Page 1

OP ER ATING MAN UAL

®

CAR TRIDGE

PUMP HEAD SYS TEM

Pump Head Models

07519-05 07519-06

Car tridge Models

Small: 07519-60

Large: 07519-50

Multi-channel peri stal tic pumps ac com mo date two sizes of snap-in tub ing

cartridges which pro vide bal anced, ad just able flow via in stantly change able

oc clu sion set ting. The sys tem mates with most ex ist ing MASTERFLEX

L/S® pump drives.

Cole-Parmer In stru ment Co.

625 East Bunker Court

Vernon Hills, Il li nois U.S.A. 60061-1844

800-MASTERFLEX (627-8373)

(847) 247-2929 (Fax)

www.masterflex.com

e-mail: techinfo@coleparmer.com

A-1299-0539

Edi tion 08

®

®

Page 2

Page 3

CON TENTS

Ti tle Page

SAFETY PRECAUTIONS .................................... ii

IN TRO DUC TION .......................................... 1

(1) Ap pli ca tion Data ..................................... 1

(2) Gen eral De scrip tion .................................. 2

IN STAL LA TION ........................................... 3

SETUP .................................................. 4

(1) Se lect Car tridges ..................................... 4

(2) Load Car tridges ...................................... 5

(3) Re tainer Ad just ment/Car tridge Re moval .................... 7

(4) Bi-Directional Pumping ................................. 7

OP ER A TION ............................................. 8

(1) Se lect Tubing and Pump Heads ......................... 8

(2) Se lect Pump Speed ................................... 9

(3) Ad just Oc clu sion Set tings on Car tridges .................... 9

MAIN TE NANCE ........................................... 11

Ser vice Parts .......................................... 11

SPEC I FI CA TIONS ......................................... 12

WAR RANTY ............................................. 13

PRO DUCT RE TURN ....................................... 13

TECH NI CAL AS SIS TANCE .................................. 13

®

AP PEN DIX A MASTERFLEX

AP PEN DIX B Car tridge Loading Ca pac ity ..................... B-1

L/S® Pump Drive Types ............ A-1

C-FLEX -Reg TM Con sol i dated Poly mer Tech nol ogies, Inc.

PHARMED, NORPRENE, TYGON -Reg TM Norton Co.

VITON -Reg TM DuPont Dow Elas to mers L.L.C.

Trade marks bear ing the ® sym bol in this pub li ca tion

are reg is tered in the U.S. and in other coun tries

These prod ucts are cov ered by one

or more of the fol low ing U.S. and

cor re spond ing for eign pat ents:

4,886,431 and 5,257,917

i

Page 4

SAFETY PRECAUTIONS

WARNINGS: Tubing break age may re sult in fluid be ing sprayed from

pump. Use ap pro pri ate mea sures to pro tect op er a tor

and equip ment.

Turn drive off be fore re mov ing or in stall ing car tridges.

Safety guards are pro vided to min i mize risk of fin gers

get ting caught be tween the roller mech a nism and the

base of the mod ule. How ever, be safe—Keep your fin gers away from these ar eas.

CAUTIONS: Ex ces sive oc clu sion can cause high pump tem per a -

tures and early tub ing and roller fail ure. Do not set

occlusion tighter than what is rec om mended in Ta ble #3.

Large Car tridge 07519-50 should not be used with

microbore tub ing—may re sult in pre ma ture tub ing

failure.

WARNING: PRO DUCT USE LIM I TA TION

These prod ucts are not de signed for, nor in tended for use in pa tient

con nected ap pli ca tions; in clud ing, but not lim ited to med i cal and den tal use, and ac cord ingly have not been sub mit ted for FDA approval.

ii

Page 5

IN TRO DUC TION

The in struc tions in this man ual are task-oriented for easy ref er ence. You

can go di rectly to a par tic u lar sec tion and quickly find the an swers. Ap pen dix A and B list MASTERFLEX

®

L/S® pump drive types that can be used

with this sys tem.

Pump Heads

MODEL TYPE

Model 07519-05

Model 07519-06

3-Roller, 4 or 8 Chan nel

4-Roller, 4 or 8 Chan nel

Car tridges

MODEL TYPE

Model 07519-50

Model 07519-60

These car tridge pumps are de signed to pro vide up to 8 si mul ta neously

driven pump chan nels and in cor po rate the fol low ing fea tures.

• Si mul ta neous dis pens ing into an 8 bank set of test tubes with one set-up

and pump cy cle.

• The four-roller de sign pro vides re duced pul sa tion.

Large

Small

(1) Ap pli ca tion Data

The Car tridge Pump Sys tem is de signed for multi-channel use where close oc clu sion con trol of a va ri ety of dif fer ent flows is re quired. All stan dard and many

spe cial tub ing sizes and ma te ri als can be used, de liv er ing from .015 mL/min to

2 L/min.

1

Page 6

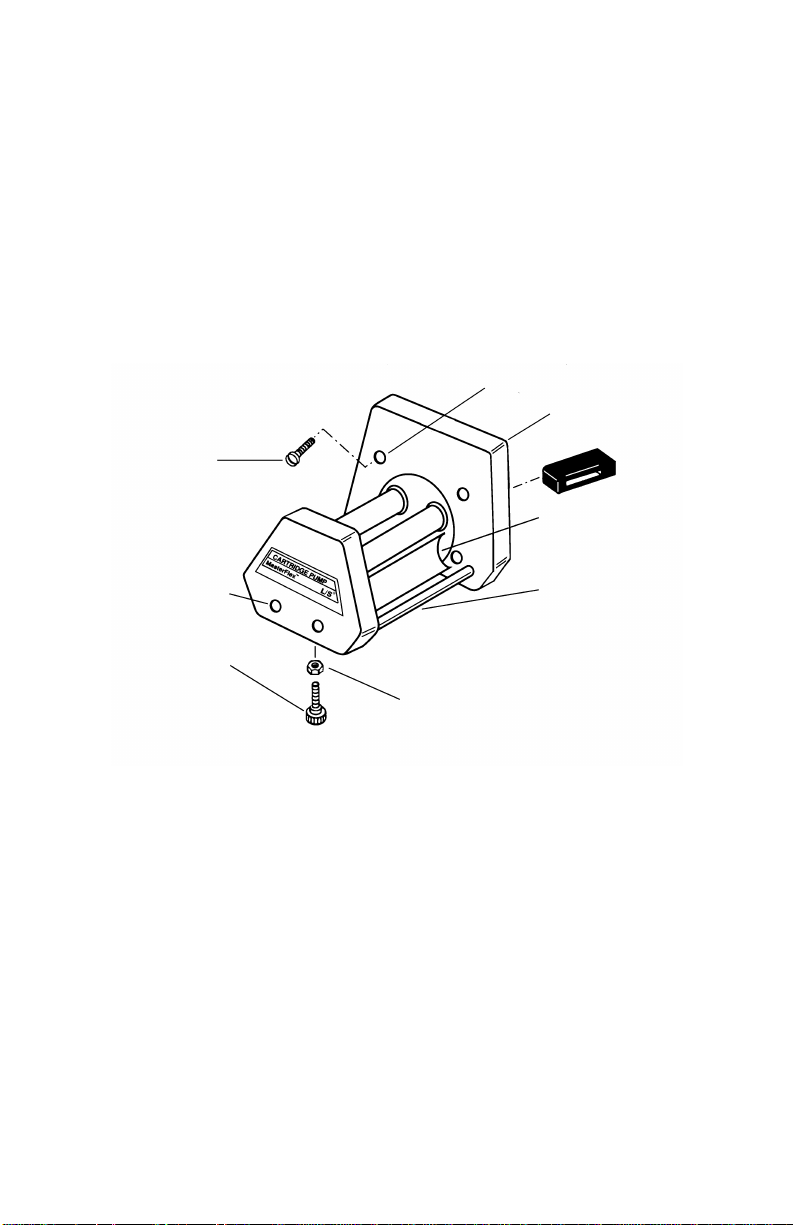

(2) Gen eral De scrip tion

Each Pump Head Sys tem is com posed of a heavy-duty Pump Head and

two sizes of snap-in tub ing car tridges, each with in di vid u ally ad just able oc clu sion set tings. The oc clu sion “wedge” de sign pro vides ac cu rate and more

bal anced flow con trol.

The Pump Heads con tain ei ther three or four roll ers. All mod els can op er ate

with a va ri ety of tub ing and with ei ther the small or the large car tridges.

®

The Pump Head quickly mounts to most ex ist ing MASTERFLEX

L/S

Pump Drive types (see Ap pen dix A and B).

MOUNTING

HOLES

TANG (REAR OF

PUMP HEAD)

®

MOTOR MOUNTING

SCREWS (4)

SCREWDRIVER

CLEARANCE HOLE

ADJUSTABLE

FOOT

LOCKNUT

FIGURE 1 PUMP MOUNTING

SAFETY

GUARD

CARTRIDGE

MOUNTING

RODS

BOOT

2

Page 7

IN STAL LA TION

Tool Re quired: Long-Shaft Phil lips Head Screw driver (pro vided).

®

Mount the Pump Head to a MASTERFLEX

1. In stall the plas tic Boot over the tang at the end of pump shaft (Fig ure 1).

This Boot pre vents metal-to-metal con tact, and thus re duces noise.

This boot should be in spected and re placed when worn or at 500-hour

in ter vals.

NOTE: The boot with closed ends (A-3480) will fit most drives. Use of

the boot with open ends (A-3514) may be re quired on some drives.

Both boots are sup plied with the pump.

A-3480

L/S® Pump Drive as fol lows:

2.

A-3514

FIGURE 2 PLASTIC BOOTS

Con nect the Pump to Drive by align ing the tang on Pump Head (in clud ing in stalled boot) with the slot in the mo tor Drive shaft.

3. At tach Pump Head to drive unit with four screws (pro vided) us ing the

long-shaft Phil lips screw driver (also pro vided).

WARNING: Tubing break age may re sult in fluid be ing sprayed from

pump. Use ap pro pri ate mea sures to pro tect op er a tor

and equip ment.

4. If the Pump Head re quires sup port, in stall the ap pro pri ate length sup -

port screw with plas tic foot and locknut (three pro vided). Level the

Pump Head with the drive unit by ad just ing the foot. Tighten the locknut

against the bot tom of the pump body.

3

Page 8

SETUP

Two car tridge sizes (0.72 in and 0.36 in thick) (see Fig ure 3) ac com mo date

a broad range of tub ing sizes as noted in the “Car tridge Loading Ca pac ity”

chart (see Ap pen dix B).

FIGURE 3 SMALL AND LARGE CARTRIDGES

(1) Se lect Car tridges

NOTE: These Pump Heads are de signed to work with the Model 07519-50

and 07519-60 Car tridges. Do not use Model 07519-55 or 07519-65 Car tridges, which are de signed for dif fer ent Pump Heads.

De pending on which Pump Head is used, up to four large or eight small tub ing car tridges can be teamed up with the Pump Head. But there is a limit de pend ing on avail able drive power and pump load. For full tub ing flow rates at

0 psi, the ta ble in Ap pen dix B show car tridge ca pac i ties for all the stan dard

MASTERFLEX

for de scrip tion of drive types). Car tridge sizes can be in ter mixed as long as

the to tal load does n’t ex ceed the drive ca pa bil ity.

The small Car tridge is de signed to de liver op ti mum per for mance with

0.9 mm (0.035 in) wall, Microbore tub ing up to 2.79 mm (0.110 in) I.D., and

will ac com mo date MASTERFLEX

the three- or the four-roller Pump Head.

The large Car tridge is de signed to de liver op ti mum per for mance with

MASTERFLEX

®

25 with ei ther the three- or the four-roller Pump Head. Large Car tridges are

L/S

fac tory set to mid-range of the “Mflex” scale.

Use only MASTERFLEX

MASTERFLEX

®

L/S® tub ing sizes and drive Types I, II, III (see Ap pen dix A

®

L/S® 13 or L/S® 14 tub ing, used with ei ther

®

L/S® pre ci sion tub ing sizes L/S® 14, L/S 16, L/S 17, L/S 18 and

®

®

pumps to en sure op ti mum per for mance.

pre ci sion and Microbore tub ing with

Use of other tub ing may void ap pli ca ble war ran ties.

4

Page 9

(2) Load Car tridges

Easy, snap-in mount ing and quick-release re moval come with a Car tridge

sys tem—no tools re quired. Since the Car tridges func tion uni formly in ei ther

di rec tion, car tridge ori en ta tion is not im por tant. How ever, you may wish to

al ter nate Car tridges so that the Ad just ment Knob on each is eas ier to turn

when sev eral small car tridges are mounted close to gether.

WARNING: Turn drive off be fore re mov ing or in stall ing Car tridges.

Safety guards are pro vided to min i mize risk of fin gers

get ting caught be tween the roller mech a nism and the

base of the mod ule. How ever, be safe—Keep your fin gers away from these ar eas.

CAU TION: Large Car tridge 07519-50 should not be used with

microbore tub ing—may re sult in pre ma ture tub ing

fail ure.

5

Page 10

With the drive stopped, fol low this pro ce dure to in stall Car tridges.

1. Turn the Ad just ment Knob (see Fig ure 4) coun ter clock wise to max i -

mum open.

OCCLUSION SETPOINT SCALE

ADJUSTMENT

KNOB

OCCLUSION

WEDGES

TUBING RETAINER

BUTTONS

LATCH

HOOK LEG

LATCH LEG

TAB

FIGURE 4 CARTRIDGE ASSEMBLY

2. Push the two Tubing Re taining But tons in and up to ac cept tub ing.

NOTE: The Re tainer But ton lo cated on the Ad just ment Knob side of the

Car tridge is a loose com po nent and may fall out. To re as sem ble, push it

back into place while press ing in the but ton.

3. Se lect tub ing and place in Car tridge (see Fig ure 5A).

4. At tach the Hook Leg of Car tridge to one of the Sup port Rods (see Fig -

ure 5B).

5. Swing the Car tridge with tub ing over the (other side of the) ro tor and

push down on tab un til the Latch snaps closed. (See Fig ure 5C.)

6. Re strain the tub ing on the in let side of pump by push ing the Tubing Re -

tainer But ton in and down firmly.

5A

5B

FIGURE 5 TUBE AND CARTRIDGE LOADING

6

5C

Page 11

7. Lightly pull the tub ing at the out let side to re move slack: then push its

Tubing Re tainer But ton in and down . This should se cure the tub ing.

8. Ad just the oc clu sion set ting. (See OP ER A TION sec tion.) For a nom i nal

set ting, turn ad just ment screw un til in side edge of the wedge is aligned

mid way be tween #3 and #4 on the la bel.

9. Start drive slowly. If tub ing creeps through pump, go to sec tion 3, Re -

tainer Ad just ment.

(3) Re tainer Ad just ment/Car tridge Re moval

There are a few com bi na tions of tub ing sizes and ma te ri als that may re quire

an ad di tional fine ad just ment of the Tubing Re tainers to pre vent the tub ing

from creep ing through the head. If this prob lem should oc cur, use the fol low ing pro ce dure to elim i nate the tub ing creep:

1. Set drive to “0” and turn drive OFF.

2. Push down on latch side of car tridge and pull latch out ward to un hook

from rod.

3. Pivot car tridge up wards and un hook Hook Leg from rod and re move

car tridge.

4. Push both tub ing re tainer but tons down one notch.

5. Re in stall car tridge by first hook ing Hook Leg on rod, then, while piv ot -

ing car tridge down wards, gently stretch sec tion of tub ing ex it ing car tridge on latch side and hook latch on rod.

6. Turn drive ON, slowly in crease drive speed and check for tub ing creep.

7. If tub ing creep per sists, re peat steps 1 through 6 again or un til the tub -

ing no lon ger creeps through the pump head.

NOTE: Over-adjustment of tub ing re tain ers may in hibit fluid flow.

(4) Bi-Directional Pumping

Fluids can be pumped into and back out of con tain ers by re vers ing the

drive. On drives that can not be re versed, use lon ger tub ing lengths and sim ply re verse the loaded car tridge.

WARNING: Tubing break age may re sult in fluid be ing sprayed from

pump. Use ap pro pri ate mea sures to pro tect op er a tor

and equip ment.

7

Page 12

OP ER A TION

This sec tion de scribes the tub ing oc clu sion set ting pro ce dures for ob tain ing

de sired per for mance.

(1) Se lect Tubing and Pump Heads

Use ta bles 1 and 2 as a guide to se lect the tub ing and Pump Head to pro vide

the re quired sin gle chan nel flow rate.

TABLE 1 SMALL CARTRIDGE PUMP FLOW RATES—07519-60

Tubing ID, MM>

Tubing ID, Inches>

Pump

Ro tor

Head

rpm Units

3-Roller6 to

3-Roller1 to

4-Roller6 to

4-Roller1 to

MICROBORE TUBING (mm ID)

0.89 1.42 2.06 2.79

FLOW RATES

mL/min

600

mL/min

100

mL/min

600

mL/min

100

0.44

0.074

7.4

0.44

0.074

7.4

to

44

to

to

44

to

1.06

0.18

1.06

0.18

0.37

0.37

2.2

to

220

to

37

2.2

to

220

to

37

to

106

to

18

to

106

to

18

0.63

0.63

MASTERFLEX

3.8

to

380

to

63

3.8

to

380

to

63

®

L/S

13 L/S® 14

0.36

to

36

0.06

to

6

0.32

to

32

0.05

to

5

®

TABLE 2 LARGE CARTRIDGE PUMP FLOW RATES—07519-50

MASTERFLEX® L/S® Tubing

Tubing ID, MM>

Tubing ID, Inches>

Pump

Head

3-Roller

3-Roller

4-Roller

4-Roller

Ro tor

rpm

to

600

to

100

to

600

to

100

6

1

6

1

Units

mL/min

mL/min

mL/min

mL/min

®

L/S

14 L/S® 16 L/S® 25 L/S® 17* L/S® 18*

FLOW RATES

0.21

0.19

1.3

to

130

to

21

1.2

to

115

to

19

0.68

4.8

to

480

0.8

to

80

4.1

to

410

to

68

1000

170

830

140

10

to

1.7

to

8.3

to

1.4

to

1700

280

13.7

1370

230

17

to

2.8

to

to

2.3

to

L/S® TUBING

1.3

to

130

0.21

to

21

1.2

to

115

0.19

to

19

23

to

2300

3.8

to

380

18

to

1800

3.0

to

300

*NOTE: Only Sil i cone and C-FLEX® tub ing are rec om mended for L/S® 17

and L/S

®

18.

8

Page 13

(2) Se lect Pump Speed

Se lect fixed speed drive or ad just speed of vari able speed drive to pro vide

de sired nom i nal flow rate within the ro tor rpm speed range shown for the

pump model se lected.

(3) Ad just Oc clu sion Set tings on Car tridges

CAU TION: Ex ces sive oc clu sion can cause high pump tem per a -

tures and early tub ing and roller fail ure. Do not set oc clu sion tighter than what is rec om mended in Ta ble #3.

NOTE: With large and small car tridges, the scale iden ti fied as “Mflex” pro -

®

vides nom i nal oc clu sion for MASTERFLEX

L/S® pre ci sion tub ing at the

#3 – #4 set ting.

With a multi-channel car tridge sys tem, flow rate, pres sure sen si tiv ity and

tub ing life can be fine-tuned—even while the pump is run ning. No lost time,

and with op er at ing speeds up to 600 rpm, you get higher max i mum flows

with the same size tub ing.

Fig ure 6 (large and small car tridge) shows the wedges ad justed at #3 on the

oc clu sion setpoint scale for the MASTERFLEX

Rotate knob to

adjust occlusion

®

tub ing.

Occlusion

Wedge

1 High Occlusion

5 Low Occlusion

FIGURE 6 OCCLUSION INDICATIONS FOR THE

MASTERFLEX

®

TUBING

The Ad just ment Knob (see Fig ure 6) con trols a screw mech a nism to move

the oc clu sion wedges. Once a Car tridge is ad justed to a de sired set ting for a

par tic u lar ap pli ca tion, there is no need to re set. Or, you can re cord set tings

and quickly re pro duce them at a later time.

9

Page 14

(a) Nor mal Oc clu sion Set tings

The fol low ing ta ble shows the ap pro pri ate oc clu sion set tings to pro vide sat is fac tory per for mance for var i ous tub ing sizes. (For op ti mum oc clu sion set tings, see fol low ing sec tion.)

TABLE 3 RECOMMENDED OCCLUSION SETTINGS

Tubing Large Car tridge

Mflex Scale

Microbore N/A #1 – #2

MASTERFLEX® L/S®

Pre ci sion

#3 – #4 #3 – #4

Small Car tridge

Mflex Scale

(b) Oc clu sion Set ting Pro ce dure:

1. Se lect the rec om mended oc clu sion value from the ta ble.

2. Turn the Ad just ment Knob to align the in side edge of the white Wedge

with the scale num ber. (Clock wise ro ta tion in creases the oc clu sion.)

(c) Op ti mized Oc clu sion Set tings

Some ap pli ca tions re quire ad di tional fine-tuning of the oc clu sion set ting to

vary the flow rate for a par tic u lar tub ing to re duce flow vari a tions caused by

changes in sys tem pres sure, or to in crease tub ing life.

1. Ad just the Oc clu sion Wedges as de scribed in the pre ced ing ta ble.

2. Re fine this set ting, de pend ing on your ob jec tives:

NOTE: To Max i mize Tubing Life

While run ning the pump, sim ply re duce the ad justed oc clu sion set ting by

turn ing the Ad just ment Knob coun ter clock wise to move the wedges to a

higher setpoint scale num ber (to ward 5). Con tinue turn ing the knob coun ter clock wise un til the flow drop-off or the pres sure sen si tiv ity be comes un ac cept able, then turn knob slightly clock wise.

NOTE: To Re duce or Elim i nate Flow Drop-Off Rate with Pres sure

Fluc tu a tions

While run ning the pump, al ter nate the backpressure be tween the ex pected

high and low val ues and in crease the ad justed oc clu sion set ting. Turn the

Ad just ment Knob clock wise to move the wedges to a lower setpoint scale

num ber (to ward 1) un til the flow drop-off is min i mized.

NOTE: To Fine-Adjust the Flow Rate

In crease or de crease the oc clu sion value to vary the flow.

10

Page 15

MAIN TE NANCE

No main te nance re quired. Wipe Pump with a clean cloth and a mild de ter gent. Never im merse nor use ex ces sive fluid.

Ser vice Parts:

Boot, A-3480, see Fig ure 2

Boot, A-3514, see Fig ure 2

Phil lips screw driver, A-3624

Screw, 8-32, 1 in Pan-PH, B-1079-0412

Level Feet As sem bly, A-4128-0002, (2 in)

Level Feet As sem bly, A-4128-0003, (1-1/4 in)

Level Feet As sem bly, A-4128-0004, (1-5/8 in)

11

Page 16

SPEC I FI CA TIONS

PUMP HEAD

Speed Range: 0 to 600 rpm

Torque Load: 5 oz-in (max.) with no car tridges

Op er ating Tem per a ture Range: 0° to 40°C (32°F to 104°F)

Stor age Tem per a ture Range: −40°C to 110 °C (−40 °F to 230°F)

Con struc tion and Fi ber glass-reinforced polysulfone

Chem i cal Re sis tance: hous ing; stain less steel, an od ized

alu mi num, sealed stain less steel

ball bear ings and Buna N

safety guard.

CAR TRIDGES

Con struc tion: Du ra ble polycarbonate frame with

filled ny lon and acetal com po nents.

An od ized alu mi num ad just ment

knob on stain less steel screw.

Di men sions:

Large 4 in Tall x 5 in W x 0.72 in Thick

(102 mm x 127 mm x 18.3 mm)

Small 4 in Tall x 5 in W x 0.36 in Thick

(102 mm x 127 mm x 9.1 mm)

12

Page 17

WAR RANTY

Use only MASTERFLEX® pre ci sion and Microbore tub ing with

MASTERFLEX

tub ing may void ap pli ca ble war ran ties.

The man u fac turer war rants this prod uct to be free from sig nif i cant de vi a tions from pub lished spec i fi ca tions. If re pair or ad just ment is nec es sary

within the war ranty pe riod, the prob lem will be cor rected at no charge if it is

not due to mis use or abuse on your part as de ter mined by the man u fac turer.

Re pair costs out side the war ranty pe riod, or those re sult ing from prod uct

mis use or abuse, may be in voiced to you.

The war ranty pe riod for this prod uct is noted on the war ranty card.

®

pumps to en sure op ti mum per for mance. Use of other

PRO DUCT RE TURN

To limit charges and de lays, con tact the seller or man u fac turer for au tho ri za tion and ship ping in struc tions be fore re turn ing the prod uct, ei ther within

or out side of the war ranty pe riod. When re turn ing the prod uct, please state

the rea son for the re turn. For your pro tec tion, pack the prod uct care fully and

in sure it against pos si ble dam age or loss. Any dam ages re sult ing from im proper pack ag ing are your re spon si bil ity.

TECH NI CAL AS SIS TANCE

If you have any ques tions about the use of this prod uct, con tact the man u fac turer or au tho rized seller.

13

Page 18

AP PEN DIX A

MASTERFLEX

®

L/S® PUMP DRIVE TYPES

FOR USE WITH CAR TRIDGE PUMP SYS TEMS

Max

rpm

600

120

600 0.05 90 II

100 0.1 360 III

Power

(hp)

0.1

0.05

Torque

oz-in

180

180

Drive

Type

I

Note: Check Max rpm and Power of the Drive or use the Torque rat ing to

de ter mine the Drive Type.

A-1

Page 19

AP PEN DIX B

CAR TRIDGE LOADING CA PAC ITY

Car tridge

Size

Small

Large

Tubing

Size

Microbore

.89 mm

Microbore

1.42 mm

Microbore

2.06 mm

Microbore

2.79 mm

L/S® 13

L/S® 14

®

L/S

L/S® 16

L/S® 25

L/S® 17

L/S® 18 Soft 43 4 2 4

14

Tubing

Ma te rial*

Soft

Stiff

Soft

Stiff

Soft

Stiff

Soft

Stiff

Soft 10 8 8 8

Stiff 26 7 3 8

Soft 10 8 8 8

Stiff 31 6 3 8

Soft 10 4 4 4

Stiff 31 4 3 4

Soft 14 4 4 4

Stiff 31 4 3 4

Soft 43 4 2 4

Stiff 80 2 1 4

Soft 43 4 2 4

Stiff 80 2 1 4

Torque**

(Avg. oz-in)

‡

‡

‡

‡

‡

‡

‡

‡

Max. No. of Car tridges

Drive

Type I

8 8 8

7 3 8

8 8 8

- - -

8 8 8

7 3 8

8 8 8

7 3 8

Drive

Type II

Drive

Type III

*Soft ma te ri als are sil i cone and C-FLEX®.

Stiff ma te ri als are NORPRENE

®

, TYGON® and VITON

®

(fluoroelastomer).

** Torque re quire ments are the same for both 3- and 4-roller ro tor pump

heads.

‡Torque data not avail able.

Printed in U.S.A.

B-1

080900

Loading...

Loading...