Page 1

VISION CREATIVE, INC.

중구 남대문로 5가 526

대우재단빌딩 16층

담 당 김세호님 TEL

MODEL

CCR-23SR,49DR,72TR/WCC-23SR/WCR-23SR/CCR-23SF,49DF,72TF/WCR-23SF

BUYER

1차 03.2.7 6차

2차 03.2.13 7차

일정 3차 03.7.22 8차

4차 03.7.25 9차

5차 03.7.28 10차

제판 03.7.28(Han)출력

인인쇄쇄

규격

MEMO

03.12.15-3page-수정 (6)추가

연연락락처처

VVIISSIIOONN

담담 당당

박선민

TEL: 757-9340 FAX: 7741039

Page 2

Refrigerator

Freezer

Installation and Operation Manual

Please read this manual completely before attempting to install or operate this equipment!

Full Stainless Steel Visible Exterior

Refrigerator

CCR-23SR

CCR-49DR

CCR-72TR

WCC-23SR

WCR-23SR

Freezer

CCR-23SF

WCR-23SF

CCR-49DF

CCR-72TF

Page 3

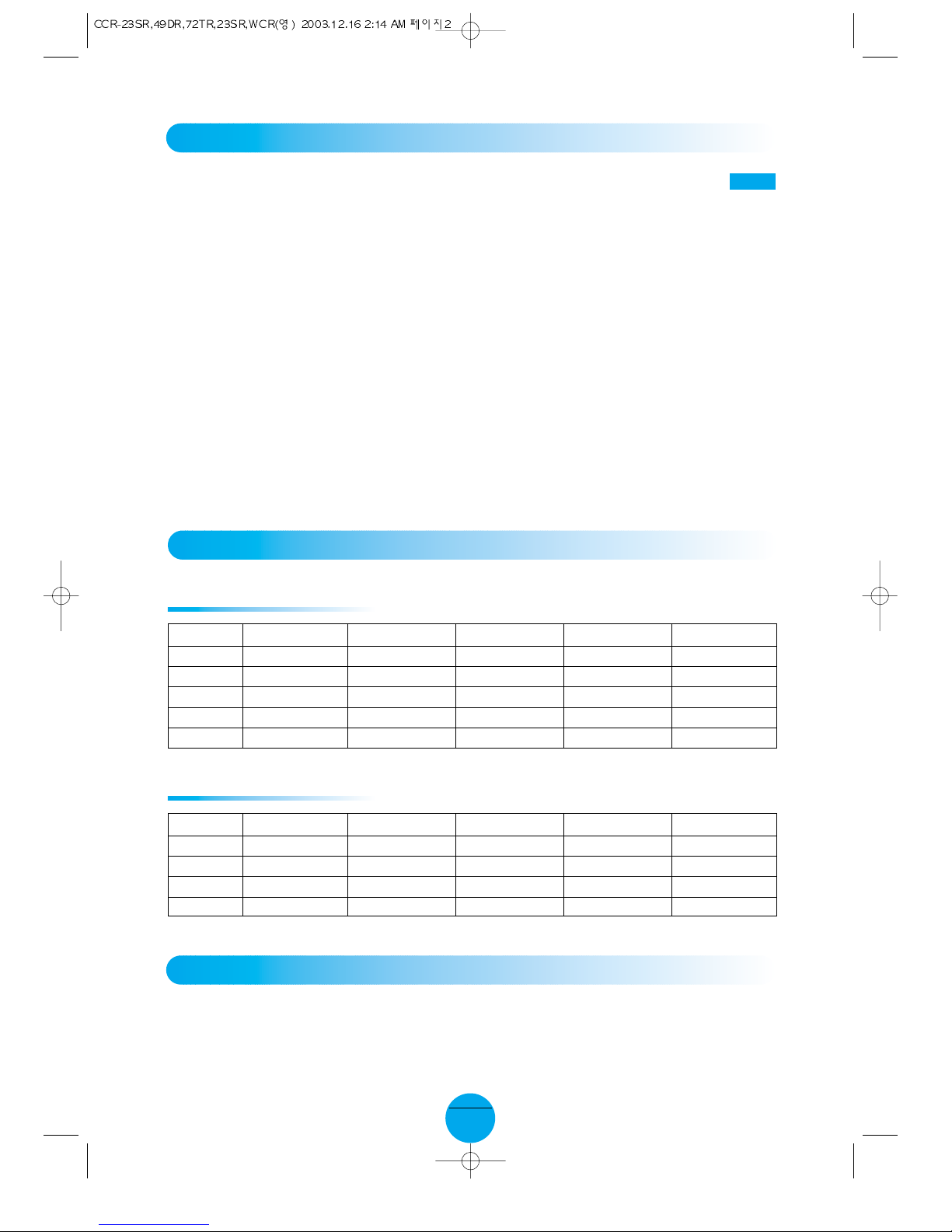

1. SPECIFICATION

..........................................................................................

2

2. SERIAL NUMBER

........................................................................................

2

3. INSTALLATION ............................................................................................ 3

4. CLEANING & CAUTION

..............................................................................

4

5. BASIC OPERATION

5-1. REFRIGERATORS........................................................................... 5~9

5-2. FREEZERS................................................................................... 10~14

6. INSTALLATION METHOD OF REVERSE DOOR

................................

15~16

7. BEFORE REQUESTING SERVICE

............................................................

17

8. WARRANTY

................................................................................................18

9. TERMS OF SALE........................................................................................19

2

CONTENTS

PAGE

The serial number is located on the data label inside.

Please retain the unit’s serial number for service purpose.

SERIAL NUMBER

Refrigerators

SPECIFICA TION

MODEL COMP H.P . V/Hz REFRIGERANT AMPS WEIGHT

CCR-23SR

1/4 1 15V/60Hz R-134a 5.5A 265lbs

CCR-49DR

1/3 1 15V/60Hz R-134a 9.2A 397lbs

CCR-72TR

2/3 1 15V/60Hz R-134a 1 1A 530lbs

WCC-23SR

1/4 1 15V/60Hz R-404a 9.0A 265lbs

WCR-23SR

1/4 1 15V/60Hz R-404a 9.0A 265lbs

Freezers

MODEL COMP H.P. V/Hz REFRIGERANT AMPS WEIGHT

CCR-23SF

1/2 1 15V/60Hz R-404a 8.7A 265lbs

CCR-49DF

3/4 1 15V/60Hz R-404a 10.5A 397lbs

CCR-72TF

5/4

1 15V/208~220V/60Hz

R-404a 10A 540lbs

WCR-23SF

1/2 1 15V/60Hz R-404a 8.7A 265lbs

Page 4

3

1. GOOD AIR CIRCULA TION

- Avoid any partitions or objects which may restrict air flow.

- Be sure there is sufficient air space to allow air flow at the rear of the unit.

2. DO NOT PLACE NEAR HEA T

- High ambient temperature will adversly affect cooling efficiency.

3. INDOOR USAGE ONL Y

- Be sure to install this unit indoors.

4. ST ABILIZING

- While in use, make sure the front wheels are locked to keep the unit in place.

5. LEVELING

- Be sure that the unit is level from the front to the back and side to side.

6. UNIT SHOULD BE ON DEDICA TED OUTLET.

INST ALLATION

Page 5

4

1. CLEANING THE INTERIOR AND EXTERIOR

- The interior and exterior of the unit can be cleaned using warm water with soap.

- Do not use an abrasive cleaner because it will scratch the stainless steel surface.

2. CLEANING THE CONDENSER FINS

- To maintain proper refrigeration performance, the Condensing coil must be free of

dust, dirt and grease.

This will require periodic cleaning. Condenser fins should be cleaned at least every

three months (90 days) or as needed.

3. CLEAN THE GASKET

- The door gasket should be cleaned frequently to maintain proper sealing.

4. CHECK AFTER CLEANING

- Check the unit again for safety .

- Check that the unit is operating properly .

1. POWER CORD

- Be sure that the power cord is connected to the proper voltage.

- A protected circuit of the correct voltage and amperage must be run for connection of

the line cord.

- Turn ‘off’ the power switch before disconnecting the power cord, whenever

performing maintenance functions or cleaning the refrigerated

cabinet.

- Dual voltage freezer (CCR-72TF) requires receptacle as the right

sides.

- Compressor warranties are void if compressor burns out due to low

voltage.

2. RE-ST ARTING

- If disconnected, wait 5 minutes before re-starting.

CAUTION

WH

E

BK RD

CLEANING

Page 6

5

BASIC OPERA TION

WCC-23SR

WCR-23SR

1. The controller(thermostat) is located at the top inside of the unit.

2. The factory setting for the control is ‘Normal’, and maintains about 38˚F (3˚C) inside.

3. Set toward “Cool” for higher temperature and “Cold” for lower temperature.

4. The thermostat controls compressor’s cycling by sensing inside temperature.

5. Interior light is activated by the door switch when door is opened.

6. Cooling fans are activated by the door switch when door is completely closed.

REFRIGERA T OR

OFF

COOL

COLD

NORMAL

T emperature Controller

(Thermostat)

Page 7

6

BASIC OPERA TION

CCR-23SR

CCR-49DR

CCR-72TR

1. Plug in and turn on the power switch located on the bottom of the top grille right side.

The Display panel will be lighted and make a beep sound. The compressor will begin

to run.

2. The default temperature setting is No. “5”.

3. The compressor is automatically cycled by the electronic controller (PCB, D-Sensor).

4. The Defrost cycle is automatically controlled by the R-sensor and the PCB.

5. Set level toward “1” for higher temperature and toward “9” for lower temperature.

6. The interior light is activated by the rocker switch at the bottom of the top grille when

the door is opened.

7. Evaporator fan motor(s) will run after all doors are completely closed.

REFRIGERA T ORS

Page 8

7

DISPLAY P ANEL OF REFRIGERATOR

9

TEMPERATURE Q.C.

8

7

6

5

4

3

2

1

FAN DOOR

QUICK COOLING

TEMPERATURE

˚F

TEMP. SETTING

QUICK COOLING

BUTTON

TEMP. CONTROL BUTTON

(SEE TO PAGE 8)

INNER TEMP.

(SEE TO PAGE 9)

(SEE TO PAGE 8)

QUICK COOLING

INDICATOR

FAN RUNNING

INDICATOR

DOOR OPENING

INDICATOR

Page 9

8

1. If you push the Q.C. (Quick Cooling) button, the compressor will run continuously until

D-Senser detect 14˚F (-10˚C) to bring down the temperature more quickly.

(max.comp.run time = 120 min.)

2. If you push the Q.C. button again during Quick Cooling mode, the compressor will

return to the normal operation.

3. During the Quick Cooling mode, the temperature Up/Down button will not affect the

compressor’s operation.

1. By pushing the up/down button, you can set the inside temperature level from ‘1’ to

‘9’.

2. If you want lower temperature, push the Down button to be lighted higher level

numbers.

QUICK COOLING

UP/DOWN BUTTON (Temperature control button)

Page 10

9

1. It displays inside temperature.

2. Display range is 14˚F to 69˚F (-10˚C ~ +20˚C).

3. When inside temperature is lower than 14˚F, the panel will display ‘ ’.

and, higher than 69˚F, the panel will display ‘ ’.

1. If the fan motor is running, fan running indicator will be turned on.

2.

Evaporator fan motor is activated when the door (both doors for CCR-49DR, all three

doors for CCR-72TR) is closed.

1. If any door is opened, door opening indicator will be turned on.

2. In case that any door was opened around 30 seconds, warning beep sound will be

ring three (3) times.

3. In case of passing around 1 minute, warning beep sound will be ring again five (5)

times.

4. In case of passing around 5 minutes, the beep sound will be ring continuously.

5. On all the conditions good, the beep sound will stop immediately if the door closed

properly .

INNER TEMPERA TURE DISPLAY

F AN RUNNING INDICATOR

DOOR OPENING INDICA T OR

Page 11

10

BASIC OPERA TION

CCR-23SF

CCR-49DF

CCR-72TF

WCR-23SF

1. Plug in and turn on the power switch located on the bottom of the top grille right side.

The Display panel will be lighted and make a beeping sound. The compressor will

begin to run.

2. The default temperature setting is No. “5”.

3. The compressor is automatically cycled by the electronic controller (PCB, F-Sensor).

4. The Defrost cycle is automatically controlled by the D-sensor, and the PCB.

5. Set toward “1” for higher temperatures and toward “9” for lower temperatures.

6. The interior light is activated by the door switch at the bottom of the top grille when

the door is opened.

7. Evaporator fan motor(s) will run after all doors are completely closed.

8. Good Air Flow in freezer unit is critical.

Be careful to load product so that it neither presses against the back wall, nor reaches

within four inches from the evaporator compartment.

FREEZERS

Page 12

11

DISPLAY P ANEL OF FREEZER

9

TEMPERATURE D.F.

8

7

6

5

4

3

2

1

FAN DOOR

MANUAL DEFROST

TEMPERATURE

˚F

TEMP. SETTING

MANUAL DEFROST

INDICATOR

FAN RUNNING

INDICATOR

DOOR OPENING

INDICATOR

MANUAL DEFROST

BUTTON

TEMP. CONTROL BUTTON

(SEE TO PAGE 12~13)

INNER TEMP.

(SEE TO PAGE 14)

(SEE TO PAGE 12~13)

Page 13

12

1. If you push MANUAL DEFROST button for 5 seconds, the Defrost will start.

2. During the Manual Defrost mode, the Up/Down button for the temp. control can not

make the compressor cycle ON or OFF.

3. If you want to change the Manual Defrost mode in the normal mode. push MANUAL

DEFROST button for 5 seconds.

1. By pushing the Up/Down button, you can set the inside temperature level from “1” to

“9”.

2. If you want to lower /temperature, push the button to lower the indicator to higher

level numbers.

1. The electronic defrost controller is set at the factory to provide a defrost cycle every 6

hours (4 defrosts per day).

2. If it is necessary to change the intervals of defrost due to unusual operating

conditions, it can be accomplished by adjusting the switch which is located on the

inside of the top grille.

3. Once all frost is eliminated, the temperature coil continues to rise until it reaches 60˚F

(15˚C). When this temperature is sensed by the defrost limit control, the defrost

control changes to refrigeration mode.

4. The panel displays “” during the defrost cycle.

MANUAL DEFROST

UP/DOWN BUTTON (Temperature control)

DEFROST

FOR CCR-23SF, CCR-49DF, CCR-72TF

Page 14

13

1. If you push MANUAL DEFROST button for 5 seconds, the Defrost will start.

2. During the Manual Defrost mode, the Up/Down button for the temp. control can not

make the compressor cycle ON or OFF.

3. If you want to change the Manual Defrost mode in the normal mode, push MANUAL

DEFROST button for 5 seconds.

1. Keep pressing up&down buttons simultaneously for five seconds, then the lock will

be cancelled with beep sound.

* This unit has lock function that prevents unauthorized person from changing the

temperature setting

2. Set the temperature setting from level 1 to level 9 by pressing the up or down button.

* The temperature setting will be locked back automatically in five seconds after you

set.

* Factory setting is level 5.

1. The electronic defrost controller is set at the factory to provide a defrost cycle every 6

hours (4 defrosts per day).

2. If it is necessary to change the intervals of defrost due to unusual operating

conditions, it can be accomplished by adjusting the switch which is located on the

inside of the top grille.

3. Once all frost is eliminated, the temperature coil continues to rise until it reaches 60˚F

(15˚C). When this temperature is sensed by the defrost limit control, the defrost

control changes to refrigeration mode.

4. The panel displays “” during the defrost cycle.

MANUAL DEFROST

HOW TO CONTROL THE TEMPERATURE (UP/DOWN BUTTON)

DEFROST

FOR WCR-23SF

Page 15

14

1. The Refrigerator/Freezer displays the inside temperature.

2. Display range is -50˚F to 50˚F (-45˚C ~ +10˚C).

3. When inside temperature is lower than -50˚F, the panel will display ‘ ’.

and, higher than +50˚F, the panel will show ‘ ’.

1. If the fan motor is running, the fan running indicator will be turned on.

2. The evaporator fan motor is activated when the door (both doors for CCR-49DF, all

three doors for CCR-72TF) is closed.

1. If door is opened, door opening indicator will be turned on.

2. Passing the thirty seconds after the door is opened, there will be a warning sound of

three “beeps”.

3. If the door remains open for a minute, there will be a warning sound of five “beeps”.

4. If the door remains open for five minutes, there will be a continuous beeping sound.

5. In all the conditions, the beep sound will stop immediately when the door is properly

closed.

INNER TEMPERA TURE DISPLAY

F AN RUNNING INDICATOR

DOOR OPENING INDICA T OR

Page 16

15

1. REMOVE THE BOTTOM GRILL

** THE BOTTOM GRILL IS FIXED BY

LA TCH, SO YOU CAN REMOVED IT BY

HANDS.

2. REMOVE THE TOP GRILL

** THE TOP GRILL IS FIXED BY SCREWS,

SO YOU NEED SCREW DRIVER.

3. REMOVE THE GRILL CAPS FROM TOP

GRILL AND BOTTOM GRILL

4. DISCONNECT THE HEA TER WIRE

FROM MAIN HARNESS (IS LOCA TED

A T SWITCH BOX) AND REMAIN WIRE

CONNECTED TOGETHER(WCR-23SF)

5. UNSCREW THE BOL TS AT THE TOP

HINGE(3POINTS)

6. REMOVE THE DOOR ASSEMBL Y

** CAUTION DAMAGE OF THE HEA TER

WIRE WHEN YOU REMOVE THE

DOOR (WCR-23SF)

7. UNSCREW THE BOL TS AT THE

BOTTOM HINGE(3POINTS)

8. SUBSTITUTE THE POSITION OF LEFT

GRILL FIXTURE AND RIGHT GRILL

FIXTURE

9. USE BOL TS FOR FIXING THE T OP HINGE AT BOTTOM LEFT SIDE

10. SET UP THE DOOR A T THE T OP HINGE AFTER ROTATING THE DOOR

1 1. PULL OUT THE HEATER WIRE FROM THE BUSH HOLE (WCR-23SF)

12. USE BOL TS FOR FIXING THE BOTT OM HINGE AT TOP LEFT SIDE

13. CONNECT HEA TER WIRE T O THE MAIN HARNESS (IS LOCATED INSIDE THE TOP

GRILL AND IT IS CONNECTED TOGETHER) (WCR-23SF)

14. ASSEMBLE THE GRILL CAP TO TOP GRILL AND BOTTOM GRILL AT RIGHT SIDE

15. SET UP THE TOP GRILL BY SCREW

16. ASSEMBLE THE BOTTOM GRILL

GRILL * T

TOP HINGE

HINGE

SHAFT

HEATER WIRE

UNDER

HINGE

GRILL * U

DOOR

ASSEMBLY

GRILL CAP

GRILL CAP

P AR T DIAGRAM

INST ALLATION METHOD OF REVERSE DOOR

Page 17

16

INST ALLATION METHOD OF REVERSE DOOR

Page 18

17

BEFORE REQUESTING SERVICE

SYMPTOMS CAUSES SOLUTIONS

Freezer is melting

food.

The unit does not

refrigerate at all.

The unit does not

refrigerate well.

There is a loud noise.

There are dew-drops

on the unit exterior.

There are dew-drops

on the unit interior.

The door does not

close tightly .

• The setting temperature is too

high to contain food fresh.

• There is a power connection

failure problem.

• The unit is in sunlight or near a

heating device.

• The unit contains hot food or too

much food.

• The unit door is opened too

frequently or left open long.

• The temp. dial is not on the

correct position.

• The condenser is clogged.

• The floor is too weak or the

leveling feet is set incorrectly .

• The back-side of the unit is too

close to the wall.

• The tray is not in the correct

position.

• High-moisture air can produce

dewdrops during rainy season.

• The door is opened too

frequently or left open long.

• Damp food is stored.

• The door is bent.

• The unit has a levelling failure.

• The door gasket has come out.

• Push the temperature down

button for lower temperature.

•

Check the power cord and plug in

it correctly

.

• Check the installation place.

• Check the condition of stored

food.

• Check the position of the temp

control dial.

• Check the installation and

adjust the tray position.

• Wipe with a dry cloth.

• Keep the door closed to

remove dewdrops.

• Level the unit again.

• Reposition the gasket.

The following points are not malfunctions:

• A water-flowing sound can be heard when the compressor stops.

This is the sound of REFRIGERANT flowing.

• The compressor does not run against defrosting function.

Page 19

18

WARRANTY

LIMITED ONE YEAR PARTS & LABOR WARRANTY

Master-Bilt Products (the "Company") warrants to the original purchaser-user that its refrigeration equipment, at the time of

delivery, will be free from defects in material and workmanship. Master-Bilt will bear the reasonable and customary labor

expense to repair or replace any component part (including said part) found to be defective under the terms and conditions as

outlined under Master-Bilt’s standard one (1) year parts warranty. Master-Bilt will reimburse said labor expenses to the

original purchaser only if after evaluating the original service invoice submitted by the original purchaser-user Master-Bilt

determines that this warranty applies. The labor warranty shall apply only to self-contained equipment installed by

authorized or approved Master-Bilt dealers, distributors, service companies or refrigeration contractors. The labor

warranty does not cover the cost (parts or labor) of installation, start-up, normal maintenance, or normal control adjustment.

Written notice of a claim under this Warranty must be received by the Company within ONE YEAR from the date of

installation but no longer than ONE YEAR AND THREE MONTHS from shipment.

Any defects caused by misapplication, abnormal use or misuse, lack of or improper maintenance, damage by third parties,

alterations, acts of God, failure to follow installation, maintenance or safety instructions or any other event beyond the control

of the Company will not be covered under this Warranty.

The obligation of Master-Bilt shall be limited to repairing or replacing (at the option of the Company) any part which is

defective in the reasonable opinion of the Company. The cost of service labor reimbursed will be based on straight-time rate

and reasonable time for the repair of the defect.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

In no event shall the Company be liable for loss of use, revenue or profit or for any other indirect, incidental, special

or consequential damages including, but not limited to, food spoilage or product loss.

This Warranty shall apply only within the continental United States, its territories and possessions and in Canada.

EXTENDED FOUR YEAR COMPRESSOR REPLACEMENT WARRANTY

The Company warrants to the original purchaser-user that it will replace the compressor on the Equipment if found, in the

reasonable opinion of the Company, to be defective in material or workmanship if written notice is received within five years

from date of shipment.

Defective conditions caused by abnormal use or misuse, lack of or improper maintenance, damage by third parties,

alterations, acts of God, failure to follow installation, maintenance or safety instructions or any other event beyond the control

of the Company will not be covered under this Warranty.

The Compressor Replacement Warranty does not apply to any part of the equipment other than the compressor. The

purchaser-user will have the sole responsibility and bear all expenses of removing and returning the defective compressor to

the Company as well as the cost of reinstalling the replacement compressor. The Company may satisfy its obligations

hereunder by supplying a replacement compressor which is reasonably similar in design and capacity.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

THE IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

In no event shall the Company be liable for loss of use, revenue or profit or for any other indirect, incidental, special

or consequential damages including, but not limited to, losses involving food spoilage or product loss.

This Compressor Replacement Warranty shall apply only within the continental United States, its territories and possessions

and in Canada.

Shipment date: Serial Number:

SAMPLE SAMPLE

Page 20

19

TERMS OF SALE

1. PRICES. Master-Bilt reserves the right to change the price of the equipment without notice. All quotations for equipment

shall be void if not accepted within 30 days.

2. DELIVERY. Shipping or delivery date is approximate. Seller will not be liable for failure to deliver due to strikes, supplier’s

delays, changes requested by buyer or any causes beyond Master-Bilt’s control.

3. SHIPMENTS. When possible, requested carrier will be used. Master-Bilt, however, reserves the right to ship via any

responsible carrier. Shipping charges are payable by consignee and any claims arising as to such charges shall be

resolved between the carrier and consignee. All prices are F.O.B. factory.

4. HANDLING CHARGES. Handling charges are applicable for all cabinets and step-ins shipped from Master-Bilt off-site

warehouses.

5. DAMAGE. Claims for damage in transit must be made by the consignee with the carrier. Master-Bilt assumes no

responsibility for damages while in transit.

6. TAXES. Federal, state, city sales or use taxes are not included with these prices.

7. CANCELLATIONS. Buyer shall compensate Seller for all special items not normally stocked. Buyer shall also

compensate Seller for special labor, material costs, special engineering, etc., on all cancelled orders.

8. RETURNED GOODS. No product may be returned unless authorized in writing by Master-Bilt’s sales office. If return of

product is so authorized, consignee shall be required to pay a handling charge of a minimum of twenty-five percent

(25%) of the invoice price. Product must be returned in original factory crate, freight prepaid and shall not have been

used and must be in the same condition as originally shipped by Master-Bilt.

9. WARRANTY. List prices include a limited one year parts and labor warranty on self-contained refrigerated cases and an

extended four year compressor warranty for all cases sold within the continental United States, its territories and

possessions and in Canada.

Loading...

Loading...