Page 1

Color profile: Disabled

Composite Default screen

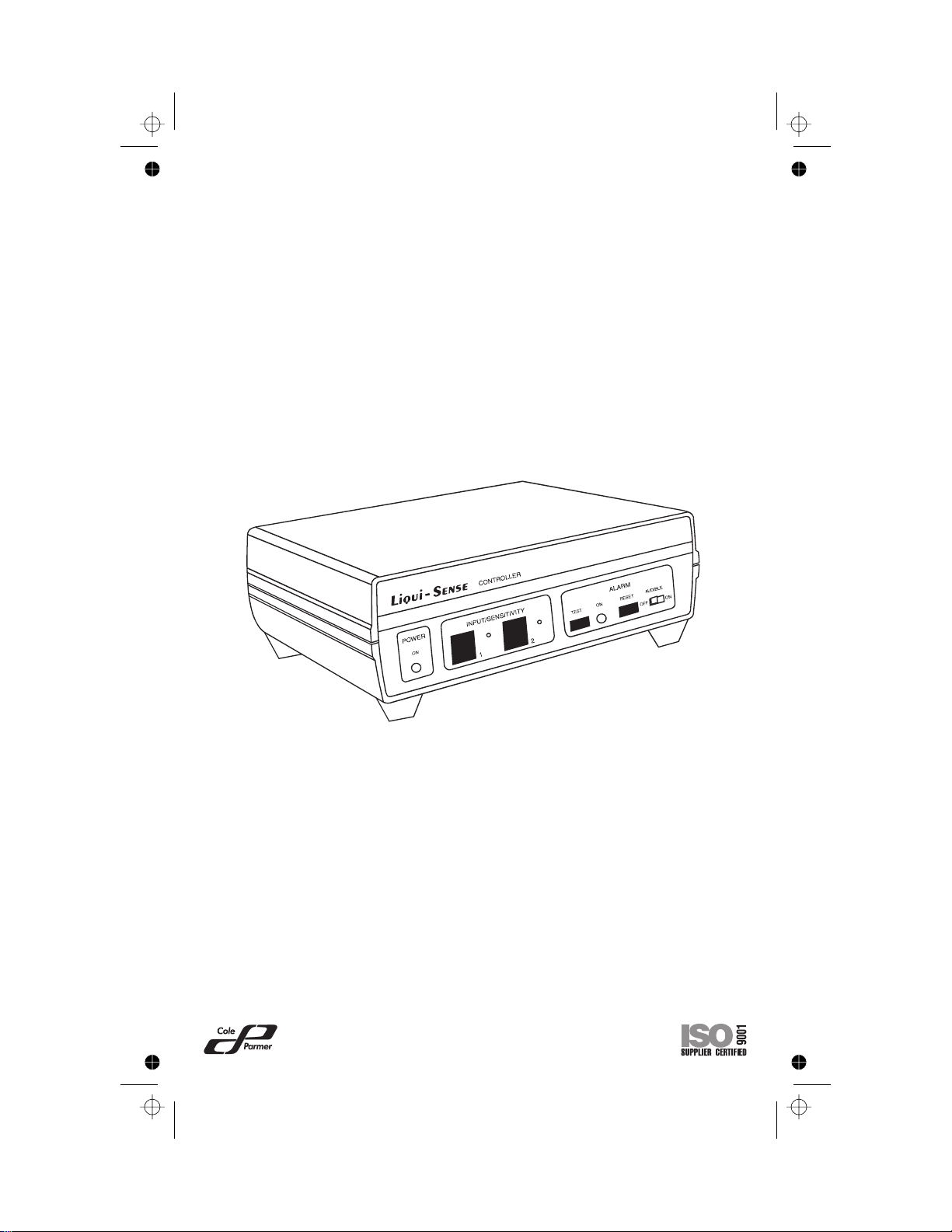

OPERATING MANUAL

LIQUI-SENSE®CONTROLLERS

MODEL NO. 77096-00

MODEL NO. 77096-05

AND

LIQUI-SENSE®DETECTORS

MODEL NO. 77095-00

MODEL NO. 77095-01

®

ek91.chp

Tue Sep 26 14:32:38 2000

Cole-Parmer Instrument Co.

625 East Bunker Court

Vernon Hills, Illinois U.S.A.60061-1844

(847) 549-7600

(847) 247-2929 (fax)

800-323-4340

www.coleparmer.com

e-mail: techinfo@coleparmer .com

A-1299-0512

Edition 03

Page 2

Color profile: Disabled

Composite Default screen

EU Declaration of Conformity

Name of Apparatus: Liqui-Sense®Controller

Model Numbers: 77096-05

Description of Apparatus: Fluid Monitor System

Barnant Company declares that the above model is in conformity to the following

harmonized standards and directives:

Applicable

Directives

73/23/EEC

93/68/EEC

89/336/EEC

92/31/EEC

93/68/EEC

The last two digitsofthe year in whichthe current configurationof the above models

was assessed per the Low Voltage Directive is:00.

Manufacturer:

Barnant Company Division

Cole-ParmerInstrument Company

28W092 Commercial Avenue

Barrington,IL 60010

USA

Tel.: 847-381-7050

Manufacturer’s Signature:

_________________________ _______________________

JamesW. Doll Date

Vice President, Engineering

Applicable

Specifications

EN61010-1/A2:1995 TR9516

EN61326-1/A1:1998 TR9519

Manufacturer’s

Report Number

22 August, 2000

SAFETY PRECAUTIONS

WARNINGS:

WARNING:

CAUTION:

If the equipment is used in a manner other than as

specified, pr otection provided by the equipment may be

impaired.

No user serviceable parts are inside of this Controller.

Refer servicing to your dealer.

TheLIQUI-SENSE Controllermustbe positioned soleaking liquid will not enter the rear power connectors. Use

of a power line with a Ground Fault Interrupt (GFI) is

recommended.

Use with caustic liquids not compatible with detector

materials voids warranty.

ek91.chp

Tue Sep 26 14:32:39 2000

–i–

Page 3

Color profile: Disabled

Composite Default screen

TABLE OF CONTENTS

Title Page

SAFETYPRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DESCRIPTION .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 6

INSTALLATION AND SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operator Control and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

SENSITIVITY ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MAINTENANCE ANDTROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . 17

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

WARRANTY . ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 21

PRODUCT RETURN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TECHNICAL ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

APPENDIX A: AUXILIARY CABLE CONNECTIONS . . . . . . . . . . . . . 22

Only the Model 77096-00 LIQUI-SENSE Controller is UL and cUL listed.

Trademarksbearing the ® symbol in this publication are registered in the U.S.and in other countries.

–1–

ek91.chp

Tue Sep 26 14:32:40 2000

Page 4

Color profile: Disabled

Composite Default screen

INTRODUCTION

The LIQUI-SENSE Controller is a two-channel alarm system used to sense

liquid leaks using a specially designed detector or used with other liquid

detectors such as high or low liquid level detectors. The Model 77096-00

LIQUI-SENSE Controller operates from 115V AC and the Model 77096-05

operatesfrom230VAC.Whenanalarm condition issensed on eitherchannel,

the LIQUI-SENSE Controller can perform the following actions:

• Disconnect power to a pump drive.

• Activate an auxiliary pump drive to resume pumping through a second

pump drive.

• Activate the front panel red ALARM ON indicator .

• Sound an audible alarm if the audiblealarm is enabled.

• Provide a contact closure output that can be used to activate an

Environment Monitor for automatically telephoning the user of the f ailure ,

or to activate any other device that operates from a contact closure input.

The contact closure may also be used to operate shut-off or switchable

valves to redirect flow.

The LIQUI-SENSE Detector Model 77095-00 (detector with cable) or Model

77095-01 (detector without cable) is used to sense leaks in pump heads

resultingfrom ruptures of thetubing.This detectoris notsuppliedwith theunit

and must be ordered separately. (See ACCESSORIES.)

ek91.chp

Tue Sep 26 14:32:41 2000

–2–

Page 5

Color profile: Disabled

Composite Default screen

APPLICATIONS

The LIQUI-SENSE Controller and LIQUI-SENSE Detector can be used with

a wide variety of different pump systems for leak detection. The alarm

controller has two inputs. These can both be used with LIQUI-SENSE

Detectors, or one input can be used with a LIQUI-SENSE Detector and the

second inputused with other typedetectors such asa liquidleveldetector for

determininghigh orlowlevelsina container.Figures 1through5show various

suggested detector arrangements in different pump systems. Tubing is

omitted for clarity.

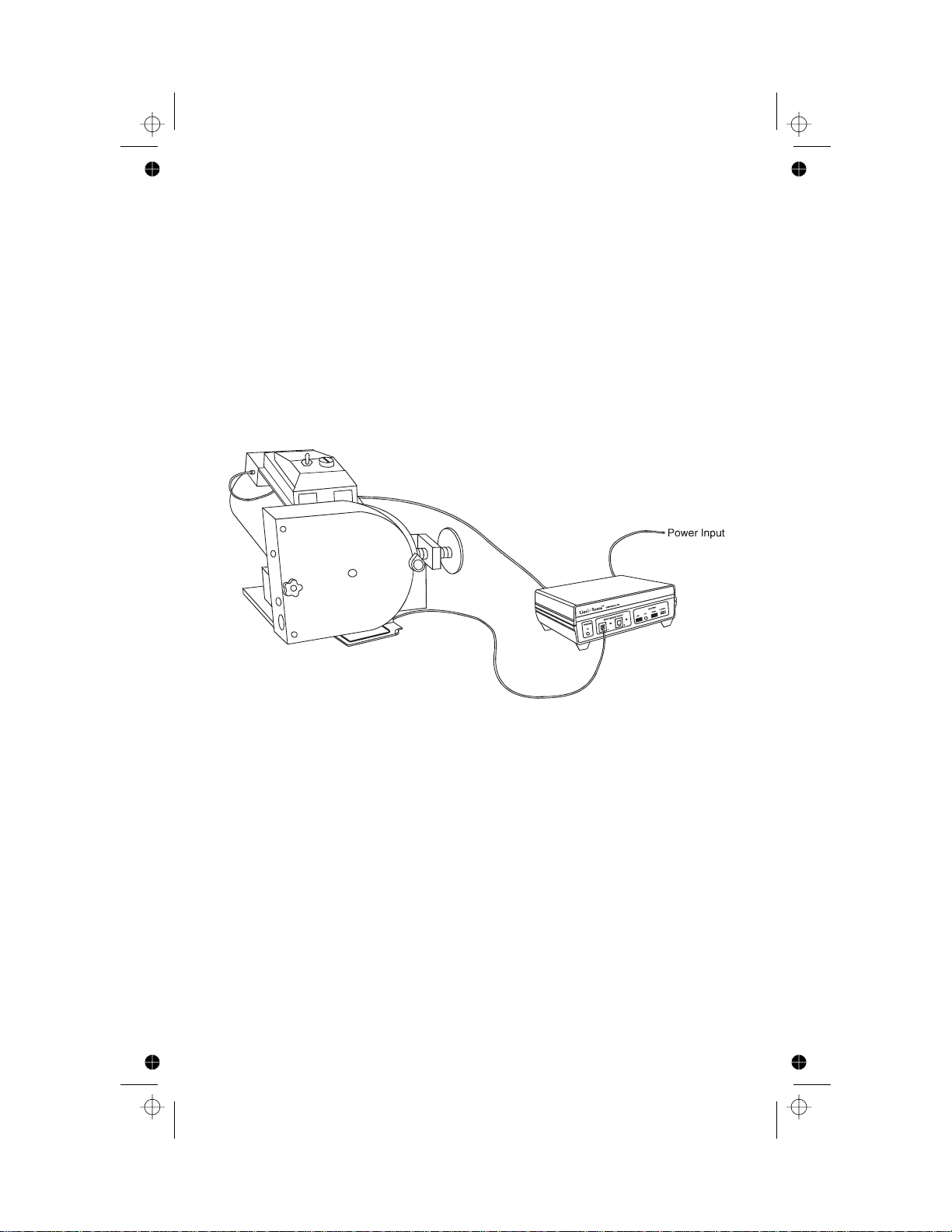

Figure 1. Typical B/T®RAPID-LOAD®Pump with LIQUI-SENSE Detector

positioned under open side of pump

–3–

ek91.chp

Tue Sep 26 14:32:43 2000

Page 6

Color profile: Disabled

Composite Default screen

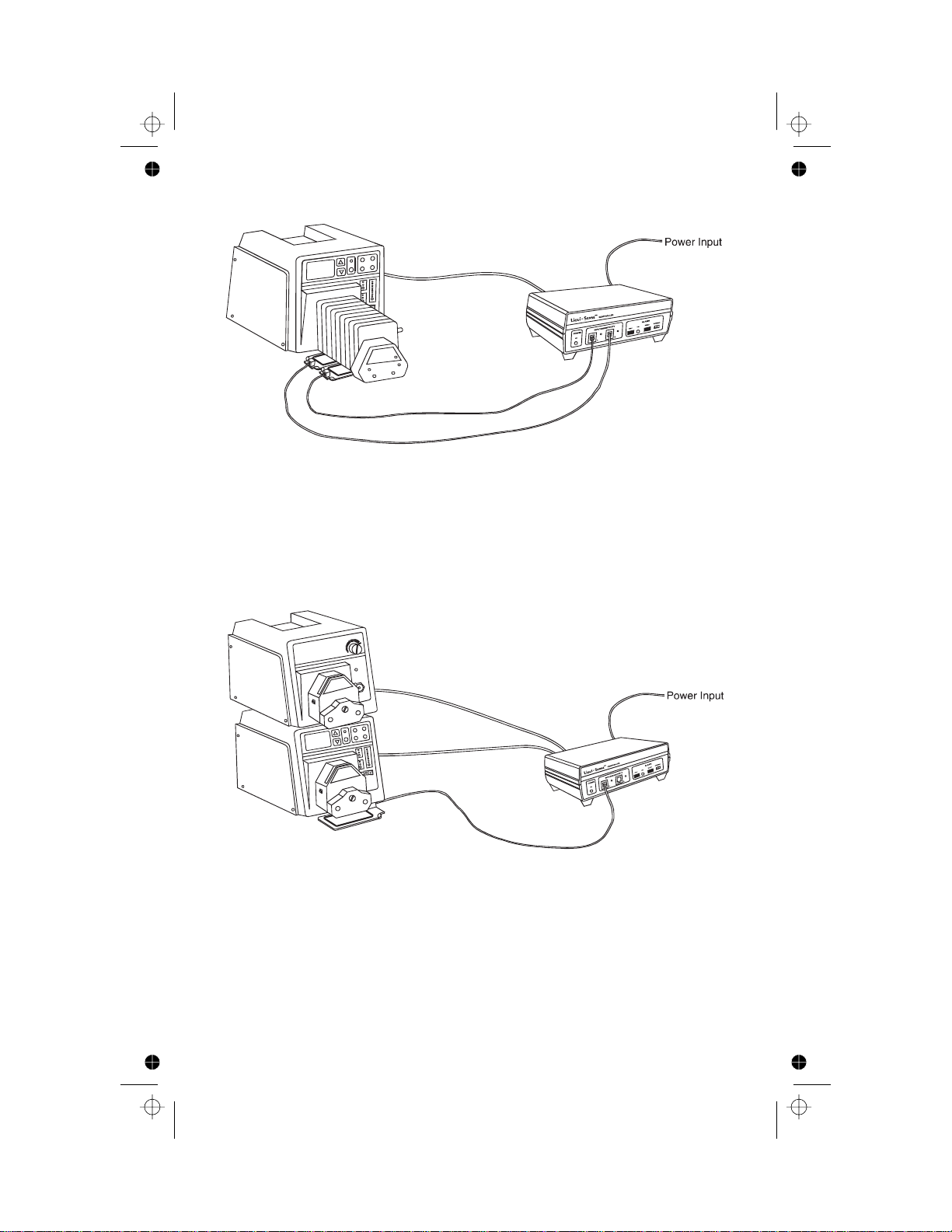

Figure 2. Typical L/S®CartridgePump with two LIQUI-SENSE Detectors

centered under the group of cartridges

Figure 3. Typical L/S EASY-LOAD®Pump with LIQUI-SENSE Detector

positioned under main pump,auxiliary pump mounted on top

of main pump and both pumps connected to Alarm Controller

for automatic swi tch over when a leak is detected

–4–

ek91.chp

Tue Sep 26 14:32:48 2000

Page 7

Color profile: Disabled

Composite Default screen

Figure 4. Typical I/P®EASY-LOAD Pump with LIQUI-SENSE Detector

centered under the pump and a level detector connected to the

second input of the Alarm Controller

Figure 5. Standard Stacked Pump System with two LIQUI-SENSE

ek91.chp

Tue Sep 26 14:32:53 2000

Detectors positioned for optimum leak detection

–5–

Page 8

Color profile: Disabled

Composite Default screen

DESCRIPTION

The LIQUI-SENSE Controller, shown in Figure 6, is used to monitor various

liquid detector devices. When an alarm condition is detected, the controller

deactivates the rear panel MAIN OUTPUT power connector and supplies

power to the AUXILIARY OUTPUT power connector .Also, when the alarm

condition is detected, a contact closure output is provided at the rear panel

CONTACT CLOSURE OUTPUT connector (a 1/8-inch phone-type

connector) for activating remote devices such as an Environment Monitor or

a second pump drive. The fault condition is indicated by a red ALARM ON

indicator on the front panel and by an audible alarm (unless the ALARM

AUDIBLE switchhas been set to OFF).

Figure6. LIQUI-SENSE Controller (Alarm Module)

The MAIN and AUXILIARY connectors, shown in Figures 7 and 8, are used

to connect to external devices such as pumps. The pump connected to the

MAIN OUTPUTconnector willoperate whenno alarmcondition exists.When

an alarm condition is detected, power to the MAIN OUTPUT connector is

turned off and power isapplied tothe AUXILIARY OUTPUT connector.Thus,

if nopump is connectedto the AUXILIARY OUTPUTconnector, pumpingwill

cease. If a pump is connected to the AUXILIARY OUTPUT connector, that

pump will be turned on. The switch over occurs within one second after

detection of an alarm condition.

–6–

ek91.chp

Tue Sep 26 14:32:56 2000

Page 9

Color profile: Disabled

Composite Default screen

Figure7. RearPanelModel 77096-00 (115VAC)

Figure8. RearPanelModel 77096-05 (230VAC)

Poweris applied to the unit through a permanently attached line cord on the

115V AC model and through an IEC 320/CEE 22 connector coupler (female

line cord/male socket) on the 230V AC units. A number of accessory input

and output power cords are av ai lab l e .(See ACCESSORIES.) The power is

controlled by the rear panel OFF-ON switch.Power-onis indicated by a front

panel green POWER ON indicator.

The CONTACT CLOSURE OUTPUT connector (rear panel) provides a

latched contact closure output, rated 30V DC at 1 ampere max., when an

alarm conditionis detected.This output can be connectedto an Environment

Monitor,which thencan telephonethe userto signalthe alarm condition.This

output can also be connected to any device that operates from a contact

closure condition, such as a warning system. An accessory cable is listed in

the ACCESSORIES Section.

–7–

ek91.chp

Tue Sep 26 14:33:03 2000

Page 10

Color profile: Disabled

Composite Default screen

The locking modular INPUT connectors (front panel) connect to external

detectors. Each input has a SENSITIVITY adjustment that is used only with

the LIQUI-SENSE Detectors. The sensitivity is factory set so that when the

detector is placed within one inch of the pump, less than one mL of

water-based liquid will trigger the detector. For other types of liquids, or to

change the sensitivity level, refer to the SENSITIVITY ADJUSTMENT

Section. Sensitivity adjustment may be required when operating with cables

longer than 3-1/2 feet or in a high-temperature, high-humidity environment.

TheLIQUI-SENSE Controllerishoused ina slate grayABSplastic enclosure,

with aluminumfront andrear panels.Theunit can beplaced ona flatsurface,

on asupport platformor on thetop surface ofsome MASTERFLEX

type pumps.

TheLIQUI-SENSE DetectorModel 77095-00(with cable)orModel 77095-01

(without cable), Figure 9, operates on a capacitance change principle. The

detectoris designedtobe placedunderthe pump.Ifa leakoccursin thepump

tubing, the liquid will fall on the top surface of the detector. When sufficient

surface area is moistened (less than 1 mL of water-based liquid when using

the factory sensitivity setting), the change in capacitance is sufficient to

activatethealarmcircuits.Thedetectorhas a lockingmodulartypeconnector.

The cable between the detector and the controller is 3-1/2 feet long with

modularlocking connectorson bothends.Ten-foot andfifteen-footaccessory

cablesare available.Refer toAPPENDIX Aforpinconfiguration forthecables

when connecting other detector types.

®

or other

Figure9. LIQUI-SENSE Detector Model 77095-01

A four-inch hook-and-loop fabric fastener strip allows for attachment of the

detector pad to a flat surface to prevent the detector pad from moving. The

detectorpad canalsobe permanentlymounted byattachingit to aflatsurface

with two #4 screws.The screw locations at the corners of the detector pad

are indicated by two circular markers. The detector structure will need to be

punctured by the screw for permanent attachment.

–8–

ek91.chp

Tue Sep 26 14:33:04 2000

Page 11

Color profile: Disabled

Composite Default screen

INSTALLATION AND SETUP

NOTE: Retain all packing materials until proper operationhas been verified.

WARNING:

Proceed as follows to setup the LIQUI-SENSE Controller:

1. Place the rear panel power OFF-ON switchin the OFF position.

NOTE: For 115V AC pump models, the pump power cord will plug directly

2. Connect pumps as follows:

a. If a main pump and a standby (auxiliary) pump are to be used,

TheLIQUI-SENSE Controllermustbe positioned soleaking

liquid will not enter the rear power connectors. Use of a

power line with a Ground Fault Interrupt (GFI) is recommended.

into the MAIN OUTPUT or AUXILIARYOUTPUT connectors on the

rearpanel ofthe LIQUI-SENSEController.For 230VACmodels, use

pump cable77096-50 forpumps withEuropean connectorsor pump

cable 77096-55 forpumps with other style connectors.

connect themain pumpto the MAINOUTPUT connector onthe rear

panel and connect the standby (auxiliary pump) to the AUXILIARY

OUTPUT connector.

b. If only the main pump is to be used with no standby, and the pump

is to shut down when an alarm condition exists, connect the main

pump to the MAIN OUTPUT connector. The AUXILIARY OUTPUT

connector can beused topower otherdevicessuch aslights, remote

alarms or other equipment.

c. If only the main pump is to be used with no standby, and the pump

isnot toshut downwhen analarm condition exists, connectthe main

pump to a separate power source. The MAIN OUTPUT connector

and the AUXILIARYOUTPUT connectorcan beused topower other

devices such as lights, remote alarms or other equipment.

3. Connect one end of the detector cable(s) to the front panel INPUT

connector(s) and the other end to the desired detector(s). Only one

detector canbe connectedto eachINPUT connector.Detectors mustbe

connected using a cable configured as shown in APPENDIX A. Make

surecable connectionsaresecure orunitwill notfunction pr operly.

4. The LIQUI-SENSE Detector mustbe positioned under the pump so that

anyleakage willdriponto thedetector padtarget area (areaoutlined with

the black lines). The detector can be secured in place using

hook-and-loop fabric fasteners or can be permanently fastened with #4

screws.Two circular marksare located onthe outer edgeof the detector

–9–

ek91.chp

Tue Sep 26 14:33:05 2000

Page 12

Color profile: Disabled

Composite Default screen

for position ofscrews.Do not insert screws in any other location on the

detector pads.The locationof the detector forvarious typical pumpsare

as follows:

a. Foratypical B/TRAPID-FLOW pump, the detectorshouldbe located

directly under the opening at the right side of the pump as shown in

Figure 10.

Figure10.Positioning a LIQUI-SENSEDetector

under a B/T RAPID-FLOW Pump

b. For typical L/S Cartridge pumps, the detector should be centered

under the group of cartridges. For large numbers of cartridges, use

two detectors as shown in Figure 11.

Figure11. Positioning LIQUI-SENSEDetectors

under an L/S CartridgePump

ek91.chp

Tue Sep 26 14:33:07 2000

–10–

Page 13

Color profile: Disabled

Composite Default screen

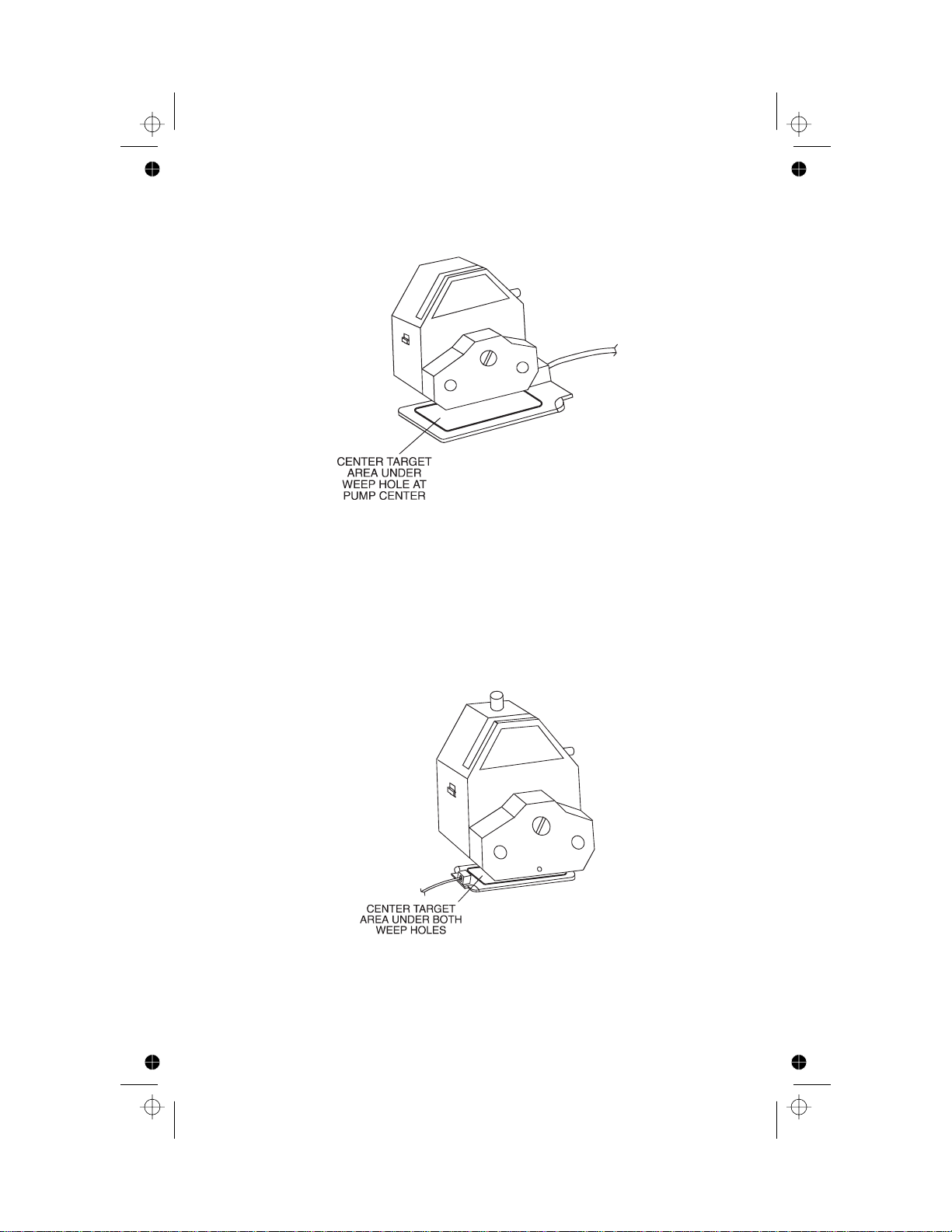

c. For typicalL/S EASY-LOAD pumps,the detector shouldbe centered

directly under the weep hole as shown in Figure 12.

Figure 12. Positioninga LIQUI-SENSE Detector under an

L/S EASY-LOAD Pump

d. FortypicalI/PEASY-LOADpumps,twoweepholesare located under

the pump. A single detector can be centered under the weep holes

as shown in Figure 13. For better reliability, two separate detectors

can be used with one centered under each weep hole as shown in

Figure 14.

Figure 13. Positioning a single LIQUI-SENSE Detector under an

I/P EASY-LOAD Pump

ek91.chp

Tue Sep 26 14:33:09 2000

–11–

Page 14

Color profile: Disabled

Composite Default screen

Figure 14. Positioningtwo LIQUI-SENSE Detectors under an

e. For typical standard stacked pumps where only one or two pumps

areused,asingledetectorcanbecenteredunderthestackofpumps.

When a larger number of pumps are used, two detectors should be

positioned to assure optimumleak detection as shown in Figure15.

I/P EASY-LOAD Pump

Figure 15. Positioning two LIQUI-SENSE Detectors under a

ek91.chp

Tue Sep 26 14:33:11 2000

stack of Standard Pumps

–12–

Page 15

Color profile: Disabled

Composite Default screen

5. If an Environment Monitor (such as a COLE-PARMER Model 08330) is

to be used or if another external device requiring a contact closure to

activateitis tobeused, connectthe1/8-inch phonecableconnectorfrom

therear panelCONTACTCLOSURE OUTPUTconnector totheexternal

device.

6. Connect the LIQUI-SENSE Controller POWER INPUT cord as follows:

a. For 115V AC unit, connect line cord to 115V AC 50/60 Hz power

source.

b. For230V ACunit, connectpower cablebetween rearpanel POWER

INPUT connector and 230V AC 50/60 Hz power source.

This completes the electrical connectors. Proceed with the OPERATION

Section.

OPERATION

OperatorControls and Indicators

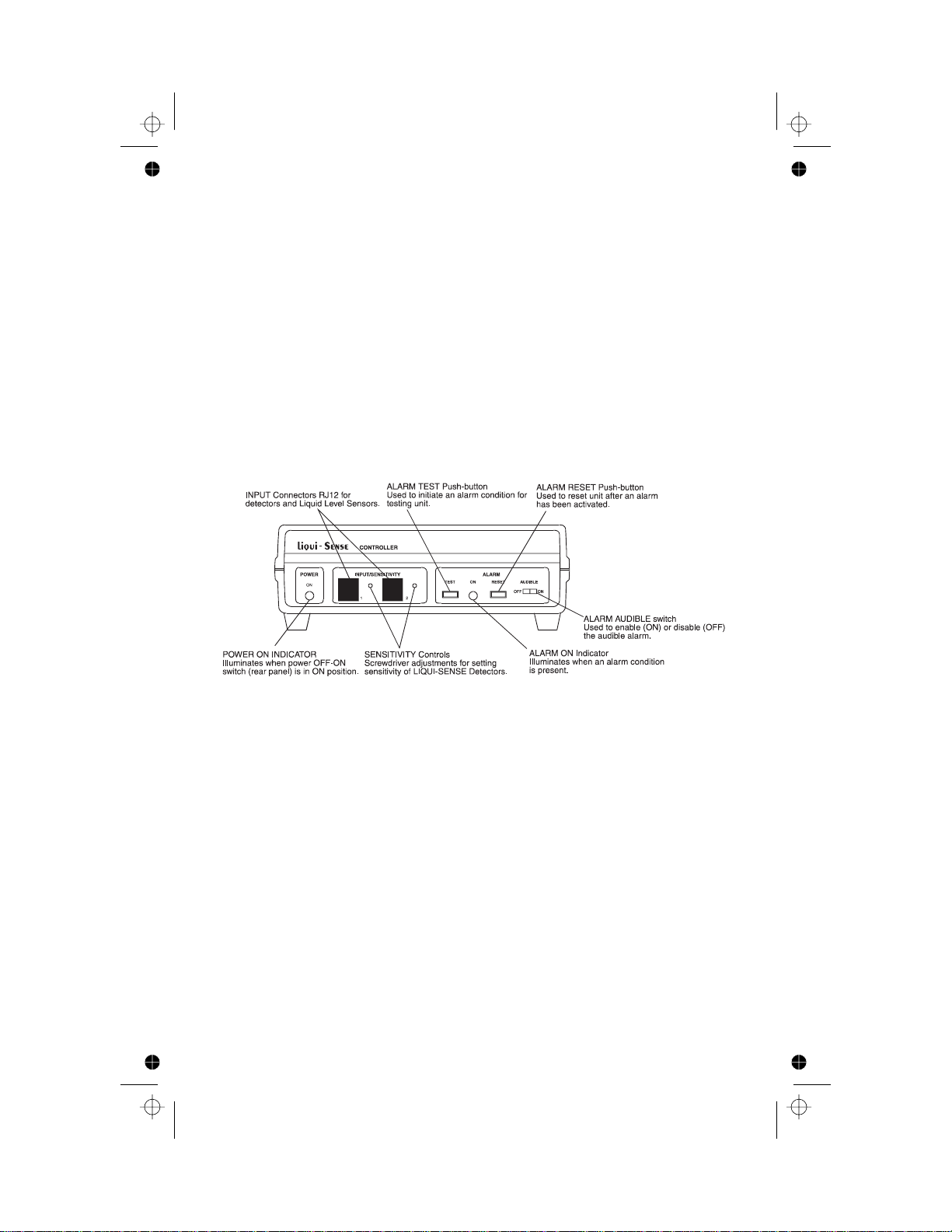

Alloperator controlsexceptthe powerOFF-ONswitchare locatedonthe front

panel as shown in Figure 16. These controls and indicatorsare as follows:

POWER ON Indicator Green LED illuminates when power

OFF-ONswitchis in theON position and

input power is present.

SENSITIVITY Controls Adjusts the sensitivity of the circuit for use

with the LIQUI-SENSE Detectors.(Pre-set

at factory for typical applications.)

ALARM TEST Momentary push-button.Tests the audible

alarm, the visual alarm, the switching of AC

power from the rear panel MAIN OUTPUT

to the AUXILIARY OUTPUT connectors and

the contact closure at the rear panel

CONTACT CLOSURE OUTPUT connector.

Theseare activated while the button is

pushed and reset automatically upon

release.

ALARM ON Indicator Red LED illuminates when an alarm

condition is present.

ek91.chp

Tue Sep 26 14:33:12 2000

–13–

Page 16

Color profile: Disabled

Composite Default screen

ALARM RESET Momentary push-button.Resets alarm

circuits afteralarm condition is removed

(detector pad wiped clean, tank filled, etc.).

Whilepush-button is held in, thesystem

reverts to the non-alarm condition.If the

alarm condition is not cleared when the

ALARM RESET switch is released, the unit

will go back into the alarm condition.It may

be convenient to hold in the ALARM

RESET button while priming or purging the

system when a leveldetector is used.

ALARM AUDIBLE

OFF-ONSwitch

In the OFF position, the audible alarm will

not sound during an alarm condition.In the

ON position, the audible alarm will sound

during an alarm condition.

PowerOFF-ON Rocker type switch located on rear panel.

Disconnects all AC powerfrom unit and

from equipment connected to the MAIN

OUTPUTor AUXILIARYOUTPUT

connectors.

Figure 16. LIQUI-SENSE Controller Front Panel

ek91.chp

Tue Sep 26 14:33:14 2000

–14–

Page 17

Color profile: Disabled

Composite Default screen

Startup Procedure

1. Check that all connections have been made as described in the

INSTALLATION Section.

2. Check that detectors are connected and properly positioned. Only one

detector can be connected to each channel. Use hook-and-loop fabric

fasteners to secure detector in position or, if permanent mounting is

desired, detector can be attached with #4 screws as described in the

INSTALLATION Section.

NOTE: Tubing may break at locations other than expected.Using a second

detector can provide for better detection.

3. If theaudible alarm isto operate, set ALARMAUDIBLE switchto theON

position. If no audible alarm is desired, place ALARM AUDIBLE switch

in the OFF position.

4. Set rear panel power OFF-ON switch to the ON position and check that

the front panel green POWER ON indicator is lit. The equipment should

now be operating normally.

5. Ifan alarmconditionexists,proceed totheSENSITIVITY ADJUSTMENT

Section. If level detectors are used, they may need to be inverted or

rotated 180° forproper operation.The audiblealarm canbe turned offby

placing the ALARM AUDIBLE s witchin the OFF position.

6. Perform the LIQUI-SENSE DetectorSensitivity Checkusing dropsof the

same liquid used in your application.

Operational Checks

LIQUI-SENSE CONTROLLER

Anoperational checkofthe LIQUI-SENSEController canbe performed using

theALARMTESTswitch.This testshouldbeperformedonlywhen temporary

transfer of power from the MAIN OUTPUT connector to the AUXILIARY

OUTPUT connector will not be disruptive.

Proceed as follows:

1. Set the ALARM AUDIBLE switch to ON for the audible alarm to be

activated or to OFF to deactivate the audible alarm.

2. Set power OFF-ON switch to ON position and check that POWER ON

indicator is illuminated.

3. Pressand holdtheALARM TESTSWITCH.Checkthatthe audiblealarm

sounds (if activated), the ALARM ON indicator isilluminated, that power

shifts from the MAIN OUTPUT connector to the AUXILIARY OUTPUT

connector and that the CONTACT CLOSURE OUTPUT activates any

equipment connected to the output.

–15–

ek91.chp

Tue Sep 26 14:33:15 2000

Page 18

Color profile: Disabled

Composite Default screen

LIQUI-SENSE DETECTOR SENSITIVITY CHECK

The LIQUI-SENSE Detector sensitivitymay be checkedas follows:

1. Connect detector to one of the front panel INPUT connectors, if not

already connected.

2. Place water one drop at a time on the detector pad. Do not drop water

from more than one inch.

3. Check numberofdrops requiredto activate alarm.Pre-setfactory setting

should activate alarm with less than 1 mL of liquid. If activation level is

not as desired, refer to SENSITIVITY ADJUSTMENT Section.

4. Afteractivatingalarm,momentarilypressthenreleasetheRESETbutton.

Alarm condition should still be present.

5. Wipe detectorsurfaceclean withadry cloth andmomentarily press,then

release, the RESET button. Alarm condition should terminate, ALARM

ON indicator should extinguish and, if activated, audible alarm should

turn off.

SENSITIVITY ADJUSTMENT

Generally, no sensitivity adjustment of the LIQUI-SENSE Controller is

required. However, various liquids or environmental conditions such as

temperature and humidity may require adjustment of the SENSITIVITY

controls for use with the LIQUI-SENSE Detectors. The SENSITIVITY

adjustment is accessed through the small hole adjacent to each INPUT

connector.Contact closure or logic level detectors do not requireadjustment

of theSENSITIVITYcontrol.

If the factory default setting for sensitivity is not activating the alarm, or is

falsely activating the alarm for the liquid being sensed, adjust the input

sensitivity with one channel connected at a time. Turn the SENSITIVITY

control clockwise to increase sensitivity (fewer drops will activate) or

counterclockwise to decrease sensitivity.

NOTE: If the sensitivity is increased so much that the red ALARM ON

indicator illuminates, the RESET button must be depressed each

time sensitivity is decreased until the indicator extingui shes.

Normal sensitivity adjustment is between one-quarter and two turns

counterclockwise from the activation point.The activation point is defined as

that sensitivity set when ALARM ON indicatorjust illuminates.Refer to Table

1fortypicalsensitivitysettings f orvarious liquids.Themiddlecolumnindicates

the number of turns counterclockwise from the activation point that the

–16–

ek91.chp

Tue Sep 26 14:33:16 2000

Page 19

Color profile: Disabled

Composite Default screen

sensitivitycontrolshouldbeset f orproper operation.Thelastcolumnindicates

the quantity of fluid required in the target area of the detector to activate the

detector.

Sensitivity will change with detector position or when used near metallic

objects (e.g., table). Also, sensitivity changes when using longer (optional)

cables.

CAUTION:

Use with caustic liquids not compatible with detector materials voids warranty.

Table 1.Typical Sensitivity Settings

Setting (Turns ccw

FluidType

Distilled Water 11⁄

Tap W at er 11⁄

Acetic Acid (10% max.) 11⁄

Alcohols 11⁄

Glycerin 11⁄

10W Motor Oil

fromactivation point) NominalVolume

2

2

2

2

2

1

⁄

2

<1mL

<1mL

<0.5mL

<0.5mL

<2.0mL

<2.0mL

MAINTENANCE ANDTROUBLESHOOTING

WARNING:

Fuse Replacement

The 115V AC LIQUI-SENSE Controller uses a 10-A Slo-Blo fuse (3AG, part

number B-1115-0052), which is located in the fuse holder on the rear panel.

The 230V AC LIQUI-SENSE Controller uses a 6.3-A fuse (5 x 20 mm, part

number B-1115-0054), which is located inthe drawer in the POWER INPUT

connector on the rear panel.Replace only with the correct fuse.

Cleaning

Clean the topsurfaceof thedetector padwith asoft, dry cloth.If liquidcleaner

is used, rinse and dry thoroughly before resuming operation. Keep the

LIQUI-SENSE Controller enclosure clean by using a mild detergent. Never

immerse or use excess fluid.

Nouserserviceable partsareinside of thisController.Refer

servicing to your dealer.

–17–

ek91.chp

Tue Sep 26 14:33:17 2000

Page 20

Color profile: Disabled

Composite Default screen

Troubleshooting

The following chart will help identify most problems that can be corrected by

the operator.If the faultcannot be located, return unit for servicing.

Troubleshooting Chart

SYMPTOM CAUSE REMEDY

POWERON indicator

does not illuminate

with PowerOFF-ON

switch in ON position

ALARM LIGHT

illuminates but

audible alarm does

not sound

Alarm does not

activate for a fault

condition

RESET button does

not reset unit when

depressed

Alarm activated but

pump continues to

operate

Alarm activated but

auxiliary pump does

not turn on

Fuse blown Replace fuse

Powercord not

Plug in power cord

plugged into active

power source

ALARM AUDIBLE

switch not set to ON

Set switch toON

position

position

Detector not connected Connect detector

Sensitivity set too low Increase sensitivity

(LIQUI-SENSE

Detector only)

Detector cable

Replace cable

defective

Detector inoperative Replace detector

Faultnot cleared Clear fault

Sensitivity settoo

high

Lower sensitivity

(LIQUI-SENSE

Detector only)

RESET button failure Return unit forservicing

Pump not connected

to MAINOUTPUT

but directly to a

power source

Auxiliary Pump not

connected to

AUXILIARY OUTPUT

Connect pump to MAIN

OUTPUTfor shutdown

when an alarm

condition is sensed.

Connect auxiliary pump

to AUXILIARY

OUTPUT

ek91.chp

Tue Sep 26 14:33:17 2000

–18–

Page 21

Color profile: Disabled

Composite Default screen

ACCESSORIES

Theaccessories andservice parts listedbelowareavailablefromyourdealer.

Part Name Part Number

LIQUI-SENSE Detector Pad and 3.5 ft Cable 77095-00

LIQUI-SENSE Detector Pad 77095-01

Cable, Detector Pad, 3.5 ft 77095-02

Cable, Detector Pad, 10 ft 77095-03

Cable, Detector Pad, 15 ft 77095-04

IEC320M/IEC320F Pump power

cable (connects modular plug

to LIQUI-SENSE Controller) 77096-50

IEC320F/F Pump power cable

(connects European plug

to LIQUI-SENSE Controller) 77096-55

Cable with 1/8-inch phone plug 23000-70

Out-of-Liquid Detector 77095-50

PowerCords for 230V AC Controllers

European (standard) 50001-70

British 50001-72

Swiss 50001-74

Italian 50001-76

NEMA Type 6-15P 50001-78

Fuse

115V: 10A, 250V, SLO-BLO, 3AG B-1115-0052

230V: T6.3A, 250V, 5220mm B-1115-0054

ek91.chp

Tue Sep 26 14:33:18 2000

–19–

Page 22

Color profile: Disabled

Composite Default screen

SPECIFICATIONS

Output:

Contact Closure Output Rating: 30V DC—1 Ampere Maximum

AudibleAlarm Sound Level: 90 dBA

Input:

Line Voltage Limits

(115V AC Controller): 102–132V AC 50/60 Hz Single Phase*

(230V AC Controller): 190–260V AC 50/60 Hz Single Phase

PowerDissipation: 1.2 kVA maximum

AC Line Current: 10 A max at 115V A C

6.3 A max at 230V AC

Installation Category: Installation Category II per IEC 664

(Local level —appliances,portable

equipment, etc.)

Construction:

Controller Dimensions: 3 in H 2 8.1in W 2 6.3 in D

LIQUI-SENSE

Detector Dimensions: 5.0 in 2 2.6 in

Weight: 3 lbs

Detector Cable Length: 3.5 feet (others av ai lab l e)

Enclosure Rating: IP22 per IEC 529

Environment:

Operating Temperature Range: 0°C(32°F) to 40°C (104°F)

Storage Temperature: −45°C(−49°F) to 65°C (149°F)

Humidity (non-condensing): 10 to 85%

Barometric Pressure: 75 to 106 kPa

Altitude: less than 2000 m

PollutionDegree: Pollution Degree 2 per IEC 664

(Indoor Usage—lab, office)

Chemical Resistance:

LIQUI-SENSE Controller: All materials withstand common

cleaning solvents.Construction

materials used are polyester

labels, ABS plastic enclosure and

zinc-plated screws.

LIQUI-SENSE Detector: Top layer — Flat polyester attached

with polyester laminate.

Bottom layer — Polyester attached

with polyester laminate.

Connector is ABS plastic.

Compliance: 115V:UL508, CSA C22.2, No.14-M91

230V (For CE Mark):

EN61010-1/A2: 1995

(EU Low Voltage Directive) and

EN61326-1/A1: 1998 (EU EMC Directive)

Unitoperating voltage rangeas tested byUnderwritersLaboratories.This unit hasbeen designedand testedby the

*

manufacturer foran extendedoperatingvoltage rangeof 90–132VAC.

ek91.chp

Tue Sep 26 14:33:19 2000

–20–

Page 23

Color profile: Disabled

Composite Default screen

W ARRANTY

The Manufacturerwarrants this product to be freefrom significant deviations

from published specifications.If repair or adjustment is necessary within the

warranty period, the problem will be corrected at no charge if it is not due to

misuse or abuse on your part, as determined by the Manufacturer. Repair

costs outside the warranty period, or those resulting from product misuse or

abuse, maybe invoiced to you.

The warranty period for this product is noted on the Warranty Card.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for

authorization and shipping instructions before returning the product, either

within or outside of the warranty period. When returning the product, please

state thereason for thereturn. For your protection, packthe productcarefully

and insure it against possible damage or loss. Any damages resulting from

improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

We reserve the right to make improvements in design, construction and

appearance of our products without notice.

ek91.chp

Tue Sep 26 14:33:20 2000

–21–

Page 24

Color profile: Disabled

Composite Default screen

APPENDIX A

AUXILIARY CABLE CONNECTIONS

Each Cable Assembly is 3-1/2 feet long and is composed of a 6-conductor

shielded flat cable with PVC jacket. Ten-foot and fifteen-foot cables are also

available. Six pin modular plugs are attached at each end. Refer to the

following chart for pin output:

Pin Signal Color

1Ground Black

2 Contact Closure or Logic Low

Input

3 12V DC Red

4 Capacitive Plate Input Green

5 Capacitive Plate Input Brown

6 Shield Guard BareTin

White

For level detector (sensors) connections,cut off one endof the sixconductor

flat cable, or cut the cable in half, if using longer cables, to make two pieces.

Strip the shield (metal) and plastic jacket back two inches.Spread the wires.

Strip back one inch of the black wire, pin 1, and white wire, pin 2. Fold the

other wires back along the plastic jacket and tape or cut off as desired.Twist

one lead of the level detector to t he black lead of the cable, pin 1, and twist

the otherlead of theleveldetector to thewhite lead ofthe cable,pin 2.Solder

the two connections together or use a wire nut if possible. Tape around

exposed bare wire areas.

FigureA-1. Level Sensor Connections

Printed in U.S.A.

030800

–22–

ek91.chp

Tue Sep 26 14:33:21 2000

Loading...

Loading...