Page 1

TECHNICAL INFORMATION,

ASSEMBLING INSTRUCTIONS,

USE AND MAINTENANCE

Vertical warm air heaters

BI SERIES

Page 2

Dear Customer,

Thank you for choosing a BI series AIR HEATER, an innovative and modern, quality and high

performance product which will assure safe and silent working for a long time. This is

particularly the case if the heater is put in the hands of DESA ITALIA Technical Assistance

Department which is specially trained end equipped to keep it working at maximum efficiency

with low running costs and has a large number of original spare parts in stock.

This instruction manual contains important instructions and suggestions for simple installation

and making the best use of the BI air heater.

Once again, thank you.

DESA ITALIA s.p.a.

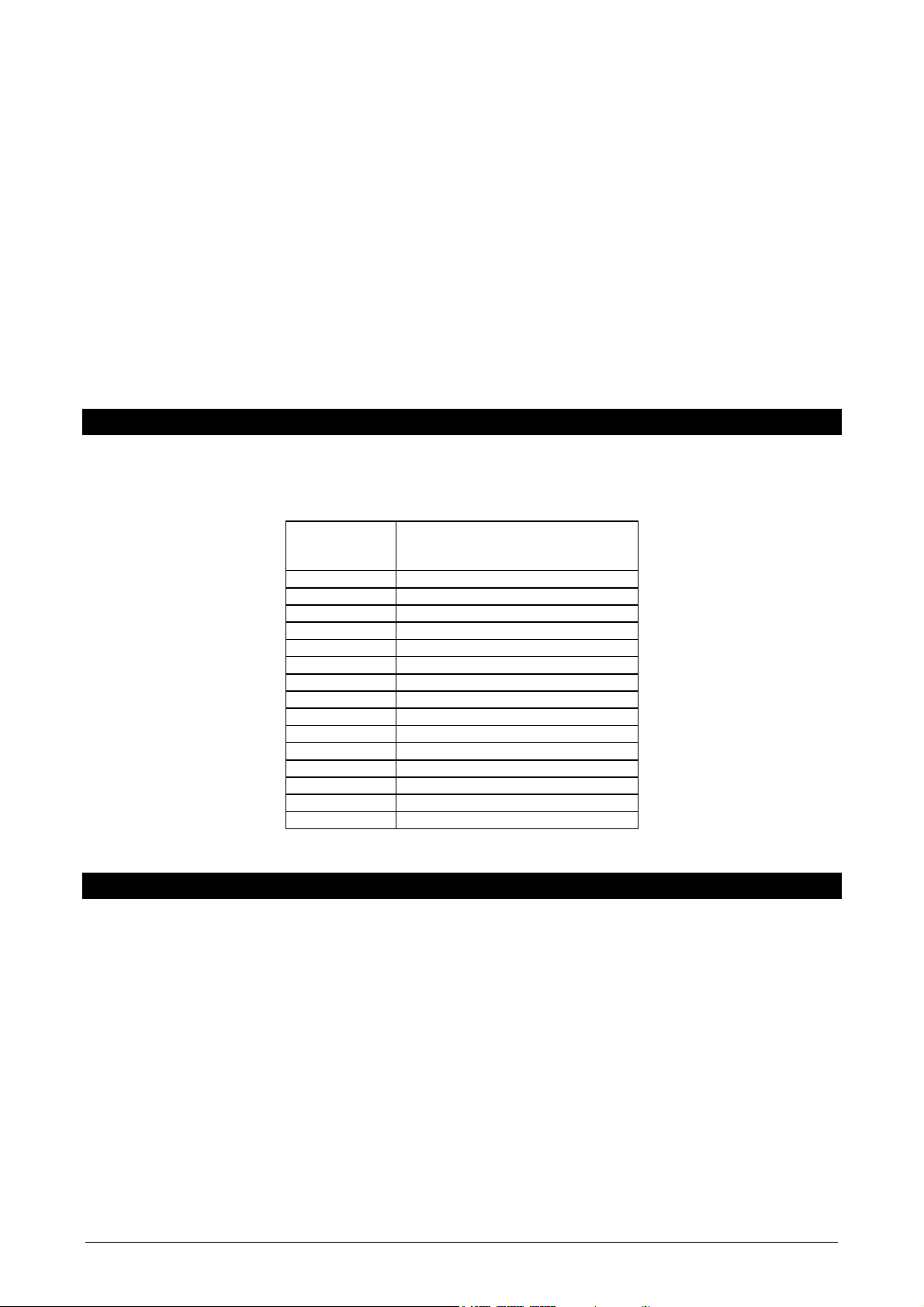

RANGE

This manual refers to TYPE. In the follo wing chart yo u will find the heaters rang e and the correspond ence b et ween Type

and the Commercial and the Trade Name.

TYPE MODEL

1 BI 60

2 BI 95

3 BI 105

4 BI 120

5 BI 160

6 BI 190

7 BI 225

8 BI 260

9 BI 320

10 BI 390

11 BI 590

12 BI 645

13 BI 770

14 BI 1000

15 BI 1100

GUARANTEE

The BI heater has a SPECIFIC GUARANTEE running from the date of the purchase, of which the customer must notify

the manufacturer. If he is unable to do so the guarantee shall run from the date of manufacture. The details of the

guarantee conditions are given in the GUARANTEE CERTIFICAT E supplied with the equipment, and which we suggest

the Customer read with care.

2

Page 3

INDEX

GENERAL

RANGE ............................................................................................................................................................................... 2

GUARANTEE ...................................................................................................................................................................... 2

GENERAL WARNINGS ...................................................................................................................................................... 4

BASIC SAFETY RULES...................................................................................................................................................... 5

DESCRIPTION OF THE EQUIPMENT ............................................................................................................................... 6

IDENTIFICATION ................................................................................................................................................................ 7

STRUCTURE ...................................................................................................................................................................... 7

COMBUSTION CHAMBER DIMENSIONS ......................................................................................................................... 8

DIMENSIONS ..................................................................................................................................................................... 9

TECHNICAL DATA ........................................................................................................................................................... 10

HANDLING AND TRANSPORTATION ............................................................................................................................. 11

LOCATION ........................................................................................................................................................................ 12

FUEL CONNECTION ........................................................................................................................................................ 12

FLUE ................................................................................................................................................................................. 12

AIR INLET CONNECTION ................................................................................................................................................ 13

AIR OUTLET CONNECTION ............................................................................................................................................ 13

FIXED PROTECTIONS ..................................................................................................................................................... 13

DIFFUSION PLENUM ....................................................................................................................................................... 13

AIR INLET FILTER ............................................................................................................................................................ 15

MOUNTING THE BURNER .............................................................................................................................................. 16

ELECTRICAL CONNECTION ........................................................................................................................................... 16

TYPE 1 WIRING DIAGRAM .............................................................................................................................................. 17

TYPE 2 TO 10 WIRING DIAGRAM ................................................................................................................................... 18

TYPES 11 TO 14 WIRING DIAGRAM .............................................................................................................................. 19

TYPE 15 WIRING DIAGRAM ............................................................................................................................................ 20

FAN-LIMIT DUAL THERMOSTAT .................................................................................................................................... 22

POSITIONING OF FAN, LIMIT AND SAFETY THERMOSTATS ...................................................................................... 22

FAN-LIMIT-SAFETY THERMOSTATS SETTING ............................................................................................................. 24

FAN START TIMER .......................................................................................................................................................... 25

SETTINGS ........................................................................................................................................................................ 25

OIL-FIRED BURNER SETTING ........................................................................................................................................ 26

FAN SPEED SET-UP ........................................................................................................................................................ 27

CHECKS ........................................................................................................................................................................... 28

CONTROLS ...................................................................................................................................................................... 28

INDICATORS .................................................................................................................................................................... 29

FAN MOTOR ABSORPTION ............................................................................................................................................ 29

WORKING CYCLE ............................................................................................................................................................ 29

START UP AND STOP ..................................................................................................................................................... 30

MAINTENANCE ................................................................................................................................................................ 30

AIR FILTER CLEANING .................................................................................................................................................... 30

BURNER CLEANING ........................................................................................................................................................ 31

HEAT EXCHANGER CLEANING ...................................................................................................................................... 31

FAN MAINTENANCE ........................................................................................................................................................ 32

LIMIT THERMOSTAT MAINTENANCE ............................................................................................................................ 32

FUME SAMPLING POSITION .......................................................................................................................................... 32

ASSISTANCE ................................................................................................................................................................... 32

FAULTS AND SOLUTIONS .............................................................................................................................................. 33

The following symbols are used in the manual:

WARNING= Where the work to be carried out requires special care and suitable training.

FORBIDDEN= Where the action MUST NOT be carried out.

This manual consists of 36 pages.

3

Page 4

GENERAL WARNINGS

This instruction booklet is an integral part of the

equipment and so it has to be carefully kept at all

times and always accompany the equipment if it

passes to another owner. If the instruction

booklet gets damaged or lost, ask DESA ITALIA

local technical assistance dept. for another copy.

After removing the packaging, check that all the

equipment is present and intact. If there is any

failure to correspond with order contact your

DESA ITALIA agent who sold the equipment.

The BI warm air heater must be installed by an

accredited company in accordance with the law

46 of 5

statement that the equipment has been properly

installed, i.e. in observance of current legislation

and the instructions given by DESA ITALIA in

this manual.

These machines are designed to heat rooms

and must be used for this in accordance with

their performance characteristics. DESA ITALIA

shall not be contractually or otherwise liable for

any damage caused to people, animals or items

because of installation mistakes, failure to

observe the rules or improper use.

A too high temperature is harmful to health and

is also a waster of energy. Do not keep rooms

closed for long periods: periodically open

windows to change stale air.

The first time the equipment gets switched on,

there may is some smell or fumes caused by the

evaporation of the liquid protecting the heat

exchanger during storage: this is normal and will

disappear after a short period. It is advisable to

keep rooms ventilated.

If the equipment remains idle for long periods,

carry out the following operations at least:

Put the main electrical switch off;

Close the main fuel supply tap.

If the heater is idle for long periods, it is

advisable to contact DESA ITALIA Technical

Assistance Department or other professionally

qualified people to restart it.

th

March 1990, which shall issue a

Only original accessories must be used on the

equipment. DESA ITALIA shall not be held liable

for any damage deriving from improper sue or

non original materials or accessories.

Laws, standards, directives and technical rules

referred to in this booklet are only for your

information and shall be considered vali d onl y as

of the time of going to press. Any new provisions

which come into effect or any amendments to

current provisions shall not give rise to any

obligations for DESA ITALIA as against third

parts.

Repairs and maintenance must be carried out by

DESA ITALIA Technical Assistance Department

or by qualified staff as indicated in this booklet.

Do not make modifications to or tamper with the

equipment as this may cause dangerous

situations to arise and the manufacturer will no

longer be responsible for any damage caused.

The plant and utilities must be connected and

affixed properly (i.e electrical supply etc.) and

must not cause obstructions which may be

tripped over.

DESA ITALIA is responsible for its product’s

compliance with the laws, directives or building

standards in force at the time of its sale. The

design engeneer, installer and user are

respectively and entirely responsible of their

awareness of and observance of the legislative

provisions and standards dealing with plant

design, installation, the working and

maintenance of the equipment.

DESA ITALIA shall not be held liable for any

failures to observe the instructions contained in

this booklet, for the consequences of any

handling or usage not specifically provided for or

for any translations which may be subject to

erroneous interpretation.

This machine has been projected to work with

the heat rate and ait throughput values as

indicated in the Technical Data paragraph. A too

low heat rate and/or a too high air throughput

might lead to the condensation of the

combustion products, with a consequent

irreparable corrosion of the heat exchanger. A

too high heat rate and/or a too low air throughput

might lead to an anomalous overheating of the

heat exchanger with a consequent cut-in of the

safety devices and damage of the echanger.

4

Page 5

BASIC SAFETY RULES

We remind you that the use of products needing electrical energy, gas or heating oil requires the observanc e of some

basic safety rules, including the following:

The unassisted use of air heaters by children or

disabled people is forbidden.

Electrical devices or equipment such as

switches, domestic appliances etc. must not be

used if there is a smell of fuel or unburnt gases

etc. In such cases:

Ventilate the room by opening doors and

windows;

Close the fuel shut-off;

Call the DESA ITALIA Technical Assistance

Dept. or other professionally qualified

personnel.

The equipment must not be touched being

barefeet of with wet or damp parts of the body.

Cleaning and maintenance operations on the

equipment must be carried out only when it is

switched off with the main electrical switch if the

‘off’ position, and with the fuel supply cut off.

It is forbidden to interfere with or alter the safety

or regulatory systems without prior authorisation

and without following the manufacturer’s

instructions.

It is forbidden to pull or twist the electric cables

coming out from the equipment, even if the

equipment is disconnected from the main

electricity supplies.

Before entering the access doors to the internal

parts of the equipment, the main switch must be

turned to ‘off’.

It is forbidden to throw away, abandon or leave

the packaging material (cardboard, fasteners,

plastic bags etc.) within the reach of children, as

they may be a source of danger.

It is forbidden to install the equipment near

to flammable materials or where there are

aggressive agents in the atmosphere.

It is forbidden to put objects on top of the

equipment or push them inside the boy shell grill

and exhaust discharge dust.

The exhaust flue must not be touched as it may

reach temperatures which are dangerously h igh

to the touch during normal working.

It is forbidden to use adapters, multiple sockets

and extension cables for the equipment

electrical connection.

It is not permitted to install the equipment

outdoors or in any place where it will be subject

to atmospheric agents.

It is forbidden to directly install the equipment in

restricted rooms with no fitting ventilation since

the air aspiration might cause a strong

depression inside the room, leading to serious

inconveniences.

5

Page 6

DESCRIPTION OF THE EQUIPMENT

The BI equipment is designed to heat the air in the room using heat en ergy produces by combustion. Essentially the

equipment consists of heat exchanger assemblies exchanging heat from the combustio n by-products from a forced gas

or heating fuel oil burner by a high performance fan assemb ly. The air to be heated is aspired by the latter and flows

against the heat exchange where its temperature rises to then be distributed either immediately or via suitable

channelling. The particular features of the centrifugal fan make the equipment well sui ted for installation where hot air

needs to be distributed through channels or generally where it is necessary to have static pressure available. A special

flange (both on inlet and outlet) enables the equipment to be connected up the channelling.

This system gives a notable reduction in the costs of the plant and also works economically, making itself particularl y

suitable where it is expected it be used intermittently or oc casionally. The equipment is designed so that it can also be

used to provide ventilation only during the summer months.

GENERAL STRUCTURE FEATURES

Heat exchanger

Built with welded steel and steal-tested in accordance with t he UNI-CIG 9462 standar ds, i t is eas y to be i nspected for the

normal cleaning and maintenance operations. It consists of:

Combustion chamber in low thermal load stainless steel with suitable shape and size;

Exchange elements in stainless steel, with modular, large surface sections with swirl impressions for an optimal heat

exchange;

Exhaust manifolds in fine steel.

External casing

The external casing consists of removable panels in pre-painted steel and also includes:

Insulation of the surfaces exposed to radiant heat from the heat exchanger;

Delivery air flange for connection to the hot air distribution circuit;

Intake guard with flanges for connection to the intake circuit.

Fan assembly

One or more high performance centrifugal fans producing low noise emissions. These are run by electrical motors

connected to a pulley and belt system. The motor has got an adjustable pulley (type 1 to type 10) which means the

system can be easily adapted to the particular needs of the customer’s premises.

Control and safety thermostats

The heater has a dual thermostat which is calibrated and electrically connected to perform the following functions:

"FAN" function (25-35°C, FAN thermostat) - controls fan start up about 60 seconds after burner ignition and stops

the fan about 4 minutes after the burner has stopped. This prevents unpleasant cold air being conveyed into the room

on start up und utilises the stored heat in the heat exchangers after the burner has been switched off.

“SAFETY” function (type 5 to 15, TR thermostat) – preset at 80°C, it has th e function of stopping the bruner in

case of anomalous overheating of the air. Automatic reset, the correct setting has to be set during the first stat-up.

"LIMIT" function (sealed setting 100°C, LM thermostat) – manual reset, switches the burner off in case of

overheating of the air.

Fume discharge outlet

The equipment has a circular outlet to which a metal exhaust pipe can be connected and safely joined.

6

Page 7

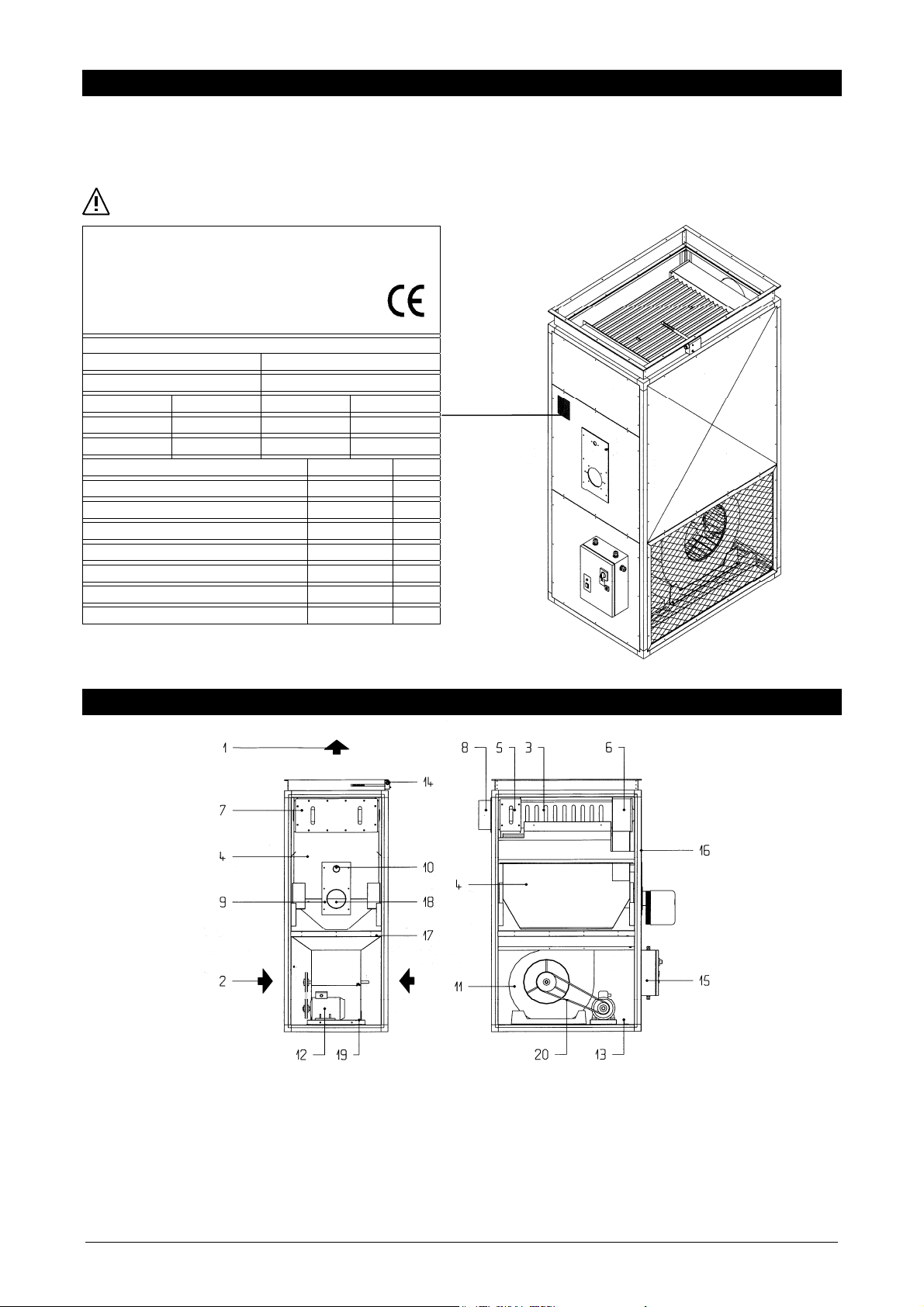

IDENTIFICATION

Hot air generators are identifiable by:

The Technical Plate bearing their main technical and performance details. The plate is located on the front of the

equipment.

If the Plate gets lost or damaged, ask for a duplicate from DESA ITALIA Technical Department.

MANUFACTURER

IDENTIFICATION

Model

Serial number

Country PIN

Code

Type Year

Thermal capacity Kw

Thermal power Kw

Air flow (+20°C) m3/h

Working static pressure Pa

Electrical supply

Fan motor power Kw

Max fan current Pa

Protection rating IP 20

AIR HEATER

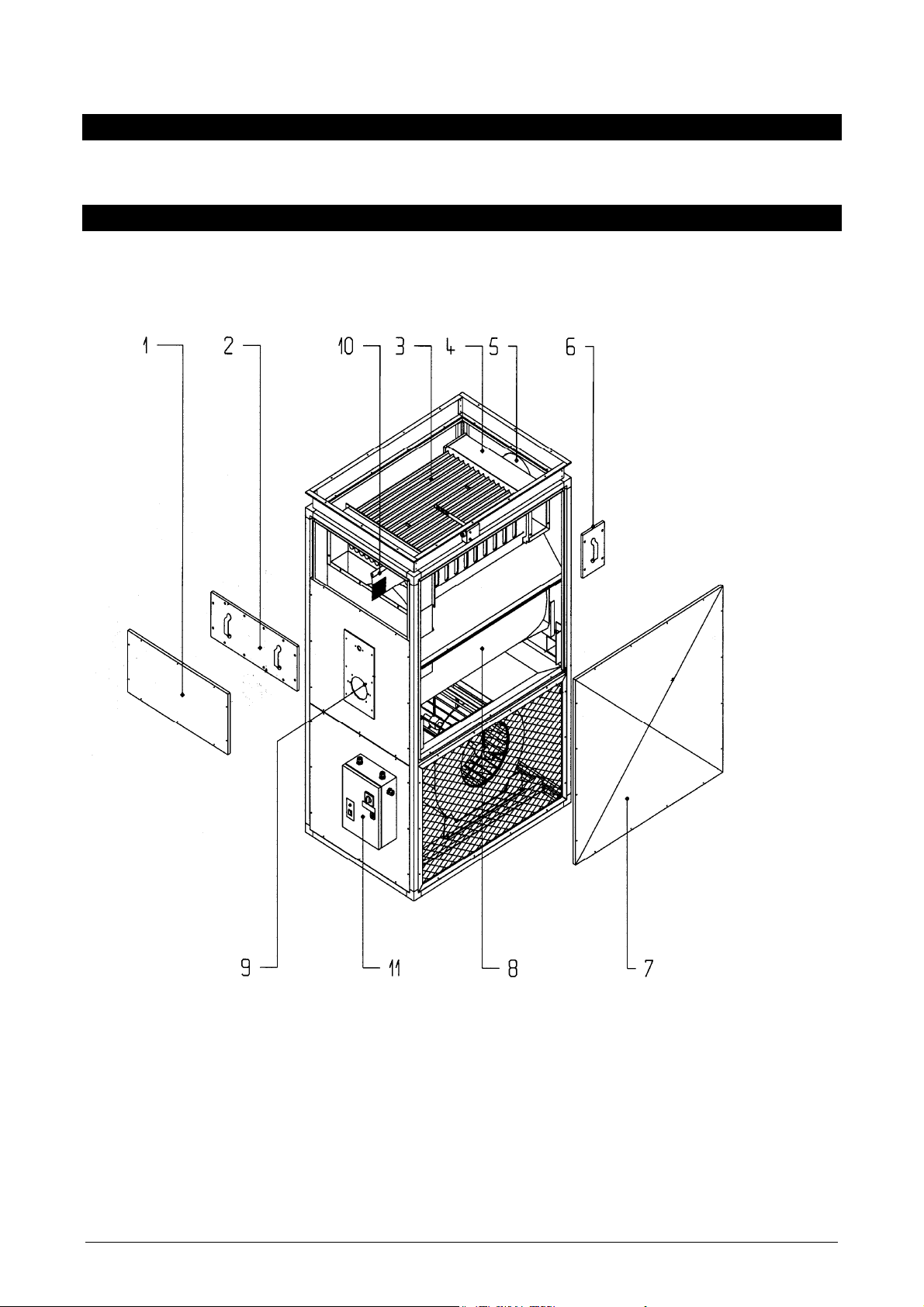

STRUCTURE

1. Air outlet

2. Air aspiration

3. Fume tubes

4. Combustion chamber

5. Back fume manifold

6. Front fume manifold

7. Inspection doors

8. Chimney

9. Burner flange

10. Combustion viewer

11. Centrifugal fan/s

12. Electric motor

13. Belt tightener

14. Dual thermostat

15. Electric equipment

16. Casing

17. Base attaching screws

18. Burner outlet

19. Motor mount plate

20. Transmission

7

Page 8

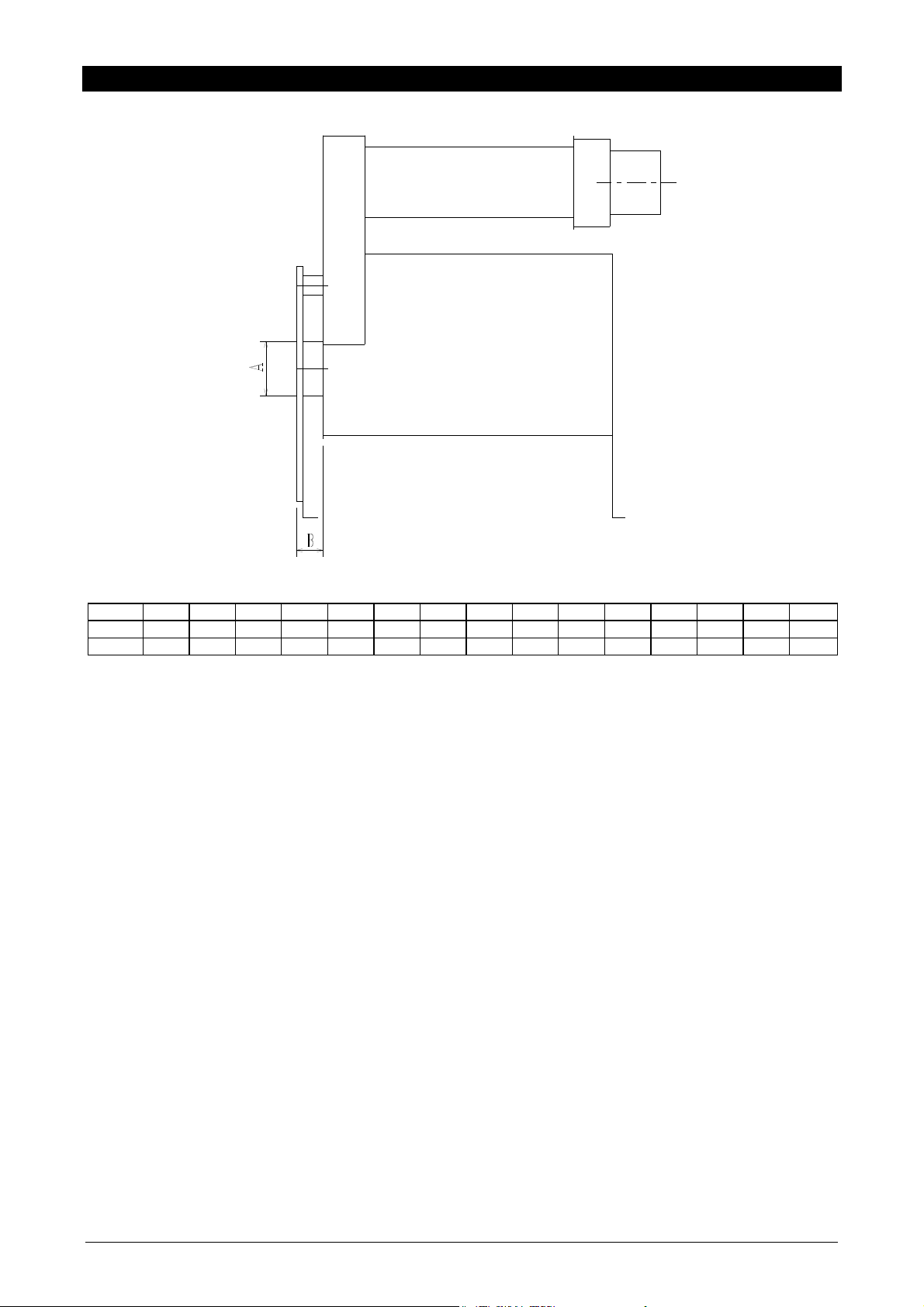

COMBUSTION CHAMBER DIMENSIONS

The three fume-cycle heat exchanger and combustion chamber have the follo wing dimensions.

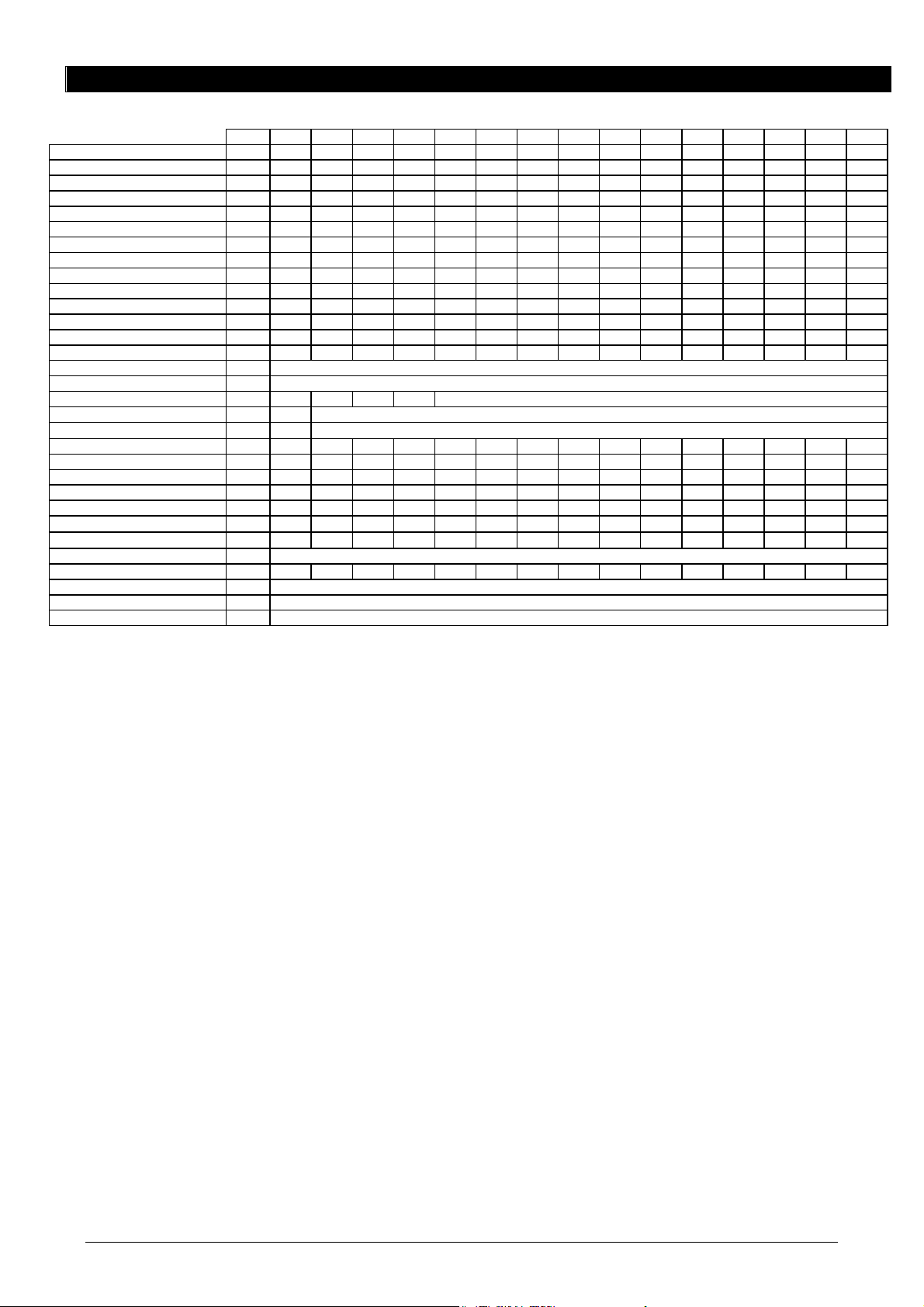

TYPE 1 2 3 4 5 6789101112 13 1415

A

120 150 170 170 170 170 220 220 220 220 300 300 300 300 300

B

Measurements in millimetres;

80 80 80 80 150 150 130 130 130 130 140 140 150 150 180

8

Page 9

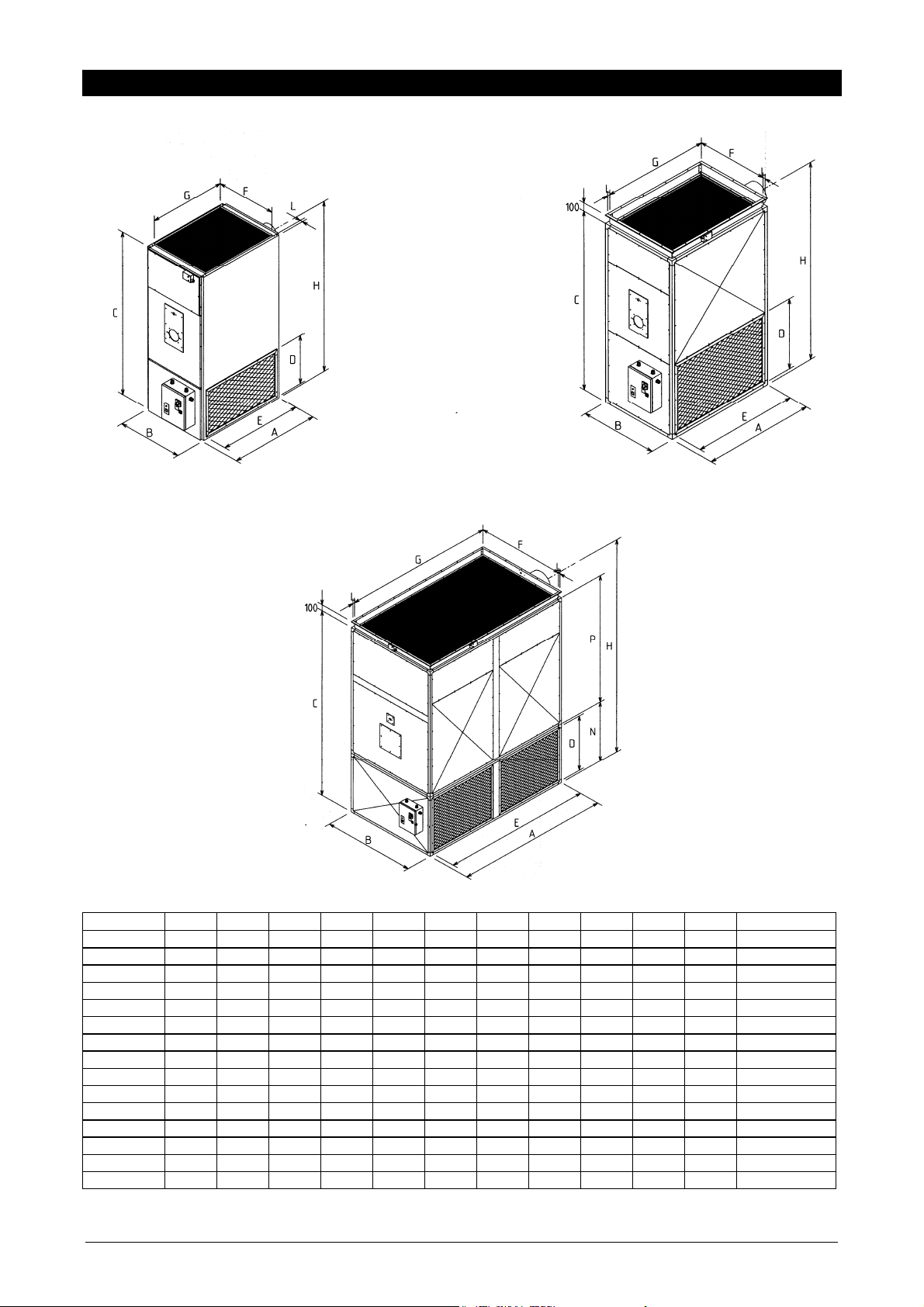

DIMENSIONS

Type 14 Type 510

Type 1115

Type A B C D E F G H L N P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

812 540 1580 400 625 490 600 1305 27 150

890 680 1800 500 715 630 700 1475 27 180

1060 760 1926 500 900 700 900 1667 30 200

1060 760 1926 500 900 700 900 1667 30 200

1300 900 2120 781 1182 840 1240 1905 30 250

1300 900 2120 781 1182 840 1240 1905 30 250

1500 1000 2120 781 1382 940 1440 1905 30 250

1500 1000 2120 781 1382 940 1440 1905 30 250

1700 1200 2350 781 1582 1140 1640 2160 30 300

1700 1200 2350 781 1582 1140 1640 2160 30 300

2090 1270 2870 882 1972 1210 2030 2585 30 1000 1870 330

2090 1270 2870 882 1972 1210 2030 2585 30 1000 1870 330

2500 1500 3120 882 2382 1440 2440 2815 30 1000 2120 370

2500 1500 3120 882 2382 1440 2440 2815 30 1000 2120 370

3500 1500 3120 882 3382 1440 3440 2815 30 1000 2120 380

Measurements in millimetres;

chimney

9

Page 10

TECHNICAL DATA

+

Heating capacity KW 60,0 94,0 103,2 122,3 161,2 190,0 225,8 258,8 322,6 391,0 460,6 590,0 645,3 769,0 1000

Kcal/h 51600 80850 88790 105150 138600 163400 194225 222600 277470 336250 396160 507300 554940 661500 860000

Heating power Kw 54,0 82,2 93,0 107,0 145,3 168,2 203,5 230,3 290,7 347,6 415,0 523,2 581,4 682,9 883,7

Efficiency % 90,1 87,4 90,1 87,5 90,1 88,5 90,1 89,0 90,1 88,9 90,1 88,7 90,1 88,8 88,3

Combustion chamber pressure Pa 20 25 8 22 8 2 17 39 21 32 20 20 20 23 10

Combustion chamber volume m3 0,08 0,13 0,23 0,23 0,49 0,49 0,64 0,64 1,05 1,05 1,62 1,62 2,7 2,7 4,36

Net fumes temperature °C 200 252 206 252 210 249 205 248 204 227 205 238 192 237 260

Combustion by-products mass Kg/h 117,7 183,8 194,6 238,0 295,6 343,4 424,5 472,5 614,5 736,2 912,8 1101,0 1253,0 1422,0 1731,4

Fuel consumption

- oil kg/h 5,06 7,9 8,7 10,3 13,6 16,0 19,0 21,8 27,2 32,9 40,8 49,7 54,4 64,8 84,3

Air flow rate at +20°C m3/h 4300 6000 7600 7600 9600 11500 13400 15300 19000 23000 28700 34500 40200 49000 67000

Working static pressure Pa 160 160 160 160 220 200 200 180 200 170 280 220 220 180 200

Thermal jump K 37 40 37 42 45 43 45 45 45 45 42 45 43 42 39

LIMIT thermostat setting °C 100

FAN thermostat setting °C 25-35

SAFETY thermostat setting °C - - - - 80

Electrical supply type mono three-phase

Electrical tension V-50Hz

Fan motor electrical power Cv 0,75 1,50 2,00 2,00 3,00 4,00 4,00 5,50 5,50 7,50 10,0 12,5 15,00 20,00 2x12,5

kW 0,55 1,10 1,50 1,50 2,20 3,00 3,00 4,00 4,00 5,50 7,50 9,00 11,00 15,00 2x9,0

Electrical power

- oil burner Kw 0,17 0,17 0,38 0,38 0,38 0,37 0,37 0,37 0,37 0,45 0,65 0,65 1,10 1,10 1,80

Fan motor absorption

- 230V 50Hz

- 400V 50Hz 3N

Electrical protection rating IP 20

Net weight (2) Kg 130 180 249 249 412 437 520 525 694 734 1072 1162 1497 1622 2090

Category II

Type B23

Working field °C -15 / +40

1. Net weight expressed in Kg, without oil burner;

The declared aeraulic do not consider the head losses due to eventual accessoires (filters, blast gate damper,

aspiration grates etc.).

TYPE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

kcal/h 46450 70700 80000 92000 125000 144600 175000 198100 250000 298950 356900 450000 500000 587400 760000

230 400 3N

A 3,7 4,8 6,4 6,4 8,8 12,1 12,1 15,8 15,8 20,7 28,6 32,9 38,9 53,6 2x33,0

A 2,8 3,6 3,6 5,1 7,0 7,0 9,1 9,1 12,0 16,5 19,0 22,5 31,0 2x19,0

2H3

10

Page 11

HANDLING AND TRANSPORTATION

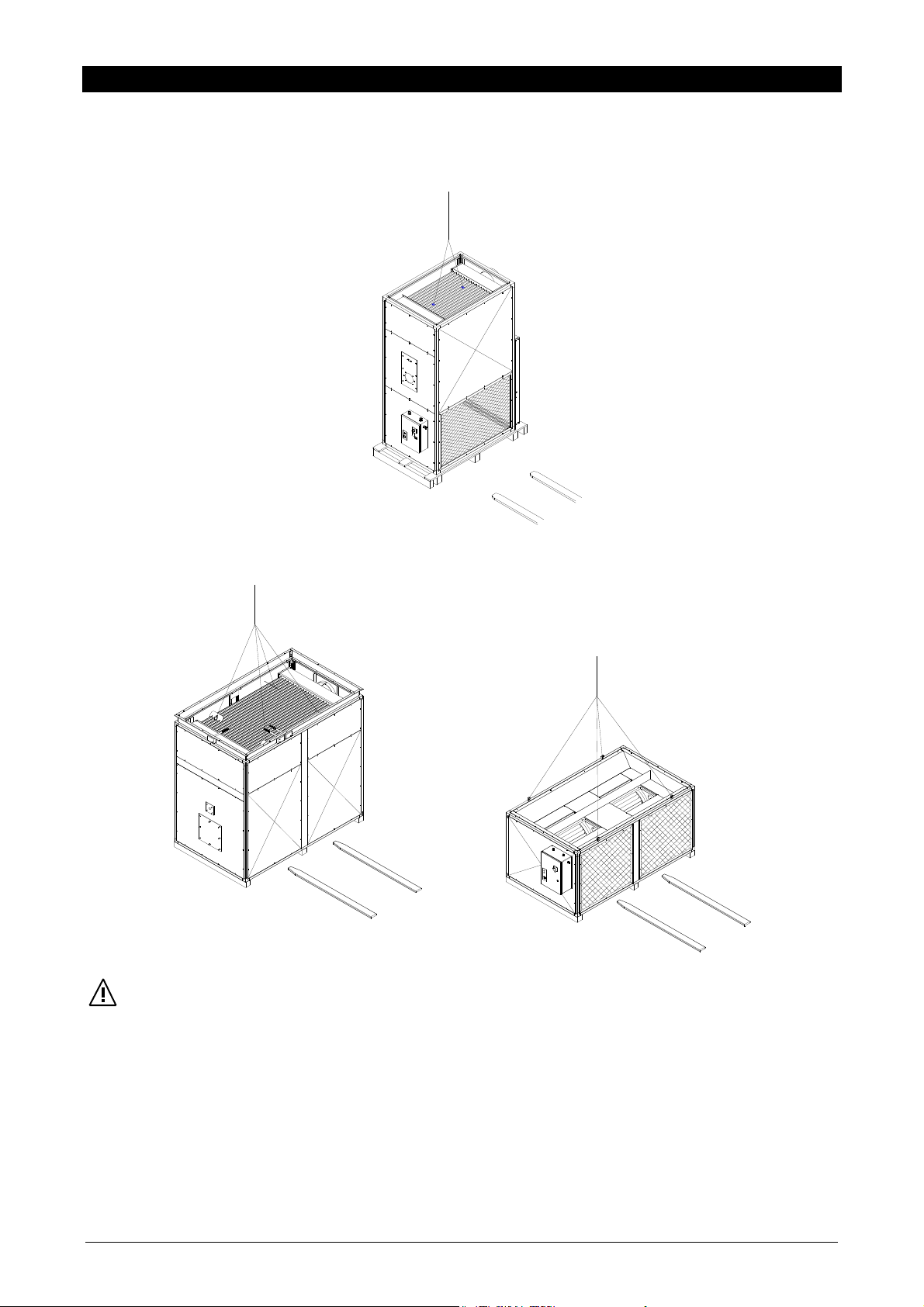

Moving the equipment must be carried out by properly equipped personnel with equipment which is suitable for the

weight of the heater. If a fork lift is used, the equipment should be taken up at the bottom using the guides in the

supporting base. If a crane is employed use the eye-bolts at the top of the heat exchanger to lift the equipment.

Type 110

Type 1115

WARNING!

Handling and transportation must be carried out with the greatest care to avoid damage the equipment and putting

people in danger.

It is forbidden for people to stand close to the equipment during handling and trans portation manoeuvres.

It is forbidden to stack more pieces of equipment than the indication on the pack aging itself and the greatest care must

be taken in aligning the packages so that they are stable.

If the equipment must be moved by hand, ensure that sufficient human strength is available for the task in relation to t he

weights indicated in the paragraph “TECHNICAL DATA” and to where and how far the equipment has to be moved.

The use of protective gloves is advisable.

11

Page 12

LOCATION

The place of installation must be established by the plant project engin eer or competent person and must take account of

the technical requirements and current legislation and regula tions which demand the obtaining of an authorisation (e.g.

building, architectural and fire regulations, environmental legislation and so on). Before installing the equipment it is

therefore advisable to apply for and obtain all the necessary authorisations.

To be correctly installed, the BI series heater has to satisfy the following:

Be placed on a level surface which is able to support its weight;

Observe the distances indicated in this manual so that there is a proper air flow and the normal cleaning and

maintenance operations can be properly carried out;

Maintain the safety distances from flammable materials;

Be easily connected to a flue;

Be easily connected uo to the fuel tank;

Be near to an electrical socket;

Allow easy carrying out of maintenance and monitoring ope r ations;

Have the openings and ventilation required by the law in force.

The installation is not advisable:

In aggressive atmosphere rooms;

In tight rooms where the sound level of the heater might be amplified by reverberations or resonances;

In coins where it might settle leaves or anything else might obstruct the air flow, reducing the equipment efficiency;

Outside;

In depressed rooms.

WARNING!

The hot air generators types 11 to 15 are, for ease of transport, shipped in t wo separated sections (base and body). To

install, proceed as follows:

Position the base so that the electrical panel is on the same side as the burner;

Mount the centring pins provided on the upper part of the base;

Place the body over the base making sure that the two frames are perfectly aligned.

FUEL CONNECTION

The oil connection must be carried out by the authorised and qualified personnel who must follow the indications in the

manual strictly as well as the law currently in force.

FLUE

The fume channel and connection to the flue must be in acc ordance with the law and regulations currently in force, using

rigid pipes resistant to mechanical, thermal and chemical stresses resulting from combustion. Recommendations:

Avoid or at least limit the horizontal stretches which must in any case tend in an upward direction;

Use piping with smooth inner surfaces made from a suitable material which is resistant to the thermal and chemical

stresses caused by combustion, with a diameter equal to or larger than that of the connector on the equipment it self;

Avoid sharp bend and diameter reductions;

Place in the system a well for taking samples for analyses of the combustion by-products.

The chimney has to ensure the minimal depression previe wed by the Regulations in force, considering as “zero” the

pressure at the flue connection (see chart page 8).

The non-insulated discharge channels might be a source of danger.

Unfitting or badly dimensioned flues or discharge channels might amplificate the combustion sound level and

negatively affect the combustion parameters.

The tightness of the joints has to be realized with materials resistant at temperature of at least 350° C (e.g. filler,

mastic, silicones preparations).

12

Page 13

AIR INLET CONNECTION

Connect any eventual channelling to the hot air distribution ci rcuit to the equipment upper delivery flange, interposing a

vibration damper joint to prevent vibrations being transmitted to the pipes.

WARNING!

The dimensioning of eventual air inlet and outlet channels has to be previewed by qualified personnel in

compliance with the maximal performances of the heater as indicated in the “TECHNICAL DATA”.

AIR OUTLET CONNECTION

Connect any channelling in the air recovery circuit to the side o pening. T he equipment is made to take the co nnection o n

the left and on the right side. To adapt the air intake side it is enough to invert the mounting of the side closing panel/s

with the intake grid/s.

FIXED PROTECTIONS

To prevent accidental contact with the moving parts of the heat er, it is not allowed to remove the equipment perman ent

guards and protections, which consist of the following:

Air recovery grid/s;

Side closing panel/s;

Burner guard.

DIFFUSION PLENUM

If the heater is to be installed inside the room to be heated, it is necessary to use a diffusion ple num which is supplied as

an accessory. To obtain optimal air diffusion it is recommended that the equipment gets installed close to a perimeter

wall, or at the centre of the room itself, with the air delivery on three or four sides respectively.

DIMENSIONAL FEATURES

Type A B H Openings N° Air terminal dimensions

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

540 800 350 4 250 X 400

680 890 550 4 600 X 400

760 1060 550 4 600 X 400

760 1060 550 4 600 X 400

900 1300 550 4 800 X 400

900 1300 550 4 800 X 400

1000 1500 550 4 800 X 400

1000 1500 550 4 800 X 400

1200 1700 550 4 1000 X 400

1200 1700 550 4 1000 X 400

1270 2090 550 6 800 X 400

1270 2090 550 6 800 X 400

1500 2500 550 6 1000 X 400

1500 2500 550 6 1000 X 400

1500 3500 550 8 1000 X 400

13

Page 14

MOUNTING INSTRUCTIONS

Free the diffusion plenum from its packaging;

Remove the delivery air outlets and the closing panel from the plenum;

Place the plenum on the top of the equipment;

Fix the plenum to the equipment using the screws provided, entering through the delivery outlet openin gs and the

closing panel;

Remount the delivery outlets and the closing panel.

WARNING!

The plenum top surface cannot be walked on.

THROW DISTANCE

The scheme shows the throw distances in metres at which the rem ainin g v elocit y is red uc ed to 0.1 m/s d epe nding on th e

inclination of the fins per individual plenum with one, two or three openings.

Opening on 2 sides Opening on 3 sides Opening on 4 sides

Fin inclination 0° 20° 30° 45° 0° 20° 30° 45° 0° 20° 30° 45°

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

WARNING!

It is not allowed to have air diffused from one side only of the plenum.

44 35 28 21 36 29 23 17 31 25 20 15

42 33 27 20 34 27 22 16 29 24 19 14

48 39 31 23 40 31 26 19 35 28 22 16

48 39 31 23 40 31 26 19 35 28 22 16

59 46 38 28 48 38 31 23 42 33 27 20

75 60 48 36 61 48 40 29 54 43 33 25

82 65 53 39 67 53 44 32 58 47 38 27

93 74 60 45 76 60 49 36 66 54 44 32

106 80 63 46 82 63 52 39 68 54 45 34

112 88 72 54 91 72 59 43 79 63 51 38

104 82 68 56 79 66 54 45 70 55 45 37

122 97 80 66 98 77 64 53 81 64 53 44

147 116 96 80 118 93 77 64 98 77 64 53

147 116 96 80 118 93 77 64 98 77 64 53

164 134 116 102 134 106 95 76 116 89 74 61

14

Page 15

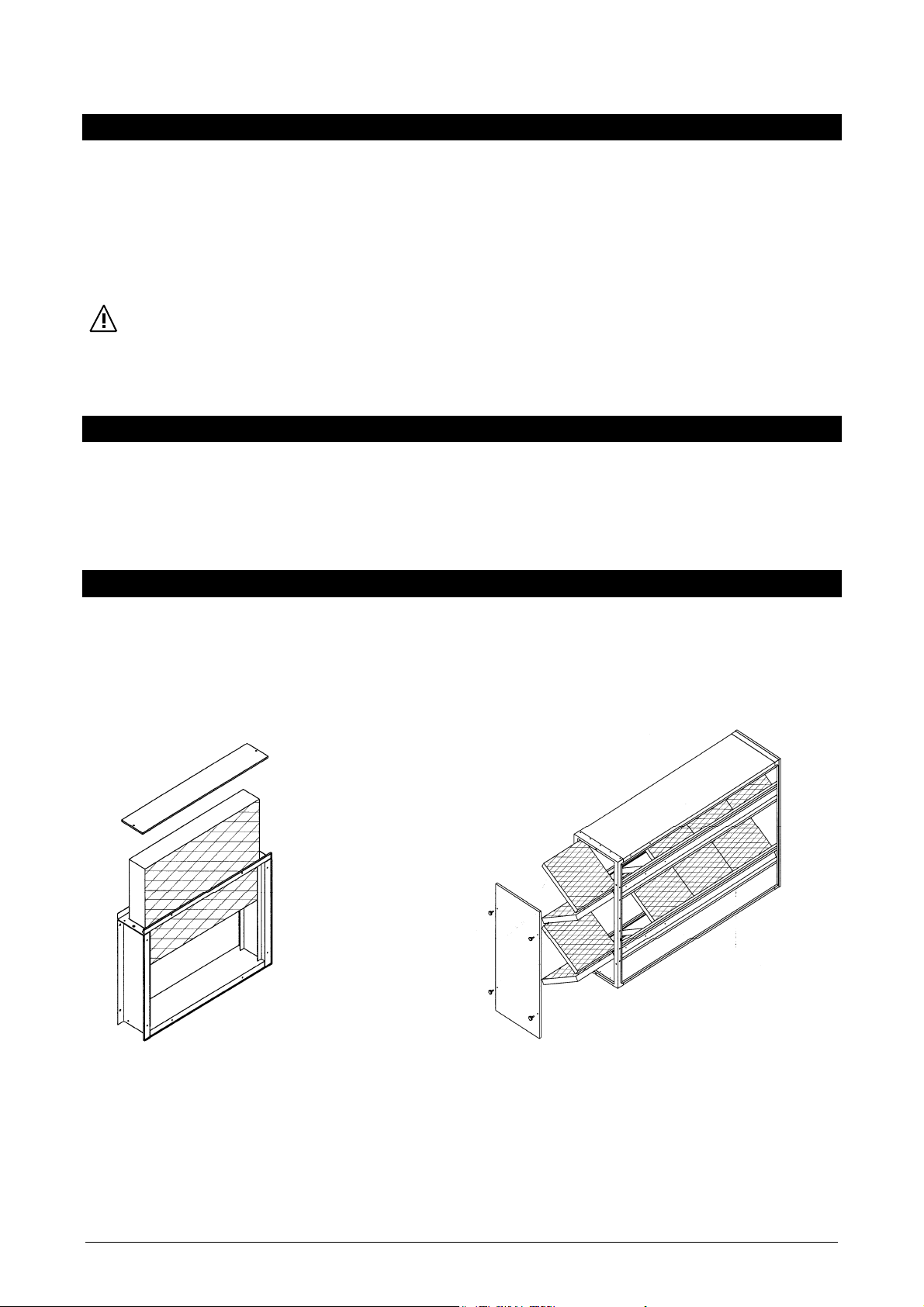

AIR INLET FILTER

Type 1 2 34 5 6789101112 13 1415

A

B

C

Cells N°

P (Pa)

690 780 965 965 1300 1300 1500 1500 1700 1700 2090 2090 2500 2500 3500

459 559 559 559 832 832 832 832 832 832 1000 1000 1000 1000 1000

115 165 165 165 325 325 325 450 450 450 450 450 450 450 450

1 1 1 1 4 4 6 6 9 9 12 12 12 12 24

12 20 23 23 17 27 25 35 23 38 32 45 35 50 70

MOUNTING INSTRUCTIONS

Type 14 Type 515

Type 14

Determine the filter mounting side;

Mount the filter using the screws supplied.

Type 5

Extract the filtering cells from the frame;

Determine the filter mounting side;

Mount the filter using the screws supplied;

15

Reinsert the filtering cells.

15

Page 16

MOUNTING THE BURNER

To proceed with the installation of the oil burner, respect a nd follow the instructions contai ned in the specifically manual

of the burner in detail.

ELECTRICAL CONNECTION

The equipment is supplied with the electrical panel mounted as standard and with the motor/s and the FAN-LIMIT

thermostat/s connected. The connections to be carried out are therefore the following:

The mains electrical connection;

The connections to the burner;

The connections to the room thermostat;

Any other accessories (fire barrier lock, humidifier, etc.).

For all connections use the cable grips in the electrical a nd the terminal block in the panel itself, in accordance with the

specific wiring diagram for each equipment model.

WARNING!

Install a magnetothermal switch before the equipm ent of suitable size based on the technical details indicated in the

paragraph “Technical and performance features” and in accordance with the law in force.

Have authorised personnel to check out the cabl e diameters and maximum electrical plant power absorption by the

equipment as indicated on the plate;

Always earth the equipment. Leave the eart h cable a little longer than the line wires so that, if they are accidentally

pulled, it is the last to get detached;

Respect the polarities when making the electrical connections.

In order to shut off the burner if there is any fault, the electrical pane l has a safety relay ( LX) with a conta ct connected in

series with the burner if the equipment safety thermostat is triggered (LM) or when the fan assembly stops du e to the

activation of the motor thermal relay.

ELECTRICITY SUPPLY DIMENSIONING CHART

Type Supply Maximal Maximal Main Motor Auxiliary Burner Line Earth

voltage Installed

(Kw) (A) (A) (A) (A) (A) (mm2) (mm2)

1

230V 50Hz

2

400V 50Hz 3N

3

400V 50Hz 3N

4

400V 50Hz 3N

5

400V 50Hz 3N

6

400V 50Hz 3N

7

400V 50Hz 3N

8

400V 50Hz 3N

9

400V 50Hz 3N

10

400V 50Hz 3N

11

400V 50Hz 3N

12

400V 50Hz 3N

13

400V 50Hz 3N

14

400V 50Hz 3N

15

400V 50Hz 3N

power (1)

0,55 3,7 - - 6,3 - 1,5 1,5

1,10 2,8 25 6 2 2 1,5 1,5

1,50 3,7 25 6 2 2 1,5 1,5

1,50 3,7 25 6 2 2 1,5 1,5

2,20 5,2 25 6 2 2 1,5 1,5

3 7,1 25 12 2 2 2,5 2,5

3 7,1 25 12 2 4 2,5 2,5

4 9,2 25 16 2 4 2,5 2,5

4 9,2 25 16 2 4 2,5 2,5

5,50 12,1 25 16 2 4 2,5 2,5

7,50 16,5 40 20 4 2 2.5 2.5

9 19 63 32 4 10 4 4

11 22,5 63 32 4 4 4 4

15 31 80 40 4 4 6 6

2x9 2x19 80 32 4 6 10 10

(1) Without burner;

(2) Included with the heater supply;

(3) The cable section ensures a less than 5% voltage drop over a length of 30 m.

absorbed

current (1)

breaker fuses (1) fuses(2) fuses (2) conductor

section (3)

conductor

section (3)

16

Page 17

TYPE 1 WIRING DIAGRAM

230V ~ 50 Hz

PA

LM

F

CV

TA

MS

C

SWITCHBOARD CONNECTING TERMINAL

FAN

ELECTRICITY SUPPLY

Contents:

FAN - FAN Thermostat (25-35°C)

LM - LIMIT Thermostat (100°C)

F - Safety fuses

PA - Motor internal protection

G - Fan motor

C - Fan motor condense

B - Burner

CV - Heating/stop/ventilation switch

TA* - Room thermostat

IMT* - Magnetothermal switch

MS* - (possibe) micro fire barrier lock

* External to the equipment and not included in the supply. To be installed by the customer.

230 V ~ 50 Hz

17

Page 18

SU

400V~ 3+N 50 Hz

TYPE 2 TO 10 WIRING DIAGRAM

IG

FV

LV

RTV

RTV

FA

FB

LX

TR

LM

LV

FAN

LXV

SWITCHBOARD CONNECTING TERMINAL

MONOPHASIC BURNER ELECTRIC

CV

LV

PPLY VARIANT

CV

LX

GROUND

ELECTRICITY SUPPLY

400 V ~ 3+N 50 HZ

Contents

FAN

FAN thermostat (25-35°C)

LM

LIMIT thermostat (100°C)

TR**

SAFETY thermostat (preset 80°C)

LV

Line remote control switch

LX

Burner safety stop relay

RTV

Thermal relay

V

Burner safety stop indicator

FA

Auxiliary fuse

* External to the equipment and not included in the supply. To be installed by the customer.

** Only for type 5 TO 10.

BURNER SUPPLY

400 V ~ 3+N 50 HZ

FB

FV

CV

TA*

MS*

IMT*

IG

G

Burner fuse

Fan motor fuse

Heating/stop/ventilation switch

Room thermostat

(possible) micro fire barrier lock

Magnetothermal switch

Main switch

Fan motor

BURNER SUPPLY

230 V ~ 50 HZ

18

Page 19

V

400V~ 3+N 50 Hz

IG

FV

LV TV SV

TYPES 11 TO 14 WIRING DIAGRAM

RTV

FA

RF

LX

FS

FAN

FB

TR

LM

TV CV CV

TZFAN

LVLV

SVTV

LXRTZ

TA

MS

RTV

Earth

GROUND

SWITCHBOARD CONNECTING TERMINAL

SV

TV

BURNER SUPPLY

400 V ~ 3+N 50 HZ

RF TZ RTZLVLXTV

ELECTRICITY SUPPLY

400 V ~ 3+N 50 HZ

Contents

FAN

FAN thermostat (25-35°C)

LM

Termostato LIMIT (100°C)

TR

SAFETY thermostat (preset 80°C)

TZ

Fan start timer

LV

Remote line switch + pneumatic starter

SV

Star remote control swtich

TV

Triangle remote control switch

LX

Safety burner stop relay

RTV

Thermal relay

RTZ

Burner starting relay

RF

Flow switch control relay

T

Voltage flag

* External to the equipment and not included in the supply. To be installed by the customer.

Safety burner stop flag

FA

Auxiliary charges fuses

FB

Burner fuses

FV

Fan motor fuses

FS

Fan flow switch control

CV

Heating/stop/ventilation switch

TA*

Room thermostat

MS*

(possible) micro fire barrier lock

IMT*

Magnetothermal switch

IG

Main switch

G

Fan motor

19

Page 20

CAPACITY:

400V~ 3+N 50 H z

TYPE 15 WIRING DIAGRAM

IG

FV1

LV1 TV1 SV1

RTV1

CONTROL:

RTV1 RTV2

FV2

LV2 TV2 SV2

RTV2

FA

FB

LX

TV

TR

LM

LM

TV2

RF

FS1

FAN

FS2

LX TV2SV2LV2

FAN

CV CV

TZ

LV1LV1

SV1TV1

TV1SV1 RF TZ RTZLV1

TV1

For contents and switchboard connecting terminal, see next page.

LXRTZ

TA

LV2LV2

MS

SV2TV2

20

Page 21

A

Earth

connection

SWITCHBOARD CONNECTING TERMINAL

Electrical supply

400V ~ 3+N 50 Hz

THERMOSTAT LINE

Contents

FAN

LM

TR

TZ

LV1-2

SV1-2

TV1-2

LX

RTV1-2

RTZ

RF

T

V

FAN thermostat (25-35°C)

LIMIT thermostat (100°C)

Safety thermostat (preset 80°C)

Fan start timer

Remote line switch + pneumatic timer

Star remote control switch

Triangle remote control switch

Safety burner stop relay

Thermal relay

Burner starting relay

Flow switch control relay

Voltage flag

Safety burner stop flag

* External to the equipment and not included in the supply. To be installed by the customer.

F

FB

FV1-2

FS1

FS2

CV

TA*

MS*

IMT*

IG

G1-2

Auxiliary charges fuses

Burner fuses

Fan motor fuses

Fan flow switch control 1

Fan flow switch control 2

Heating/stop/ventilation switch

Room thermostat

(possible) micro fire barrier lock

Magnetothermal switch

Main switch

Fan motor

Burner supply

400V ~ 3+N 50 Hz

21

Page 22

FAN-LIMIT DUAL THERMOSTAT

This thermostat sensor is positioned at the hot air delivery outlet and has the doubl e function of controlling the start up

and the stopping of the fan (FAN function), as well as the safety shutting off of the equipment in case of overheating.

FAN FUNCTION (FAN Thermostat – setting 25-35°C) Causes the fans to start up about 60 seconds after burner,

ignition and causes them to stop about 4 minutes after the burner has switched off. This prevents the emission of

unpleasant cool air on start up and to utilise the thermal energy accumulated in the heat exchanger to ensure its

complete use before the system is stopped (calibrated 35°C). The function is carried out by an thermostat, with sensor in

the air outlet.

SAFETY FUNCTION (Typ 5÷15) Thermostat TR – Pre-setting at 80°C, will interrupt the burners’ run in case of air

overheating. Automatic reset. The function will be carried out by a thermostat with the sensor at the air outlet. The right

setting have to be done at the first equipment’s start up.

LIMIT FUNCTION (LM THERMOSTAT – permanent setting 100°C), this must be reset manually and cuts off the

burner in case of overheating of the air. If the ‘limit’ is triggered the resetting is done using a special button after having

first ensured that the causes of the fault have been removed (calibrated at 100°C).

ELECTRICAL CONNECTION AND SETTING METHOD

The hot air generator comes with its electrical connections and dual thermostat calibration already done. If these opera-

tions have to be carried out for any reason (as a result of maintenance work, checks or parts replacement), the

instructions to follow are given below.

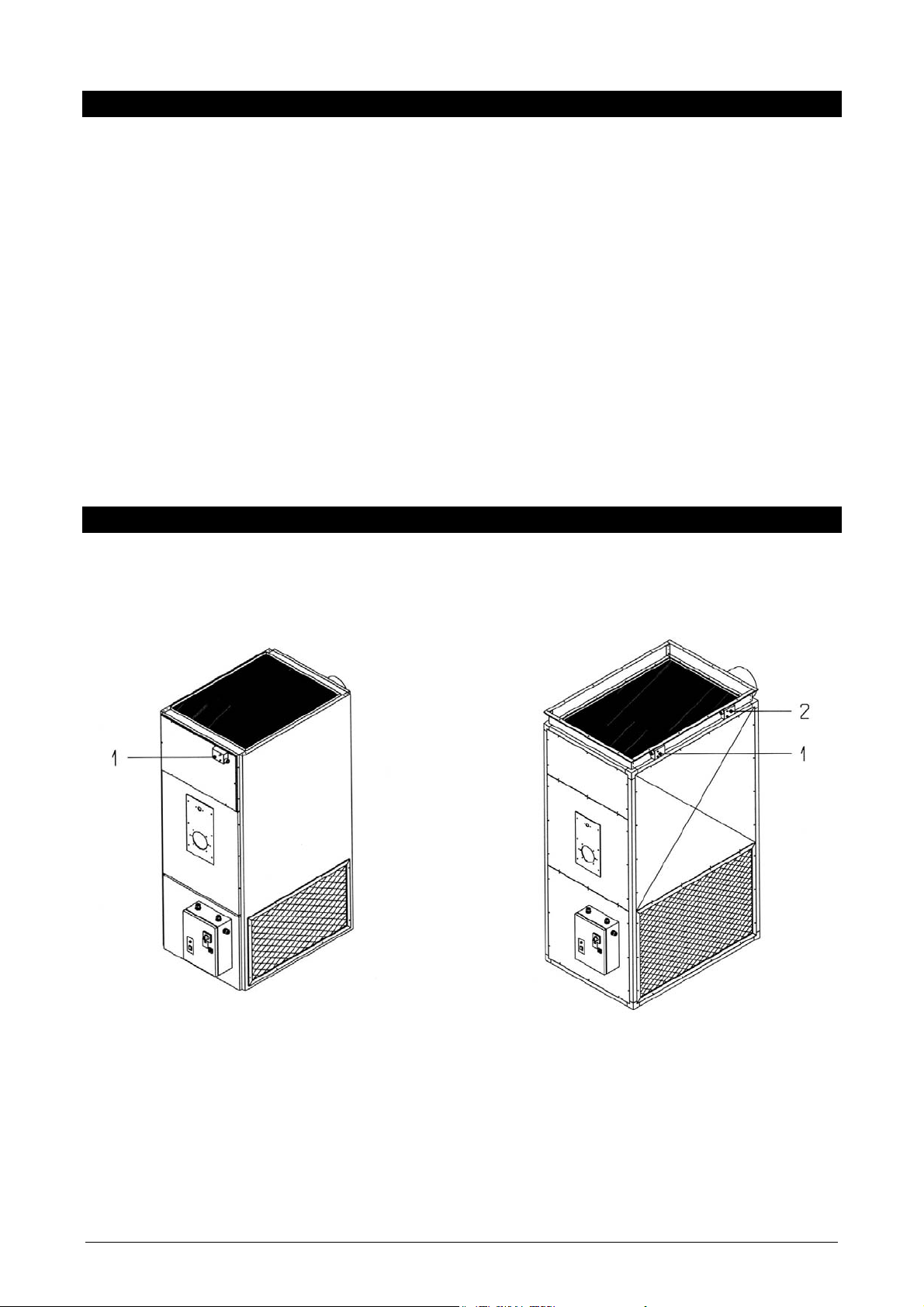

POSITIONING OF FAN, LIMIT AND SAFETY THERMOSTATS

POSITIONING

Equipments Typ 1÷10, will be delivered with the thermostat(s) still moounted in the right position.

Typ 1÷4 Typ 5÷10

Contents:

1. Bi-thermostat (FAN – LM):

FAN function connected. Setting ( by manufacturer ) 25–35°C;

LIMIT function connected. Setting ( by manufacturer ) 100°C.

2. Bi-thermostat (TR):

ONLY SAFETY function connected. Setting (by manufacturer) 80°C.

22

Page 23

The equipments typ 11 to 15 , will be delivered, due theirs possibility to be handled, in 2 separated sections. For this

reason the thermostats will be connected to the electric boards but not positioned: they need to be posit ioned during the

installation. Please follows this instructions:

Typ 11÷14

Typ 15

Contents:

1. Bi-thermostat (FAN - LM):

FAN function connected. Setting 25 – 35°C;

LIMIT function connected. Setting 100°C;

2. Bi-thermostat (TR):

ONLY SAFETY function connected. Setting (by

manufacturer) 80°C.

3. Bi-thermostat (FAN):

ONLY FAN function connected. Setting (by

manufacturer) 25-35°C;

WARNING!

The different thermostats and their positioning are

recognisable and can not be inverted thanks to a l abelling

on the thermostats and on the placements sites on the

equipment. Furthermore, the different length of their

sheathing helps.

23

Page 24

FAN-LIMIT-SAFETY THERMOSTATS SETTING

The thermostats will be supplied with the setting pointed out in the table here under:

FAN thermostat: 25 – 35°C

LIMIT (1) thermostat 100°C

SAFETY (2) thermostat Pre-setting 80°C

(1) The LIMIT thermostat have a permanent setting and do not have to be touched;

(2) The SAFETY Thermostat (Typ 515) need to be set as specified in the manual during the installation.

To control od re-set the set-point in the different thermostats, operate as hereby descripted:

Contents:

1. White automatic-manual ventilation switch (where

available).

2. FAN function electrical connections.

3. Dual thermostat graduated reading.

4. Fixture holes.

5. Fans stop temperature flag.

6. LIMIT-SAFETY intervention temperatures flag

7. Cabl e grip slits. Inserting a screwdriver the terminal is

released and it is possible to pass the wire. Removing

the end of the screwdriver the terminal locks the wire

auto matically into the terminal.

WARNING!

Pull gently on the wire to make sure it is in fact

locked in place.

8. Fan starts temperature flag.

9. LIMIT-SAFETYfunctions electrical connections.

10. Red button to release LIMIT response.

11. Metal bridge (where available).

WARNING!

For the typ 1 the metal bridge 11 must be present.

For the models from typ 2 until typ 15 the metal bridge 11

must be removed.

SAFETY THERMOSTAT SETTING (Typ 515)

The setting have to be done as follows:

Start the equipment in normal running conditions;

Make sure that the burner ist set at the right heating power;

Make sure that the air flow is correct;

As the equipments runs at full capacity, check the air temperature clos e to the TR safety thermostat sensor

(verifying the positioning of graduated rea ding), and after this set the intervention temperature at list 15-20

degrees over. For example, if the air temperature would be 40°C, then the thermostat intervention

temperature have to be 60°C.

Typ 1

Typ 215

24

Page 25

FAN START TIMER

POSITIONING

Housed inside the electrical panel in the models typ 11 to typ 14.

FUNCTION

This is connected in parallel with the FAN (FA) thermostat and

controlled by the RTZ relay with the function of ensuring the start up of

the fan assembly after a maximum time of 1 minute from the ignition of

the burner flame. The fan assembly is controlled onl y by the FAN (FA)

thermostat.

SETTING

The TZ timer is supplied electrically on the closing of the room

thermostat’s contact (TA) which coincides with the ligh-ting of the burner

flame. The stopping of the fan assembly is controlled only by the FAN

(FA) thermostat.

Owing to the different cycle times of the installed burner it is esse ntial to

carry out an adjustment of the time set on the TZ timer.

A

B

To make this adjustment proceed as follows:

1. Time with a stop-watch the time between the closing of the room thermo stat contact (TA) and the ignition of the

burner flame (time of any control test for the gas ramp seal, pre-wash time etc.).

2. Increase time by 1 minute and set it at the TZ timer, using cross cut screw after having selected a suitable scale

means of the micro-switches 1.

A: Set on value 10;

B: Set on 0,1min.

WARNING!

When the setting has been carried out run complete cycle of the g enerator ignition sequ ence and mak e sure that the fan

does in fact come on 1 minute maximum from the ignition of the burner flame.

SETTINGS

BURNERS MATCHING TABLE

The burners which can be matched for the best performance of the generators are as follows:

RIELLO Oil burners:

Typ Burner model Electrical supply

1 R40 G5

RG 2

2 R40 G10

RG 2

3 R40 G10

RG 2

4 R40 G20

RG 3

5 R40 G20

RG 3

6 R40 G20

RG 4S

7 R40 G20S

RG 4S

8 RL 28 tc

RL 28/1 tc

RG 5S

9 RL 28 tc

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

25

Page 26

RL 28/1 tc

RL 34/1 MZ tc

10 RL 38 tc

RL 34/1 MZ tc

11 RL 50 tc

RL 44 MZ tc

12 RL 50 tc

13 RL 70 tc

14 RL 70 tc

15 RL 100 tc

230V 50Hz

230V 50Hz

230V 50Hz

230V 50Hz

400V 50Hz 3N

400V 50Hz 3N

400V 50Hz 3N

400V 50Hz 3N

400V 50Hz 3N

400V 50Hz 3N

OIL-FIRED BURNER SETTING

The assembly and adjustment of the oil-fired burner must be carried out by authorised personnel strictly following the

burner’s own instruction booklet.

26

Page 27

FAN SPEED SET-UP

The equipment is supplied as standard with the transmission ratio adjusted in such a way that the nominal air flow can be

obtained with plenum diffusion through three or four of its sides and with air intake from one or t wo sides through the

intake grills.

WARNING!

Air diffusion from one side only of the plenum is not allowed.

For any usage other then the above mentioned normal working, inv olving the diffusion of channel led air, the insertion of

filter and so on, i.e. any arrangement which cause variations in the air resistance, it is essential to carry out a check on

the air flow and regulate it, if necessary, so that it is at the nominal levels.

This check can be carried out with precise instruments or for a good rough approximation, by checking the thermal jump

between the air delivery and air intake when the burner is set at its nominal thermal capacity. The result should be

checked against the data indicated in the paragraph TECHNICAL DATA.

It is in any case necessary to check that the direction of rotation of the fans is the same as that of the arrow on the screw.

To alter the direction of rotation, in the case of a three phase electric motor, just invert one phase of the supply line

without interfering with the electrical panel. It is also nece ssary to check that the motor output does not exceed that

indicated on the plate; if necessary change the fan rpm to obtain this result.

To change the fan rpm proceed as follows:

TYP 14

Loosen screws 2 to slacken the belts;

Remove belt 1;

Slacken the dowels 4 of the moving part of the pulley 3 with a hexagonal wrench 5;

Turn the mobile part of the pulley so as to obtain the desired pitch line diameter;

Tighten the dowels hard 4 at the hollow in the boss;

Mount and tighten the belt 1.

Ty

p 510

Loosen screw 1 to slacken the belts;

Remove belt 5;

Slacken the dowels 3 of the moving part of the pulley 4 with a hexagonal wrench 2;

Turn the mobile part of the pulley so as to obtain the desired pitch line diameter;

Tighten the dowels hard 3 at the hollow in the boss;

Mount and tighten the belt 5.

WARNING!

Never stretch the belts too tight as the fan shaft could bre ak. Hand pressu re on the belt s hould be ab le to move it

by 20-30 mm.

Increasing the pitch line diameter of the pulley motor increases the fan rpm and the motor’s electrical absorption.

Reducing the pitch line diameter of the pulley motor increases the fan rpm and the motor’s electrical absorption.

The equipments typ 1115 are provided with a fixed gearing transmission and to change the rpm of the fan the

exchange of a poulley is needed.

Typ 14 Typ 510

27

Page 28

CHECKS

To ensure the proper working of the equipment it is necessary certain basic parameters must be checked. Switch the

equipment on and carry out the following:

Check that the fan assembly starts up about 1 minute after the burner runs.

When the generator is up to temperature and working normall y (after ab out 20 minutes of continuo us working), carry out

the following operations:

Check there are no leaks of combustible materials.

Check the fuel pressure, using the meter (where possible).

Check that the fumes temperature is that given in the paragraph TECHNICAL DATA, with a tolerance of +/ - 10°C.

Check the setting of the dual thermostat is that indicated in the chapter TECHNICAL DATA.

Check the graduated reading on the dual thermostat indicates 50-60°C and that the LIMIT function is not triggered.

Check that the thermal jump corresponds to that indicated in the chapter TECHNICAL DATA, with tolerance of ±5°C.

Turn the dual thermostat’s dial manually to simulate the intervention of the LIMIT thermostat and check that the

burner is in fact switched off.

Open the room thermostat’s contact and check that it acts only on the burner and does not also cause the fan

assembly to stop.

Check the motor absorption does not exceed that indicated on the plate.

Check the thermal safety relay is set at the motor absorption value.

Check that the fan runs 4 minutes longer after the turn off of the burner, before to stop.

Check that the intervention temperatur e of the safety fan is 15-20 °C over the air temperature close to the sensor of

the safety fan.

It is compulsory to check that no condensation will appare into the heat exchanger durino the runnin g. Fot this

ckeck, after ½ Hour of running turn the burner off, and check both through the chimney connection and the

smokes pipes the absence of humidity into the smokes collector and exhausts pipes.

CONTROLS

HEATING-STOP-VENTILATION SWITCH

This is located on the equipment’s electrical panel and its function is select the working cycle:

When set at the ‘heating’ symbol it programs the equipment so that the fan and burner function automatically

according to the demands for heat.

When set at ‘fan’ it controls the equipment excluding the burner. Only the fan is active providing summer ventilation.

When set at ‘stop’ it stops the hot air generator. The fan works for a certain tim e to use up the heat accumulated in

the heat exchanger.

ROOM THERMOSTAT

To be installed about 1.5 m above ground and in an area sheltered from hot or cold air currents. It controls the switching

on and off of the equipment to maintain the temperature at the set level. It must be requested as an accessory additional

to the standard delivery.

BURNER RESET BUTTON

Located on the burner itself, its function is to reset the burner when it gets locked off.

LIMIT THERMOSTAT RESET BUTTON

A red button on the FAN-LIMIT dual thermostat with the function of resetting the burner after a overheating lock.

FAN MOTOR THERMICAL PROTECTION RESET BUTTON

Located into the control box, on the thermic relais block, needs to restart the fan functioning after a block for

malfunctioning or exceeding electrical absorbance by the fan motor.

WARNING!

Before any resetting it is essential to find and remove th e cause of the safety system being triggered. If in any do ubt call

the nearest authorised technical assistance centre which will give you any assistance you require.

28

Page 29

INDICATORS

VOLTAGE ON INDICATOR

Located on the electrical panels of the types 1115 models. It is an orange light which comes on when there is voltage.

BURNER LOCKED INDICATOR

This red button is located on the burner and lights up when the burner is locked. It is also the reset button.

SAFETY STOP BUTTON

This red button is located on the electrical panel of the Types 1115 models and lights up in the following cases:

LIMIT thermostat triggered;

Fan motor thermal safety triggered.

FAN MOTOR ABSORPTION

FAN MOTOR ELECTRICAL ABSORPTION MEASUREMENT

To check the motor absorption proceed as follows:

1. Insert ammeter in one phase of the mains supply;

2. Set the equipment at summer ventilation, so as to cut out all other parts (burner and auxiliaries);

3. Take the ammeter reading for the electrical absorption a nd check against the details on the motor’s plate, als o given

in the paragraph TECHNICAL DATA.

If it is necessary to check the absorption reading after the remote co ntrol switch or the remote starter, proceed as

follows:

1. Insert the ammeter in a phase of the motor’s supply after the remote control switch or the remote starter;

2. Set the equipment at summer ventilation, so as to cut out all other parts (burner and auxiliaries);

3. Take the ammeter reading for the electrical absorption a nd check against the details on the motor’s plate, als o given

in the paragraph TECHNICAL DATA.

If the case of equipment with direct start up (typ 210) the absorption measured corresponds to that of the li ne an d must

be checked on the data on the motor plate and given in the paragraph TECHNICAL DATA.

If the case of equipment with star/Y reduced tension start up (typ 1115), the absorption measured c orresponds to that

of the phase and, divided by 1.73, must be checked against the data on the motor plate and given in the par agraph

TECHNICAL DATA.

WORKING CYCLE

VENTILATION CYCLE

This cycle works in accordance with the following stages:

Give power to the equipment;

Set the main switch on posiotion “ventilation”;

The fan assembly only now works and intake temperature re air is directed into the room.

HEATING CYCLE

This cycle works in accordance with the following stages:

Give power to the equipment;

Set the main switch on posiotion “heating”;

Set room thermostat to the desired temperature;

The burner is now given electrical supply and, after the combustion chamber pre-wash function, the flame is ignited;

After about 1 minute the fan runs and hot air is delivered into the room.

When the temperature set at the thermostat has been reached the burner stops and after about 2 to 3 minutes the fan

also stops. The whole cycle is repeated when the temperature in the room falls below the set value.

29

Page 30

START UP AND STOP

START UP

Follow the instructions in the chapter WORKING CYCLE.

STOP

To stop the equipment it is necessary follow the procedure below:

Set the room thermostat at ‘no frost’ or set the switch at “STOP”;

Wait for the fan to stop and then, if necessary, switch off the mains supply.

WARNING!

Never stop the generator by cutting off the supply at the mains as the the rmal e nergy ac cumul ated i n the heat exchanger

may trigger the LIMIT safety device resulting in the need to carry out a manual unlocking. If this is repeated there is also

a danger of dangerously overheating the heat exchanger.

MAINTENANCE

For the proper working and conservation of the equipm ent periodic maintenance and cleaning operations need to be

carried out.

Any such work must be carried out by specialised personnel which is authorised and the work should be d one when the

equipment is cold and the electrical and combustible fuel supplies cut off. All maintenanc e and c leaning oper ations which

require the use of ladders or other access means must be used with sui table and absolutely safe equipment.

AIR FILTER CLEANING

The cleaning of any intake air filter present must be periodically carried out and it is an extremely important task. If the

filter baffle is too dirty, the air flow will be reduced and cause over heating od the air and t he heat excha nger which lea ds

to the LIMIT thermostat being triggered. How often the cleaning is necessary will depend on the environment in which the

equipment is installed but as a rough guide it should be carried out on a weekly basis.

To clean the filter, proceed as follows:

Type 14 Type 515

Remove the upper panel and remove the filtrating cells

from the box.

Clean the filter cell with an air jet, vacuum cleaner or

sim ply by knocking the cell. For more complete

cleaning immerse the cell i n warm water with a neutral

detergent rinse and dry out away from sources of heat.

Remount the cell when it is perfectly dry.

30

Remove the side panel and remove the filtration cell

from the box.

Clean the filter cell with an air jet, vacuum cleaner or

sim ply by knocking the cell. For more complete

cleaning immerse the cell in warm water with a neutral

detergent rinse and dry out away from sources of heat.

Remount the cell when it is perfectly dry.

Page 31

BURNER CLEANING

The cleaning of the burner must be carried out by authorised people strictly following the burner own instructions man ual.

HEAT EXCHANGER CLEANING

The cleaning of the heat exchanger must be carried out by authorised people and is subject to specific regulations.

Generally speaking, the operation should be carried out annually at the start of each winter.

Proceed as follows:

Remove the inspection panel 1;

Remove the inspection door 2;

Remove the burner;

Only on type 14, disconnect the chimney pipe from the connector 5;

Only on type 515, remove the side panels 7 and the inspection doors 6;

Pull out any tubing 10;

Clean the tube pack 3 with a tube brush and, with a vacuum cleaner through t he burner opening 9 remove any soot

and obstructions which have been depositating in the combustion chamber 8;

Remove the soot and obstrucions depositated in t he rear fume manifold 4 using a vacuum cleaner in the chimney

connector 5 for type 14, or through the side inspection openings for type 515;

Reassemble everything taking care that the seal is good and replacing any seals if necessary.

31

Page 32

FAN MAINTENANCE

Periodically check the tightness of the transmission belts

and the alignment between the motor pulley and the fan

pulley. The belts must not be more taut than necessary to

stop them slipping; when the two sides of the belt are

pressed with the hands, it should give by at least 2-3 cm.

Adjust tightness with the belt-tightening bolts.

The bearings on type 1

loaded.

The type 11 - 12 - 13 - 1 4 - 15 (the last only on the side

opposite the transmission) have single-piece support

bearings which do not normally require grea sing but have

a grease connection.

On the transmission side in the case of type 13 - 14 there

are cast iron pedestal bearings which have to be greased

periodically with lithium soap-based grease to be

introduces after having been introduced after the pedestal

has been opened.

10 fans are also hermetic pre-

The motor bearings are hermetic, pre-loaded and hav e a

grease reservoir, which means that in normal usage the y

do not require maintenance.

LIMIT THERMOSTAT MAINTENANCE

Verify the functionality of the LIMIT dual thermostat every year by turning normally the gradu ated reading beyond the

100°C and veryfing that the burner turns off. Moreover, verify that the reset is regular by acting on the provided

unblocking button.

FUME SAMPLING POSITION

The distancese indicated below must be respected when taking samples for analyses of the equipment combustion:

ASSISTANCE

The mounting, start-up and maintenance of the hot air generators by Tecnoclima must be carried out by authorised

technicians. You may request the direct technical assistance from the nearest Manifacturer’s Assistance centre.

32

Page 33

FAULTS AND SOLUTIONS

FAULT CAUSE SOLUTIONS

THE GENERATOR

DOESN’T WORK NEITHER

IN VENTILATION NOR IN

HEATING MODE

THE GENERATOR

DOESN’T WORK IN

VENTILATION MODE

THE GENERATOR

DOESN’T WORK IN

HEATING MODE

THE OIL BURNER FLAME

TURNS ON BUT IT TURNS

OFF FEW SECONDS

LATER

No voltage

No electricity supply to tha fan

motor

No electricity supply to the oil

burner

Incorrect electrical connection

To be verified or out of order

burner

Check electrical connections

Check line fuses and auxiliaty charges wholeness

Check electrical connections

Check line fuses and auxiliary charges wholeness

Check for an eventual cut-in of the motor thermal

protection (only three-phase electricity supply

versions)

Check electrical connections

Check line fuses and auxiliary charges wholeness

Check the room thermostat positive connection

Check for an eventual cut-in of the motor thermal

protection (only three-phase electricity supply

versions)

Check for an eventual LIMIT thermostat cut-in

Check the electricity supply (phase + neutral + earth)

Check the burner setting

Replace the electronic control box of the burner

Check and/or replace the burner photocell

33

Page 34

FAULT CAUSE SOLUTIONS

THE BURNER STOPS

ANOMALOUSLY AND

CASUALLY

LIMIT THERMOSTAT CUT-IN

FAN MOTOR THERMAL

PROTECTION CUT-IN (FOR

THREE-PHASE VERSIONS)

THE FAN DOESN’T START

WITHIN ABOUT A MINUTE

LIMIT thermostat cut-in

Burner flame detached

Room thermostat incorrectly

installed

Obstruction on the air circuit

Hot air recirculation

To be verified or out of order fan

Excessive thermal power

Excessive fan motor electric

absorption and/or heating

Insufficient thermal power

Check the opening of the flow

directing fins

Check for the absence of

obstructions on air inlet grids

Check fan motor

Check the burner setting

Check that the generator doesn’t

work in a depressed room

Check that the room thermostat

sensor is not installed on the hot air

outlet

Check the opening of the flow

directing fins

Check for the absence of

obstructions on air inlet grids

Check the opening of the flow

directing fins so that it can be

excluded a hot air recirculation from

outlet to inlet

Check the air inlet temperature

Check that the fan wheel is clean

Check the fan motor efficiency

Check the state and the tension of

the belts (for three-phase versions)

Verify an eventual anomalous cut-in

of the fan motor thermal protection

(for three-phase versions)

Check the burner setting

Check that the air diffusion plenum

is mounted

Check the electricity supply voltage

Check the air inlet temperature

Check the burner setting

FROM THE STARTING OF

THE BURNER

To be verified or out of order

FAN-LIMIT dual thermostat

Check FAN index setting

Replace the FAN-LIMIT dual

thermostat

34

Page 35

FAULT CAUSE SOLUTIONS

THE FAN DOESN’T STOP

WITHIN ABOUT 4 MINUTES

FROM THE STOPPING OF

THE BURNER

THE FAN DOESN’T WORK

THE FAN RUNS

INTERMITTENTLY

THE FAN PRESENTS

FUNCTION LAPSES

THE GENERATOR GETS

ANOMALOUSLY DIRTY

INTERNAL CONDENSATION

OF THE CUMBUSTION

PRODUCTS

DIFFICULTIES TO REACH

THE TEMPERATURE SET ON

THE ROOM THERMOSTAT

Obstructed chimney

Incorrect burner setting

Incorrectly installed room thermostat

Too high room temperature

To be verified or out of order

FAN-LIMIT dual thermostat

To be verified or out of order fan

To be verified or out of order

FAN-LIMIT dual thermostat

To be verified or out of order

FAN-LIMIT dual thermostat

Insufficient thermal power

Hot air recirculation

Incorrect burner setting

Insufficient thermal power

Low thermal exchange rate due to

dirty heat exchanger

Check the air inlet temperature

Check for an eventual solar

irradiation

Check FAN index setting

Verify that the white button Is on the

AUT position

Replace the FAN-LIMIT dual

thermostat

Check the fan motor efficiency

Check the capacitor of the fan motor

(for three-phase versions)

Verify transmission belts (for threephase versions)

Verify an eventual cut-in of the fan

motor thermal protection (for threephase versions)

Check FAN index setting

Replace the FAN-LIMIT dual

thermostat

Check FAN index setting

Replace the FAN-LIMIT dual

thermostat

Check the burner setting

Check the opening of the flow

directing fins so that it can be

excluded a hot air recirculation from

outlet to inlet

Check the air inlet temperature

Check the burner setting

Clean the fumes discharge and the

chimney

Check the burner setting

Clean the heat exchanger

Check the burner setting

Check that the room thermostat

sensor is not installed on the hot air

outlet

35

Page 36

PRODUCT DISPOSAL

This product was designed and made with high qualità material and components which

can be recycled and reused.

When finding the symbol of a wheeled crossed bin on a product, be aware of the fact that

the component is covered by the European Directive 2002/96/EC.

Get informed about your local waste separation system as far as electric and electronic

products are concerned.

Respect your in force local rules and do not dispose old products with your household

waste. A correct product disposal helps preventing possible negative consequences on

human and environmental health.

NOTES

36

Page 37

EC CONFORMITY DECLARATION

DÉCLARATION DE CONFORMITÉ À LA CE

EU-ÜBEREINSTIMMUNGSERKLÄRUNG

CONFORMITEITSVERKLARINGVOOR DE EU

DICHIARAZIONE DI CONFORMITÀ

DECLARACION DE CONFORMIDAD CON LA CE

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

EU:N VAATIMUSTENMUKAISUUSVAKUUTUS

EU OVERENSSTEMMELSESERKLÆRING

EU-SAMSVAR

DEKLARACJA ZGODNOŚCI WE

ЗAЯBЛEHИE O COOTBETCTBИИ TPEБOBAHИЯМ CTAHДAPTOB EC

EC MEGFELELŐSÉGI NYILATKOZAT

PROHLÁŠENÍ O DODRŽENÍ NAŘÍZENÍ EC

EC ATITIKTIES DEKLARACIJA

EL VASTAVUSAVALDUS

EC ATBILSTĪBAS DEKLARĀCIJA

ΔΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

AT UYGUNLUK BEYANI

VYHLÁSENIE ZHODY S ODPORÚČANIAMI EURÓPSKEHO SPOLOČENSTVA

DECLARAŢIA DE CONFORMITATE CU RECOMANDĂRILE COMUNITĂŢII EUROPENE

ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ НА ЕВРОПЕЙСКАТА ОБЩНОСТ

DEKLARACIJA USKLAĐENOSTI S PREPORUKAMA EUROPSKE UNIJE

ДЕКЛАРАЦІЯ ВІДПОВІДНОСТІ EC

DESA ITALIA s.p.a. Via Tione, 12 - 37010 - Pastrengo (VR) ITALY

Portable forced air heaters: - Appareils de chauffage individuels à air forcé: - Tragbare hochdruck-heissluftturbinen: - Mobiele

ventilator-luchtverwarmer: - Generatore d’aria calda: - Calentadores móviles de aire forzado: - Portabel värmeäkt med forcerat

luftöde: - Siirrettävä kuumailmapuhallin: - Flytbare luftcirkulations apparater: - Flyttbar varmekanon: - Przenośne nagrzewnice

powietrza pod ciśnieniem: - Тепловой генератор: - Hordozható hőlégfúvók: - Přenosná topná tělesa na dm chan vzduch: - Kilnojami

aukšto slėgio oro šildytuvai: - Kaasaskantav õhusoojendi: - Pārvietojamie gaisa sildītāji ar piespiedu gaisa padevi: - Φορητη

θερμαστρα εξαναγκασμενησ ροησ αερα: - Priprava za vpihavanje toploga zraka: - Portatıf basinçli hava isiticilar: - Prenosný tlakový

teplovzdušný ohrievač: - Încălzitoare portabile de aer: - Преносими отоплители под налягане: - Uređaj za upuh toploga zraka: -

Портативні повітрянагрівачі:

BI 60 - BI 95 - BI 105 - BI 120 - BI 160 - BI 190 - BI 225 - BI 260

It is declared that these models conform to: - Ces modèles ont été déclarés conformes à:

Hiermit wird bescheinigt, daß diese Modelle in Übereinstimmung: - Hierbij wordt verklaard dat deze modellen:

Si dichiara che questi generatori sono conformi: - Se declara por este medio que estos modelos:

Ovanstående modeller överensstämmer: - Näiden mallien todistetaan täten noudattavan:

Det attesteres herved, at anførte modeller er i overensstemmelse: - Det erklæres at disse modellene er i samsvar:

Oświadcza się, że niniejsze modele zgodne są z zarządzeniem: - Hacтoящим мы зaявляем, что эти нагрeвaт

ели oтвечают

требованиям стандартов на оборудование: - Kijelentjük, hogy fenti modellek megfelelnek

Prohlašujeme, že tyto modely odpovídají Nařízení pro stroje: - Vastab järgmistele el direktiividele ja standarditele:

Atbilst sekojošu es standartu un direktīvu prasībām: - Δηλώνεται ότι αυτά τα μοντέλα είναι σε συμμόρφωση με την οδηγία περί

Μηχανημάτων: - İşbu modellerin: - Potvrdzujeme, že tieto modely sú zhodné s nariadením: - Declară că modelele sunt produse

conform hotărârii: - Декларира, че горепосочените модели съответстват Директивата за: - Očituje se da su spomenuti modeli

sukladni sa uredbom: - Декларується що ці моделі відповідають:

98/37 CE, 91/368, 93/44, EMC 89/336, 92/31, 93/68, 73/23

Pastrengo, 06/04/2010

Raffaele Legnani (Managing Director)

BI 320 - BI 390 - BI 590 - BI 645 - BI 770 - BI 1000 - BI 1100

Page 38

DESA ITALIA s.p.a.

Via Tione, 12 – 37010

Pastrengo (Verona) – Italy

www.desaitalia.com

info@desaitalia.com

06/08 Ind. rev. 9 Cod. 39/D

DESA POLAND Sp. Z.o.o

ul Magazynova 5A, 62-023

Gadki, Poland

www.desapoland.pl

office@desapoland.pl

DESA HEATING

EQUIPMENT

SHANGHAI CO., LTD

Rm. 2203, 218, HengFeng Rd,

Shanghai, China, 200070

www.desa-china.com

info@desa-china.com

Loading...

Loading...