Page 1

3185550/146127

BLAST CHILLERS/ FREEZERS

CELLULES DE REFROIDISSEMENT RAPIDE/CELLULES MIXTES

OPERATION AND INSTALLATION MANUAL

MANUEL D’UTILISATION ET D’INSTALLATION

Rev.2 07/2010

Page 2

GB

FR

Carefully read the instructions contained in the handbook. You may find important safety instructions and

recommendations for operation and maintenance.

Please retain the handbook for future reference.

The Manufacturer is not liable for any change s to this handbook, which may be altered w ithout prior

notice.

Lire avec attention les instructions contenues dans ce livret car elles fournissent d'importants renseignements

pour ce qui concerne la sécurité, l'emploi et l'entretien.

Garder avec soin ce livret pour des consultations ultérieures de différents opérateurs.

Le constructeur se réserve le droit d'apporter des modifications à ce manuel, sans préavis ni

responsabilité d'aucune sorte.

Page 3

-

I

N

D

E

X

-

-

I

N

D

-

I

N

1st PART OPERATION MANUAL ……………………………………3

2st PART INSTALLATION MANUAL ………………………………26

0 INFORMATION FOR THE READER ………………………………………………3

1 GENERAL INSTRUCTIONS ON DELIVERY ……………………………………3

• GENERAL INSTRUCTIONS ……………………………… ……………………………………3

• TECHNICAL DATA ………………………………………………………………………………3

• LIST OF REGULATION REFERENCES ……………………………………………………3

• GENERAL INSTRUCTIONS ……………………………… ……………………………………3

• SETTING UP ………………………………………………………………………………………4

2 CONTROL PANEL …………………………………………………………………7

• DESCRIPTION OF CONTROLS ………………………………………………………………7

3 OPERATION ..……………………….………………………………………………10

• PROGRAMS .…………………….………………………………………………………………10

• MANUAL CYCLES .…………….………………………………………………………………15

• STORING CYCLES …………...………………………………………………………………20

• DEFROSTING ………………………….………………………………………………………21

• PRINTING …………………………………….…………………………………………………21

4 MAINTENANCE ……………………………………………………………………23

• MAINTENANCE AND CLEANING ……………………………………………………………23

MACHINE LOADING …………………………………… ……………………………………………………………5

POSITION OF TRAYS ………………………………………………………………………………………………5

STORAGE TIME AND TEMPERATURE …………………………………………………………………………5

CORE PROBE ………………………………………………………………………………………………………6

IFR CHILLING CYCLE ………….………….…………………………………………… …………………………10

RECOMMENDED WORKING CYCLES ………………….………………………………………………………11

USER’S CYCLE …………………………………………….………………………………………………………11

User’s programs ..…………….………………………………………………………………………………11

Storing User’s programs ………..……………………………………………………………………………12

Delete a User’s programs ……………………………………………………………………………………13

Rename a User’s programs …....……………………………………………………………………………13

PRE-COOLING CYCLE ………… ……… ………… ……… ………… ……… ………… ……… ………… ………1 4

Negative freezing cycle with core probe …………………………………………………………………16

Negative freezing cycle with timer …………………………………………………………………………16

Soft positive chilling cycle with core probe ………..……………………………………………………17

Soft positive chilling cycle with timer ……………….……………………………………………………18

Hard positive chilling cycle with core probe ………….…………………………………………………18

Hard positive chilling cycle with timer ……………………………………………………………………19

POSITIVE STORE ………………………….………………………………………………………………………20

NEGATIVE STORE ………………………………………..………………………………………………………20

CLEANING THE CABINET …………………………………………………………………………………………23

CLEANING THE AIR CONDENSER ……………………………………………………………………………24

STAINLESS-STEEL MAINTENANCE ……………………………………………………………………………24

DISCONTINUED USE ……………………………………………………………………………………………25

D

E

E

X

X

-

-

Page 4

-

I

N

D

E

X

-

-

I

N

D

-

I

N

• INSTALLATION ……………………………………………………………………………… …26

• CLOCK SETTING ………………………………………………………………………………29

• LANGUAGE …….………………………………………………………………………………29

• ALARMS AND FAULT ANALYSIS …………………………………………………………30

• SERVICE ……………..…………………………………………………………………………32

• INPUTS/OUTPUTS ………………………….…………………………………………………37

• PRINTER INSTALLATION ………………………..…………………………………………37

• MAINTENANCE OF PANEL BOARD ………………………………………………………38

• WIRING DIAGRAM PLATE …………………………………………………………………39

• CONTROL AND SAFETY SYSTEMS ………………………………………………………39

• DISPOSAL ………………………………………………………………………………………39

• DOOR REVERSAL ……………………………………………………………………………40

• REFRIGERANT MATERIAL SAFETY DATA SHEET ………………………………………40

• DIMENSIONS …………………………………………………………………………………42

APPENDIX …………………………………………………………………………44

INTRODUCTION ……………………………………………………………………………………………………26

MAX ROOM TEMPERATURE ……………………………………………………………………………………26

LOCATION ….………………………………………………………………………………………………………26

WIRING ………………………………………………………………………………………………………………2 7

CONNECTION TO CONDENSATE DRAIN ……………………………………………………………………28

TESTING ……………………………………………………………………………………………………………28

PARAMETERS ………………………………………………………………………………………………………32

Description of parameters ……………………………………………………………………………………32

Changing parameters ………………………………………………………………………………………34

RESET MEMORY …………………………………………………………………………………………………35

RESTORING DEFAULT PARAMETERS …………..……………………………………………………………36

D

E

E

X

X

-

-

Page 5

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

INFORMATION FOR THE READER CHAPTER 0

This manual is subdivided into two parts.

1st part: covers all the information

necessary to the user.

GENERAL INSTRUCTIONS ON DELIVERY CHAPTER 1

GENERAL INSTRUCTIONS

Make sure that the product has not been tampered with or damaged during transport.

After unpacking the cooling cabinet make sure all sections or components have been included and

specifications and conditions are as to your order.

If not, please inform the seller immediately.

We assure you have made the best choice in purchasing our products and hope you will be fully satisfied

with our their performance. To this purpose, we recommend you strictly follow with the instructions and

regulations contained in this handbook.

Please remember that no reproductions of this handbook are allowed. Due to our constant technological

updating and research, the features described in this handbook may be altered without prior notice.

2nd part: covers all the information necessary to

the qualified operators authorized to move,

transport, install, service, repair and demolish the

appliance.

While users are instructed to refer to the 1st part

only, the 2nd part is addressed to skilled

operators. They may also read the 1st part for a

more complete picture of the information provided

if necessary.

U

A

A

L

L

-

-

TECHNICAL DATA

Please refer to the technical data of your own appliance. (tab.1a-1b), see page 44.

LIST OF REGULATION REFERENCES

The cooling cabinet we manufacture fully complies with the following regulations:

UL Listed for electrical safety

NSF standard 7 for sanitation

GENERAL INSTRUCTIONS

The quick cooler is a refrigerating appliance which can cool cooked foodstuffs to a temperature of +38 [°F]

(positive quick cooling) and to 0 [°F] (negative quick cooling).

Machine capacity as to the quantity to be cooled depend on the model purchased.

3

Page 6

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

SETTING UP

Before setting to operation thoroughly clean the cooling cabinet with a suitable detergent or sodium bycarb

dissolved in lukewarm water. Clean the appliance inside to remove any condensate caused by the

Manufacturer's final testing.

Cooling and freezing speed depends on the following factors:

a) container shape, type and material;

b) whether container lids are used;

c) foodstuff features (density, water contents, fat contents);

d) starting temperature;

e) thermal conduction inside the foodstuffs

Positive /Negative quick cooling time depends on type of foodstuffs to be processed.

Full-speed cycle is recommended for high-density or large-sized foodstuffs. However, the following limits

should never be exceeded : a 2” thickness for freezing and an 3” thickness for cooling (tab.2).

The low-speed cycle is suitable to process delicate foodstuffs, such as vegetables, creamy products, creamy

desserts or low-thickness products.

We recommend making sure that any positive quick cooling cycles, to +38 [°F] to the core of the product, do

not last over 180 minutes, and that negative quick cooling cycles, to 0 [°F] to the core of the product, do not

last over 4 hours.

The processing room is to be pre-cooled before starting the positive and /or negative quick cooling cycle.

Moreover, avoid covering the foodstuffs during the cycle, which would increase the cycle length.

We recommend using the core probe in order to have the exact core temperature reading. Do not stop the

cycle before reaching a temperature of +38 [°F] during positive quick cooling and 0 [°F] during negative quick

cooling.

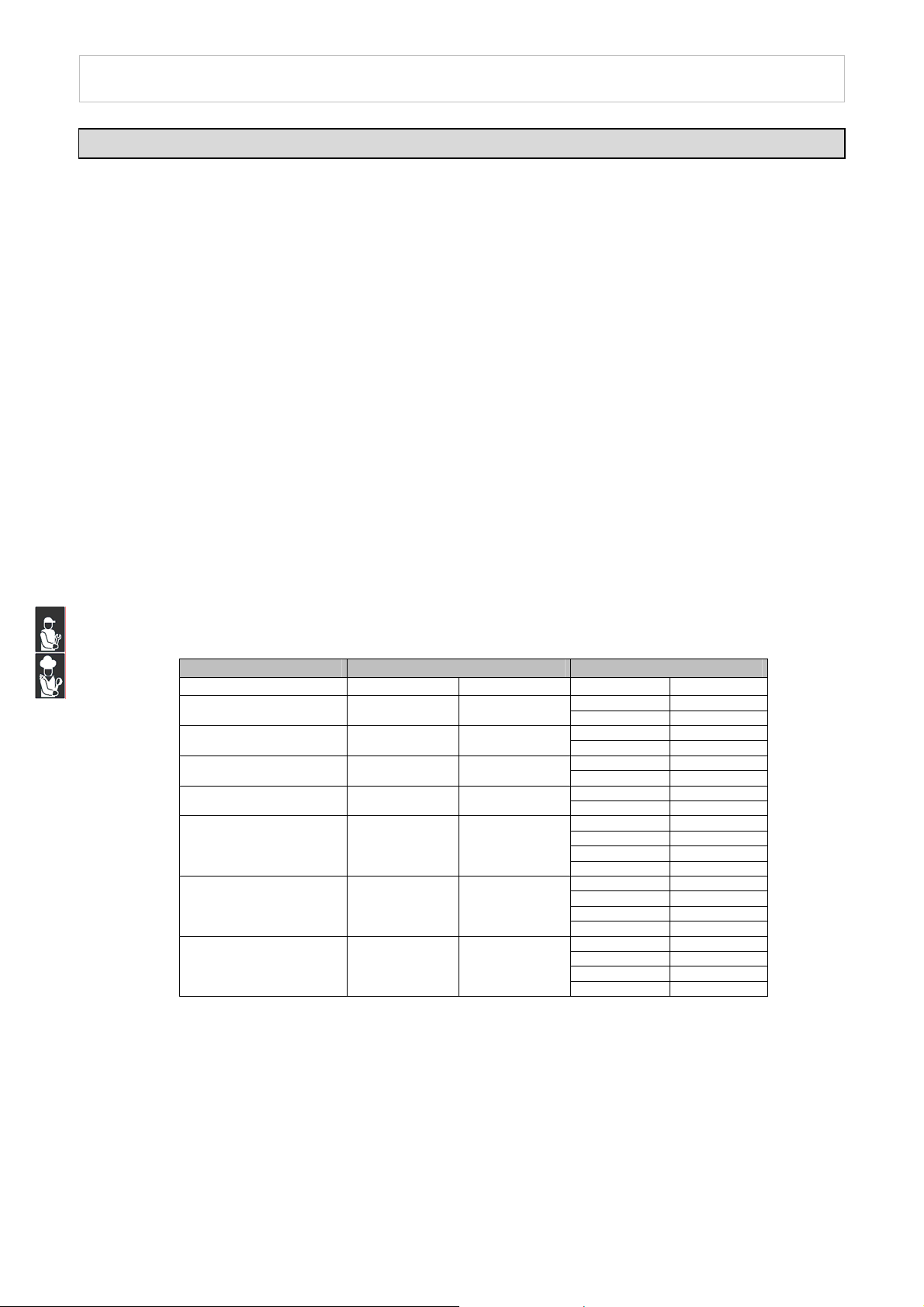

Tab.2

Model Max. output/cycle Capacity

+160[°F] to+38[°F] +160[°F] to +0[°F] max shelves pan size

BCF44244- BCB44244 44[lb] 24[lb]

BC40-4 40[lb] -

BCF93558 93[lb] 55[lb]

BC80-8 80[lb] -

BCF11514 115[lb] 55[lb]

BC113-14 113[lb] -

BCF22020 220[lb] 110[lb]

A

U

A

5 12“x20“x1.5“

4 12“x20“x2.5“

5 12“x20“x1.5“

4 12“x20“x2.5“

14 12“x20“x1.5“

8 12“x20“x2.5“

14 12“x20“x1.5“

8 12“x20“x2.5“

26 12“x20“x1.5“

14 12“x20“x2.5“

13 18“x26“x1.5“

7 18“x26“x2.5“

26 12“x20“x1.5“

14 12“x20“x2.5“

13 18“x26“x1.5“

7 18“x26“x2.5“

32 12“x20“x1.5“

20 12“x20“x2.5“

16 18“x26“x1.5“

10 18“x26“x2.5“

L

L

-

-

4

Page 7

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

-

O

P

E

R

A

T

I

O

N

M

A

N

-

O

P

E

R

A

T

I

O

N

M

A

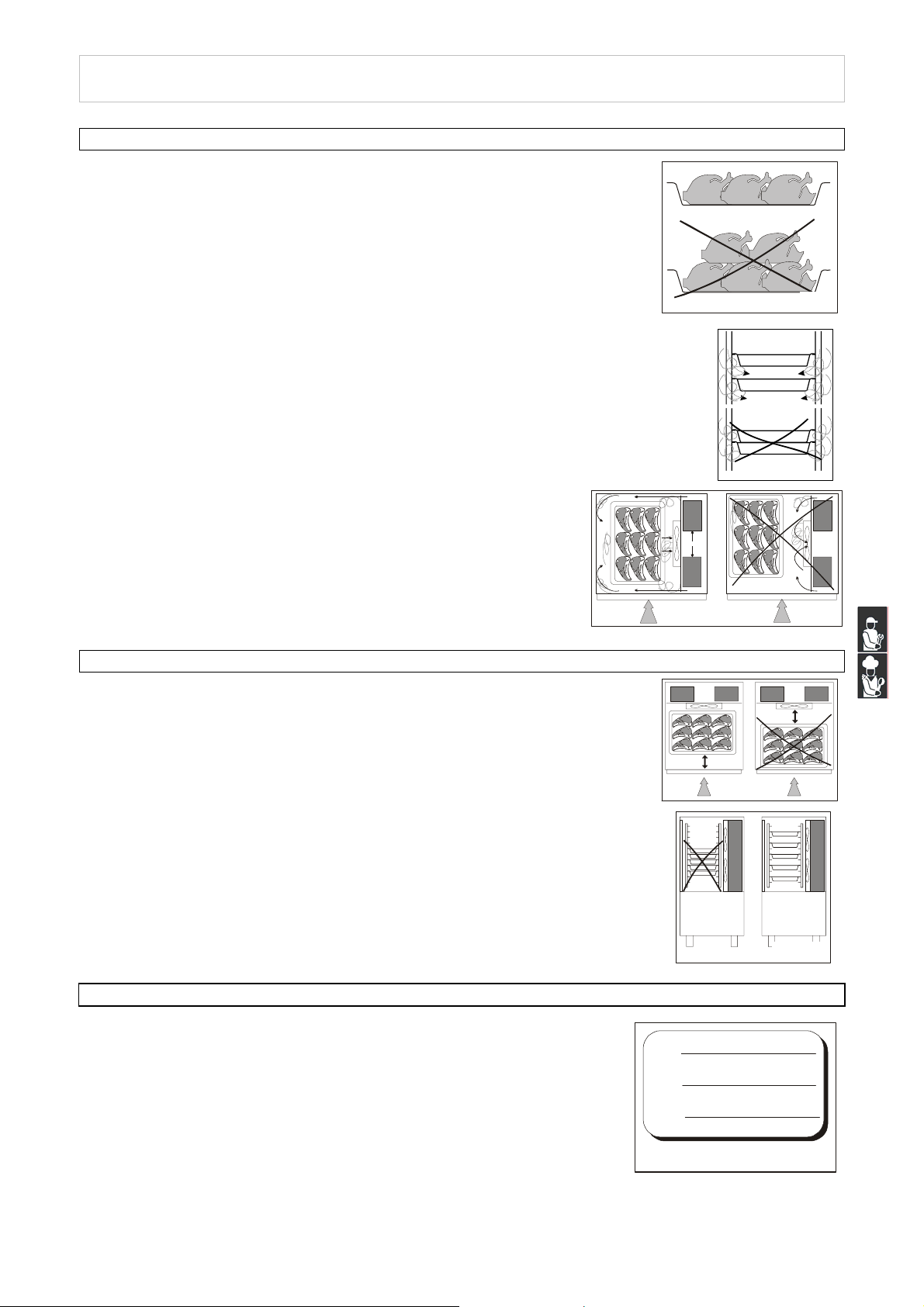

MACHINE LOADING

Do not stack foodstuffs to be cooled. Thickness should be lower than 2” in

negative quick cooling and lower than 3” in positive quick cooling. (pict.1)

Make sure air circulation is not hampered between food trays. (pict.2)

The grid-holding frame (included in those models which include

trolleys) is to be located at the center of the cabinet. (pict.3)

POSITION OF TRAYS

Place the trays as close to the evaporator as possible. (pict.4)

If the cabinet is not full place the trays at equal distance from one another. (pict.5)

STORAGE TEMPERATURES AND TIMES

Cooled or frozen processed foodstuffs may be stored in a refrigerator for 5

days of processing without food quality degradation.

Storing time may be increased to approx. two weeks by using vacuum

processing.

After a negative quick cooling cycle, foodstuffs may be stored safely for 3 to 18

months, according to the type of foodstuff processed.

It is strongly recommended to keep storing temperatures at 0[°F] or below.

N

U

U

A

A

L

L

L

-

-

-

Pict.1

0,19”-0,79”

Pict.2

Pict.3

Pict.4

Pict.5

A

B

C

Pict.6

5

Page 8

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

Table 3 shows the storing time rates for a few examples of frozen food.

Do not leave cooked products at room temperature before quick cooling, as

this may allow the loss of moisture, which will affect food freshness.

The cooled product should be wrapped in a specific film for foodstuffs (better

still, vacuum stored) and provided with a sticker reporting the content [A], date

of processing [B] and expiration date [C] written in permanent type ink (pict.6).

Tab.3

Foodstuff Storage tmperature

Pork 0 6

Beef 0 9

Poultry 0 10

Fat fish 0 2

Lean fish 0 4

Peas 0 12

Strawberries 0 12

Spinach 0 6

Note: the above storage times and temperatures are recommendations. Consult food and drug

administration (FDA) documentation for current agency approved storage temperatures and times.

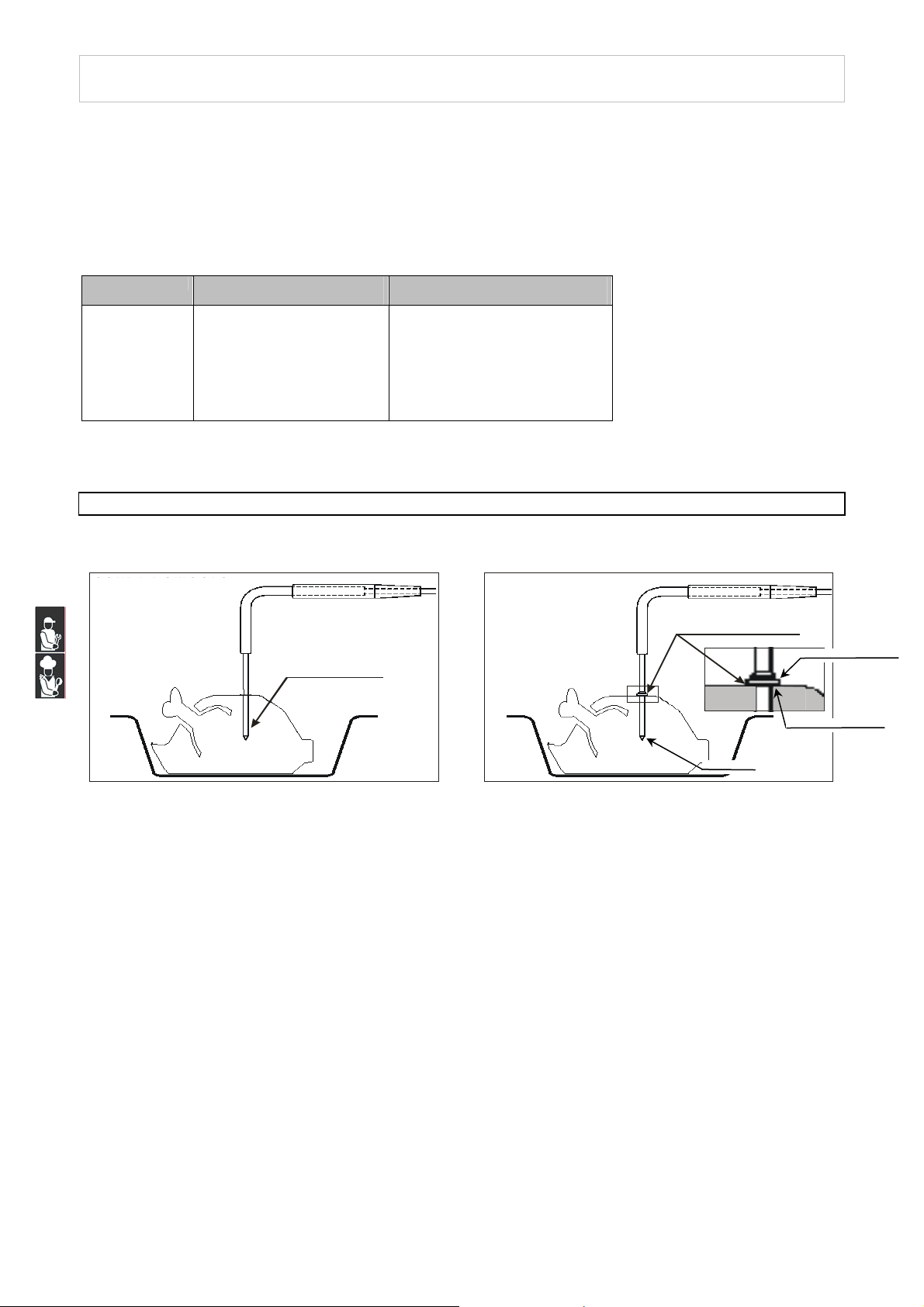

For proper position of the probe, refer to the following pictures.

SONDA A SING OLO

SINGLE-DETECTOR

RILEVAMENTO

PROBE

[°F]

PRODUCT CORE

CUORE PROD OTTO

CORE PROBE

Storage time

months

SONDA A MULTIPLO

MULTI-DETECTOR

RILEVAMENTO

PROBE

U

A

A

L

-

L

-

PRODUCT SURFACE

SUP ER FICIE PR OD OT TO

OVER SURFACE PROBE

UNDER SURFACE PROBE

CORE PROBE

6

Page 9

-

_

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

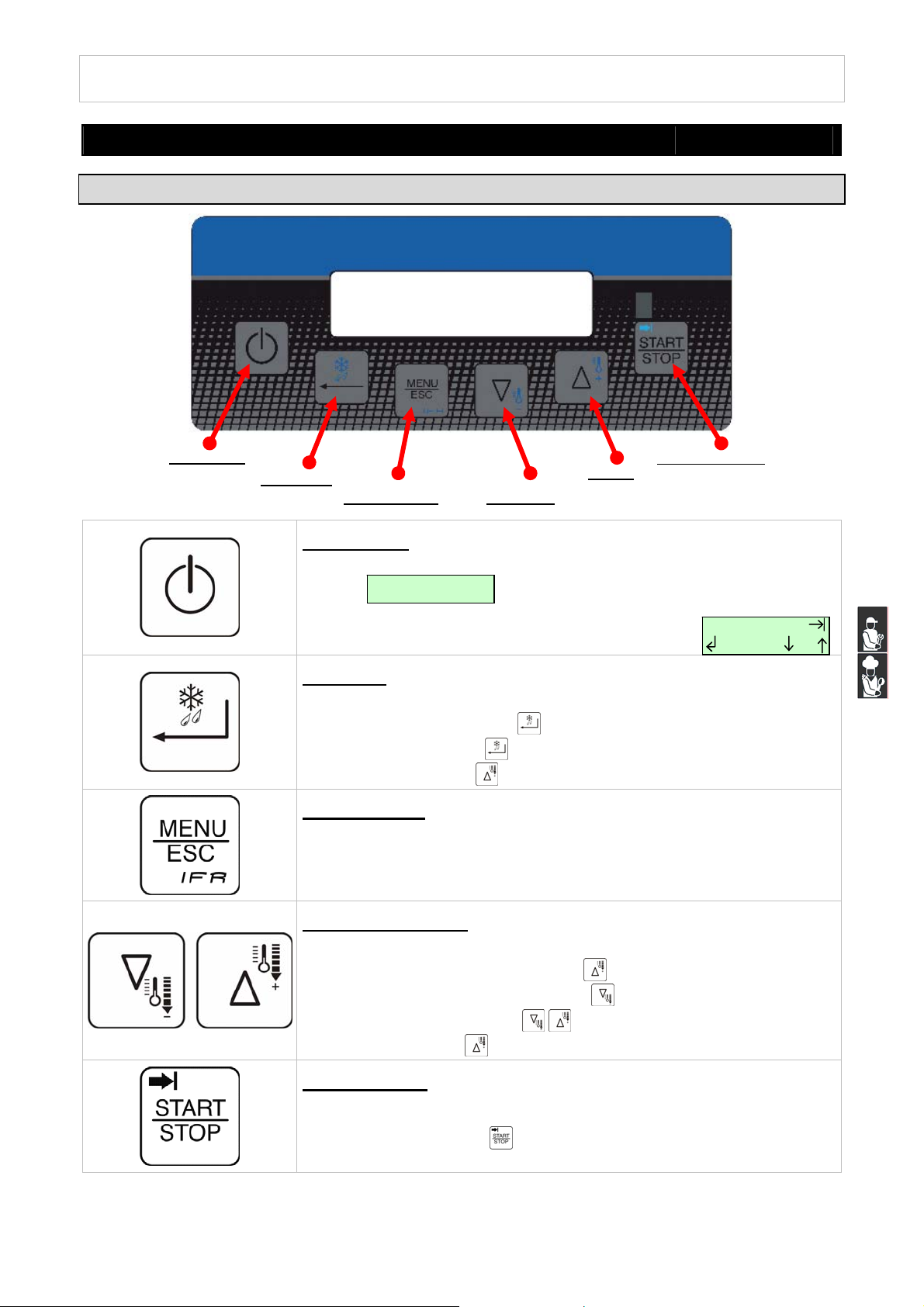

CONTROL PANEL CHAPTER 2

U

A

A

L

L

-

-

ON/OFF KEY

DESCRIPTION OF CONTROLS

ENTER KEY

MENU/ESC KEY

ON/OFF key

Pressing the key for 5 sec the controller turns off and the sign blinks on the

display

When this button is pressed the controller lights up

again, preparing itself to start an IFR chilling cycle.

OFF

DOWN KEY

UP KEY

START/STOP KEY

IFR

Esc

Enter key

Allows access to a menu or parameter selection.

Manual defrost: press the key fro 5 s (default param eter values)

During a cycle: press the

the ongoing cycle. Press

Menu/Esc key

Allows access to the main menu or return to the previous menu.

Quick IFR chilling key: pre ss the key for 5 s (d efault parameter values)

Up and Down keys

Use to scroll the different menus or change parameter values.

Quick Soft posit. chilling key: press the key for 5 s (default parameter values)

Quick negative freezing key: press the key

Keyboard lock: press the keys

During a cycle: press the

Start/Stop key

Use to start/stop a quick cooling cycle.

Quick cooling key: keep the

button to display all the information regarding

to scroll through this information.

for 5 s (defa ult parameter values)

for 5s (default parameter values)

button to display, for a few seconds, the elapsed time.

key pressed for 5 s (default parameters)

7

Page 10

-

O

P

E

R

-

O

P

-

O

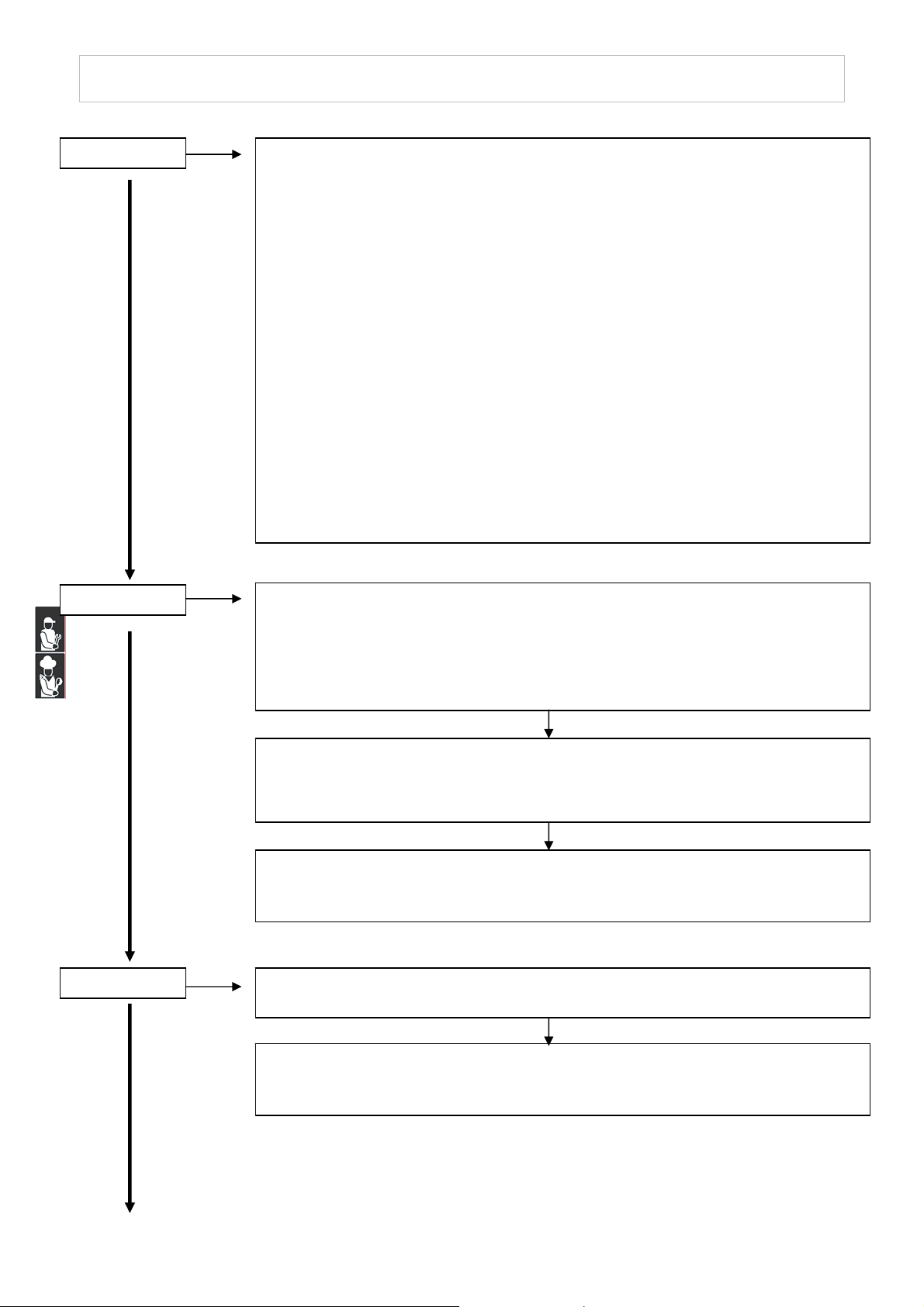

Programs Program selection

E

P

E

IFR: Automatic quick cooling program

Values setting not required. Can be activated with core probe only.

With the IFR program, there is no freezing on foodstuffs outer surface. (no risk

of third-degree freezing).

The IFR program must not be used in negative quick cooling cycles.

Recommended: preset programs

Meat (core probe chilling)

Dairy (time-controlled chilling)

Pie (time-controlled chilling)

Stew (time-controlled chilling)

Fish (time-controlled chilling)

Poultry (time-controlled chilling)

Vegetables (time-controlled chilling)

Freezing Temp (with core probe freezing)

Freezing Time (time-controlled freezing )

User: 01 – 20 numbers available for programming according to the customers’

needs.

Cooling: this program cools the room before any chilling cycle.

R

R

A

A

A

T

T

T

I

I

I

O

O

O

N

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

Manual

Store

Negative = QC with max. refrigerating air temp -13°F, max. core temp 0°F

Positive Soft = QC with max. refrigerating air temp. +14°F, max. core temp. +36°F

Positive Hard = QC, 40% of time at -13°F, remaining time at +14°F, core temp. is set

to +50°F. Suitable for big cuts of meat.

Automatic temp. regulation prior to ice formation on the surface.

… Core

… Time

If the core probe stays off, time-control turns on automatically.

Manual setting

Use the menu to manually configure core temperature values or the time and/or

speed of the fans.

Positive = storing-cooling at + 36°F

Negative = storing-freezing at -8°F

8

Manual setting

Menu allows the user to set the products storing temp. after quick cooling.

Page 11

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Defrost

Print

Clock Setting Clock setting

Language Set language

Defrost start

Select Ok or No

Menu for printing memorized quick cooling cycles

With printer available, select: Ok or No

Set date and time

Select the desired language

Alarm Menu for displaying the alarms.

(reading only)

S = alarm start, E = alarm stop, Service = customer service

Service

Inputs/Outputs

Appliance basic setting. Set password “-19”.

Parameters customer service parameters

Reset Memory memory complete deletio n

Restore default parameters restore

Menu for displaying inputs/outputs state.

(reading only)

9

Page 12

-

P

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

OPERATION CHAPTER 3

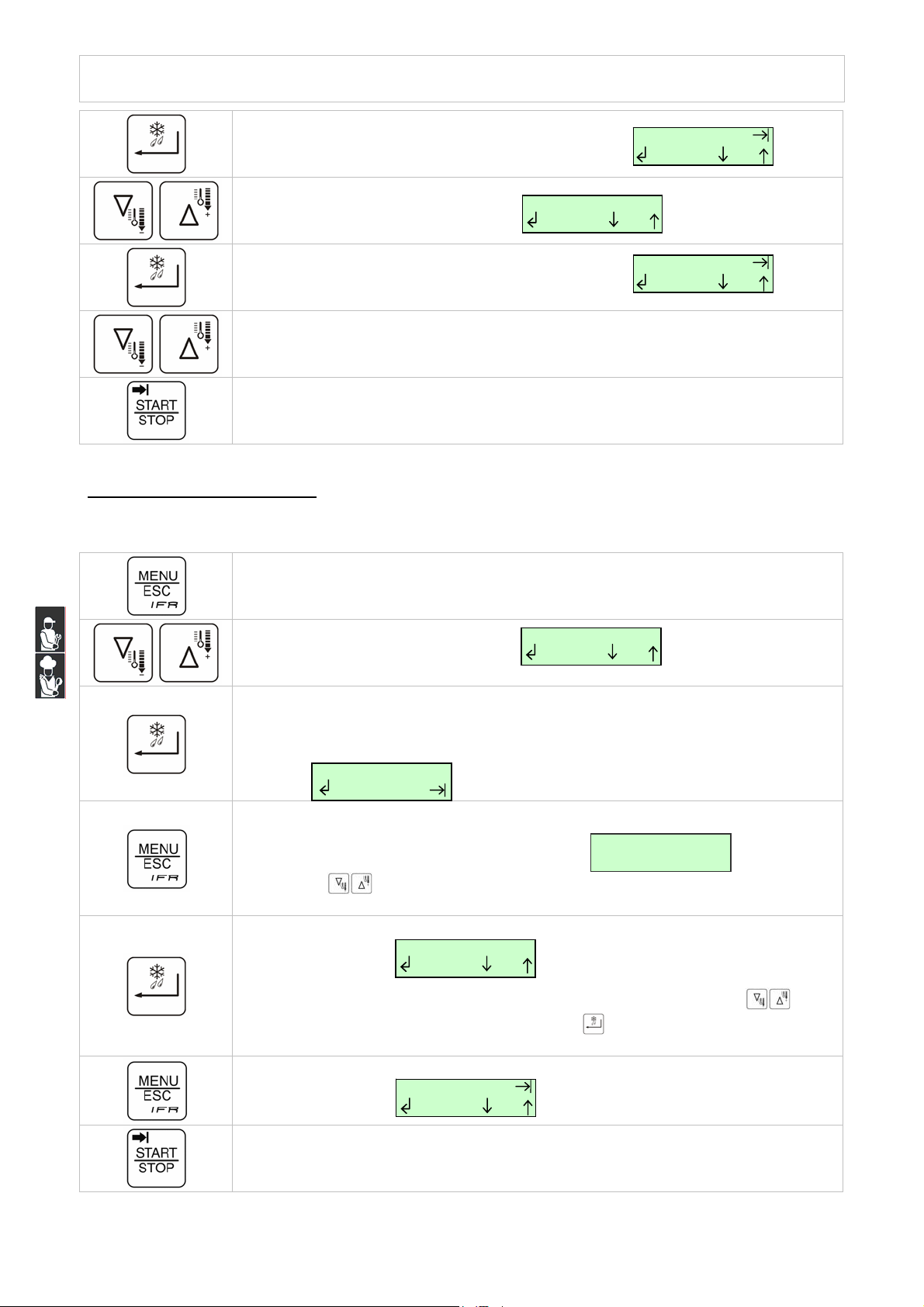

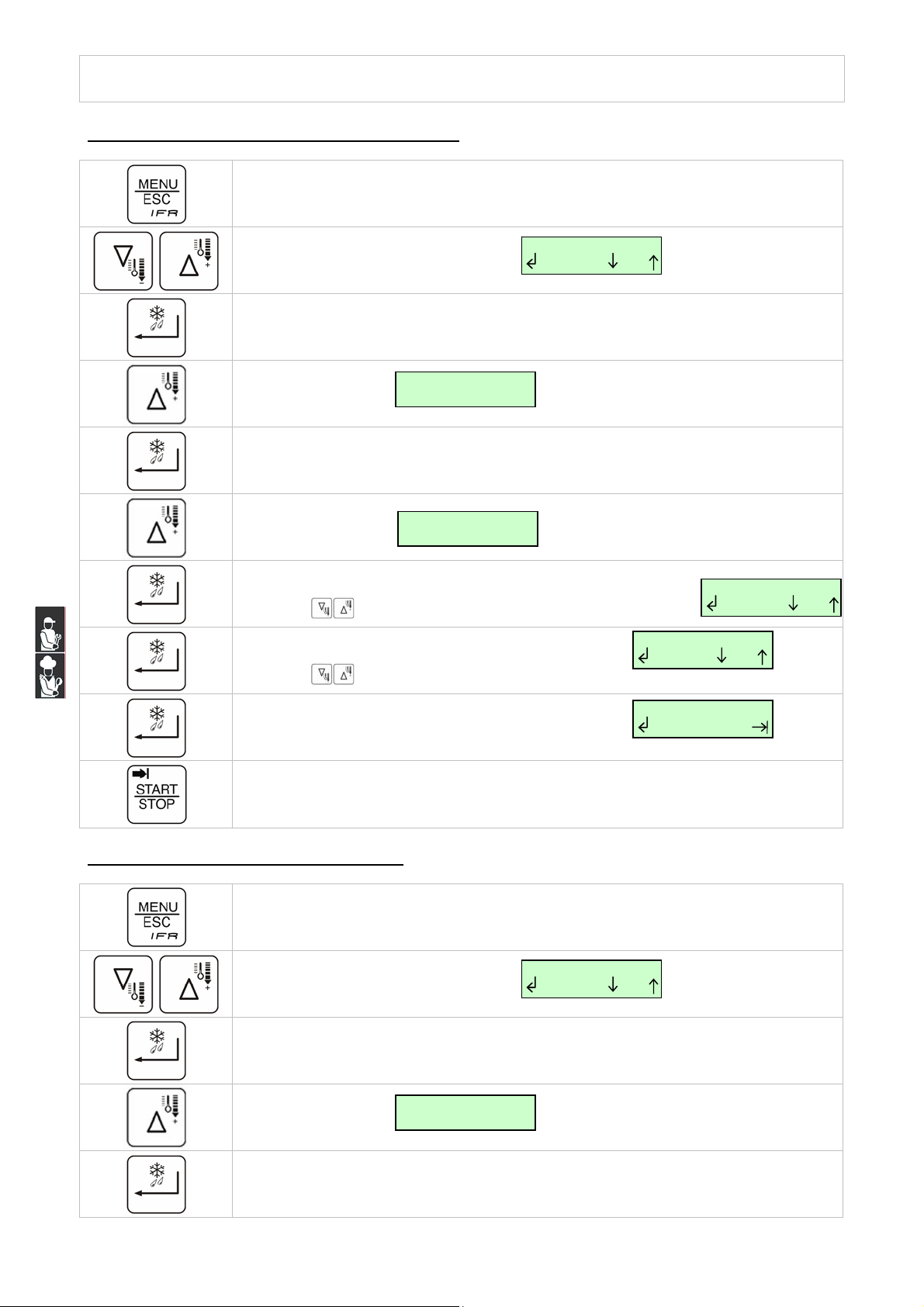

PROGRAMS

IFR CHILLING CYCLE

The IFR is an innovative patented system of positive quick cooling which allows the cycle optimization for

each type of foodstuffs by preventing superficial freezing.

Temperatures are detected by a three-sensor needle probe (ref. page 6,

“Core probe”).

Press menu/esc to select the desired menu

Notes:

- immediately after power up

the cycle will start immediately.

- from the main menu

- during the cycle

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Press start/stop to immediately activate the selected cycle

, the controller automatically prepares itself to start an IFR chilling cycle: simp ly pre s s and

it is possible to immediately start an IFR chilling cycle: keep the pressed for 5 seconds.

it is possible to view fan speed by p ressing ; use the button to modify the value.

F

176

140

104

68

32

-4

-40

100

50

0

F

176

140

104

68

32

-4

-40

100

50

0

Esc

rograms

PRODUCT CORE

INTERMEDIATE

PRODUCT SURFACE

ROOM VENTILATION SPEED

IFR

Esc

ROOM TEMPERATURE

10

Page 13

-

P

R

d

P

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

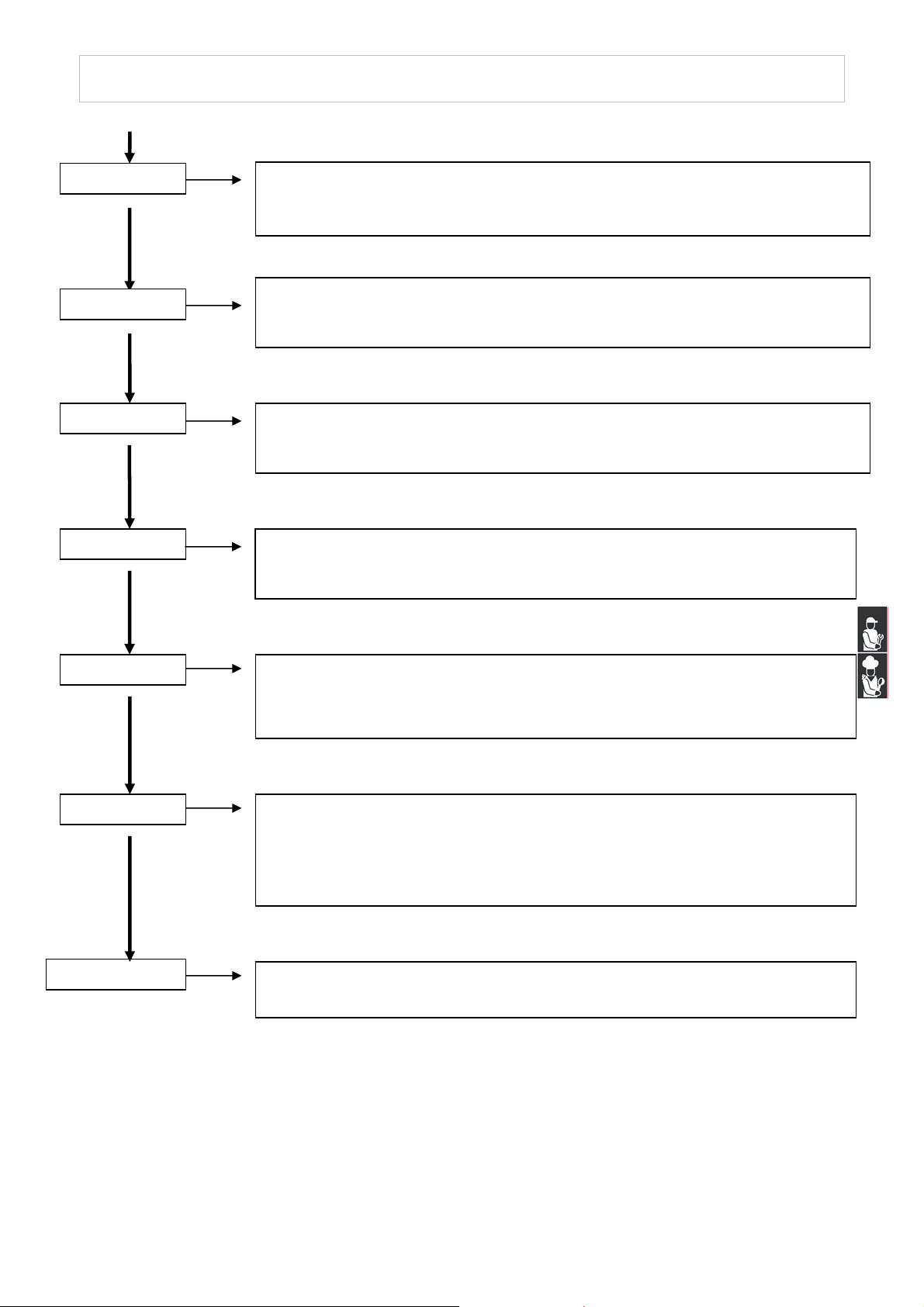

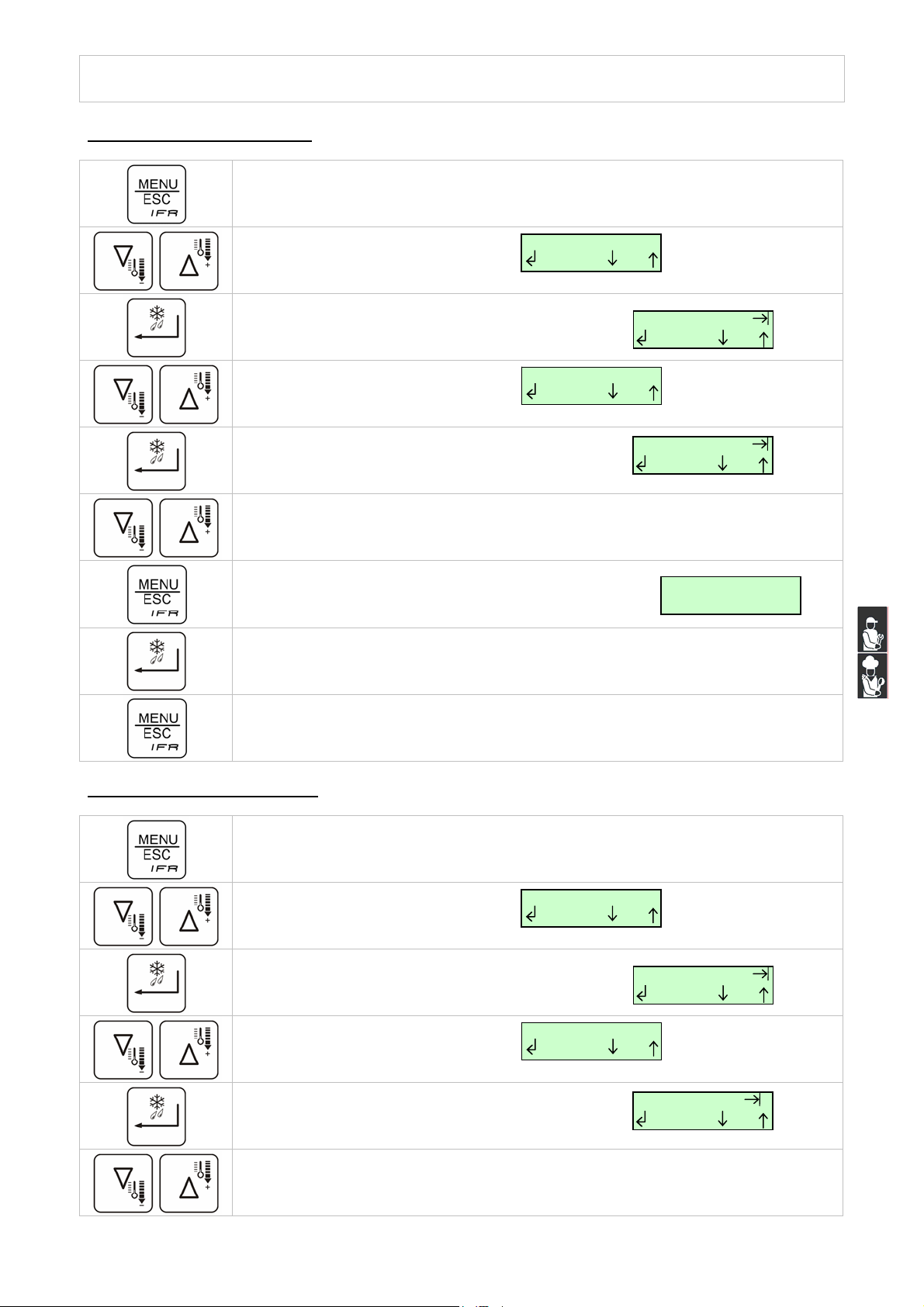

RECOMMENDED WORKING CYCLES

Recommended working cycles are pre-programm ed. Parameters cannot be changed.

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Use the keys up and down to display

Press enter to gain acces to the saved programs selection (21-29)

The display shows the program number and name

Use the keys up and down to scroll all the saved programs

Esc

ecommende

Esc

A

U

A

rograms

-

L

L

IFR

Esc

Meat

Esc

-

-

Press start/stop to immediately activate the selected cycle

The recommended programs are listed below:

Prog Name of the program

21

22

23

24

25

26

27

28

29

Note: It is the responsibility of the user that the storage temperature and pull down is time appropriate for

their application

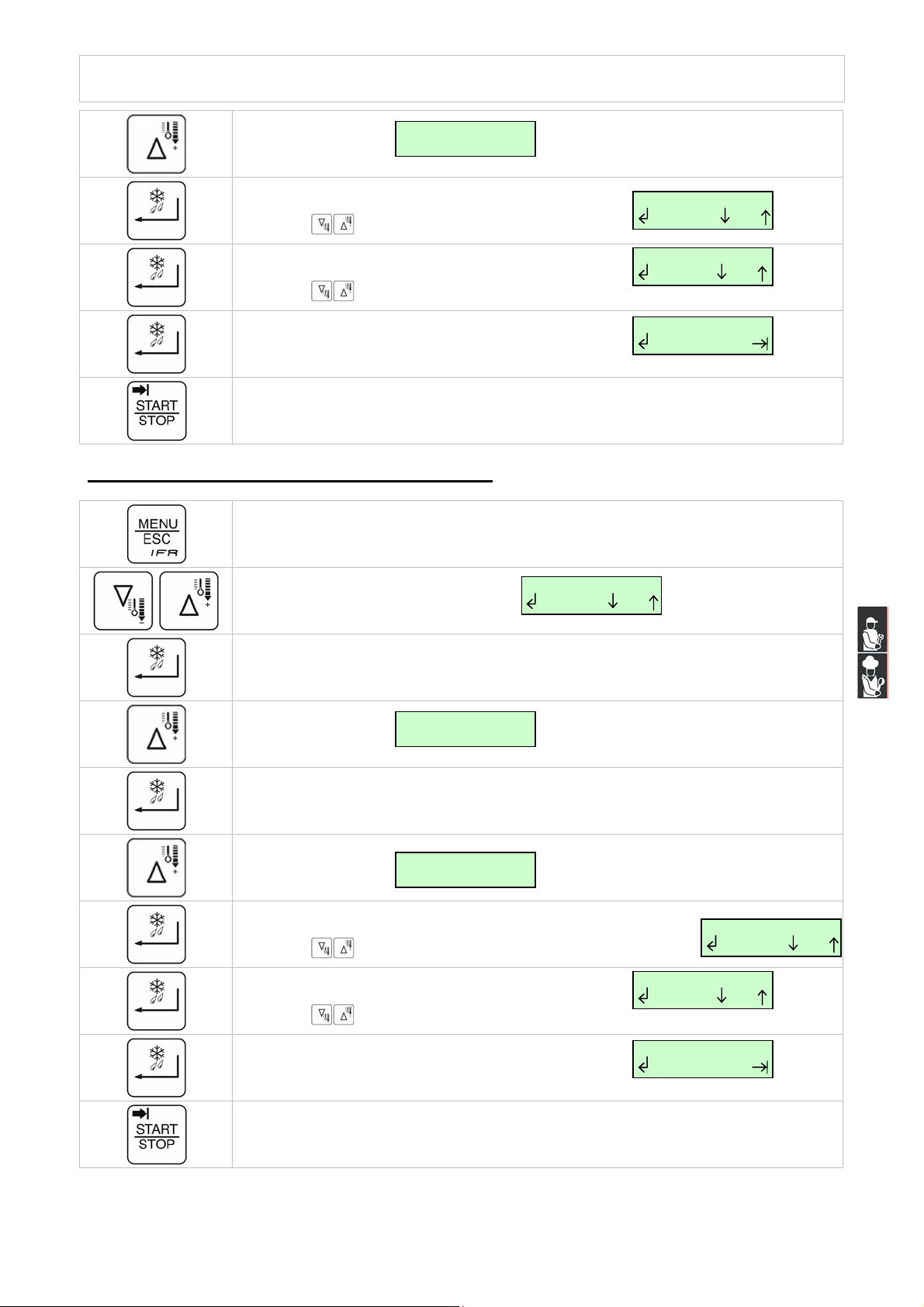

USER’S PROGRAMS

The saved USER programs can be activated as follows:

Meat positive core yes +35°F 120 min 100%

Dairy positive

Pie positive

Stew positive

Fish positive

Poultry positive

Vegetables positive

Fre e z i n g T e m p negative

Freezing Time negative

Positive

negative

Time/Core hard

time no +35°F 90 min 100%

time no +35°F 90 min 100%

time no +35°F 90 min 100%

time yes +35°F 90 min 100%

time yes +35°F 90 min 100%

time no +35°F 90 min 100%

core yes -8°F 240 min 100%

time yes -8°F 240 min 100%

USER’S CYCLE

Room set

storing

time Ventilat.

Press menu/esc to select the desired menu

Use the keys up and down to display

rograms

Esc

11

Page 14

-

U

N

P

A

_

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Press enter to confirm your choice.The display shows

STORING USER’S PROGRAMS

It is possible to save up to 20 USER programs.

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Use the keys up and down to scroll all the saved programs

Press start/stop to immediately activate the selected cycle

ser

Esc

(example)

IFR

Esc

01 NAME

Esc

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

Select the manual cycle as described in the previous paragraphs, replaci ng the

standard values with the desired ones.

Once the cycle is completely configured, the display will show.

(example)

Keep menu/esc pressed for 5 seconds to save the program.

The display will show the first available position

Use buttons

and select the desired position.

Press enter to confirm the selected position.

The display shows

Type in the name of the program which is to be memorised using buttons

scroll through the letters and numbers, and press

next character

Press menu/esc to save the name.

The display shows

Press start/stop to immediately activate the selected cycle

eg Core

Esc

to scroll through the 20 programs

(example)

_ _ _ _ _

Esc

NAME

Esc

Manual

Esc

rograms 03

to confirm and move on to the

---------

to

12

Page 15

-

U

P

P

U

O

O

O

P

P

P

-

-

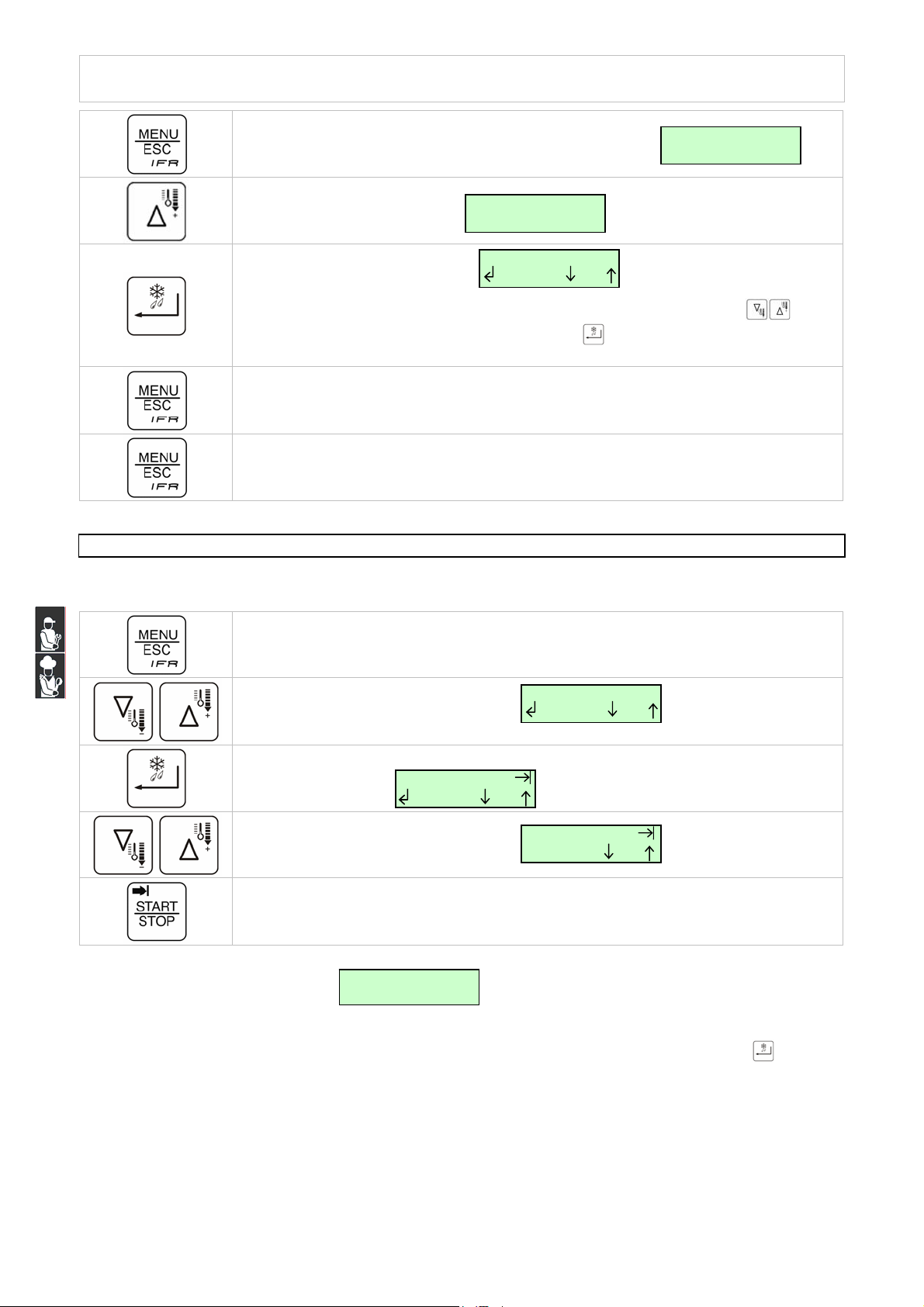

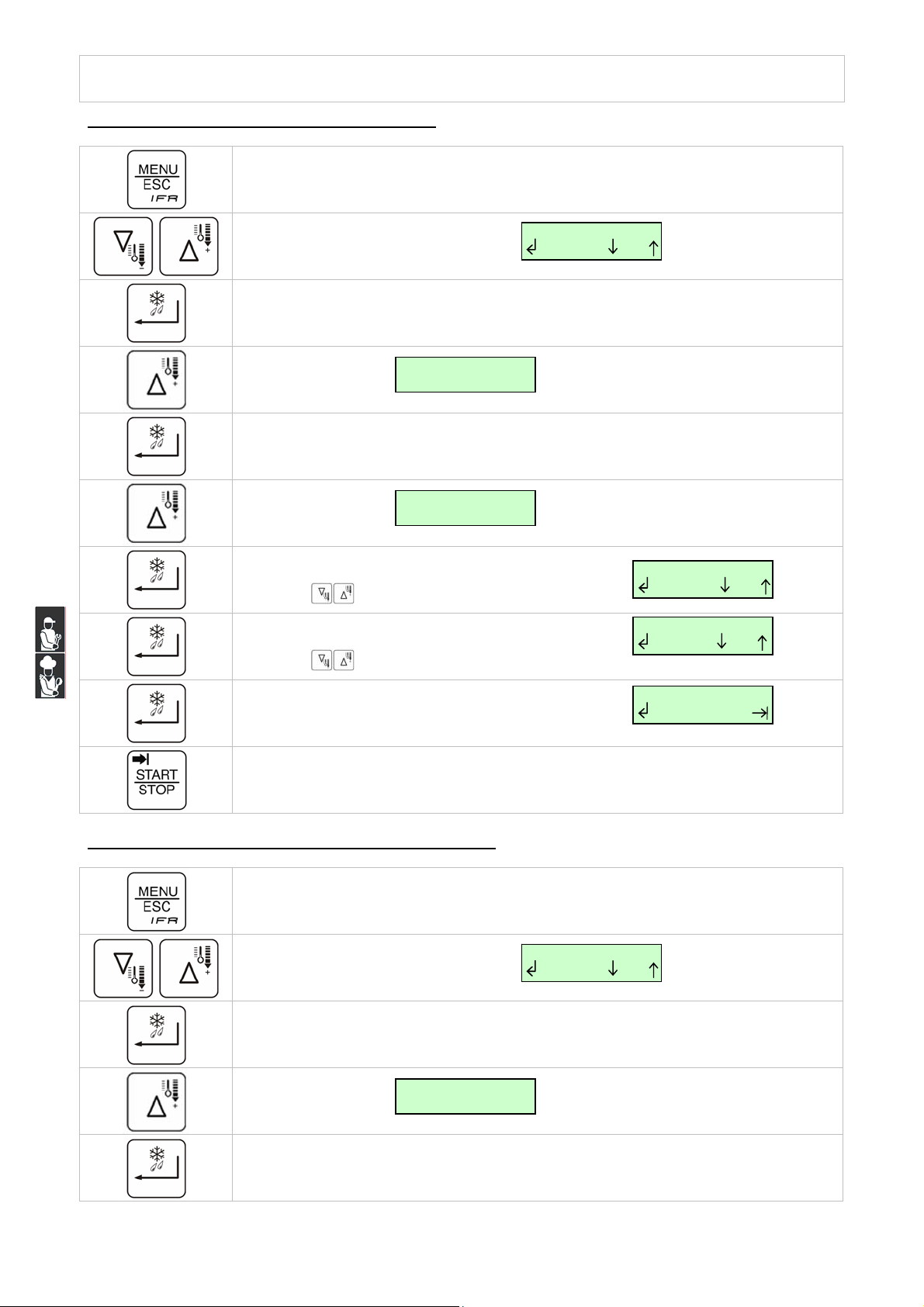

DELETE A USER’S PROGRAM

Press menu/esc to select the desired menu

E

E

E

R

R

R

A

A

A

T

T

T

I

I

I

O

O

O

N

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Use the keys up and down to scroll all the saved programs

Keep menu/esc pressed for 5 seconds. The display

shows

Press enter to cancel the program

rograms

Esc

ser

Esc

IFR

Esc

01 NAME

Esc

Cancel progr

Ok No

Press menu/esc to exit

RENAME A USER’S PROGRAM

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Use the keys up and down to display

Press enter to confirm your choice.The display shows

Use the keys up and down to scroll all the saved programs

rograms

Esc

ser

Esc

IFR

Esc

01 NAME

Esc

13

Page 16

-

-

1

R

A

_

P

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Keep menu/esc pressed for 5 seconds. The display

shows

It is advisable to run a cooling cycle prior to selecting any chilling cycle.

Press up. The display shows

Press enter. The display shows

Type in the name of the program which is to be memorised using buttons

scroll through the letters and numbers, and press

next character.

Press menu/esc to confirm the new name

Press menu/esc to exit

PRE-COOLING CYCLE

ename progr

Ok No

_ _ _ _ _

Esc

Cancel progr

Ok No

to confirm and move on to the

to

Press menu/esc to select the desired menu

Once the temperature in the room reaches -13°F, the buzzer will sound for 10 seconds, and the “insert

product” request will be displayed.

Closing the door terminates the cooling cycle.

Note: From the main menu it is possible to immediately activate a cooling cycle; sim ply keep the

pressed for 5 seconds.

Use the keys up and down to display

Press enter to confirm your choice.

The display shows

Use the keys up and down to display

Press the start/stop button to immediately activate the cooling cycle

Room

Insert prod

IFR

Esc

3°F

rograms

Esc

Cooling

Esc

button

14

Page 17

-

O

O

O

P

P

P

-

-

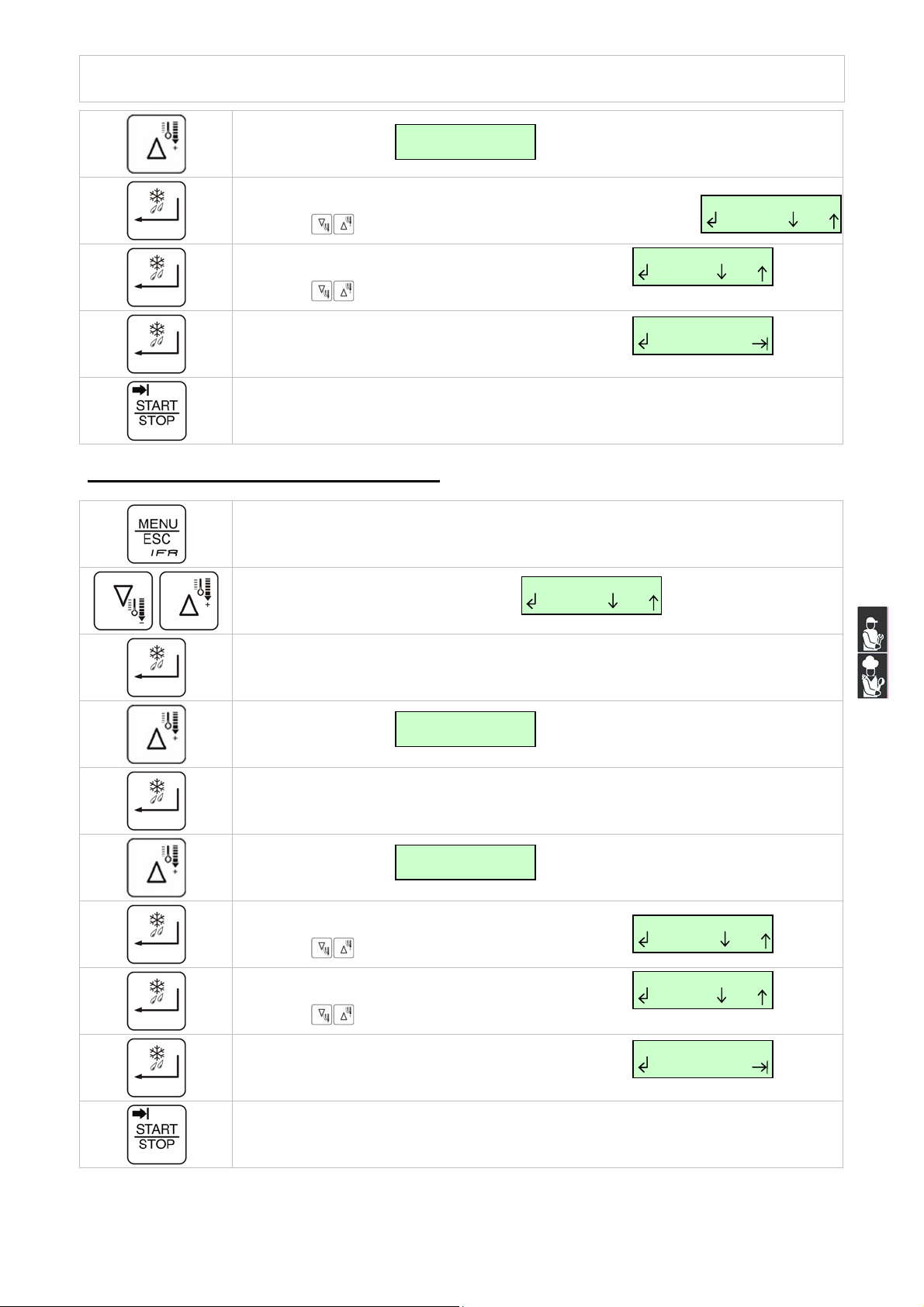

NEGATIVE FREEZING CYCLE

WITH CORE PROBE: cycle suitable for freezing foodstuffs using a room temperature of

about -22[°F]. The cycle is controlled by the core probe.

WITH TIMER: cycle suitable for freezing foodstuffs using a roo m temperatu re of ab out -22[° F].

The cycle is time-controlled.

E

E

E

R

A

T

I

O

N

R

A

T

I

R

A

MANUAL CYCLES

T

I

O

O

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

SOFT POSITIVE CHILLING CYCLE

WITH CORE PROBE: cycle suitable for cooling foodstuffs with thickness lower than 1.5”

using a room temperature of about +32[°F]. The cycle is controlled by the core probe.

WITH TIMER: cycle suitable for cooling foodstuffs with thickness lower than 1.5” using a

room temperature of about +32[°F]. The cycle is time-controlled.

HARD POSITIVE CHILLING CYCLE

WITH CORE PROBE: cycle suitable for cooling foodstuffs with thickness exceeding 1.5” using a

room temperature ranging from -22[°F] to +23[°F]. The cycle is controlled by the core probe.

WITH TIMER: cycle suitable for cooling foodstuffs with thickness exceeding 1.5” using a

room temperature ranging from -22[°F] to +2 3[°F]. The cycle is time-controlled.

NOTE: At the end of the chilling or freezing cycle the system will automatically switch to the conservation

mode (+36°F at the end of the positive chilling and –8°F at the end of the freezing phase).

During the conservation mode, the condenser fan and compressor remain on and the evaporator fans are

set to 50%.

Cooling time

FOODSTUFF SHEET MAX. LOAD

Bechamel GN1/1 h60 0.21 cuft 1.5” 70 minutes HARD POSITIVE

Meat broth GN1/1 h110 0.28 cuft 2.7” 110 minutes HARD POSITIVE

Cannelloni GN1/1 h40 9 lbs 1.5” 40 minutes HARD POSITIVE

Vegetable soup GN1/1 h100 0.17 cuft 2” 100 minutes HARD POSITIVE

Fresh pasta GN1/1 h40 0.5 lbs 2” 20 minutes NEGATIVE

Meat and tomato sauce GN1/1 h60 11 lbs 2” 90 minutes HARD POSITIVE

Bean soup GN1/1 h60 11 lbs 2” 100 minutes HARD POSITIVE

Fish soup GN1/1 h60 9 lbs 2” 110 minutes HARD POSITIVE

Roast pork GN1/1 h60 17.7 lbs 4” 110 minutes HARD POSITIVE

Braised beef GN1/1 h60 17.7 lbs 6” 110 minutes HARD POSITIVE

Boiler beef GN1/1 h60 13.24 lbs 6” 110 minutes HARD POSITIVE

Chicken breast GN1/1 h40 11 lbs 2” 30 minutes SOFT POSITIVE

Roast-beef GN1/1 h40 9 lbs 4” 80 minutes HARD POSITIVE

Baked grouper GN1/1 h40 6.5 lbs 2” 110 minutes HARD POSITIVE

Squill GN1/1 h40 4.4 lbs 1.2” 25 minutes HARD POSITIVE

Vacuum-stored mussel GN1/1 h60 4.4 lbs max 2.5” 20 minutes HARD POSITIVE

Fish salad GN1/1 h40 8.8 lbs 1.5” 30 minutes NEGATIVE

Boiled polyp GN1/1 h60 11 lbs - 60 minutes HARD POSITIVE

Stewed cuttlefish GN1/1 h60 8.8 lbs 2” 60 minutes HARD POSITIVE

Carrots trifolate GN1/1 h60 8.8 lbs 2” 60 minutes HARD POSITIVE

Mushrooms trifolati GN1/1 h60 8.8 lbs 2” 60 minutes HARD POSITIVE

Zucchinis trifolate GN1/1 h60 6.6 lbs 2” 90 minutes HARD POSITIVE

Vanilla / chocolate pudding GN1/1 h60 0.21 cuft 2” 90 minutes SOFT POSITIVE

Creme anglaise GN1/1 h60 0.1 cuft 2” 100 minutes SOFT POSITIVE

Custard GN1/1 h60 0.1 cuft 2” 100 minutes SOFT POSITIVE

Panna cotta (single portion) GN1/1 h40 0.1 cuft 2.3” 60 minutes SOFT POSITIVE

Ice-cream GN1/1 h40 6.6 lbs 2.3” 50 minutes SOFT POSI TIVE

Tiramisù GN1/1 h60 11 lbs 2” 45 minutes SOFT POSITIVE

PRODUCT

THICKNESS

FIRST COURSES

MEAT AND POULTRY

FISH

VEGETABLES

PASTRY/DESSERT

QUICK COOLING

TIME

CYCLE

15

Page 18

-

Neg

-

1

S

O

P

E

R

A

T

I

-

O

P

E

R

-

O

P

E

NEGATIVE FREEZING CYCLE WITH CORE PROBE

Press menu/esc to select the desired menu

R

A

A

T

T

I

I

O

O

O

N

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

Use the keys up and down to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice. The display shows

Use buttons to modify the set point value of the temperature in the room.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed

Press enter to confirm your choice. The display shows

Negative

Ok Esc No

Core

Ok Esc No

Manual

Esc

Neg Core

Neg Core

Esc

peed 100%

Esc

Esc

3°F

Press start/stop to immediately activate the selected cycle

NEGATIVE FREEZING CYCLE WITH TIMER

Press menu/esc to select the desired menu

16

Use the keys up and down to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice.

Negative

Ok Esc No

Manual

Esc

Page 19

-

S

Neg

S

-

1

S

S

P

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Press up to display

SOFT POSITIVE CHILLING CYCLE WITH CORE PROBE

Press enter to confirm your choice. The display shows

Use buttons to modify the duration of the cycle.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed

Press enter to confirm your choice. The display shows

Press start/stop to immediately activate the selected cycle

Press menu/esc to select the desired menu

Use the keys up and down to display

Time

Ok Esc No

Manual

Esc

Neg Time 90’

Esc

peed 100%

Esc

Neg Time

Esc

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice. The display shows

Use buttons to modify the set point value of the temperature in the room.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed

Press enter to confirm your choice. The display shows

ositive Soft

Ok Esc No

oft Core

Ok Esc No

peed 100%

Esc

oft Core

Esc

Soft Core

Esc

3°F

Press start/stop to immediately activate the selected cycle

17

Page 20

-

S

S

S

S

P

P

d

O

P

E

R

A

T

I

-

O

P

E

R

-

O

P

E

SOFT POSITIVE CHILLING CYCLE WITH TIMER

Press menu/esc to select the desired menu

R

A

A

T

T

I

I

O

O

O

N

N

N

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

-

-

-

Use the keys up and down to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice. The display shows

Use buttons to modify the duration of the cycle.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed

Press enter to confirm your choice. The display shows

ositive Soft

Ok Esc No

oft Time

Ok Esc No

Manual

Esc

oft Time 90’

Esc

peed 100%

Esc

oft Time

Esc

Press start/stop to immediately activate the selected cycle

HARD POSITIVE CHILLING CYCLE WITH CORE PROBE

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice.

ositive Har

Ok Esc No

Manual

Esc

18

Page 21

-

Har

-

13°

F

S

H

Hard

S

Hard

Hard

P

d

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Press up to display

HARD POSITIVE CHILLING CYCLE WITH TIMER

Press enter to confirm your choice. The display shows

Use buttons to modify the set point value of the temperature in the room.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed

Press enter to confirm your choice. The display shows

Press start/stop to immediately activate the selected cycle

Press menu/esc to select the desired menu

Use the keys up and down to display

d Core

Ok Esc No

Manual

Esc

Hard Core

Esc

peed 100%

Esc

ard Core

Esc

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice. The display shows

Use buttons to modify the duration of the cycle.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed

Press enter to confirm your choice. The display shows

ositive Har

Ok Esc No

Time

Ok Esc No

Time 90’

Esc

peed 100%

Esc

Time

Esc

Press start/stop to immediately activate the selected cycle

19

Page 22

-

S

P

S

S

-

8

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

STORING CYCLES

POSITIVE STORE

Press menu/esc to select the desired menu

U

A

A

L

L

-

-

Use the keys up and down to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice. The display shows

Use buttons to modify the set point value of the temperature in the room.

Press enter to confirm your choice. The display shows

Use buttons to modify fan speed.

Press enter to confirm your choice. The display shows

Press the start/stop key to immediately start the storing cycle

ositive

Ok No

tore

Esc

Set Point 36°F

Esc

peed 50%

Esc

Store

Esc

NEGATIVE STORE

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

Press up to display

Press enter to confirm your choice. The display shows

Use buttons to modify the set point value of the temperature in the room.

Negative

Ok No

tore

Esc

Set Point

Esc

°F

20

Page 23

-

S

D

S

Room

5°F

P

P

a

?

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Press enter to confirm your choice. The display shows

Press

The defrosting cycle finishes after 15 min or when the defrosting probereaches 46[°F].

Note: immediate defrost can be started from the main menu by pressing the key

to stop the defrosting cycle

NOTE: the printer is not supplied as standard equipment. It is an optional item.

Use buttons to modify fan speed.

Press enter to confirm your choice. The display shows

Press the start/stop key to immediately start the storing cycle

DEFROSTING

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to gain access to the defrost activation

The display shows

Press enter to immediately activate the defrosting cycle.

The display shows

Ok No

Defrost

PRINTING

tart?

7

efrost

peed 50%

Esc

Esc

for at least 5 seconds

Store

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to gain access to the mode for printing the quick cooling cycles saved

The display shows

rint Dat

Ok No

rint

Esc

21

Page 24

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

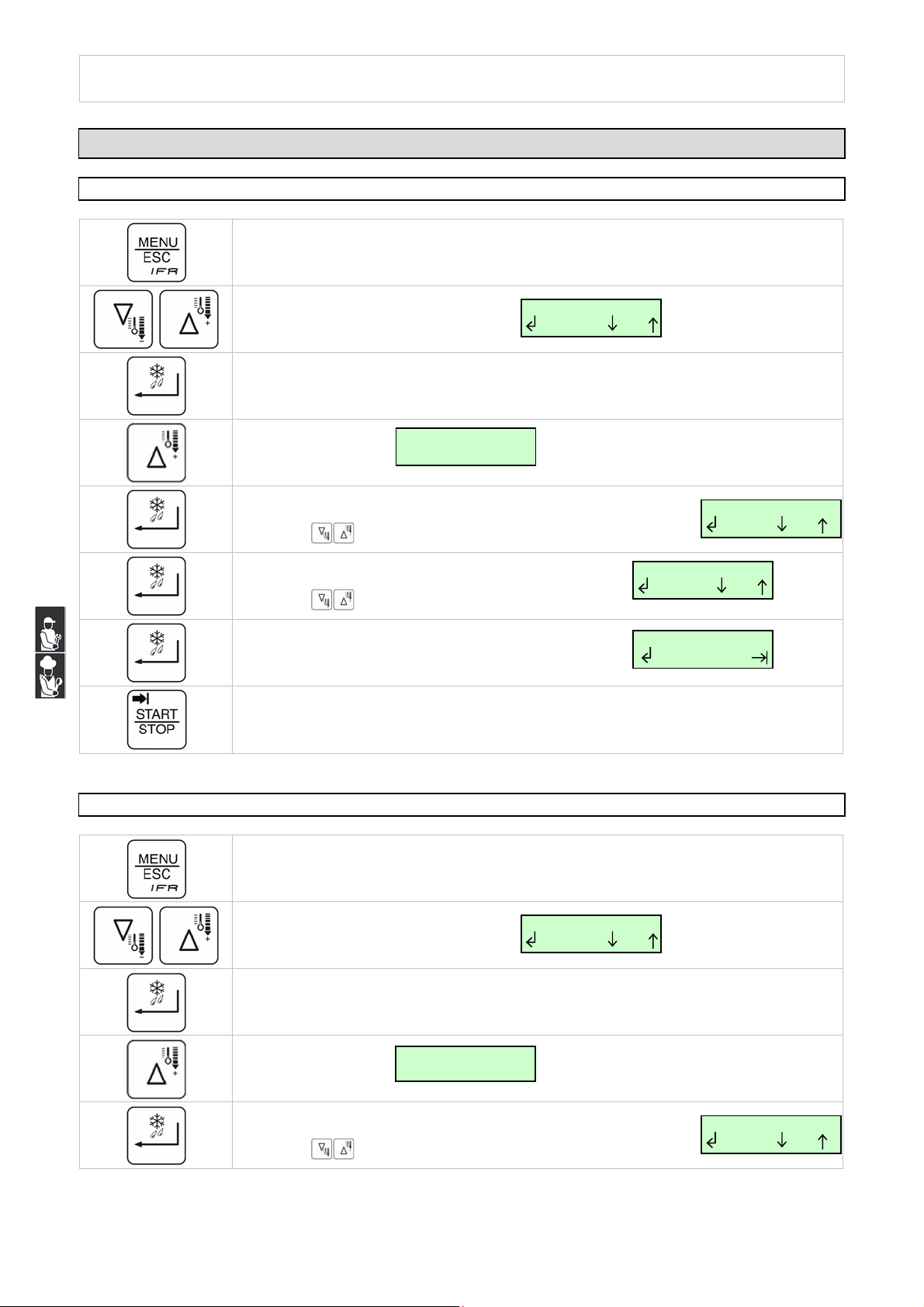

Press enter to start printing the saved cycles

(quick cooler name, date, number of program being used,

name of program being used, temperature setpoint and quick

cooling type, starting time and room/core temperature, end-ofcycle time and room/core temperature)

U

A

A

L

L

-

-

22

Page 25

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

MAINTENANCE CHAPTER 4

MAINTENANCE AND CLEANING

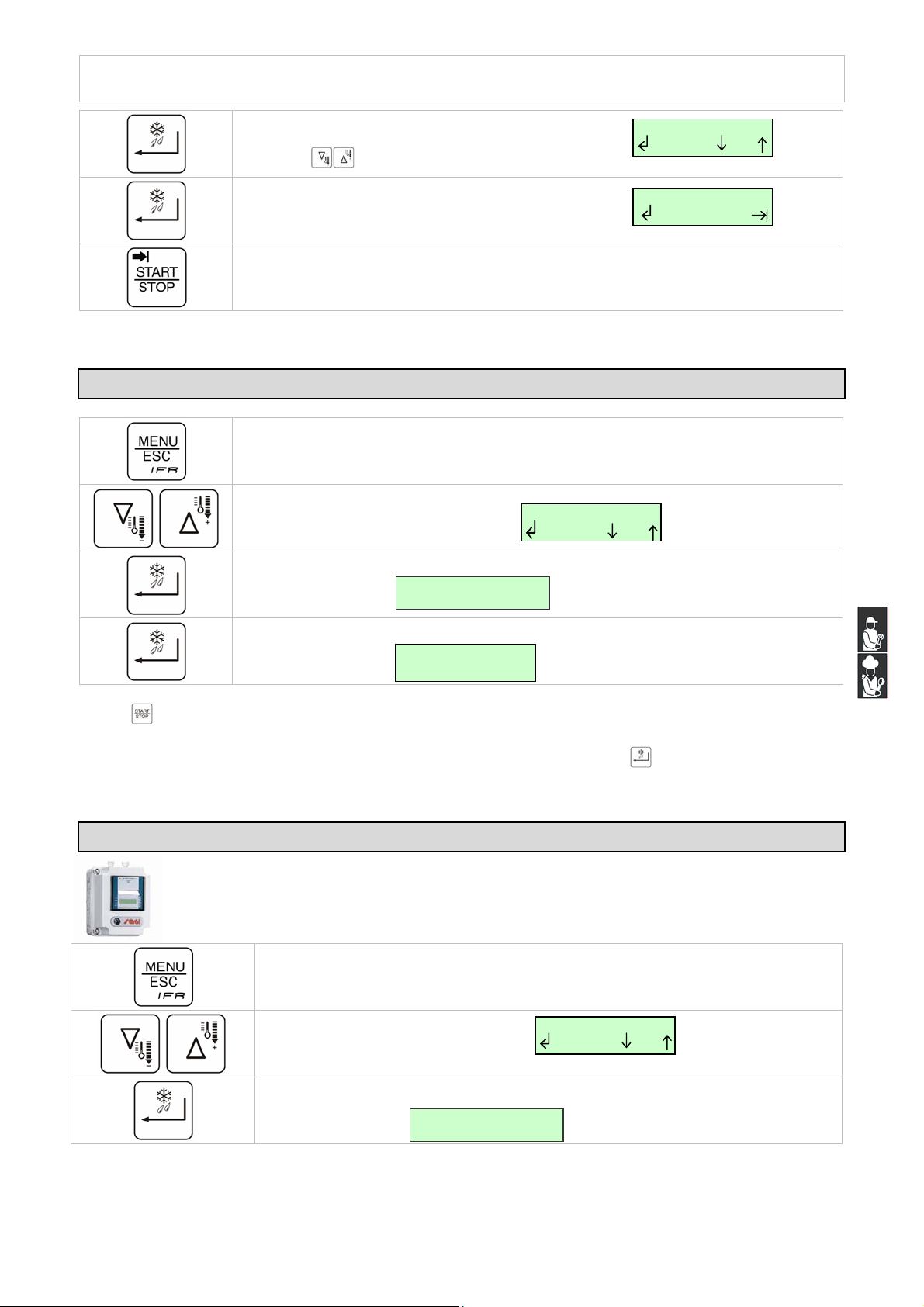

CLEANING THE CABINET

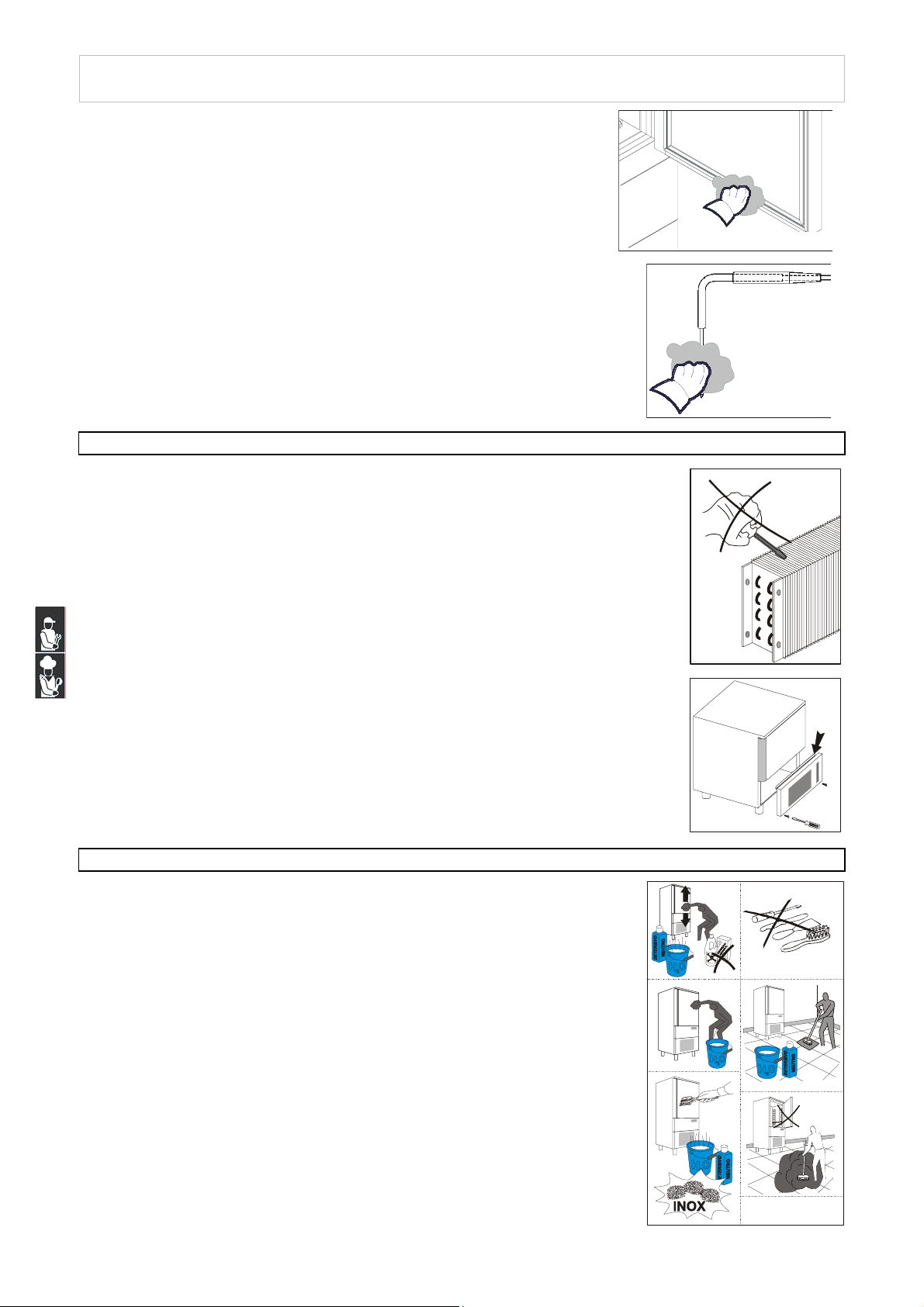

Clean inside the cooling cabinet daily.

Both the cabinet and all the internal components have been designed and shaped to

allow washing and cleaning all parts easily.

Before cleaning, defrost the appliance and remove the internal drain.

Disconnect the master switch.

Clean all components (stainless-stell, plastic or painted parts) with lukewarm water

and detergent.

Then rinse and dry without using abrasives or chemical solvents. (pict.8)

Do not wash the appliance by spraying high-pressure water on the machine. (pict.9)

-

O

V

O

I

S

V

R

I

E

S

T

A

E

R

D

B

A

Pict.8

Pict.9

Do not rinse with sharp or abrasive tools, especially the evaporator. (pict.10)

You may clean inside the evaporator afte r removi ng the knobs and rot ating th e prote ction

component. (pict.11)

Remove the front control board with a tool and clean the raceway to remove all dirt.

(pict.12)

Pict.10

Pict.11

Pict.12

23

Page 26

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

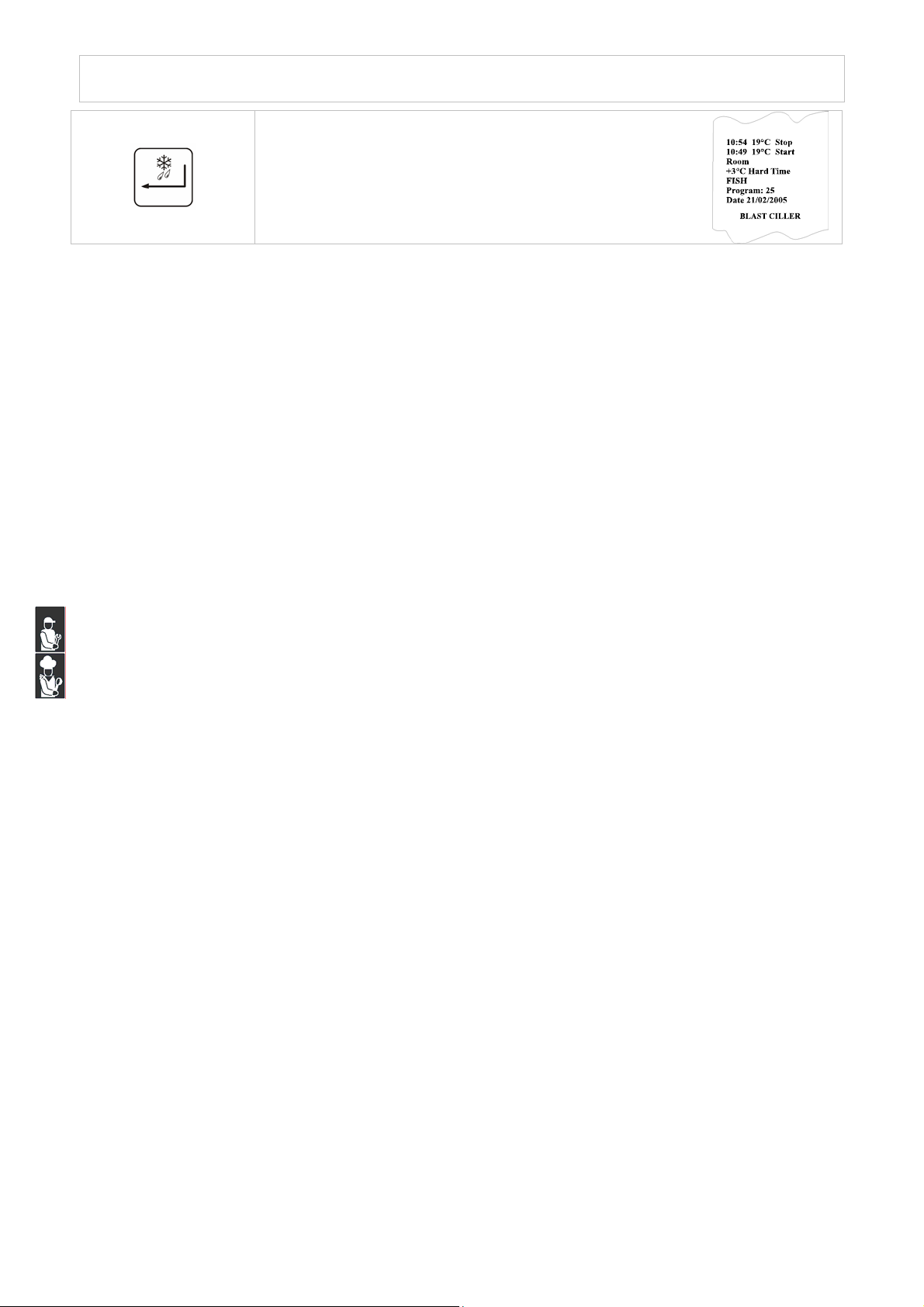

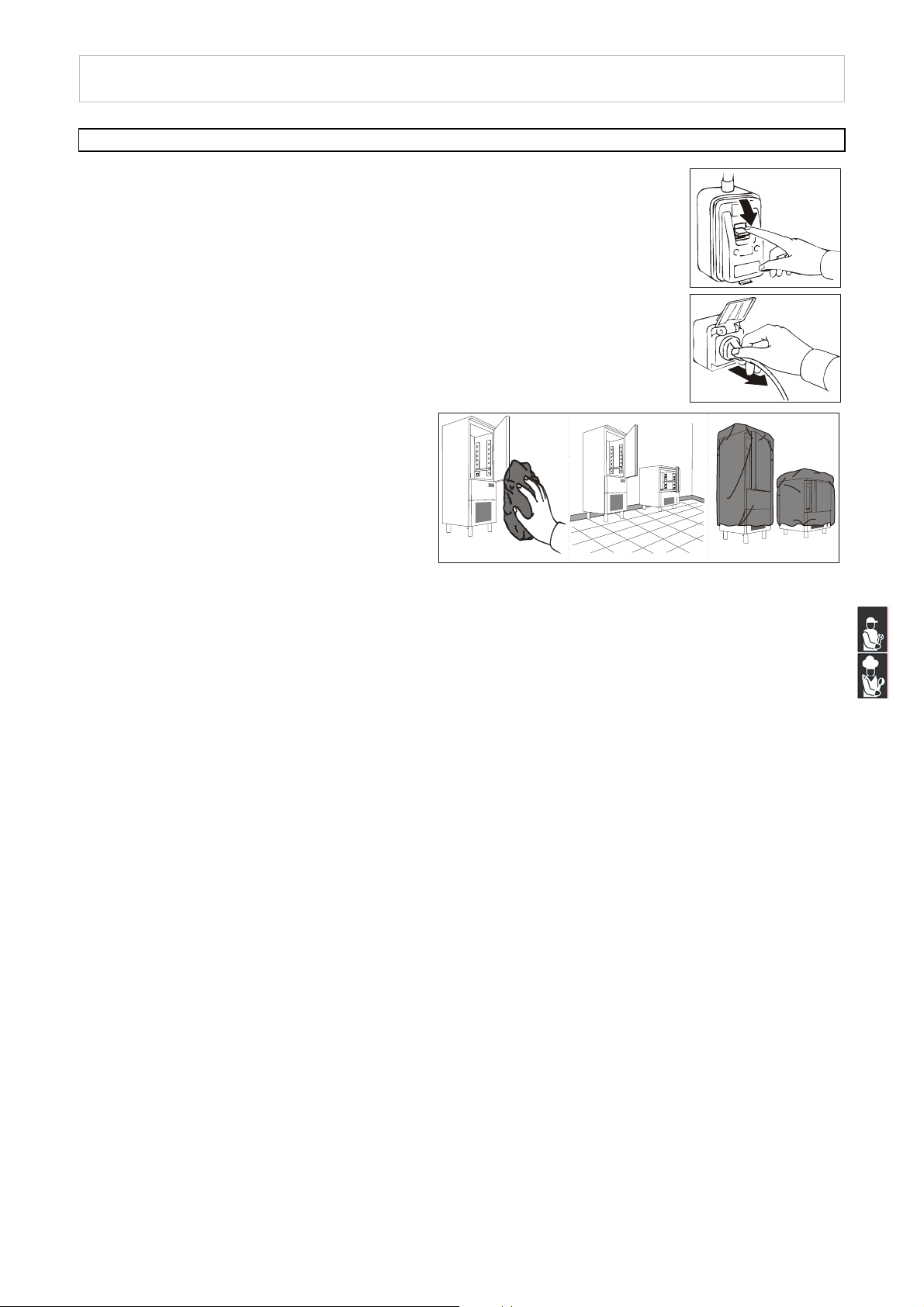

Wash the door gasket with water. Accurately dry with a dry cloth. We

recommend wearing protecting gloves throughout the operations. (pict.13)

Hand-wash the probe using lukewarm water and a mild detergent or products

with biodegradability higher than 90%. Rinse with water and sanitary solution.

Do not use detergents containing solvents (such as trichloroethylene, etc) or

abrasive powders

ATTENTION: do not use hot water to wash the probe (pict.14)

CLEANING THE AIR CONDENSER

The air condenser should be kept clean to ensure the appliance's performance and

efficiency, as air should freely circulate inside the appliance. (pict.15)

The condenser should therefore be cleaned every 30 days, using non-metal brushes

to remove all dust and dirt from condenser blades.

Access to the condenser is obtained by removing the front panel. (pict.16)

STAINLESS-STEEL MAINTENANCE

By stainless steel we mean INOX AISI 304 steel. We recommend following the

instructions below for the maintenance and cleaning of stainless-steel parts.

This is of the utmost importance to ensure the non-toxicity and complete

hygiene of the processed foodstuffs. Stainless-steel is provided with a thin

oxide layer which prevents it from rusting. However, some detergents may

destroy or affect this layer, therefore causing corrosion. Before using any

cleansing product, ask your dealer about a neutral cleansing product, as to

avoid steel corrosions. If the surface has been scratched, polish it with fine

STAINLESS-STEEL wool or a synthetic-fibre abrasive sponge. Always rub in

the direction of the grain. (pict.17)

WARNING: Never use iron wool for cleaning STAINLESS STEEL.

Furthermore, avoid leaving iron wool on the appliance surface as tiny iron

deposits may cause the surface to rust by contamination and affect the

hygiene of the appliance.

U

A

A

L

L

-

-

-

Pict.13

Pict.14

Pict.15

Pict.16

24

Pict.17

Page 27

-

O

P

E

R

A

T

I

O

N

M

A

N

U

A

L

-

O

P

E

R

A

T

I

O

N

M

A

N

U

-

O

P

E

R

A

T

I

O

N

M

A

N

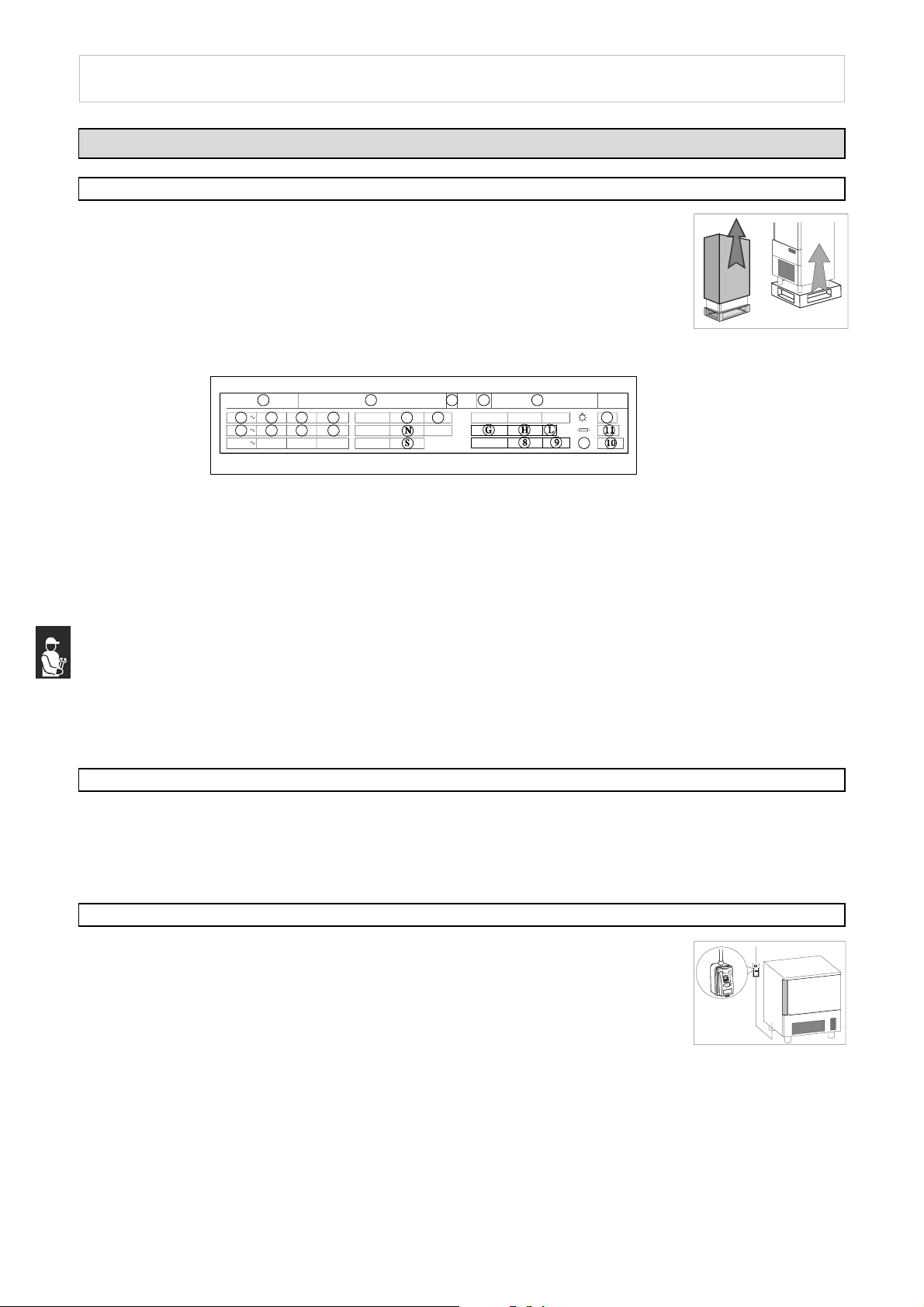

DISCONTINUED USE

Should the machine be disconnected over long periods, follow the instructions below

to maintain the appliance in good condition:

Turn the main switch OFF. (pict.18)

Disconnect the plug. (pict.19)

Empty the appliance and clean it in accordance

with the instructions given in the chapter

"CLEANING". Leave the door ajar to prevent a

bad smell.

Cover the compressor unit with a nylon cloth to

protect it from dust. (pict.20)

In case of appliances with remote control, if you

decide to turn it off, remember to put the switch

off also in the remote control.

U

A

A

L

L

-

-

-

Pict.18

OFF

Pict.19

Pict.20

25

Page 28

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

INSTALLATION

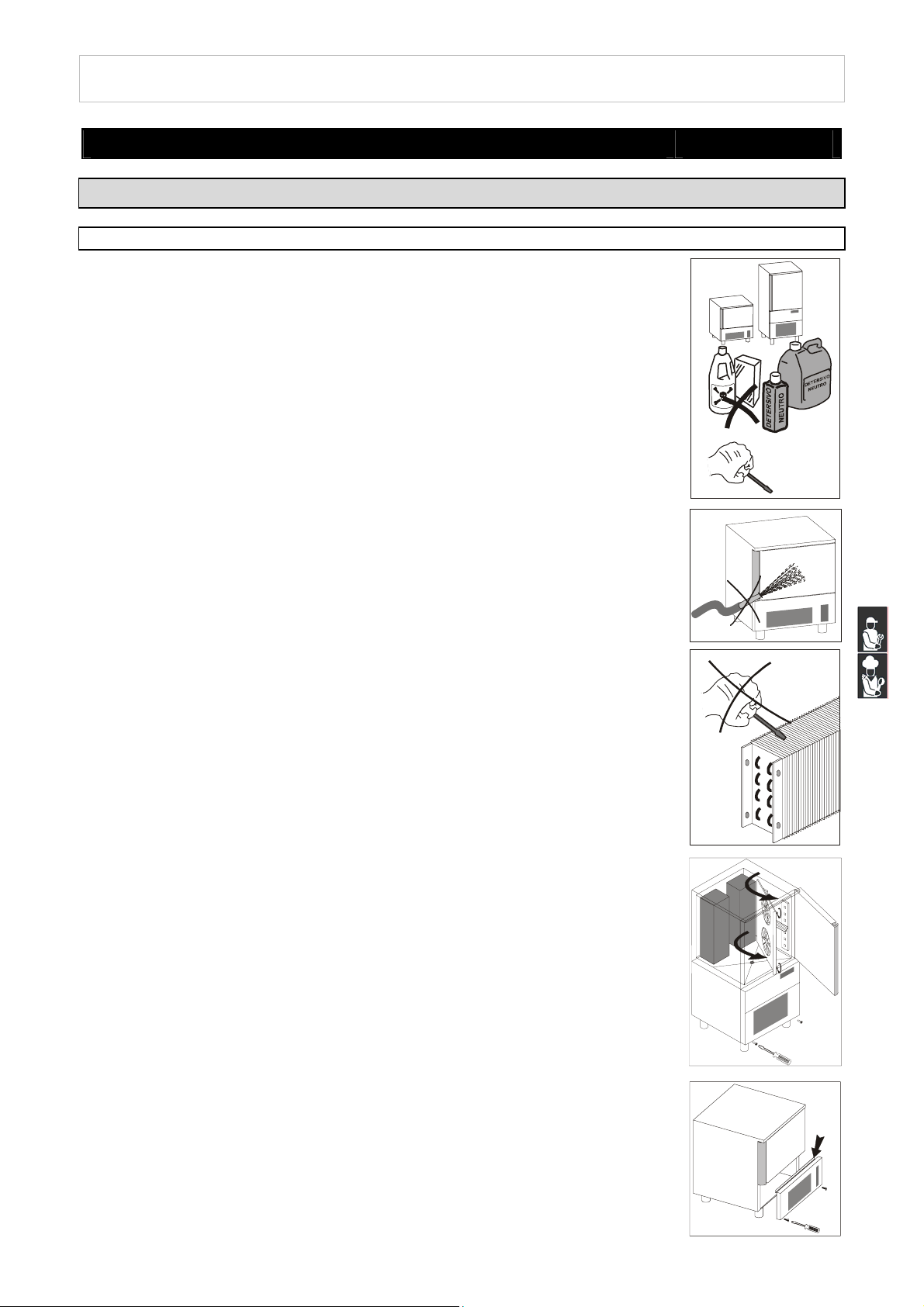

INTRODUCTION

After unpacking the appliance make sure it has not been damaged. (pict.21)

Make sure the supply wiring comply with the ratings (i.e., V, kW, Hz, no. of phases

and main power). Check and record the coolant type inside the refrigeration system

and refer to this recorded data upon any refrigerant refill.

Please quote the product's serial number (shown on the rating plate) on any inquiry to

the Manufacturer. (pict.22)

Detail of above data plate:

1)

Model

2) Manufacturer’s name and address

3) Date of make

4) Year of make

5) Serial number

6) Power insulation class

8) Maximum pressure of refrigerant

9) Minimum pressure of refrigerant

10) Minimum Circuity Amp.

11) Max Fuse Size

A) Input voltage

Maximum output is not guaranteed above 90[°F].

The appliance must be installed and tested in full compliance with accident-prevention

regulations contained in national law and current guidelines. Installers are to comply

with any current local regulations.

An omnipolar switch is to be installed before the appliance, in compliance with the

current regulations applied in the country where the appliance is installed.(pict.24)

1 2 634 5

A

B

A

B

D

C

D

C

MAX ROOM TEMPERATURE (TAB.4)

P

Q

LOCATION

B) Electric current intensity

C) Frequency

D) Number phases

E) Total lamp power

G) Refrigerant type

H) Refrigerant quantity

L) Class of temperature

N) Condenser fan current and fans number

P) Current rated compressor

Q) Locked rotor compressor

S) Evaporator fan current and fans number

N

Pict.22

U

U

E

A

A

L

L

L

-

-

-

Pict.24

Pict.21

26

Page 29

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Do not place the refrigerated compartment near heat sources. (pict.25)

Remove pvc protective film from all over the appliance. (pict.26)

Place the appliance onto the required working site.

(pict.27)

Avoid locations with exposure to direct sunlight.

Do not place the appliance in hot, poorly-ventilated rooms.

Leave a min. 4” clearance around the appliance on the sides where air inlet and

outlet are located. (pict.28)

Level the appliance by means of adjustable feet. (pict.29)

Use suitable fork lift trucks to level heavier appliances

(39[lb] models onwards).

WARNING: If the appliance is not properly leveled the performance and condensate drain may be

hampered.

WIRING

The connection to power supply may be carried out at the back of the appliance after

removing the protection grid. (pict.31)

Pict.27

Pict.25

Pict.26

Pict.28

Pict.29

Pict.31

27

Page 30

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

CONNECTION TO CONDENSATE DRAIN

On certain models, a condensation discharge 1.2” diameter hose

installation is necessary, ("SAREL" or any similar type). The

current general and local regulations pertaining to drains are to be

complied with. (pict.36)

The guarantee is voided and the Manufacturer will not be liable for any damage to appliances or

operators arising from the non-compliance with and tamperings to any part of the appliance

(electric, thermodynamic or hydraulic plant).

TESTING

Carry out the following checkings:

1) Ambient temperatures must be between 50[°F] and 90[°F].

2) Check power input.

3) Carry out at least one full quick cooling cycle

If the appliance was transported horizontally instead of a vertical position DO NOT START THE

APPLIANCE IMMEDIATELY. WAIT FOR AT LEAST 4 HOURS BEFORE OPERATING.

Pict.36

U

A

A

L

L

-

-

28

Page 31

-

C

D

L

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

CLOCK SETTING

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to gain access to the clock setting mode

The display shows

Use the keys up and down to change the flashing digit

Press enter to confirm and pass to the next value

Press menu/esc to exit

ate: 06/11/05

Hour: 14:22:46

lock Setting

Esc

U

A

A

L

L

-

-

LANGUAGE

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to display the first language available

Use the keys up and down to select the desired language

Press enter to confirm your choice

Press menu/esc to exit

anguage

Esc

English

Esc

29

Page 32

-

m

A

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

ALARMS AND FAULT ANALYSIS (TAB.5)

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to gain access to the mode for displaying alarms

If there are no alarms saved, the display shows

If there are alarms saved, the display shows the last alarm starting time as well as the

progressive number ranging from A01 to A30

Press enter to get further information about the alarm.

The max. or min. temperature, the duration, call SERVICE, the alarm de-activation

time or the indication that the alarm is still in progress.

Use the keys up and down to display all the saved alarms

Alar

Esc

A

U

A

Esc

05 Err Room

Present

L

-

L

-

No Data

A05 Insert probe

S 14:21 15/12/03

Press menu/esc to exit

If the fault is not corrected by following the above instructions ask for skilled assistance and avoid carrying

out any other operations, especially on the electricals. When informing the servicing company of the fault,

state 1 and 5 numbers (pict.37)

1 2 634 5

A

B

A

B

D

C

D

C

P

Q

E

Pict.37

30

Page 33

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

TAB.5

FAULT CAUSE REMEDY

No voltage on

Anomalous stop

Compressor failure High and Low-pressure pressure-

The compressor is working but

the cabinet is not cooling

Evaporator fans are not working Fan failure or short-circuit

The cycle cannot start Wrong cycle programming Check time and temperature parameters

AL High Press High Pressure Switch Qualified technician required

AL Room Probe Room Probe interrupted Qualified technician required

AL Evap Probe Evap Probe interrupted Qualified technician required

AL Cond Probe Cond Probe interrupted Qualified technician required

AL Needle Probe Needle Probe interrupted If a probe cycle is running, the cycle is time-controlled

AL Insert Needle Needle Probe not inserted Check the probe inserting cone

High T Room Room Temp above set value If the temperature is not within the specified range, apply

Low T Room Room Temp below set value If the temperature is not within the specified range, apply

AL BlackOut No power supply When power is restored, check the max. temperature

AL Door Open QC room door open

No power supply

Blown fuse

Loosened connections

switch on

Clicker on

Contactor failure

Compressor thermal relay on

Frosted evaporator

No coolant inside the refrigerating

system

Delivery solenoid valve failure

Door micro failure

Door micro faulty

Restore power supply

Replace fuses

Check connection fitting

Ask for skilled assistance

Ask for skilled assistance

Ask for skilled assistance

Ask for skilled assistance

Open the door and carry out defrost cycle

Ask for skilled assistance

Ask for skilled assistance

Ask for skilled assistance

Ask for skilled assistance

Qualified technician required

to a qualified technician

to a qualified technician

reached inside the room

Close the door

Qualified technician required

U

A

A

L

L

-

-

31

Page 34

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

SERVICE

PARAMETERS

DESCRIPTION OF PARAMETERS

Parameter Description

P01 Room SetPoint in pos. quick cooling, Soft phase 23°F 23°F -22°F 86°F

P02 SetPoint in pos. quick cooling, Hard -12°F -12°F -40°F 86°F

P03 Needle SetPoint in pos. quick cooling , Soft phase 37°F 37°F -22°F 86°F

P04 Needle SetPoint in Hard quick cooling 68°F 68°F -22°F 86°F

P05 Positive quick cooling duration 90min 90min 0min 900min

P06 Hard phase duration expressed as % in relation to P05 60% 60% 0% 100%

P07 Room SetPoint in pos. storing 36°F 36°F -22°F 86°F

N01 Room SetPoint in neg, quick cooling -12°F -12°F -40°F 86°F

N02 Needle SetPoint in neg. quick cooling 0°F -0°F -22°F 86°F

N03 Negative quick cooling duration 240min 240min 0min 900min

N04 Room SetPoint in neg. storing -7°F -7°F -40°F 86°F

A01 Temperature alarm hysteresis 4°F 4°F 0°F 18°F

A02 High temperature limit alarm in pos. storing in relation to P07 18°F 18°F 0°F 90°F

A03 Low temperature limit alarm in pos. storing in relation to P07 -17°F -17°F -90°F 0°F

A04 High temperature limit alarm in neg. storing in relation to N04 18°F 18°F 0°F 90°F

A05 Low temperature limit alarm in neg. storing in relation to N04 -17°F -17°F -90°F 0°F

A06 Temperature alarm delay fron storing or defrost start 60min 60min 0min 300min

A07 Temperature alarm delay 30min 30min 0min 300min

A08 Duration of the buzzer in the alarm mode 1min 1min 0min 240min

D01 Temperature unit of measurement (0 Ce l s i u s ; 1 F a h r e n h e i t ) 1 1 0 1

D02 Room probe Offset 0°F 0°F -18°F 18°F

D03 BackLight (0 on when pressing a key; 1 always on) 0 0 0 1

D04 Core probe offset 0°F 0°F -18°F 18°F

D05 Under surface probe offset 0°F 0°F -18°F 18°F

D06 Over surface probe offset 0°F 0°F -18°F 18°F

S01

S02 End-of-defrost temperature 46°F 46°F 14°F 86°F

S03 Defrost max. duration 15 min 15 min 1 min 90 min

S04 Interval between defrosts in storing (0=excluded) 0 hour 0 hour 0 18 hour

S05

S06 Dripping time 1 min 1 min 0 min 90 min

S07 Compressor activation delay with hot gas defrost 0 sec 0 sec 0 sec 600 sec

S08 First defrost activation time from storing start (0=excluded) 0 0 0 90 min

S09 Ignores compressor protection delays in defrost 0 0 0 1

S10

Performs defrost on quick cooling start

0 = No; 1 = Yes

Type of defrost:

0= electrical or due to compressor stop

1= hot gas

2= air

Defrost type started through keyboard:

0= electrical or due to compressor stop

1= hot gas

2= air

Default

(BCF...)

POSITIVE QUICK COOLING

NEGATIVE QUICK COOLING

ALARMS

DISPLAY

DEFROST

A

U

A

Default

(BC...)

0 0 0 1

2 2 0 2

2 0 0 2

L

L

-

-

min MAX

32

Page 35

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Parameter Description

CONFIGURATION

C01 Door input (0 de-activated; 1 activated) 1 1 0 1

C02 Door open polarity 0 0 0 1

C03 Door open alarm delay 2 min 2 min 0 min 60 min

C04 Activates buzzer (0 de-activated; 1 activated) 1 1 0 1

C05 Buzzer duration at the end of quick cooling cycle 10 sec 10 sec 0 600 sec

C06

C07

C08

C09 Compressor stop delay due to door opening 30 sec 30 sec 0 sec 60 sec

C10 Control pressure alarm detection time 5 sec 5 sec 0 sec 60 sec

C11 High pressare digital input polarity 0 0 0 1

C12 Resistances starting SetPoint 23°F 23°F 14°F 68°F

R01 Compressor start/stop hysteresis 5°F 38°F 0°F 36°F

R02 Min. interval between 2 compressor starting 2 min 2 min 0 min 30 min

R03 Compressor start delay from card activation 0 sec 0 sec 0 sec 300 sec

R04 Compressor Duty-Cycle time with faulty room probe in storing 10 min 10 min 0 min 90 min

R05 Compressor ON time faulty room in pos. storing 3 min 3 min 0 min 90 min

R06 Compressor ON time with faulty room in neg. storing 8 min 8 min 0 min 90 min

R07 Needle min. temperature for starting quick cooling 158°F 158°F 32°F 194°F

R08 Compressor block temperature 194°F 194°F 32°F 212°F

R09 Compressor Protection function activation time 24 hour 24 hour 0 hour 240 hour

R10 Pulse duration 2 sec 2 sec 1 sec 10 sec

R11 Pause between pulses 8 sec 4 sec 1 sec 10 sec

R12 Number of pulses 3 3 1 20

R13 Temperature at the end of the Cooling cycle -13°F -13°F -58°F 50°F

F01 Evaporator fans activation hysteresis 4°F

F02 Condenser fans activation hysteresis 4°F

F03 Evaporator fans activation SetPoint 41°F 41°F -58°F 122°F

F04 Condenser fans activation SetPoint 59°F 59°F -58°F 122°F

F05

F06

F07 Fans stop time after defrost 1 min 1 min 0 min 30 min

F08 Condenser fans stop delay 30 sec 30 sec 0 sec 300 sec

F09

F10

F11 Evaporator fans block temperature 158°F 158°F 32°F 194°F

PR1 Sampling time 10 min

CF1 Evaporator fan min. speed 30

CF2 Evaporator fan min. speed selectable in a quick cooling cycle 50

Temperature difference in the first phase of needle insertion

test (0 = test excluded)

Duration of the second phase of needle insertion test (0=test

excluded)

Activates condenser probe

0 = no probe

1 = probe

ADJUSTMENT

FANS

Evaporator fans during defrost

0 = fans OFF; 1 = fans ON

Condenser fans during defrost

0 = fans OFF; 1 = fans ON

Evaporator fans control during quick cooling:

0 = fans always ON

1 = fans thermostated by evaporator temperature

Evaporator fans control during storing:

0 = fans in parallel with the compressor

1 = fans thermostated by evaporator temperature

PRINT

VENTILATION SPEED (P.W.M.)

Default

(BCF...)

13°F 45°F 0 140°F

56 sec 56 sec 0 600 sec

1

0 0 0 1

0 0 0 1

0 0 0 1

0 0 0 1

Default

(BC...)

1

36°F

36°F

10 min

20

50

min MAX

0

0°F 36°F

0°F 36°F

1 min 60 min

0 100

0 100

1

33

Page 36

-

S

S

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

A

L

L

-

-

Parameter Description

I.F.R.

B01 Room thermostating temperature in the first phase -48°F -13°F -58°F 122°F

B02 Under surface T control start temperature

B03 First coefficient of the control relation

B04 Second coefficient of the control relation

B05 Third coefficient of the control relation

B06 Under surface T initial value determining the end of the first phase

B07 Phase two formula coefficient

B09 Under surface t min. value allowed during the third phase

B10 End of intelligent quick cooling core temperature

B11

B12 First phase temperature detection time

B13 First phase min. duration

B16 Defrost on starting intell. QC cycle (0=no 1=yes)

B17 Inhibition temperature

B18

B19 Max. duration possibile for intelligent QC process

B20

B21 First coefficient of the room thermostating curve (third phase)

B22

B23

B24 Room thermostat Set-point in storing

B26 Core temperature limit for the timer start

B27 Adjuster of fans speed in the third phase

B28 Cold pulse adjuster

ADD Device Address 1 1 1 147

SC

MB1 BaudRate: 0 = 2400; 1 = 4800; 2 = 9600; 3 = 18200

MB2 Parity: 0 = no parity; 1 = odd; 2 = even

G01

CHANGING PARAMETERS

Delay from the positive result of the needle test for starting the

procedure to determine the end of the first phase

Room Set point in the event of automatic switch to time or

temperature mode

Under surface T safety value determining the end of the first

phase

Second coefficient of the room thermostating curve (third

phase)

Storing activation at the end of intell. QC cycle

(0 = no; 1 = yes)

COMMUNICATION

Serial Control :

0 = not activated

1 = print

2 = ModBus

TYPE OF CYCLE

Positive QC cycles only :

0 = Positive and Negative

1 = Positive only

Default

(BCF...)

41°F 86°F -58°F 210°F

0 -2 -50 50

0 16 -50 50

-8 -8 -50 50

30°F 34°F -58°F 210°F

99 10 0 99

32°F 30°F -58°F 210°F

46°F 38°F -58°F 210°F

60 sec 60 sec 0 sec 99 sec

30 sec 30 sec 0 sec 99 sec

6 min 6 min 0 min 99min

0 0 0 1

194°F 176°F -58°F 210°F

19°F 32°F -58°F 210°F

999 min 150 min 1 min 999 min

30°F 38°F -58°F 210°F

10 -25 -90 99

-50 -28 -90 99

1 1 0 1

36°F 36°F -130°F 194°F

999 0 0 999

99 0 0 99

10 0 0 99

1

2 2 0 3

2 2 0 2

0 0 0 1

Default

(BC...)

1

min MAX

0

2

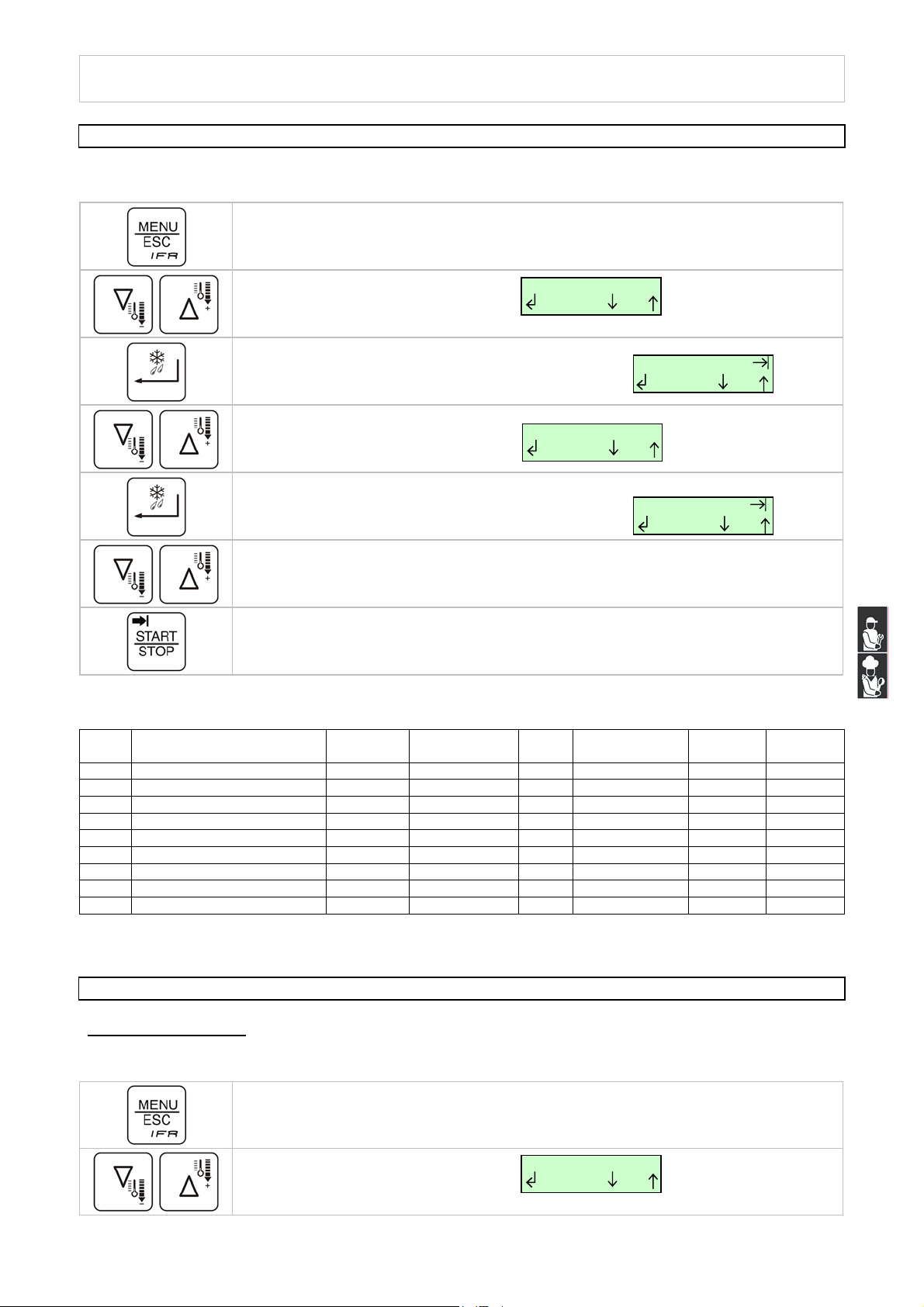

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

The display shows

34

ervice

Password 0

ervice

Esc

(only the 1st time)

Page 37

-

P

P

S

S

P

R

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

Use the keys up and down to select the password “-19”

Press enter to confirm your choice.

The display shows

Press enter to gain access to the parameter programming mode

The first parameter is displayed

Use the keys up and down to scroll all the controller parameters

Press enter to confirm your choice

Use the keys up and down to select the new value of the parameter

Press enter to confirm your choice

arameters

Esc

01 = 23°F

Set Room Pos

U

A

A

L

L

-

-

Press menu/esc to exit

RESET MEMORY

This function erases the saved data, but not the saved user’s programs.

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

The display shows

Use the keys up and down to select the password “-19”

Press enter to confirm your choice.

The display shows

Use the keys up and down to display

ervice

Password 0

arameters

Esc

ervice

Esc

(only the 1st time)

eset Memory

Esc

35

Page 38

-

R

O

R

?

O

Serv

i

S

P

R

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

Press enter to gain access to the mode for cancelling the data stored in the memory

The display shows

Press Enter to erase the saved data

eset Memory?

k No

U

A

A

L

L

-

-

This function restores the original parameters.

ATTENTION

the manufacturer for proper setting of the electronic controller configuration parameters.

: should you use the device with the “RESTORE” option, available on the card, please contact

Press menu/esc to exit

RESTORING DEFAULT PARAMETERS

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to confirm your choice.

The display shows

Use the keys up and down to select the password “-19”

ervice

Password 0

Esc

(only the 1st time)

ce

Press enter to confirm your choice.

The display shows

Use the keys up and down to display

Press enter to gain access to the mode for restoring the data stored in the memory

The display shows

Press Enter to restore the memory

Press menu/esc to exit

arameters

Esc

estore

k No

estore

Esc

36

Page 39

-

R

P

p

p

y

I

p

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

L

-

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

INPUTS/OUTPUTS

Press menu/esc to select the desired menu

Use the keys up and down to display

Press enter to gain access to the mode for displaying inputs and outputs

The display shows

Use the keys up and down to scroll the data to display

Room 21°F

Probe 59°F

Food 93°F

External 90°F

Evap. 14°F

Cond. 70°F

C D FE FC L R A

1 0 0 1 1 0 0

DI1 DI2 FAN

0 1 80

Press menu/esc to exit

oom 21°F

robe 59°F

Room: Room air temperature

Probe: Core tem

Food: under surface probe – see core probe section

External: over surface

Evaporator and Condenser temperature values

Outputs state

1 = relay activated

0 = rela

Digital inputs state and evaporator

fan s

de-activated

eed

nputs/Outputs

Esc

erature –see core probe section

robe –see core probe section

A

U

A

C Compressor R Door resistance

D Defrost A Alarm

FE Evaporator fan DI1 Inputs state micro

FC Condenser fan DI2 Inputs state thermostat

L Sterilization FAN Evaporator fan speed

L

L

-

-

PRINTER INSTALLATION

The printer is not supplied as standard equipment .

Should you purchase the printer, please follow the installation instructions to install.

37

Page 40

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

U

A

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

N

-

I

N

S

T

A

L

L

A

T

I

O

N

M

A

ELECTRICAL COMPARTMENT ACCESS

The following operations are to be carried out by skilled staff only.

Turn the main switch OFF. (pict.38)

Disconnect the plug. (pict.39)

To be able to access the electrical compartment:

Mod. BCF44244 / BCB44244 / BC40-4

Remove the front panel (pict.40) with a tool and move the electric board box

(pict.41) along the slides

Remove the electrical compartment cover with a tool to access the internal

components.

Two delayed fuses are inserted in the power supply line.

To replace a blown fuse, remove the cover by unscrewing the fixing screws, extract

the blown fuse and replace it with a fuse having the same characteristics. (pict.42)

Mod. BCF93558 / BC80-8 / BCF11514 / BC113-14 / BCF22020

Remove the front panel (pict.43) and the control panel by means of a suitable tool.

Remove the cover to have access to the components using a suitable tool (pict.44).

N

U

U

A

A

L

L

L

-

-

-

Pict.38

OFF

Pict.39

Pict.40

Pict.41

Pict.42

Pict.43

Pict.44

38

Page 41

-

I

N

S

T

A

L

L

A

T

I

O

N