Page 1

OPERATING MANUAL

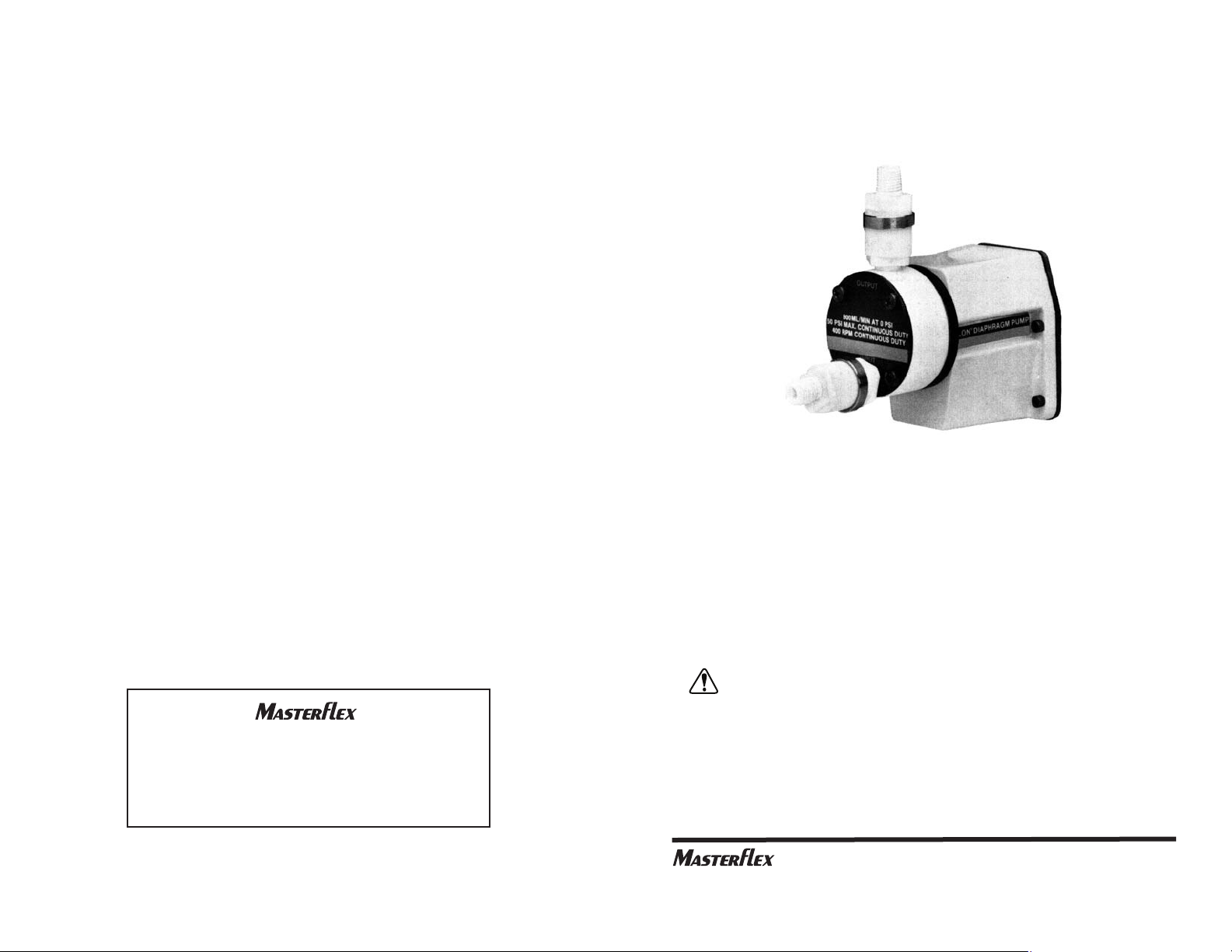

PTFE DIAPHRAGM PUMP

MODEL NO. 07090-42

All wetted surfaces are of PTFE. This heavy-duty, drive-operated pump is

built to deliver virtually any corrosive chemical without harm to its components. Or, the purest fluids can be delivered without risking contamination from the pump. The 07090-42 PTFE Diaphragm Pump handles intermediate size flows (up to 800 mL/min) of a wide range of concentrations

and viscosities. It can also pump fluids through filters and other restrictions, and can pressurize containers.

Flexibility? The PTFE DIAPHRAGM PUMP can be teamed-up with your

existing MASTERFLEX

®

L/S®variable speed drive (10:1) range.

WARNING: THIS PUMP IS CAPABLE OF DEVELOPING PRESSURES IN EXCESS OF

THE MAXIMUM RATED 100 PSIG INTERMITTENT DUTY. APPROPRIATE

PRECAUTIONS SUCH AS A PRESSURE RELIEF VALVE MUST BE

INSTALLED TO PROTECT THE PUMP AND ANCILLARY CONNECTIONS

FROM ACCIDENTAL OVER-PRESSURIZATION.

WARRANTY

The Manufacturer warrants this product to be free from significant deviations from published specifications. If repair or adjustment is necessary

within the warranty period, the problem will be corrected at no charge if it

is not due to misuse or abuse on your part as determined by the

Manufacturer. Repair costs outside the warranty period, or those resulting

from product misuse or abuse, may be invoiced to you.

The warranty period for this product is two (2) years from the date of

purchase.

PRODUCT RETURN

To limit charges and delays, contact the seller or Manufacturer for authorization and shipping instructions before returning the product, either within or outside of the warranty period. When returning the product, please

state the reason for the return. For your protection, pack the product carefully and insure it against possible damage or loss. Any damages resulting

from improper packaging are your responsibility.

TECHNICAL ASSISTANCE

If you have any questions about the use of this product, contact the

Manufacturer or authorized seller.

14

Printed in U.S.A.

(US & Canada only) Toll Free 1-800-MASTERFLEX • 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 • 1-847-381-7050

www.masterflex.com • techinfo@masterflex.com

*EN809 manufactured by:

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010

®

A-1299-0238B

Edition 13

(US & Canada only) Toll Free 1-800-MASTERFLEX ● 1-800-637-3739

(Outside US & Canada) 1-847-549-7600 ● 1-847-381-7050

www.masterflex.com ● techinfo@masterflex.com

®

Page 2

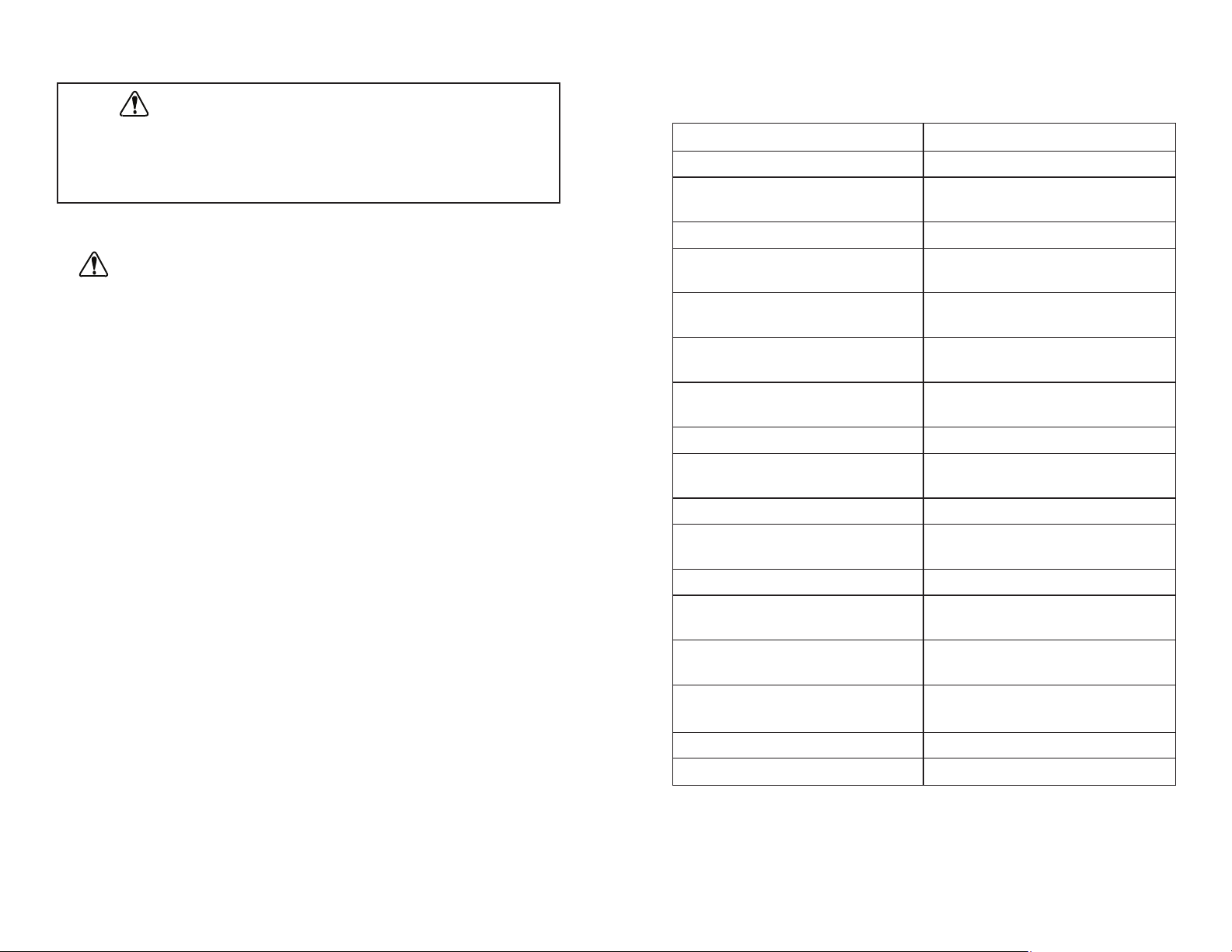

SPECIFICATIONS

PTFE Diaphragm Pump

Model: 07090-42

Flow Rate*: 80 to 800 mL/min

Flow Rate vs. Speed

Conformity Variation: Better than 10% (typical)

Metering Pressure Range: 3 to 50 psig

Max. Rated Pressure: 50 psig (Continuous)

75 psig (Intermittent)

Metering Accuracy: Better than 2% dispensed

volume

Min. Lift: 2 ft (dry)

16 ft (wet)

Pump Head

Dead Volume: 16 mL

Overall Dimensions: 6 in H x 7 in L x 3 in W

Max. Rated Speed: 400 rpm (Continuous)

600 rpm (Intermittent)

Min. Rated Speed: 40 rpm

Operating Fluid: 150° F (Continuous)

Temperature Range: 230° F (Intermittent)

Liquid Viscosity Range: 1 to 500 centipoise

Motor hp at max.

pressure and speed: 1/20 hp

Pump Torque at 0 psig: 2.8 lb-in (AVG)

4.9 lb-in (Peak)

Pump Torque at 5.2 lb-in (AVG)

Max. Pressure: 9.6 lb-in (Peak)

Noise level: <70 dBA @ 1 meter

Compliance (for CE mark): EN809 (EU Machine Directive)

*Performance at 0 psig, 400 rpm, 70°F ambient.

13

SAFETY PRECAUTIONS

WARNING: CHECK VALVES are intended for use on this pump only. Do

not use separately from the pump as forward flow at higher

flow rates will suddenly restrict, causing a rapid increase in

backpressure with resultant hose and connection bursting.

INTRODUCTION

The instructions in this manual are task-oriented for easy reference. You

can go directly to a particular section and quickly find the answers to your

questions. The step-by-step installation and operating instructions are

easy to follow.

Also for easy reference, the component designations used in the illustrations are CAPITALIZED in the text.

i

WARNING: PRODUCT USE LIMITATION

This product is not designed for, nor intended for use in patient

connected applications; including, but not limited to medical

and dental use, and accordingly has not been submitted for

FDA approval.

PUMP FOR LIQUIDS

ORIGINAL INSTRUCTIONS

Page 3

Title Page

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

OPERATING DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Flow/Pressure Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chemical Resistance of PTFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Metering/Dispensing Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PUMP CONSTRUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

How Drive Mechanism Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

(1) Mount the Pump on Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

(2) Attach Tubing Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

(3) Replacement of Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

(4) Attach Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

(5) Install Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

(6) Adjust Drive Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

(7) Calibrate the Pump (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TROUBLESHOOTING GUIDE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SERVICE PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

(1) How to Clean the Pump Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

(2) How to Replace Diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

(3) How to Replace Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . 11

(4) How to Replace Reagent Head. . . . . . . . . . . . . . . . . . . . . . . . . . 13

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PRODUCT RETURN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TECHNICAL ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Trademarks bearing the ® symbol in this publication

are registered in the U.S. and in other countries.

12

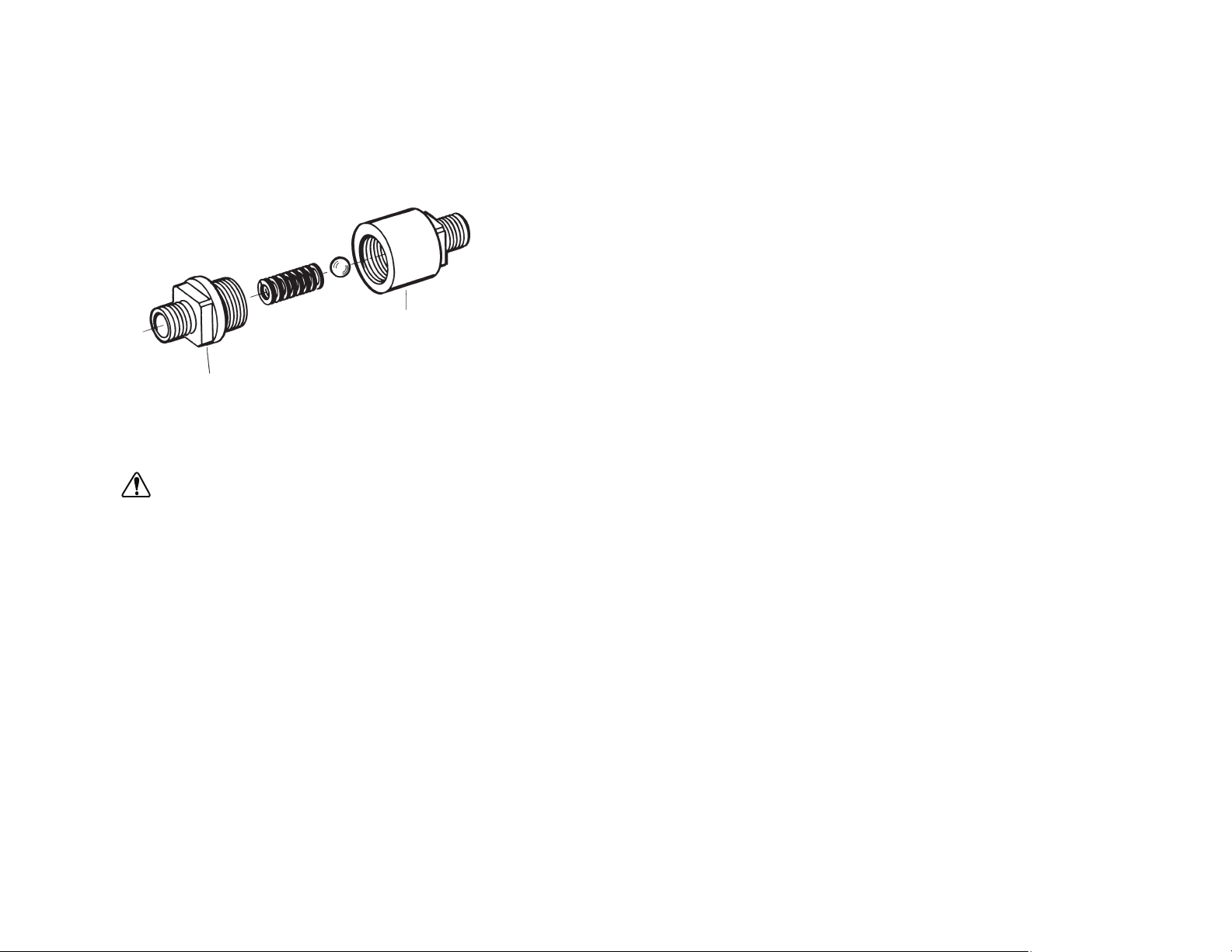

IMPORTANT: It is essential that the inlet end of the CHECK VALVE

be installed in the INLET PORT of the REAGENT HEAD. Similarly,

the outlet end must be installed in the OUTLET PORT.

See Fig. 6 for the correct orientation. The ball seats in the end

shown. When assembled, you can see the ball through the outlet

end of the CHECK VALVE. The pump will not operate unless the

CHECK VALVES are properly installed.

nn To seal, use PTFE tape on threads.

CAUTION: Hand-tighten only. Over-tightening can damage the

PTFE parts.

nn Test the new CHECK VALVE performance by pumping some fluid

under operating conditions.

(4) How to Replace Reagent Head

nn For replacement of the REAGENT HEAD (Part No. D-2027), see

preceding instructions for DIAPHRAGM replacement.

ACCESSORIES

Description Part No.

Female Pipe Adapter with 1/4 NPT

Use with 3/8 in OD tubing 06376-14

PFA Tubing, 3/8 in OD x 1/4 in ID. Pack of 25 ft (7.6 m) 06375-05

External Check Valve 07090-45

Service Kit. Contains PTFE diaphragm, two PTFE 07090-43

check valve assemblies, two drive-tang boots, installation

GAGE/wrench, instructions.

ii

FITS IN INLET

PORT

FITS IN OUTLET

PORT

Figure 6.

TABLE OF CONTENTS

Page 4

nn Using a screwdriver in the slot in the DIAPHRAGM SHAFT and the

7/16 in wrench on the LOCKING NUT, lock the DIAPHRAGM in

place.

nn Recheck to verify that the DIAPHRAGM is at its furthest excursion

and that it just touches the GAGE. If necessary repeat the above

adjustment procedure until the DIAPHRAGM just touches the

GAGE when it is at its furthest excursion.

nn Replace SPACING RING segments.

nn Realign holes in the DIAPHRAGM with holes in the pump housing

by turning the slot in the DIAPHRAGM SHAFT (with a screwdriver)

at back of pump.

nn Attach the REAGENT HEAD to the PUMP BODY.

nn Replace the BACKING PLATE.

nn Tighten the 4 PHILLIPS SCREWS (with washers) uniformly. Make

sure all 4 screws are seated under light torque before tightening

them to specifications (25 pound-inch).

CAUTION: I

f screws are not tightened correctly, the unit will leak

between head and diaphragm. Before placing in service,

test the pump with inert fluid under operating pressure

.

(3) How to Replace Check Valves

The CHECK VALVES can be serviced or replaced individually or in pairs

without disassembly of Pump Head.

WARNINGS: First purge the Pump to flush out any hazardous fluid.

CHECK VALVES are intended for use on this pump only. Do

not use separately from the pump as forward flow at

higher flow rates will suddenly restrict, causing a rapid

increase in backpressure with resultant hose and connection bursting.

nn Unscrew CHECK VALVE from head. Place the wrench (3/4 in)

across the flats adjacent to the threads to be unscrewed. If placed

on the flats farthest from the threads, the valve body halves may

become loose.

Install new CHECK VALVES. Place the wrench (3/4 in) across the

flats adjacent to the threads to be tightened into the Pump. If placed

on the flats farthest from the threads, the Pump halves could

become overstressed and leak under pressure.

11

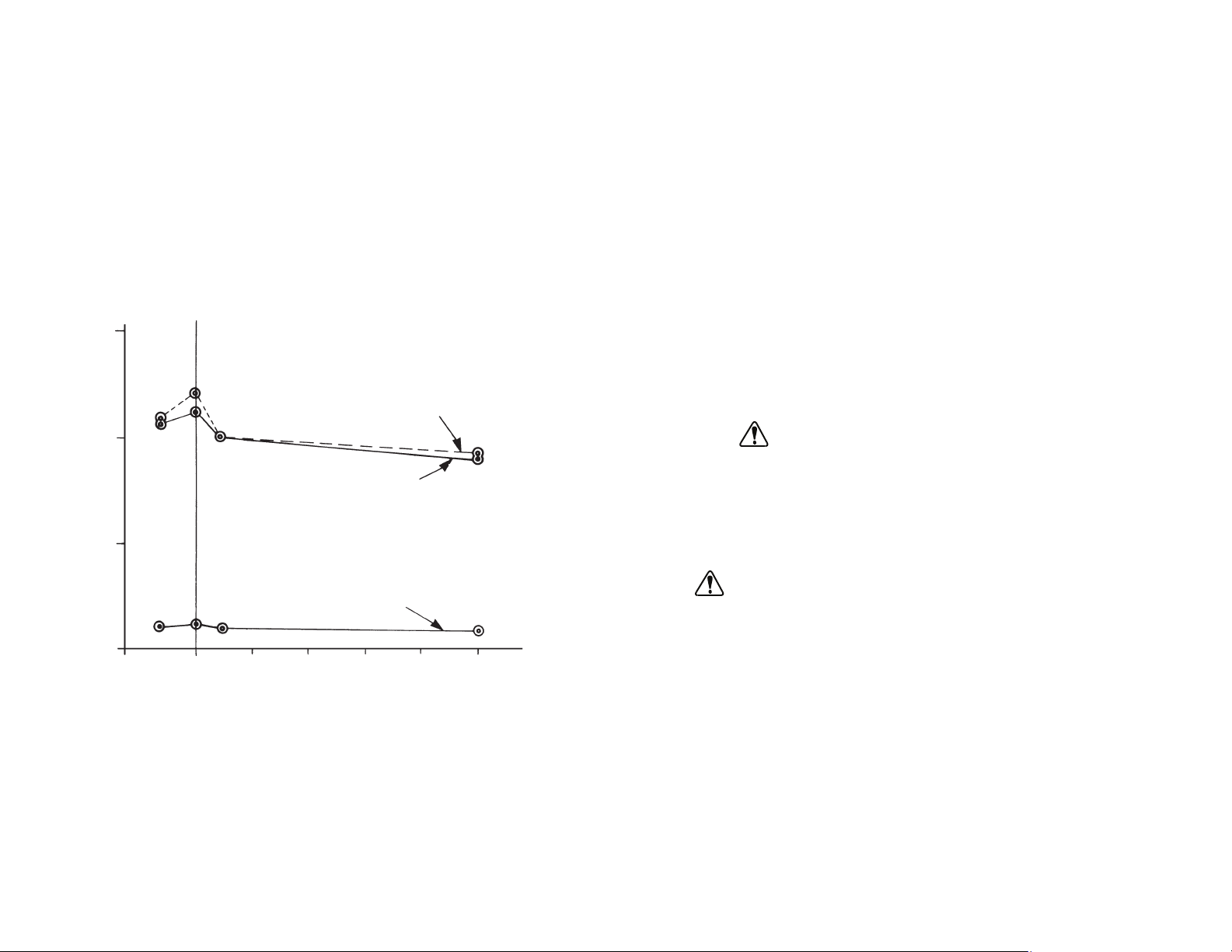

OPERATING DATA

The Pump delivers fluids at accurately metered flow rates ranging from 80

to 800 mL/min (400 rpm). Intermittent operation up to 1200 mL/min (600

rpm) is permissible. The unit may be run dry—loss of fluid will not harm the

Pump. (See Specifications section for complete details.)

Flow/Pressure Performance

The following graph summarizes pump performance at various speeds,

flows, pressures and viscosities. The DIAPHRAGM can work continuously

against back pressures up to 50 psig (intermittently up to 75 psig) while

providing a wet suction lift of 16 feet of water or more. (Drylift, 24 inches or

more.)

Note the uniform performance at widely varying viscosities. Liquids with

viscosities up to 500 centipoise can also be metered accurately at up to

400 rpm. When pumping very viscous liquids, slight flow rate shifts can be

expected (as compared with water).

2

Figure 1.

EFFECT OF PRESSURE, SPEED AND VISCOSITY ON FLOW

PERCENT RATED FLOW

INLET VACUUM in Hg

400 RPM 1 CENTIPOISE

400 RPM 300 CENTIPOISE

OUTLET VACUUM PSIG

40 RPM 1 & 300 CENTIPOISE

-10 0 10 20 30 40 50

0

50

100

150

Page 5

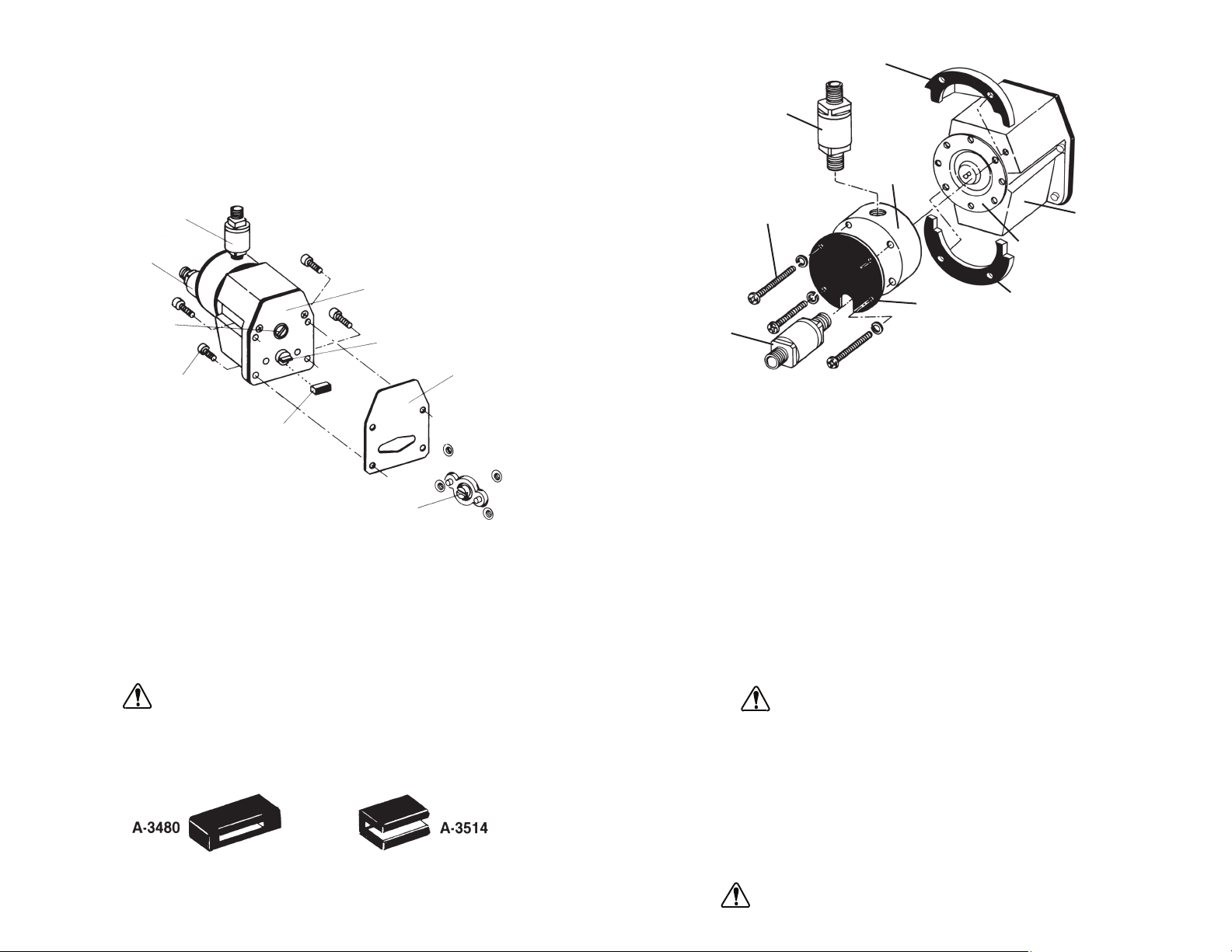

nn Disconnect Pump Head from Drive by removing 4 SOCKET HEAD-

SCREWS. (See Fig. 2.)

nn Disconnect BACKING PLATE from Pump Head by removing 4

PHILLIPS SCREWS with washers. (See Fig. 4.)

nn With the DIAPHRAGM now loose, remove the SPACING RING seg-

ments. (See Fig. 4.)

nn Remove the REAGENT HEAD (with CHECK VALVES still attached).

NOTE: If a damaged REAGENT HEAD (Part No. D-2072) must be

replaced, also order the complete Service Kit (Part No. 07090-43).

nn To remove the worn DIAPHRAGM, hold a screwdriver in the slot of

the DIAPHRAGM shaft (at back of Pump—see Fig. 2) while simultaneously loosening the LOCKING NUT adjacent to the

DIAPHRAGM. Use a 7/16 in open end wrench.

NOTE: A GAGE furnished with the service kit has such a wrench at

one end—see Fig. 5.

nn Loosen diaphragm locknut at shaft using supplied wrench and

remove diaphragm

nn Install 1/4-20 locknut on stud of replacement diaphragm. Locate nut

approximately 1/2" from bottom of stud

nn Install replacement diaphragm into shaft.

nn To obtain maximum durability from the new DIAPHRAGM, and to

prevent it from striking the REAGENT HEAD or the PUMP BODY,

adjust its height correctly by using the GAGE provided. First, while

holding the GAGE against the PUMP BODY, rotate the INPUT

SHAFT (TANG) until the DIAPHRAGM is extended its maximum

distance from the PUMP BODY.

nn Screw the DIAPHRAGM into or out of the DIAPHRAGM SHAFT as

necessary until the letter “B” on the DIAPHRAGM just touches the

GAGE.

Chemical Resistance of PTFE

PTFE has the highest chemical resistance classification (Excellent) for virtually all chemicals—even at high temperatures. For details about resistance and physical properties for specific chemicals consult your dealer.

WARNING: Extended pumping with halogen compounds, including per-

chloric acid, chloroethanol dichlorobenzines, methyl ethyl

ketones, is not recommended and may cause a hazardous

condition.

Metering/Dispensing Accuracy

The 07090-42 Pump delivers fluid with repeatable accuracy of better than

2% volume variation. Best accuracy is achieved under conditions of constant pressure at a preset speed with a fully flooded pump suction. A back

pressure of at least 3 psig assures quick seating of CHECK VALVES and

improves accuracy. For best repeatability, the Pump should be operated

with no suction lift.

PUMP CONSTRUCTION

A rugged cast aluminum housing encloses the unique drive mechanism,

composed of a double convoluted short-stroke PTFE DIAPHRAGM which

flexes in response to a nutating bearing linked to a spring-loaded spool.

The PTFE REAGENT HEAD has INLET/OUTLET PORTS for the CHECK

VALVES, each composed of a PTFE spring-loaded PTFE ball on a PTFE

seat. Body halves will withstand pressures up to 75 psig intermittently.

WARNING: Use a pressure relief valve to prevent higher pressures.

The OUTLET PORT is positioned perpendicular to the DIAPHRAGM axis

to avoid air entrapment, which can affect metering accuracy and cause

reagent contamination. Minimum dead volume improves dispensing accuracy and reduces the amount of liquid trapped in pump.

The gas-purging Pump Head design permits self-priming to a minimum of

24 in of water suction dry lift. Primed wet suction lift is a minimum of 16 feet

of water useful for liquid transfer applications. There’s no need for a separate transfer pump when drawing liquids from the bottom of large tanks.

How Drive Mechanism Works

The drive mechanism is composed of a nutating bearing with a fixed offset

drive coupled to a motor shaft. The bearing rolls against a beveled metal

spool to provide a very efficient and balanced short-stroke drive mechanism. The double convoluted diaphragm (with molded-in stud) flexes with

310

LOCKING

NUT

GAGE

DIAPHRAGM

TANG

PUMP

BODY

Figure 5.

7/16 in

.532

.532

Page 6

each rotation of the nutating bearing, thus pumping fluid at a precise drive

rate. This linear stroking motion imposes very low stress on the

DIA PHRAGM.

NOTE: This drive mechanism never requires lubrication or cleaning.

INSTALLATION PROCEDURES

(1) Mount the Pump On Drive

If your Pump is not already installed on a Drive, follow this procedure:

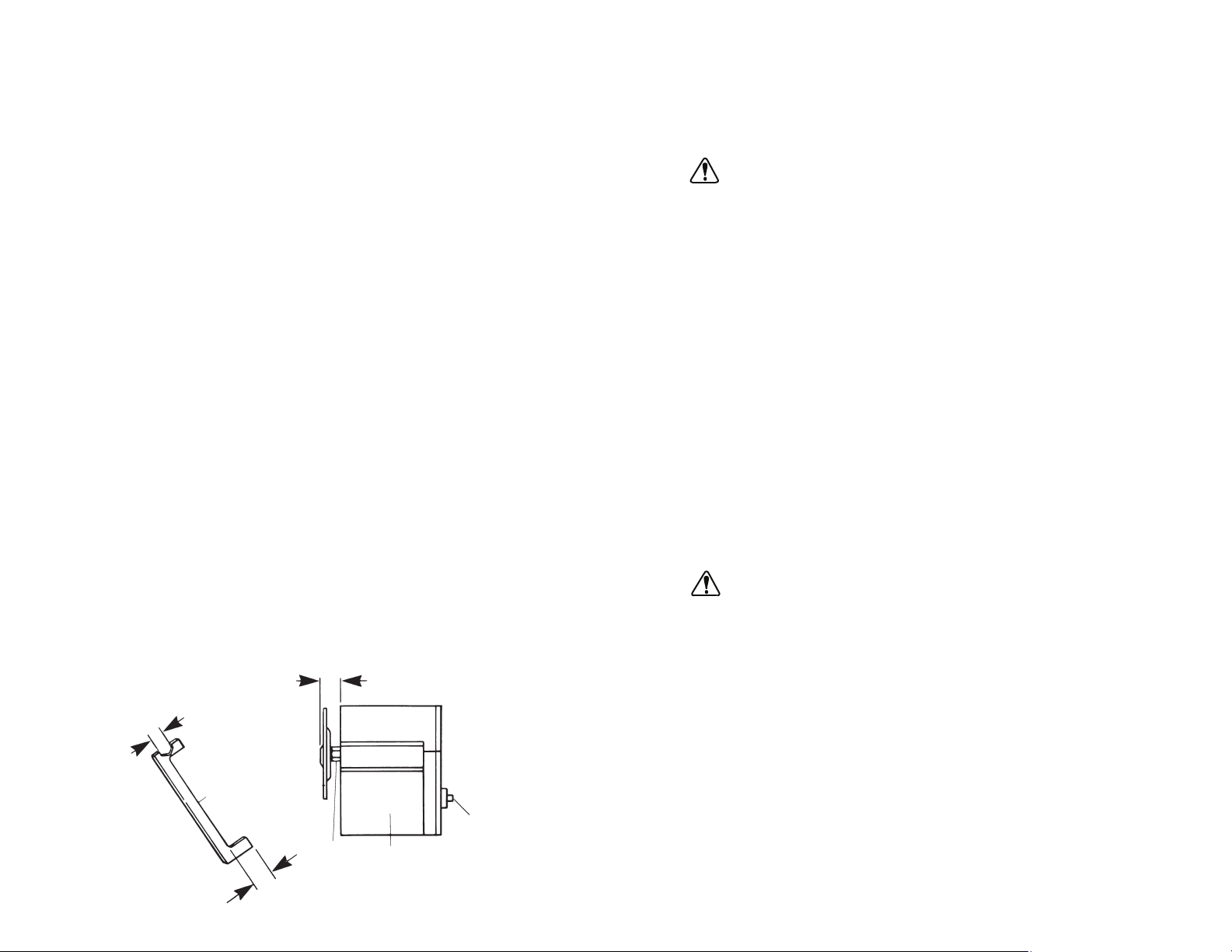

nn Install the plastic BOOT over the TANG at the end of the pump shaft

(Fig. 2). This BOOT should be inspected and replaced when worn

or at 1500 hour intervals.

CAUTION: Not using the BOOT will damage the Pump.

NOTE: The BOOT with closed ends (A-3480) will fit most drives.

Use of the BOOT with open ends (A-3514) may be required on

some drives. Both BOOTS are supplied with the pump.

nn Remove the SPACING RING segments.

nn Remove the REAGENT HEAD, with CHECK VALVES still attached.

nn Clean the surfaces with water or suitable chemicals, depending

upon the fluid previously pumped.

nn Unscrew the CHECK VALVES. Place the wrench across the flats

adjacent to the threads to be unscrewed. If placed on the flats farthest from the threads, the valve body halves may become loose.

Clean the valves. When the valves are reassembled, do not use

more than 7 inch-pounds of torque. Excessive torque may overstress the threads holding the pump halves together, causing leakage when under pressure. To install the valve into the pump, place

the wrench across the flats adjacent to the threads to be screwed

into the pump.

WARNING: Never try to clean the PUMP BODY drive mechanism.

Especially don’t drop it into a solvent. And, repeat, do

not autoclave the unit—this might compromise its inter-

nal lubricating qualities and lead to pump failure.

nn Reassemble all components and connect Pump to the Drive unit.

(2) How to Replace Diaphragm

There’s minimum pump downtime when a damaged or contaminated

DIAPHRAGM must be replaced.

WARNING: Before disassembly, purge the pump. Be sure any haz-

ardous fluid previously pumped is completely flushed out.

94

Figure 3.

SPACING RINGS

PUMP BODY

DIAPHRAGM

BACKING

PLATE

INLET

VALV E

PHILLIPS

SCREWS (4)

OUTLET

VALV E

SPACING

RINGS

REAGENT

HEAD

Figure 4.

Figure 2.

CHECK VALVE

(Outlet)

CHECK VALVE

(Inlet)

BEARING PLATE

TANG

GASKET

SLOT IN DRIVE

MOTOR SHAFT

BOOT

SOCKET HEAD

SCREWS

SLOT IN

DIAPHRAGM

SHAFT

Page 7

nn Connect the Pump to Drive by aligning the TANG on Pump Head

(including installed BOOT) with the SLOT in the motor Drive shaft.

NOTE: It may be easier to turn the shaft on the Drive unit to align

with the Pump Head TANG (using a screwdriver).

nn With the two shafts now connected, fasten the Pump securely to the

Drive unit with the 4 (8-32 x 3/4) SOCKET HEADSCREWS furnished, using the long hex key provided.

(2) Attach Tubing Fittings

Select PTFE fittings (with internal 1/4 NPT thread) required for the

expected backpressure conditions. (Consult your dealer for assistance.)

nn Before attaching tubing fittings to valves, wrap 1 1/2 or 2 1/2 turns

of the 4 mil thick PTFE tape around the 1/4 NPT threads on CHECK

VALVES. This should provide a tight seal.

CAUTION: Don't allow any tape to protrude beyond the end of

threads. Particles could get into CHECK VALVES and

disrupt performance.

nn DO NOT OVER-TIGHTEN PTFE THREADS AND CONNECTIONS.

PTFE has the property of “cold-flowing” when stressed. If over-tightened, PTFE threads will continue to become loose!

CAUTION: It is important to tighten two PTFE parts using the prop-

er wrenches located as close to the joint as practical.

nn Attach tubing fittings to the CHECK VALVES. Place a wrench across

the outer flats (adjacent to the threads) and hold stationary to prevent rotation of valve halves (i.e., valve assembly) relative to each

other. Never allow an already joined part to rotate further than previous joint, when fastening to it.

CAUTION: PTFE threads may strip or PTFE parts may break if

valve body halves rotate relative to each other or if the

valve rotates relative to the head. This will also cause

seal failure of the CHECK VALVE.

nn Tighten your female threaded fitting onto the valve using 60 oz-in

(hand-tighten) of torque.

CAUTION: Exceeding rated torque may strip PTFE threads or

break PTFE parts.

5

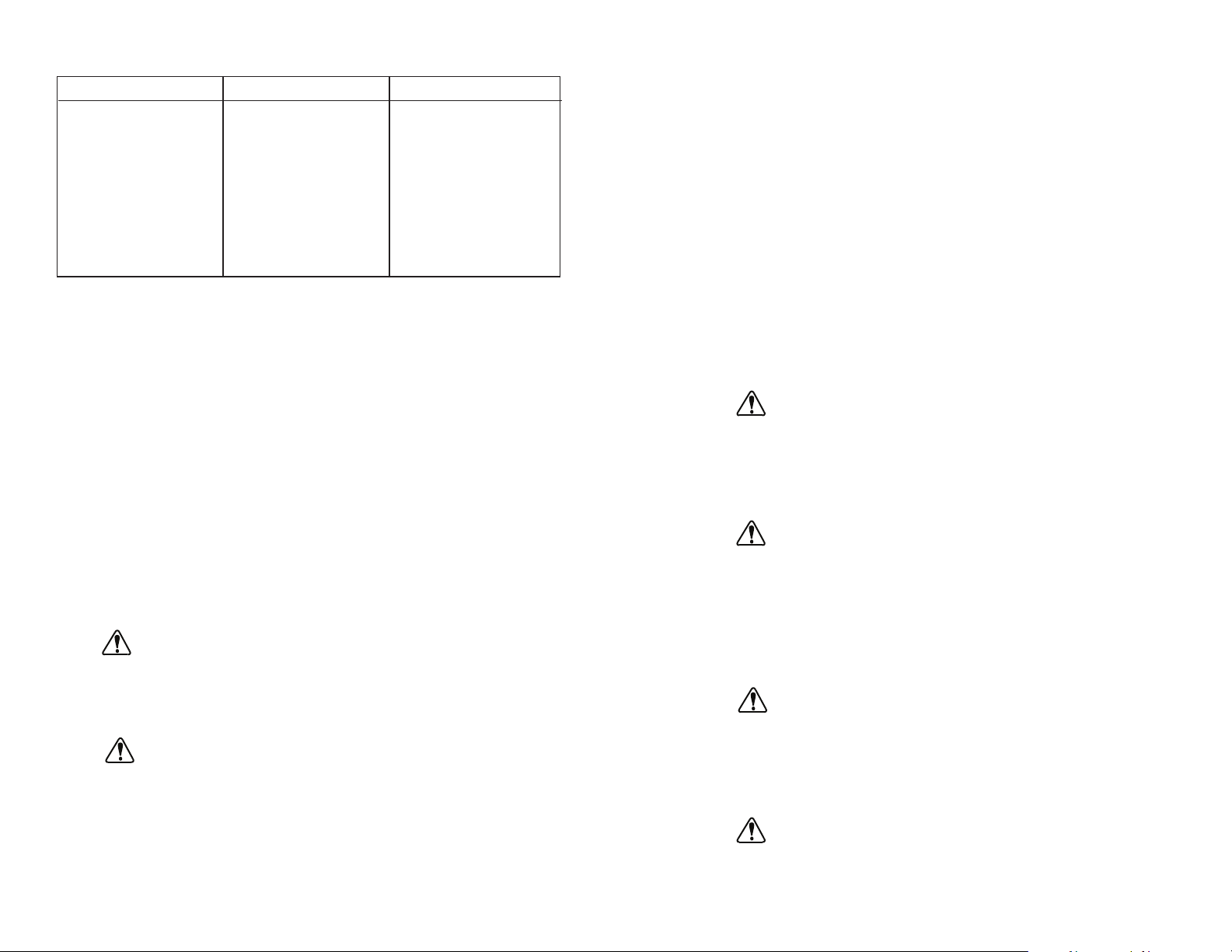

Troubleshooting Solutions (cont.):

Symptom Possible Cause Solution

V REDUCTION IN

FLOW RATE:

1 - Gradually Diaphragm fatigue Replace Diaphragm

& Check Valves

2 - Erratically (a) Dirt in system Clean system

affecting valves Install inlet filter—May

require new Check

Valves

(b) Backpressure Check system

changes plumbing

SERVICE PROCEDURES

The 07090-42 Diaphragm Pump is built for long, hard use, handling the

most corrosive fluids. But if wear problems occur, the DIAPHRAGM,

CHECK VALVES and REAGENT HEAD can be quickly replaced to extend

product life and/or restore flow capacity.

A Service Kit (Part No. 07090-43), ordered separately, contains:

1 DIAPHRAGM (including a GAGE/Wrench to aid in installation)

2 CHECK VALVES

2

Plastic BOOTS for TANG (if ordered separately, use Part No. A-3480

for closed end or Part No. A-3514 for open ends)

.

Following are the most common service procedures:

(1) How to Clean the Pump Head

CAUTION: DO NOT AUTOCLAVE. The use of conventional autoclave

cleaning procedures is not recommended. Consult with

your Dealer if you have special cleaning requirements.

The 07090-42 Pump is easily cleaned because it’s so simple to disassemble the Pump Head after each use.

WARNING: Before disassembly, purge the pump with a suitable fluid.

Be sure any hazardous material previously pumped is

completely flushed out.

nn Disconnect the Pump Head from Drive. Remove 4 SOCKET HEAD-

SCREWS. (See Fig. 2.)

nn Disassemble the Pump Head, (but don’t remove the DIAPHRAGM).

First, disconnect the BACKING PLATE by removing 4 PHILLIPS

SCREWS and washers. (See Fig. 4.)

8

Page 8

TROUBLESHOOTING GUIDE

Symptom Possible Cause Solution

I CLACKING NOISE Tang BOOT worn out Replace BOOT

II FLUID DRIPPING

FROM:

1 - Bottom of Housing Ruptured diaphragm Replace Diaphragm

& Check Valves

2 - Check Valves (a) Loose fittings Remove, retape, install,

hand-tighten

(b) Loose Check Valve Remove, retape, install,

hand-tighten

(c) Check Valve seal Replace valves

failure

(d) Excessive back- Check/reduce

pressure backpressure

3 - Reagent Head (a) Loose screws Tighten screws

(b) Head damage Replace Head

Check Diaphragm for

possible replacement

III BUBBLES IN (a) Fitting leaking Remove, clean and

DISCHARGE LINE tape fittings, reinstall,

torque until tight

(b) Dissolved gases; Increase backpressure

volatilize fluids on pump to stop outgas-

ing or cavitation of fluid.

IV FLUID IS NOT (a) Drive not operating Remove pump &

BEING PUMPED check drive.

Consult drive manual.

(b) Dirt in Check Operate pump at speeds

Valves, or plumb- above 40 rpm. Fill pump

ing problems, or with water and check for

failed Diaphragm, inlet suction. Proper

or failed Drive suction indicates a

mechanism plumbing problem.

No suction indicates a

pump problem: Check for

fluid dripping from housing—which indicates a

Diaphragm failure. If no

dripping, remove Check

Valves, operate pump,

look into ports to see if

Diaphragm is flexing. If

flexing, replace Check

Valves. If not flexing,

the Drive Mechanism has

failed—consult Dealer.

(3) Replacement of Valves

If a valve is to be replaced use a thin 1/2 in open end wrench on the

valve flats closest to the pump to remove the old valve and to install the

new one. Be sure to wrap 2 layers of PTFE tape on the pipe thread.

(4) Attach Tubing

The INLET and OUTLET VALVES on Pump Head are appropriately

labeled.

nn Attach tubing to the inlet and outlet CHECK VALVE fittings.

nn Apply a clamp to secure tubing at each fitting.

WARNINGS: CHECK VALVES are intended for use on this

pump only. Do not use separately from the pump

as forward flow at higher flow rates will suddenly

restrict, causing a rapid increase in backpressure

with resultant hose and connection bursting.

THIS PUMP IS CAPABLE OF DEVELOPING PRESSURES

IN EXCESS OF THE MAXIMUM RATED 100 PSIG INTERMITTENT DUTY. APPROPRIATE PRECAUTIONS SUCH AS

A PRESSURE RELIEF VALVE MUST BE INSTALLED TO

PROTECT THE PUMP AND ANCILLARY CONNECTIONS

FROM ACCIDENTAL OVER-PRESSURIZATION.

(5) Install Filter

Suspended particles in the fluid might cause CHECK VALVE leakage,

resulting in metering inaccuracies. Install a Filter at the pump inlet, if

required.

(6) Adjust Drive Speed

Adjust the variable speed Drive until the required flow rate is achieved.

(Refer to instructions provided with Drive.) Typically, flow will be about

200 mL/min per 100 rpm.

7) Calibrate the Pump (if required)

If best precision is required, each metering session should begin with

a flow calibration procedure. Do this in accordance with anticipated

conditions of speed, temperature and pressure operation.

Allow the pump to run continuously for 5 minutes. This will ensure that

any air drawn into pump during priming has passed through the

DIAPHRAGM HEAD. This warmup period also allows the valves to

properly seal. Also, it stabilizes operating temperatures for the drive

motor and controls. During the first hour of pump/drive operation, minor

warmup considerations may affect metering accuracy.

6 7

Loading...

Loading...