Page 1

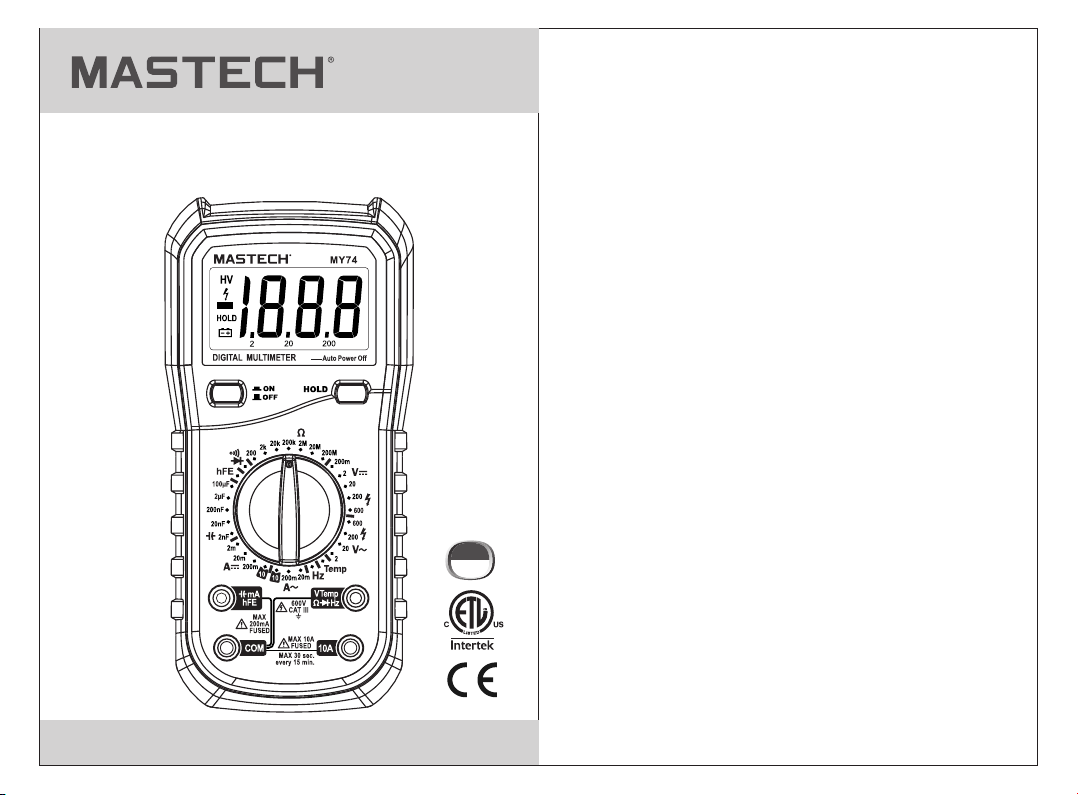

MY70/74/74B

DI GI TA L M U LT I M E T E R

OP E R A T I O N MA N U A L

CAT III

600V

Page 2

CONTENTS CONTENTS

1. General instructions

1.1 Safety information

1.1.1 Safety instructions

1.1.2 Safe working habits

1.1.3 Safety symbols

1.1.4 Safe maintenance habits

1.2 Input protection measures

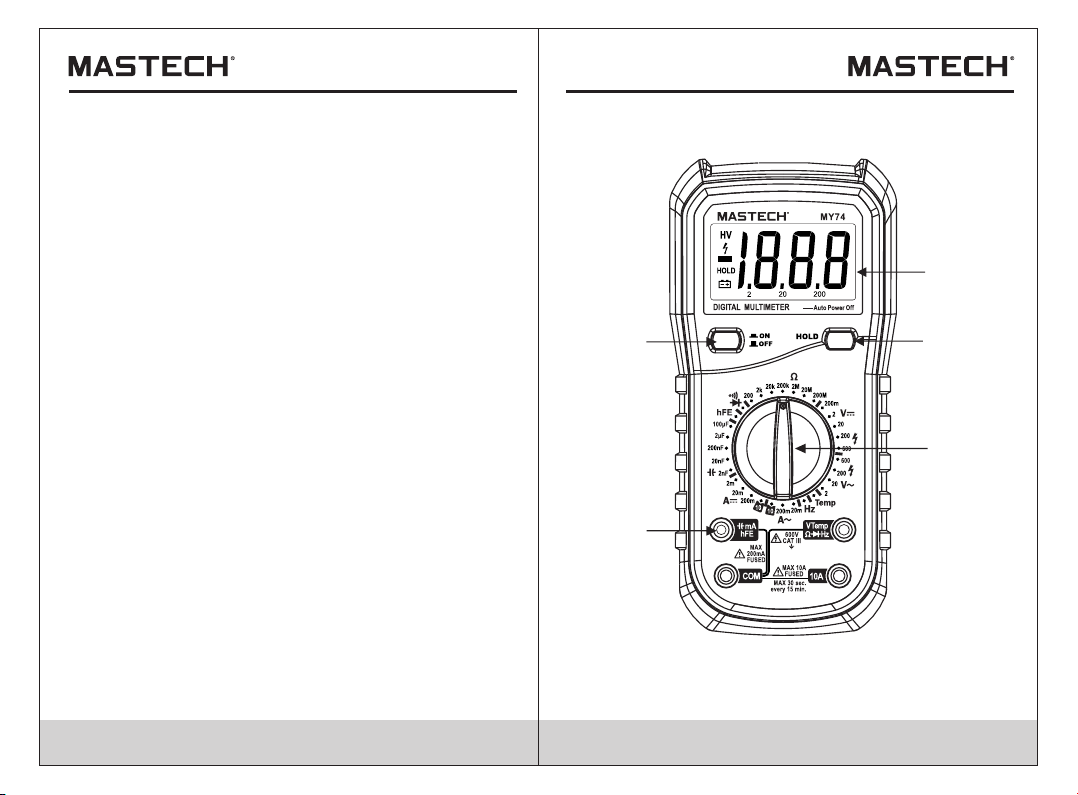

2. Meter appearance description

2.1. Meter appearance

2.2 LCD display

2.3 Input socket

.......

.......................................................8

3. Operating guidance

3.1 General operation

3.1.1 Reading maintenance mode

3.2 Measuring guidance

3.2.1 Measuring AC and DC voltage

3.2.2 Measuring resistance

3.2.3 Testing diode

3.2.4 Audible continuity testing

3.2.5 Measuring capacitance (MY74,MY74B)

3.2.6 Transistor measuring

3.2.7 Measuring frequency (MY74,MY74B)

........................................1

..............................................1

............................................1

..........................................2

.................................................4

...................................5

...............................5

......................6

.............................................6

.................................................7

..........................................9

.............................................9

............................9

........................................9

..........................9

......................................10

.................................................11

...............................12

............12

.....................................13

...............13

3.2.8 Measuring temperature (MY74,MY74B)

3.2.9 Measuring current

4. Technical indicators

4.1. Comprehensive indicators

4.2. Accuracy indicators

4.2.1 DC voltage

4.2.2 AC voltage

4.2.3 Frequency (only for MY74,MY74B)

4.2.4 Resistance

4.2.5 Diode

4.2.6 Audible continuity

4.2.7 Transistor

4.2.8 Capacitance (only for MY74,MY74B)

4.2.9 Temperature (only for MY74,MY74B)

4.2.10 DC current

4.2.11 AC current

.............................................................18

5. Meter maintenance

5.1 General maintenance

5.2 Replace battery and fuse

5.3 Replacing Test L eads

5.4 Cleaning an d Dec ont ami nat ion

6. Accessories

............14

..........................................14

.......................................16

.............................16

........................................17

......................................................17

......................................................17

..................18

.....................................................18

...........................................19

.......................................................19

...............19

...............19

....................................................20

....................................................20

.........................................21

......................................21

................................21

....................................21

.................21

......................................................21

Page 3

1. General instructions

The meter is design ed and manufactured accor ding to

saf ety requi rements of EN/UL /CSA 61010-1, 61010-2-030,

610 10-2-033 on electronic measuring instrument and

han d held digital multipurpose meter. The produc t meets

wit h the requirements of 600 V CAT III and pollution

deg ree 2.

• All saf ety gui delin es outl ined sh ould be f oll ow ed, I f th e

equi pment i s used in a m anner n ot spec ified b y the

manu factu rer, the p rotec tion pr ovide d by the eq uipme nt

may be i mpair ed.

• War ning sy mbols i n the man ual ale rt user s of pote ntial

dang erous s ituat ions.

• Prec autio ns are to p reven t the use r from da magin g the

inst rumen t or the te st obje ct.

WARNING:

The sp ec ial att en tion sh ou ld be pai d wh en usin g th e

mete r be cause t he i mprop er u sage ma y ca use ele ct ric

shoc k an d damag e th e meter . Th e safet y me asure s in

comm on s afety r eg ulati on s and ope ra ting in st ructi on

shou ld b e compl ie d with wh en u sing. I n or der to ma ke

full y us e of its fu nc tions a nd e nsure s af e opera ti ons

plea se c omply w it h the usa ge i n this se ct ion car ef ully.

1.1 Safety information

1.1.1 Safety instructions

* When using this meter, the user should comply with the

following standard safety procedures:

- The safety procedures to prevent electric shock

- The safety procedures to prevent wrong use

* To ensure your safety, please use the test probe provided

with the meter. Before use, please check and make sure

that it is intact.

1.1.2 Safe working habits

* If the meter is used near a source of significant electromagnetic

interference, meter readings will become unstable and have

large errors.

* Don’t use the meter or probe when it is broken.

* If you do not use the meter in accordance with the instructions,

safety functions provided by the meter may become invalid.

* When you work around the bare conductor or bus bar, you

should be extremely careful.

* Do not use the meter near explosive gas, vapor or dust.

* Measure known voltage with meter to verify that the meter is

working properly. If the meter is working abnormally, do not use.

Protective equipment may be damaged. If there is doubt,

the meter should be sent to repair.

* The meter should be used with correct input, function and

measuring range.

* When you can’t determine the size range of signal to be tested,

please switch the measuring range to the maximum position.

* Input value can’t exceed the input limit specified in each

measuring range to prevent damage to the meter.

* When the meter is connected to the circuit being measured,

do not touch the unused input end.

* When the voltage to be tested exceeds 60Vdc or 30Vac

effective value, please operate carefully to prevent electric

shock.

* When you measure with test probe, first connect the common

testing end of black test probe to the common testing end of

circuit to be tested, then connect red test leads to the test

circuit of the test probe to the test end of circuit to be tested.

When the measurement is completed, you should first remove

the red test probe, then remove the black common test probe.

01 02

Page 4

* When use the test probe to measure, you should place your

fingers at the back of retaining ring.

* Before changing the measuring range, you must ensure that

the test probe is not connected to circuit to be tested.

* For all DC functions, including manual or automatic measuring

range, to avoid the risk of electric shock due to possible

incorrect readings, please use AC function to verify the

existence of any AC voltage. Then, select DC voltage

measuring range equal to or greater than the AC measuring

range.

* Before testing resistance, diode, capacitance measurement

or on-off states, you should first cut off power to the circuit

being tested, and discharge all high voltage capacitors.

* Don’t measure resistance or make on-off tests on a live circuit. .

* Before current measurement, you should firstly check the

meter's fuse. Before the meter is connected to the circuit

under testing,you should firstly power off the circuit to be

tested.

* When you make TV repairs or measure power conversion

circuits, you should note the high amplitude voltage pulse

of circuits being tested. The TV filter should be used to

weaken these pulses to avoid the meter damage.

* This meter uses a 9V 6F22 battery. The battery should be

properly installed in the meter’s battery compartment.

* When the battery indicator appears, the battery should be

replaced immediately. Low battery will cause meter reading

errors, and possibly result in electric shock or personal injury

* When you make type III voltage measurement, the voltage

should not exceed 600V; when you make type TV voltage

measurement, the voltage should not exceed 600V.

* When the meter shell (or part of shell) is removed, do not use

the meter.

1.1. 3 Safet y symbo ls

Symbols used on the meter surface and instructions:

Note -Impo rtant s afety i nform ation , refer t o the

inst ructi on manu al.

Caut ion, po ssibi lity of e lectr ic shoc k

Equi pment p rotec ted thr ougho ut by dou ble

insu latio n or rein force d insul ation .

Co nfo r ms to UL STD . 6 101 0 -1, 6 1 010 -2-0 30,

61 010 - 2-0 33; Ce rtif ied to C SA STD. C2 2.2

NO . 6101 0-1 , 6 101 0 -2- 030, 6 1010 -2- 033

Comp lies wi th Euro pean (E U) safe ty

stan dards

Eart h (grou nd) TERMI NAL

Dire ct curr ent

Alter natin g curre nt

MEASUREMENT CATEGORY III is applicable to test

CAT III

and measuring circuits connected to the distribution

part of the building's low-voltage MAINS installation.

03 04

Page 5

1.1.4 Safe maintenance habits

* To open the meter shell or remove the battery cover, you

should first pull out the test probe.

* When performing meter maintenance, you should use

specified replacement parts.* Before opening the meter,

you should disconnect all power supplies and ensure that

you have no static electricity to avoid damaging the meter

components.

* Meter calibration, maintenance, repair and other operations

only can be performed by technicians who fully understand

the meter and electrical shock hazards.

* Before opening the meter, you should be aware that there

may be dangerous voltages remaining in some capacitances

in the meter even after powering off.

* If you find any abnormal phenomena on the meter, the meter

should be immediately turned off and repaired. Ensure that it

can not be used before passing inspection.

* When the meter is not used for a long time, please remove

the battery and avoid storing it in a high temperature and

humidity environment.

1.2 Input protection measures

* When making voltage measurements (not including 200mV

grade), the maximum input voltage is 600V DC or 600V AC.

(The maximum input voltage of 200mV grade is 250V AC or

equivalent RMS value voltage).

* When making frequency, resistance, on-off and diode

measurements, the maximum voltage is 250V AC or

equivalent RMS value voltage.

* When making capacitance, temperature, mA current, and

triode hFE measurements, the meter is protected through

a fuse (FF 400mA H 600V).

2. Meter appearance description

2.1. Meter appearance

2

5

1. LCD(liquid crystal display) 2. Mains Switch

3. HOLD Key 4. Rotary Switch 5. Input Socket

1

3

4

05 06

Page 6

2.2 LCD display

See Table 1 for information about the display.

Fig. 1 Display

Table 1 Display Symbols

Symbols

HV

HOLD

Low battery.

To avoid wrong readings causing

electric shock or personal injury,

when the low battery symbol appears,

the battery should be replaced

immediately.

Negative input polarity indication

High voltage symbol, in AC600V or DC600V.

Keep the current measurement value

Indication

2.3 Input socket

Table 2 Input Socket

Input Socket

All common input ends to be measured are

COM

VΩHz

TEMP

mA,

10A

connected with common output socket of

black test probe or dedicated multifunction

test socket.

Positive input end of voltage, resistance,

frequency, diode, buzzer measurement and

temperature test (connected with the red test

probe).

Positive input end of current mA, temperature

and triode hFE (connected with output socket

of black test probe or dedicated multifunction

test socket).

Positive input end of 10A

(connected with the red test probe).

Description

07 08

Page 7

3. Operating guidance

3.1 General operation

3.1.1 Reading maintenance mode

In reading maintenance mode, the current readings will be

kept on the display. Change the measurement function grade,

or press HOLD key to exit reading maintenance mode.

To enter and exit reading maintenance mode:

1. Press “HOLD” key, the reading will be maintained and

“ ”symbol will display on LCD display simultaneously.

2. Press “HOLD” key again to return the meter to normal

measurement state.

3.1.2 Battery saving energy function

The meter power will disconnect automatically after about

40 minutes, to save battery power.

3.2 Measuring guidance

3.2.1 Measuring AC and DC voltage

WARNING:

To prevent electrical shock and/or meter damage. Don’t

measure any RMS voltage higher than 600V DC or 600V AC

between common end and ground.

Voltage is the potential difference between two points.

AC voltage polarity changes over time, while DC voltage

polarity does not change over time.

DC voltage measuring range of this meter: 200.0mV, 2.000V,

20.00V, 200.0V and 600V; AC voltage measuring range of this

meter: 200mV (only for MY70), 2.000V, 20.00V, 200.0V and 600V.

09 10

To measure AC and DC voltage:

1. Rotate the switch to the appropriate position.

2. Respectively connect black and red test probe to COM input

socket and V input socket.

3. Measure the voltage of circuit to be tested with other two

ends of test probes. (Connected with the circuit to be tested

in parallel)

4. Read the measuring voltage value from LCD display.

When measuring DC voltage, the display will simultaneously

show the voltage polarity which is connected with red test

probe.

• Note:

In the DC 200mV and AC 2V measuring range, the meter will

have a number of displays even without input or connecting

with test probe. In this case, just make a short circuit between

“V-” and “COM”, so that the meter will display zero.

3.2.2 Measuring resistance

WARNING:

To avoid damaging meter or device to be measured, before

measuring resistance, cut off all circuits being tested and

discharge all high voltage capacitors.

Resistance is resistance force of current. The unit of resistance

is ohm ( Ω ).

Resistance range of this meter: 200.0Ω, 2.000kΩ, 20.00kΩ,

200.0kΩ, 2.000MΩ, 20.00MΩ, 200.0 MΩ.

To measure resistance:

1. Rotate switch to the appropriate position.

2. Respectively connect black and red test probe to VΩ input

socket and V input socket.

3. Measure the resistance value of circuit to be tested with

other two ends of test probes.

4. Read the measuring resistance value from LCD display.

Page 8

Here are some tips for measuring resistance:

• The resistance measured on circuit is usually different from

the rated value of resistance. This is because the test current

of the meter will flow through all possible channels between

test probes.

• When measuring low resistance, in order to accurately

measure, make a short circuit between two test probes to

read the resistance value when short circuited. This resistance

value should be subtracted after measuring the resistance to

be tested.

• At grade 20MΩ and 200 MΩ, the reading will be stable after

several seconds. A high resistance measuring is normal.

• When there is no input (for example, in an open circuit),

the display will show “1”, which means that the measured

value is out of range.

3.2.3 Testing diode

WARNING:

To avoid damaging meter or device to be measured, before

measuring diodes, cut off all circuits being tested and

discharge all high voltage capacitors.

To test diode outside circuit:

1. Rotate the switch to position.

2. Respectively connect black and red test probe to COM input

socket and input socket.

3. Respectively connect black and red test probe to negative

pole and positive pole of the diode to be tested.

4. The meter will display the forward bias voltage value of diode

being tested. If the test probe polarity is reversed, the meter

will display “1”.

In a circuit, a good diode should still produce a forward voltage

drop of 0.5V to 0.8V; but the reverse bias voltage will vary

depending on resistance values of other channels between

two test probes.

11 12

3.2.4 Audible continuity testing

WARNING:

To avoid damaging meter or device to be measured, before

testing buzzer continuity, cut off all circuits being tested and

discharge all high voltage capacitors.

To make continuity testing:

1. Rotate the switch to position.

2. Respectively connect black and red test probe to COM input

socket and input socket.

3. Measure the resistance value of circuit to be tested with other

two ends of test probes

4. During on-off testing, if the measured circuit resistance is not

greater than about 50, the buzzer will sound continuously.

3.2.5 Measuring capacitance (MY74, MY74B)

WARNING:

To avoid damaging meter or device to be measured, before

measuring capacitance, cut off all circuits being tested and

discharge all high voltage capacitors. Determine that capacitors

are discharged with DC voltage measurement function.

Capacitance range of this meter: 2.000nF, 20.00nF, 200.0nF,

2.000µF and 100.0µF.

To measure capacitance:

1. Rotate switch to the appropriate position.

2. Respectively connect black and red test probe to COM input

socket and input socket.

3. Measure the capacitance value of circuit to be tested with

other two ends of test probes and read the measuring value

from LCD display.

Here are some tips for measuring capacitance:

• When measuring bulk capacitor with this meter, readings will

stabilize after a few seconds.

Page 9

• To improve the accuracy below 2nF, subtract the distributed

capacitance of meter and cable.

3.2.6 Transistor measuring

WARNING:

To prevent electrical shock and/or meter damage. Don’t apply

any RMS voltage higher than 250V DC or AC between common

end and mA end,

1. Rotate the switch to hFE position.

2. Plug multi-function socket with correct polarity (the “+” end

of multi-function socket is connected with mA end, “COM”

end is connected with common end).

3. Determine that the transistor is NPN or PNP type, then insert

three pins of transistor to the corresponding holes of the

dedicated multi-functional socket

4. Read hFE approximation of transistor to be measured from

LCD display.

3.2.7 Measuring frequency (MY74, MY74B)

WARNING:

To prevent electrical shock and/or meter damage. Don’t

measure the frequency of RMS voltage higher than 250V DC

or AC.

To measure frequency:

1. Rotate the switch to Hz position.

2. Respectively connect black and red test probe to COM

input socket and Hz input socket.

3. Measure the frequency value of circuit to be tested with

other two ends of test probes.

4. Read the measuring frequency value from LCD display.

3.2.8 Measuring temperature (MY74, MY74B)

WARNING:

Don’t measure the surface of object with electric quantity

higher than 60V DC or 24V AC RMS, to prevent electrical

shock. Don’t measure the temperature in a microwave oven

to prevent fire or meter damage.

To measure t emperat ure:

1. Pl ug the red en d of the K-ty pe thermo couple in to the

“ ”jack an d black end i nto the“C OM”jack .

VtempΩ H z

2. Se t the rotar y switch to t he“Temp”p os ition .

3. Touch the su rface of th e object or a rea with th e

temp er ature s en sor for m ea surem en t.

4. Re ad the meas uring val ue from LCD d isplay.

3.2.9 Measuring current

WARNING:

When the ground voltage of open circuit voltage exceeds 250V,

do not try to make current measurements on the circuit. If the

fuse is blown when making a measurement, you may damage

the meter or injure yourself. To avoid damage to meter or

device, before measuring current, please check the meter's

fuse. When measuring, you must use the correct input socket,

function and measuring range. When the test probe is inserted

to the current input socket, don’t connect the other end of the

test probe with any circuit in parallel

Current range of this meter: 20μA/200μA (only for MY70)

2.000mA, 20.00mA, 200.0mA and 10.00A;

13 14

Page 10

To measure current:

1. Cut off the power supply of circuit to be tested. Discharge

all high voltage capacitors on the circuit to be tested.

2. Rotate switch to the appropriate position.

3. Connect the black test probe to the COM input socket.

If the current to be tested is lower than 200mA, connect

the red test probe to the mA input socket. If the measured

current is between the range of 200mA~10A, the red test

probe should be connected to 10A input socket.

4. Cut off the circuit to be tested. The black test probe is

connected to one end of disconnected circuit (low voltage

relatively), and the red test probe is connected to the other

end of disconnected circuit (high voltage relatively).

(Connecting test probe in reverse would make the reading

negative, but the meter won’t be damaged. )

5. Connect the power supply of circuit, then read the display

reading. If the display shows only “1”, the input is out of the

selected input range, therefore please rotate the switch to

a higher measuring range.

6. Cut off the power supply of circuit to be tested. Discharge

all high voltage capacitors. Remove the test probe of meter

and restore the circuit to its original condition.

4. Technical indicators

4.1. Comprehensive indicators

• Operating environment and condition:

600V CAT III pollution grade: 2

Elevation < 2000 m

Environment temperature and humidity:

O

0~40 C (<80% RH, <10°C, it is not to be considered).

Storage temperature and humidity:

O

0~60 C (<70% RH, remove the battery).

• Temperature coefficient: 0.1 Accuracy / C(<18 C or >28 C).

• The maximum allowable voltage between measurement end

and ground: 600V DC or 600V AC RMS

• Fuse protection:

mA grade: Fuse F1 FF 400mA H 600V;

A grade: Fuse F2 FF 10A H 600V.

• Sampling rate: about 3 times/sec.

• Maximum value display:1999. Automatically display unit

symbols in accordance with measurement function grade.

• Over-range indication: LCD will show “1”.

• Low battery indication: When the battery voltage is lower than

the normal operating voltage, “ ”will display on the LCD display.

• Input polarity indication: automatically display “ - ” symbol.

• Power supply: DC 9V

• Battery type: NEDA 1604, 6F22 or 006P.

• Outside measurement: 188 mm(L)×93 mm(W)×50mm(H).

• Weight: about 380g (include battery).

O O O

15 16

Page 11

4.2. Accuracy indicators

Accuracy: ± ( % reading + word) with one year of warranty.

Reference conditions: environmental temperature is from

18 °C to 28 °C, relative humidity is not more than 80%.

4.2.1 DC voltage

Measuring range

200mV

2V

20V

200V

600V

Resolution

0.1mV

1mV

10mV

100mV

1V

±(0.5% of reading + 2digits)

±(0.8% of reading + 2digits)

Input impedance: 10MΩ

Maximum input voltage: 600Vdc or 600Vac RMS, 250Vdc

or ac RMS with the measuring range of 200mV.

4.2.2 AC voltage

Measuring range

200mV

(only for MY70)

2V

20V

200V

600V

Resolution

0.1mV

1mV

10mV

100mV

1V

±(1.2% of reading + 3digits)

±(0.8% of reading + 3digits)

±(1.2% of reading + 3digits)

Input impedance: 10MΩ

Maximum input voltage: 600Vdc or 600V ac RMS, 250Vdc

or ac RMS with the measuring range of 200mV.

Frequency response: 40Hz-400Hz sine wave RMS

(average response)

The frequency response is 200Hz for 600V

Accuracy

Accuracy

4.2.3 Frequency (only for MY74, MY74B)

Measuring range

20kHz

Resolution

10Hz

±(2.0% of reading + 5digits)

Accuracy

Input voltage range: 200mV-10V ac RMS

Overload protection: 250V dc or 250V ac RMS

4.2.4 Resistance

Measuring range

200Ω

2kΩ

20kΩ

200kΩ

2MΩ

20MΩ

200MΩ

Resolution

0.1Ω

1Ω

10Ω

100Ω

1kΩ

10kΩ

100kΩ

±(0.8% of reading + 3digits)

±(0.8% of reading + 2digits)

±(1.0% of reading + 2digits)

±(6.0% of reading + 10digits)

Accuracy

Overload protection: 250V dc or 250V ac RMS

Open circuit voltage: below 700mV

4.2.5 Diode

Function

Diode Test

Measuring range

1V

Resolution Test environment

Test current: about 1mA.

Open circuit voltage:

0.001V

about 2.8V.

Display approximation

of diode forward voltage

drop.

Overload protection: 250V dc or 250V ac RMS

17 18

Page 12

4.2.6 Audible continuity

Function Test environment

Description

When built-in buzzer

sounds, the resistance

to be tested is not more

than 50Ω.

Test current: about 1mA.

Open circuit voltage:

about 2.8V.

4.2.7 Transistor

Measuring

range

hFE

Description

hFE approximation on

the display, (0 -1000)

Test environment

Base current 10μA

Vce is about 2.8V

Overload protection: Fuse (FF 400mA H 600V )

4.2.8 Capacitance (only for MY74, MY74B)

Measuring range

2nF

20nF

200nF

2μF

100μF

Resolution

1pF

10pF

0.1nF

1nF

100nF

±(4.0% of reading + 3digits)

±(6.0% of reading + 10digits)

Accuracy

Overload protection: Fuse (FF 400mA H 600V)

4.2.9 Temperature (only for MY74, MY74B)

Measuring range

-20°C~0°C

1°C~400°C

401°C~1000°C

Resolution

1°C

±(5.0% of reading + 4digits)

±(2.0% of reading + 3digits)

±(2.0% of reading + 5digits)

Accuracy

Temperature indicator does not include thermocouple error.

Overload protection: Fuse (FF 400mA H 600V)

4.2.10 DC current

Measuring range

20μA (for MY70, MY74B)

200μA (only for MY70)

2mA (for MY70, MY74)

20mA

200mA

10A

Resolution

0.01μA

0.1μA

1μA

10μA

0.1mA

10mA

±(2.0% of reading + 5digits)

±(0.8% of reading + 1digits)

±(1.5% of reading + 1digits)

±(2.0% of reading + 5digits)

Accuracy

Overload protection: fuse with measuring range of mA (FF400mA

H 600V); fuse with measuring range of 10A (FF10A H 600V).

Maximum input current: mA grade: 200mA DC or AC RMS;

10A grade: 10A DC or AC RMS

When measured current is greater than 10A, continuous

measurement time should not be more than 10 seconds. Stop the

current being measured after 15 minutes.

4.2.11 AC current

Measuring range

20μA

(for MY70)

200μA

(only for MY70)

2mA

(for MY70, MY74)

20mA

200mA

10A

Resolution

0.01μA

0.1μA

1μA

10μA

0.1mA

10mA

±(2.0% of reading + 5digits)

±(1.0% of reading + 5digits)

±(1.8% of reading + 5digits)

±(3.0% of reading + 7digits)

Accuracy

Overload protection: fuse with measuring range of mA (FF400mA

H 600V); fuse with measuring range of 10A (FF10A H 600V)

Maximum input current: mA grade: 200mA DC or AC RMS; 10A

grade: 10A DC or AC RMS

When measured current is greater than 10A, continuous

measurement time should not be more than 10 seconds. Stop the

current being measured after 15 minutes.

Frequency response: 40Hz-400Hz, sine wave RMS

(average response)

19 20

Page 13

5. Meter maintenance

This section provides basic maintenance information,

including instructions for replacement of fuse and battery.

Do not try to repair the meter unless you are an experienced

maintenance person with the relevant calibration, performance

testing and maintenance data

5.1 General maintenance

WARNING:

To avoid electrical shock or damage to the meter, don’t wet the

inner surfaces of the meter. Before opening shell or battery

cover, you should remove the connecting cable between the

test probe and the input signal.

Regularly clean the meter shell with damp cloth and a small

amount of detergent. Do not use abrasives or chemical solvents.

If you make input socket dirty or wet, it may affect the readings.

To clean input socket:

Turn off the meter, and pull out all test probes from the input

socket.

Remove all dirt from the socket.

Apply detergent or lubricant (such as WD-40) to a new cotton

ball.

Clean each socket with a cotton ball. Lubricant can prevent

contamination related with moisture on the socket.

5.2 Replace battery and fuse

WARNING:

To avoid electrical shock or personal injury, before opening the

battery cover to replace battery, you should turn the meter off

and make sure that the test probe is disconnected from the

measurement circuit.

To avoid wrong readings, electric shock or personal injury, when

“ ”appears on the meter display, replace the battery

immediately.

Use only a fuse with specified amperage, fusing rated value,

voltage rated value and fusing speed (F1:FF 400mA H 600V,

F2:FF 10A H 600V)

Please follow below steps to replace battery or fuse:

1. Turn off the power supply of the meter.

2. Pull out all test probes from the input socket.

3. Loosen two screws on the fixed battery cover with screwdriver.

4. Remove the battery cover.

5. Remove the old battery or damaged fuse.

6. Replace with a new battery with 9V (6F22) or a new fuse.

7. Replace the battery cover and tighten the screws.

5.3 Replacing Test L eads

If ins ul ation o n le ads is da ma ged, re pl ace it.

WARNING:

Use me et E N 61010 -0 31 stan da rd, rat ed C AT III 60 0V,

10A or b et ter tes t le ads.

5.4 Cleaning an d Dec ont ami nat ion

1. The meter can be cleaned with a soft cloth to remove any

oil, grease or grime.

2. Do not use liquid solvent or detergent.

6. Accessories

Test Leads 1set

•

Package 1pcs

•

9V Battery 1pcs

•

User's Manual 1pcs

•

21 22

Page 14

00-05-4176

Loading...

Loading...