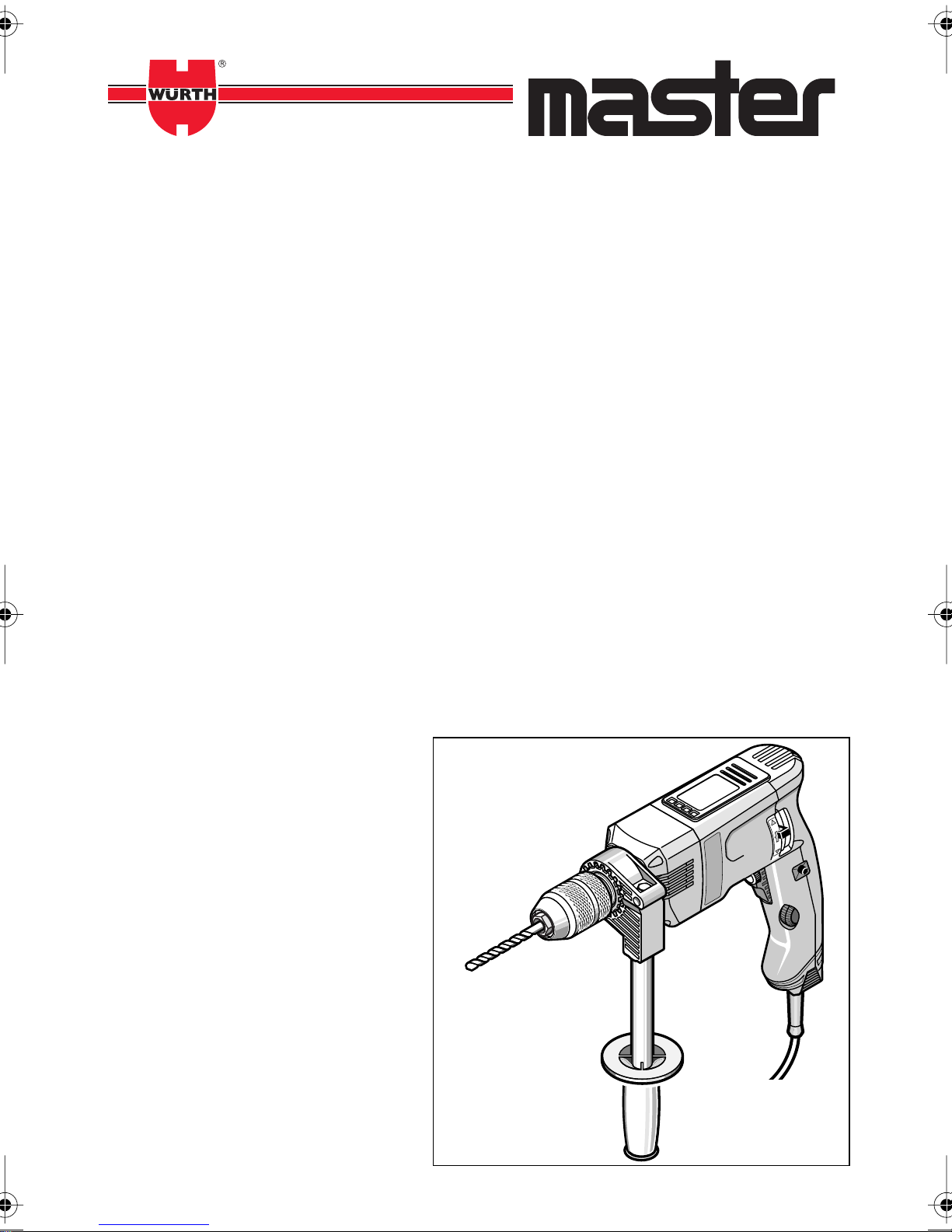

BS 13-SEC

Bedienungsanleitung

Operating Instructions

Istruzioni d’uso

Notice d’utilisation

Instrucciones para el manejo

Instruções de utilização

Gebruiksaanwijzing

Betjeningsvejledning

Bruksanvisning

Käyttöohje

Bruksanvisning

Οδηγίες χειρισµού

Kullanım kılavuzu

Instrukcja obs∆ugi

Kezelési Utasítás

Návod k obsluze

Návod na obsluhu

Instrucøiuni de utilizare

Navodila za uporabo

Ръководство на потребителя

Kasutusjuhend

Vartojimo informacijà

EkspluatÇcijas instrukcija

Руководство по эксплуатации

2

4

3

1

5

6

7

9

10

8

11

A B

GB

For Your Safety

Working safely with this machine is possible only when the operating and safety

information are read completely and the

instructions contained therein are strictly

followed. In addition, the general safety

notes in the enclosed booklet must be observed.

Before using for the first time, ask for a practical

demonstration.

The unit must not be damp and must not

be used in a wet environment.

Wear hearing protection. Exposure to

noise can cause hearing loss.

❏ When working with the machine, always hold it

firmly with both hands and provide for a secure

stance. The power tool is guided more secure with

both hands.

❏ Secure the workpiece. A workpiece clamped with

clamping devices or in a vice is held more securely

than by hand.

❏ Do not work materials containing asbestos.

Asbestos is considered carcinogenic.

❏ Always wait until the machine has come to a

complete stop before placing it down. The tool

insert can jam and lead to loss of control over the

power tool.

For further notes on safety refer to the enclosed sheet

☞

❏ Hold the machine with a firm grip. High reaction

torque can briefly occur while driving in and loosening screws.

❏ Do not use a machine with a damaged mains

cable. Do not touch the damaged cable and pull

the mains plug when the cable is damaged while

working. Damaged cables increase the risk of an

electric shock.

❏ Connect machines that are used in the open via a

residual current device (RCD).

❏ Always use the auxiliary handle supplied with

the machine. Loss of control can cause personal

injury.

❏ Use suitable detectors to determine if utility lines

are hidden in the work area or call the local utility company for assistance.

Contact with electric lines can lead to fire and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property

damage or may cause an electric shock.

❏ Hold the machine only by the insulated gripping

surfaces, when performing an operation where

the cutting tool may run into hidden wiring. Con-

tact with a “live” wire will make exposed metal

parts of the tool “live” and shock the operator.

❏ Use only original Würth parts and accessories.

Machine Elements

The numbering of the machine elements refers to the

illustration of the machine on the graphics page.

1 Keyless chuck

2 Spanner surface

3 Auxiliary handle collar

4 Ventilation slots

5 Rotational direction switch

6 Lock-on button

7 Torque-Control thumbwheel

8 Latch for mains cable module

9 On/Off switch

10 Speed selector thumbwheel

11 Auxiliary grip

Not all of the accessories illustrated or described are included

as standard delivery.

Intended Use

The drill can be used for drilling in wood, metal and

plastics and for screwdriving.

The user is responsible for damage caused by usage

other then intended.

Noise/Vibration Information

Measured values determined according to

EN 60 745-1.

Typically the A-weighted sound pressure level of the

product is 73 dB (A). The noise level when working can

exceed 85 dB(A).

Wear hearing protection!

The typical hand/arm vibration is below 2.5 m/s2.

7

Tool Specifications

Screw driving drill BS 13-SEC

Article number 0702 315

Rated input power 1200 W

Output power 640 W

No-load speed 70 – 530 min

Rated speed 530 min

Maximum drilling Ø

Steel 16 mm

Wood 70 mm

Screw dia., max. Wood 12 mm

Screw dia., max. Aluminium 8 mm

Thread of work spindle 1/2“ x 20 UNF

Spindle collar 43 mm

Chuck opening width 13 mm

Weight approx. 2.7 kg

Protection class II /

(Protective insulation)

-1

-1

Unscrewing chuck

(see figure )

Loosen and unscrew the drill chuck with two

open-ended spanners as illustrated.

Mounting takes place in the reverse order.

A

Fitting the working tool

Before any work on the machine itself, pull the mains

plug.

Inserting the tool

Grip rear collar of keyless chuck 1 and rotate front collar until chuck is open sufficiently for tool to be inserted.

Clamping the tool (see figure )

Grip rear collar and manually rotate front collar until

tight. An audible "click" indicates that the chuck has

automatically locked.

The locking mechanism is automatically released when

the front collar is rotated in the opposite direction in

order to remove the tool.

B

Substantial torque reactions are possible when larger

drill bits are being used. Here the auxiliary grip provides extra safety.

Connect the mains cable module to the handle. The plug

must latch.

Switching on and off

Intermittant use:

Switching on: Press trigger switch 9.

Switching off: Release trigger switch 9.

Continuous use:

Switching on: Press the on-off switch 9 and then the

locking button 6, after that release

on-off switch.

Switching off: Press the on-off switch 9 and then

release.

Restarting protection

Prevents uncontrolled restarting of the machine after a

power interruption.

Putting into operation again: Switch on-off switch to off

position and switch on again.

Continuously Variable Speed Control

The speed can be infinitely varied by pressure on the

on-off switch up to the preselected level.

RPM Preselection (electronic)

The desired rotational speed can be preselected with

the thumbwheel 10 (also possible during operation).

After long periods at low operating speed, run the

machine at high speed and without load for approx.

3 minutes.

Changing rotational direction

Take hold of the rotational direction

switch 5 on both sides.

Set rotational direction selector 5 to

R (right or clockwise) or L (left or

anticlockwise). (Rotational direction

selector 5 is locked when ON-OFF

switch 9 is activated).

If the rotational direction switch 5 is set between the

positions “R” and “L”, the machine cannot be switched

on.

The reversing or anticlockwise operation enables application for tasks such

as loosening of screws.

Change rotational direction only when

machine is not running.

Starting Operation

Always use the correct supply voltage: The power supply voltage must match the information quoted on the

tool identification plate.

Mounting the Auxiliary Handle and the Mains Cable

Module

Auxiliary grip 11 is attached to spindle collar 3.

8

Electronic torque control

(Torque-Control)

Thumbwheel 7 can be used to determine the amount of

torque acting upon the drill spindle.

1 = low torque

10 = maximum torque

When the preselected torque is reached during drilling,

the unit switches off and remains off.

Environmental Protection

80 min

10

9

8

7

6

5

Torque - Control

4

3

2

1

0

-1

530 min

-1

5025

Torque (Nm)

Advices for operation

Sharpening drill bits

Only HSS drill bits in perfect condition (HSS = high speed

steel) should be used for drilling metal. Würth quality is

guaranteed by the Würth accessory program.

Maintenance and Cleaning

Before any work on the machine itself, pull the

mains plug.

For safe and proper working, always keep the machine

and the ventilation slots clean.

Keep the tool holder clean at all times.

If the machine should happen to fail despite the care

taken in manufacture and testing, repair should be carried out by an authorized customer service agent for

Würth power tools.

In all correspondence and spare parts orders, please

always include the 8-digit order number given on the

nameplate of the machine.

For the current spare parts list of this machine, log into

the Internet under “http://www.wuerth.com/partsmanager” or ask for a copy at your nearest Würth branch

office.

Recycle raw materials instead of disposing as waste.

The machine, accessories and packaging

should be sorted for environmental-friendly recycling.

The plastic components are labelled for categorized

recycling.

Warranty

For this Würth tool, we provide a warranty in accordance with statutory/country-specific regulations from

the date of purchase (proof of purchase by invoice or

delivery note). Damage that has occurred will be corrected by replacement or repair.

Damage caused by normal wear, overloading or

improper handling is excluded from the warranty.

Claims can be recognised only when the tool is presented undisassembled to a Würth branch office or a

Würth field service employee.

Declaration of Conformity

We declare under our sole responsibility that this product is in conformity with the following standards or

standardization documents: EN 60 745-1,

EN 60 745-2-1, EN 55 014-1, EN 55 014-2,

EN 61 000-3-2, EN 61 000-3-3 according to the provisions of the regulations 98/37/EC, 73/23/EC,

89/336/EEC.

05

Adolf Würth GmbH & Co. KG

P. Zürn R. Bauer

Subject to change without notice

9

Würth

worldwide:

Würth Albania Ltd.

Rr. Asim Vokshi

Pall 49/1 Ap. 9

AL-Tirana

Albania

Tel. ++355/42/29748

Fax. ++355/42/29748

wuerthal@icc.al.eu.org

Würth Armenia Co. Ltd.

63 Tigran Mets Ave.

AM-375005 Yerevan

Armenia

Tel. ++3741/559970

Fax. ++3741/559972

wuerth@arminco.com

Würth Handelsges.m.b.H.

Würth Strasse 1

AT-3071 Böheimkirchen

Austria

Tel. ++43/2743/70700

Fax. ++43/2743/70703333

info@wuerth.at

Würth Australia Pty Ltd

4 Redwood Drive

AU-Dingley VIC 3172

Australia

Tel. ++61/3/95517244

Fax. ++61/3/95512994

info@wurth.com.au

Wurth Aztur Ltd

Mir Galal Str.63.

AZ-370134 Baku

Azerbaijan

Tel. ++994/12/601934

Fax. ++994/12/601934

wurth@azdata.net

Wurth BH d.j.l.

Dzemal Biedia 162

BA-71000 Sarajevo,BIH

Bosnia

Tel. ++387/33/461770

Fax. ++387/33/461825

Würth Belux N.V.

Everdongenlaan 29

BE-2300 Turnhout

Belgium

Tel. ++32/14/445566

Fax. ++32/14/423077

info@wurth.be

Wuerth Bulgaria EOOD

Iskarsko Chaussee Boul. 12

BG-1592 Sofia

Bulgaria

Tel. ++359/2/9659955

Fax. ++359/2/9659966

wuerth_bg@ibm.net

Würth Belarus Ltd.

Botanitscheskaja Str. 5a-603

BY-220038 Minsk

Belarus

Tel. ++375/172/363919

Fax. ++375/172/852512

wuerthbel@open.by

Würth AG

Dornwydenweg 11

CH-4144 Arlesheim

Switzerland

Tel. ++41/61/7059111

Fax. ++41/61/7059494

infos@wuerth-ag.ch

Würth Guangzhou

International Trading Co., Ltd.

Room 601, North Tower,

Nantian Building,

3 Jiangong Road

Tianhe High and New

Technology

Industry Development Zone

CN-510665 Guangzhou

China

Tel. ++86/20/85552840

Fax. ++86/20/855550245

wurthgz@public.guangzhou.gd.

cn

Würth Hong Kong Co. Ltd.

Unit B 6/f Prince Ind Bidg

106 King Fuk St.,

San Po Kong, Kowloon

CN-Hong Kong

China

Tel. ++8/52/27508118

Fax. ++8/52/27530084

info@wuerth-hk.com

Wuerth China-Shanghai

Langsheng Trading Co., Ltd.

2nd Floor (West)

No. 18 Factory Site

No. 481 Gui Ping Road

CN-200233 Shanghai

China

Tel. ++86/21/64951418

Fax. ++86/21/64848610

wuerthcn@public3.sta.net.cn

Würth Tianjin International

Trade Co., Ltd.

Jie Fang Nan Lu Str. 518-1

CN-300221 Tianjin

China

Tel. ++86/22/88242263

Fax. ++86/22/88243813

tjwuerth@public.tpt.tj.cn

Wuerth Cyprus LTD

Strovolos industrial estate

P.O. Box 8899

CY-2083 Nicosia

Cyprus

Tel. ++357/2/512086

Fax. ++357/2/512091

wuerthcy@cytanet.com.cy

Würth, spol. s r.o.

Sazecská 2

CZ-10800 Praha 10

Czech Republic

Tel. ++420/2/72106111

Fax. ++420/2/72106119

info@wuerth.cz

Adolf Würth GmbH

& Co. KG

Postfach

D-74650 Künzelsau

Reinhold-Würth-Str. 12-16

DE-74653 Künzelsau

Germany

Tel. ++49/7940/15/0

Fax. ++49/7940/15/1000

info@wuerth.com

Würth Danmark A/S

Montagevej 6

DK-6000 Kolding

Denmark

Tel. ++45/79/323232

Fax. ++45/75/517250

Würth Estonia AS

Liimi 3 A

EE-10621 Tallinn

Estonia

Tel. ++372/6563509

Fax. ++372/6563494

wuerth@wuerth.ee

Würth Egypt for Trading

S.A.E.

27th. Km Alexandria Cairo

Desert Road, Behind Mercedes

EG-Amriya Alexandria

Egypt

Tel. ++2/03/4700432

Fax. ++2/03/4700432

wurth@wurthegypt.com

Würth España S.A.

Poligono Riera de Caldes

Carrer Dels Joiers 21-23

ES-08184 Palau de Plegamans

Barcelona

Spain

Tel. ++34/93/8629500

Fax. ++34/93/8646203

webmaster@wurth.es

Würth Oy

Herajoki

FI-11710 Riihimäki

Finland

Tel. ++358/19/7701

Fax. ++358/19/729010

Würth France S.A.

Z.I. Ouest

Rue Georges Besse

FR-67158 Erstein Cedex

France

Tel. ++33/3/88645300

Fax. ++33/3/88646200

Wurth U.K. Ltd.

1 Centurion Way

Erith

GB-Kent DA 18 4 AE

Great Britain

Tel. ++44/208/3196000

Fax. ++44/208/3196400

info@wurth.co.uk

Würth Georgia Ltd.

Marshal Gelovani Avenue 36

GE-380059 Tbilisi

Georgia

Tel. ++995/32/530610

Fax. ++995/32/250610

gewuerth@caucasus.net

Würth Hellas S.A.

23. Klm. National Road

Athens-Lamia

145 68 Krioneri Attikis

P.O. Box 51877

Attikis

GR-145 02 Agios Stefanos

Attikis

Greece

Tel. ++30/1/6290800

Fax. ++30/1/8134756

info@wurth.gr

Würth- Hrvatska d.o.o.

Franje Lucica 23/III

HR-10000 Zagreb

Croatia

Tel. ++385/1/3498784

Fax. ++385/1/3498783

wurth.hrvatska@zg.hinet.hr

Würth Szereléstechnika KFT

Gyár utca 2

HU-2040 Budaörs

Hungary

Tel. ++36/23/418130

Fax. ++36/23/421777

wuerth@wuerth.hu

PT Wuerth Indah

JI. Meruya Ilir Raya No. 82 A-B

ID-Jakarta 11360

Indonesia

Tel. ++62/21/5860036

Fax. ++62/21/5861043

wuerth@idola.net.id

Würth Ireland Ltd.

Monaclinoe Industrial Estate

Ballysimon Road

IR-Limerick

Ireland

Tel. ++353/61/412911

Fax. ++353/61/412428

Würth Israel Ltd.

Alon Hatavor 2

Zone 1

IL-Caesarea Industrial Park

P.O. Box 3585

IL-Caesarea Industrial Park

Zip 38900

Israel

Tel. ++972/4/6273939

Fax. ++972/4/6270999

Wuerth India Pvt. Ltd.

33, Santosh Building,

Marol Co-operative Industrial

Estate,

M V Road, Andheri (East)

IN-Mumbai 400 059

India

Tel. ++91/22/8507023

Fax. ++91/22/8507020

wuerth@bom4.vsnl.net.in

Würth Teheran Ltd.

Pasdaran St.-Corner of

Negarestane 5-No.183

IR-16619 Teheran-Iran

Iran

Tel. ++98/21/2842828

Fax. ++98/21/2856171

wuerthtehran@irost.com

Würth á Íslandi ehf.

Veslurhraun 5

IS-210 Gar∂abær

Iceland

Tel. ++354/5302000

Fax. ++354/5302001

ebse@wurth.is

Würth S.r.l. - GmbH

Via Stazione, 51

I - 39044 Egna (BZ)

Tel. ++39/0471/828 111

Fax. ++39/0471/828 600

vendite@wuerth.com

Wurth- Jordan Co. Ltd.

Al-yadoudeh

P.O. Box 951

JO-Amman-11592

Jordan

Tel. ++962/6/4122512

Fax. ++962/6/4122510

wurthjor@go.com.jo

Würth Japan Co., Ltd.

MT Building

33 Sanmaicho, Kanagawa-ku

JP-Yokohama 221-0862

Japan

Tel. ++81/45/4884186

Fax. ++81/45/4884187

sat_ueda@wuerth.co.jp

jun_ando@wuerth.co.jp

Würth Nippon GmbH

& Co. KG

6F Tsuruga Bldg., 1-29-15

Shinyokohama, Kohoku-Ku

JP-Yokohama 222-0033

Japan

Tel. ++81/45/4704633

Fax. ++81/45/4704621

jj.wn@poem.ocn.ne.jp

Wuerth Kenya Ltd.

P.O. BOX 16751

Meru Road

KE-Mombasa

Kenya

Tel. ++254/11/312403

Fax. ++254/11/312437

wuerth@africaonline.co.ke

Würth Foreign Swiss

Company Ltd.

3 Erkindik Boulevard

KG-Bishkek, 720040

Kyrgyzstan

Tel. ++996/312/227976

Fax. ++996/312/661025

wurth@imfiko.bishkek.su

Würth Kosova

No. 36 Pashe Dibra

Bregu i diellit

Prishtina

Tel. ++377/44/186514

wurthkosova@hotmail.com

Wurth Korea Co. Ltd.

128-1, O-Keum Dong,

KR-Song Pa-Gu, Seoul, Korea

(138-859)

South Korea

Tel. ++82/2/4009311

Fax. ++82/2/4009315

wurth-kr@wurth.co.kr

Wuerth Kazakhstan Ltd.

Abai 125, 2nd floor

KZ-480008, Almaty

Kazakhstan

Tel. ++7/3272/622432

Fax. ++7/3272/622495

wurthkaz@kaznet.kz

Würth Lietuva

Dariaus ir Gireno 21

LT-2038 Vilnius

Lithuania

Tel. ++370/2/263045

Fax. ++370/2/264108

info@wurth.lt

Würth Reinsurance

Company, S.A.

B.P. 2217

L-1022 Luxembourg

Siège social

65, Avenue de la gare

LU-1611 Luxembourg

Tel. ++352/494177

Fax. ++352/494188

Würth Maroc SARL

48 Avenue Pasteur

MA-Casablanca 20150

Marocco

Tel. ++212/2/2405700

Fax. ++212/2/2405706

Würth Moldova Ltd.

b-dul Stefan cel Mare, nr 4

Hotel National

MD-Chisinau

Moldavia

Tel. ++373/2/540398

Fax. ++373/2/540398

Würth Makedonien GmbH

ul. Gorce Petrov 108a

MK-91000 Skopje

Macedonia

Tel. ++389/233/2230

Fax. ++389/233/2083

wurthmak@unet.com.mk

Würth Caraibes Sarl

Z.I. Cocotte Canal

MQ-97224 Ducos-Martinique

Tel. ++596/560701

Fax. ++596/564369

wurth.caraibes@wanadoo.fr

Würth Limited

Würth House

Triq il- Masgar

MT-Qormi QRM09

Malta

Tel. ++356/494604

Fax. ++356/441081

wuerth@maltanet.net

Wuerth (Malaysia) Sdn.

Bhd.

6, Jalan Permas 9/13

Taman Permas Jaya

MY-81750 Masai Johor

Malaysia

Tel. ++60/7/3876280

++60/7/3881712

Fax. ++60/7/3884391

wuerth@po.jaring.my

Würth Nederland B.V.

Moeskampweg 13

NL-5222 AW 's-Hertogenbosch

Postbus 344

NL-5201 AH 's-Hertogenbosch

Netherlands

Tel. ++31/73/6291911

Fax. ++31/73/613137

info@wurth.nl

Würth Norge AS

Postboks 84

NO-1483 Skytta

Morteveien 12, Gjellerasen

Naeringspark

NO-1481 Hagan

Tel. ++47/670/62500

Fax. ++47/670/62711

kontakt@wuerth.no

Würth New Zealand Ltd.

42 Hobill Avenue,

P.O. Box 97079

Manukau City

NZ-South Auckland/Mail Centre

New Zealand

Tel. ++64/9/2623040

Fax. ++64/9/2623030

info@wurth.co.nz

Wuerth Philippines, Inc.

Air-Rich Building

Km. 19.5 East Service Road,

South Expressway

PH-Parañaque City,

Philippines

Tel. ++63/2/8382697

Fax. ++63/2/8382195

wuerthphils@pacific.net.ph

Würth Polska Sp. z o.o.

ul. Plochinska 33

PL-03-044 Warzawa

Poland

Tel. ++48/22/819041

Fax. ++48/22/8117190

biuro@wurth.pl

Würth Portugal Tecnica

de Montagem, Ldo.

Estrada Nacional, 249-4

Abrunheira

P-2710-089 Sintra

Portugal

Tel. ++351/21/9157200

Fax. ++351/21/9151038

wurth.portugal@mail.telepac.pt

Würth Romania S.R.L.

Zapada Mielior 16-18

Sector 1

P.O. 18-85

RO-Bucarest 71529

Romania

Tel. ++40/1/2323282

Fax. ++40/1/2328933

wuerth@moon.ro

Wuerth Mittelrussland

c/o Logovaz

Transportnaja Ul. 20

RU-394043 Voronezh

Russia

Tel. ++7/0732/727065

Fax. ++7/0732/727065

wurth@wurth.vrn.ru

Würth Irtysch

Ul. Dobrovolskogo 8/1

RU-644099 Omsk

Russia

Tel. ++7/3812/245291

Fax. ++7/3812/245291

rus@wuerth.omsk.su

Würth Russia

Bulwar Generala

Karbyschewa, 8, Of.504

RU-123154 Moskau

Russia

Tel. ++7/095/9468028

Fax. ++7/095/9468028

sale@wurth.ru

Würth Nordkaukasus Ltd.

Krasnoarmejskaja Str. 206

RU-344010 Rostow am Don

Russia

Tel. ++7/8632/618051

Fax. ++7/8632/618054

wuerthnk@icomm.ru

ZAO Wuerth-Siberia

Serebrennikovskaja, 14, of. 501

RU-630007 Novosibirsk

Russia

Tel. ++7/3832/234673

Fax. ++7/3832/234673

wuerthsb@drbit.ru

Würth St. Petersburg

Prospekt Dunaiski 68

RU-192 288 St. Petersburg

Russia

Tel. ++7/812/1726166

Fax. ++7/812/1726085

web@wurth.spb.ru

ZAO Wuerth-Ural

Institutskaja, 6, of. 202

RU-620016 Ekaterinburg

Russia

Tel. ++7/3432/432393

Fax. ++7/3432/432393

wurth_ur@etel.ru

ZAO Wuerth-Volga

Novosadovaja st., 221, of. 205

RU-443011 Samara

Russia

Tel. ++7/8462/703252

Fax. ++7/8462/703252

wurth_ur@etel.ru

Niederlassungen:

Aachen

Jülicher Straße 236-248

52070 Aachen

Telefon (02 41) 5 68 79-0

Telefax (02 41) 5 68 79 50

nl.aachen@wuerth.com

Aalen

Robert-Bosch-Straße 47

73431 Aalen

Telefon (0 73 61) 92 30-0

Telefax (0 73 61) 92 30 50

nl.aalen@wuerth.com

Augsburg

Flotowstraße 15

86368 Gersthofen

Telefon (08 21) 2 97 61 20

Telefax (08 21) 2 97 61 50

nl.augsburg@wuerth.com

Backnang

Gewerbegeb. Backnang-Süd

Beim Erlenwäldchen 8

71522 Backnang

Telefon (0 71 91) 90 40-0

Telefax (0 71 91) 90 40 50

nl.backnang@wuerth.com

Bad Mergentheim

Industriepark Würth, Gebäude 1

97980 Bad Mergentheim

Telefon (0 79 31) 9 24 05-0

Telefax (0 79 31) 92 40 59

nl.badmergentheim@wuerth.com

Bamberg

Biegenhofstraße 24

96103 Hallstadt

Telefon (09 51) 7 00 84-0

Telefax (09 51) 7 00 84 50

nl.bamberg@wuerth.com

Bayreuth

Hasenweg 6

95448 Bayreuth

Telefon (09 21) 7 92 05-0

Telefax (09 21) 7 92 05 50

nl.bayreuth@wuerth.com

Berlin-Charlottenburg

Spandauer Damm 60-64

14059 Berlin

Telefon (0 30) 32 67 84 30

Telefax (0 30) 32 67 83 51

nl.berlin-charlottenburg

@wuerth.com

BerlinHohenschönhausen

Grenzgrabenstraße 4

13053 Berlin

Telefon (0 30) 98 60 01-0

Telefax (0 30) 98 60 01 55

nl.berlin-hohenschoenhausen

@wuerth.com

Berlin-Reinickendorf

Osramhöfe

Seestraße/Oudenarderstraße 16

13347 Berlin

Telefon (0 30) 45 08 27 60

Telefax (0 30) 45 08 27 53

nl.berlinreinickendorf@wuerth.com

Biberach

Riss-Center

Riss-Straße 19

88400 Biberach

Telefon (0 73 51) 5 87 98-0

Telefax (0 73 51) 5 87 98 50

nl.biberach@wuerth.com

Bielefeld

Obere Hillegosser Str. 37

33699 Bielefeld

Telefon (05 21) 9 24 18-0

Telefax (05 21) 9 24 18 27

nl.bielefeld@wuerth.com

Bochum

Harpener Feld 27

44805 Bochum

Telefon (02 34) 9 55 43-0

Telefax (02 34) 9 55 43 50

nl.bochum@wuerth.com

Böblingen

Hanns-Klemm-Straße 46

71034 Böblingen-Hulb

Telefon (0 70 31) 2 11 76-0

Telefax (0 70 31) 2 11 76 50

nl.boeblingen@wuerth.com

Braunschweig

Hansestraße 66

38112 Braunschweig

Telefon (05 31) 3 54 78-0

Telefax (05 31) 3 54 78 90

nl.braunschweig@wuerth.com

Bremen

Gewerbegebiet Bayernstraße

Straubinger Straße 11

28219 Bremen

Telefon (04 21) 3 99 88-0

Telefax (04 21) 3 99 88 51

nl.bremen@wuerth.com

Chemnitz

Gewerbegebiet

Südring/Neefestraße

Carl-Hamel-Straße 5

09116 Chemnitz

Telefon (03 71) 2 71 47-0

Telefax (03 71) 2 71 47 50

nl.chemnitz@wuerth.com

Cottbus

Gewerbegebiet

An der Reichsbahn

Am Gleis 15

03042 Cottbus-Sandow

Telefon (03 55) 7 56 61-0

Telefax (03 55) 7 56 61 50

nl.cottbus@wuerth.com

Crailsheim

Industriegebiet Zur Flügelau

Roßfelder Straße 60

74564 Crailsheim

Telefon (0 79 51) 96 37-0

Telefax (0 79 51) 96 37 50

nl.crailsheim@wuerth.com

Darmstadt

Weiterstadt Park

Brunnenweg 19

64331 Weiterstadt

Telefon (0 61 50) 18 18-0

Telefax (0 61 50) 18 18 50

nl.darmstadt@wuerth.com

Dortmund

Wilhelmstraße 35A

59439 Holzwickede

Telefon (0 23 01) 9 12 62-0

Telefax (0 23 01) 91 26 50

nl.dortmund@wuerth.com

Dresden-Löbtau

Malterstraße 37

01159 Dresden

Telefon (03 51) 4 38 47-0

Telefax (03 51) 4 38 47-50

nl.dresden-loebtau@wuerth.com

Dresden-Mickten

Marie-Curie-Straße 6

01139 Dresden

Telefon (03 51) 4 14 53-0

Telefax (03 51) 4 14 53-50

nl.dresden-mickten@wuerth.com

Düsseldorf

Lierenfelder Straße 53

40231 Düsseldorf

Postfach 105532

40046 Düsseldorf

Telefon (02 11) 9 73 06-0

Telefax (02 11) 9 73 06 50

nl.duesseldorf@wuerth.com

Erfurt

Über dem Feldgarten 11

99198 Erfurt-Linderbach

Telefon (03 61) 4 20 57-0

Telefax (03 61) 4 20 57 50

nl.erfurt@wuerth.com

Essen

Heinz-Bäcker-Straße 15

45356 Essen

Telefon (02 01) 8 66 45-0

Telefax (02 01) 8 66 45 50

nl.essen@wuerth.com

Esslingen

Plochinger Straße 45

73779 Deizisau

Telefon (0 71 53) 92 94-0

Telefax (0 71 53) 92 94 50

nl.esslingen@wuerth.com

Frankfurt

Weiskirchen, Gewerbegeb. Ost

Daimlerstraße 19

63110 Rodgau

Telefon (0 61 06) 84 01-0

Telefax (0 61 06) 84 01 50

nl.rodgau@wuerth.com

Frankfurt II

Hanauer Landstraße 338

60314 Frankfurt/Main

Telefon (0 69) 42 69 38-0

Telefax (0 69) 42 69 38 50

nl.frankfurt-main@wuerth.com

Freiburg

Industriegebiet Nord

Mitscherlichstraße 5

79108 Freiburg

Telefon (07 61) 5 59 66-0

Telefax (07 61) 5 59 66 50

nl.freiburg@wuerth.com

Gera

Gewerbegebiet Bieblach Ost

Heinrich-Hertz-Straße 14

07552 Gera

Telefon (03 65) 4 37 28-0

Telefax (03 65) 4 37 28 50

nl.gera@wuerth.com

Gießen

Gewerbegebiet Gießen-West

Robert-Bosch-Straße 16

35398 Gießen

Telefon (06 41) 9 62 36-0

Telefax (06 41) 9 62 36 50

nl.giessen@wuerth.com

Göppingen

Industriegebiet Ost

Heilbronner Straße 12

73037 Göppingen

Telefon (0 71 61) 6 80 61

Telefax (0 71 61) 6 89 00

nl.goeppingen@wuerth.com

Goslar

Gewerbegebiet Bassgeige

Alte Heerstraße 15

38644 Goslar

Telefon (0 53 21) 35 19 30-0

Telefax (0 53 21) 3 51 93 50

nl.goslar@wuerth.com

Halle (Saale)

Delitzscher Straße 70

06112 Halle (Saale)

Telefon (03 45) 6 85 90 10

Telefax (03 45) 5 75 56 54

nl.halle-saale@wuerth.com

Hamburg

Industriegebiet Nettelkrögen

Gutenbergring 44

22848 Norderstedt

Telefon (0 40) 53 43 61-0

Telefax (0 40) 53 43 61 50

nl.hamburg@wuerth.com

Hamburg-Süd

Helmspark Hittfeld

Helmsweg 6-16

21218 Seevetal-Hittfeld

Telefon (0 41 05) 58 44-0

Telefax (0 41 05) 58 44 50

nl.seevetal@wuerth.com

Hannover

Gewerbegebiet Godshorn

Bayernstraße 37

30855 Langenhagen-Godshorn

Telefon (05 11) 7 86 80-0

Telefax (05 11) 7 86 80 50

nl.hannover@wuerth.com

Heidelberg

Gewerbegebiet Rohrbach-Süd

Redtenbacher Straße 1/1

69126 Heidelberg

Telefon (0 62 21) 5 89 88-0

Telefax (0 62 21) 5 89 88 50

nl.heidelberg@wuerth.com

Heilbronn

Dieselstraße 8

74076 Heilbronn

Telefon (0 71 31) 95 56-0

Telefax (0 71 31) 95 56 50

nl.heilbronn@wuerth.com

Ingolstadt

Eriagstraße 8

85053 Ingolstadt

Telefon (08 41) 95 67 78 70

Telefax (08 41) 9 31 87 51

nl.ingolstadt@wuerth.com

Jena

Löbstedter Straße 80

07749 Jena

Telefon (0 36 41) 45 12-0

Telefax (0 36 41) 45 12 50

nl.jena@wuerth.com

Karlsruhe

Printzstraße 2a

76139 Karlsruhe

Handwerk Holz:

Telefon (07 21) 62 52 2-0

Telefax (07 21) 6 25 22 50

nl.karlsruhe@wuerth.com

Kassel

Industriegebiet Waldau West

Otto-Hahn-Straße 18

34123 Kassel

Telefon (05 61) 9 98 68-0

Telefax (05 61) 9 98 68 50

nl.kassel@wuerth.com

Kempten

Messerschmittstraße 16

87437 Kempten

Telefon (08 31) 5 74 48-0

Telefax (08 31) 5 74 48 50

nl.kempten@wuerth.com

Kiel

Seekoppelweg 7a

24113 Kiel

Telefon (04 31) 6 47 40-0

Telefax (04 31) 6 47 40 50

nl.kiel@wuerth.com

Koblenz

Auf dem Hahnenberg 51

56218 Mülheim-Kärlich

Telefon (0 26 30) 94 70-0

Telefax (0 26 30) 94 70 50

nl.koblenz@wuerth.com

Köln

Köhlstraße 43

50827 Köln-Ossendorf

Telefon (02 21) 95 64 42-0

Telefax (02 21) 95 64 42 50

(08 00) 8 65 13 90

nl.koeln@wuerth.com

Künzelsau-Gaisbach

Verkaufsniederlassung

Schliffenstraße 22

74653 Gaisbach

Telefon (0 79 40) 15 25 55

Telefax (0 79 40) 15 45 55

nl.gaisbach@wuerth.com

Landshut

Sonnenring 17a

84032 Altdorf

Telefon (08 71) 9 53 71-0

Telefax (08 71) 9 53 71 50

nl.landshut@wuerth.com

LE Stetten

Industriegebiet Stetten

Sielminger Straße 65

70771 LE-Stetten

Telefon (07 11) 22 06 29-0

Telefax (07 11) 22 06 29 50

nl.leinfelden-echterdingen

@wuerth.com

Leipzig

Zum Bahnhof 20

04178 Leipzig/Rückmarsdorf

Telefon (03 41) 4 90 14-0

Telefax (03 41) 4 90 14 40

nl.leipzig@wuerth.com

Würth Service-Container

Am Airport 2000

Postfach 1244

04029 Leipzig

Telefon (03 41) 2 24 19 76

Telefax (03 41) 2 24 19 77

Funk (01 70) 6 33 70 73

andre.grieger@wuerth.com

Leonberg

Hertichstraße 10

71229 Leonberg-Eltingen

Telefon (0 71 52) 9 28 24-0

Telefax (0 71 52) 9 28 24 29

nl.leonberg@wuerth.com

Lübeck

Taschenmacherstraße 10

23556 Lübeck (RoggenhorstNord)

Telefon (04 51) 8 71 92-0

Telefax (04 51) 8 71 92 50

nl.luebeck@wuerth.com

Magdeburg

Silberbergweg 29

39128 Magdeburg

Telefon (03 91) 2 55 87-0

Telefax (03 91) 2 55 87 50

nl.magdeburg@wuerth.com

Mainz

Carl-Zeiss-Straße 13

55129 Mainz-Hechtsheim

Telefon (0 61 31) 6 27 39-0

Telefax (0 61 31) 6 27 39 50

Mannheim

Fraunhoferstraße 7

68309 Mannheim

Telefon (06 21) 7 27 46-0

Telefax (06 21) 7 27 46 50

nl.mannheim@wuerth.com

Minden

Ringstraße 49-51

32427 Minden

Telefon (05 71) 82 97 68 60

Telefax (05 71) 3 98 38 53

nl.minden@wuerth.com

Mönchengladbach

Gewerbegebiet Engelbleck

Borsigstraße 13

41066 Mönchengladbach

Telefon (0 21 61) 4 77 69-0

Telefax (0 21 61) 4 77 69 50

(08 00) 7 24 16 70

nl.moenchengladbach@wuerth.c

om

München

Am Lenzenfleck 2

85737 Ismaning

Telefon (0 89) 96 07 03-0

Telefax (0 89) 96 07 03 50

nl.muenchenismaning@wuerth.com

München 2

Ridlerstraße 65

80339 München

Telefon (0 89) 43 19 72-0

Telefax (0 89) 43 19 72 50

nl.muenchen-tuev@wuerth.com

Münster

Harkortstraße 11

48163 Münster

Telefon (02 51) 2 65 37-0

Telefax (02 51) 2 65 37 50

nl.muenster@wuerth.com

Neubrandenburg

Gneisstraße 8

17036 Neubrandenburg

Telefon (03 95) 4 30 48-0

Telefax (03 95) 4 30 48 50

nl.neubrandenburg@wuerth.com

Nordhausen

Freiherr-vom-Stein-Straße 30c

99734 Nordhausen

Telefon (0 36 31) 4 78 93-0

Telefax (0 36 31) 47 89 50

nl.nordhausen@wuerth.com

Nürnberg

Lenkersheimer Straße 10a

90431 Nürnberg

Telefon (09 11) 9 31 92-0

Telefax (09 11) 9 31 92 50

nl.nuernberg@wuerth.com

Offenburg

Robert-Bosch-Straße 2

77656 Offenburg-Elgersweier

Telefon (07 81) 9 69 84-0

Telefax (07 81) 9 69 84 50

nl.offenburg@wuerth.com

Oldenburg

Ammerländer Heerstaße 246

26129 Oldenburg

Telefon (04 41) 2 19 89-0

Telefax (04 41) 2 19 89 50

nl.oldenburg@wuerth.com

Osnabrück

Hettlicher Masch 12

49084 Osnabrück

Telefon (05 41) 9 09 01-0

Telefax (05 41) 9 09 01 50

nl.osnabrueck@wuerth.com

Paderborn

Frankfurter Weg 70-72

33106 Paderborn

Telefon (0 52 51) 8 71 91 30

Telefax (0 52 51) 8 73 67 50

nl.paderborn@wuerth.com

Papenburg

Siemensstraße 22-24

26871 Papenburg

Telefon (0 49 61) 66 87-0

Telefax (0 49 61) 66 87 50

nl.papenburg@wuerth.com

Passau

Regensburger Straße 14

94036 Passau

Telefon (08 51) 9 56 62-0

Telefax (08 51) 9 56 62 50

nl.passau@wuerth.com

Pforzheim

Gewerbegebiet

Wilferdinger Höhe

Rastatter Straße 36

75179 Pforzheim

Telefon (0 72 31) 56 86 80

Telefax (0 72 31) 56 87 99

nl.pforzheim@wuerth.com

Potsdam

Am Verkehrshof 1

14478 Potsdam

Telefon (03 31) 88 88 40

Telefax (03 31) 8 88 84 50

nl.potsdam@wuerth.com

Regensburg

Franz-Hartl-Straße 4

93053 Regensburg

Telefon (09 41) 7 83 98-0

Telefax (09 41) 7 83 98 50

nl.regensburg@wuerth.com

Reutlingen

Industriegebiet West

Ferdinand-Lassalle-Straße 55

72770 Reutlingen

Telefon (0 71 21) 56 95-0

Telefax (0 71 21) 56 95 50

nl.reutlingen@wuerth.com

Rhein-Sieg

Redcarstraße 2b

53842 Troisdorf-Spich

Telefon (0 22 41) 2 34 02-0

Telefax (0 22 41) 2 34 02 50

nl.rhein-sieg@wuerth.com

Rodgau

siehe bei Frankfurt/Main

Rosenheim

Isarstraße 1A

83026 Rosenheim

Telefon (0 80 31) 2 30 89-0

Telefax (0 80 31) 2 30 89 50

nl.rosenheim@wuerth.com

Rostock

Gewerbegebiet

Neu-Roggentiner-Straße 4

18184 Roggentin

Telefon (03 82 04) 6 16-0

Telefax (03 82 04) 6 16 50

nl.rostock@wuerth.com

Saarbrücken

Im Rotfeld 21

66115 Saarbrücken

Telefon (06 81) 9 48 65-0

Telefax (06 81) 9 48 65-50

nl.saarbruecken@wuerth.com

Schwäbisch Hall

Industriegebiet Hessental-Ost

Schmollerstraße 41

74523 Schwäbisch Hall

Telefon (07 91) 4 07 23-0

Telefax (07 91) 4 07 23 50

nl.schwaebisch-hall@wuerth.com

Siegen

(Kaan-Marienborn)

Hauptstraße 84

57074 Siegen

Telefon (02 71) 6 60 49-0

Telefax (02 71) 6 60 49 29

nl.siegen@wuerth.com

Sinsheim

In der Au 22

74889 Sinsheim

Telefon (0 72 61) 40 21-0

Telefax (0 72 61) 40 21 50

nl.sinsheim@wuerth.com

Stuttgart

Kölner Straße 10

Hallschlag

70376 Stuttgart

Telefon (07 11) 9 55 73-20

Telefax (07 11) 9 55 73 50

nl.stuttgart@wuerth.com

Trier

Ohmstraße 6-8

54292 Trier

Telefon (06 51) 4 36 99-0

Telefax (06 51) 4 36 99 50

nl.trier@wuerth.com

Ulm/Neu-Ulm

Carl-Zeiss-Straße 3

89231 Neu-Ulm

Telefon (07 31) 9 78 98-0

Telefax (07 31) 9 78 98 50

nl.ulm-neu-ulm@wuerth.com

Urbach

Schorndorfer Straße 22

73660 Urbach

Telefon (0 71 81) 4 88 66-0

Telefax (0 71 81) 48 86 56

nl.urbach@wuerth.com

Villingen-Schwenningen

Industriegebiet Vockenhausen

Heinrich-Hertz-Straße 9

78052 VS-Villingen

Telefon (0 77 21) 87 19-0

Telefax (0 77 21) 87 19 50

nl.villingen-schwenningen

@wuerth.com

Weingarten/Ravensburg

Hähnlehofstraße 5

88250 Weingarten

Telefon (07 51) 5 61 04-0

Telefax (07 51) 5 61 04 50

nl.weingarten-ravensburg

@wuerth.com

Weißenburg

Dettenheimer Straße 11

91781 Weißenburg

Telefon (0 91 41) 99 55-0

Telefax (0 91 41) 99 55 50

nl.weissenburg@wuerth.com

Wiesbaden

Hagenauer Straße 17-19

65203 Wiesbaden

Telefon (06 11) 1 86 97-0

Telefax (06 11) 1 86 97 50

nl.wiesbaden@wuerth.com

Wuppertal

Industriegebiet

Nächstebreck

Möddinghofe 21

42279 Wuppertal

Telefon (02 02) 6 47 71-0

Telefax (02 02) 6 47 71 25

nl.wuppertal@wuerth.com

Würzburg

Gewerbegebiet Ost

Sandäcker 11

97076 Würzburg

Telefon (09 31) 2 79 89-0

Telefax (09 31) 2 79 89 18

nl.wuerzburg@wuerth.com

0702 315 BA 0502 - Printed in Germany - Imprimé en Allemagne MWV-OSW-02/05 • © by Adolf Würth & Co. KG • Nachdruck, auch auszugsweise, nur mit Genehmigung.

Postfach · 74650 Künzelsau · Telefon (0 79 40) 15-0 · Telefax (0 79 40) 15 10 00

Adolf Würth GmbH & Co. KG

Internet: http://www.wuerth.com · e-mail: info@wuerth.com

Loading...

Loading...