Page 1

EN Installation, Operation and Maintenance Instructions

FR Instructions d’installation, d’utilisation et d’entretien

ES Instrucciones de instalación, operación y mantenimiento

Built in Refrigerators

Réfrigérateurs intégrées

Refrigeradores

empotradas

MP15BCG4**

MP15BCF4**

MP24BCG4**

MP24BCF4**

MP24BRG4**

MP24BRF4**

MP24RAS4**

MP24RAP4**

MP24WBG4**

MP24WBF4**

Page 2

CONTENTS

Contents:

Safety information ...............................................................2

Unpacking your appliance ..................................................3

Warranty registration .....................................................3

Installing your appliance ......................................................4

Cabinet clearances .........................................................4

Leveling the appliance ....................................................4

Electrical connection ......................................................5

Product dimensions ............................................................6

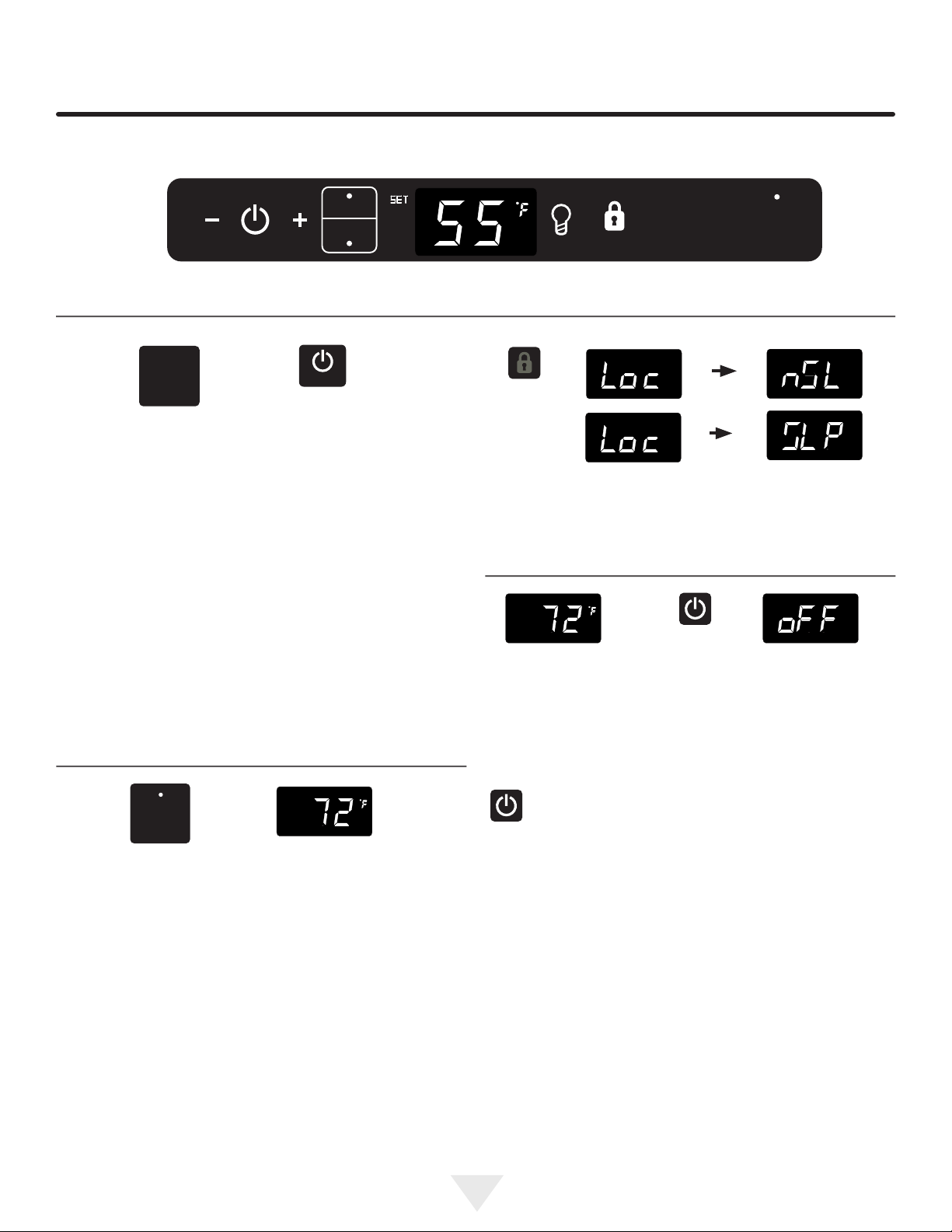

Using your Electronic control .............................................8

Starting your appliance ...................................................8

Sleep mode ....................................................................8

Turning your appliance "ON" or "OFF" ...........................8

Interior display lighting ....................................................9

Adjusting the temperature ..............................................9

Temperature mode ........................................................10

Control lock ...................................................................10

Temperature sensor error codes ...................................10

Alarms ..........................................................................11

Door ajar ...................................................................11

Power failure ............................................................11

Temperature alarm ...................................................11

Vacation mode ..............................................................12

Overlay door panel installation ........................................12

Shelving congurations ....................................................18

Care and cleaning .............................................................21

Energy saving tips .............................................................21

Obtaining service .............................................................22

Troubleshooting ................................................................23

Warranty ...........................................................................24

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situations that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!

CAUTION

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

!

WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!

WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm..

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for occupational health and safety from Lloyd’s Register Quality

Assurance.

2

Page 3

UNPACKING YOUR APPLIANCE

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding internal components in place. The owners manual is shipped

inside the product in a plastic bag along with the warranty

registration card, and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condition. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly.

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your appliance or you

can register online at www.agamarvel.com.

The following information will

be required when registering

your appliance.

Service Number

Serial Number

Date of Purchase

Dealer’s name and address

The service number and serial number can be found on the

serial plate which is located inside the cabinet on the left

side near the top. See gure 1.

Online registration

available at

www.agamarvel.com

!

WARNING

WARNING - Dispose of the plastic bags which can

be a suffocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

NOTE

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

!

CAUTION

XXXXXXXXXXXX

XXXXXXXXXXXX

Figure 1

!

WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous - even if they sit out for "just a few hours".

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

If the appliance was shipped, handled, or stored in other

than an upright position for any period of time, allow the appliance to sit upright for a period of at least 24 hours before

plugging in. This will assure oil returns to the compressor.

Plugging the appliance in immediately may cause damage

to internal parts.

Before you throw away your old refrigerator or

freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

3

Page 4

INSTALLING YOUR APPLIANCE

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the unit will

be out of direct sunlight and away from heat sources. To

ensure your product performs to specications, the recommended installation location temperature range is from 55

to 100°F (13 to 38°C).

Cabinet Clearance

Ventilation is required from the bottom front of the appliance. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the appliance as long as the front grille remains unobstructed. All Marvel Professional models with articulated hinges

are intended for built-in applications only.

!

WARNING

An optional stacking kit, for 24" wide models, is required to stack products. Failure to use a stacking kit

could result in personal injury. Contact your dealer or

Aga Marvel customer service at 800-223-3900 to order.

For safety concerns 15" wide models should not be

stacked.

Front Grille,

keep this area

open.

Front Leveling

Legs

Figure 2

Rear

Leveling

Legs

Leveling Legs

Adjustable legs at the front and rear corners of the appli-

ance should be set so the unit is rmly positioned on the

oor and level from side to side and front to back. The over-

all height of your Marvel appliance may be adjusted higher

(by turning the leveling leg out, CCW) and lower (by turning

the leveling leg in, CW) dimensions as shown in Table "A".

To adjust the leveling legs, place the appliance on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the appliance back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning

the legs. Repeat this process for the rear by tilting the appliance forward using caution. On a level surface check the

appliance for levelness and adjust accordingly.

!

CAUTION

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat exchanger. Restrictions to this air ow will result in increased

energy usage and loss of cooling capacity. For this reason

it is important this area to not be obstructed and the grille

openings kept clean. AGA MARVEL does not recommend

the use of a custom made grille as air ow may be restricted. (See Figure 2).

The front grille screws may be loosened and the grille adjusted to the desired height. When adjustment is complete

tighten the two front grille screws. (See Figure 5).

Model Door Style

MP(15)(24)* (S) or (G)

MP(15)(24)* (F)

Minimum

Height

34"

(86.4 cm)

34"

(86.4 cm)

Table A

Maximum

Height

35"

(88.9 cm)

35"

(88.9 cm)

4

Page 5

INSTALLING YOUR APPLIANCE

!

WARNING

Figure 3

Do not remove

ground prong

Figure 4

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any circumstances, be installed to an un-grounded electrical supply.

• Do not remove the grounding prong from the power

cord. (See Figure 3).

• Do not use an adapter. (See Figure 4).

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable local codes and ordinances (see Figure 6). If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third ground prong should not, under any circumstances, be cut or removed.

Figure 5

Front grille

Front grille screw

Figure 6

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to nuisance tripping which will cause the appliance to shut down.

GFCI’s are generally not used on circuits with power equipment that must run unattended for long periods of time, unless required to meet local building codes and ordinances.

5

Page 6

PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

MODEL "A" "B" "C" "D" "E" "F" "G" "H" "J"

MP15BCG

MP15BCF

MP24**S

MP24**G

MP24**F

15"

(38.1 cm)

15"

(38.1 cm)

24"

(61 cm)

24"

(61 cm)

24"

(61 cm)

DOOR STYLE

(S) Solid Door

(G) Glass Frame Door

(F) Frame Glass Overlay Door (no handle)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

24"

(61 cm)

* 24"

(61 cm)

24"

(61 cm)

24"

(61 cm)

* 24"

(61 cm)

147⁄8"

(37.8 cm)

147⁄8"

(37.8 cm)

237⁄8"

(60.7 cm)

237⁄8"

(60.7 cm)

237⁄8"

(60.7 cm)

34" to 35"

(86.4 to 88.9 cm)

34" to 35"

(86.4 to 88.9 cm)

34" to 35"

(86.4 to 88.9 cm)

34" to 35"

(86.4 to 88.9 cm)

34" to 35"

(86.4 to 88.9 cm)

2323⁄32"

(60.2 cm)

227⁄8"

(58.1 cm)

2323⁄32"

(60.2 cm)

2323⁄32"

(60.2 cm)

227⁄8"

(58.1 cm)

267⁄32"

(66.6 cm)

-

267⁄32"

(66.6 cm)

267⁄32"

(66.6 cm)

-

3713⁄32"

(95 cm)

71⁄2"

(95.2 cm)

4613⁄32"

(117.9 cm)

4613⁄32"

(117.9 cm)

461⁄2"

(118.1 cm)

(44.3 cm)

(35.9 cm)

(67.2 cm)

(67.2 cm)

(58.7 cm)

177⁄16"

141⁄8"

267⁄16"

267⁄16"

231⁄8"

Figure 7a

Figure 8

"B"

"A"

Figure 7

(S) solid door

"C"

"E"

shown

"D"

If necessary to gain clearance inside the rough-in

opening a hole can be cut through the adjacent cabinet and the power cord routed through this hole to a

power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this application as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application, (see Figure 8).

6

Page 7

PRODUCT DATA

MODEL

MP15BCG 115V/60Hz/15A

MP15BCF 115V/60Hz/15A

MP24**S 115V/60Hz/15A

MP24**G 115V/60Hz/15A

MP24**F 115V/60Hz/15A

ELECTRICAL

REQUIREMENTS #

PRODUCT DIMENSIONS

PRODUCT

WEIGHT

105 lbs

(47.6 kg)

105 lbs

(47.6 kg)

140 lbs

(63.6 kg)

140 lbs

(63.6 kg)

140 lbs

(63.6 kg)

"J"

"H"

"G"

"D"

Figure 9

(S) solid door

shown

"E"

31⁄2" (8.9 cm)

Minimum

"F"

211⁄2"

(54.6 cm)

* To install (F) models with the door face ush with adjacent cabinetry doors, custom decorative panel thickness

cannot exceed 3⁄4" (19 mm).

** Minimum rough-in opening required is to be larger than

the adjusted height of the cabinet.

# A grounded 15 amp dedicated circuit is required. Follow

all local building codes when installing electrical and appliance.

7

Page 8

Temp

Minus

keypad

USING YOUR ELECTRONIC CONTROL

Upper/Lower

On/Off

keypad

Temp

Plus

keypad

zones

(Dual Zone

models only)

Display Area

Figure 10

Electronic control

Lights

keypad

Lock

keypad

System Status

indicators

Power Failure

ALARM RESET

Starting your appliance (single and dual

zone):

Plug the appliance power cord into a 115 volt wall outlet.

Your appliance is shipped from the factory in the "On" position and will begin start-up of cooling as soon as power is

supplied. If the appliance does not start, conrm that the

wall outlet has power, and that the control is in the "On"

position, (See "Turning your appliance On and Off" below).

The control display is covered with a clear plastic lm. This

lm may be removed by carefully lifting the lm at a corner.

On initial power up, the control display will indicate a

"Power Failure" alarm. This is a normal condition as the appliance was powered-up at the factory for quality inspection

and then removed from power. A momentary press of the

"On/Off" keypad will reset this alarm condition. (See Alarms

section on page 11).

The sleep mode can be disabled if you prefer to have the

display on continuously. Press and hold the "Lock" keypad until the display goes past "Loc" and reads "nSL". To

enable the sleep mode, repeat the instruction, again going

past "Loc" until the display reads "SLP".

Turning your appliance ON and OFF (single

and dual zone):

If the appliance is "On", (and out of sleep mode) the temperature will be shown in the display area of the control.

To turn the appliance "Off", press and hold the "On/Off"

keypad for 4-seconds. "OFF" will now be displayed on the

control.

Sleep mode (single and dual zone):

If no keypads are pressed for 60 seconds, the display will

enter sleep mode to conserve power. The control panel will

go dark with the exception of the system status "OK" indicator which will remain enabled. Alarm conditions will wake

the display, (see alarms on page 11).

To make the following changes to the control settings

(turning the appliance ON/OFF, adjusting the temperature, changing the interior lights, and activating vacation mode), the control must be awake.

To wake the display press any keypad. A conrm tone will

sound, and the current storage compartment temperature

will be displayed.

To turn the appliance "On", press and hold the "On/Off"

keypad for 4-seconds.

8

Page 9

USING YOUR ELECTRONIC CONTROL

Interior Lighting:

Display lighting :

Display lighting is intended for glass door models only, to

illuminate the interior with the door closed.

With the control out of sleep mode press the "Light" keypad

once to activate the interior lighting display feature at full

illumination. A conrmation tone will sound, and the light

bulb "Icon" will illuminate. Pressing the "Light" keypad a

2nd time will dim the lighting to 50%. A 3rd press will deactivate the display lighting feature. The display lighting will

automatically deactivate after 4-hours.

If you have a solid door/drawer product the display lighting

function is only used to select the color of the interior light.

Changing the Tri-Color lighting:

To change the color between white, amber, or blue, with the

control out of sleep mode, momentarily press the "Light"

keypad. The keypad will illuminate. Then press and hold

the keypad for approximately 3 seconds the interior light

will start to cycle through the 3 available colors. On solid

door/drawer product this will need to be done with the door/

drawer open to be able to observe the colors. Release the

keypad when the desired color is on, and your interior light

will be changed to that color. After selection of color for

solid door/drawer product, the display light feature should

be turned-off, ("Light" keypad not illuminated).

Factors that affect the storage compartment stabilized

temperature:

• Changes to temperature setting.

• Room temperature changes.

• Temperature of stored contents.

- Loading warm contents.

- Cold content load will delay the change to a warmer

set-point temperature.

- Warm content load will delay the change to a colder

set-point temperature.

• Usage, (number and duration of the door openings).

• Use of the storage compartment display lighting, (glass

door product only).

• Installation of the appliance in direct sunlight or next to

a heat source.

Single Zone Models:

To set or check the set-point temperature (with the control

out of sleep mode), press the "-" or "+" keypads. "SET" will

be indicated on the user interface panel and the current

set-point temperature will display and ash. Subsequent

presses of the "-" or "+" keypads will adjust the temperature

colder or warmer respectively. When you have reached

your desired set-point temperature, press the "On/Off" keypad to accept, or do nothing and the "Set" mode will timeout in 10-seconds accepting the displayed temperature as

the new set-point.

Adjusting the Temperature:

NOTE

When initially loading your product with warm contents, it

may take up to 48-hours for the storage compartment temperature to stabilize.

When making temperature set-point changes, it may take

up to 24-hours for the stored contents to stabilize at your

new set-point temperature.

The available set-point temperature range for your appliance is 34°F (1.2°C) to 42°F (5.7°C). If you attempt to

adjust the temperature outside of this range you will receive

an audible notication.

Lower zone

selected

Upper zone

selected

Dual Zone Models:

Temperatures can be set for each individual zone (upper

and lower) in the dual zone wine / beverage center. To

do so you must rst select the zone you want to set the

temperature for. You do so by pressing the upper or lower

button on the display. When pressed the LED light will be

illuminated for the respective display.

9

Page 10

USING YOUR ELECTRONIC CONTROL

To change the set temperature for a particular zone, with

the zone selected and out of sleep mode, press the "-" or

"+" keypads. "SET" will be indicated on the user interface

panel and the current set-point temperature will display

and ash. Subsequent presses of the "-" or "+" keypads

will adjust the temperature colder or warmer respectively.

When you have reached your desired set-point temperature, press the "On/Off" keypad to accept, or do nothing

and the "Set" mode will time-out in 10-seconds accepting

the displayed temperature as the new set-point.

The available set-point temperature range for your appliance is 34°F (1.2°C) to 42°F (5.7°C) for the lower zone

and 45°F (7°C) to 60°F (16°C) for the upper zone. If you

attempt to adjust the temperature outside of these ranges

you will receive an audible notication.

Temperature mode:

The temperature mode is preset from the factory in Fahrenheit (°F) but you have the option to change it to Centigrade

(°C). To change the mode, press and hold the "-" keypad,

while pressing the "+" keypad, then release the "-" keypad.

The temperature will now be displayed in Centigrade (°C).

Repeat the procedure to change the temperature mode

back to Fahrenheit (°F).

NOTE

The upper zone is designed exclusively for the storage of

wine. The upper zone cannot attain storage temperatures

suitable for fresh food storage.

Temperature Sensor Error Codes

The temperature sensors are monitored continuously. Any

OPEN or SHORTED circuit condition will initiate an

ERROR CODE as listed below:

Single Zone Models:

Temperature Sensor Error Codes

Sensor Displayed Code Error Description Action to Take

Single Zone

Temperature Sensor

Defrost Sensor

Dual Zone Models:

Failed temperature sensor in the single

zone compartment. Can lead to unwant-

ed wine storage temperatures.

Failed defrost temperature sensor.

Causes unit to not defrost properly and

can create large frost build-up. Can lead

to water damage to the unit and sur-

Control lock:

The control panel can be locked to avoid unintentional

changes. To lock the control, press and hold the "Lock" keypad until the display reads "Loc" then immediately release

your nger from the keypad. The lock icon will ash 3-times

and then continuously illuminate. When the control panel is

locked, only the Lock keypad, System Status OK indicator

, and the Alarm indicator are active. To un-lock the control

panel, repeat this instruction until the display reads "nLc",

then immediately release your nger from the keypad.

Call service to have the tem-

perature sensor replaced.

Unplug the power cord imme-

diately and call service to have

the defrost sensor replaced.

rounding oor.

Temperature Sensor Error Codes

Sensor Displayed Code Error Description Action to Take

Upper Zone

Temperature Sensor

Lower Zone

Temperature Sensor

Defrost Sensor

Failed temperature sensor in the upper

zone compartment. Can lead to unwant-

ed wine storage temperatures.

Failed temperature sensor in the lower

zone compartment. Can lead to unwant-

ed wine storage temperatures.

Failed defrost temperature sensor.

Causes unit to not defrost properly and

can create large frost build-up. Can lead

to water damage to the unit and sur-

rounding oor.

Call service to have the tem-

perature sensor replaced.

Call service to have the tem-

perature sensor replaced.

Unplug the power cord imme-

diately and call service to have

the defrost sensor replaced.

10

Page 11

USING YOUR ELECTRONIC CONTROL

NOTE

If the control lock is active (illuminated lock icon) the control

will have to be unlocked before using the keypad to reset

an alarm condition. See page 10 (Control Lock) for instructions for unlocking the control.

Alarms (single and dual zone):

The control will alert you to conditions that could adversely

affect the performance of the appliance.

Door Ajar

ALARM RESET

• Door ajar - If the door is open, or not closed prop-

erly, for more than 5-minutes the System Status OK

indicator will turn-off, the "Door Ajar" indicator will ash,

and a tone will sound every 60 seconds. Additionally,

an "ALARM RESET" indicator will be displayed below

the "On/Off" keypad.

NOTE

Temp

ALARM RESET

• Temperature alarm - If the storage compart-

ment temperature deviates excessively from your

set-point temperature for an extended period of time,

the "TEMP" indicator will ash, and an audible tone

will sound every 60 seconds. Additionally, an "ALARM

RESET" indicator will be displayed below the "ON/

OFF" keypad.

NOTE

After a high temperature alarm condition, check all perishables to ensure they are safe for consumption.

NOTE

The temperature alarm may occur as a result of high usage

or introduction of warm contents to the storage compartment. If the temperature alarm continues to occur, your unit

may require service.

The audible alarm can be muted, for each occurrence,

by pressing the lock keypad.

This alarm condition can be reset by closing the door or

momentarily pressing the "On/Off" keypad, (i.e.-if you

are cleaning the storage compartment, etc.). The alarm

will recur in 5-minutes if the alarm condition persists.

Power Failure

ALARM RESET

• Power failure - If power to the appliance is inter-

rupted the System Status indicator will turn-off and

the "Power Failure" indicator will ash. Additionally, an

"ALARM RESET" indicator will be displayed below the

"On/Off" keypad. No audible tone will sound. This alarm

condition can be reset by momentarily pressing the

"On/Off" keypad. If this alarm occurs, it is recommended that you check the condition of any perishables,

even if the appliance is operating normally and the temperature has recovered, as prolonged power outages

could result in excessive temperature excursions which

may spoil perishables.

NOTE

The audible alarm can be muted, for each occurrence, by

pressing the lock keypad.

This alarm condition can be reset by momentarily pressing

the "On/Off" keypad. If this alarm occurs it is recommended

that you check the condition of your stored contents, even

though the appliance is operating normally and the temperature has recovered, as prolonged temperature excursions

could spoil perishables.

Door Ajar

NOTE

Multiple alarms are possible, i.e.- "Door Ajar" for a prolonged period may trigger a "Temp" alarm, in which case

both "Door Ajar" and "Temp" indicators will activate.

Temp

11

Page 12

OVERLAY DOOR PANEL INSTALLATION

Vacation mode (single and dual zone):

This operating mode can be used to save energy during

high cost energy periods, or when you won't be using your

appliance for an extended period of time by disabling the

lights, alarm tones, and keypad entry tones. Vacation mode

also serves as a Sabbath mode, disabling functions and

its controls in accordance with the weekly Sabbath and

religious holidays observed within the Orthodox Jewish

community. When used as Sabbath mode, you may open

or close the door at any time to access contents without

concern of directly turning on or off any lights, digital readouts, solenoids, fans, valves, compressor, icons, tones, or

alarms.

When activated, the display, alarm indicators and tones,

keypad touch tones, interior lights, and all options are disabled. All keypad functions are disabled, with the exception

of the "On/Off" keypad which is required to exit Vacationmode. Storage compartment temperatures are monitored

and controlled at the settings prior to entering Vacation

mode.

Overlay door panel installation:

If you purchased an overlay panel model, your unit is

equipped with articulated hinges to allow fully integrated

built-in installations. Custom panel thicknesses of 5⁄8" (15

mm) and 3⁄4" (18 mm) are accommodated.

!

CAUTION

It is important to use the factory provided grille that came

with the product to assure proper air ow is maintained

through the condenser. The use of a custom grille is not

recommended and will void the warranty.

!

WARNING

Overlay panel models are designed for use with builtin installations only. Use in freestanding installations

could result in personal injury.

To enter Vacation Mode (with the control out of sleep

mode), press and hold the "On/Off" keypad until the display

goes past "OFF" and reads "VAC". The display will ash

"VAC" 3-times to acknowledge your request, then will

display "VAC" continuously until Vacation mode is exited.

A power outage will not exit Vacation mode, exiting can

only be accomplished manually. To exit Vacation mode and

return to normal operation, press and hold the "On/Off"

keypad until the control displays the temperature.

Step 1: Removing the Door

With a phillips screwdriver remove the screw and "P" clamp

from the bottom of the door near the hinge. See Figure 11b.

Disconnect the door wire harness by pressing and holding

down the locking tab on the wire connector and pulling the

connector apart. See Figure 12.

Open the door and loosen the screws holding the hinges to

the cabinet (2 at the top and 2 at the bottom hinge). Do not

remove the screws but loosen them enough so the hinges

can be slipped off of the screws when sliding the door to

the side.

!

WARNING

The articulated hinges have many pinch points. Carefully close / collapse the hinges as soon as the door is

removed from the cabinet.

With a helper, and being careful not to scratch the cabinet

or the door, slide the door to the side about 1⁄2 inch and

remove the hinges and door from the unit.

12

Page 13

OVERLAY DOOR PANEL INSTALLATION

!

WARNING

Use extreme caution with the articulated hinges. The

hinge is self closing and many pinch points exist prior

to built-in installation. Do not remove the cabinet "Z"

bracket from the top of the cabinet.

Press and hold this down

this tab on the wire connector and pull the connector

apart.

Step 2: Remove the door gasket

With the door laying on a at surface and starting at a

corner of the door remove the magnetic door gasket from

the interior side of the door, see Figure 13. Set the gasket

aside on a at surface.

There are 10 holes in the gasket retainer extrusions, (3 on

each side and 2 at the top and bottom which are used to

fasten the panel to the front of the door. The screws are

provided in the literature pack along with the door lock,

which is provided on certain models.

Loosen (do not remove ) these

2 phillips head screws on the

top and bottom hinges

Figure 11a

Cabinet

"Z" Bracket

Figure 12

Holes in

gasket

retainer.

Figure 13a

Overlay panel

ush with top

and side of

door.

Overlay panel to

be centered on

width of door.

Figure 11

"P" clamp

and screw

Figure 11b

Bottom of

door

Wire connector

see Figure 12

Magnetic Gasket

remove starting at a

corner, grasp and pull

away from the door.

Figure 13

Step 3: Cut and drill the overlay panel

Depending on your model cut the overlay door panel to the

dimensions shown in Figures 14 to 21. The window cut out

is for glass door models only. If your appliance has a lock

also drill the lock hole in the panel, see Figure 22.

13

Page 14

Clearance for

screw head,

4 places

OVERLAY DOOR PANEL INSTALLATION

!

CAUTION

Weight of overlay door panel must not

exceed 15 pounds (6.8 kg) for a solid

door model or 10 pounds (4.5 kg) for a

glass door model.

Clearance

for hinge

2 places

Top of door

Clearance

for hinge

2 places

1" (25.4 mm) diameter

counter bore 1⁄4" (6.4mm)

deep 4 places.

327⁄32"

(9.7 cm)

31⁄8"

(7.9 cm)

Minimum

15⁄32"

(2.9 cm)

41⁄8"

(10.5 cm)

Minimum

Hinge side of door

Figure 14

Left Hand Hinged Door

15" (38.1 cm) wide appliance

143⁄4"

(37.5 cm)

5"

(12.7 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

This side

facing interior

47⁄8"

(12.4 cm)

1

31⁄8"

(7.9 cm)

31⁄8"

(7.9 cm)

Minimum

⁄4" (6 mm)

Deep

13⁄4"

(4.4 cm)

3011⁄32"

(77.1 cm)

Figure 16

Right Hand Hinged Door

15" (38.1 cm) wide appliance

1

⁄4" (6 mm)

13⁄4"

(4.4 cm)

3011⁄32"

(77.1 cm)

Deep

31⁄8"

(7.9 cm)

31⁄8"

(7.9 cm)

Minimum

(37.5 cm)

47⁄8"

(12.4 cm)

This side

facing interior

143⁄4"

5"

(12.7 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

Hinge side of door

Clearance for

screw head,

4 places

1" (25.4 mm) diameter

counter bore 1⁄4" (6 mm)

deep 6 places.

327⁄32"

(9.7 cm)

31⁄8"

(7.9 cm)

Minimum

15⁄32"

(2.9 cm)

11⁄2"

111⁄16"

(4.3 cm)

(3.8 cm)

typical

Figure 15

Left Hand Hinged Door

15" (38.1 cm) Wide Appliance

311⁄16"

(9.4 cm)

2"

(5.1 cm)

14

2"

(5.1 cm)

311⁄16"

(9.4 cm)

11⁄2"

(3.8 cm)

typical

111⁄16"

(4.3 cm)

Figure 17

Right Hand Hinged Door

15" (38.1 cm) wide appliance

41⁄8"

(10.5 cm)

Minimum

Page 15

OVERLAY DOOR PANEL INSTALLATION

Clearance for

screw head,

4 places

Top of door

24" (61 cm) wide appliance

233⁄4"

(60.3 cm)

Clearance

for hinge

at top and

bottom

Hinge side of door

Figure 18

Left Hand Hinged Door

1

⁄4"

(6 mm)

Deep

Clearance

for hinge

Top of door

at top and

bottom

Hinge side of door

Figure 20

Right Hand Hinged Door

24" (61 cm) wide appliance

233⁄4"

1

⁄4"

(6 mm)

Deep

(60.3 cm)

Clearance for

screw head,

4 places

31⁄8"

(7.9 cm)

15⁄32"

(2.9 cm)

111⁄16"

(4.3 cm)

11⁄2"

(3.8 cm)

typical

47⁄8"

(12.4 cm)

14"

(35.6 cm)

13⁄16"

(3 cm)

327⁄32"

(9.8 cm)

1

⁄4" (6 mm)

radius is

permissible

31⁄8"

(7.9 cm)

This side

to door

41⁄8"

(10.5 cm)

1" (2.5 cm) diameter

x 1⁄4" (6 mm) deep

4 places

Figure 19

Left Hand Hinged Door

24" (61 cm) wide appliance

(4.4 cm)

31⁄8"

(7.9 cm)

311⁄16"

(9.4 cm)

13⁄4"

(5.1 cm)

3011⁄32"

(77.1 cm)

2"

15

(4.4 cm)

31⁄8"

(7.9 cm)

3011⁄32"

(77.1 cm)

2"

(5.1 cm)

13⁄4"

31⁄8"

(7.9 cm)

311⁄16"

(9.4 cm)

14"

(35.6 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

327⁄32"

(9.8 cm)

(12.4 cm)

radius is

permissible

This side

to door

41⁄8"

(10.5 cm)

1" (2.5 cm) diameter

x 1⁄4" (6 mm) deep

4 places

Figure 21

Right Hand Hinged Door

24" (61 cm) wide appliance

47⁄8"

31⁄8"

(7.9 cm)

15⁄32"

(2.9 cm)

111⁄16"

(4.3 cm)

11⁄2"

(3.8 cm)

typical

Page 16

!

CAUTION

OVERLAY DOOR PANEL INSTALLATION

Weight of overlay door panel must not exceed 15

pounds (6.8 kg) for a solid door model or 10 pounds

(4.5 kg) for a glass door model.

Material Type #10 Wood Screw

Hardwood

Softwood

1

⁄8" (3.2 mm) Diameter. Pilot Hole

7

⁄64 (2.8 mm) Diameter. Pilot Hole

Table B

Step 4: Assemble the panel to the door

The preferred method of attaching the panel to the door

is to clamp the panel to the door so it cannot move while

drilling the screw pilot holes. Use bar clamps or "C" clamps

with pads on the clamping surfaces that will not mar the

panel or the door. The custom overlay panel should be

ush with the top of the door and centered along the width

of the door. See Figure 13a. Drill holes through the gasket

extrusion using the 10 holes as pilot holes. Use the drill

size from the chart in Table "B", being careful not to drill

through the front surface of the panel. If the overlay panel is

thinner than 5⁄8" (16 mm) thick shorter screws will have to be

obtained. Fasten the panel to the door with the 10 screws

provided in the literature pack. (See Figure 22a). Remove

the clamps and replace the gasket in the gasket extrusion

channels of the door. Some force may be required to seat

the gasket into the channels. Be sure the gasket corners

are seated properly.

#10 x 1⁄2"

screw

17

⁄32"

(13.7 mm)

Counter bore

lock hole

on back side.

Figure 22a

31⁄2"

(89 mm)

1

⁄2" (13 mm) diameter drill

through door panel, from

other side (see detail

above) 13⁄16" (20.5 mm)

counter bore, 7⁄16" (11 mm)

deep.

16

Hinge side of door

Figure 22

Page 17

OVERLAY DOOR PANEL INSTALLATION

Step 5: Assemble lock parts

Two (2) lock extensions are provided with the lock. Use the

longer extension for 3⁄4" thick overlay panels and the shorter

one for 5⁄8" thick overlay panels. Assemble the lock exten-

sion, cam stop washer, spring washer, and set screw to the

lock as shown in Figure 23 and 24.

Install this lock assembly into the lock hole in the overlay

panel and secure with the retaining nut on the back side

with a 15 mm socket and ratchet. Make sure the key slot in

the front of the lock is vertical.

BRASS EXTENSION

SPRING WASHER

NUT

LOCK

1/2 HOLE

13/16 COUNTER

BORE 7/16 DEEP

CAM

PHILLIPS SCREW

Step 7: Install the door

Carefully open the top and bottom hinges on the door being

careful as there are many pinch points. Place the hinges

over the 4 screws in the cabinet, 2 at the top and 2 at the

bottom and slide the door into position. Tighten the 4 hinge

screws with a phillips screwdriver. (See Figures 11 and

11a). Place wire harness from the grille and mount to the

bottom of the door with the screw and "P" clamp removed

in step 1. (See Figure 11b). Reconnect the wire harness,

(See Figure 12).

Step 8: Secure the cabinet

Use the #8 x 3⁄4" black screws from the literature pack to

secure the counter top to the cabinet top through the holes

in the cabinet "Z" bracket.

INNER

3/4 INCH

WOOD PANEL

SECTION A-A

SCALE 1 : 1

DOOR

Figure 23

Step 6: Install lock cam

Attach the lock cam to the back of the lock assembly with

the phillips head screw provided. Orient the lock cam vertically when installing on the lock.

Screw

Brass

extension

(2 lengths

provided)

Key

Retainer

nut

Spring

washer

Lock

Cam

Cam stop

washer

Figure 24

Set screw

Cabinet

"Z" bracket

#8 x 3⁄4" black

screws

(3 places)

Figure 25

17

Page 18

SHELVING CONFIGURATIONS

Loading Tips and Suggestions

Your appliance is equipped with a cantilever shelf system

which provides maximum adjust ability and customizing of

the shelving arrangements listed below.

Figure 26

Beverage Center:

15" (38.1 cm) Wide Models:

Shown with a glass door. Figure 26.

(2) glide out wine convertible glass shelf (See

Figure 31).

Beverage Center:

Figure 27

24" (61 cm) Wide Models:

Shown with a glass overlay door. Figure 27.

(2) glide out wine convertible glass shelf. (See Figure 32).

(1) Five bottle rollout display rack with vibration dampening

mat (See Figure 33).

Refrigerator:

Figure 28

24" (61 cm) Wide Models:

Shown with a solid door with door racks. Figure 28.

(1) half width metal cantilever shelf

(See Figure 36).

(1) full width slide out cantilever metal shelf.

(See Figure 35).

(1) frame and at glass crisper cover.

(1) roll-out crisper pan.

(1) full width door storage rack.

(1) half width door storage rack.

Beverage Refrigerator:

Figure 29

24" (61 cm) Wide Models:

Shown with a glass door. Figure 29.

(1) half width at glass cantilever shelf. (See Figure 34).

(1) wine cutout and at glass cantilever shelf.

(See Figure 32).

(1) frame and at glass crisper cover.

(1) roll-out crisper pan

Dual Zone Wine / Beverage Center

24" (61 cm) Wide Models:

Upper Zone:

(1) Seven bottle rollout wine display rack with

vibration dampening mat. (See gure 37).

Lower Zone:

(1) Four bottle rollout wine shelf with glass and

vibration dampening mat. (See gure 39).

(1) Three quarter wide rollout glass shelf and

frame. (See gure 38).

Figure 30

18

Page 19

SHELVING CONFIGURATIONS

Figure 31

glide out wine

convertible glass shelf

Figure 36

half width metal cantilever

shelf

Wine shelf

underneath glass

Figure 32

Wine cutout and at glass shelf with

vibration dampening mat, the glass

can be removed for wine storage.

Figure 34

Frame and at glass shelf

with trim

Figure 37

Figure 33

5 bottle rollout display

rack with vibration

dampening mat

Figure 38

Figure 35

Slide out metal cantilever shelf

Figure 39

19

Page 20

Installed shelf

tang

Rear tang

(hook) on

shelf

SHELVING CONFIGURATIONS

Tall bottle

storage area

Shelf support

slot

Door storage racks

Figure 41

To remove the crisper :

Pull out until it stops. Lift up on the

front of the pan, and remove it from

the frame.

Figure 40a

Tall bottle

storage

area

Figure 40

To Add or Remove a Shelf

Remove stored product from the shelf. Do not try to remove

a loaded shelf from the appliance. Grasp the shelf front with

both hands, rotate the front upward and lift out. (See Figure

40b). To install a shelf insert the shelf in the appliance and

insert the top hooks into the shelf support slots and drop

the shelf down so the hooks drop over the bottom of the

slots.

Figure 40b

Grasp the shelf by the front with

both hands and rotate the front

of the shelf up, then lift the shelf

up and remove the shelf from the

shelf ladders.

!

CAUTION

Make sure your cantilever shelf is secure on the shelf

supports by pressing down on the shelf before loading the

shelf.

!

CAUTION

Never try to move a loaded shelf, remove everything from

the shelf before moving. Use both hands when moving a

shelf.

20

Page 21

CARE AND CLEANING AND ENERGY SAVING TIPS

Front Grille

Be sure that nothing obstructs the required air ow openings in front of the cabinet. At least once or twice a year,

brush or vacuum lint and dirt from the front grille area (see

page 4).

!

CAUTION

SHOCK HAZARD: Disconnect electrical power from the

appliance before cleaning with soap and water.

Cabinet

The painted cabinet can be washed with either a mild soap

and water and thoroughly rinsed with clear water. NEVER

use abrasive scouring cleaners.

Interior

Wash interior compartment with mild soap and water. Do

NOT use an abrasive cleaner, solvent, polish cleaner or

undiluted detergent.

Care of Appliance

1. Avoid leaning on the door, you may bend the door

hinges or tip the appliance.

2. Exercise caution when sweeping, vacuuming or mopping near the front of the appliance. Damage to the

grille can occur.

3. Periodically clean the interior of the appliance as

needed.

4. Periodically check and/or clean the front grille as

needed.

In the Event of a Power Failure

If a power failure occurs, try to correct it as soon as possible. Minimize the number of door openings while the

power is off so as not to adversely affect the appliance's

temperature.

The following suggestions will minimize the

cost of operating your refrigeration appliance.

1. Do not install your appliance next to a hot appliance

(cooker, dishwasher, etc.), heating air duct, or other

heat sources.

2. Install product out of direct sunlight.

3. Ensure the front grille vents at front of appliance beneath door are not obstructed and kept clean to allow

ventilation for the refrigeration system to expel heat.

4. Plug your appliance into a dedicated power circuit. (Not

shared with other appliances).

5. When initially loading your new product, or whenever

large quantities of warm contents are placed within

refrigerated storage compartment, minimize door

openings for the next 12 hours to allow contents to pull

down to compartment set temperature.

6. Maintaining a relatively full storage compartment will

require less appliance run time than an empty compartment.

7. Ensure door closing is not obstructed by contents

stored in your appliance.

8. Allow hot items to reach room temperature before placing in product.

9. Minimize door openings and duration of door openings.

10. Use the warmest temperature control set temperature

that meets your personal preference and provides the

proper storage for your stored contents.

11. When on vacation or away from home for extended pe-

riods, set the appliance to warmest acceptable tem perature for the stored contents.

12. Set the control to the “off” position if cleaning the

appliance requires the door to be open for an extended

period of time.

13. For wine storage products:

When serving temperatures are not required,

return the compartment(s) set temperature to the

ideal red and white wine long term storage tem perature of 13°C / 55°F.

Light assembly replacement

All models use an LED to illuminate the interior of the appliance. This component is very reliable, but should it fail,

contact a qualied service technician for replacement of the

LED.

21

Page 22

OBTAINING SERVICE

If Service is Required:

• If the product is within the rst year warranty period

please contact your dealer or call AGA MARVEL Customer Service at 800.223.3900 for directions on how to

obtain warranty coverage in your area.

• If the product is outside the rst year warranty period,

AGA MARVEL Customer Service can provide recommendations of service centers in your area. A listing

of authorized service centers is also available at www.

agamarvel.com under the service and support section.

• In all correspondence regarding service, be sure to

give the service number, serial number, and proof of

purchase.

• Try to have information or description of nature of the

problem, how long the appliance has been running, the

room temperature, and any additional information that

may be helpful in quickly solving the problem.

• Table "C" is provided for recording pertinent information

regarding your product for future reference.

For Your Records

Date of Purchase

Dealer’s name

Dealer’s Address

Dealer’s City

Dealer’s State

Dealer’s Zip Code

Appliance Serial Number

Appliance Service Number

Date Warranty Card Sent (Must

be within 10 days of purchase).

Table C

22

Page 23

TROUBLESHOOTING

Before You Call for Service

If the appliance appears to be malfunctioning, read through

this manual rst. If the problem persists, check the troubleshooting guide below. Locate the problem in the guide and

refer to the cause and its remedy before calling for service.

The problem may be something very simple that can be

solved without a service call. However, it may be required

to contact your dealer or a qualied service technician.

!

WARNING

Electrocution Hazard

• Never attempt to repair or perform maintenance on

the appliance until the main electrical power has been

disconnected. Turning the appliance control "OFF"

does not remove electrical power from the units wiring.

• Replace all parts and panels before operating.

!

CAUTION

In the unlikely event you lose cooling in your unit, do not

unplug the product from the electric supply, but do call

a qualied service technician immediately. It is possible

that the loss of cooling capacity is a result of excessive

frost build-up on the evaporator cooling coil. In this case,

removing power to the unit will result in the melting of this

excessive quantity of ice, which could generate melt water

that exceeds the capacity of the defrost drain system and

could result in water damage to your home. The end-user

will be ultimately responsible for any water damage caused

by prematurely turning the unit off without appropriately

managing the excess water run-off.

Problem Possible Cause Remedy

Appliance not cold enough

(See “Adjusting the temperature" on

page 9)

Appliance too cold

(See “Adjusting the Temperature” on

page 9)

No interior light. • Failed LED light assembly or light

Light will not go out when door is

closed

Noise or Vibration • Appliance not level

Appliance will not run. • Appliance turned off

• Control set too warm

• Content temperature not stabilized.

• Excessive usage or prolonged

door openings.

• Airow to front grille blocked.

• Door gasket not sealing properly.

• Control set too cold

• Door gasket not sealing properly.

switch.

• Display light is turned on. (Glass

door models only.

• Door not activating light switch.

• Failed light switch

• Fan hitting tube obstruction.

• Power cord not plugged in.

• No power at outlet.

• Adjust temperature colder. Allow 24 hours for temperature to

stabilize.

• Allow temperature to stabilize for

at least 24 hours.

• Airow must not be obstructed to

front grille. See “clearances” on

page 4.

• Check door alignment and/or

replace door gasket.

• Adjust temperature warmer.

Allow 24 hours for temperature to

stabilize.

• Check door alignment and/or

replace door gasket.

• Contact a qualied service technician.

• Turn off display light, shut door.

• Appliance not level, level appliance, (See page 4, “leveling legs”)

• Contact a qualied service technician.

• Level appliance, see “Leveling

Legs” on page 4.

• Contact a qualied service technician.

• Turn appliance on. See “Starting

your appliance” on page 8.

• Plug in power cord.

• Check house circuit.

23

Page 24

HOUSEHOLD PRODUCT WARRANTY

Entire Product

Limited One Year Parts and Labor Warranty

AGA MARVEL warrants that it will supply all necessary

parts and labor to repair or replace in the end user’s home

or ofce, any component which proves to be defective

in material or workmanship, subject to the condition and

exclusions stated below, for a period of one year from the

date of purchase by the end user.

Additional Second Through Fifth Year

Limited Parts Only Warranty

During the four years following expiration of the one year

limited warranty, AGA MARVEL will supply replacement

parts for the hermetically sealed refrigeration system which

consists of the compressor, condenser, drier, accumulator,

bypass valve, connecting tubing and the evaporator that

are proven to be defective due to workmanship or materials

subject to the conditions and exclusions below.

The above warranties do not cover:

• Shipping costs of replacement parts or returned defective parts.

• Customer education or instructions on how to use the

appliance.

• Any content loss due to product failure.

• Removal or installation of product.

Nor do the above warranties cover failure of this product or

its components due to:

• Transportation or subsequent damages.

• Commercial use or use other than normal household or

small ofce.

• Improper installation, misuse, abuse, accident or alteration, use of wiring not conforming to electrical codes,

low or high voltages, failure to provide necessary maintenance, or other unreasonable use.

Parts or Service

Not Supplied or Designated by AGA MARVEL

The above warranties also do not apply if:

• The original bill of sale, deliver date, or serial number

cannot be veried.

• Defective parts are not returned for inspection if so

requested by AGA MARVEL.

• The refrigeration equipment is not in the possession of

the original end use purchaser.

The warranties set forth herein are the only warranties

extended by AGA MARVEL. Any implied warranties, including the implied warranty of merchantability, are limited to

the duration of these express warranties. In no event shall

AGA MARVEL be liable for any consequential or incidental

damages or expenses resulting from breach of these or any

other warranties, whether express or implied.

Some states do not allow the exclusion or limitation of consequential damages or a limitation on how long an implied

warranty lasts, so the above exclusion or limitation may not

apply to you. This warranty gives you specic legal rights

and you may have other rights that may vary from state to

state.

No person, rm, or corporation is authorized to make any

other warranty or assume any other obligation for AGA

MARVEL. These warranties apply only to products used in

any of the fty states of the United States and the District of

Columbia.

To obtain performance of this warranty, report any defects

to:

1260 E. VanDeinse St.

Greenville MI 48838

Phone: 800.223.3900

24

Page 25

252627

Page 26

Page 27

Page 28

1260 E. VanDeinse St.

Greenville MI 48838

800.223.3900

www.agamarvel.com

41014796-EN Rev B

4/6/17

All specications and product designs subject to change without notice. Such revisions do not entitle

the buyer to corresponding changes, improvements, additions, replacements or compensation for

previously purchased products.

Page 29

EN Installation, Operation and Maintenance Instructions

FR Instructions d’installation, d’utilisation et d’entretien

ES Instrucciones de instalación, operación y mantenimiento

Built in Refrigerators

Réfrigérateurs intégrées

Refrigeradores

empotradas

MP15BCG4**

MP15BCF4**

MP24BCG4**

MP24BCF4**

MP24BRG4**

MP24BRF4**

MP24RAS4**

MP24RAP4**

MP24WBG4**

MP24WBF4**

Page 30

CONTENU

Contenu :

Informations de sécurité.......................................................2

Déballage de votre appareil ..................................................3

Enregistrement de la garantie ......................................3

Installation de votre appareil ..............................................4

Dégagements par rapport à l’armoire .............................4

Mise à niveau de l’appareil .............................................4

Raccordement électrique.................................................5

Dimensions du produit.......................................................6

Utilisation de votre commande électronique .....................8

Démarrage de votre appareil .........................................8

Mode veille ....................................................................8

Mise en marche et arrêt de votre appareil ......................8

Éclairage intérieur d’exposition.......................................8

Réglage de la température .............................................9

Mode température ........................................................10

Verrouillage des commandes ........................................10

Codes d’erreur des capteurs de température ..............10

Alertes...........................................................................11

Porte entrouverte ......................................................11

Panne de secteur ......................................................11

Alerte de température ...............................................11

Mode vacances ............................................................12

Installation de panneau de revêtement ............................13

Congurations de étagères .............................................20

Entretien et nettoyage ......................................................24

Conseils pour l’économie d’énergie ................................24

Obtention de service ........................................................25

Dépannage................................................................26

Garantie...........................................................................27

Importantes instructions de sécurité

Les avertissements et les instructions de sécurité qui apparaissent dans ce guide n’ont pas la prétention de couvrir

toutes les conditions et situations possibles pouvant arriver.

Il faut faire preuve de bon sens, de précautions et de soins,

pour installer, utiliser ou entretenir cet appareil.

Reconnaissance des symboles,

des mots et des étiquettes

concernant la sécurité.

!

AVERTISSEMENT

AVERTISSEMENT - Risque possible de décès ou

de blessure grave si vous ne suivez pas les instructions.

!

ATTENTION

ATTENTION - Risques ou pratiques dangereuses

pouvant entraîner des blessures individuelles, des dégâts

matériels ou des dommages au produit.

REMARQUE

!

AVERTISSEMENT

Avertissements de la proposition 65 de l'État de Californie

: Ce produit contient au moins un produit chimique connu par

l’État de Californie pour être à l’origine de cancers.

REMARQUE - Information importante pour réaliser une

installation et une utilisation sans problèmes.

!

AVERTISSEMENT

Avertissements de la proposition 65 de l'État de Californie

: Ce produit contient au moins un produit chimique connu par

l’État de Californie pour être à l’origine de malformations et

autres déciences de naissance.

s’engage à fabriquer un produit de

qualité d’une manière ne nuisant pas à l’environnement. Nos

procédés sont sévèrement contrôlés et surveillés de près.

Nous avons obtenus les certications ISO 9001 d’assurance

qualité, et ISO 14001 de gestion environnementale, et

OHSAS 18001 pour hygiène et sécurité du travail de Lloyd’s

Register Quality Assurance.

2

Page 31

DÉBALLAGE DE VOTRE APPAREIL

!

AVERTISSEMENT

AVERTISSEMENT

RISQUE DE POIDS EXCESSIF

Utilisez deux personnes ou plus pour déplacer le produit.

Sinon vous pourriez vous blesser.

Enlèvement de l’emballage intérieur

Votre réfrigérateur a été emballé pour l’expédition avec toutes les

pièces pouvant être endommagées par le mouvement solidement

attachées. Enlevez les matériaux d’emballage intérieur et toute

bande maintenant des composants intérieurs en place. Le manuel

de l’utilisateur est envoyé à l’intérieur de l’appareil dans un sac en

plastique, accompagné de la carte d’enregistrement de la garan-

tie, et d’autres articles accessoires.

Important

Conservez votre carton d’emballage jusqu'à ce que votre réfrigérateur ait été complètement inspecté et trouvé en bon état.

S’il présentait des dommages, cet emballage serait nécessaire

comme preuve qu’ils sont survenus durant le transit. Ensuite

veuillez mettre tous ces matériaux d’emballage au rebut d’une

façon responsable.

Enregistrement de la garantie

Il est important que vous postiez votre carte de garantie

immédiatement après avoir pris livraison de votre réfrigérateur.

Les informations suivantes seront nécessaires au moment de

l’enregistrement de votre

appareil :

Numéro de service

Numéro de série

Date d’achat

Nom et adresse du revendeur

Le numéro de service et le numéro de série se trouvent sur la

plaque signalétique qui est située à l’intérieur de l’armoire, du

côté gauche près du haut (Voyez la Figure 1).

Enregistrment en ligne

disponible sur

www.agamarvel.com

!

AVERTISSEMENT

AVERTISSEMENT - Jetez bien les sacs en plastique qui

représentent un risque de suffocation.

Note pour le client

Cette marchandise a été soigneusement et complètement inspectée avant de quitter notre usine. La responsabilité pour sa livrai-

son sûre a été assumée par le revendeur à l’acceptation de cette

expédition. Les réclamations pour perte ou dommages survenus

durant le transit sont à adresser au revendeur.

REMARQUE

NE RENVOYEZ PAS DE MARCHANDISE ENDOMMA-

GÉE AU FABRICANT – DÉPOSEZ UNE RÉCLAMATION

AUPRÈS DU REVENDEUR.

!

ATTENTION

Si l’appareil a été livré, manipulé ou entreposé dans une position autre que debout, pendant une durée quelconque, laissez-le

reposer debout pendant au moins 24 heures avant de la brancher

électriquement. Cela assurera le retour de l’huile au compresseur.

Un branchement immédiat de l’appareil pourrait endommager des

parties internes.

XXXXXXXXXXXX

XXXXXXXXXXXX

Figure 1

!

AVERTISSEMENT

AVERTISSEMENT - Contribuez à éviter des tragédies

L’emprisonnement d’enfants et leur asphyxie ne sont pas

des problèmes du passé. Des épaves de réfrigérateurs

abandonnés continuent de présenter un danger - même

en restant dehors pour «juste quelques heures».

Si vous devez vous débarrasser de votre vieil appareil

de refroidissement, veuillez suivre ces instructions pour

aider à éviter des accidents possibles.

Avant de jeter votre vieux réfrigérateur ou congélateur :

• Démontez ses portes ou enlevez ses tiroirs.

• Laissez les étagères en place de façon à ce que des

enfants ne puissent pas facilement monter dedans.

3

Page 32

INSTALLATION DE VOTRE APPAREIL

Choix de l’emplacement

Un bon emplacement assurera une performance de pointe pour

votre appareil. Nous recommandons un endroit où l’appareil ne

sera pas exposé directement au rayonnement solaire et restera

écarté de sources de chauffage. Pour assurer que les performances de votre produit soient au niveau de ses spécications, la

plage de températures recommandée au lieu d’installation sera de

55 à 100°F (13 à 38 °C).

Dégagements par rapport à l’armoire

Une ventilation est nécessaire depuis la section frontale du bas de

l’armoire. Gardez cette zone libre et exempte de toutes obstruc-

tions. Des meubles et comptoirs peuvent être installés autour de

l’unité de façon adjacente dans la mesure où sa grille frontale

restera non obstruée. Les modèles à revêtement de porte avec

charnières articulées sont prévus pour des applications encas-

trées uniquement.

!

AVERTISSEMENT

Un kit optionnel d’empilage est nécessaire, pour les modèles

de 24 po de largeur, pour empiler des produits. Le fait de ne

pas utiliser de kit d’empilage peut entraîner une blessure corporelle. Contactez votre revendeur ou le service à la clientèle

de Marvel au 800-223-3900 pour le commander. Aux raisons

de sécurité, les modèles de 15 po de largeur ne doivent pas

être empilés.

Grille frontale,

gardez cette

zone dégagée.

Pieds de mise à

niveau avant

Figure 2

Pieds de

mise à niveau

arrière

Pieds de mise à niveau

Des pieds réglables aux angles avant et arrière de l’armoire

doivent être ajustés pour qu’elle soit fermement positionnée

au sol et bien d’aplomb, d’un côté à l’autre et d’avant en arrière. La hauteur totale de votre appareil Marvel peut être ajustée

entre le minimum (en vissant les pieds de mise à niveau, CW ↷)

et le maximum (en dévissant les pieds de mise à niveau CCW ↶)

des dimensions comme c’est montré au Tableau «A».

Pour régler ces pieds de mise à niveau, placez l’appareil

sur une surface solide, en protégeant le sol en dessous

pour ne pas le rayer. Avec l’aide d’une autre personne, inclinez vers l’arrière de l’appareil pour accéder aux pieds de

mise à niveau de l’avant. Levez ou abaissez ces pieds à la

hauteur requise en les tournant. Répétez la procédure pour

les pieds arrière en inclinant le réfrigérateur vers l’avant en

faisant attention. Sur une surface plane, vériez le niveau

de l’appareil et ajustez les pieds en conséquence.

!

ATTENTION

Grille frontale

N’obstruez pas la grille frontale. Les ouvertures au travers de la

grille frontale permettent l’écoulement de l’air par l’échangeur

thermique du condenseur. Des restrictions de ce ux d’air vont

augmenter la consommation d’énergie et affecter sa capacité de

refroidissement. C’est pourquoi il est important que cette zone

ne soit pas obstruée et soit maintenue propre. AGA MARVEL

recommande de ne pas utiliser de grilles personnalisées, car

l’écoulement d’air en serait diminué (Voyez la Figure 2).

Les vis de la grille frontale peuvent être desserrées et la

grille ajustée à la hauteur voulue. Quand le réglage est fait

resserrez les vis de la grille frontale (Voyez la Figure 5).

Style de

Modèle

MP(15)(24)* (S) (G)

MP(15)(24)* (F)

Porte

Tableau A

Hauteur

minimum

34 po

(86,4 cm)

34 po

(86,4 cm)

Hauteur

maximum

35 po

(88,9 cm)

35 po

(88,9 cm)

4

Page 33

Figure 3

INSTALLATION DE VOTRE APPAREIL

!

Risque de commotion électrique

• N’utilisez pas de rallonge secteur avec cet appareil. Cela

N’enlevez pas la

borne de terre de

la che du cordon

secteur.

peut être dangereux et peut affecter la performance du

produit.

• Cet appareil ne doit sous aucun prétexte être installé sur

une alimentation électrique sans liaison de terre.

• N’enlevez pas la borne de terre de la che du cordon

secteur. (Voyez la Figure 3).

• N’utilisez pas d’adaptateur entre che et prise. (Voyez la

Figure 4).

• N’envoyez pas d’eau par éclaboussure ou par jet d’un

tuyau sur l’appareil. Cela pourrait causer une commotion électrique, entraînant potentiellement des blessures

graves voire mortelles.

Raccordement électrique

Un circuit secteur dédié en 115 V supportant 15 A est nécessaire.

AVERTISSEMENT

Figure 4

Ce produit est équipé en usine d’un cordon secteur comportant

une che avec terre à trois broches. Il faut la brancher dans une

prise secteur correspondante avec terre, en conformité avec la

norme électrique américaine et les normes et réglementations

locales applicables (Voyez la Figure 6). Si le circuit ne comporte

pas une prise avec terre, le client doit en fournir une adéquate;

c’est sa responsabilité et son obligation. La troisième broche de

terre ne doit en aucun cas être coupée ou enlevée.

Figure 6

Figure 5

Grille frontale

Vis de grille

frontale

REMARQUE

Un disjoncteur sur détection de courant de fuite (GFCI) a tendance à provoquer des déclenchements intempestifs qui peuvent

arrêter l’appareil. Ce type de protection n’est en général pas

utilisé sur de l’équipement électrique qui doit tourner sans surveillance pendant de longues périodes, sauf si c’est imposé par les

normes de construction et réglementations locales.

5

Page 34

DIMENSIONS DU PRODUIT

DIMENSIONS D’OUVERTURE BRUTE DIMENSIONS D’ARMOIRE

MODÈLE «A» «B» «C» «D» «E» «F» «G» «H» «J»

MP15BCG

MP15BCF

MP24**S

MP24**G

MP24**F

15 po

(38.1 cm)

15 po

(38.1 cm)

24 po

(61 cm)

24 po

(61 cm)

24 po

(61 cm)

STYLE DE PORTE

(S) Porte pleine

(G) Porte en verre

(F) Porte en verre à revêtement (sans poignée)

**341⁄4 po à 351⁄4 po

(87 à 89,5 cm)

**341⁄4 po à 351⁄4 po

(87 à 89,5 cm)

**341⁄4 po à 351⁄4 po

(87 à 89,5 cm)

**341⁄4 po à 351⁄4 po

(87 à 89,5 cm)

**341⁄4 po à 351⁄4 po

(87 à 89,5 cm)

24 po

(61 cm)

* 24 po

(61 cm)

24 po

(61 cm)

24 po

(61 cm)

* 24 po

(61 cm)

147⁄8 po

(37.8 cm)

147⁄8 po

(37.8 cm)

237⁄8 po

(60.7 cm)

237⁄8 po

(60.7 cm)

237⁄8 po

(60.7 cm)

34 po à 35 po

(86.4 à 88.9 cm)

34 po à 35 po

(86.4 à 88.9 cm)

34 po à 35 po

(86.4 à 88.9 cm)

34 po à 35 po

(86.4 à 88.9 cm)

34 po à 35 po

(86.4 à 88.9 cm)

2323⁄32 po

(60.2 cm)

227⁄8 po

(58.1 cm)

2323⁄32 po

(60.2 cm)

2323⁄32 po

(60.2 cm)

227⁄8 po

(58.1 cm)

267⁄32 po

(66.6 cm)

-

267⁄32 po

(66.6 cm)

267⁄32 po

(66.6 cm)

-

3713⁄32 po

(95 cm)

71⁄2 po

(95.2 cm)

4613⁄32 po

(117.9 cm)

4613⁄32 po

(117.9 cm)

461⁄2 po

(118.1 cm)

177⁄16 po

(44.3 cm)

141⁄8 po

(35.9 cm)

267⁄16 po

(67.2 cm)

267⁄16 po

(67.2 cm)

231⁄8 po

(58.7 cm)

Figure 7a

Figure 8

«B»

«A»

«E»

«C»

Figure 7

Vue de du (S)

porte pleine

«D»

S’il est nécessaire de gagner du dégagement à l’intérieur

de l’ouverture brute, un trou peut être percé au travers du

meuble adjacent et le cordon d’alimentation passé par ce

trou jusqu’à une prise secteur. Une autre façon d'augmenter

la profondeur disponible dans l’ouverture est d’encastrer la

prise secteur dans le mur arrière an de gagner l’épaisseur

de la che du cordon.Tous les types de prises secteur

encastrées ne fonctionneront pas pour cette application car

elles pourraient être trop étroites, mais un modèle équivalent

à l’Arlington #DVFR1W est recommandé pour cette application (Voyez la Figure 8).

6

Page 35

DONNÉES DE PRODUIT

MODÈLE

MP15BCG 115V/60Hz/15A

MP15BCF 115V/60Hz/15A

MP24**S 115V/60Hz/15A

MP24**G 115V/60Hz/15A

MP24**F 115V/60Hz/15A

BESOINS

ÉLECTRIQUES #

DIMENSIONS DU PRODUIT

POIDS DU

PRODUIT

105 lb

(47.6 kg)

105 lb

(47.6 kg)

140 lb

(63.6 kg)

140 lb

(63.6 kg)

140 lb

(63.6 kg)

«D»

«J»

«H»

«G»

«F»

Figure 9

Vue de du (S)

porte pleine

* Pour installer les modèles (F) avec la face de porte

alignée avec les portes des meubles de rangement adja-

cents, l’épaisseur du panneau décoratif du client ne peut

pas dépasser ¾ po (19mm).

** L’ouverture brute minimale nécessaire doit être supérieure à la hauteur ajustée de l’armoire.

# Un circuit secteur dédié avec liaison de terre support-

ant 15 A est nécessaire. Appliquez toutes les normes de

construction locales à l’installation de l’électricité et de

l’appareil.

«E»

31⁄2 po (8.9 cm)

Minimum

211⁄2 po

(54.6 cm)

7

Page 36

UTILISATION DE VOTRE COMMANDE ÉLECTRONIQUE

Diminution

de

température

Marche/

Arrêt

Augmen-

tempéra-

tation

de

ture

Zones

supérieure/

inférieure

(Modèles à

deux zones

uniquement)

Zone d’afchage

Figure 10

Commandes électroniques

Power Failure

ALARM RESET

Démarrage de votre réfrigérateur :

Branchez la prise du cordon d’alimentation du réfrigérateur dans

une prise murale de secteur 115 V. Votre appareil sort de l’usine

en position de marche (ON) et va commencer le refroidissement

dès sa mise sous tension. Si l’appareil ne démarre pas, vériez

que la prise murale est alimentée et que la commande est bien

en position de marche (ON). Voyez la partie «Mise en marche et

arrêt de votre appareil».

L’afcheur de votre commande est protégé d’un lm transparent

en plastique. Ce lm doit être ôté en le pelant soigneusement à

partir d’un angle.

Allumage

d’éclairage

Verrouillage

des touches

Indicateur de

statut du système

Le mode veille peut être désactivé si vous préférer obtenir un

afchage continu. Appuyez sur la commande de verrouillage

(symbôle de verrouillage) jusqu’à ce que l’afcheur quitte «Loc»

et montre «nSL». Pour activer le mode de veille, répétez la

même opération, jusqu’à ce que l’afcheur quitte «Loc» et montre

«SLP».

Au démarrage initial, l’afcheur du contrôle montre une alerte

«Panne secteur». C’est une condition normale, car le réfrigéra-

teur a été alimenté en usine pour l’inspection de qualité et a été

débranché. Un appui momentané sur la touche M/A (ON/OFF) va

effacer cette condition d’alerte. (Voyez la section sur les alertes en

page 11).

Mode veille :

Si aucune commande n’est actionnée pendant 60 secondes,