Page 1

INSTALLATION & OPERATIONS INSTRUCTIONS

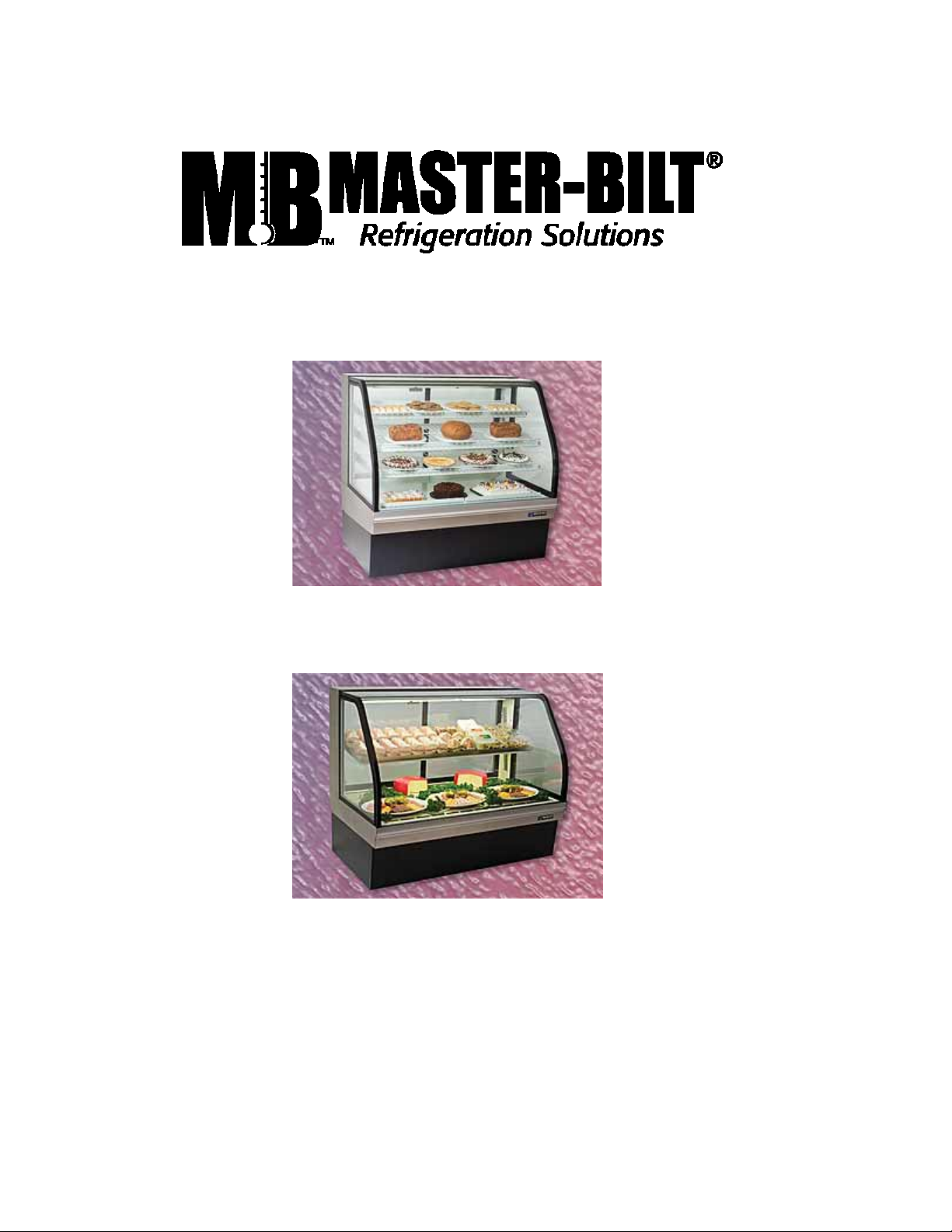

CGB-50, CGB-59, CGB-77

CGD-50, CGD-59, CGD-77

KEEP THIS MANUAL FOR FUTURE REFERENCE

Engineering and technical data are subject to change without notice.

Master-Bilt Products

908 Highway 15 North

New Albany, MS 38652

Phone: (800) 684-8988

6/16 Rev. A 57-02502 1

Page 2

CONTENTS

INTRODUCTION ....................................................................................................................................... 3

WARNING LABELS & SAFETY INSTRUCTIONS ............................................................................. 4

PRE-INSTALLATION PROCEDURES .................................................................................................. 5

Inspection For Shipping Damage ................................................................................................ 5

INSTALLATION INSTRUCTIONS ......................................................................................................... 5

Locating The Display Case ......................................................................................................... 5

Removing Case From Shipping Skid .......................................................................................... 5

Grill Removal .............................................................................................................................. 6

Condensate Evaporator ............................................................................................................... 7

Cleaning ...................................................................................................................................... 7

Refrigeration Installation ................................................................................................................. 7

ELECTRICAL INFORMATION & GROUNDING ............................................................................... 8

OPERATING INSTRUCTIONS ............................................................................................................... 9

Controls ....................................................................................................................................... 9

Shelves ........................................................................................................................................ 9

Rear Package Shelf ..................................................................................................................... 9

Doors ........................................................................................................................................... 9

Placing Product Into Case ......................................................................................................... 10

SHELVING INSTALLATION & REMOVAL ................................................................................. 11-13

Shelves and shelf light quantity ................................................................................................ 13

SHELF INSTALLATION ........................................................................................................................ 13

Wire Shelves ............................................................................................................................. 13

Metal Shelves ............................................................................................................................ 13

MAINTENANCE ...................................................................................................................................... 14

Shelf Light Bulb Replacement .................................................................................................. 14

Top Light Bulb Replacement .................................................................................................... 14

PERIODIC MAINTENANCE ................................................................................................................. 15

Cleaning Condenser Coil .......................................................................................................... 15

CLEANING INSTRUCTIONS ........................................................................................................... 16-18

Daily Cleaning .......................................................................................................................... 16

Weekly Cleaning ....................................................................................................................... 17

Interior Cleaning .................................................................................................................. 17-18

Exterior Cleaning ...................................................................................................................... 18

SERVICE INFORMATION .................................................................................................................... 19

Pre-Service Checklist ................................................................................................................ 20

Special Service Situations ......................................................................................................... 21

SALE & DISPOSAL ................................................................................................................................. 21

Owner Responsibility............................................................................................................ 2129

REFRIGERATION & ELECTRICAL DATA ...................................................................................... 22

MAIN WIRING DIAGRAMS ................................................................................................................. 23

LIGHT WIRING DIAGRAMS .......................................................................................................... 24-26

REPLACEMENT PARTS ....................................................................................................................... 27

6/16 Rev. A 57-02502 2

Page 3

INTRODUCTION

Thank you for purchasing a Master-Bilt® cabinet. This manual contains important instructions for

installing and servicing the Master-Bilt® Curved Glass Display Cases. A repair parts list and wiring

diagram are also included in the manual. Read all of these documents carefully before installing or

servicing your case.

NOTICE

Read this manual before installing your case. Keep this manual and refer to it before doing any

service on the equipment. Failure to do so could result in personal injury or damage to the

case.

NOTICE

Installation and service of the electrical components in the case must be performed by a

licensed electrician.

The portions of this manual covering components contain technical instructions intended only for

persons qualified to perform electrical work.

DANGER

Improper or faulty hookup of electrical components in the case can result in severe injury or

death.

All electrical wiring hookups must be done in accordance with all applicable local, regional, or

national standards.

SERIAL NUMBER

Record the model and serial numbers of the case for easy reference. Always refer to both model and

serial numbers in your correspondence regarding the case.

Case Model Serial Number

Condensing Unit Model Serial Number

This manual cannot cover every installation, use, or service situation. If you need additional

information, call or write us:

Technical Service Department

Master-Bilt Products

Highway 15 North

New Albany, MS 38652

Phone: (800) 684-8988

Fax: (866) 882-7629

Email: service@master-bilt.com

6/16 Rev. A 57-02502 3

Page 4

CAUTION

RISK OF ELECTRIC

SHOCK DISCONNECT

WARNING LABELS & SAFETY

INSTRUCTIONS

This is the safety-alert symbol. When you see this symbol on your case or in the

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe

operating procedures.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses, or services your case is

thoroughly familiar with all safety information and procedures.

Important safety information is presented in this section and throughout the manual. The

Following signal words are used in the warning and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your case can occur if you ignore the message.

NOTICE: This is important installation, operation, or service information. If you ignore the

message, you may damage your case.

The warning and safety labels shown throughout this manual are placed on your

case at the factory. Follow all warning label instructions. If any warning or safety labels become lost or

damaged, call our customer service department at (800) 684-8988 for replacements.

POWER BEFORE

SERVICING UNIT.

91-12340

This label is located on the back of the display case. This label is located below the display pan.

6/16 Rev. A 57-02502 4

Master-Bilt®

CAUTION

HAZARDOUS MOVING PARTS

DO NOT OPERATE UNIT WITH

DISPLAY PANS REMOVED.

Page 5

PRE-INSTALLATION PROCEDURES

Inspection for Shipping Damage

You are responsible for filing all freight claims with the delivering truck line. Inspect all cartons

and crates for damage as soon as they arrive. If damage is noted to shipping crates, cartons, or if

a shortage is found, note this on the bill of lading (all copies) prior to signing.

If damage is discovered when the case is uncrated, immediately call the delivering truck line and

follow up the call with a written report indicating concealed damage to your shipment. Ask for

an immediate inspection of your concealed damage item. Crating material must be retained to

show the inspector from the truck line.

INSTALLATION INSTRUCTIONS

Locating the Display Case

The case should be located where it is not subjected to the direct rays of the sun, heating ducts,

grills, radiator, or ceiling fans, nor should it be located near open doors or main door entrances.

Also, avoid locations where there are excessive air movement or air disturbances.

The condenser air inlet and discharge is located at the rear of the case. Do not block this inlet

and do not locate the air inlet near a source of heat.

Removing Case From Shipping Skid

CAUTION:

door frames when removing the case from the skid or moving the case. Case

damage or glass breakage could result.

1. Remove crate top and sides and note missing or damaged items as explained in the pre-installation

procedures outlined above.

2. Move the case as near as possible to the final location and before removing it from the shipping skid.

3. If your case is supplied with plastic end panels, remove them by lifting them in an upward direction.

Set these end panels aside to be reinstalled after case is placed in proper position.

4. Remove the (4) brackets that secure the case to the shipping skid.

5. Lift case off of skid and into required position.

6/16 Rev. A 57-02502 5

Do not push against the top glass, front glass, end glass, doors or

Page 6

6. Level and square the case as needed by adjusting the leg leveler in each corner of base. (Use the

wrench provided.) (The case must be level for proper drainage of defrost condensate to the

condensate evaporator and allow for proper alignment of front glass.) The 59”, & 77” cases also

have a set of leg levelers in the center. These must be adjusted so the base is flat.

7. The leveled case must be sealed to the floor using a NSF Listed Sealant.

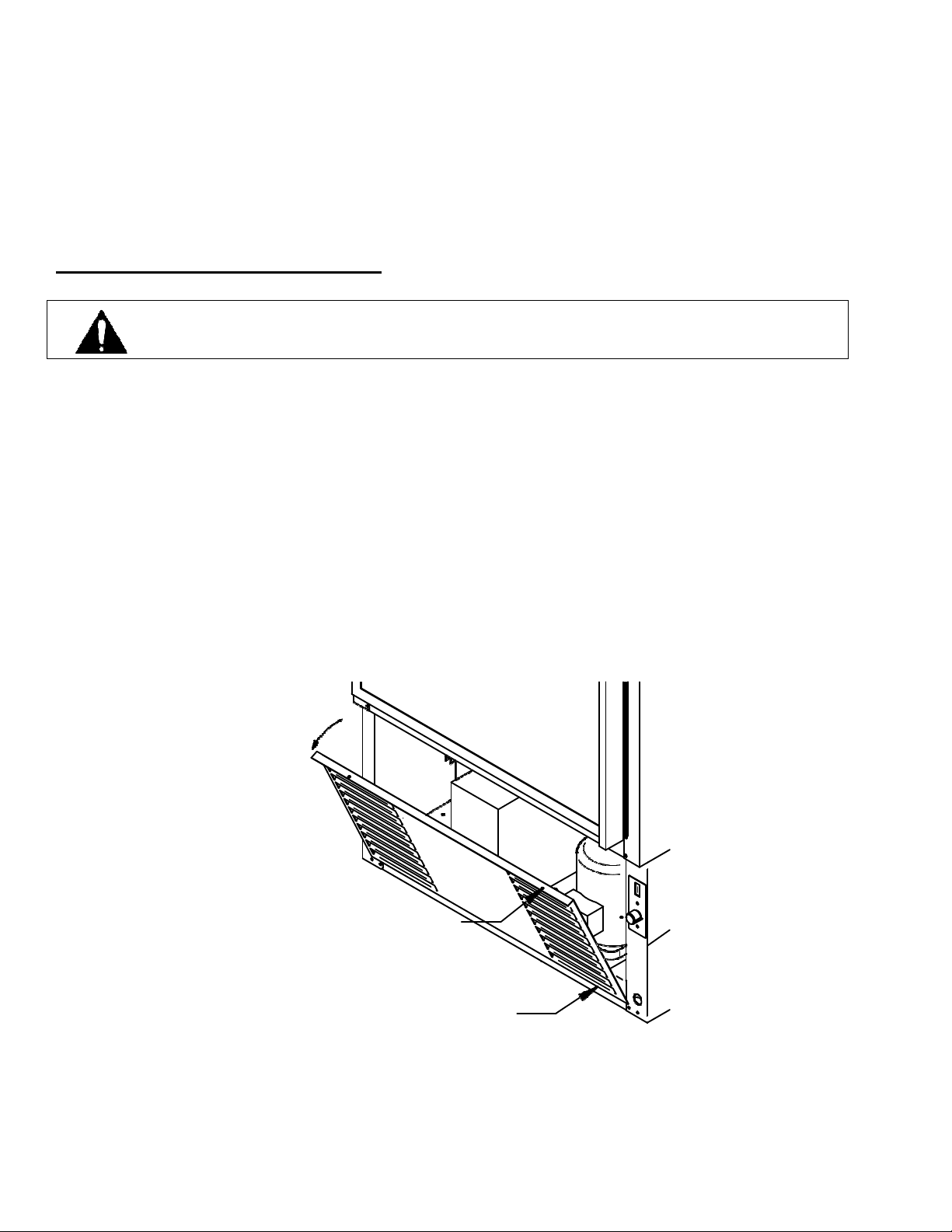

Grill Removal (Refrigerated Units)

DANGER:

There is a removable slotted panel at the rear of the case. The panel allows access to the

condensing unit, the light ballast, the condensate pan, and the field wiring connection box.

Remove this panel to make field wiring connections. See electrical information and grounding

section of this manual before wiring case.

Note: If electrical connection has been performed, disconnect power to case before removing grill panel.

1. Remove the rear grill panel screws from top of rear grill.

2. Tilt the top of rear grill panel outward as shown in illustration on the right.

3. Pull rear grill panel tabs up and out of slots in base of case.

Electric shock hazard. Do not operate unit with panels removed.

2.

1. REAR GRILL

PANEL SCREWS

3. REAR GRILL

PANEL TABS

6/16 Rev. A 57-02502 6

E1954-7

Page 7

Condensate Evaporator

This case is furnished with an electrical condensate evaporator. Plumbing connections are not

required.

The condensate evaporator is located toward the front of the machine compartment and is

accessible from the rear of the case. After removal of rear grill panel, make sure that the drain

line has not been dislodged during shipment and that the drain trap is located properly over the

water reservoir of the condensate evaporator pan.

Cleaning

For initial setup, clean the case as outlined in the weekly cleaning section of this manual.

Refrigeration Installation

Self Contained Models

The self-contained models are shipped from the factory with a completely operational 134A

refrigeration system and require no modifications or adjustments upon installation.

6/16 Rev. A 57-02502 7

Page 8

ELECTRICAL INFORMATION &

GROUNDING

This Case Must Be Grounded

DANGER:

Improper or faulty hookup of electrical components in the

display case can result in severe injury or death.

Only a licensed electrician must perform all case electrical connections.

All electrical wiring hookups must be done in accordance with all applicable local, regional, or national

electrical standards.

A separate circuit for each display case is recommended to prevent other appliances on the same circuit

from overloading the circuit and causing malfunction.

The electrical service must be grounded upon installation.

This unit is designed for permanent connection to a power source. See the electrical data plate located at

the rear of the case for proper circuit size and wire ampacity.

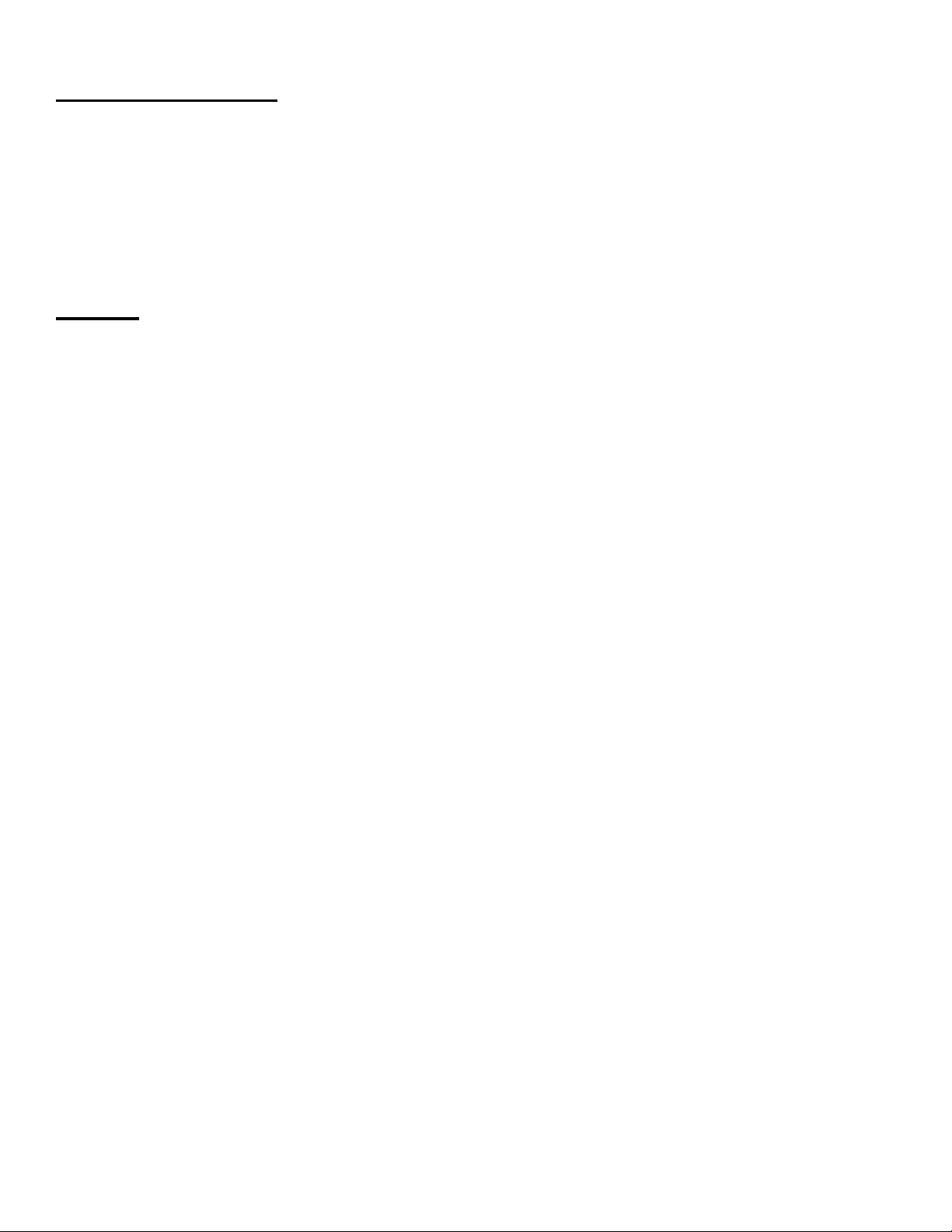

The electrical connection box is accessible from the rear of the case. Remove rear grill on refrigerated

models. (See “Grill Removal” in the installation section of this manual.) See diagram below for

location of the field wiring connection box.

BACK OF CASE OVERHANGS

BASE 1".

7/8" DIA. ELECTRICAL ENTRANCE

ON REAR OF CASE,

1" FROM SIDE OF BASE

1-3/4" FROM BOTTOM OF BASE

7/8" DIA. ELECTRICAL ENTRANCE

IN BOTTOM OF CASE,

2-3/4" FROM SIDE OF BASE,

2-1/8" FROM REAR OF BASE.

FIELD CONNECTION COVER

FOR REFRIGERATED CASES

E3233-1

6/16 Rev. A 57-02502 8

Page 9

OPERATING INSTRUCTIONS

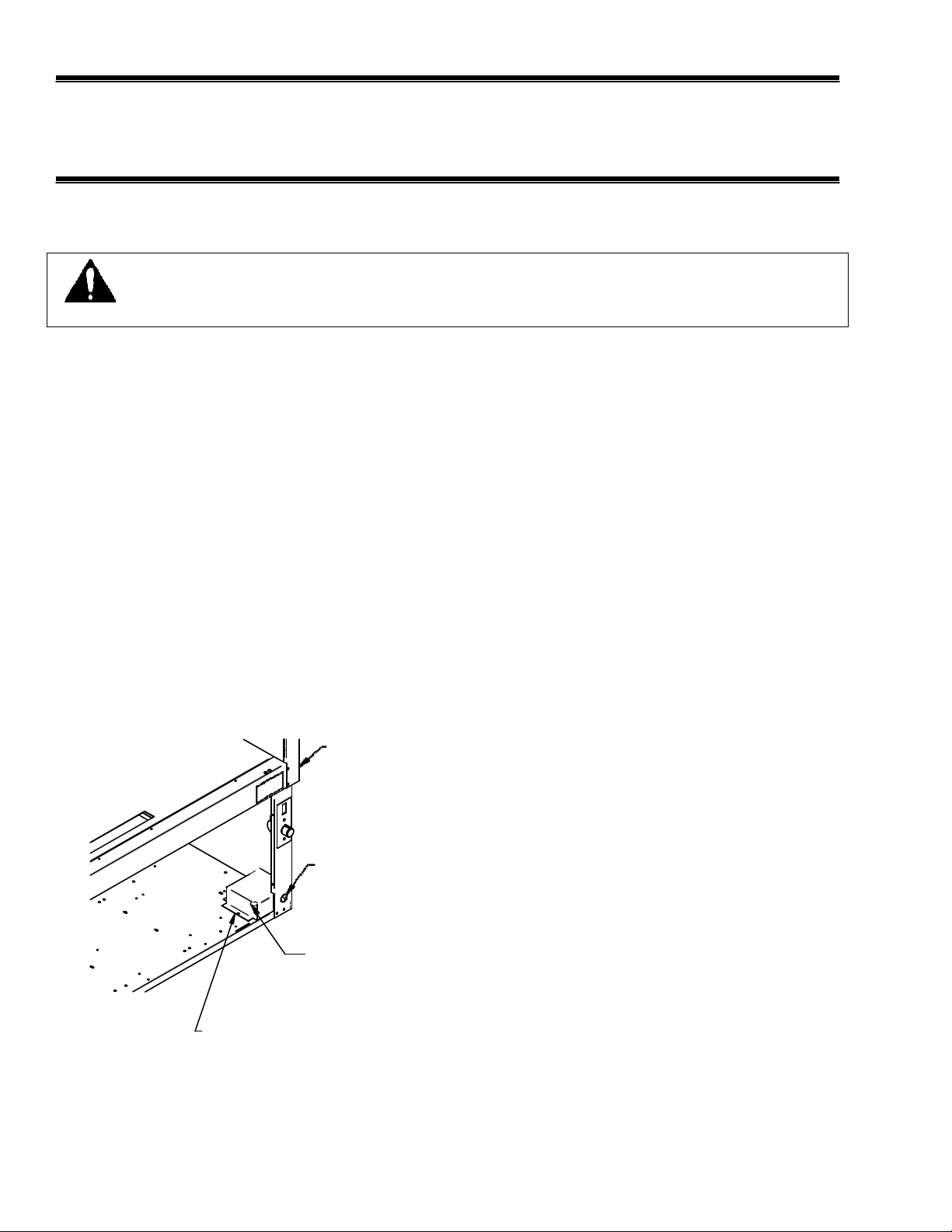

LIGHT SWITCH

TEMPERATURE CONTROL

E1954-8

Controls

Light Switch

This switch controls the power to the lighting circuit. The switch rocker is red in the “on”

position, black in the “off” position.

Temperature Control

This controls the refrigerated side by cycling the compressor/condensing unit. It has an “off”

position and the coldest setting when the knob is set all the way in the clockwise position. Set

this control at the lowest setting possible, while maintaining desired case temperature.

Shelves

Each display is furnished with shelves that are adjustable up and down and can be tilted in three

angular positions. See “Shelving Installation & Removal” section of this manual for proper

installation, adjustment and removal of shelving.

Sliding Rear Doors

The doors can be easily removed by lifting doors upward until the bottom edge of door clears the

lower track. Swing the bottom of door outward and down out of top track.

Clean the door track frequently for easy door operation. A Very light film of lubricant, such as

PAM, will help the doors slide easily.

6/16 Rev. A 57-02502 9

Page 10

Placing Product into Case

After completing shelving installation as outlined in “Shelving Installation and Removal” section

of this manual you may begin placing product into the display case.

- Do not exceed 150 pounds of weight per shelf. Heavy product should be distributed evenly

across the entire shelving area.

- Determine desired shelving location and angle before placing product in case. Product must be

removed to readjust shelf location and angle.

- Do not overhang the front of wire shelves with product. Product may overhang rear of shelf,

but allow a minimum of 1-1/2” between product and rear door. Improper clearance in front and

rear of shelf will block the refrigerated airflow and could cause product loss.

-Do not block the slots along the front or rear of the case display pan. Covering these slots will

block the refrigerated airflow and could cause product loss.

-The display pan is removable for cleaning and can become dislodged in shipment. To ensure

proper airflow and performance of the case, make sure that the display pan is pushed completely

down into evaporation tub. Check that the pan is installed properly before placing product the

display pans.

-Allow refrigerated models to run for at least two hours before placing pre chilled product into

unit. Turn temperature control to the lowest possible position that maintains required interior

cabinet temperature.

-CASE SHOULD BE STOCKED WITH PRE-CHILLED PRODUCT

ONLY.

ATTENTION:

- Refrigerated display cases are designed to operate in a maximum

environment of 75 DEG. F and 55% relative humidity. Exceeding these

limits could cause poor case performance and sweating of glass

panels.

6/16 Rev. A 57-02502 10

Page 11

SHELVING INSTALLATION & REMOVAL

METAL SHELF

WIRE SHELF

WIRE RETAINER

CLEAR PLASTIC

CLIP

SHELF BRACKET

SHELF LIGHT

SHELF SUPPORT

FEMALE SHELF

LIGHT SOCKET

SHELF RETAINER

CLEAR PLASTIC CLIP

WIRE SHELF ONLY

SHELF BRACKET

1. Turn the light switch to the off position, on units with sliding rear doors, remove both rear doors

from track by lifting doors upward until the bottom edge of door clears the lower track. Swing the

bottom of door outward and down out of top track.

2. Insert a shelf bracket in the desired shelf standard slot on one side of case. The short set of shelf

brackets are for the top shelf and the longer shelf brackets are for the middle and bottom shelves.

Follow the instruction in the illustration below. Place an additional shelf bracket in the same shelf

standard slot on the opposite end of case. Repeat for additional shelf tiers.

6/16 Rev. A 57-02502 11

Page 12

INSTALLATION

1

2

3

4

E1954-3

SHELF STANDARD

TOP HOOK

1

2

3

SHELF BRACKET

BOTTOM TAB

4

12° NOTCH

6° NOTCH

A.. Place shelf bracket top hook into desired shelf

standard slot.

B. Lift shelf bracket top hook to allow shelf bracket

bottom tab to clear shelf standard slot.

C. Swing shelf bracketbottom tab into shelf standard

slot.

D. Place the desired shelf bracket notch of 0, 6, or 12

degrees onto bottom of shelf standard slot.

0° NOTCH

REMOVAL

A. Lift shelf bracket up to allow shelf bracket notch

to clear the bottom of shelf standard slot.

B. Swing shelf bracket bottom tab out of shelf

standard slot.

C. Drop shelf bracket down to allow shelf bracket top

hook to clear top of shelf standard slot.

D. remove shelf bracket top from shelf standard slot.

3. Hang one end of shelf light housing on the front notch of a shelf bracket and then the other end of

shelf light housing on the notch of the shelf bracket on the opposite end. Repeat for each additional

shelf tiers

4. Push shelf light cords into clear plastic clip located on inside of shelf brackets.

5. Remove the cap from the appropriate female light sockets. If socket is not being used for a shelf

light, the cap must be plugged into socket for entire light system to operate. NOTE: Grip each side

of cap firmly and wiggle and pull cap straight out of socket. Do not roll cap during removal.

RIGHT

WRONG

6. Plug in each shelf light by aligning the male pins on the appropriate shelf light cord plugs with the

female light sockets and push together. NOTE: Do not roll plug during insertion.

6/16 Rev. A 57-02502 12

Page 13

7. Hang one end of the shelf support on to the rear notch of one shelf bracket and then on the rear notch

of the shelf bracket on the opposite side. Repeat for additional shelf tiers.

8. Place supplied shelving onto shelf supports as outlined in the appropriate “Shelf Installation” section

of this manual.

9. On units with sliding rear doors, re-install both rear doors by lifting top of door into top track and

swinging bottom of door onto bottom track. Install door labeled “inner door” first on inner track and

door labeled “outer door” second on outer track.

Shelves and shelf light quantity

It is not required that all shelves and shelf lights supplied with each case are used. The quantity of

shelves and shelf lights can be tailored to your specific needs. If the supplied quantity of shelves and

shelf lights are not required, cap unused female socket located in interior of the case mullion with caps

supplied. Failure to do so will prevent entire lighting system from operating.

SHELF INSTALLATION

Wire Shelves

1. The CGB models are provided with 22” wire shelves for the bottom and middle shelf and the 16”

wire shelf is for the top shelf.

2. With rear sliding doors removed place front of wire shelf onto front shelf light and snap the front of

shelf into the clear plastic clips on front light housing.

3. Snap the rear of shelf into the clear plastic clips on rear shelf support.

4. Repeat 2 & 3 for each tier.

NOTE: Units with 73” long rear shelf supports uses (2) wire shelves per tier. All other units use (1)

wire shelf per tier.

Metal Shelves

1. The CGD models are provided with a single metal shelf.

2. With rear sliding door removed, or rear swing door open, place front of metal shelf on to front shelf

light.

3. Set the rear of the metal shelf on to the rear shelf support so that the notch at each end of metal shelf

straddles the rear shelf support. If clear plastic clips were factory-installed on top of rear shelf

support or front shelf light, remove and discard clear plastic clips.

4. Repeat steps 2 & 3 for each tier if supplied with more than (1) tier of shelving.

6/16 Rev. A 57-02502 13

Page 14

MAINTENANCE

Shelf Light Bulb Replacement

1. All shelf light fixtures use a spring-loaded socket at one end. To remove the bulb push the bulb

towards the spring-loaded socket until the opposite ends drops out of the socket.

2. The bulb is inside a clear shatter proof tube with a black plastic cap on each end. Be careful not

to allow bulb to slide out of shatter proof tube.

3. Reinstall new bulb in to the existing shatter proof tube and reuse black plastic end caps. Reinstall

bulb assembly in the same manner as described in the Bulb Removal Procedure. Be sure bulb is

secure in bulb receptacles

Note: Be sure to use a direct equivalent to the original bulb.

Top Light Bulb Replacement

1. On units with sliding rear doors, remove both rear doors from track by lifting doors upward until the

bottom edge of door clears the lower track. Swing the bottom of door outward and down out of top

track. On units with rear swing doors completely open doors to allow access to interior of case.

2. Remove all shelves, shelf supports and Shelf lights from unit through rear door opening. (See

“Shelving Installation and Removal” section of this manual for instruction if needed)

3. Remove top light lens clip screw(s), lens clip(s), and top light lens as illustrated below.

4. To remove bulb from top light housing, grip the bulb receptacle end caps at each end of bulb. Pull

the bulb receptacle end caps straight outward toward front of case. Once bulb and bulb receptacle

end caps are removed from top light housing remove the bulb receptacle end caps from end of bulb.

(Note: 50”dual zone models do not have end caps.)

5. Reinstall new bulb in the same manner as described in the Bulb Removal Procedure. Be sure bulb is

secure in bulb receptacles. Note: Be sure to use a direct equivalent to the original bulb.

6. Reinstall top light lens, lens clips, and lens clip screws in reverse order as shown in illustration

below.

BULB END CAPS

TOP LIGHT LENS

2

1

LENS CLIP SCREW(S)

LENS CLIP(S)

BULB END CAPS

3

E1954-4

6/16 Rev. A 57-02502 14

4

TOP LIGHT LENS

Page 15

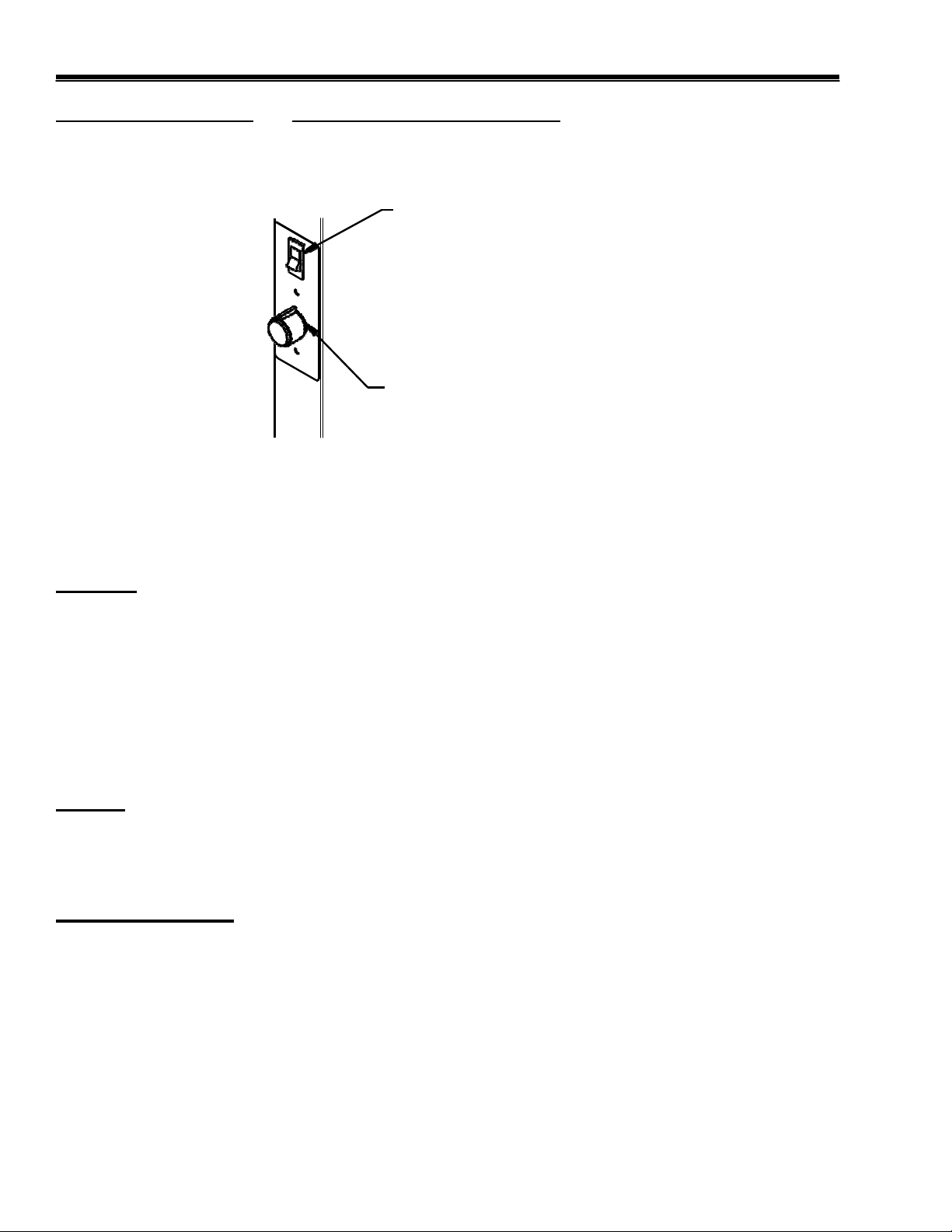

PERIODIC MAINTENANCE

Cleaning Condenser Coil

It is very important that the Condenser coil is cleaned twice per month to insure proper

refrigeration performance and to prevent compressor failure. Failure to clean condenser

coil will void condenser warranty.

1. Disconnect power to the unit.

2. Remove the back base panel located on the back bottom of unit by removing the panel retaining

screws.

3. Carefully vacuum the front surface of condenser coil. Take care not to bend coil fins with

vacuum cleaner nozzle.

4. Reinstall back panel and retaining screws.

VACCUM

CONDENSER

COIL FINS

AIR INTAKE

REAR PANEL

6/16 Rev. A 57-02502 15

Page 16

CLEANING INSTRUCTIONS

NOTICE:

Remove all product from case before proceeding with cleaning

NOTICE:

Shut off lights and power switches and remove all product from case.

proceeding with cleaning.

NOTICE:

Avoid splashing or soaking any electrical components with water to

Daily Cleaning

The case should be cleaned thoroughly, as described in the weekly cleaning section, before it is

used for the first time.

prevent electrical damage to the case.

Allow sufficient time for the unit to reach room temperature before

procedure.

Note: For major spills or foreign material buildup use complete weekly cleaning instructions.

1. Clean all foreign materials from the door opening.

2. Wipe complete interior of case using a damp cloth.

3. Tilt the front glass forward as described in the illustrations below. This will allow easier

access to clean interior front and side glass. The glass can then be cleaned with common

window cleaners.

OPEN FRONT

1.

Stand in front of unit and grab the pull

GLASS:

handle with both hands.

2.

Pull front glass outward until the glass

rests on front glass stops.

CLOSE FRONT GLASS

1.

Stand in front of unit and push on front

:

of pull handle with both hands.

2.

Firmly push glass towards rear of unit

until front glass rests in closed position

4. The remaining exterior surface should be wiped down using any soapy warm water.

Note: Do not use detergents or chlorine and do not use abrasive cleaners or pads to prevent

scratching of surfaces.

6/16 Rev. A 57-02502 16

Page 17

Weekly Cleaning

NOT

ICE:

Avoid splashing or soaking any electrical components with water to

NOTICE:

Shut off light and power switches and remove all product from case. Allow

with cleaning.

This procedure is recommended on a weekly basis. It may need to be performed more often if

necessary to maintain a clean, sanitary case. The case should be cleaned to this procedure before

using the first time.

Interior Cleaning

REFRIGERATED

MODELS ONLY

FAN SHROUD

MOUNTING TABS

EVAP FAN SHROUD

prevent electrical damage to the case.

sufficient time for the unit to reach room temperature before proceeding

REAR DOOR

REAR DOOR

OUTER

INNER

SHELVING

EVAP. FAN

DISPLAY PAN

SHELF

SHELF

SUPPORT

SHELF BRACKET

SHELF STANDARD

LIGHT

E1954-9

6/16 Rev. A 57-02502 17

Page 18

1.

Remove all interior shelving as described in the shelving installation and removal section of this

manual.

2.

Remove both shelf standards from interior of case. First remove thumbscrew at bottom of shelf

standard and then slide shelf standard up to allow top key slot to clear.

3.

Lift the display pan up and out of evaporator tub. Remove display pan through rear opening.

4.

Remove the evaporator fan shroud. First remove the thumbscrews along the backside of

evaporator fan shroud. Lift the rear of the evaporator fan shroud allowing the front to hinge on

fan shroud mounting tabs. Reach in and unplug the evaporator fan motor cord. Continue to lift

the evaporator fan shroud while at the same time pulling it to the door opening of case until the

slots in the evaporator fan shroud can clear the fan shroud mounting tabs. Remove evaporator

fan shroud through rear opening.

5.

Clean the entire interior of the case using warm soapy water. Wipe off all soapy water with a

damp cloth and allow todry.

NOTE: Depending on the amount of usage and spillage of foreign material, some fasteners may have to

be removed and parts disassembled to allow proper cleaning of the unit.

6.

Clean all shelves, shelf support bars, shelf light housings, shelf light housings, shelf brackets,

and display pans using warm soapy water and a brush. Rinse thoroughly and allow to dry.

7.

Clean all foreign material from inner and outer rear door tracks using warm soapy water and a

brush. Apply a light film of lubricant such as PAM to make the doors operate smoother.

8.

Clean both sides of the doors and interior of the front glass using any common window cleaner.

NOTE: Front glass can be tilted forward to simplify front glass cleaning. See “Daily Cleaning” section

for glass tilting operation.

9.

Reassemble the case in reverse order starting with Step 6.

Exterior Cleaning

1.

Clean the front glass using any common window cleaner.

2.

The exterior surfaces should be wiped down using any ammoniated cleansers or warm soapy

water.

NOTE: For major spills or foreign material build-up use complete weekly cleaning instruction.

6/16 Rev. A 57-02502 18

Page 19

SERVICE INFORMATION

CAUTION:

Before servicing case turn off power at the main breaker of

CAUTION

RISK OF ELECTRIC

SHOCK

Service problems or request for repair parts from authorized service agencies, trained service personnel,

or owners should be referred to:

DISCONNECT POWER

Pre-Service Checklist

You may avoid the cost and inconvenience of an unnecessary service call by first reviewing this

checklist of frequently encountered situations that can cause unsatisfactory case performance.

Before any service work is

performed on the case, make sure all

power is disconnected to the case.

fuse box.

Technical Service Department

Master-Bilt Products

Highway 15 North

New Albany, MS 38652

Phone: (800) 684-8988

Fax: (866) 882-7629

Email: service@master-bilt.com

6/16 Rev. A 57-02502 19

Page 20

Pre-Service Checklist

Case Does Not Operate

Check for disconnected power supply.

Check for tripped breaker or blown fuse.

Check that the thermostat is not “off”.

Lights Do Not Operate

Check that light switch is on.

Be sure light is properly seated in the sockets.

Check that light cord(s) are tight in the sockets.

Plug unused light sockets with socket cap provided with socket.

Case Temperature Too Warm

Check that the cold air inlet and outlet slots are not blocked.

Be sure that the rear doors are closed and tightly sealed.

Check for a blocked or dirty condenser coil filter or condenser coil fins.

Check cold airflow. Lack of adequate cold airflow could be a defective evaporator fan or

blocked evaporator coil. Check that paper or foreign material is not blocking evaporator.

If the evaporator coil is blocked due to excessive frost, turn the thermostat knob to the

“off” position for approximately one hour to defrost. Excessive frost will buildup if the

case is operated with the door open or ajar.

Check that the display pans are installed properly.

Glass Fogging

Check room ambient – Case is designed to operate in an environment not to exceed 75°F

and 55% relative humidity.

Check case temperature – Case is designed to operate between 38°F and 42°F.

Check that nothing is placed on the top of the case glass.

6/16 Rev. A 57-02502 20

Page 21

Special Service Situations

There are rare occasions when the refrigerant charge must be evacuated from a case in order to

perform service work. In those situations the refrigerant charge must be evacuated into a

recovery system to prevent the possibility of hydrofluorocarbons (HFC’s) from being released

into the atmosphere.

If moisture or liquid is observed around or under case, an immediate investigation should be

made by qualified personnel to determine the source of the moisture or liquid. The investigation

made should determine if the case is malfunctioning or if there is a simple housekeeping

problem.

Moisture or liquid around or under a case is a potential slip/fall hazard for persons walking by or

working in the general area of the case. Any case malfunction or housekeeping problem that

creates a slip/fall hazard around or under a case should be corrected immediately.

SALE & DISPOSAL

Owner Responsibility

If you sell or give away your

the Installation-Service Manual are included with it. If you need replacement labels or

manuals, Master-Bilt will provide them free of charge. Contact the technical service

department at Master-Bilt at (800) 684-8988.

The technical service department at Master-Bilt should be contacted at the time of sale or

disposal of your case so records may be kept of its new location.

If you sell or give away your

before shipment. Master-Bilt recommends that the charge be evacuated into a recovery

system to prevent the possibility of HFC’s from being released into the atmosphere.

Master-Bilt®

Master-Bilt®

case you must make sure that all safety labels and

E32case and you evacuate the refrigerant charge

6/16 Rev. A 57-02502 21

Page 22

REFRIGERATION & ELECTRICAL DATA

REFRIGERANT

LIGHTS

EVAPORATOR

CONDENSATE

COMPRESSOR

TOTAL

DATA

R-134 (OZ)

FAN MOTOR

PAN HEATER

RLA LRA AMPS

REFRIGERATED SELF CONTAINED

CGB-50 28 0.7 0.4 1.2 8.8 58.8 10.5

CGB-59 32 0.9 0.4 1.2 8.8 58.8 11.6 CGB-77 36 1.3 0.8 1.2 10.1 68 14.2

CGD

-

50 28 0.7 0.4 1.2 8.8 58.8 10.5

CGD

-

59 32 0.9 0.4 1.2 8.8 58.8 11.6

CGD

-

77 36 1.3 0.8 1.2 10.1 68 14.2

Refer to the data plate attached to rear of the case for maximum fuse size and minimum circuit ampacity.

REFRIGERATION

&

ELECTRICAL

6/16 Rev. A 57-02502 22

Page 23

MAIN

WIRING

DIAGRAM

DETAIL

BL K

R

EAR SWING

DOO R

UNIT S

ONLY

CONDENSATE

EVAP.

BLK BLK

(HEATER)

BL K

LIGHT

(SEE LIGHT WIRING

E VAP .

M

(BALLAST)

W

TO L IGHT

INCLUDED ON 77 UNITS ONLY

HIGH PRESS .

CONDENSER

BL K

CORD

ON 36 ,59DZ

BLK

BL

K/RIB (THE RM.)

SEE DIAGRAM

COLOR

CODE

FIE LD

BLK

=

BLACK

YELLOW

G = GREEN

91-1 414 6 12/2 2/98

120 VOLTS

UNIT

MUST

BE GROUNDED

MAIN WIRING DIAGRAMS

D

L1

120 VOLT REFRIGERATED SELF CONTAINED

DOOR TRIM HEATER

M

FAN

MOTOR

FAN

MOTOR

BLK/RIB

BL K

BL K/RIB

IN COMP.

FOR DETAILS.

CONDENSINGUNI

T

BL K

BLK/ RIB

BLK

BLK /RIB

RECEPTACLE

W

G

G

GN

(HEA TER)

(SWITCH)

K

BL

BLK/ RIB

K

W

BL

CONNECTION

BO X

N

BLK

BL K/RIB

SWITCH

G

CUTOUT

& 77DZ ONLY

W = WHITE

R = RED

EVAPORATOR

DIAGRAM DETAIL)

BALLAST

(THERM.)

6/16 Rev. A 57-02502 23

60 HERTZ

1 PHASE

B = BLUE

Y =

Page 24

LIGHT WIRING DIAGRAMS

LIGHT

WIRING

DIAGRAM

B (T1)

TOP LIGHT

LAMP

G

W

W

RECP.&

BLK

B

(BALLAST)

BLK

B

(A)

TO LIGHT

SW.

(SWITCH)

BLK

G PLUG

G

G

(SEE

MAIN

WIRING DIAGRAM

DETAIL)

91-13924

04/16/01

COLOR CODE:

B =

BLUE

YELLOW

G = GREEN

CGD-50, CGD-59 & CGD-77

DETAIL

(2) F017T8, FO25T8, FO32T8, FO40T8

R (T1)

(BALLAST)

TO GROUND

BALLAST

R

(A)

BLK = BLACK

W = WHITE

R = RED

R (S1)

B (S1)

BLK (B)

BLK

SHELF LIGHT

R

B

LAMP

Y =

6/16 Rev. A 57-02502 24

Page 25

CGB-50 & CGB-59

LIGHT WIRING DIAGRAM

DETAIL

TO LIGHT SW.

TO GROUND

(BALLAST)

W

(4) FO15T8,F017T8, FO25T8, FO32T8

ONLY 1 YELLOW

ON F15 BALLAST

ALL BL TO Y

Y

W

BLK

(BALLAST)

(SWITCH)

BALLAST

Y

BLK

G

(A)

R

R

B (R)

B (R)

(A)

BLK

G

B (S1)

R (S1)

BLK

BLK

G

R (S2)

B (S2)

BLK

BLK

G

R (S3)

B (S3)

BLK

BLK

G

B (T1)

R (T1)

RECP.&

PLUG

R

B

G

RECP.&

PLUG

R

B

G

RECP.&

PLUG

R

B

G

TOP LIGHT

LAMP

SHELF LIGHT

LAMP

SHELF LIGHT

LAMP

SHELF LIGHT

LAMP

(SEE MAIN WIRING DIAGRAM DETAIL)

91-13927

6/16 Rev. A 57-02502 25

5/7/08

(R) (R) FOR FO15

COLOR CODE:

BLK = BLACK

W = WHITE

R = RED

B = BLUE

Y = YELLOW

G = GREEN

Page 26

CGB-77

LIGHT

WIRING

DIAGRAM

DETAIL

(4) F040T8

B (T1)

TOP LIGHT

LAMP

CAP

BLUE

LEADS

NOT

USED

G

B

RECP.&

BALLAST

R

R (S1)

G

PLUG

R

B

LAMP

G

RECP.&

B (S2)

PLUG

R (S2)

G

RECP.&

R

BLK

BALLAST

(BALLAST)

B

R

TO LIGHT

SW.

(SWITCH)

BLK

B (S3)

COLOR CODE:

BLK = BLACK

B

(A)

LAMP

G

(SEE MAIN WIRING DIAGRAM DETAIL)

91-13928

04/16/01

B =

BLUE

YELLOW

G = GREEN

R (T1)

W

SHELF LIGHT

(BALLAST)

W

TO GROUND

BLK

B

(A)

G

B (S1)

BLK

BLK

BLK

BLK

G

R (S3)

BLK

BLK

G

PLUG

SHELF LIGHT

B

R

LAMP

SHELF LIGHT

6/16 Rev. A 57-02502 26

W = WHITE

R = RED

Y =

Page 27

REPLACEMENT PARTS

MODELS

LIGHT

LIGHT

LIGHT

BULB

LIGHT BULB

SHELF LIGHT

SHELF

TOP LIGHT

LIGHT

SC MAIN

CGB-50

41-11066

39-12904

42-11069

42-15441

43-15888

43-13920

42-14141

43-15889

42-13643

91-13927

91-14146

CGD-50

41-11066

39-12902

42-11069

42-15441

43-15888

43-13922

42-14141

43-15889

42-13643

91-13924

91-14146

CGB-59

41-11066

39-12904

42-11070

42-15441

43-15888

43-13920

42-14142

43-15889

42-13644

91-13927

91-14146

CGD-59

41-11066

39-12902

42-11070

42-15441

43-15888

43-13922

42-14142

43-15889

42-13644

91-13924

91-14146

CGB-77

41-11066

39-12903

42-11071

42-15441

43-15888

43-13920

42-14164

43-15889

42-13645

91-13928

91-14146

CGD-77

41-11066

39-12903

42-11071

42-15441

43-15888

43-13922

42-14164

43-15889

42-13645

91-13924

91-14146

MODELS

CURVED

END GLASS

END GLASS

END GLASS

FRONT

CGB-50

50-18936

-

3 50-18938

50-18938

-

L 50-18938

-

R 64-13122

CGD-50

50-18936

-

3 50-18938

50-18938

-

L 50-18938

-

R 50-18938

-

R

CGB-59

50-18936

-

4 50-18938

50-18938

-

L 50-18938

-

R 50-18938

-

R

CGD-59

50-18936

-

4 50-18938

50-18938

-

L 50-18938

-

R 50-18938

-

R

CGB-77

50-18936

-

5 50-18938

50-18938

-

L 50-18938

-

R 50-18938

-

R

CGD-77

50-18936

-

5 50-18938

50-18938

-

L 50-18938

-

R 50-18938

-

R

MODELS

CONDENSING UNIT

CGB-50

30-14218

30-15328

33-13357

32-12625

41-13363

72-12254

32-12391

32-15495

SA-2134 40-13362

CGD-50

30-14218

30-15328

33-13357

32-12625

41-13363

72-12254

32-12391

32-15495

SA-2134 40-13362

CGB-59

30-14218

30-15328

33-13358

32-12625

41-13363

72-12254

32-12391

32-15495

SA-2134-1 40-13362

CGD-59

30-14218

30-15328

33-13358

32-12625

41-13363

72-12254

32-12391

32-15495

SA-2134-1 40-13362

CGB-77

30-14219

30-15329

33-13359

32-12625

41-13363

72-12254

32-12391

32-15495

SA-2134-1 40-13362

CGD-77

30-14219

30-15329

33-13358

32-12625

41-13363

72-12254

32-12391

32-15495

SA-2134-1 40-13362

MODELS

DOOR LEFT

DOOR RIGHT

DOOR LEFT

DOOR RIGHT

WIRE SHELF

WIRE SHELF

WIRE SHELF

SHELF

STAINLESS

SHELF

SHELF

CGB-50

53-13676

53-13677

53-13692

53-13693

63-13815

-

2 63-13815

-

1 81-30618

SA4842

-

3 N/A 67-14293

67-15229

CGD-50

53-13676

53-13677

53-13692

53-13693

N/A N/A N/A SA4842

-

3 M11558

-

1 67-14293

67-15229

CGB-59

53-13676

53-13677

53-13692

53-13693

63-13816

-

2 63-13816

-

1 81-30618

SA4842

-

4 N/A 67-14293

67-15229

CGD-59

53-13676

53-13677

53-13692

53-13693

N/A N/A N/A SA4842

-

4 M11558

-

2 67-14293

67-15229

CGB-77

53-13680

53-13681

53-13696

53-13697

63-13817

-

2 63-13817

-

1 81-30618

SA4842

-

5 N/A 67-14293

67-15229

CGD-77

53-13680

53-13681

53-13696

53-13697

N/A N/A N/A SA4842

-

5 M11558

-

3 67-14293

67-15229

ELECTICAL COMPONENTS

SWITCH

BALLAST

GLASS COMPONENTS

FRONT

GLASS

CLEAR

REFL. L.H.

REFRIGERATION COMPONENTS

R

(SC) 120V (SC) 240V

O

AT

L

EVAPOR

COI

CAP

REFL. R.H.

N

O

NSI

A

EXP

VALVE

SHELF LIGHT

CORD

GLASS EDGE

SEAL 3'

R

O

AT

EVAPOR

TOP LIGHT

LENSE

WIRING

DIAGRAM

WIRING

DIAGRAM

RECEPT.

HARNESS

LENS

LENS

WIRE

HARNESS

R

TOR

E

O

M

BLAD

FAN

W/

O

DE

AT

BLA

FAN

EVAPOR

ER

I

DR

ER

LT

FI

T

TA

THERMOS

E

SY

S

ENSAT

A

PAN

COND

E

ENSAT

TER

COND

HEA

DOOR & SHELF COMPONENTS

CLEAR

CLEAR

REFLECTIVE

6/16 Rev. A 57-02502 27

REFLECTIVE

WHITE

TOP

WHITE

MID/BTM

CLIP

LIGHT ASSY

SHELF

BRACKET

TOP

BRACKET

MID/BTM

Loading...

Loading...