIRECTION (CW or CCW).

7. PRIME and CALibrate the pump (if required).

8. Press FLOW key and watch display to set the flow rate with

UP/DOWN keys.

9. Press STOP/START key to begin pumping.

NOTE: Under some circumstances, tubing may creep into pump. If this

problem occurs it can be remedied by installing a hose clamp or fitting

immediately upstream of and very close to the inlet port.

NOTE: Pump will restart automatically after a brownout or powerout condition.

3-2 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 25

Section 3

Operation

Calibration

1. Select correct tubing size and flow rate.

2. Press CAL, calibration volume appears.

3. Press STOP/START, the pump will use its stored memory to dispense

the specified calibration sample quantity. The pump will stop

automatically.

4. Weigh/measure the sample.

5. Use UP/DOWN arrow keys to correct the flashing display.

NOTE: If the adjusted calibration is too great, “Err” will appear in the

display. If this occurs, press the CAL control and repeat the calibration

procedure. The microprocessor will retain one special calibration value per

tubing size, even when power is turned off. The next calibration will

replace the existing value.

6. Press size to exit the calibration cycle.

Maximum Flowrate

(OTHER Tubing)

1. To set the maximum flowrate for non-standard pumps or tubing sizes,

OTHER press CAL, then FLOW. The maximum flowrate will then

flash on the display.

2. Use UP/DOWN arrow keys to set desired flowrate.

3. Press SIZE to exit.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 3-3Masterflex

Page 26

Section 3

Operation

DISPense/copy

A first press of the DISP key results in the last entered dispense volume

being displayed. The “VOL” annunciator will illuminate and flash. The

INC/DEC keys are used to change the dispense volume, if desired. The

STOP/START key then initiates delivery of the set volume. The amount

remaining to be dispensed will be displayed during countdown. The

dispense function is exited by pressing any key except Increment,

Decrement, DISP, or STOP/START.

A second press of the DISP key causes the COPY annunciator to

illuminate and flash. The STOP/START key is then used to set the desired

volume without the need to know the volume in specific units. A third

press of the DISP key enters the volume dispensed. The COPY

annunciator stops flashing. The STOP/START key is then used to initiate

delivery of the copied volume. The number of copies dispensed will be

displayed after each dispense. The STOP/START key is used to pause the

copy dispense during dispensing; copy dispense can then be continued

using the STOP/START key.

A fourth press of the DISP key results in the last entered dispense time

being displayed. The SEC annunciator will illuminate and flash. The

INC/DEC keys are used to change the dispense time, if desired, from 1 to

9999 seconds. The STOP/START key then initiates delivery for the set

time interval. The remaining time will be displayed during countdown.

Pressing the DISP key a fifth time exits this mode.

Keypad Lockout

Enable/Disable

Remote Control

Press and hold FLOW. After five (5) seconds, display will change to all

dashes. Then, while holding FLOW, press PRIME five (5) times.

The MODE “INT”: annunciator will flash when the keypad is locked.

Selectable input (0–20 mA, 4–20 mA, 0–10V DC )

±0.5% linearity control

2300V isolation potential

STOP/START; CW/CCW; PRIME via contact closure

3-4 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 27

Section 3

Operation

Remote Control Setup

1. Place the power switch in the off position.

CAUTION: Power must be turned off before connecting the

external remote control cable to prevent damage to the drive.

2. Connect the cable from the external remote control to the mating

receptacle on the bottom panel.

3. Select type of remote control input and output required as follows:

a). Press and hold the MODE key while turning the power switch

to the “ON” (1) position. After two seconds, release the

MODE key. The initial display will show: “inP”. After two

seconds the display will show either 0–20 or 4–20.

NOTE: Press the up (increment) or down (decrement) arrows to select

between 4–20 and 0–20 for current loop control.

b). Press the MODE key again. The initial display will show:

“out”. After two seconds the display will show either 0–20,

4–20, or 0–10.

NOTE: Press the up (increment) or down (decrement) arrows to select

between 4–20 and 0–20 for current loop output, or 0–10 for voltage output.

4. Press the MODE key to select mode of operation. The LED’s indicate

the selected mode. Select either mA or V.

NOTE: If only remote STOP/START, PRIME and/or CW/CCW is to be

used, the MODE control can be set to any of the three positions.

5. To adjust the voltage or current scaling for other than zero to full scale:

a). Press the MODE key and then the FLOW key at the same

time. The display will show “LO” and then the flow rate for

minimum current/voltage (factory default = 0).

b). Use the UP/DOWN arrow keys to change the flow rate for

minimum current/voltage.

c). Press the FLOW key. The display will show “HI” and then the

flow rate for maximum current/voltage. Use the UP/DOWN

arrow keys to change the flow rate for maximum

current/voltage or press the SIZE key to set it to maximum

flow rate (factory default). Press any other key to save and exit.

The same scaling will be used for both input and output. Each

tube size has its own scaling.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 3-5Masterflex

Page 28

Section 3

Operation

Remote Control Setup

(continued)

NOTE: The maximum flow rate for a tubing will change after a calibration

is performed. To retain control of the entire flow range, the “HI” scale

setting must be changed to the new maximum flow rate after a calibration

is performed.

6. Remote STOP/START can be configured to be optional (“OFF”) or

mandatory (“ON”). When “ON” is selected, drive will not run unless

remote STOP/START is closed When “OFF” is selected (factory

default), remote STOP/START can be used to start drive, but drive

can also be started by keypad or remote inputs when remote STOP/

START is open. Internal mode or remote mode (mA or V) each have

their own STOP/START configuration, so first select the desired

operating mode before changing STOP/START setup.

a) Press and hold the MODE key until the display changes to

“STOP”. The display will alternate with an “ON” or “OFF”.

b) Use the UP/DOWN arrow keys to select “ON” or “OFF”.

c) Press any other key to save and exit.

Figure 3-3. Remote Control Connector Pin Configuration

3-6 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 29

Section 3

Operation

Remote Control Setup

(continued)

A1) RED/YELLOW

B1) BLUE

C1) GREEN

D1) YELLOW

E1) WHITE

F1) ORANGE

G1) BLACK

H1) BROWN

I1) VIOLET

J1) RED

K1) GREY

L1) TAN

M1) PINK

N1) RED/GREEN

O1) RED/BLACK

P1, Q1, R1) N.C.

A) STOP/START

B) CW/CCW

C) OUTPUT 0-20mA; 4-20mA

D) INPUT 0-20mA; 4-20mA

E) INPUT 0-10V

F) OUTPUT 0-10V

G) TACH OUTPUT

H) PRIME

I) MOTOR RUNNING N.O. CONTACT

J) MOTOR RUNNING N.C. CONTACT

NOTE: Colors are those of Remote Cable, Cat. number 77300-32.

Figure 3-4. Remote Control Wiring Schematic

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 3-7Masterflex

Page 30

Section 3

Operation

Models 77111-60

and 77111-67

Controller

Models 77111-60 (115V model) and 77111-67 (230 V model) are

supplied with an electronic controller (see Figure 3-5) for controlling

pump speed.

1. Place FWD-OFF-REV switch in the desired position, clockwise

(FWD) or counterclockwise (REV) direction.

2. Adjust SPEED control for the desired pump speed.

115V AC

Figure 3-5. Controller

230V AC

3-8 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 31

Section 3

Operation

Model 77111-80

Adjust flow rate with adjustment knob on top of regulator. Vary flow rate

from 10 psig to 60 psig. At higher pressures, the pump speed may exceed

321 rpm.

CAUTION: Do not exceed 321 rpm. Speeds in excess of 321 rpm

may cause damage to unit.

(Lock flow rate by using snap-action push-pull knob on filter regulator.)

For continuous-duty or high-speed application, use of the lubricator is

recommended. Adjust the lubricator with the adjustment knob on top. For

higher speeds, set lubricator to provide 1–3 drops/minute. Use a lower

setting for lower speeds. See below for RECOMMENDED LUBRICANTS.

(Lock lubrication rate by using snap-action push-pull knob.)

Recommended

Lubricants

Figure 3-6. Model 77111-80

Use a misting type oil rated 50 to 200 SSU (ISO Grade 7 to 46) at 100°F

(38°C). Unscrew the bowl to fill the lubricator. Press up on the bottom

drain to empty bowl.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 3-9Masterflex

Page 32

Section 3

Operation

Models 77111-30

and 77111-37

Operating Controls

The following chart highlights items included in each model and the

operating controls.

Model No. Motor Included ON-OFF Switch

77111-30 Yes Yes

77111-37 Yes Yes

Figure 3-7. Model 77111-30

3-10 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 33

Section 4 Maintenance and Troubleshooting

REPLACING

MOTOR BRUSHES

MODELS 77111-12

77111-17

77111-40

77111-47

77111-60

77111-67

Tools Required: Phillips screwdriver

WARNING: Power must be removed from motor before

performing this procedure.

1. Cut off power to the pump by disconnecting line cord or, if wired

permanently, by removing the fuse. Do not assume that turning off the

switch at the motor (or controller) is "safe enough."

2. To access the motor brushes, remove six screws securing the access

plate and remove plate (see Figure 4-1).

3. Loosen screw terminal at top of brush housing and disconnect brush wire.

4. Press down on brush retainer to disengage tabs then rotate brush

retainer slightly toward front of motor and remove brush retainer.

5. Slide brush assembly out of housing.

6. Install new brush assembly with brush wire toward rear of motor and

spring assembly on top.

7. Insert brush retainer against brush springs and push down, then rotate

retainer slightly toward rear of motor to engage tabs of retainer under

rear edge of brush housing.

8. Attach brush wire to screw terminal at top of brush housing. Be sure

wire is clear of access opening.

9. Attach cover plate with six screws.

NOTE: Always replace both brushes at the same time.

SCREW TERMINAL

BRUSH HOUSING

SPRING

TAB

BRUSH ASSEMBLY

BRUSH

RETAINER

Figure 4-1. Motor Brush

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 4-1Masterflex

ACCESS PLATE

SCREWS

Page 34

Section 4

Maintenance and Troubleshooting

REPLACING ROLLERS

To replace rollers:

1. Using a retaining ring tool (Part Number 109852-CR), remove the

retaining rings from the ends of the roller axles and slide the rollers off.

Take care to avoid opening the retaining rings too wide.

2. Check to be sure that the wave washers are installed on the axles

against the rotor plate.

3. Slide the new rollers, Replacement Roller Kit 07584-02, onto the axles,

placing the ends with the flush bearing surface inward toward the rotor

plate against the wave washers, and the etched ends with the recessed

bearing surface outward toward the free ends of the roller axles.

4. Replace the retaining rings. You may have to push the rollers in to

compress the wave washers to allow the retaining rings to engage the

grooves in the axles.

Figure 4-2. Exploded Roller Sub-Assembly

4-2 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 35

Section 4

A

B

C

D

E

Maintenance and Troubleshooting

MOTOR

REPLACEMENT

Tools required:

56 C frame mounting, 5/16 inch Hex key.

ISO-71 frame mounting, 10 mm wrench.

To install replacement motor refer to Figure 4-3 and follow these steps:

1. Apply anti-seize compound to shaft and key. Slide motor forward to

engage the male motor coupling with the female gear head coupling.

Rotate pump rotor if necessary to align the couplings.

2. Using the 5/16 inch hex key, bolt the motor to the gear head adapter

by inserting the four bolts through the gear head adapter into the

motor. Torque bolts from 17 to 19 foot-pounds.

A) Gear Head B) Bolt C) Shaft

D) Base E) Door Assembly

Figure 4-3. Motor Mounting

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 4-3Masterflex

Page 36

Section 4

Maintenance and Troubleshooting

Replacement Parts

The following list identifies the replaceable parts and includes the part numbers.

Description Part Qty

Number per Unit

Motor Brush Set (115V AC), Models 77111-10, 77111-40 and 77111-60 A-4156-CR 1

Motor Brush Set (230V AC), Models 77111-17, 77111-47 and 77111-67 A-4158-CR 1

Door Assembly 109473-CR 1

MASTERFLEX B/T, Roller Kit 07584-02 1

MASTERFLEX B/T, Rotor Assembly/with Rollers 108024-CR 1

Window 109467-CR 1

Shoulder Spacer Kit 109461-CR 6

Interlock Switch Assy for all models except 77111-30 109388-CR 1

Interlock Switch Assy for model 77111-30 only 111022-CR 1

Fuse - T8A 5 × 20 mm, Models 77111-10, 77111-37 and 77111-40 77500-27 1

Fuse - 8A 3AG, Model 77111-60 77500-28 1

Fuse - T15A 5 × 20 mm, Model 77111-30 77500-30 1

Fuse - T4.0A, 5 × 20mm, (230V AC),

Models 77111-15, 77111-67 and 77111-47 77500-26 1

Controller (115V AC) for Model 77111-60 77111-10 1

Controller (230V AC) for Model 77111-67 77111-15 1

Motor (115V AC)

Models 77111-60 109545-CR 1

Models 77111-10and 77111-40 109593-CR 1

Models 77111-30 111020-CR 1

Motor (230V AC)

Models 77111-15 and 77111-47 109594-CR 1

Model 77111-67 109546-CR 1

Model 77111-37 111021-CR 1

Air Motor, Model 77111-80 110519-CR 1

Motor Mounting Hardware 108688-CR 1

Retaining Ring Kit 07584-07 1

Cable, Control, Extension 20 ft. 108680 1

Line Cord - European, Models 77111-15, 77111-67, 77111-37 and 77111-47 50001-70 1

All MASTERFLEX PERFECTPOSITION B/T tubing formulations in

Accessories

sizes B/T 87 and B/T 91 can be used with this pump. Be sure tubing

material matches application.

Description Part Number

Retaining Ring Tool 109852-CR

Cable, Interlock Extension, 25 ft. 109389

Mounting Bracket Digital Controller Models 77111-40 and 77111-47 only 77111-90

Remote Cable 77111-10, 77111-15, 77111-40 and 77111-47 ONLY 77300-32

Handheld Remote Controller 77111-10, 77111-15, 77111-40 and 77111-47 ONLY 07592-83

Cleaning

Footswitch Washdown 77111-10, 77111-15, 77111-40 and 77111-47 ONLY 07592-30

Keep the drive enclosure clean with mild detergents. Never immerse nor

use excessive fluid.

4-4 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 37

Section 4

Maintenance and Troubleshooting

Troubleshooting

Models 77111-40

and 77111-47

Error Codes

Symptom Cause Remedy

A. Motor does not rotate. A1. No power. 1. Check fuse and replace if defective.

Display does not light.

A2. Defective remote control. 1. Place power switch in off position.

B. Motor does not rotate. B. MODE control not properly set. 1. Check that the MODE control is set to INT for

Display lights.

2. Check that unit is plugged into a

live line.

3. Check connection of power cord.

4. Check the line cord for continuity and replace if

defective.

5. Return for servicing.

2. Check that remote cable connector is inserted

fully into the AC receptacle.

3. If motor still does not rotate, select INT with the

MODE control and press the STOP/START

control.

4. If the motor rotates, replace the remote control

with similar unit. If motor will not rotate, return

drive for servicing.

operation with front panel control or to mA or V

for operation with remote control.

2. If motor still does not rotate, return for

servicing.

If an error message is displayed, refer to the following list for possible

corrective action you can take. If these do not correct the problem, contact

your dealer.

Symptom Cause Remedy

“Err 1” Changing speed reference too fast (motor undershoots). Clear by pressing stop/start.

No encoder pulses from motor. Check all motor/encoder

connections.

“Err 2” Changing speed reference too fast (motor overshoots). Clear by pressing stop/start.

Motor over-speed. Check all motor/encoder

connections.

“Err 4” Bad PROM. Return unit for repair.

“Err 5” Bad zero crossing detector or crystal. Return unit for repair.

“Err 6” Bad EEPROM data, operator parameters set to default Avoid fast switching of power to

values. the unit.

“Err 7” Bad EEPROM data, A/D span cal, span cal set to default. Return unit for repair.

“Err 8” EEPROM write/verify error. Return unit for repair.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 4-5Masterflex

Page 38

Page 39

Section 5 Specifications

Models 77111-10

77111-12

77111-15

77111-17

77111-40

77111-47

Output:

Speed: 11 to 321 rpm

Torque output, Maximum: 1440 oz-in (104 kg•cm)

Speed regulation:

Line ±0.25% F.S.

Load ±0.25% F.S.

Drift ±0.25% F.S.

Display: Four-digit, seven segment LED

Remote outputs:

Voltage speed output (0–10V DC)

Current speed output (0–20 mA or 4–20 mA)

Tach output (TTL, 128 to 7680 Hz)

Motor running output (N.O. & N.C. contact closure)

Tubing Compatibility: Sizes B/T 87 or B/T 91

Flow Range: up to 11.1 GPM (42.0 LPM)

Input:

Supply voltage limits:

77111-40 90 to 130 Vrms @ 50/60 Hz

77111-47 200 to 260 Vrms @ 50 Hz

Current, max.:

77111-40 6.5A

77111-47 3.3A

Remote Inputs: Start/Stop, CW/CCW, PRIME (contact closure)

Voltage input (0–10V DC)

Current input (0–20 mA or 4–20 mA)

Construction:

Dimensions (L × W × H):

77111-10, 77111-15 9 in × 11 in × 4 1/2 in

(229 mm × 279 mm × 114 mm)

77111-12, 77111-17 28.25 in × 15.88 in × 15.13 in

718 mm × 403 mm × 384 mm

Weight:

77111-10, 77111-15 9.4 lbs (4.3 kg)

77111-12, 77111-17 89.0 lbs (40.37 kg)

Enclosure Rating: IP 56 (NEMA 4) Per IEC 60529

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 5-1Masterflex

Page 40

Section 5

Specifications

Models 77111-10

77111-12

77111-15

77111-17

77111-40

77111-47

(continued)

Environment:

Temperature, Operating: 32° to 104°F (0° to 40°C)

Temperature, Storage: –49° to 149°F (–45° to 65°C)

Humidity (non-condensing): 10% to 90%

Altitude: Less than 2000 m

Pollution Degree: Pollution Degree 3 (Sheltered locations)

Noise Level: <75 dBA @ 1 meter

Chemical Resistance: Exposed material is painted

aluminum, plastic and vinyl

Compliance: 115V: conforms to UL STD 61010-1

certified to CSA C22.2 No. 61010-1

This product has been tested to the

requirements of CAN/CSA No. 61010-1,

second edition, including Amendment 1, or later

version of the same standard incorporating the

same level of testing requirements.

230V (for CE Mark):

EU Low Voltage Directive

(EN61010-1),

EU EMC Directive

(EN61326) and

EU Machinery Directive (EN809)

5-2 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 41

Section 5

Specifications

Models 77111-60

and 77111-67

Output:

Pump Speed: 12 to 321 rpm

Torque output, maximum: 1100 oz-in (104 kg

Tubing compatibility: Sizes B/T 87 or B/T 91

Flow Range: Up to 11.1 GPM (42.0 LPM)

Input:

Supply voltage limits:

Model 77111-60 90 to 130 Vrms @ 60 Hz

Model 77111-67 200 to 260 Vrms @ 50 Hz

Current, max:

Model 77111-60 6.5A

Model 77111-67 3.3A

Construction:

Dimensions (L × W × H):

Models 77111-60, -67 27.63 in × 15.88 in × 16.75 in

701 mm × 403 mm × 426 mm

Weight:

Models 77111-60, -67 89 lbs (40.4 kg)

Enclosure Rating:

Models 77111-60, -67 IP56 per IEC 60529

•cm)

Environment:

Temperature, Operating: 0°C to 40°C (32°F to 104°F)

Temperature, Storage: -20°C to 60°C (-4°F to 140°F)

Humidity:

(non-condensing) 10% to 90%

Altitude: Less than 2000 m

Pollution Degree: Degree 3 per EN 61010-1

(Sheltered Locations)

Noise Level: <75 dBA @ 1 meter

Chemical Resistance: Exposed material is painted aluminum,

plastic and vinyl

Compliance: 115V: conforms to UL STD 61010-1

certified to CSA C22.2 No. 61010-1

This product has been tested to the

requirements of CAN/CSA No. 61010-1,

second edition, including Amendment 1, or later

version of the same standard incorporating the

same level of testing requirements.

230V (for CE Mark):

EU Low Voltage Directive

(EN61010-1),

EU EMC Directive

(EN61326) and

EU Machinery Directive (EN809)

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 5-3Masterflex

Page 42

Section 5

Specifications

Model 77111-80

Output:

Pump Speed: 35 to 321 rpm

Torque output, maximum: 2200 oz-in (208 kg-cm)

Tubing compatibility: Sizes B/T 87 and B/T 91

Flow Range: up to 11.1 GPM (42.0 LPM)

Input:

3

Compressed air: 30 cfm (0.85 m

/min) @ 60 psig

Construction:

Dimensions (L × W × H): 27.63 in × 15.88 in × 15.13 in

701 mm × 403 mm × 384 mm

Weight: 63 lbs (28.5 kg)

Enclosure Rating: IP56 per IEC 60529

Environment:

Temperature, Operating: 1°C to 40°C (34°F to 104°F)

Temperature, Storage: –10°C to 65°C (–14°F to 149°F)

Humidity:

(non-condensing) 20% to 80%

Altitude: Less than 2000 m

North American Rating: Class I, Division 2, Groups A, B, C, & D, T6

ATEX Rating: CE II 3 G c IIC T6

Group: II (Non-mining equipment)

Category: 3 (No ignition source)

Zone: 2 (Infrequent exposure)

Type of Atmosphere: G (Gas)

Gas Group IIC (Hydrogen/Acelylene)

Method of Protection: “c” (Non-electrical equipment construction)

Temperature Classification: T6 (85°C max. surface temperature)

Noise Level: <88 dBA @ 1 meter

Chemical Resistance: Exposed materials are powder coated

aluminum, CRS, plastic, and vinyl

Compliance (for CE mark): EN809 (EU Machine Directive)

EN13463-1 and EN13463-5 (EU ATEX Directive)

5-4 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 43

Section 5

Specifications

Models 77111-30

and 77111-37

Output:

Pump Speed:

Model 77111-30 321 rpm

Model 77111-37 271 rpm

Torque output, maximum: 2200 oz-in (208 kg-cm)

Tubing compatibility: Sizes B/T 87 or B/T 91

Flow Range: Up to 11.1 GPM (42.0 LPM)

Input:

Supply voltage limits:

Model 77111-30 90 to 130 Vrms @ 60 Hz

Model 77111-37 200 to 260 Vrms @ 50 Hz

Current, max:

Model 77111-30 12.4A

Model 77111-37 6.2A

Construction:

Dimensions (L × W × H): 27.63 in × 15.88 in × 15.13 in

701 mm × 403 mm × 384 mm

Weight: 88 lbs (39.9 kg)

Enclosure Rating: IP55 per IEC 60529

Environment:

Temperature, Operating: 0°C to 40°C (32°F to 104°F)

Temperature, Storage: -10°C to 60°C (-14°F to 140°F)

Humidity:

(non-condensing) 10% to 90%

Altitude: Less than 2000 m

Pollution Degree: Degree 3 per EN 61010-1 (Sheltered Locations)

Noise Level: <75 dBA @ 1 meter

Chemical Resistance: Exposed material is painted aluminum, plastic

and vinyl

Compliance: 115V: conforms to UL STD 61010-1

certified to CSA C22.2 No. 61010-1

This product has been tested to the

requirements of CAN/CSA No. 61010-1,

second edition, including Amendment 1, or later

version of the same standard incorporating the

same level of testing requirements.

230V (for CE Mark):

EU Low Voltage Directive

(EN61010-1),

EU EMC Directive

(EN61326) and

EU Machinery Directive (EN809)

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 5-5Masterflex

Page 44

Section 5

Specifications

Models 77111-50

and 77111-55

Output:

Pump Speed: 35 to 321 rpm

Torque output, maximum: 2200 oz-in (208 kg-cm)

Tubing compatibility: Sizes B/T 87 or B/T 91

Flow Range: Up to 11.1 GPM (42.0 LPM)

Input: 1750 rpm maximum

1 hp (0.75 kW)

586 oz-in minimum

NEMA 56C motor for 77111-50 or

IEC 72 71-14F130 frame for 77111-55

Construction:

Dimensions (L × W × H): 27.63 in × 15.88 in × 15.13 in

701 mm × 403 mm × 384 mm

Weight: 63 lbs (28.5 kg)

Enclosure Rating: IP65 per IEC 60529

Environment:

Temperature, Operating: 1°C to 40°C (34°F to 104°F)

Temperature, Storage: –10°C to 65°C (–14°F to 149°F)

Humidity:

(non-condensing) 20% to 80%

Altitude: Less than 2000 m

Noise Level: <75 dBA @ 1 meter

Chemical Resistance: Exposed materials are powder coated

aluminum, CRS, plastic, and vinyl

Compliance (for CE mark): EN809 (EU Machine Directive)

5-6 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 45

Section 6 Warranty, Product Return and

Use only MASTERFLEX precision tubing with MASTERFLEX pumps to

ensure optimum performance. Use of other tubing may void applicable

warranties.

The warranty period for this product is two (2) years from date of purchase.

Technical Assistance

Warranty

This product is warranted against defects in material or workmanship, and

at the option of the manufacturer or distributor, any defective product will

be repaired or replaced at no charge, or the purchase price will be refunded

to the purchaser, provided that: (a) the warranty claim is made in writing

within the period of time specified on this warranty card, (b) proof of

purchase by bill of sale or receipted invoice is submitted concurrently with

the claim and shows that the product is within the applicable warranty

period, and (c) the purchaser complies with procedures for returns set

forth in the general terms and conditions contained in the manufacturer's

or distributor's most recent catalog.

This warranty shall not apply to: (a) defects or damage resulting from: (i)

misuse of the product, (ii) use of the product in other than its normal and

customary manner, (iii) accident or neglect, (iv) improper testing,

operation, maintenance, service, repair, installation, or storage, (v)

unauthorized alteration or modification, or (b) post-expiration dated

materials.

THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE

PURCHASER, AND THE MANUFACTURER AND DISTRIBUTOR

DISCLAIM ALL OTHER WARRANTIES, WHETHER EXPRESS,

IMPLIED, OR STATUTORY, INCLUDING WITHOUT

LIMITATION, WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. NO EMPLOYEE,

AGENT, OR REPRESENTATIVE OF THE MANUFACTURER OR

DISTRIBUTOR IS AUTHORIZED TO BIND THE

MANUFACTURER OR DISTRIBUTOR TO ANY OTHER

WARRANTY. IN NO EVENT SHALL THE MANUFACTURER OR

DISTRIBUTOR BE LIABLE FOR INCIDENTAL, INDIRECT,

SPECIAL OR CONSEQUENTIAL DAMAGES.

B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual 6-1Masterflex

Page 46

Section 6

Warranty

Product Return

Technical Assistance

To limit charges and delays, contact the Manufacturer or authorized seller

for authorization and shipping instructions before returning the product,

either within or outside of the warranty period. When returning the

product, please state the reason for the return. For your protection, pack

the product carefully and insure it against possible damage or loss. Any

damages resulting from improper packaging are your responsibility.

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

6-2 B/T®RAPID-LOAD®Peristaltic Pumps and Drive Operating Manual Masterflex

Page 47

Page 48

US & Canada only

®

Toll Free 1-800-MASTERFLEX | 1-800-637-3739

Outside US & Canada

1-847-549-7600 | 1-847-381-7050

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue, Barrington, IL 60010

techinfo@masterflex.com | www.masterflex.com

Loading...

Loading...