Master BF 35, BF 45, BF 75, BF 95, BF 105 Maintenance Manual

GB – Hot air generator

Operation and maintenance manual

4111.805

Edition 10

Rev. 01

BF 35

BF 35BF 35

BF 35

BF 45

BF 45BF 45

BF 45

BF 75

BF 75BF 75

BF 75

BF 95

BF 95BF 95

BF 95

BF 105

BF 105BF 105

BF 105

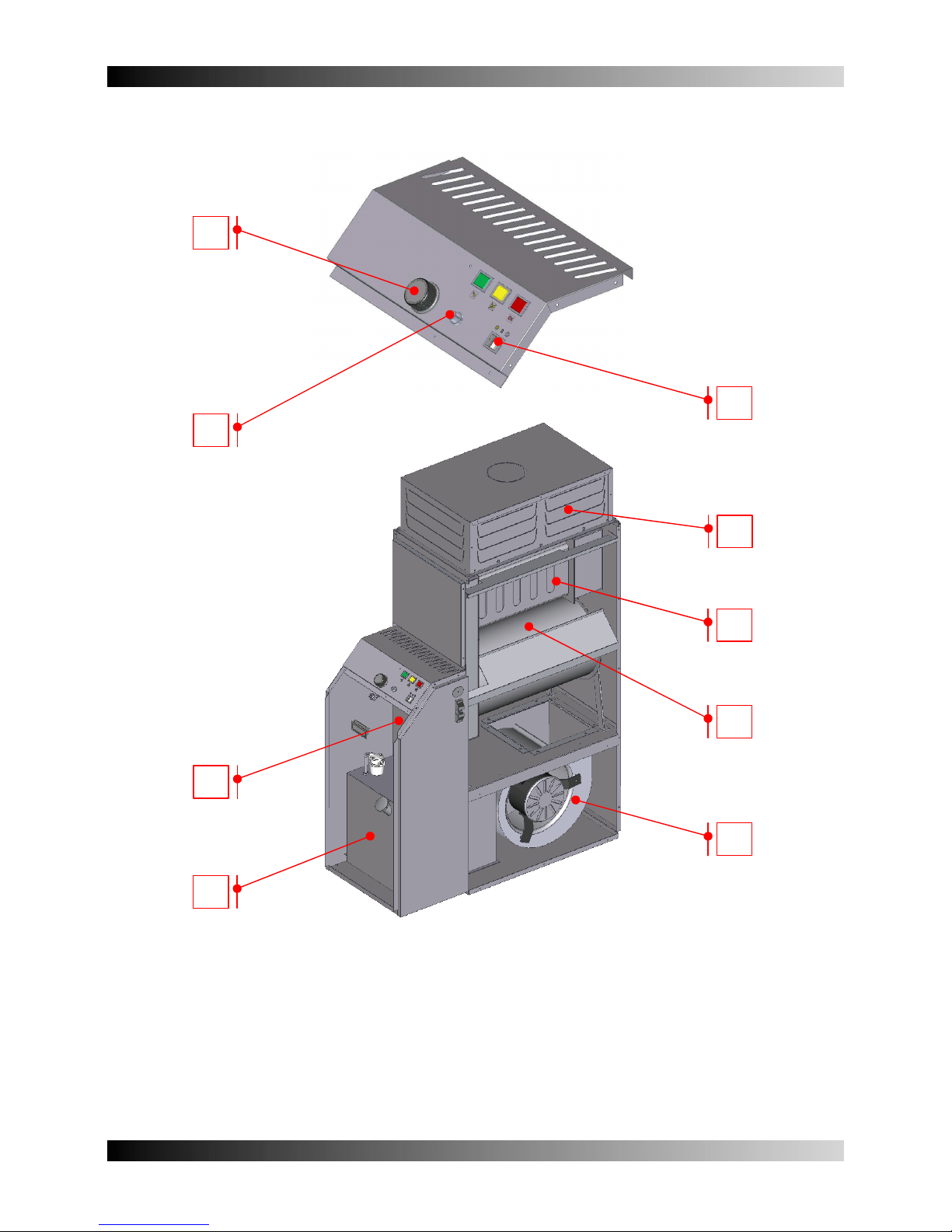

CONTROL BOARD

1. Commutator

2. Room thermostat

3. Burner

4. Fuel tank

5. Limit thermostat

6. Fan

7. Heat exchanger

8. Combustion chamber

9. Adjustable air head

5

3

2

1

4

6

7

8

9

WARNING: To avoid an overheating of the combustion chamber the fins must never be completely

closed. For this reason a blocking bar prevents the complete closure of the fins.

BF space heaters have been designed for use in medium to big sized rooms and buildings where a fixed heating

system is needed.

Heat is produced by combustion and the heat from smoke is transmitted to fresh air through the metal walls of the

combustion chamber and the heat exchanger. The combustion chamber is of the type where smoke follows a

course of two modules.

Air and smoke pass through separated ducts, both of which are welded and sealed. When, after combustion, the

waste gases have cooled, they get expelled through a duct that has to be connected to a chimney or chimney flue

which must be big enough to guarantee that smoke gets efficiently expelled.

Air used for combustion gets aspirated directly from the room or building that is being heated. It is therefore very

important the room or building to be properly ventilated so that there is enough fresh air circulating at all times.

Hot air can be sent in the desired direction by moving the fins on the air head.

BF heaters can operate with ON-OFF type and fuelled by heating oil burners. Where burners use oil, a front

attached fuel tank is provided (4). There are two safety devices which are activated in case of serious

malfunctioning. The burner control device, which is mounted on the burner and is provided with a restart button

that automatically stops the burner if the flame turns off, while the manual restarting type overheat thermostat

activates if the temperature of the combustion chamber reaches the set maximum limit.

If any of those safety devices are activated, you should check carefully what the problem is before pressing the

restart button and restarting the heater (check the “FUNCTIONING PROBLEMS: CAUSES AND SOLUTIONS”

paragraph).

GENERAL ADVICE

WARNING: Only chosen and by the manufacturer supplied burners can be used. If another type of

burner is used, the heater no longer complies with the CE regulations.

The space heater has to be installed, set up and used in accordance with existing laws. Here are a few general

guidelines which should be followed:

• Follow the instructions of this manual very carefully.

• Don’t install the heater in places where there might be risk of explosion or fire.

• Flammable material should be kept at a safe distance from the heater (3 meters minimum).

• All fire prevention measures have to be enforced.

• The room or building to heat has to be sufficiently ventilated so that the heather disposes of the needed ait

to work properly.

• The heater has to be near a chimney or a chimney flue and a suitable electric switchboard.

• Don’t let any children or animal get near the heater.

• After use, make sure that the disconnecting switch if off.

When using any type of space heater, it is compulsory to:

• Not exceed the maximum furnace heat output level.

• Make sure that a proper air circulation and supply is provided and that nothing might obstruct the air

aspiration and expulsion: that can be caused, for example, by placing covers or other objects on the

heater, or by positioning it too close to walls or other large objects. If there is an inadequate air supply,

the combustion chamber might start overheating, getting the overheat thermostat to intervene.

INSTALLATION

WARNING!

The following operations must be carried out by qualified personnel only.

ELECTRIC CONNECTIONS AND SETTINGS:

WARNING!

The main heater electricity supply has to be provided with grounding and a magneto-thermal switch

with a differential. The power wire has to be connected to a switch board linked to a disconnecting

switch.

The basic equipment of the heater includes all control and safety devices which can guarantee the correct

functioning of the machine: control board, room thermostat (2), fan and manual safety thermostat are already

connected.

The following operations have now to be carried out:

• Plug the power wire in after having read the adhesive label that shows electricity supply characteristics;

After having completed those operations, make carefully sure that all the electric connections match with the

wiring diagram. When the heater gets turned on for the first time, you should make sure that the fan does not

absorb more current than the maximum indicated limit. Eventually, to regulate the burner, follow the instructions

of the burner manual.

HOT AIR DUCTS CONNECTION

The space heater provides heat by releasing and diffusing hot air.

An air head which can be connected to air ducts, if the users chooses this option, is supplied with every machine.

In this case, and in particular if the diameter and length of the ducts get changed, or if the number of bends gets

modified, air output may vary. Consequently, it is very important to check and regulate air output when any

modification is made to air heads or ducts.

In all circumstances, you should make sure that:

• The fan engine does not absorb more current than the maximum indicated limit.

• The air flow volume matches with its recommended level.

CHIMNEY AND CHIMNEY FLUE CONNECTION

Efficient combustion and trouble-free working of the burner depend on an efficient smoke evacuation:

• The pipe which through which smoke passes should as short as possible and ascending.

• There should be no sharp bends and the diameter of the pipe should never be reduced.

• Every heater should have its own chimney.

• The chimney draught should at least enough and adequate for the needs of the equipment.

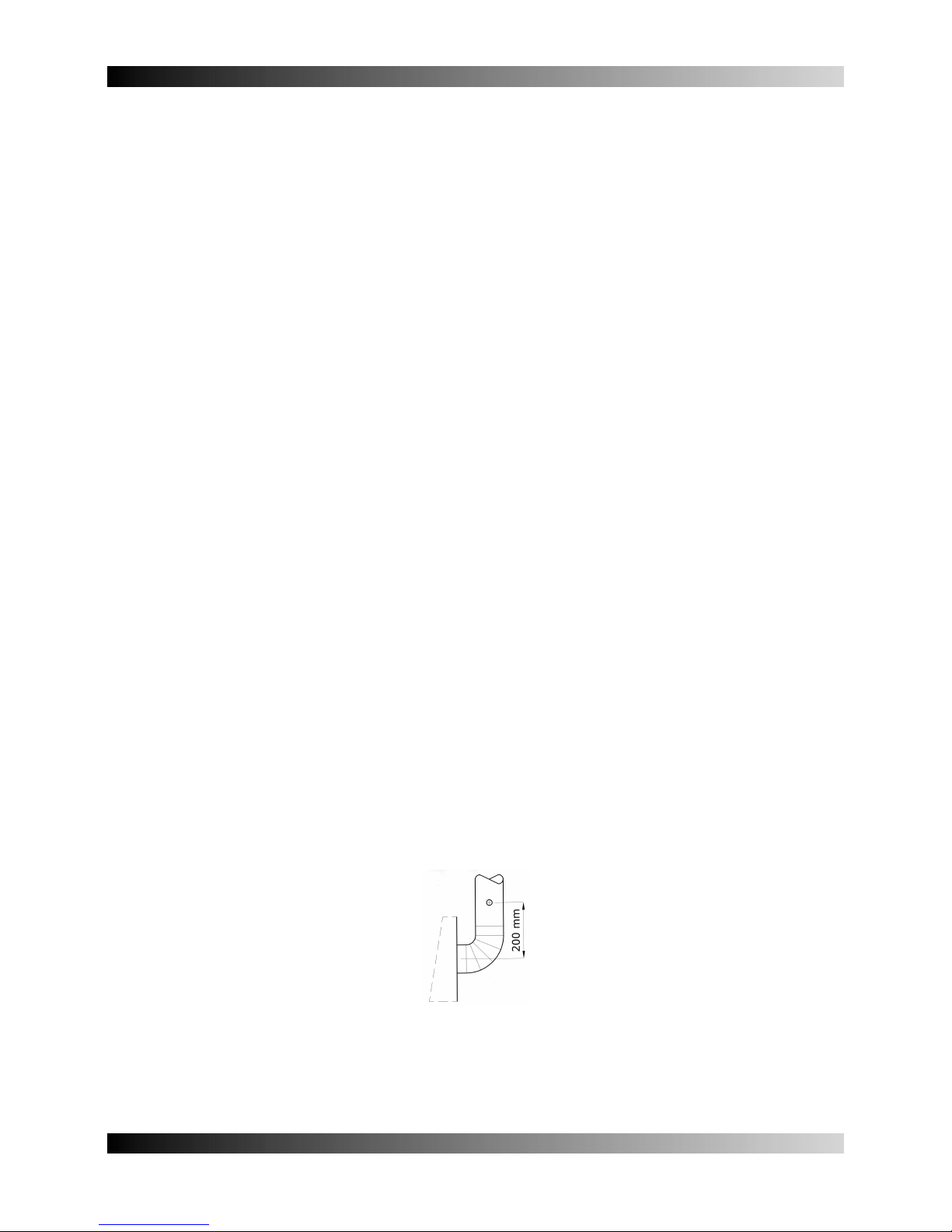

WASTE PRODUCTS ANALYSIS

The probes to check the combustion waste products composition and smoke temperature have to be positioned as

the picture below indicates.

When those tests have been completed, the hole drilled has to be sealed using a high temperature resistant

material which will ensure that the pipe remains airtight.

Loading...

Loading...